Bolt surface oiling system

A technology of oiling and bolting, which is applied to the device for coating liquid on the surface, pretreatment of the surface, coating, etc., which can solve the problems of labor and time consumption, low work efficiency, and the impact on workers' health, so as to improve work efficiency , reduce labor intensity, improve the effect of overall anti-corrosion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

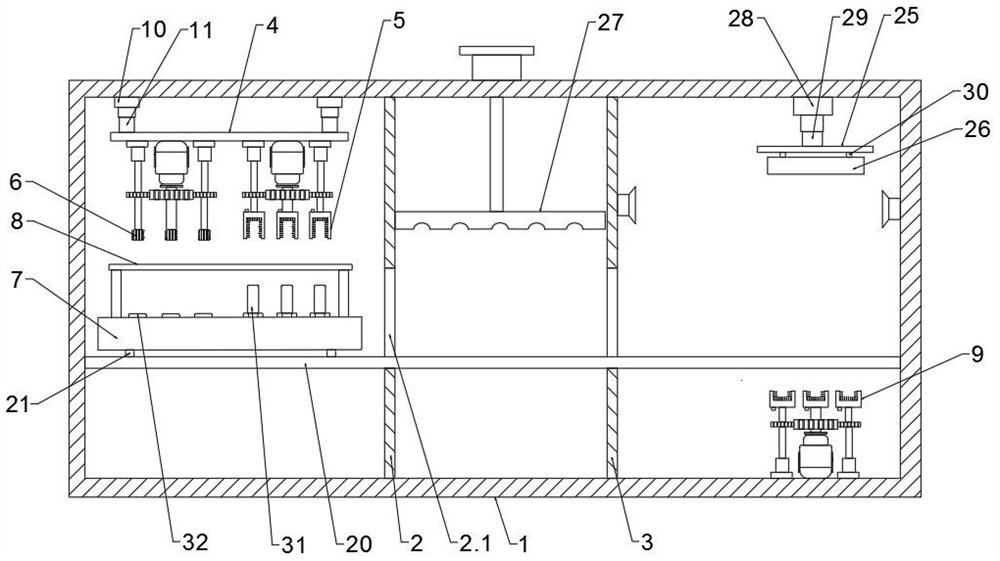

[0031] see figure 1 , a bolt surface oiling system of the present invention includes a box body 1, a left box door, a right box door and a controller. The inside of the box body 1 is sequentially fixed with a first partition plate 2 and a second partition plate from left to right. Plate 3, the first partition 2 and the second partition 3 divide the inside of the box 1 into a first oiling room, a drying room and a second oiling room from left to right, and the left box door and the right box door are respectively It is fixedly installed on the front side of the first oiling room and the second oiling room. By opening the left box door and the right box door, the operation of loading and unloading can be carried out respectively, and the operation is convenient.

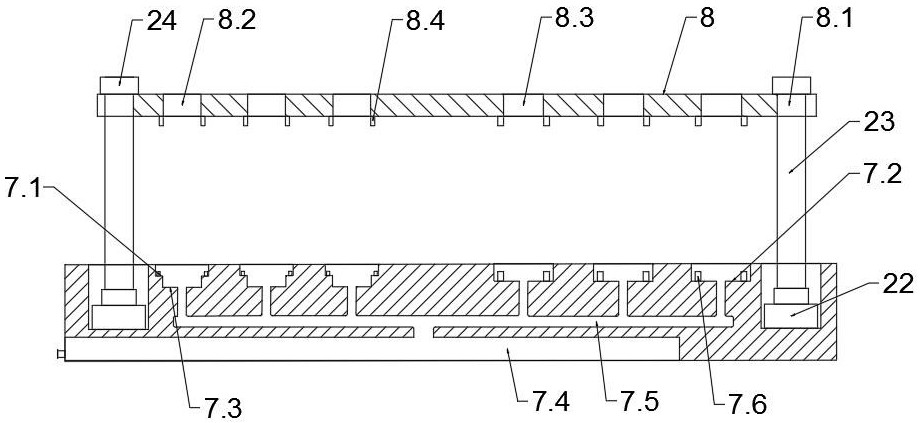

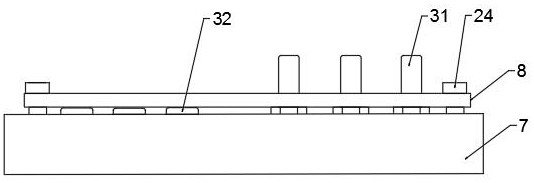

[0032]The interior of the first oiling chamber is provided with a first oiling mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com