3D printing method of continuous fiber self-enhancement composite material

A technology for enhancing composite materials and 3D printing, which can be used in additive processing, additive processing of mixtures of solid materials and liquid materials, processing and manufacturing, etc. High recycling rate and the effect of promoting stress transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, a method for 3D printing continuous fiber self-reinforced composite materials, comprising the following steps:

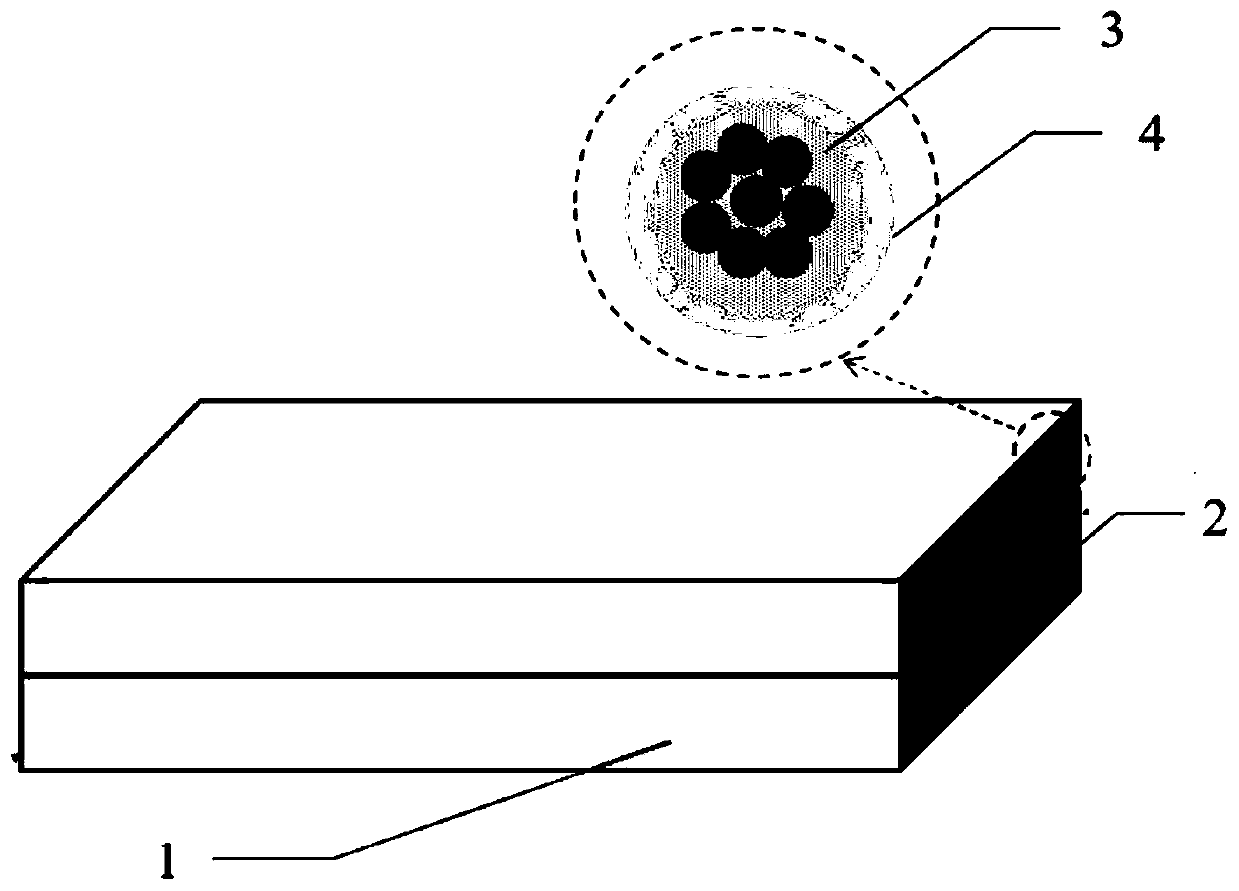

[0018] 1) Establish a three-dimensional model of self-reinforced composite parts: refer to figure 1 According to the requirements of self-reinforced composite parts, use the computer-aided design software CAD SolidWorks to build a 180×10×2 three-dimensional model 1, and export the three-dimensional model as a stl format file;

[0019] 2) Determine the printing temperature range: the self-reinforced composite material is a thermoplastic polymer material with different physical forms, a reinforcing phase 2 and a matrix phase 4 with the same chemical structure and different melting points, and the ultra-high molecular weight polyethylene fiber UHMWPE is selected as the reinforcing phase 2, High-density polyethylene HDPE is the matrix phase 4, the melting point of high-density polyethylene HDPE is 135 degrees, the melting point of ultra-high molecul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com