Step cutting plane integral bursting type fragile cover and preparation method thereof

A technology of cutting plane and fragile cover, applied in chemical instruments and methods, offensive equipment, lamination devices, etc., can solve the problems of poor practicability, difficult control of quality stability, complicated process, etc., and it is easier to achieve quality stability The effect of control, strong design and controllable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the objectives, technical solutions and effects of the present invention clearer and clearer, the following examples are given to further illustrate the present invention in detail. It should be pointed out that the specific implementation described here is only used to explain the present invention, but not to limit the present invention.

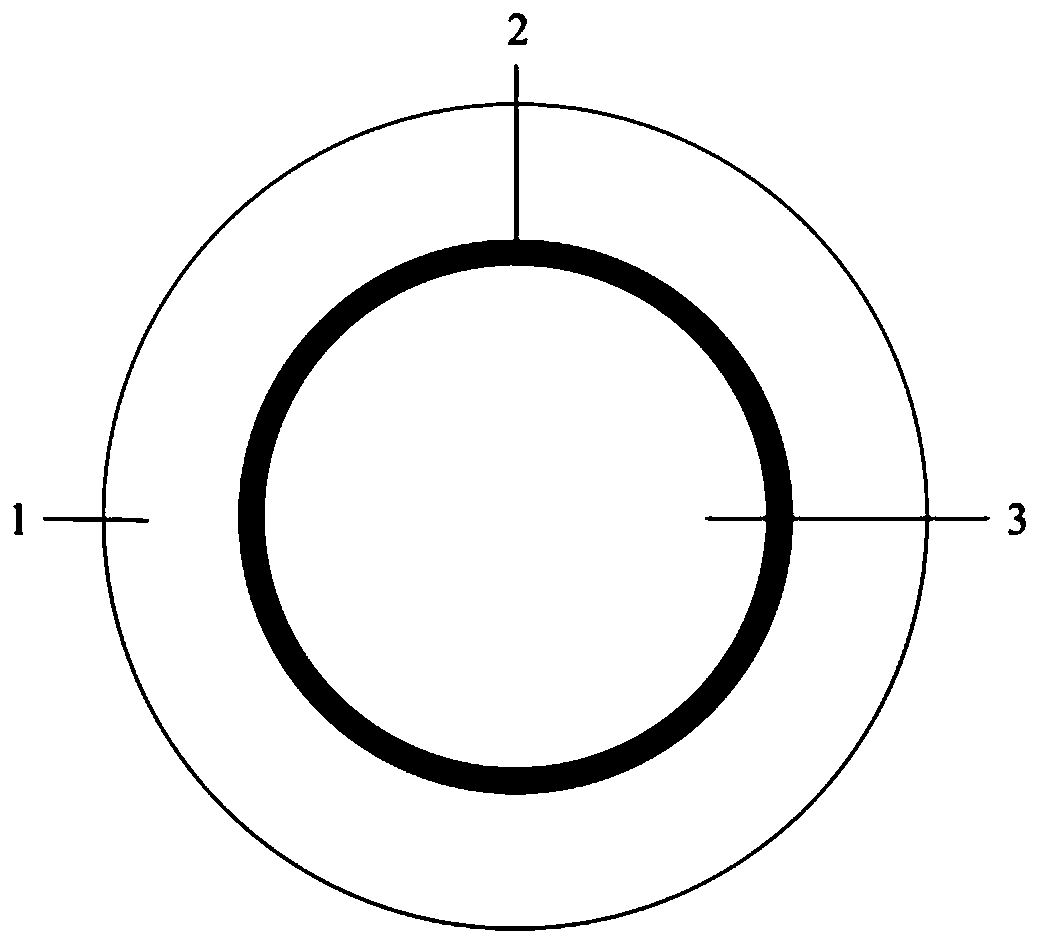

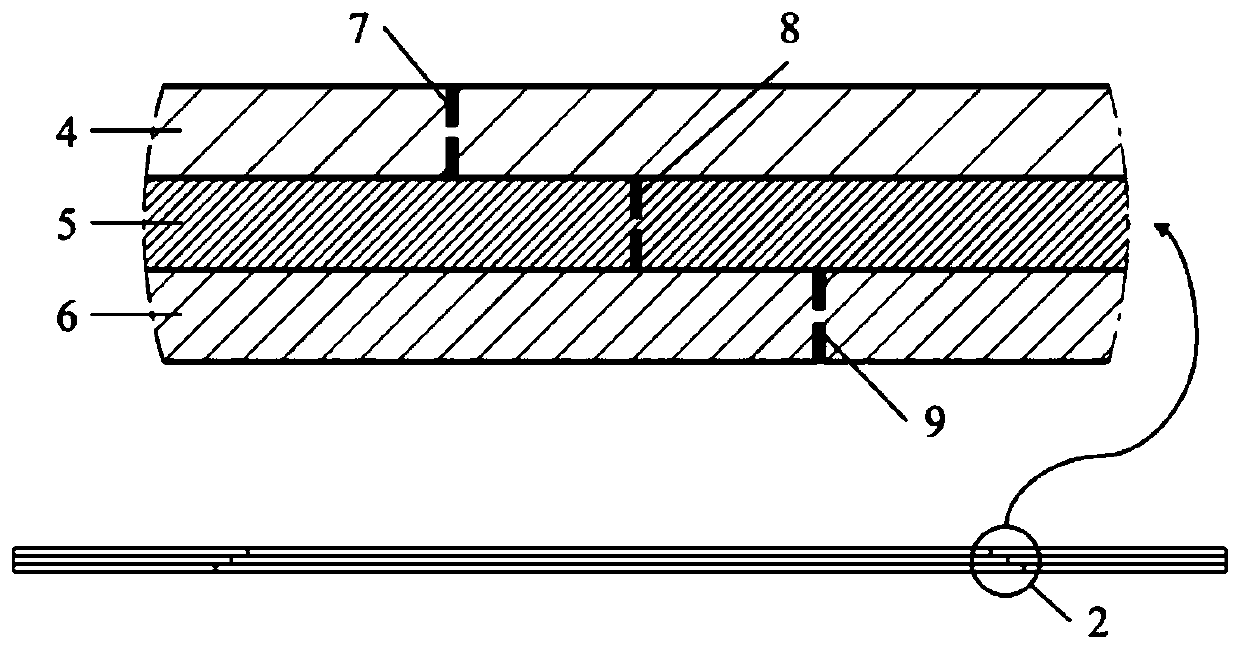

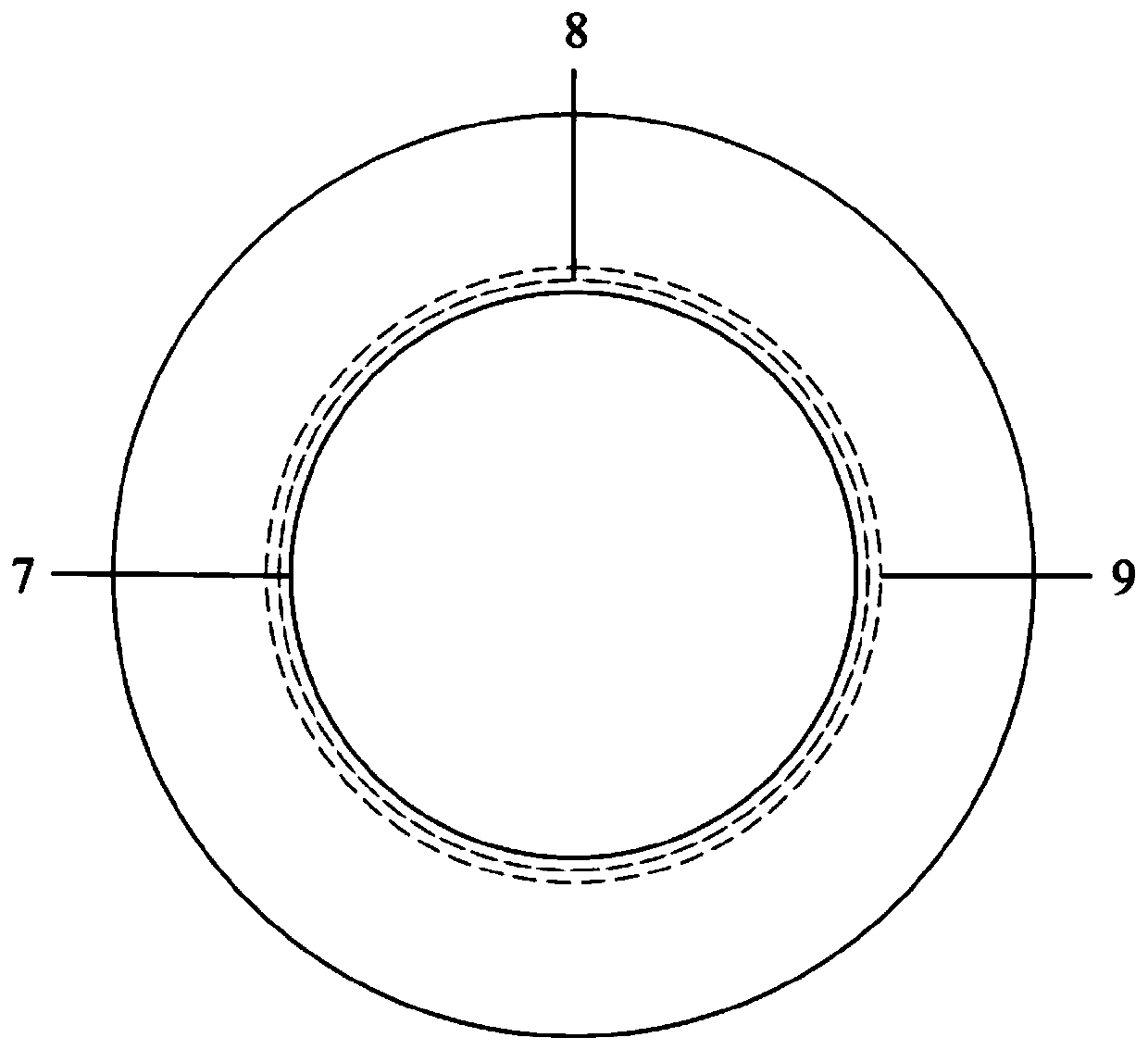

[0037] In this implementation, the step-cut plane integrally breakable fragile cover, the preparation process includes the following steps:

[0038] 1) Cut out 6 pieces of 330mm×330mm high-strength bidirectional glass fiber cloth;

[0039] 2) Clean the mold, put a rubber pad on the mold, and paste polyester fragile plastic paper on the rubber pad;

[0040] 3) Prepare epoxy resin;

[0041] 4) Divide 6 pieces of cloth into 3 sub-cutting layers, each sub-cutting layer 2 pieces of cloth, respectively in the order of [(0 / 90) / (±45)], and make each layer of glue evenly penetrate;

[0042] 5) Paste polyester fragile plastic paper on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com