Patents

Literature

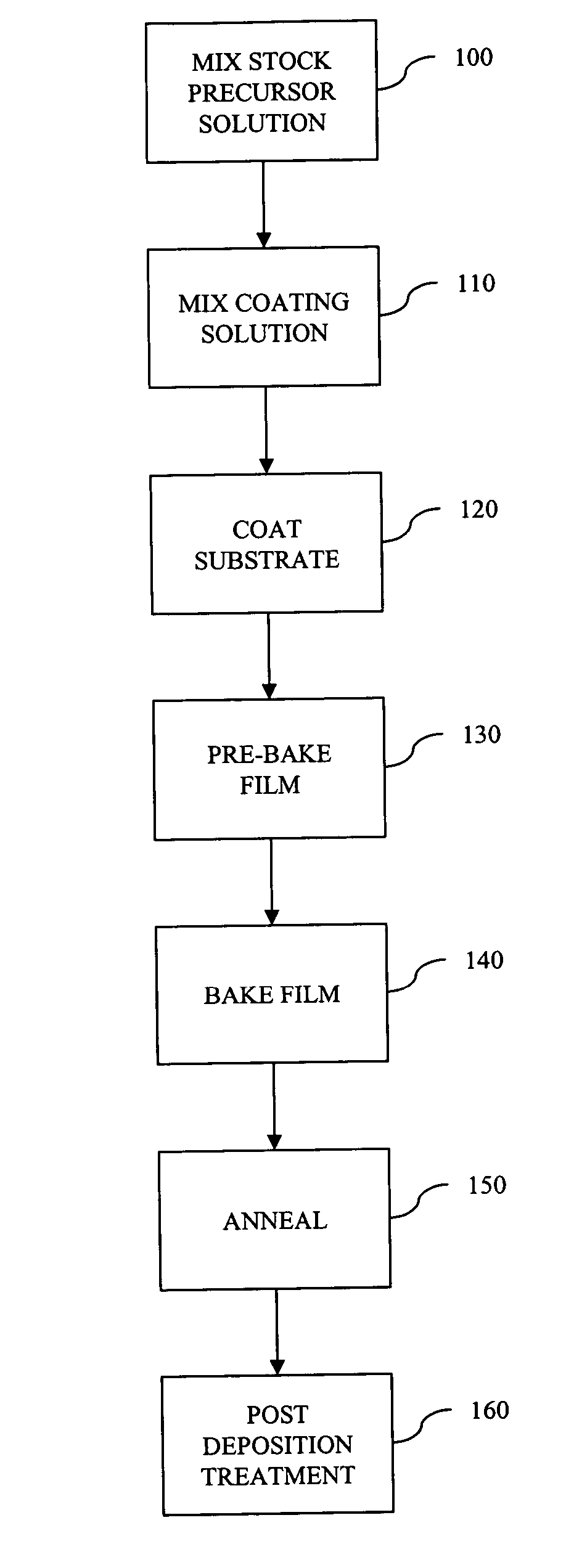

33results about How to "Solve the lack of mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

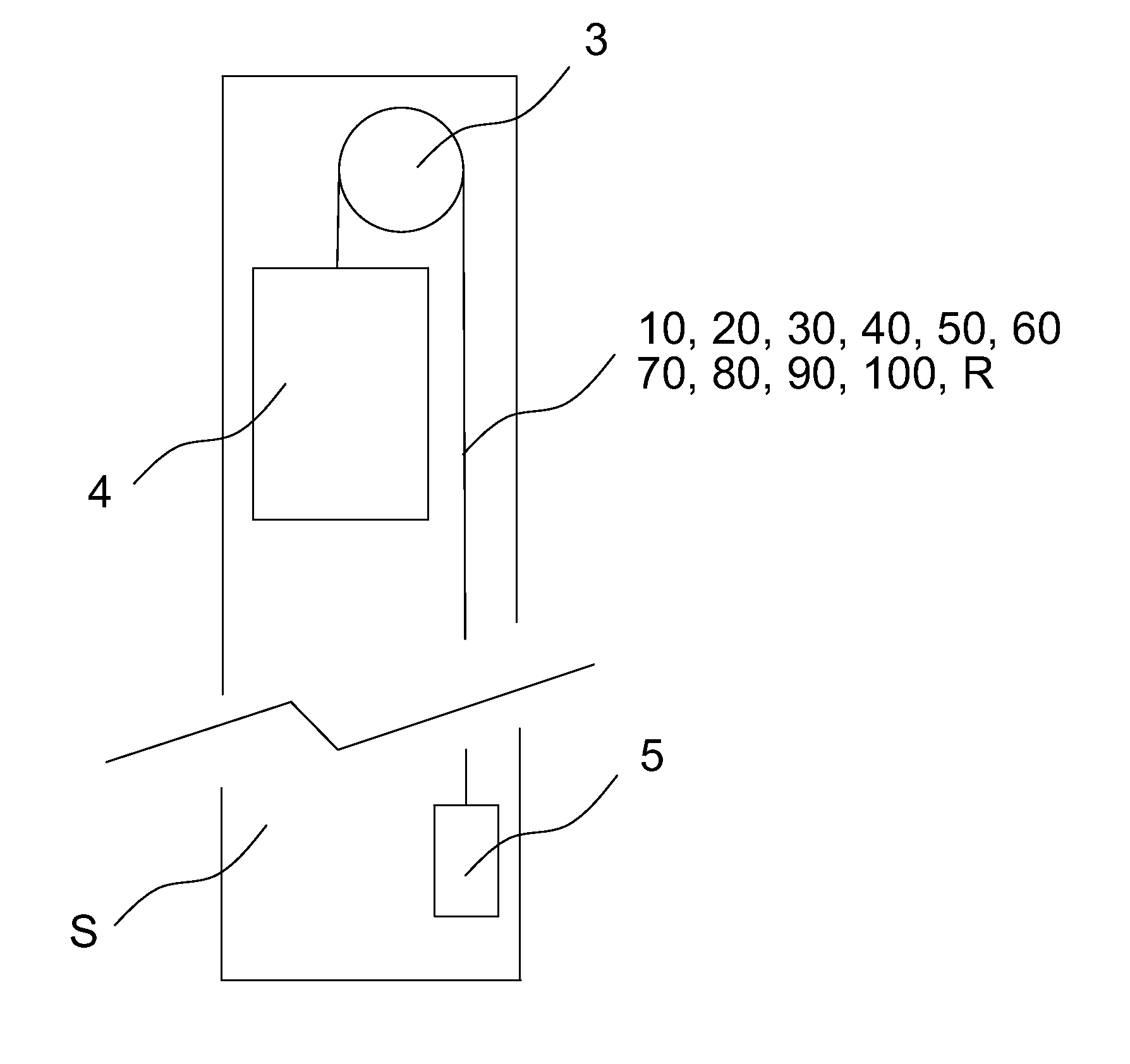

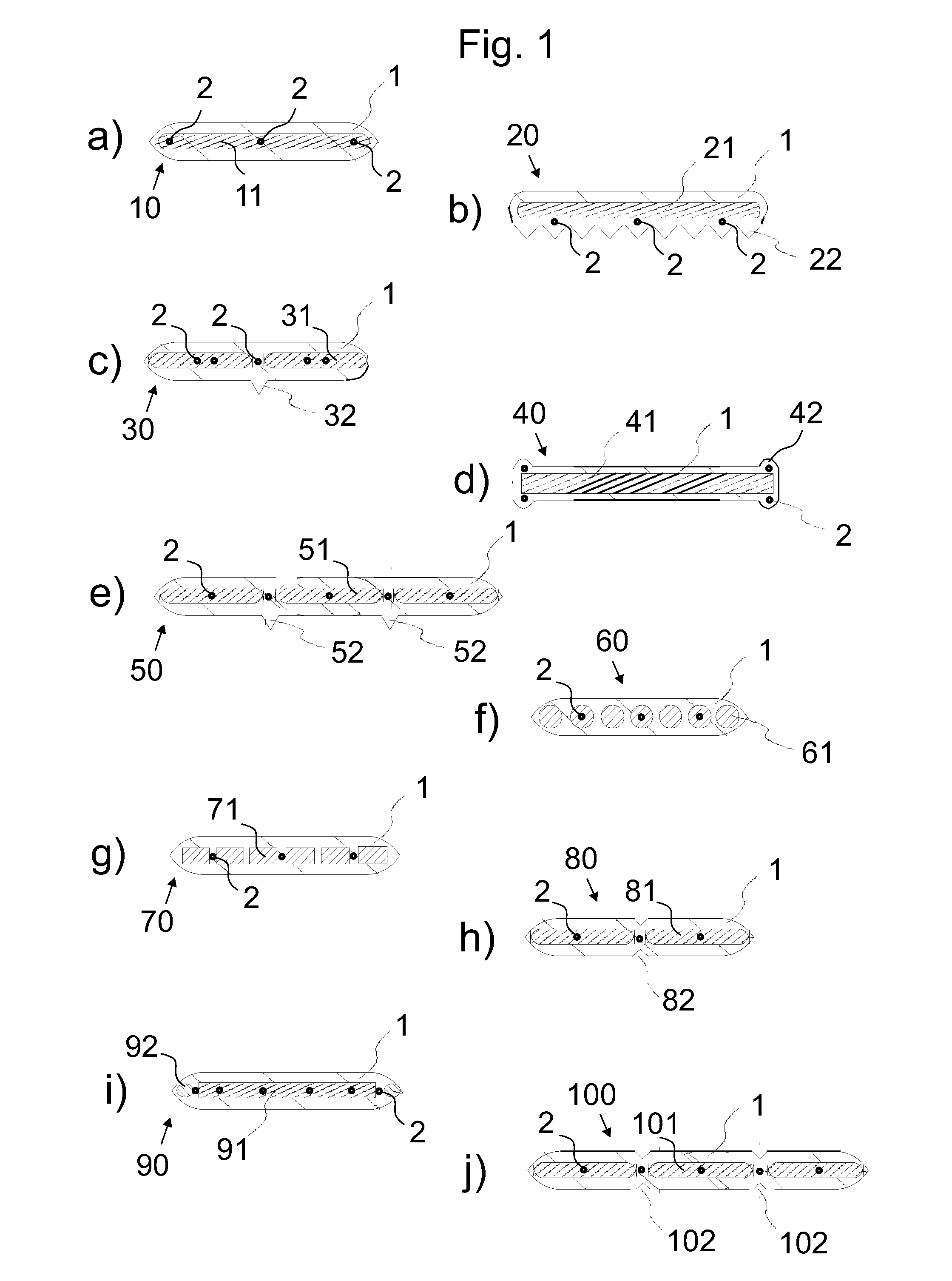

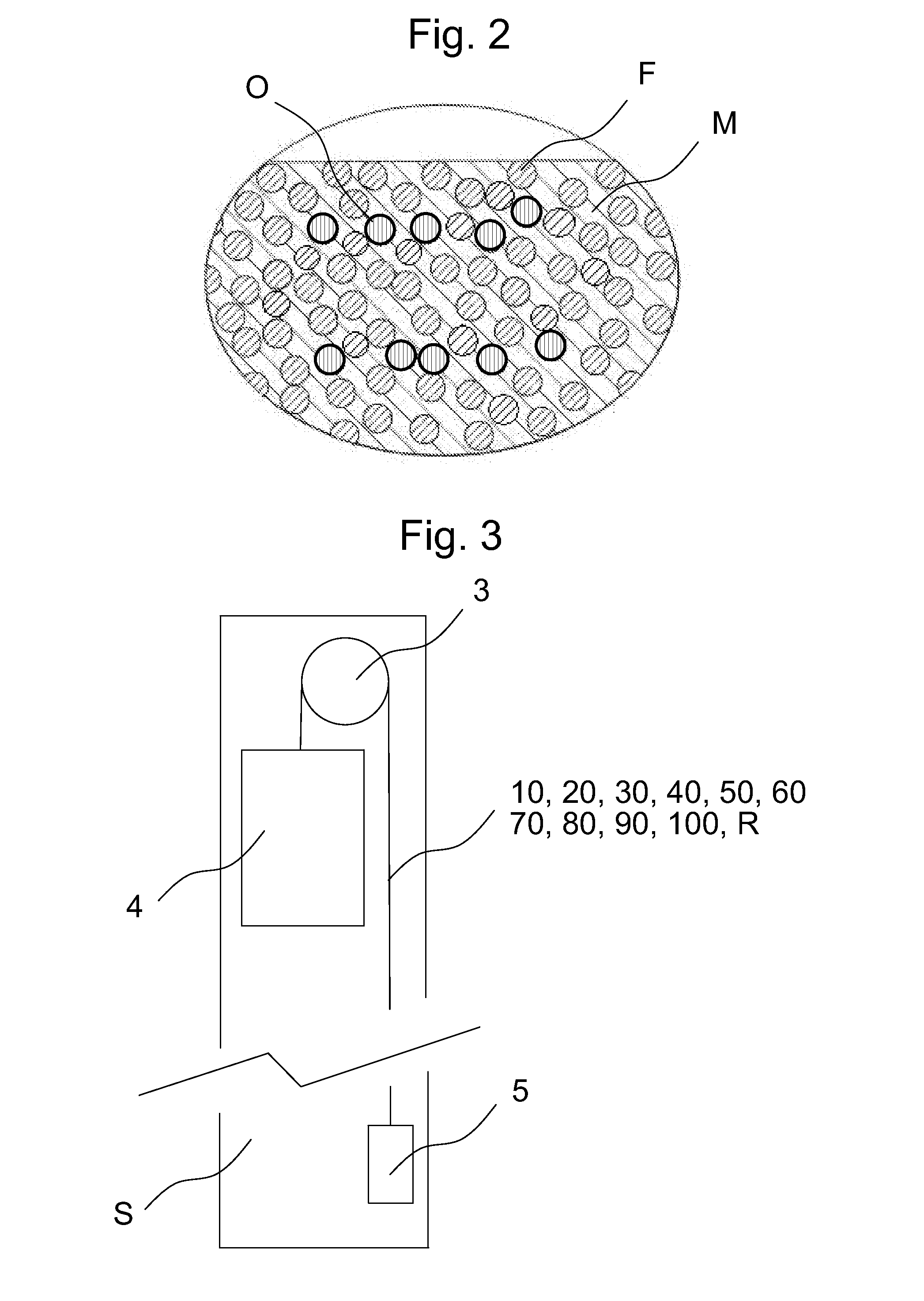

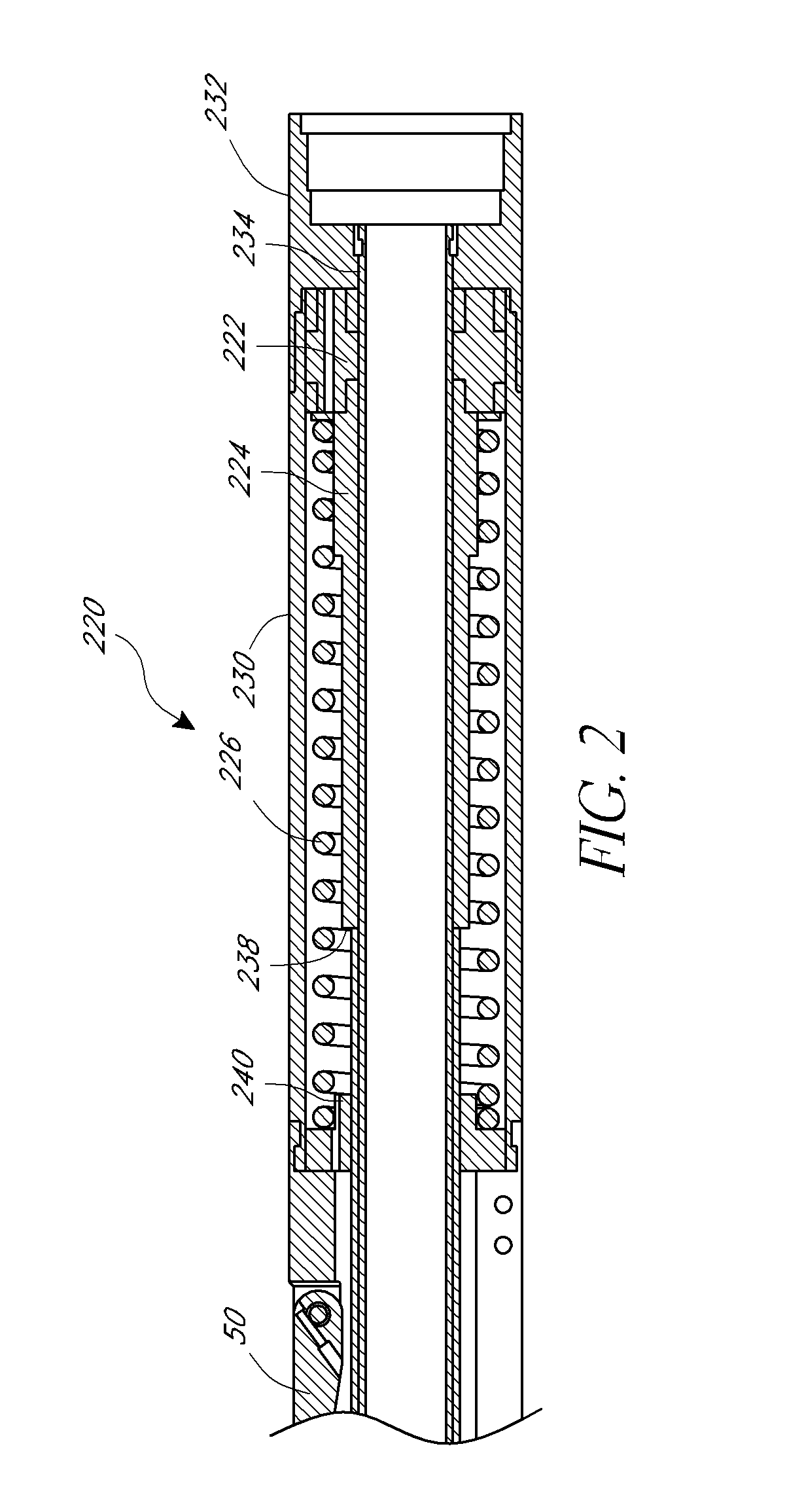

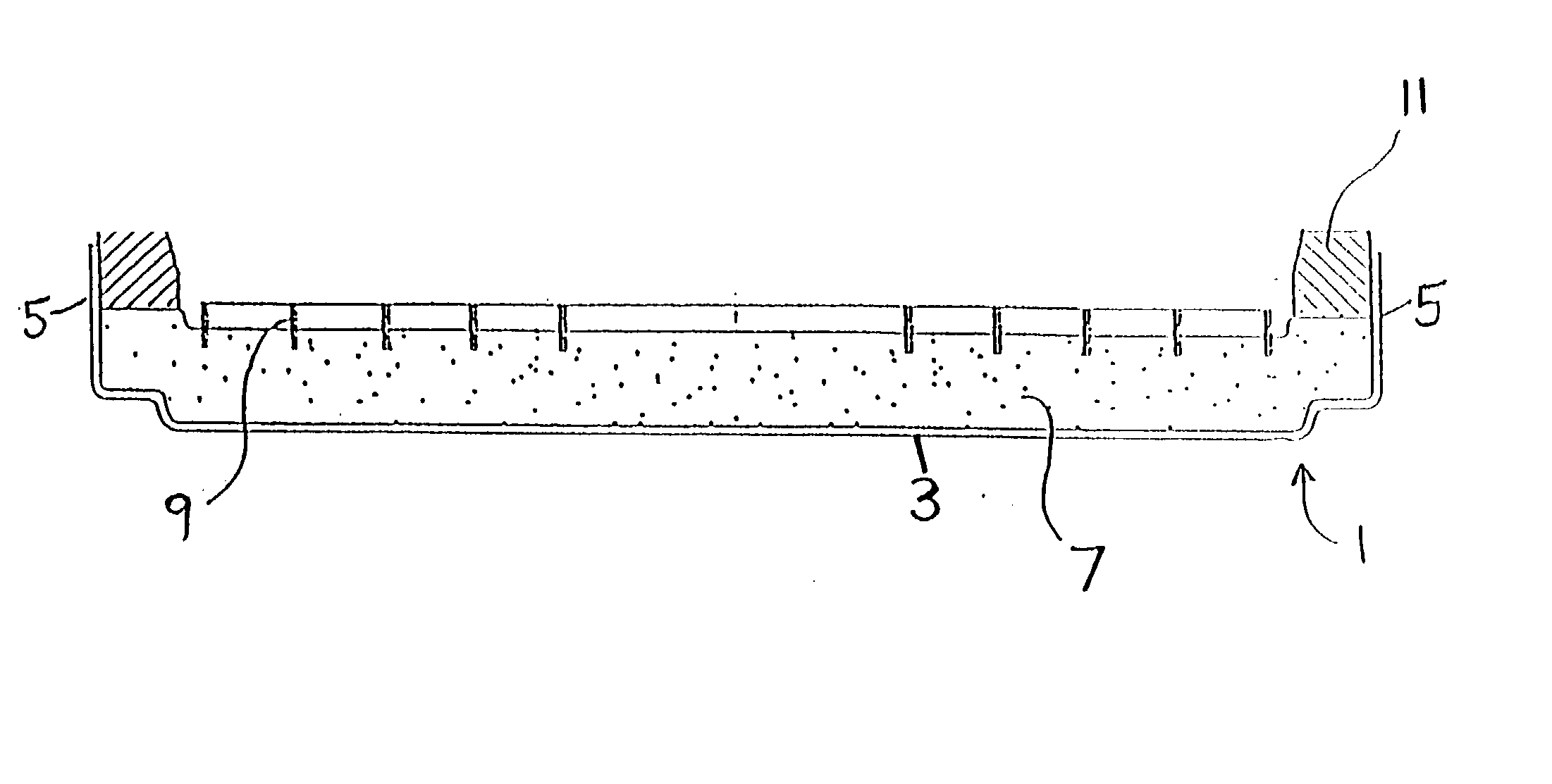

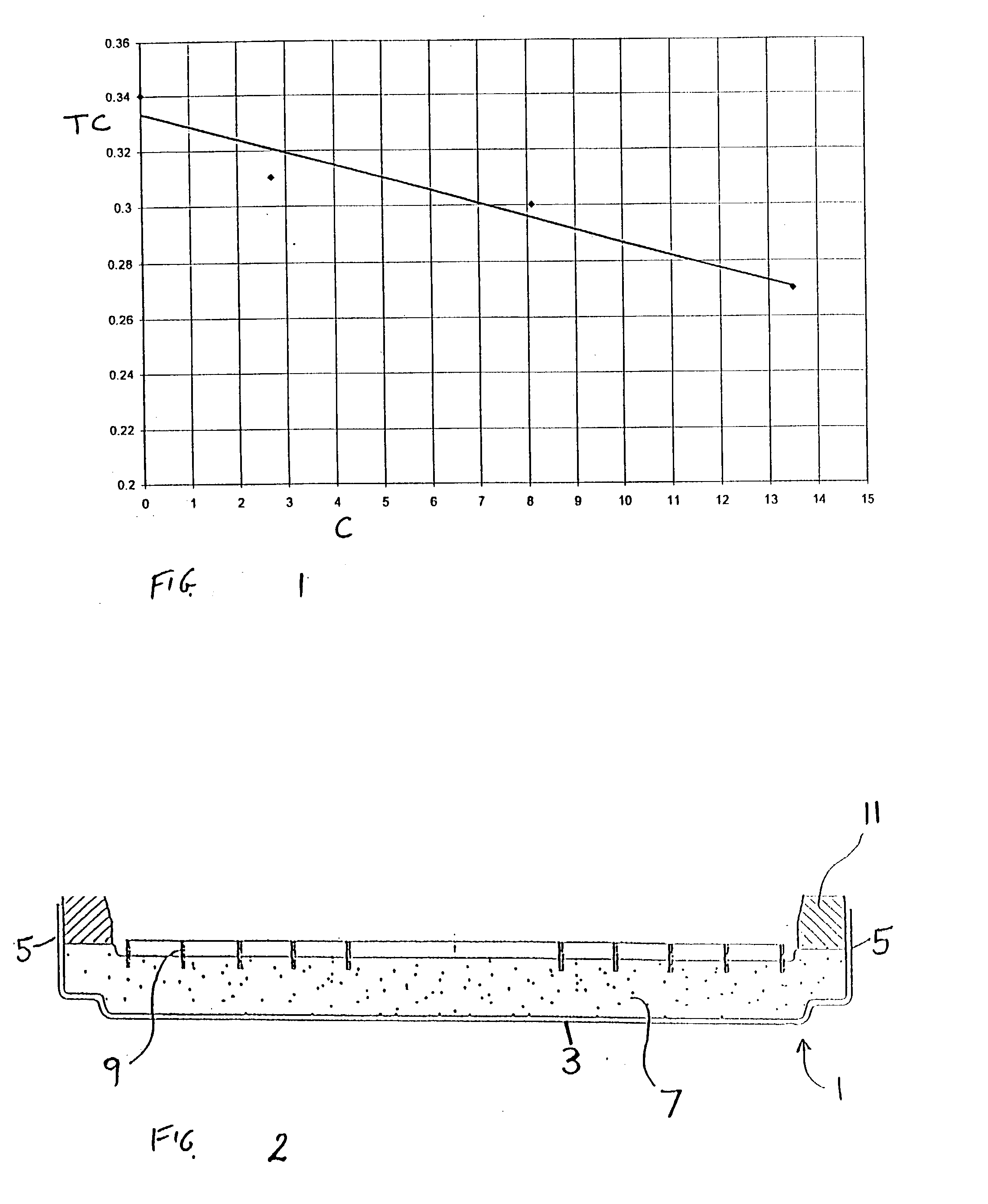

Rope of a lifting device, a rope arrangement, an elevator and a condition monitoring method for the rope of a lifting device

ActiveUS20140305744A1Solve the lack of mechanical propertiesConvenient condition monitoringElevatorsBuilding liftsGlass fiberCarbon fibers

In a rope of a lifting device, particularly of a passenger transport elevator and / or freight transport elevator, the width of which rope is greater than the thickness in the transverse direction of the rope, which rope includes a load-bearing part in the longitudinal direction of the rope, which load-bearing part includes carbon-fiber reinforced, aramid-fiber reinforced and / or glass-fiber reinforced composite material in a polymer matrix, and which rope includes one or more optical fibers and / or fiber bundles in connection with the load-bearing part and the optical fiber and / or fiber bundle is laminated inside the load-bearing part and / or the optical fiber and / or fiber bundle is glued onto the surface of the load-bearing part and / or and that the optical fiber and / or fiber bundle is embedded or glued into the polymer envelope surrounding the load-bearing part, as well as to a condition monitoring method for the rope of a lifting device.

Owner:KONE CORP

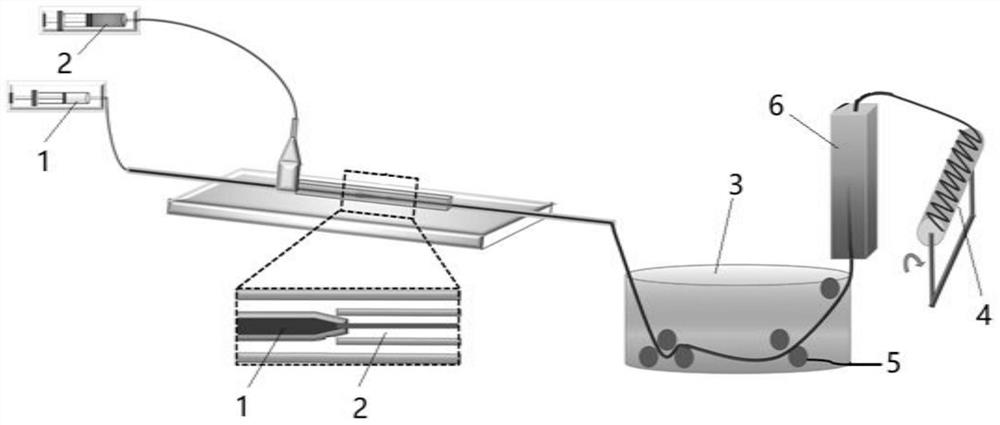

Preparation method for polyimide with cross-linked structure and application of polyimide nanofiber membrane in lithium battery diaphragm

InactiveCN103474600ASolve the lack of mechanical propertiesReduce thicknessMaterial nanotechnologySecondary cellsPolymer sciencePolyolefin

The invention provides a preparation method for a polyimide nanofiber membrane with a cross-linked structure and application of the polyimide nanofiber membrane in a lithium battery diaphragm, belonging to the field of high polymer materials. The preparation method comprises the following steps: subjecting a polyamide acid solution to electrostatic spinning to prepare a polyamide acid nanofiber membrane; etching the polyamide acid nanofiber membrane in an aqueous ammonia solution with a pH value of 8 to 10 for 60 s to form the cross-linked structure; and carrying out washing, drying and imidization at a temperature of 300 DEG C so as to prepare the polyimide nanofiber membrane. The lithium ion battery diaphragm provided by the invention has high mechanical properties, heat stability, high porosity and excellent electrochemical performance. The battery diaphragm has the cross-linked structure and high mechanical properties, thereby overcoming the problems of low strength and an over-open pore structure of a nonwoven polyimide nanofiber membrane. Meanwhile, the diaphragm has porosity of about 80% and can resist a high temperature of 300 DEG C without any deformation, thereby overcoming the disadvantages of low porosity and poor temperature resistance of a polyolefin microporous diaphragm. In particular, the diaphragm provided in the invention has specific capacity substantially better than that of the traditional polyolefin microporous diaphragm under the conditions of high-rate rapid charging and discharging.

Owner:BEIJING UNIV OF CHEM TECH

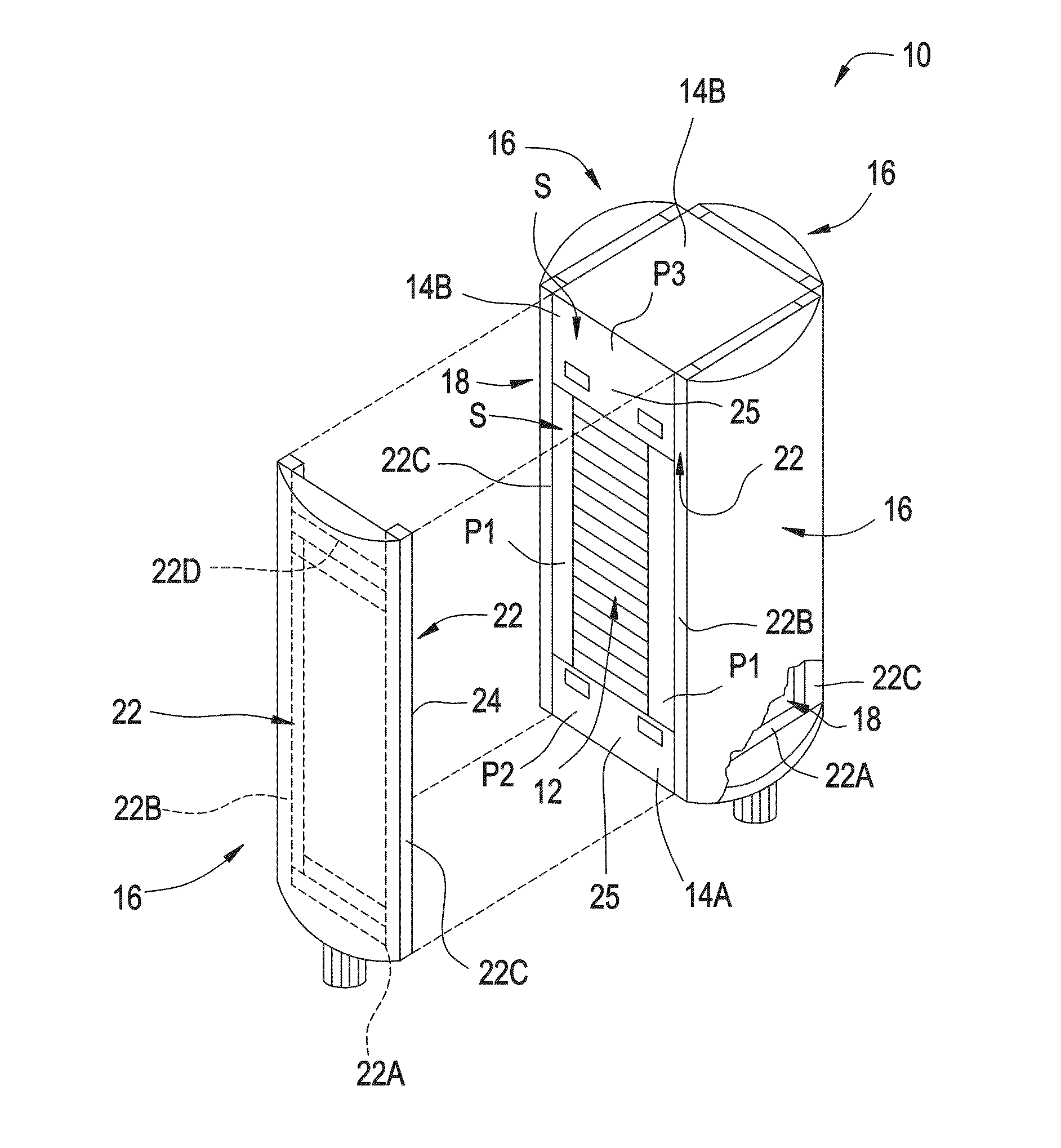

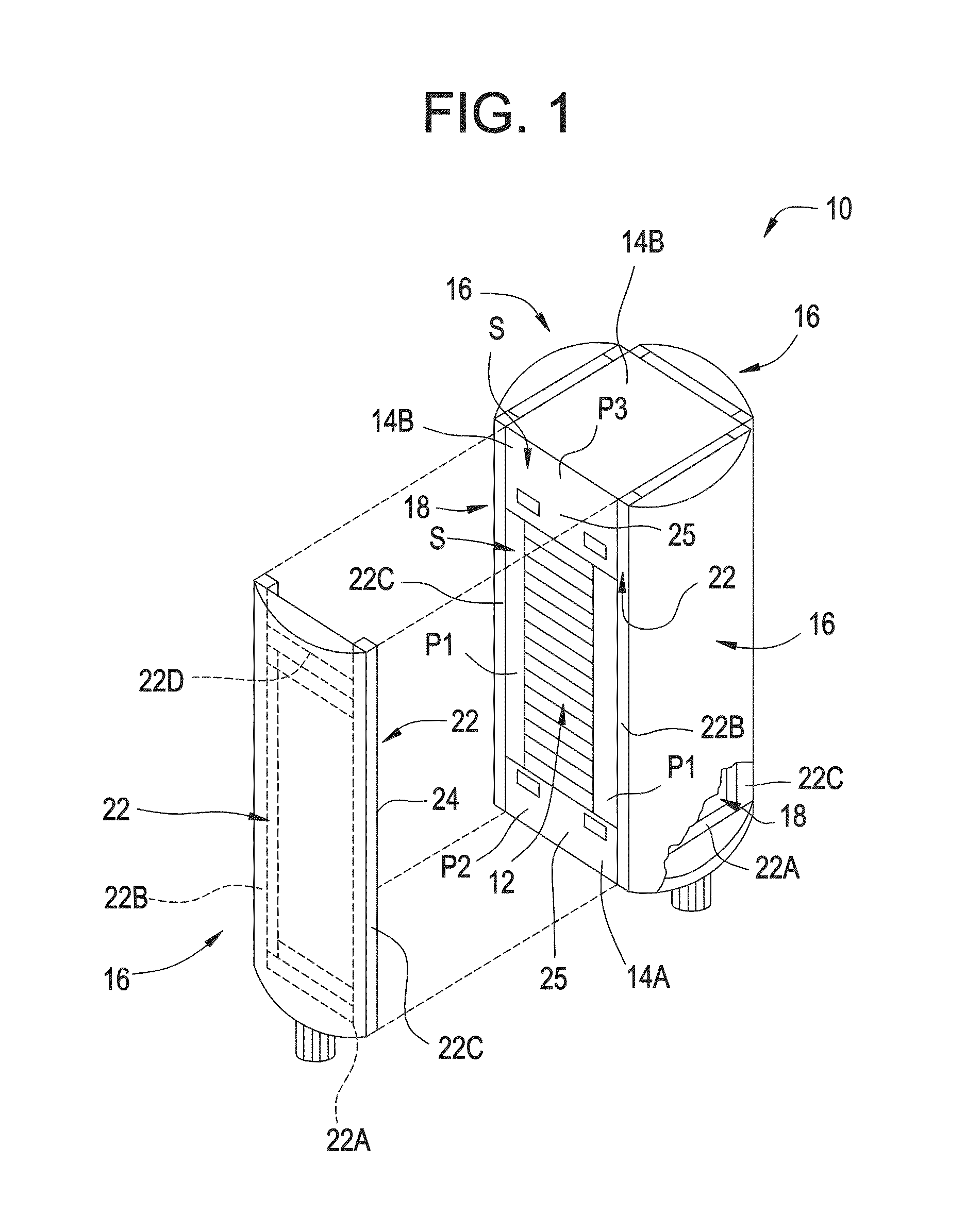

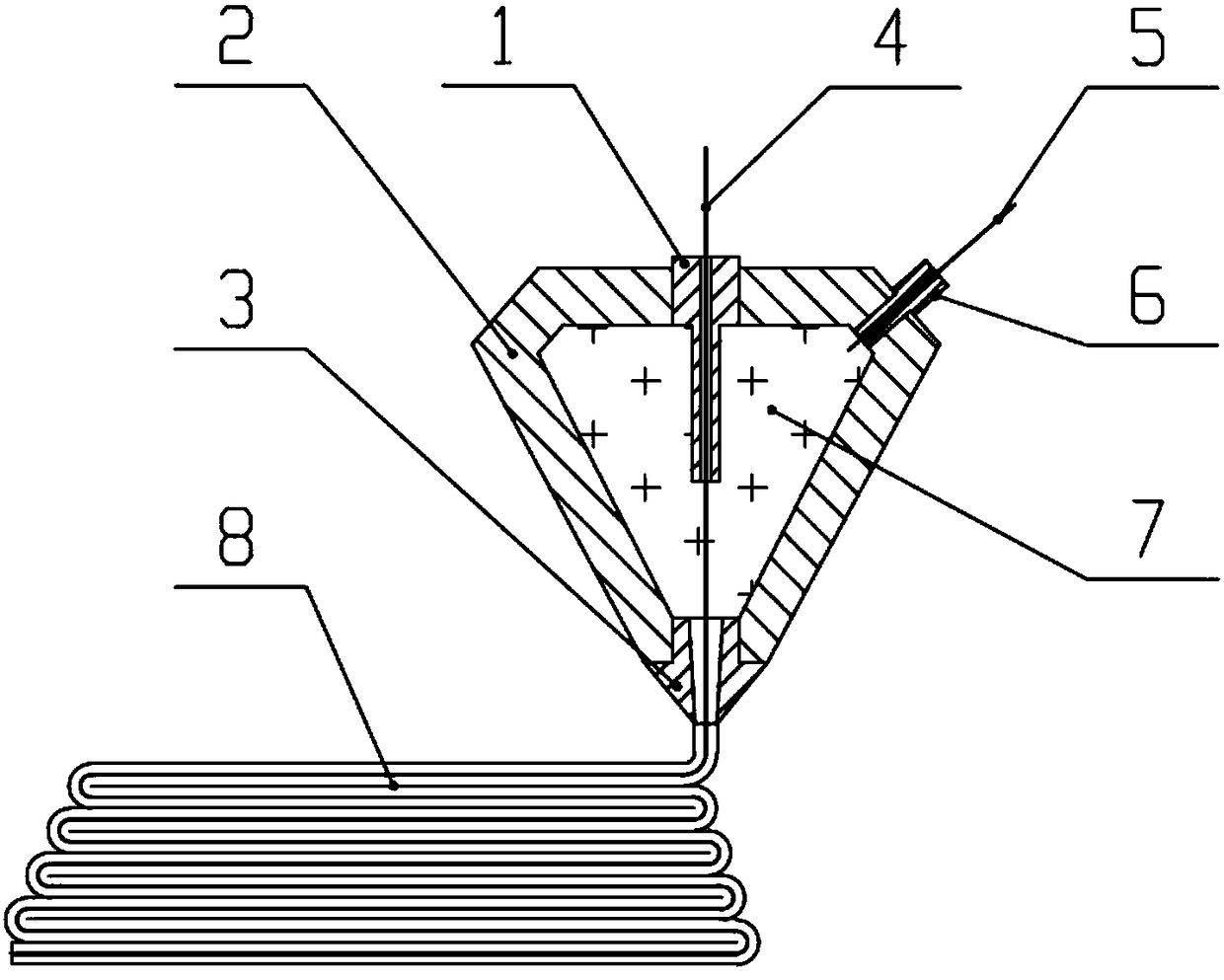

Eccentric linkage gripper

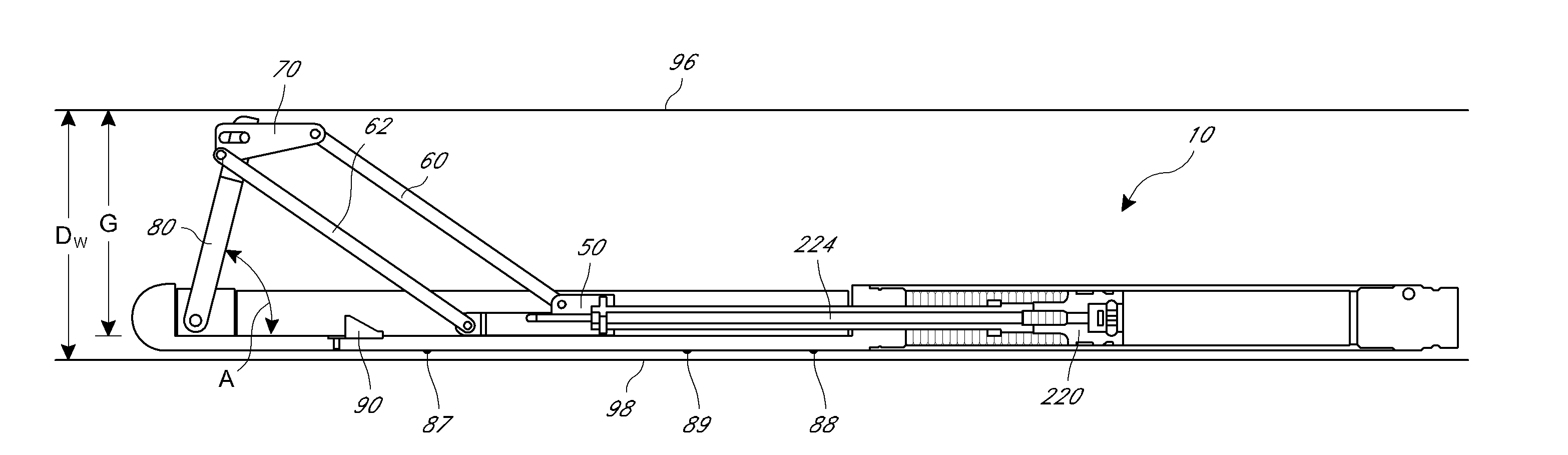

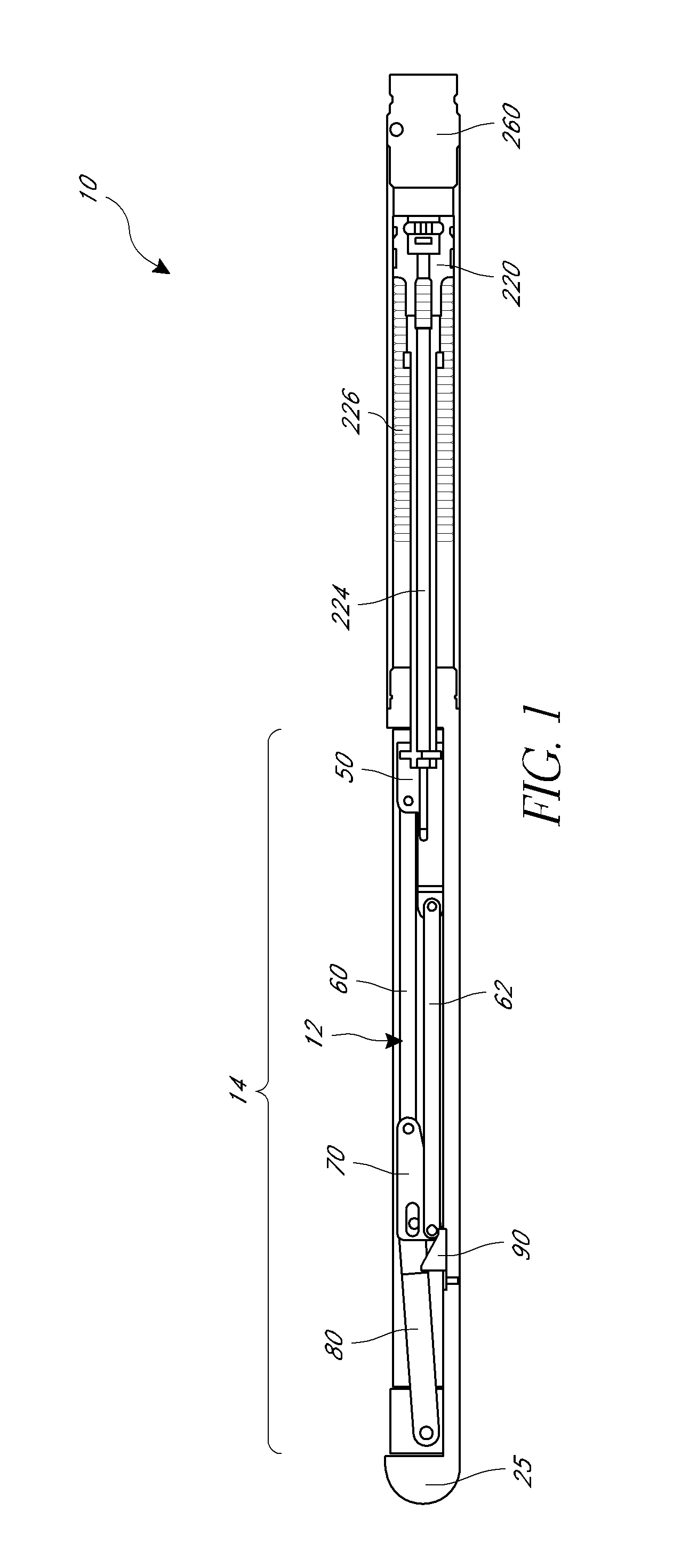

ActiveUS20150211312A1Solve the lack of mechanical propertiesGuaranteed uptimeFluid removalBorehole drivesAxial forceEngineering

A gripper mechanism for a downhole tool is disclosed that includes an eccentric linkage mechanism. In operation, an axial force generated by a power section of the gripper expands the linkage mechanism, which applies a radial force to the interior surface of a wellbore or passage. A sliding portion allows the gripper to slide along a surface of the formation in response to the radial force applied to the interior surface of the wellbore or passage.

Owner:WWT NORTH AMERICA HLDG +1

Composition Coextrudable with PVDF and having no stress-whitening effect

InactiveUS20050187354A1Good mechanical integritySolve the lack of mechanical propertiesSynthetic resin layered productsThin material handlingMeth-Ultraviolet

The present invention relates to a composition coextrudable with PVDF and comprising: 30 to 50 parts of PVDF; 70 to 50 parts of a copolymer comprising, by weight, 90 to 50% of methyl methacrylate (MMA) per 10 to 50% of an alkyl (meth)acrylate respectively, the alkyl having from 2 to 24 carbon atoms; 1 to 4 parts of a UV absorber; the total making 100 parts. The invention also relates to coextruded films consisting of this composition as the adhesive layer and a PVDF-based layer of 50 to 100 parts of PVDF per 50 to 0 parts of PMMA respectively. These films possess mechanical properties sufficient to allow them to be used as a coating transparent to visible light but opaque to UV radiation.

Owner:ARKEMA FRANCE SA

Non-crosslinked flame-retardant resin compsition, and an insulated wire and a wire harness using the same

InactiveUS20070048524A1Sufficient flame retardancySolve the lack of flexibilityPlastic/resin/waxes insulatorsSpecial tyresAdditive ingredientPliability

To provide a non-crosslinked flame-retardant resin composition possessing sufficient flame retardancy, mechanical properties, flexibility and workability, and also delivering excellent heat resistance over a long period of time as it is hard to be molten when used under high temperature environment and its material is not deteriorated even if used in contact with a vinyl chloride resin material and the like, and an insulated wire and a wiring harness using the same. The composition includes (A) a non-crosslinked base resin which contains a propylene resin containing 50 wt % or more of propylene monomer and a thermoplastic resin of which a melting point is 180° C. or more, (B) a metallic hydrate, (C) a hindered phenolic antioxidant, (D) a sulfurous antioxidant, and (E) a metallic oxide. Polymethylpentene, an imidazole compound and an oxide of zinc are preferably utilized as the thermoplastic resin, the ingredients (D) and (E), respectively. The composition is used as an insulated covering material for a non-halogenous insulated wire, which is used in a wire bundle of the wiring harness.

Owner:AUTONETWORKS TECH LTD +2

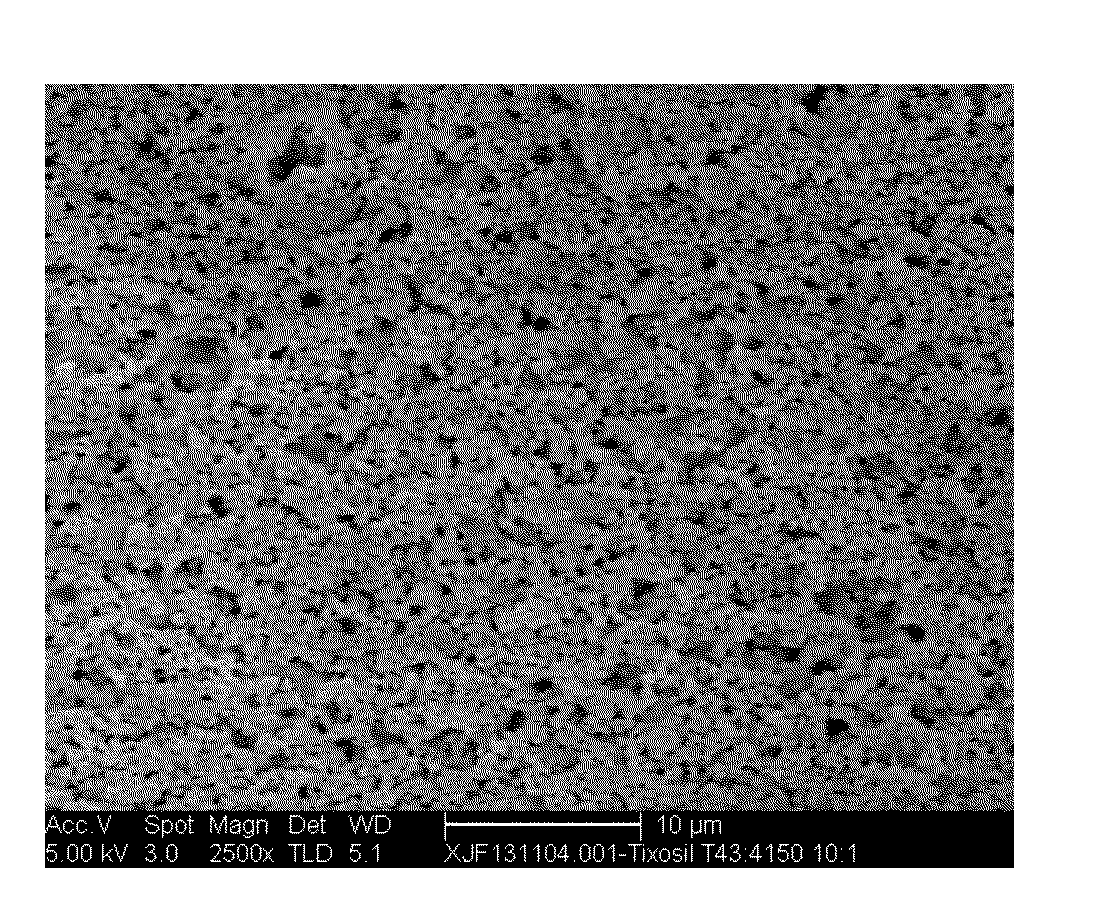

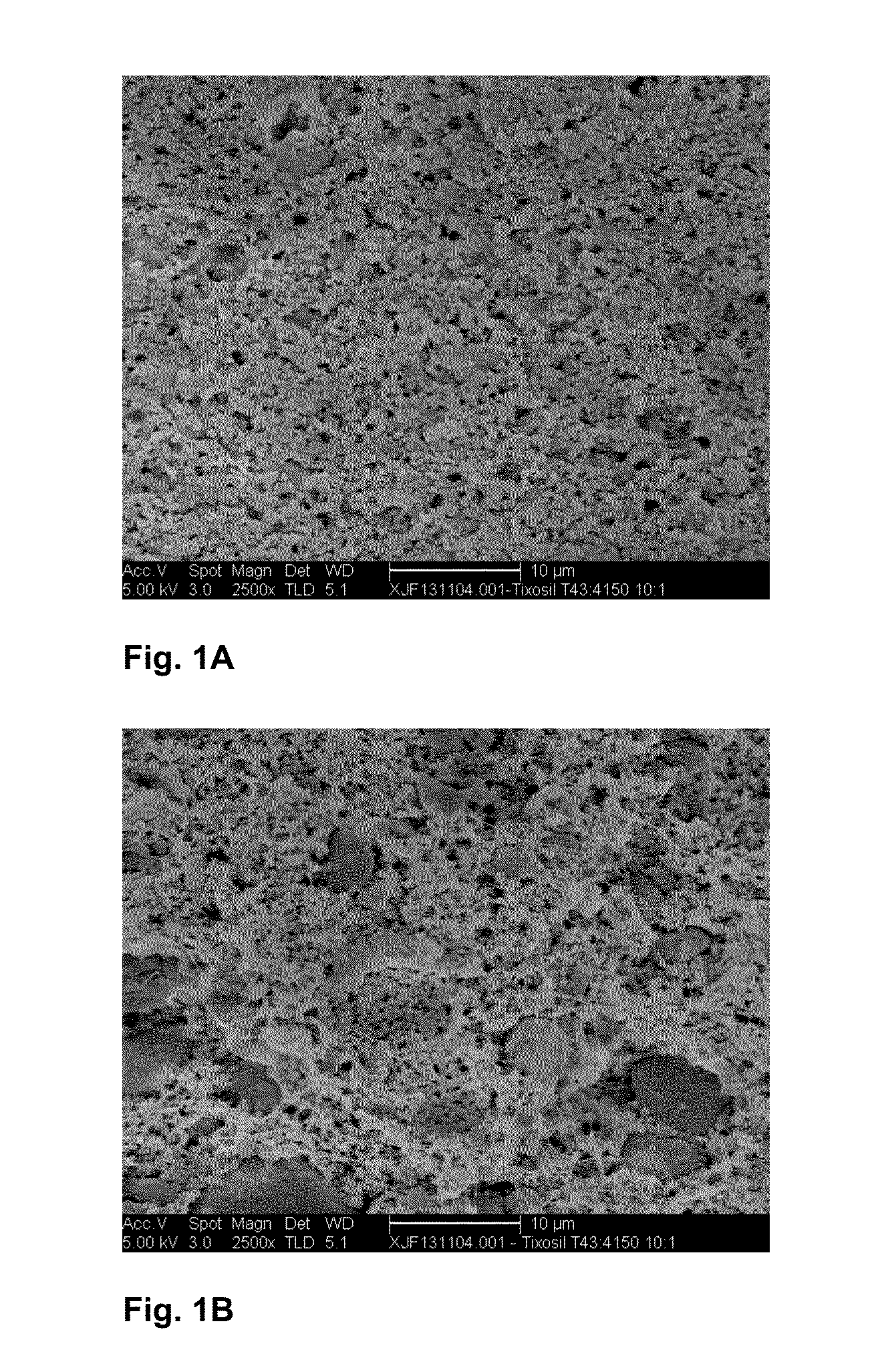

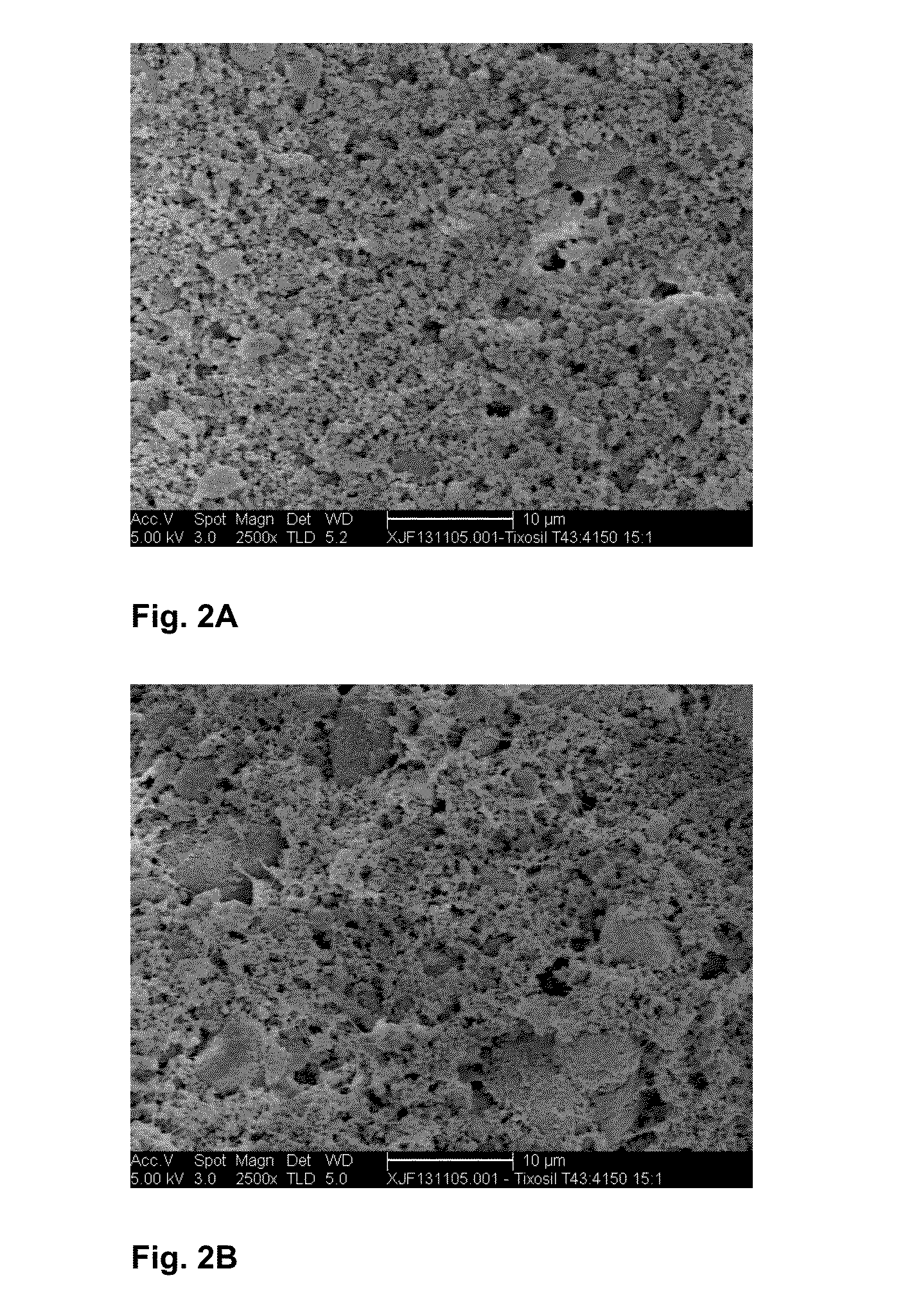

High porosity silica-containing microporous sheets

ActiveUS20150207121A1High porosityImprove mechanical propertiesLead-acid accumulatorsCell component detailsPorosityPolymer science

A flexible microporous polymer sheet having first and second opposite major surfaces comprises a polymer matrix binding a filler component that exhibits high oil absorption capacity in its initial state before the start of material processing. The polymer matrix includes a polyolefin component and has three-dimensional interconnecting and interpenetrating pore and polymer networks through which the bound filler component is distributed from the first major surface to the second major surface. The polyolefin and filler components are included in amounts that result in a microporous polymer sheet having between about 75% and about 90% porosity and containing less than about 10 wt. % polyolefin component. Preferred polyolefin and filler components include ultrahigh molecular weight polyethylene and high oil absorption precipitated silica, respectively.

Owner:AMTEK RES INT

Method for preparing starch-g-PVA graft starch slurry for improving mechanical property of starch film and use thereof

InactiveCN1844172AReduce the degree of phase separationImprove mechanical propertiesFibre treatmentChemistrySizing

This invention is a preparation method of starch-g-PVA amylopectin starch slurry which could increase starch film's mechanic properties. It belongs to converted starch slurry technology used in weaving and warp sizing. We adopt graft copolymerization and the following hydrolytic reaction to add polyvinyl alcohol grafting branch chain onto starch macromolecules. Then we get starch-g-PVA amylopectin starch slurry constitutes. Mix the starch with PVA in certain proportion. This invention is advantageous in solving layers problem of slurry mixture, irregular dressing and starch lump blemishes. It also increases the mechanic properties of the mixed starch and PVA, increase weaving efficiency and reduce weaving end breakage rate.

Owner:JIANGNAN UNIV

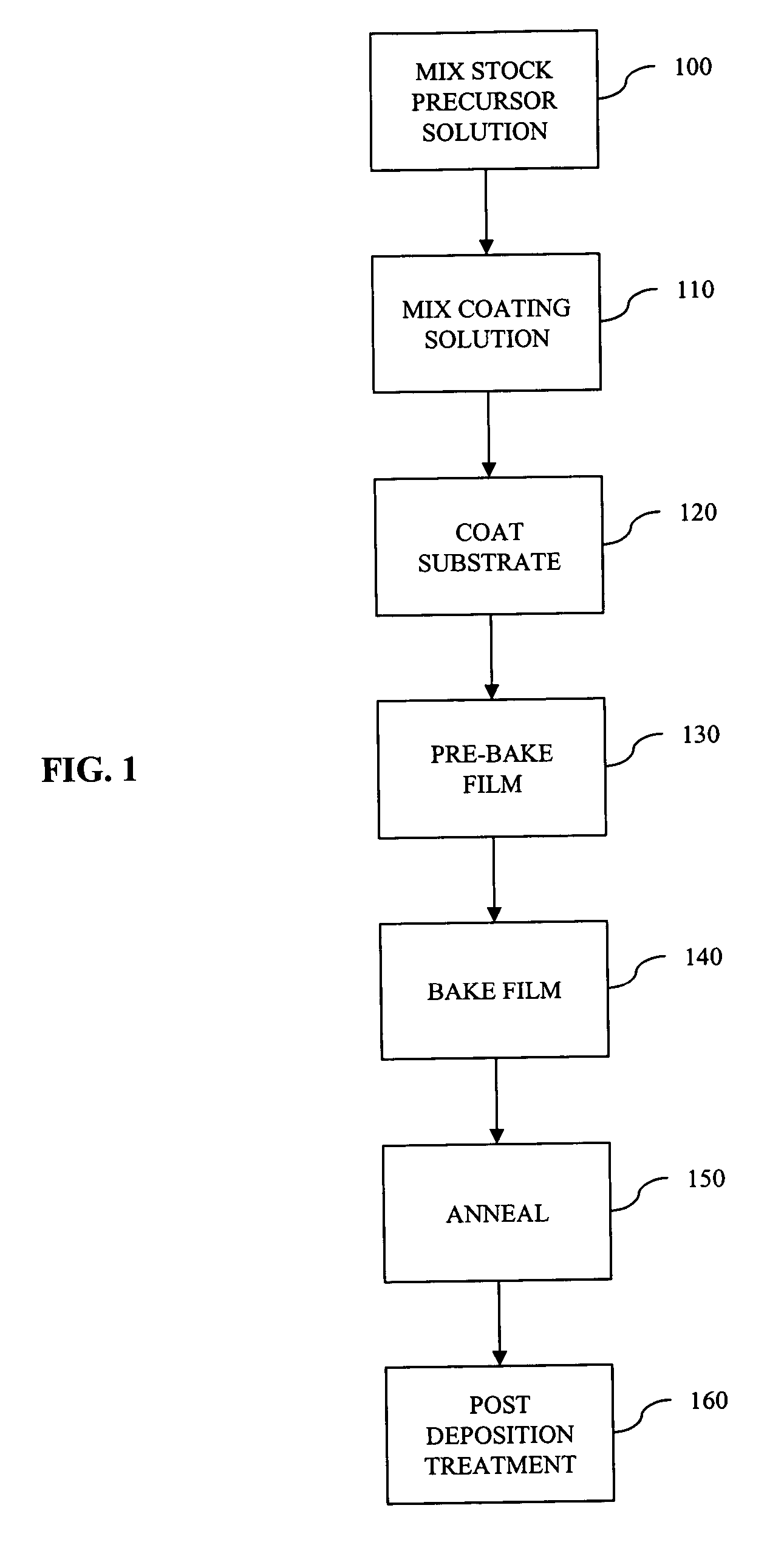

Ionic additives for extreme low dielectric constant chemical formulations

InactiveUS7265062B2Solve the lack of mechanical propertiesMinimal levelSilicaSemiconductor/solid-state device manufacturingMechanical propertyImpurity

A process for depositing porous silicon oxide-based films using a sol-gel approach utilizing a precursor solution formulation which includes a purified nonionic surfactant and an additive among other components, where the additive is either an ionic additive or an amine additive which forms an ionic ammonium type salt in the acidic precursor solution. Using this precursor solution formulation enables formation of a film having a dielectric constant less than 2.5, appropriate mechanical properties, and minimal levels of alkali metal impurities. In one embodiment, this is achieved by purifying the surfactant and adding ionic or amine additives such as tetraalkylammonium salts and amines to the stock precursor solution.

Owner:AIR PROD & CHEM INC +1

Method for preparing titanium material through powder metallurgy with modifier

The invention discloses a method for preparing a titanium material through powder metallurgy with a modifier, relates to a method for preparing the titanium material through powder metallurgy and aimsto solve the problems that a titanium material prepared by using a conventional powder metallurgy material is large in texture and degraded in plasticity as textures cannot be controlled. The methodcomprises the following steps: I, performing mechanical powder stirring and mixing, namely mechanically mixing modifier powder, pure titanium and titanium alloy powder by using a stirring and mixing machine so as to obtain composite powder; II, performing sintering, namely sintering the composite powder in a vacuumed sealed container, and naturally cooling to a room temperature, thereby obtaininga modified powder metallurgy titanium material with controllable textures.

Owner:HARBIN INST OF TECH

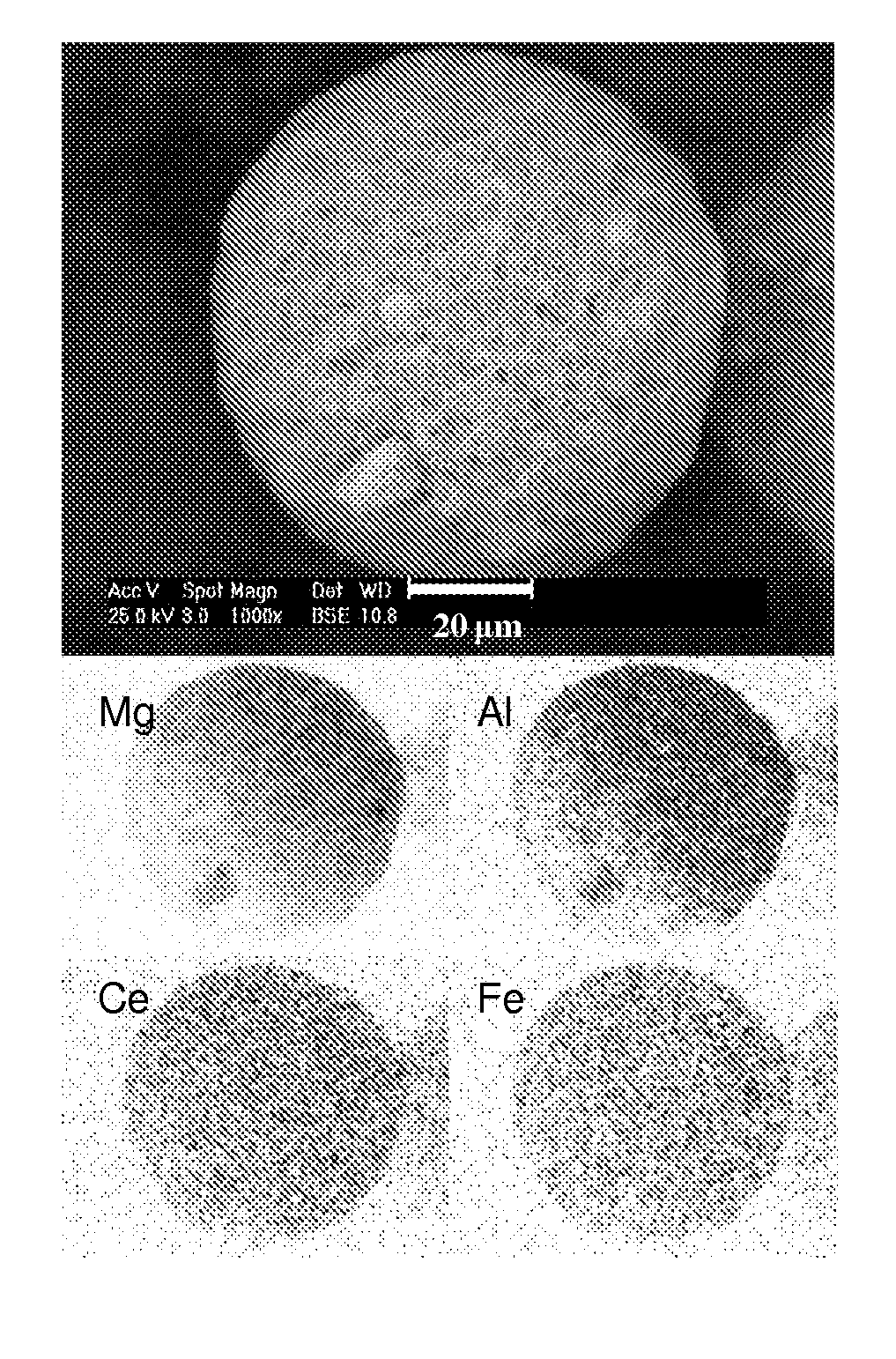

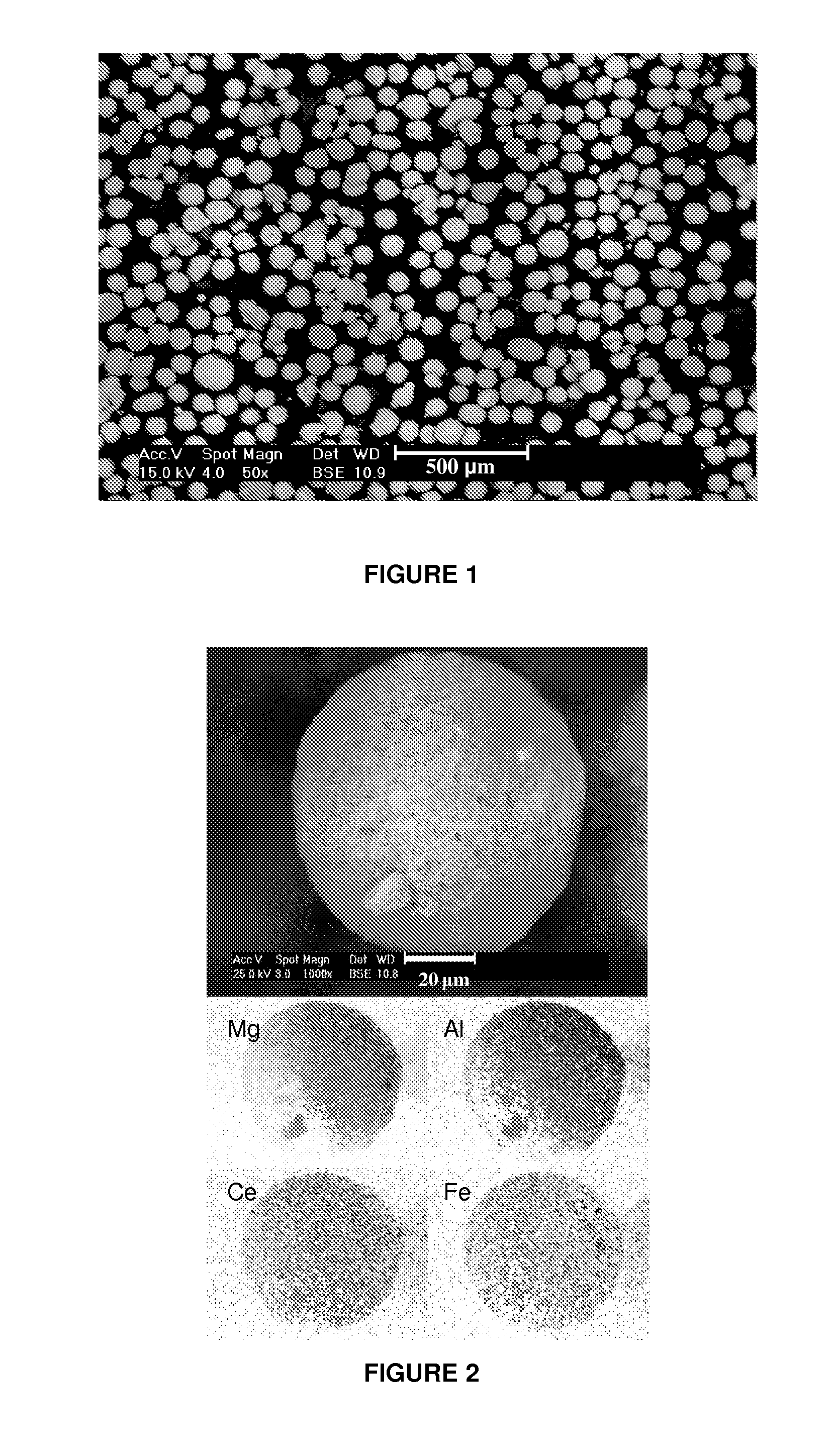

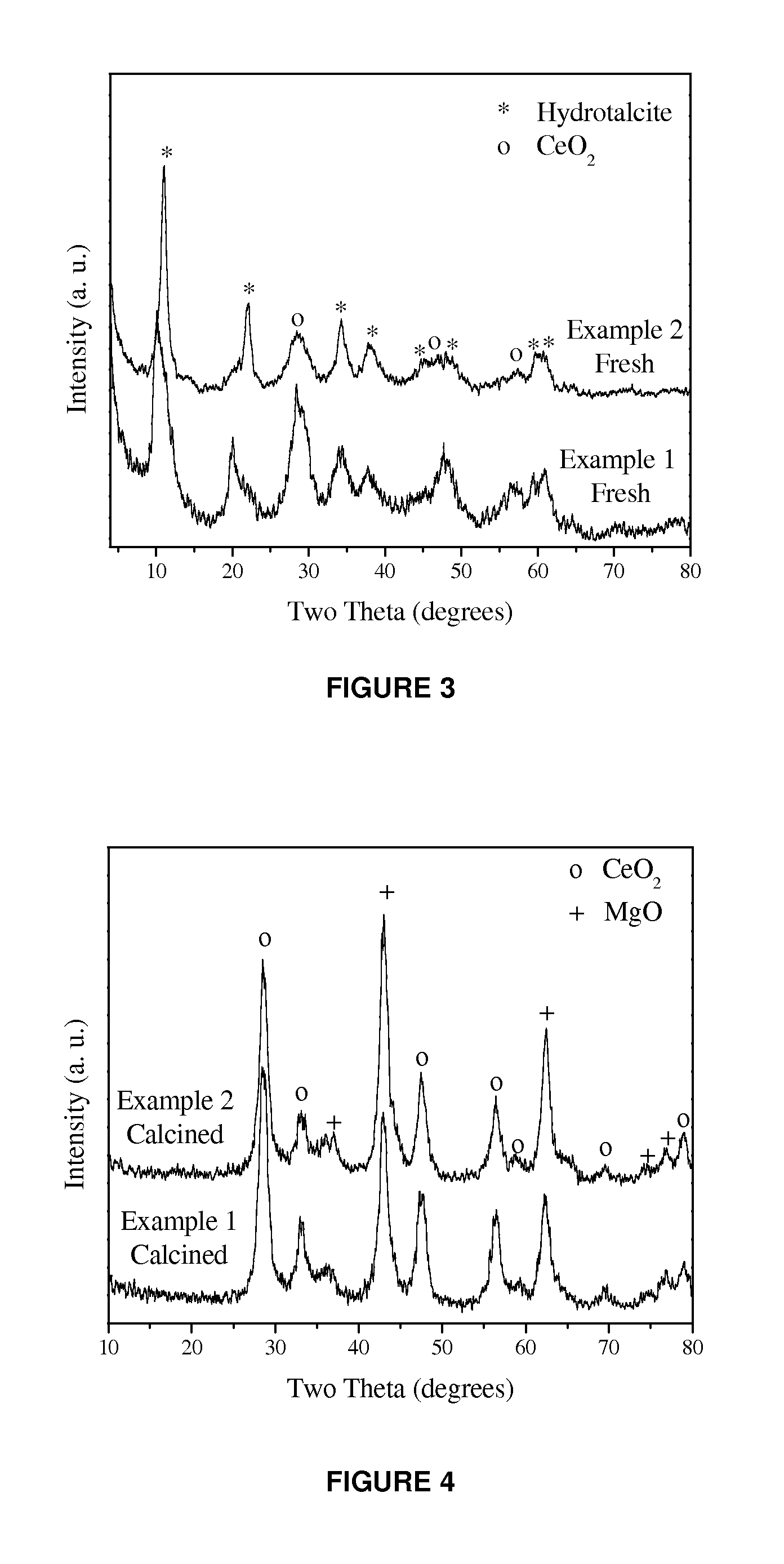

Multimetallic anionic clays and derived products for SOx removal in the fluid catalytic cracking process

InactiveUS20120067778A1Increase capacityMaterial efficiencyCatalytic crackingMolecular sieve catalystsPtru catalystHydrocotyle bowlesioides

The present invention relates to the preparation of Multimetallic Anionic Clays (MACs) through a simple method, which are then shaped by spray-drying into microspheres with adequate mechanical properties, suitable to be fluidized. The microspheres are appropriate for application as additives in the Fluid Catalytic Cracking (FCC) process, i.e. blended with the conventional catalyst, to in situ remove sulfur oxides (SOx) from the combustion gases produced in the regeneration stage of the FCC process, when cracking sulfur-containing hydrocarbon feeds. An oxidation promoter is added to the MACs in order to promote the oxidation of SO2 to SO3, a key step in SOx removal, providing more efficient and versatile materials, which are apt to be used in atmospheres with variable oxygen concentration.

Owner:INST MEXICANO DEL GASOLINEEO

Gasket for fuel cell system manifold seal

ActiveUS20140038081A1Prevent leakageSolve the lack of mechanical propertiesReactant parameters controlCell component detailsMetallurgyFiber

A gasket for a manifold seal for a fuel cell system includes a first layer of fibrous ceramic material having a first compressibility, a second layer of fibrous ceramic material having a second compressibility and a third layer of fibrous ceramic material having third compressibility. The third layer of fibrous ceramic material is positioned between and engaged with the first layer of fibrous ceramic material and the second layer of fibrous ceramic material. The third compressibility is less than the first compressibility and less than the second compressibility.

Owner:FUELCELL ENERGY INC

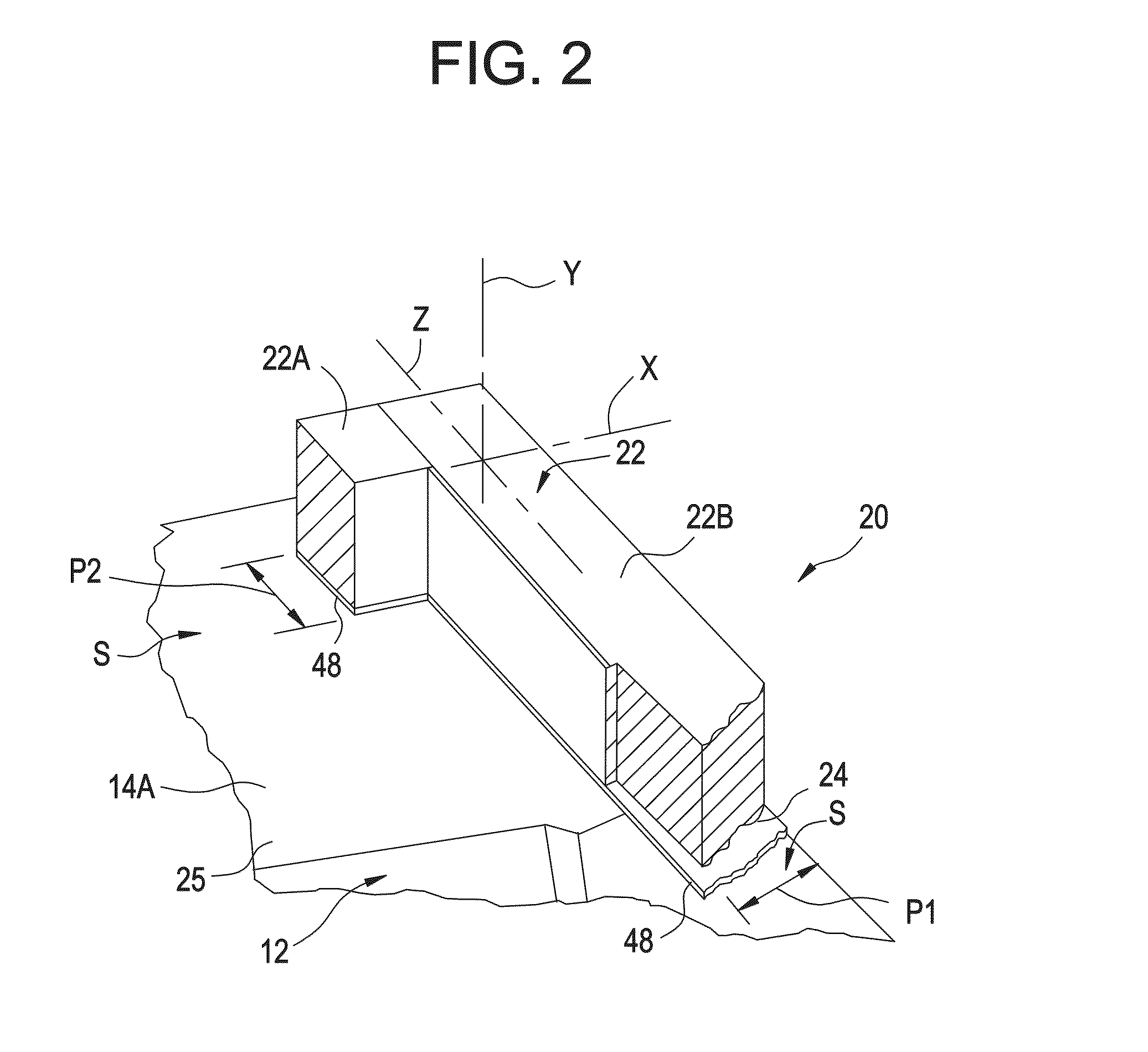

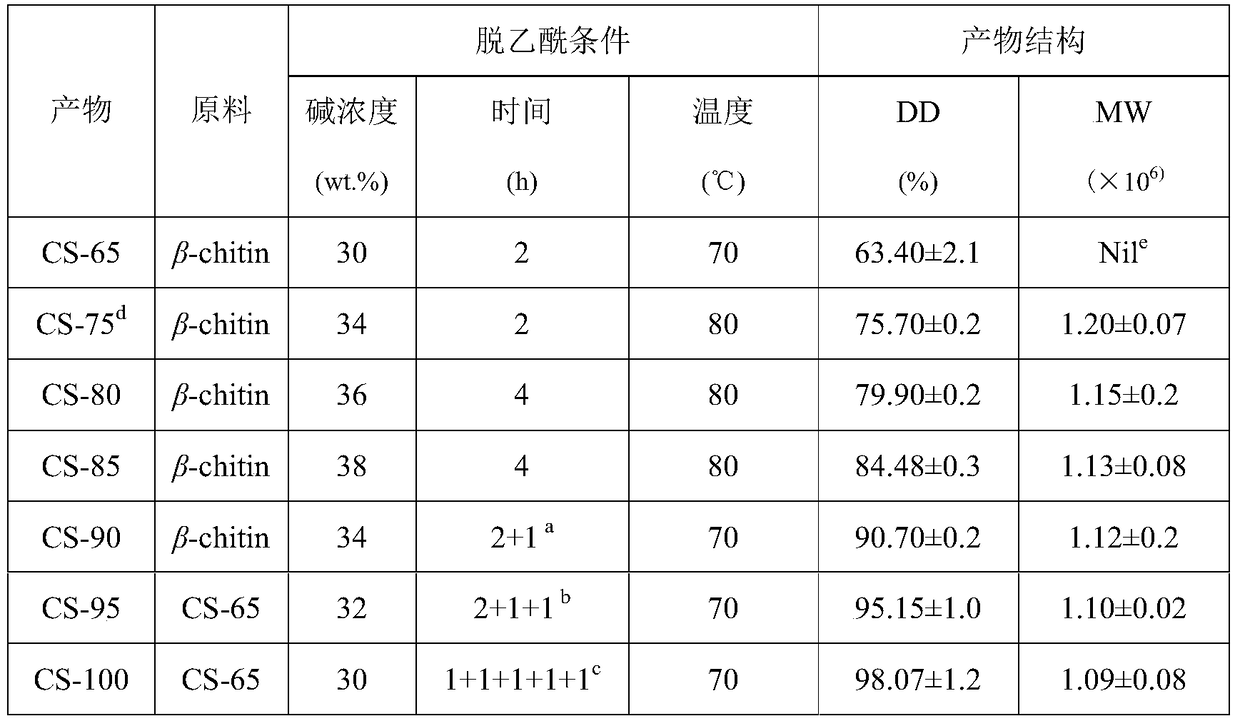

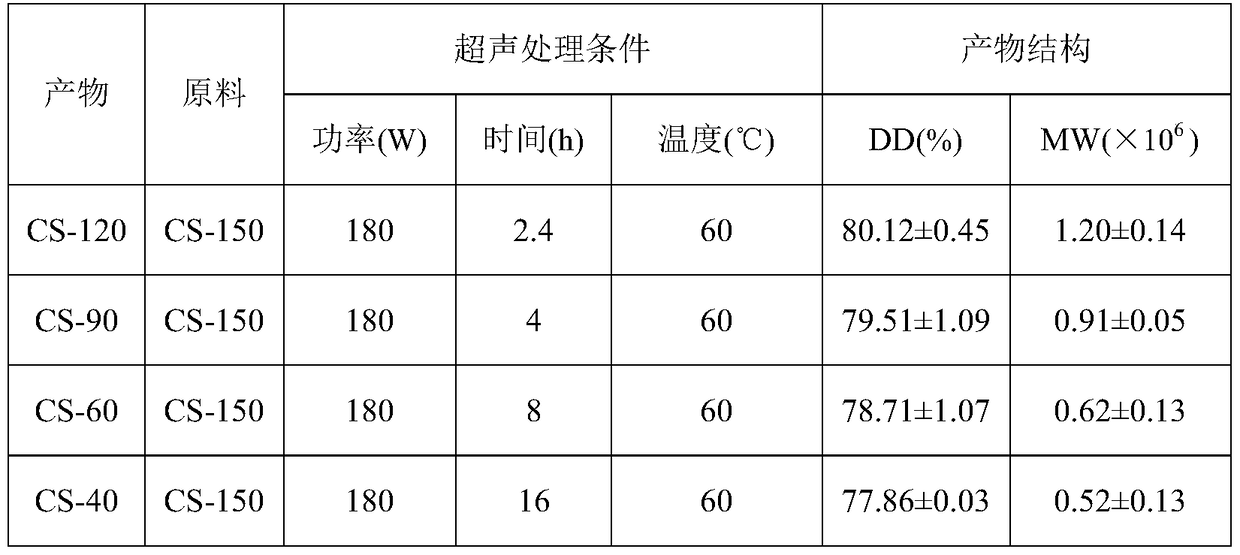

A kind of absorbable surgical suture and preparation method thereof

ActiveCN105133088BUniform diameterGood biocompatibilitySuture equipmentsFibre chemical featuresMechanical propertyBiomedical engineering

Disclosed are an absorbable surgical suture and a preparation method therefor. The preparation method comprises the following steps: S1, dissolving squid cartilage chitosan to obtain a spinning solution, the deacetylation degree of the squid cartilage chitosan being greater than 60%, and the molecular weight of the squid cartilage chitosan being greater than 0.5*106; and S2, spinning the spinning solution and then drying to obtain the absorbable surgical suture. The absorbable surgical suture prepared by the method has a mechanical property reaching the requirements of clinical application, can be gradually absorbed by a human body and effectively promote the healing of a wound tissue, and has a better application prospect.

Owner:SHENZHEN BRIGHT WAY NOVEL BIO MATERIALS TECH CO LTD

Thermal insulation material

InactiveUS20040023015A1Low thermal conductivitySolve the lack of mechanical propertiesCeramic layered productsGlass/slag layered productsThermal insulationFiber

A thermal insulation material comprises an intimate mixture of: 60-90% by dry weight expanded vermiculite; 6.5-20% by dry weight inorganic binder; 1-14.5% by dry weight microporous material; 0.1-3.5% by dry weight reinforcing fibres; and 0.5-10% by dry weight infrared opacifier.

Owner:CERAMASPEED

CoCrNiCuFeMnAl high-entropy alloy and preparation method thereof

The invention belongs to the field of metal alloy materials, and relates to a CoCrNiCuFeMnAl high-entropy alloy. The CoCrNiCuFeMnAl high-entropy alloy comprises the following components of, in percentage by weight, 5.2-38.03 wt.% of cobalt powder, 4.5-34.53 wt.% of chromium powder, 5.17-37.92 wt.% of nickel powder, 5.68-40.25 wt.% of copper powder, 0.2-20.61 wt.% of iron powder, 0.5-33.45 wt.% ofmanganese powder and 0.3-20.03wt.% of aluminum powder. The preparation method comprises the steps that firstly, the metal simple substance powder is subjected to mechanical alloying in a ball mill, then the obtained high-entropy alloy powder is subjected to prepressing forming and annealing treatment and then subjected to hot pressing sintering, a sintered body is subjected to annealing treatment,finally the surface of the annealed sintered body is ground and polished, residual external impurities in the sample sintering process and burrs generated on the edge in the sintering process are removed, so that the CoCrNiCuFeMnAl high-entropy alloy block material is prepared. Compared with a traditional alloy, the high-entropy alloy has better density, hardness and compressive strength.

Owner:YANSHAN UNIV

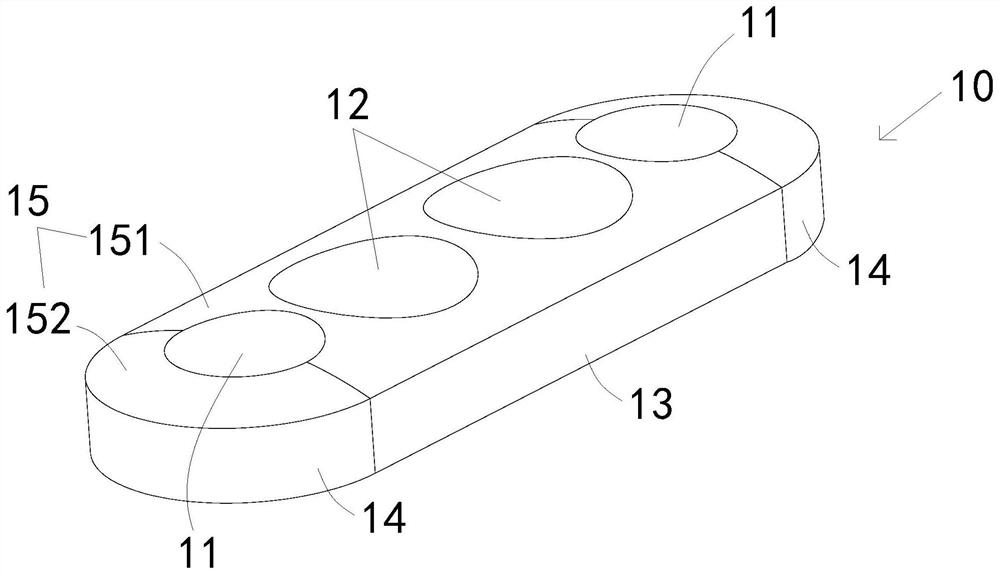

Novel belt-loop magnesium plate with high strength and corrosion resistance

ActiveCN113425457AGood mechanical modulusGood biocompatibilityLigamentsMusclesBone tunnelMicro arc oxidation

The invention discloses a novel belt-loop magnesium plate with high strength and corrosion resistance. The surface of the novel belt-loop magnesium plate is covered with a nanocrystal layer, the surface of the nanocrystal layer is covered with a ceramic membrane through a micro-arc oxidation technology, the novel belt-loop magnesium plate is provided with a pull rope hole and a graft hole, the pull rope hole and the graft hole both penetrate through the novel belt-loop magnesium plate, the pull rope hole is used for a pull rope to pass through, and the graft hole is used for a graft to pass through. As the main material of the novel belt-loop magnesium plate is magnesium, magnesium ions of the novel belt-loop magnesium plate can play a role in promoting osteogenesis, so that the formation of callus at the thighbone part is accelerated, the micromotion of a tendon graft in a bone tunnel is slowed down, the widening of the bone tunnel is inhibited, and the reconstruction success rate is improved; and the problems of insufficient mechanical property and poor corrosion resistance of magnesium metal can be solved through the nanocrystal layer and the ceramic membrane, so that the problems of unstable fixation and bone tunnel expansion of an existing tendon graft are practically solved.

Owner:SUN YAT SEN UNIV

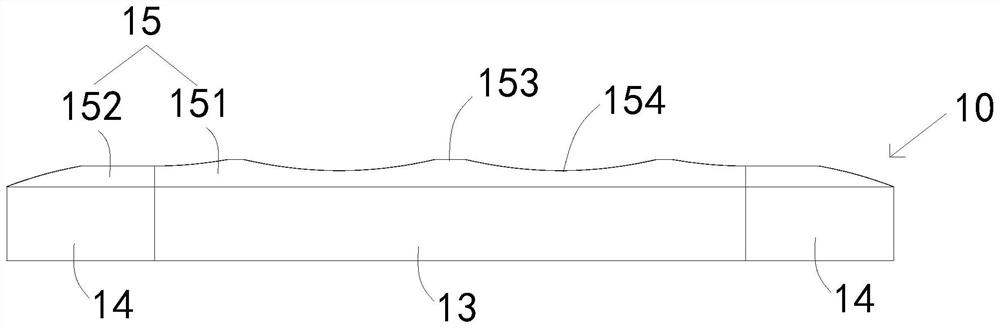

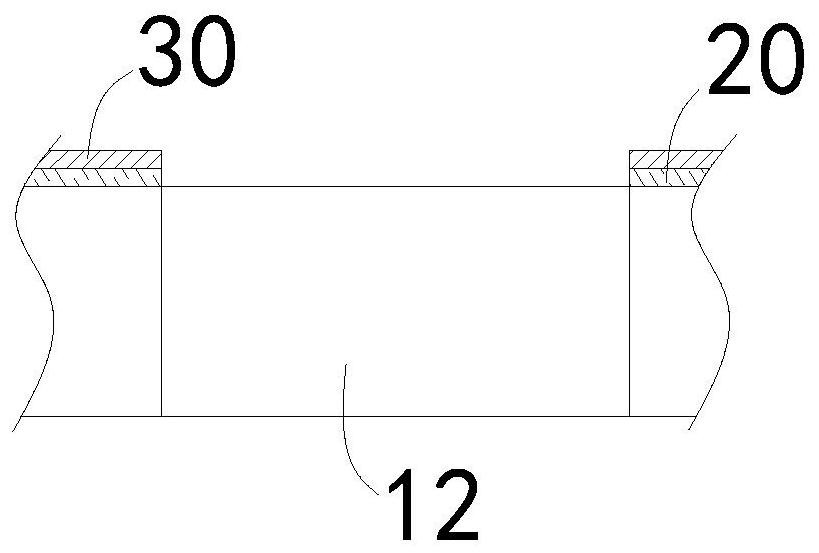

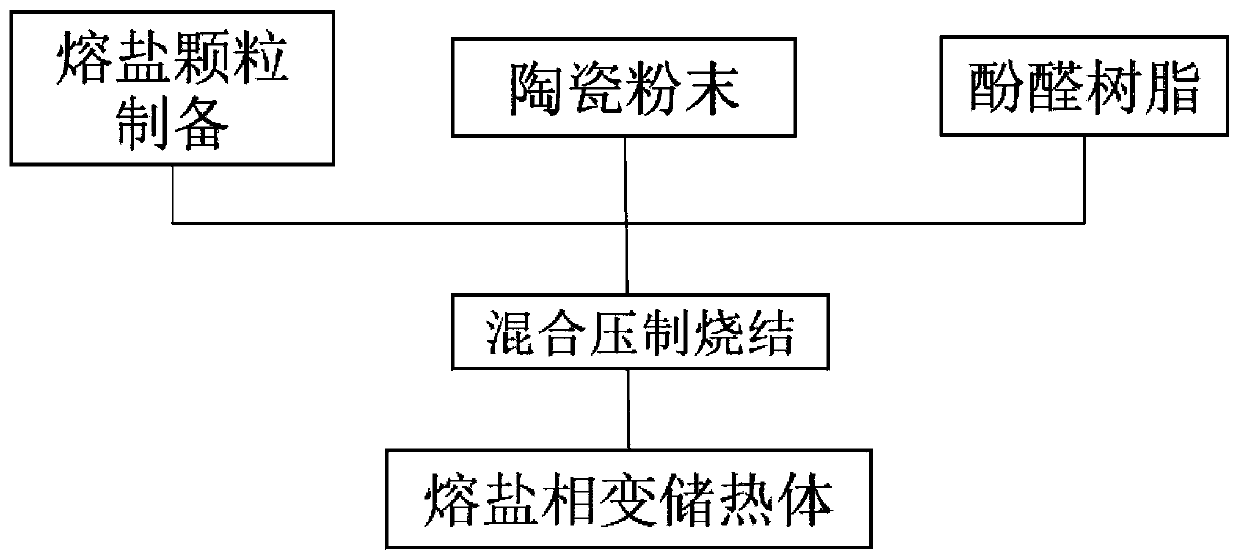

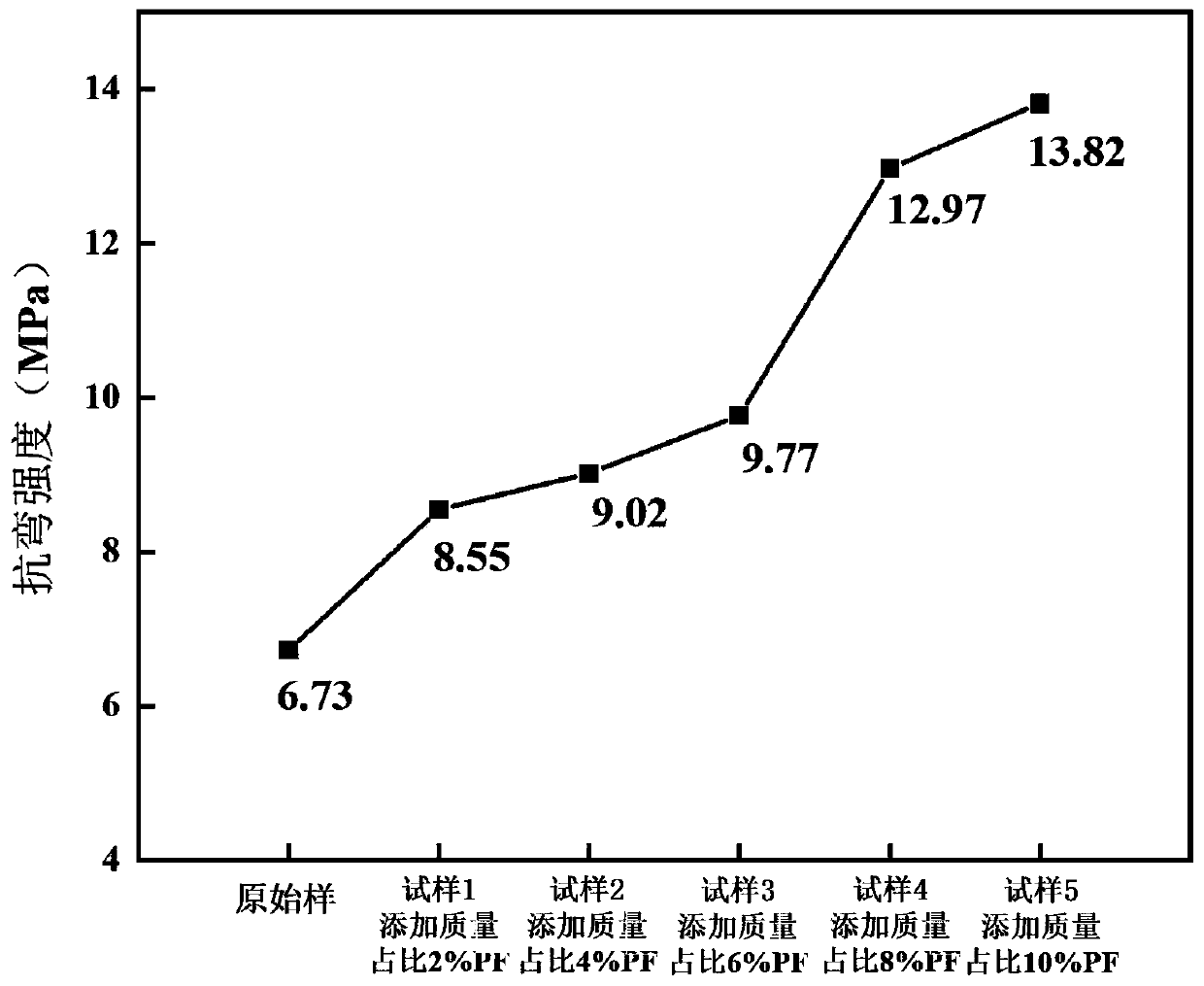

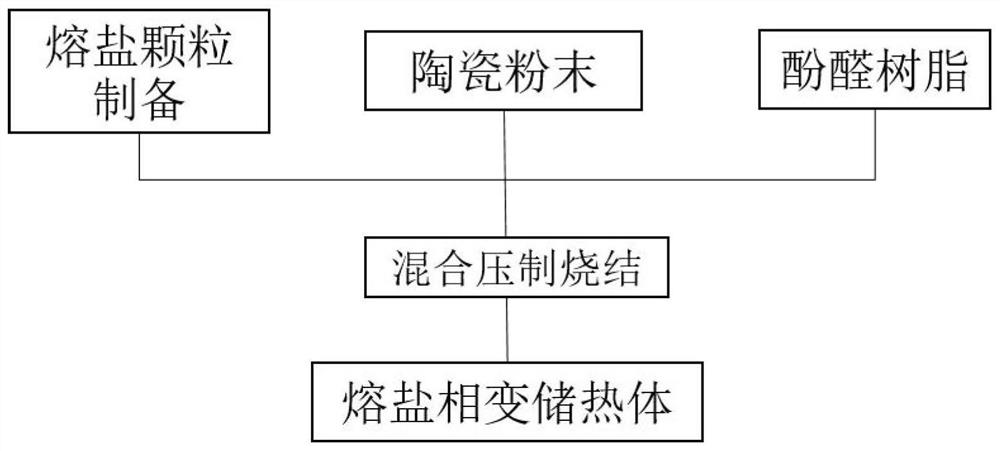

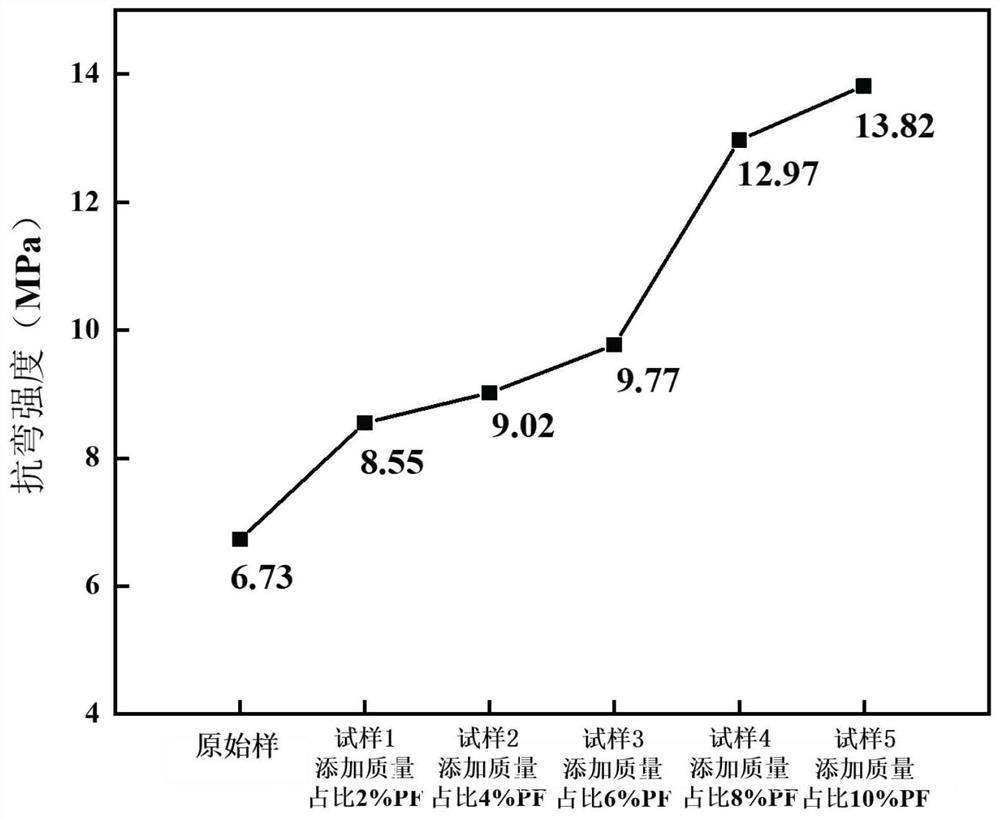

Method for improving strength of fused salt phase-change heat storage material by utilizing phenolic resin

ActiveCN111454693AImprove mechanical propertiesImprove heat storage performanceHeat-exchange elementsHeat storage materialPhenol formaldehyde resin

The invention discloses a method for improving the strength of a fused salt phase-change heat storage material by utilizing phenolic resin, and belongs to the field of phase change heat storage materials. Based on a preparation method of the stable molten salt phase-change material, a ceramic material is used as a matrix, phenolic resin is used as a binder, a stable structure is provided through the ceramic matrix, the phenolic resin provides formability, and the molten salt phase-change heat storage body with excellent mechanical properties can be prepared by adding a carbon structure generated after the high-temperature part of the phenolic resin is cracked. The preparation method disclosed by the invention is simple, low in cost and capable of realizing large-scale production, solves the common problem of insufficient mechanical properties of the fused salt phase-change heat storage body at present, and has important significance for expanding the application range of the fused saltphase-change heat storage material.

Owner:UNIV OF SCI & TECH BEIJING

One component thermosetting epoxy resin compositions

InactiveUS20210163665A1Solve the lack of mechanical propertiesSufficient mechanical propertyEpoxy resin adhesivesEpoxyThermal dilatation

A one-component thermosetting epoxy resin includes compositions that are particularly suitable for the bonding of substrates having different coefficients of thermal expansion, especially in the shell construction of modes of transport or white goods. The one-component thermosetting epoxy resin composition includes a) at least one epoxy resin A having an average of more than one epoxy group per molecule; b) at least one 2,4-diamino-1,3,5-triazine GU containing, in the 6 position, —an alkyl radical having 1 to 20 carbon atoms, in which one hydrogen atom in the α position has been replaced by a 2,4-diamino-1,3,5-triazin-6-yl radical, a cycloalkyl radical having 5 to 12 carbon atoms or -an aryl radical having 6 to 12 carbon atoms; and c) at least one toughness improver D, which is a terminally blocked polyurethane polymer D1.

Owner:SIKA TECH AG

Macromolecular material based on modified montmorillonite clay and preparation method thereof

The invention discloses a macromolecular material based on modified montmorillonite clay and a preparation method thereof. The preparation method comprises the following steps of mixing montmorillonite clay, a silane coupling agent and absolute ethyl alcohol, and filtering to obtain the modified montmorillonite clay; mixing the modified montmorillonite clay, methacrylic acid, polyvinyl chloride, dimethylbenzene, polylactic acid and ethylene glycol to obtain a mixed solution M, and subjecting the mixed solution to thermoforming to obtain a copolymer plate; adding the copolymer plate into a liquid resin matrix, so as to obtain a mixed solution N, and subjecting the mixed solution N to the thermoforming to obtain the macromolecular material based on the modified montmorillonite clay. The problems that the montmorillonite clay is poorer in dispersity in resin, is autologously easily agglomerated and is poorer in the compatibility with the resin when being used as an additive for a composite material and the made composite material is insufficient in mechanical performance are solved.

Owner:芜湖市三山区绿色食品产业协会

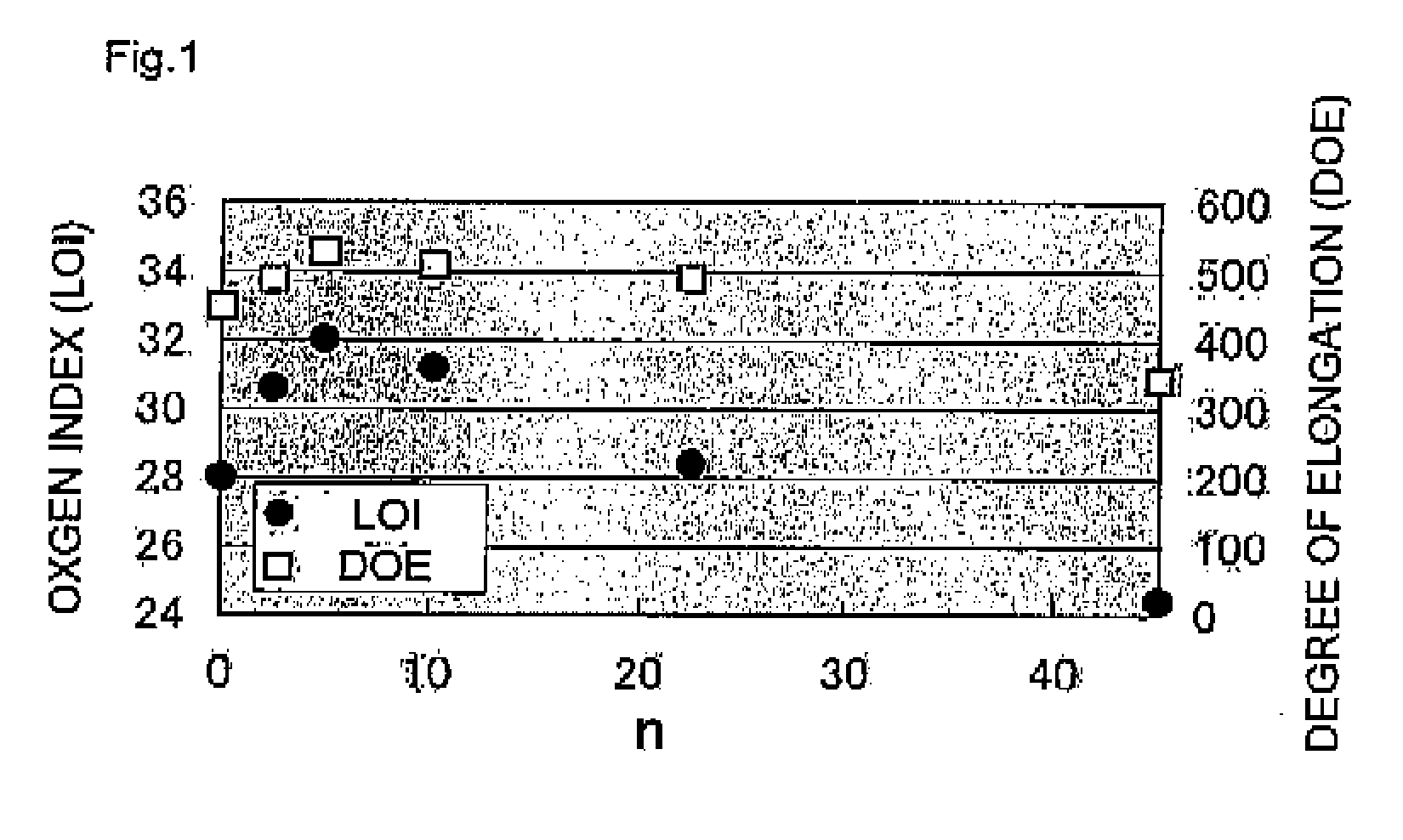

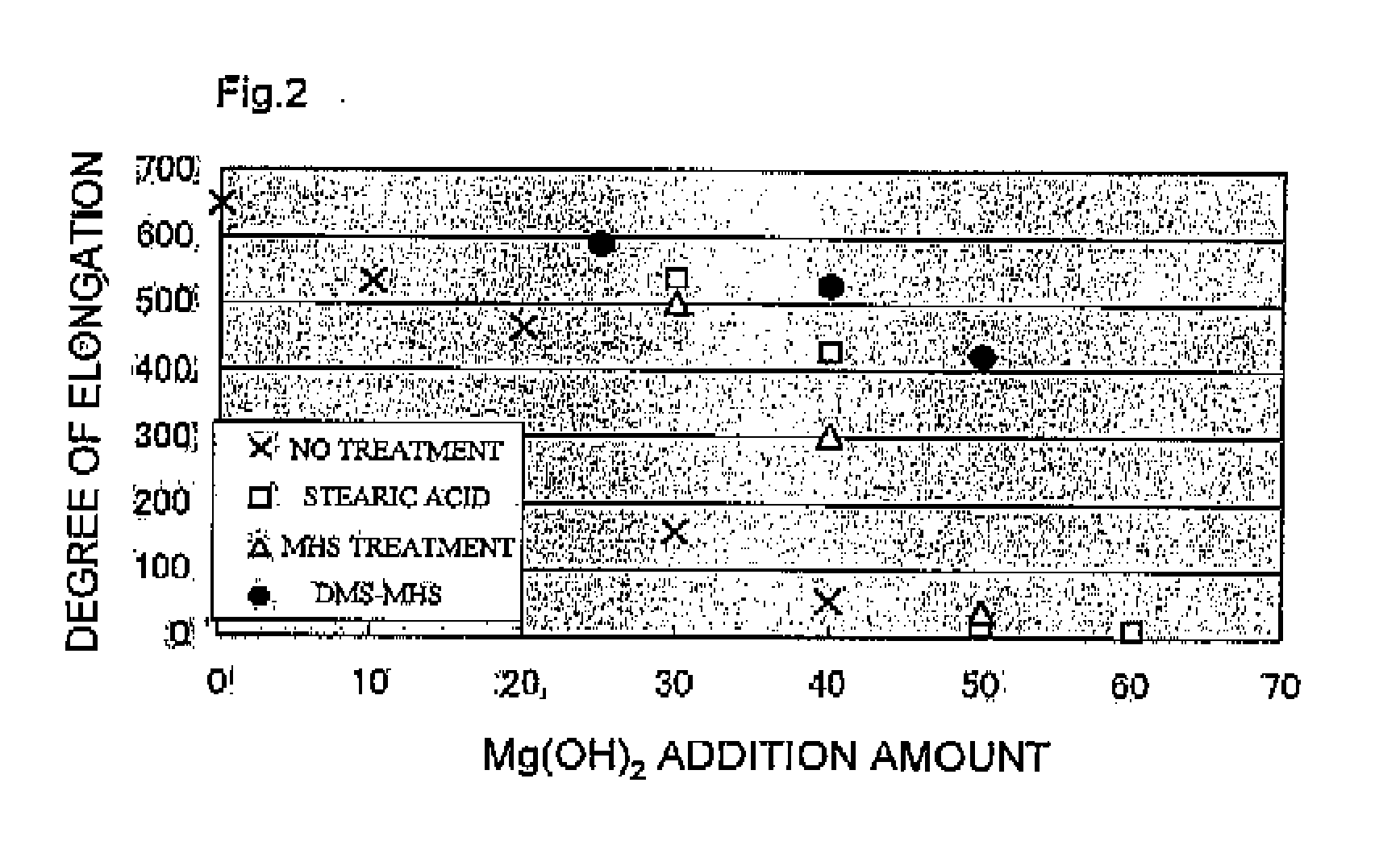

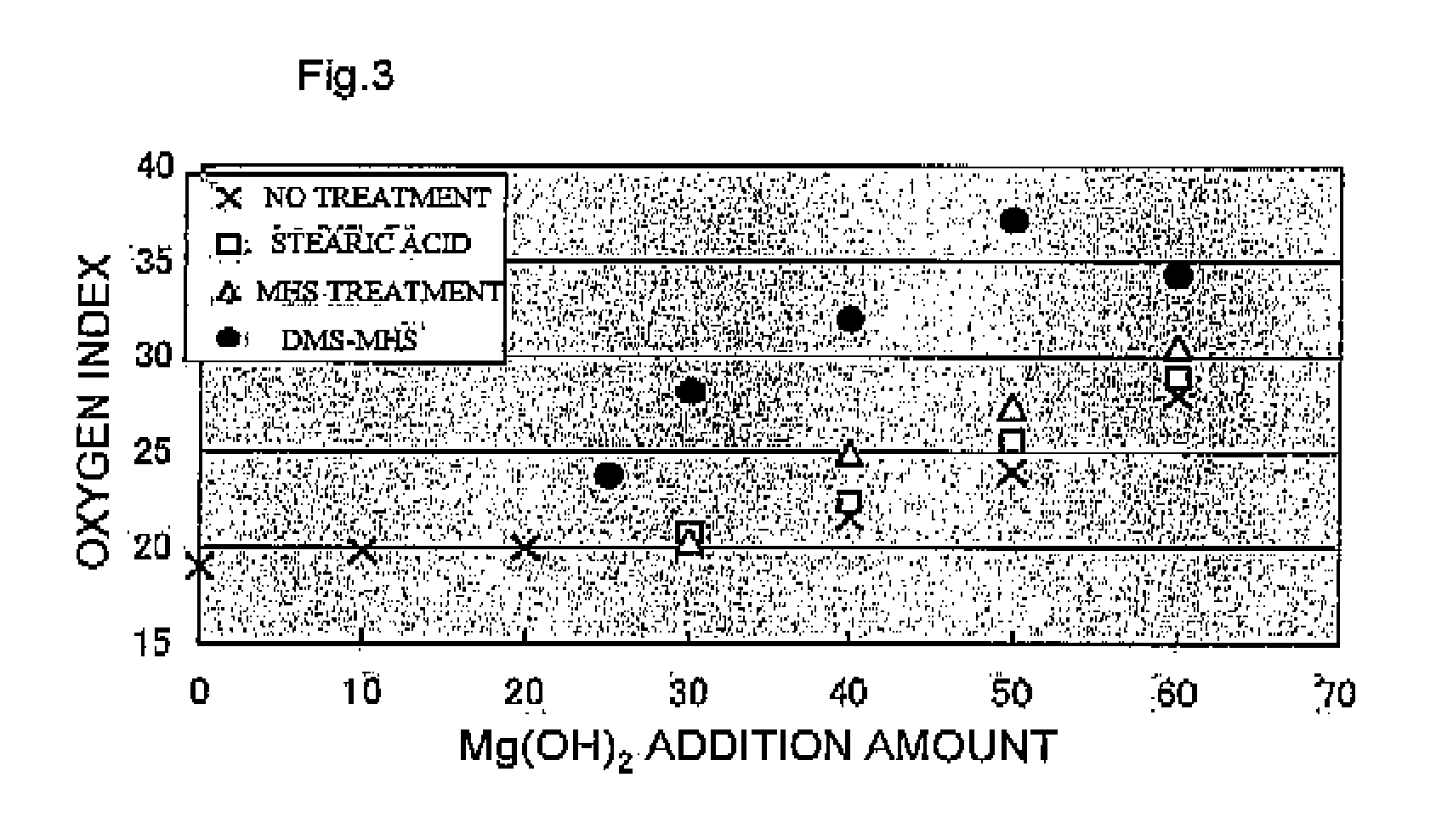

Silicone surface-treated magnesium hydroxide

InactiveUS20110266506A1Sufficient retardancyMaintain sufficiencyPigmenting treatmentHydrogen atomSilicone oil

Silicone surface-treated magnesium hydroxide which is surface treated by a silicone oil, the silicone oil comprising: a polyorganosiloxane containing a plurality of first siloxane units each of which contains hydrogen atom bonded silicon atom. The first siloxane units shares 50 mol % or less of total siloxane units in one molecule in average. Accordingly, sufficient fire retardancy and mechanical properties such as sufficient elongation are achieved.

Owner:YAZAKI CORP +2

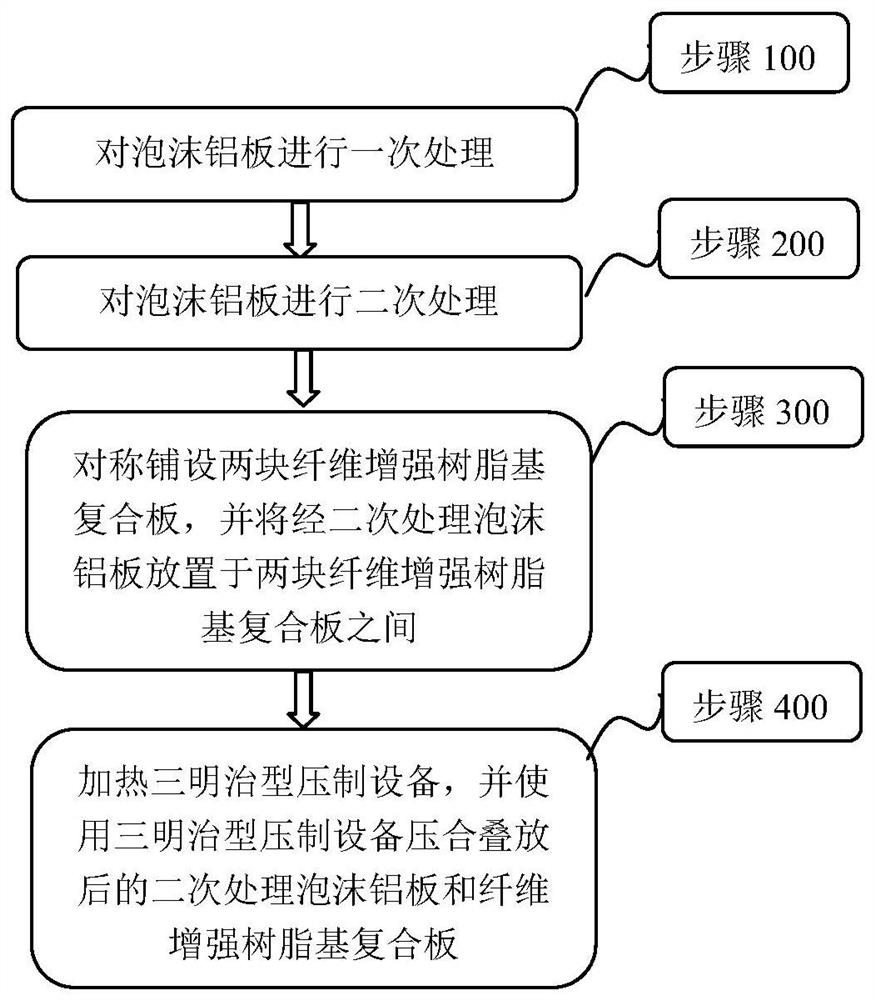

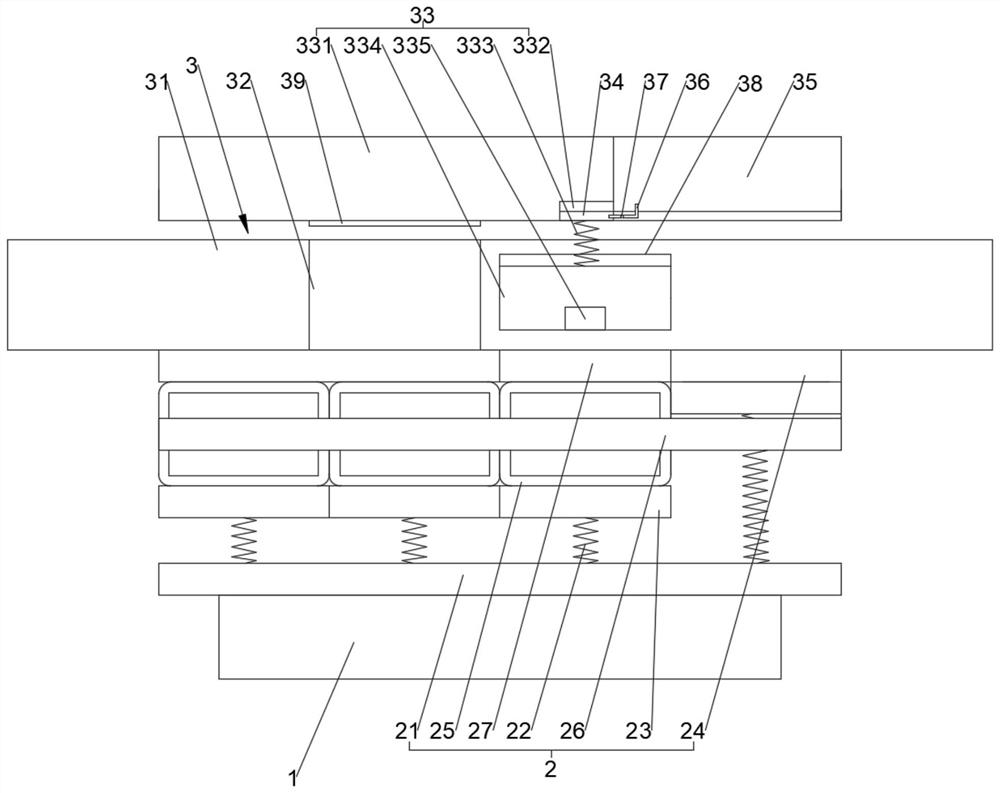

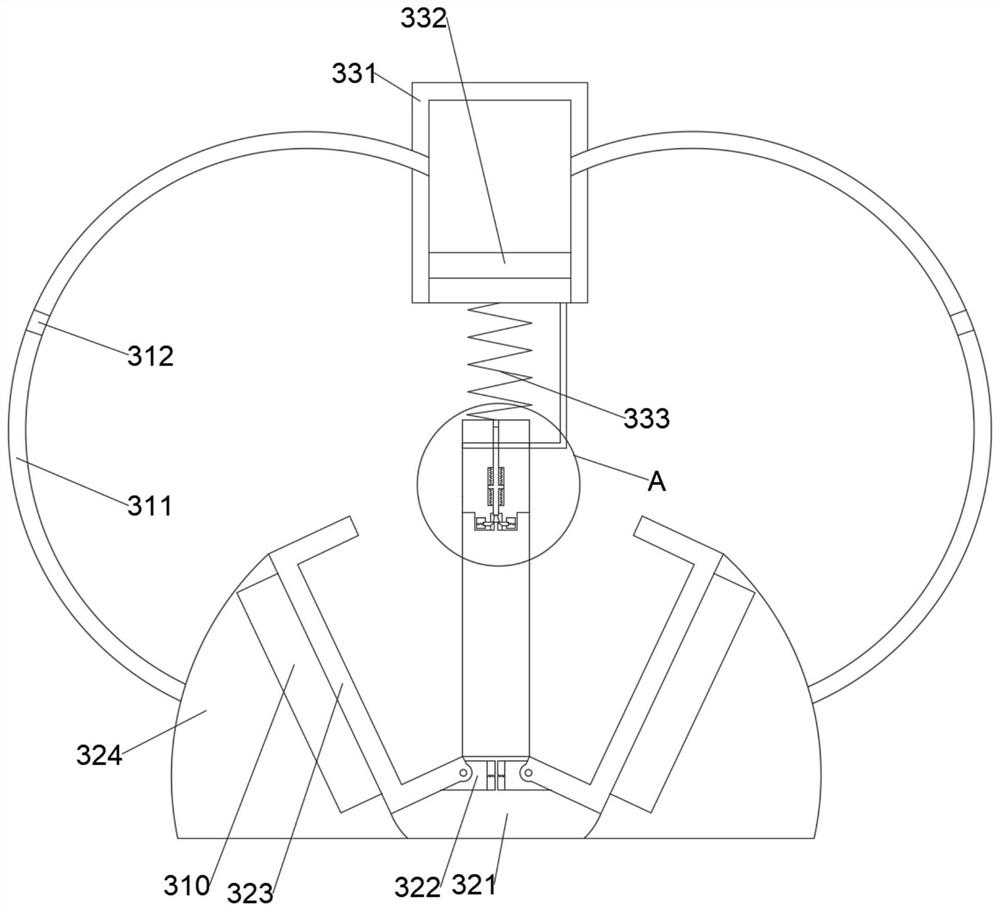

Integral forming process of foamed aluminum and fiber reinforced resin-based composite sandwich panel

ActiveCN113211928AImprove the coupling effectSolve the lack of mechanical propertiesLamination ancillary operationsLaminationComposite plateSandwich panel

The invention discloses an integral forming process of a foamed aluminum and fiber reinforced resin-based composite sandwich panel, which comprises the following steps: step 100, carrying out chemical coating treatment on the surface of a foamed aluminum plate to obtain a primarily treated foamed aluminum plate; 200, performing pore filling treatment on the surface of the foamed aluminum plate subjected to primary treatment by using a dielectric material to obtain a foamed aluminum plate subjected to secondary treatment; 300, laying two fiber-reinforced resin-based composite boards symmetrically on the two sides of a mold, and placing the foamed aluminum board subjected to secondary treatment between the two fiber-reinforced resin-based composite boards; and 400, heating the sandwich type pressing equipment to the preset temperature, and enabling a combined structure formed by the two fiber-reinforced resin-based composite boards and the foamed aluminum board subjected to secondary treatment to be pressed and formed under the preset pressure through the sandwich type pressing equipment. According to the invention, the coupling property between the foamed aluminum sandwich layer and the composite material laminated plate is improved.

Owner:中机精密成形产业技术研究院(安徽)股份有限公司

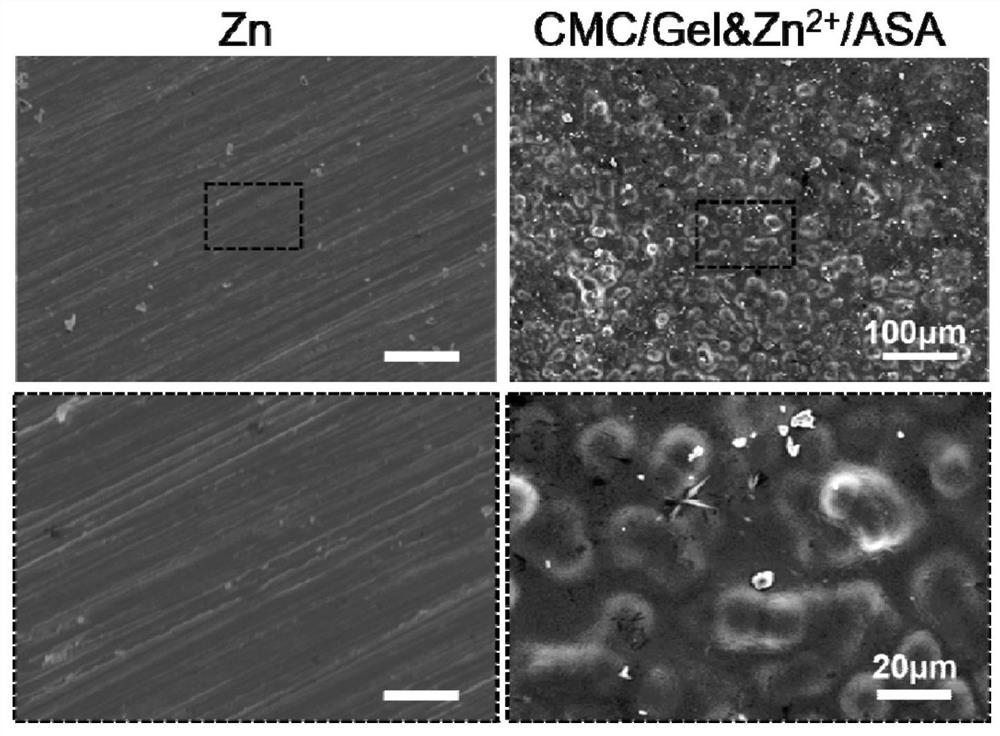

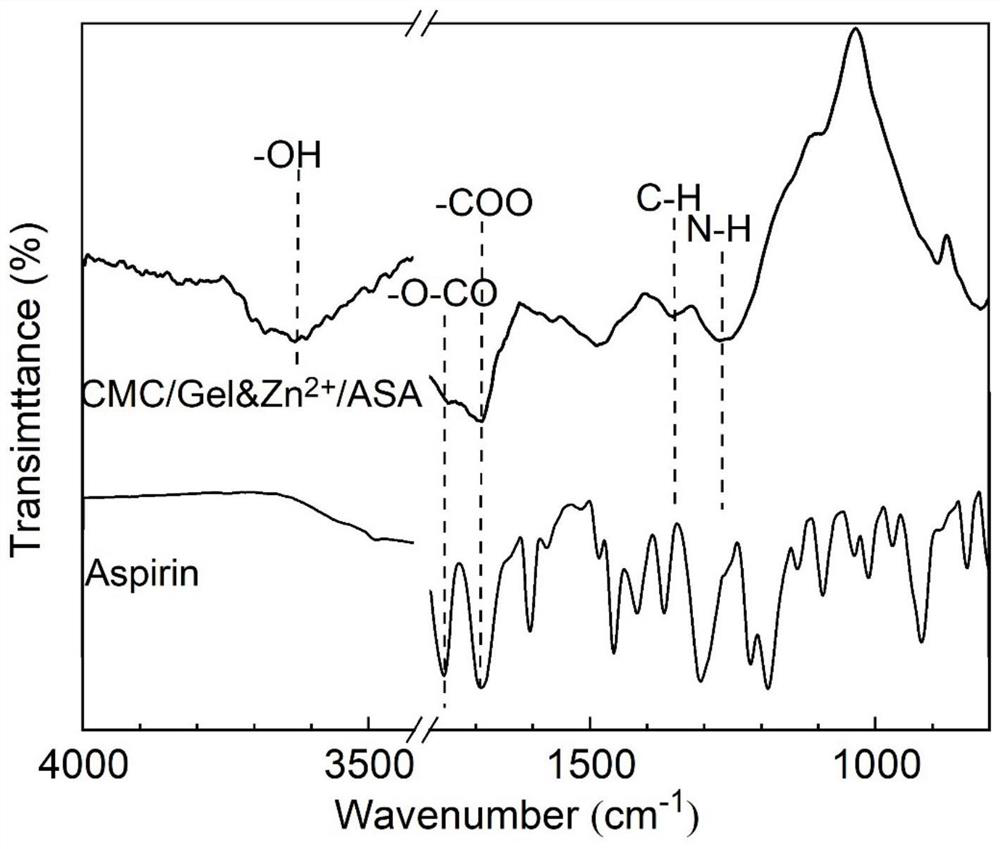

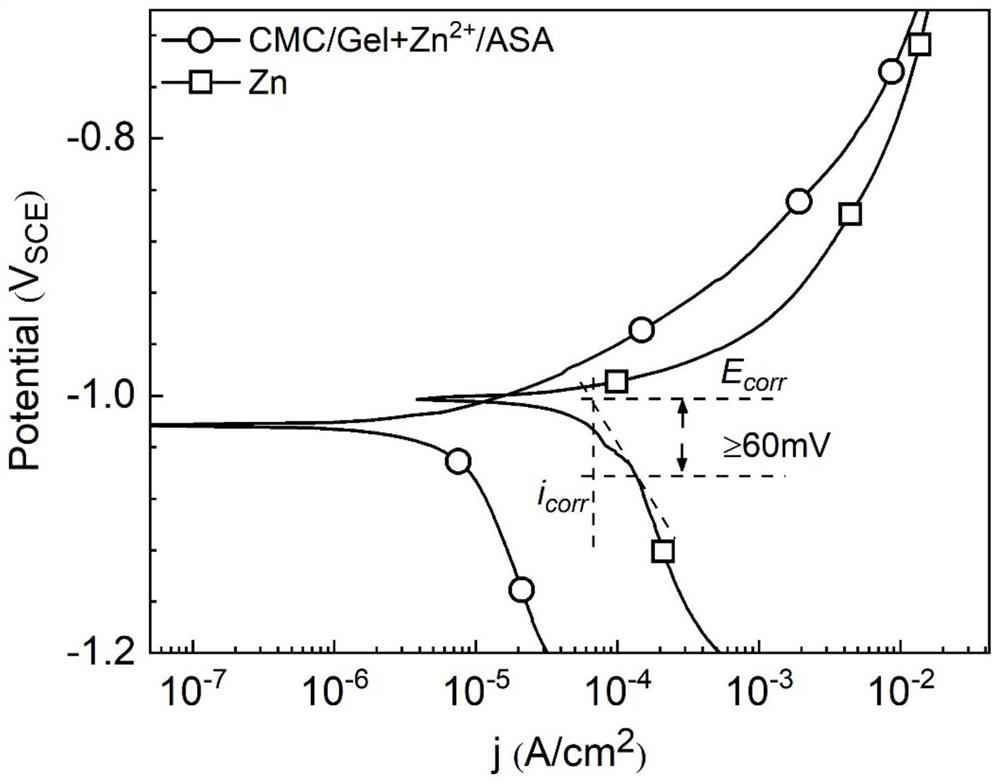

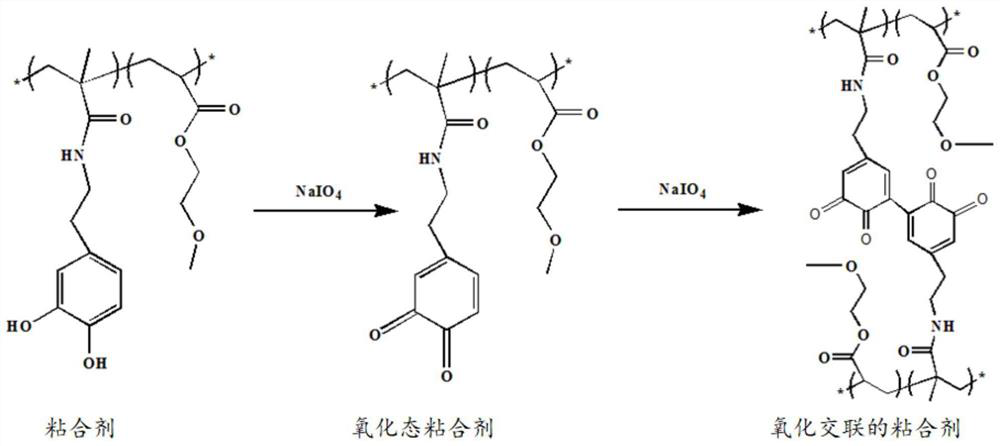

Method for constructing ionic gel drug-loaded coating on surface of biodegradable metal

The invention discloses a method for constructing an ionic gel drug-loaded coating on the surface of biodegradable metal, and belongs to the technical field of surface modification of biodegradable metal materials, the method comprises the following steps: step (1): carrying out phosphorylation treatment on the surface of a pretreated zinc substrate; and (2) alternately depositing the zinc substrate obtained in the step (1) in the carboxymethyl chitosan / gelatin mixed solution and the zinc ion / carrier drug mixed solution. According to the invention, a gelatin / carboxymethyl chitosan coating is formed on the surface of zinc metal by utilizing covalent binding between gelatin and carboxymethyl chitosan; zinc ions are added as a chelating agent / ionic cross-linking agent, and aspirin and other drugs are added as carrier drugs; and after alternate deposition, a layer of ionic gel coating loaded with a medicine is constructed on the surface of the zinc metal. According to the surface modification method for the biodegradable zinc metal, the aims of controlling corrosion and degradation of the zinc-based metal and improving the biological functionality are both achieved.

Owner:SOUTHWEST JIAOTONG UNIV

Mussel bionic adhesive-calcium phosphate high-strength bone repair material, high-strength composite cap scaffold and preparation method thereof

ActiveCN110180021BSolve the lack of mechanical propertiesEasy to preparePharmaceutical delivery mechanismTissue regenerationRestorative materialCalcium pidolate

Owner:SOUTHWEST JIAOTONG UNIV

A method of improving the strength of molten salt phase change heat storage material by using phenolic resin

ActiveCN111454693BImprove mechanical propertiesWell mixedHeat-exchange elementsMolten saltHeat storage material

The invention discloses a method for improving the strength of a molten salt phase-change heat storage material by using a phenolic resin, and belongs to the field of phase-change heat storage materials. The present invention is based on a preparation method of a stable molten salt phase change material, using ceramic materials as a matrix and phenolic resin as a binder to provide a stable structure through the ceramic matrix, and formability provided by the phenolic resin, plus the carbon structure produced by the high-temperature partial cracking of the phenolic resin Furthermore, a molten salt phase change heat storage body with excellent mechanical properties can be obtained. The preparation method of the invention is simple, low in cost and can be produced on a large scale, solves the currently common problem of insufficient mechanical properties of molten salt phase-change heat storage materials, and has great significance for expanding the application range of molten salt phase-change heat storage materials.

Owner:UNIV OF SCI & TECH BEIJING

3D printing method for magnesium alloy-polymer composite biodegradable biological scaffold

InactiveCN108478881AControl degradation timeImprove mechanical propertiesAdditive manufacturing apparatusTissue regenerationFiberPolymer science

Owner:XI AN JIAOTONG UNIV

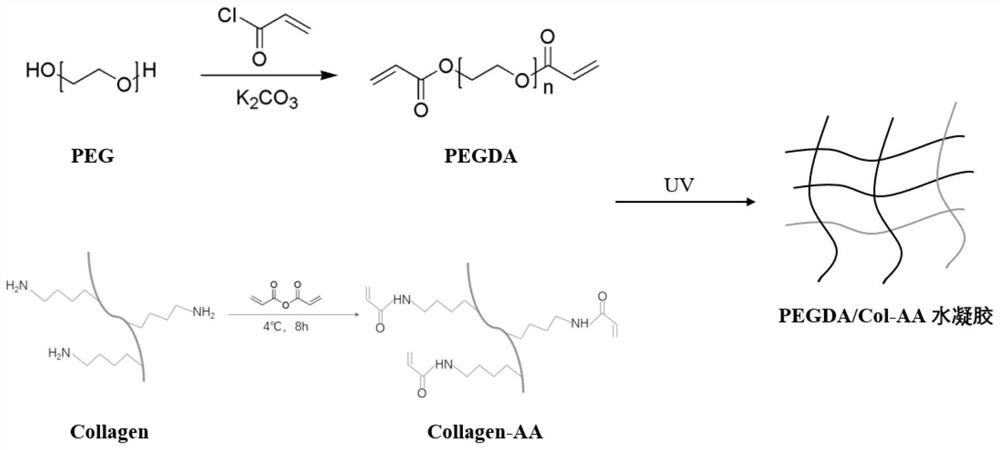

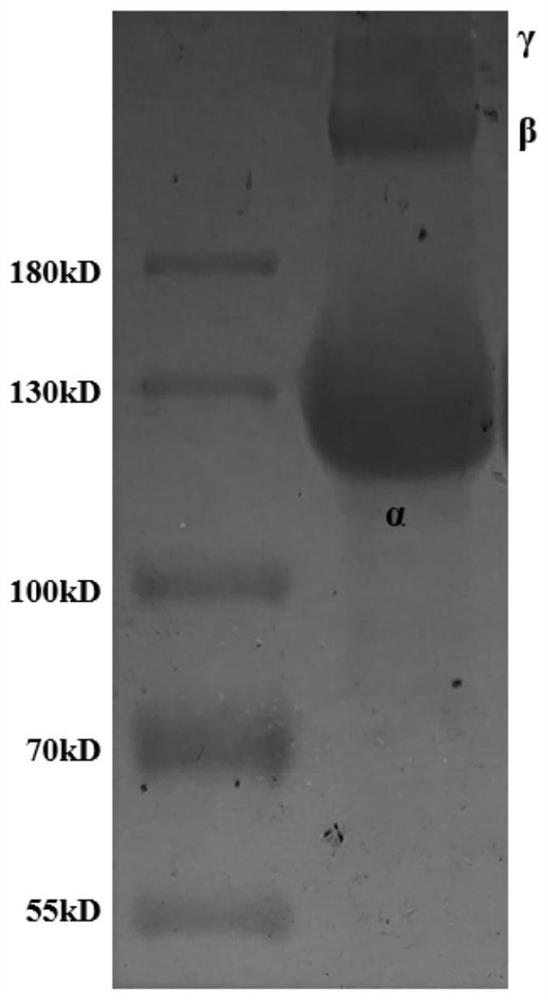

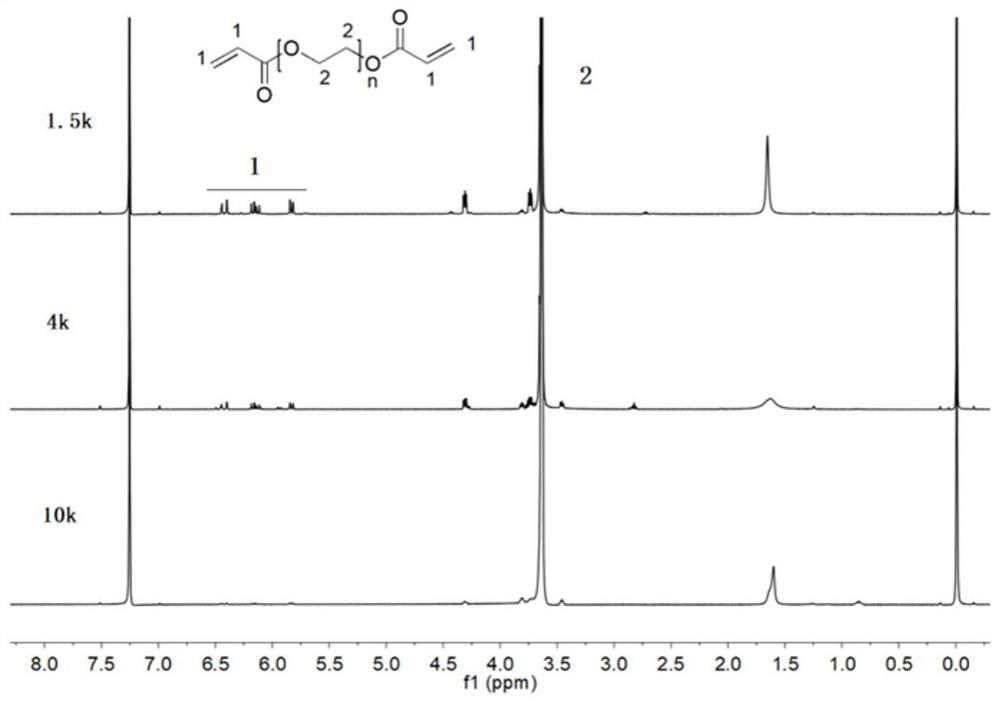

A kind of hydrogel material and its preparation method and application

ActiveCN112126027BImprove mechanical propertiesImprove biological activityTissue regenerationProsthesisPolymer sciencePolyethylene glycol

The invention discloses a hydrogel material and its preparation method and application. The preparation raw materials of the hydrogel material include acrylic anhydride modified collagen, polyethylene glycol diacrylate, photoinitiator and solvent. Among them, the combination of acrylic anhydride-modified collagen and polyethylene glycol diacrylate can achieve complementary performance; specifically, by adding acrylic anhydride-modified collagen to polyethylene glycol diacrylate, the hydrogel material can be endowed with Biological activity, and the existence of polyethylene glycol diacrylate can solve the defect of insufficient mechanical properties of collagen when used alone; and by using acrylic anhydride to modify collagen, it can solve the problem that collagen cross-linking relies more on toxic or expensive chemical cross-linking agents Disadvantages: The modified collagen can be cross-linked and cured by ultraviolet light, the molding process is simple, the three-dimensional structure is not limited, and the application range is wide. Through the above methods, the hydrogel material of the present invention has excellent mechanical properties and biological activity.

Owner:SUN YAT SEN UNIV

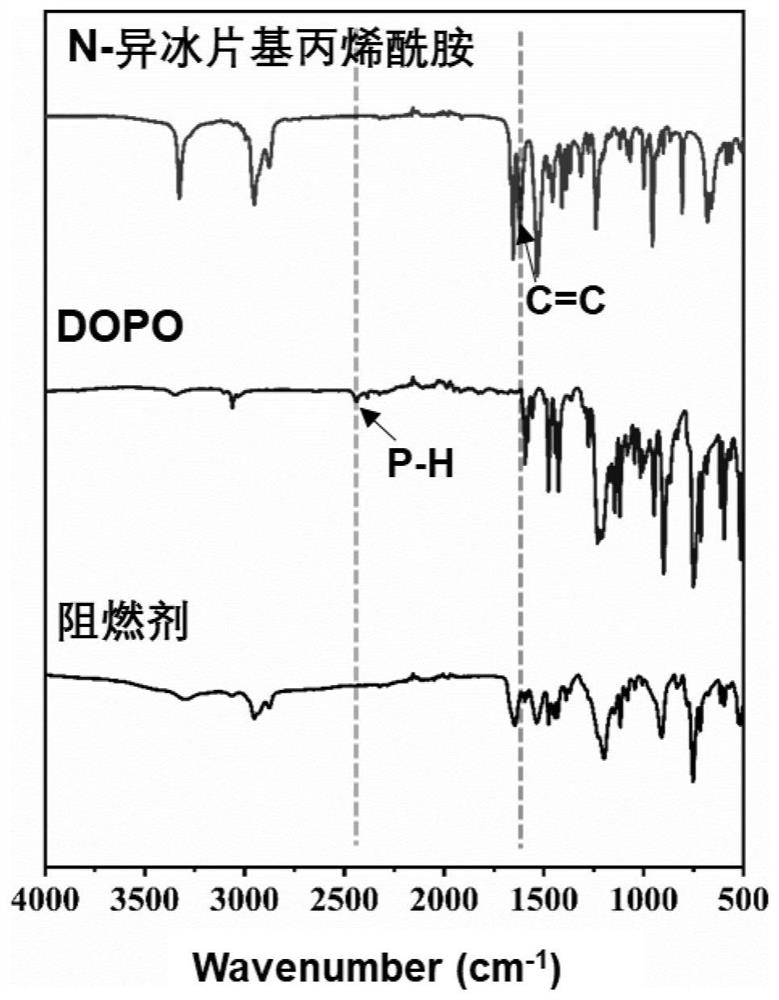

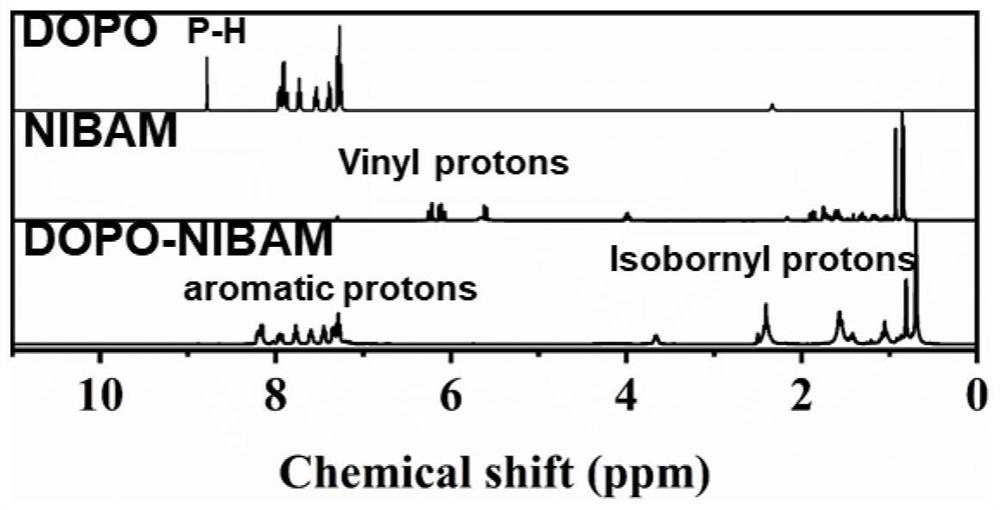

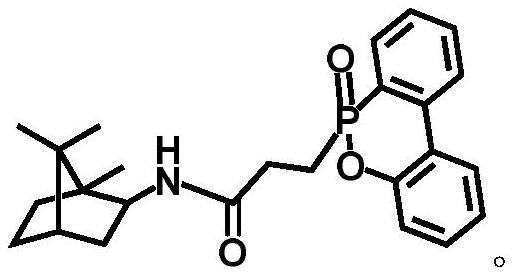

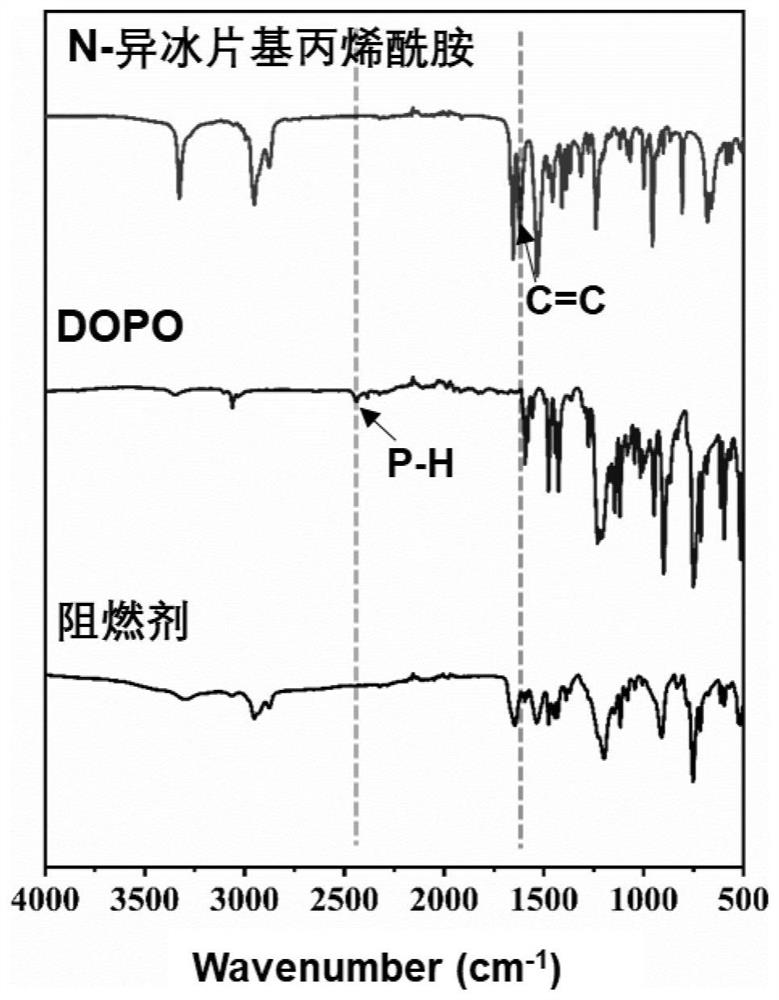

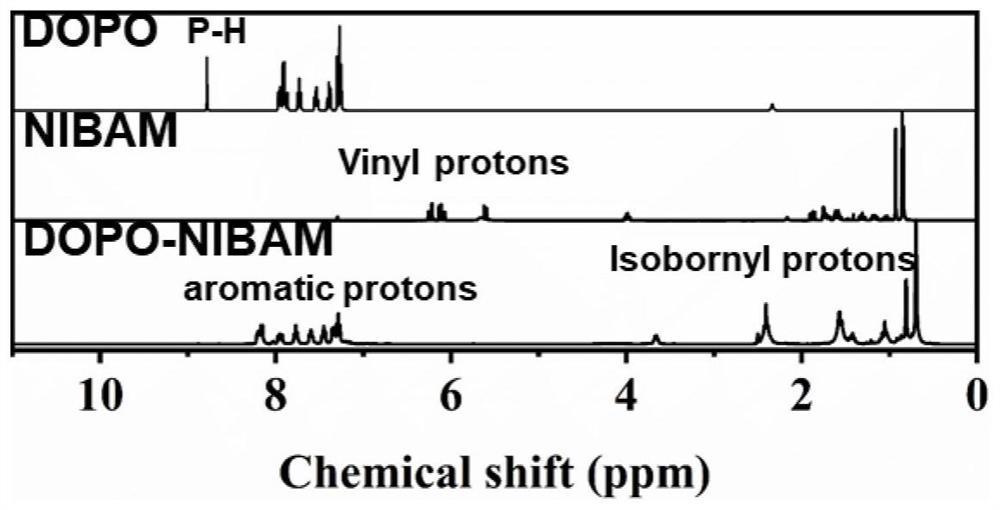

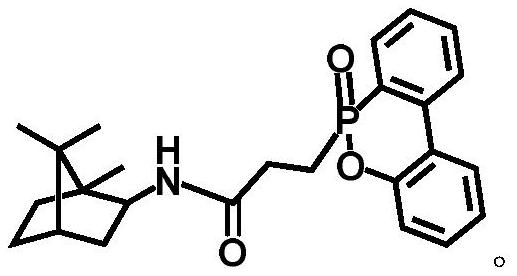

A kind of isobornyl acrylamide containing phosphorus phenanthrene oxide, its preparation method and application

ActiveCN113372391BImprove flame retardant performanceSolve the lack of mechanical propertiesGroup 5/15 element organic compoundsPolyolPhosphate

The invention discloses an isobornyl acrylamide phosphorus-containing phenanthrene oxide, its preparation method and its application. The structural formula of the isobornyl acrylamide phosphorus-containing phenanthrene oxide is as follows: The present invention isobornyl acrylamide phosphorus-containing Phenanthrene oxide has excellent flame retardancy enhancement performance, and isobornyl acrylamide containing Phosphophenanthrene oxide, and then blended with polyols, isobornyl acrylamide-containing phosphophenanthrene oxides can be dissolved in polyols, and then reacted with polyols and isocyanates to obtain flame retardant and excellent mechanical properties Rigid polyurethane foam.

Owner:NANJING FORESTRY UNIV

Phosphaphenanthrene-containing isobornyl acrylamide oxide, and preparation method and application thereof

ActiveCN113372391AImprove flame retardant performanceSolve the lack of mechanical propertiesGroup 5/15 element organic compoundsPolymer sciencePolyol

The invention discloses aphosphaphenanthrene-containing isobornyl acrylamide oxide, and a preparation method and application thereof. The structural formula of thephosphaphenanthrene-containing isobornyl acrylamide oxide is shown in the specification, the phosphaphenanthrene-containing isobornyl acrylamide oxide has excellent flame-retardant enhancement performance. N-isobornyl acrylamide reacts with 9, 10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide to obtain the phosphaphenanthrene-containing isobornyl acrylamide oxide, then the phosphaphenanthrene-containing isobornyl acrylamide oxide is blended with polyhydric alcohol, and is dissolved in the polyhydric alcohol, and then the polyhydric alcohol reacts with isocyanate to prepare rigid polyurethane foam with good flame retardant property and excellent mechanical property.

Owner:NANJING FORESTRY UNIV

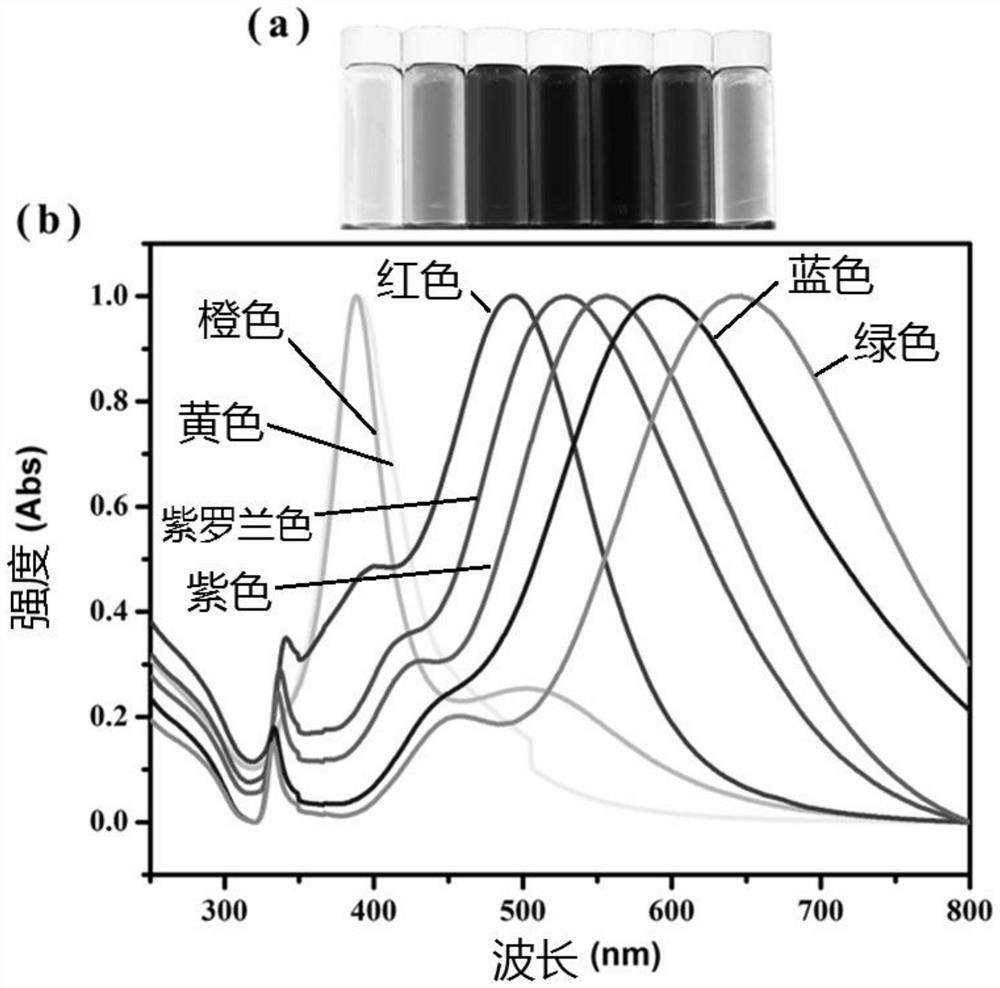

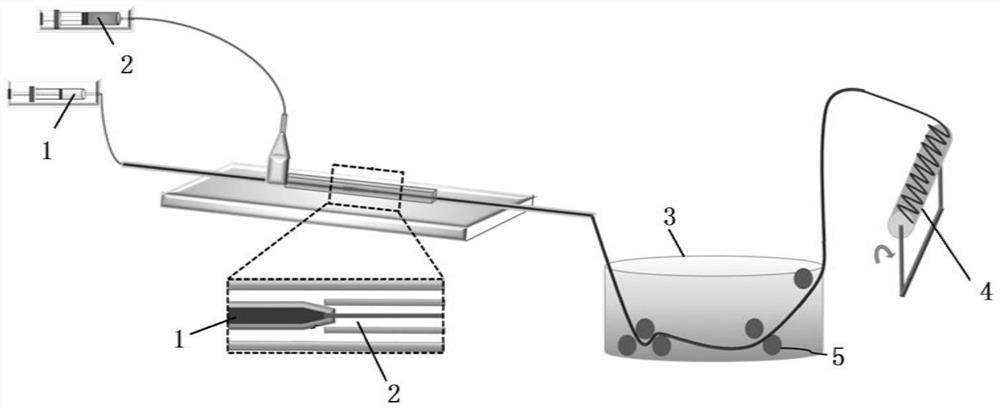

Modification method of physical color fiber based on flake silver nanoparticles

ActiveCN111719195BNo pollution in the processThe experimental method is simpleTransportation and packagingArtificial filament washing/dryingFiberSpinning

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

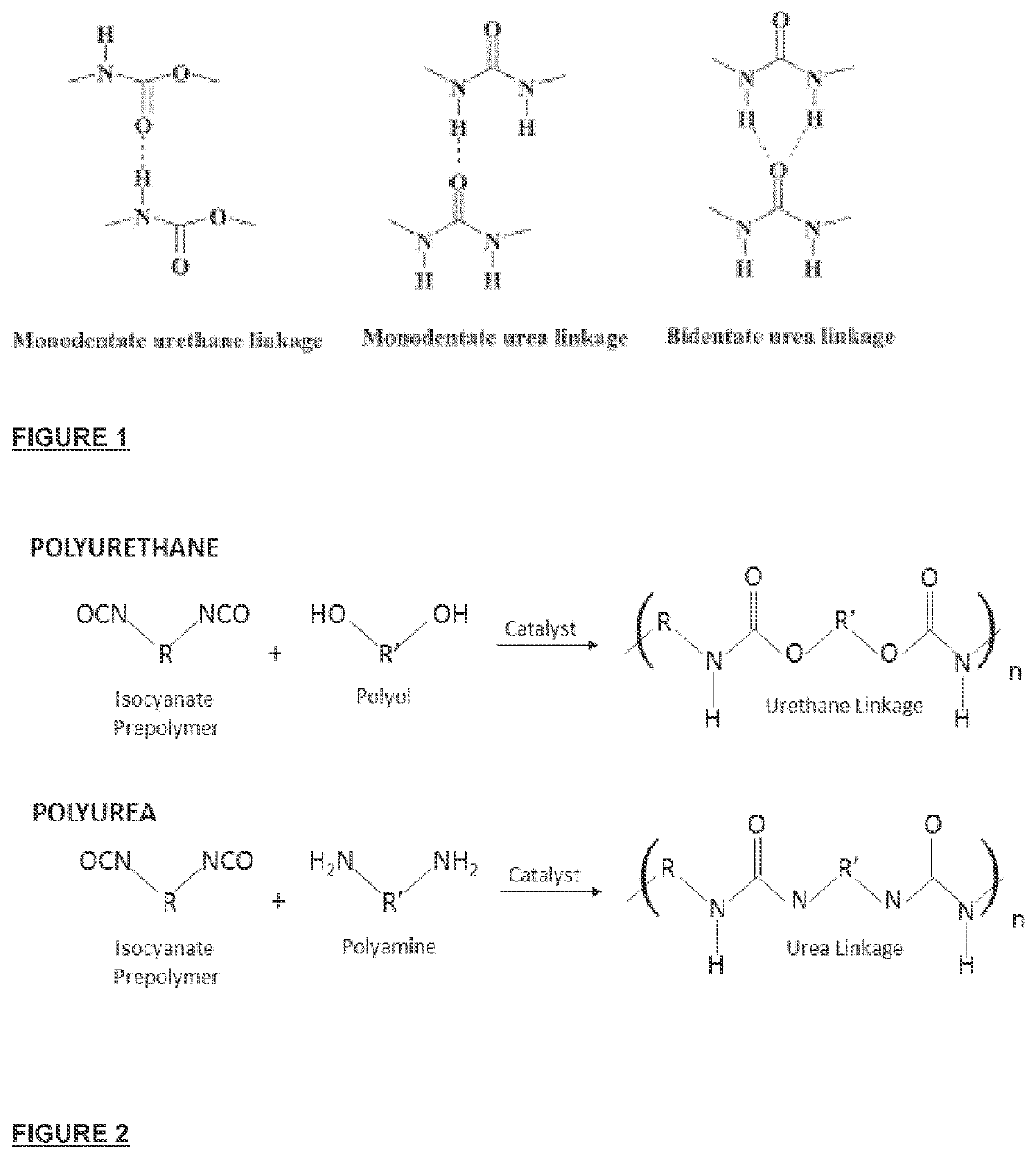

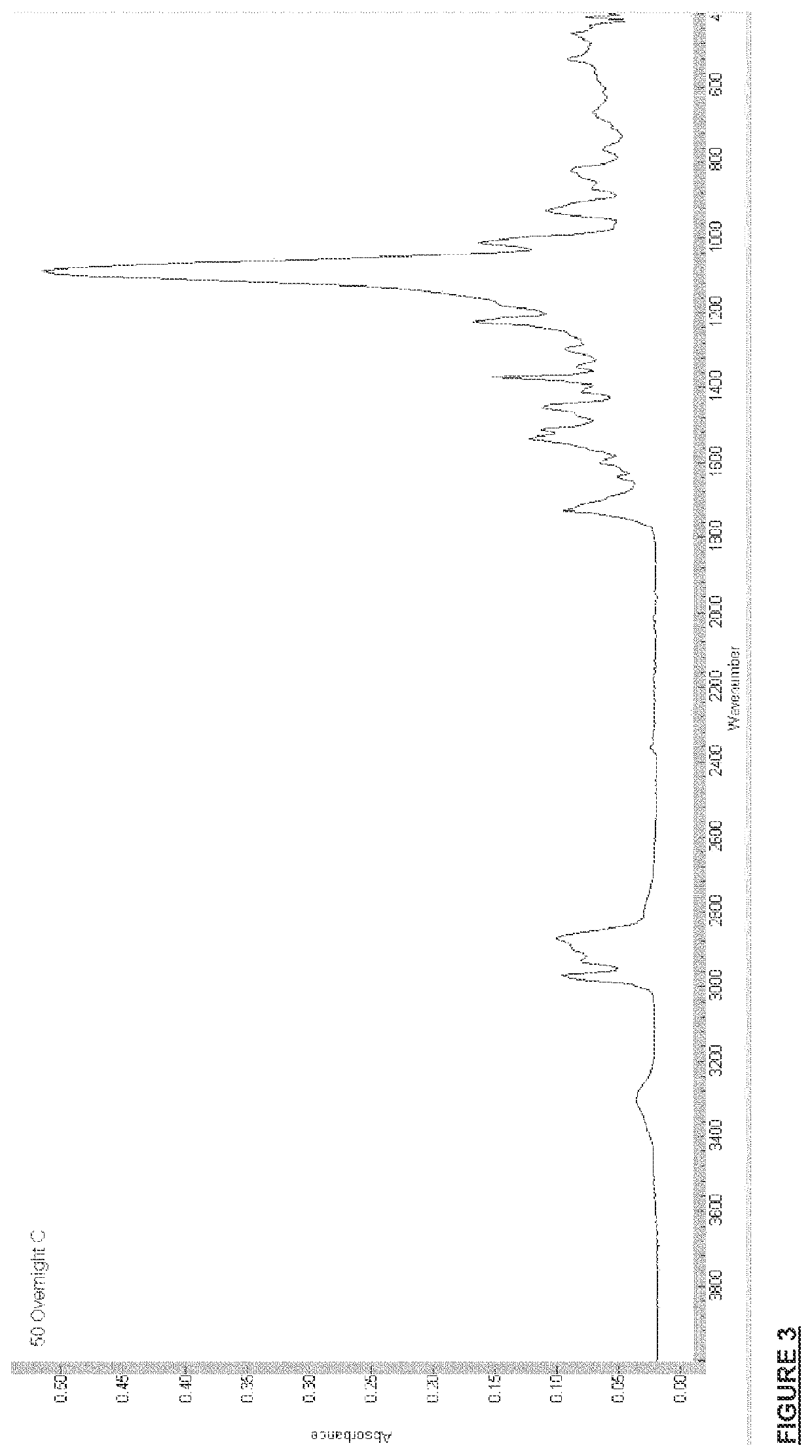

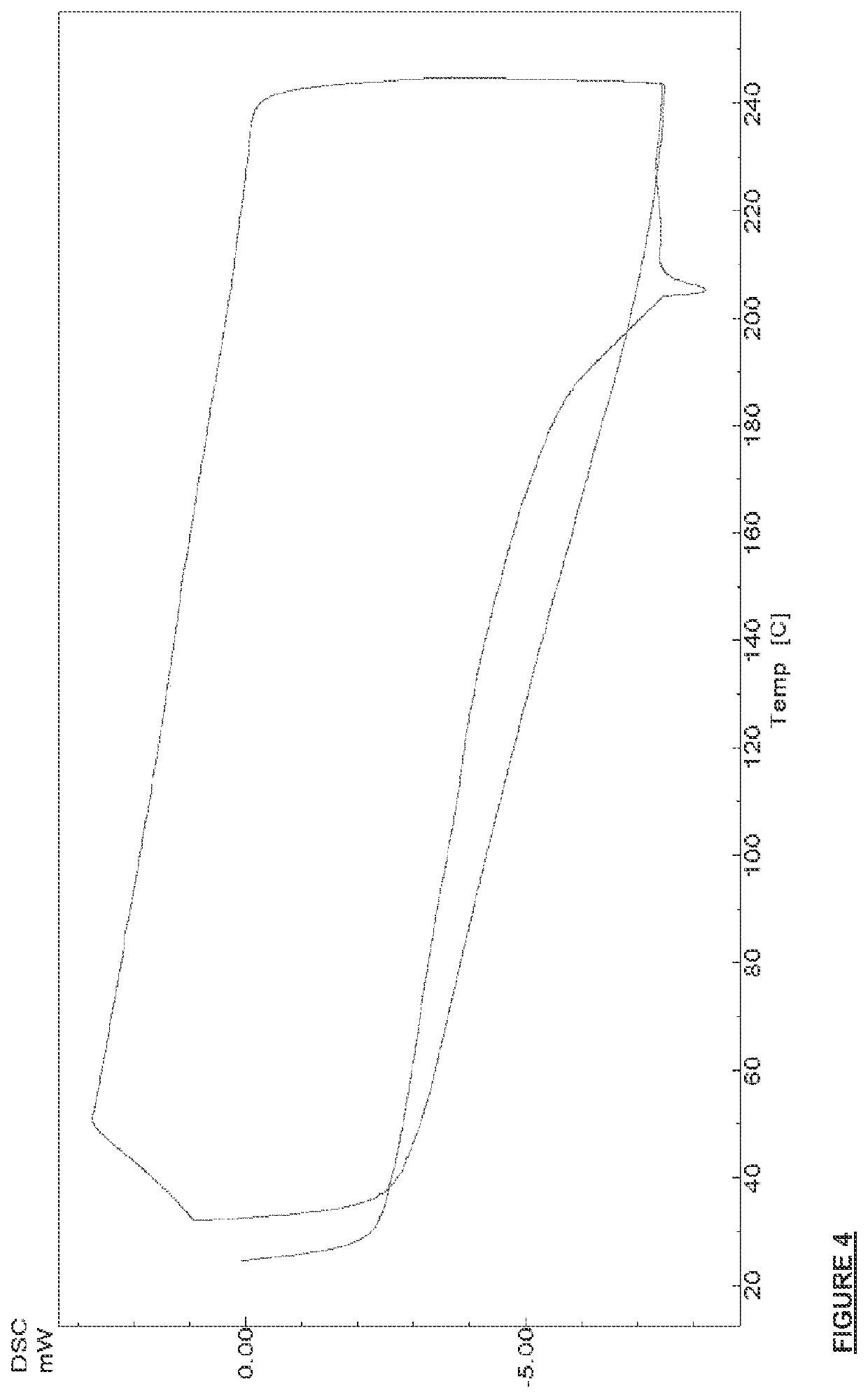

Implantable biomaterial, and method of manufacturing thereof

A method of forming an implantable biomaterial comprising the steps of providing a polyether-diisocyanate prepolymer, reacting the prepolymer with one or more chain extender molecules typically including benzene 1,4-diol to form a mouldable polymer selected from a polyurethane or polyurethane-urea polymer or a polyurethane-urea block copolymer; placing the mouldable polymer into an implantable biomaterial shaped mould, and shaping and curing the mouldable polymer in the implantable biomaterial shaped mould to form the implantable biomaterial. An implantable biomaterial such as a heart valve leaflet is also disclosed.

Owner:THE NAT UNIV OF IRELAND GALWAY

A coCRNICUFEMNAL high entropy alloy and its preparation method

The invention belongs to the field of metal alloy materials, and relates to a CoCrNiCuFeMnAl high-entropy alloy, which comprises cobalt powder 5.2-38.03wt.%, chromium powder 4.5-34.53wt.%, nickel powder 5.17-37.92wt.%, copper powder 5.68-40.25 wt.%, iron powder 0.2-20.61wt.%, manganese powder 0.5-33.45wt.% and aluminum powder 0.3-20.03wt.%. The preparation method is to mechanically alloy the above metal elemental powder in a ball mill, and then The obtained high-entropy alloy powder is pre-pressed and annealed, and then hot-pressed and sintered, and the sintered body is annealed, and finally the surface of the annealed sintered body is ground and polished to remove external impurities remaining in the sample sintering And the burrs generated on the edge during the sintering process, so as to prepare the CoCrNiCuFeMnAl high-entropy alloy bulk material. Compared with traditional alloys, the high-entropy alloy of the invention has better compactness, hardness and compressive strength.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com