Preparation method of dimethyl methylphosphonate (DMMP) molecular imprinting polymer microspheres

A technology of dimethyl methylphosphonate and molecular imprinting, which is applied in the field of bioengineering, can solve the problem of undiscovered reports on imprinted polymers of dimethyl methylphosphonate, limited binding sites between template molecules and functional monomers, and difficult Trace detection of template molecules and other issues, to achieve the effect of increasing specific surface area, increasing binding sites, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

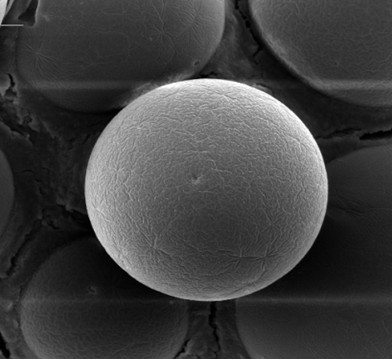

[0027] Take 1mmol of dimethyl methylphosphonate (DMMP) and 4mmol of methacrylic acid (MAA), dissolve them in 20ml of chloroform solution, vibrate ultrasonically for 10min, and put them in the refrigerator for 8 hours to form template molecule-monomer complexes. Weigh 20 mmol of cross-linking agent ethylene glycol dimethacrylate (EGDMA) and add it to the prepared template molecule-monomer complex, ultrasonically degas for 30 min, and pass through at least N 2 After 15 minutes, add 0.3 mmol of initiator azobisisobutyronitrile (AIBN), seal it, and polymerize in water at 60°C for 24 hours, take it out and cool it to room temperature, centrifuge, and use methanol / acetic acid 9 / 1 (V / V) to obtain the polymer Wash until there are no imprinted molecules, then wash with chloroform, dry in a vacuum oven at 50°C to constant weight, and finally obtain a molecularly imprinted polymer with an average particle size of 20-50 μm. The inventive effect is as follows: figure 1 As shown, the surfac...

Embodiment 2

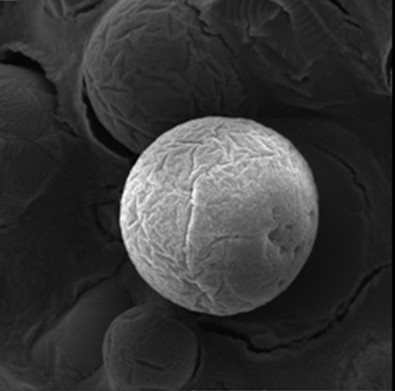

[0031] Take 1mmol of dimethyl methylphosphonate (DMMP), 4mmol of acrylic acid (MAA), and 1mmol of zinc porphyrin, dissolve them in 20ml of chloroform solution, oscillate ultrasonically for 5min, and put them in the refrigerator for 8 hours to form a template molecule-unit body complex, weighed 20mmol cross-linking agent trimethylolpropane trimethacrylate (TRIM) and added it to the prepared template molecule-monomer complex, ultrasonic degassed for 30min, and at least N 2 After 15 minutes, add 0.4 mmol of initiator azobisisobutyronitrile (AIBN), seal, and polymerize in water at 60°C for 28 hours, take it out and cool to room temperature, centrifuge, and the obtained polymer is mixed with methanol / acetic acid 9 / 1 (V / V) Wash until there are no imprinted molecules, then wash with chloroform, dry in a vacuum oven at 75°C to constant weight, and finally obtain a molecularly imprinted polymer with an average particle size of 20-50 μm. The inventive effect is as follows: figure 2 As ...

Embodiment 3

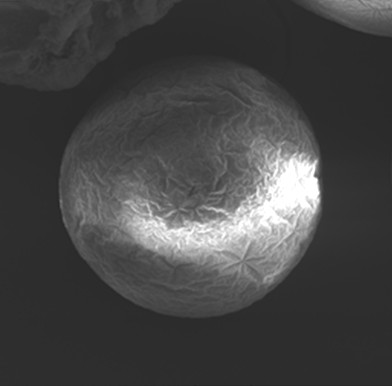

[0034]Take 1mmol of dimethyl methylphosphonate (DMMP), 4mmol of methacrylate (MMA), and 0.3mmol of gadolinium porphyrin, dissolve them in 10ml of chloroform solution, oscillate ultrasonically for 5min, and put them in the refrigerator for 8 hours to form Template molecule-monomer complex, weigh 20mmol cross-linking agent ethylene glycol dimethacrylate (EGDMA) and add it to the prepared template molecule-monomer complex, ultrasonic degassing for 30min, at least N 2 After 15 minutes, add 0.28 mmol of initiator azobisisobutyronitrile (AIBN), seal it, and polymerize it in water at 70°C for 24 hours, take it out and cool it to room temperature, and centrifuge. The obtained polymer is mixed with methanol / acetic acid 9 / 1 (V / V) Wash until there are no imprinted molecules, then wash with chloroform, dry in a vacuum oven at 70°C to constant weight, and finally obtain a molecularly imprinted polymer with an average particle size of 20-50 μm. The inventive effect is as follows: image 3 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com