Preparation method of three-dimensional double-connected structure composite material based on additive manufacturing

A composite material and additive manufacturing technology, applied in the direction of additive manufacturing, manufacturing tools, additive processing, etc., can solve the problems of foam permeability and strength limitation, no reliability, no 3D distribution of reinforcement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

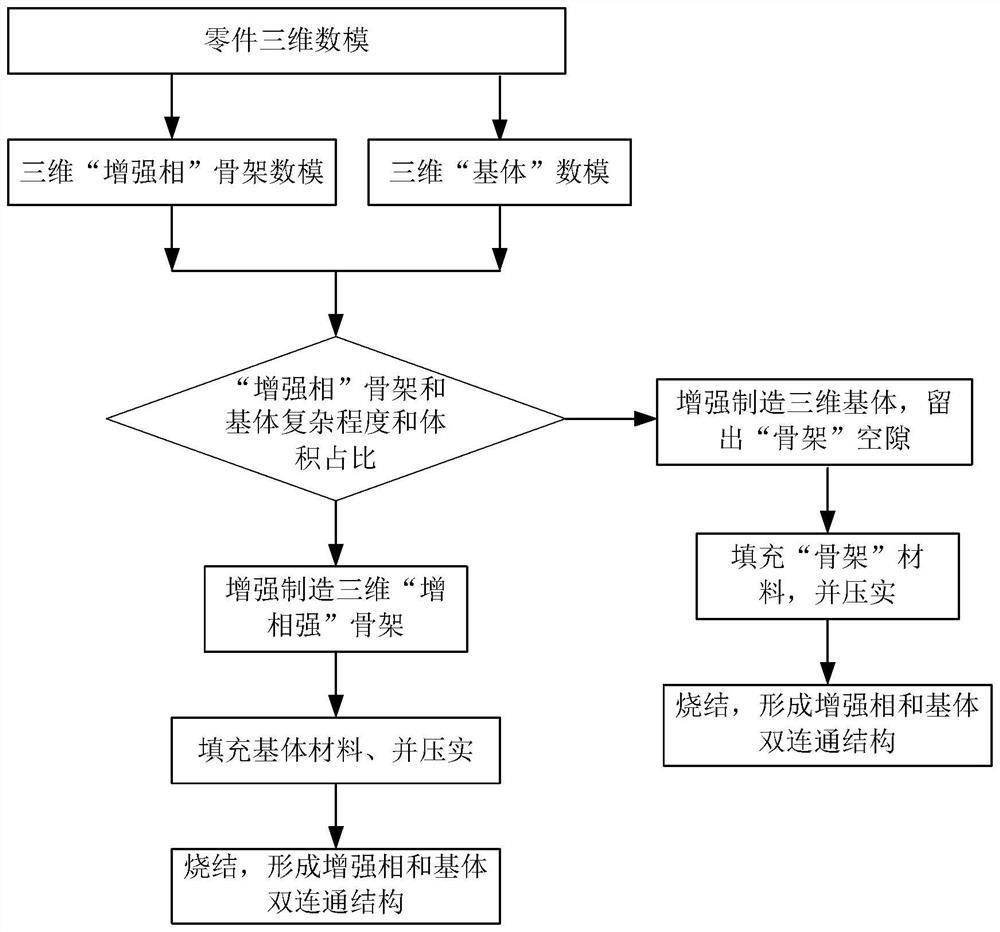

Method used

Image

Examples

Embodiment 1

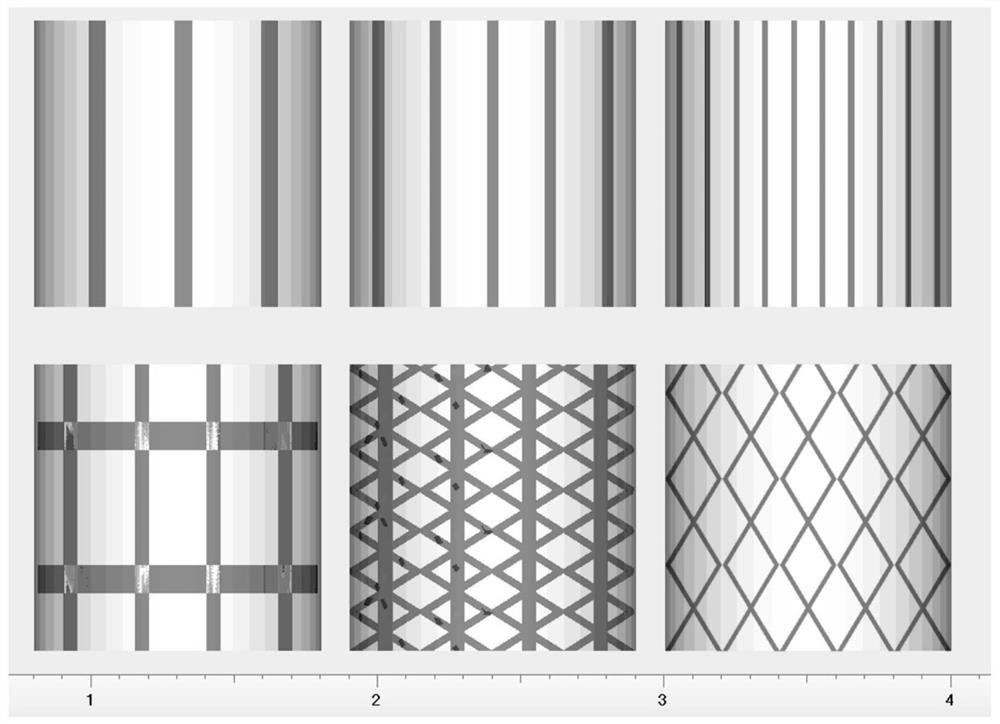

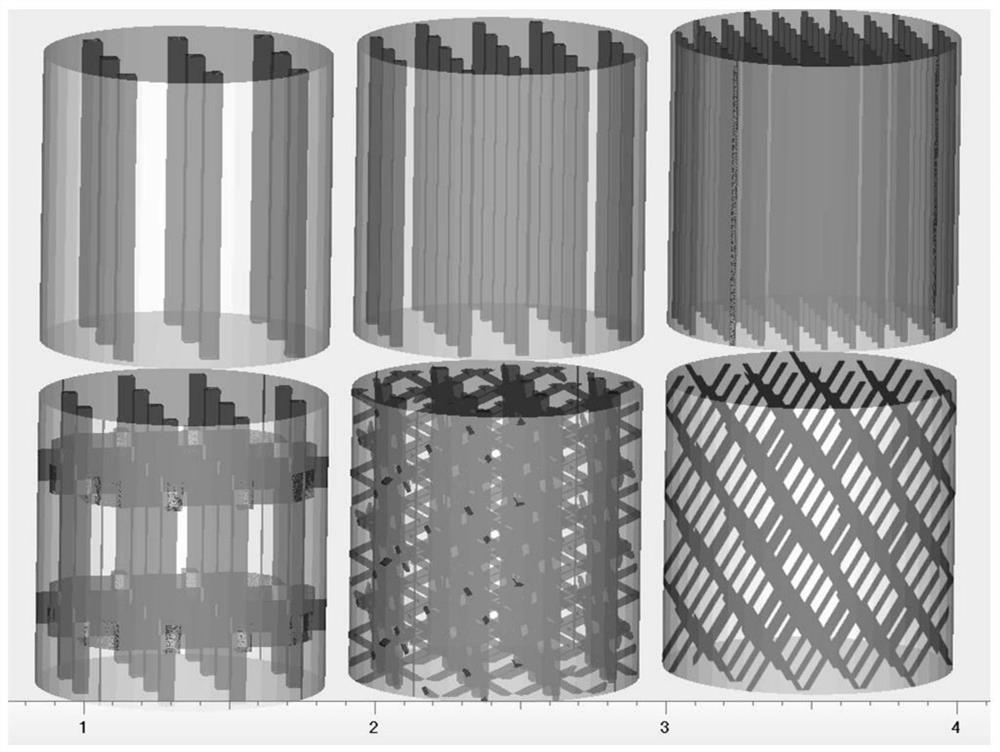

[0076] (1) Determine the shape of the part as the shaft, the matrix powder is aluminum alloy powder, and the reinforcing phase powder is TC4 titanium alloy. The strength performance requirement is 600MPa, the strength of aluminum alloy is 400MPa, and the strength of TC4 titanium alloy is 900Mpa. According to 400×a%+900×b%=600, a%+b%=100%, a=0.6, b=0.4 ; According to the shape of the part shaft, the "reinforced phase" space form (the shape of the reinforced phase) of the part is obtained as a skeleton to obtain a group of cylinders that are equal in length to the axis and parallel to the center line of the shaft, and the volume ratio (the totality of the reinforced phase and the part volume ratio) is 40%, the diameter of the rod (the size of the cross-section of the reinforced phase rod) is 0.8 mm, and the cross-sectional shape of the rod is circular.

[0077] (2) Selected area laser melting technology performs layered processing on the three-dimensional model of the "enhanced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com