Patents

Literature

56results about How to "Avoid multiple transfers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Operating method for olefin conversion device

ActiveCN102020523AFast heatingAvoid cloggingCatalyst regeneration/reactivationHydrocarbon from oxygen organic compoundsCombustorCombustion chamber

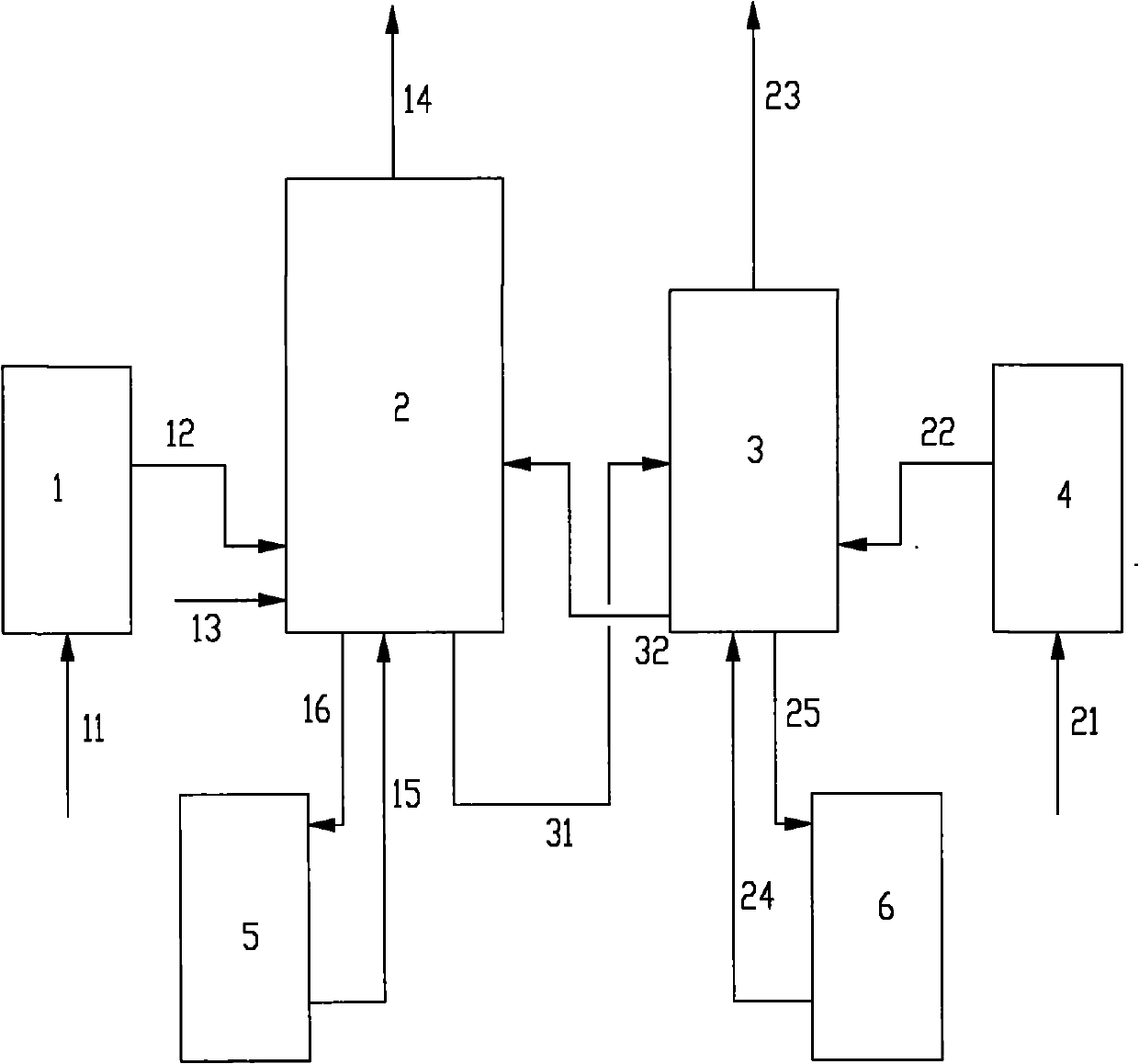

The invention belongs to an operating method for an olefin conversion device and relates to a device for preparing olefin such as methanol to olefin (MTO) and methanol to propylene (MTP) by using organic oxides such as methanol, dimethyl ether and the like. The method is characterized by comprising the following steps that: when the device is operated, catalysts of a reactor 2 and a regenerator 3are respectively introduced from respective catalyst tank and are added in two paths; and the catalysts respectively added into the reactor and the regenerator are heated depending on an external heat source and a heating medium which are independently arranged, namely, the reactor 2 is provided with an operating steam superheater 1 to heat the catalyst by using high-temperature steam and the regenerator 3 is provided with an auxiliary combustor to heat the catalyst by using high-temperature air. When added, the catalysts are not transferred from the regenerator 3 to the reactor 2, namely thecatalysts are not transferred between the reactor and the regenerator.

Owner:CHINA PETROLEUM & CHEM CORP +1

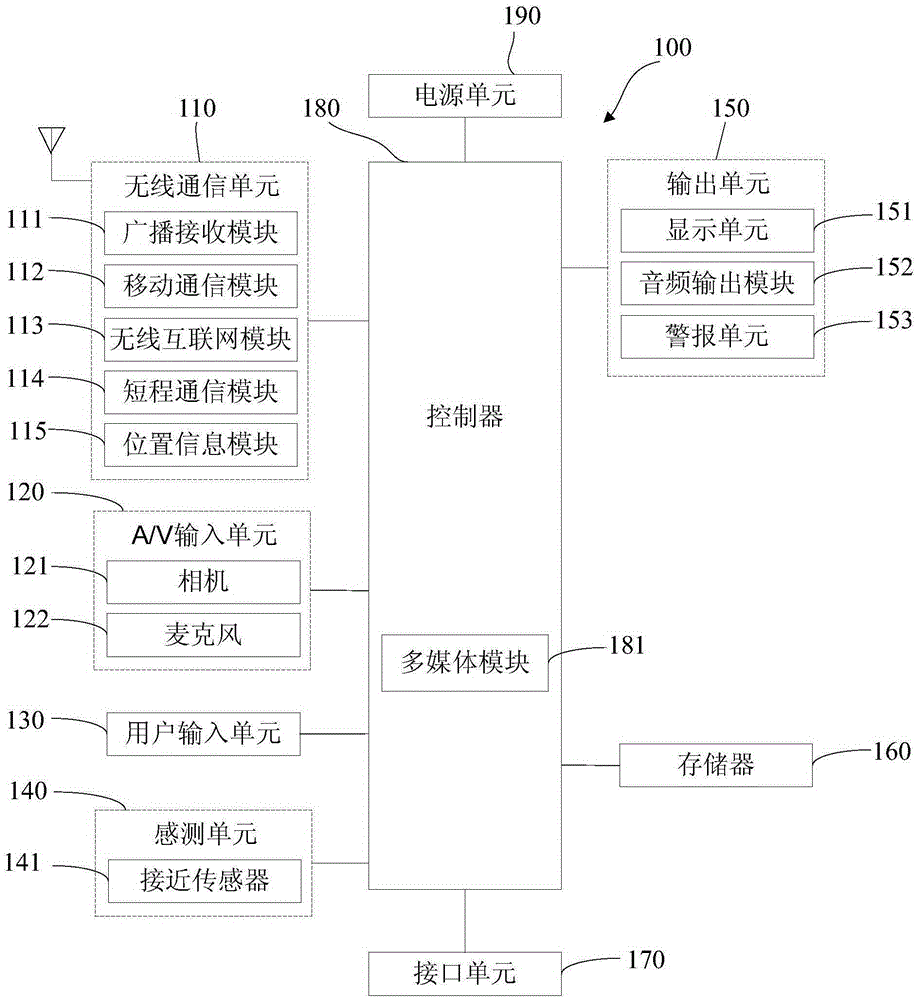

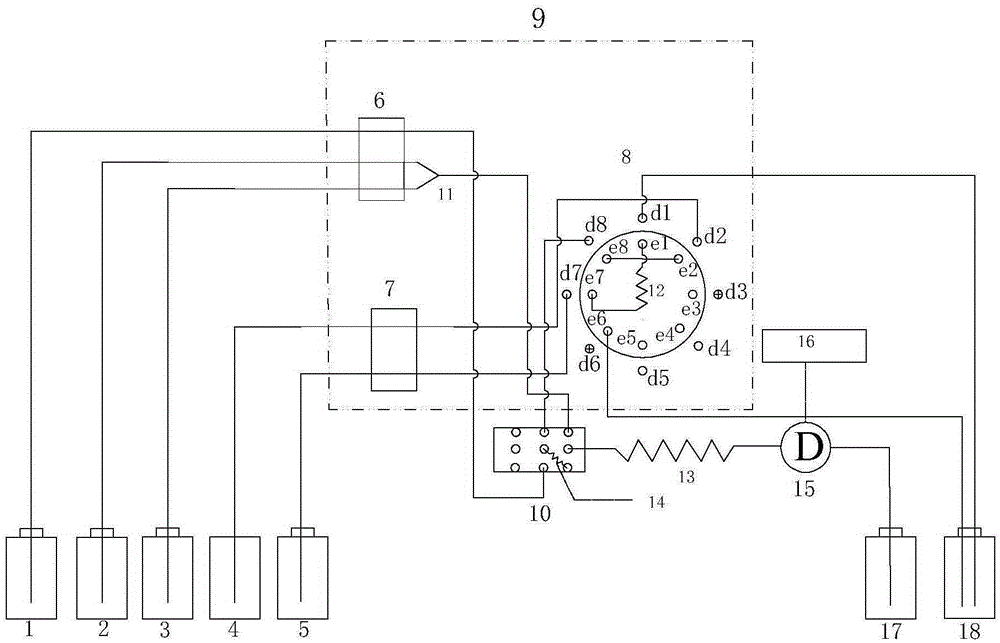

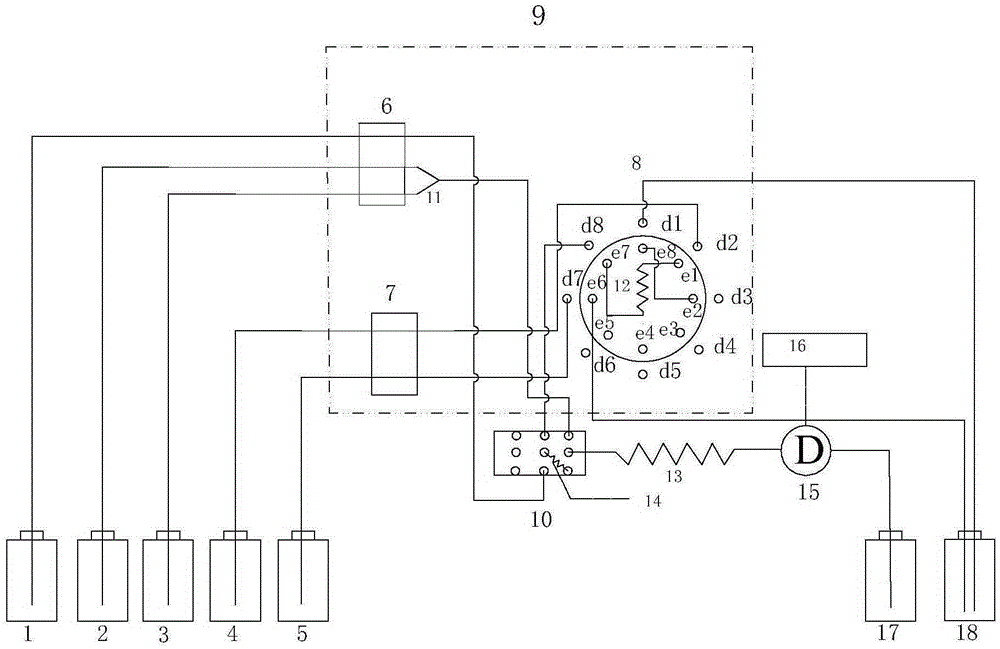

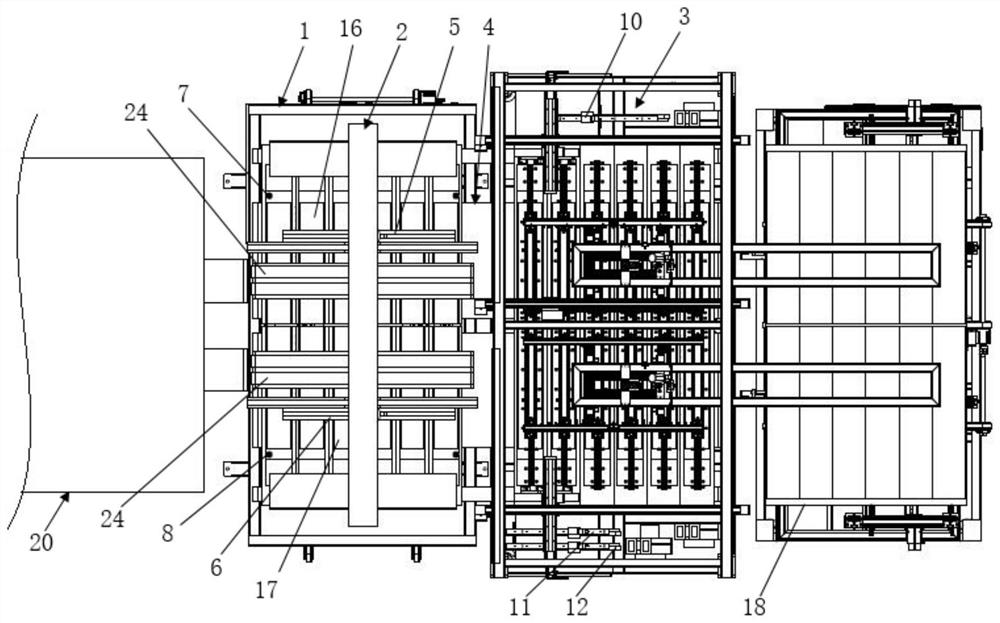

DSA composite operating room intelligent control system

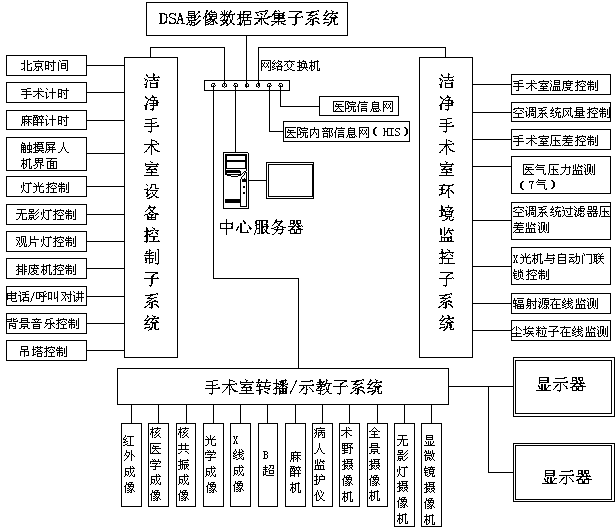

InactiveCN103720515AReduce accessReduce frequency of trips to and from the operating roomDiagnosticsSurgeryConsultation systemInformation resource

A DSA composite operating room intelligent control system comprises a center server, a network switch, a DSA image data collecting subsystem, an operating room rebroadcasting / showing subsystem, an operating room environment monitoring subsystem and an operating room equipment control subsystem. The center server is connected with the DSA image data collecting subsystem, the operating room rebroadcasting / showing subsystem, the operating room environment monitoring subsystem and the operating room equipment control subsystem through the network switch respectively. The technical problems that information resources of a traditional medical teaching system cannot be stored in a unifying mode, and operation long-distance showing and medical image concentrating displaying cannot be achieved are solved, system interactivity is greatly improved, accordingly, real-time dynamic cooperating is achieved, the functions such as long-distance showing and digital image transmission are achieved, and high-quality transmission of high-definition digitization images between an operation image rebroadcasting system, a teaching system, an academic report communication system and a specialist consultation system is achieved.

Owner:SHENZHEN HUIJIAN MEDICAL ENG

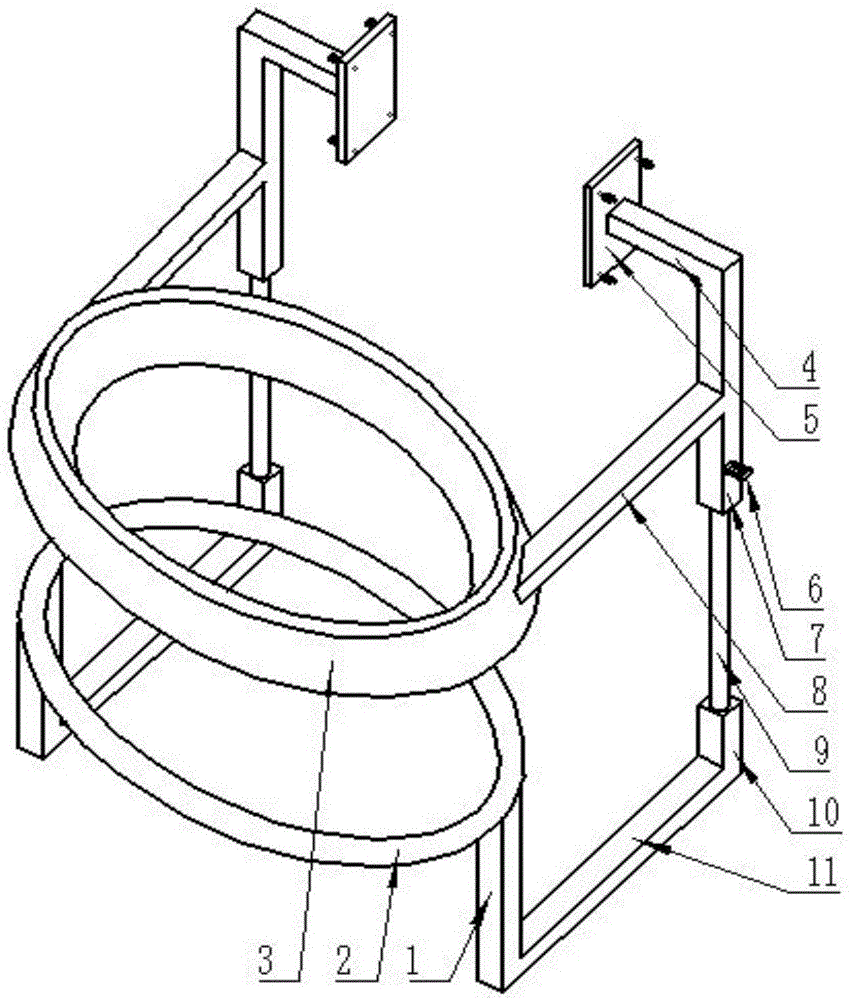

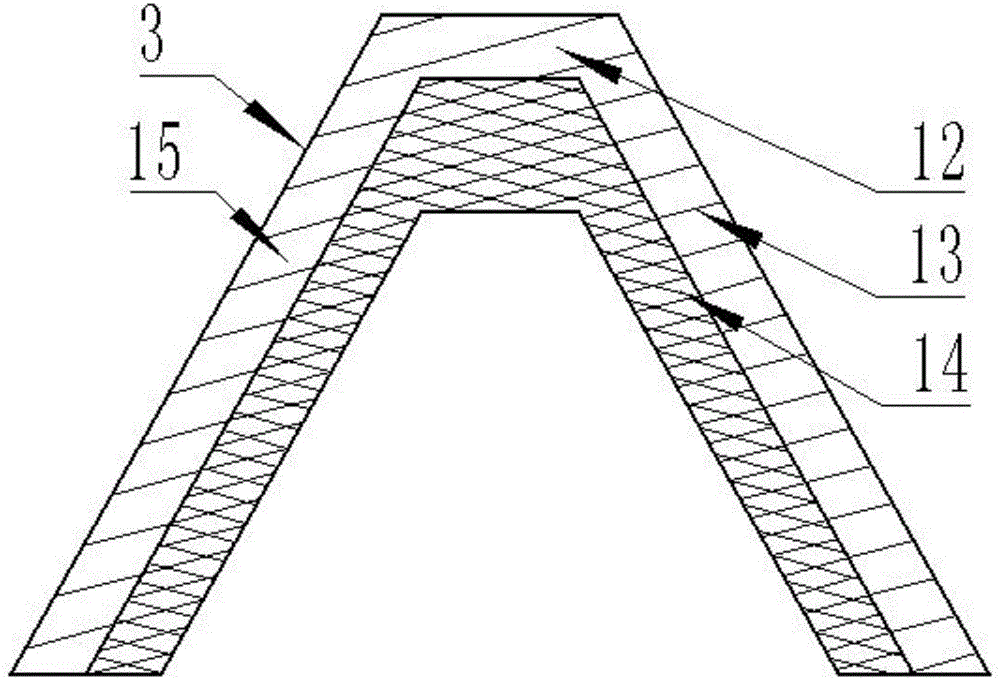

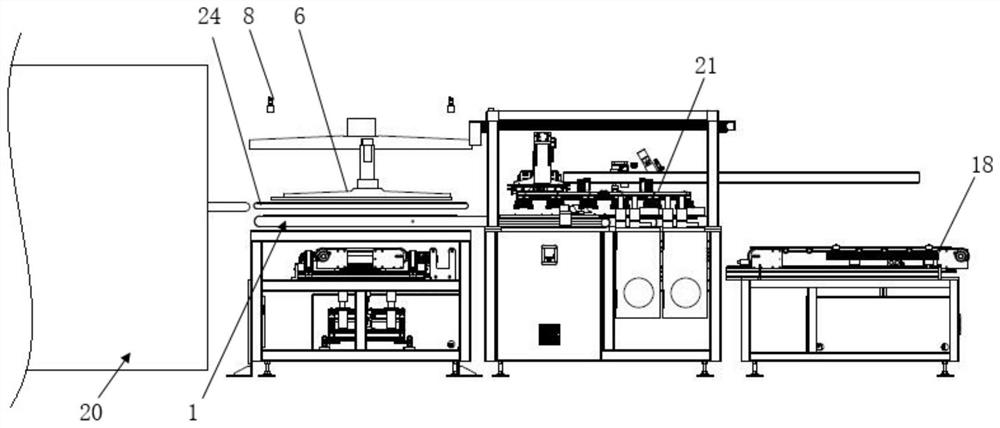

Polyethylene coated steel pipe, online production and equipment thereof

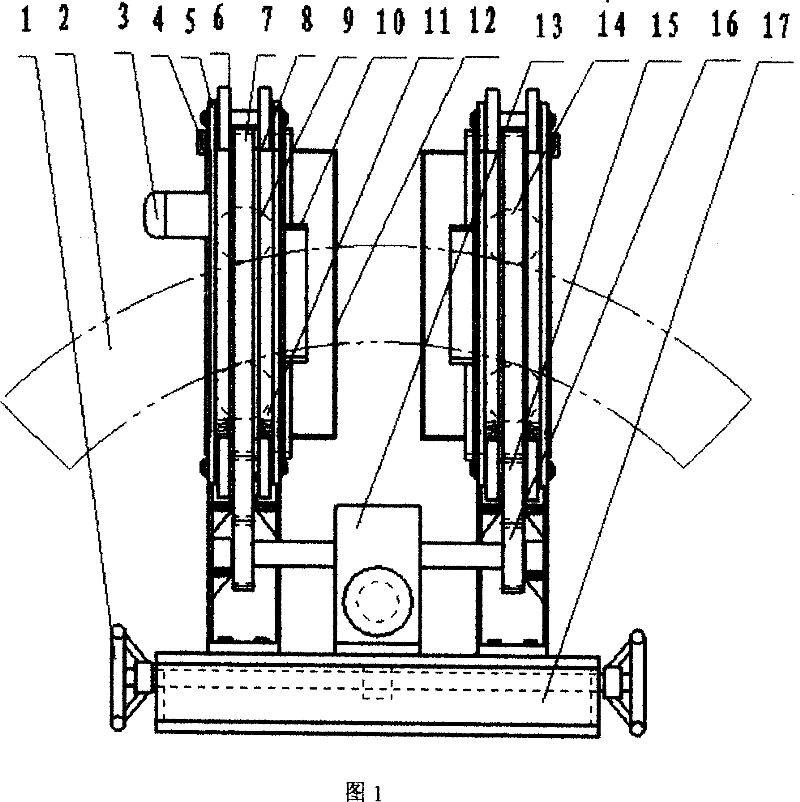

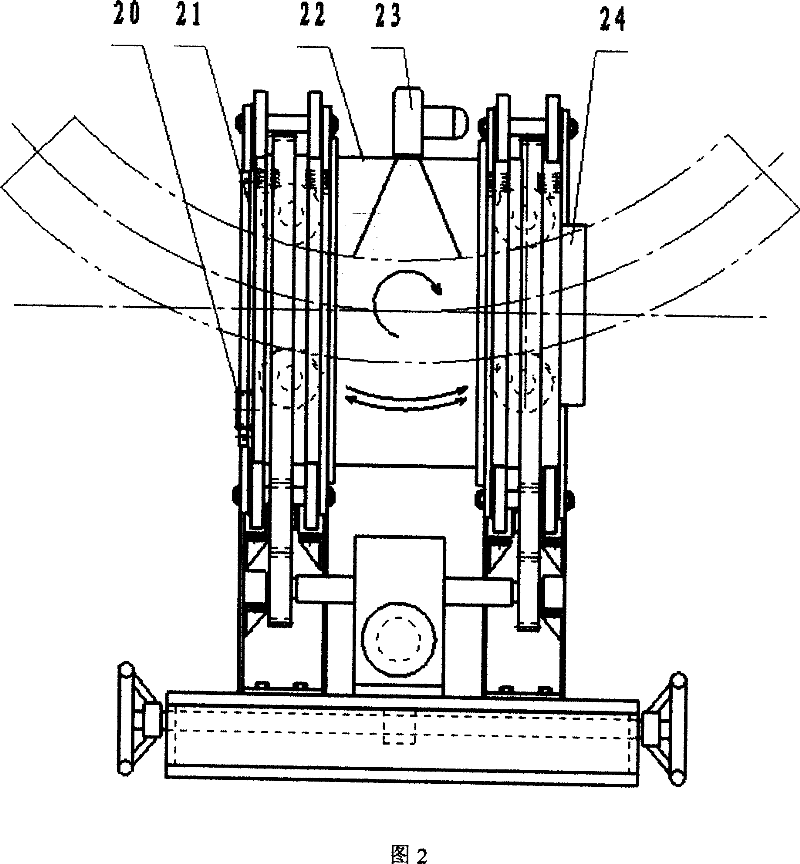

InactiveCN101038048AOvercoming qualityOvercome mechanical propertiesRigid pipesTransformerLow voltage

The invention relates to a polyethylene coated steel pipe and on-line method and apparatus for preparing same. Steel pipe is employed as base material for polyethylene coated steel pipe, and the outer surface of the steel pipe is coated with jointless annular polyethylene gummed tape. Production facilities of the pipe includes steel pipe shot-blast rust cleaning machine comprised of a rotating cylinder bracket, a rotating cylinder, a feeding wheel, a support wheel, a feeding worm wheel speed reducer, a feeding direct current dynamo, a high-frequency induction heating coil, a driving worm wheel speed reducer, a driving AC motor and a electrical control cabinet, and a steel pipe outer anticorrosion coating machine comprised of a induction heating transformer, a walking frame, a swing frame, a rotating frame, a winding device, a supporting frame, a low-voltage electrical casing and a controller. In pipeline installation locale, the steel pipes are welded into pipelines after derusted by the steel pipe shot-blast rust cleaning machine, the steel pipe outer anticorrosion coating machine is nested on the pipeline and carries out helical motion, after high-frequency induction heating on the steel pipe, the spray head injects the epoxy powder on outer surface of the steel pipe, after high-frequency induction heating of the belt-winding cylinder, adhesive tape and polyethylene gummed tape pulled out from the winding device become hot tapes, by helical motion of the steel pipe outer anticorrosion coating machine along pipeline centre-line, the adhesive tape and polyethylene gummed tape are coated on the outer surface of the steel pipes.

Owner:陈炯

Polyethylene coating steel pipe and its producing method and production line

InactiveCN101191577AOvercoming qualityOvercome mechanical propertiesLiquid surface applicatorsCorrosion preventionEpoxyAdhesive

The invention relates to a steel pipe painted with polythene and manufacturing method and mobile production line. A drum type rust remover, a drum type threading machine, a drum type spray coater, a drum type winding machine, a drum type cooling fan, a drum type dust removing threading machine, and a drum type spray winding machine are connected in turn to form the mobile production line. At a pipe laying site, a steel pipe in turn enters the drum type rust remover, the drum type threading machine, the drum type spray coater, the drum type winding machine and the drum type cooling fan, and makes helical movement under the support of a feeding wheel and a supporting roller in a rotating drum body. The steel pipe is heated through a high-frequency induction heating method, and rust spots are removed from the external surface of the steel pipe through a mechanical method and the steel pipe is threaded also through a mechanical method, the epoxy powder spray coater is used to spray epoxy powder to the external surface of the steel pipe, the epoxy powder and a composite polythene cold adhesive tape are heated indirectly through the high-frequency induction heating method and the cold adhesive tape is turned into a composite polythene hot adhesive tape, and through a mechanical winding method, the composite polythene adhesive tape is applied onto the epoxy powder layer to produce the steel pipe painted with polythene.

Owner:陈炯

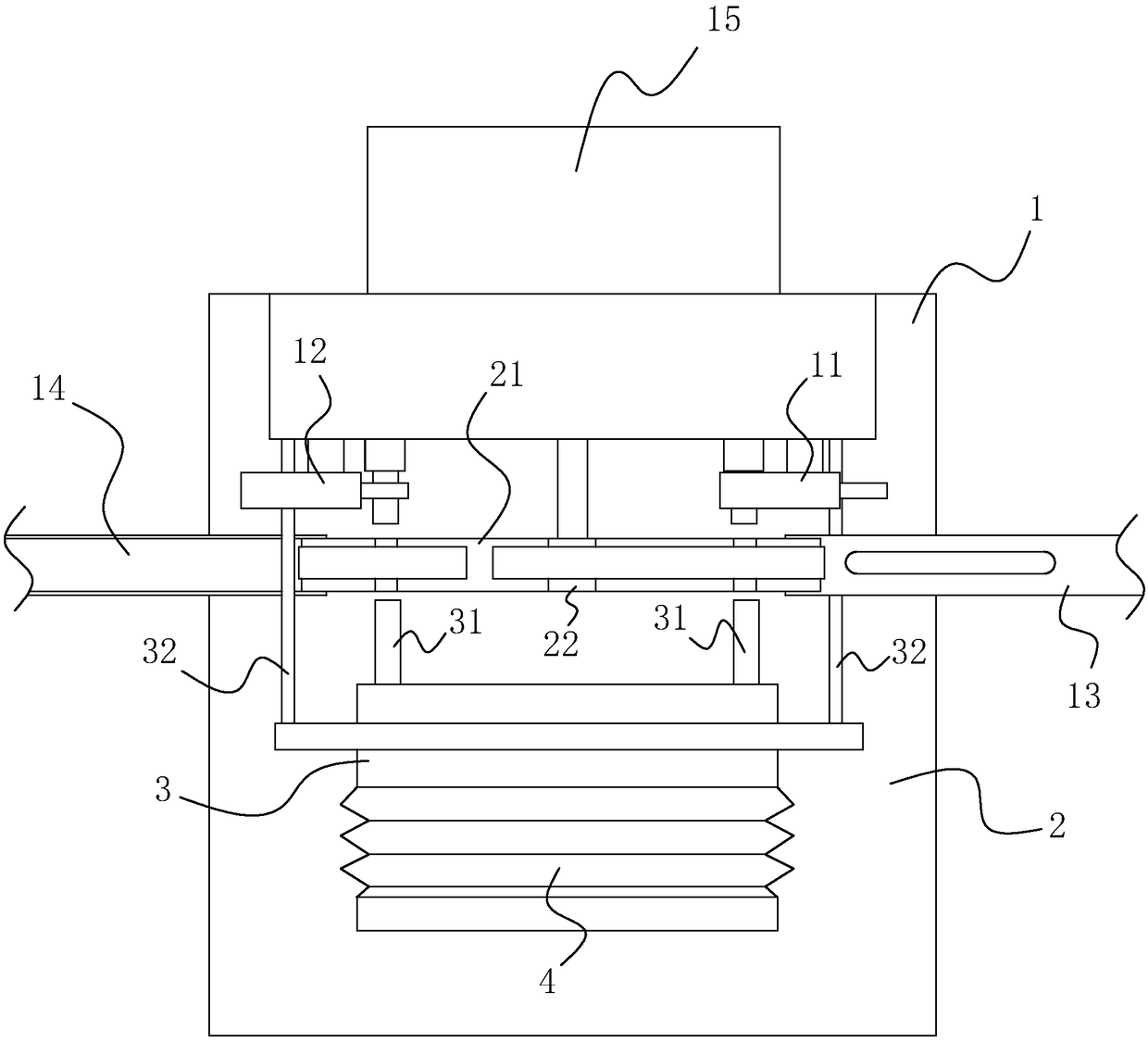

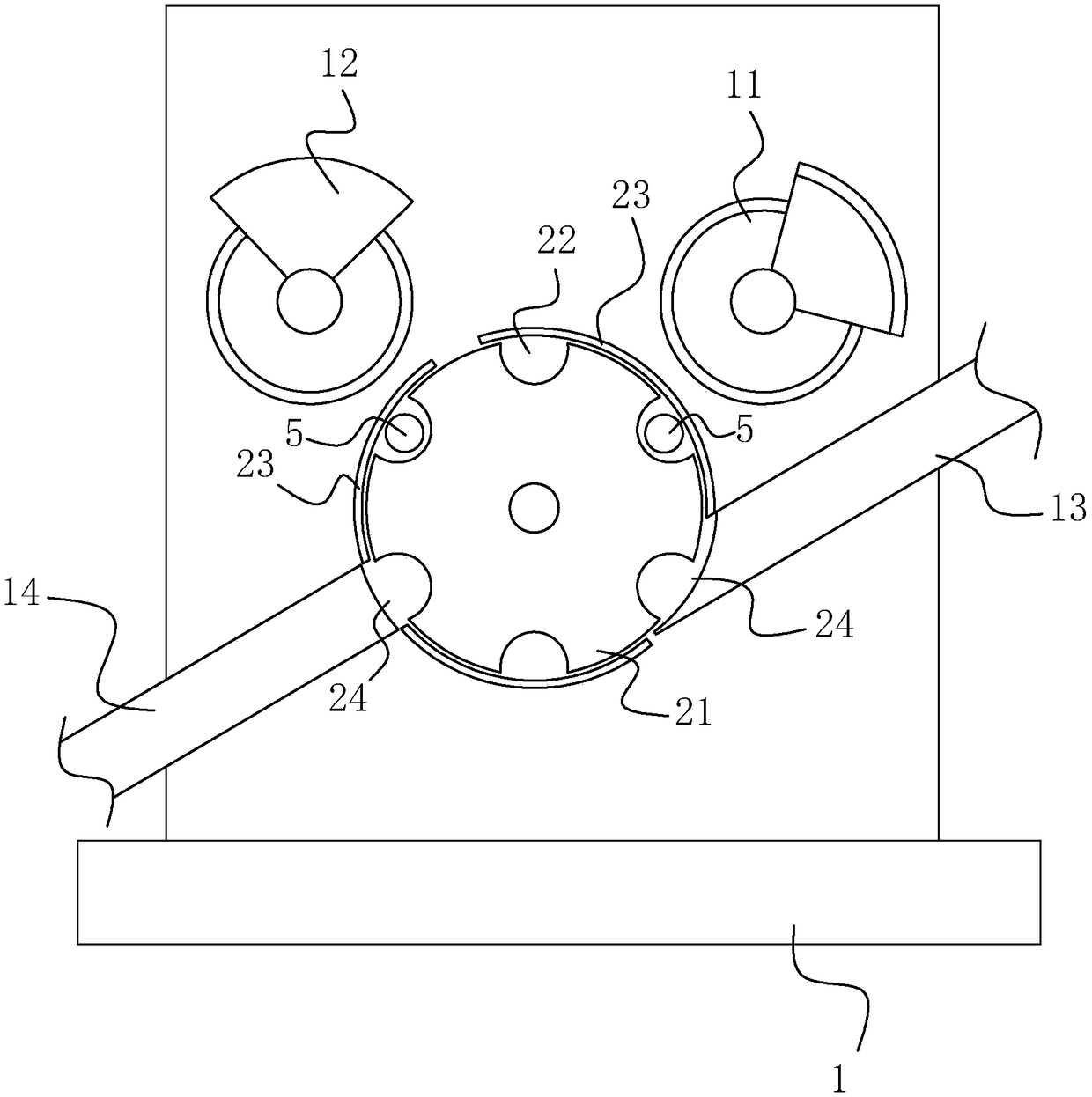

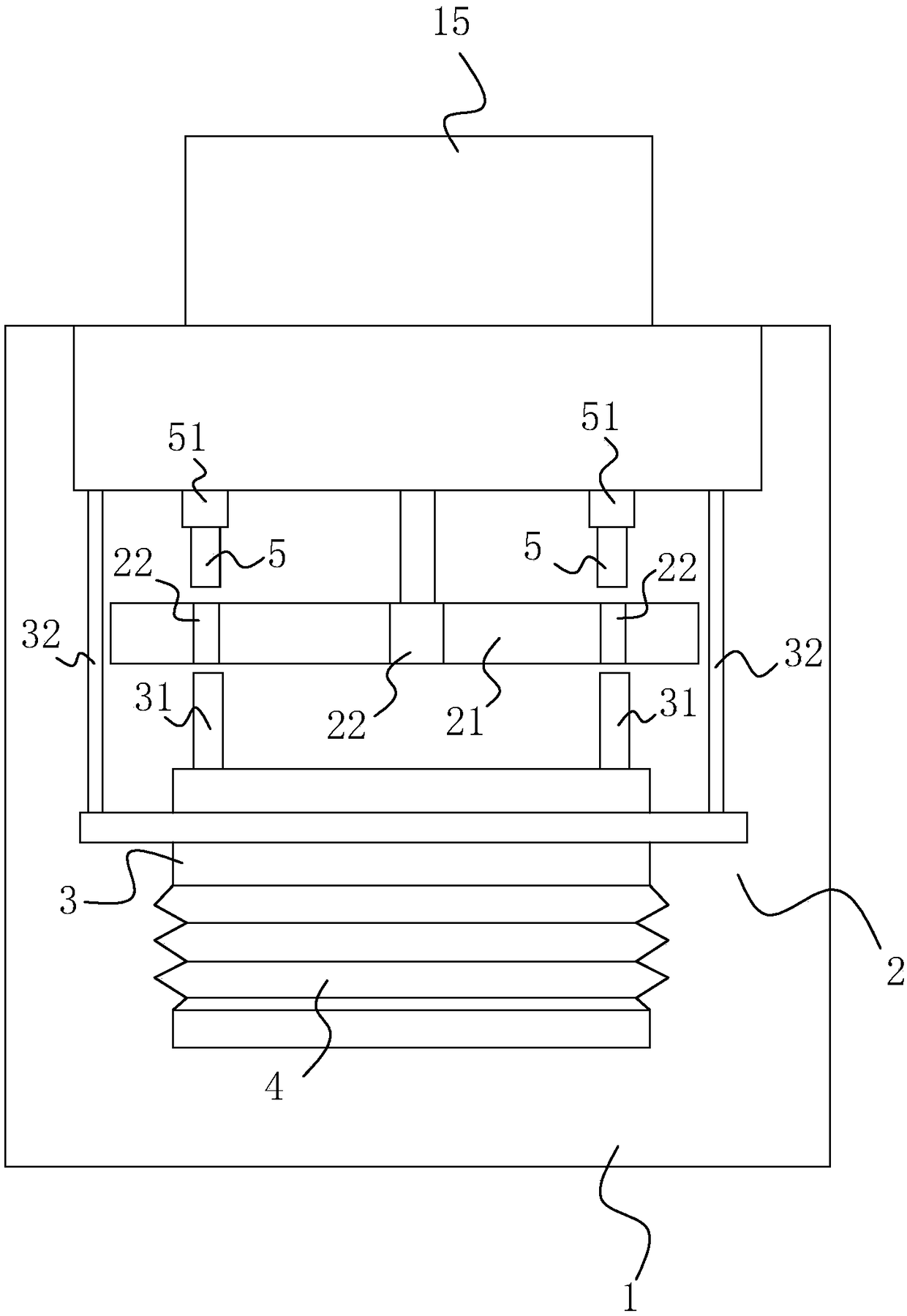

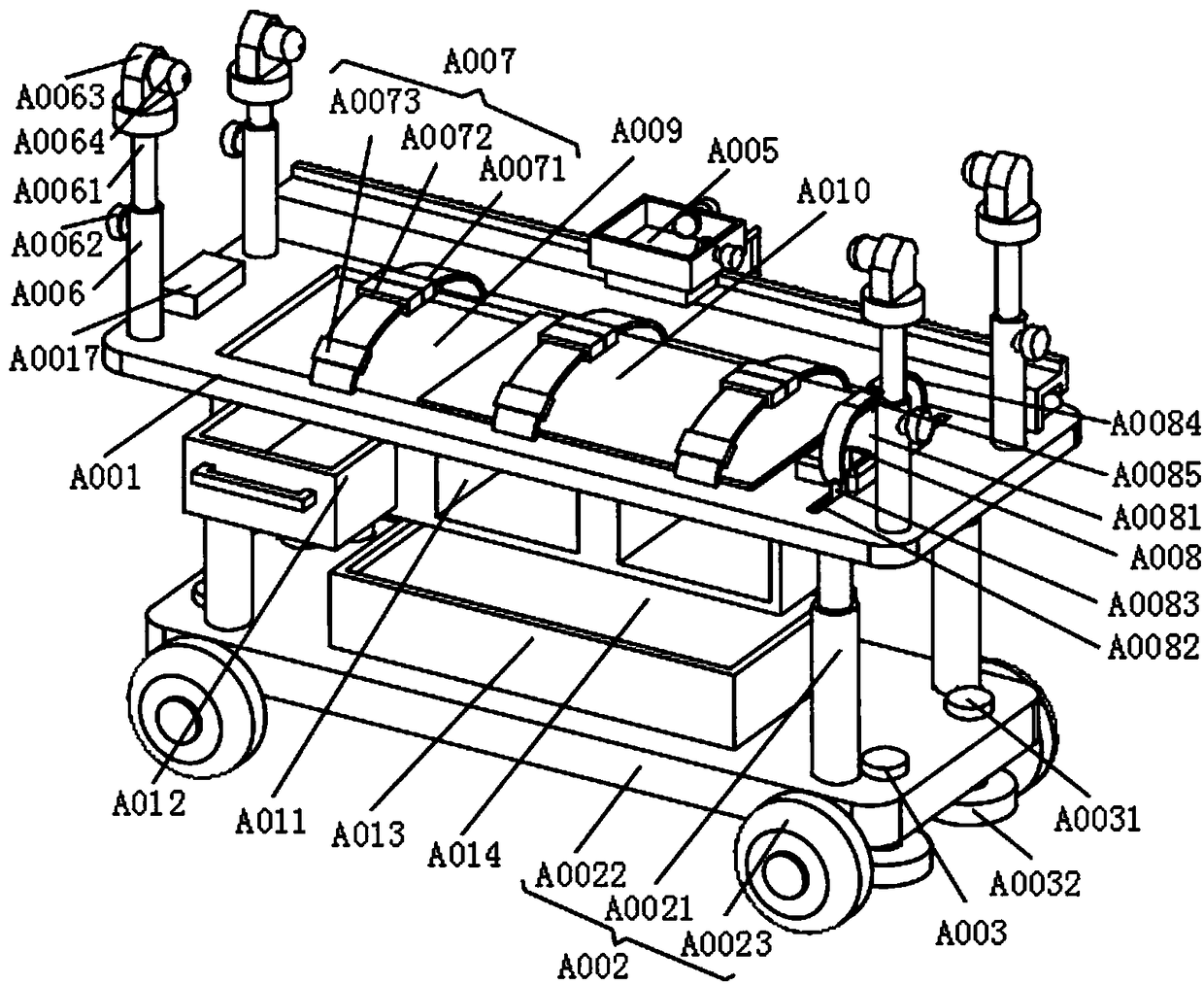

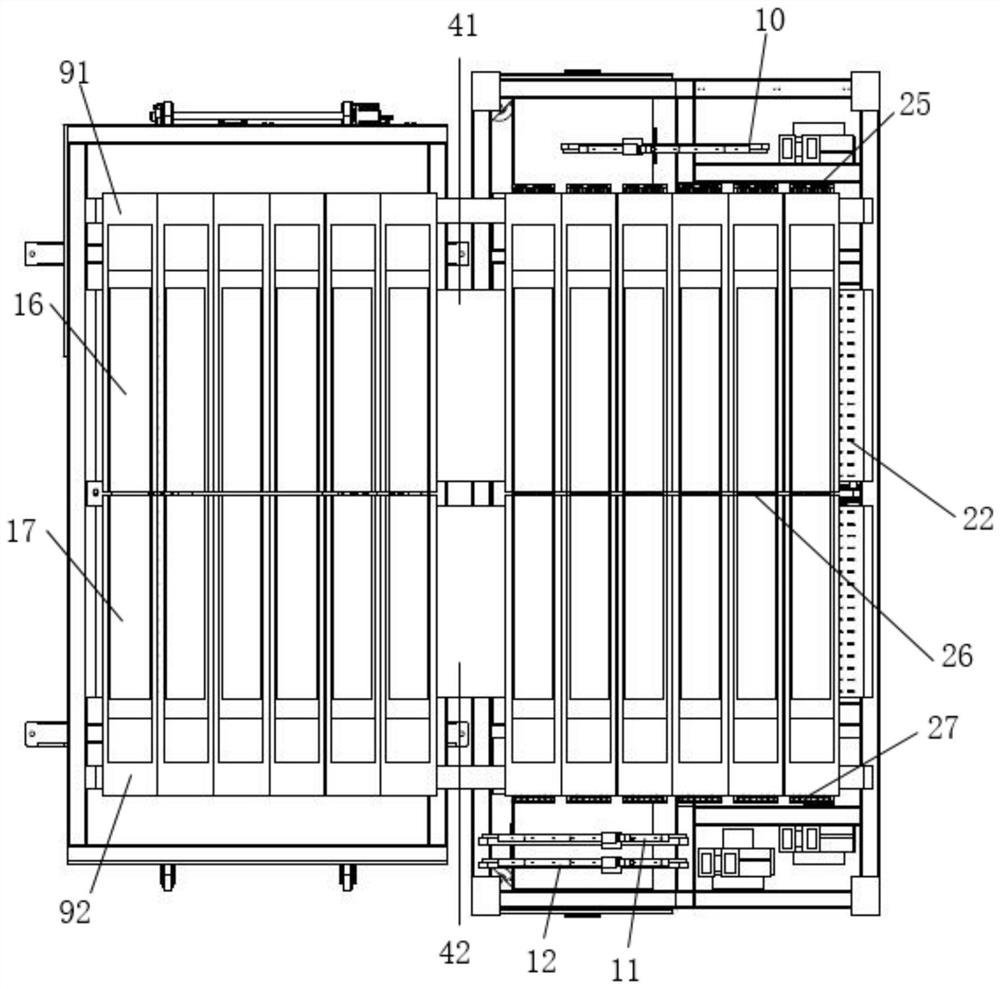

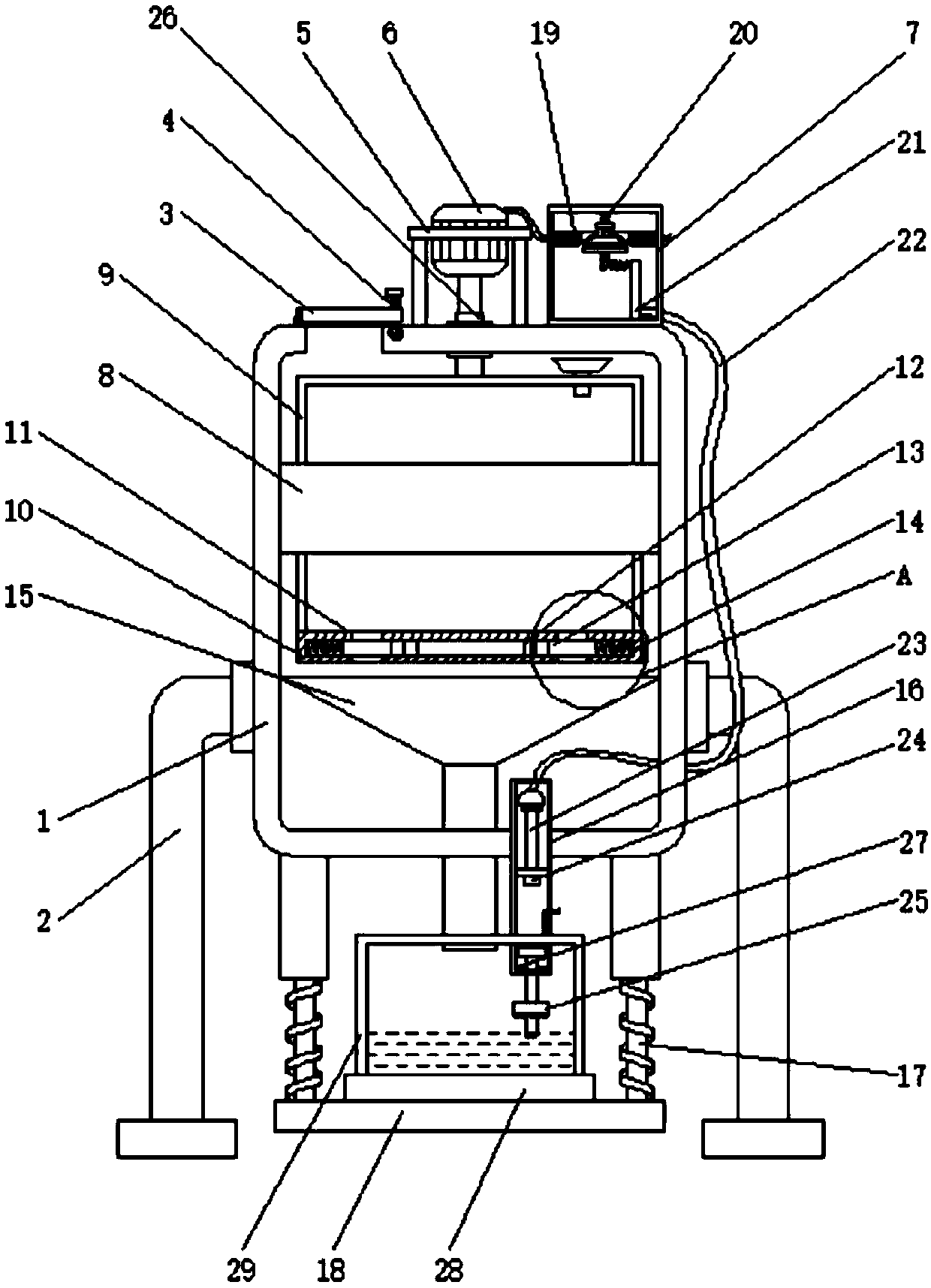

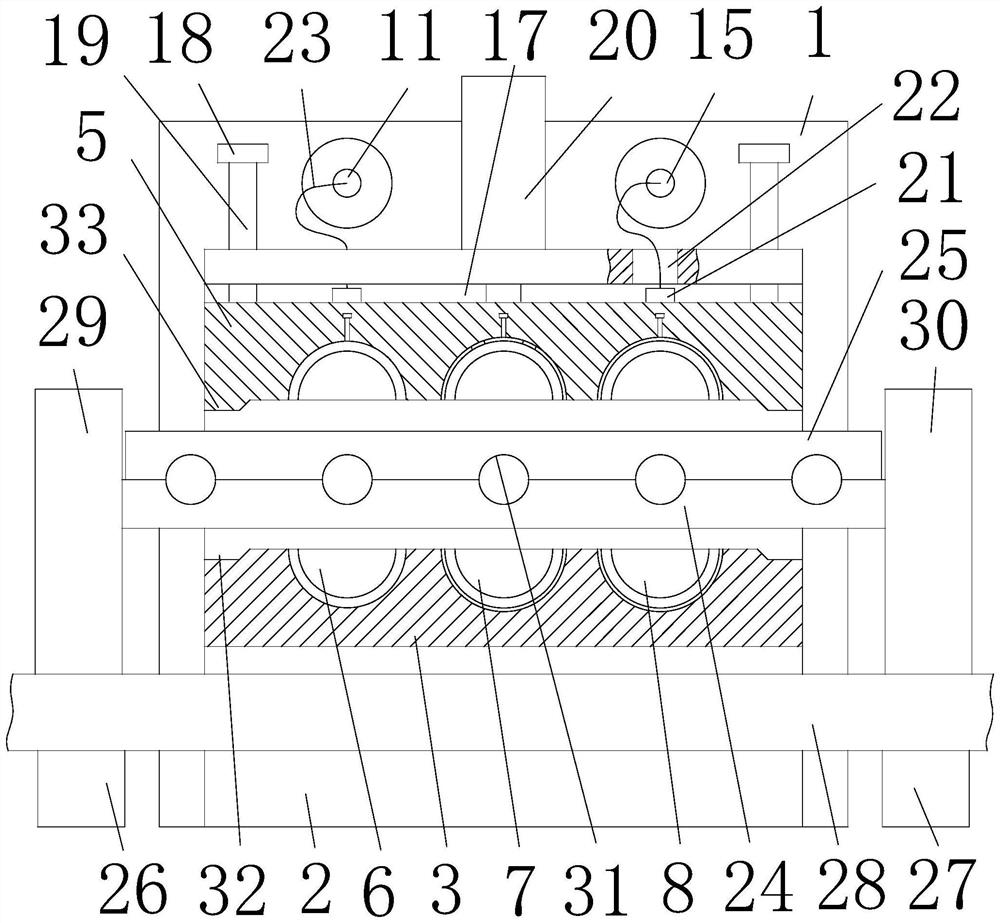

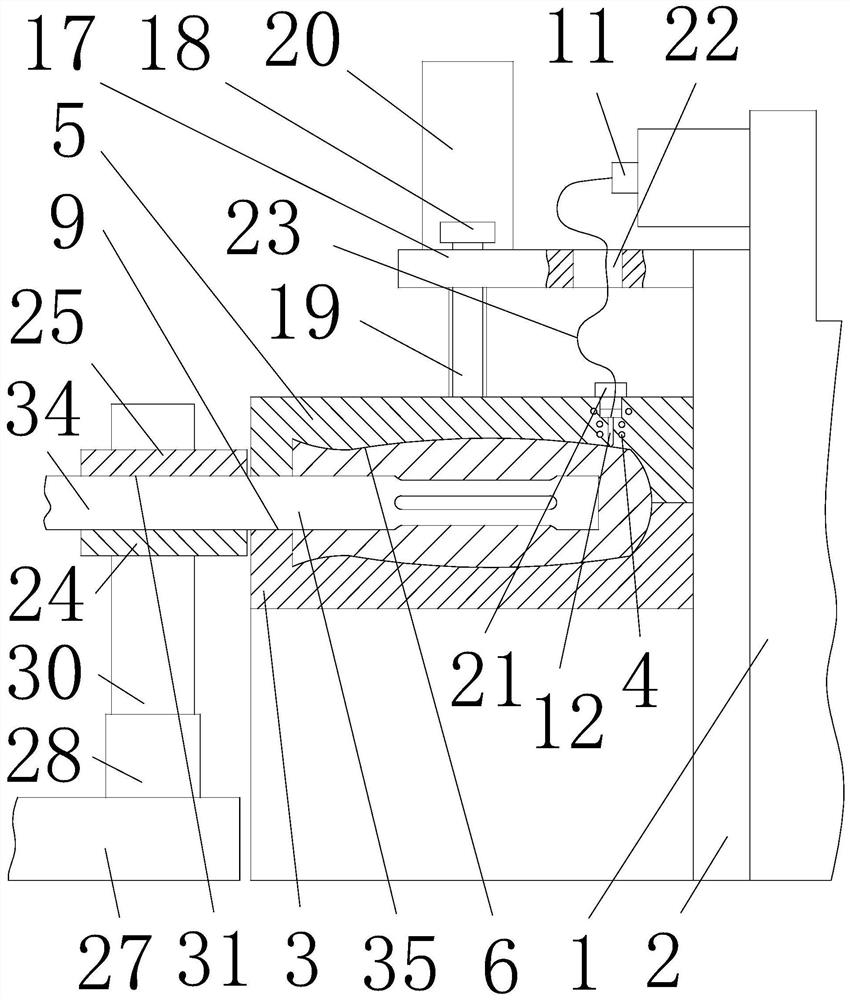

Knurling and lettering integrated machine

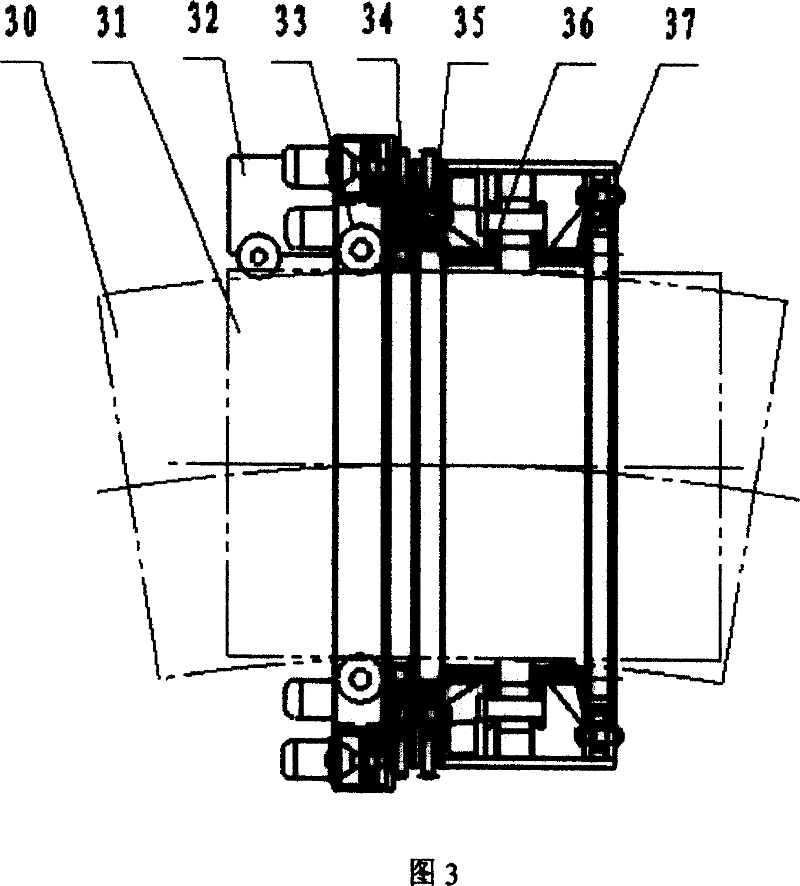

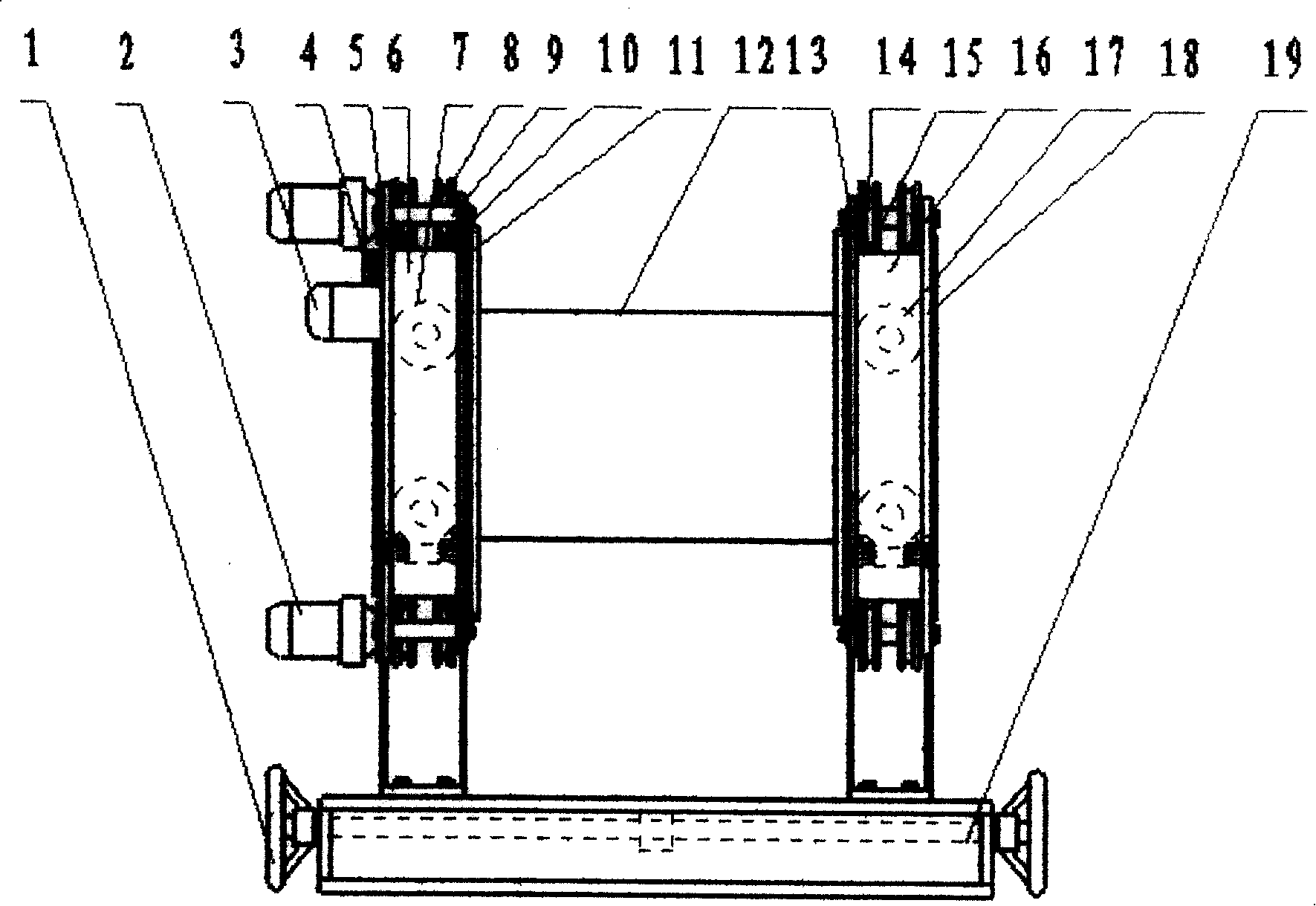

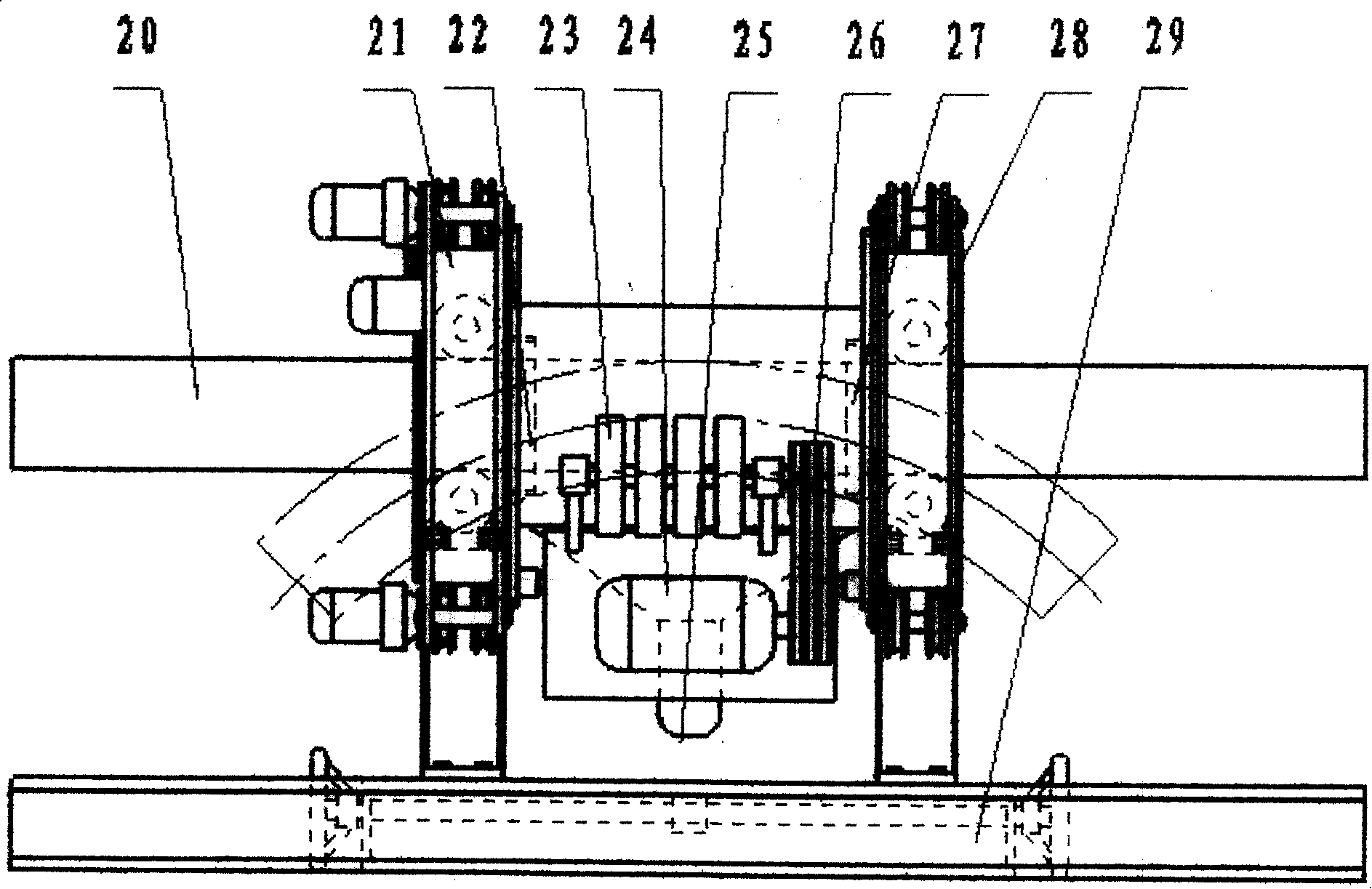

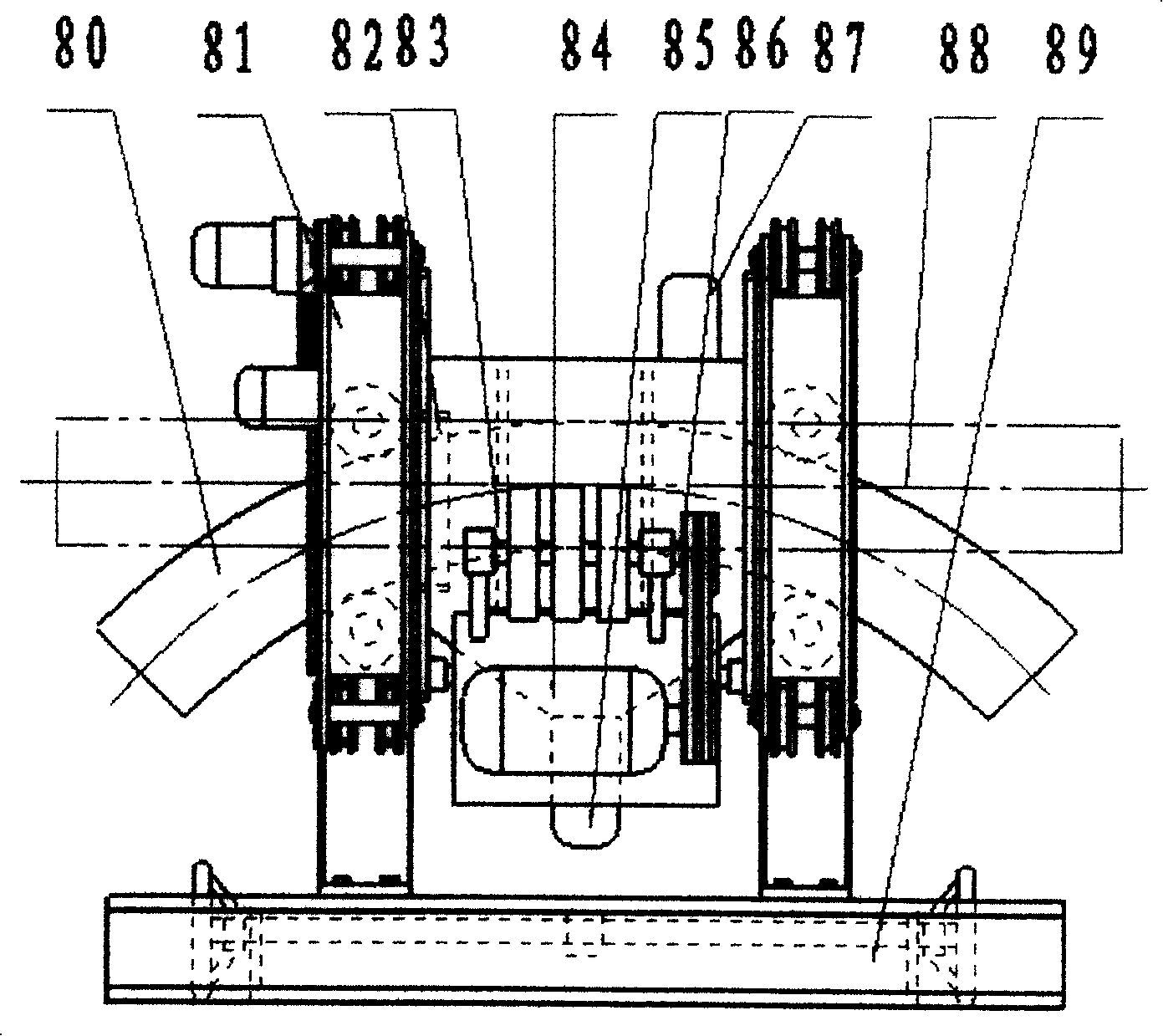

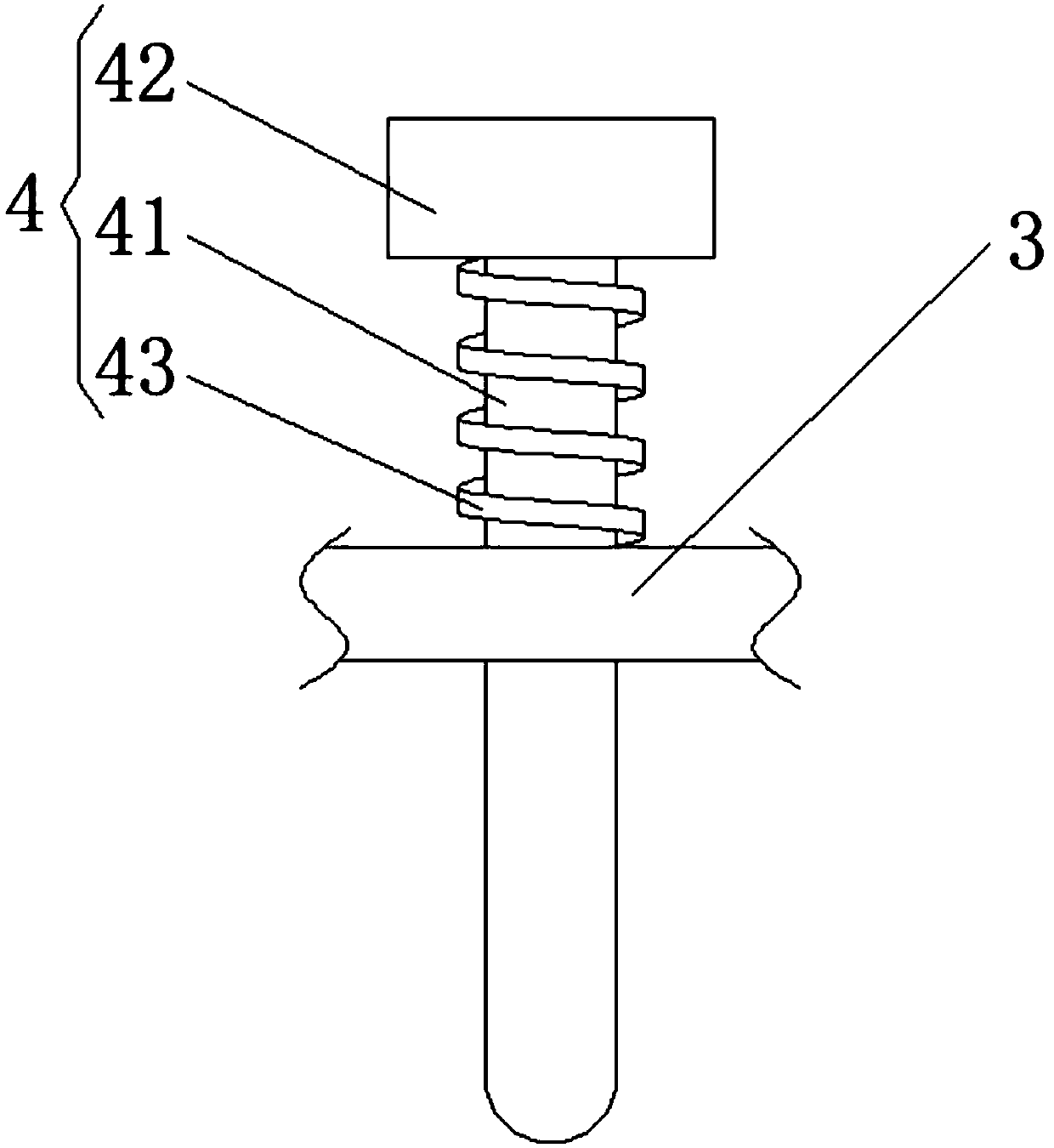

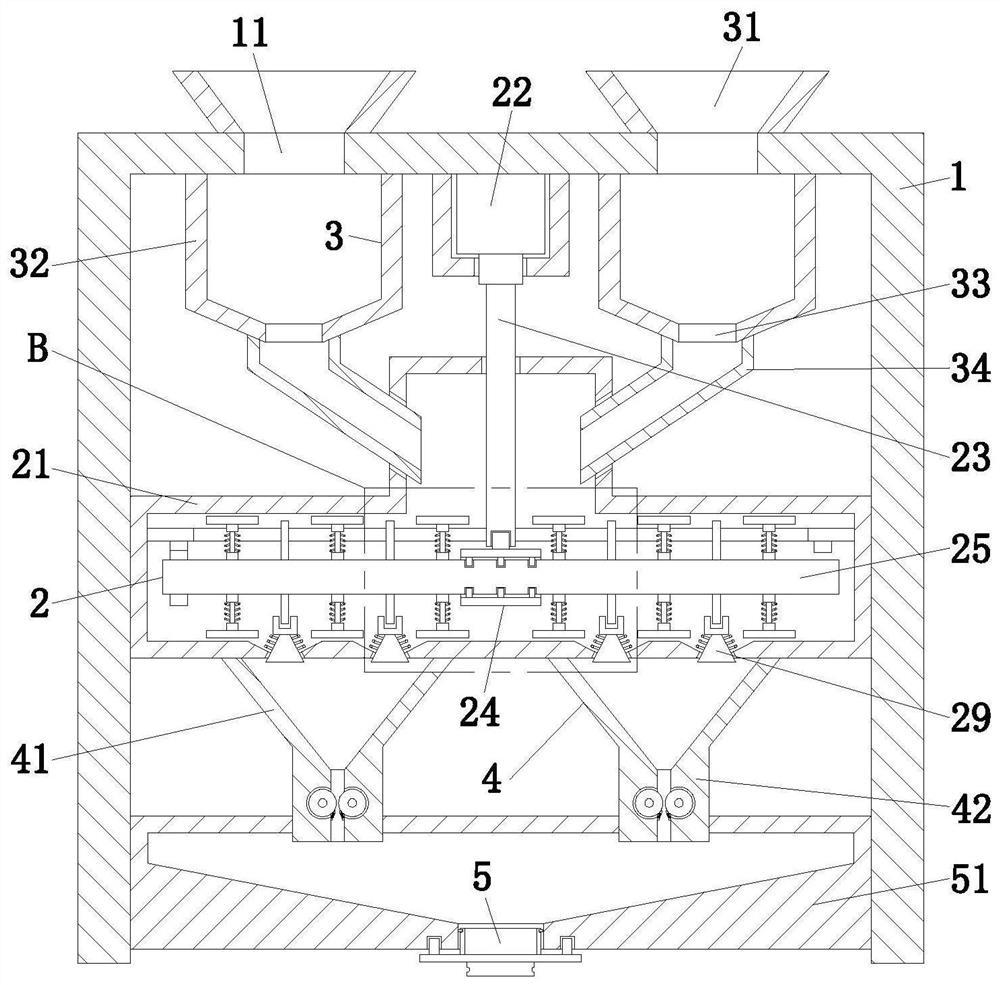

PendingCN108819590AAvoid multiple transfersReduce scratchesStampingEmbossing decorationsKnurlingEngineering

The invention relates to a knurling and lettering integrated machine, aiming to solve the problem of low working efficiency caused by two procedures for knurling and lettering in the prior art. The knurling and lettering integrated machine is characterized in that the knurling and lettering integrated machine comprises a machine body provided with a knurling device and a lettering device; the machine body is provided with a feed track, a discharge track, a transfer mechanism and a driving mechanism; the transfer mechanism is arranged between the feed track and the discharge track, and is usedfor sequentially moving aluminum bottle caps on the feed track to a knurling position, a lettering position and the discharge track; the driving mechanism is used for driving the knurling device, thelettering device and the transfer mechanism to move. The knurling and lettering integrated machine has the advantages that knurling and lettering are integrated in one procedure, so that the processing efficiency is improved effectively, and the yield is increased; the aluminum bottle caps are prevented from being transferred for many times, so that unnecessary friction is avoided, surface scratches of products are reduced, and product appearance is perfected.

Owner:连云港永发包装有限公司

Data transmission device and method

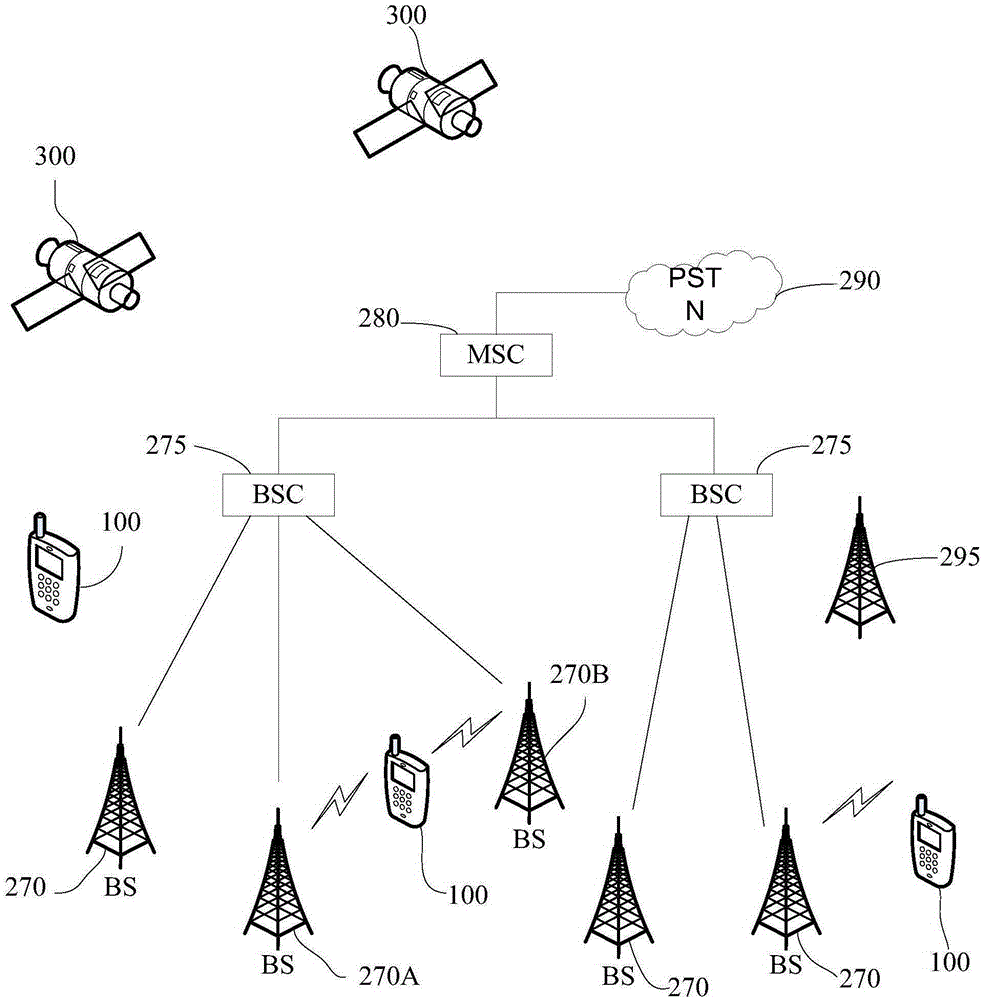

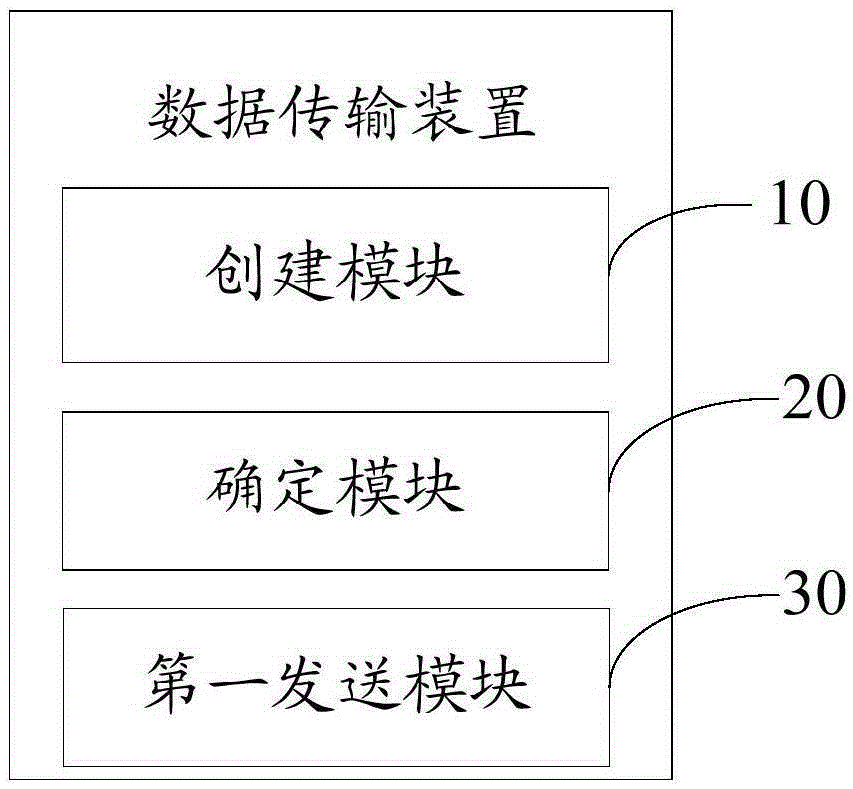

ActiveCN105263195AAvoid multiple transfersImprove transmission efficiencyConnection managementComputer hardwareData transmission

The invention discloses a data transmission device. The device comprises an establishment module used for receiving a data transmission instruction sent by a first terminal of a first operating system, and then establishing a storage path corresponding to the data transmission instruction according to the received data transmission instruction; a determination module used for determining whether the storage path corresponding to the data transmission instruction has been established or not; and a first sending module used for sending a successful establishment massage to the first terminal after the successful establishment of the storage path. In this way, the first terminal can transmit data to a second terminal based on the successful establishment massage. The invention also discloses a data transmission method. According to the invention, the data transmission efficiency is improved.

Owner:NUBIA TECHNOLOGY CO LTD

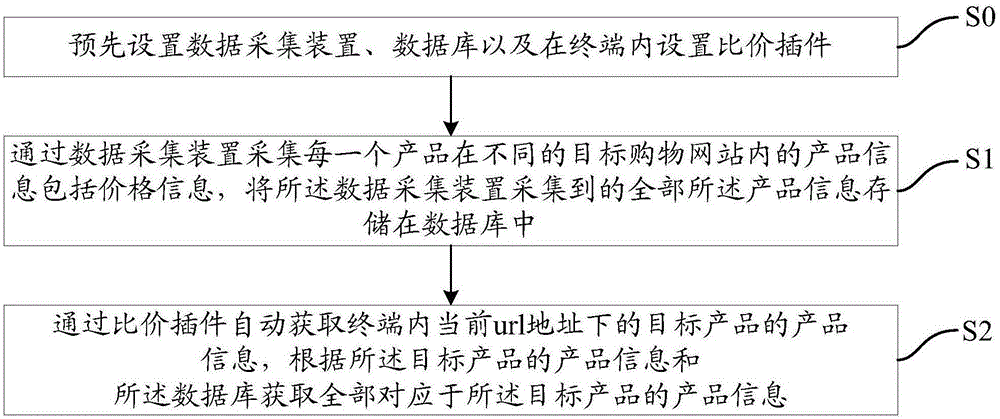

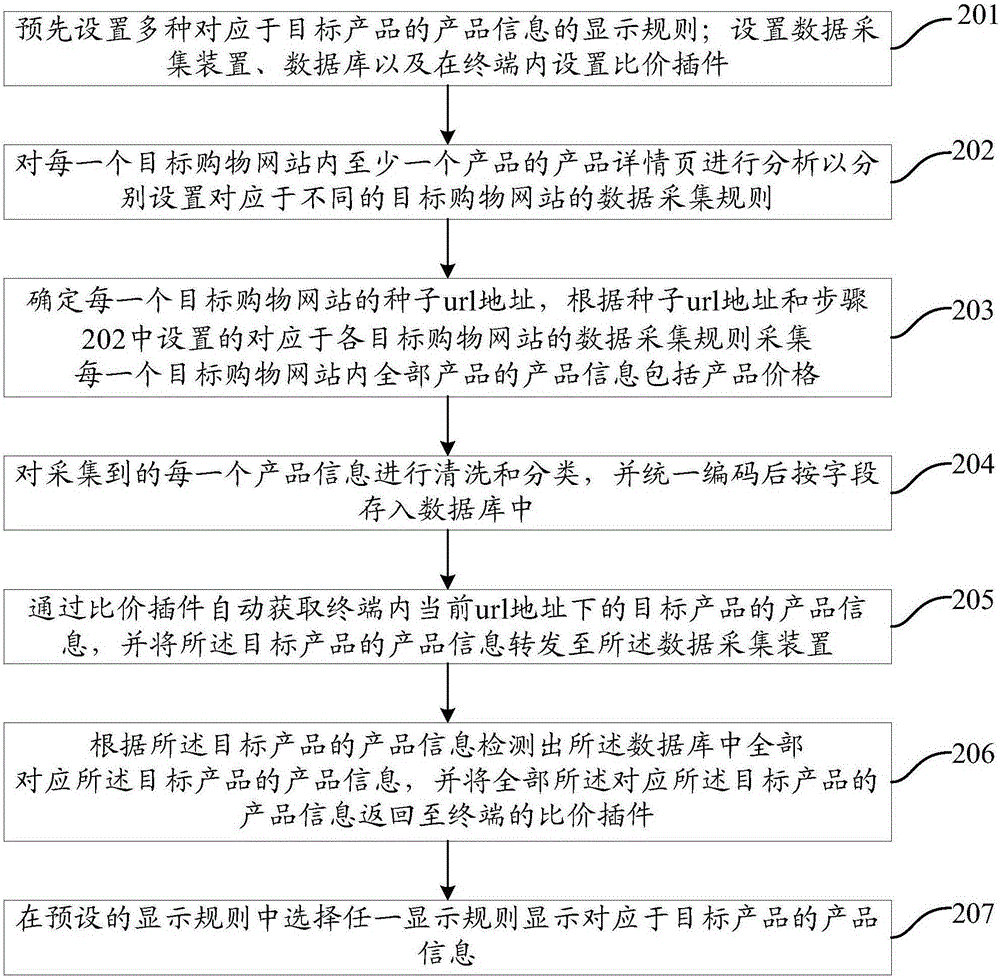

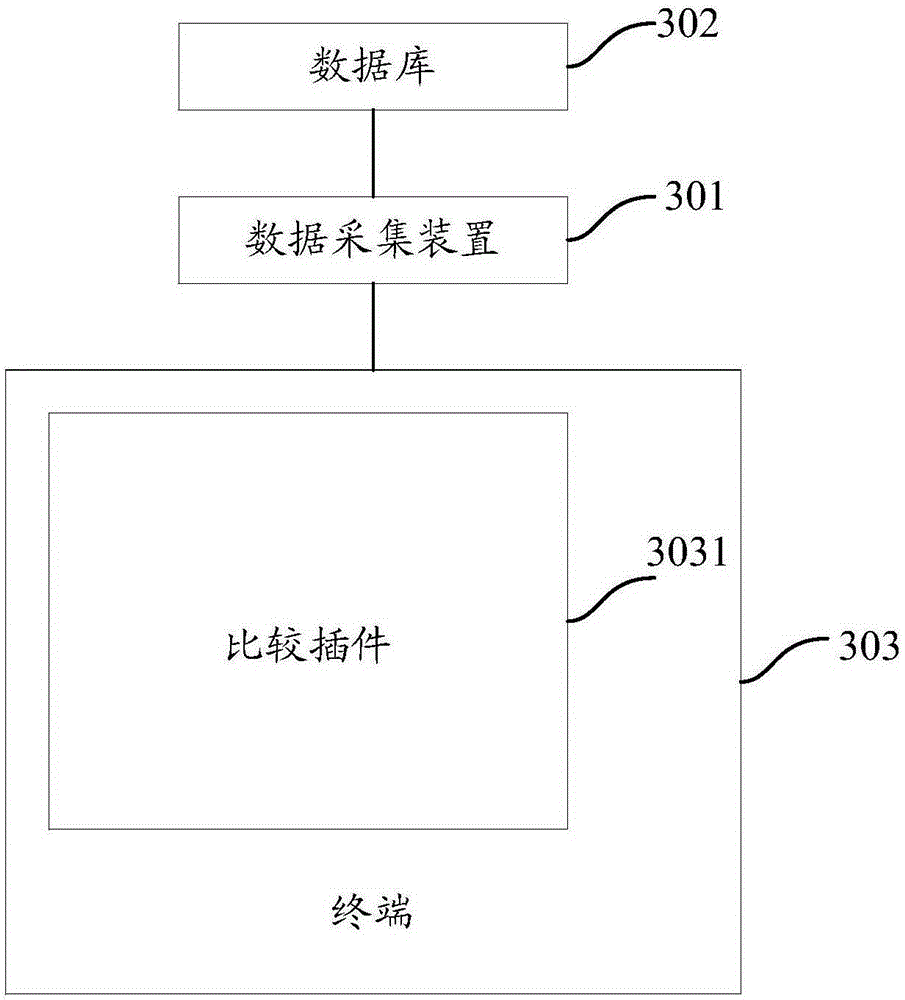

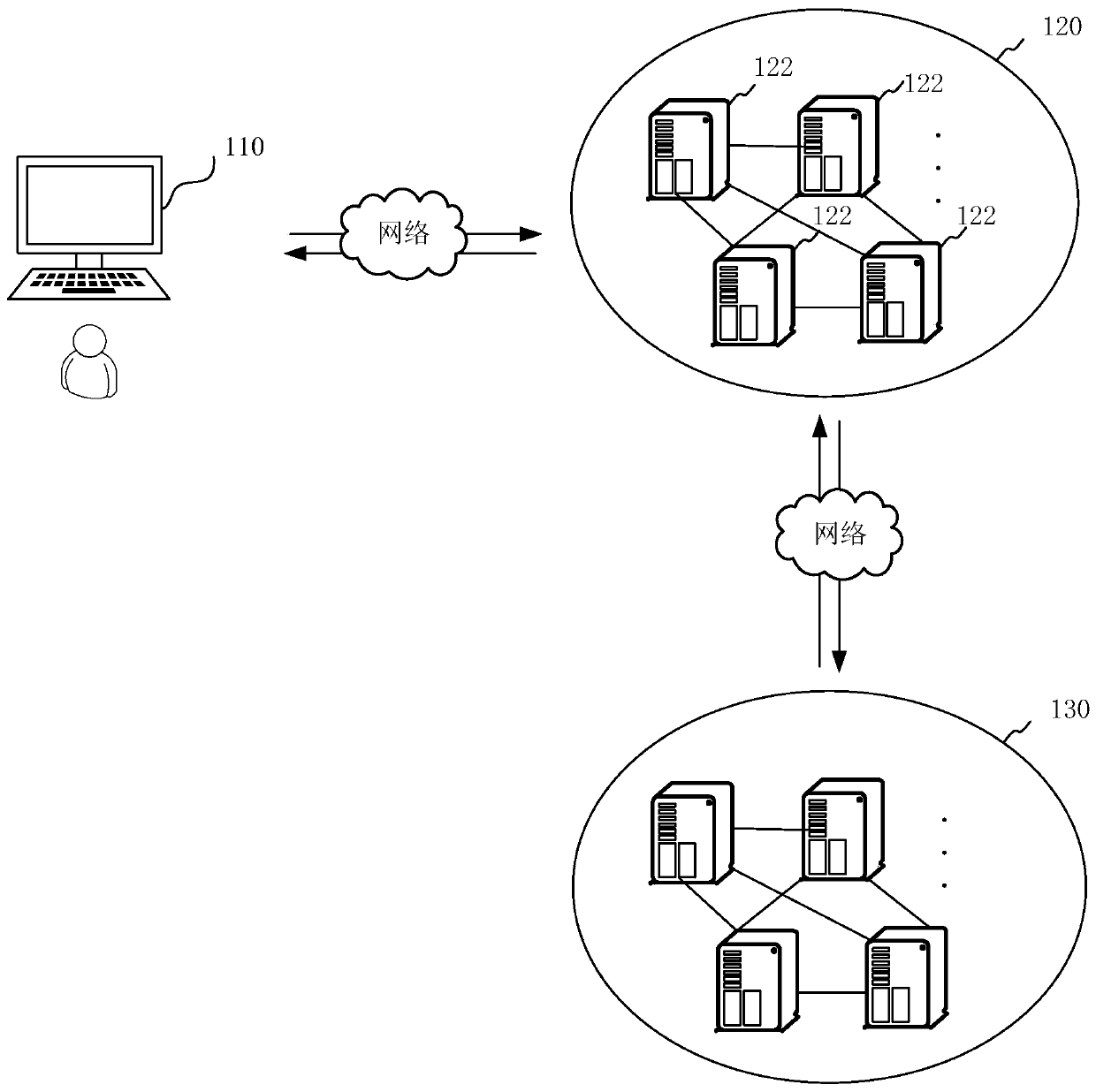

Method and system for obtaining product price information

InactiveCN105205686AReduce use costImprove experienceMarketingSpecial data processing applicationsData acquisitionComputer terminal

The invention provides a method and system for obtaining product price information. The method comprises: S0, arranging a data acquisition device and a database in advance and arranging a price comparison plug-in in a terminal, and further comprises the following steps: S1, acquiring product information of each product in different object shopping websites through the data acquisition device, including product prices, and storing all the product information acquired by the data acquisition device in the database; and S2, automatically obtaining product information of an object product at a current url address through the price comparison plug-in, and according to the product information of the object product and the database, obtaining product information all corresponding to the object product. Through the technical scheme provided by the invention, the price information of the same object price on other object shopping websites can be known by a user without leaving a current shopping platform, such that multiple page flows are avoided, the application cost of the user is decreased, and user experience is improved.

Owner:INSPUR QILU SOFTWARE IND

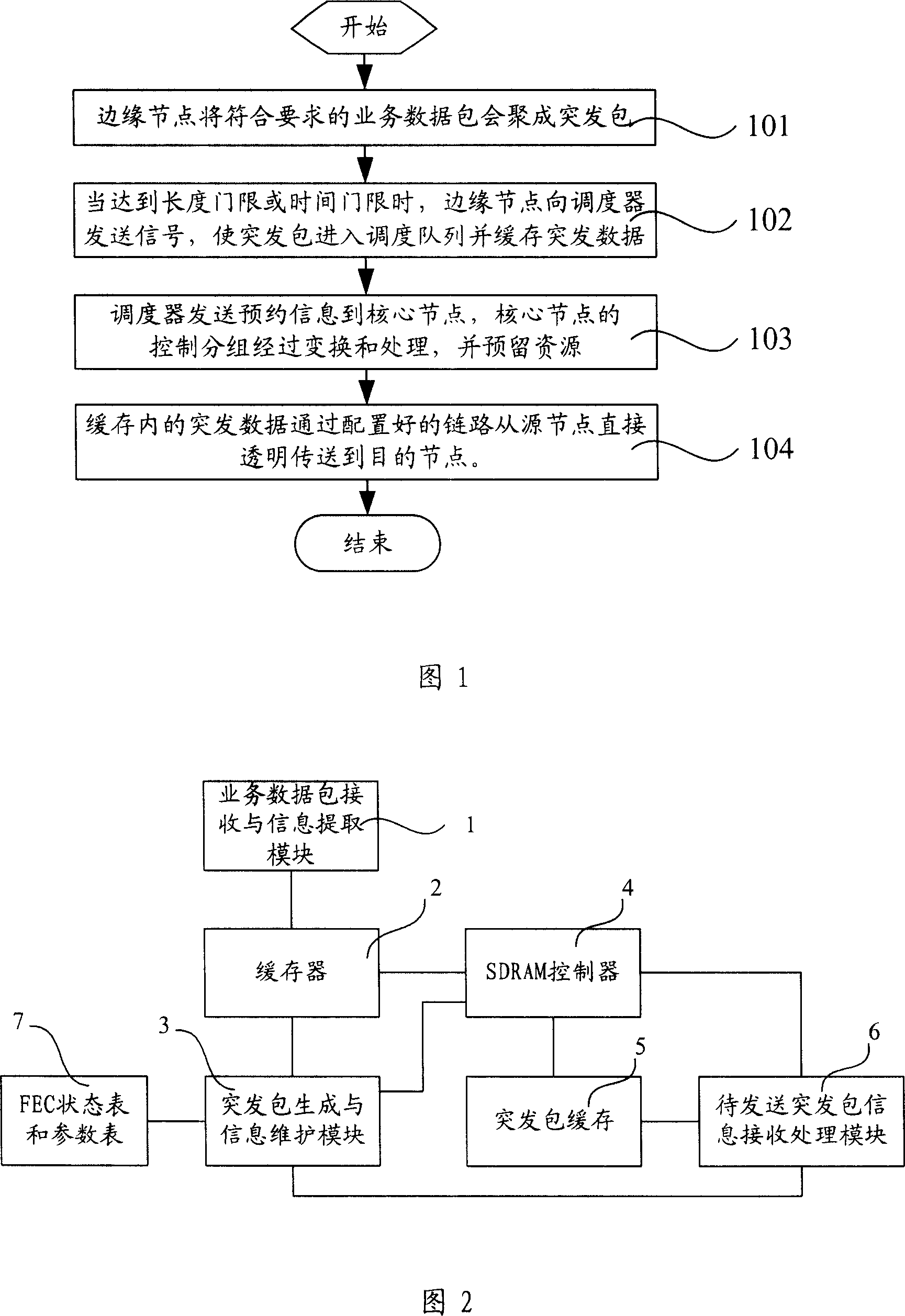

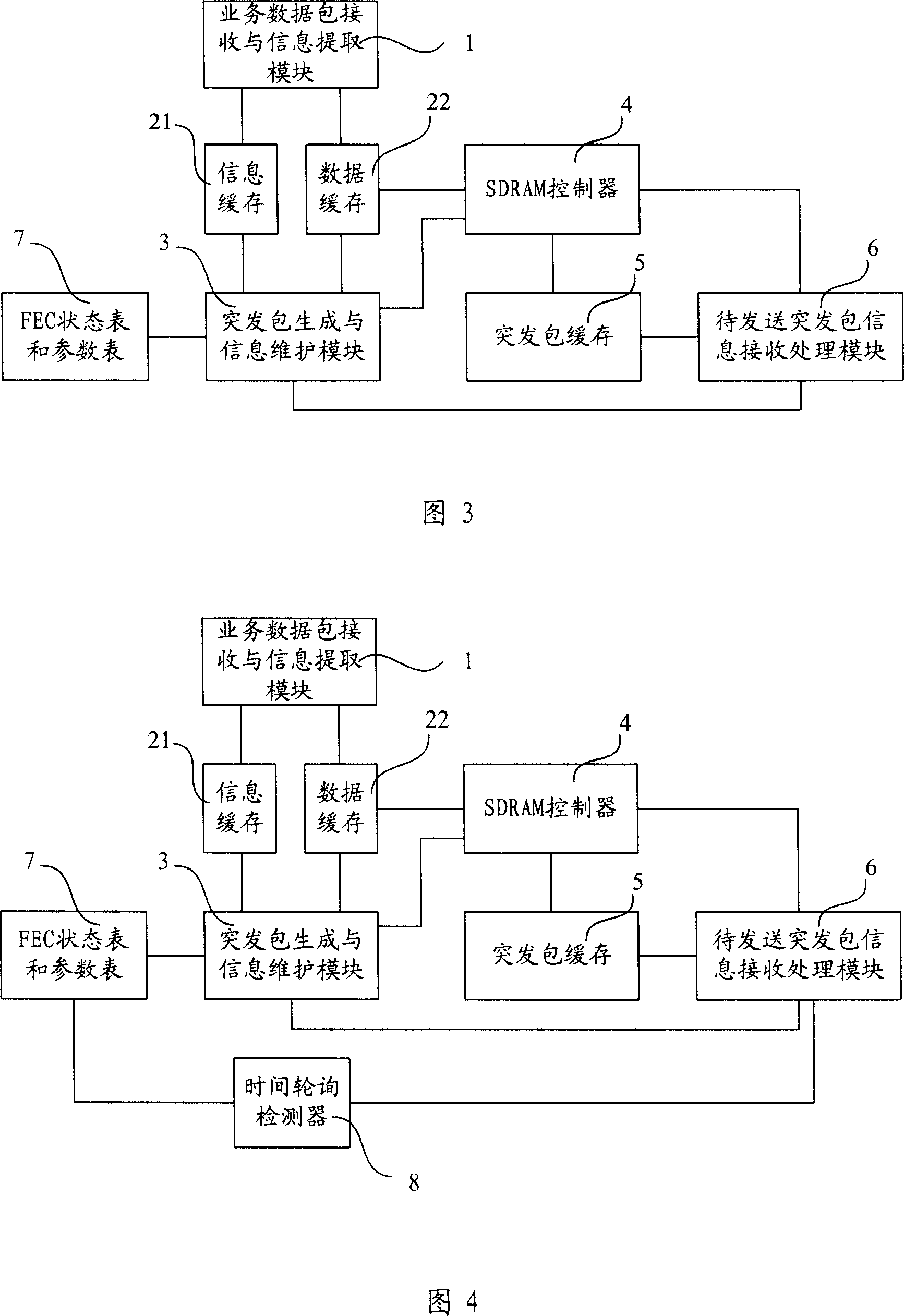

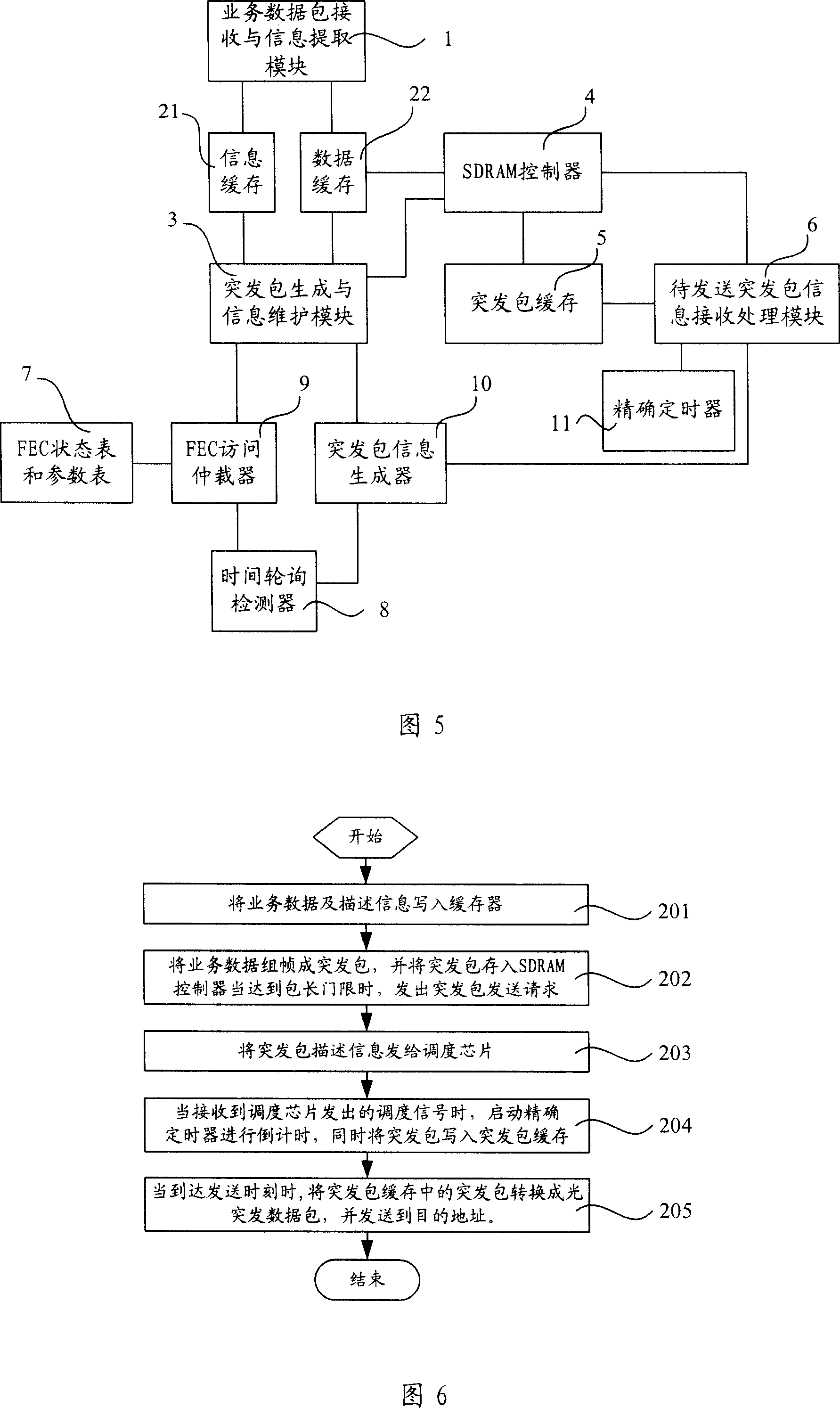

Optical burst switch network based burst packet dispatching system and method

InactiveCN101098298AAvoid multiple transfersImprove assembly efficiencyMultiplex system selection arrangementsData switching networksExchange networkComputer science

Owner:BEIJING UNIV OF POSTS & TELECOMM +1

Automatic and rapid detection method and system for trace iron ions in power plant water vapor and application

ActiveCN105388309AImprove processing efficiencyAvoid multiple transfersMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsWater vaporEngineering

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

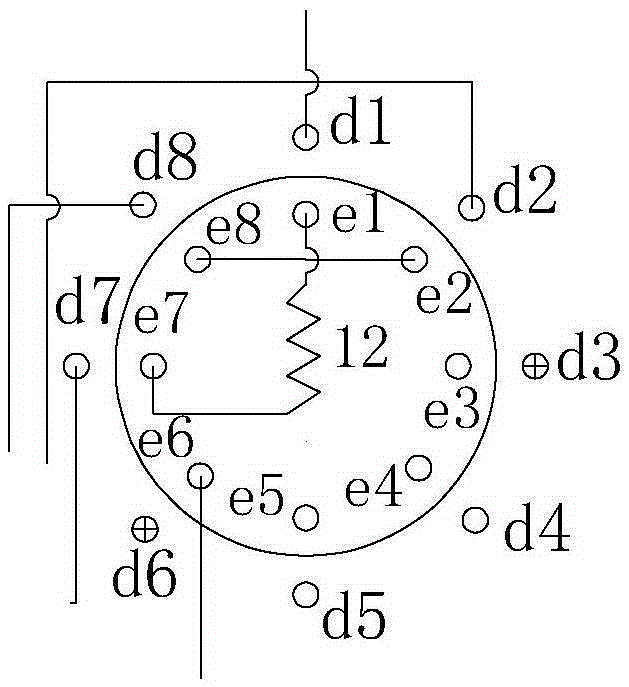

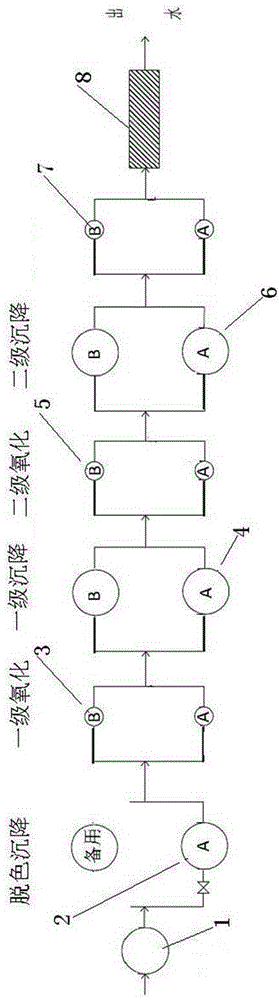

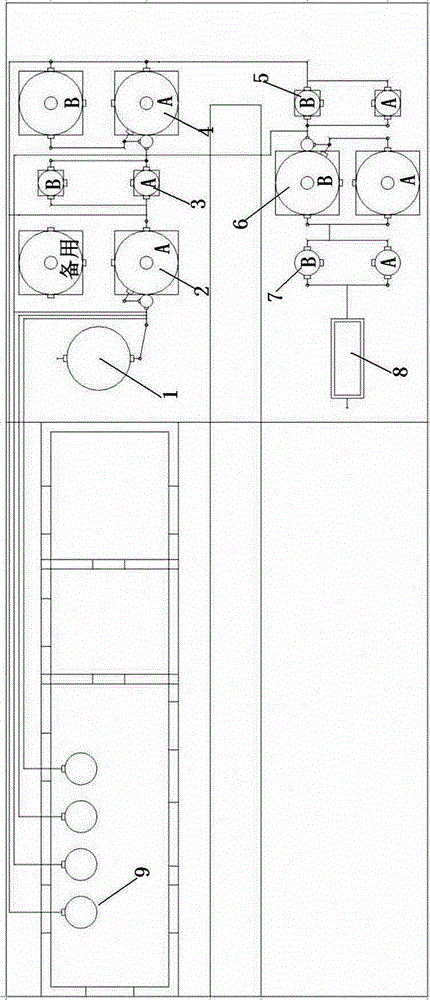

Method and application for using compound microorganisms for landfill leachate treatment

ActiveCN105417732AEmissions don't stinkDischarge water is not smellyTreatment with anaerobic digestion processesMultistage water/sewage treatmentBiologyPhotosynthetic bacteria

The invention discloses a method and application for using compound microorganisms for landfill leachate treatment. The method is achieved by treating landfill leachate through compound organisms. The compound organisms are compounds containing photosynthetic bacteria and florae, saccharomycetes and florae, actinomycetes and florae, nitrogen-fixing bacteria and florae, lactic acid bacteria and florae, bifidobacteria and florae, spore bacteria and florae, and DL bacteria and florae. Applied treatment devices include an anaerobic reaction device, a decoloration and sedimentation device, a treatment unit and a microorganism fluidization device which are sequentially connected. The treatment unit comprises a microorganism reaction device and a dense sedimentation device arranged behind the microorganism reaction device. The anaerobic reaction device, the microorganism reaction device and the microorganism fluidization device are filled with compound microorganisms. By means of the method and application for using compound microorganisms for landfill leachate treatment, the effects of sludge removal and zero emission can be achieved, and discharged water is free of odor and corrosion, colorless and tasteless, and various physicochemical indexes reach national standards.

Owner:上海天微环保科技有限公司

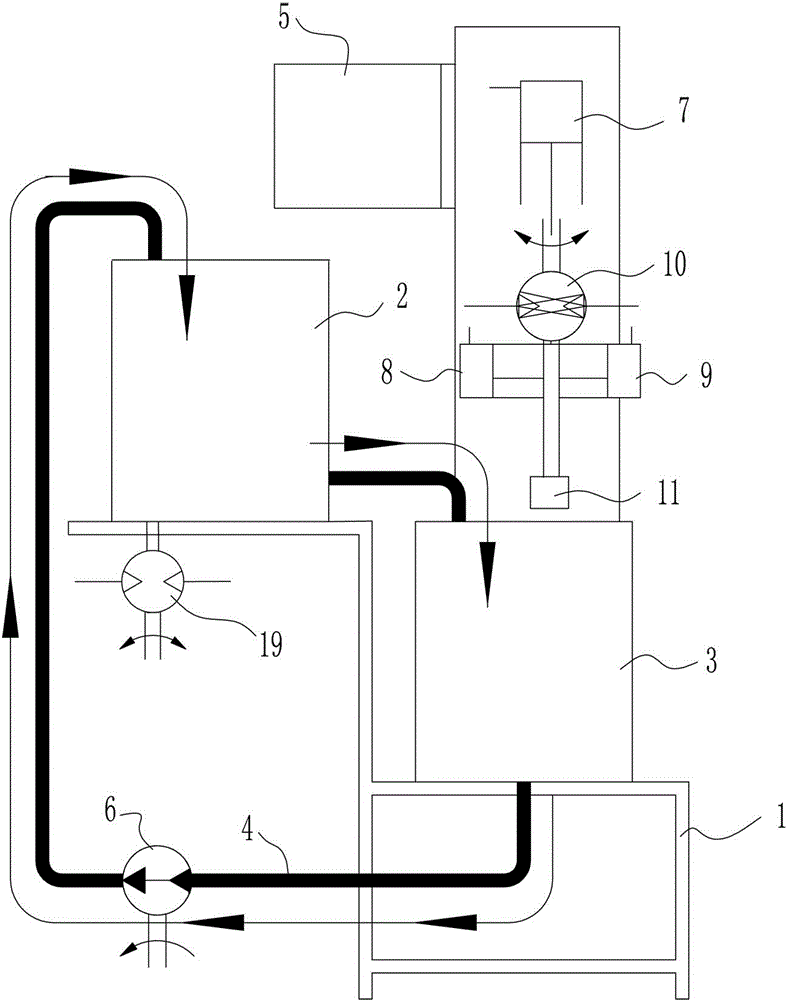

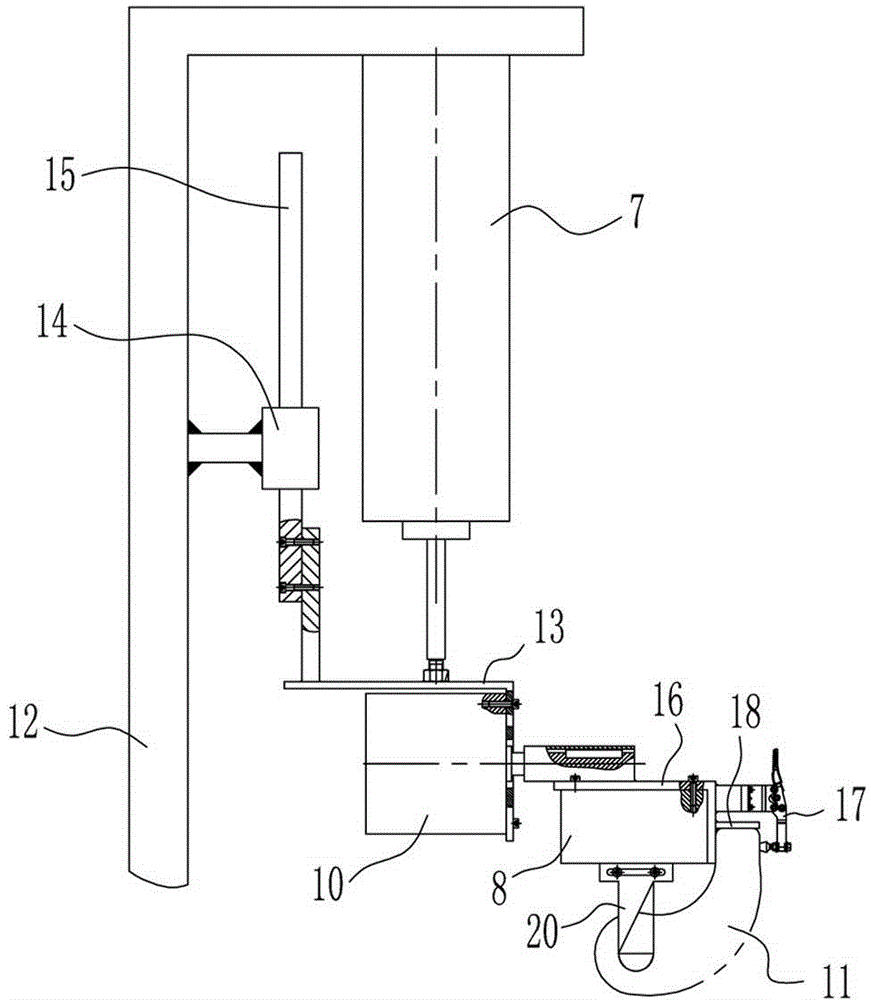

Surface treatment device for sand core of housing

The invention discloses a surface treatment device for a sand core of a housing. The device mainly comprises a supporting base, a tool clamp, a driving device and a PLC control system as well as a stirring tank and a dip-coating tank which are arranged on the supporting base, wherein the stirring tank is communicated with the dip-coating tank by virtue of a pipeline to form a closed loop; a hydraulic pump is arranged on the pipeline; the tool clamp is arranged above the dip-coating tank and is fixedly arranged on the lower end part of the driving device; the PLC control system is electrically connected with the tool clamp and the driving device; the PLC control system controls the tool clamp to clamp the sand core and controls the driving device to penetrate the clamped sand core into the dip-coating tank to be dip-coated. According to the surface treatment device disclosed by the invention, the coating in the dip-coating tank is still in a dynamic state, the sand core is clamped by virtue of the tool clamp and the moving trajectory of the sand core is controlled by virtue of the driving device, and the time of dip-coating the sand core is controlled, so that a consistent surface coating thickness is obtained, and therefore, the stability of the product dimension is facilitated; moreover, the working environment of the operator is effectively improved, personnel allocation is optimized, and the work efficiency is greatly improved.

Owner:西峡县众德汽车部件有限公司

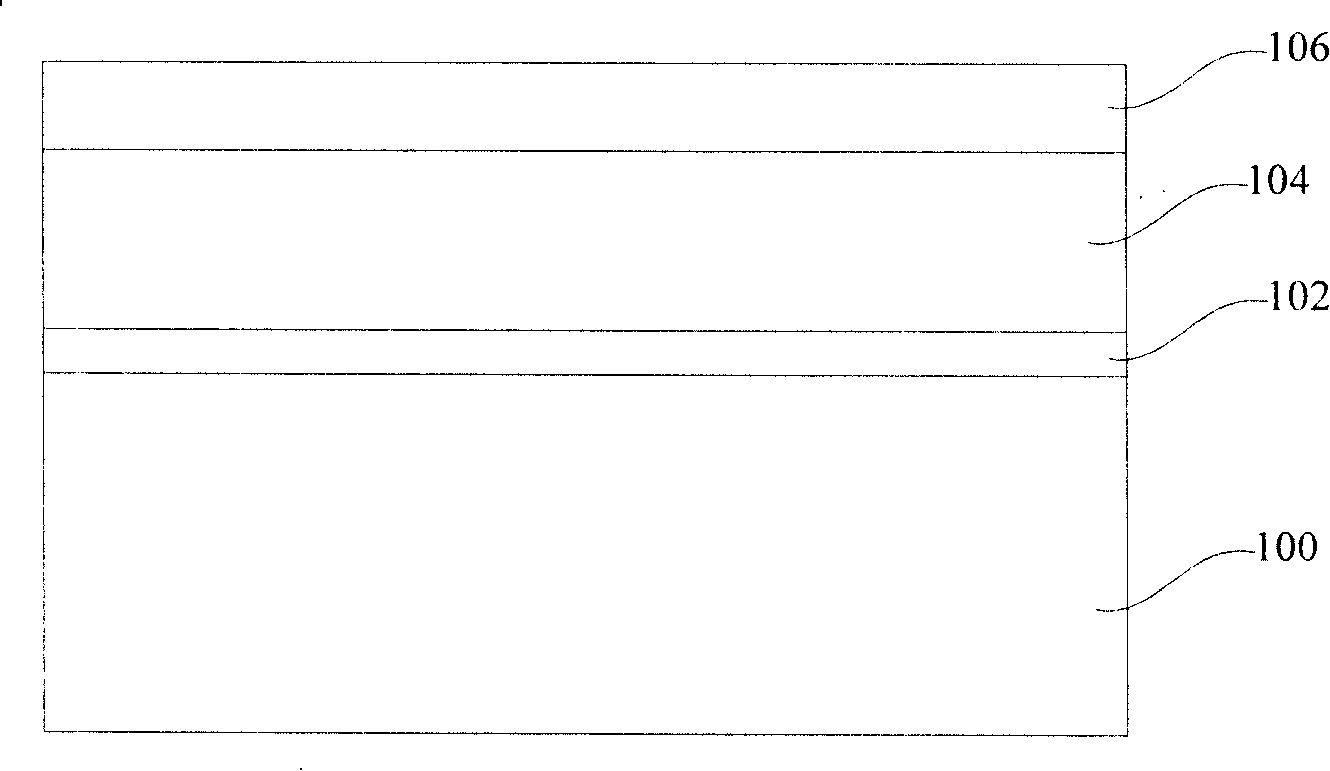

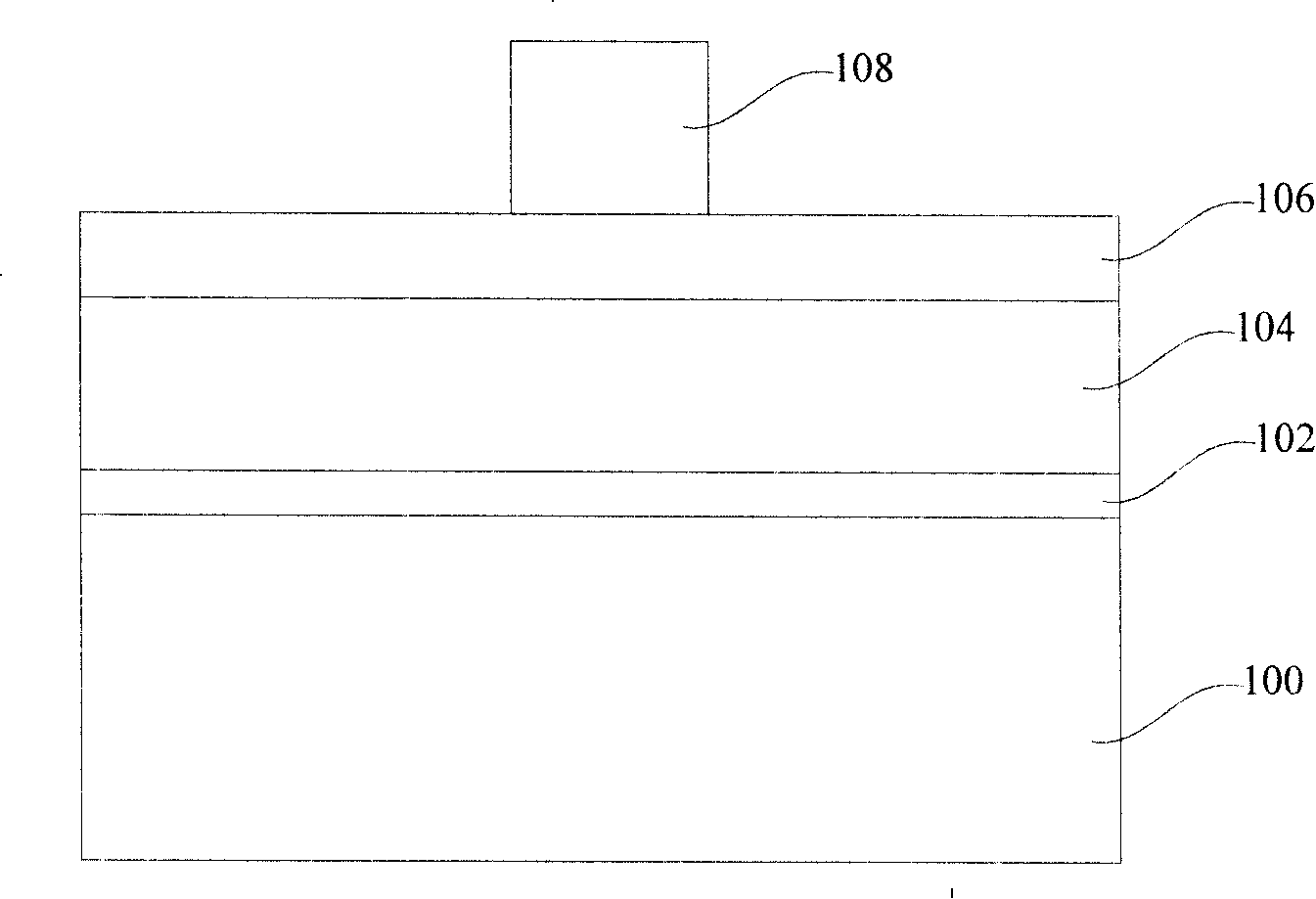

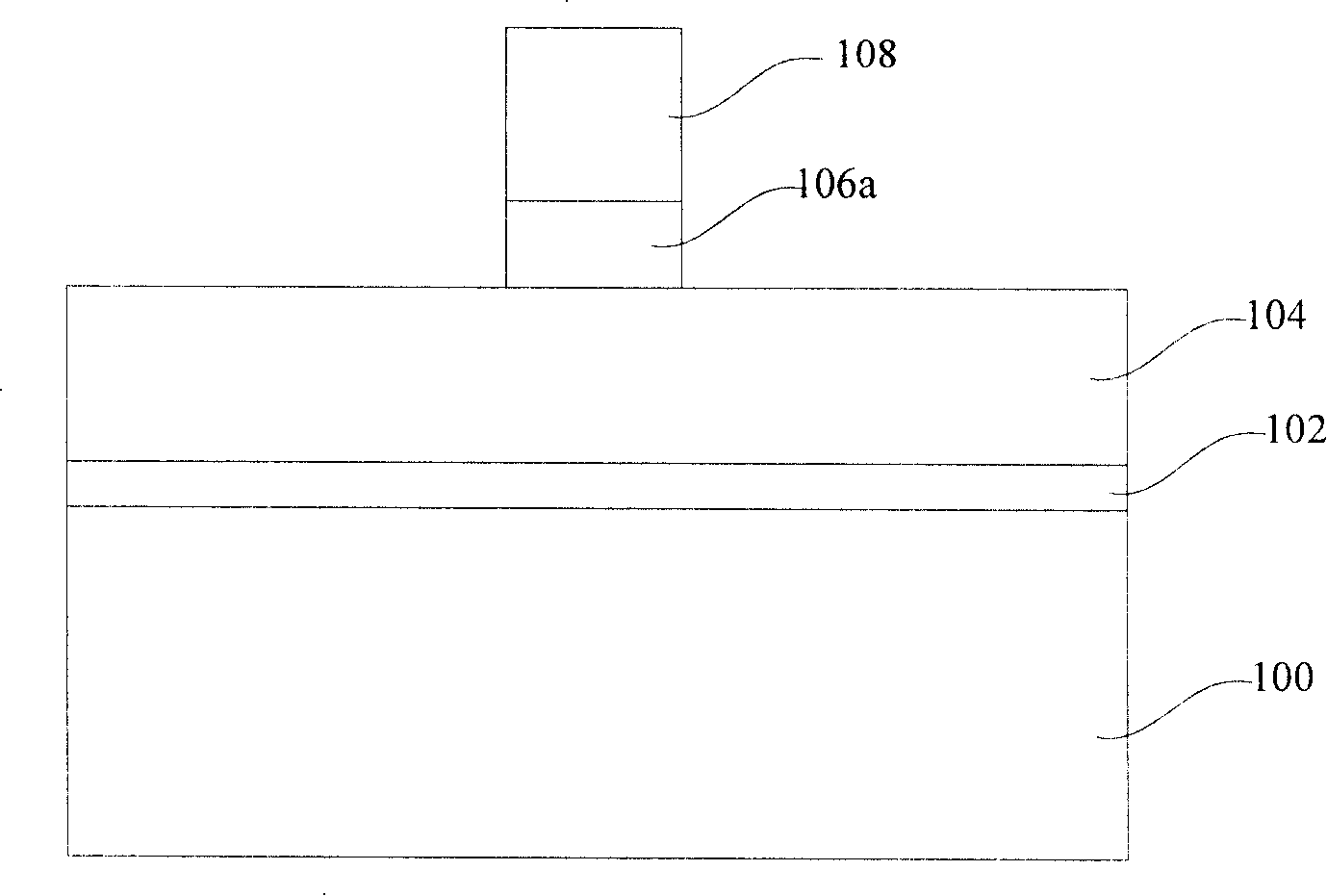

Grids production method

InactiveCN101197262AImprove contourEnable sensitive and controllableSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingElectrical conductorGrid pattern

The invention relates to a manufacture method for grid, which comprises the following steps of: providing a semi-conductor substrate and forming a conductive layer on the semi-conductor substrate; revolving and coating optical carved glue layer on the conductive layer and imaging to form a grid pattern; transferring the grid pattern to the conductive layer through etching; measuring the line width of the grid and judging whether the bottom of the grid has a foot-shaped drawback, and performing directional plasma etching for the grid which has the foot-shaped drawback. The grid formed by the method has a better side wall profile.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Bag clamping device realizing movable clamping through bag sleeving ring

The invention discloses a bag clamping device realizing movable clamping through a bag sleeving ring. The bag clamping device comprises first brackets, fourth brackets, fifth brackets, fixing plates, clamping ring supports, piston rods, third brackets and second brackets, wherein each fixing plate is connected with one end of the corresponding fifth bracket, the other end of the fifth bracket is connected with one end of the corresponding fourth bracket, the middle of the fourth bracket is connected with one end of the corresponding clamping ring support, the other end of the clamping ring support is connected with a clamping ring, a hydraulic cylinder is arranged at the other end of the fourth bracket, a piston of the hydraulic cylinder is connected with one end of the corresponding piston rod, the other end of the piston rod is connected with one end of the corresponding third bracket, the other end of the third bracket is connected with one end of the corresponding second bracket, the other end of the second bracket is connected with one end of the corresponding first bracket, and the other end of the first bracket is connected with the lower end of the bag sleeving ring. Materials required to be bagged can be directly discharged into a bag, repeated transfer is avoided, and the labor intensity is reduced; meanwhile, the contact areas of the bag sleeving ring and the clamping ring with the bag are larger when the bag sleeving ring and the clamping ring clamp the bag, and the bag can be clamped stably.

Owner:重庆市江津区前进焊接材料厂

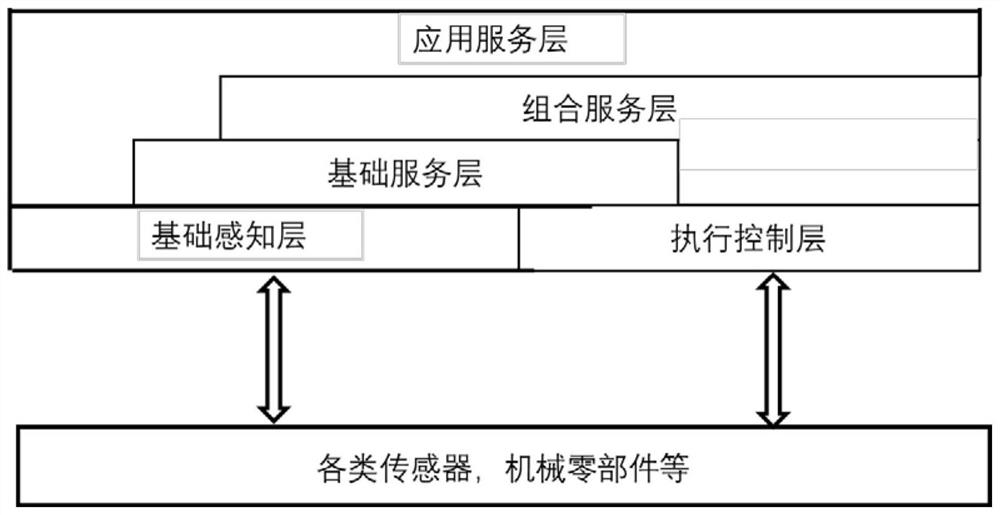

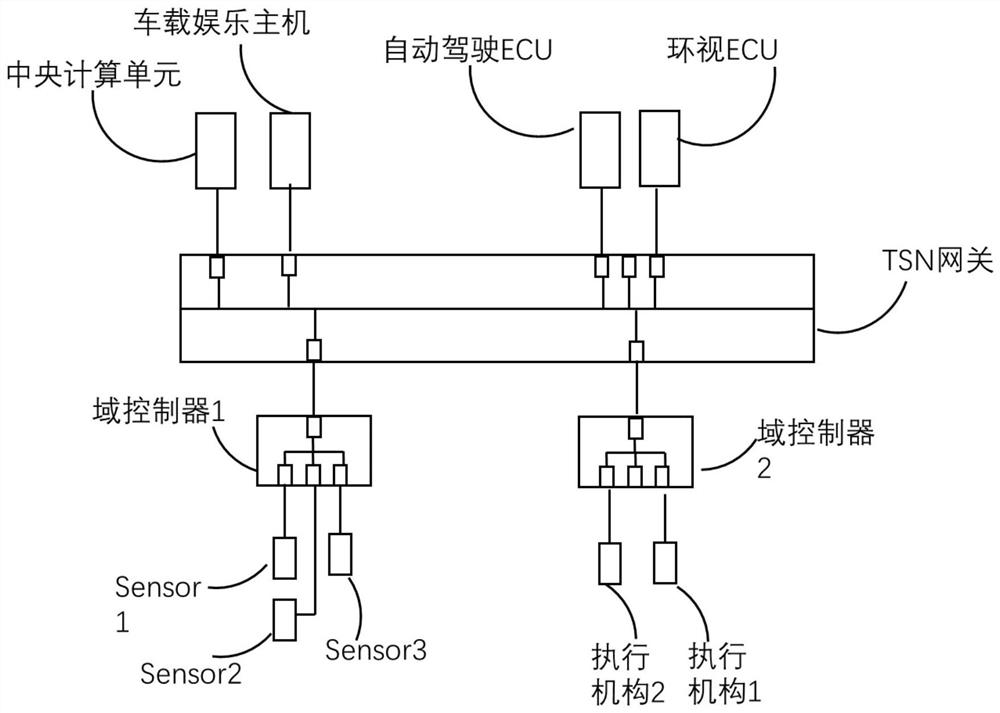

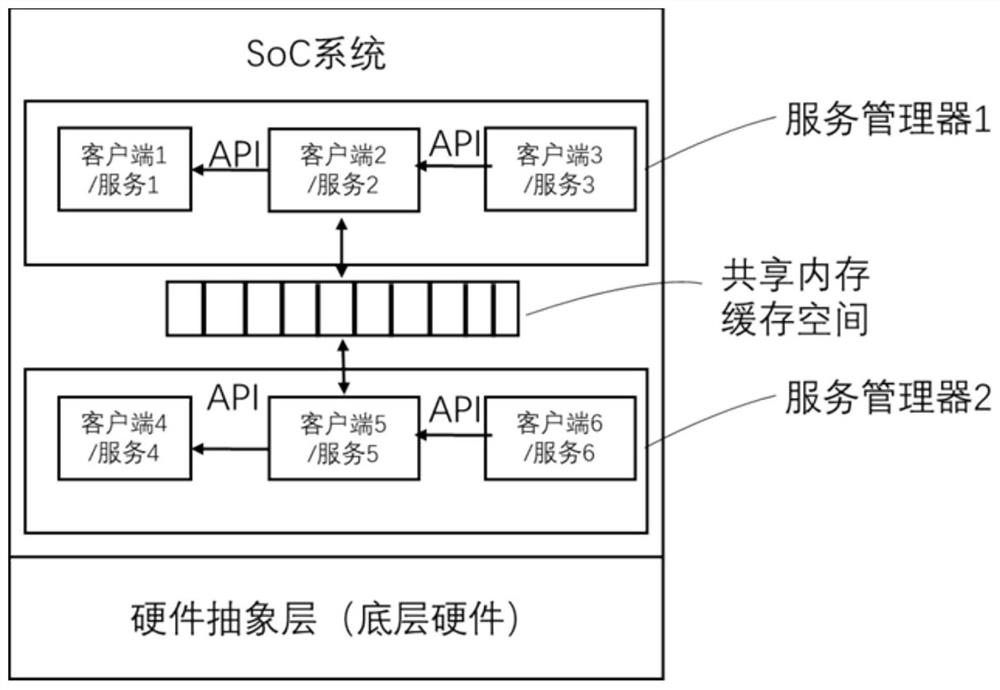

Vehicle-mounted network communication method for service-oriented architecture

The invention provides a vehicle-mounted network communication method for a service-oriented architecture, and the method comprises a basic sensing layer which is used for receiving data collected by external equipment; the basic service layer is used for receiving the data from the basic sensing layer, analyzing the data and converting the data into corresponding services; and the combined service layer is used for receiving the service provided by the basic service layer, processing a service calling algorithm and issuing a corresponding service request to the basic service layer according to a processing result. In the technical scheme provided by the invention, hierarchical management and control are provided. Each layer realizes a specific function, the combined service layer provides upper-layer function services, high-order function services are realized in the combined service layer, bottom-layer service processing is realized in the basic service layer, and multiple times of transmission of information generated by multiple times of calling among services among the services among vehicle-mounted networks is avoided.

Owner:SHANGHAI HEQIAN ELECTRONICS TECH CO LTD

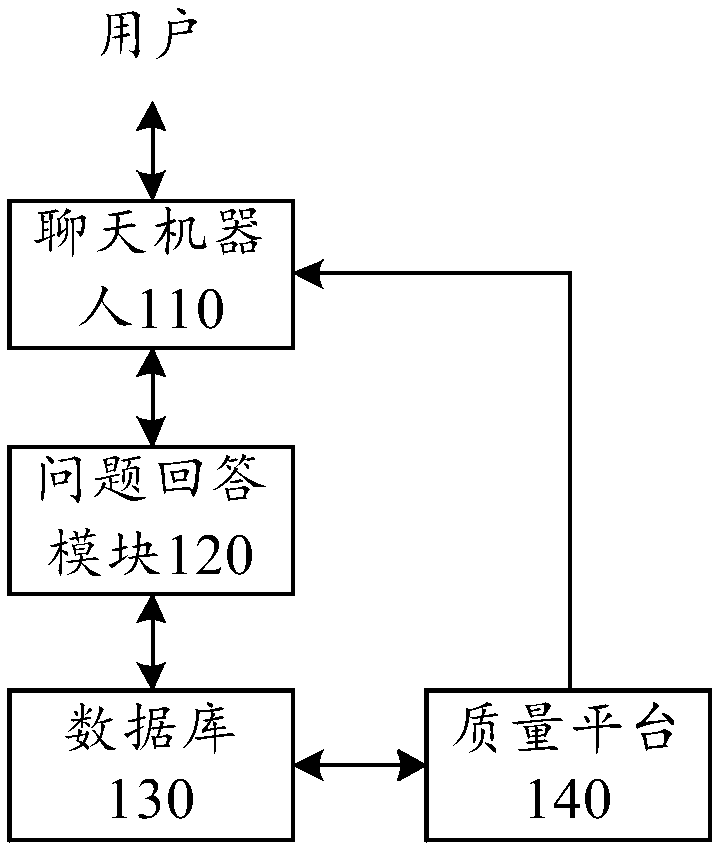

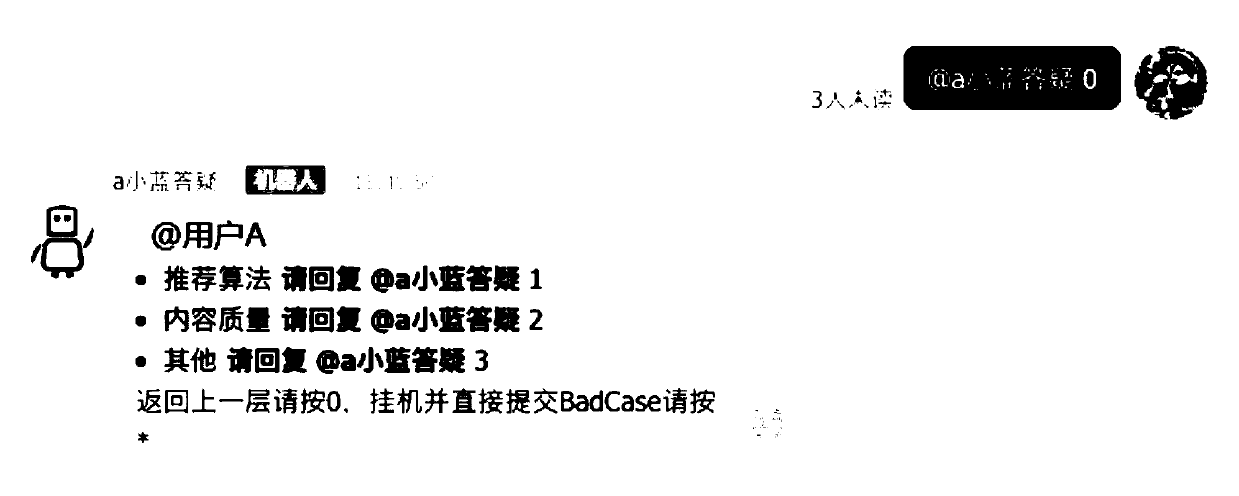

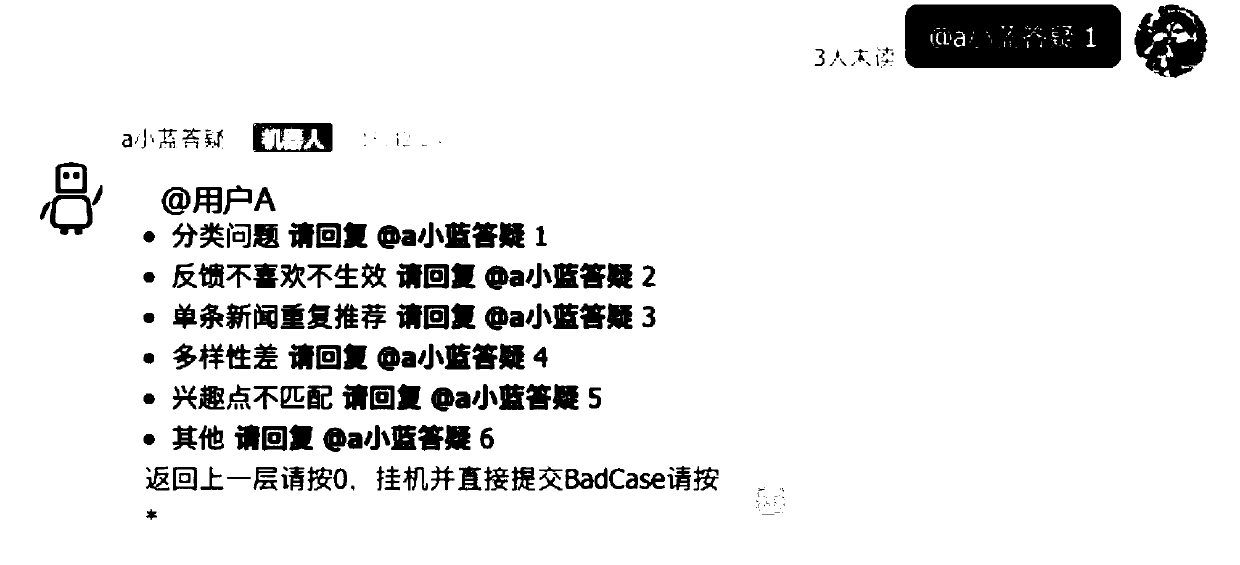

System and method for collecting user question

ActiveCN109525480AImprove online qualityEasy to trainData switching networksStructural ProblemInformation Harvesting

The invention discloses a system and a method for collecting user questions. The system comprises a chat robot, a question answering module, a database, and a quality platform. The chat robot is usedfor actual interaction with a user. The question answering module is used for guiding the chat robot to interact with the user to locate user question types and obtaining questions reported by the user and user information. The database is used for storing the located user question types, the questions reported by the user, and the user information. The quality platform obtains the user question types, the questions reported by the user, and the user information for analysis. Thus, the process of recording the entire process of problem classification, information collection, problem analysis and problem tracking is realized without human participation by taking the chat robot as a front end entrance. The structural problem obtained through analysis can be automatically provided to the back-end research personnel, thereby improving the recommendation precision of the whole recommendation system.

Owner:ALIBABA (CHINA) CO LTD

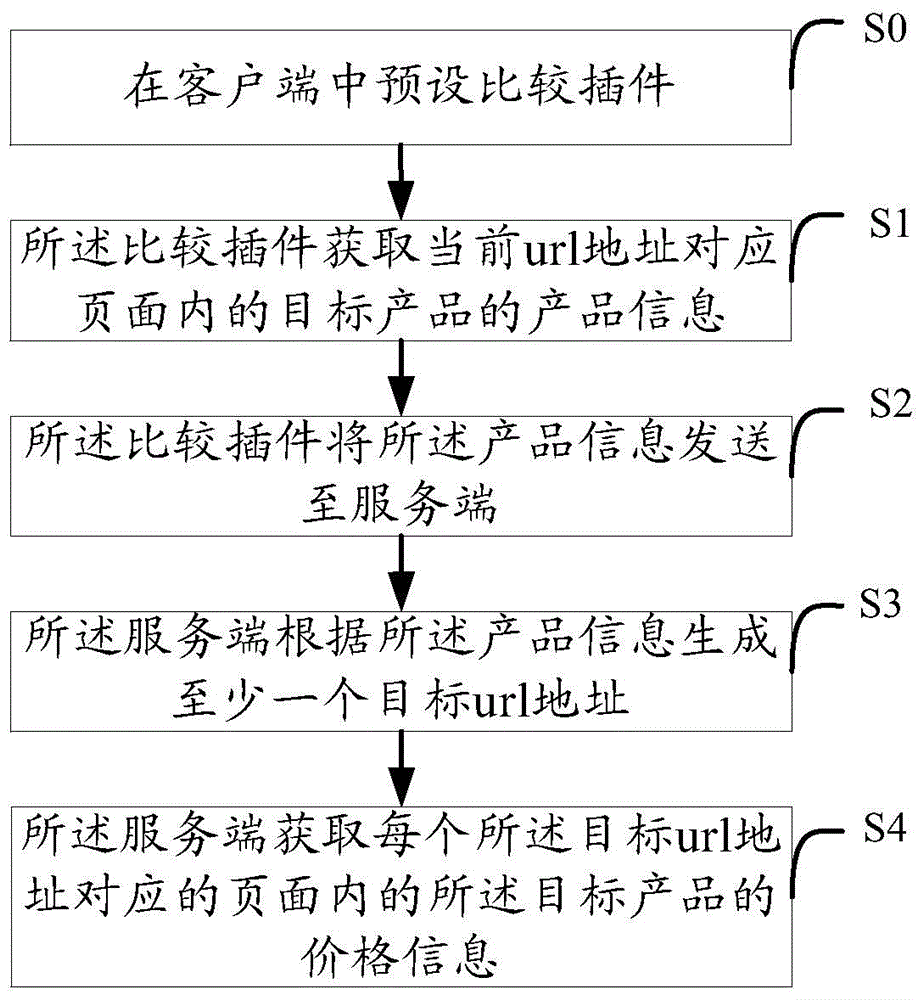

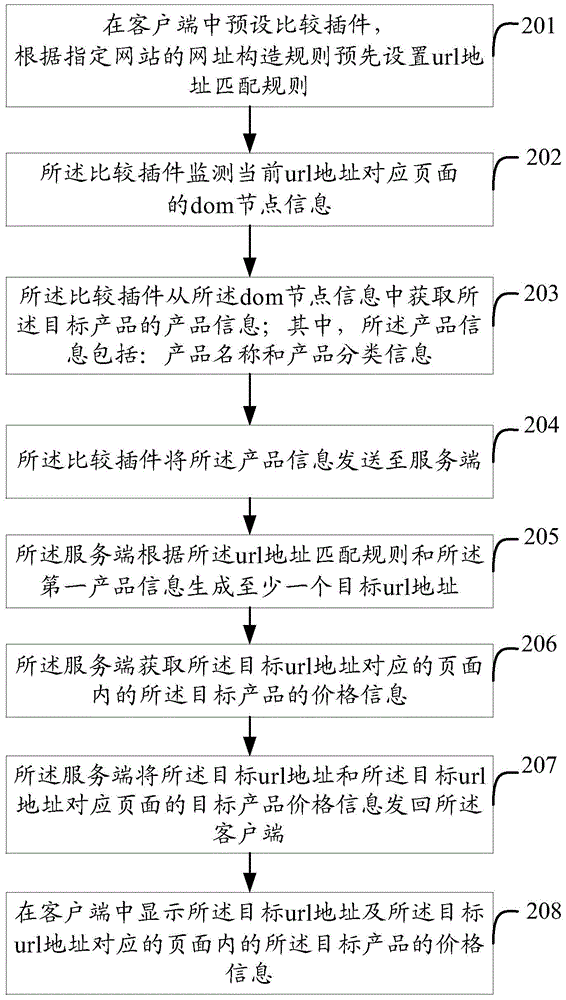

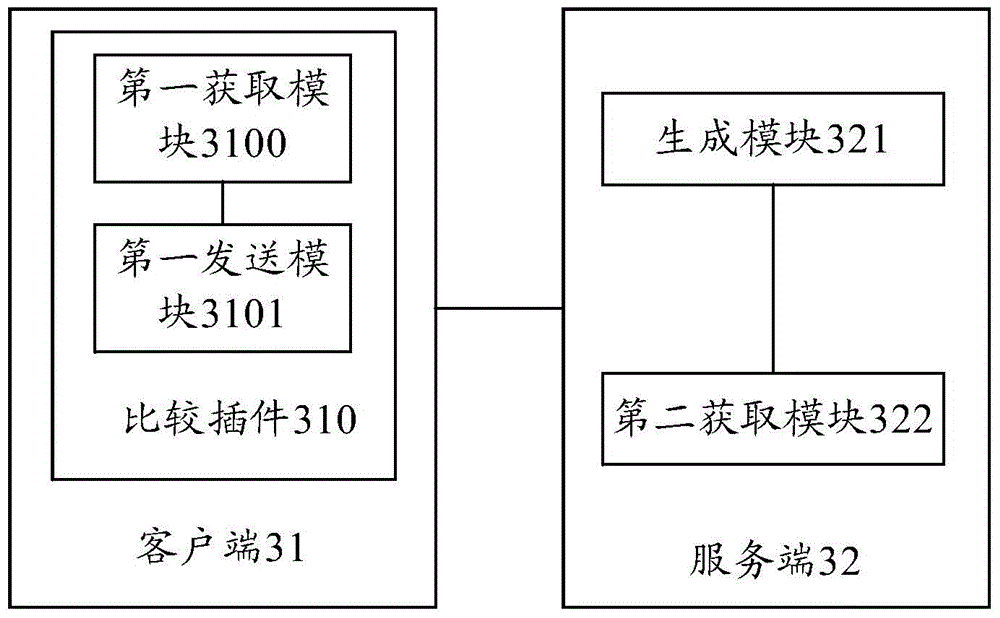

Product price information obtaining method and system

InactiveCN104978410AAvoid multiple transfersReduce use costWeb data indexingBuying/selling/leasing transactionsUniform resource locatorProduct price

The invention provides a product price information obtaining method and system. The method comprises the step of presetting a comparison plug-in in a client, and further comprises the steps that S1: the comparison plug-in obtains product information of a target product in a page corresponding to a current url address; S2, the comparison plug-in sends the product information to a server; S3: the server, according to the product information, generates at least one target url address; and S4: the server obtains price information of the target product in the page corresponding to each target url address. Through the technical scheme, the use costs of consumers in a price comparison process can be reduced.

Owner:INSPUR QILU SOFTWARE IND

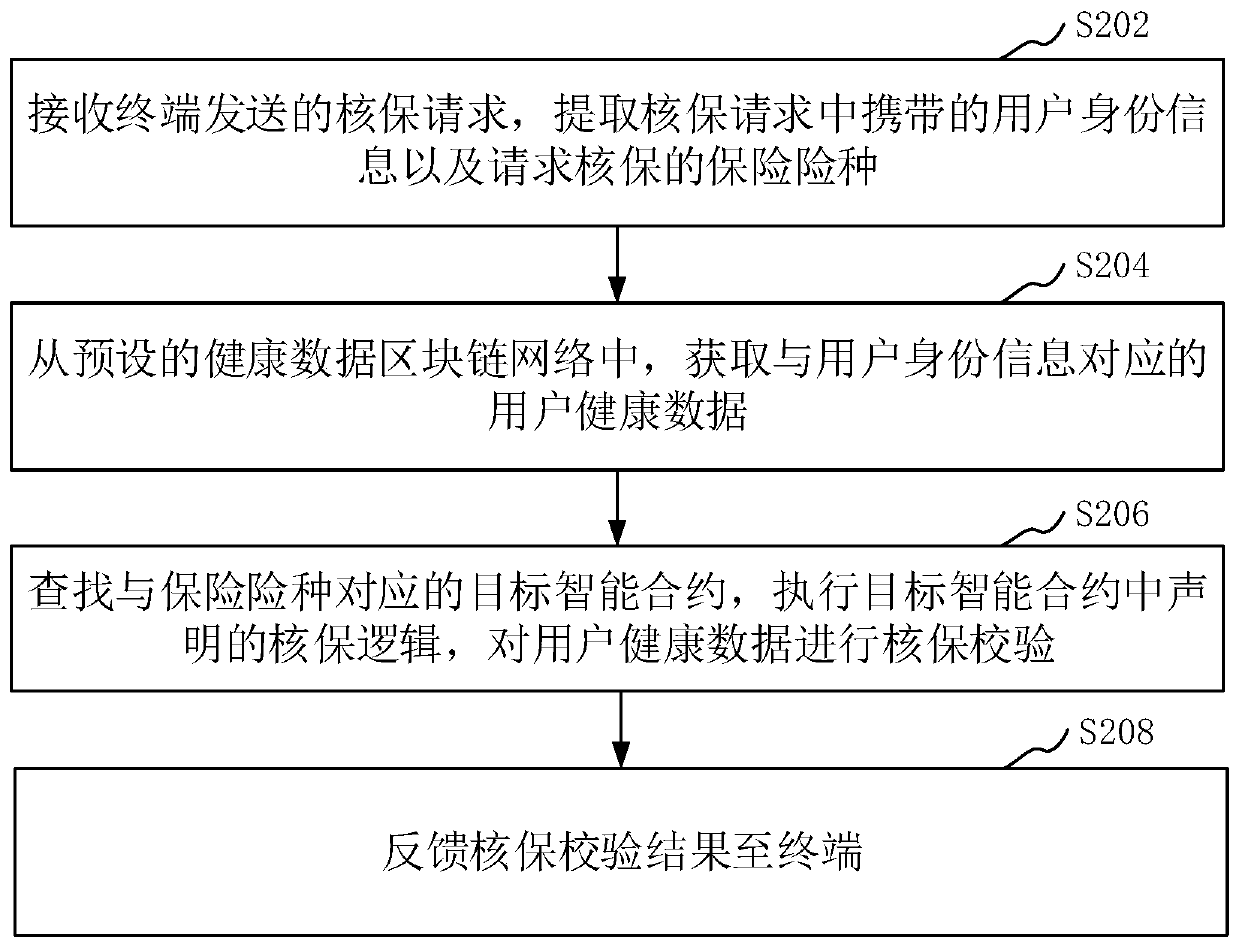

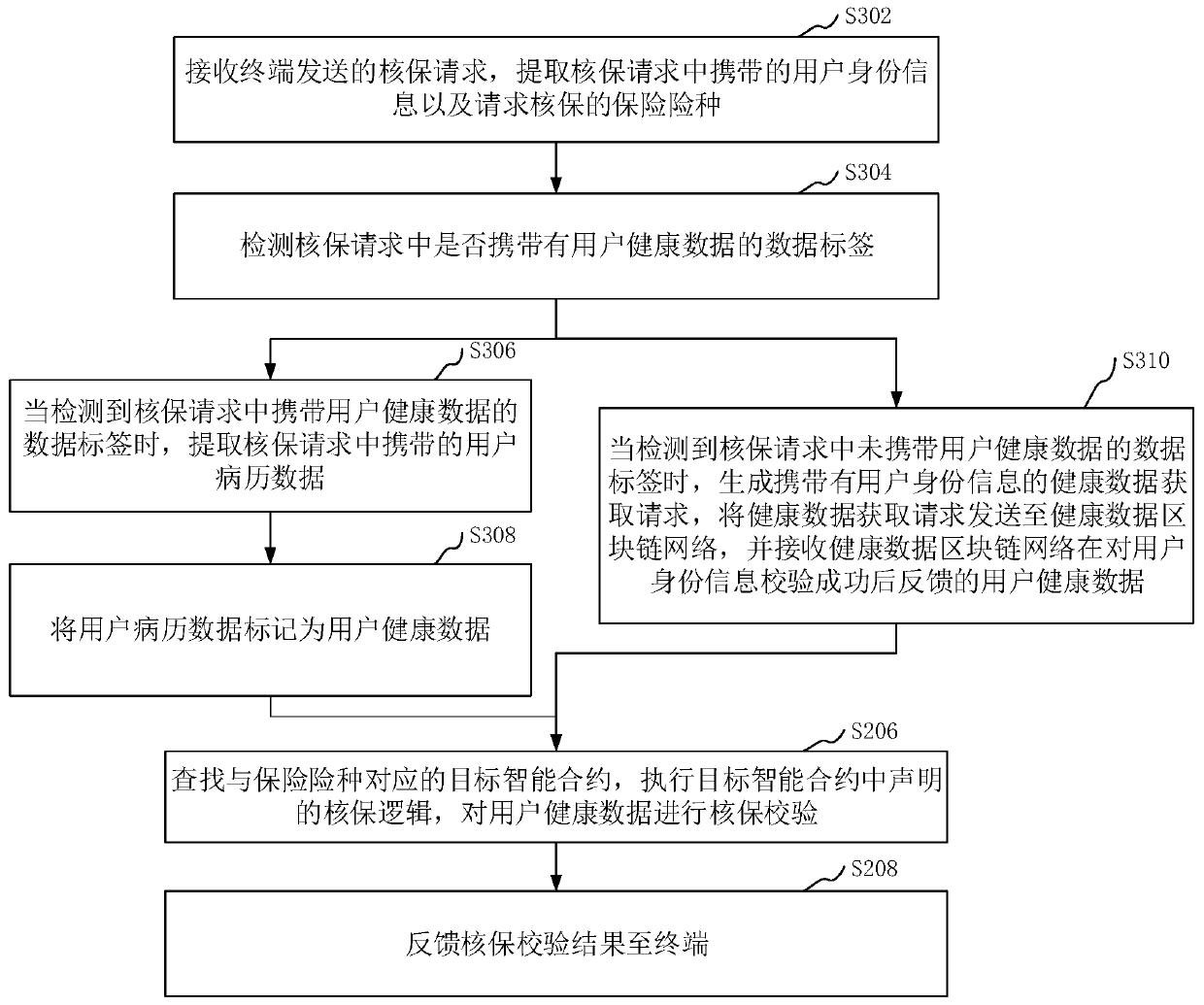

Insurance service data processing method and device based on block chain and storage medium

PendingCN110599357AGuarantee authenticityAvoid multiple transfersFinanceFile access structuresData verificationChain network

The invention relates to an insurance service data processing method and device based on a block chain, a computer readable storage medium and a computer device. The method comprises the following steps: receiving an underwriting request sent by the terminal, extracting user identity information carried in the underwriting request and an insurance type requesting underwriting; and obtaining user health data corresponding to the user identity information from a preset health data block chain network, searching a target intelligent contract corresponding to the insurance type, executing underwriting logic declared in the target intelligent contract, performing underwriting verification on the user health data, and feeding back an underwriting verification result to the terminal. According tothe scheme provided by the invention, multiple times of circulation and man-machine interaction of the data in the underwriting process can be avoided, the resource consumption is reduced, the processing efficiency is improved, the authenticity and reliability of a data source and the safety of a data verification process can be ensured, and the underwriting accuracy is further improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

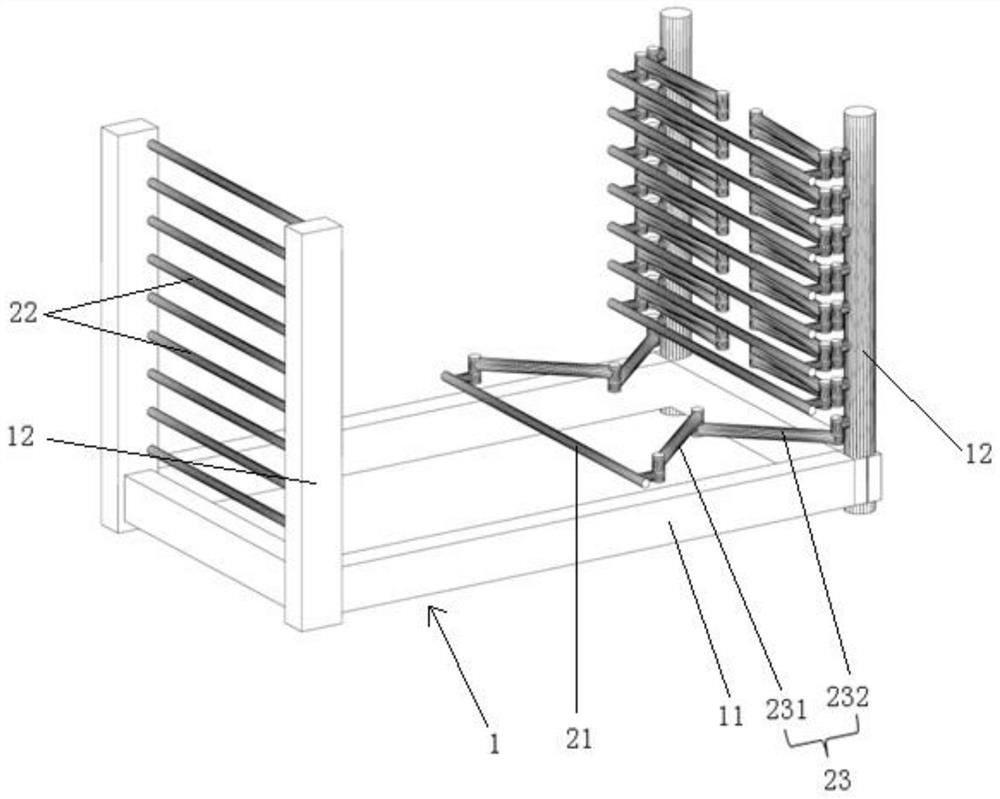

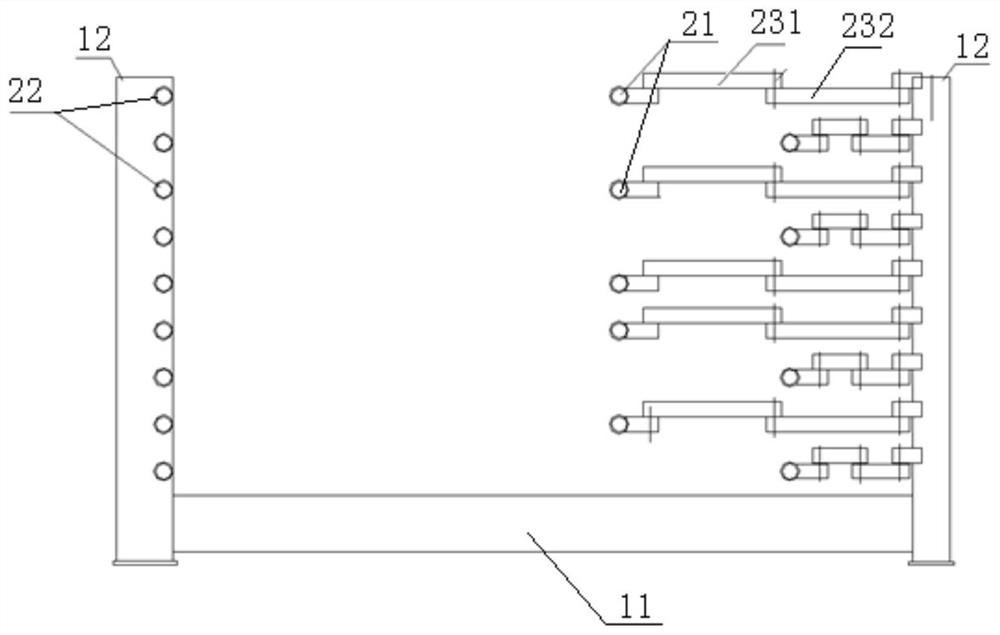

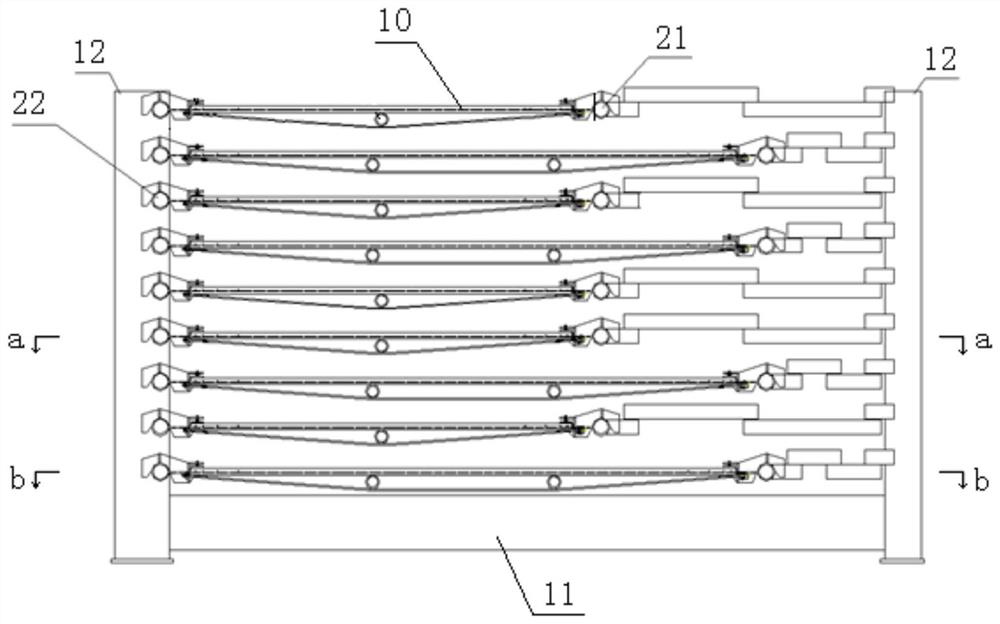

Prefabricated slab transportation frame

ActiveCN113443272AAchieve stackingSave storage spaceExternal framesArchitectural engineeringStructural engineering

The invention discloses a prefabricated slab transportation frame. The prefabricated slab transportation frame comprises a frame body and two opposite supporting rods arranged on the frame body, wherein one supporting rod is a movable supporting rod, the movable supporting rod telescopically moves relative to the other fixed supporting rod, and the distance between the two supporting rods is adjusted so as to adapt to supporting and fixing of prefabricated slabs of different sizes. At least two pairs of fixed supporting rods and movable supporting rods which are arranged in the vertical direction are arranged on the frame body. The movable supporting rod is connected with the frame body through a horizontal telescopic arm. By adjusting the distance between the movable supporting rod and the fixed supporting rod, supporting and fixing of the prefabricated slabs of different sizes can be adapted. Moreover, every two adjacent prefabricated slabs do not affect each other, damage to the prefabricated slabs in the transportation process is avoided, secondary or multiple times of transferring on a construction site can be avoided, the storage yard space of the prefabricated slabs on a construction site is saved, and the construction efficiency is improved.

Owner:ELITE ARCHITECTURAL CO LTD

Detection platform for internal medicine with functions of assisting and fixing

The invention discloses a detection platform for internal medicine with functions of assisting and fixing. The detection platform comprises a bed plate, wherein the lower surface of the bed plate is provided with a moving base and is fixedly connected with a telescopic end of a first electric telescopic rod of the moving base, the lower surface of a bottom plate of the moving base is provided withfour positioning devices which are arranged in a rectangle, a storage box is arranged in the middle part of the upper surface of the bottom plate, a storage battery pack is arranged in the storage box, a storage frame is arranged in the middle part of the lower surface of the bed plate, a drawer is movably clamped in a rectangular groove at the side surface of the storage frame, a positioning frame is arranged at the rear end of the upper surface of the bed plate. The detection platform for the internal medicine with the functions of assisting and fixing is good in stability and can move, theheight of the bed plate can be adjusted, the detection platform can assist and fix patients and medical equipment respectively and prevent the patients from being transferred many times and can conveniently help medical personnel to inspect the patients, the operation is simple and the use is convenient.

Owner:张帅

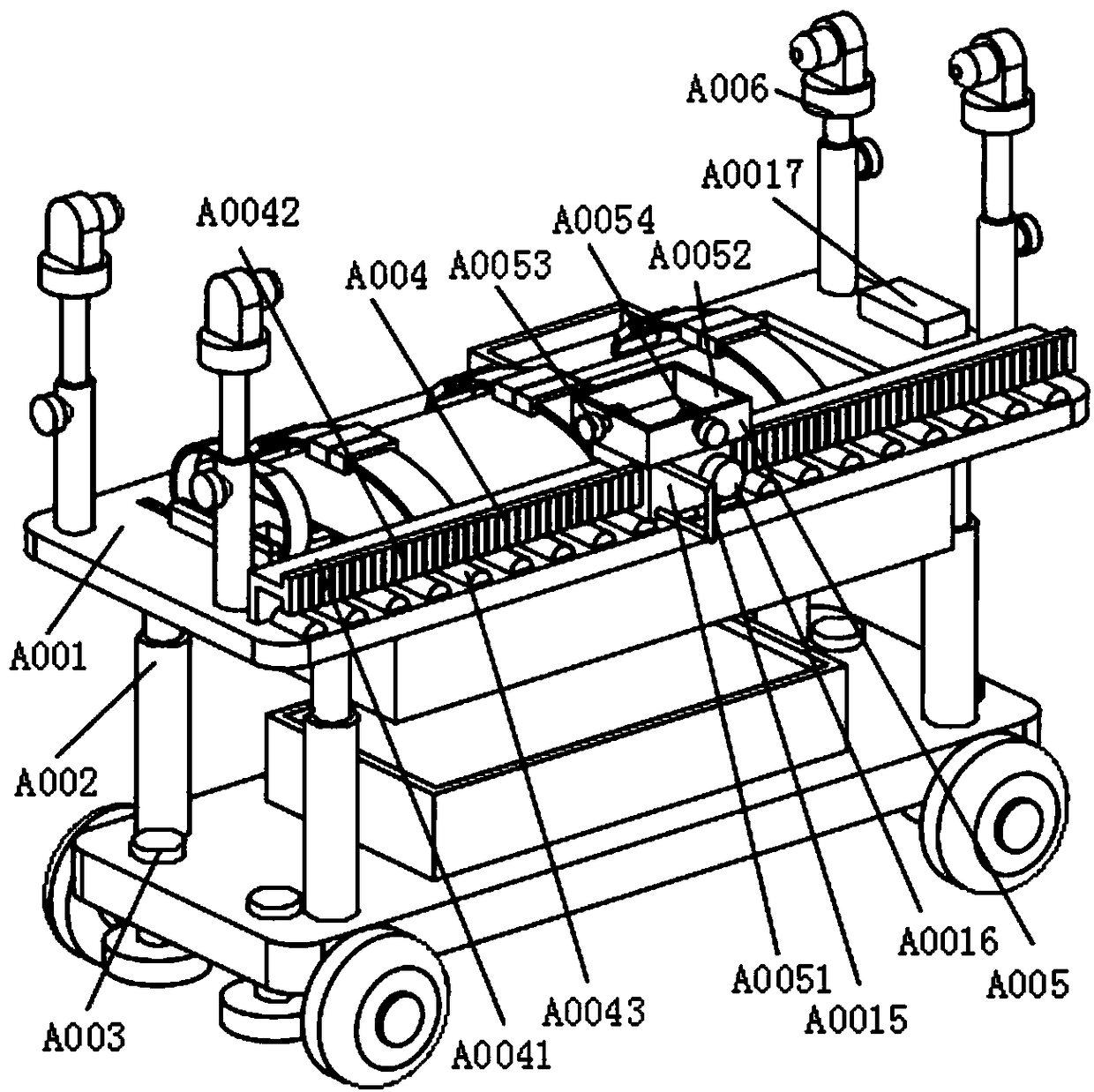

Typesetting and stitch welding all-in-one machine

PendingCN114784143AIncrease production capacityAvoid multiple transfersWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingElectrical batteryIndustrial engineering

The invention relates to a typesetting and stitch welding all-in-one machine which comprises a conveying part, a typesetting part and a stitch welding part. The typesetting part is used for picking up the battery strings and typesetting the battery strings to the feeding end of the conveying part according to a preset typesetting mode; the conveying part is used for receiving and positioning the battery strings placed by the typesetting part, and after battery string groups meeting requirements are formed on the conveying part after typesetting, the conveying part conveys the battery string groups to a welding station; the stitch welding part is used for welding bus bars to the reserved long welding strips of the battery string set located at the welding station, and the reserved long welding strips are located at the two ends of each battery string in the battery string set. Typesetting and positioning of battery strings and conveying of a battery string group are achieved through matched arrangement of the conveying part and the typesetting part, bus bars are directly welded to long welding strips at the ends of the battery string group at a welding station through arrangement of the stitch welding part, equipment and procedures are saved, multiple times of transferring of the battery strings are avoided, the equipment cost is reduced, and the production efficiency is improved. And the welding quality of the assembly is improved.

Owner:WUXI AUTOWELL TECH

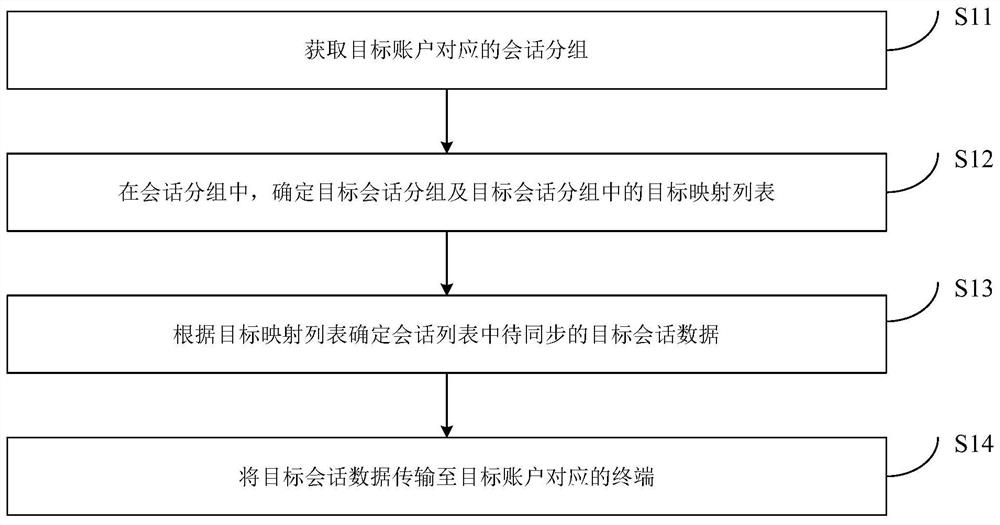

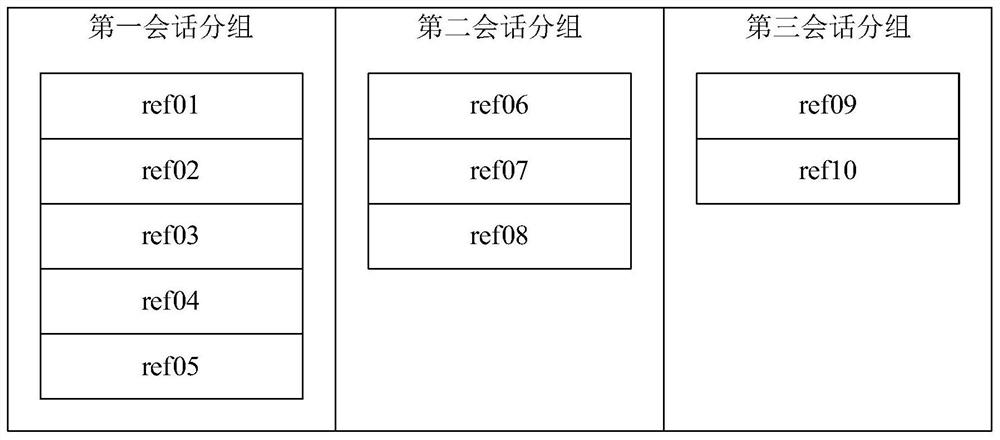

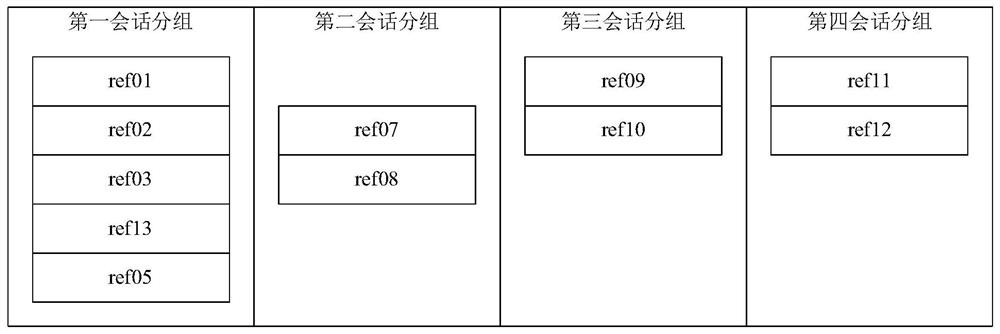

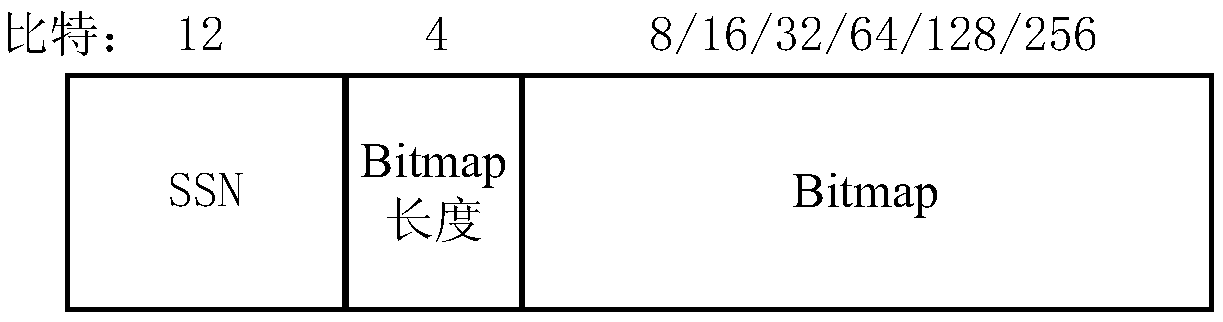

Data synchronization method and device, electronic equipment, storage medium and program product

PendingCN112769677ARelieve stressSave network resourcesData switching networksData transmissionEquipment computers

The invention relates to an instant messaging data synchronization method and device, electronic equipment, a computer readable storage medium and a computer program product, and the method comprises the steps: obtaining a session group corresponding to a target account, wherein the session group comprises a mapping list, the mapping list is used for pointing to a session list corresponding to the target account, and session data is stored in the session list; determining a target session group and a target mapping list in the session groups; determining target session data in the session list according to the target mapping list; and transmitting the target session data to a terminal corresponding to the target account. According to the invention, the server determines the to-be-synchronized target session data in the session list according to the mapping list in the session group, and transmits the target session data to the terminal at one time, thereby avoiding the repeated determination and repeated transmission of the to-be-synchronized session data, reducing the system resource occupation amount of the server, reducing the processing pressure of the server, and saving network resources between the terminal and the server.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

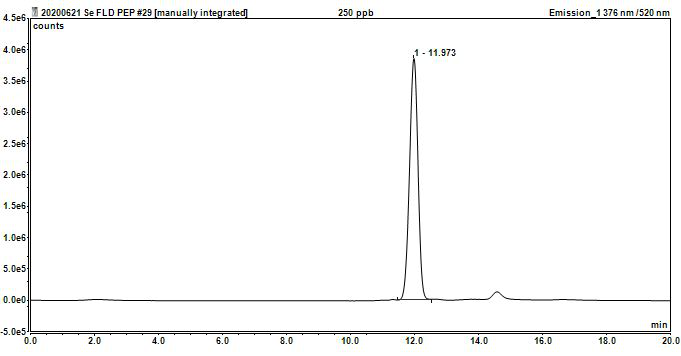

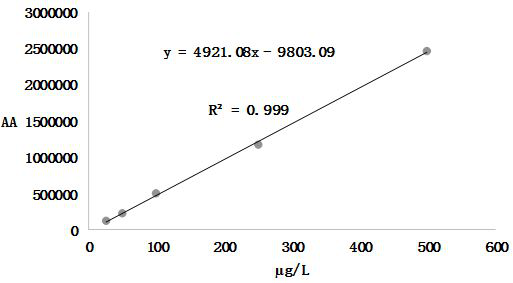

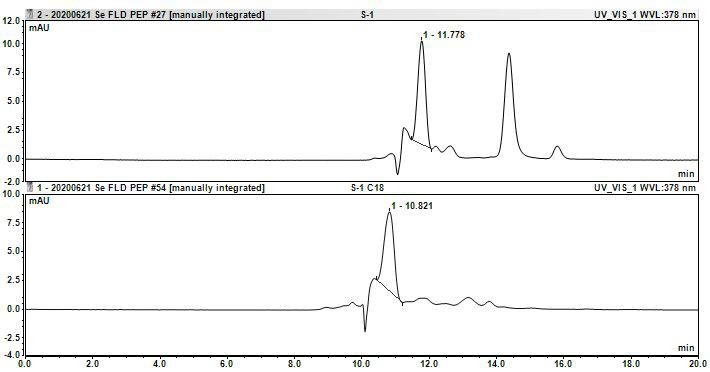

Method for determining total selenium content in selenium-rich proteoglycan by high performance liquid chromatography

ActiveCN111855847AAchieve accurate quantificationAvoid multiple transfersComponent separationFluorescence/phosphorescenceChlorobenzeneChromatography column

The invention discloses a method for determining the content of total selenium in selenium-enriched proteoglycan by high performance liquid chromatography. The invention relates to a method for producing 2, 3, 5, 6-tetramethylpiperidine, 2, 3-diaminonaphthalene is used as a chelating agent; 400 microliters of acetonitrile is used as a dispersing agent; the method comprises the following steps: diluting a chelate (4, 5-benzo kohlrabi selenium brain) of selenium (IV) and 2, 3-diaminonaphthalene by acetonitrile, directly separating by using a PFP chromatographic column, eluting by using acetonitrile, measuring the fluorescence intensity by using a fluorescence detector under the conditions that the excitation wavelength is 376 nm and the emission wavelength is 520 nm, and quantifying by usingan external standard method. The method has the characteristics of stable experimental result, less sample transfer, less reagent consumption, high recovery rate and the like.

Owner:ZHEJIANG UNIV

Liquid chemical raw material quantitative loading control meter

InactiveCN109529726AAchieving sustainable feedingGuaranteed tightnessFeed devicesElectric machineryDrive motor

The invention relates to the technical field of chemical loading equipment, and discloses a liquid chemical raw material quantitative loading control meter. The liquid chemical raw material quantitative loading control meter comprises a centrifugal bin, supporting seats are arranged at the bottoms of two sides of the centrifugal bin, and a sealing cover is movably connected to one side of the topof the centrifugal bin. One side of the sealing cover is connected with the centrifugal bin by a clamping device in a clamped mode, a mounting frame is fixedly mounted on the middle part of the top end of the centrifugal bin, and a driving motor is arranged at the top of the mounting frame. An insulating bin is fixedly mounted on the side, away from the sealing cover, of the top of the centrifugalbin, and a bearing is arranged at the top of an inner cavity of the centrifugal bin. The liquid chemical raw material quantitative loading control meter can facilitate the addition of chemical raw materials through the cooperation of the sealing cover and the clamping device, the sustainable feeding of the device is realized, the sealing property in the centrifugal bin is ensured, the oxidation reaction when chemical raw materials in a stirring bin are in contact with air is avoided, the content of chemical raw material components is reduced, and the quality of chemical product production isimproved.

Owner:刘璐

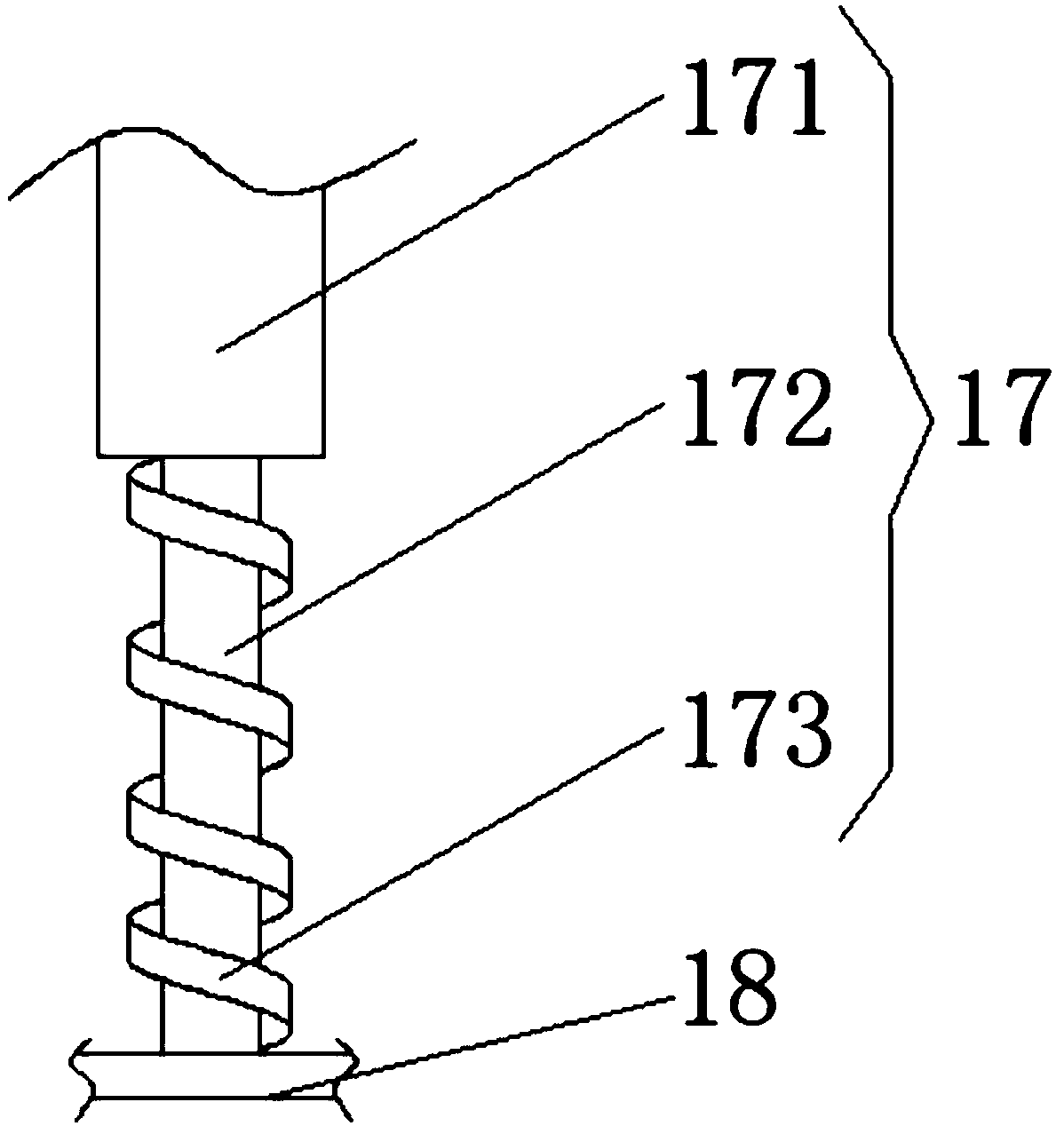

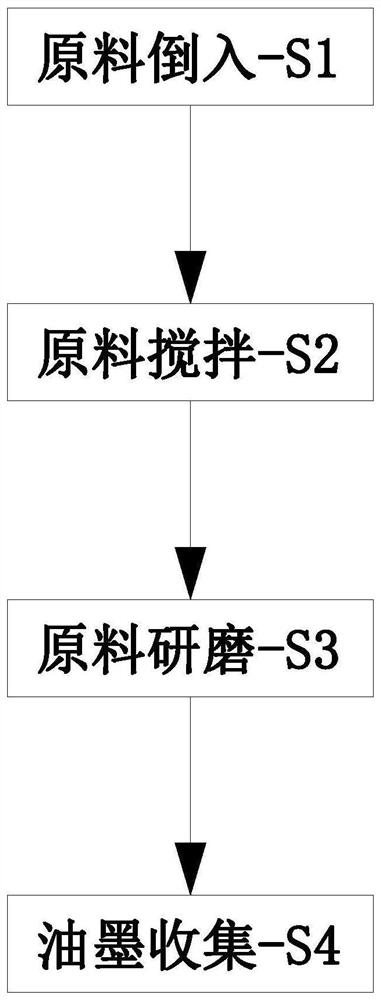

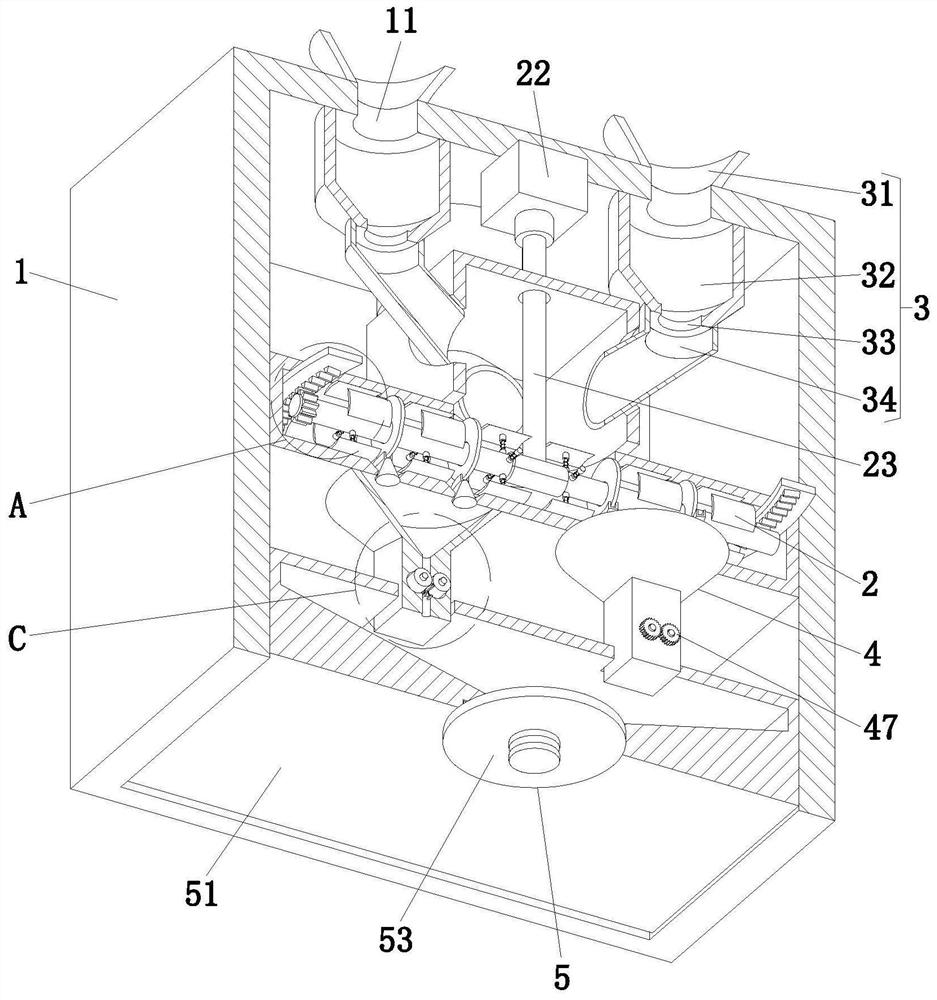

Printing ink production and preparation technology

InactiveCN113385095AEasy to produceImprove the mixing effectRotary stirring mixersTransportation and packagingProcess engineeringPrinting ink

The invention provides a printing ink production and preparation technology, the following printing ink production and preparation device is adopted by the printing ink production and preparation technology, the printing ink production and preparation device comprises a processing barrel, a stirring unit, a material guiding unit, a grinding unit and a material collecting unit, the stirring unit is arranged on the inner wall of the processing barrel, the material guiding unit is arranged above the stirring unit, the grinding unit is mounted at the lower end of the stirring unit, and the material collecting unit is arranged at the lower end of the grinding unit; according to the invention, the following problems can be solved: 1, during production and preparation of traditional printing ink, the printing ink is mostly stirred by the stirring shaft provided with the blade paddle, the stirring area of the blade paddle is small, and only the printing ink at the bottom can be stirred so that the stirring strength is low, a large amount of time needs to be consumed, and the stirring effect is poor; and 2, after the raw materials of the printing ink are stirred, workers need to transfer the raw materials into the existing three-roller type grinding equipment, so that the workload is increased, and potential safety hazards exist in manual feeding.

Owner:有限会社林平

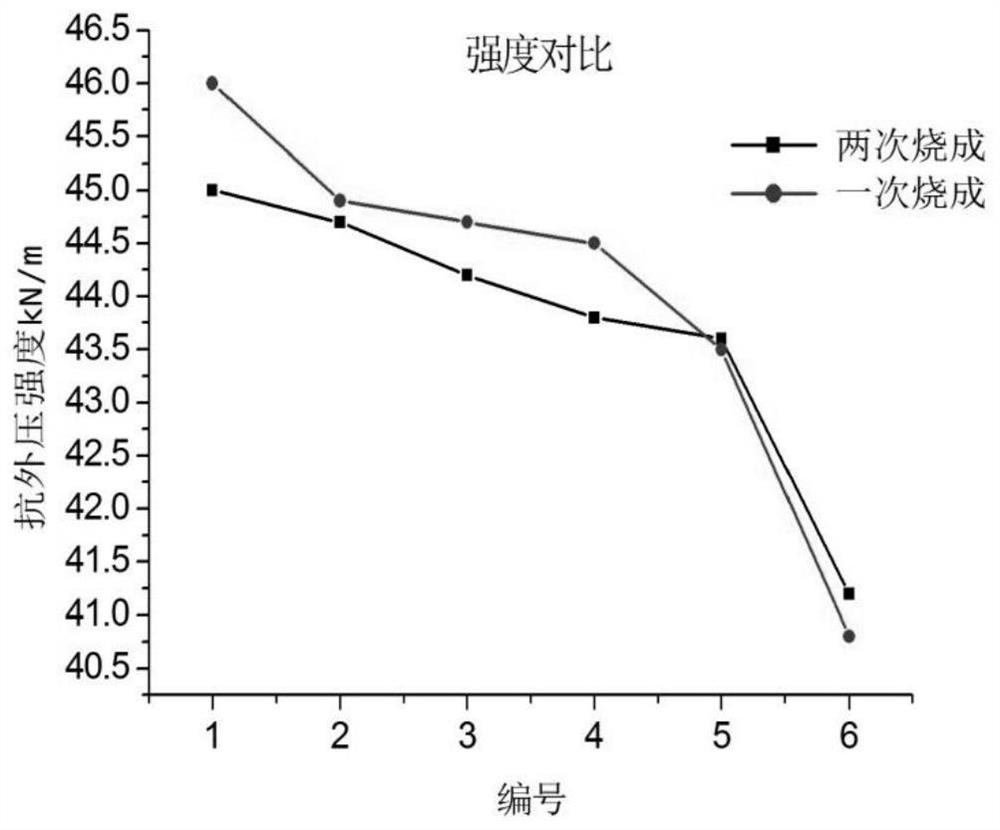

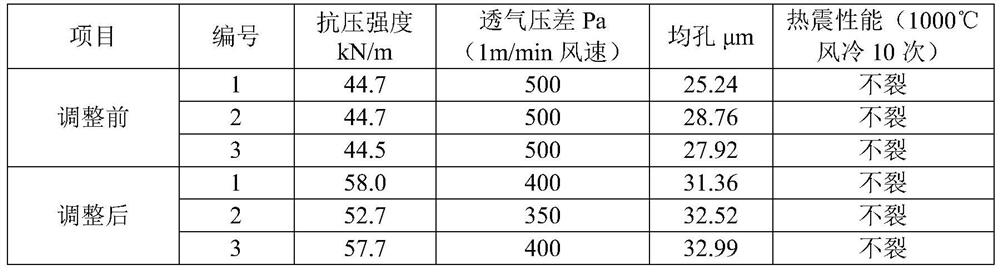

Silicon carbide ceramic membrane and preparation method and application thereof

ActiveCN112209719ALower firing temperatureRealize one firingSemi-permeable membranesDispersed particle filtrationGlass fiberSuspending Agents

The invention discloses a silicon carbide ceramic membrane and a preparation method and application thereof and the silicon carbide ceramic membrane. The silicon carbide ceramic membrane comprises a support body and a membrane layer connected with the support body, wherein the support body comprises the following raw materials in parts by weight: 85-92 parts of silicon carbide, 6-10 parts of a pore forming agent, 8-15 parts of a firing binding agent and 3-8 parts of a forming aid, the film layer is prepared from the following raw materials in parts by weight: 70 to 90 parts of emery, 10 to 30parts of a firing binding agent, 10 to 20 parts of a pore forming agent, 38 to 50 parts of water, 0 to 0.3 part of a dispersing agent and 0 to 0.3 part of a suspending agent, wherein the sintering binding agent comprises the following components in parts by weight: 76-96 parts of Zhangcun soil, 5-16 parts of dolomite and 3-16 parts of glass fiber powder. The sintering temperature of the support body is reduced by changing a formula system of the support, and the sintering temperature of the support body and the film layer is controlled within the same temperature interval, so that the film layer and the support body are sintered at one time, and the original twice sintering of the support body and the film layer is replaced.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

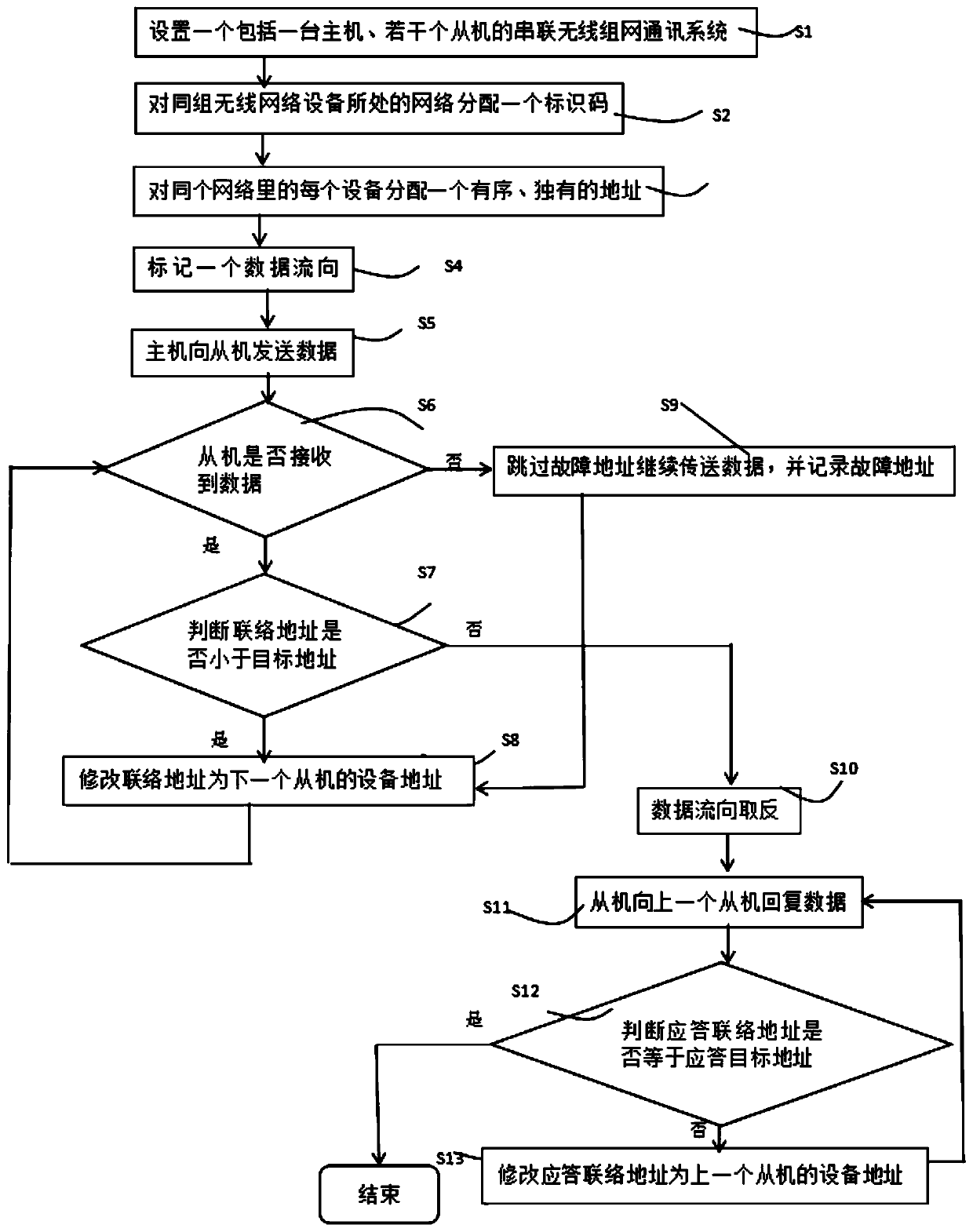

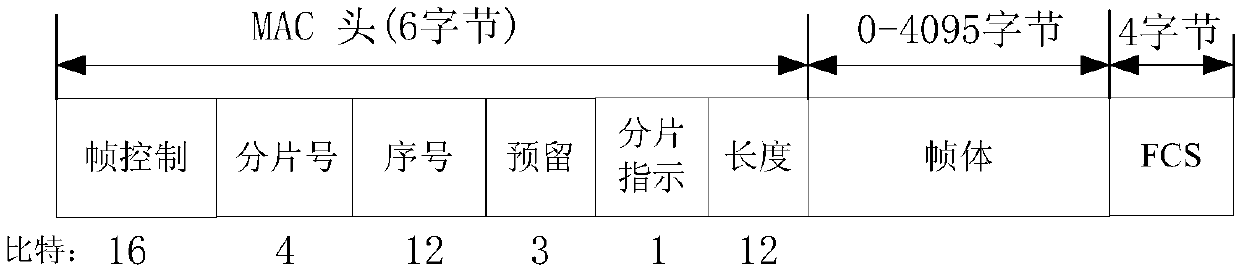

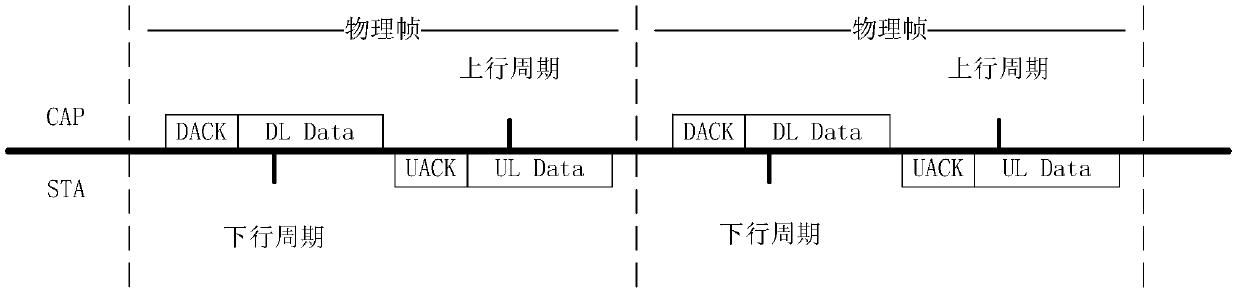

System and method for single-host wireless equipment series networking data communication

ActiveCN110267220AAvoid double sendingResolve interferenceNetwork topologiesInformation formatComputer networkData information

The invention discloses a system and a method for single-host wireless equipment series networking data communication. The system comprises a host machine, multiple slave machines, wherein the host and the plurality of slaves are connected in sequence through a serial wireless network; the host converts the data information into data in a target data format for transmission, the slave receives the data in the target data format, relays and responds the data, and transmits the data to the last slave, and the last slave converts the data into data in a response format for responding to the host. The method is suitable for occasions with simple series networks, small data volumes and low requirements on real-time performance, can effectively obtain and transmit data, and is high in anti-interference capability, simple, reliable and low in cost.

Owner:泉州维盾电气有限公司

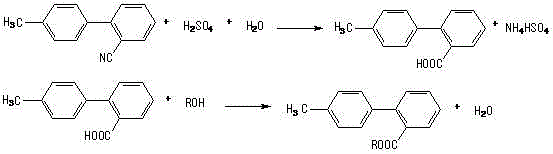

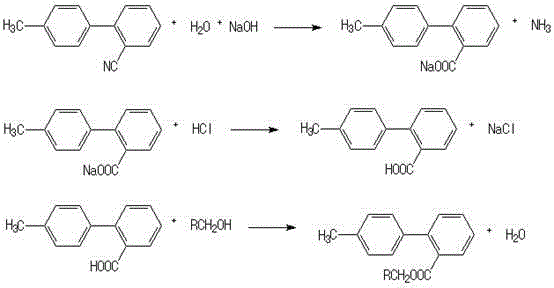

One-pot technology of 4'-methyl-2-carboxylate biphenyl

InactiveCN105085271AAvoid multiple transfersAvoid it happening againOrganic compound preparationCarboxylic acid esters preparationPtru catalystOrganosolv

The invention discloses a one-pot technology of 4'-methyl-2-carboxylate biphenyl. In a same reaction container, under the acidic condition, 4'-methyl-2-cyanobiphenyl is hydrolyzed within 24 h to generate 4'-methyl-2-biphenyl carboxylate; an organic solvent which is hard to dissolve in water is then used to carry out refluxing so as to remove superfluous water; organic compounds containing hydroxyl groups such as alcohol and the like are added; and under the catalysis of an esterification catalyst such as sulfuric acid and the like, 4'-methyl-2-carboxylate biphenyl is generated. Multiple flowing of materials is avoided, generation of ammonia gas and salt-containing wastewater is avoided, and environmental friendliness is increased. Investment in ammonia gas absorption and intermediate product separation equipment is minimized, synthesis period is short, manpower and material resources are saved, and costs are reduced. A by-product ammonium sulfate can be used as a raw material of an agricultural compound fertilizer, thus achieving the purpose of comprehensive utilization.

Owner:SHANDONG FANGMING PHARMACEUTICAL CO LTD

Ultrahigh throughput wireless broadband data transmission method and system

InactiveCN110875806AAvoid multiple transfersReduce processing timeError prevention/detection by using return channelSignal allocationWiBroWireless broadband

The invention provides an ultrahigh throughput wireless broadband data transmission method, which can be used for fragmenting data according to available channel resources, and comprises the followingsteps that: a sending end sends a plurality of data frames and / or fragmented data according to the resources allocated by a channel; the successfully received data frame and / or fragmented data is confirmed according to the confirmation management frame fed back by the receiving end; the unsuccessfully received data frames and / or fragmented data are retransmitted; and when retransmission is carried out, fragmentation processing is carried out on the data frame and / or the fragmented data again according to the current available resources. Channel resources can be used to the maximum extent andare not influenced by the size of a fixed fragment; a large number of fragmentation can be avoided under the condition that resources are sufficient, the processing time of a processor is shortened while the expenditure of wireless resources is reduced, and the overall cost is reduced; through immediate acknowledgement, acknowledged received fragments are prevented from being transmitted for multiple times, and meanwhile, the network delay is effectively reduced.

Owner:GUANGDONG NUFRONT COMP SYST CHIP

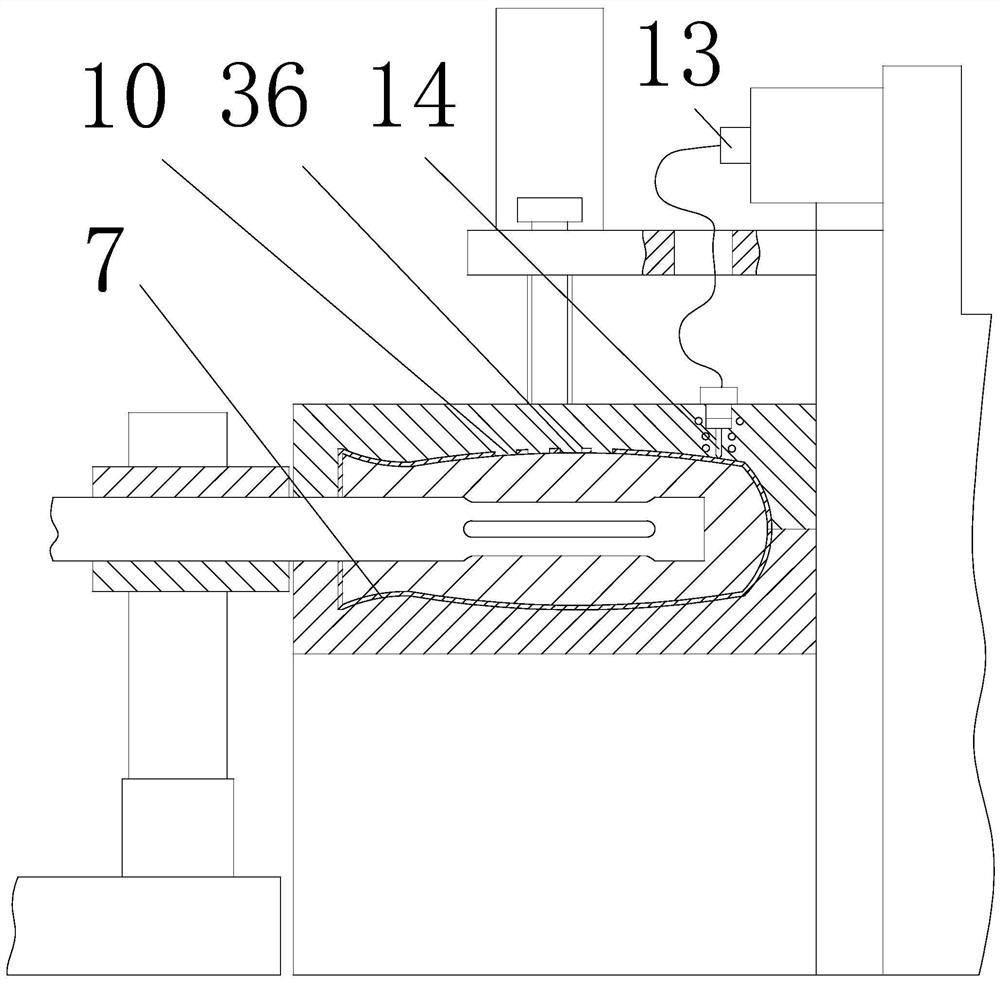

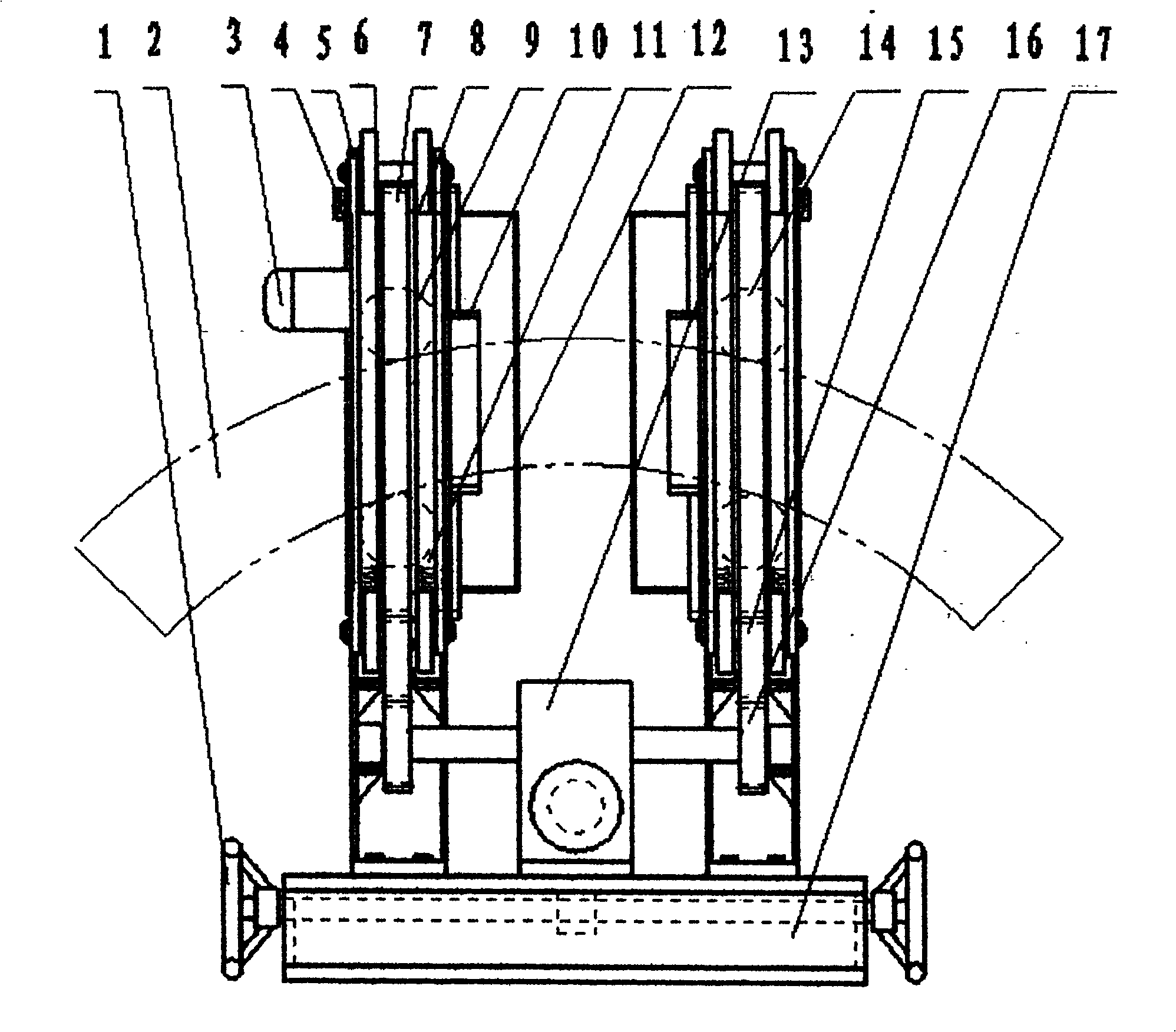

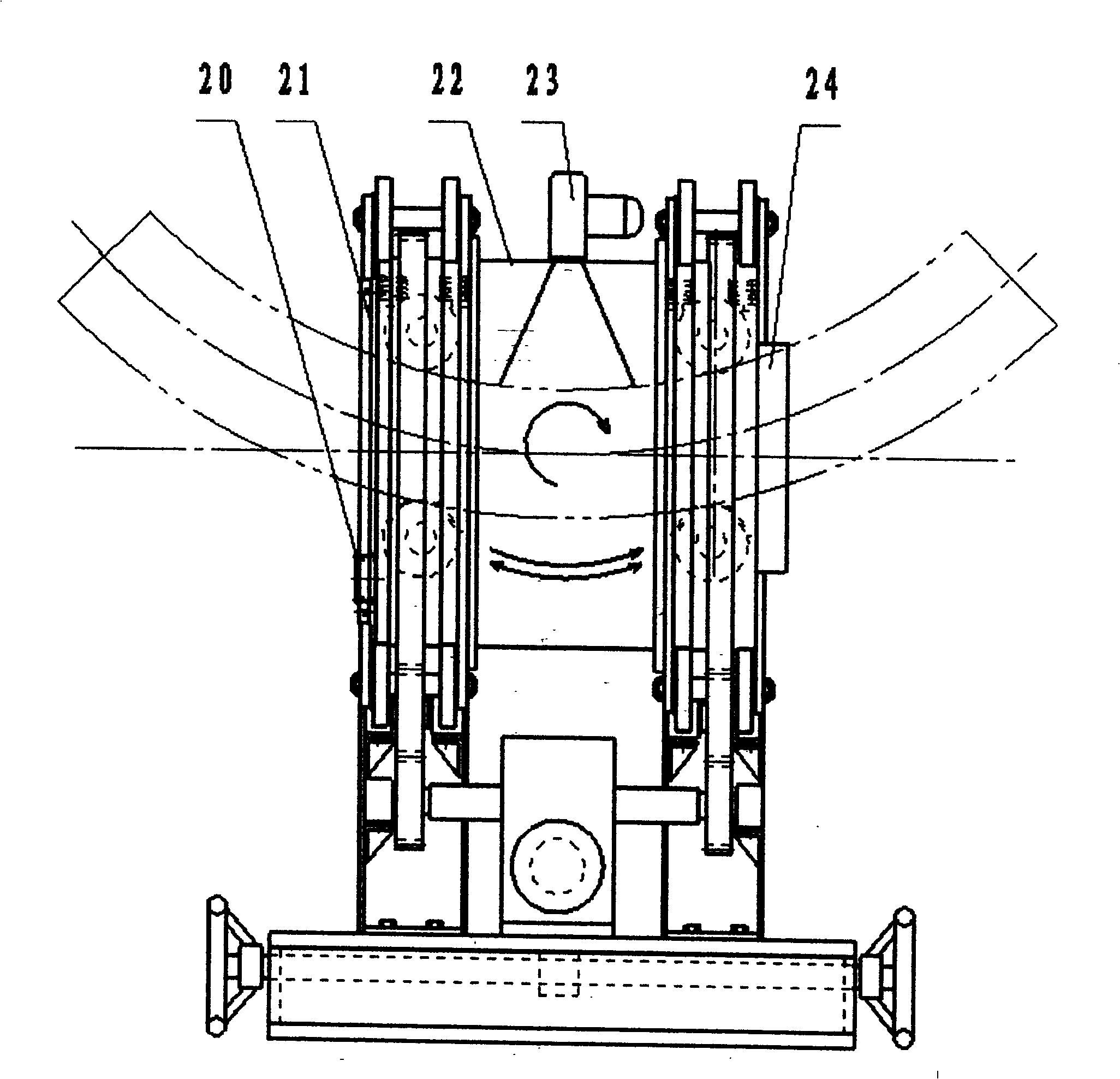

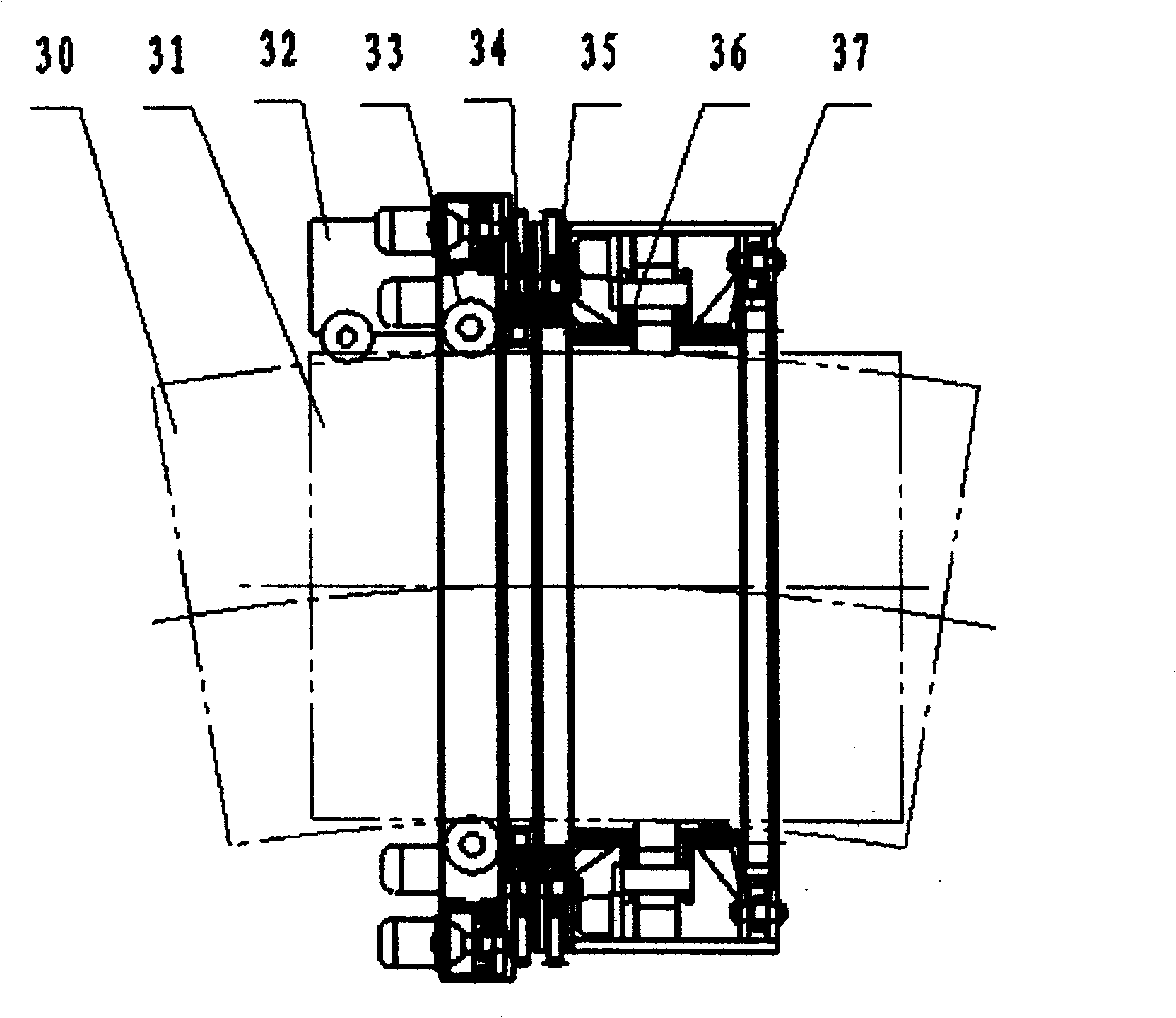

Tool handle secondary injection molding device and method

PendingCN112776253AImprove clarityTransposition is beneficialCoatingsEngineeringMechanical engineering

The invention relates to a tool handle secondary injection molding device. The tool handle secondary injection molding device comprises a three-color injection molding machine, a mold frame, a lower mold arranged at the front end of the mold frame, an upper mold provided with a heater, an upper mold lifting device, a workpiece clamping and transposition device, a primary injection molding cavity, a secondary injection molding first-color injection molding cavity, a secondary injection molding second-color injection molding cavity, and three accommodating holes of which the rear ends communicating with the primary injection molding cavity, the secondary injection molding first-color injection molding cavity and the secondary injection molding second-color injection molding cavity in a one-to-one correspondence manner. The primary injection molding cavity, the secondary injection molding first-color injection molding cavity and the secondary injection molding second-color injection molding cavity are encircled by the upper mold and the lower mold and sequentially arranged in the left-right direction. A trademark character bump is arranged on the upper side of the secondary injection molding first-color injection molding cavity. The upper mold is provided with a primary injection molding runner which separately communicates with the primary injection molding cavity and a first injection molding opening of the three-color injection molding machine, a secondary injection molding first-color runner which separately communicates with the secondary injection molding first-color injection molding cavity and a second injection molding opening of the three-color injection molding machine, and a secondary injection molding second-color runner which separately communicates with a trademark character arranged in the secondary injection molding second-color injection molding cavity and a third injection molding opening of the three-color injection molding machine.

Owner:HANGZHOU UNITED TOOLS CO LTD

Polyethylene coated steel pipe, online production and equipment thereof

InactiveCN101038048BAvoid multiple transfersShorten construction timeRigid pipesTransformerLow voltage

The invention relates to a polyethylene coated steel pipe and on-line method and apparatus for preparing same. Steel pipe is employed as base material for polyethylene coated steel pipe, and the outer surface of the steel pipe is coated with jointless annular polyethylene gummed tape. Production facilities of the pipe includes steel pipe shot-blast rust cleaning machine comprised of a rotating cylinder bracket, a rotating cylinder, a feeding wheel, a support wheel, a feeding worm wheel speed reducer, a feeding direct current dynamo, a high-frequency induction heating coil, a driving worm wheel speed reducer, a driving AC motor and a electrical control cabinet, and a steel pipe outer anticorrosion coating machine comprised of a induction heating transformer, a walking frame, a swing frame,a rotating frame, a winding device, a supporting frame, a low-voltage electrical casing and a controller. In pipeline installation locale, the steel pipes are welded into pipelines after derusted by the steel pipe shot-blast rust cleaning machine, the steel pipe outer anticorrosion coating machine is nested on the pipeline and carries out helical motion, after high-frequency induction heating on the steel pipe, the spray head injects the epoxy powder on outer surface of the steel pipe, after high-frequency induction heating of the belt-winding cylinder, adhesive tape and polyethylene gummed tape pulled out from the winding device become hot tapes, by helical motion of the steel pipe outer anticorrosion coating machine along pipeline centre-line, the adhesive tape and polyethylene gummed tape are coated on the outer surface of the steel pipes.

Owner:陈炯

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com