Steel ball conveying device

A conveying device and steel ball technology, which is applied in the field of steel ball manufacturing, can solve the problems of oil stains on the steel ball packaging box, easy rusting of steel balls, uneven oil spraying on the surface of steel balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

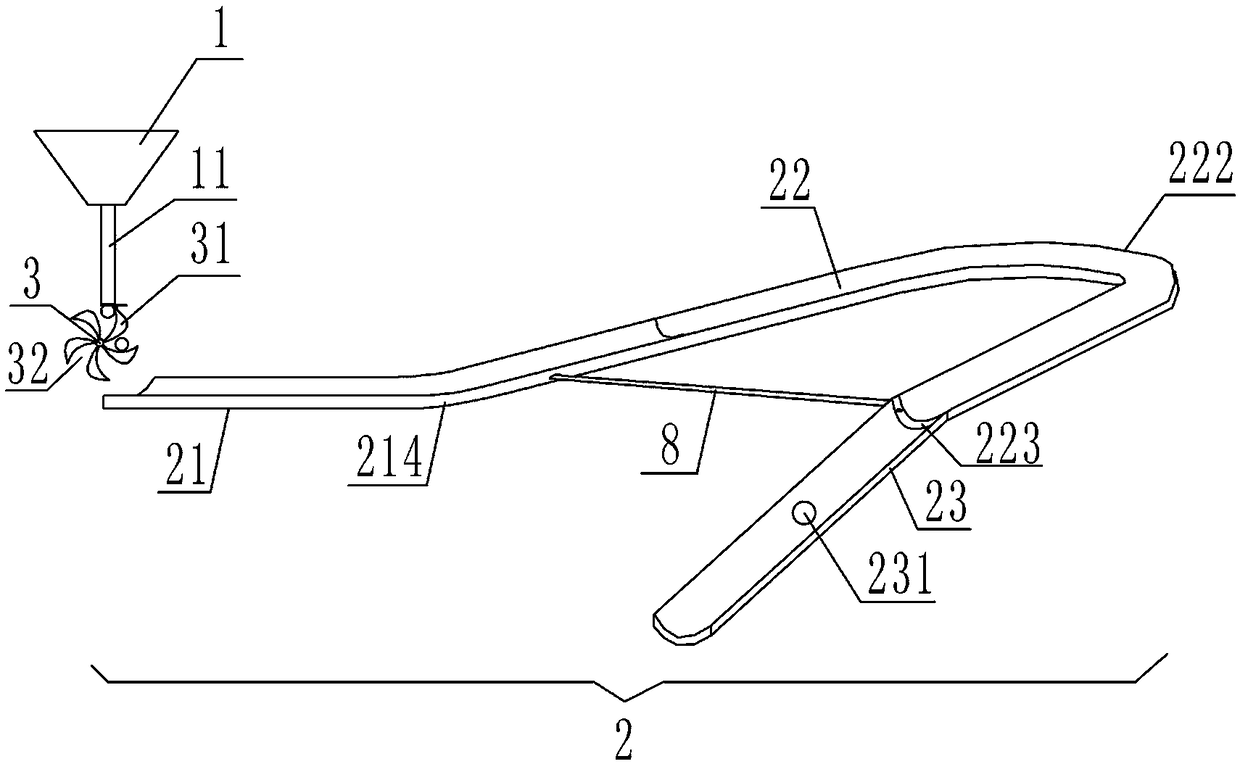

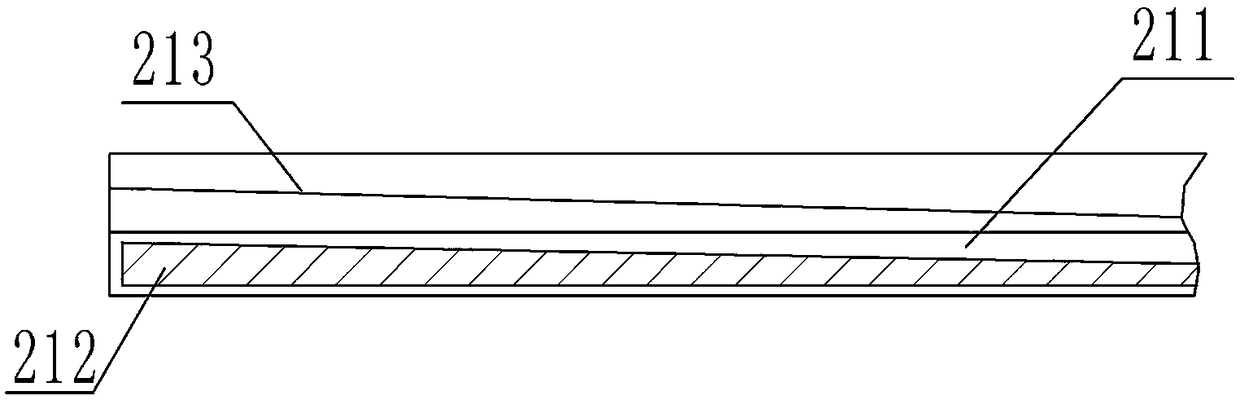

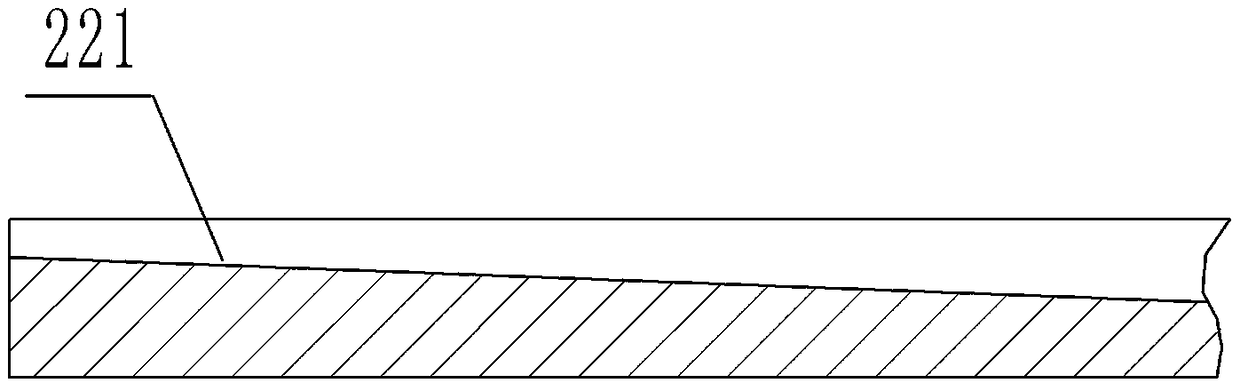

[0027] The reference signs in the accompanying drawings of the description include: charging funnel 1, conveying pipe 11, conveying track 2, oiling section 21, oil chamber 211, sponge layer 212, cotton cloth layer 213, oil chamber track bending part 214, draining oil Section 22, rubber layer 221, oil drain track bending part 222, oil collection chamber 223, screening section 23, screening hole 231, fan-shaped transmission part 3, transmission blade 31, steel ball chamber 32, guide rail 4, retainer 5, spring 6, dial 7, pipeline 8.

[0028] see figure 1 , figure 2 with image 3As shown, the steel ball conveying device includes a charging funnel 1, a conveying track 2 for conveying steel balls, and a fan-shaped conveying part 3 driven by a motor; the lower end of the charging funnel 1 is connected with a conveying pipe 11 that only allows one steel ball to pass through; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com