Polyethylene coating steel pipe and its producing method and production line

A polyethylene and production line technology, applied to the surface coating liquid device, coating, pipeline protection, etc., can solve the problems of increasing the purchase cost of anti-corrosion equipment, increasing the auxiliary cost of anti-corrosion coating, and the labor intensity of production workers. Achieve the effect of reducing equipment purchase costs and power consumption, saving purchase costs and power consumption, and reducing power equipment purchase costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

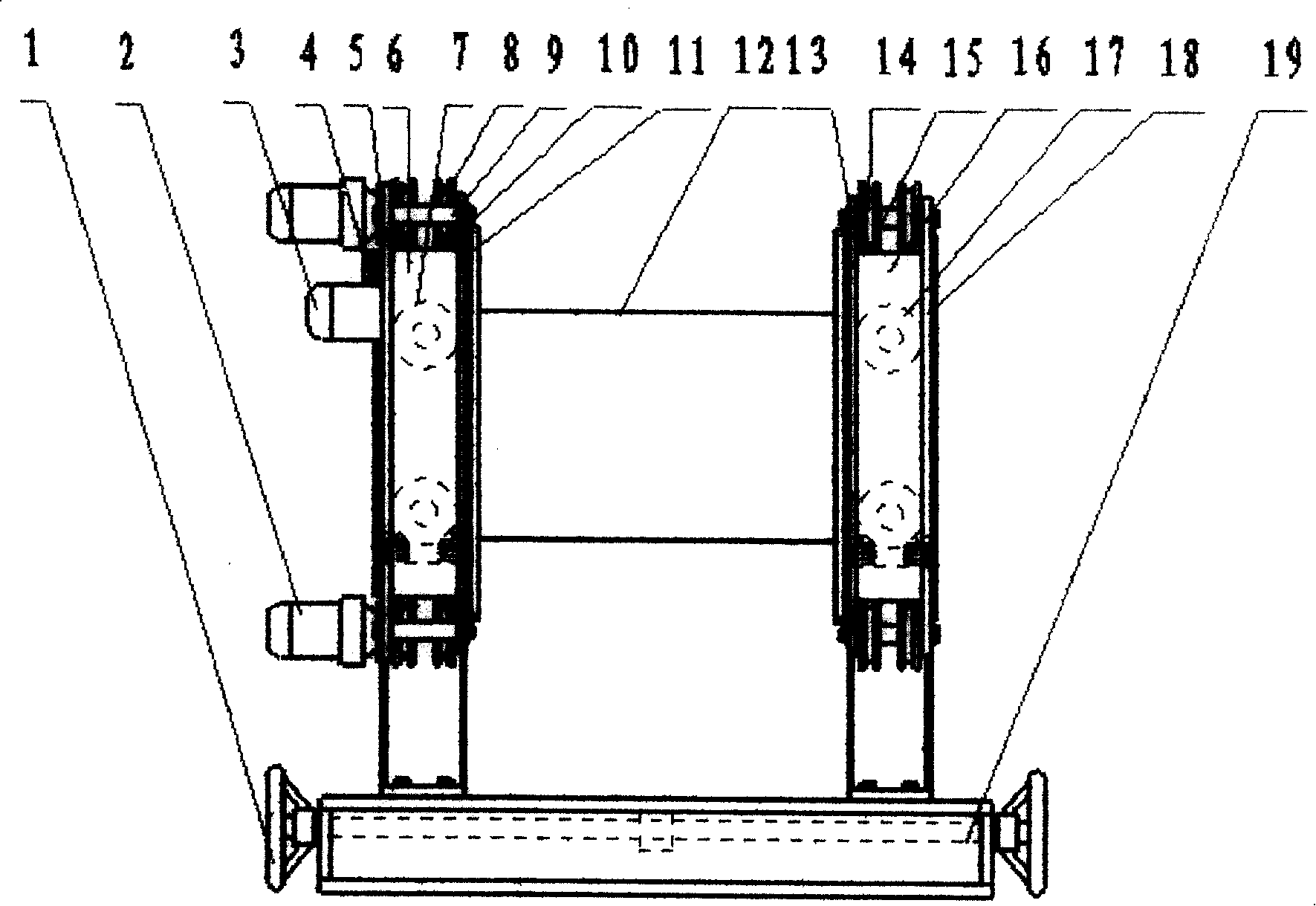

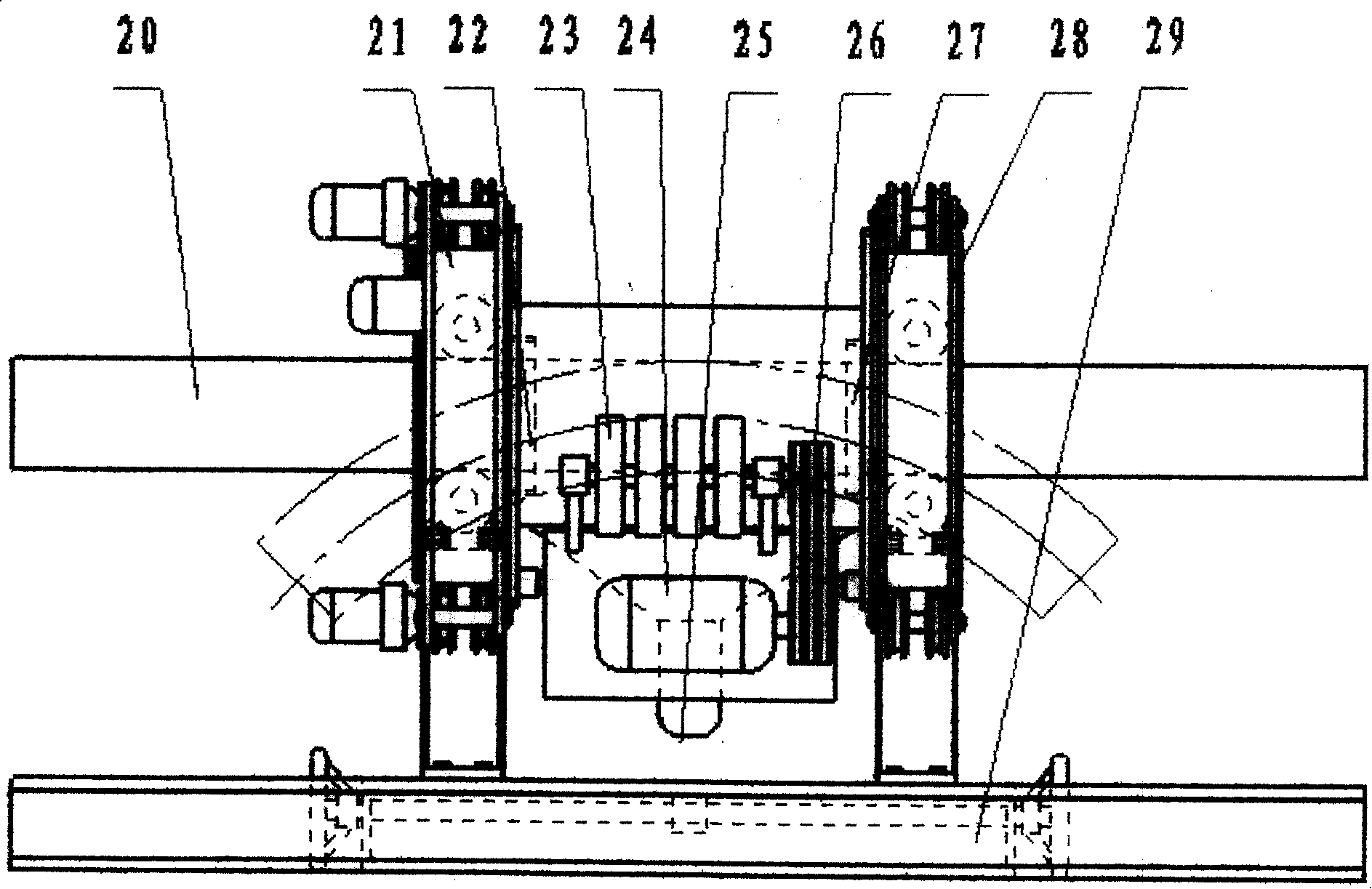

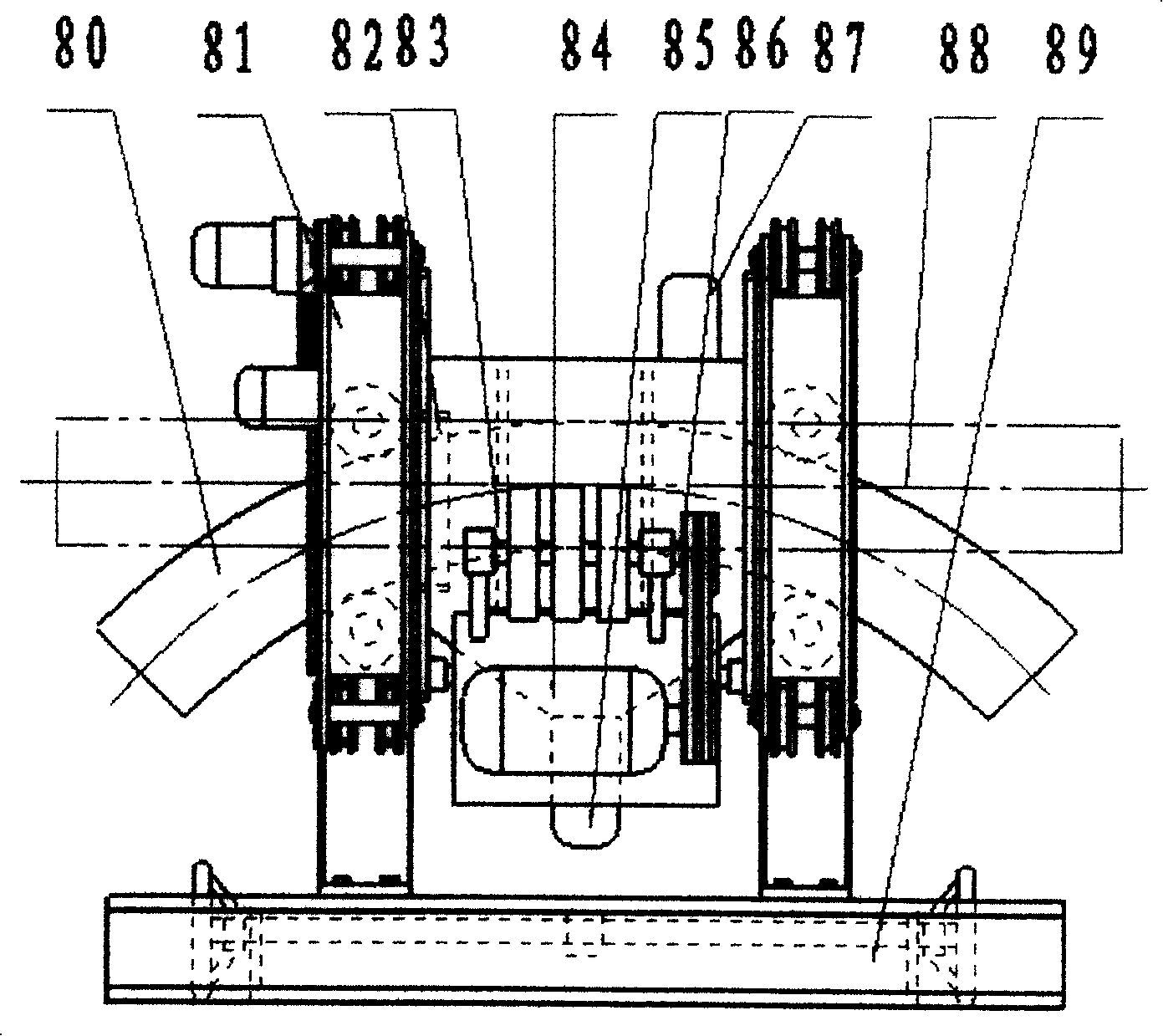

Image

Examples

Embodiment Construction

[0037] The following examples illustrate the polyethylene-coated steel pipe production method and the mobile polyethylene-coated steel pipe production line of the present invention.

[0038] The production method of polyethylene coated steel pipe of the present invention comprises:

[0039] (1) Steel pipes that have passed the visual inspection are put into the cylindrical derusting machine;

[0040] (2) Start the high-frequency induction heating power supply on the cylindrical derusting machine, and the high-frequency induction heating ring will heat the outer surface of the steel pipe to 50 degrees; start the cylindrical derusting machine, the steel pipe will perform a spiral movement, and start the disc-shaped steel wire Brush group, the rotation direction of the disc-shaped steel wire brush group is opposite to the rotation direction of the steel pipe, to remove the rust spots on the outer surface of the steel pipe;

[0041] (3) Steel pipes qualified for rust removal ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com