Patents

Literature

85results about How to "Controllable mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

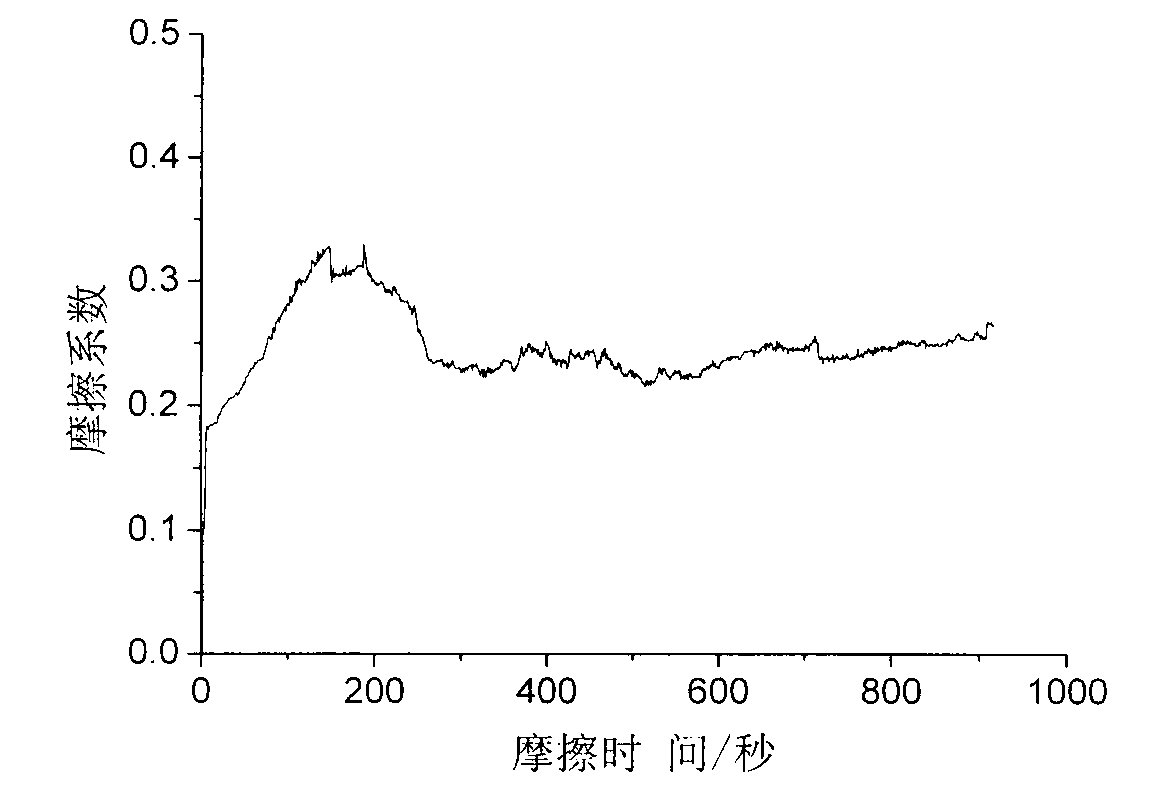

Method for preparing polyurethane/rubber interpenetrating network type water-swellable rubber

The invention belongs to the technical field of sealing materials and relates to a method for preparing polyurethane / rubber interpenetrating network type water-swellable rubber. The method comprises the following steps: firstly, mixing rubber and super-absorbent resin for 10 to 40 minutes in an open mill; further adding solid softener, colorant, anti-ager and promoter to the open mill, and mixing for 10 to 40 minutes; then, adding zinc oxide, reinforcing agent and plasticizer to the open mill, and mixing for 10 to 50 minutes; further adding vulcanizer to the open mill, and mixing to obtain a mixture A; evenly mixing polyethylene glycol and MDI (methyl-di-p-phenylene isocyanate) by equal molar weight to obtain a mixture B; blending the mixture A and the mixture B in the open mill to obtain a product; and finally, vulcanizing the product in a mold on a plate vulcanization machine with the temperature and pressure being respectively controlled at 150 to 160 DEG C and at 10MPa to 15MPa, to obtain the interpenetrating network type water-swellable rubber. The method of the invention has the advantages of simple preparation process, high product expansion ratio, high ion resistance and controllable water absorption rate and mechanical properties.

Owner:QINGDAO UNIV OF SCI & TECH +1

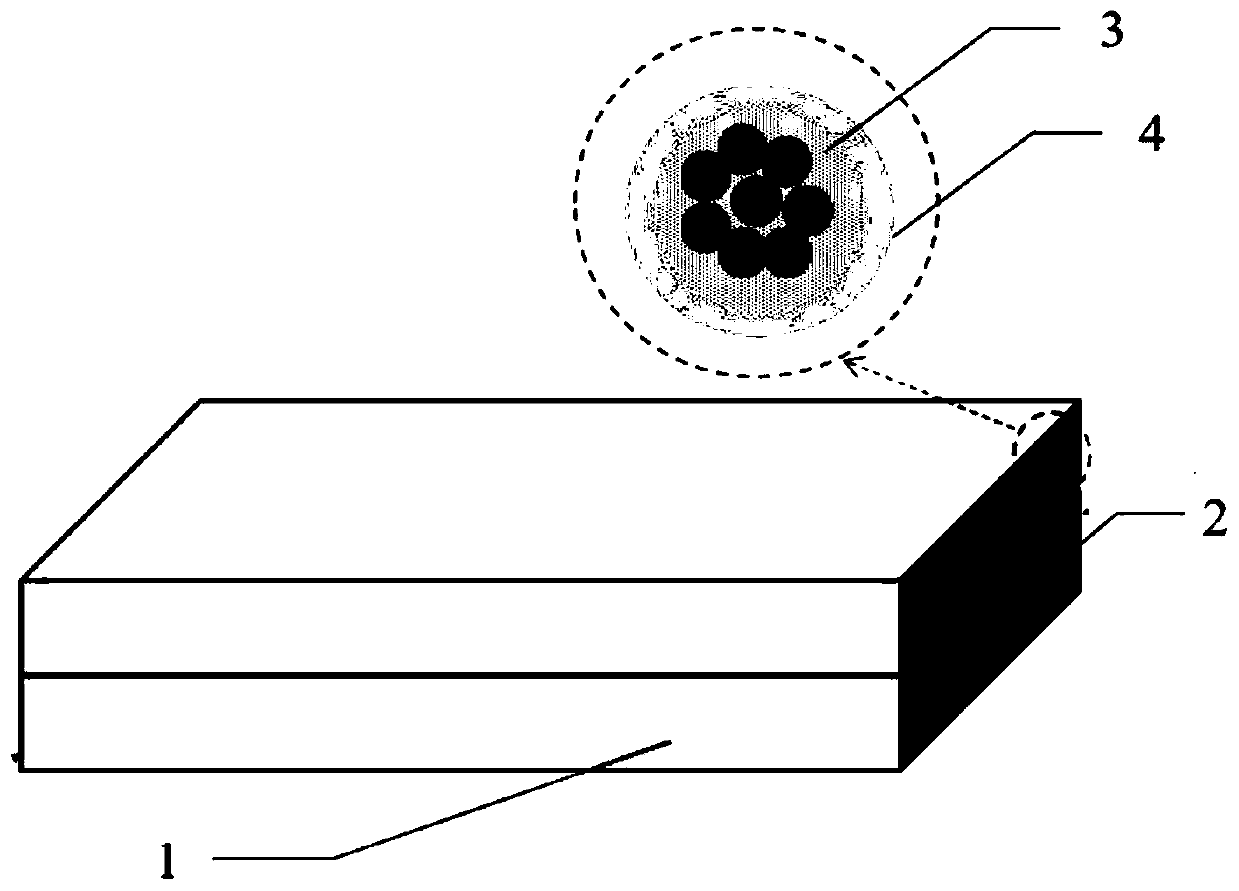

Photo-curing hydrogel for multi-cell sorting and stem cell area-selecting differentiation and preparation method thereof

ActiveCN105294955AHigh affinityGood formabilityArtificial cell constructsSkeletal/connective tissue cellsHardnessPhoto curing

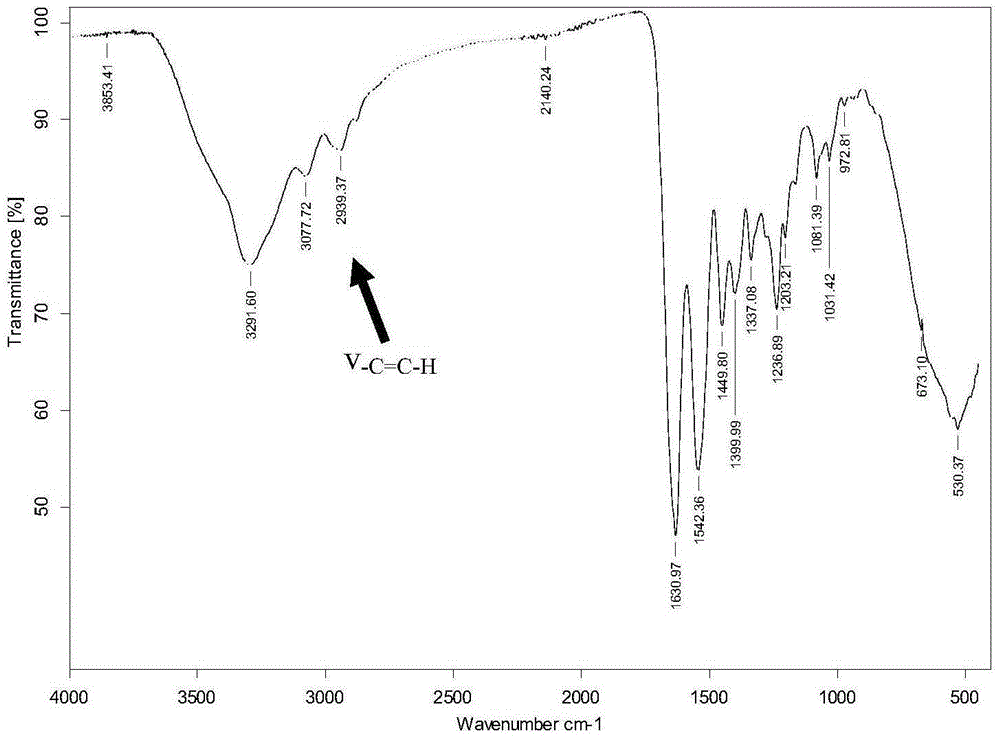

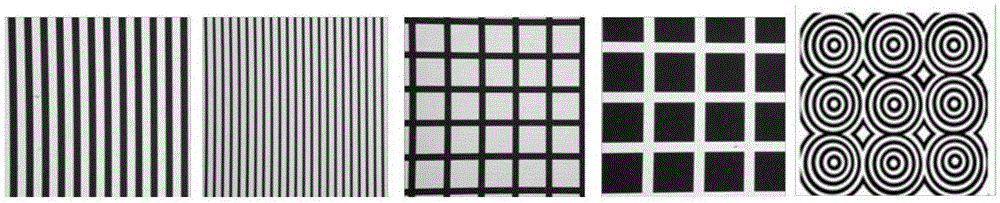

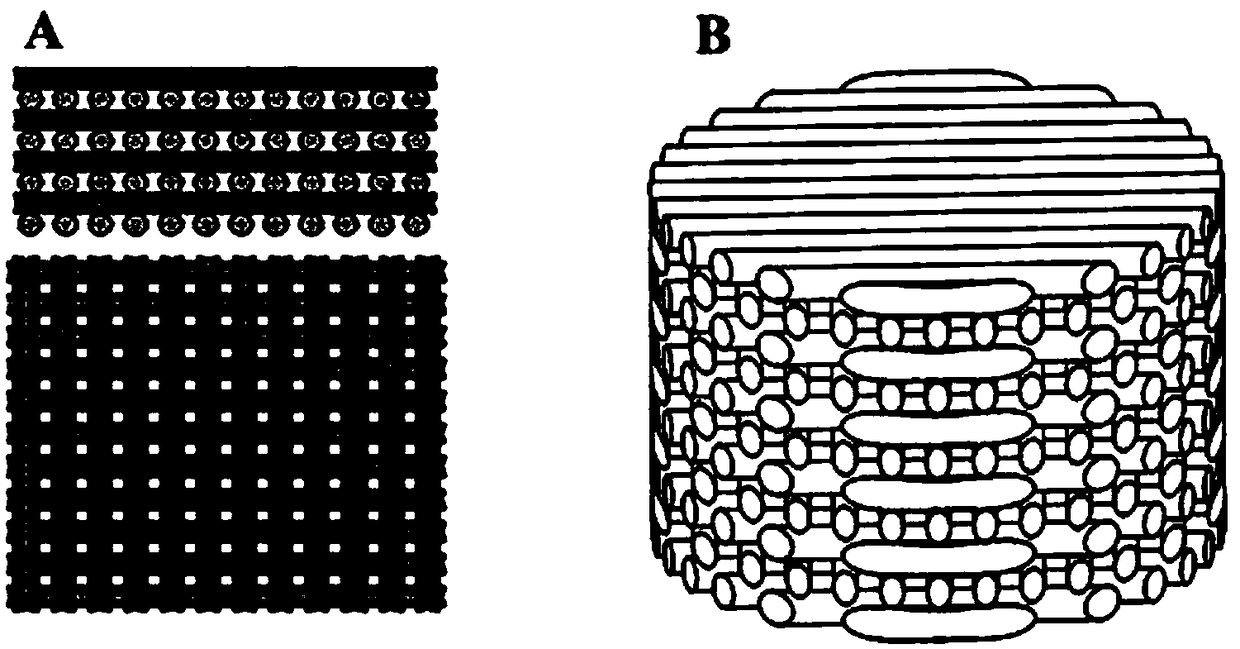

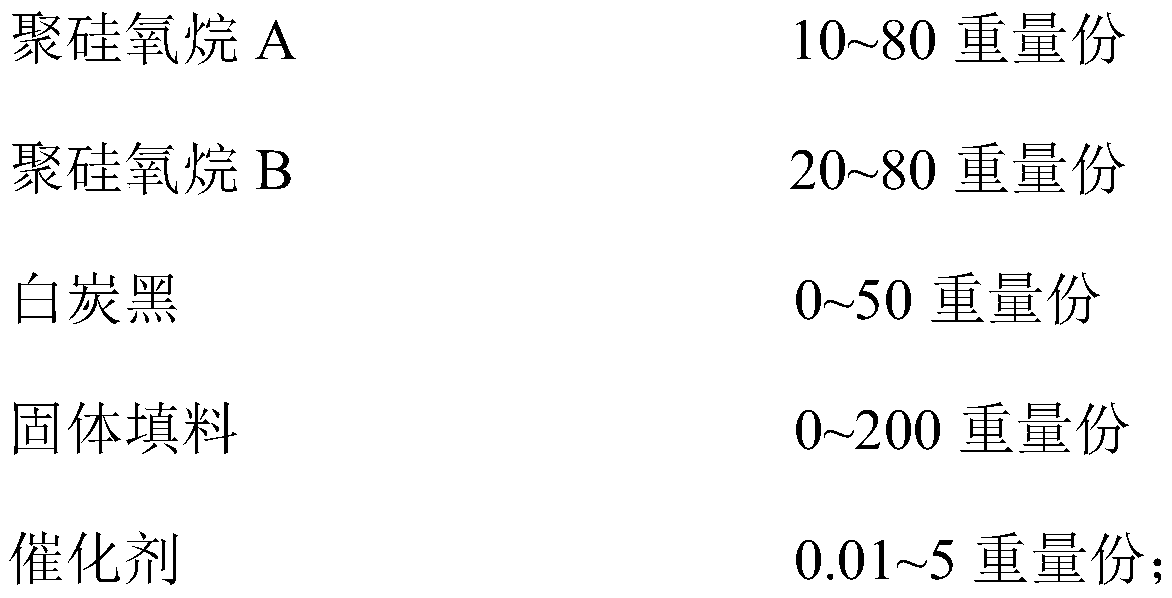

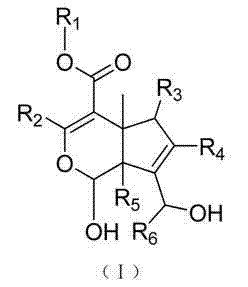

The invention belongs to the field of biomedical materials, and particularly relates to photo-curing hydrogel for multi-cell sorting and stem cell area-selecting differentiation and a preparation method thereof. The photo-curing hydrogel is prepared by taking modified high-polymer materials with the photo-curing performance as raw materials and are divided into multiple different areas by straight-stripe-shaped or net-stripe-shaped or annular-stripe-shaped micro-pattern structures, the hardness of the photo-curing hydrogel in the same area is same, the hardness of the photo-curing hydrogel in the different areas is same or different, and the overall photo-curing hydrogel at least has two kinds of the hardness. According to the photo-curing hydrogel for multi-cell sorting and stem cell area-selecting differentiation and the preparation method thereof, on one hand, the elasticity moduli of all the areas of the photo-curing hydrogel are different by controlling the ultraviolet radiation curing degree; on the other hand, all the areas with the different elasticity moduli present the micro-pattern structures on the photo-curing hydrogel, selective adhesion, proliferation and differentiation of cells on the photo-curing hydrogel can be achieved by combining the elasticity moduli with the micro-pattern structures, and therefore controllable cell sorting or stem cell area-selecting differentiation can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

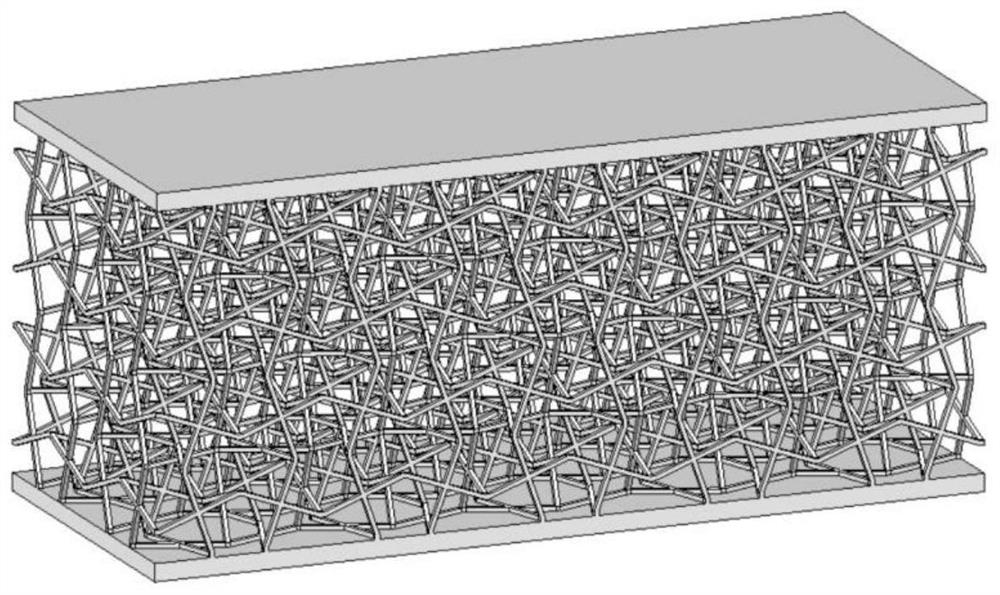

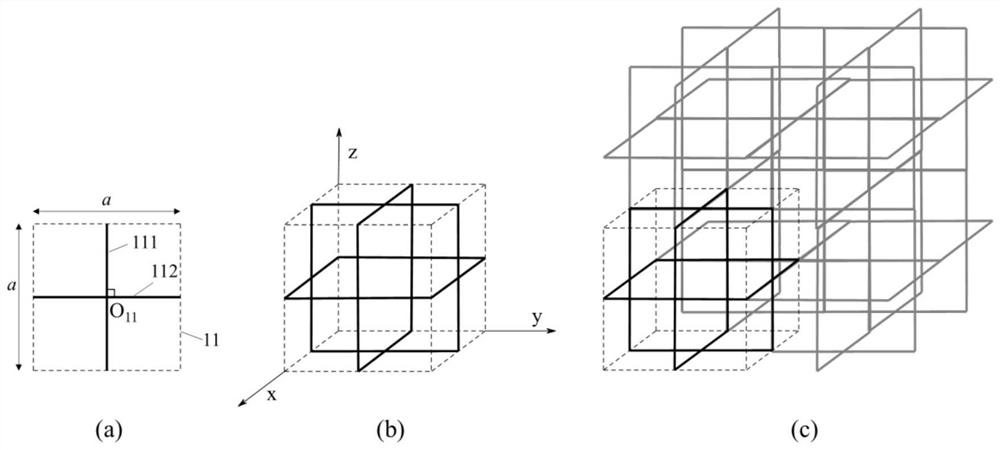

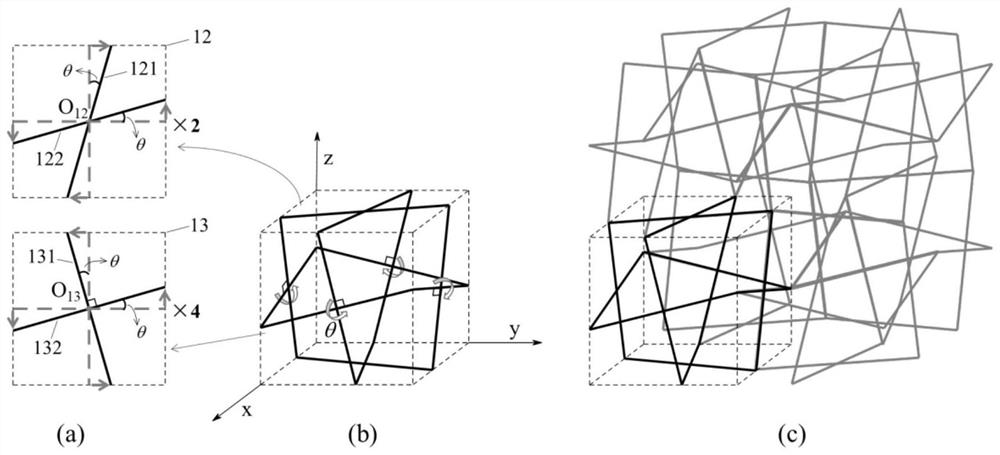

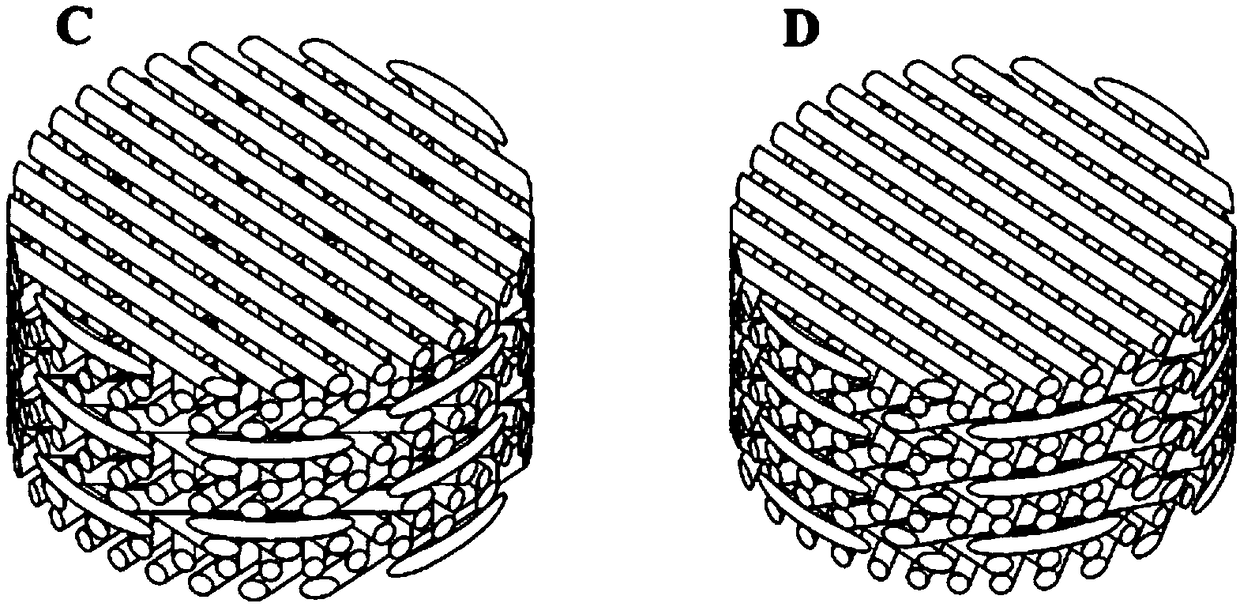

Impact-resistant and high-energy-absorption lattice sandwich structure with negative poisson ratio characteristic

PendingCN112140647AResistance to compressive loadsLight structureLayered productsHigh energySpecific modulus

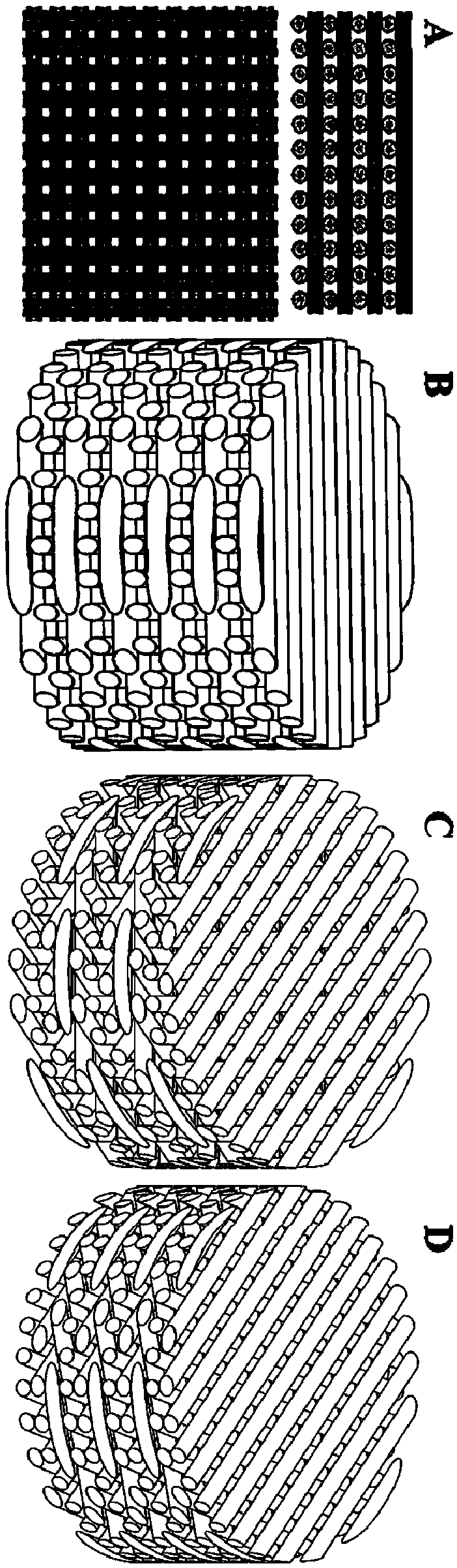

The invention discloses an impact-resistant and high-energy-absorption lattice sandwich structure with a negative poisson ratio characteristic. The lattice sandwich structure is formed on the basis ofa high-performance negative poisson ratio lattice core material. The negative poisson ratio lattice core material is obtained by changing an included angle between a supporting column and a coordinate axis through a three-dimensional cubic structure. When the included angle between the supporting column and the coordinate axis is not equal to zero, the negative poisson ratio lattice core materialis obtained. The negative poisson ratio lattice material and two thin plates form a novel negative poisson ratio lattice sandwich structure, and the structure has the characteristics of a traditionalauxetic lattice structure and a traditional lattice sandwich structure at the same time, that is, the structure has the characteristics of the negative poisson ratio and the same-direction curvature;meanwhile, has excellent mechanical properties such as ultra-light weight, high specific modulus, high specific strength, impact resistance and high energy absorption. In addition, the sandwich structure has high adjustability, and the mechanical property of the lattice sandwich structure can be adjusted and controlled within a large range by adjusting the deflection angle of the supporting column and the relative density of the lattice material. The lattice sandwich structure has a great application prospect in the field of aerospace.

Owner:BEIHANG UNIV

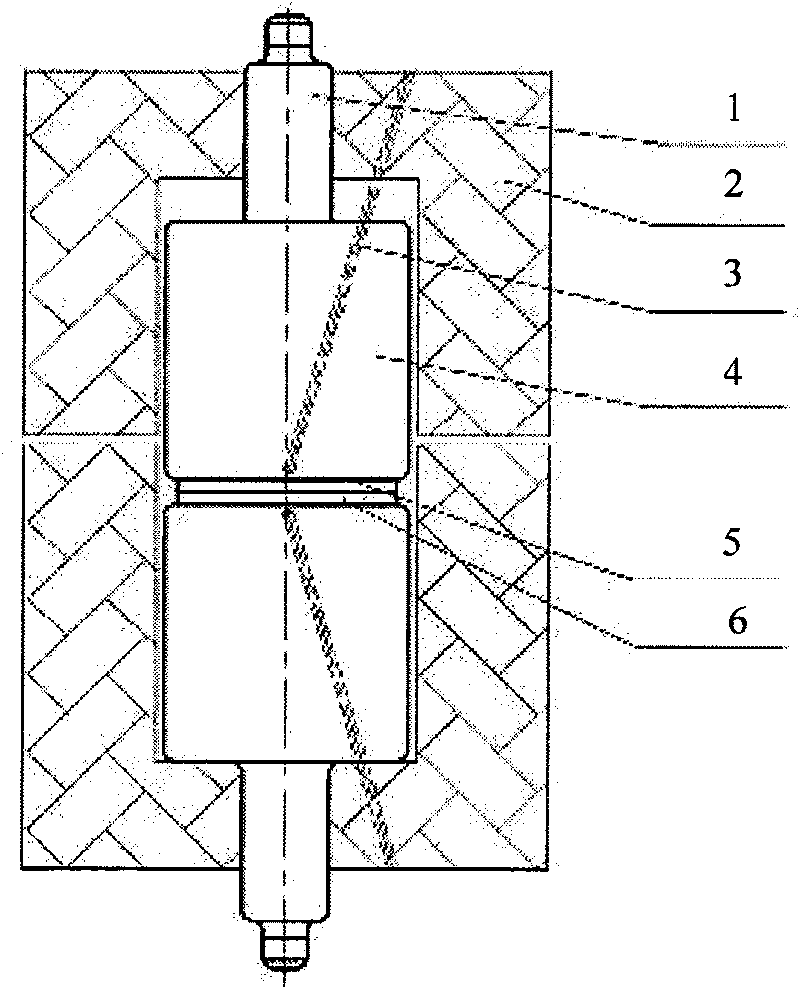

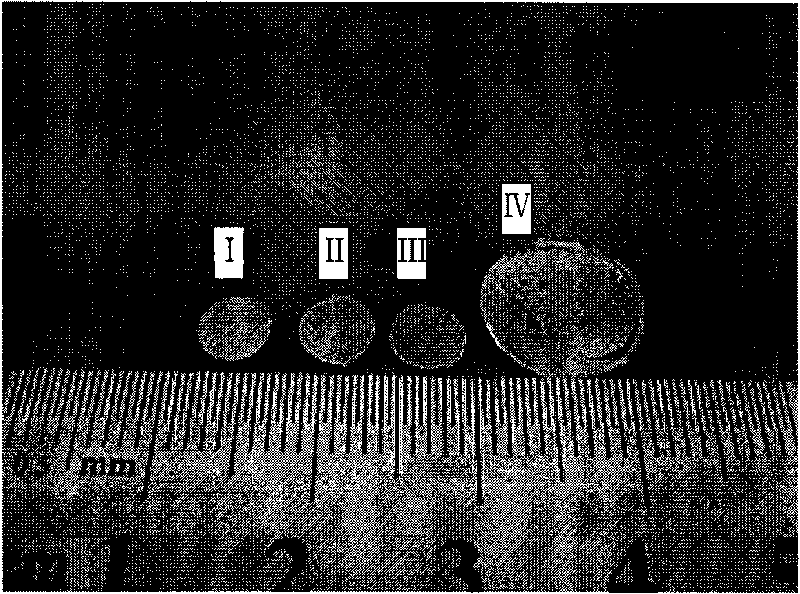

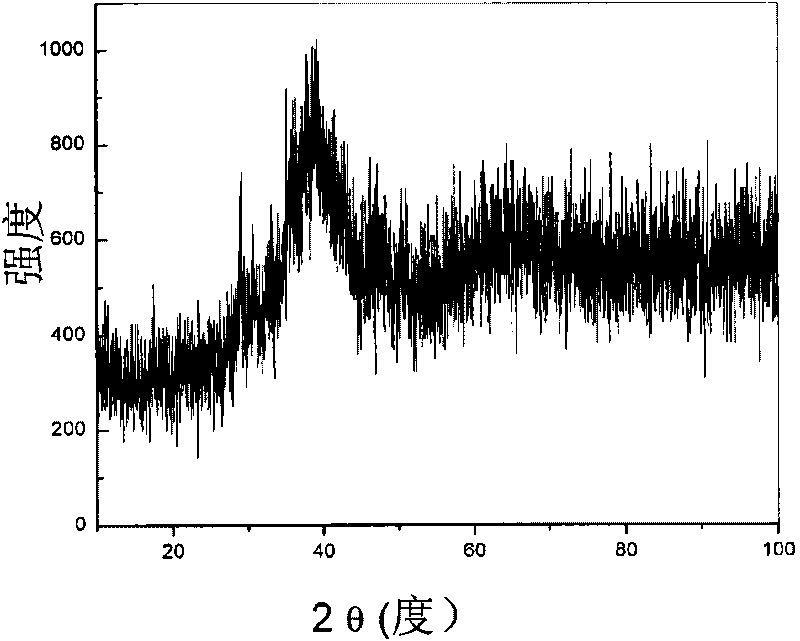

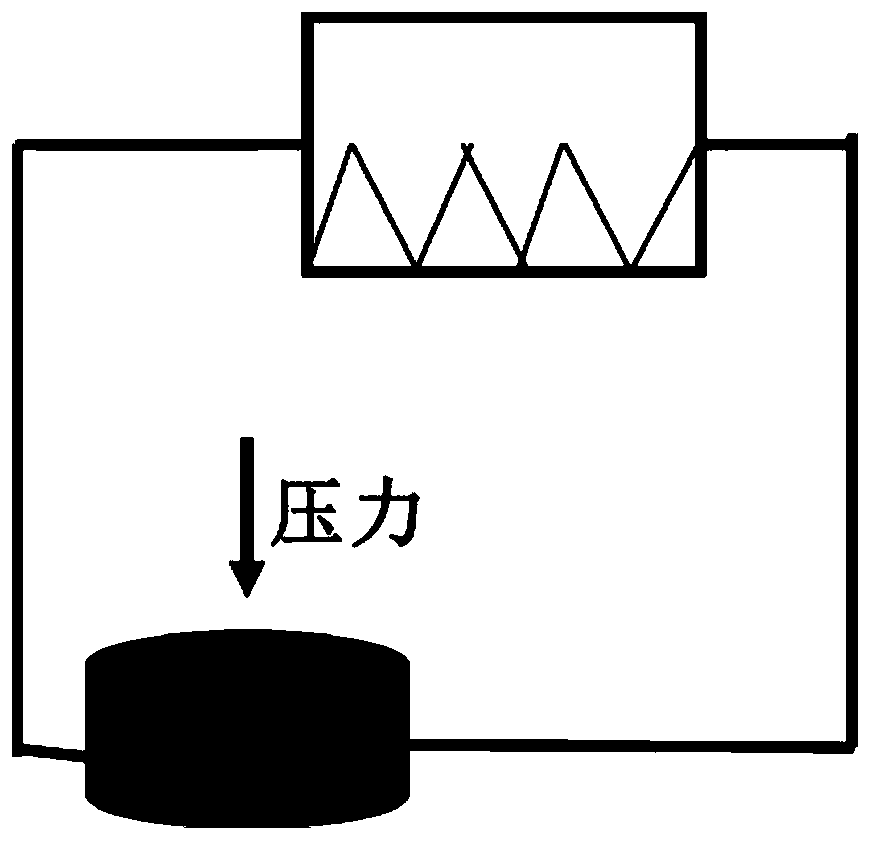

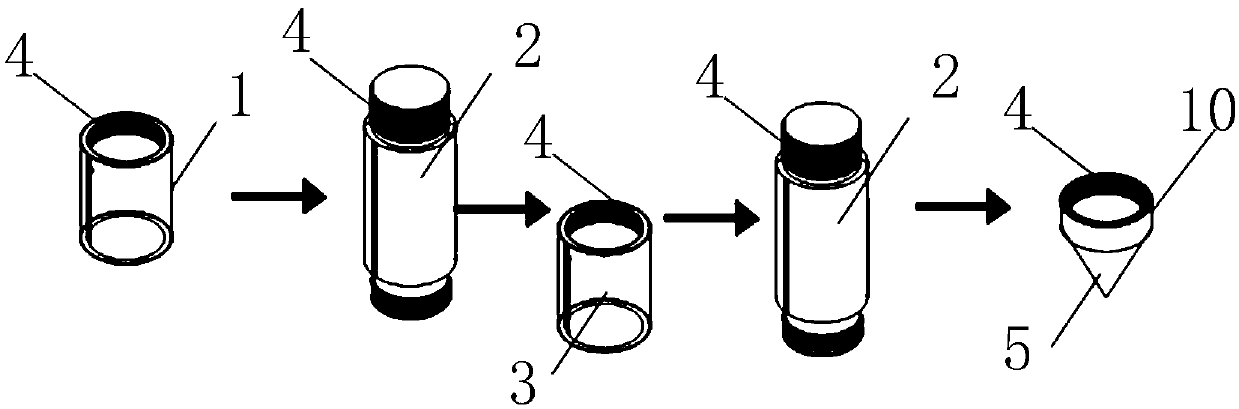

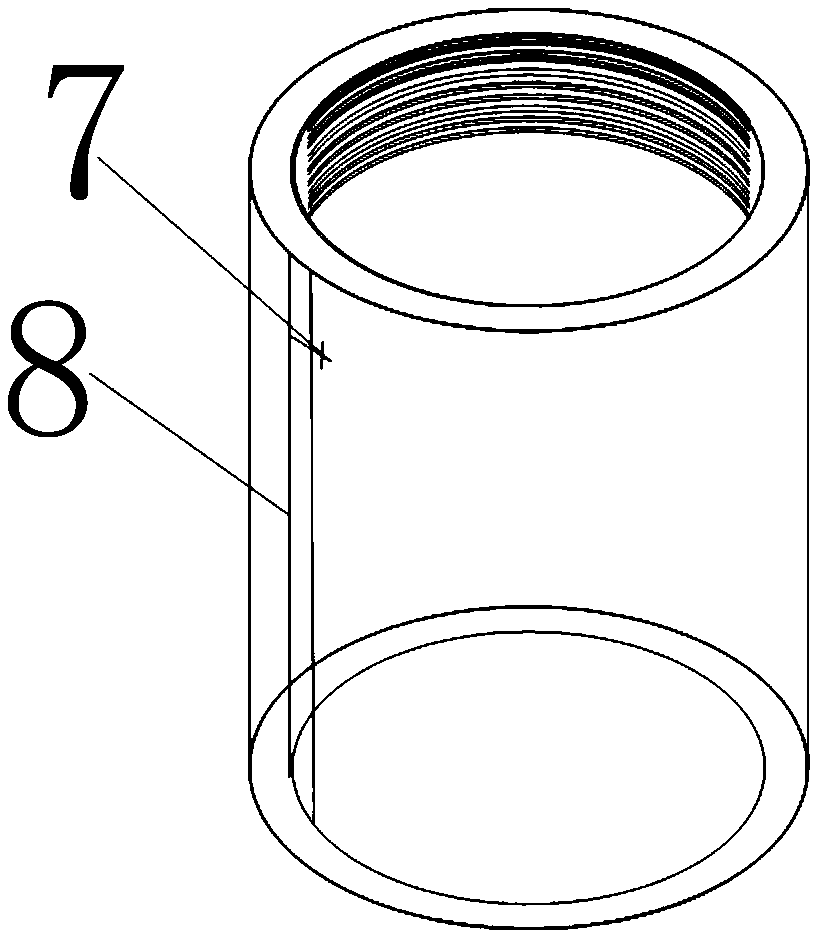

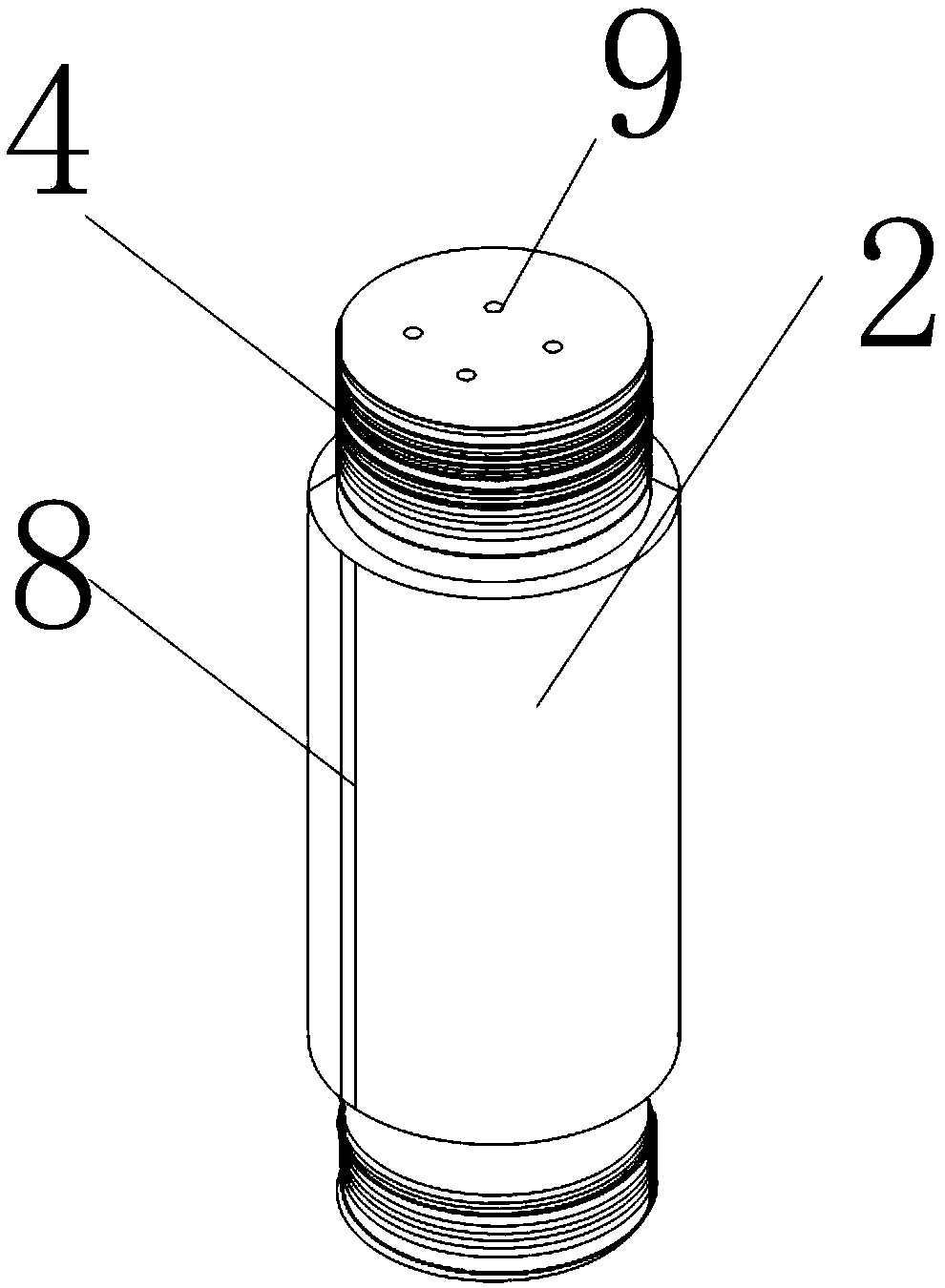

Method and device for preparing large-size bulk amorphous composite materials

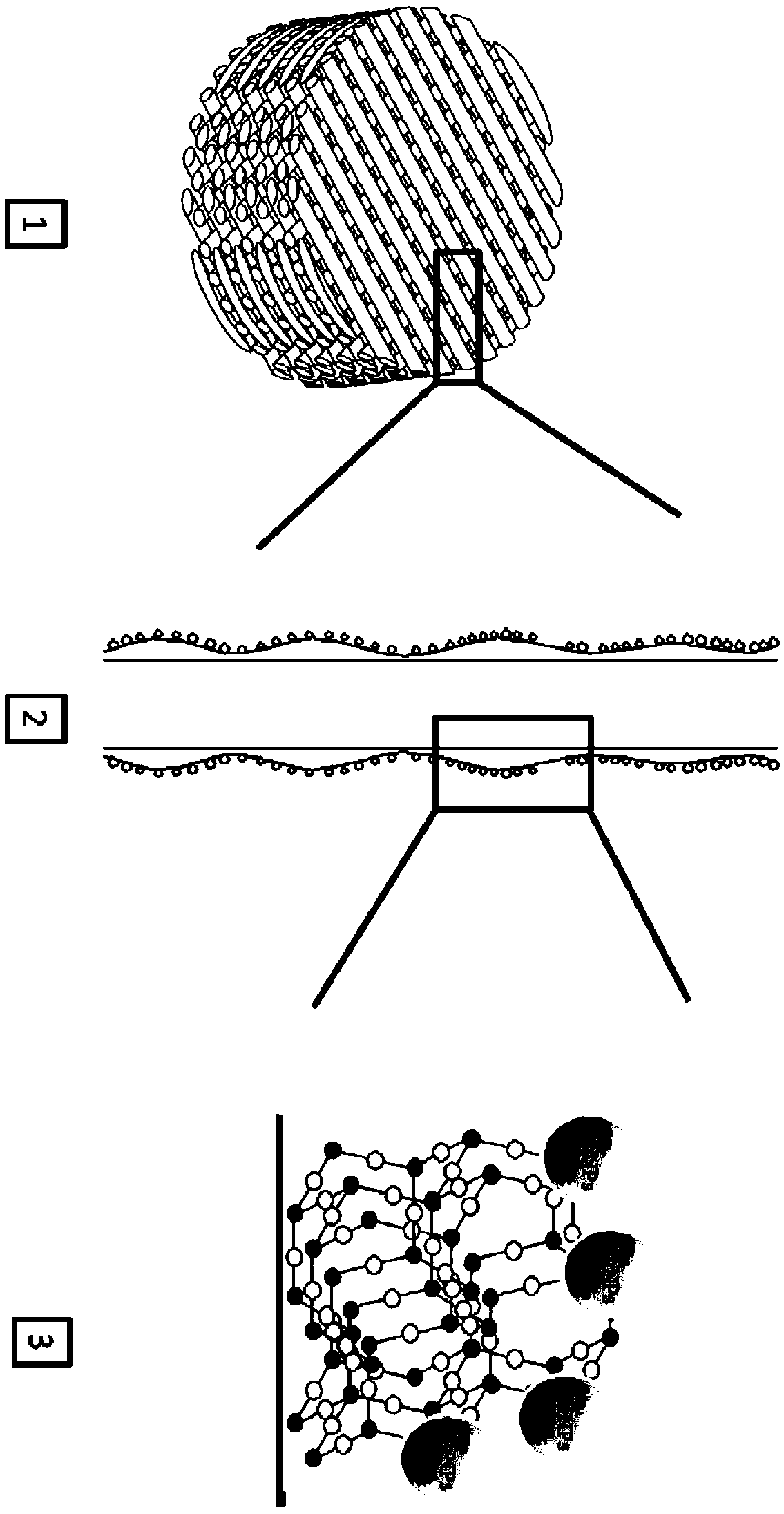

The invention provides a method for preparing large-size bulk amorphous composite materials, which belongs to the field of preparing amorphous alloy (metallic glass) and composite materials thereof. The method applies to superplastic diffusion bonding of bulk amorphous substances and fiber, and is characterized in that the bulk amorphous substances and the fiber are arranged in a certain mode (such as a layered mode and the like), put into a mold, pressurized and thermally insulated under gas protection or vacuum for superplastic diffusion bonding; pressure is released after a certain period of time; and workpieces are taken out of the mold. The invention also provides a novel device for preparing large-size bulk amorphous, fiber / amorphous composite materials through superplastic diffusion bonding. The device consists of a heating system, a heat insulation system, a mold system, a loading system, a gas protection system and a cooling system. The method and the device have the advantages of reinforcing the fiber, enabling the shape of amorphous alloy-base composite materials to be designed, enabling the volume of the fiber in the composite materials to be controlled and enabling the fiber to be used in other various amorphous alloy systems low in amorphous formation capability, and are applicable to armor boards, armor-piercing shells and the like.

Owner:UNIV OF SCI & TECH BEIJING

Water-swelling rubber composite material, and preparation method and application thereof

InactiveCN103570985AImprove mechanical propertiesHigh expansion ratioDrilling compositionPolyethylene glycolAccelerant

The invention discloses a water-swelling rubber composite material. The rubber composite material is formed from the following components in parts by weight: 100 parts of rubber, 30-100 parts of super adsorbent resin, 2-10 parts of metal ion sealing agent, 0.5-2.5 parts of solid softening agent, 0.5-3.5 parts of coloring agent, 1-7 parts of anti-aging agent, 1-7 parts of accelerant, 1-8 parts of zinc oxide, 5-45 parts of reinforcing agent, 5-20 parts of plasticizer, 0.1-2.6 parts of vulcanizing agent, and 5-45 parts of mixture of PEG (polyethylene glycol) and MDI (diphenylmethane diisocyanate) at a molar ratio of 1:1. The invention further provides a preparation of the rubber composite material, in particular provides an application of the rubber composite material as superfine rubber swelling particles in a large pore path or high-permeability belt of a reservoir deep strata for profile control and water shutoff of an oil-water well.

Owner:CHINA PETROLEUM & CHEM CORP +1

Collagen-based biomedical material by taking dialdehyde polyethylene glycol as cross-linking agent and preparation method thereof

ActiveCN104262648ANon-irritatingAvoid Metabolic Toxic PhenomenaAbsorbent padsProsthesisBiologic scaffoldPolymer science

Owner:SICHUAN UNIV

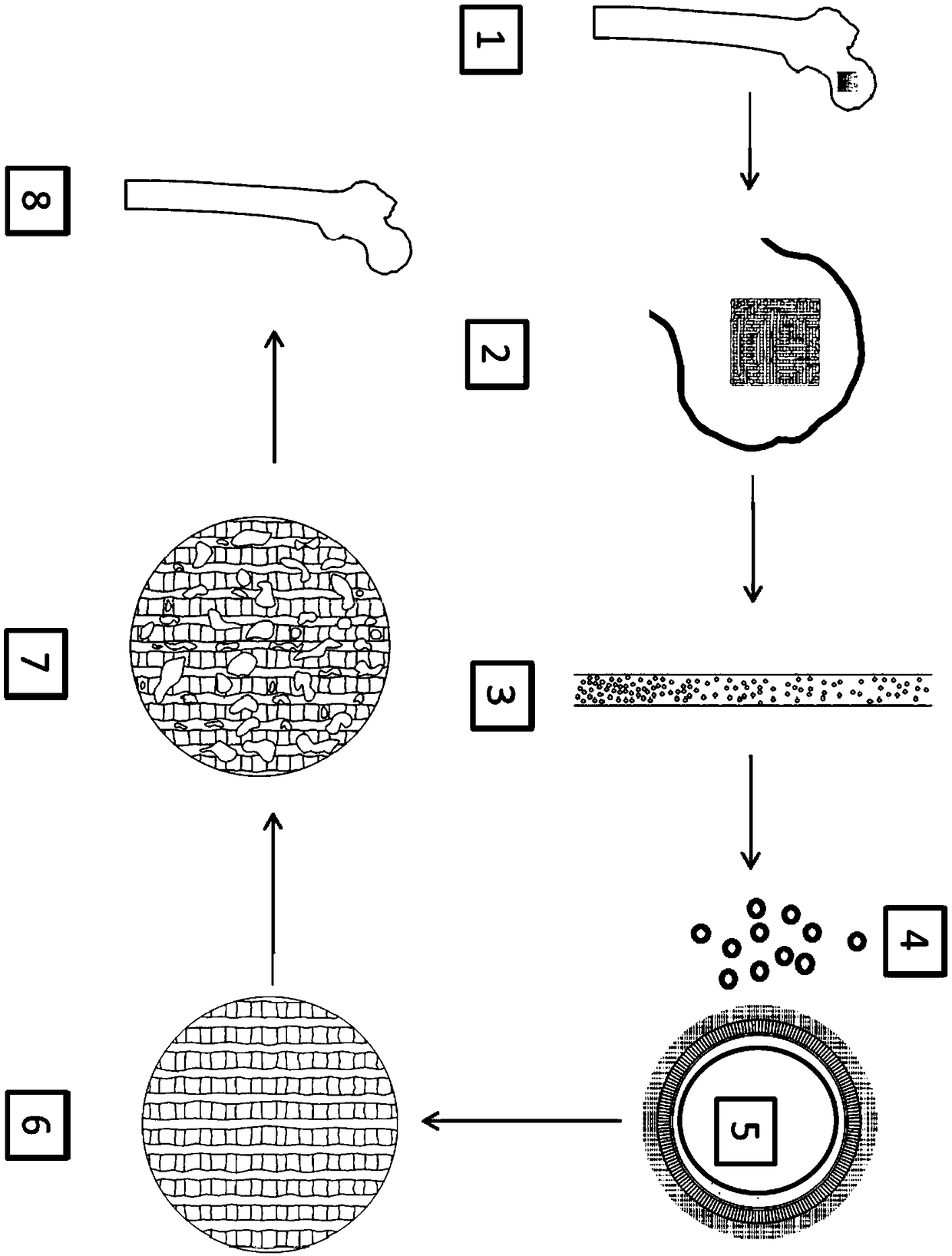

Three-dimensional-structured silk fibroin/hydroxyapatite composite stent and preparation method thereof

InactiveCN107137774AUniform particle sizeCan control the microstructureAdditive manufacturing apparatusProsthesisPorosityCell adhesion

The invention discloses a three-dimensional-structured silk fibroin / hydroxyapatite composite stent and a preparation method thereof. The preparation method of the three-dimensional-structured silk fibroin / hydroxyapatite composite stent comprises preparing silk fibroin / hydroxyapatite composite powder uniform in size through biomimetic mineralization; then through the three-dimensional printing technology, precisely controlling the appearance of the composite stent and the shape, size and connectivity of internal holes to obtain the special three-dimensional-structured silk fibroin / hydroxyapatite composite stent applicable to bone tissue engineering for facilitating cell growth and ossification. The three-dimensional-structured silk fibroin / hydroxyapatite composite stent has the advantage of achieving one stent in one structure and is a bone repair composite material stent high in porosity and pore connectivity and controllable in mechanical property, thereby being beneficial to osteogenic induction and differentiation and cell adhesion, migration and proliferation and capable of creating microenvironment meeting growth demands of osteoblasts. The three-dimensional-structured silk fibroin / hydroxyapatite composite stent is simple and practicable in preparation, low in process and equipment requirements, easy to control of experiment parameters and capable of promoting popularization and application of the three-dimensional printing technology in the biological field.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

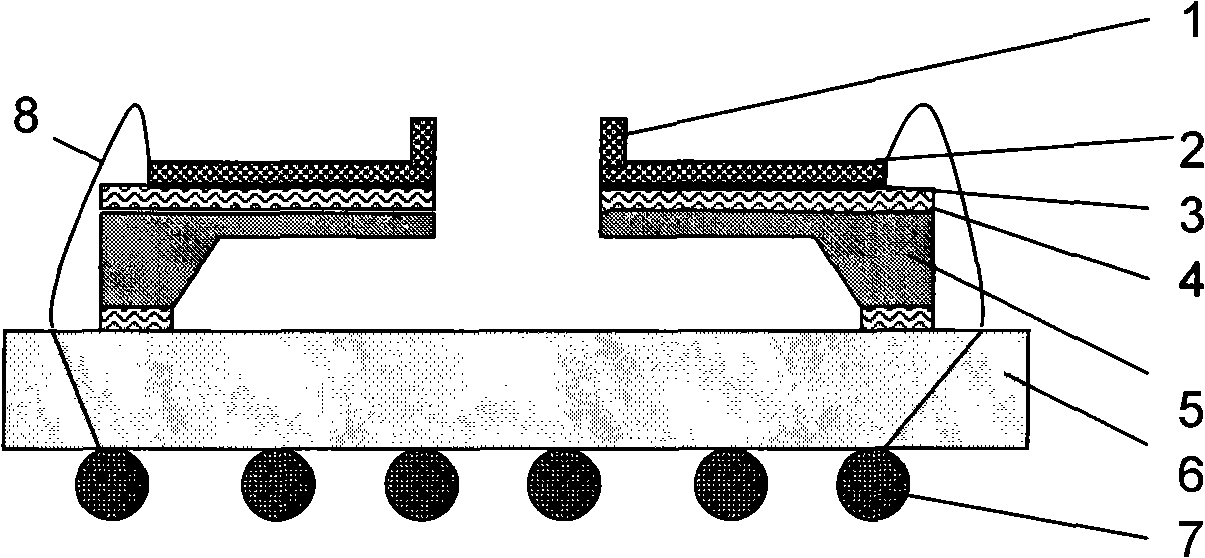

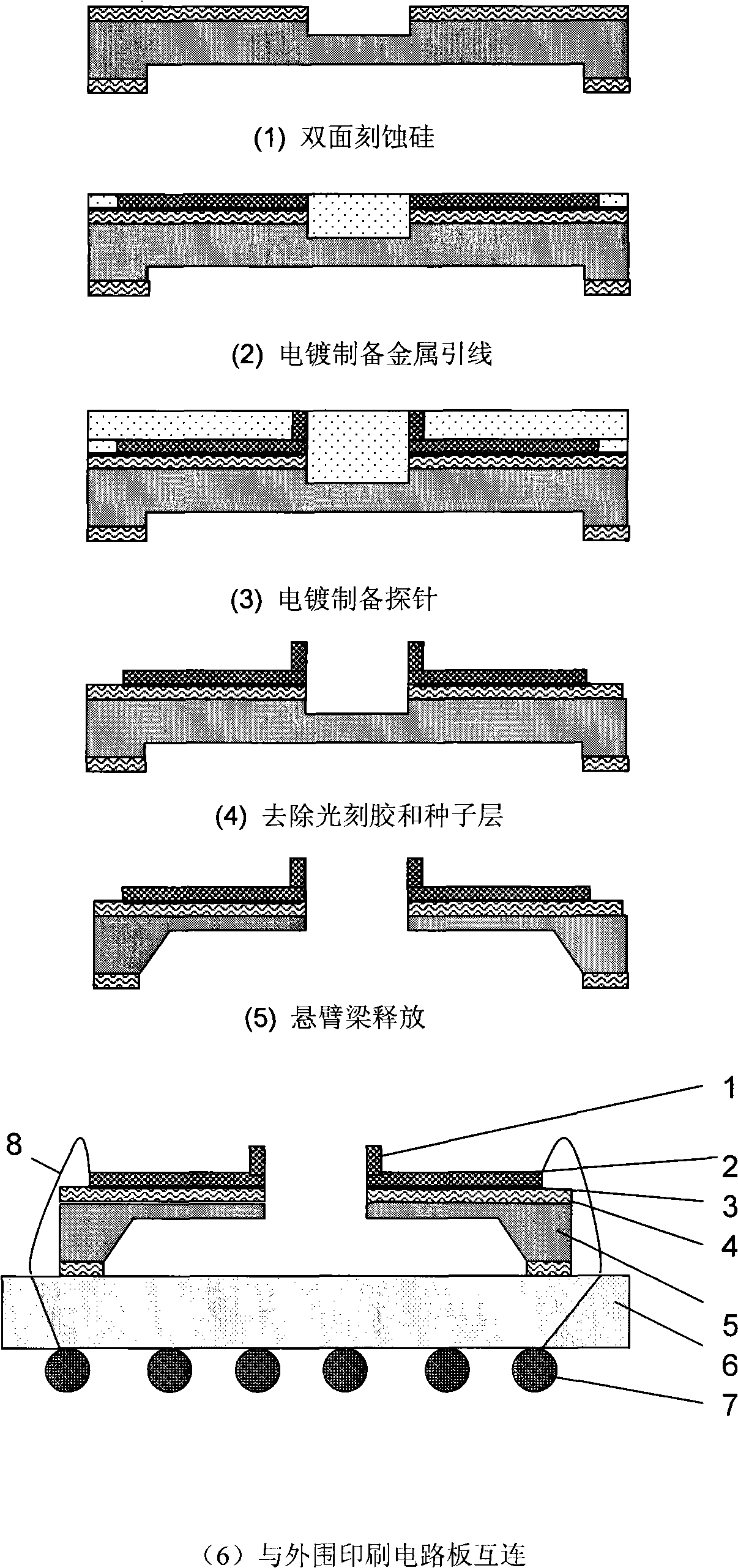

Metal-silicon compound cantilever beam type microelectronic mechanical system probe card and manufacture method thereof

InactiveCN101354404AImprove electrical performanceImprove mechanical propertiesTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamProbe card

The invention relates to a metal-silicon composite cantilever beam typed micron-electronic mechanical system probing card and a preparation method thereof; an ultraviolet thick film photolithography and bulk silicon micro-processing composite process is adopted to prepare a metal-silicon composite cantilever beam probing card structure, thus replacing an existing probing card structure consisting of single silicon or metal. The ultraviolet thick film photolithography process is used for preparing the metal probe with high depth / width ratio and metal circuit transmission wires below the probes, and the bulk silicon micro-processing composite process is used to prepare the silicon cantilever beam structure. The force during the testing process is commonly borne by the silicon cantilever beam and the metal circuit above the silicon cantilever beam; the electric and mechanical property of the probing card structure is controlled by adjusting the geometrical parameters of the metal circuit leads and the silicon cantilever beam; the probes above the probing card can be arranged by the positions of the pins of the chip to be tested; the probe tips are corresponding to the position of the pins of the chip one by one. The end of the metal circuit transmission wire leads the circuit to be connected on the back surface by a through hole electro-plating or wire punching type on a silicon substrate and leads the circuits to be connected onto printing circuit boards and test machine platforms further.

Owner:SHANGHAI JIAO TONG UNIV

Flexible self-healing conductive hydrogel sensor and preparation method thereof

InactiveCN110698693AGood tensile mechanical propertiesImprove fatigue resistanceFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsPolyvinyl alcoholMaterials science

The invention relates to a flexible self-healing conductive hydrogel sensor and a preparation method thereof. According to the preparation method, the flexible self-healing conductive hydrogel sensoris prepared through following steps: blending an acrylamide solution and an acetoacetated polyvinyl alcohol solution, initiating polymerization to obtain a flexible precursor hydrogel, and then soaking the flexible precursor hydrogel in a ferric trichloride solution to obtain a finished product. The prepared hydrogel has excellent sensing performance and can be successfully used for monitoring human motion or physiological signals, meanwhile, the hydrogel device has good fatigue durability and self-healing performance, and therefore the requirements of sensing devices on the service life and signal stability can be met.

Owner:DONGHUA UNIV

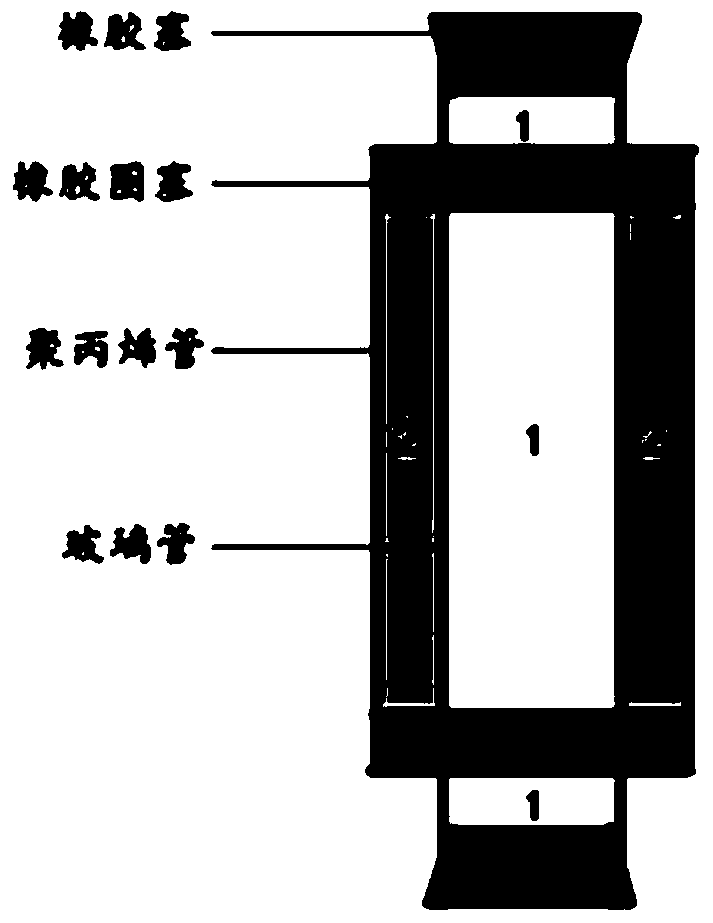

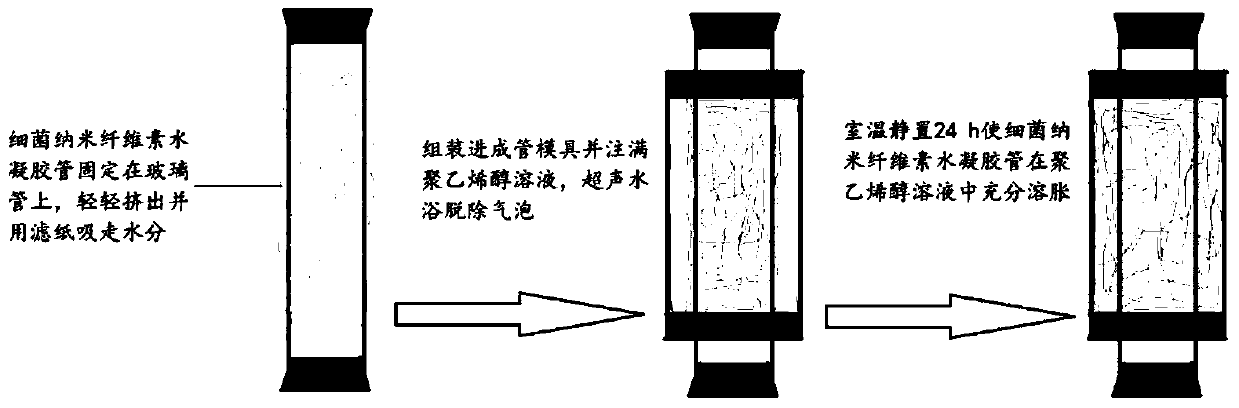

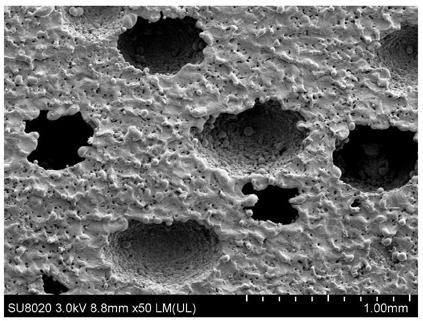

Porous elastic polyvinyl alcohol/bacterial nano-cellulose composite hydrogel tube, as well as preparation method and application of composite hydrogel tube

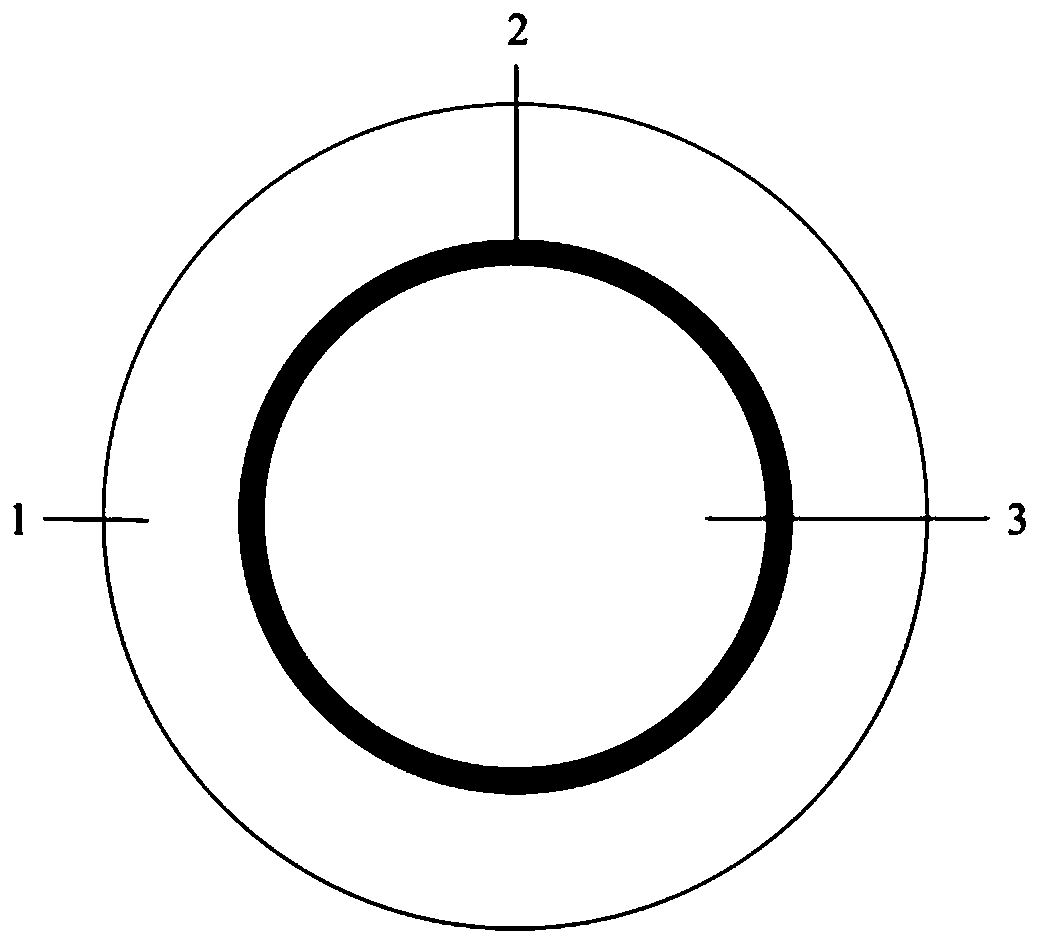

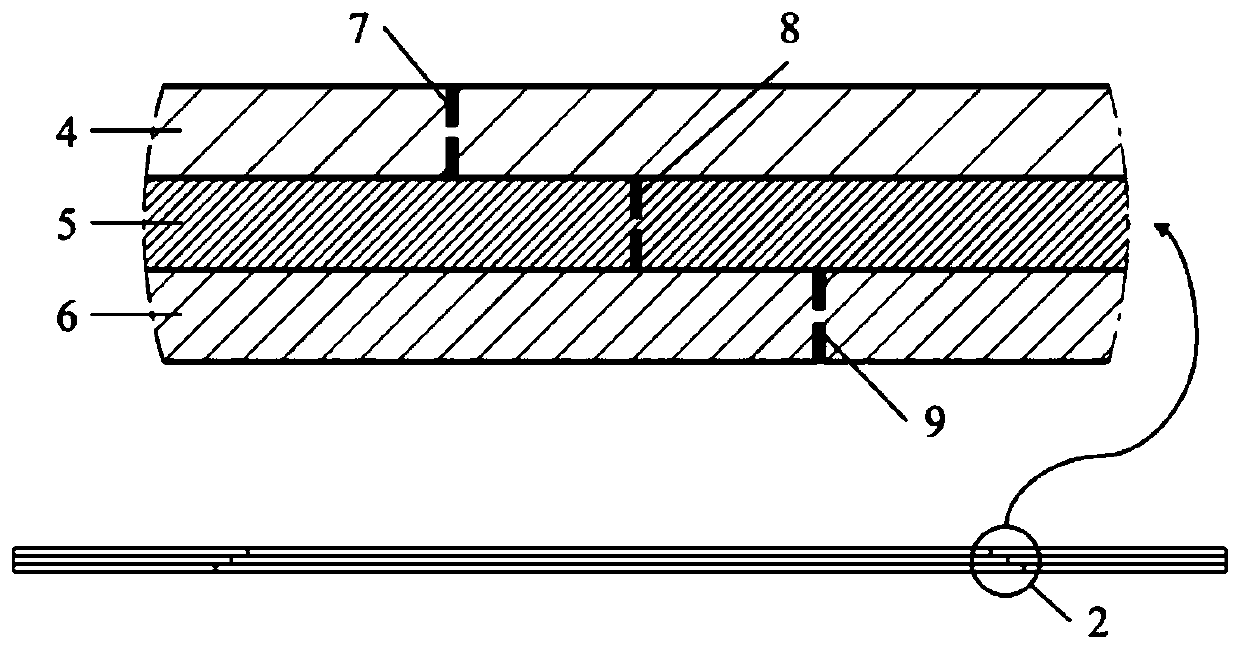

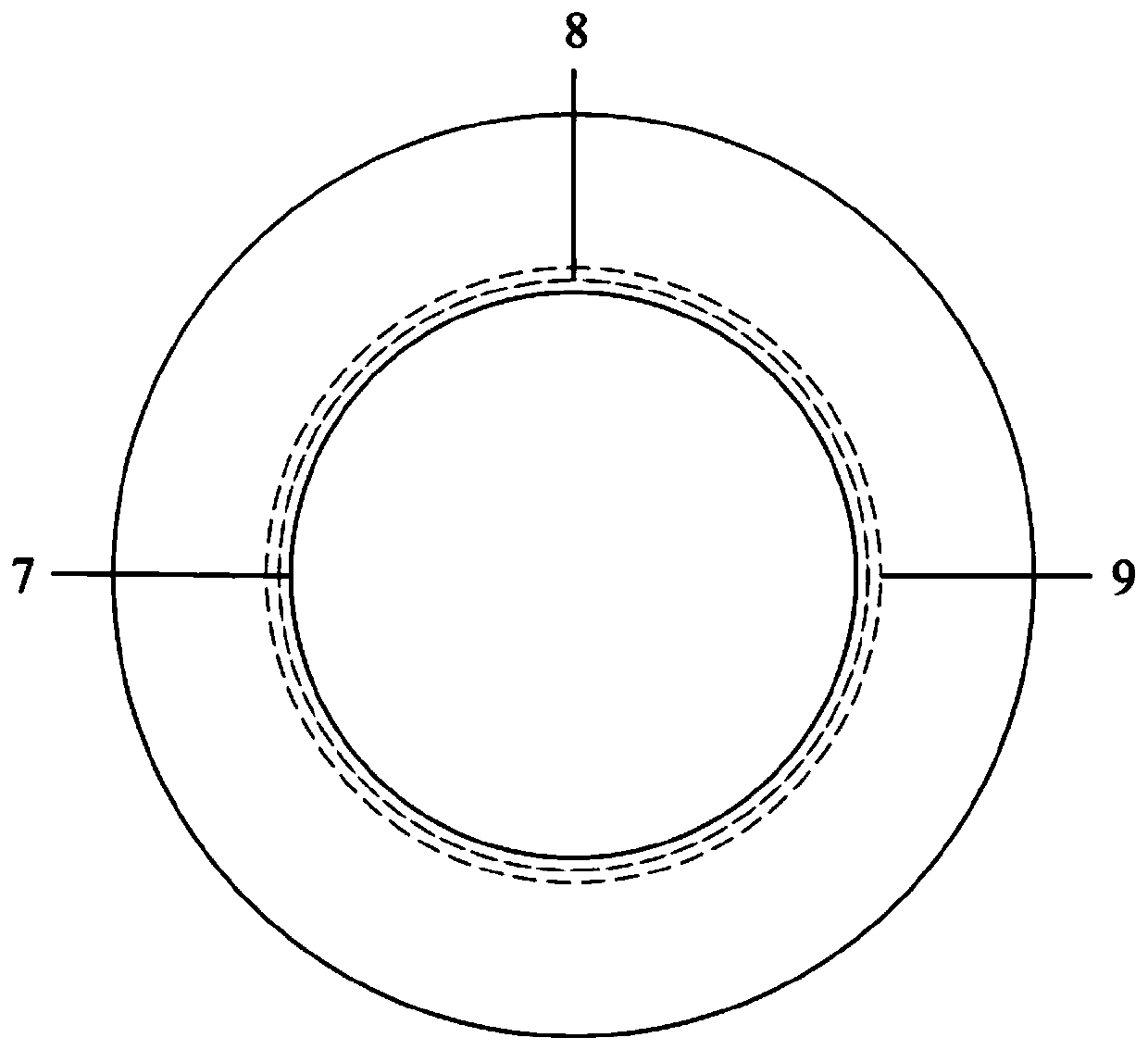

ActiveCN104208759AExcellent Mechanical PropertiesControllable mechanical propertiesSurgeryProsthesisFiber networkAdhesion process

The invention relates to a porous elastic polyvinyl alcohol / bacterial nano-cellulose composite hydrogel tube, as well as a preparation method and application of the composite hydrogel tube. The composite hydrogel tube comprises a surface layer and a lining layer, wherein the surface layer has a smooth surface, and the lining layer is of a nano-fiber network structure. The preparation method comprises the following steps: pretreating the bacterial nano-cellulose composite hydrogel tube; preparing a polyvinyl alcohol solution; freezing at minus 80 DEG C for molding; unfreezing by ethanol at minus 20 DEG C; and soaking in ultrapure water at room temperature to replace the ethanol. The porous elastic polyvinyl alcohol / bacterial nano-cellulose composite hydrogel tube is controllable in mechanical performance and can meet the requirements of multiple tissue repairing stents, the nano-fiber network structure of the composite hydrogel tube is advantageous to cell adhesion and proliferation, and the mutually communicated porous structure of the composite hydrogel structure is advantageous to nutrition transmission and cell ingrowth; and the porous elastic polyvinyl alcohol / bacterial nano-cellulose composite hydrogel tube is simple in preparation process and low in cost, and has a good application prospect in vascular repairing stents and nerve repairing stents.

Owner:DONGHUA UNIV

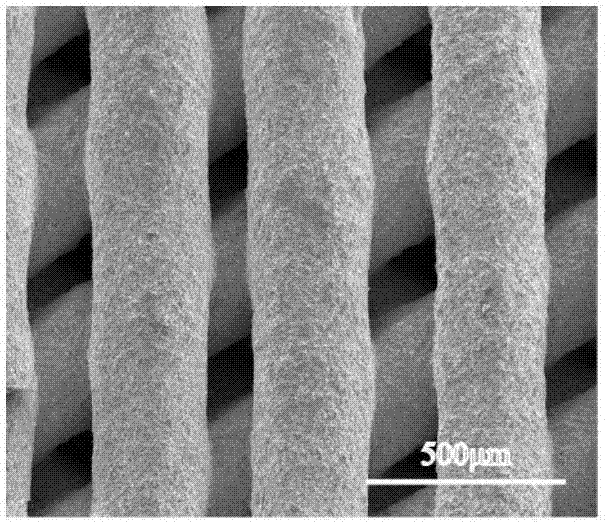

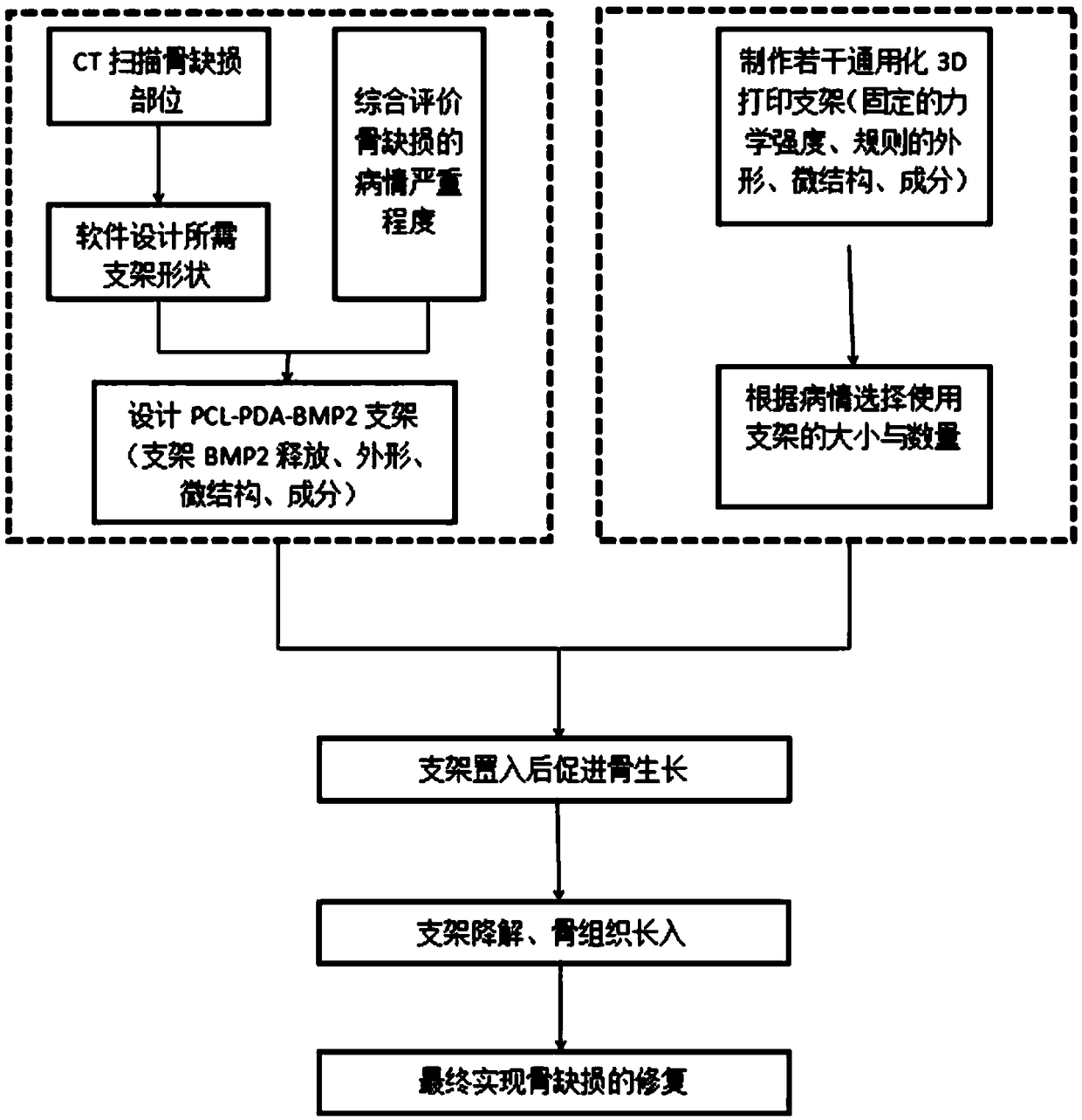

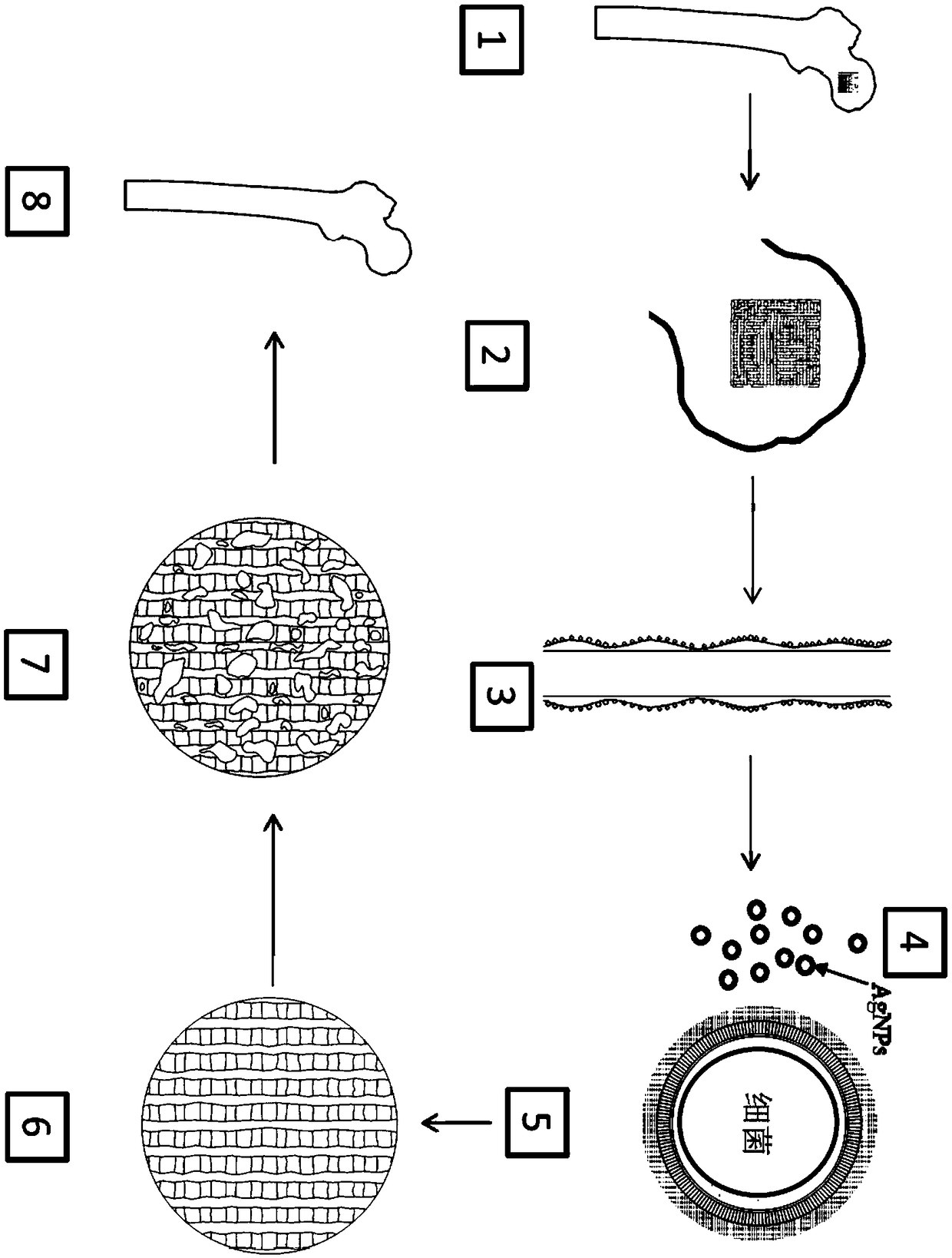

3D printed PCL-PDA-BMP2 bone tissue engineering scaffold and preparation method thereof

InactiveCN108904880APromote ingrowthPromotes new bone tissue formationAdditive manufacturing apparatusPharmaceutical delivery mechanismBone tissue engineeringMicrostructure

The invention discloses a 3D printed PCL-PDA-BMP2 bone tissue engineering scaffold and a preparation method thereof. The 3D printed PCL-PDA-BMP2 bone tissue engineering scaffold is prepared accordingto the following steps: adopting a fusion extruding forming type 3D printing technology for extruding PCL and forming fiber bundles and preparing a 3D printed PCL scaffold through a splicing frameworkof the fiber bundles; forming a PDA coating by automatically polymerizing dopamine on the fiber surface of the 3D printed PCL scaffold, thereby preparing a 3D printed PCL-PDA scaffold; lastly, soaking the acquired 3D printed PCL-PDA scaffold in a BMP2 solution, thereby acquiring the 3D printed PCL-PDA-BMP2 bone tissue engineering scaffold. The scaffold prepared according to the invention has theadvantages of simple and reliable structure, controllable appearance and microstructure, reliable mechanical properties and controllable ion release property, and can be used for restorative treatmentof bone trauma, bone tumors and bone defect after bone infection.

Owner:NANJING FIRST HOSPITAL

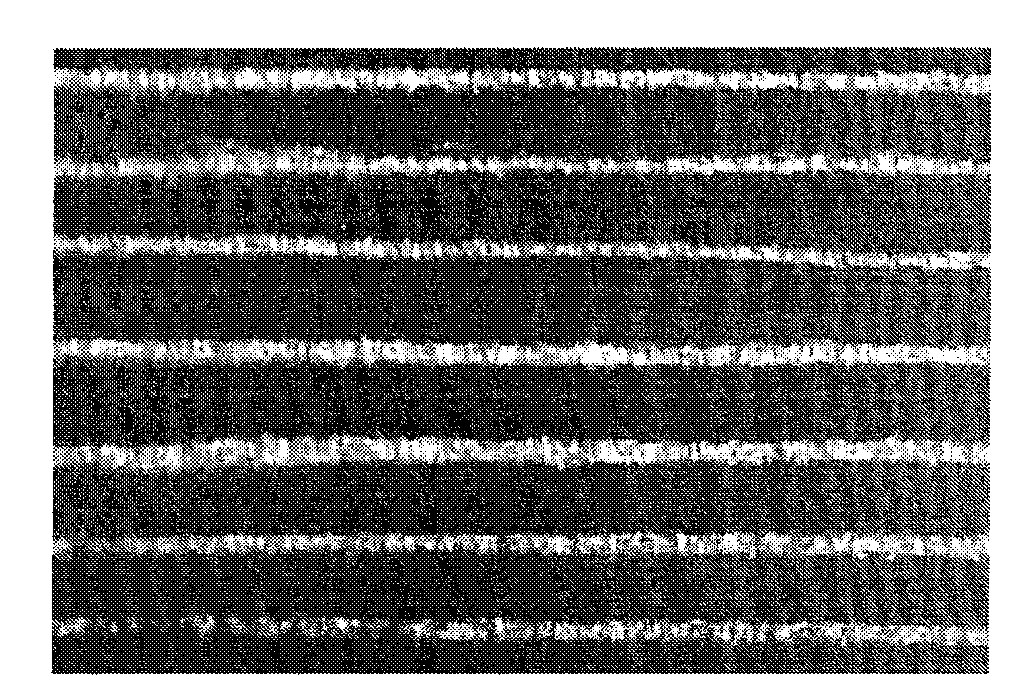

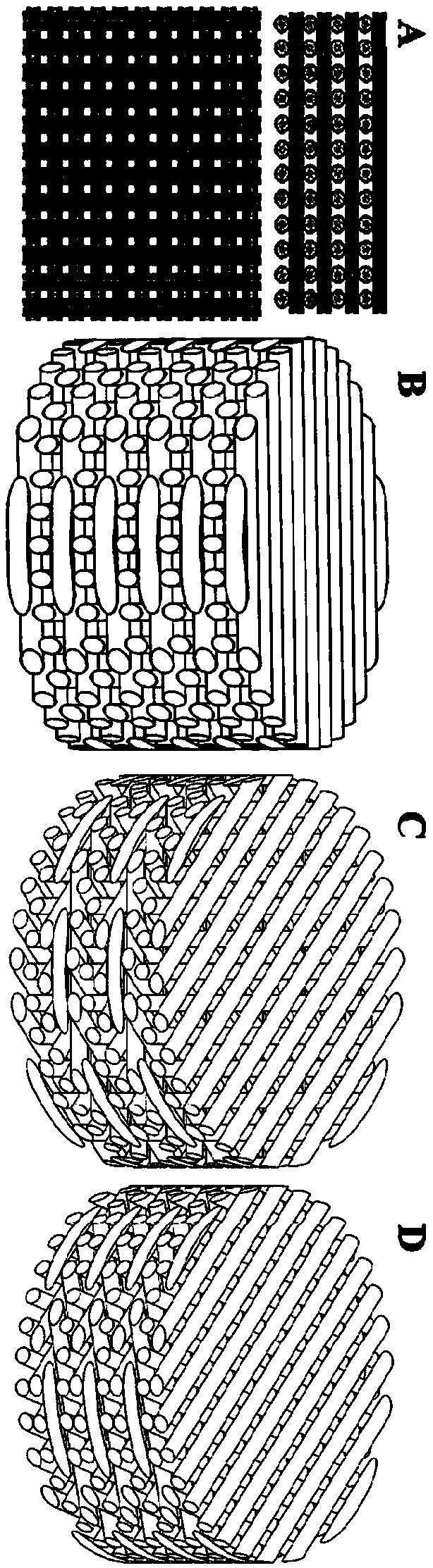

Al2O3 ceramic composite materials with bionic structure and preparation method thereof

ActiveCN103158295AControllable mechanical propertiesHigh purityLaminationLamination apparatusCeramic compositeFlexural strength

The invention discloses Al2O3 ceramic composite materials with a bionic structure and a preparation method thereof. The ceramic composite materials are in a multiple layers of structure and are formed by Al2O3 and metal Mo in an alternating overlapping mode, a surface layer is an Al2O3 layer, and a spacer layer is a metal Mo layer. After being alternatively overlapped in a graphite mold, Al2O3 powder and metal Mo powder are directly placed in a hot press furnace for hot pressing and sintering, and the Al2O3 ceramic composite materials are obtained. The Al2O3 ceramic composite materials are controllable in mechanical property (mainly breaking tenacity and bending strength), high in purity, excellent in high-temperature friction performance and capable of being used for lubricating and sealing materials in extremely severe environments (high temperature, corrosion, special atmosphere and the like).

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

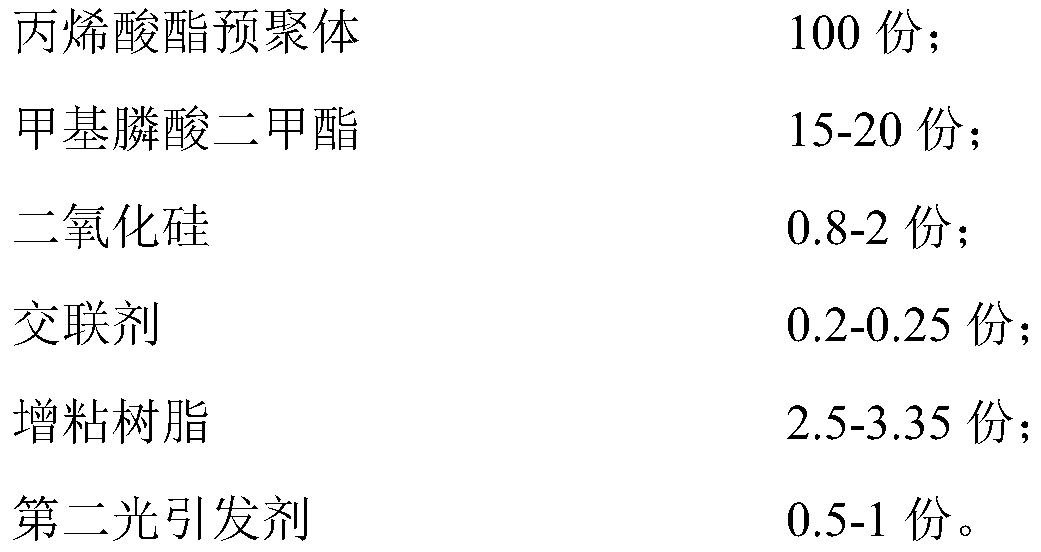

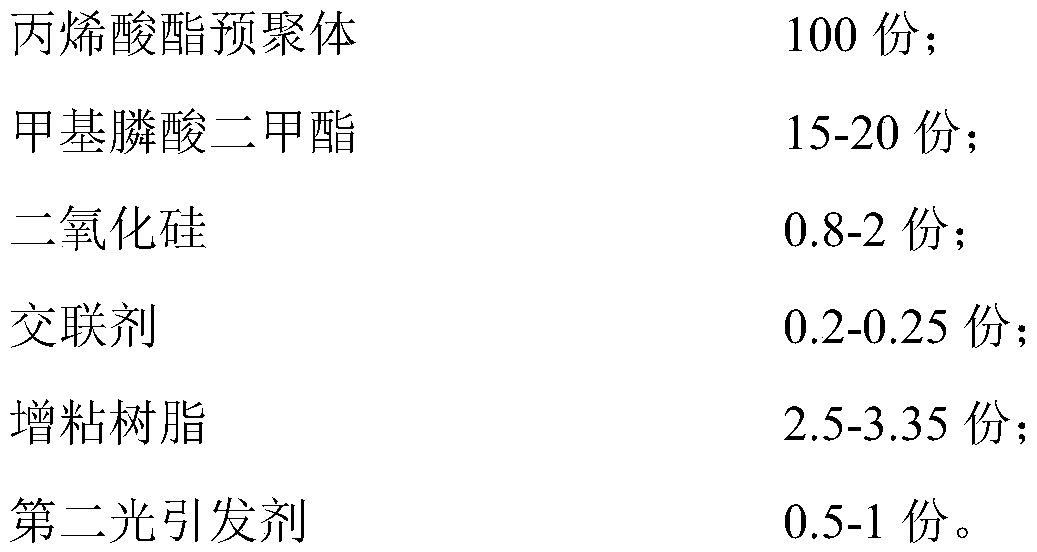

Halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive and pressure-sensitive adhesive tape, and preparation method thereof

ActiveCN110655872AImprove flame retardant performanceImprove adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceDimethyl methylphosphonate

The invention discloses a halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive and a pressure-sensitive adhesive tape, and a preparation method thereof. The halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive comprises the following raw materials in parts by weight: 100 parts of an acrylate prepolymer, 15 to 20 parts of dimethyl methylphosphonate, 0.8 to 2 parts of silicon dioxide, 0.2 to 0.25 part of a cross-linking agent, 2.5 to 3.35 parts of tackifying resin, and 0.5 to 1 part of a second photoinitiator. The pressure-sensitive adhesive tape formed by the halogen-free flame-retardant UV-cured acrylate pressure-sensitive adhesive is good in flame-retardant effect, excellent in pressure-sensitive adhesive property and wide in application range.

Owner:湖南省和祥润新材料有限公司

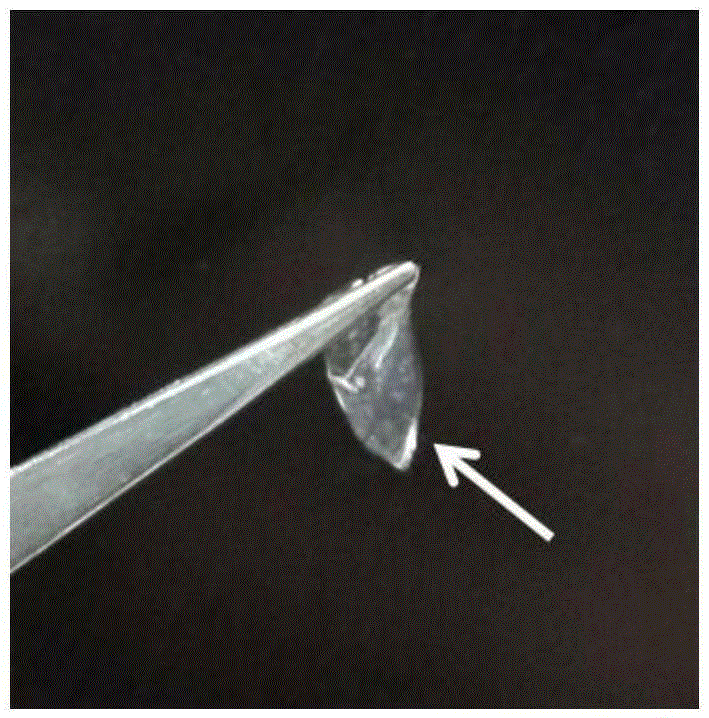

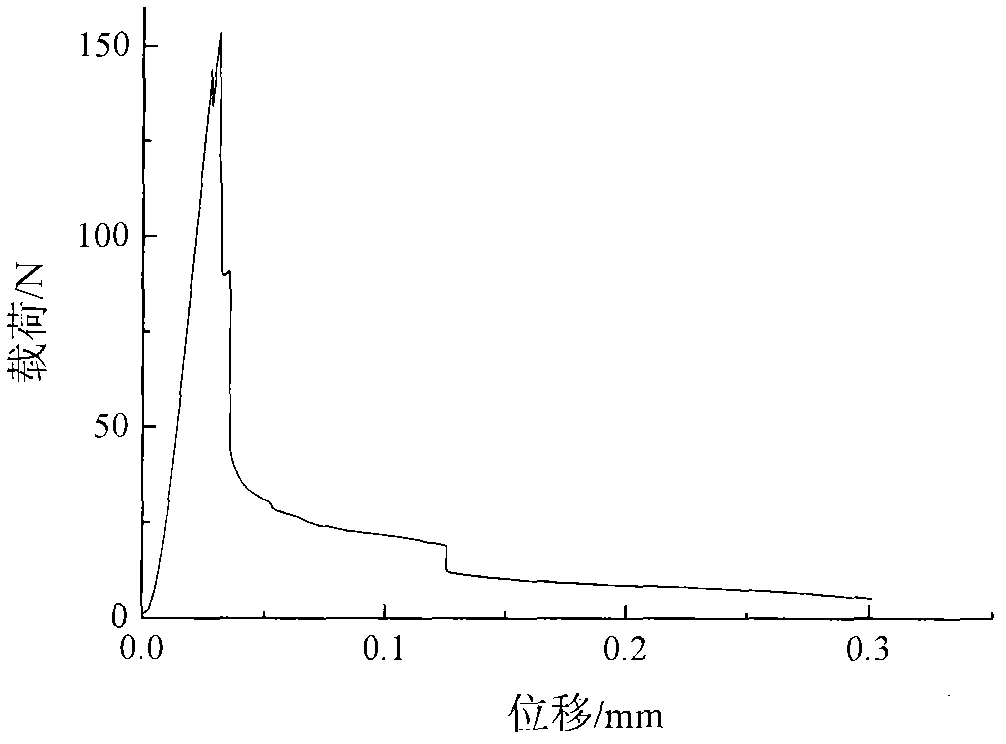

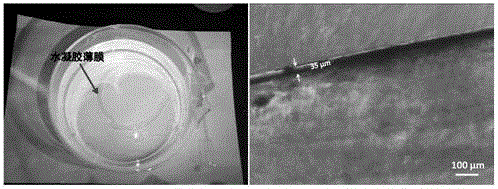

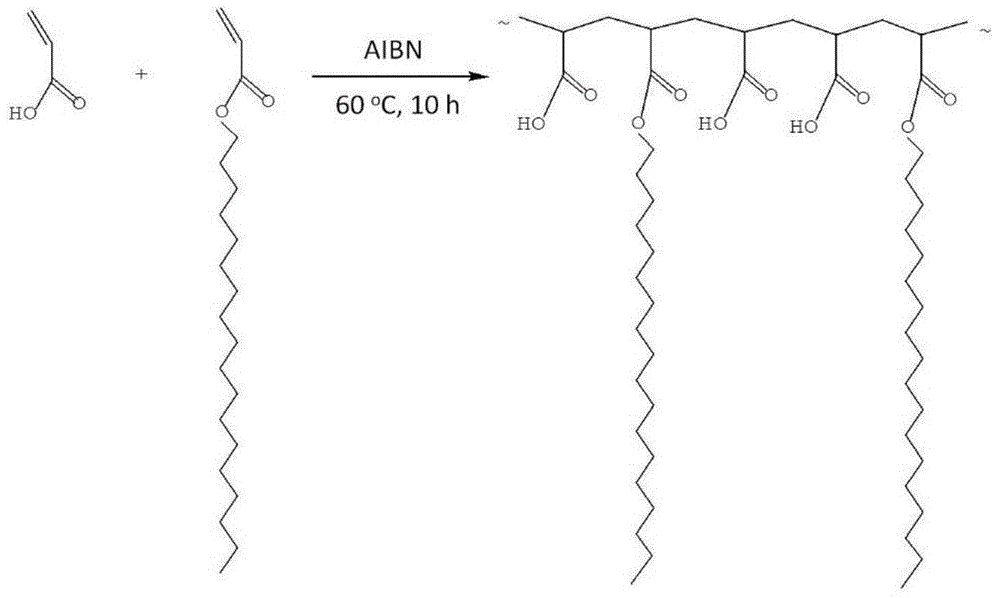

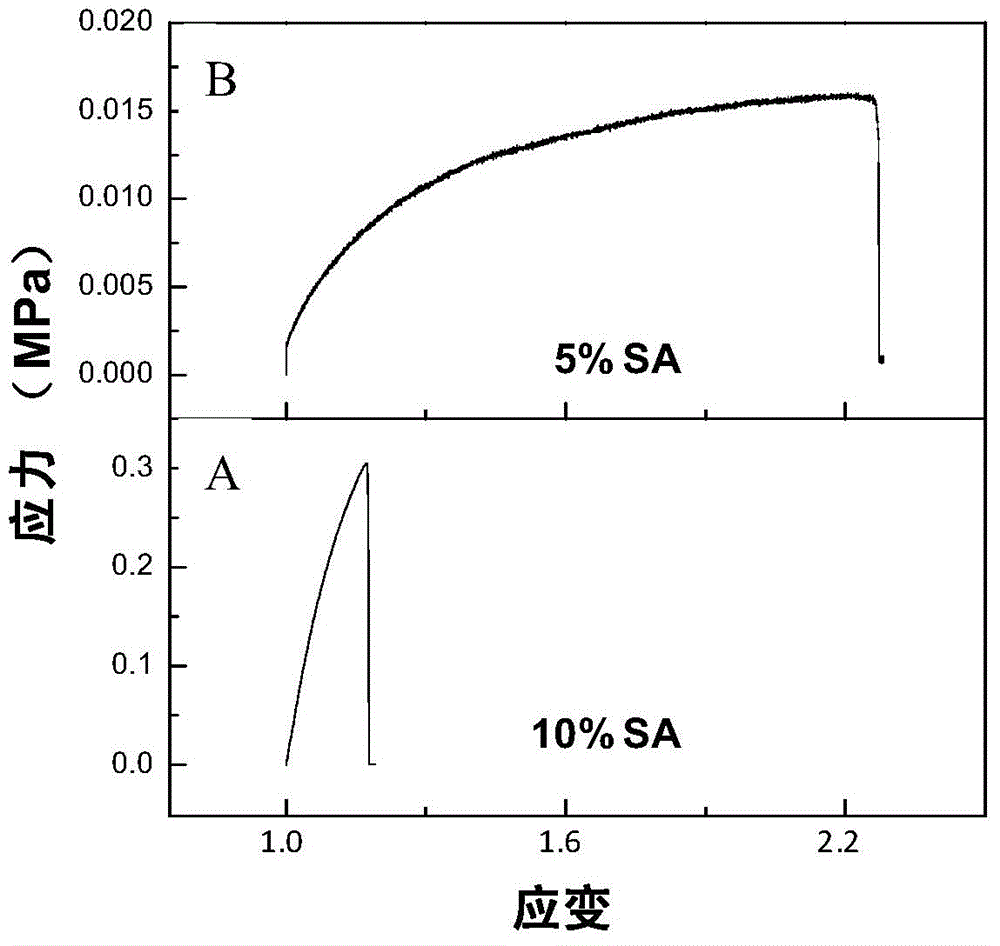

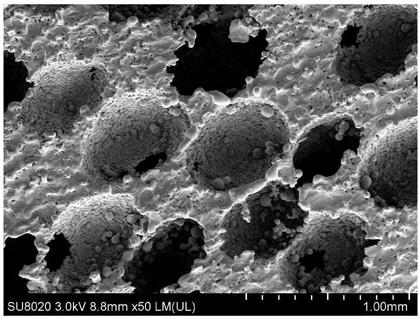

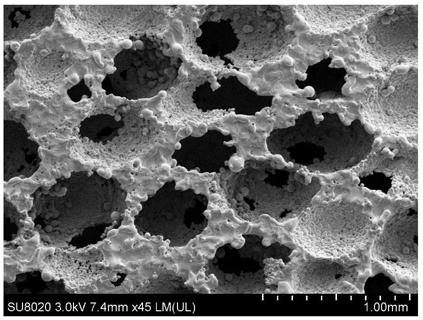

Preparation method and product of ultrathin high strength hydrogel membrane

The invention discloses a preparation method of an ultrathin high strength hydrogel membrane. The preparation method comprises the steps of mixing a hydrophilic monomer, a hydrophobic monomer, an initiator and a solvent A to obtain a mixed liquor, and performing free radical polymerization to obtain a random copolymer solution; and dripping the random copolymer solution into a solvent B, spreading on the surface of the solvent B to form an ultrathin high strength hydrogel membrane, wherein the solvent A is a single solvent or a mixed solvent capable of simultaneously dissolving the hydrophilic monomer, the hydrophobic monomer and the random copolymer, the solvent B is a poor solvent of the random copolymer and is a single solvent or a mixed solvent, and the solvent A and solvent B are much different in surface tension. The hydrogel membrane prepared by the method has the thickness of 10-200mu m, has good mechanical property, can be converted into sol and has repairable function under stimulation of pH, temperature and solvent, and can be used in the fields of medical wound dressing, separating membrane materials, facial mask base materials.

Owner:ZHEJIANG UNIV

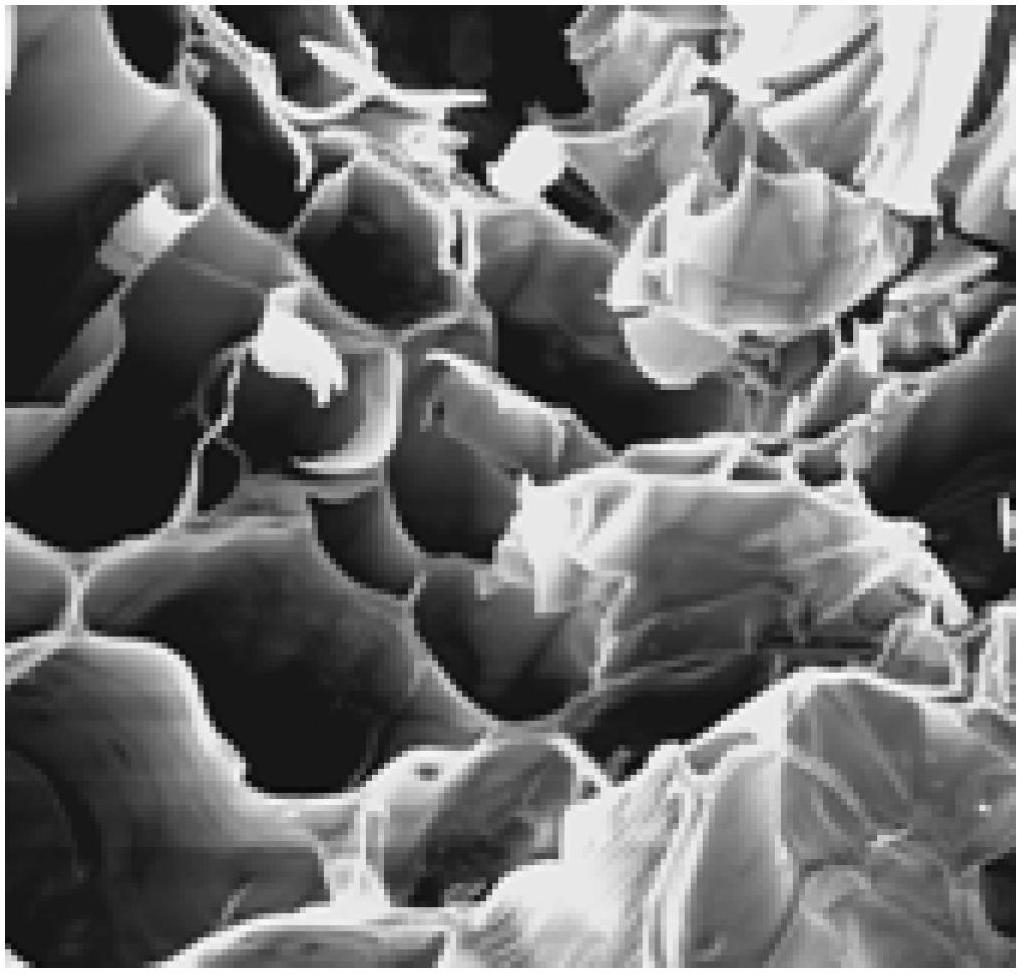

Preparation method of porous titanium and titanium alloy

The invention discloses a preparation method of porous titanium and titanium alloy, and belongs to the technical field of porous metal materials. The preparation method of the porous titanium and titanium alloy with an anisotropic elongated pore structure suitable for bone tissue to grow in includes the steps that stearic acid, a binder and a titanium raw material are mixed evenly; the obtained mixture is subjected to press forming and then dried, and a pressed blank is obtained; the pressed blank is subjected to vacuum sintering and cooling, and the porous titanium or porous titanium alloy isobtained. By adjusting the mass ratio of the titanium raw material to stearic acid, adjusting the size of stearic acid and optimizing the forming pressure condition, control over the porosity, pore size and pore shape of the porous titanium and titanium alloy is realized, and the porous titanium and titanium alloy with an orderly elongated pore structure are obtained.

Owner:PANZHIHUA UNIV

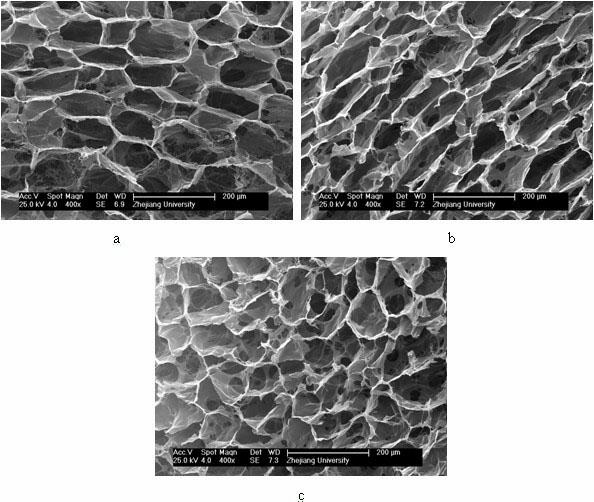

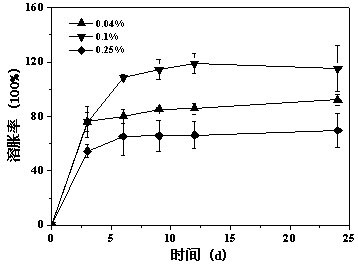

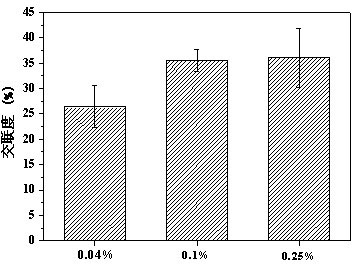

Method for preparing cross-linked collagen/chitosan tissue engineering porous support in one-step freeze-drying mode

ActiveCN102580163AControllable mechanical propertiesAppropriate degradation rateProsthesisChemistryBiological materials

The invention discloses a method for preparing a cross-linked collagen / chitosan tissue engineering porous support in one-step freeze-drying mode, which uses natural biological material of collagen and chitosan as raw materials, directly adds collagen / chitosan mixed swelling solutions in a glutaraldehyde solution and prepares the collagen / chitosan tissue engineering porous support through a one-step refrigeration freeze-drying mode. The collagen / chitosan support prepared through the method has the advantages of being controllable in mechanical property, proper in degradation rate and good in biocompatiability. Further, the method only needs a one-step freeze-drying process and effectively solves the problems of support collapsing, micro-structure breaking and the like caused by a traditional preparing method. The method is simple and practical, low in energy consumption, time-saving, material-saving and good in repeatability, and the constructed collagen / chitosan porous support can be widely used in the field of tissue engineering and has good clinical application prospect.

Owner:ZHEJIANG UNIV

Putty type silicone rubber composition and preparation method and application thereof

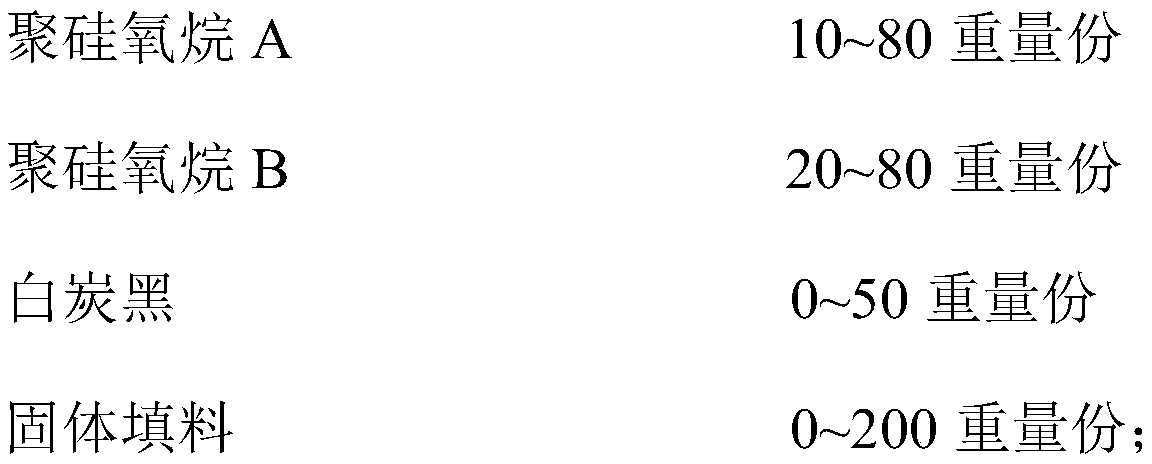

The invention provides a putty type silicone rubber composition and a preparation method and application thereof. The putty type silicone rubber composition comprises a crosslinking component and a catalytic component, wherein the crosslinking component comprises a polysiloxane A, a polysiloxane B, white carbon black and a solid filler, and the catalytic component comprises a polysiloxane A, a polysiloxane B, white carbon, a solid filler and a catalyst; and the polysiloxane A is a silicone oil, and the polysiloxane B is a silicone raw rubber. The putty type silicone rubber material is a two-component material, the operation time and curing time matched with the actual application can be obtained by changing the ratio of the crosslinking component and the catalytic component, the form of the putty and mechanical properties of the material are controlled by the synergistic cooperation of the silicone oil and the raw rubber, and the curing reaction is not limited to platinum-catalyzed hydrosilylation. The putty type silicone rubber composition is a novel silicone rubber material with high safety, good mechanical properties and strong applicability.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

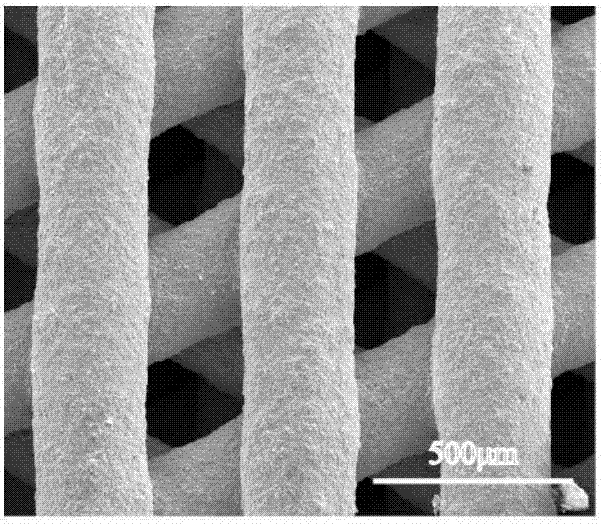

Three dimensional (3D) printed PCL-PDA-AgNPs scaffold for anti-infective bone tissue engineering as well as preparation method and application of 3D printed PCL-PDA-AgNPs scaffold

ActiveCN109045364AImprove hydrophilicity and biocompatibilityConducive to exchangeAdditive manufacturing apparatusTissue regenerationBone tissue engineeringEpsilon-caprolactone

The invention relates to a three dimensional (3D) printed PCL-PDA-AgNPs scaffold for anti-infective bone tissue engineering as well as a preparation method and application of the 3D printed PCL-PDA-AgNPs scaffold, belonging to bioengineered human implants. According to the method, poly(epsilon caprolactone) is used as a base material, polydopamine is used as a surface modification material, and silver nanoparticles with anti-infective biological properties are combined for use, so that the biological functions of anti-infection, bone growth promotion and bone defect repair are realized. The 3Dprinted PCL-PDA-AgNPs scaffold for the anti-infective bone tissue engineering has the advantages of being simple and reliable in structure, controllable in appearance and micro-structure, reliable inmechanical properties, controllable in ion release property, convenient in implantation, less in trauma and low in cost.

Owner:南京冬尚生物科技有限公司

Silk fibroin sericin composite membrane and preparation method of composite membrane

ActiveCN111821514AHigh strengthImprove toughnessTissue regenerationProsthesisPolymer scienceTissue repair

The invention provides a preparation method of a silk fibroin sericin composite membrane. The method comprises the following steps: (A) putting silk fibroin in warm water for pretreatment, then placing the silk fibroin in water at 65-95 DEG C, and conducting drying to obtain a pre-treated silk; (B) treating the initially-treated silk in a neutral salt solution, then purifying the obtained silk fibroin sericin composite solution, and obtaining a silk fibroin sericin composite solution; and (C) concentrating the silk fibroin sericin composite solution into a film, placing the obtained initial composite film in a small molecule monohydric alcohol for treatment, then conducting washing and drying, and obtaining the silk fibroin sericin composite film. According to the application, the silk fibroin sericin composite solution is prepared by adopting mild degumming and one-step dissolution method, the composite membrane prepared by the silk fibroin sericin composite solution has high strengthand high toughness, and the neck sticking technical problem of insufficient mechanical properties of tissue repair materials derived from natural biopolymers for hard tissue repair such as endocranium and dura mater, is solved.

Owner:SUZHOU UNIV

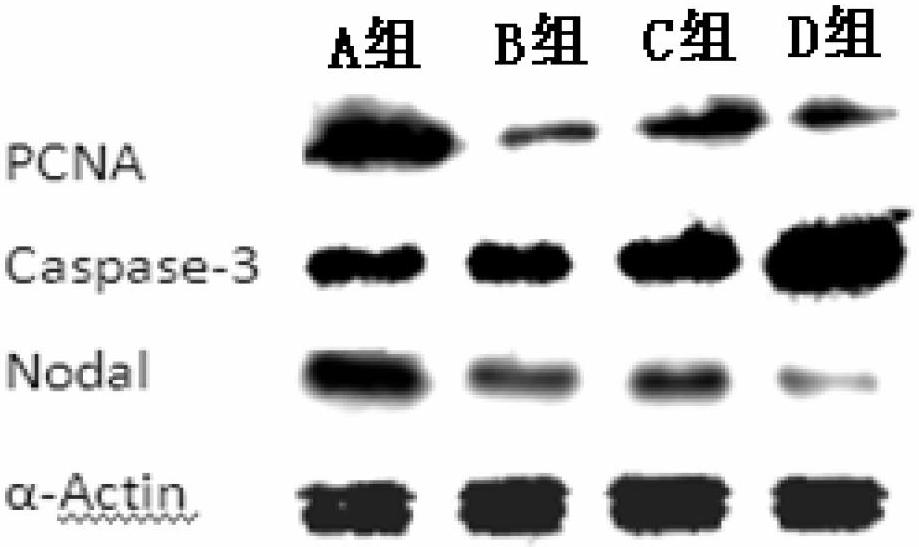

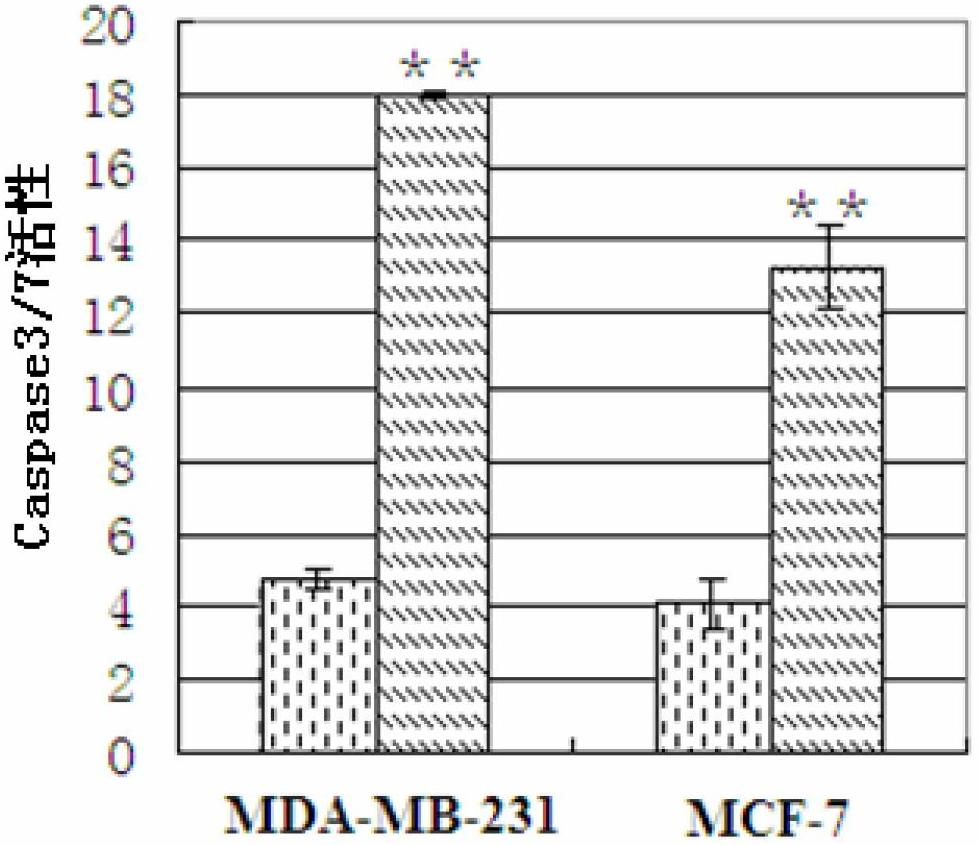

Method for preparing bioactive injectable hydrogel materials for oncotherapy

ActiveCN102657599AIncrease intakeIncrease moisture contentPeptide/protein ingredientsPharmaceutical delivery mechanismFreeze-dryingMechanical property

A method for preparing bioactive injectable hydrogel materials for oncotherapy relates to the method for preparing the bioactive injectable hydrogel materials and is a novel strategy for the oncotherapy. The method for preparing the bioactive injectable hydrogel materials for the oncotherapy includes the following steps of (1) preparing transparent hyaluronic acid solution, adding sodium periodate and ethylene glycol, shaking table for oxidization, adding absolute ethyl alcohol for precipitating oxidized transparent hyaluronic acid; (2) adding water into the oxidized transparent hyaluronic acid, dialyzing, freeze-drying, sterilizing with alcohol, and preparing oxidized transparent hyaluronic acid solution; (3) preparing ADH (antidiuretic hormone) solution, mixing the same with the oxidized transparent hyaluronic acid solution after being filtered, adding anti-cripto monoclonal antibody and active peptide, and mixing to obtain the hydrogel materials. By the method for preparing the bioactive injectable hydrogel materials for the oncotherapy, the prepared hydrogel materials are provided with high moisture content, loose and porous structures, nutriment intake, metabolic waste metabolic waste and air exchange are facilitated, and the mechanical property is controllable. The method for preparing the bioactive injectable hydrogel materials for the oncotherapy is used for the field of the oncotherapy.

Owner:HARBIN INST OF TECH

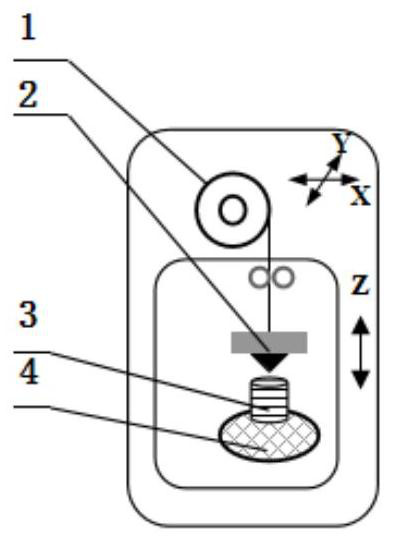

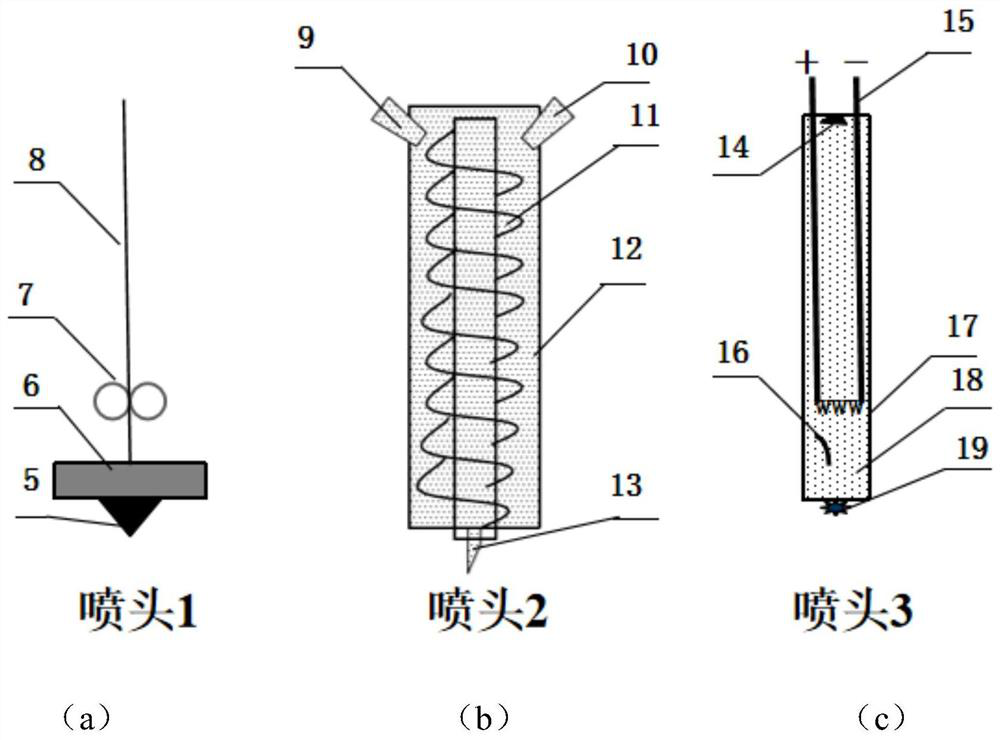

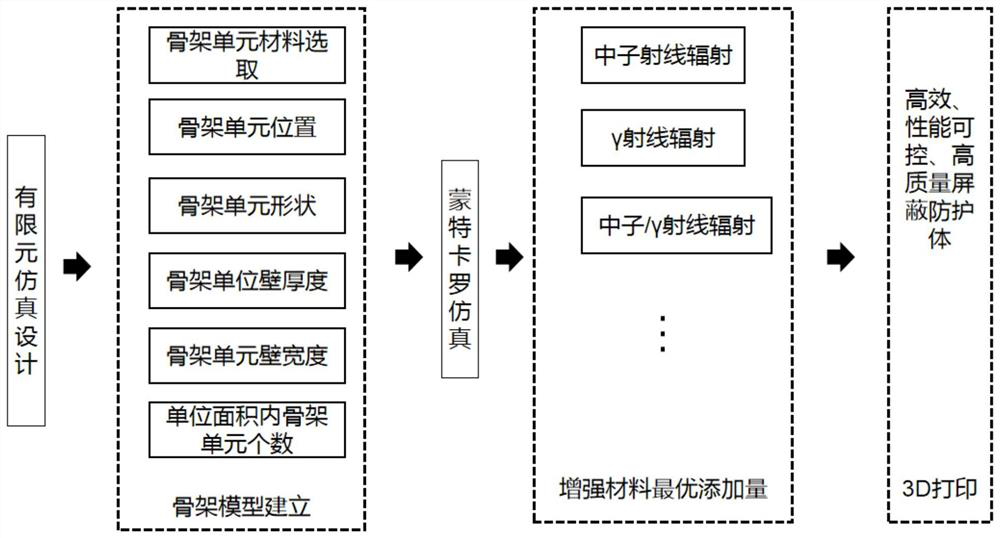

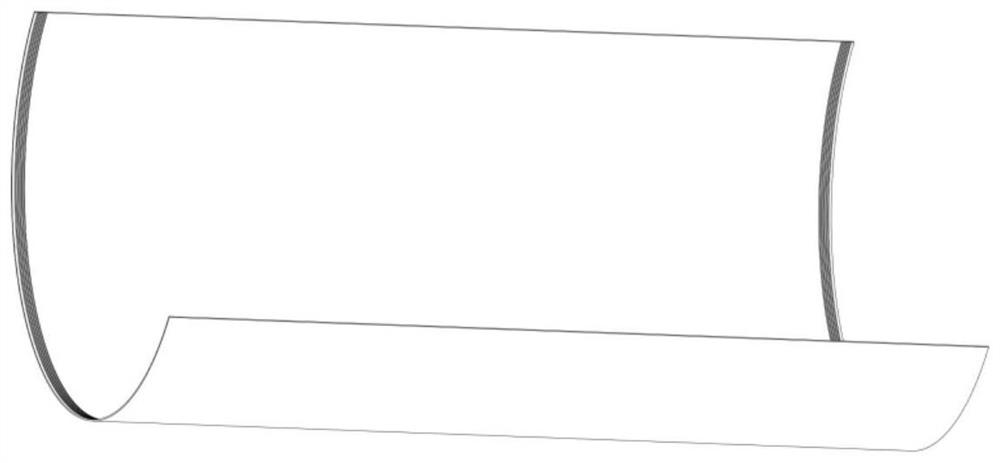

Efficient directional radiation shielding protection structure and 3D printing method thereof

ActiveCN112192837AHigh precisionThe mechanical properties of the shield are controllableAdditive manufacturing apparatusShieldingThin membraneMacromolecule

The invention discloses an efficient directional radiation shielding protection structure and a 3D printing method thereof. The 3D printing method comprises the following steps that a first spray headis adopted for printing a base material to form a framework unit with a filling cavity; a filling reinforcing material is printed in the filling cavity of the framework unit through a second spray head; a fixing material is sprayed on the upper surface layer of the reinforcing material through a third spray head to form a thin film and solidify the thin film; and the steps are repeated until theprocessing is finished. According to the 3D printing method, through a framework unit structure, the defects of warping, deformation and the like in the large workpiece solid filling manufacturing process of a macromolecule single material are overcome, and the manufactured workpiece has high precision.

Owner:XI AN JIAOTONG UNIV

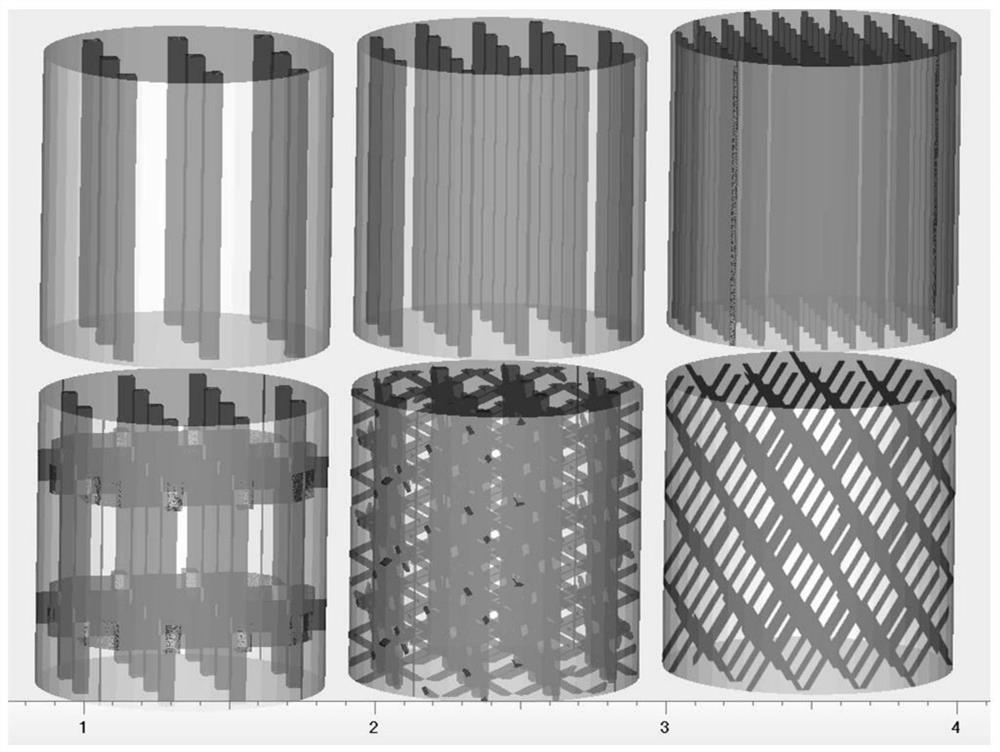

Forming preparation method of fiber composite material shell of solid rocket engine

PendingCN114559686ASmall sizeReduce processing costsWeight reductionRocket engine plantsButt jointComposite material

The invention relates to a forming preparation method of a fiber composite material shell of a solid rocket engine. Comprising the following steps: preparing an inflatable rubber core mold; preparing a lining layer and a heat insulating layer on the outer layer of the rubber core mold; a plurality of 0-degree fiber layers of which the sections are arc sections are arranged in two pultrusion ends; preparing an integrated metal piece, wherein the integrated metal piece comprises pre-tightening force teeth matched with the tooth grooves of the 0-degree fiber layer, a connecting flange, a butt joint skirt and an end socket; the two integrated metal pieces and the multiple 0-degree fiber layers with the sections being arc sections are assembled, and a combination is obtained; a fiber layer is wound around the periphery of the combined body in the circumferential direction, and the shell is obtained after curing forming. The 0-degree fiber layer and the 90-degree fiber layer are arranged, and through tooth connection of the integrated metal piece and the inflatable rubber core mold, the rigidity and bearing requirements of the solid rocket engine shell are met, rapid and repeated use of the core mold is achieved, and low cost and high performance of composite shell preparation are achieved.

Owner:NANJING UNIV OF TECH

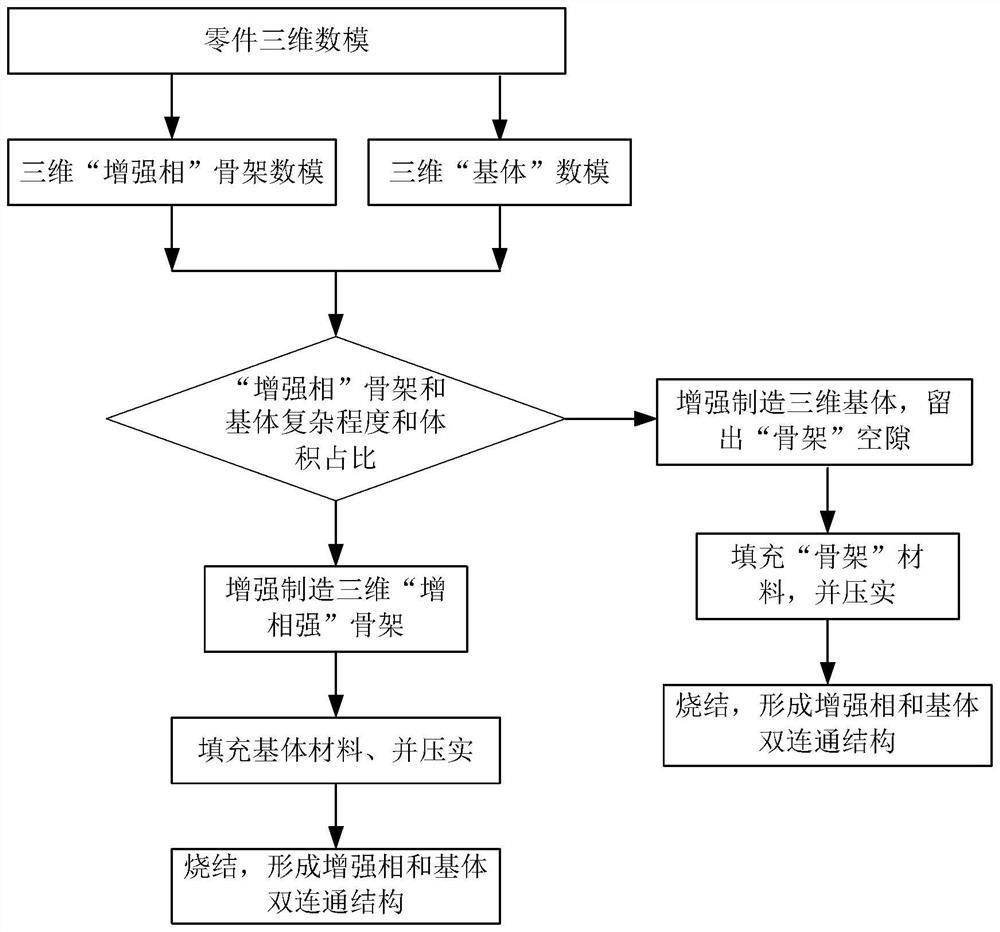

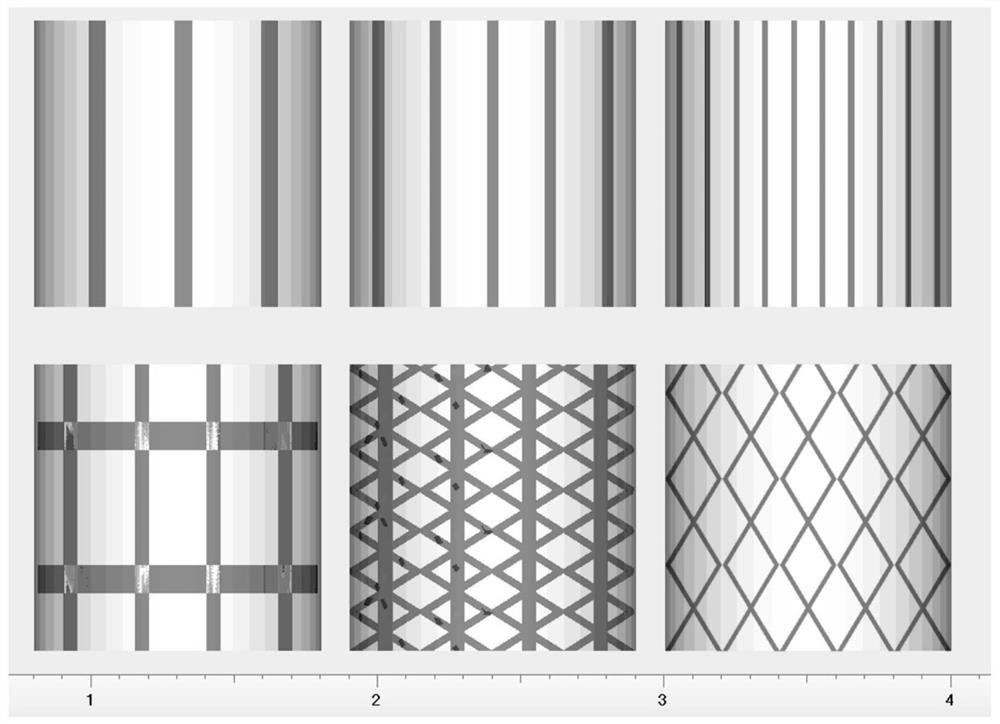

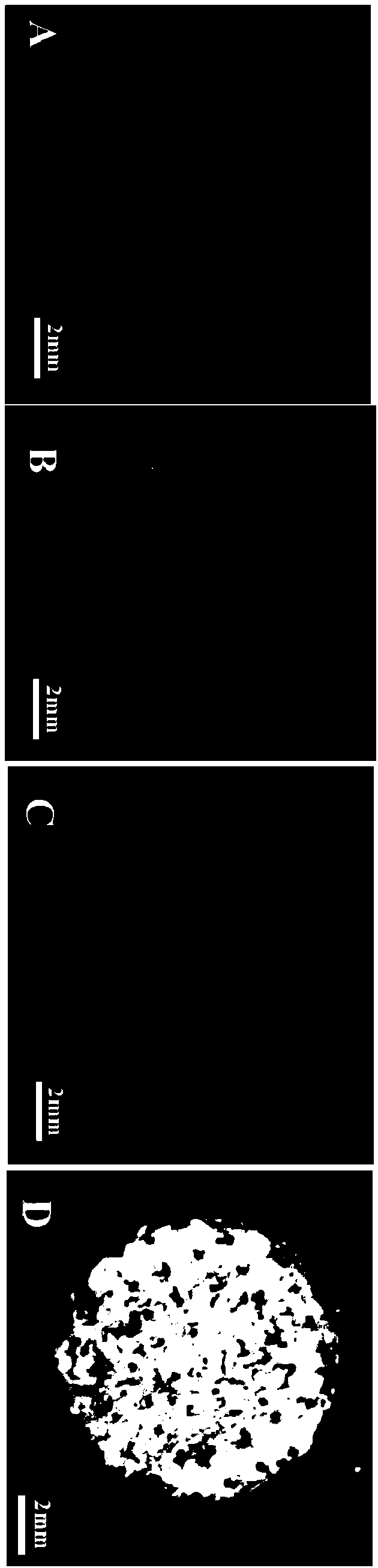

Preparation method of three-dimensional double-connected structure composite material based on additive manufacturing

PendingCN114192801AHigh strengthImprove toughnessAdditive manufacturing apparatusCeramic shaping apparatusSelective laser meltingMaterials preparation

The invention relates to the technical field of composite material preparation, in particular to a preparation method of a three-dimensional double-connected structure composite material based on additive manufacturing. The three-dimensional double-connected structure composite material comprises a reinforced phase network skeleton and a matrix filling skeleton, wherein the reinforced phase network skeleton is constructed by reinforced phase rods; the method comprises the following steps: firstly, designing a reinforced phase spatial form, a volume ratio, a reinforced phase rod diameter and a reinforced phase rod cross section shape, and constructing a reinforced phase network skeleton and a matrix filling skeleton; then preparing a reinforced phase network skeleton by using a selective laser melting method, then filling matrix powder, compacting and sintering to obtain the three-dimensional double-connected structure composite material, according to the composite material preparation method based on additive manufacturing, high designability and customization of a 3D reinforced framework are achieved, and a compact defect-free three-dimensional double-communication structure composite material is prepared in combination with a subsequent sintering process.

Owner:SHENYANG AEROSPACE UNIVERSITY

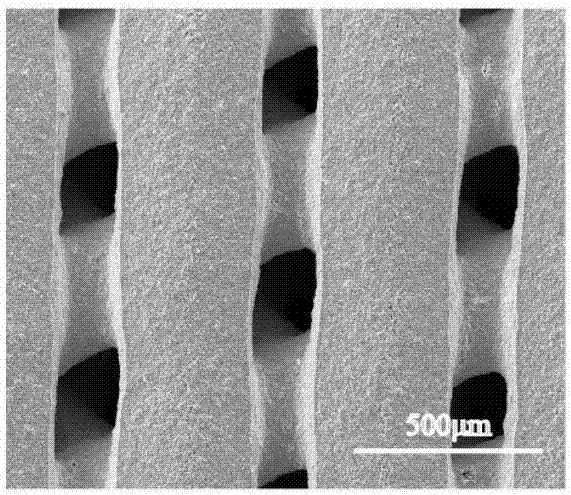

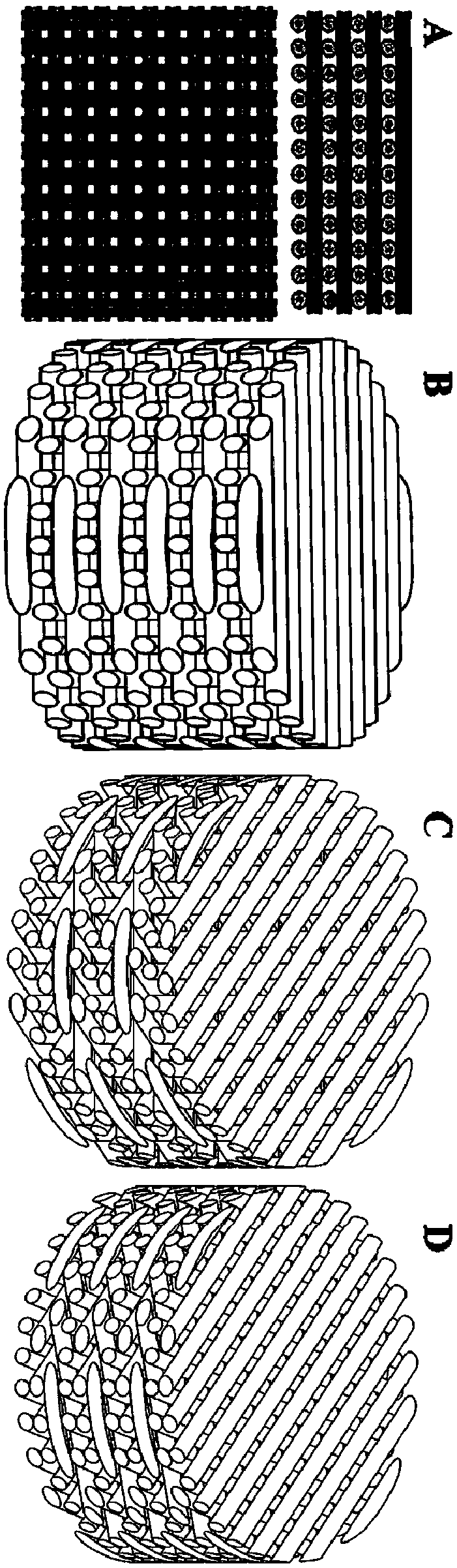

3D-printing PCL-PMMA-vancomycin anti-infection bone scaffold, and preparation method and application thereof

InactiveCN109395158AImprove mechanical propertiesControl mechanical propertiesAdditive manufacturing apparatusTissue regenerationOsseointegrationPolymethyl methacrylate

The invention provides a 3D-printing PCL-PMMA-vancomycin anti-infection bone scaffold, and a preparation method and an application thereof and belongs to engineering human implants. In the method, poly-epsilon-caprolactone and polymethyl methacrylate serve as base materials and vancomycin serves as an anti-infection medicine, thus achieving biofunctions of anti-infection and promotion of osseointegration and bone defect filling surrounding the implant. The method includes: firstly, extruding PCL to form fiber bundles through a melting extrusive shaping 3D printing technology, and preparing a 3D-printing PCL scaffold by means of the jointing structure of different layers and angles of the fiber bundles; then under certain conditions, adding a PMMA monomer solution to a powder, and adding the vancomycin to the PMMA to prepare a PMMA-vancomycin mixture; filling the gaps in the 3D-printing PCL scaffold with the PMMA-vancomycin mixture in a semi-fluidized period, thereby forming the 3D-printing PCL-PMMA-vancomycin anti-infection bone scaffold. The bone scaffold has simple and reliable structure, controllable appearance and microstructure, reliable mechanical properties and controllability of medicine release performance. The bone scaffold is convenient to implant and is invasive-less and low-cost.

Owner:NANJING FIRST HOSPITAL

Step cutting plane integral bursting type fragile cover and preparation method thereof

ActiveCN111322909ACompact and beautiful structureMeet new requirementsRocket launchersLamination ancillary operationsFiberStructural engineering

The invention belongs to the technical field of missile launching and protection, and particularly relates to a step cutting plane integral bursting type fragile cover and a preparation method thereof. The fragile cover comprises a frame and a throwing-out body, and a joint of the frame and the throwing-out body is a weak area; the weak area is an area where fiber cloth between the frame and the throwing-out body is cut off in a stepped manner; and the fiber cloth in the cover body sub-cutting layers in the area is cut off according to circular tracks with different radiuses, and stepped gluing lap jointing is formed between the cover body sub-cutting layers. The fragile cover is simple in structure, light in weight and easy and convenient to operate, the fragile cover is integrally formed, cutting and reinforcing are not needed after forming, the air tightness, the pressure bearing performance and the weak area strength of the fragile cover can be adjusted by adjusting the number of steps, the width of the steps and the number of layers of the fiber cloth contained in each step, and therefore the fragile cover can bear pressure within a specific range, the fragile cover can be burst smoothly by missile fuel gas, and the fragile cover is a fragile cover with a novel structure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

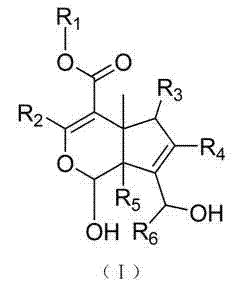

A kind of modification method of extracellular matrix

ActiveCN102284083AEnhanced extracellular matrixControllable mechanical propertiesProsthesisBiophysicsGenipin

The invention discloses a method for modifying an extracellular matrix. Genipin or a derivate thereof is used as a cross-linking agent, and at least one of biological functionalization agent, pigment and chain extender, and the extracellular matrix are subjected to contact reaction. The method can realize the enhancement of the extracellular matrix and / or dyeing or bionic functionalization, the Genipin or the derivate thereof is used as the cross-linking agent, the chain extender, the biological functionalization agent and the like are introduced, and the aims of the controllable mechanical property of the modified extracellular matrix are fulfilled by controlling reaction conditions.

Owner:GUANGZHOU SUN SHING BIOTECH CO LTD

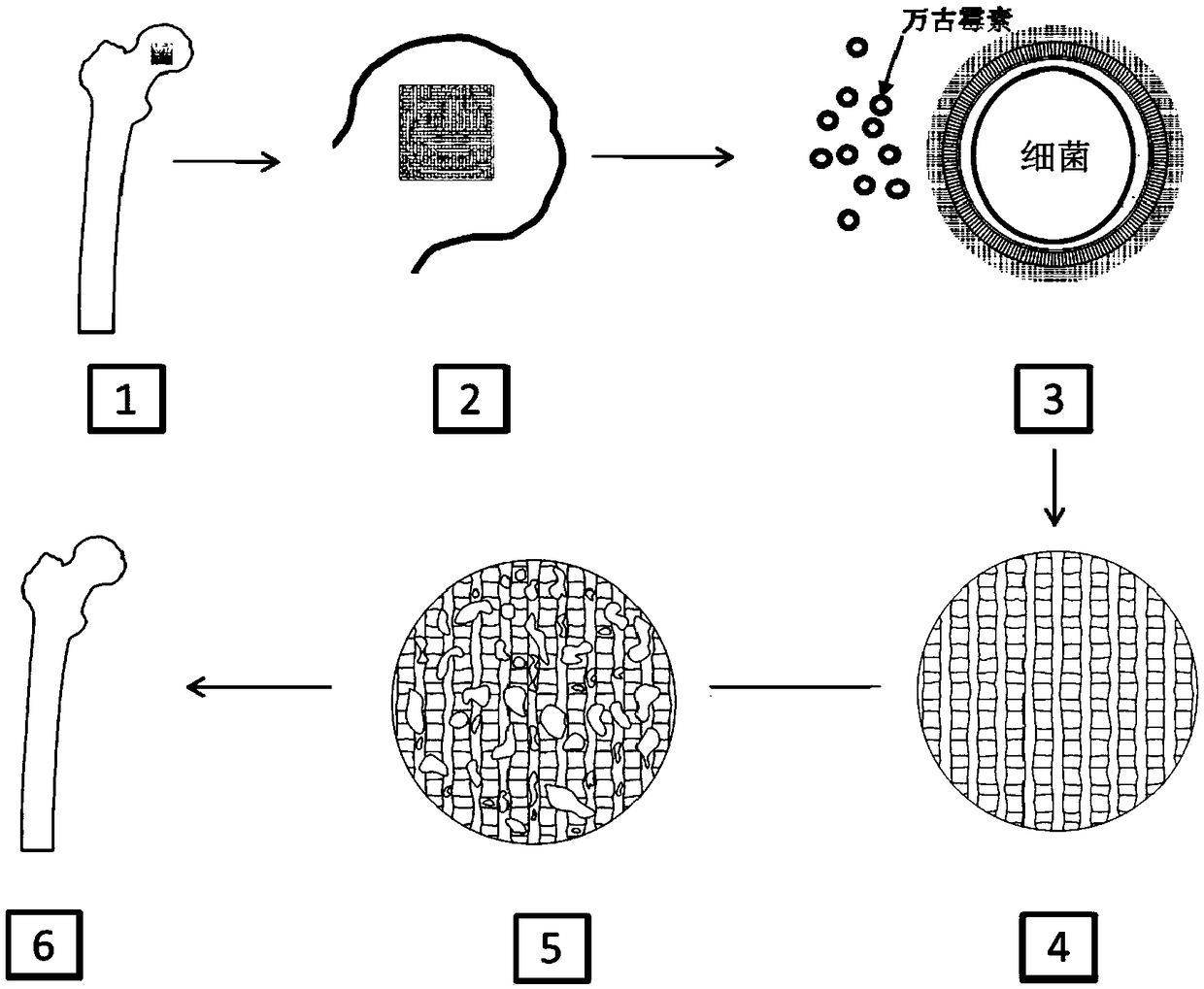

3D-printing PCL-vancomycin anti-infection bone tissue engineering scaffold, and preparation method and application thereof

InactiveCN109395157AReliable releaseControl releaseAdditive manufacturing apparatusTissue regenerationBio engineeringDrug release

The invention provides a novel 3D-printing PCL-vancomycin anti-infection bone tissue engineering scaffold, and a preparation method and an application thereof and belongs to bioengineering human implants. In the engineering scaffold, poly-epsilon-caprolactone and vancomycin respectively serve as a base material A and an anti-MRSA medicine B, wherein the A is heated by a heating system in a meltingextrusive shaping 3D printer to form a liquid substance C; then in a FDM extrusion channel, the C is gradually cooled and meanwhile is mixed with a solution, containing the B, at a spinning nozzle ofthe 3D printer, thus extruding shaped fiber bundle D; by means of the jointing structure of different layers and angles of the fiber bundles D, the product is produced through steps of room temperature shaping at 23 DEG C, drying, and ethylene oxide disinfection. The scaffold has simple and reliable structure, controllable appearance and microstructure, reliable mechanical properties and controllability of medicine release performance. The scaffold is convenient to implant and is invasive-less and low-cost.

Owner:NANJING FIRST HOSPITAL

Electrode pile having slope protection function and use method thereof

PendingCN109629584AAvoid enteringImprove structural stabilityExcavationsSoil preservationReinforced concreteLandslide

The invention discloses an electrode pile having a slope protection function and a use method thereof. The electrode pile comprises an electrode pile pair and a reinforced concrete pile, wherein the electrode pile pair comprises a plurality of sets of anode piles and cathode piles, the cathode piles and the anode piles are respectively connected to the two ends of the reinforced concrete pile, andthe cathode piles, the reinforced concrete pile and the anode piles are cyclically installed, and the length of the electrode piles is greater than that of a sliding surface of a soil body. The use method comprises the steps of making electrode piles, pressing the electrode piles, connecting a connection circuit to a power supply, and beginning to execute treatment. The effect of an electric field is fully utilized to prevent moisture from entering the deep part of the soil body and causing large-area landslide and enhance the structural stability of the soil body.

Owner:TIANJIN CHENGJIAN UNIV

3D printing method of continuous fiber self-enhancement composite material

InactiveCN110920063AFacilitate stress transferImprove recycling ratesAdditive manufacturing apparatusManufacturing recyclingHigh polymerSelf reinforced

The invention discloses a 3D printing method of continuous fiber self-enhancement composite material. The 3D printing method comprises the following steps: at first, establishing a three-dimensional model of a self-enhancement composite material workpiece, and deriving the three-dimensional model as an stl formatted file; determining a printing temperature interval, wherein the self-enhancement composite material is thermoplastic high polymer material with different physical forms and is provided with a reinforced phase and a matrix base, the reinforced phase and the matrix base have the samechemical construction and different melting points, the reinforced phase is continuous fiber, and the matrix phase is resin; the printing temperature scope is higher than the melting point of the matrix phase and is lower than the melting point of the reinforced phase; preparing the self-enhancement composite material through 3D printing, finally, recycling the self-enhancement composite material,physically crushing the self-enhancement composite material, heating the crushed self-enhancement composite material to above the melting point to completely melt the self-enhancement composite material, and recycling the self-enhancement composite material as the raw material. On one hand, the 3D printing method solves the problems that the interfacial properties are poor and recycling is difficult when 3D printing is carried out on the composite material, and on the other hand, low-cost rapid manufacturing of the continuous fiber self-enhancement composite material is realized.

Owner:XI AN JIAOTONG UNIV

Bionic composite bone scaffold and preparation method thereof

The invention provides a preparation method for a bionic composite bone scaffold. The preparation method comprises the following steps: A) placing silk into warm water for pretreatment, then placing the silk into water with a temperature of 65-95 DEG C for treatment, and carrying out drying so as to obtain primarily treated silk; B) treating the primarily treated silk into a neutral salt solution,and re-purifying an obtained silk fibroin and sericin composite dissolved solution so as to obtain a silk fibroin and sericin composite solution; and C) concentrating the silk fibroin and sericin composite solution, carrying out freeze-drying, placing an obtained initial skeleton into micromolecular monohydric alcohol for treatment, and carrying out freeze-drying so as to obtain the bionic composite bone scaffold. According to the invention, the silk fibroin and sericin composite solution is prepared by adopting a mild degumming and one-step dissolving method, and the bionic composite bone scaffold prepared by utilizing the silk fibroin and sericin composite solution has high strength, high modulus and high toughness; and the bionic composite bone scaffold solves the neck-clamping technical problem of insufficient mechanical properties of a natural biopolymer tissue engineering scaffold for bone regeneration and repair.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com