Patents

Literature

208 results about "Self reinforced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

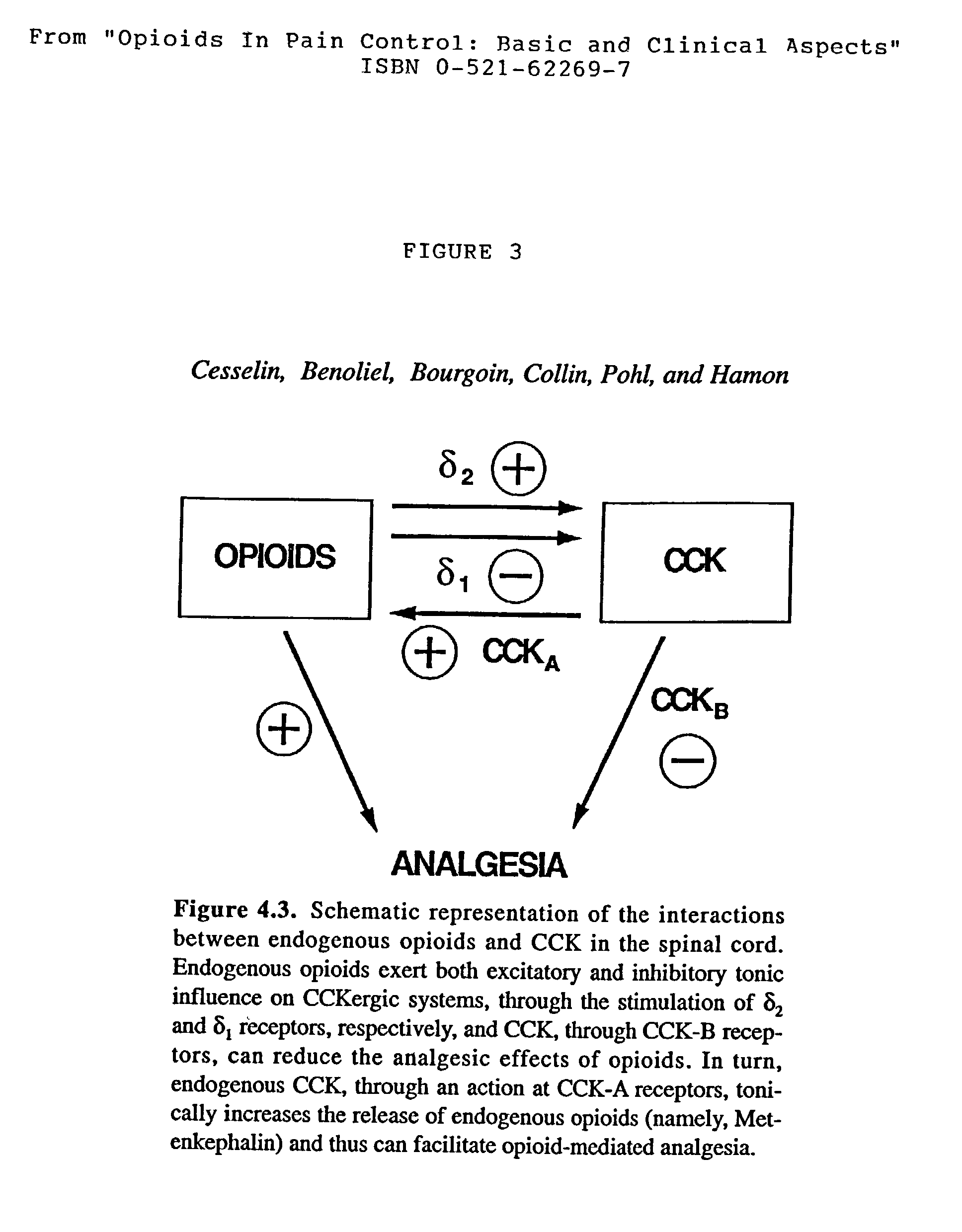

Self-reinforcement is a method of self-conditioning that acts to strengthen the association between certain stimuli and certain responses [8]. In the behavioral theory of operant conditioning, the most fundamental principle is that a response followed by a reinforcer is strengthened and is therefore more likely to occur again [7].

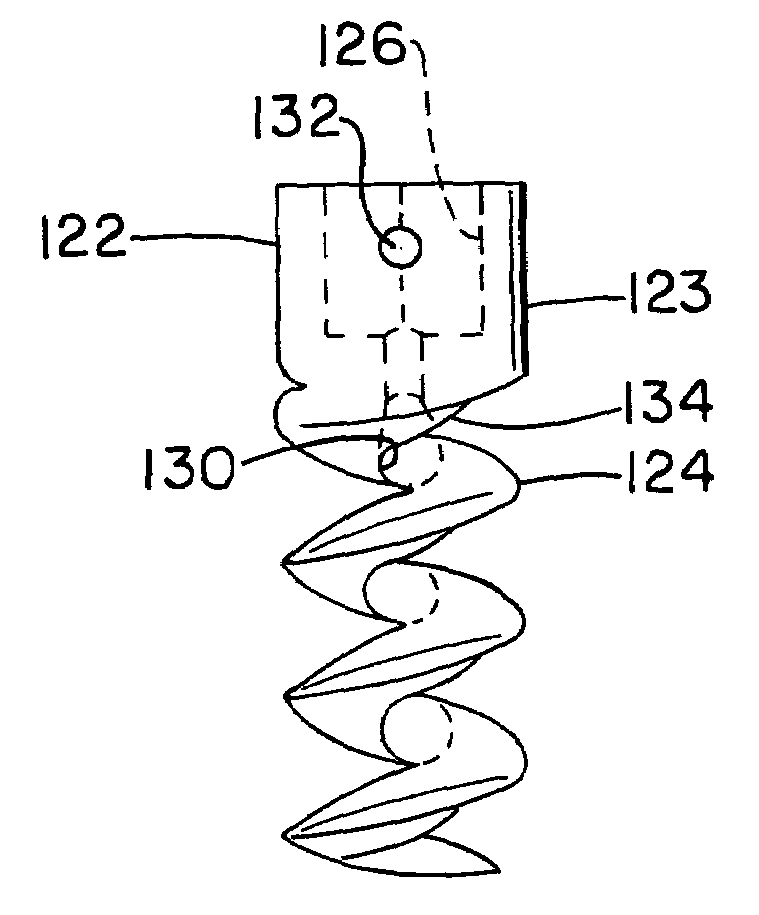

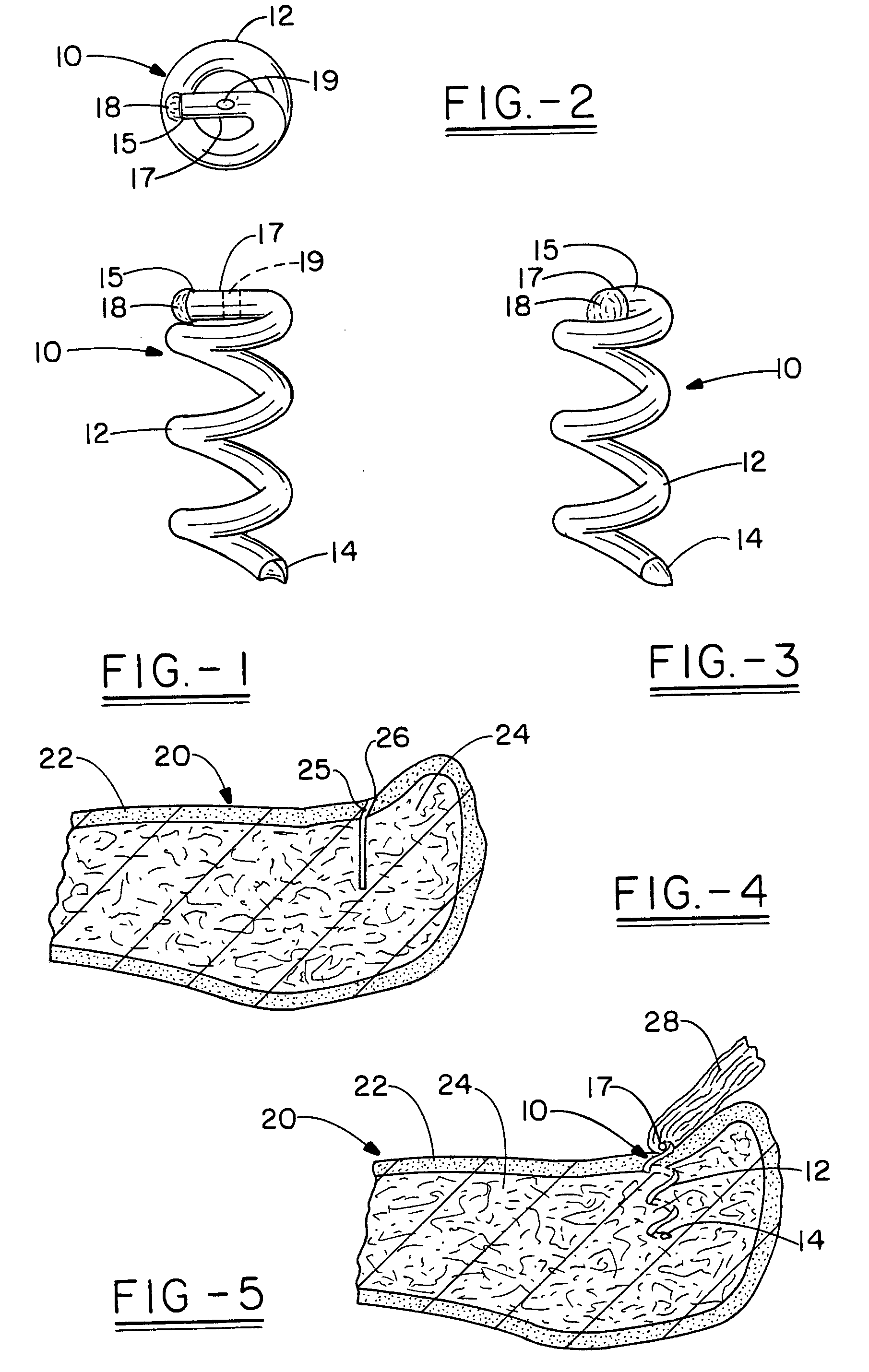

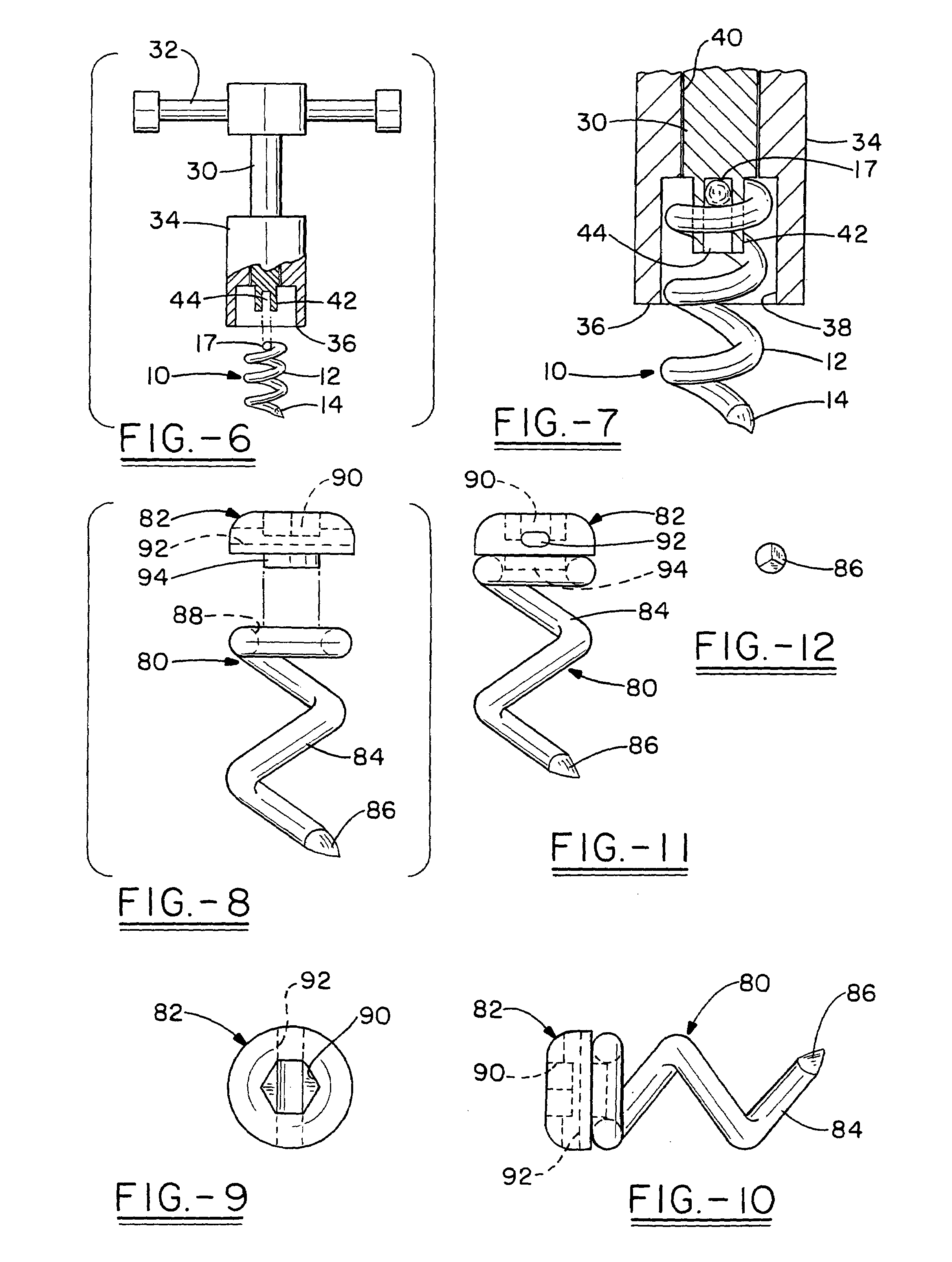

Open helical organic tissue anchor having recessible head and method of making the organic tissue anchor

InactiveUS7189251B2Easy to anchorStrengthens helixSuture equipmentsPinsSelf reinforcedLigament structure

The invention relates to a tissue anchor which is an open helix of biocompatible material having a slope of from 0.5 to 10 turns per centimeter, a length from 3 to 75 millimeters, a diameter of from 1.5 to 11 millimeters, and an aspect ratio of from about 3 to about 5 to 1. The anchor can have a head which is capable of securing or clamping tissue together, such as holding a suture to secure a ligament or tendon to bone. The anchor can also have a head which causes an inward, compressive loading for use in fastening bone to bone, orthopedic plates to bone, or cartilage to bone. The head may be an integral member and may include a self-reinforcing wedge which joins the helix to the head. Further, the elongate member, or filament that forms the helix may have a tapering diameter along its length.

Owner:ORTHOHELIX SURGICAL DESIGNS

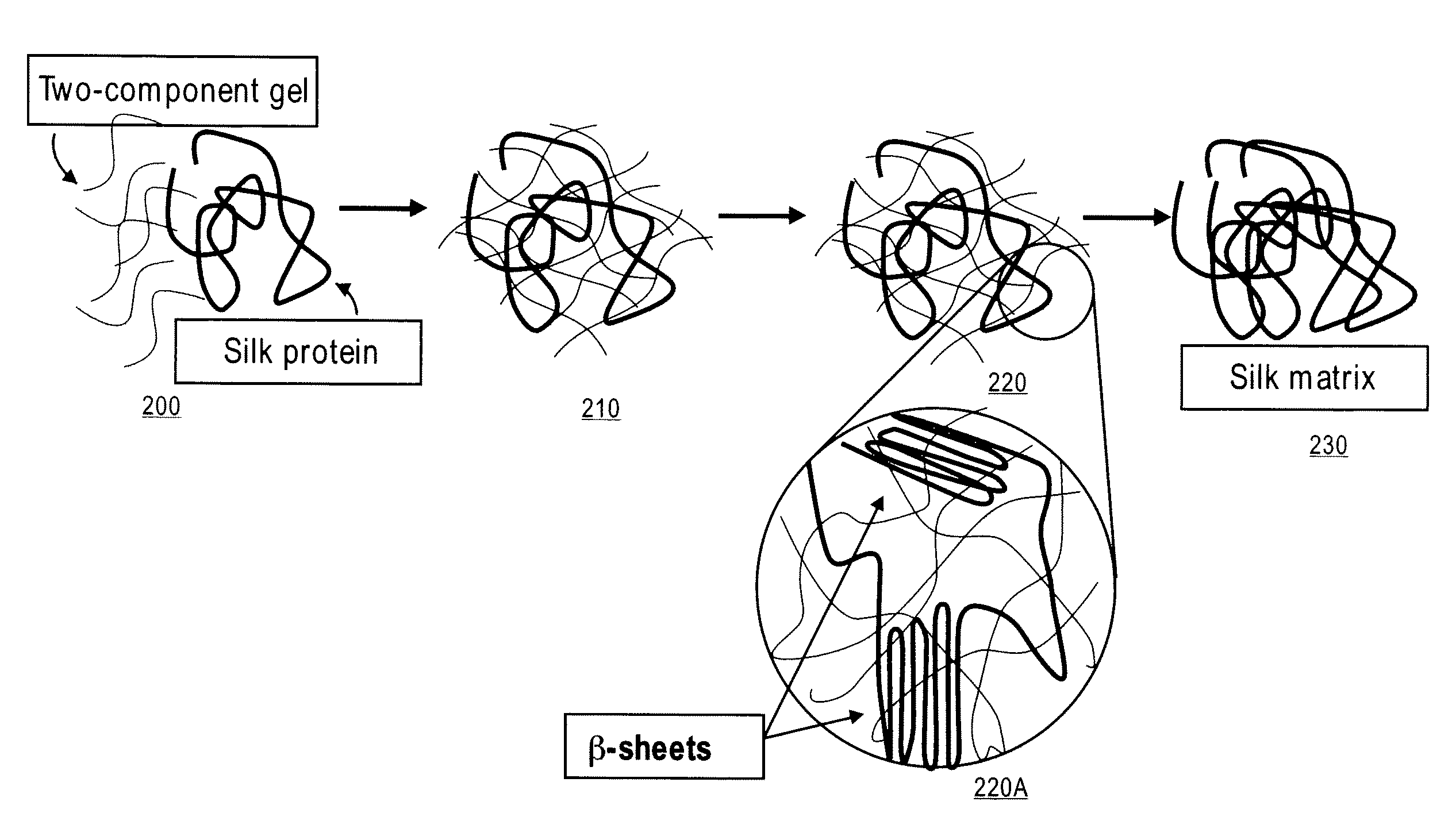

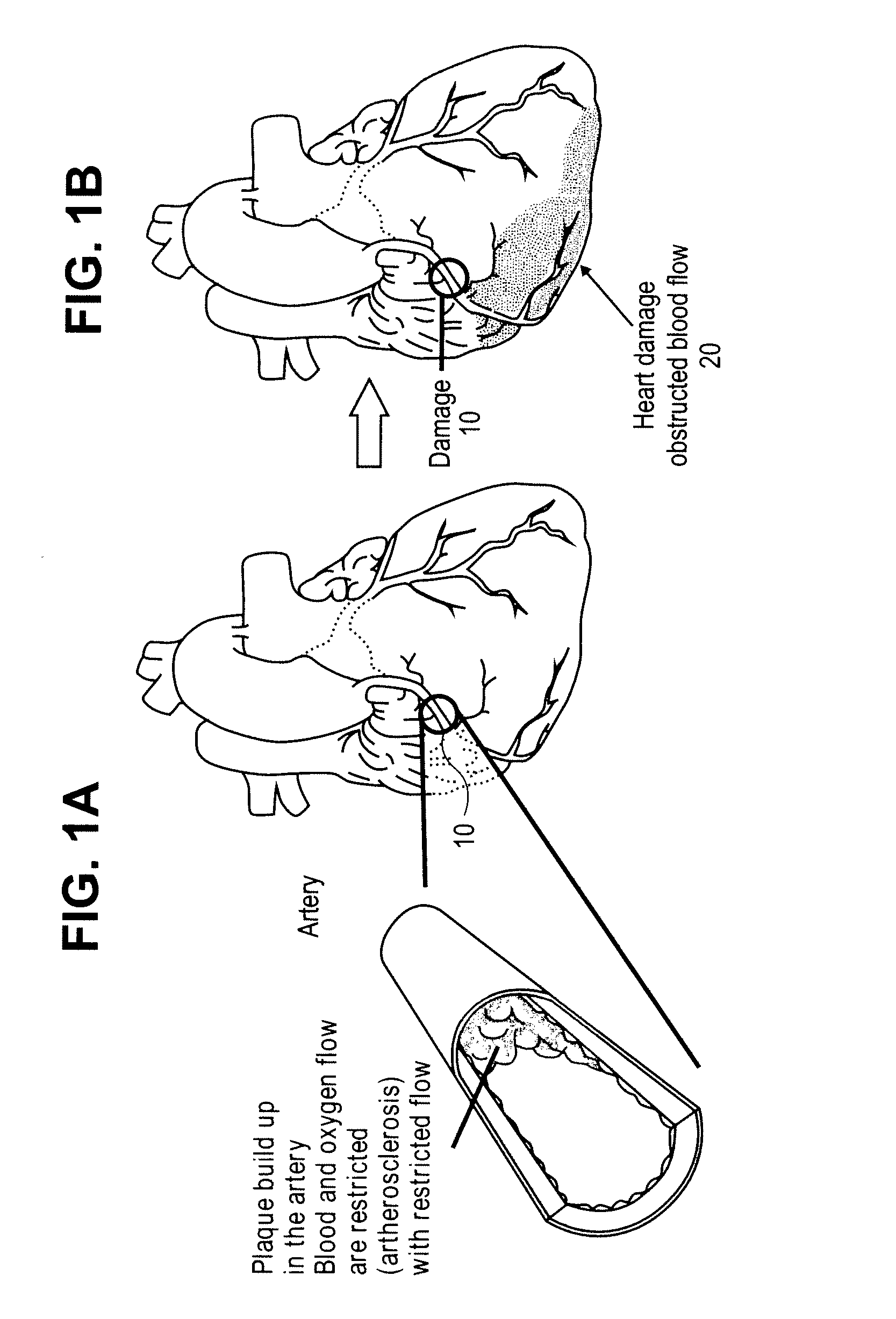

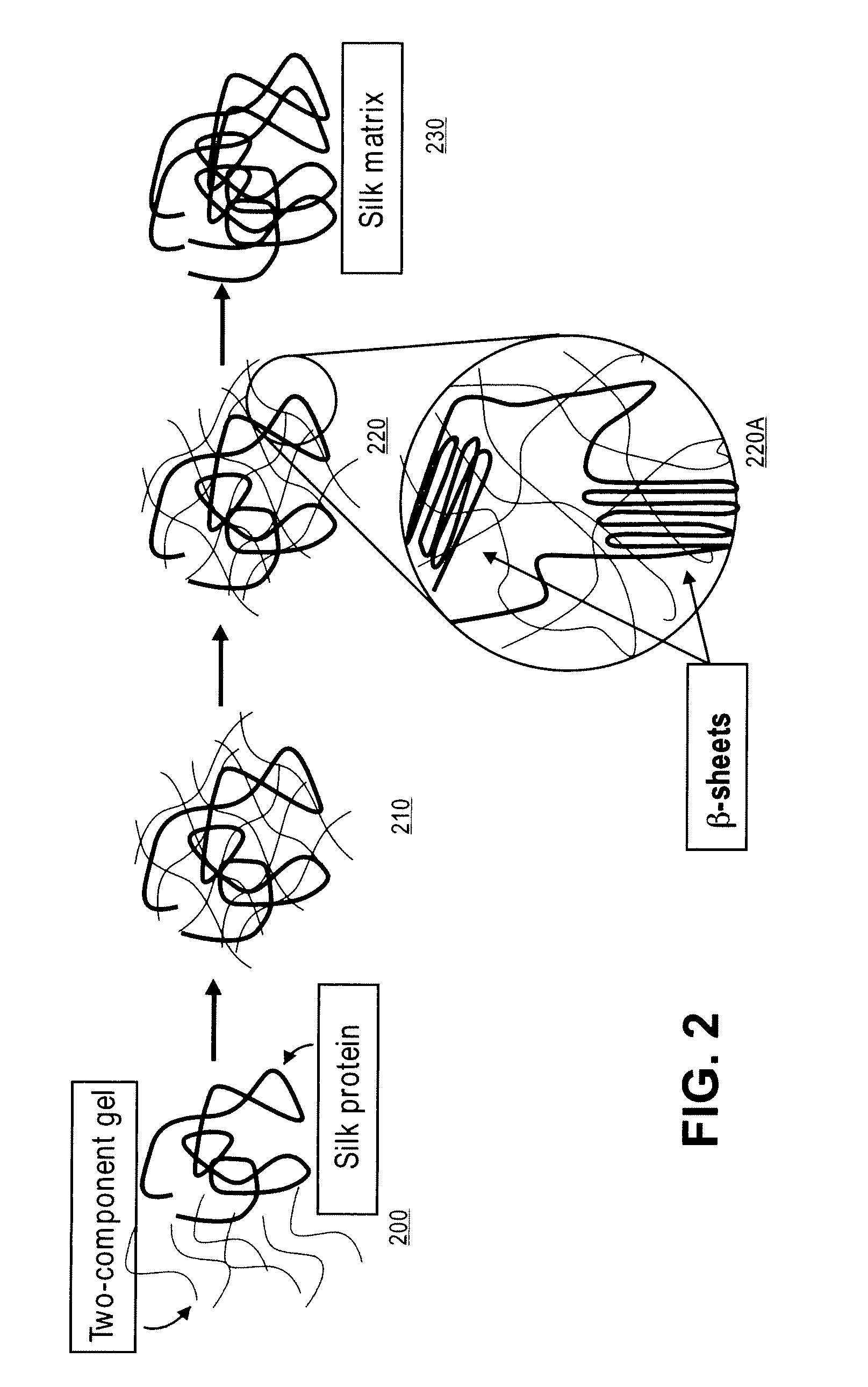

Methods and Compositions for Treating Tissue Using Silk Proteins

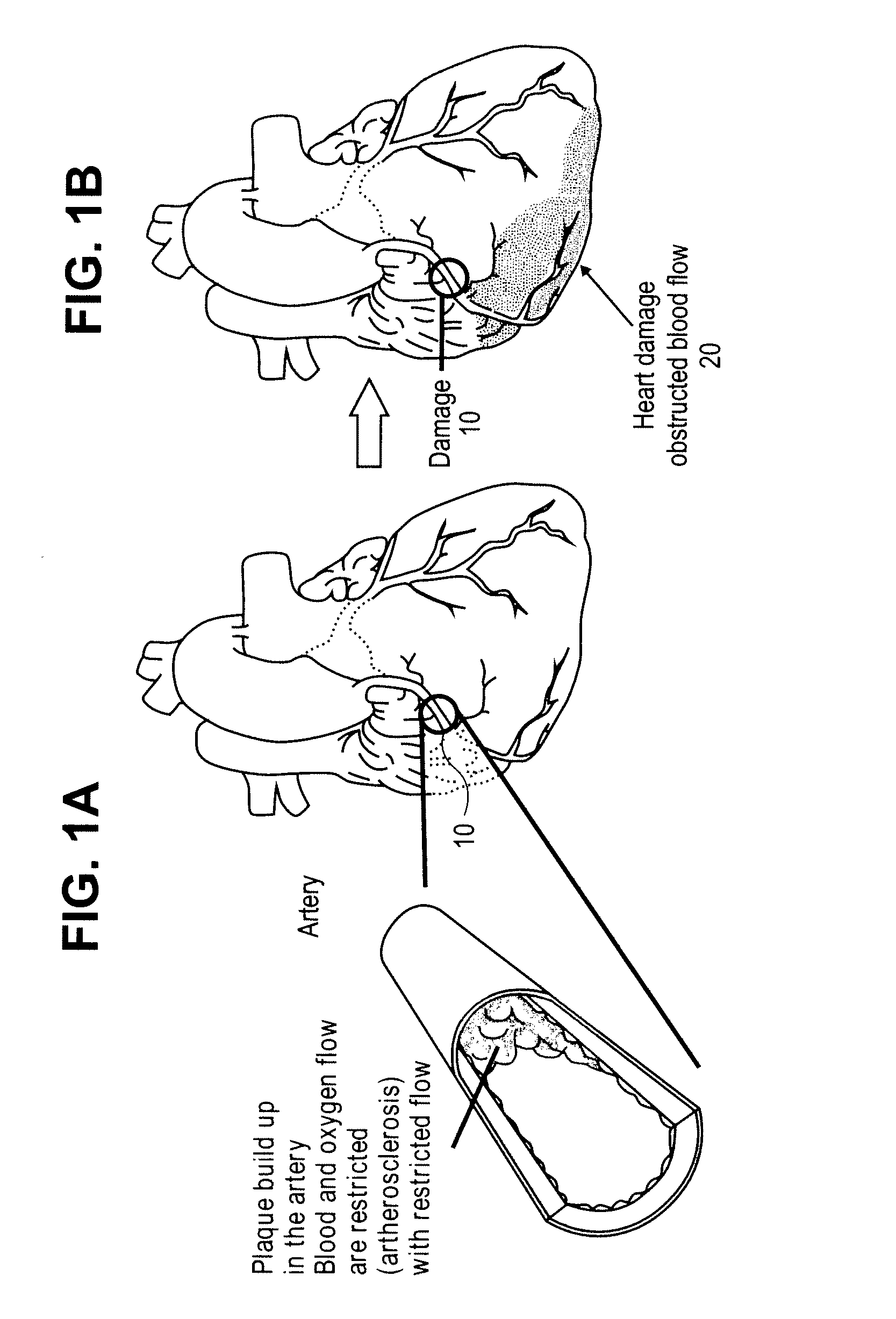

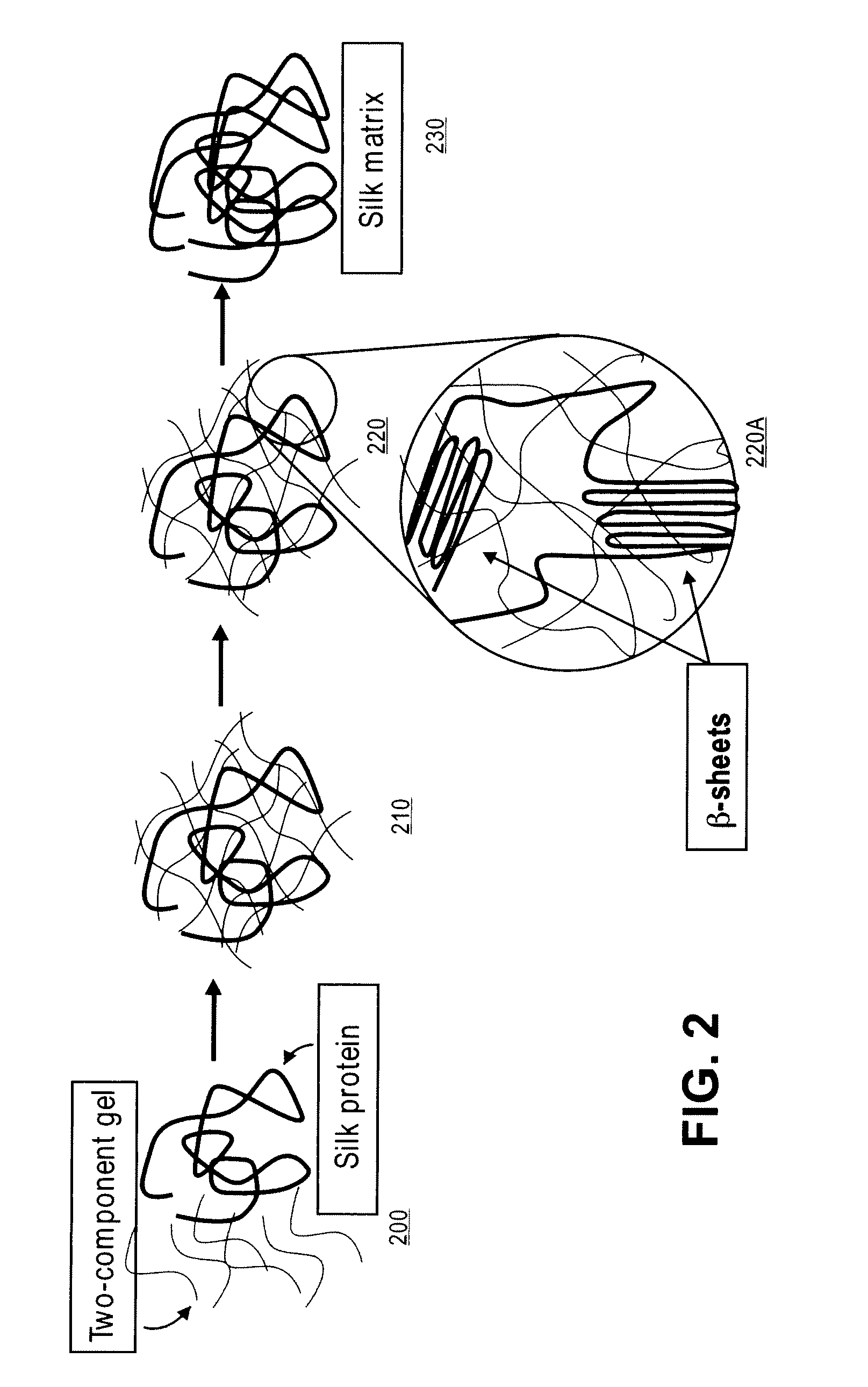

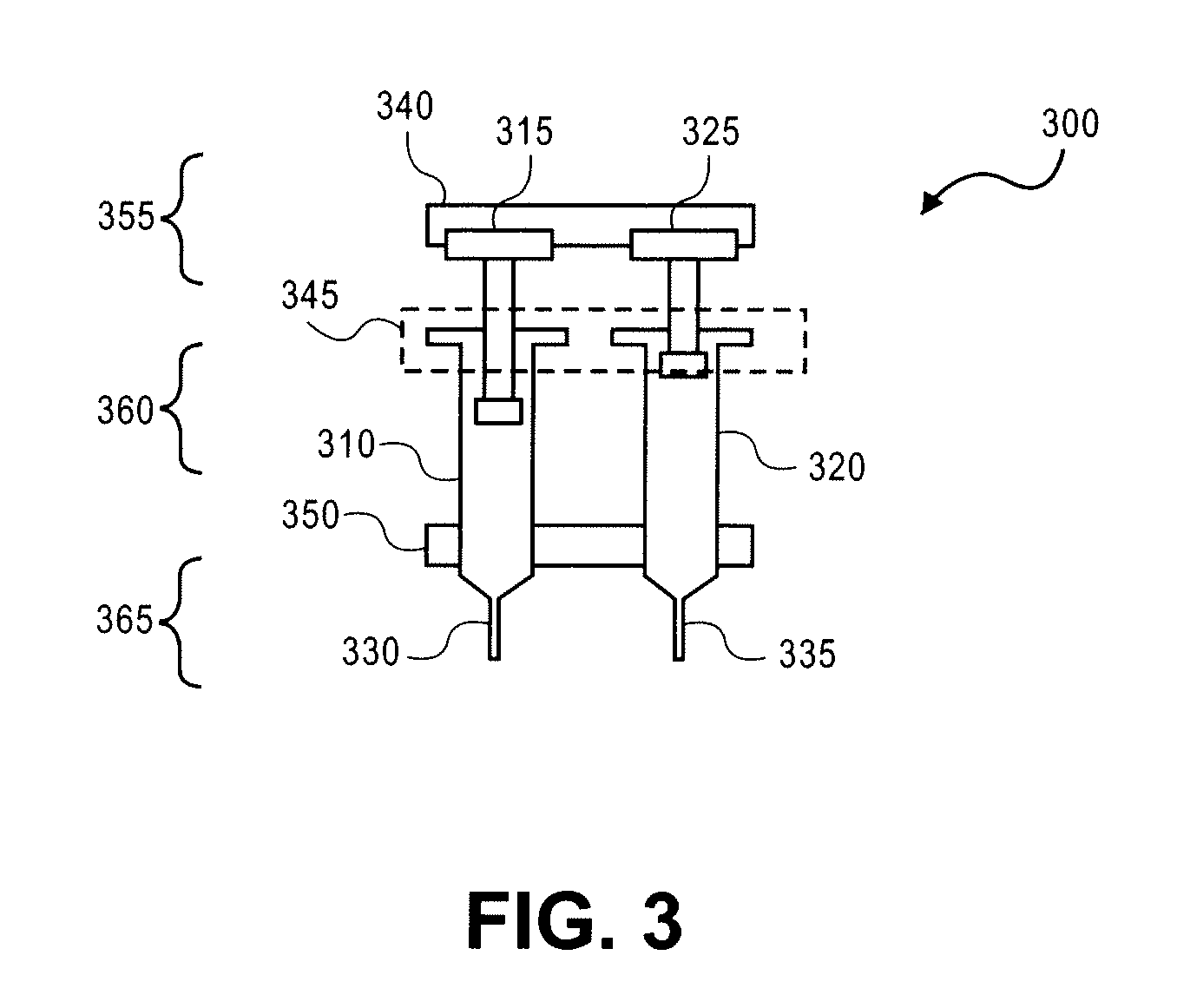

Compositions for forming a self-reinforcing composite biomatrix, methods of manufacture and use therefore are herein disclosed. Kits including delivery devices suitable for delivering the compositions are also disclosed. In some embodiments, the composition can include at least three components. In one embodiment, a first component can include a first functionalized polymer, a second component can include a second functionalized polymer and a third component can include silk protein or constituents thereof. In some embodiments, the composition can include at least one cell type and / or at least one growth factor. In some embodiments, the composition can include a biologic encapsulated, suspended, disposed within or loaded into a biodegradable carrier. In some embodiments, the composition(s) of the present invention can be delivered by a dual lumen injection device to a treatment area in situ, in vivo, as well as ex vivo applications.

Owner:ABBOTT CARDIOVASCULAR

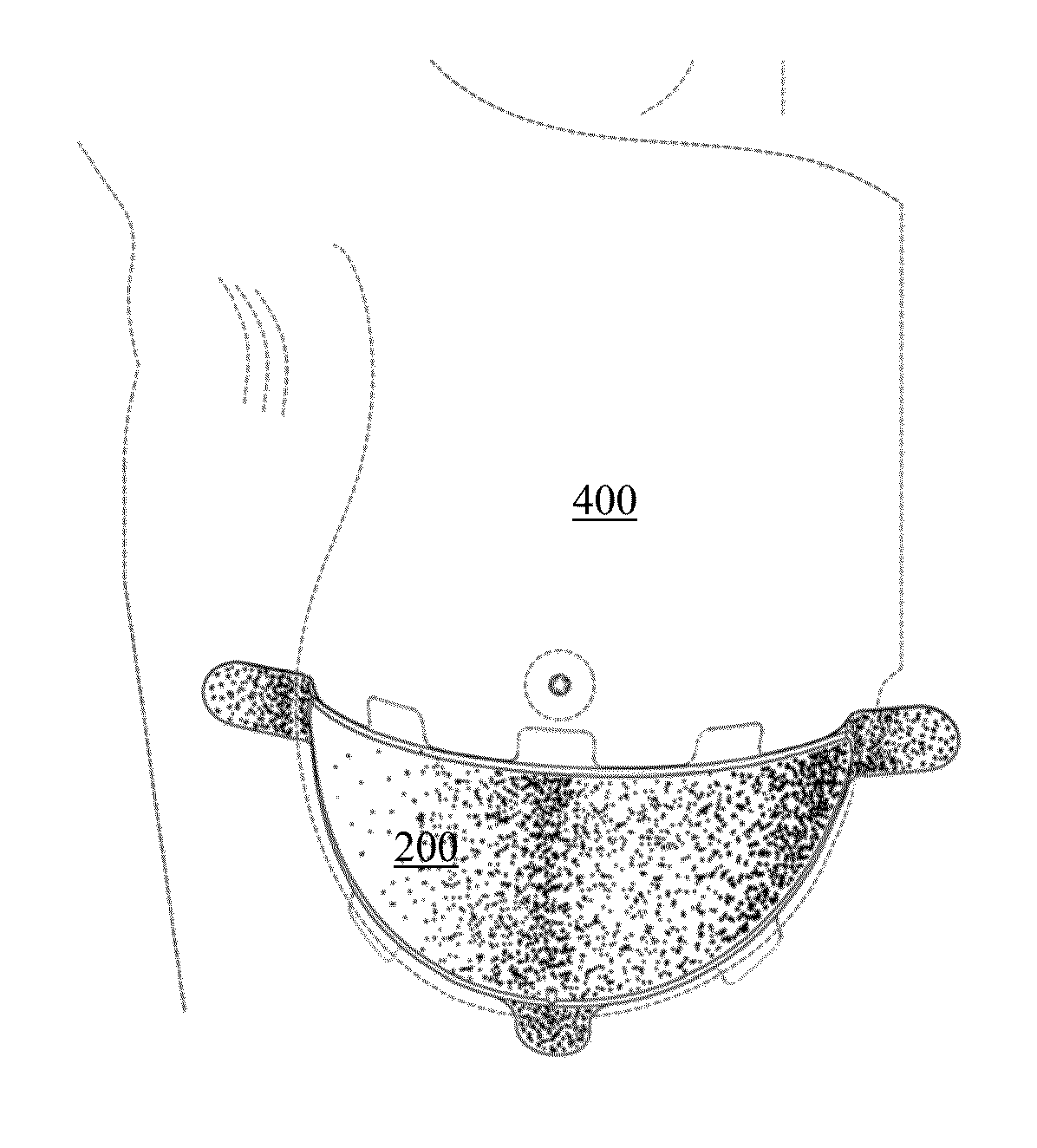

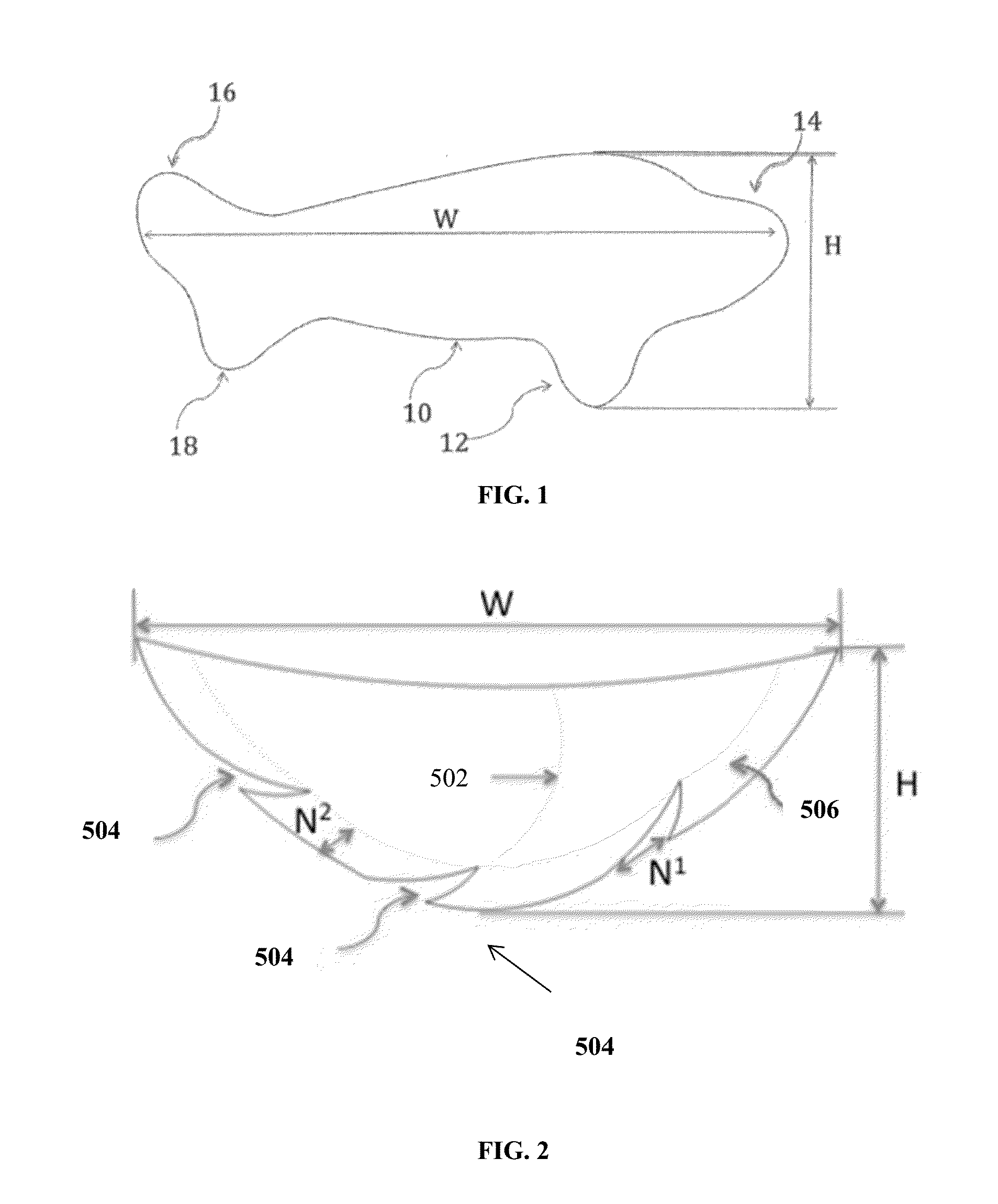

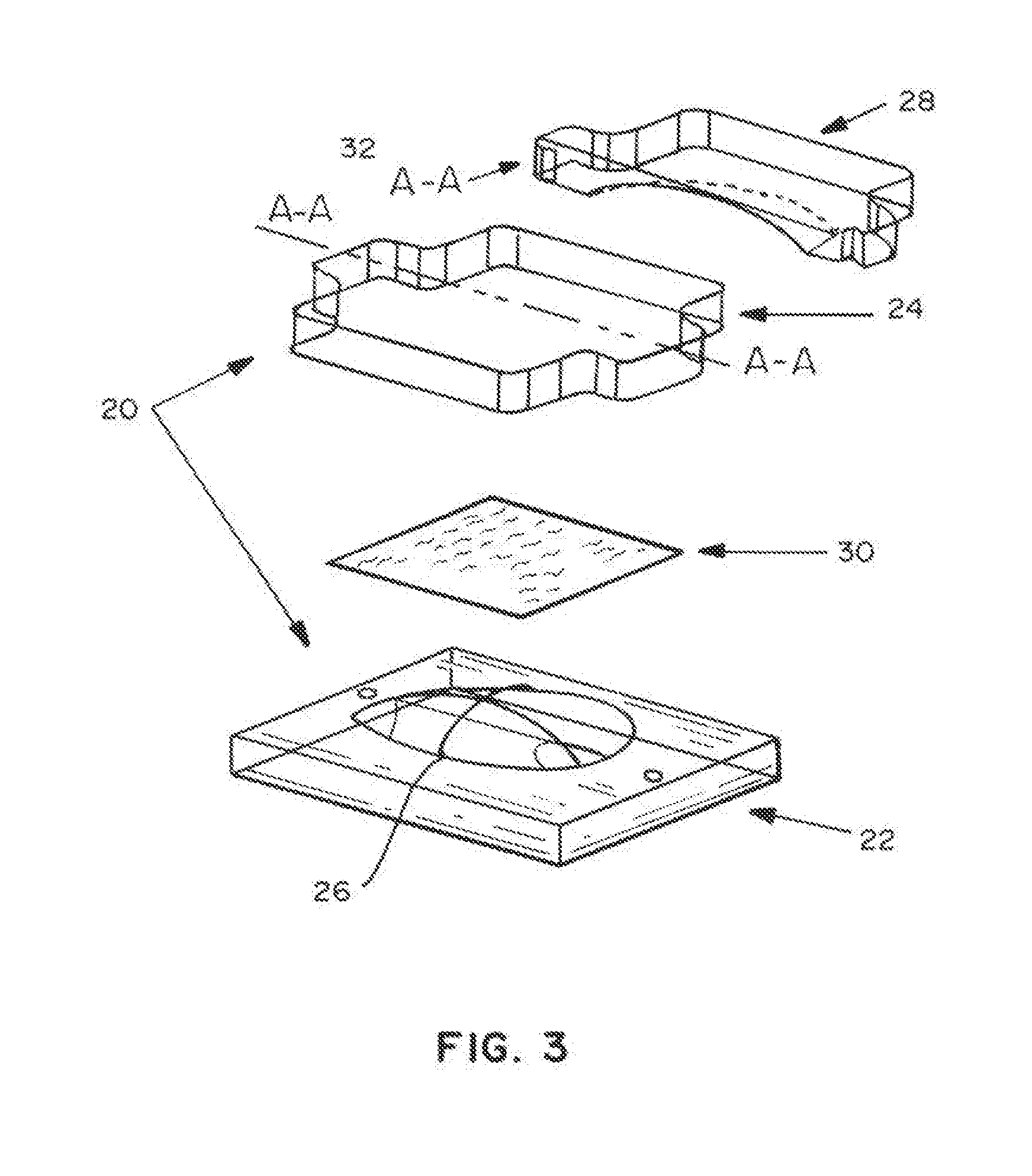

Absorbable implants for plastic surgery

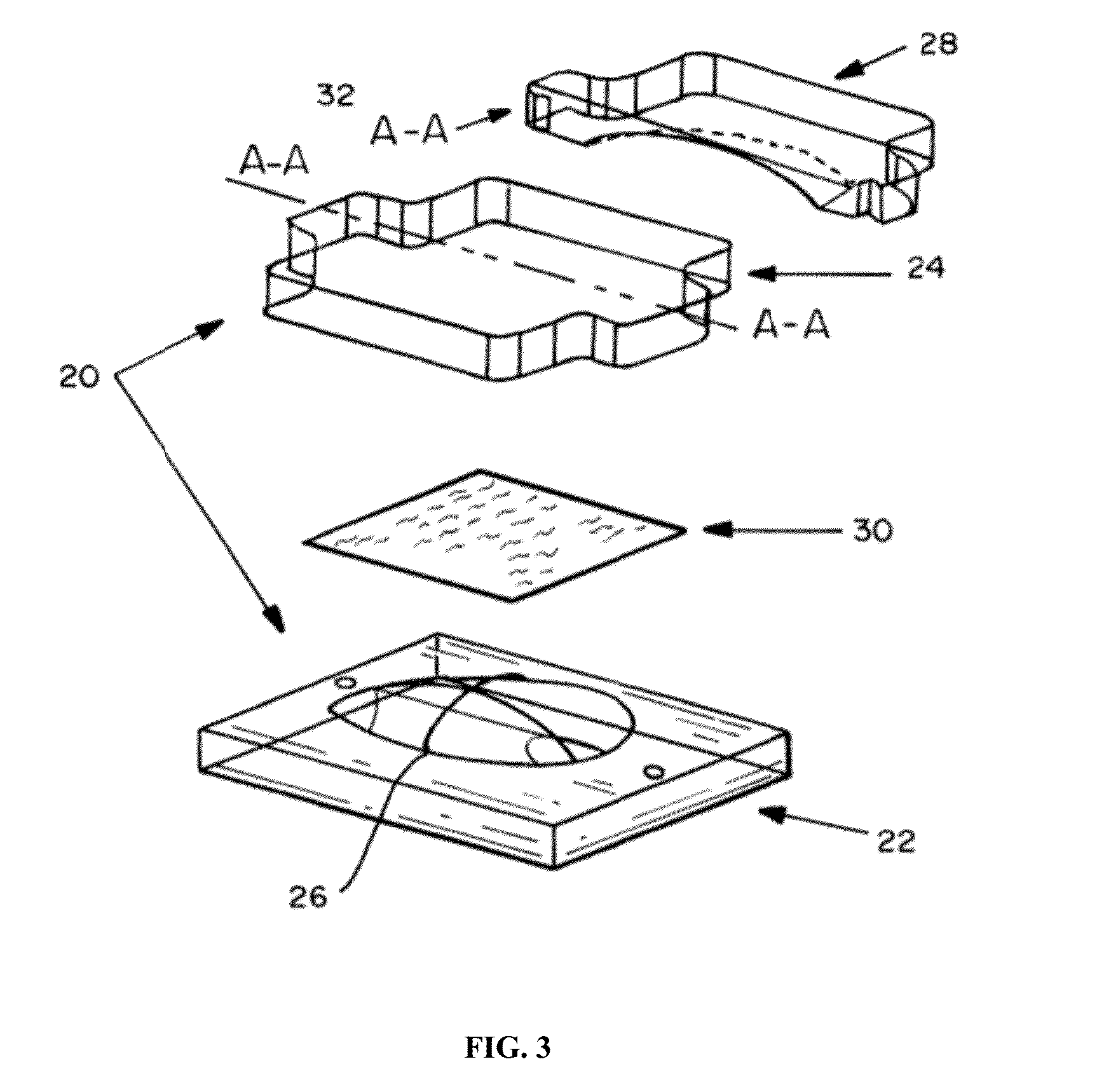

ActiveUS20150223928A1Solve the lack of mechanical propertiesMinimization requirementsMammary implantsDiagnosticsPullout strengthThree dimensional shape

Absorbable implants for breast surgery that conform to the breast parenchyma and surrounding chest wall have been developed. These implants support newly lifted breast parenchyma, and / or a breast implant. The implants have mechanical properties sufficient to support a reconstructed breast, and allow the in-growth of tissue into the implant as it degrades. The implants have a strength retention profile allowing the support of the breast to be transitioned from the implant to regenerated host tissue, without significant loss of support. Three-dimensional implants for use in minimally invasive mastopexy / breast reconstruction procedures are also described, that confer shape to a patient's breast. These implants are self-reinforced, can be temporarily deformed, implanted in a suitably dissected tissue plane, and resume their preformed three-dimensional shape. The implants are preferably made from poly-4-hydroxybutyrate (P4HB) and copolymers thereof. The implants have suture pullout strengths that can resist the mechanical loads exerted on the reconstructed breast.

Owner:TEPHA INC

Methods and compositions for treating tissue using silk proteins

Compositions for forming a self-reinforcing composite biomatrix, methods of manufacture and use therefore are herein disclosed. Kits including delivery devices suitable for delivering the compositions are also disclosed. In some embodiments, the composition can include at least three components. In one embodiment, a first component can include a first functionalized polymer, a second component can include a second functionalized polymer and a third component can include silk protein or constituents thereof. In some embodiments, the composition can include at least one cell type and / or at least one growth factor. In some embodiments, the composition can include a biologic encapsulated, suspended, disposed within or loaded into a biodegradable carrier. In some embodiments, the composition(s) of the present invention can be delivered by a dual lumen injection device to a treatment area in situ, in vivo, as well as ex vivo applications.

Owner:ABBOTT CARDIOVASCULAR

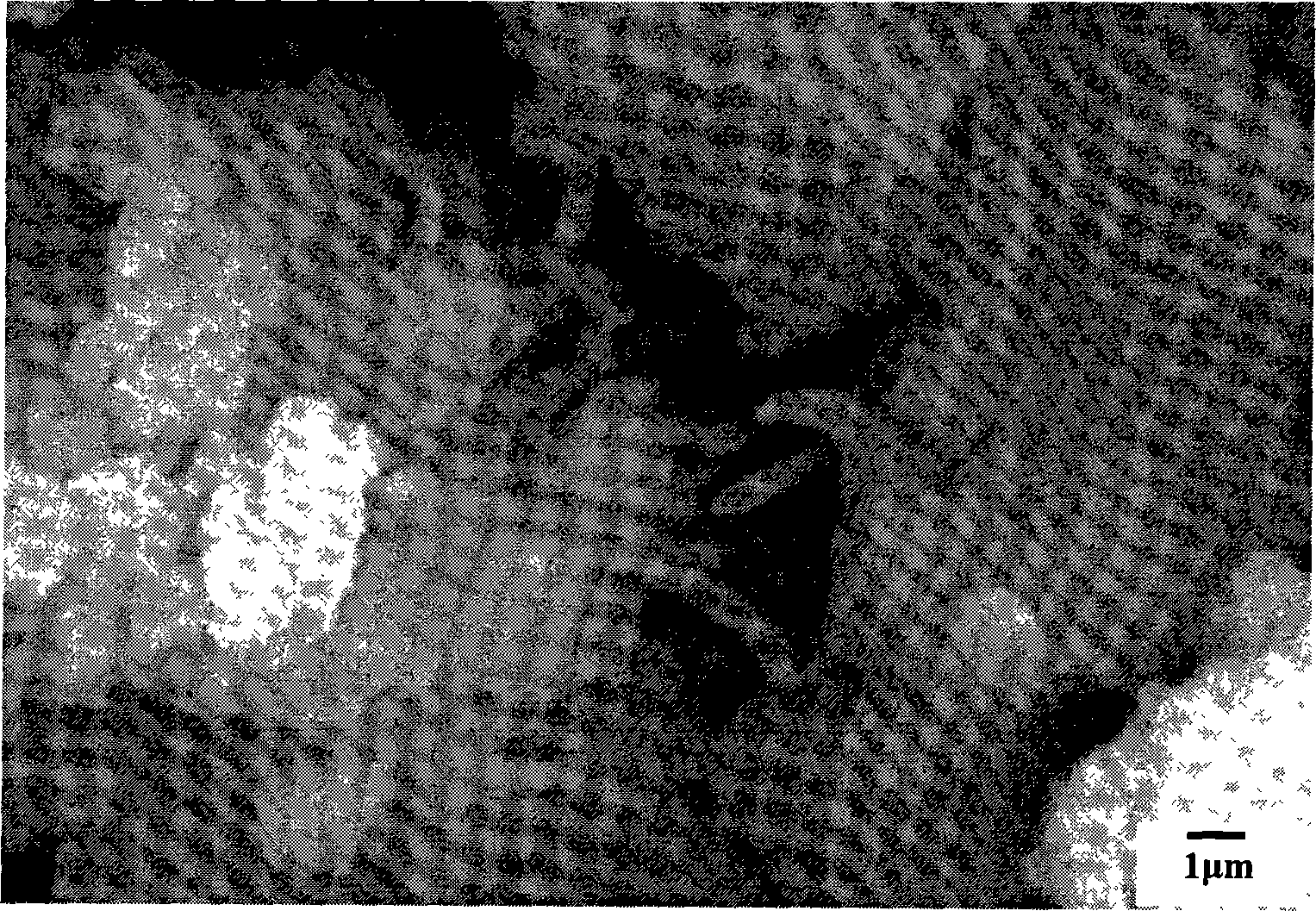

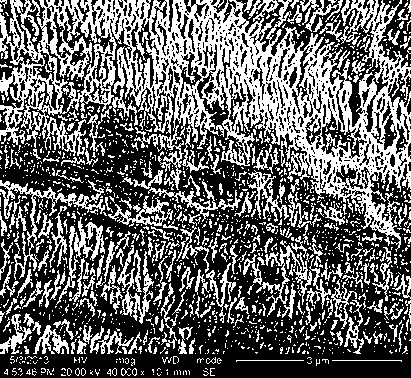

Preparation method for self-complement sub-micron crystal alumina ceramic

The invention relates to a preparation method of a low-cost self-reinforced submicron grain alumina ceramic, which belongs to the fine ceramic field. The method comprises the steps of: adopting industrial aluminum hydroxide or boehmite as a raw material, adding fine grain Alpha-alumina and water for ball milling so as to obtain an even slurry; adding water for mixing at a temperature between 70 and 90 DEG C, and adding acid to control the pH value at 2 to 5, so as to form an emulsion; and adding an additive which is a mixture selected from one or more than two of zinc oxide, magnesium oxide, calcium oxide, yttrium oxide, lanthanum oxide, zirconium oxide, boric oxide, ferric oxide, vanadium oxide, silicon oxide or titanium oxide for forming a gel after water is evaporated, and drying the gel and then sintering the gel under high temperature for preparing the self-reinforced submicron grain alumina ceramic containing alumina elongated grains. The ceramic is characterized in that crystal grains have diameters of less than 0.5mu m, and a microstructure contains elongated alumina grains have length-diameter ratios of larger than 5, and has the advantages of high hardness, high toughness and good wear resistance, and can be widely used in ceramic grinding media and the abrasives industry.

Owner:SUZHOU CHUANGYUAN INVESTMENT DEV

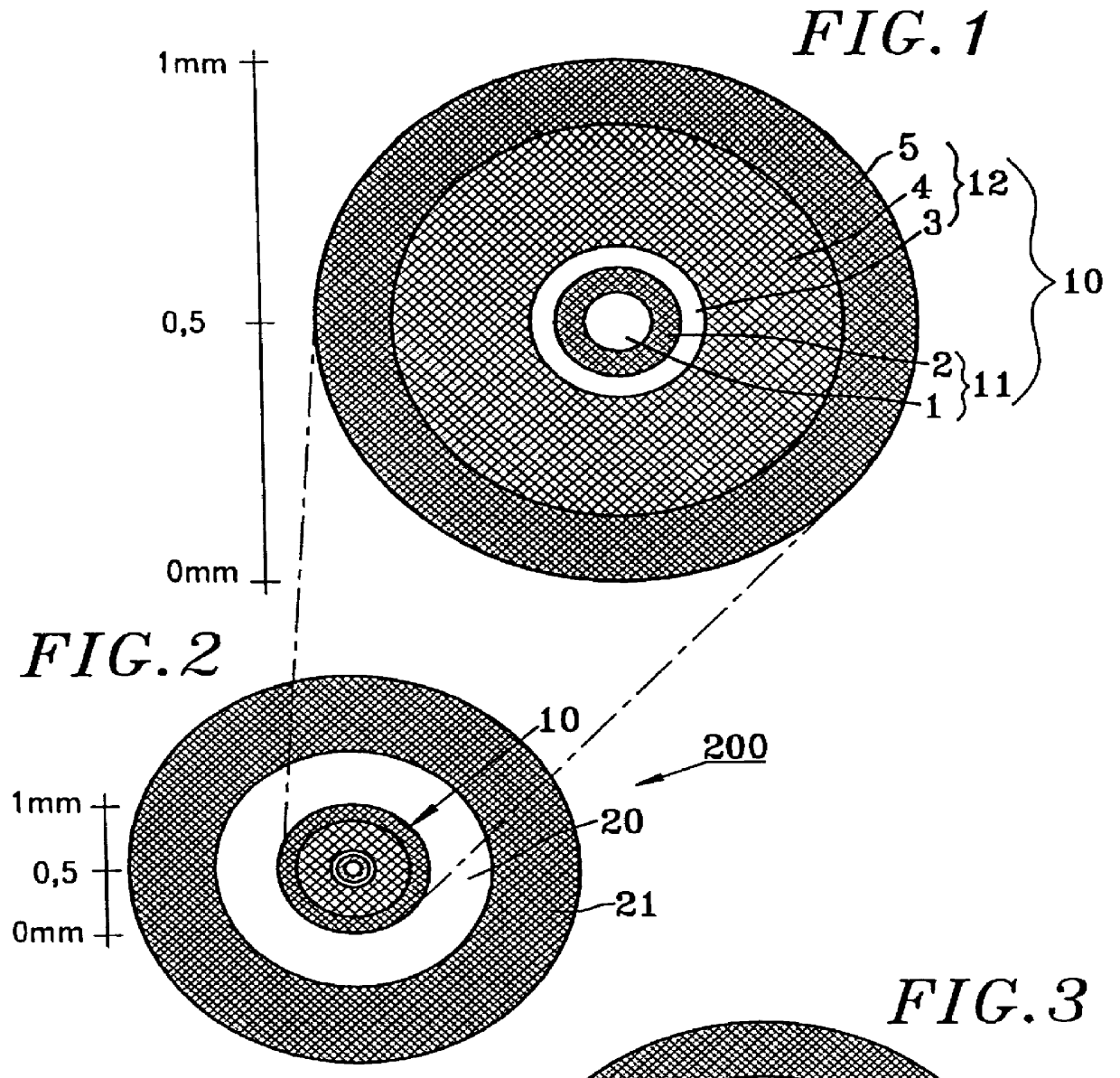

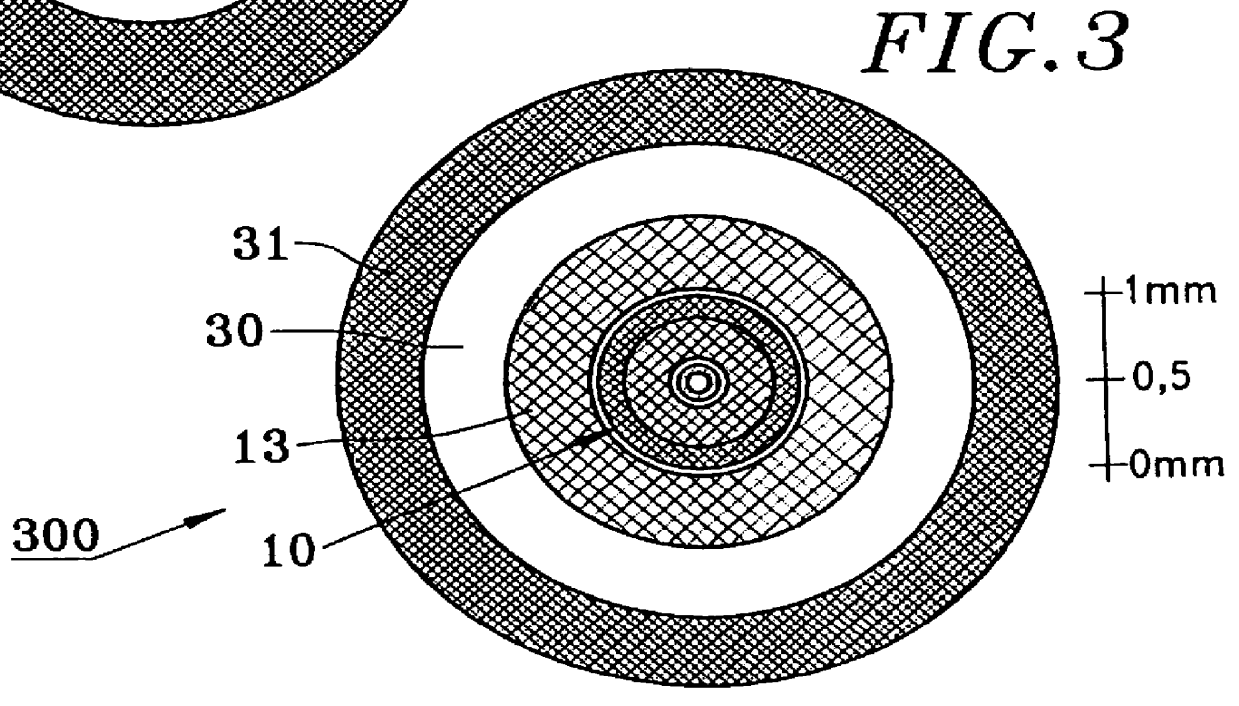

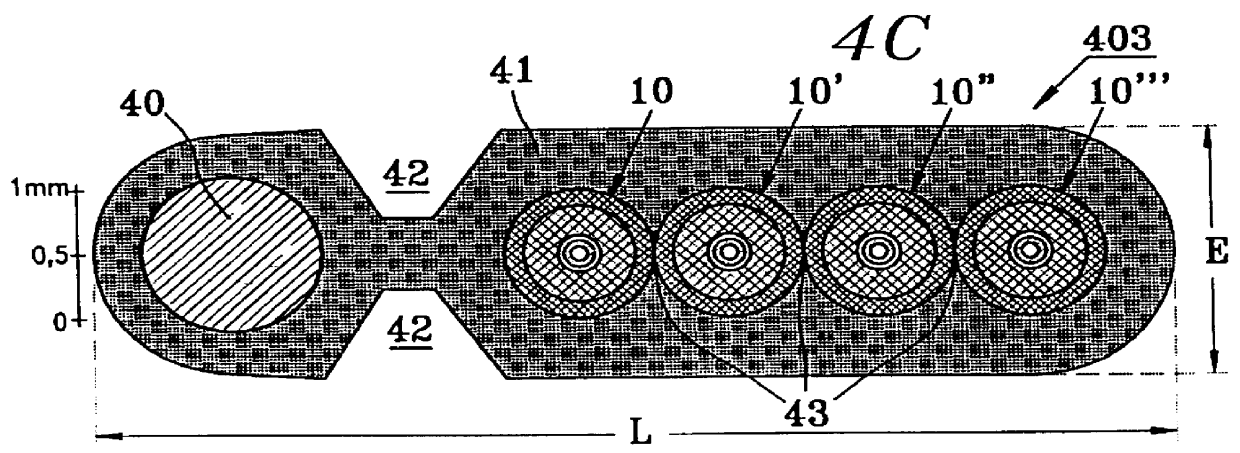

Structures of optical fiber cables self-reinforced against compression

InactiveUS6067394AIncrease flexibilityHigh compressive strengthFibre mechanical structuresFiberOptical Module

A modular optical transmission cable which has several reinforcement and optical modules, each optical module having: a sheathed optical fiber, coated with: an intermediate decoupling layer, and with a rigid shell forming a microcarrier, a reinforcement module being associated with an optical module, the modules being molded in an external sheath. A flexible reinforcement module is associated with at least one optical module that is self-reinforced against compression in order to obtain a cable having high flexibility combined with high compressive strength. The disclosure can be applied in the field of optical fiber cables and especially that of the reinforcement structures of such cables and fibers.

Owner:HANGER SOLUTIONS LLC

Multifunctional implant device

InactiveUS20070191851A1Mechanical strengthAchieve mechanical strengthInternal osteosythesisBone implantSelf reinforcedBioactive glass

Bone fixation or augmentation in a mammalian body to enhance the mechanical strength of a fracture is provided by reinforcement fixing bone ends together using the implant device. A resorbable device can be rendered anti-osteolytic by incorporating materials such as bisphosphonates. It can also be rendered osteoconductive by the incorporation of an osteoconductive material such as bioactive glass or TCP. The implant device has a matrix as one phase, where the matrix is made of a bioresorbable polymer. One phase of the implant is made from self-reinforcing elements and the matrix contains an antiosteolytic agent component. The implant contains further osteoconductive and / or osteoconductive material.

Owner:ASHAMMAKHI NUREDDIN

Absorbable Implants for Plastic Surgery

ActiveUS20160022416A1Sufficient mechanical propertyMinimization requirementsMammary implantsSurgeryPullout strengthThree dimensional shape

Absorbable implants for breast surgery that conform to the breast parenchyma and surrounding chest wall have been developed. These implants support newly lifted breast parenchyma, and / or a breast implant. The implants have mechanical properties sufficient to support a reconstructed breast, and allow the ingrowth of tissue into the implant as it degrades. The implants have a strength retention profile allowing the support of the breast to be transitioned from the implant to regenerated host tissue, without significant loss of support. Three-dimensional implants for use in minimally invasive mastopexy / breast reconstruction procedures are also described, that confer shape to a patient's breast. These implants are self-reinforced, can be temporarily deformed, implanted in a suitably dissected tissue plane, and resume their preformed three-dimensional shape. The implants are preferably made from poly-4-hydroxybutyrate (P4HB) and copolymers thereof. The implants have suture pullout strengths that can resist the mechanical loads exerted on the reconstructed breast

Owner:TEPHA INC

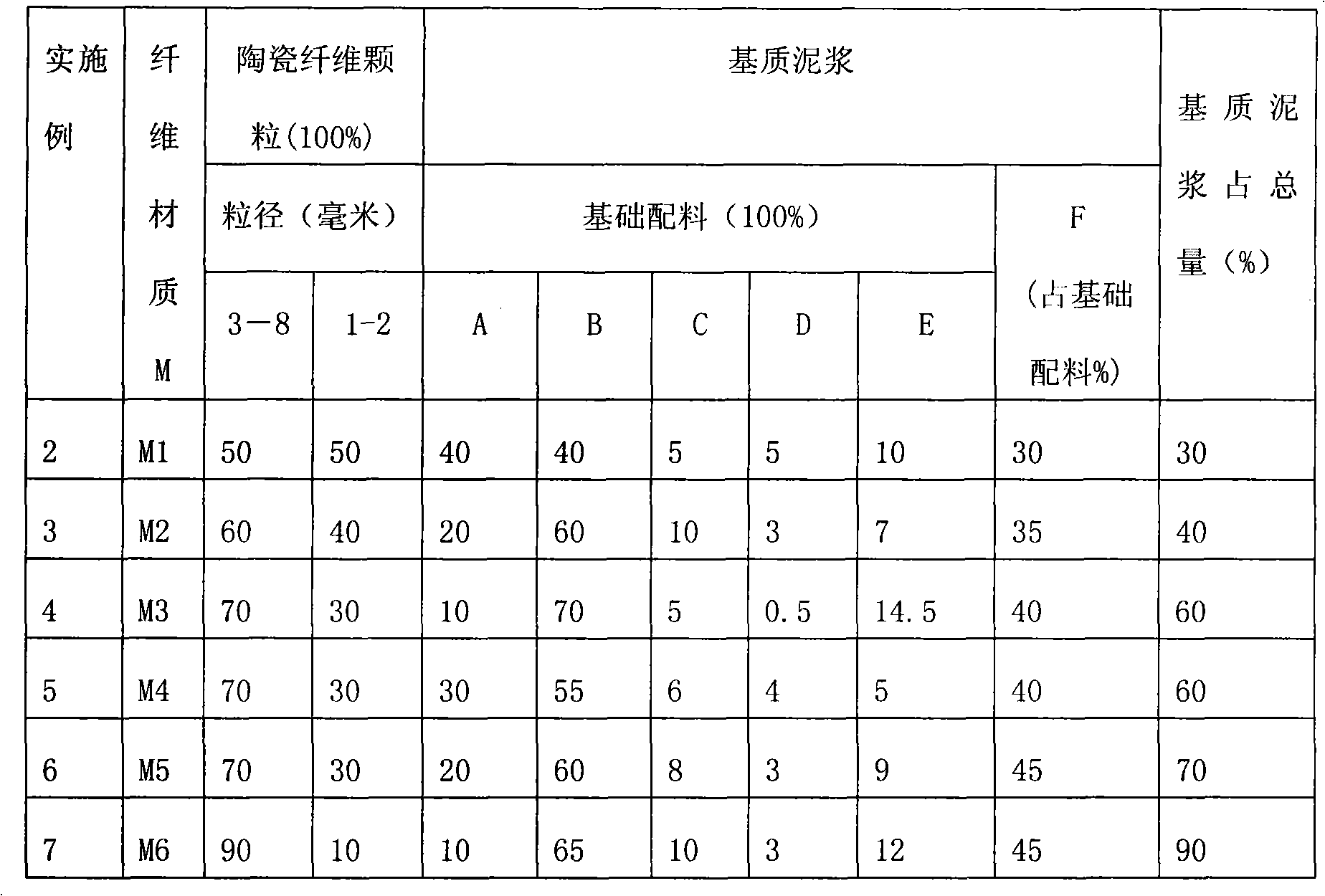

Self-reinforcing type ceramic fibre pouring material and preparation thereof

The invention discloses a self-enhanced type ceramic fiber castable and a method for preparing the same. The ceramic fiber castable is mixed by a matrix slurry and a grading ceramic fiber particle which is mixed by a ceramic fiber particle with a grain size of 3-8mm and a ceramic fiber particle with a grain size of 1-2mm, wherein each component content(weight) range is as follows: grading ceramic fiber particle 70%-10% and the matrix slurry 30%-90%. The matrix slurry is mixed by a based burden and a polyvinyl alcohol solution accounting for 30%-45% of the based burden weight, wherein each component content range (by total weight 100%) of the based burden is as follows: short ceramic fiber with a length less than or equal to 7mm 10-40%, ceramic powder with a grain size less than or equal to 0.088mm 70%-40%, foaming agent 5%-10%, plasticizer 0.5%-5% and high temperature binding agent 14.5%-5%. The castable of the invention has advantages of good high temperature resistance and heat insulation performance, high intension and nonchalking of the ceramic fiber in the furnace lining after long time usage at high temperature.

Owner:MAANSHAN JINMA FURNACE IND

Turbine components with thermal barrier coatings

InactiveUS7226672B2Low thermal conductivityRare earth metal oxides/hydroxidesMolten spray coatingComposite ceramicSelf reinforced

A turbine component has a substrate formed from a ceramic material selected from the group consisting of a monolithic ceramic material and a composite ceramic material and a thermal barrier coating bonded to the substrate. In one embodiment, the ceramic material forming the substrate is selected from the group of silicon nitride and self-reinforced silicon nitride. In another embodiment, the ceramic material forming the substrate is selected from the group consisting of a silicon carbide-silicon carbide material and a carbon-carbon material. At least one bond coat layer may be interposed between the substrate and the thermal barrier coating.

Owner:RAYTHEON TECH CORP

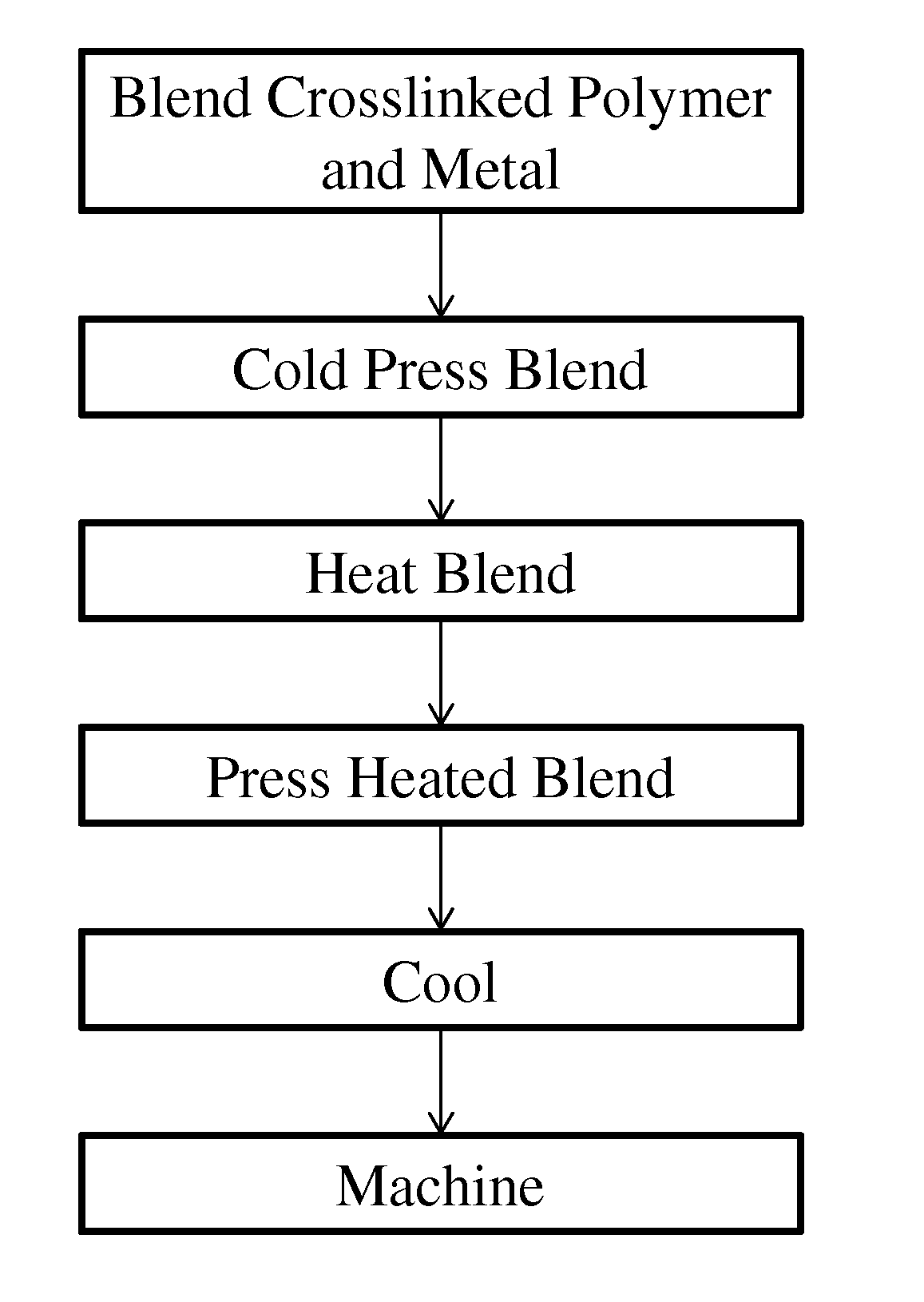

Mixed metal polymer composite

InactiveUS20140018489A1Conductive materialNon-conductive material with dispersed conductive materialPolymer scienceSelf reinforced

A metal-polymer composite includes a crosslinked polymer; and a metal which is removably disposed among the crosslinked polymer. A method of making the metal-polymer composite includes combining a crosslinked polymer and a metal; blending the crosslinked polymer and the metal to form a blend; cold pressing the blend; heating the blend to a forging temperature; and applying pressure to the blend at the forging temperature to form the metal-polymer composite. A downhole article includes a crosslinked polymer including a crosslinked product of a polymer including polyphenylene sulfide, polyphenylsulfone, self-reinforced polyphenylene, polysulfone, polyethersulfone, polyarylsulfone, derivatives thereof, or a combination comprising at least one of the foregoing; and a metal disposed among the crosslinked polymer and removable by contact with a downhole fluid.

Owner:BAKER HUGHES INC

Preparation of carbon nano-tube/cement self-enhancing damping composite material damping ratio testing method

InactiveCN101239801AHigh strengthPossesses steric stabilitySolid waste managementSelf reinforcedData acquisition

A method for preparing the carbon nano-tube / cement self-reinforcing amortization composite material and testing the damping ratio, relates to a method for preparing the cement self-reinforcing amortization composite material and testing the damping ratio. The invention settles the problems of nonuniform dispersion of carbon nano-tube, bad binding capability to the substrate interface, low damping ratio and expensive device for testing the damping ratio, complicated test or big data error in the carbon nano-tube / cement self-reinforcing amortization composite material prepared currently. The preparing method comprises the following steps: adding the cement mixing material, deionized water, superplasticiser, and the latex mixture of cement and polymer in sequence into the carbon nano-tube disperse phase miscible liquid for mixing to uniform and eliminating the bubble, afterwards encasing into the specimen mold for molding by casting; removing the mold and standard maintaining to the prescribed lifetime, then the carbon nano-tube / cement self-reinforcing amortization composite material is obtained. The testing method comprises the following procedures: constructing an elastic system, connecting the acceleration gauge and the strength hammer to the data acquisition system, vertically flipping the test piece with the strength hammer and testing the damping ratio.

Owner:HARBIN INST OF TECH

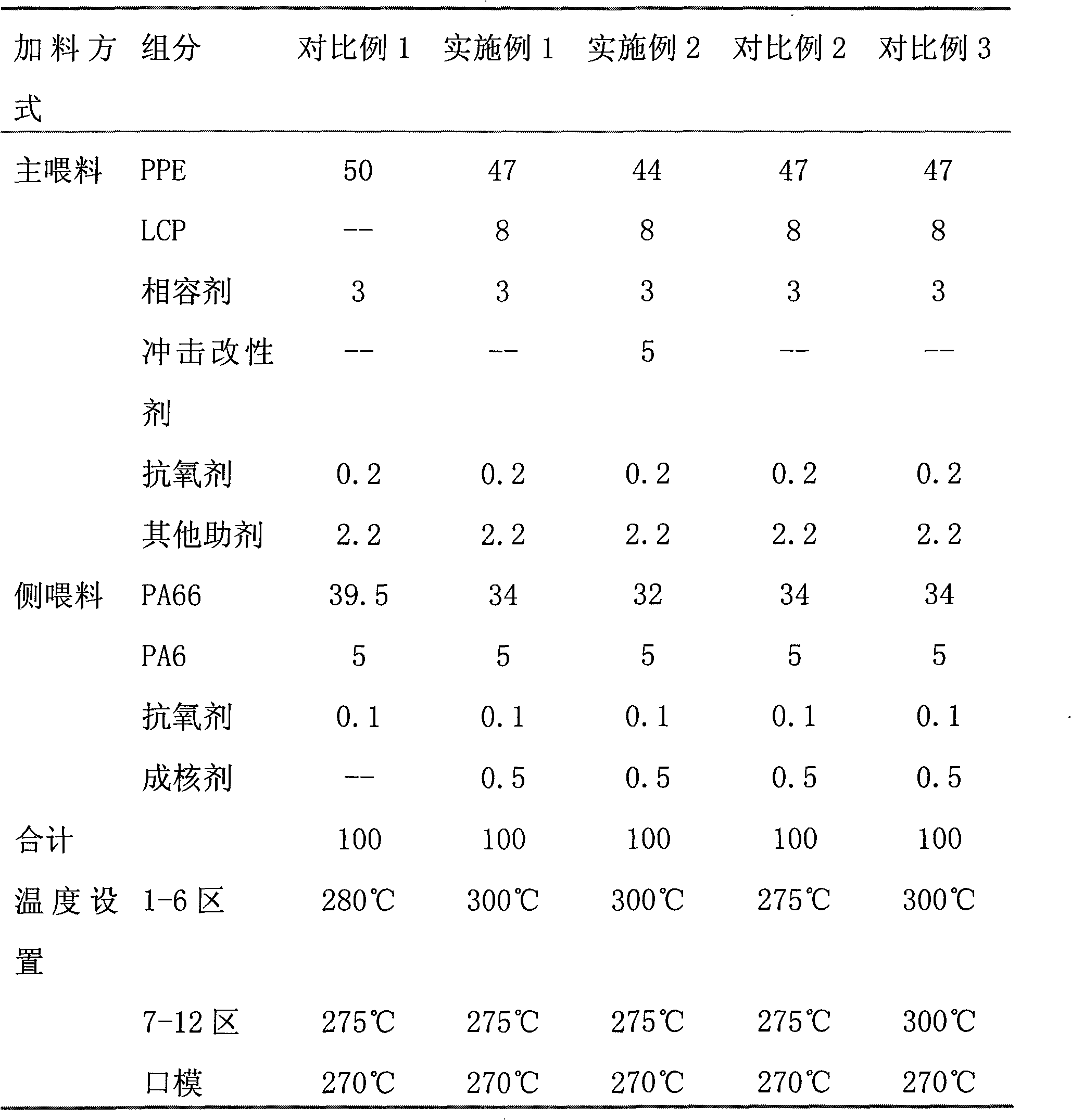

Rapid molding high heat-resistant polyamide-polyphenyl ether alloy and preparation method thereof

The invention discloses a rapid molding high heat-resistant polyamide-polyphenyl ether alloy and a preparation method thereof. The weight ratios of raw materials of the rapid molding self-reinforced high heat-resistant polyamide-polyphenyl ether alloy are 20-75 parts of a polyphenyl ether resin, 10-80 parts of a polyamide resin, 1-35 parts of a liquid crystalline polymer resin, 0.1-3 parts of a nucleating agent and 1-10 parts of a compatilizer. Compared with a conventional alloy, the rapid molding self-reinforced high heat-resistant polyamide-polyphenyl ether alloy has a series of the advantages of low specific gravity, good surface gloss, high mechanical strength, good heat resistance, good chemical resistance, short molding period, etc.

Owner:ZHEJIANG EXPO NEW MATERIALS CO LTD

Self-reinforced hybrid hydrogel used for artificial muscles and preparation method thereof

InactiveCN103224633AHigh strengthAvoid breakingProsthesisMetal ions in aqueous solutionControllability

The invention relates to a self-reinforced hybrid hydrogel used for artificial muscles and a preparation method thereof. According to the invention, sodium alginate is used as a high-molecular skeleton, acrylamide and derivative thereof are used as polymerizable monomers, divinyl benzene, N,N'-methylene bis acrylamide or ethylene glycol dimethacrylate is used as a chemical cross-linking agent, an aqueous metal salt solution is used as an ion cross-linking agent, and then the hydrogel with high elasticity and high toughness is prepared. During a process of preparing the hydrogel, an organic matter emulsion containing metal ion aqueous solution is added. When the prepared hydrogel is stretched by external forces to a certain extent, the gel deforms to extrude the organic matter emulsion, and metal ions are released and then crosslinked with the sodium alginate in the hybrid gel, thereby substantially improving gel intensity and preventing gel fracture. The preparation method has advantages of good controllability, simple technology and low cost, the obtained hydrogel material can be self-reinforced, and is expected to be applied in fields of artificial cartilage, artificial muscle, flexible robot manufacture, etc.

Owner:TIANJIN POLYTECHNIC UNIV

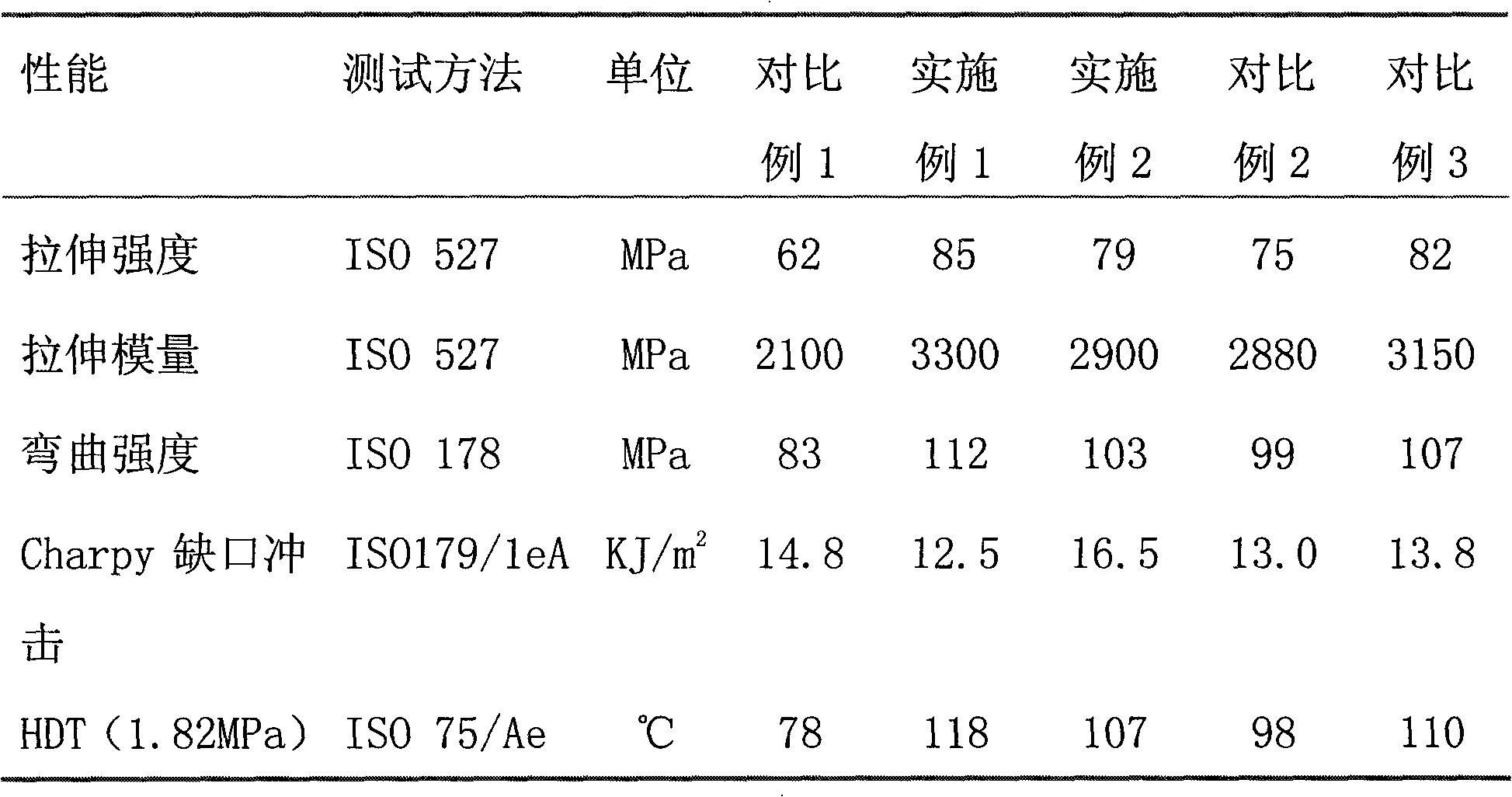

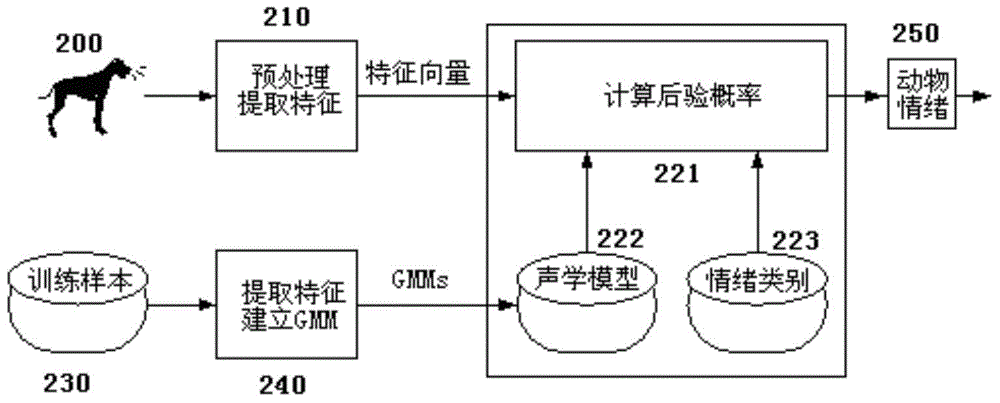

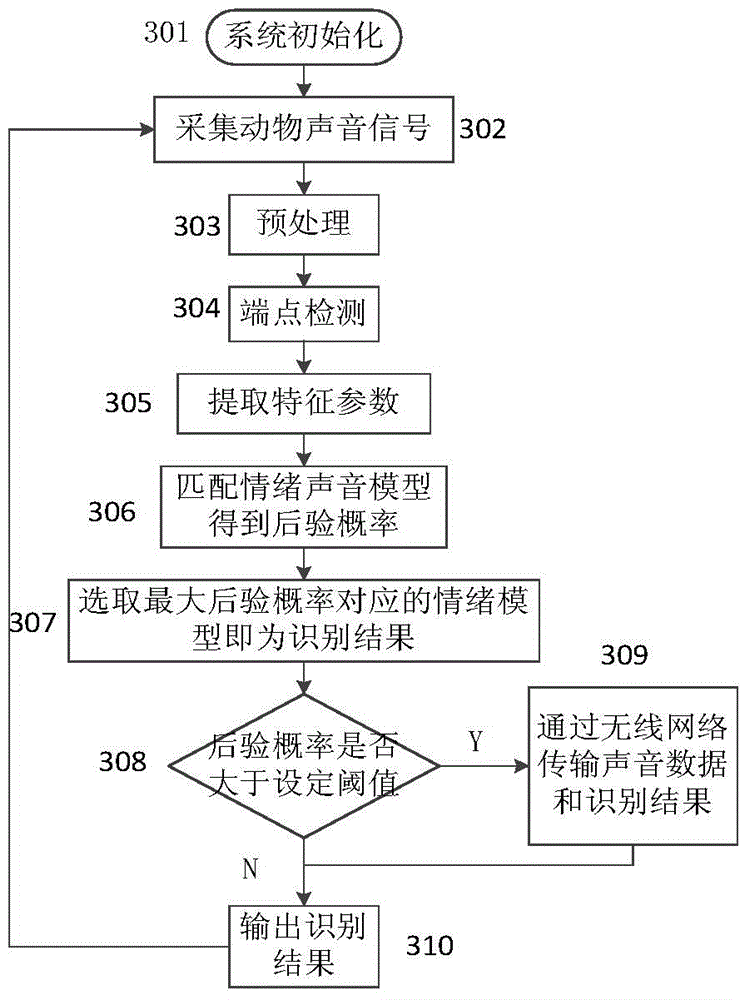

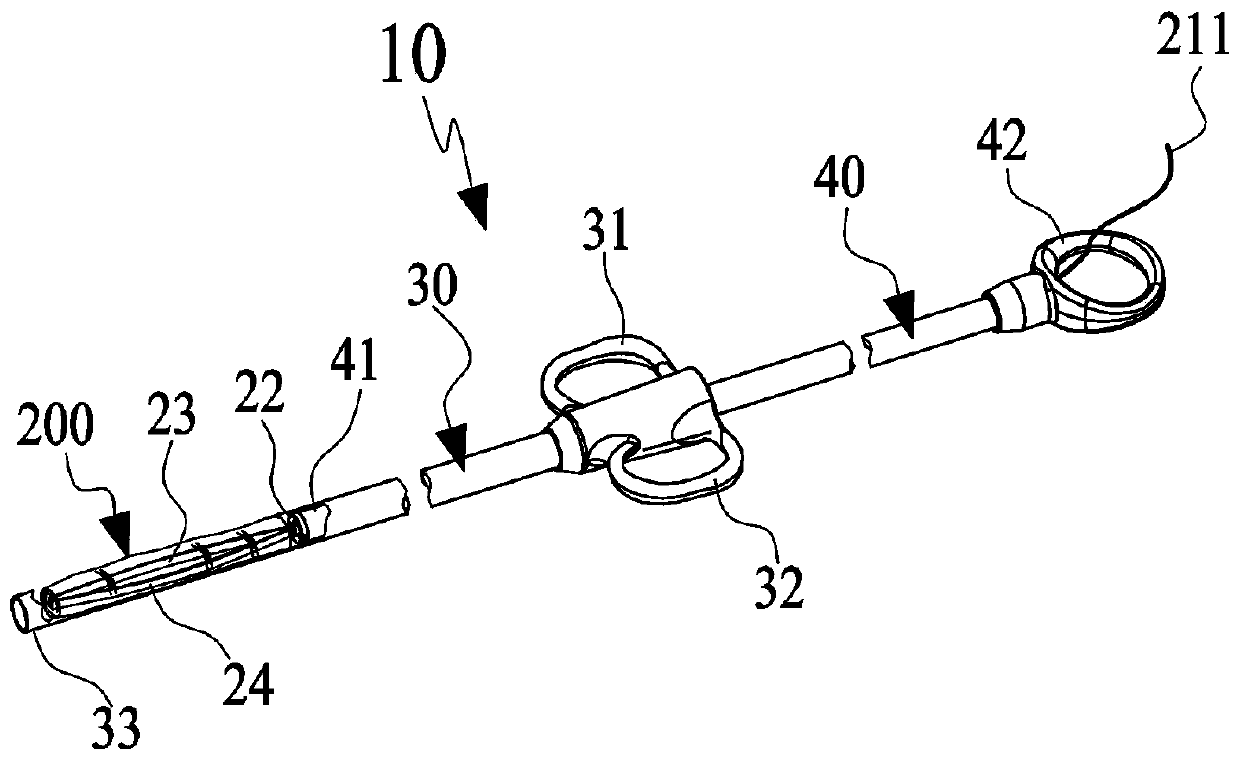

System and method for recognizing voice emotion of animal

InactiveCN104700829AMaster life habitsImprove recognition rateSpeech recognitionWireless transmissionSelf reinforced

The invention discloses a system and a method for recognizing voice emotion of animal, and relates to the voice recognizing technology. The system comprises an audio processing device (10), a data processing device (20), a wireless transmission device (30) and a power supply (40) the audio processing device (10), the data processing device (20) and the wireless transmission device (30) are sequentially connected; the power supply (40) is respectively connected with the audio processing device (10) and the data processing device (20). The method comprises the steps of (1) building a voice data template database and a model; (2) recognizing the emotion; (3) self-reinforcing the model. The system and the method are applicable to a zoo, an agricultural and forestry division and a wildlife protection division to timely master the living habit of the animal as well as preparing protection strategies. The system and the method are also applicable to mutual communication of people and pets in daily life.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

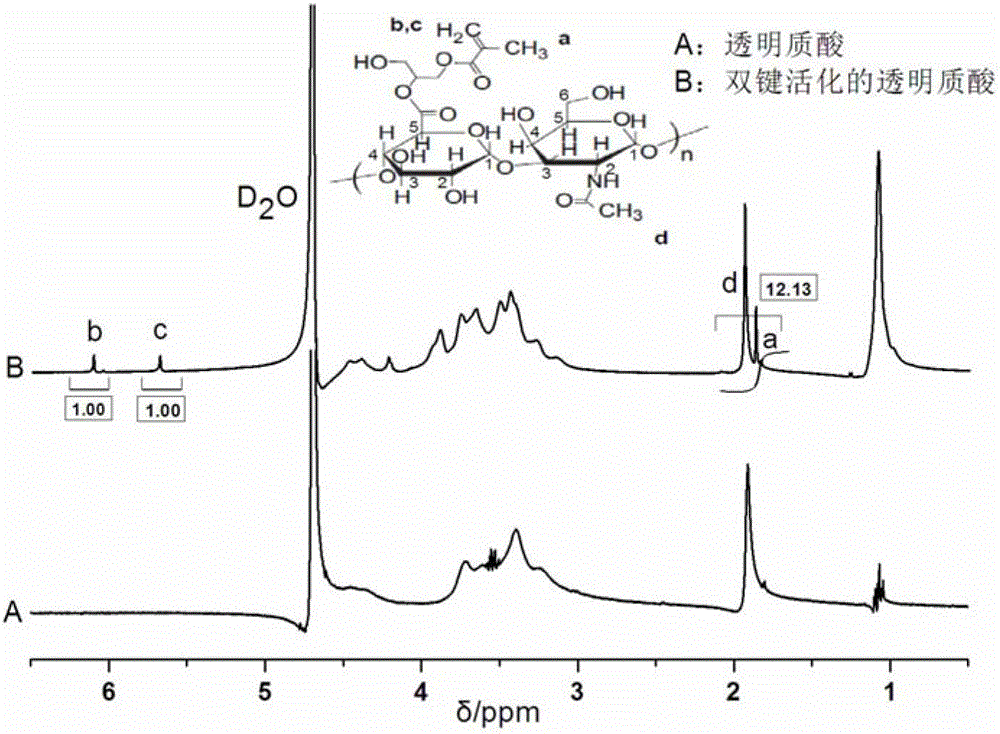

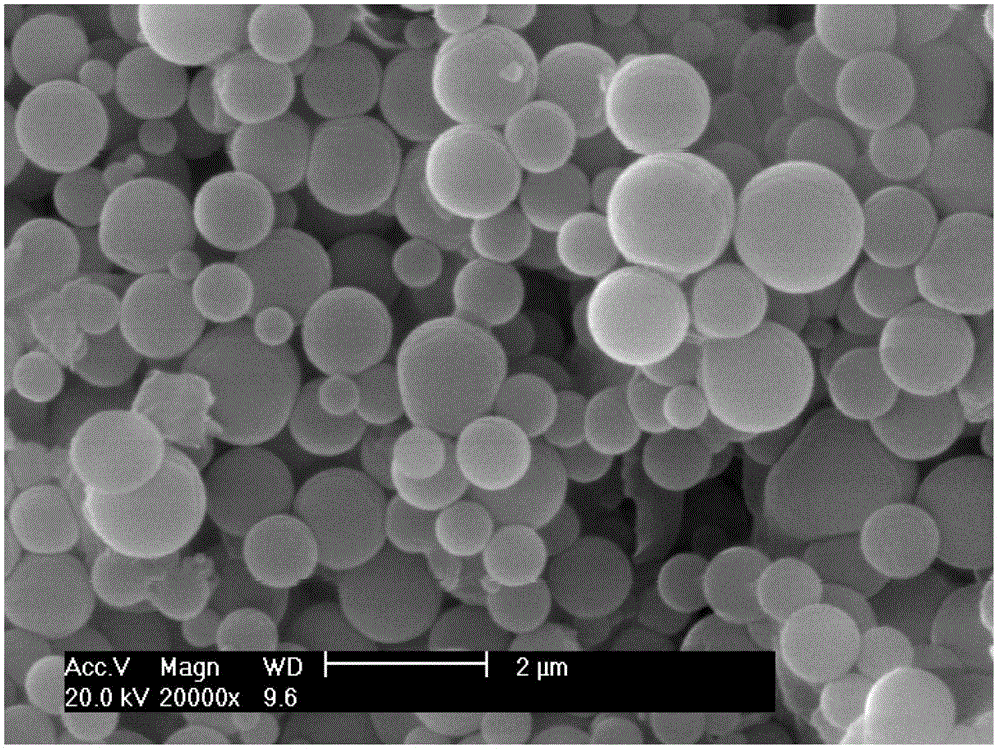

Self-reinforced bi-crosslinking hyaluronic acid hydrogel and preparation method thereof

ActiveCN102942699AImprove water absorptionInjectableMicroballoon preparationMicrocapsule preparationControlled releaseMicrosphere

The invention, belonging to the technical field of biomedical materials and tissue engineering, discloses a self-reinforced bi-crosslinking hyaluronic acid hydrogel and a preparation method thereof. The preparation method disclosed herein comprises the following steps: preparing double-bond activated hyaluronic acid, preparing hyaluronic acid microballoons, preparing double-bond activated hyaluronic acid microballoons, and preparing the self-reinforced bi-crosslinking hyaluronic acid hydrogel. The self-reinforced bi-crosslinking hyaluronic acid hydrogel prepared by the method is obtained by using double-bond activated hyaluronic acid microballoons as reinforced particles to react with the double-bond activated hyaluronic acid molecules, and has a bi-crosslinking network structure, wherein the diameter of the double-bond activated hyaluronic acid microballoons is 1-10 mum, the pore size of the bi-crosslinking hyaluronic acid hydrogel is 10-70 mum, and the double-bond substitution degree is 2.8-65%. Compared with a single crosslinking hyaluronic acid hydrogel, the hydrogel disclosed herein has better elastic energy, and well prolongs the sustainable control release time of bovine serum albumin.

Owner:浙江天妍生物科技有限公司

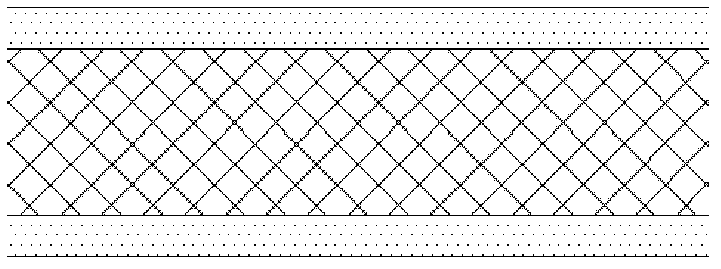

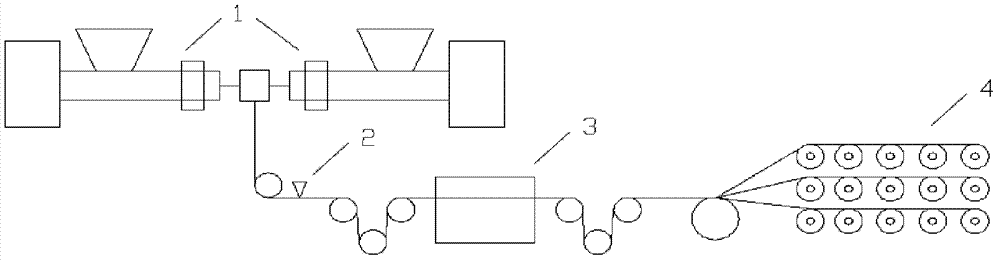

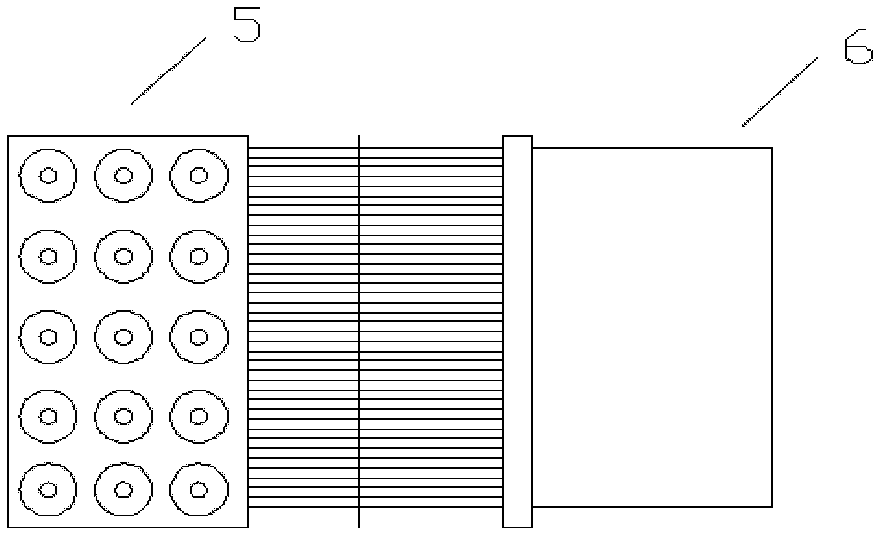

Self-reinforced polypropylene composite material and preparation method thereof

InactiveCN103112224AIncrease the range of process applicationsHigh tensile strengthSynthetic resin layered productsPolypropylene compositesPolymer science

The invention relates to a self-reinforced polypropylene composite material and a preparation method thereof. The preparation method comprises the following steps: preparing a sheet composed of high-melting-point polypropylene and low-melting-point polypropylene by screw coextrusion, separating the sheet into strips which are 5-20mm wide, carrying out hot stretching, and coiling into cylinders; weaving the cylindrical strips into a fabric; and finally, carrying out hot pressing on a plurality of layers of fabrics to obtain the composite material. Compared with the prior art, the invention widens the hot pressing temperature window of the self-reinforced polypropylene composite material sheet, and the prepared product has favorable properties.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

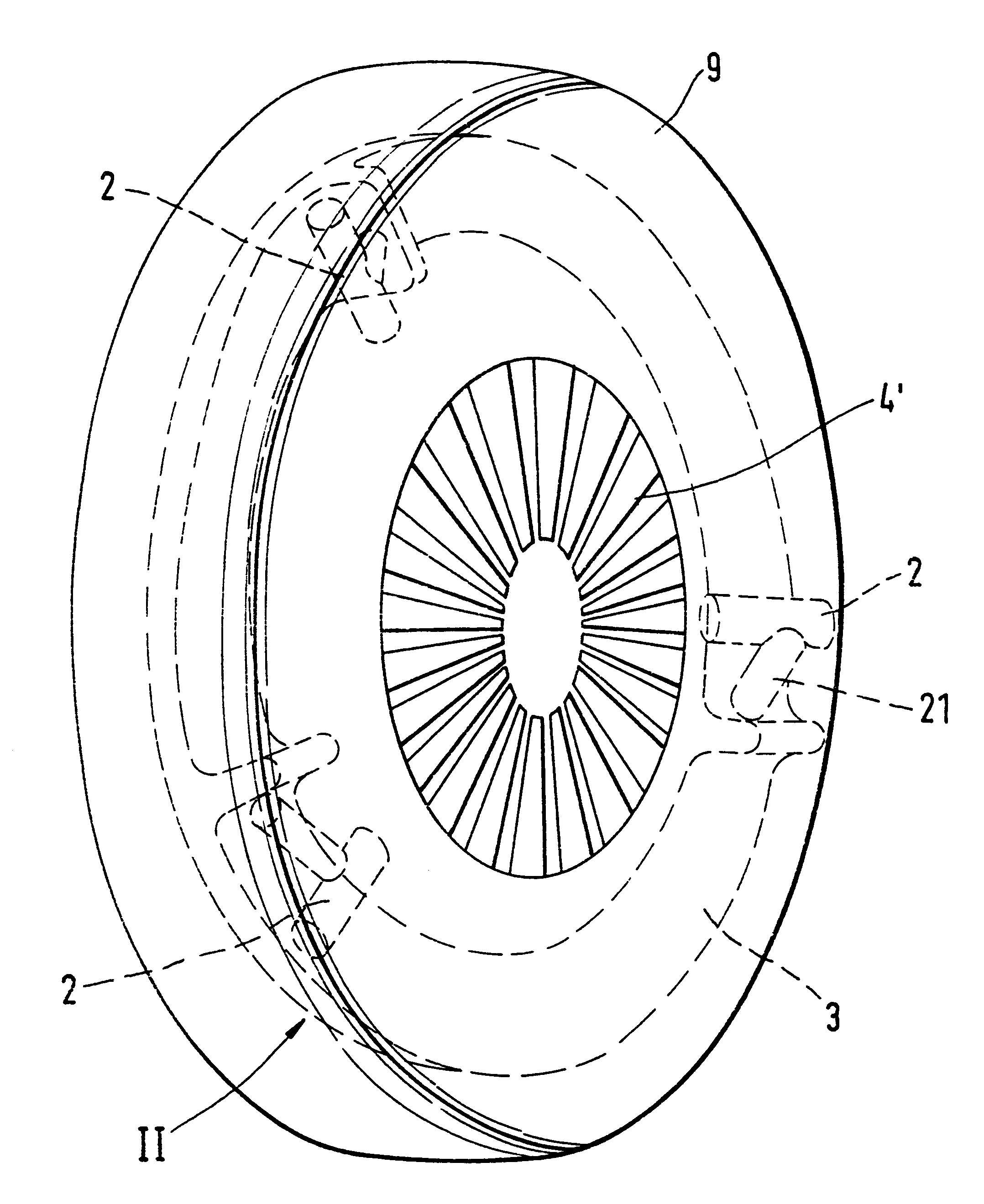

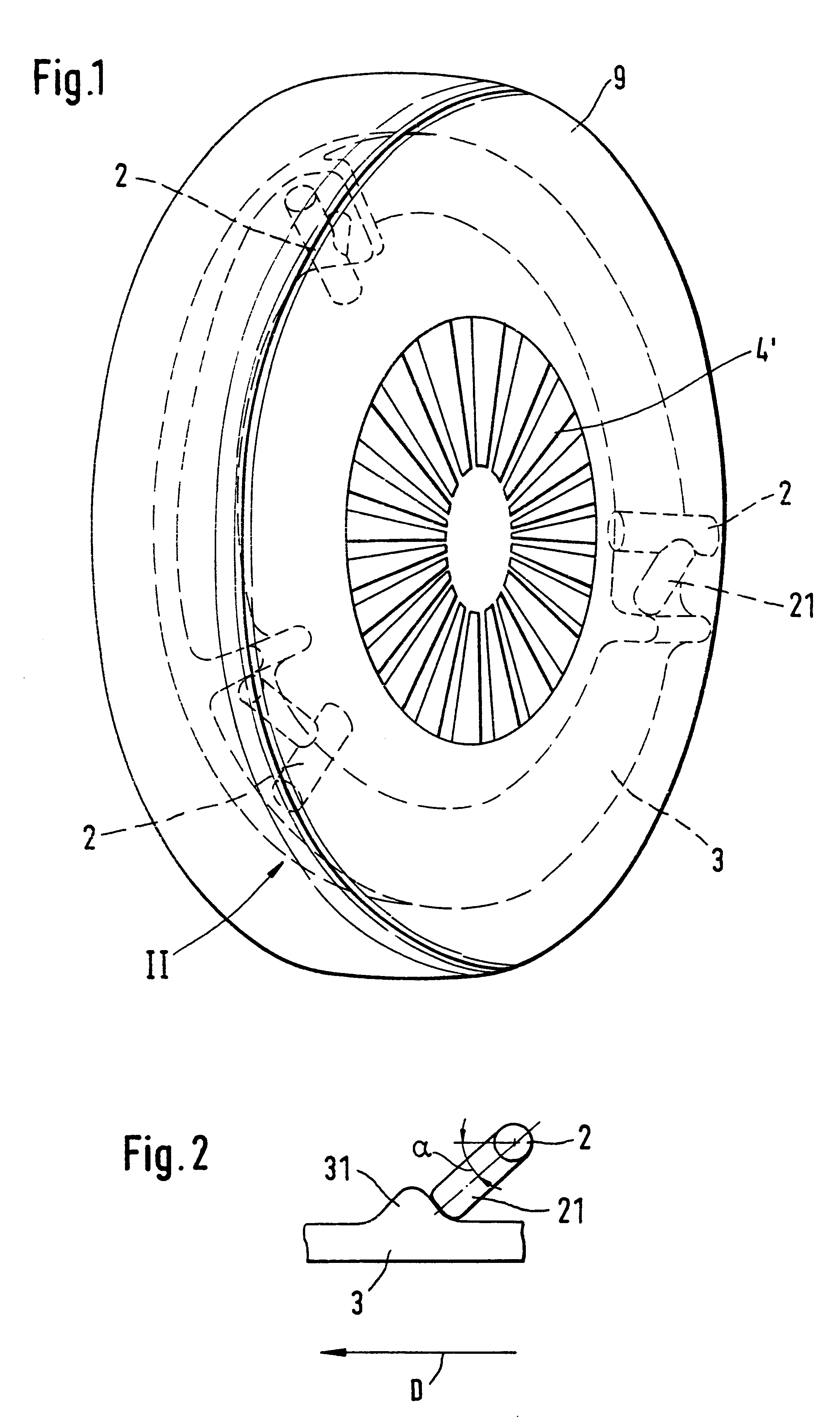

Self-reinforcing friction clutch

InactiveUS6189667B1Reduce thicknessLittle strengthFriction clutchesInterengaging clutchesMobile vehicleFreewheel

A friction clutch for motor vehicles has a casing which can be connected in a rotationally fixed manner to a driven flywheel mass. A pressure plate is arranged inside the casing with a pressure spring supported between the clutch casing and the pressure plate so that the pressure plate presses a clutch disk, which is provided with friction linings, onto the flywheel mass. The pressure spring, during engagement of the clutch, exerts a varying pressure force on the pressure plate. The friction clutch also having a device which acts on the pressure plate and varies essentially proportionally to the force of the pressure spring to force of the pressure plate.

Owner:MANNESMANN SACHS AG

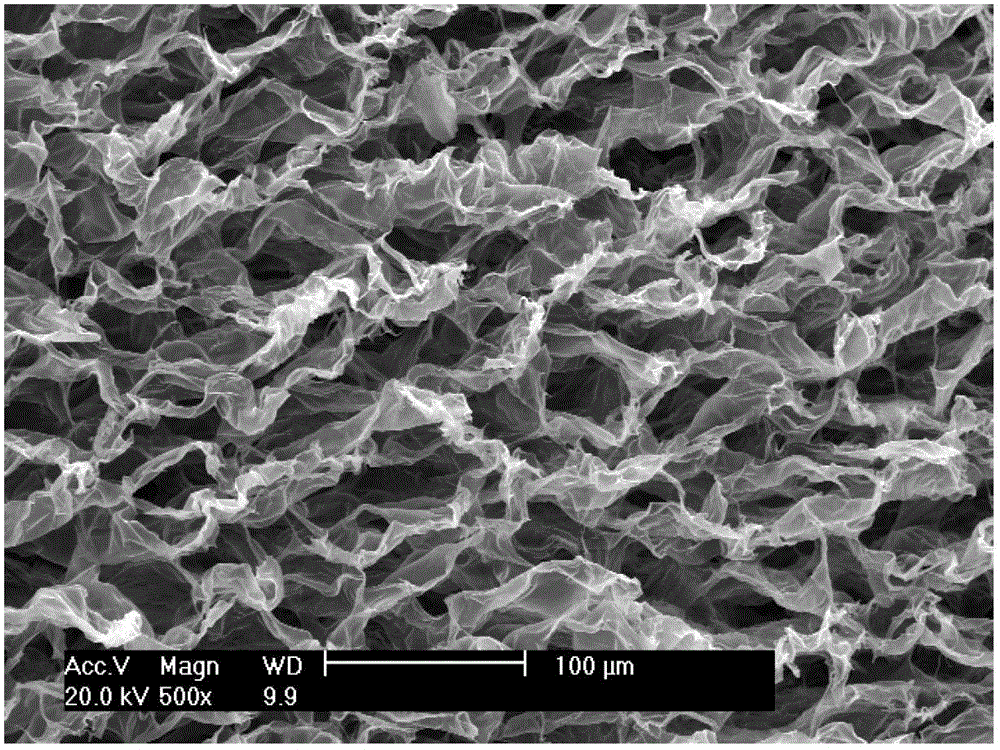

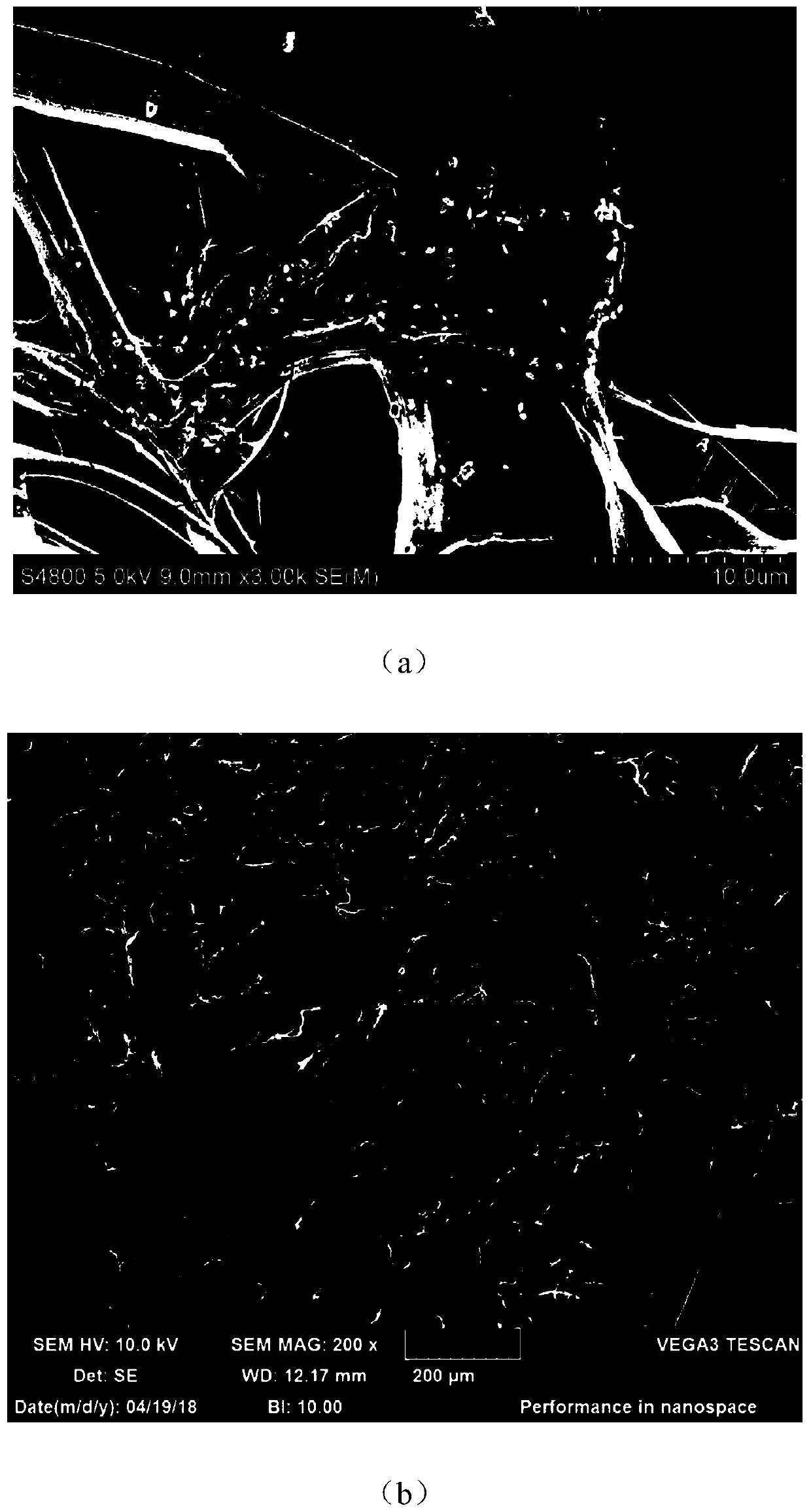

High-strength aramid paper and method for preparing same through dissolving and re-pressing self-reinforcing

ActiveCN106087529AFully contactedFully bondedNon-fibrous pulp additionMechanical paper treatmentProcess equipmentAramid

The invention discloses a high-strength aramid paper and a method for preparing the same through dissolving and re-pressing self-reinforcing. The method comprises the following steps: subjecting polyphenylene sulfide fiber to pretreatment, then mixing the pretreated polyphenylene sulfide fiber, aramid fiber and aramid pulp, subjecting dried raw paper to dipping and then pressing treated sample paper; soaking the treated sample paper in a washing solution and removing an organic solvent and inorganic salt left in the paper; and pressing the treated sample paper. When the high-strength aramid paper has gram weight of 10 to 200 g / m<2>, the aramid paper has a thickness of 20 to 400 [mu]m, tensile strength of 10 to 150 KN / m and dielectric strength of 30 to 70 kV / mm. According to the invention, aramid paper and polyphenylene sulfide are used as raw materials; the method is environment friendly and low in cost; the prepared paper has high strength and good evenness; and industrial production can be realized through partial reconstruction of conventional paper machines.

Owner:SOUTH CHINA UNIV OF TECH

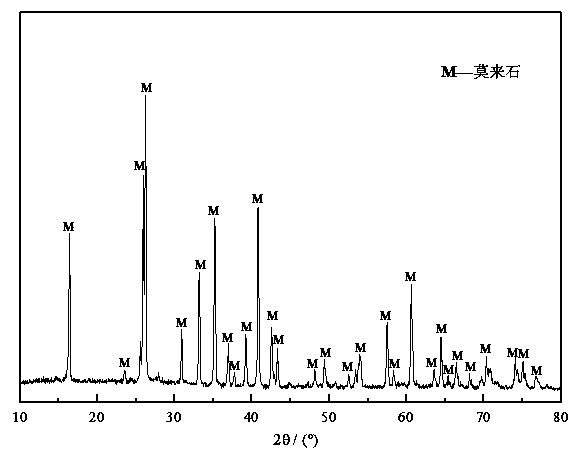

Preparation method of self-reinforced mullite porous ceramic

The invention relates to a preparation method of self-reinforced mullite porous ceramic. The preparation method comprises the following technical steps: carrying out dosing on 30-50% by mass of a mineral or solid waste containing Al2O3 and SiO2, 25-55% by mass of industrial alumina powder and 0.5-30% by mass of starch, adding 1-30% by mass of ammonium salt additives in total mass of the mixture, regulating the molar ratio of Al2O3 to SiO2 in the raw materials to be 3:2, and carrying out mixing, carrying out ball milling and forming; sintering a formed biscuit for 1-6 hours at the temperature of 1400-1600 DEG C, so as to obtain the self-reinforced mullite porous ceramic. The self-reinforced mullite porous ceramic prepared by utilizing the preparation method is in-situ fiber-reinforced mullite porous ceramic having the characteristics that mullite is taken as a primary crystalline phase, the strength is high (40-80MPa), the porosity is high (30-60%), and the aperture is small.

Owner:NORTHEASTERN UNIV

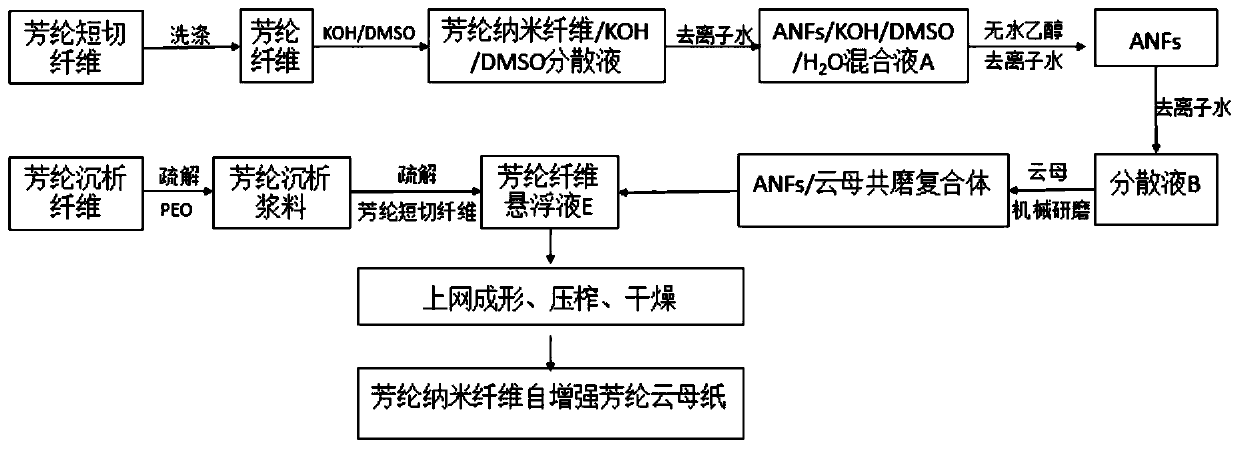

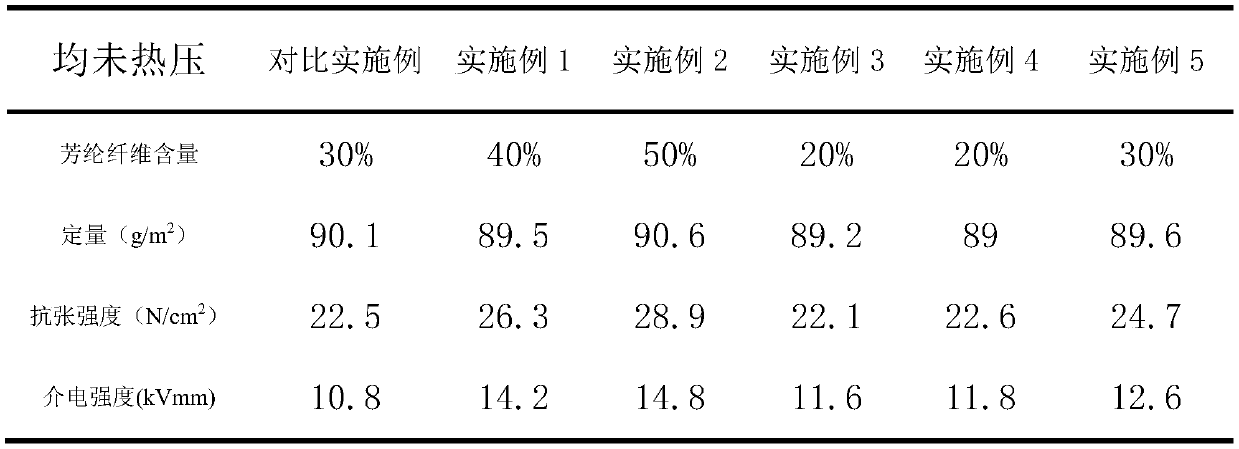

Preparation method of aramid nanofiber self-reinforced aramid mica paper

ActiveCN110205862AImprove retentionHigh dielectric strengthSynthetic cellulose/non-cellulose material pulp/paperInorganic compound additionSelf reinforcedPapermaking

The invention discloses a preparation method of aramid nanofiber self-reinforced aramid mica paper. By means of the method, the retention rate of mica in the wet papermaking process of the aramid micapaper is increased, and the dielectric strength and mechanical strength of the aramid mica paper are further improved; the problems are solved that in the wet papermaking process of existing aramid mica paper, the retention rate of mica is low, and as large-particle-size mica is randomly stacked and arbitrarily accumulated, gaps and pores are generated and the improvement of mechanical strength and dielectric strength is limited; meanwhile, through simple operation of the method, the dielectric strength and mechanical strength of the aramid mica paper are significantly improved, and the insulating property is remarkably improved.

Owner:SHAANXI UNIV OF SCI & TECH

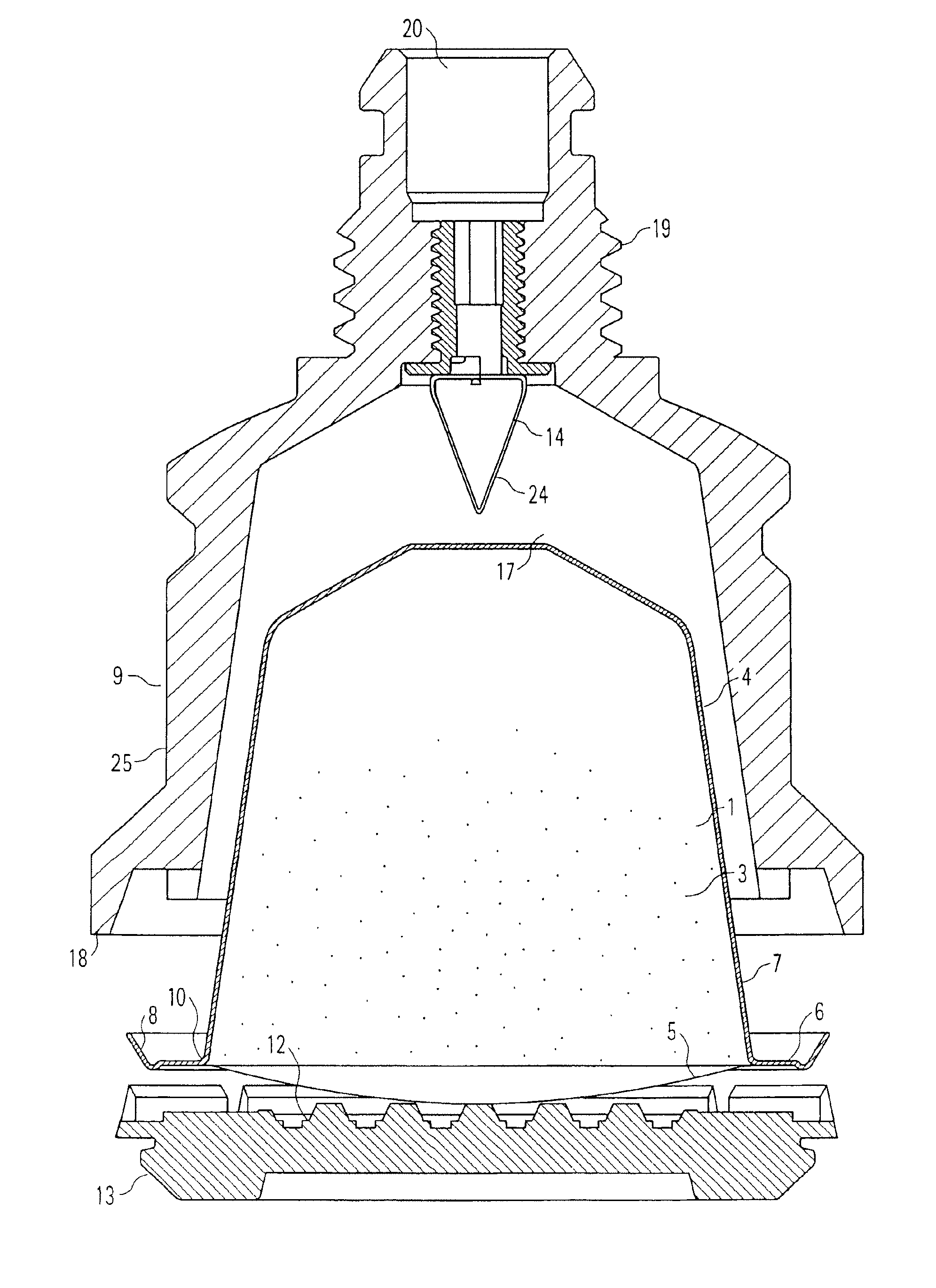

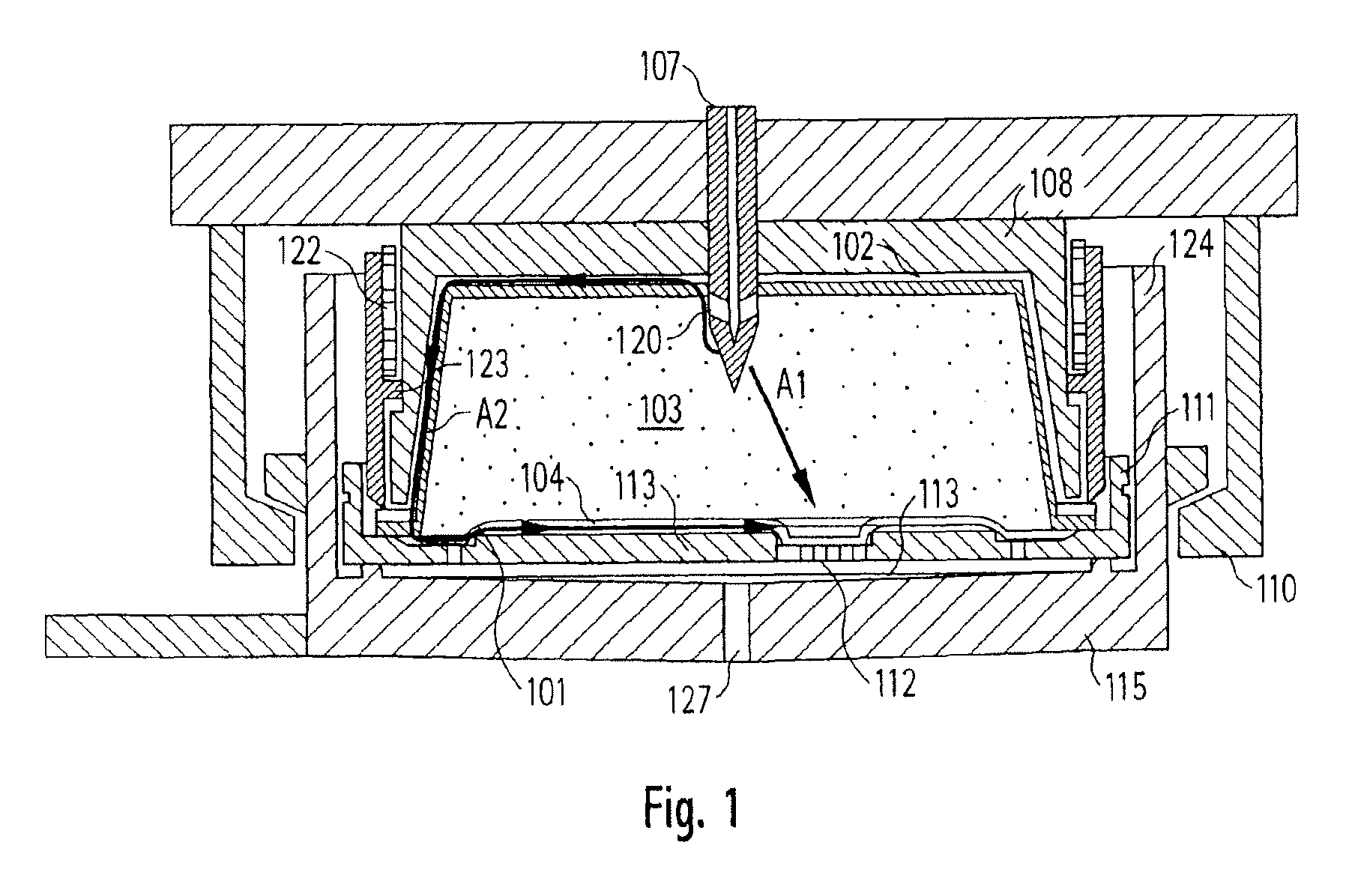

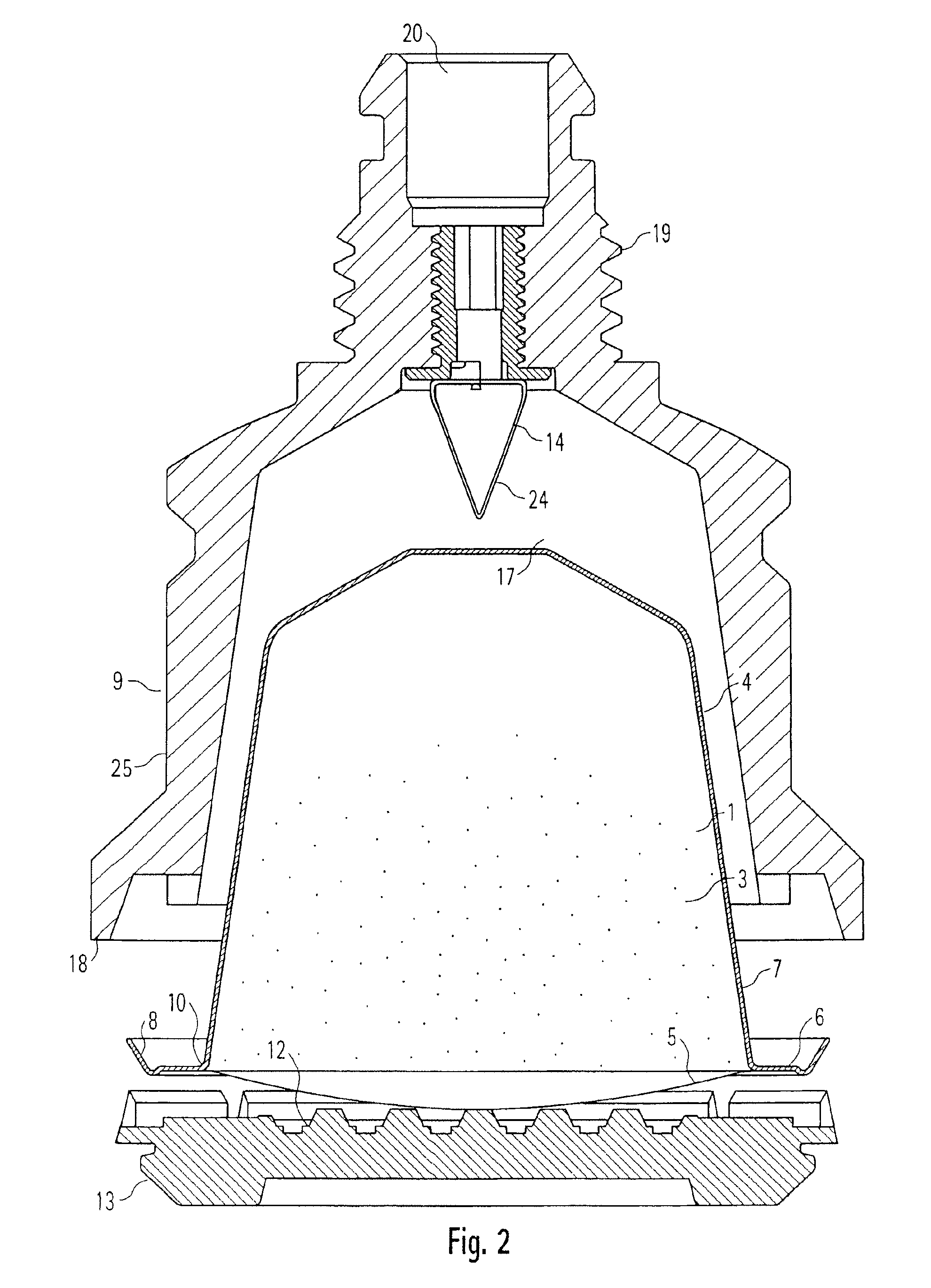

Capsule with biasing sealing member

ActiveUS7926415B2Functioning of sealing can be assuredNo hygienic problemsBeverage vesselsPackaging foodstuffsSelf reinforcedBiomedical engineering

A capsule for containing beverage ingredients is designed to be inserted in a beverage production device in order to have water under pressure enter the capsule in order to interact with the ingredients in the capsule. The capsule includes a base body and a foil member closing the base body by being attached to a flange-like rim extending from the side wall of the base body of the capsule. The capsule thereby includes a resiliently deflectable sealing member which is designed to be biased against a sealing surface of a holder of the beverage production device when the capsule is positioned in the beverage production device. The sealing engagement of the sealing member of the capsule and the sealing surface is self-reinforcing when pressurized.

Owner:SOC DES PROD NESTLE SA

Non-heat treatment self-reinforcing aluminium-silicon alloy and preparation technology thereof

The invention discloses a non-heat treatment self-reinforcing aluminium-silicon alloy preparation technology, which comprises the following steps: adding pure magnesium ingot, intermediate alloys AL-Si, AL-Mn, AL-Cu, and AL-Ti in a fusing aluminium liquid at temperature of 740-760 DEG C, after fusing, insulating for 30 minutes at 740 DEG C; heating the temperature of an alloy liquid to 780 DEG C, adding mixing rare earth, removing the scummings on the surface after fusing the mixing rare earth, stirring for 3-6 minutes and increasing the temperature of the alloy liquid to 770-780 DEG C, insulating and standing for 30 minutes; finally cooling the alloy liquid to 750 DEG C for refining, refining for 15 minutes, removing the slag, degassing, and finally completing the casting production. According to the invention, the mixing rare earth and an element Mn are used for refining Si and Cu in an aluminium alloy material according to strict mol fraction ratio, reinforcement effect can be provided, and the aluminium-silicon alloy having advantages of high heat resistance, high elongation percentage and excellent deformation capability can be obtained.

Owner:FENGYANG L S NET FORMING CO LTD +1

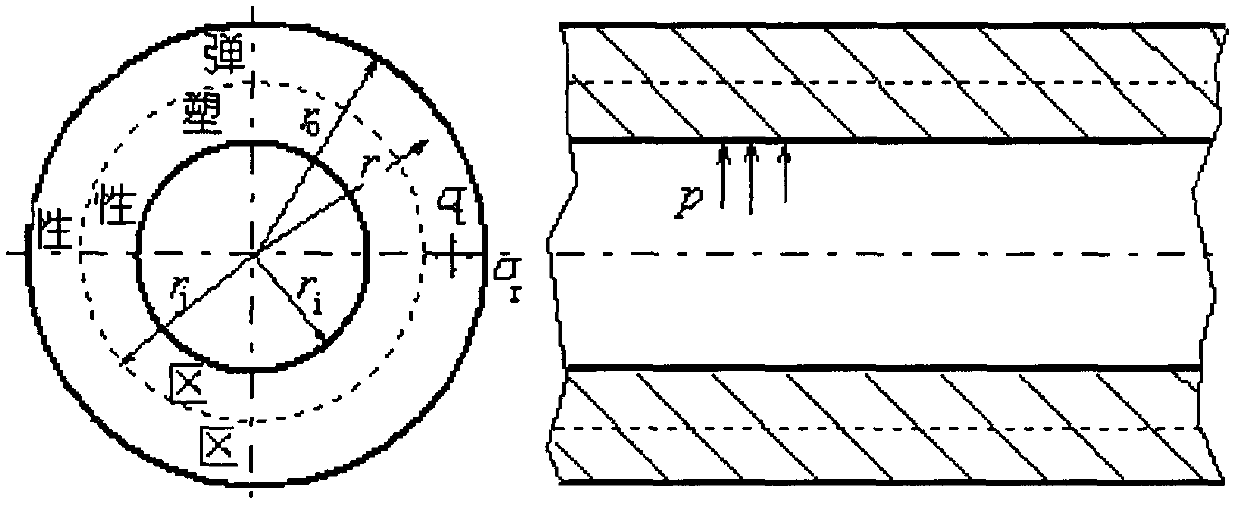

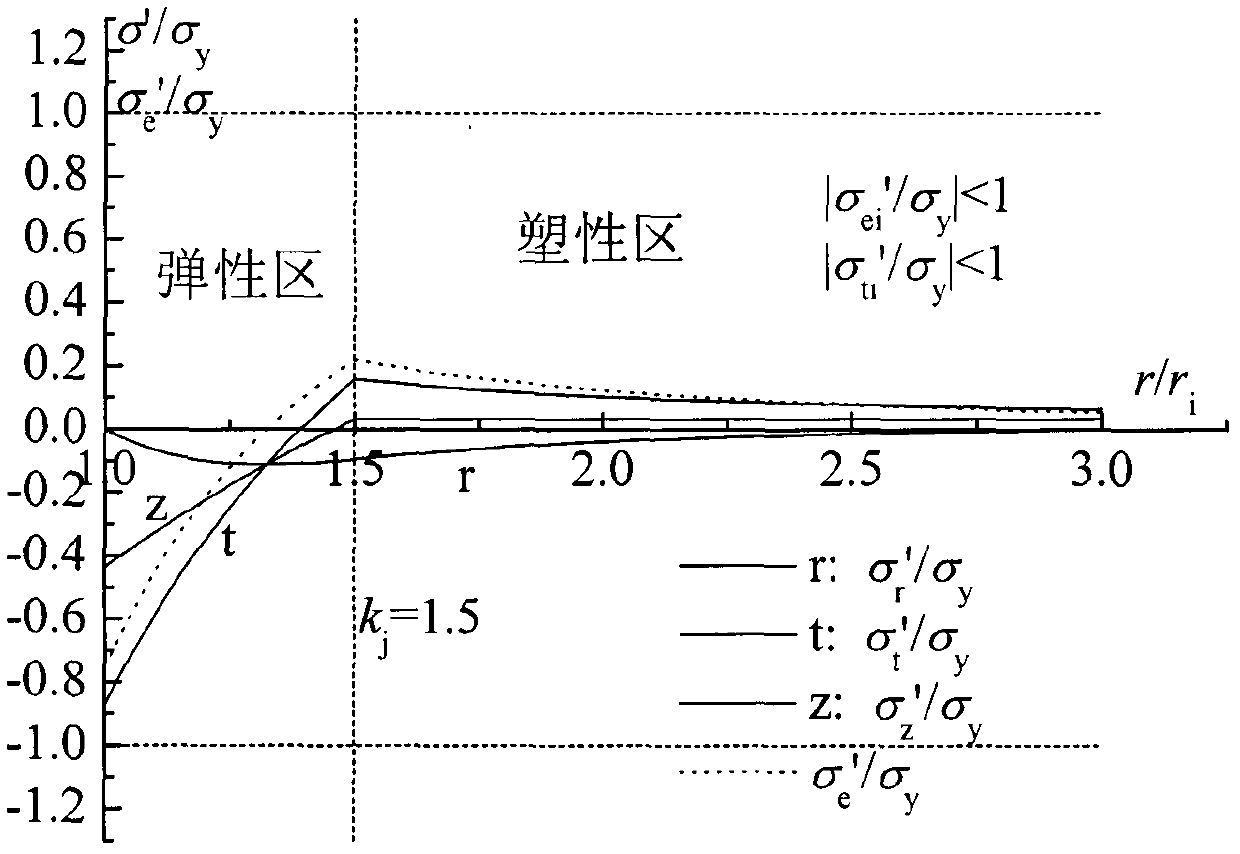

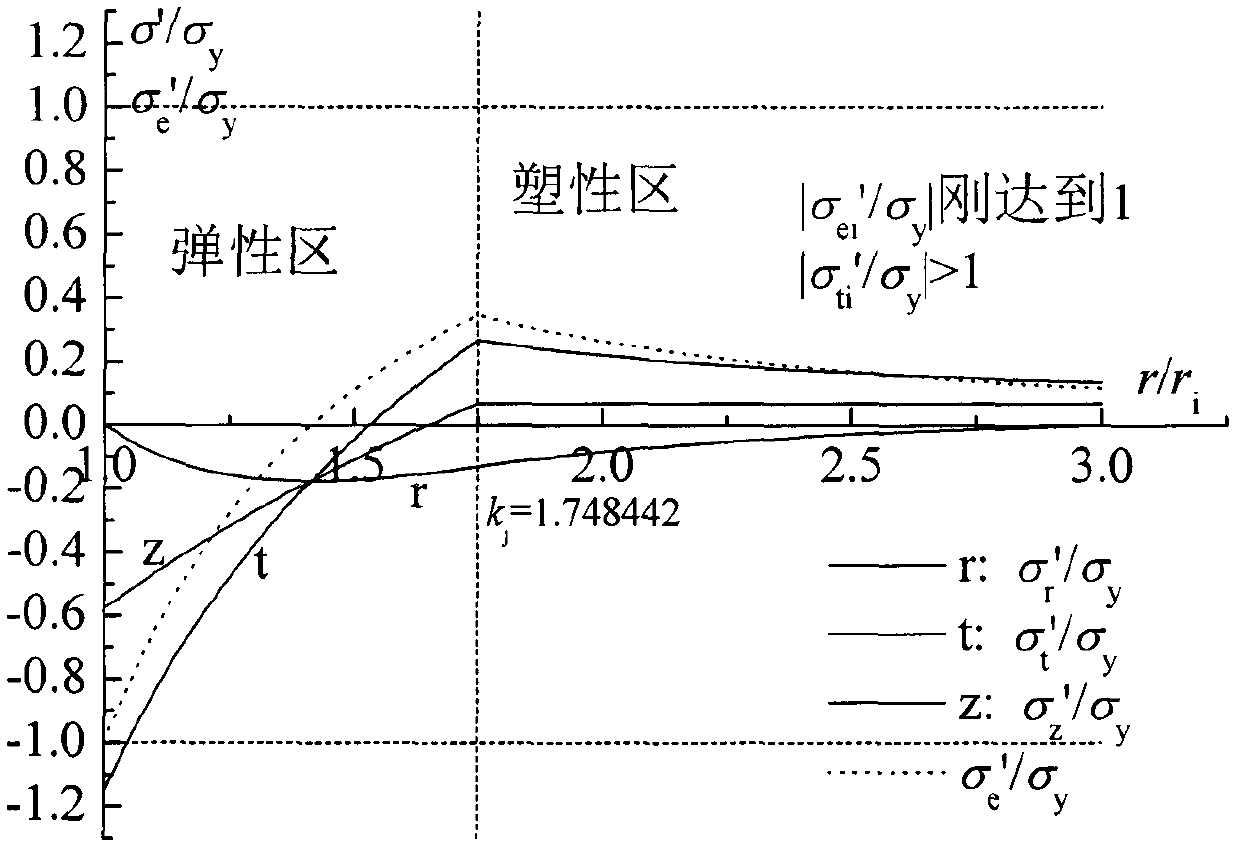

Self-reinforcing pressure container based on safety design technical conditions

InactiveCN102563063AReduce depthReduce wall thicknessPressure vesselsInternal pressureSelf reinforced

The invention provides a self-reinforcing pressure container based on safety design technical conditions, and is used for improving the safety and the bearing capability of the container and solving the technical problems of the prior art that the calculation is complicated, inaccurate or not safe enough. The essentials of the technical scheme are as follows: the depth of a plastic region of the container is calculated according to the specification so that residual stress does not exceed sigma y and reverse yielding is not generated; and a bearing capability is calculated according to the specification so that the absolute value of sigma ej is less than or equal to the sigma y and the absolute value of sigma ei is less than or equal to the sigma y, wherein k is the diameter ratio, kj is the ratio of an elastic-plastic interface radius to an inner diameter, the sigma y is the yield strength, p is the inner pressure borne by the container, pe is the maximum elastic bearing capability of a non-self-reinforcing container, the sigma ej is the equivalent stress of the total stress of an elastic-plastic interface and the sigma ei is e equivalent stress of the total stress of an inner wall; when the k is less than the determined value, namely when the k is less than 2.024678965...., the container does not generate the reverse yielding after the self-reinforcing pressure is removed no matter how large the kj is.

Owner:HUNAN NORMAL UNIVERSITY

Self-reinforced interlayer shearing intensity resin base fiber reinforced composite material preparation method

InactiveCN1762686AHigh breaking strengthIncreased interlaminar shear strengthMetallurgyAtmospheric temperature

The invention discloses a resin fiber composite material making method of self-reinforced interlayer shearing strength, which is characterized by the following: weighing 5-100 liquid crystal resin; preparing prepreg according to wet method or melting method; or adapting liquid phase modeling craft to form composite material without preparing prepreg according to the conventional composite material moulding method; paving prepreg layer; forcing static magnetic field or variable pulse magnetic field with 2-20 T magnetic strength in the moulding course; orienting the solid liquid crystal at the given direction; cooling the moulded mold to atmospheric temperature naturally then demoulding; or doing after-treatment again to demould after cooled to atmospheric temperature naturally. The invention improves the shearing strength and, which reduces cost.

Owner:ZHEJIANG UNIV

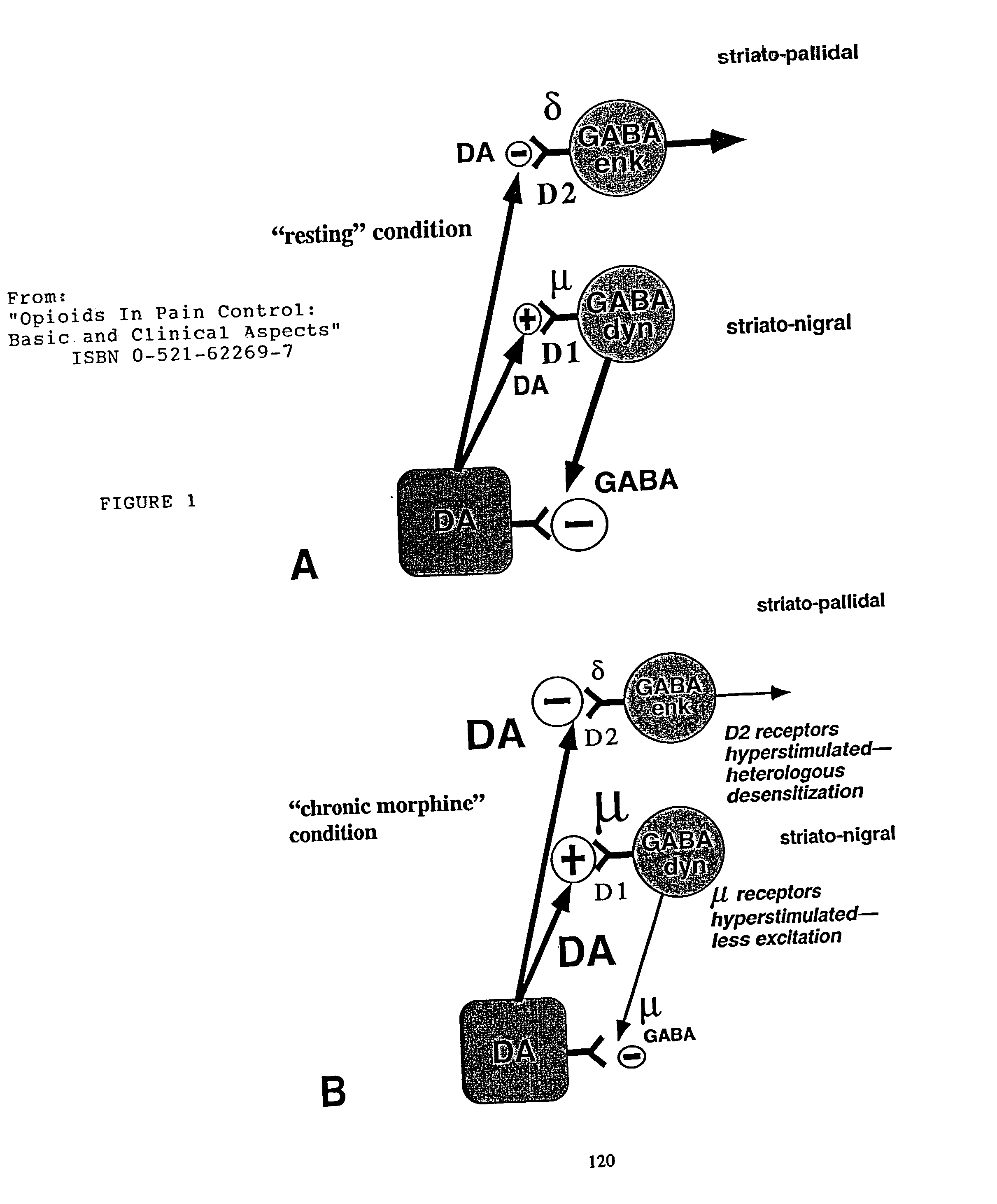

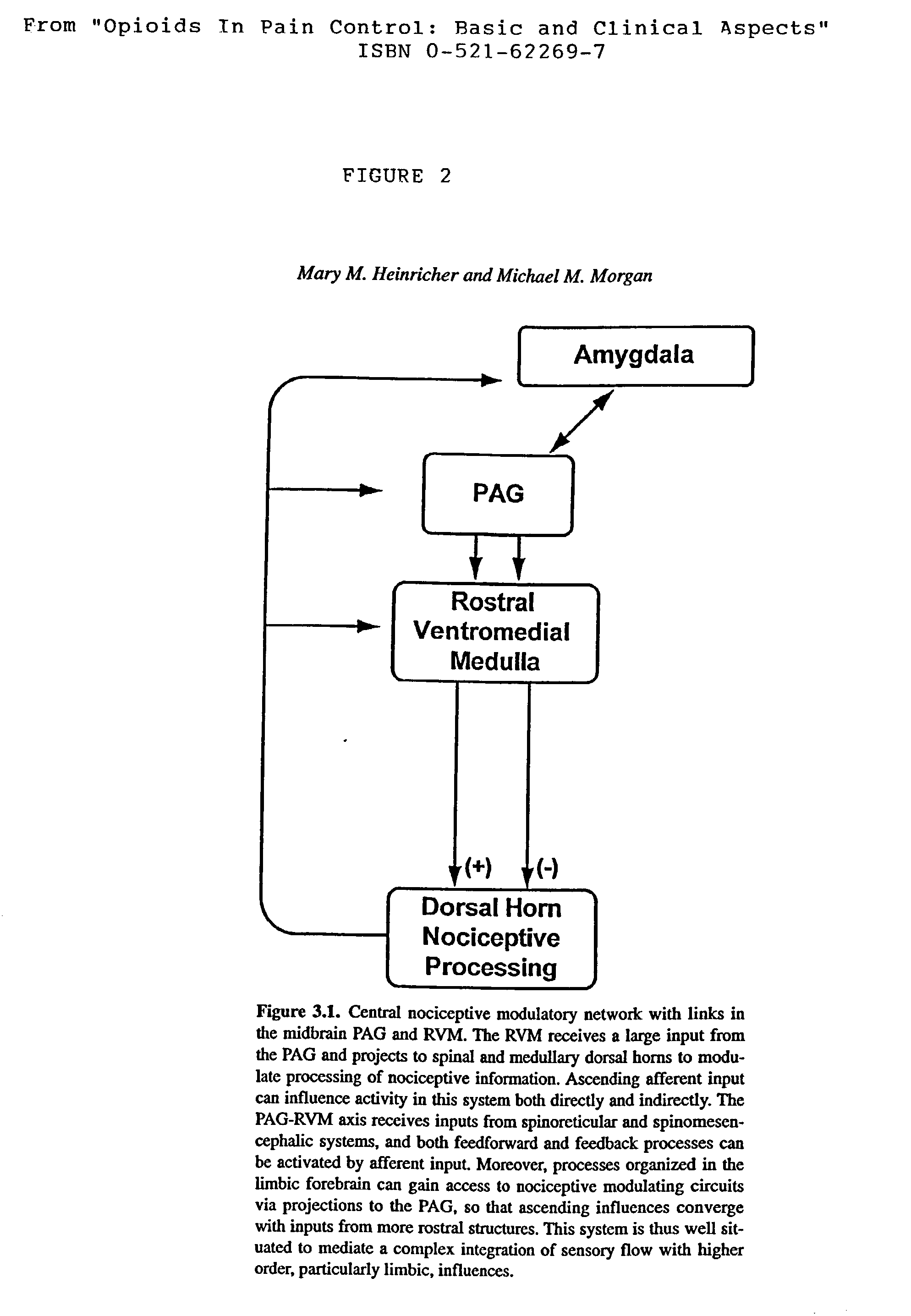

Pharmaceutical compositions containing alpha3beta4 nicotinic receptor antagonists and methods of their use

InactiveUS20030199496A1Relief the painIncreased dopamineBiocidePeptide/protein ingredientsAntiepileptic drugAmphetamine use

A pharmaceutical composition comprising an .alpha.3.beta.4 nicotinic receptor antagonist effective to diminish the brain-derived feeling of pleasure due to increased dopamine in the pleasure-reward center of the brain typically associated with administration of an opioid agonist analgesic, a muscle relaxant, an anti-seizure medication, an anxiolytic drug, an amphetamine, a central nervous system stimulant, a tetrahydrocannabinol or that associated with an otherwise pleasurable or self-reinforcing behavior.

Owner:SIMON DAVID LEW

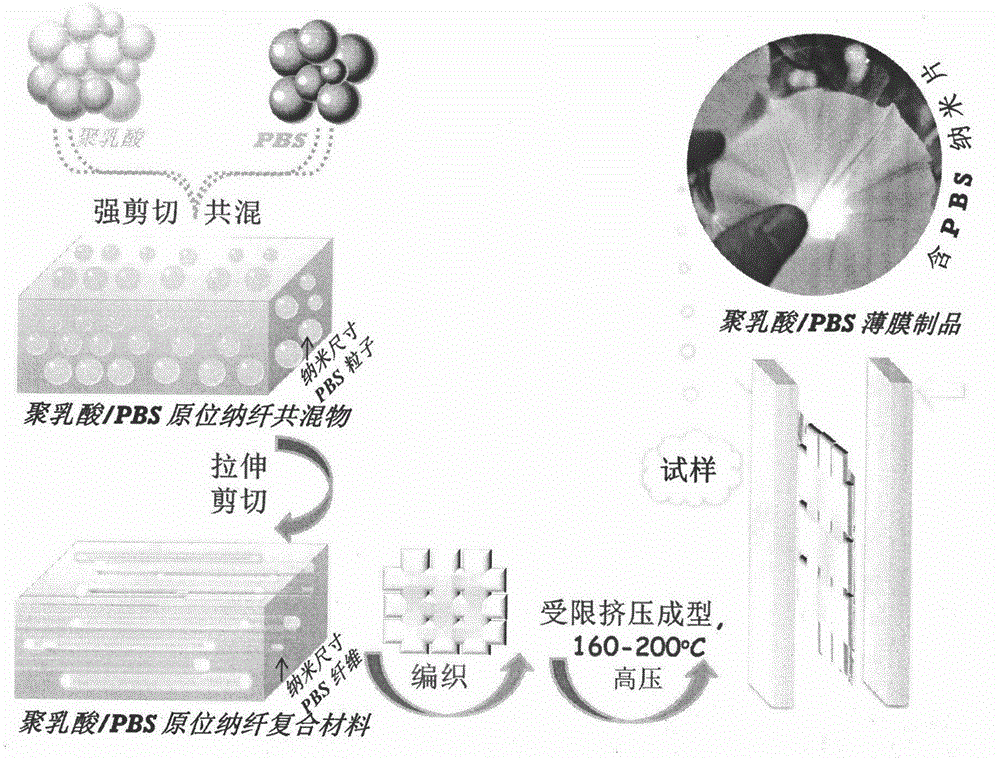

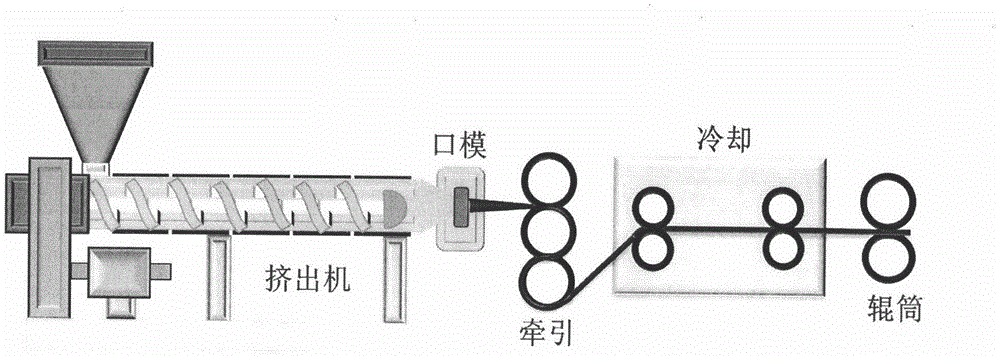

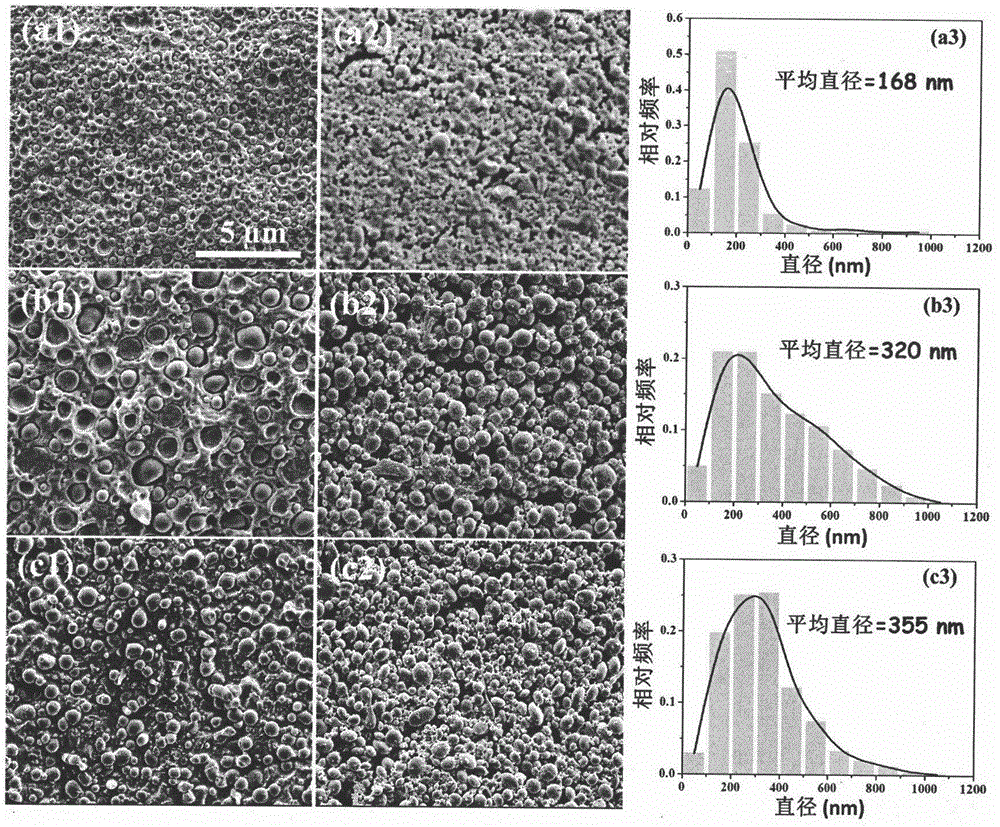

Preparation method of full-degradable high-strength high-barrier polylactic acid film by in-situ introduction of poly butylene succinate nanosheet

InactiveCN105733212AContinuous industrial productionDoes not compromise biodegradable propertiesPoly(butylene succinate)Quenching

The invention discloses a preparation method of a fully degradable high-strength and high-barrier polylactic acid film. The method is to firstly melt and blend polylactic acid and PBS under strong shear, so that the PBS droplets are violently broken into nanoparticles in the matrix. The strong tensile / shear field transforms PBS nanoparticles into nanofibers, and finally uses the "confined sheet" method to transform PBS nanofibers into regular and dense PBS nanosheets in a molding machine or a twin-roller continuous extrusion molding device, A polylactic acid high-strength and high-barrier film containing PBS nanosheets was obtained. The polylactic acid film products containing PBS nanosheets prepared by the present invention retain the good biodegradability of PBS and polylactic acid on the one hand, and on the other hand, a large number of oriented and straightened PBS nanosheets can block the infiltration of gas / water molecules and act as self-reinforcement The structural unit obtains simultaneous improvement of mechanical properties and barrier properties.

Owner:谢兰 +2

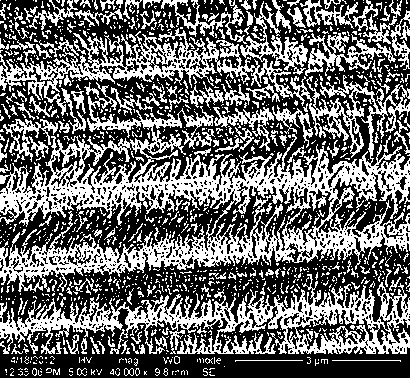

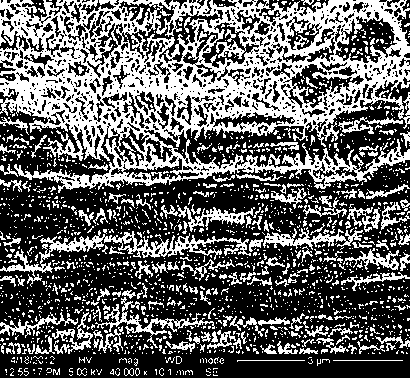

Irradiation crosslinked polyethylene blending material for artificial joints and preparation method thereof

The invention provides an irradiation crosslinked polyethylene blending self-reinforcing material for artificial joints and a preparation method thereof. The polyethylene blending material for artificial joints is prepared by blending low molecular weight polyethylene (LMWPE) and irradiation crosslinked ultrahigh molecular weight polyethylene (UHMWPE). The preparation method comprises the following steps: (1) preparing irradiation crosslinked UHMWPE, (2) preparing LMWPE master batch, (3) preparing irradiation crosslinked UHMWPE / LMWPE blending material, and (4) vibration injection molding. The irradiation crosslinked polyethylene blending self-reinforcing material for artificial joints has the advantages that the relative content of UHMWPE in polyethylene blend is improved to the maximum extent during the process of vibration injection molding and the excellent performance is reserved, a shish-kebab self-reinforcing structure is formed in the inner part due to vibration injection molding, and tensile property, impact strength and wear-resisting property are improved remarkably. Therefore, the irradiation crosslinked polyethylene blending self-reinforcing material is suitable for joint prosthesis implant material.

Owner:SICHUAN UNIV

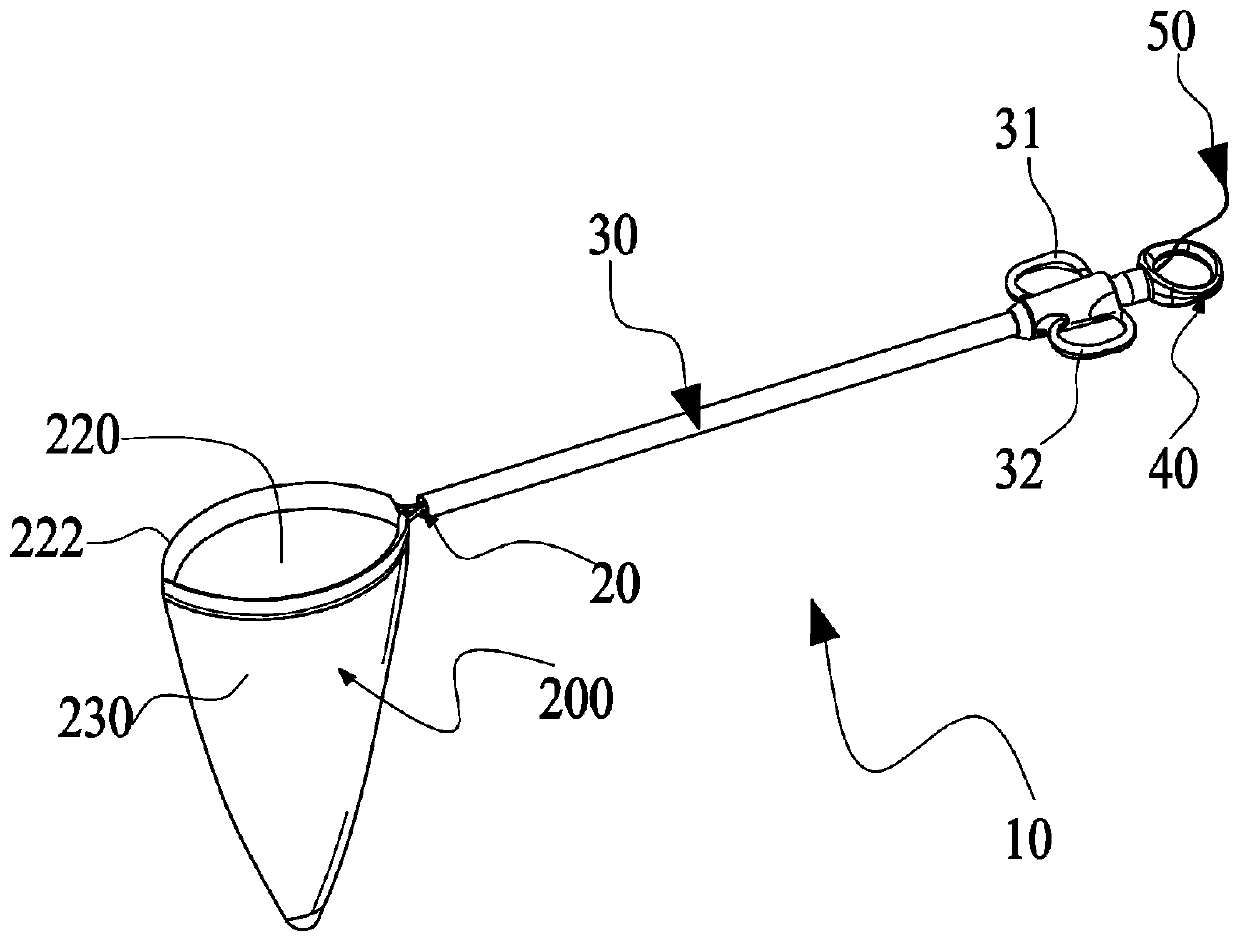

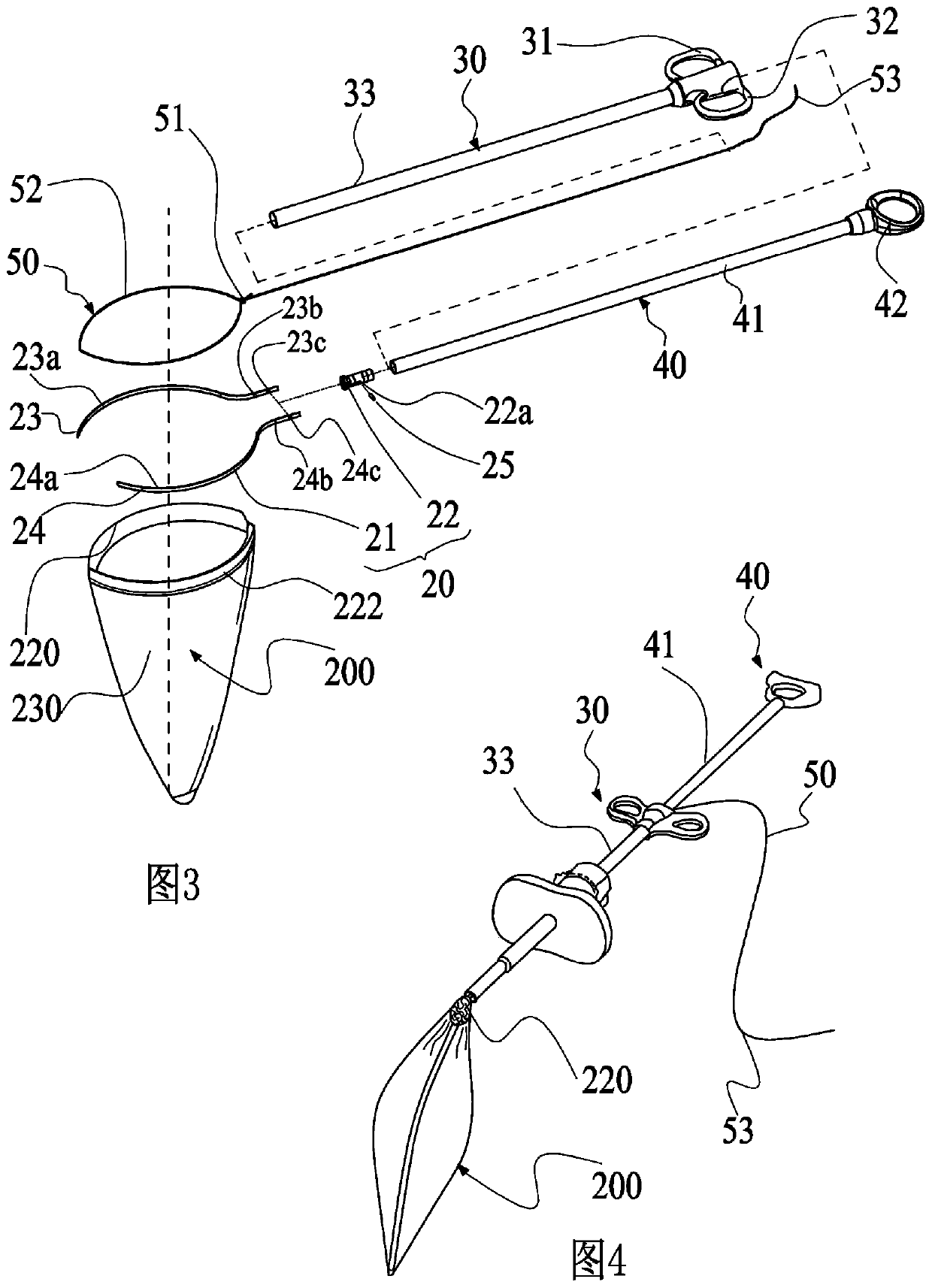

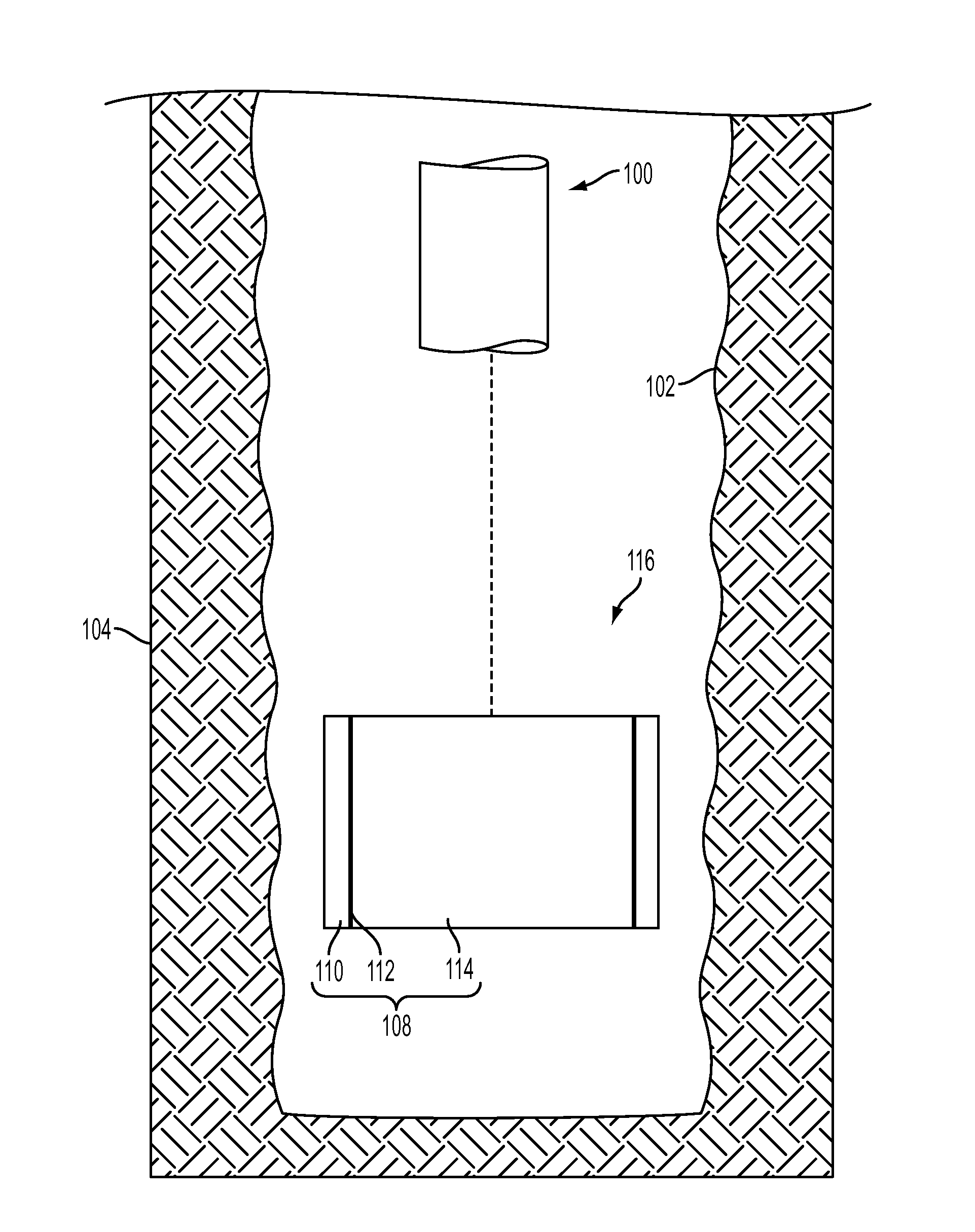

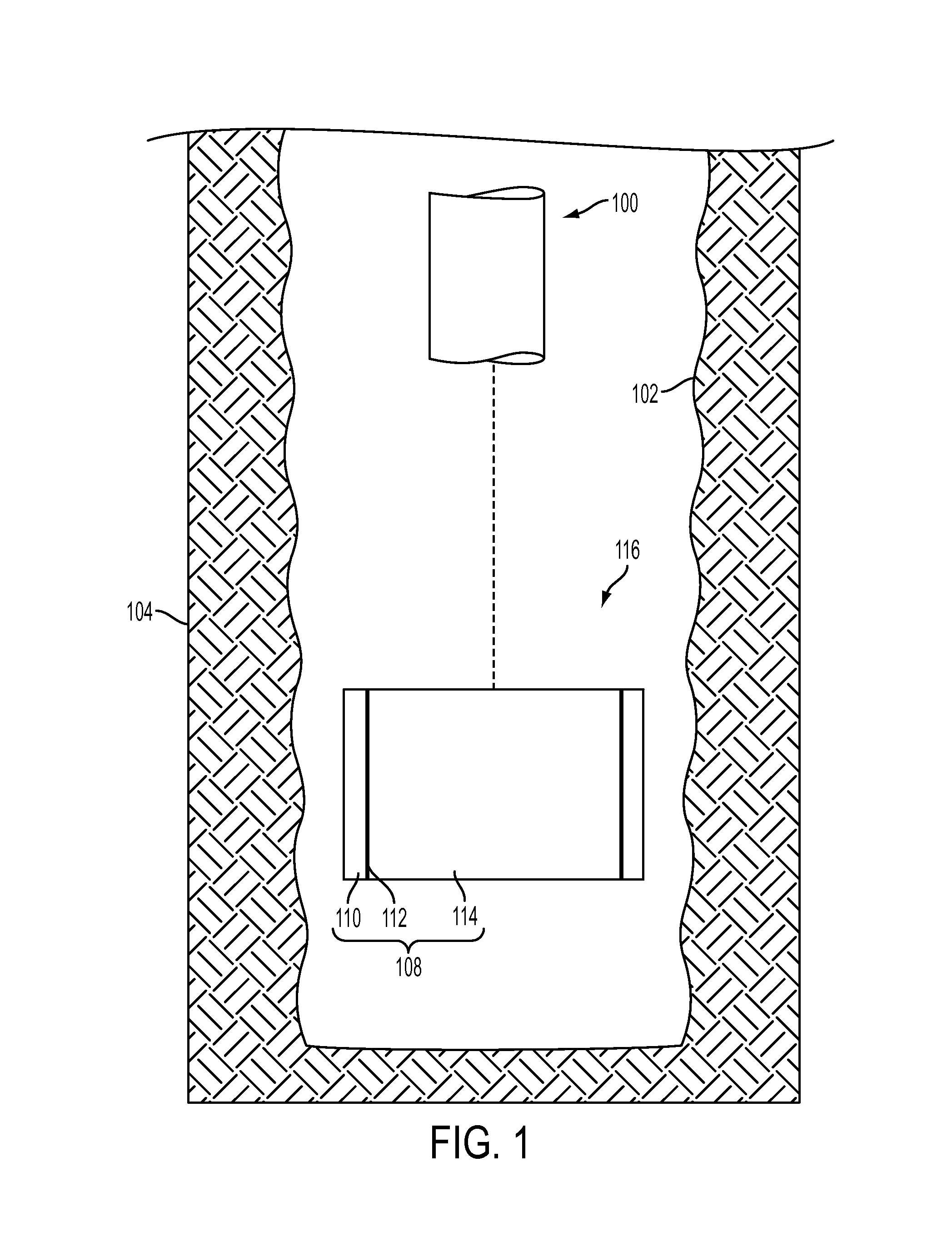

Lap fusion specimen bag and fetching device

Owner:5R MED TECH CHENGDU CO LTD

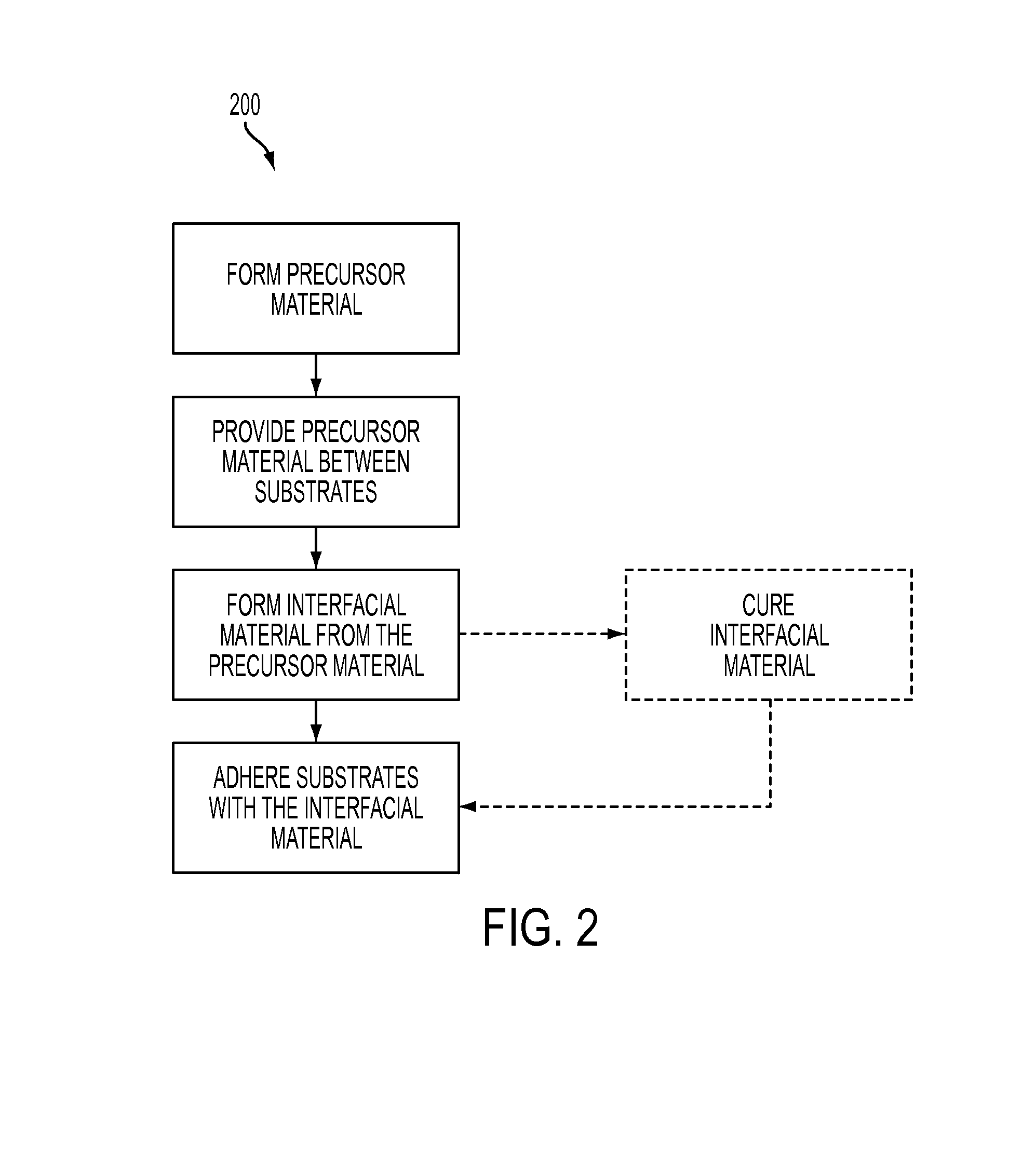

Methods of forming structures for downhole applications, and related downhole structures and assemblies

InactiveUS20160101600A1Improve propertiesImprove efficiencyLamination ancillary operationsSynthetic resin layered productsSelf reinforcedEngineering

A method of forming a structure for a downhole application comprises forming an interfacial material comprising at least one of self-reinforced polyphenylene, polyphenylene sulfide, polysulfone, and polyphenylsulfone between opposing surfaces of a first substrate and a second substrate. A downhole structure and a downhole assembly are also described.

Owner:BAKER HUGHES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com