Methods of forming structures for downhole applications, and related downhole structures and assemblies

a technology of forming structures and downhole applications, applied in the directions of transportation and packaging, synthetic resin layered products, paper/cardboard containers, etc., can solve the problems of limiting operational efficiency, degrading the interfacial materials of structures, tools and assemblies used in various downhole applications, and exhibiting extremely aggressive environments, etc., to achieve enhanced mechanical strength, thermal resistance, chemical resistance, and enhanced mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

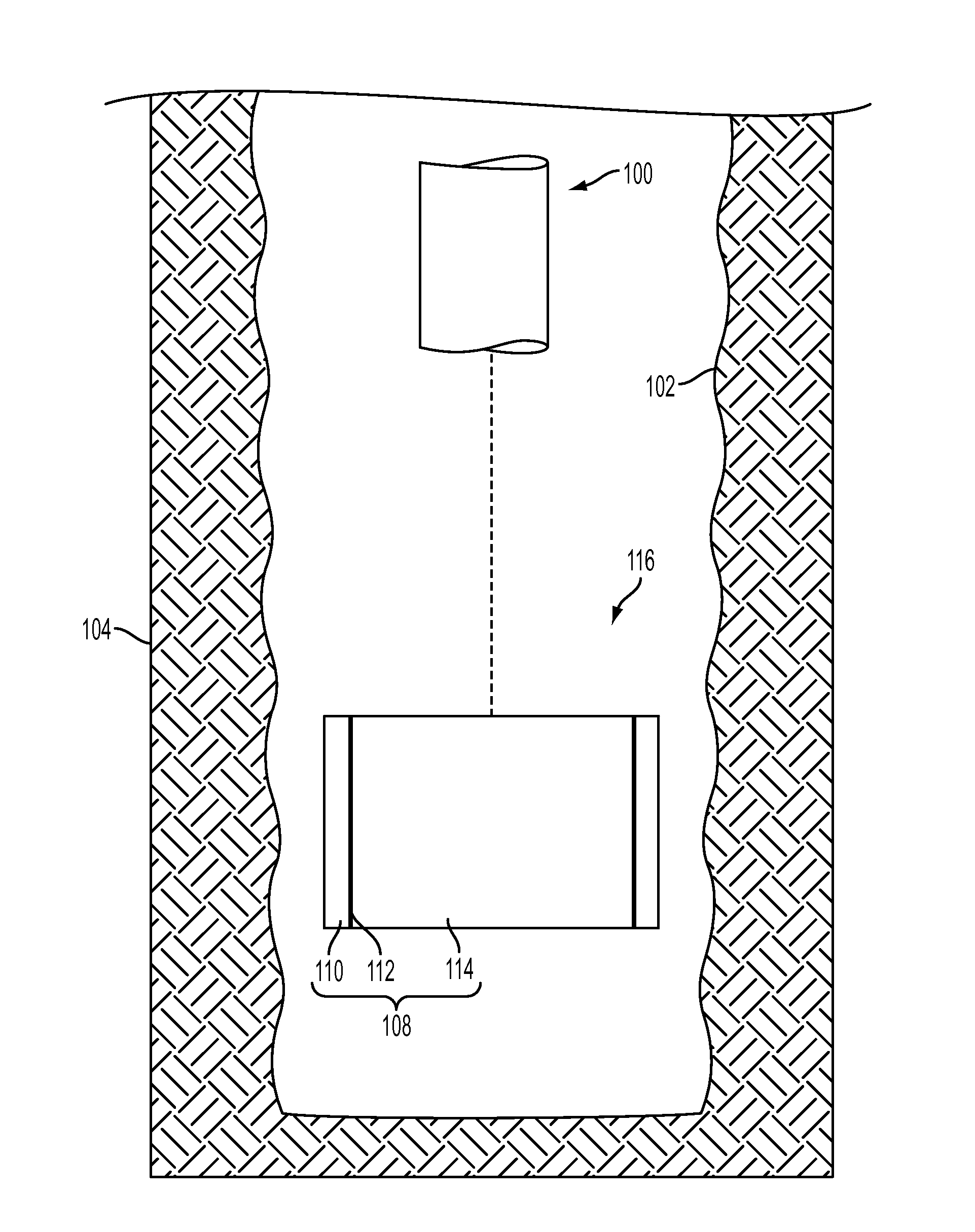

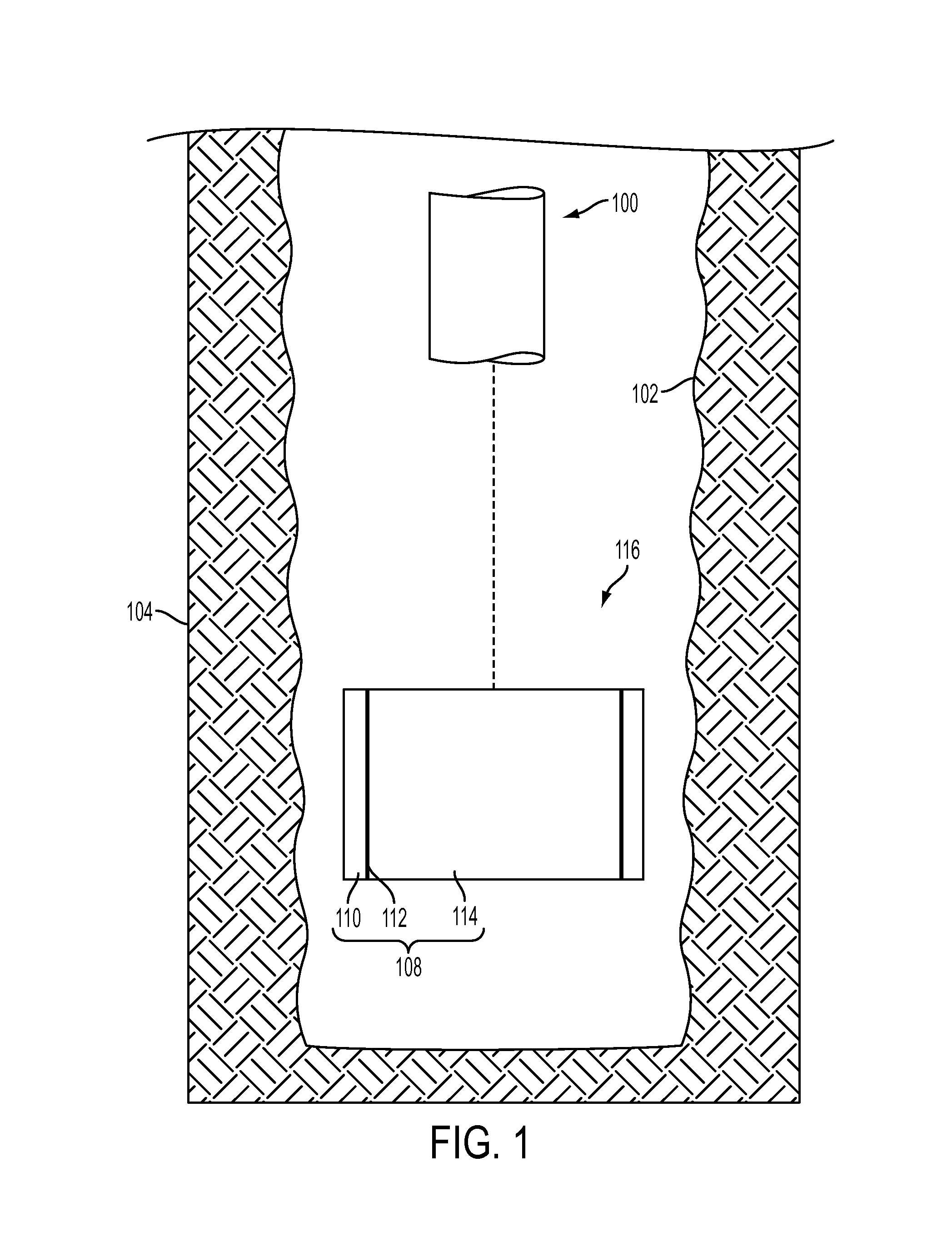

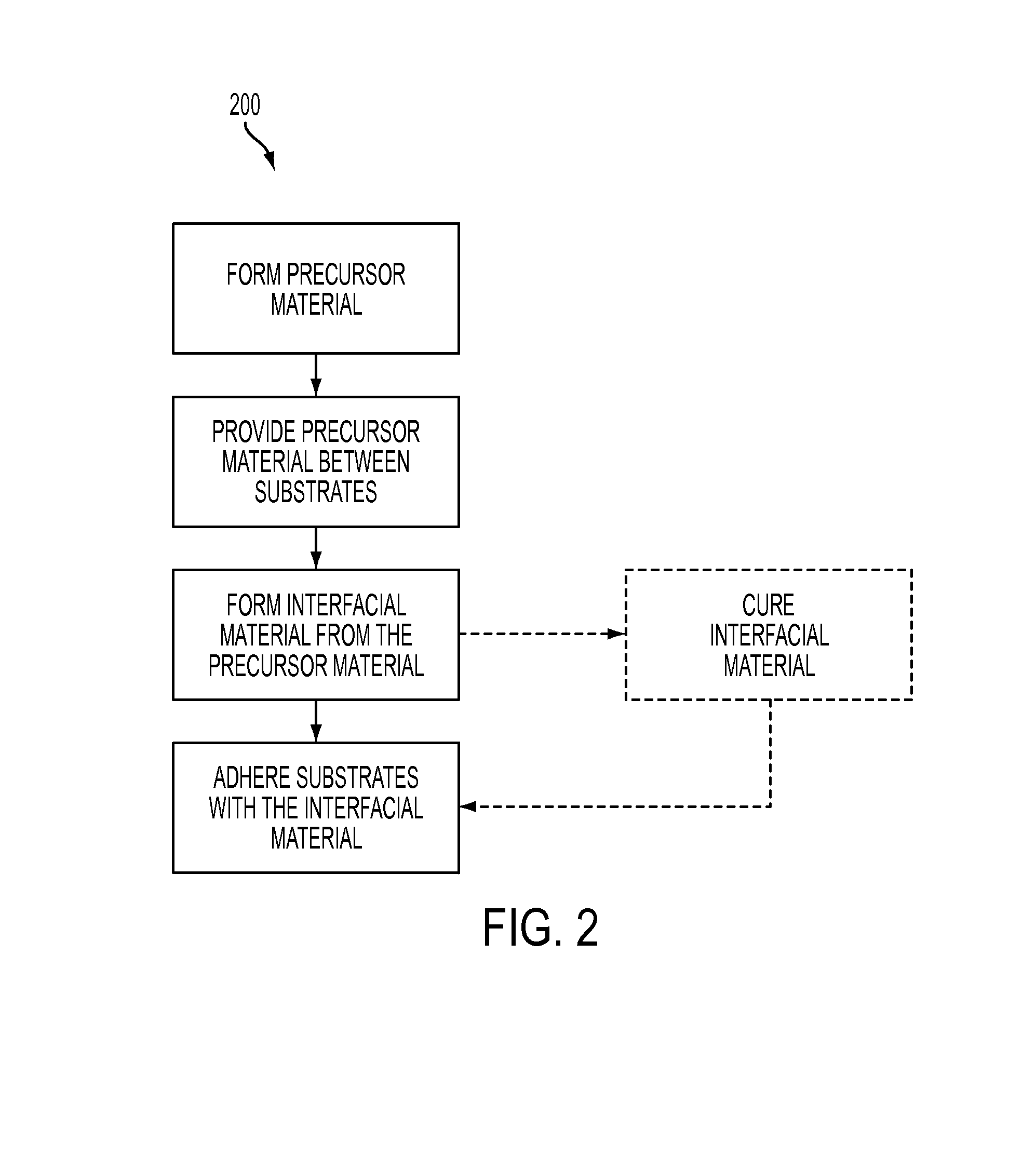

[0010]Methods of forming structures for use in downhole applications are described, as are downhole structures and downhole assemblies. In some embodiments a method of forming a structure for a downhole application comprises forming interfacial material comprising at least one of self-reinforced polyphenylene, polyphenylene sulfide, polysulfone, and polyphenylsulfone between a first substrate and a second substrate. The interfacial material and downhole structures, tools, and assemblies including the interfacial material may exhibit enhanced properties (e.g., enhanced mechanical strength, adhesion strength, wear resistance, thermal resistance, chemical resistance, etc.) favorable to the use of the interfacial material and the downhole structures, tools, and assemblies incorporating the interfacial material in downhole applications. The methods, materials, and structures of the disclosure may increase the efficiency of downhole operations and reduce costs as compared to corresponding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com