Halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive and pressure-sensitive adhesive tape, and preparation method thereof

An acrylate, pressure-sensitive tape technology, used in pressure-sensitive films/sheets, adhesives, non-polymer organic compound adhesives, etc. Problems such as low adhesive holding force and initial adhesion force, poor compatibility between flame retardants and pressure-sensitive adhesives, etc., achieve the effects of controllable mechanical properties, low cost, and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing a halogen-free flame-retardant UV-curable acrylate pressure-sensitive adhesive and a pressure-sensitive adhesive tape according to an embodiment of the present invention, comprising the following steps:

[0033] (1) Preparation of acrylate prepolymer

[0034]According to 85 parts by weight of isooctyl acrylate, 5 parts by weight of acrylic acid, 10 parts by weight of isobornyl acrylate and 0.05 parts by weight of the first photoinitiator (TPO, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide) The parts are mixed evenly, and the polymerization reaction occurs under UV light under a nitrogen atmosphere. When the viscosity of the system reaches 450mPa.s-600mPa.s, the reaction is terminated by feeding oxygen to obtain an acrylate prepolymer;

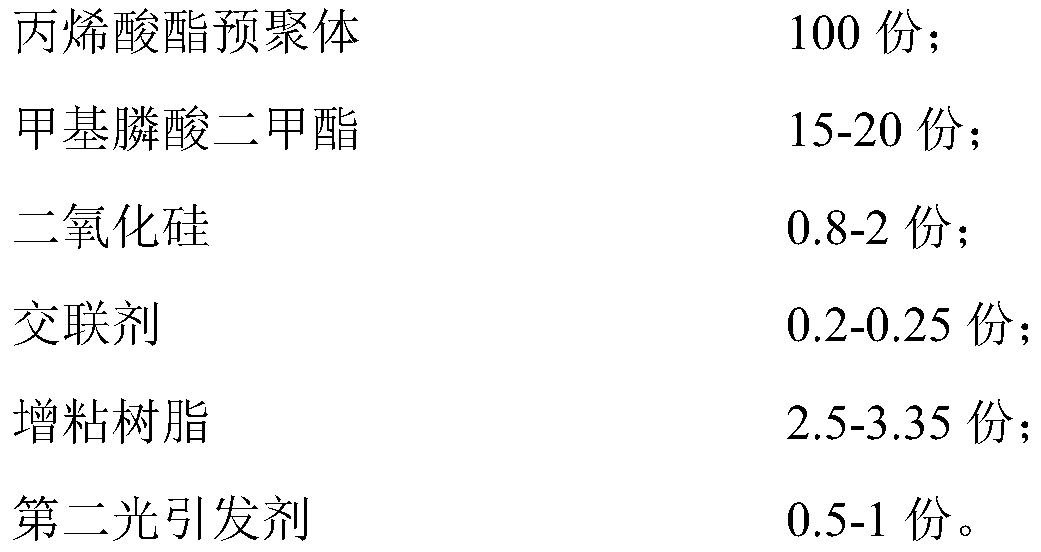

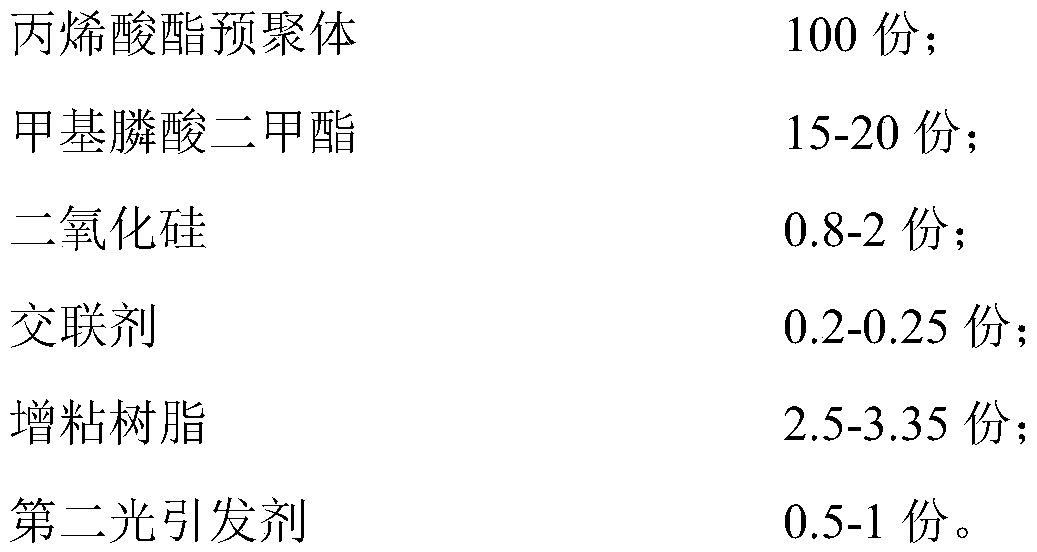

[0035] (2) Preparation of pressure-sensitive adhesive

[0036] Add 15 parts by weight of the flame retardant dimethyl methylphosphonate (DMMP) and 2 parts by weight of silicon dioxide to the acrylate prepolymer p...

Embodiment 2

[0042] The preparation method of this embodiment is roughly the same as that of Example 1, except that the amounts of dimethyl methylphosphonate and silicon dioxide are different from those of Example 1. In this embodiment, the amount of dimethyl methylphosphonate is 20 parts by weight, and the amount of silicon dioxide is 1 part by weight.

[0043] Cut the pressure-sensitive tape sample obtained after the coating film in this example is cured and save it in strips. Test the 180° peel strength of the strip on an electronic tensile machine according to the GB / T 2792-2014 standard, and test it on a horizontal and vertical burning instrument according to the UL94-2006 standard. The flame retardant grade of the test rubber strip. The test results are shown in Table 1.

Embodiment 3

[0045] The preparation method of this example is roughly the same as that of Example 1, the main difference is that 20 parts by weight of dimethyl methylphosphonate and 0.8 parts by weight of silicon dioxide are used as the flame retardant.

[0046] Cut the pressure-sensitive tape sample obtained after the coating film in this example is cured and save it in strips. Test the 180° peel strength of the strip on an electronic tensile machine according to the GB / T 2792-2014 standard, and test it on a horizontal and vertical burning instrument according to the UL94-2006 standard. The flame retardant grade of the test rubber strip. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com