Method for preparing titanium material through powder metallurgy with modifier

A powder metallurgy and modifying agent technology, which is applied in the field of powder metallurgy to prepare titanium materials, can solve the problems of uncontrollable structure, reduced plasticity, coarse structure, etc., and achieve strengthening and toughening, tensile strength and elongation, and increase The effect of the ability to deform uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

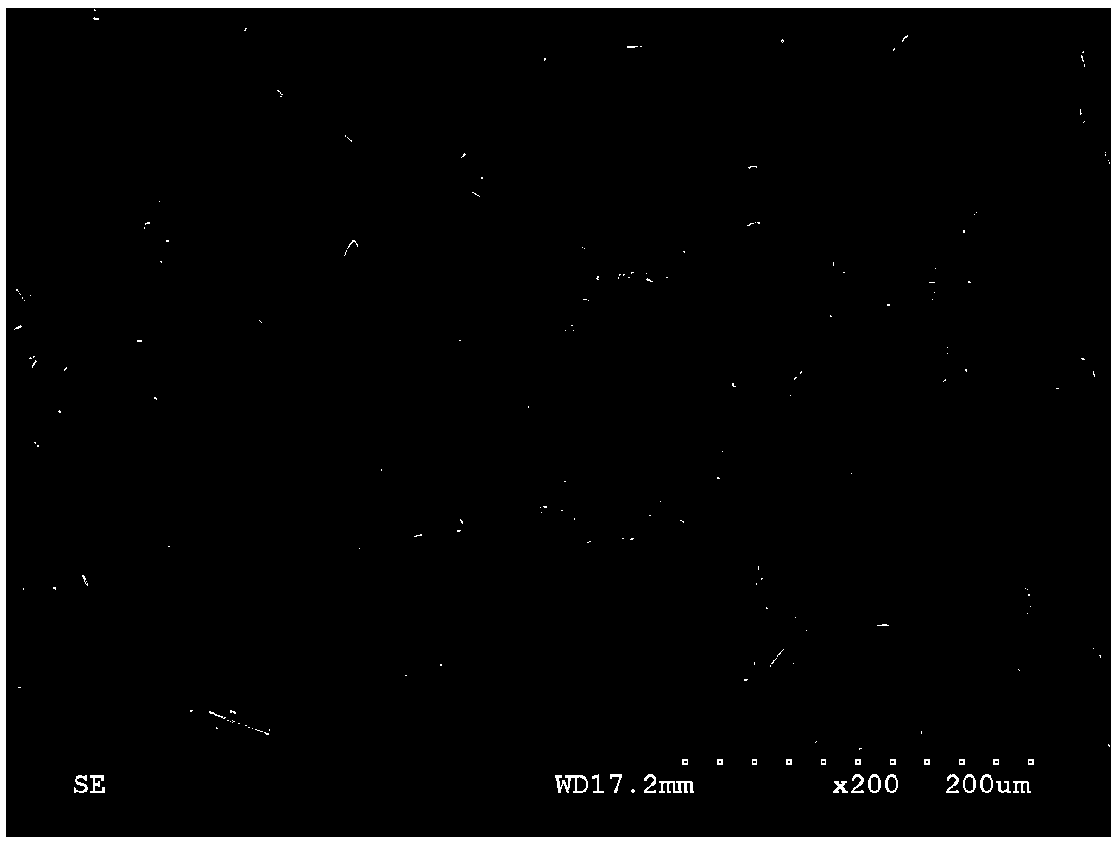

Image

Examples

specific Embodiment approach 1

[0013] Embodiment 1: A method for preparing titanium material by powder metallurgy in this embodiment is carried out according to the following steps:

[0014] 1. Mechanical stirring and powder mixing: 0.05% to 1% of the modifier powder and 99% to 99.95% of the titanium material powder are mechanically mixed with a stirring mixer according to the mass percentage, and the powder mixing time is 1h to 15h to obtain Composite powder; the titanium material is pure titanium or a titanium alloy; the modifier powder has a particle size of 0.1-5 μm, and the titanium material powder has a particle size of 37-300 μm;

[0015] 2. Sintering: Put the composite powder into a vacuumized airtight container for sintering, sintering at a sintering temperature of 850-1500°C and a pressure of 10-200MPa for 0.5h-5h, and naturally cool to room temperature to obtain a controllable structure Modified powder metallurgy titanium materials.

specific Embodiment approach 2

[0016] Embodiment 2: This embodiment differs from Embodiment 1 in that the titanium alloy described in step 1 is an α+β-type dual-phase high-strength titanium alloy TC4-TC21 series titanium alloy. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the titanium alloy described in step 1 is a TA1-TA19 series titanium alloy of a near-α-type high-temperature titanium alloy. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com