Patents

Literature

33results about How to "Improve the quality of anticorrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

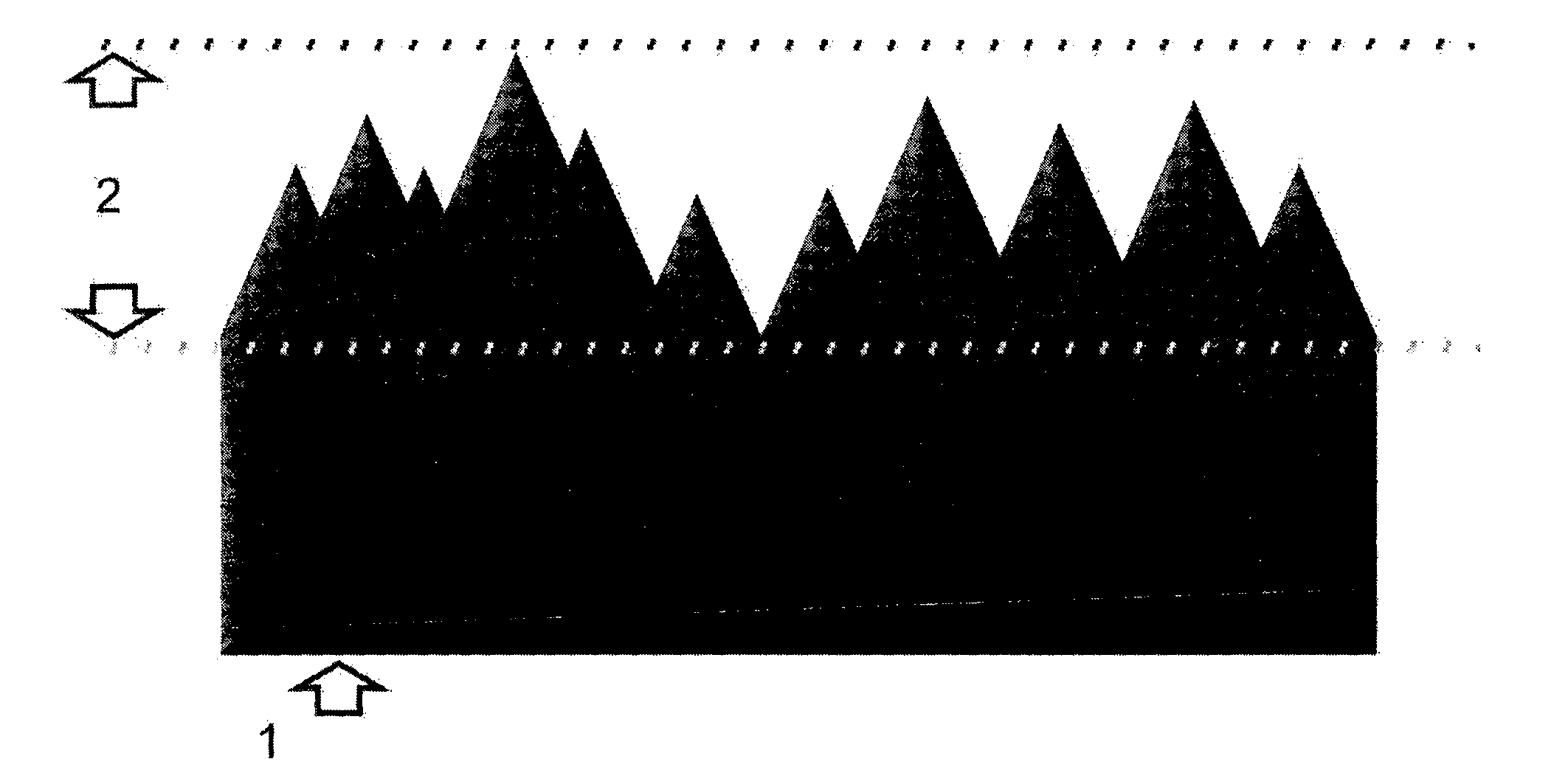

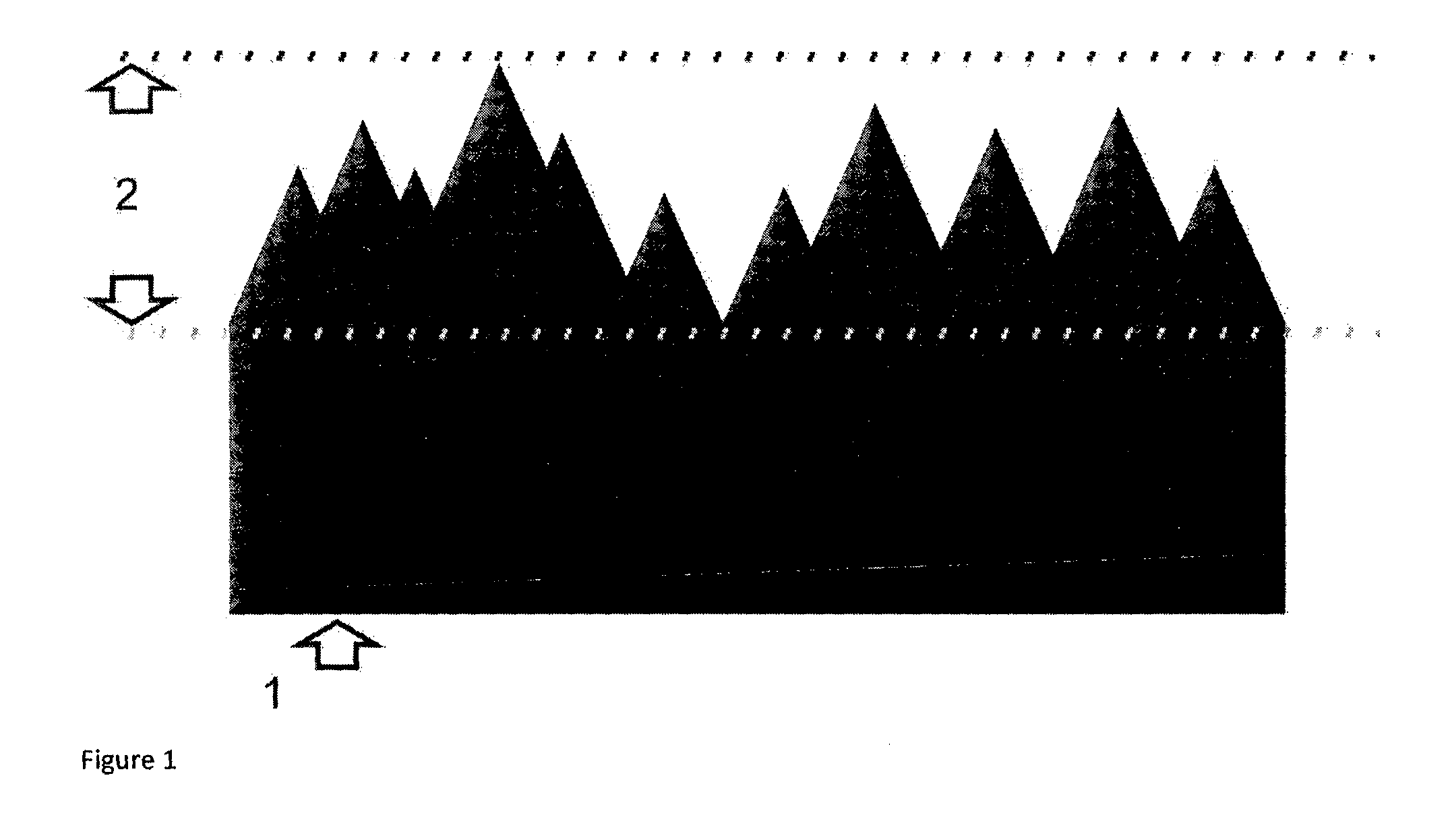

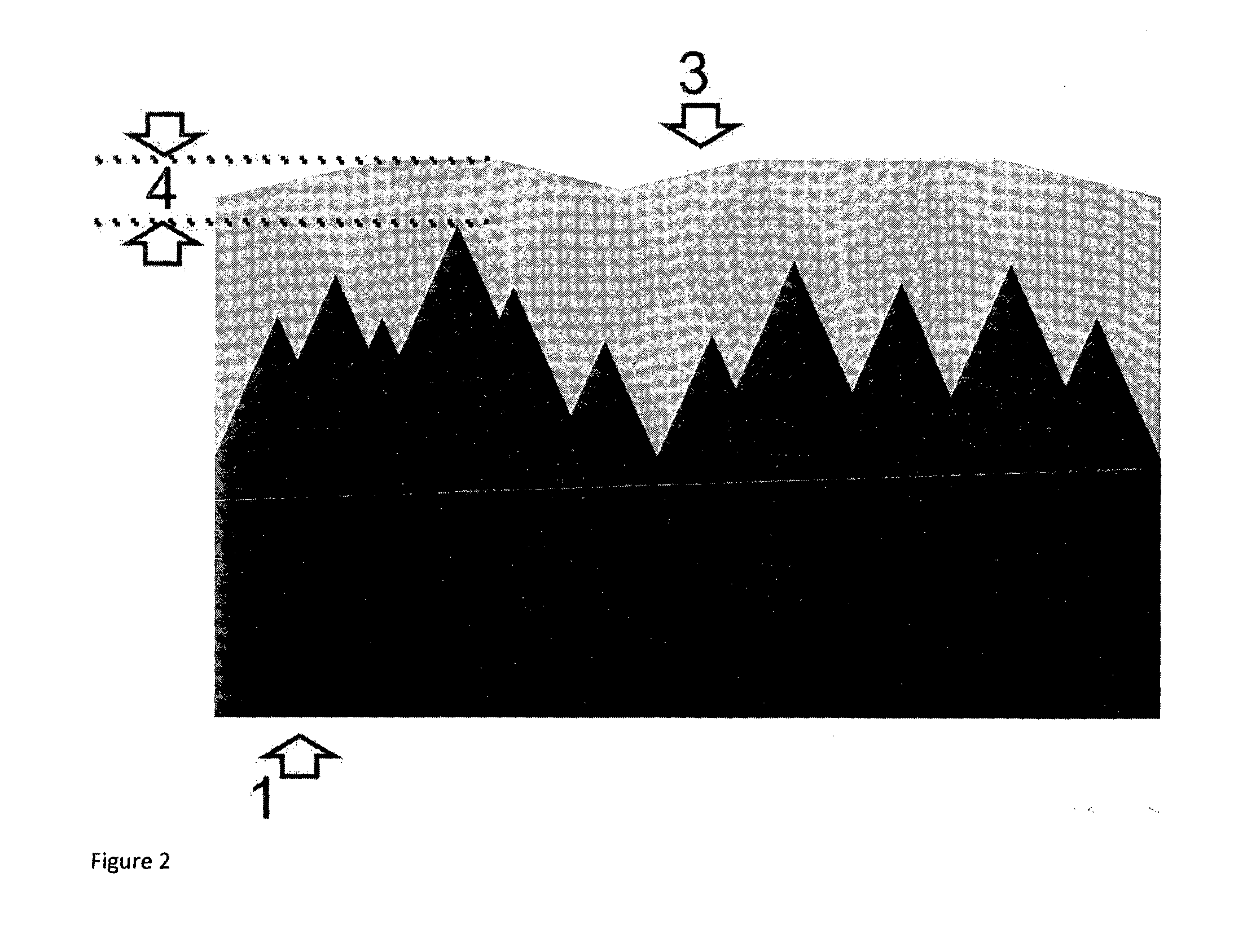

Spin-on-glass assisted polishing of rough substrates

InactiveUS20150197455A1Reduce polishing costsImprove the quality of anticorrosionDecorative surface effectsVacuum evaporation coatingOptical radiationPolymer science

A method produces a smooth surface on a rough substrate. The rough substrate is coated with a film or particles of spin-on-glass (SOG) dissolved in a solvent using spin coating, spray coating or dip coating. The SOG is made to reflow by using thermal melting and solvent thinning. The reflow is done in an atmosphere containing a partial pressure of the solvent. The reflow allows the SOG to partially melt and to decrease the surface roughnesss of the film. The SOG is cured by thermal curing or UV exposure radiation curing into a hard durable and chemical inert silicon dioxide film. The SOG can be hydrogen silsesquioxane or methyl silsesquioxane dissolved in either methyl isobutyl ketone or volatile methyl siloxanes. The method can include embossing, chemical mechanical polishing, etching and functionalizing the surface. The substrate can be a cast, mould or form for producing a polymer or a glass replica.

Owner:INMOLD BIOSYST

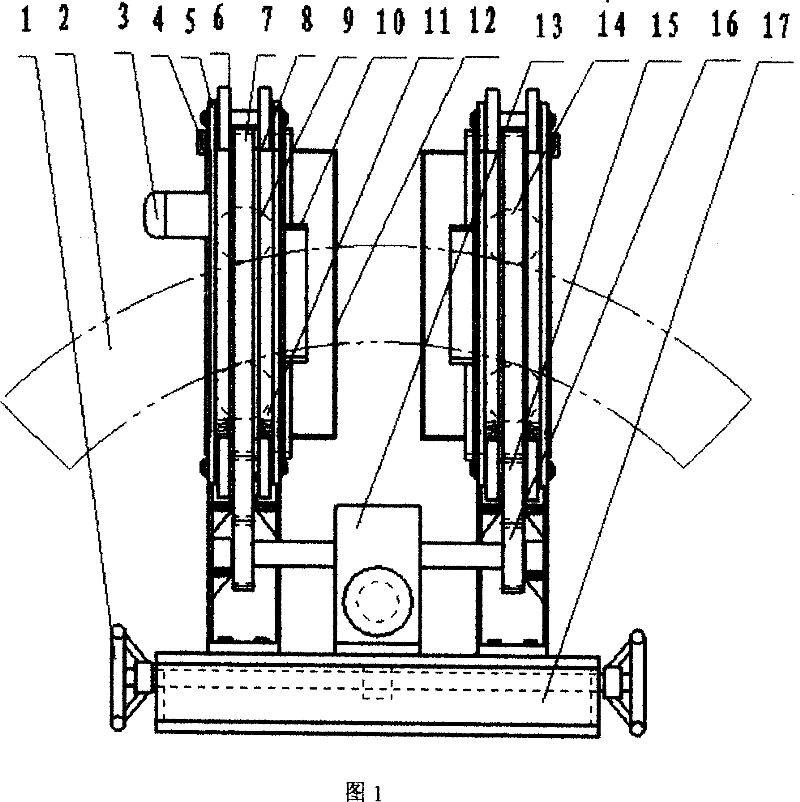

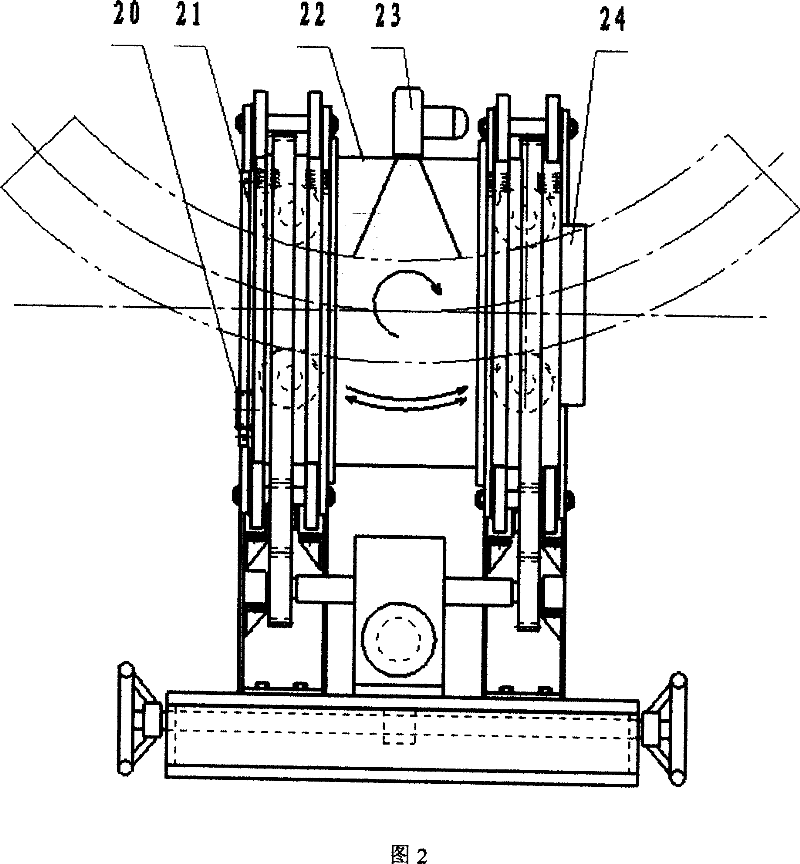

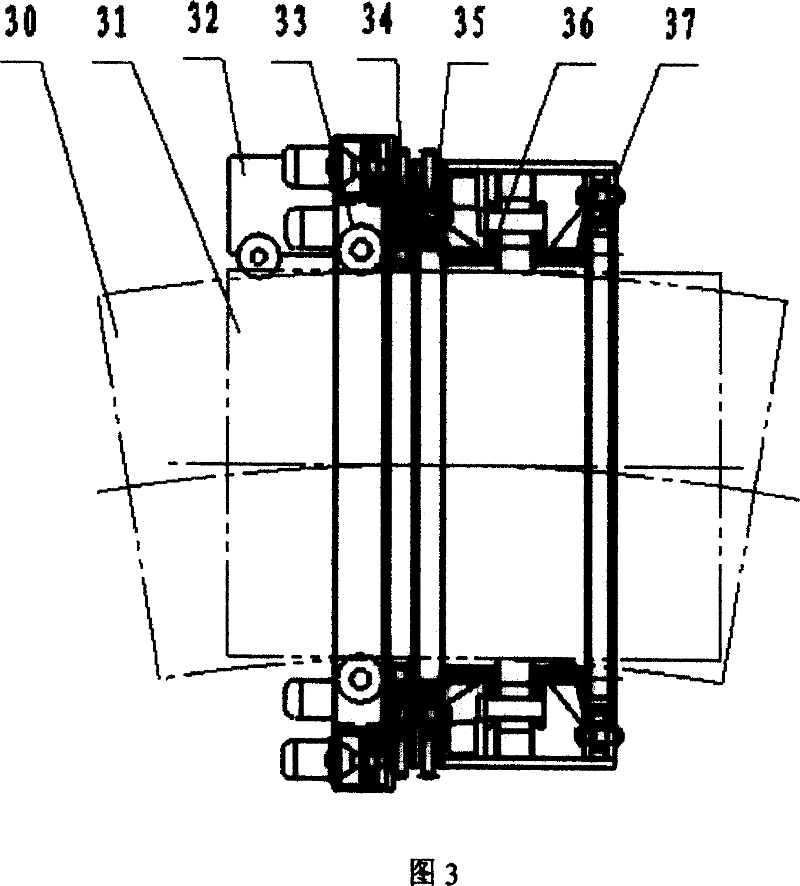

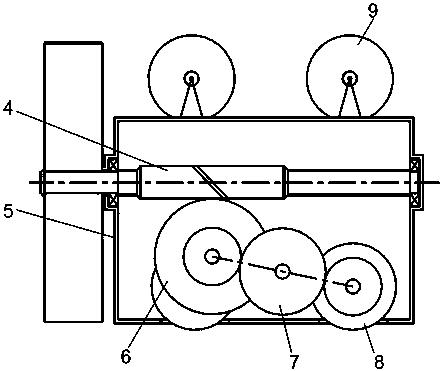

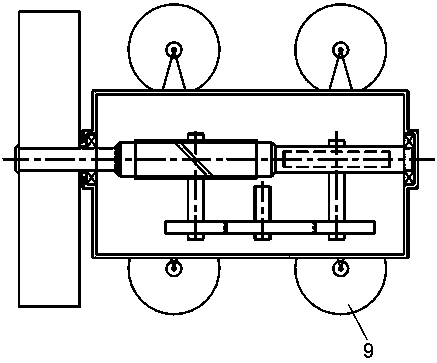

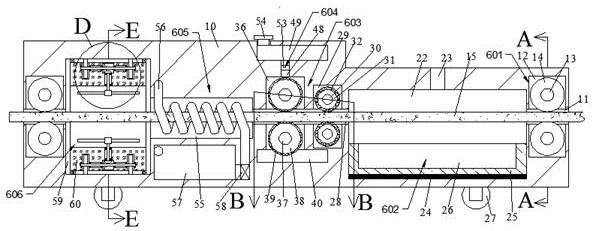

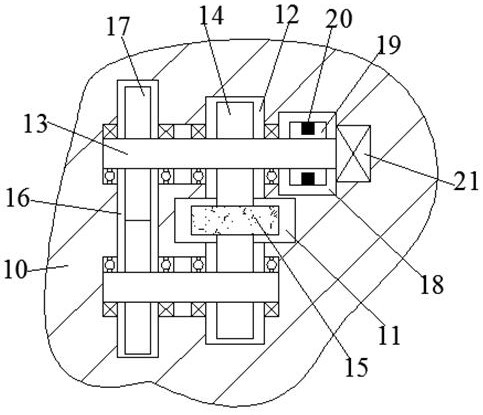

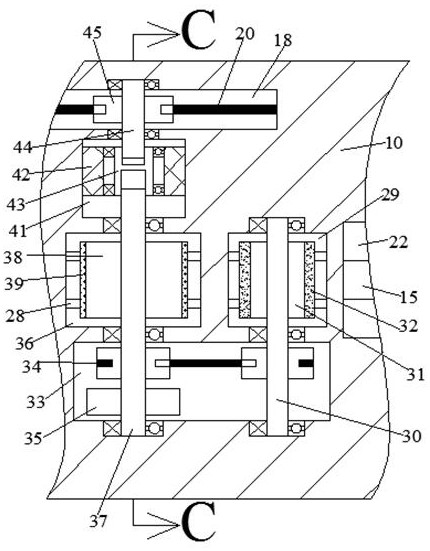

Polyethylene coated steel pipe, online production and equipment thereof

InactiveCN101038048AOvercoming qualityOvercome mechanical propertiesRigid pipesTransformerLow voltage

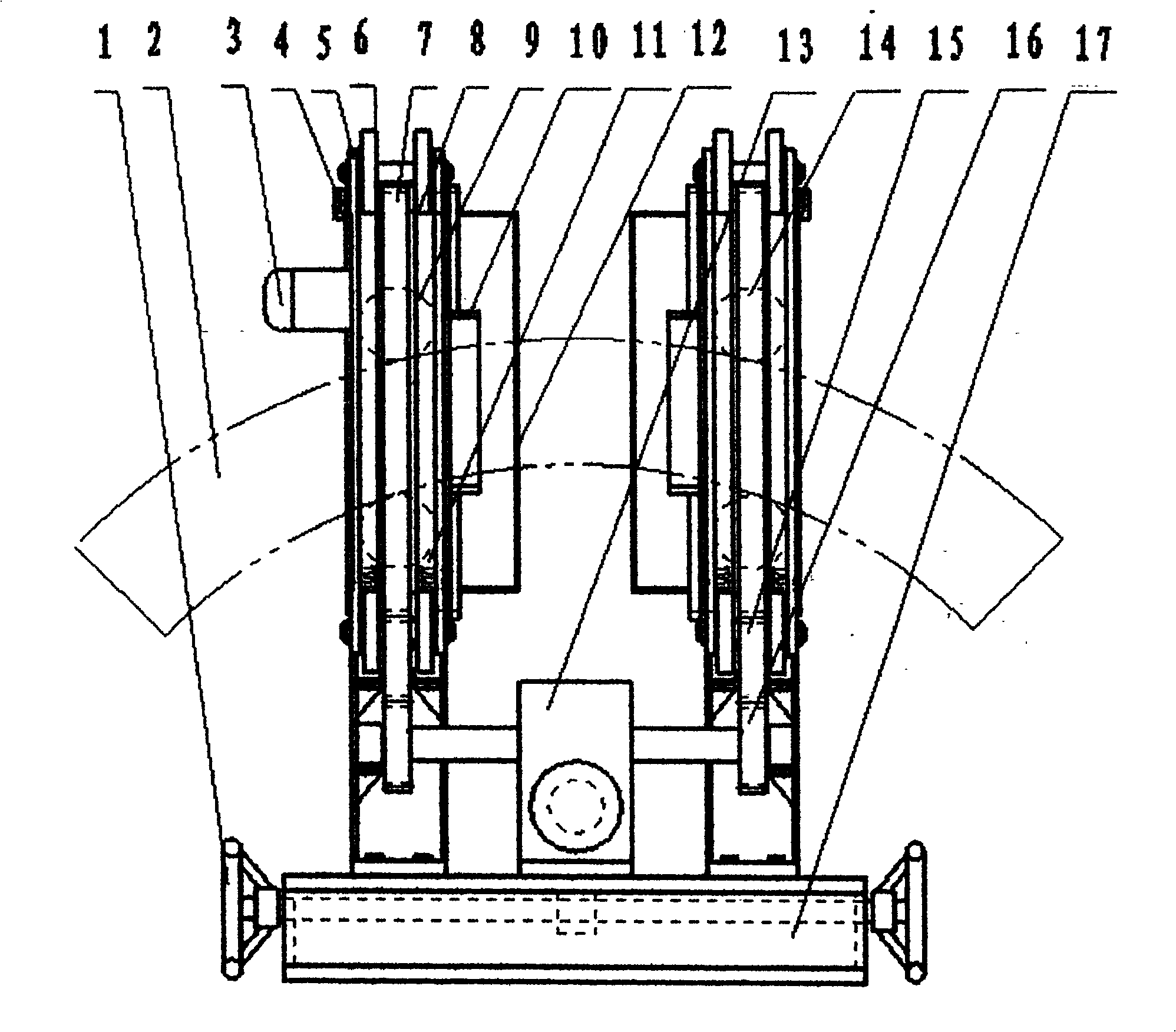

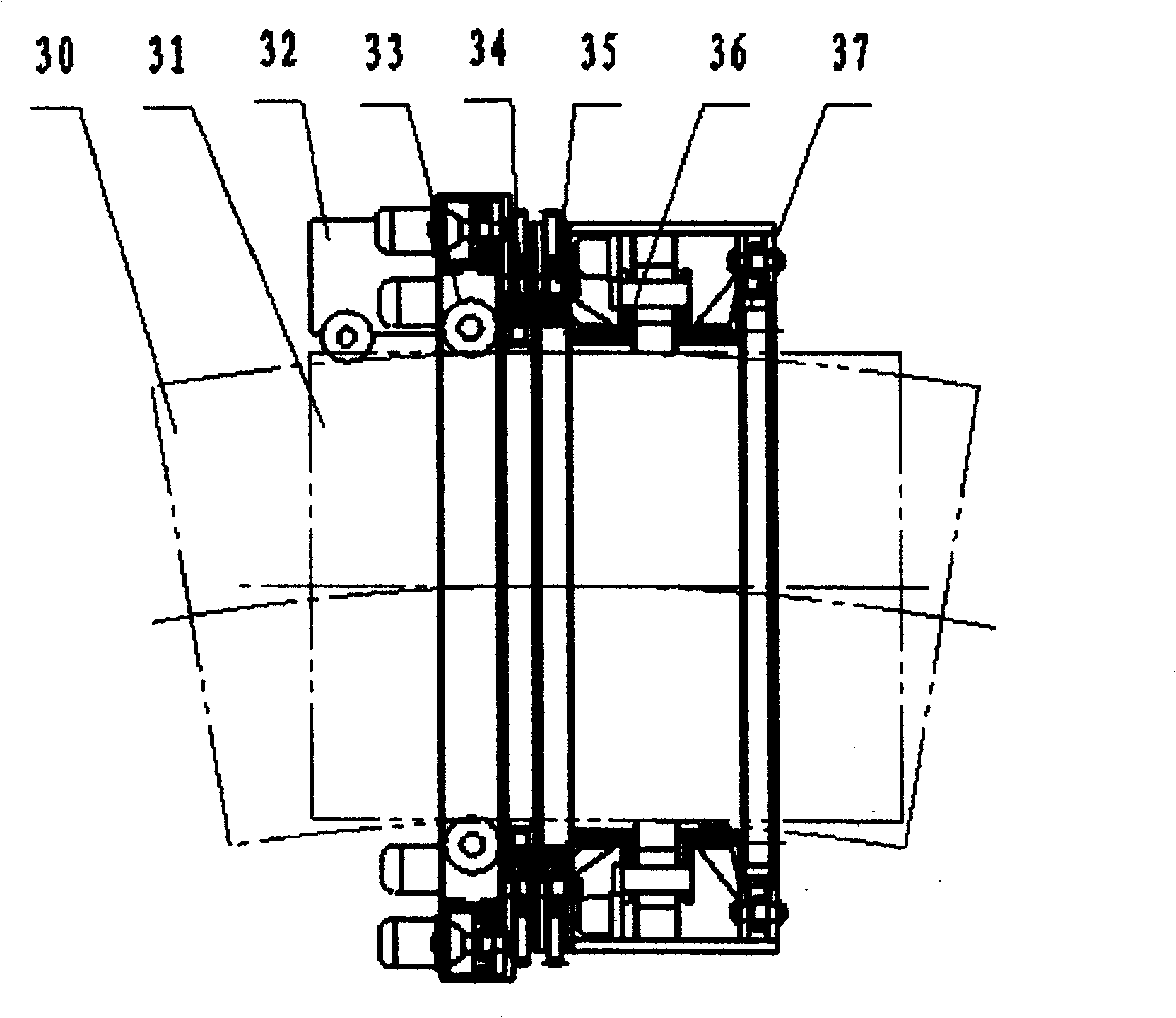

The invention relates to a polyethylene coated steel pipe and on-line method and apparatus for preparing same. Steel pipe is employed as base material for polyethylene coated steel pipe, and the outer surface of the steel pipe is coated with jointless annular polyethylene gummed tape. Production facilities of the pipe includes steel pipe shot-blast rust cleaning machine comprised of a rotating cylinder bracket, a rotating cylinder, a feeding wheel, a support wheel, a feeding worm wheel speed reducer, a feeding direct current dynamo, a high-frequency induction heating coil, a driving worm wheel speed reducer, a driving AC motor and a electrical control cabinet, and a steel pipe outer anticorrosion coating machine comprised of a induction heating transformer, a walking frame, a swing frame, a rotating frame, a winding device, a supporting frame, a low-voltage electrical casing and a controller. In pipeline installation locale, the steel pipes are welded into pipelines after derusted by the steel pipe shot-blast rust cleaning machine, the steel pipe outer anticorrosion coating machine is nested on the pipeline and carries out helical motion, after high-frequency induction heating on the steel pipe, the spray head injects the epoxy powder on outer surface of the steel pipe, after high-frequency induction heating of the belt-winding cylinder, adhesive tape and polyethylene gummed tape pulled out from the winding device become hot tapes, by helical motion of the steel pipe outer anticorrosion coating machine along pipeline centre-line, the adhesive tape and polyethylene gummed tape are coated on the outer surface of the steel pipes.

Owner:陈炯

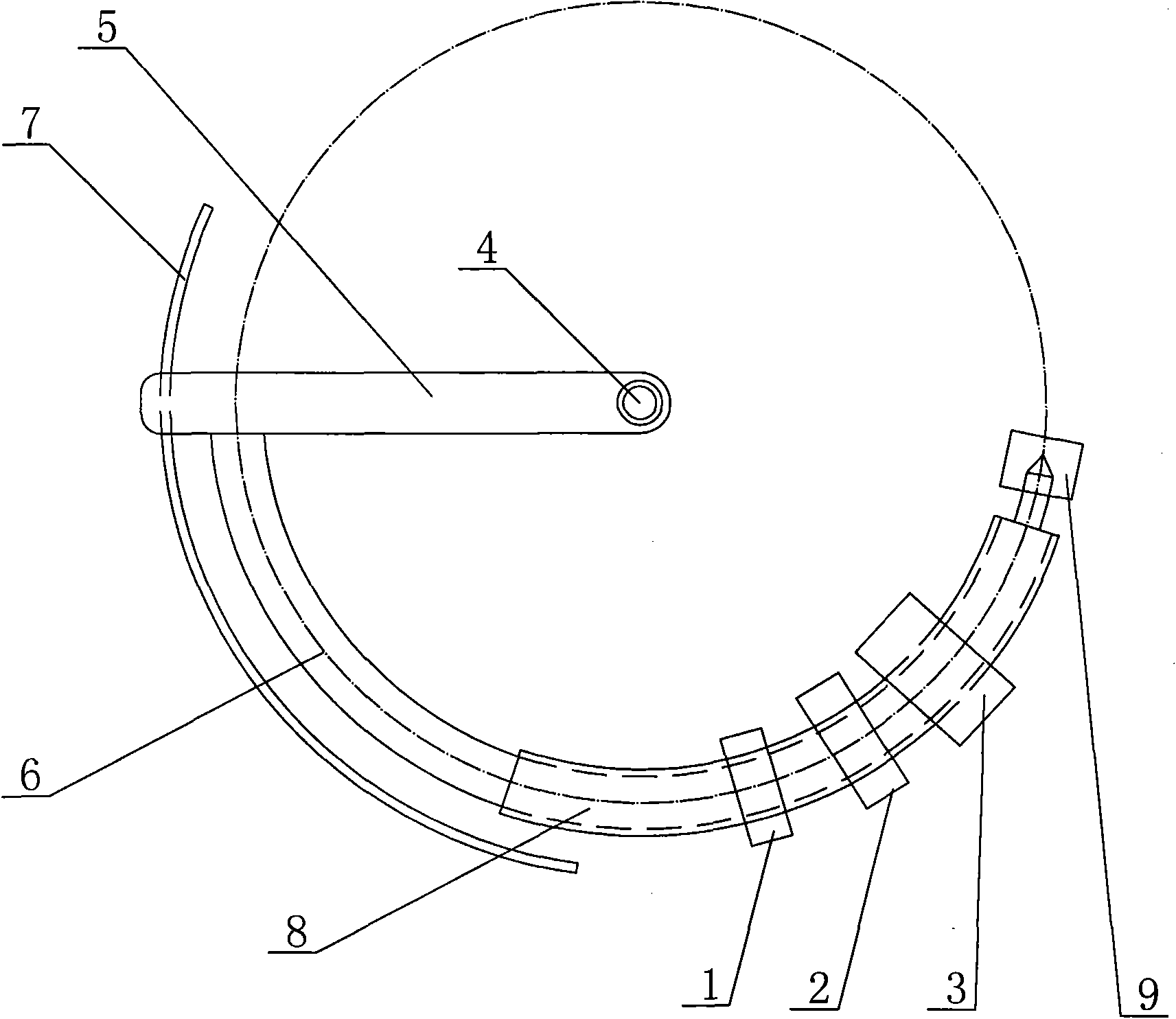

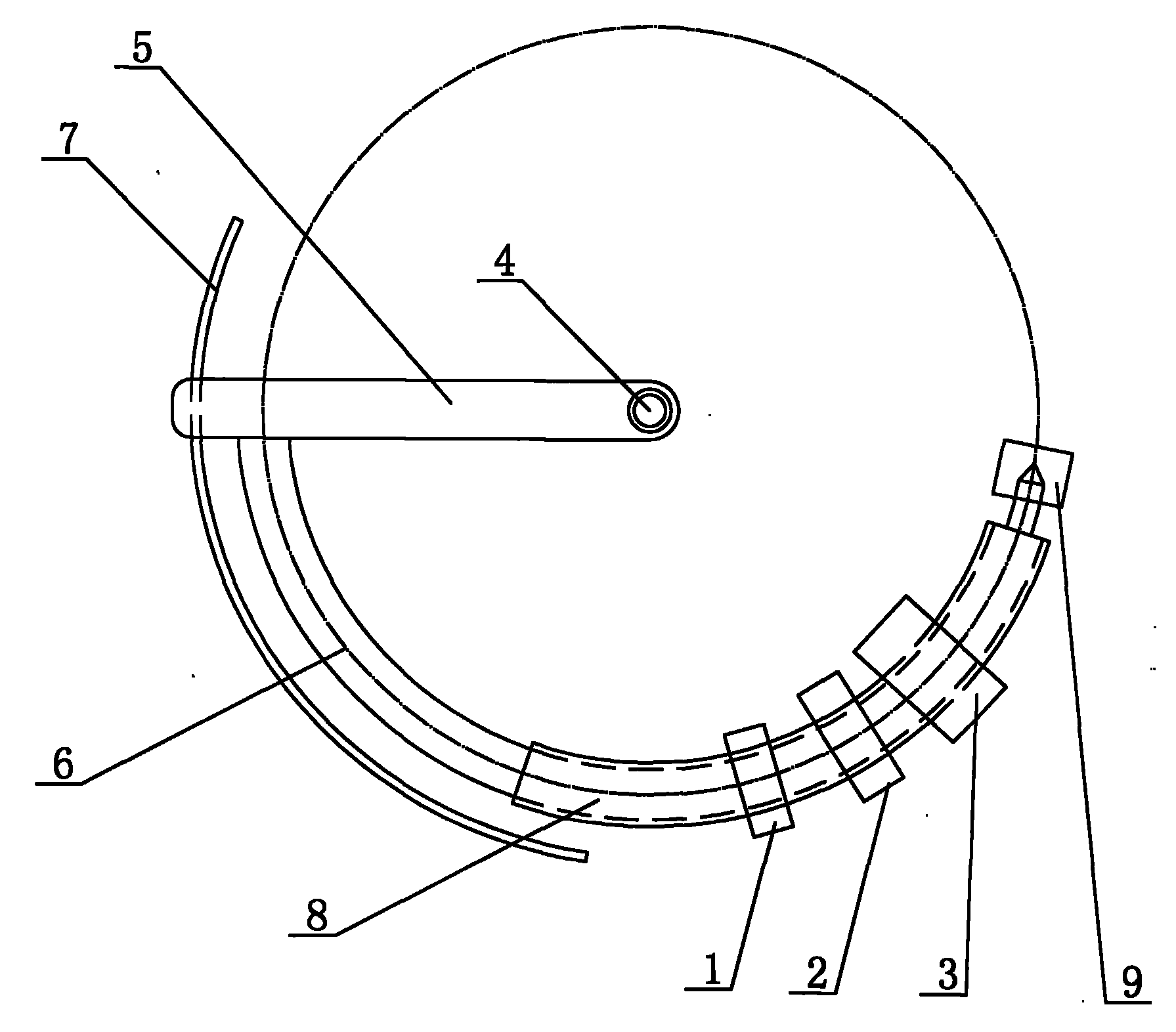

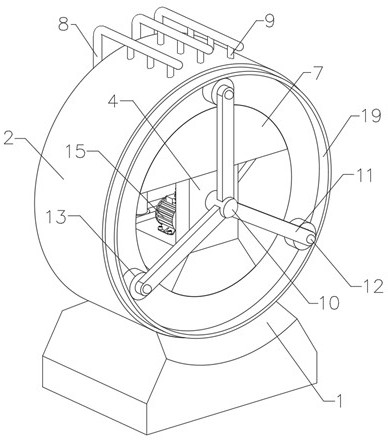

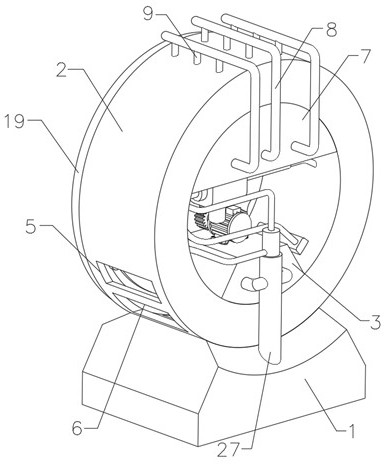

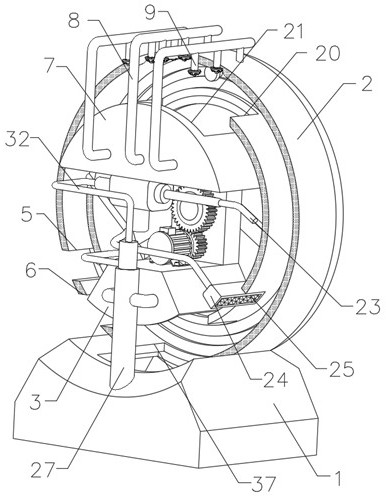

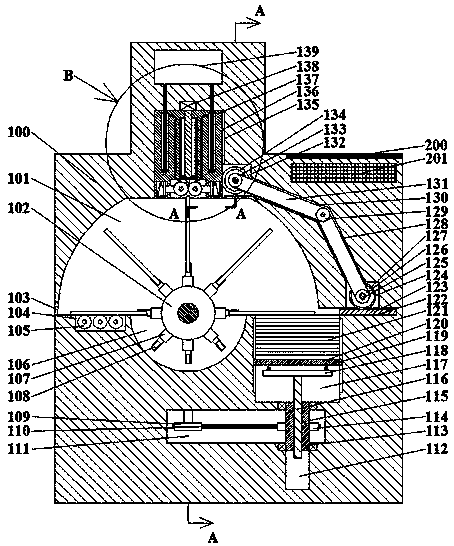

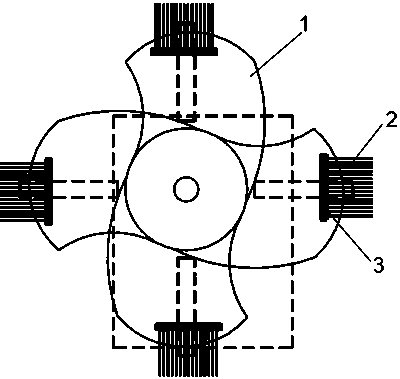

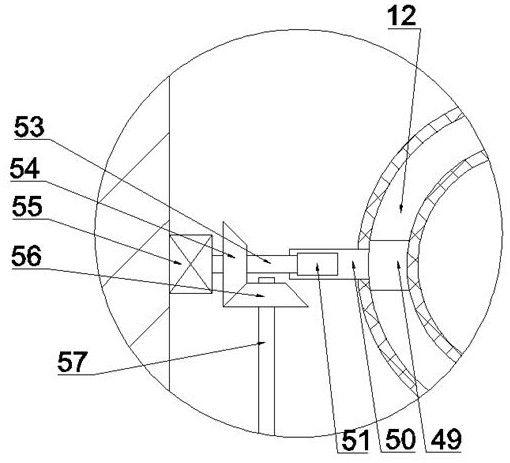

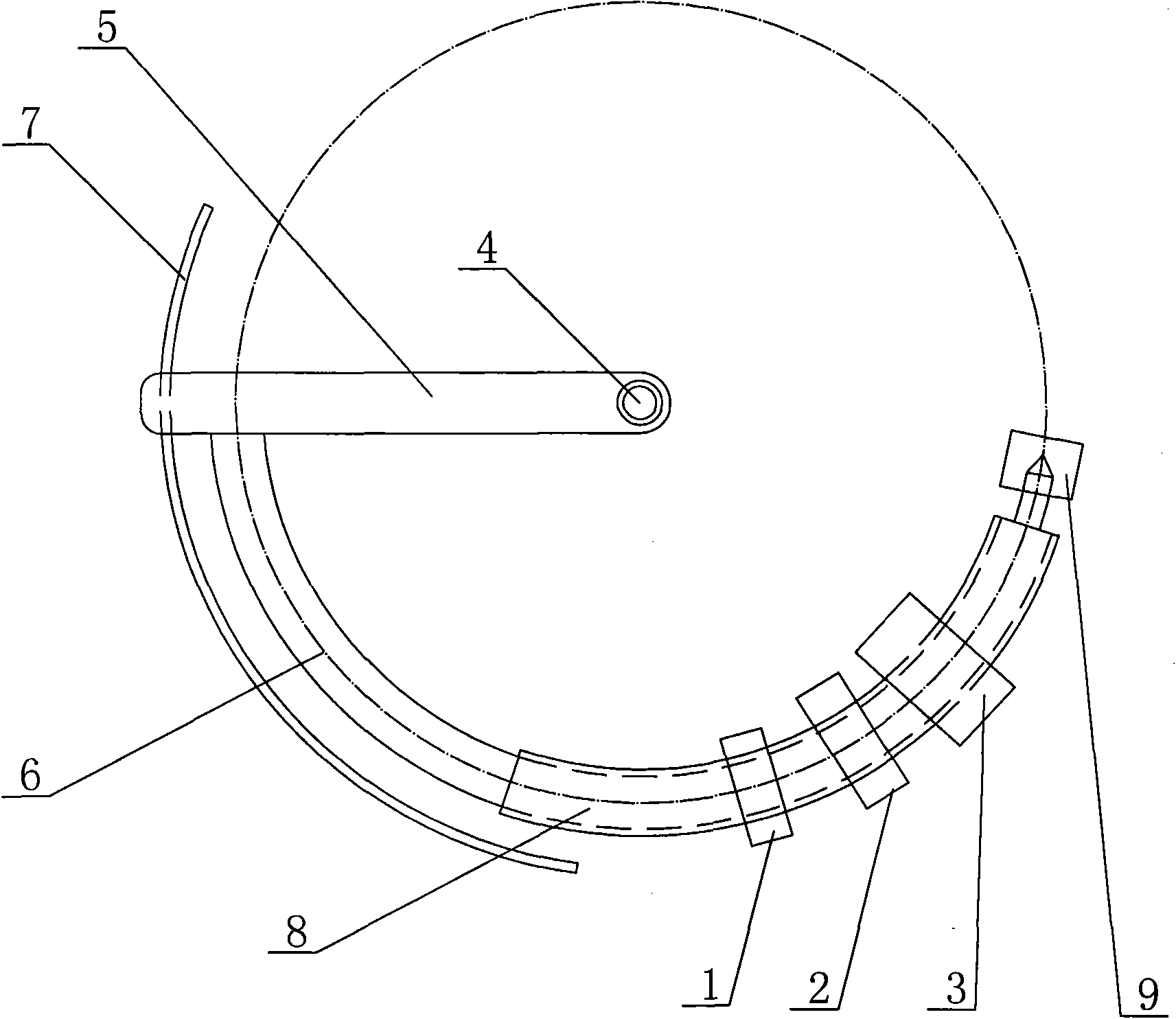

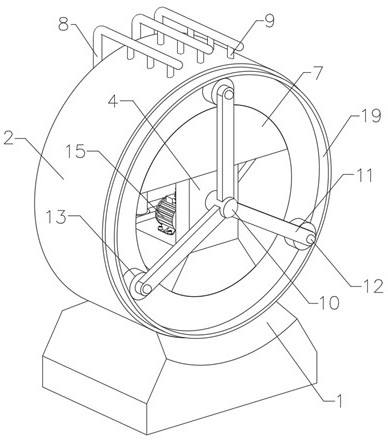

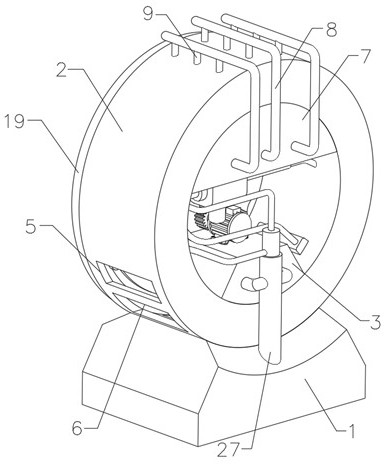

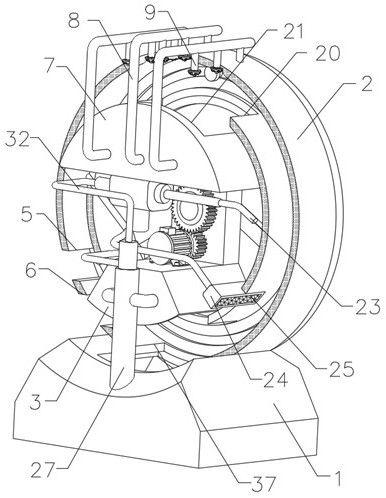

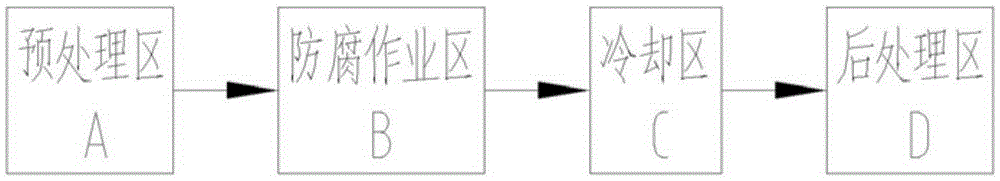

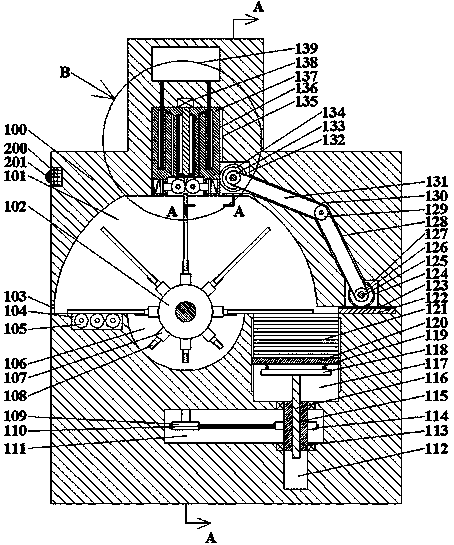

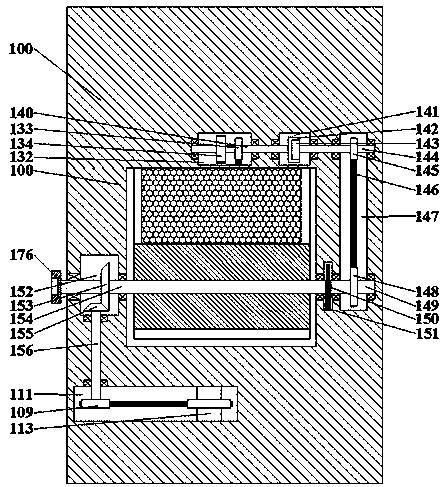

Antiseptic operation system of hot bending bent pipe and operation method thereof

InactiveCN101846230AImprove anti-corrosion performanceExtended service lifeCorrosion preventionPipe protection against corrosion/incrustationMedium frequencyEngineering

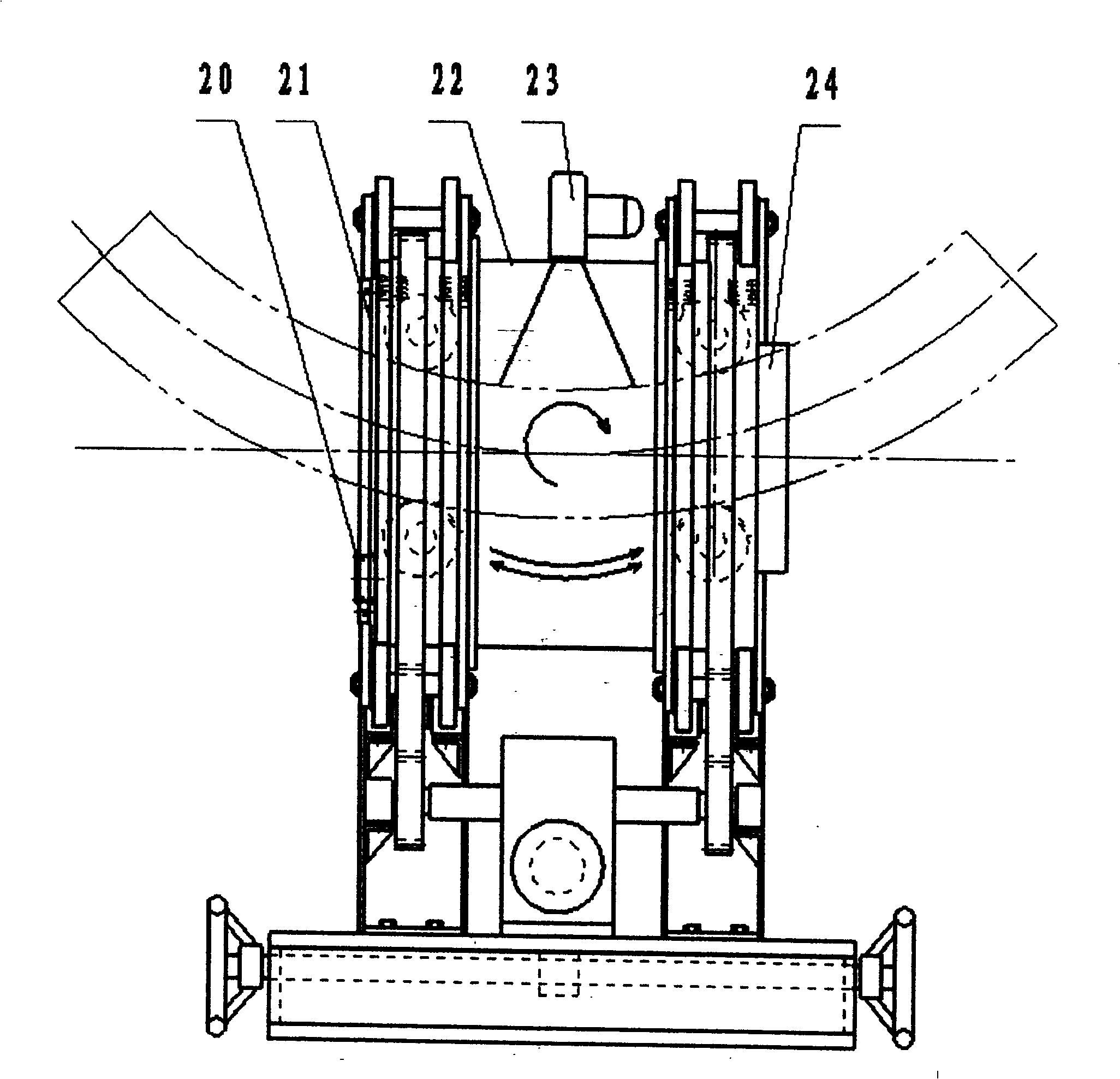

The invention discloses an antiseptic operation system of a hot bending bent pipe and an operation method thereof. The antiseptic operation system of the hot bending bent pipe comprises a rotary cantilever which comprises a rotary beam and an arc-shaped cantilever, wherein the rotary beam rotates along a revolving axle, and the arc-shaped cantilever is arranged on the rotary beam; one end of the rotary beam is installed on the revolving axle, and the other end of the rotary beam is supported on an arc-shaped rail; the hot bending bent pipe is fixedly arranged on the arc-shaped cantilever; a medium-frequency heating device, a powder spraying device, a winding device and a cooling device are arranged along the movement locus of the arc-shaped cantilever; and the hot bending bent pipe is successively matched with the medium-frequency heating device, the powder spraying device, the winding device and the cooling device. The invention can simplify the antiseptic drive lines of three layers of PE of the hot bending bent pipe, can quickly improve the operation time of the antiseptic production of the three layers of the PE of the hot bending bent pipe, improves the efficiency of mechanical antiseptic production of the three layers of the PE of the hot bending bent pipe and realizes the mechanical high-efficiency antiseptic production of the three layers of the PE of the hot bending bent pipe.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

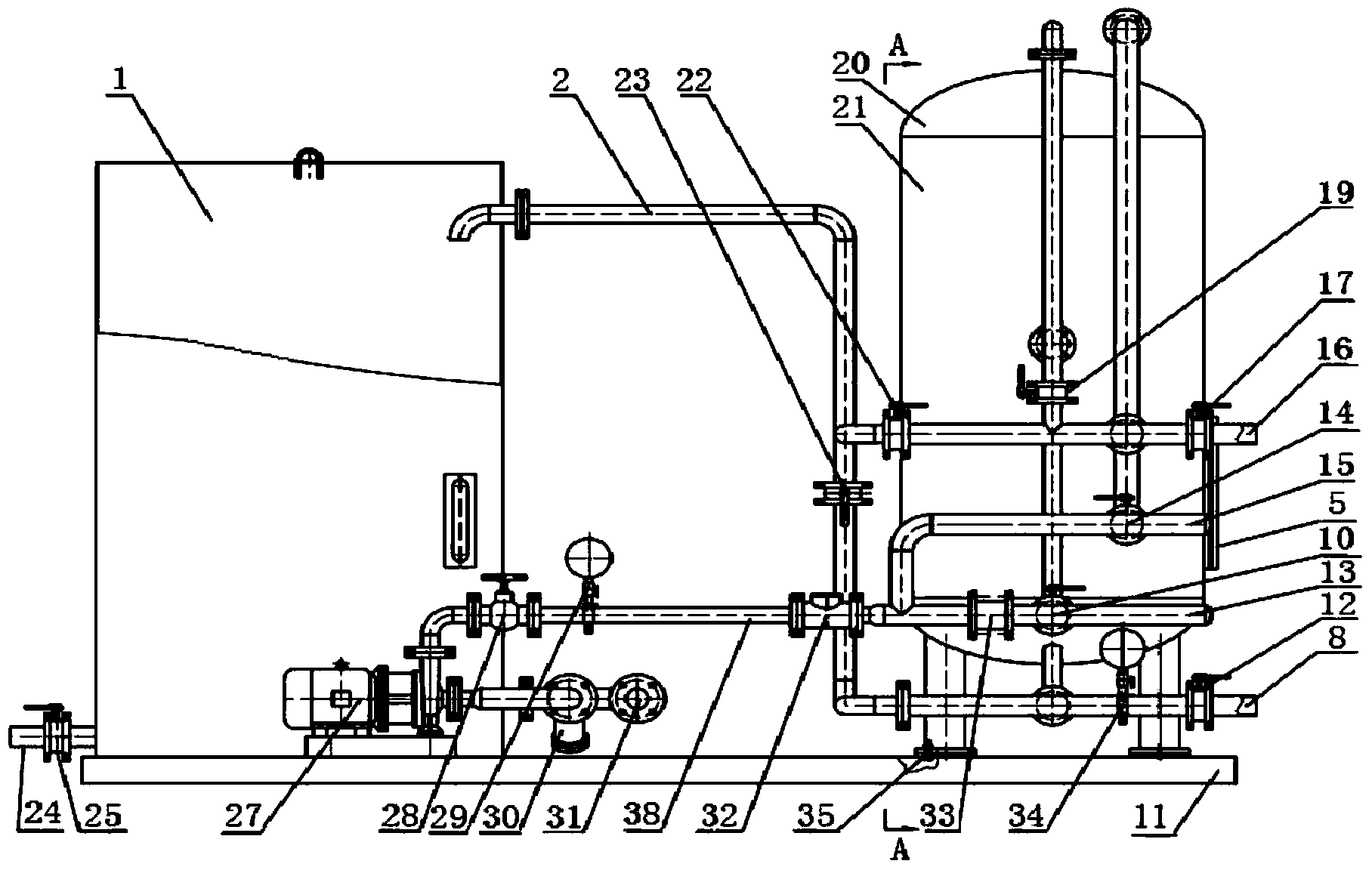

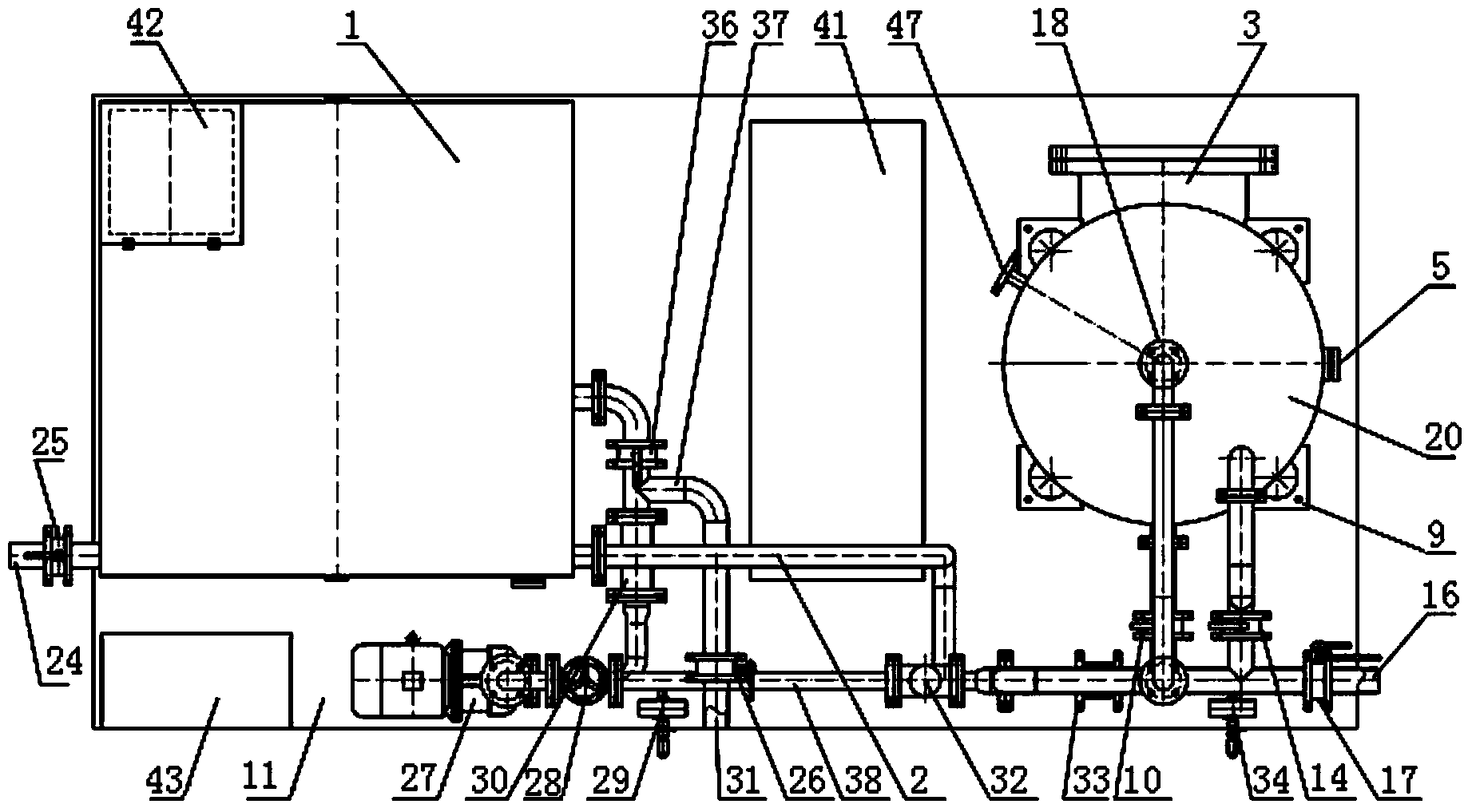

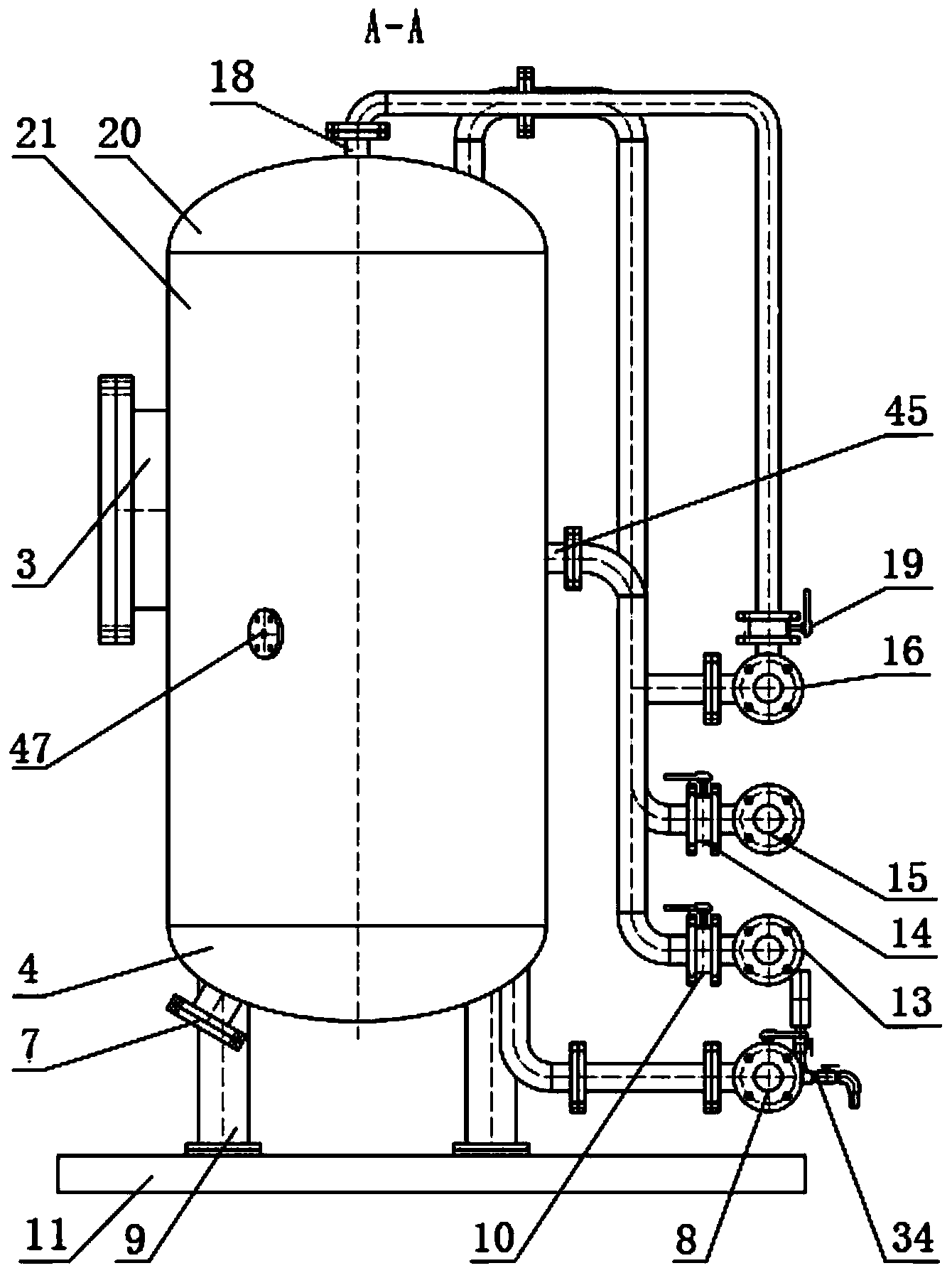

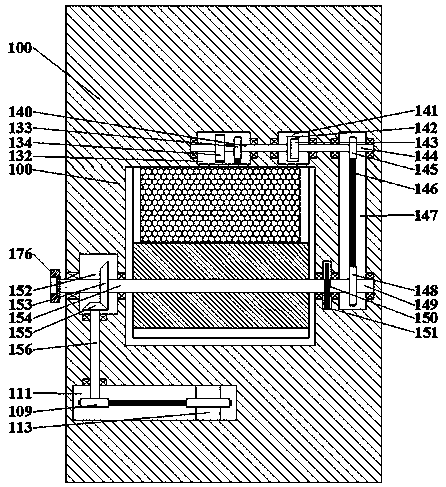

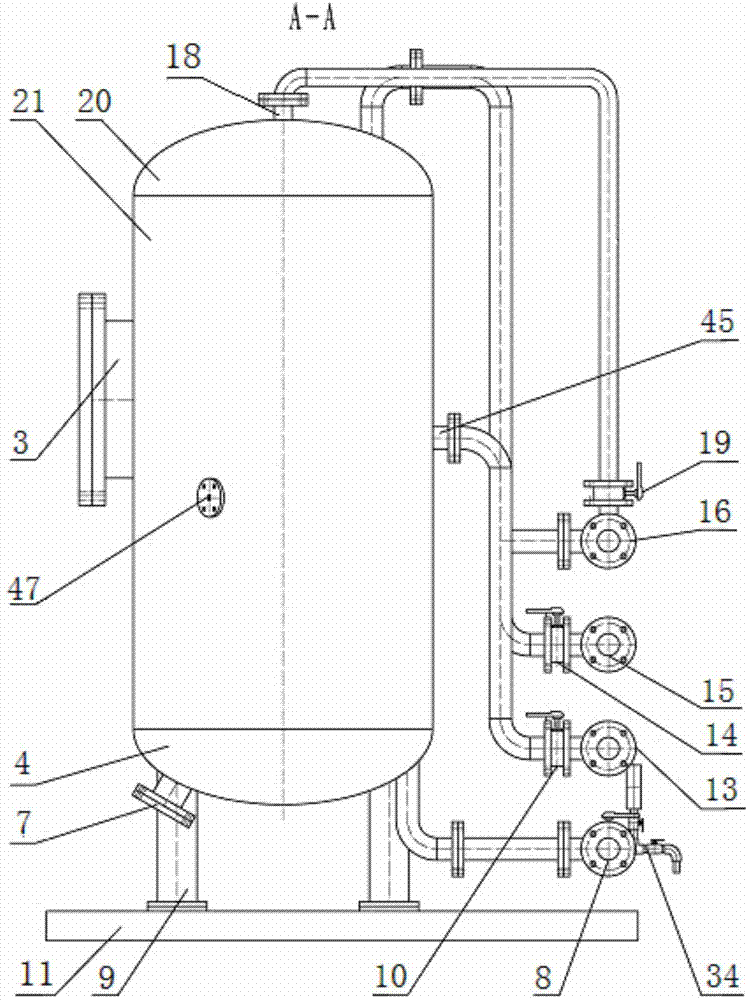

High-efficiency energy-saving granular filter

ActiveCN103623626ASimple structureEliminate the defect of stirring seal leakageLoose filtering material filtersGravity filtersWater sourceControl system

The invention relates to a high-efficiency energy-saving granular filter which comprises a filter body, a backwashing assembly, a backwashing water tank, an air compressor and a control system. A tank body and upper and lower oval sealing heads are arranged on the filter body; upper and lower sieve tubes / plates are arranged in the tank body; an oil / gas discharge port and a sewage inlet assembly are arranged at the top of the upper oval sealing head; a water outlet, a discharge port and supporting legs are arranged at the end of the lower oval sealing head; a backwashing water inlet and a backwashing gas inlet are arranged on the backwashing assembly; after being connected with a water inlet pipe, a backwashing water inlet pipe is connected with a backwashing spray nozzle; the backwashing water tank is connected with a filter by a return pipe; after being connected with a gas control valve, a gas check valve and the like, the air compressor is connected with the backwashing gas inlet by pipelines; by the control system, each valve, a backwashing water source and a backwashing gas source are automatically controlled to carry out operation according to the program. The filter disclosed by the invention has a simple structure, adopts a three-phase flow backwashing technology, is convenient to operate, is low in backwashing water consumption, is effective and energy-saving to backwash and has long equipment service life.

Owner:武汉市汉江石油物资技术开发有限责任公司

Anti-corrosion treatment device for ventilation fan blade machining

ActiveCN113275304AReduce uncertaintyThe feeding process is stable and effectiveCompression machinesDrying gas arrangementsWater flowEngineering

The invention discloses an anti-corrosion treatment device for ventilation fan blade machining. The anti-corrosion treatment device for ventilation fan blade machining comprises a water tank, wherein a treatment box is fixed to the upper end of the water tank, a building table is fixed to the lower portion of the inner side of the treatment box, a driving mechanism is arranged at the upper end of the building table, and a charging port and a discharging port are formed in the circumferential outer wall of the treatment box in a penetrating mode; and a paint box is fixed to the upper portion of the inner side of the treatment box, a backflow groove is formed in the upper wall of the paint box in a penetrating mode, and a collecting groove communicating with the backflow groove is formed in the inner wall of the treatment box in a penetrating mode. The anti-corrosion treatment device for ventilation fan blade machining has the following advantages: uncertainty caused by manual loading is reduced due to automatic loading and unloading, so that that a stable and effective loading process is ensured, the overall efficiency is effectively increased through circular machining, blades are washed by water flow to be cleaned, dust and stains cannot be carried to enter the subsequent steps, and therefore the overall spraying anti-corrosion treatment quality is improved; and drying treatment can be carried out on the blades sprayed with the paint through circular flowing of the hot air flow, so that subsequent transfer and storage are facilitated.

Owner:南通清风通用机械有限公司

High-seawater-resistant epoxy coating suitable for ocean platforms and ships as well as preparation method and application method of high-seawater-resistant epoxy coating

InactiveCN104194558AReduce dock repairsStrong adhesionAntifouling/underwater paintsPaints with biocidesHydrophobic silicaSilicon dioxide

The invention relates to a high-seawater-resistant epoxy coating suitable for ocean platforms and ships as well as a preparation method of the high-seawater-resistant epoxy coating. A liquid A is composed of bisphenol A liquid epoxy resin, C9 petroleum resin, an epoxystearic acid alkyl ester, a polyurethane modified high-molecular compound, a modified hydrogenated castor oil, a silicone polyether, a nonionic surfactant, a mixture of dimethyl polysiloxane and hydrophobic silica, aerosol, micaceous iron oxide gray, quartz powder, silica micropowder, titanium dioxide powder, carbon black and aluminium triphosphate. A liquid B is a phenolic aldehyde amine curing agent with an amine value of 305 to 335. When the epoxy coating is used, the liquid A and the liquid B are mixed to form a coating layer which has a good adhesive force with a steel base material and is excellent in seawater resistance, salt spray resistance and cathodic disbonding resistance, so that the anticorrosion quality of ocean steel structures is effectively improved. Thus, the dock repairing of the ocean platforms, the ships and the like due to the failure of the coating layers is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

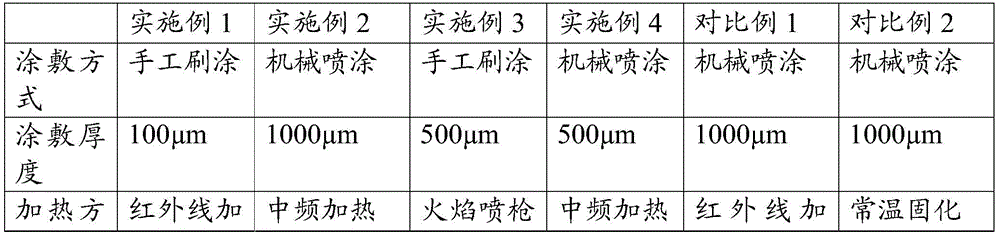

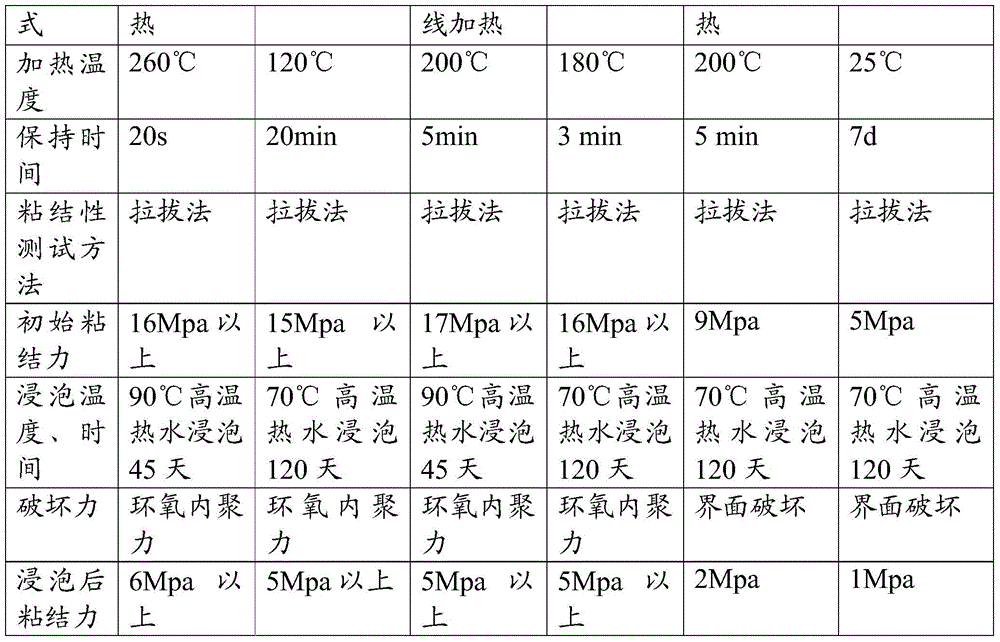

Application of Solvent-free Two-component Epoxy Coatings in Pipeline Coating and Anticorrosion

ActiveCN104449244BImprove adhesionMeet the needs of long-term serviceAnti-corrosive paintsEpoxy resin coatingsEpoxyChain structure

The invention discloses the application of a solvent-free two-component epoxy coating to joint wrapping anticorrosion of pipelines, and belongs to the field of coatings. The epoxy coating contains an aliphatic chain structure in the length of about 36 carbon atoms. When being used in the joint wrapping, the solvent-free two-component epoxy coating coats on the surface of a three-layer polyethylene coating and heated under high temperature of 120 to 260 DEG C for 20 s-20 min. The epoxy coating can form a fusion bonding with the three-layer polyethylene coating, so as to enhance the initial adhesion stress and durable adhesion stress between coatings.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Anti-leakage method of corroded and perforated iron sheet gutter

InactiveCN110512891AEasy to remove rustWith rust removal functionRoof coveringBuilding repairsEngineeringMaterial Perforation

The invention discloses an anti-leakage method of a corroded and perforated iron sheet gutter, and belongs to the technical field of anti-leakage. The anti-leakage method of the corroded and perforated iron sheet gutter comprises the steps of base layer cleaning, gutter reinforcement, anti-seepage and anti-corrosion treatments on the inner and outer surfaces of the gutter, the base layer cleaningcomprises the steps of treatment measures such as cleaning dirt, floated rust, and end craters, the gutter reinforcement treatment is divided into separate fine holes and large-area perforation situations and repair measures thereof, and the inner surface treatment measure of the gutter is a cold bonding construction method with wall-to-wall carpeting SBS waterproofing coils. According to the anti-leakage method of the corroded and perforated iron sheet gutter, the SBS waterproofing coil material is used, the price is much lower than that of anticorrosive paints, the service life is long, theconstruction technology is simple, immediate work engagement is facilitated, the result is quick, working time is saved, the labor efficiency is improved, meanwhile quality of anticorrosion is more easily ensured, the problem that the construction period is delayed due to the unsatisfactory anticorrosion quality is eliminated, other hidden dangers that may be caused by the replacement of the gutter to a profiled steel plate on the roof can be avoided, and the replacement cost is lowered.

Owner:SHANDONG LAIGANG CONSTR CO LTD

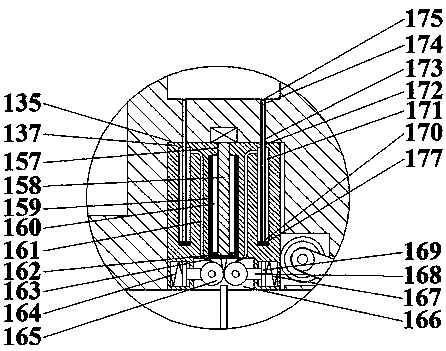

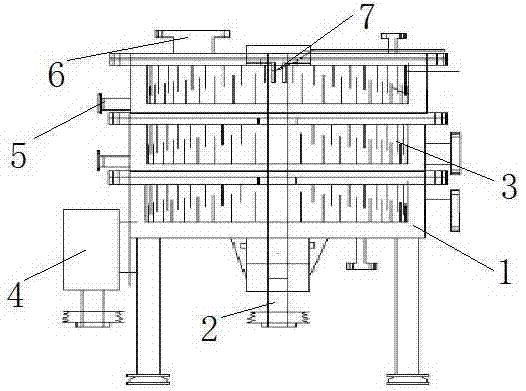

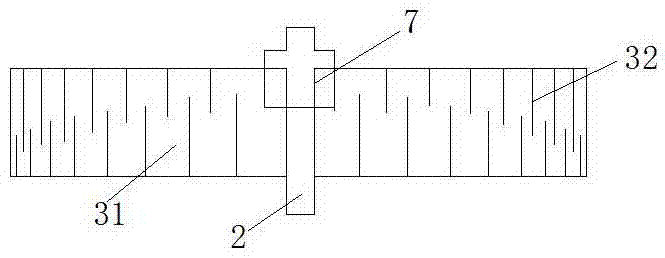

Novel wood preservation improvement method

InactiveCN108858588AApply evenlyDry fastWood treatment detailsCoating impregnationImproved methodMechanical engineering

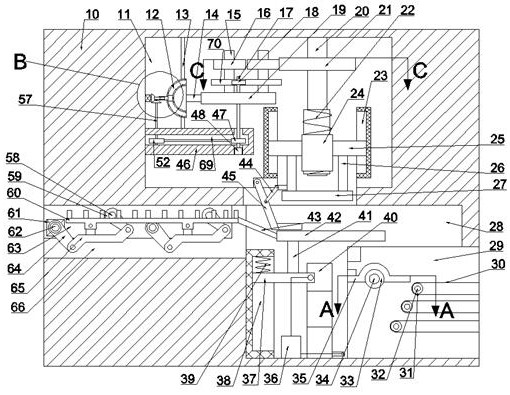

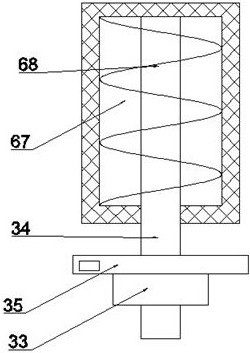

The invention discloses a piece of novel wood preservation improvement equipment which comprises a machine body, a first cavity formed in the machine body and a first transmission cavity formed in themachine body. A second cavity of which an opening is downward is formed in the top wall of the first cavity; a third cavity of which an opening is upward is formed in the bottom wall of the first cavity; a fourth cavity communicated with the first cavity is formed in the left side end wall of the third cavity; a fifth cavity communicated with the first cavity is formed in the right side end wallof the third cavity; and a second transmission cavity is formed in the front side end wall of the first cavity. The equipment disclosed by the invention is simple in structure and convenient to operate; by adopting the same power source to drive conveying and oil coating of a wood board, setting progressive oil feeding in the oil coating process to more uniformly coat wood preservation oil and meanwhile, using a drying device in the coating process to accelerate drying of the wood preservation oil, each process is matched mutually, but cannot influence each other, so that not only are oil coating efficiency and preservation quality improved, but also practical performance of the device is improved.

Owner:象山知航机电科技有限公司

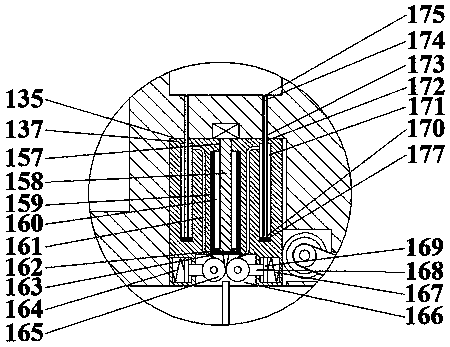

Cleaning device for inner wall of steel pipe for driving flocculent materials to work through wind energy

The invention relates to a cleaning device for the inner wall of a steel pipe for driving flocculent materials to work through wind energy. Blades in a cyclone power working device are mounted on a shaft with a worm, and the blades are provided with fluid channels. The flocculent materials are evenly distributed along the circumferences of the blade and are compressed and fixed through pressing bar compressing devices. The worm on the shaft with the worm in an advancing guide device drives a turbine, the turbine drives a transmission gear for advancing, the transmission gear drives a power wheel to advance, and the power wheel is stably guided and advances at constant speed with the supporting assistance of multiple supporting wheels. According to the cleaning device, fluid output by a pipeline fan flows into the blade channels in the axial direction to drive the blades to rotate, the rotary blades push the steaming-around fluid in the axial direction, pushing of the blades works on the fluid, and the energy of the fluid is increased and discharged in the axal direction. At this moment, the flocculent materials are influenced by the rotating speed to generate centrifugal gravity, the flocculent materials are thrown into an arc through the gravity and scour the inner wall of the steel pipe, and the inner wall of the steel pipe is powerfully cleaned.

Owner:SHANGHAI SUPERHIGH ENVIRONMENTAL PROTECTION TECH CO LTD

Potato chip delivery package sealing performance testing and screening equipment

InactiveCN112354893AImprove the quality of anticorrosionImprove shipping qualitySortingChipped potatoesProduction line

The invention discloses a potato chip delivery package sealing performance testing and screening equipment, comprising a shell. A pressure cavity is formed in the shell; a driving motor is fixedly arranged on the left side wall of the pressure cavity; a main motor shaft is rotatably arranged on the right side of the driving motor; a motor bevel gear is fixedly arranged at the left end of the mainmotor shaft; a rear connecting rod is fixedly arranged at the right end of the main motor shaft; and a sliding block connecting rod is fixedly arranged on the rear side of the rear connecting rod. According to the potato chip delivery package sealing performance testing and screening equipment, pressure testing can be rapidly performed on delivered potato chip package sealing performance, originalqualified potato chip packages cannot be damaged, and air leakage potato chips are screened out; and the equipment is established on a potato chip package production line, is convenient and fast, improves the later-period corrosion prevention and transportation quality of the potato chips, avoids deterioration of the potato chips, can repackage the potato chips with damaged packages, and reducesthe waste.

Owner:杭州云淡包装有限公司

High-temperature resistant and corrosion-resistant cyclone shearing type gas-liquid separator

InactiveCN106914026AFully contactedAnti-corrosionFractional distillationCycloneVapor–liquid separator

The invention discloses a high-temperature resistant and corrosion-resistant cyclone shearing type gas-liquid separator. The gas-liquid separator comprises a shell body, a rotating shaft, a rotating disk, a motor, a gas phase inlet / outlet, a liquid phase inlet / outlet, a mixed solution downcomer, a moving disk and a static disk, wherein the rotating shaft is arranged at the center of the shell body, and the motor is arranged on the side surface of the shell body; the rotating shaft is connected with the motor through a belt, and the rotating disk which rotates along with the rotating shaft is arranged on the rotating shaft; the rotating disk comprises the moving disk and the static disk, and the static disk is arranged at the upper end of the moving disk; the gas phase inlet / outlet and the liquid phase inlet / outlet are formed in the rotating disk; a moving ring and a static ring are separately arranged on the moving disk and the static disk; and the mixed solution downcomer is further arranged at the joint of the rotating shaft and the rotating disk. According to the high-temperature resistant and corrosion-resistant cyclone shearing type gas-liquid separator, through improving internal structures of the moving and static disks, the gas-liquid separator can be corrosion-resistant, easy and feasible, the gas-liquid contact can be more thorough, and the efficiency of rectification is increased; and the practicability is high, so that popularization is facilitated.

Owner:苏州汇博龙环保科技有限公司

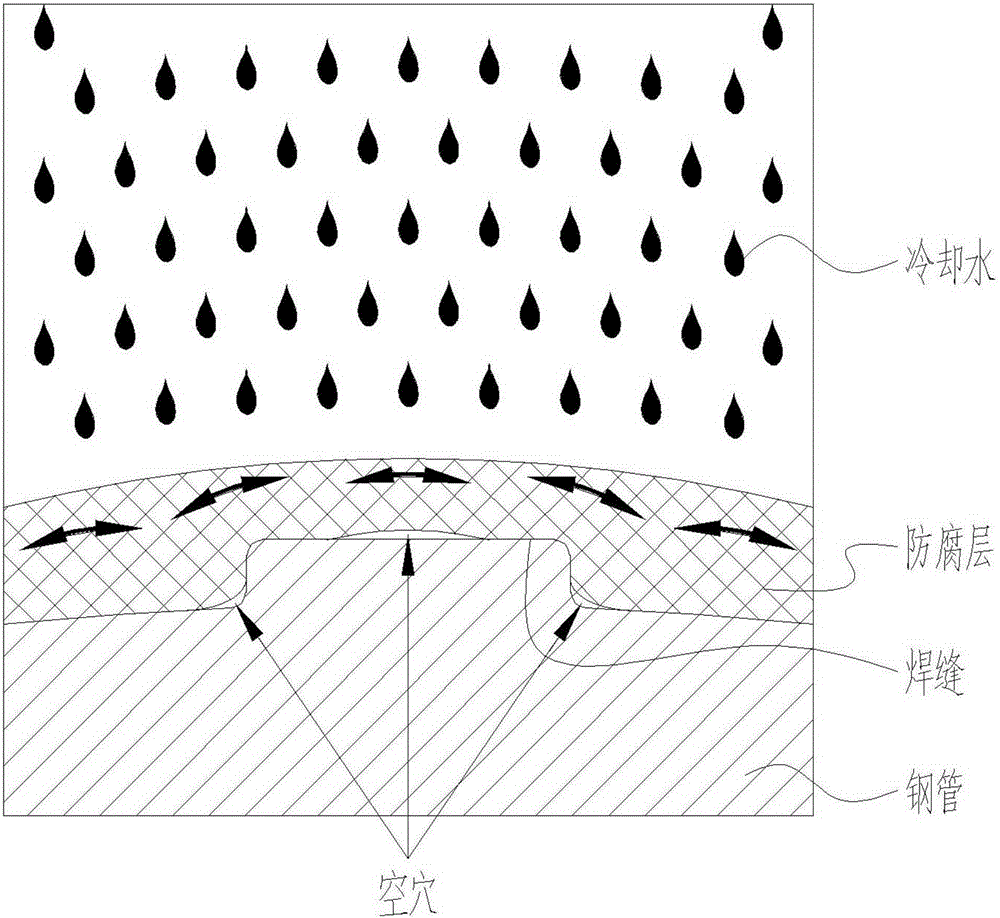

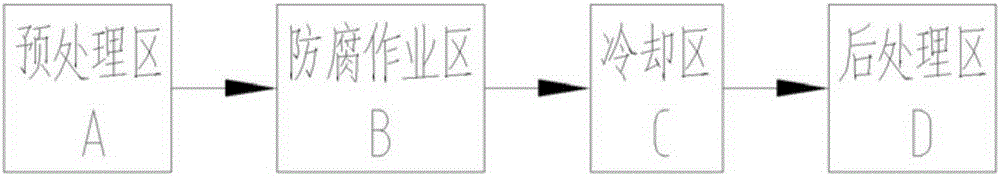

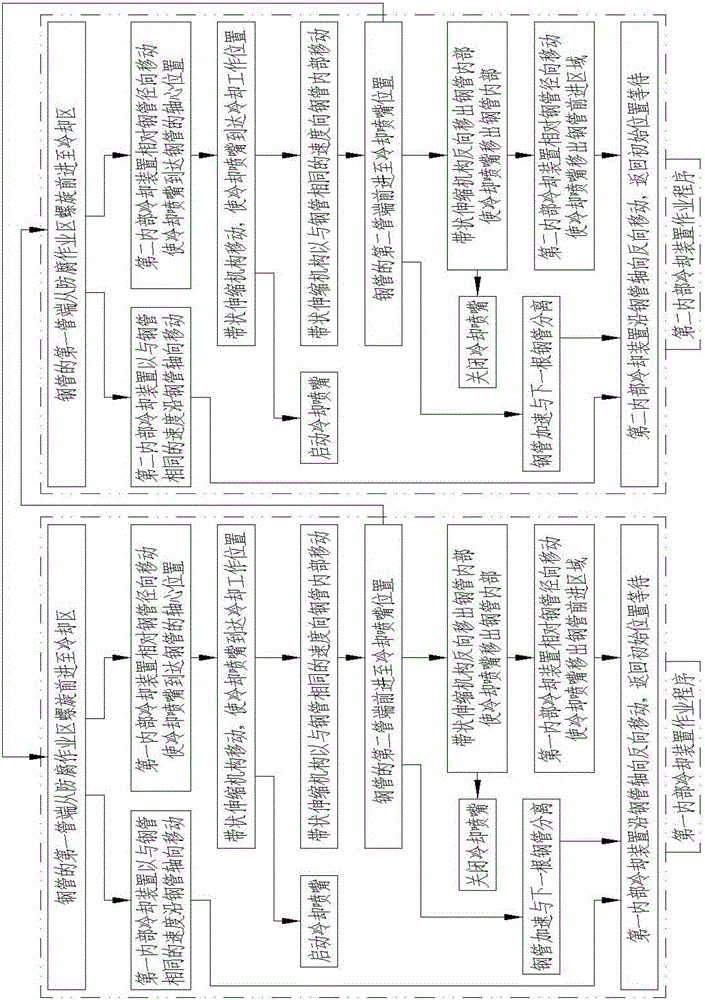

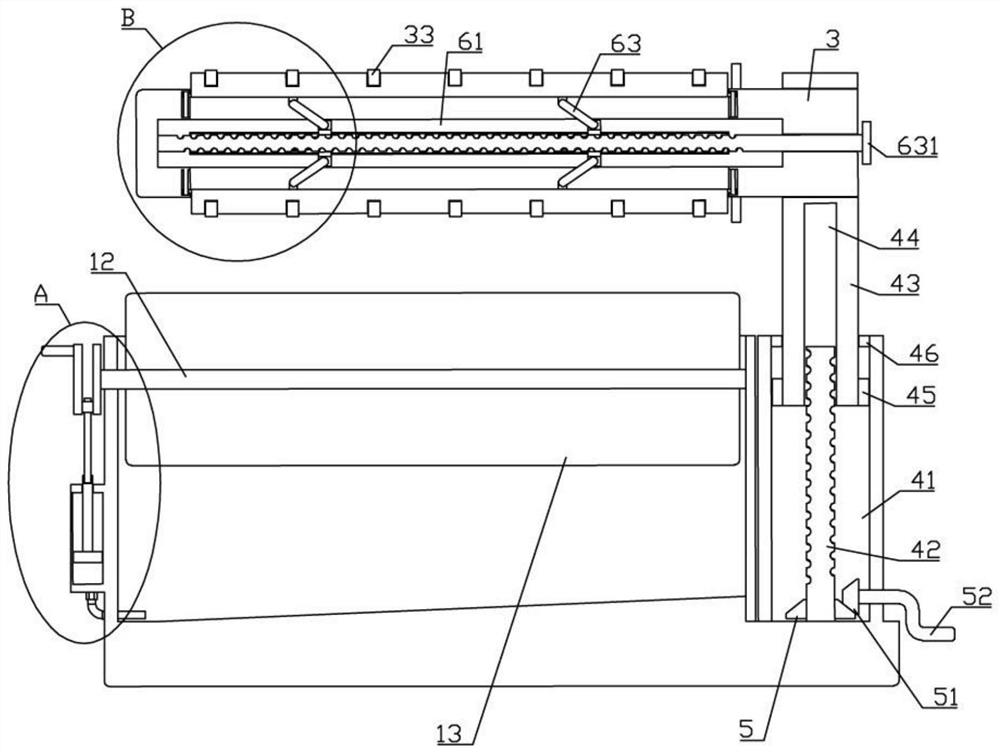

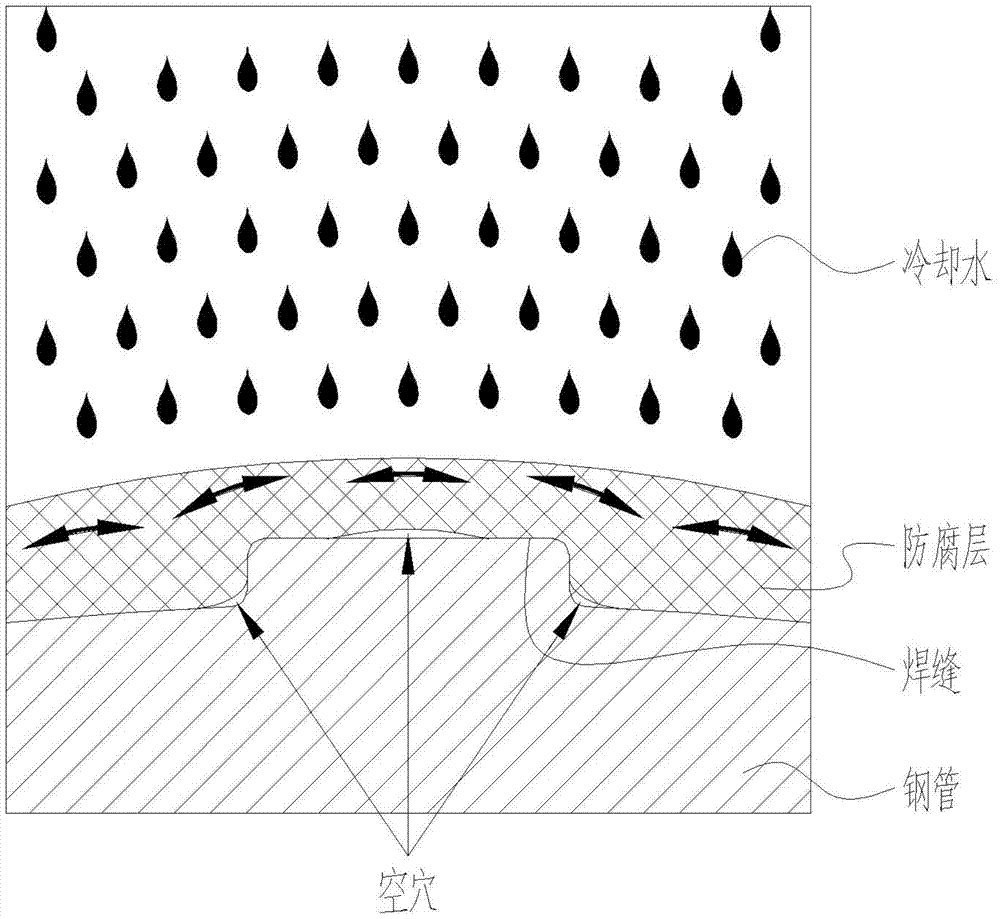

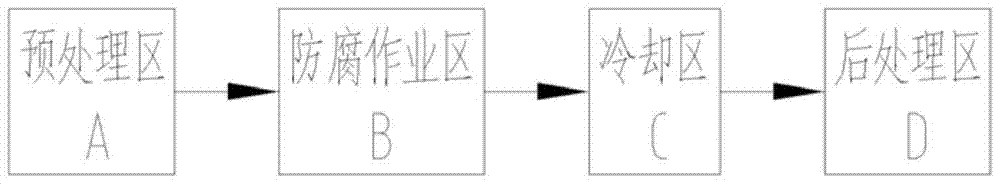

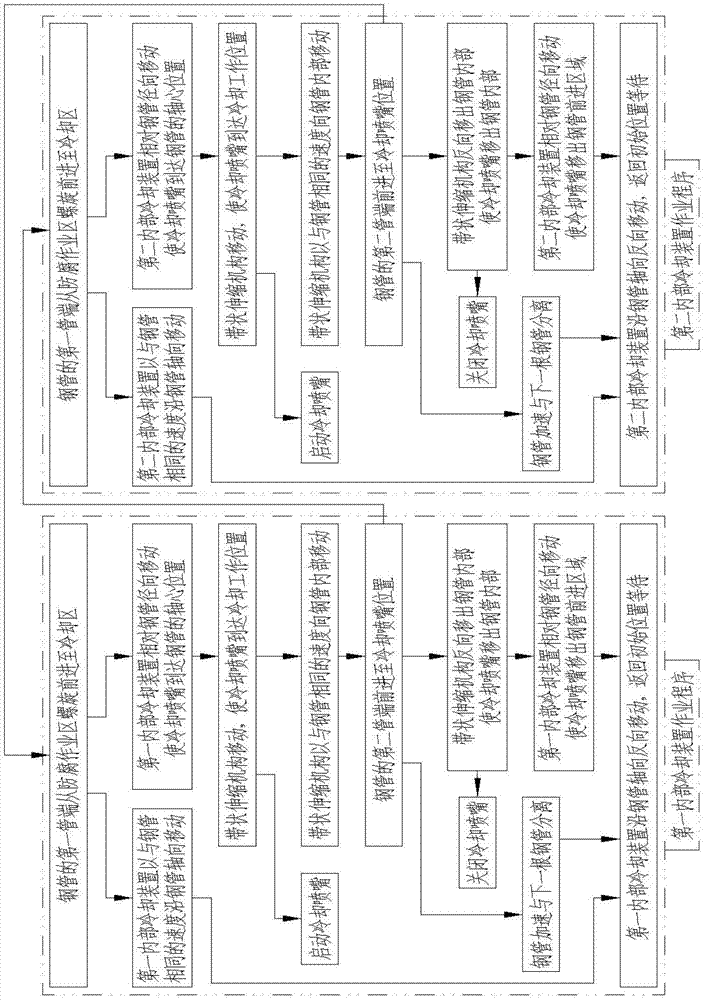

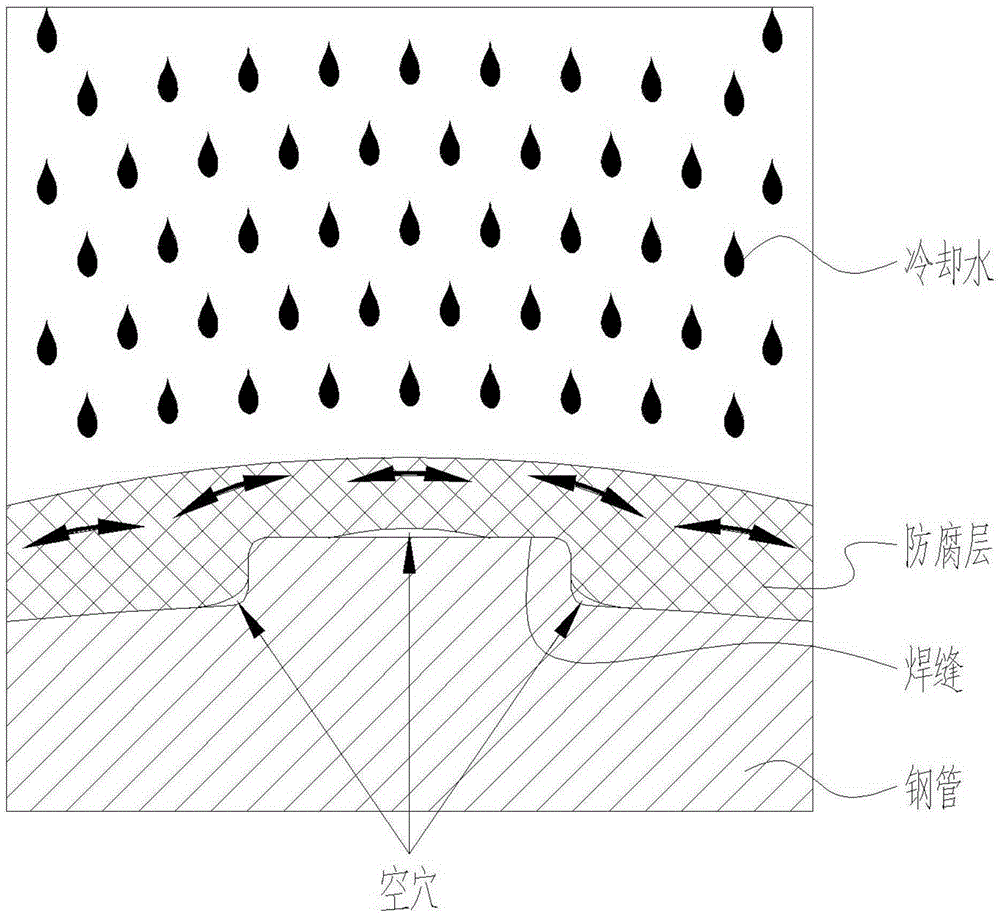

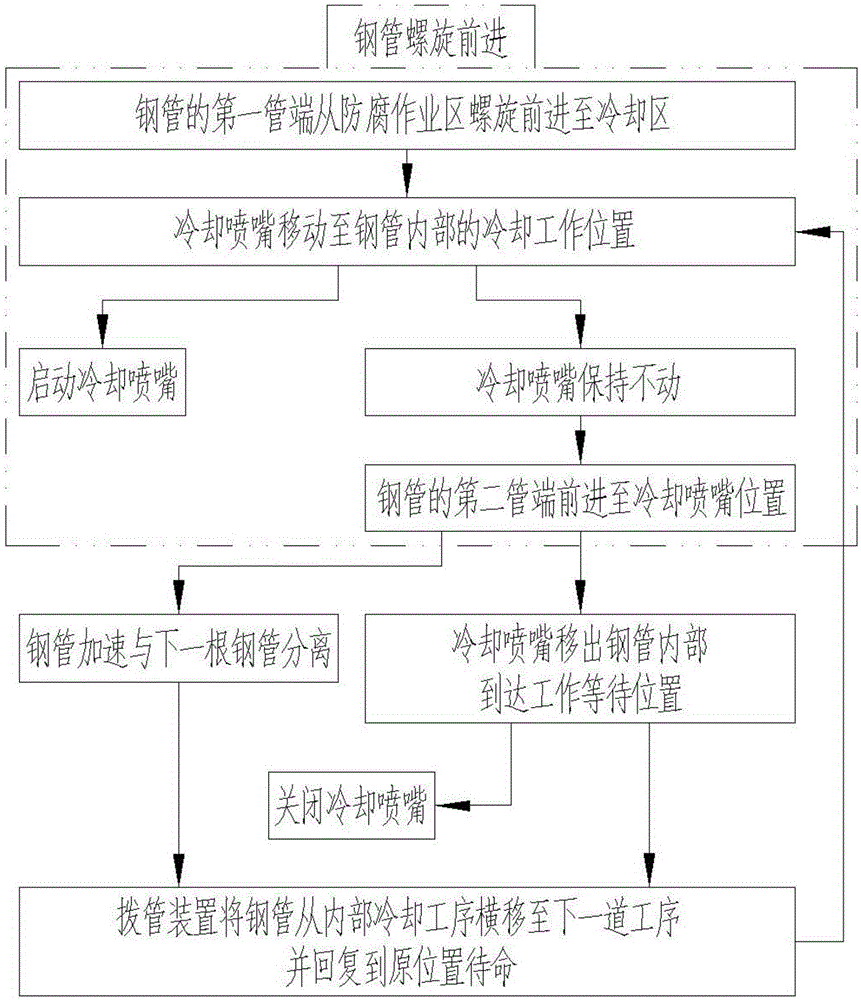

Cooling method and device for anticorrosion steel pipe manufacturing

ActiveCN105238918AUninterrupted internal coolingEasy to upgradeFurnace typesHeat treatment furnacesControl systemEngineering

The invention provides a cooling method and device for anticorrosion steel pipe manufacturing. The cooling method for anticorrosion steel pipe manufacturing includes the steps that after the first pipe end of a steel pipe enters a cooling region from an anticorrosion working region, a first internal cooling device moves in the axial direction of the steel pipe at the same speed as the steel pipe, a cooling nozzle arrives at the cooling working position and is opened, a belt-shaped telescopic mechanism moves towards the interior of the steel pipe at the same speed as the steel pipe as well, and the cooling nozzle is kept still; when the second pipe end of the steel pipe enters the cooling nozzle position, the cooling nozzle is closed, and the first internal cooling device returns to the initial position for use; and the first internal cooling device and a second internal cooling device alternately conduct interior cooling on steel pipes passing the cooling region continuously. The cooling device applying the cooling method comprises a transmission device, the first internal cooling device, the second internal cooling device and a control system. By means of the cooling method and device, the anticorrosion quality and cooling efficiency of the steel pipes are improved, and production cost is lowered.

Owner:HUNAN KUANGWEI TECH CO LTD

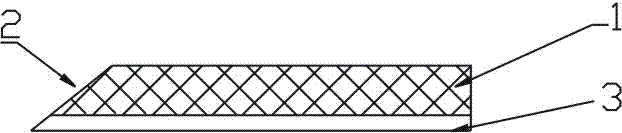

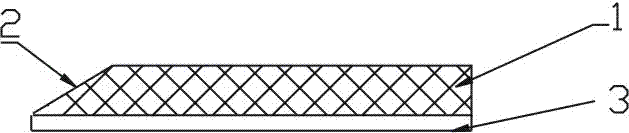

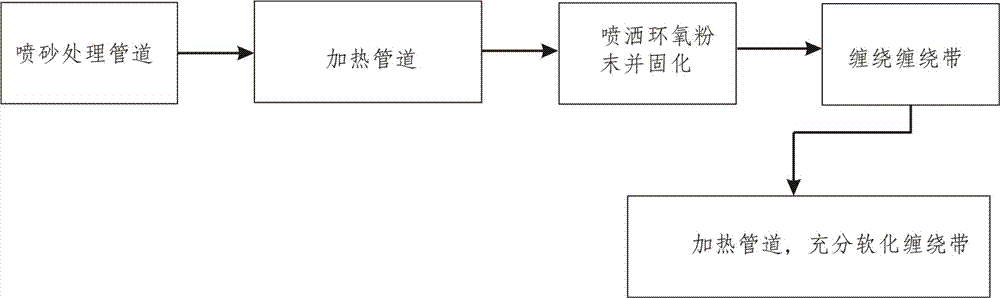

Wrapping belt for pipeline repaired opening corrosion prevention and construction method

ActiveCN107255207AImprove the quality of anticorrosionExtended service lifePipe elementsCoatingsEpoxyAdhesive

The invention discloses a wrapping belt for pipeline repaired opening corrosion prevention and a construction method. The wrapping belt is composed of a hot melting adhesive layer and a PE material layer. The PE material layer and the hot melting adhesive layer are arranged in sequence from the surface to the bottom face, and the side edge of the wrapping belt is a slope. According to the wrapping belt and the construction technology, the product performance and the construction quality stability can be effectively improved, the cooperative construction technology comprising the steps of spraying epoxy primer (formed by curing epoxy powder) to the surface of a pipeline and then adopting a special adhesive (hot melting adhesive) and the special (high-strength) PE material layer for forming the wrapping belt is adopted, the problem of construction quality instability is solved, the anti-corrosion quality and the reliability are improved, and the product service life is prolonged.

Owner:四川久远辐射技术有限公司

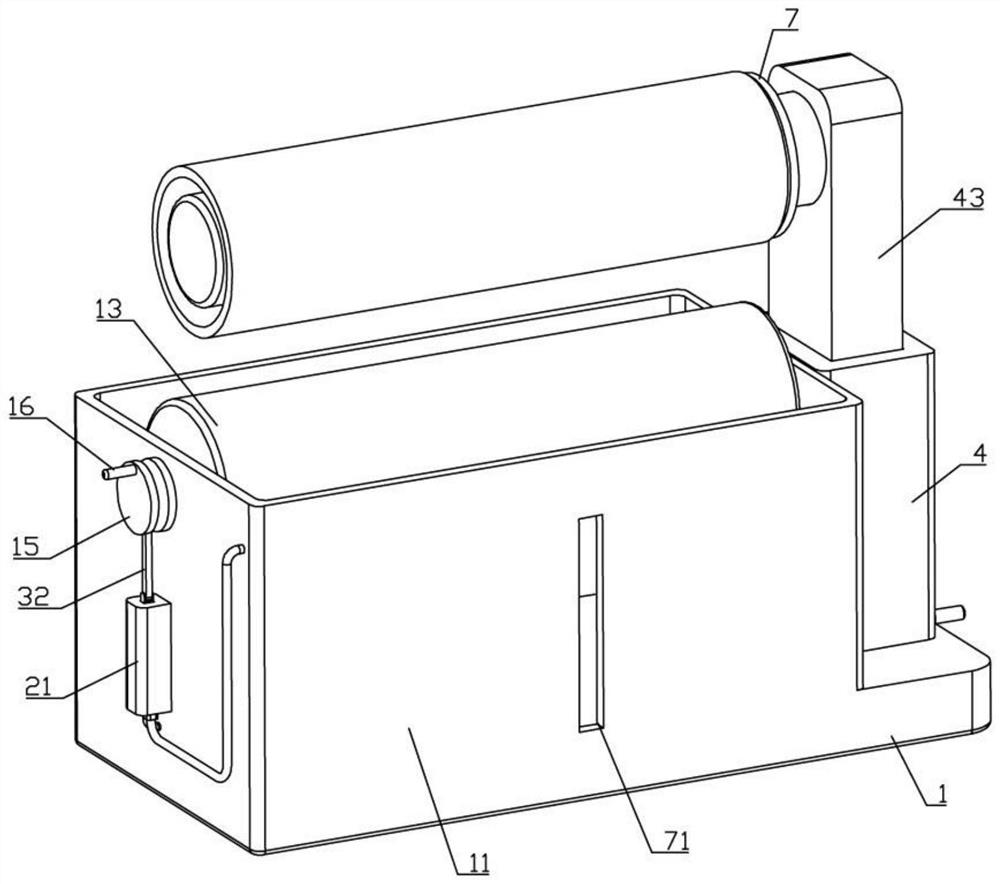

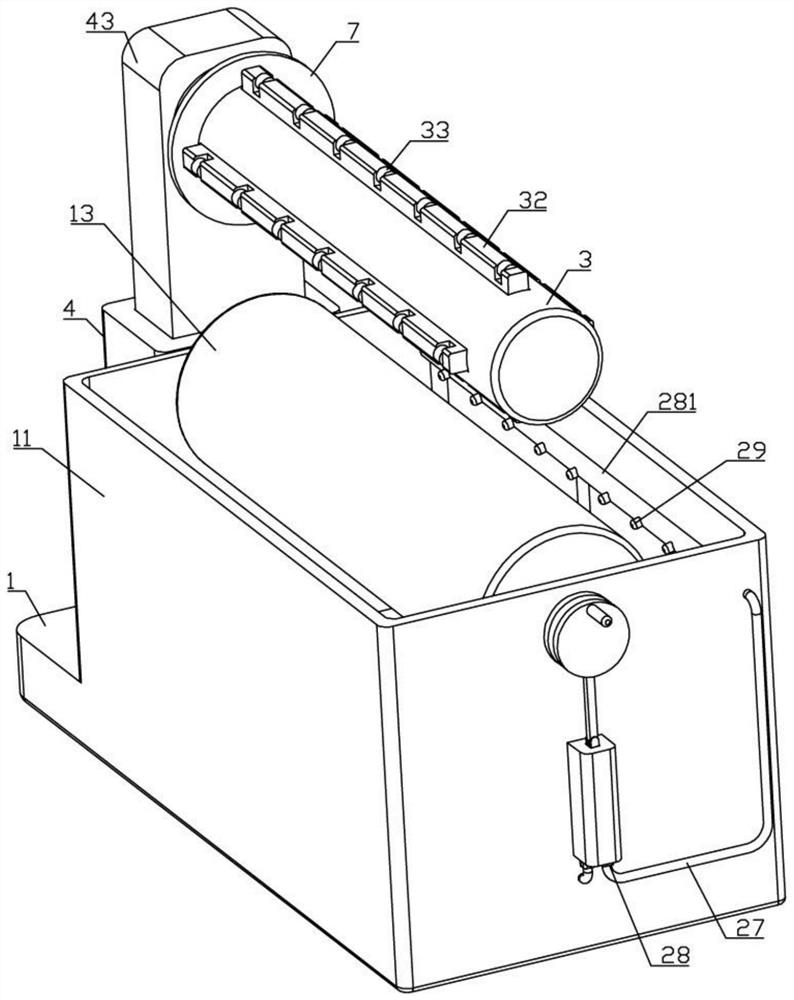

Metal pipeline anti-corrosion treatment device

ActiveCN113814106ASimple structureEasy to handleLiquid surface applicatorsCoatingsStructural engineeringMechanics

The invention belongs to the technical field of metal pipeline corrosion prevention, and particularly relates to a metal pipeline anti-corrosion treatment device. The device comprises a bottom plate; a coating roller fixedly connected with a rotating shaft is assembled in a liquid storage frame; the other end of a connecting rod is fixedly connected with a second rotating piece matched with a first rotating piece in position; a sealing block is slidably assembled in a cavity; a liquid inlet pipe communicated with the cavity is assembled at the lower end of a mounting seat; the other end of the liquid inlet pipe extends into the lower side in the liquid storage frame; the liquid storage pipe is provided with a plurality of nozzles pointing to a coating roller; the upper side of a height adjusting mechanism is in height connection with a fixed cylinder; four ejector rods are each vertically and rotatably provided with a plurality of rollers; and a jacking mechanism matched with the ejector rods is assembled in the fixed cylinder. The outer wall of a metal pipeline is painted instead of manual work, so that the metal pipeline is uniformly painted while the treatment effect is fast, the anti-corrosion quality is improved, the workload is reduced, and the working efficiency is improved.

Owner:TONGREN UNIV

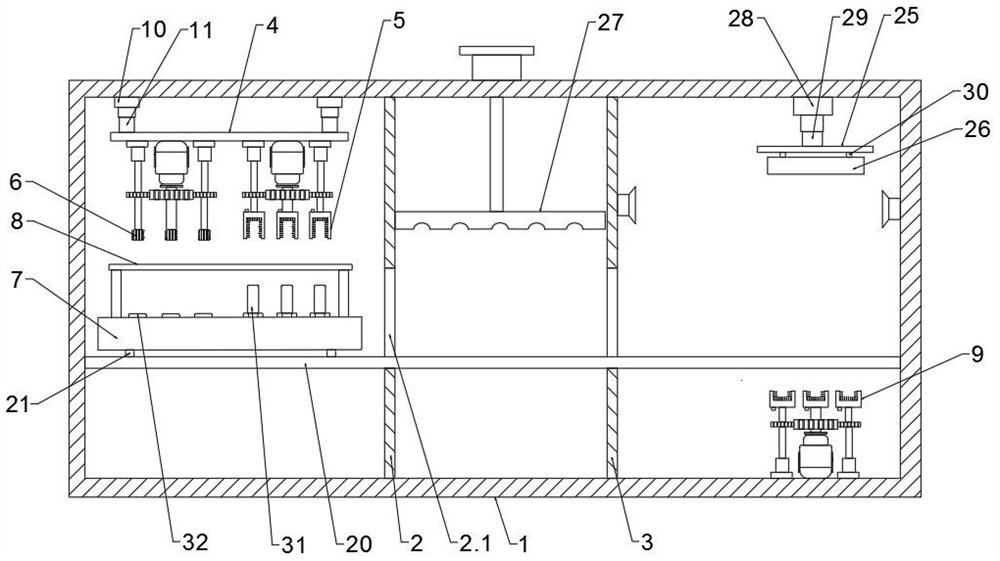

Bolt surface oiling system

ActiveCN113510033AOiled to achieveImprove corrosion resistancePretreated surfacesCoatingsStructural engineeringMechanical engineering

The invention discloses a bolt surface oiling system. The system comprises a box body, a left box door, a right box door and a controller; a first partition plate and a second partition plate are sequentially and fixedly arranged in the box body from left to right; the first partition plate and the second partition plate sequentially divide the interior of the box body into a first oiling chamber, a drying chamber and a second oiling chamber from left to right; the left box door and the right box door are fixedly installed on the front side of the first oiling chamber and the front side of the second oiling chamber respectively; a set of horizontal guide rails sequentially penetrating through the first oiling chamber, the drying chamber and the second oiling chamber are further installed in the box body; and a first oiling mechanism and a clamping and moving mechanism are arranged in the first oiling chamber. According to the system, a nut, the rod part of a bolt and the head part of the bolt can be subjected to oiling treatment, the labor intensity of workers is reduced to a great extent, and the working efficiency and the overall anti-corrosion quality of a product are improved.

Owner:JIANGSU YONGHAO HIGH STRENGTH BOLT

Antiseptic operation system of hot bending bent pipe and operation method thereof

InactiveCN101846230BImprove anti-corrosion performanceExtended service lifeCorrosion preventionPipe protection against corrosion/incrustationMedium frequencyEngineering

The invention discloses an antiseptic operation system of a hot bending bent pipe and an operation method thereof. The antiseptic operation system of the hot bending bent pipe comprises a rotary cantilever which comprises a rotary beam and an arc-shaped cantilever, wherein the rotary beam rotates along a revolving axle, and the arc-shaped cantilever is arranged on the rotary beam; one end of the rotary beam is installed on the revolving axle, and the other end of the rotary beam is supported on an arc-shaped rail; the hot bending bent pipe is fixedly arranged on the arc-shaped cantilever; a medium-frequency heating device, a powder spraying device, a winding device and a cooling device are arranged along the movement locus of the arc-shaped cantilever; and the hot bending bent pipe is successively matched with the medium-frequency heating device, the powder spraying device, the winding device and the cooling device. The invention can simplify the antiseptic drive lines of three layers of PE of the hot bending bent pipe, can quickly improve the operation time of the antiseptic production of the three layers of the PE of the hot bending bent pipe, improves the efficiency of mechanical antiseptic production of the three layers of the PE of the hot bending bent pipe and realizes the mechanical high-efficiency antiseptic production of the three layers of the PE of the hot bending bent pipe.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

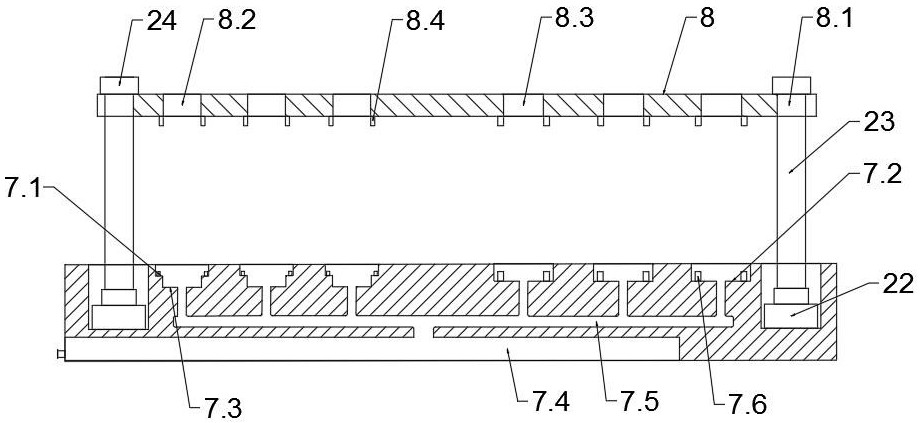

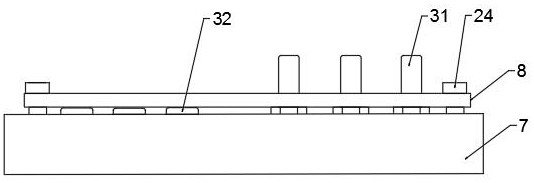

A kind of anti-mildew and anti-corrosion treatment device for finished bamboo strips

ActiveCN110053122BImprove the quality of anticorrosionImprove efficiencyWood treatment detailsReed/straw treatmentElectric machineryEnergy consumption

Owner:资溪县大觉溪旅游开发有限公司

Polyethylene coated steel pipe, online production and equipment thereof

InactiveCN101038048BAvoid multiple transfersShorten construction timeRigid pipesTransformerLow voltage

The invention relates to a polyethylene coated steel pipe and on-line method and apparatus for preparing same. Steel pipe is employed as base material for polyethylene coated steel pipe, and the outer surface of the steel pipe is coated with jointless annular polyethylene gummed tape. Production facilities of the pipe includes steel pipe shot-blast rust cleaning machine comprised of a rotating cylinder bracket, a rotating cylinder, a feeding wheel, a support wheel, a feeding worm wheel speed reducer, a feeding direct current dynamo, a high-frequency induction heating coil, a driving worm wheel speed reducer, a driving AC motor and a electrical control cabinet, and a steel pipe outer anticorrosion coating machine comprised of a induction heating transformer, a walking frame, a swing frame,a rotating frame, a winding device, a supporting frame, a low-voltage electrical casing and a controller. In pipeline installation locale, the steel pipes are welded into pipelines after derusted by the steel pipe shot-blast rust cleaning machine, the steel pipe outer anticorrosion coating machine is nested on the pipeline and carries out helical motion, after high-frequency induction heating on the steel pipe, the spray head injects the epoxy powder on outer surface of the steel pipe, after high-frequency induction heating of the belt-winding cylinder, adhesive tape and polyethylene gummed tape pulled out from the winding device become hot tapes, by helical motion of the steel pipe outer anticorrosion coating machine along pipeline centre-line, the adhesive tape and polyethylene gummed tape are coated on the outer surface of the steel pipes.

Owner:陈炯

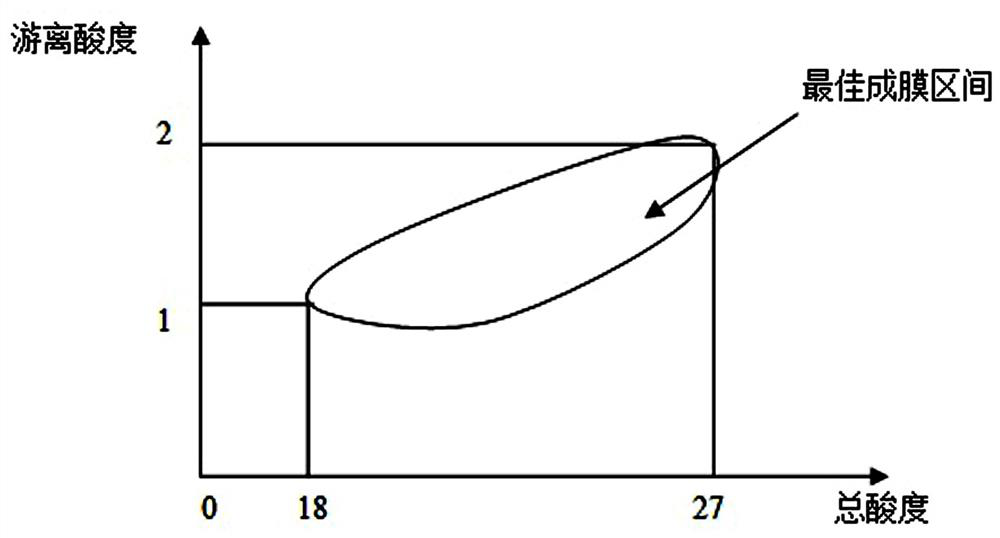

A kind of phosphorus spraying film-forming liquid and phosphorus spraying process

ActiveCN108998787BQuality improvementSolve the problem of product surface anti-corrosion quality declineMetallic material coating processesPhosphorPhysical chemistry

The invention discloses a novel phosphorus-spraying film-forming liquid and its process for spraying phosphorus. The phosphorus-spraying film-forming liquid is composed of raw materials with the following mass ratios: Zn 2+ : 3000PPm~6000PPm, Mn 2+ : 300PPm~600PPm, F ‑ : 600PPm~1200PPm, MoO 4 2‑ : 250PPm~500PPm, NO 3 ‑ : 8000PPm~15000PPm, PO 4 3‑ : 11000PPm~19000PPm, composite accelerator A 300PPm~900PPm, additive B 600PPm~1200PPm, the balance is water, of which PPm is one millionth, and adjust the free acid, total acidity and acid ratio of the bath to control Temperature, pump pressure, nozzle spray density and spray time. The invention solves the difficulty of spraying and phosphating the high-strength steel projectiles and parts of missile products, improves the anti-corrosion performance of missile products, thereby ensuring the effectiveness of missile products and prolonging their service life to ensure national defense security. Realize automatic production, improve production efficiency, and meet the requirements of lean production and clean production advocated by the state.

Owner:HENAN NORTHERN HONGYANG ELECTROMECHANICAL CO LTD

Sealable container anticorrosion technology

InactiveCN103157589AImprove preservation methodsComprehensive anti-corrosionSpecial surfacesCoatingsEngineeringElectrical and Electronics engineering

The invention discloses a sealable container anticorrosion technology. In order to solve problems, the technical scheme includes that an anti-corrosion method for a sealable container is further improved, corrosion prevention can be comprehensively performed for the sealable container, the penetrability of liquid is utilized for performing in-place protection for clearances existing in the interior of the sealable container, rotation is utilized for enabling the surface of the interior of the sealable container to be high in quality and even in paint film, the thickness of a paint film is easy to control, and anticorrosion quality can be effectively improved.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

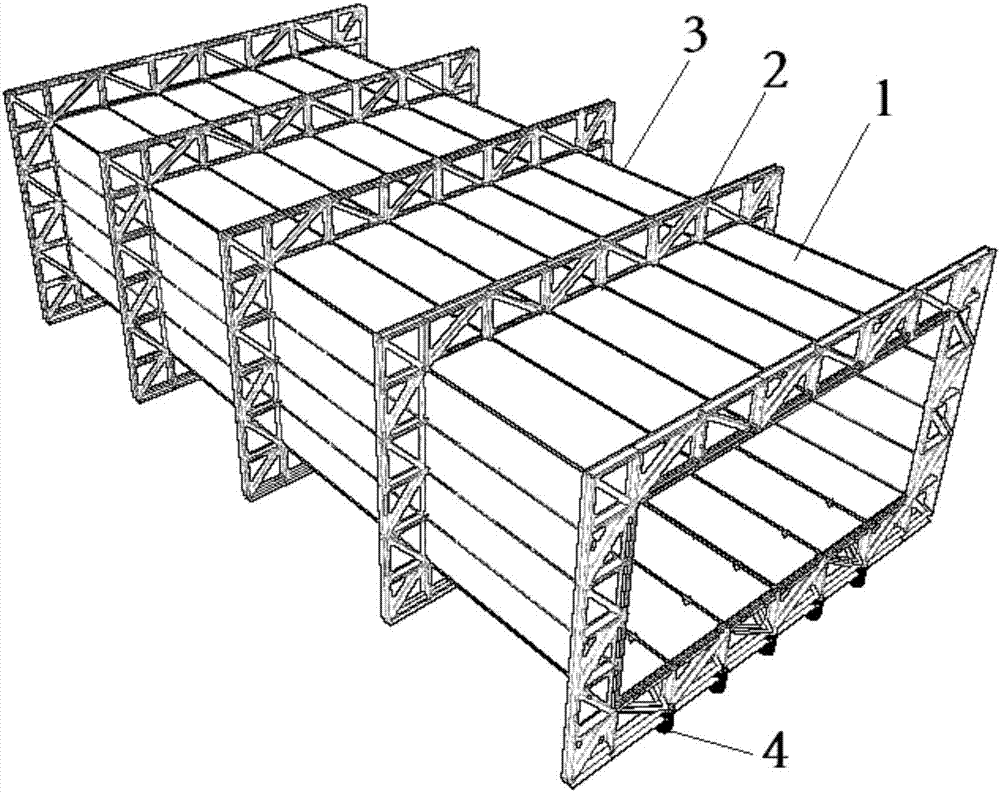

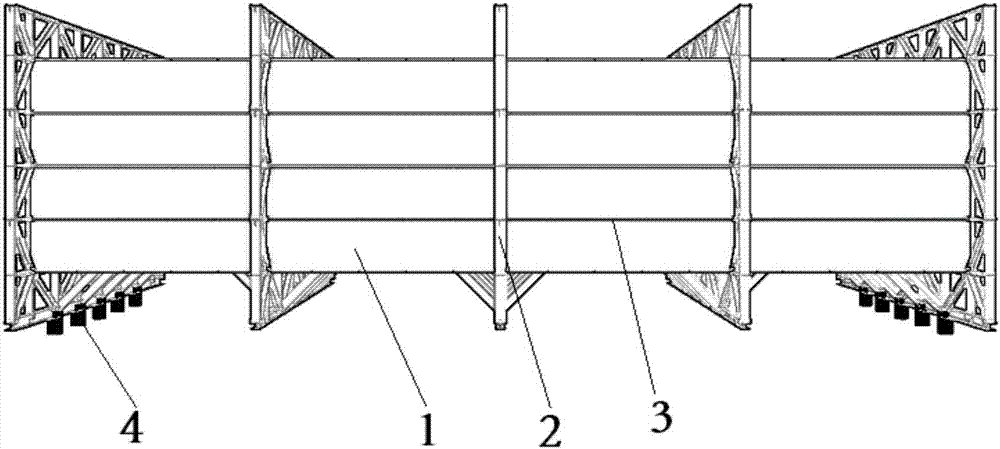

Rectangular flue gas duct system without internal supporting rods

The invention discloses a rectangular flue gas duct system without internal supporting rods. The system comprises a flue gas duct body and a plurality of trusses in annular structures, the trusses in annular structures axially and sequentially sleeves the outer wall of the flue gas duct body, and a plurality of supporting hangers are arranged at bottoms of the trusses in annular structures. A plurality of reinforcing ribs are arranged between every two adjacent trusses in annular structures and uniformly and axially distributed on the outer wall of the flue gas duct body, and each reinforcing rib is connected with all of the trusses in annular structures. The system is low in resistance, uniform in flow field of the flue gas duct, low in investment cost and small in floor space, and the problem of proneness to abrasion, dust accumulation and shedding of the internal supporting rods is avoided.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

A method for fusion bonding of epoxy coating and three-layer polyethylene coating

ActiveCN104449431BImprove adhesionImprove the quality of anticorrosionAdhesive processes with adhesive heatingEpoxy resin coatingsMolten stateEpoxy

The invention discloses a fusion bonding method of an epoxy coating with a three-layer polyethylene coating, and belongs to the field of joint wrapping anticorrosion. The method comprises the following steps: first, removing the dirt on the surface of the three-layer polyethylene coating by water; then coating epoxy coating on the surface of the clean three-layer polyethylene coating, and heating at the temperature of 120- 260 DEG C for 20 s-20 min. The epoxy coating is a solvent-free two-component epoxy coating comprising a fatty chain structure with molecular chain length of about 36 carbon atoms. According to the invention, the three-layer polyethylene coating and epoxy coating are heated, so that the long fatty chain of the three-layer polyethylene coating and the long fatty chain of the epoxy coating twisted in the molten state and further form fusion bonding between the three-layer polyethylene anticorrosion coating and the oxygen coating; and the initial adhesion and durable adhesion of the coatings for the pipeline joint wrapping anticorrosion are improved, and the quality of joint wrapping anticorrosion is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-efficiency energy-saving granular filter and backflushing method

ActiveCN103623626BSimple structureEliminate the defect of stirring seal leakageLoose filtering material filtersGravity filtersWater sourceControl system

The invention relates to a high-efficiency energy-saving granular filter which comprises a filter body, a backwashing assembly, a backwashing water tank, an air compressor and a control system. A tank body and upper and lower oval sealing heads are arranged on the filter body; upper and lower sieve tubes / plates are arranged in the tank body; an oil / gas discharge port and a sewage inlet assembly are arranged at the top of the upper oval sealing head; a water outlet, a discharge port and supporting legs are arranged at the end of the lower oval sealing head; a backwashing water inlet and a backwashing gas inlet are arranged on the backwashing assembly; after being connected with a water inlet pipe, a backwashing water inlet pipe is connected with a backwashing spray nozzle; the backwashing water tank is connected with a filter by a return pipe; after being connected with a gas control valve, a gas check valve and the like, the air compressor is connected with the backwashing gas inlet by pipelines; by the control system, each valve, a backwashing water source and a backwashing gas source are automatically controlled to carry out operation according to the program. The filter disclosed by the invention has a simple structure, adopts a three-phase flow backwashing technology, is convenient to operate, is low in backwashing water consumption, is effective and energy-saving to backwash and has long equipment service life.

Owner:武汉市汉江石油物资技术开发有限责任公司

Anti-corrosion treatment device for fan blade processing

ActiveCN113275304BReduce uncertaintyThe feeding process is stable and effectiveCompression machinesDrying gas arrangementsWater flowStructural engineering

The invention discloses an anti-corrosion treatment device for fan blade processing, comprising a water tank, a treatment box is fixed at the upper end of the water tank, a building platform is fixed at the lower part inside the treatment box, and a driving mechanism is provided at the upper end of the building platform , the peripheral outer wall of the treatment box is provided with a material inlet and a material outlet, the upper part of the inner side of the treatment box is fixed with a paint box, and the upper wall of the paint box is provided with a backflow groove. The inner wall of the tank is penetrated with a collecting tank communicating with the return tank. The advantages are: automatic loading and unloading, which reduces the uncertainty caused by manual loading, ensures the stability and effectiveness of the feeding process, and the circular processing can effectively improve the overall efficiency. The blades are cleaned by washing with water, and will not carry dust and stains Entering the next step, so as to improve the quality of the overall spraying anticorrosion treatment, the circulating flow of hot air can dry the blades sprayed with paint, which is convenient for subsequent transfer and storage.

Owner:南通清风通用机械有限公司

A cooling method and cooling equipment for the manufacture of anti-corrosion steel pipes

ActiveCN105238918BUninterrupted internal coolingEasy to upgradeFurnace typesHeat treatment furnacesControl systemEngineering

Owner:HUNAN KUANGWEI TECH CO LTD

Cooling method for anti-corrosion steel pipe manufacturing and cooling device

InactiveCN105256124AUninterrupted internal coolingEasy to upgradeFurnace typesHeat treatment furnacesControl systemMetallurgy

The invention provides a cooling method for anti-corrosion steel pipe manufacturing, and a cooling device. The cooling method for anti-corrosion steel pipe manufacturing includes the steps that after the first pipe end of a steel pipe advances in a spiral manner to enter a cooling area from a corrosion prevention operating area, a cooling spray nozzle moves to a cooling work position in the steel pipe and keeps still, the steel pipe continues to advance in the spiral manner, and the inner wall of the steel pipe is continuously cooled through cooling water; when the second pipe end of the steel pipe advances to the position of the cooling spray nozzle, the cooling spray nozzle moves out of the steel pipe and arrives at a work waiting position, and meanwhile separation between the steel pipe and a next steel pipe is accelerated; a pipe pulling device pulls the steel pipe where internal cooling has been completed to the next procedure; and the steps are repeatedly executed, the cooling spray nozzle moves to the cooling work position to cool the inner portion of the next steel pipe. The cooling device for achieving the cooling method comprises a transmission device, an internal cooling device, the pipe pulling device and a control system. By means of the cooling method and the cooling device, the anti-corrosion quality and the cooling efficiency of the steel pipes are improved, and the production cost is reduced.

Owner:HUNAN KUANGWEI TECH CO LTD

Corrosion prevention process of sealed container

InactiveCN102485342AImprove preservation methodsComprehensive anti-corrosionPretreated surfacesCoatingsLacquerRotational energy

Aiming at solving the problems in the prior art, the invention adopts the following technical schemes: a corrosion prevention method of a sealed container is further improved, thus the comprehensive corrosion prevention is carried out on the sealed container; and the internal gaps of the sealed container can be protected by utilizing the penetrability of the liquid, and the internal surface quality is high, the lacquer film is uniform and the thickness of the lacquer film is easy to control by utilizing rotational energy, thus the corrosion prevention quality is effectively improved.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

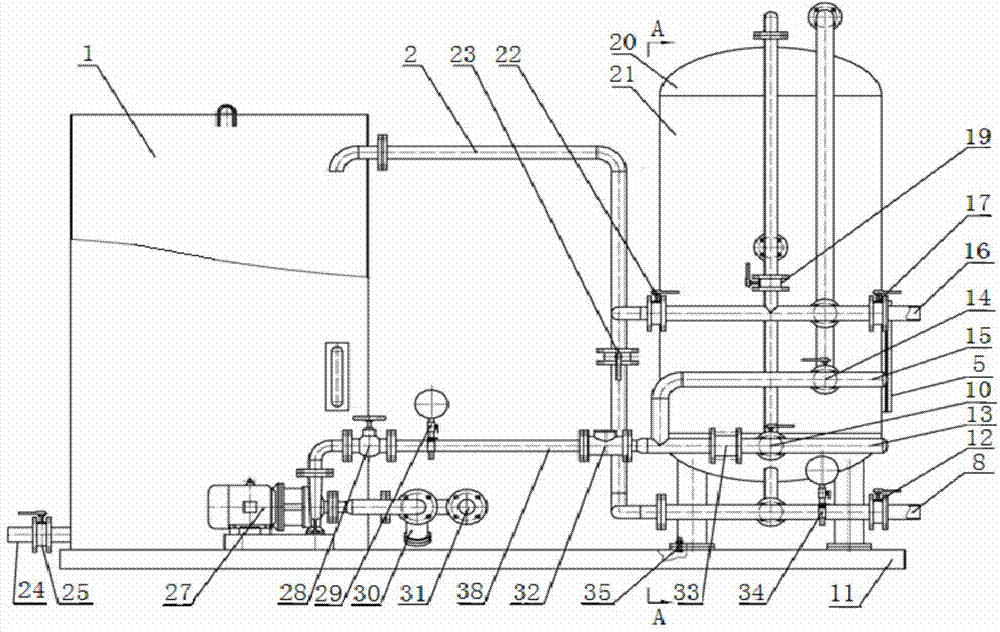

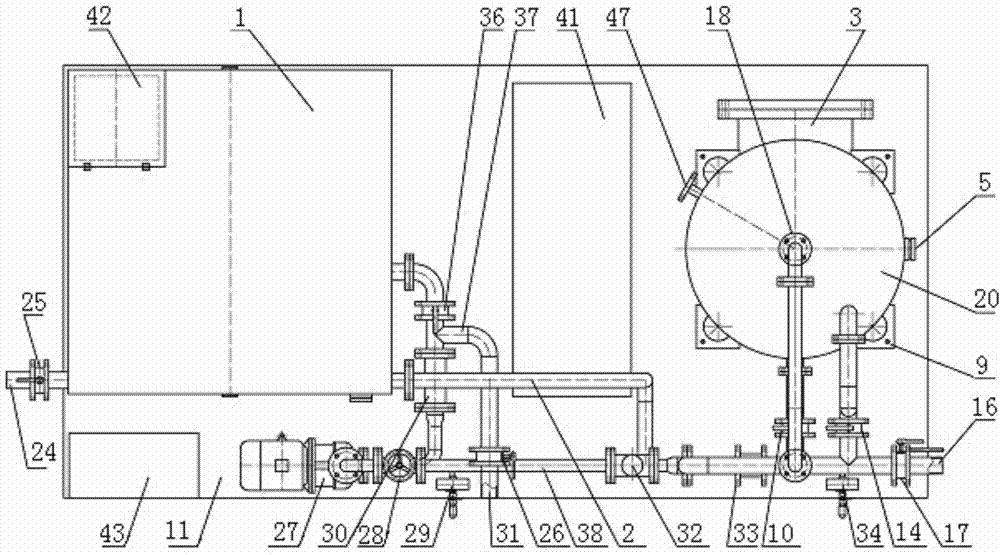

Anticorrosion equipment of sealable container

InactiveCN102485339AImprove preservation methodsComprehensive anti-corrosionLiquid surface applicatorsCoatingsMicrocomputerProgrammable logic controller

The invention relates to anticorrosion equipment of a sealable container. Specifically, rotational moulding technological parameters, such as rotational moulding time, rotational moulding temperature, rotation speeds of main and counter shafts, alternate time of main and counter shafts, and the like, are set on the operation panel of an electric control cabinet. A workpiece for rotational moulding is loaded on driving vehicle mould frameworks, two supporting bases of which are equipped with bearings inside. The inside of a supporting base on one end is provided with a hollow main shaft, the inside of which is provided with a counter shaft. The power of the main shaft is provided by a front chain wheel, while the power of the counter shaft is provided by a back chain wheel. And a pair of bevel gears changes the rotation angle so as to drive a die filling disc to rotate, thus realizing 360-degree rotation of the mould frameworks along two vertical shafts. When a mould needs to enter a heating chamber from a cooling position or to move out of the heating chamber to the cooling position, a PLC (programmable logic controller) microcomputer can initiate a walking part electric motor to drive a small vehicle to move and stop automatically when moving to a right place.

Owner:QINGDAO SANLI ZHONGDEMEI WATER EQUIP

High efficient improved wood preservation method

InactiveCN108927866ASimple equipment structureEasy to operateWood treatment detailsCoating impregnationEngineeringPreservation methods

The invention discloses a high efficient improved wood preservation facility, which comprises a body, a first cavity arranged in the body, and a first transmission cavity arranged in the body. A second cavity with a downward opening is arranged in the top wall of the first cavity. A third cavity with an upward opening is arranged in the bottom wall of the first cavity. A fourth cavity that is communicated with the first cavity is arranged in the left wall of the third cavity. A fifth cavity that is communicated with the first cavity is arranged in the right wall of the third cavity. A second transmission cavity is arranged in the front wall of the first cavity. The provided facility has the advantages of simple structure and convenient operation. A wood plate is delivered and oil-painted by a same power source; during the oil painting process, the oil is gradually supplied, the anticorrosion oil can be painted more uniformly; at the same time, during the painting process, a drying device is used to accelerate the drying of the wood anticorrosion oil; steps cooperate with each other and do not influence other steps, the oil painting efficiency and anticorrosion quality are both improved, and the practicality of the facility is enhanced.

Owner:象山知航机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com