A method of improving the strength of molten salt phase change heat storage material by using phenolic resin

A technology of phase change heat storage material and phenolic resin, which is applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of insufficient mechanical properties of heat storage materials and low impact on heat storage performance, and achieve the solution of insufficient mechanical properties, The effect of low cost and widening the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

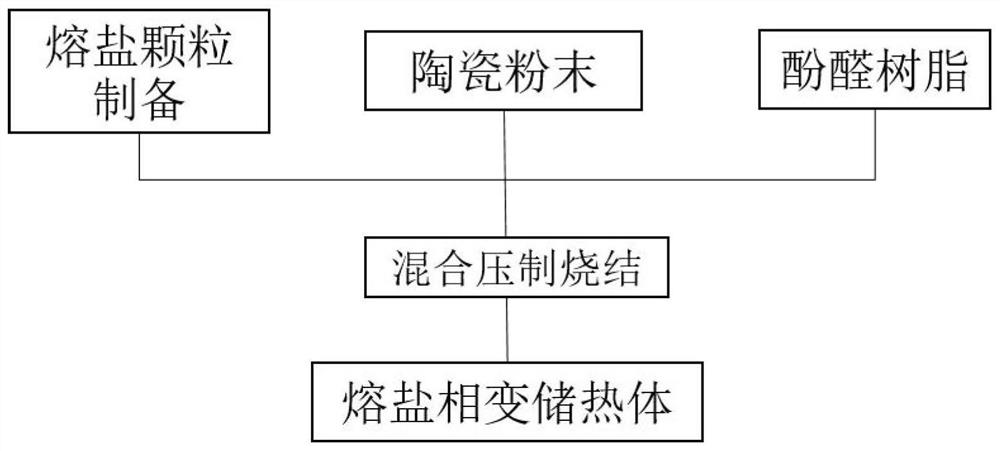

Method used

Image

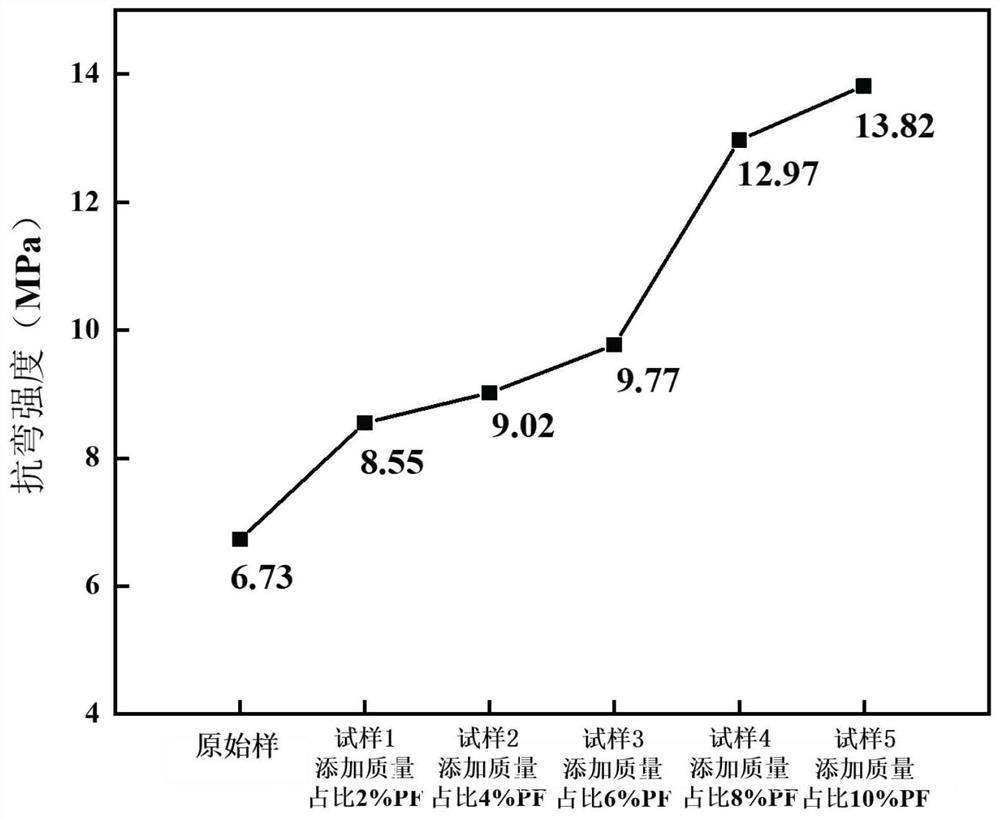

Examples

Embodiment 1

[0019] The method for improving the strength of molten salt phase change heat storage material by using phenolic resin provided in this embodiment includes the following steps:

[0020] 1. Preparation of molten salt particles

[0021] (1) Select Na 2 CO 3 with K 2 CO 3 As a heat storage medium, mix with a ratio of 52:48, and use a ball mill to mill at a ball-to-material ratio of 1:1 and a speed of 110 rpm for 30 minutes to make Na 2 CO 3 with K 2 CO 3 Mix well to prepare hydrated eutectic salt.

[0022] (2) dissolving the mixed mixture in water, stirring evenly, placing it in an oven, and drying it for 72 hours to prepare a hydrated eutectic salt;

[0023] (3) Crush and grind the prepared hydrated eutectic salt into powder, place the powder in spherical abrasives of different diameters, add a small amount of water, press at a pressure of 10Mpa, and sinter at 680°C to prepare Molten salt particles of different particle sizes are ready for use.

[0024] 2. Press and si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com