Patents

Literature

119results about How to "Reduce polishing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

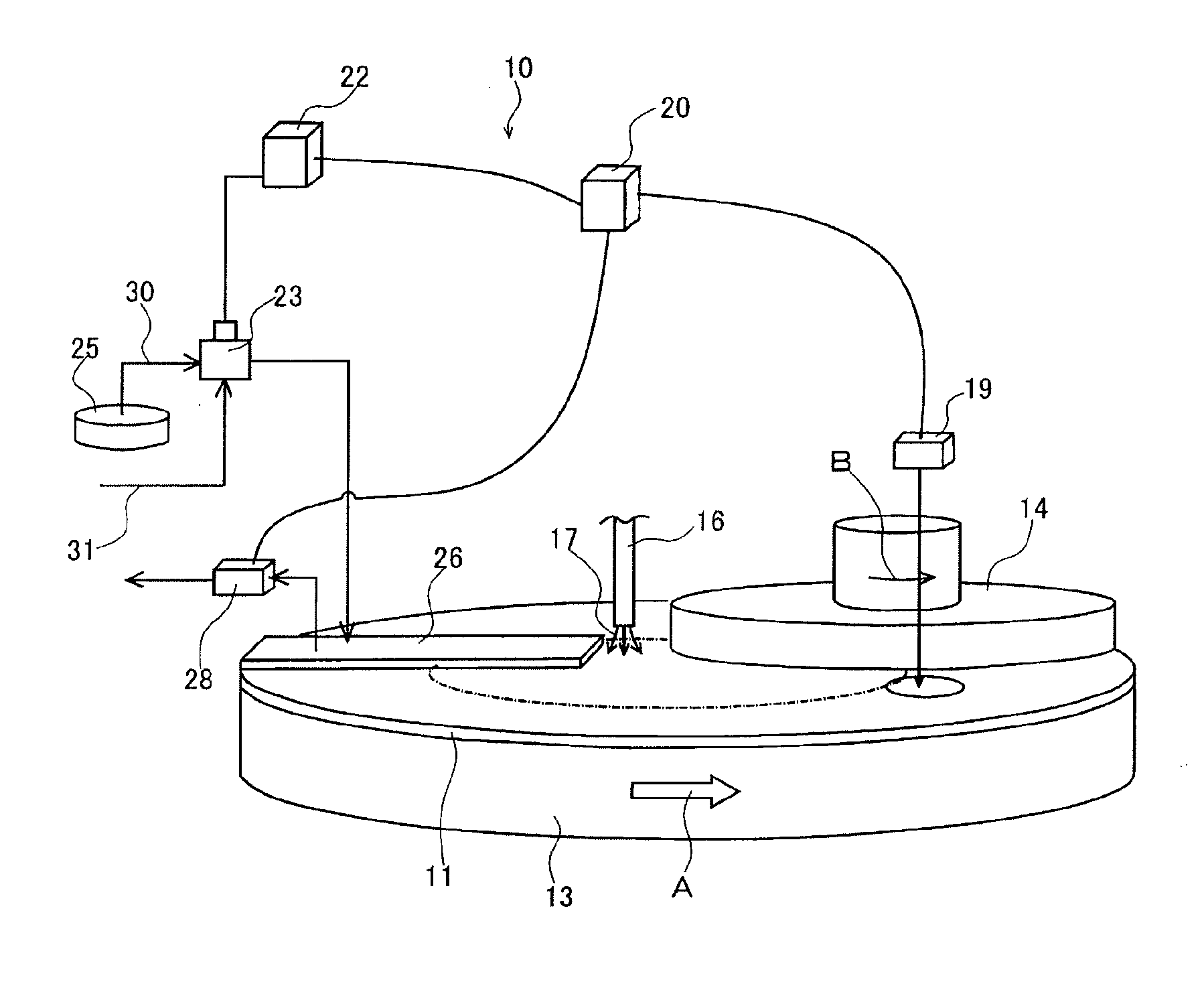

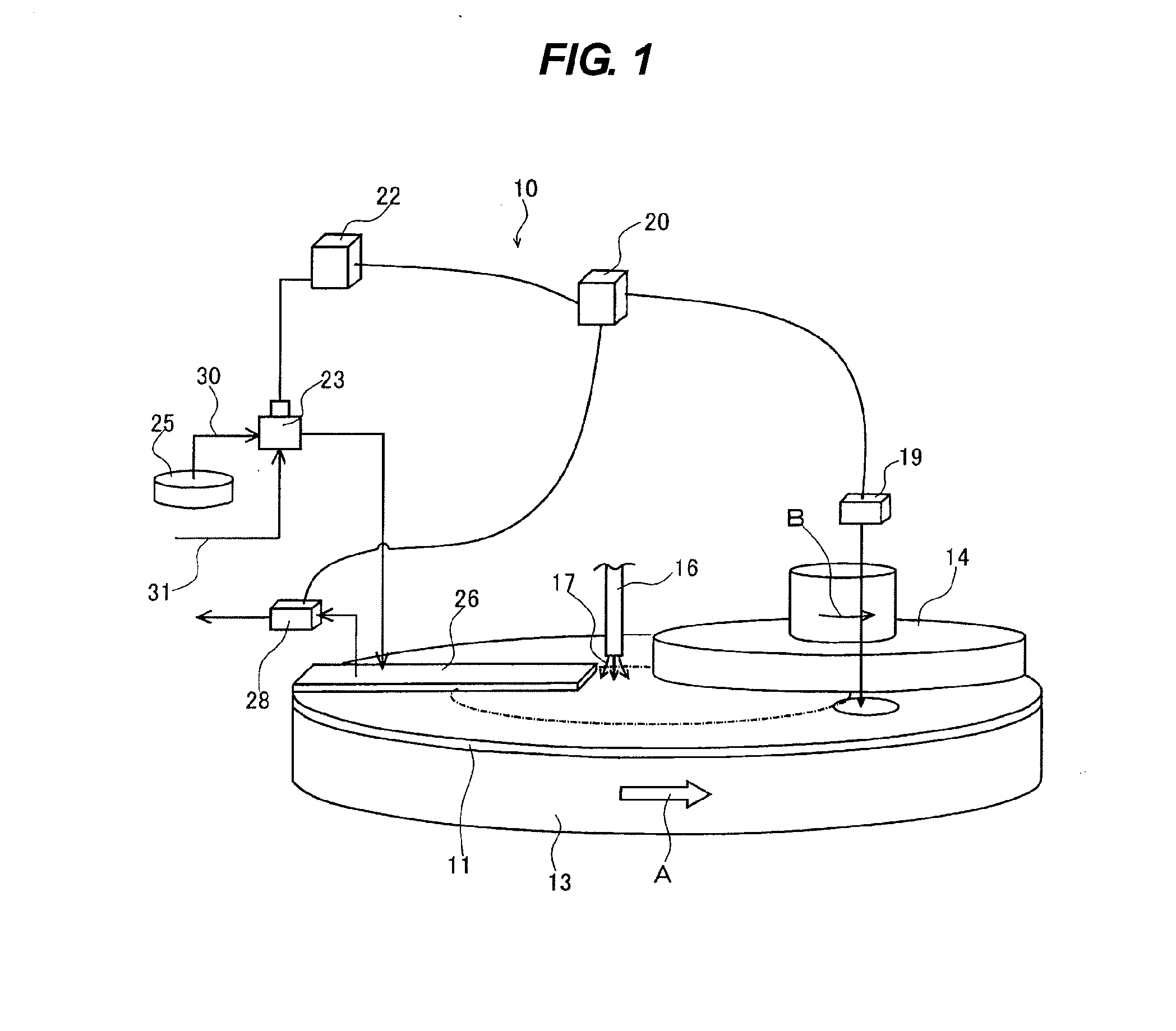

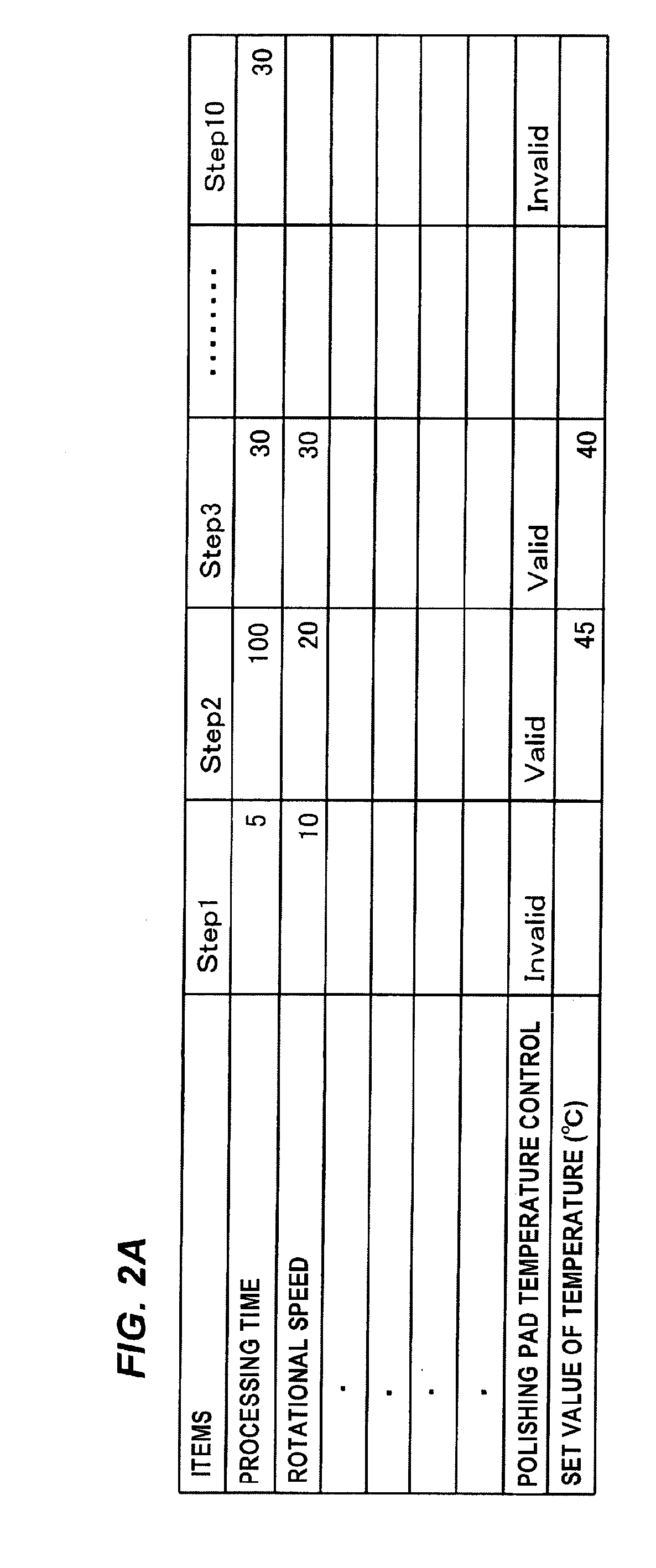

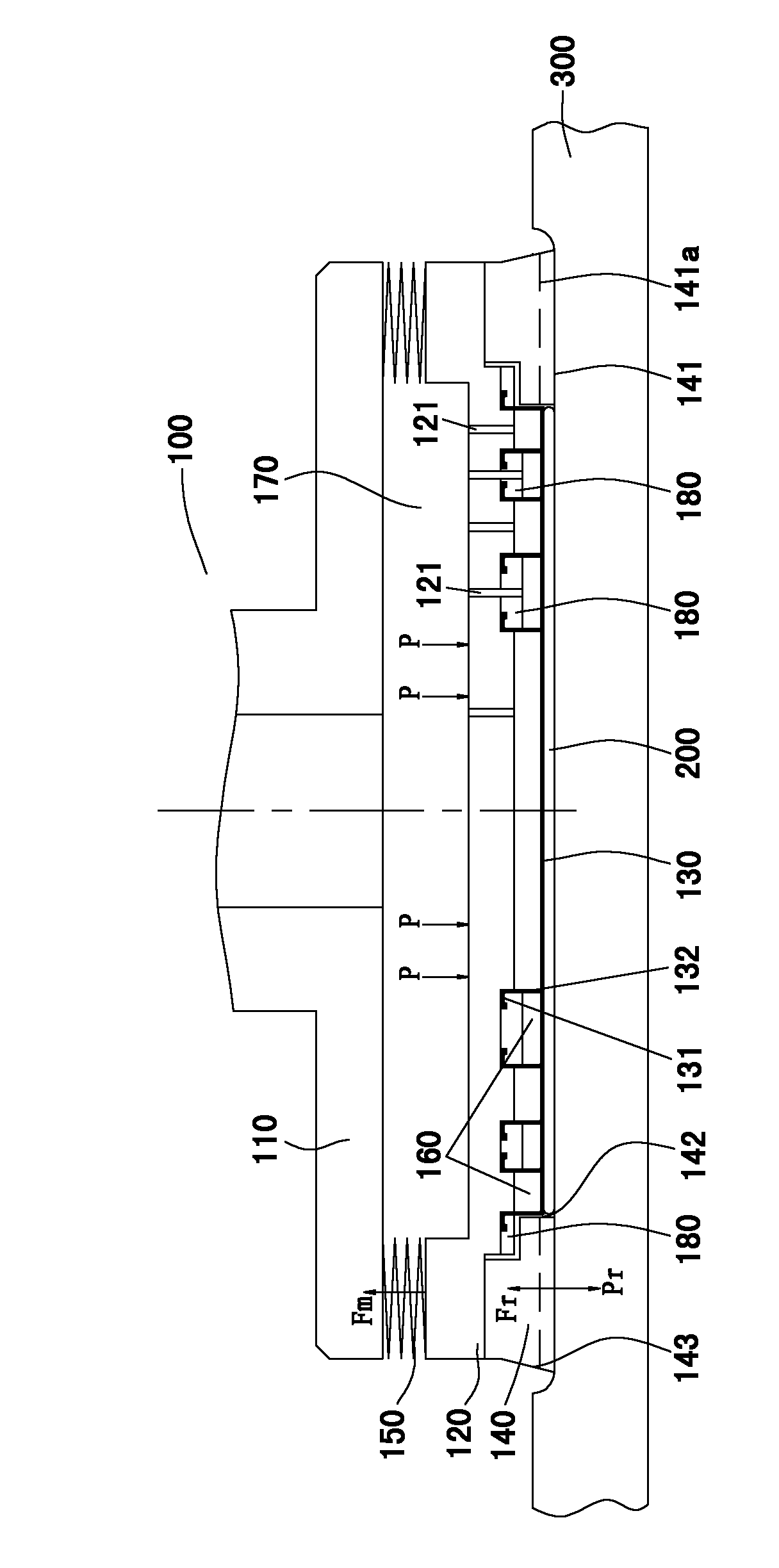

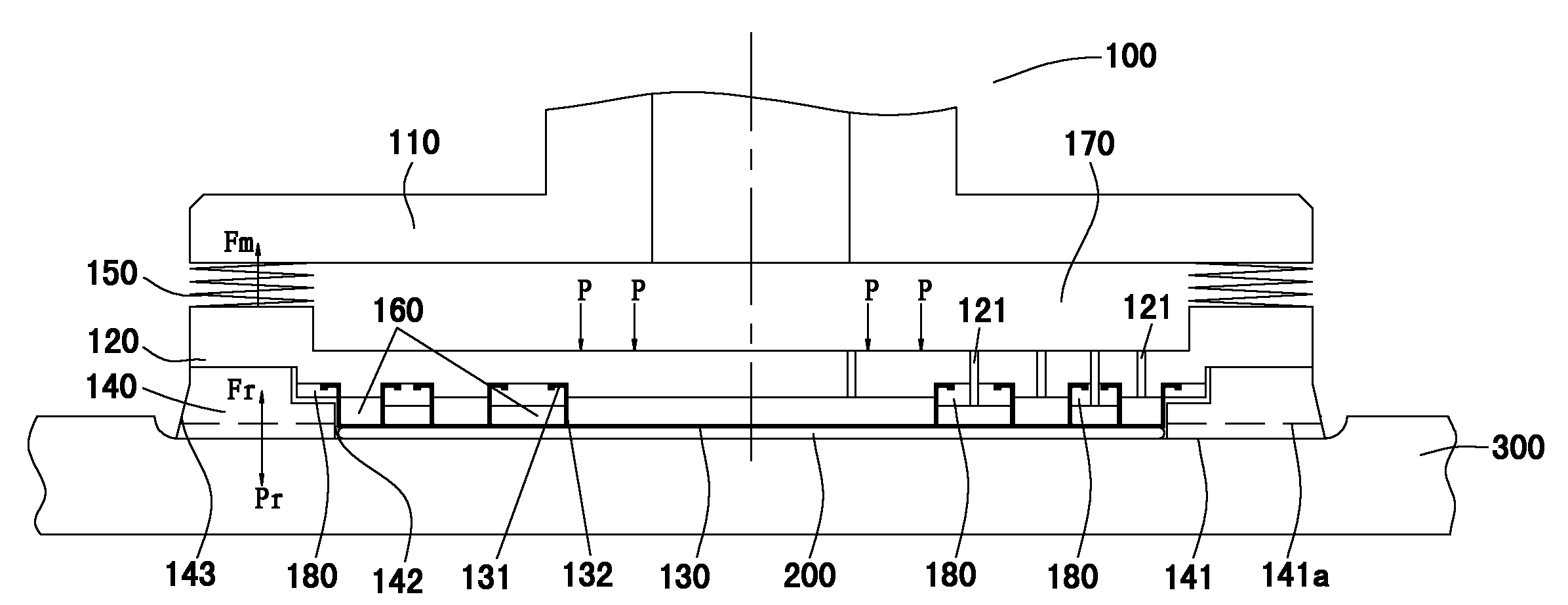

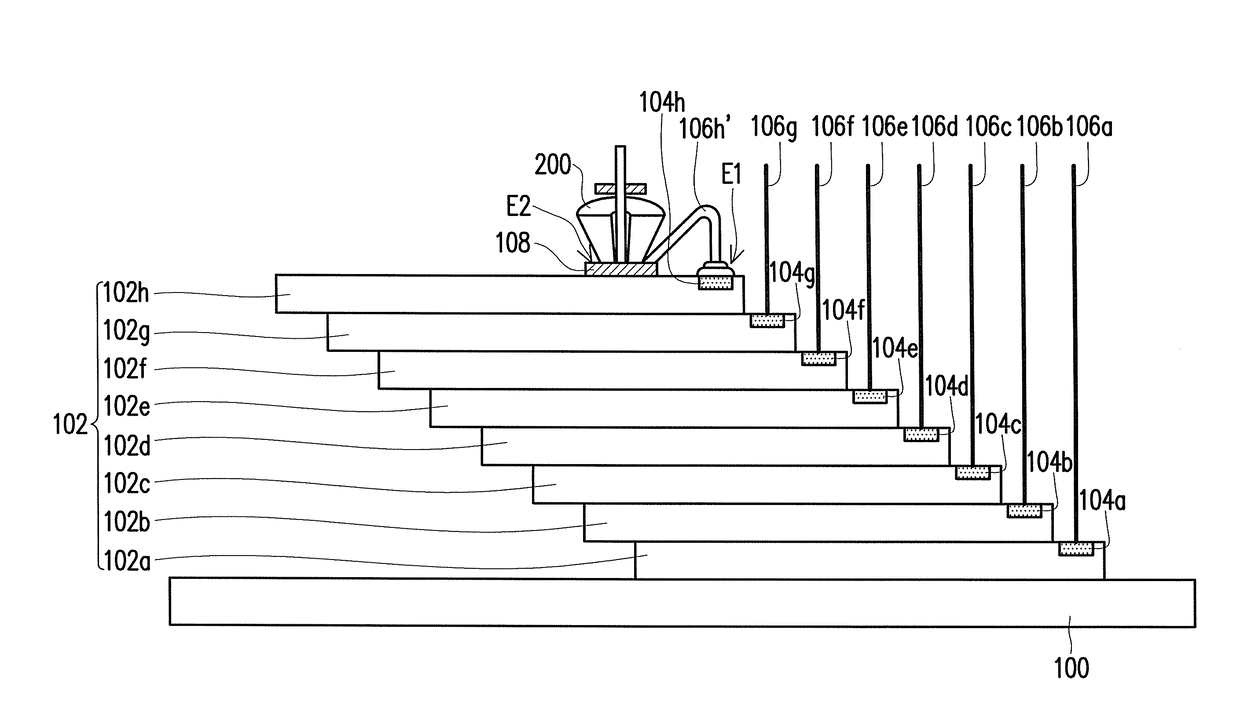

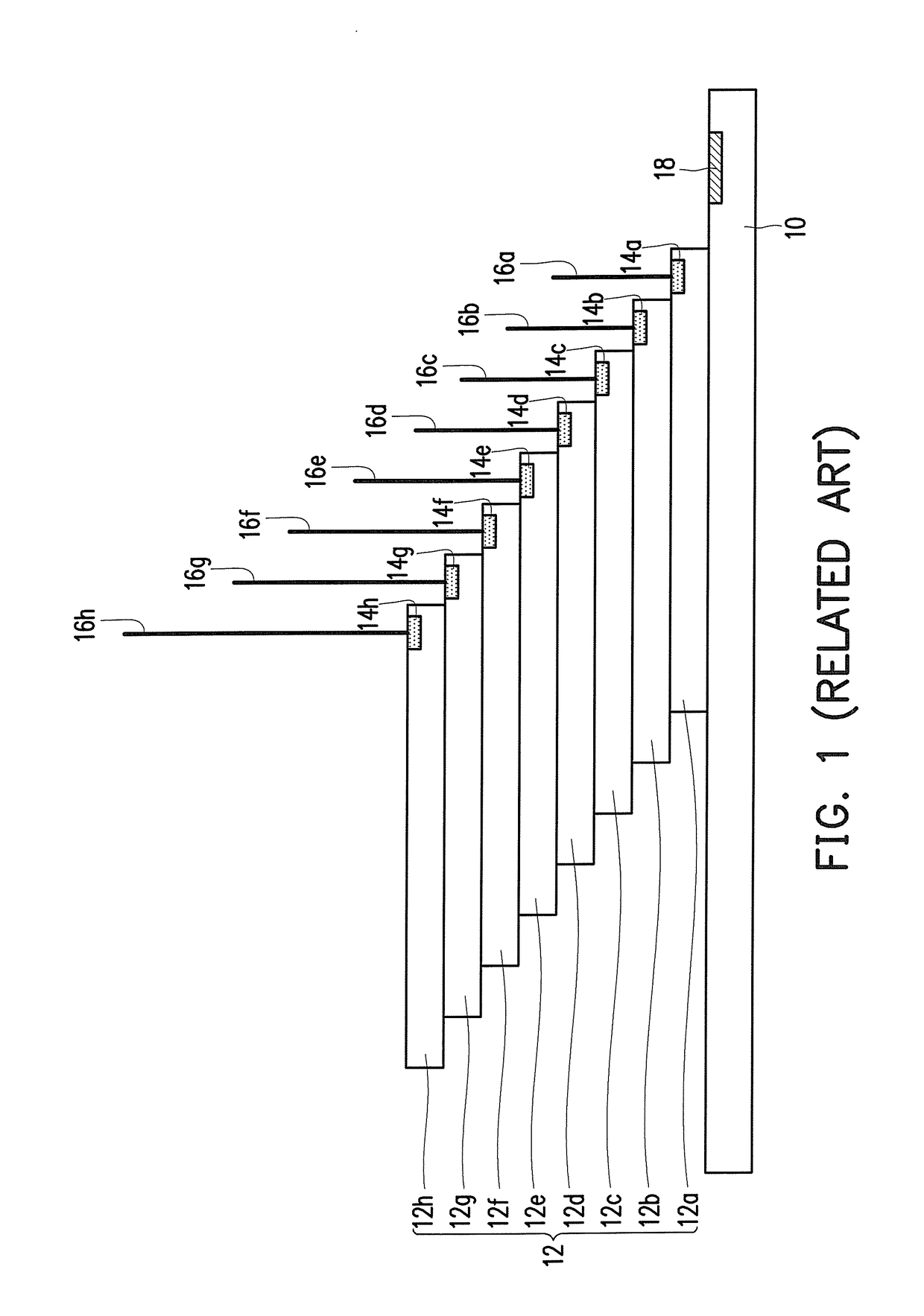

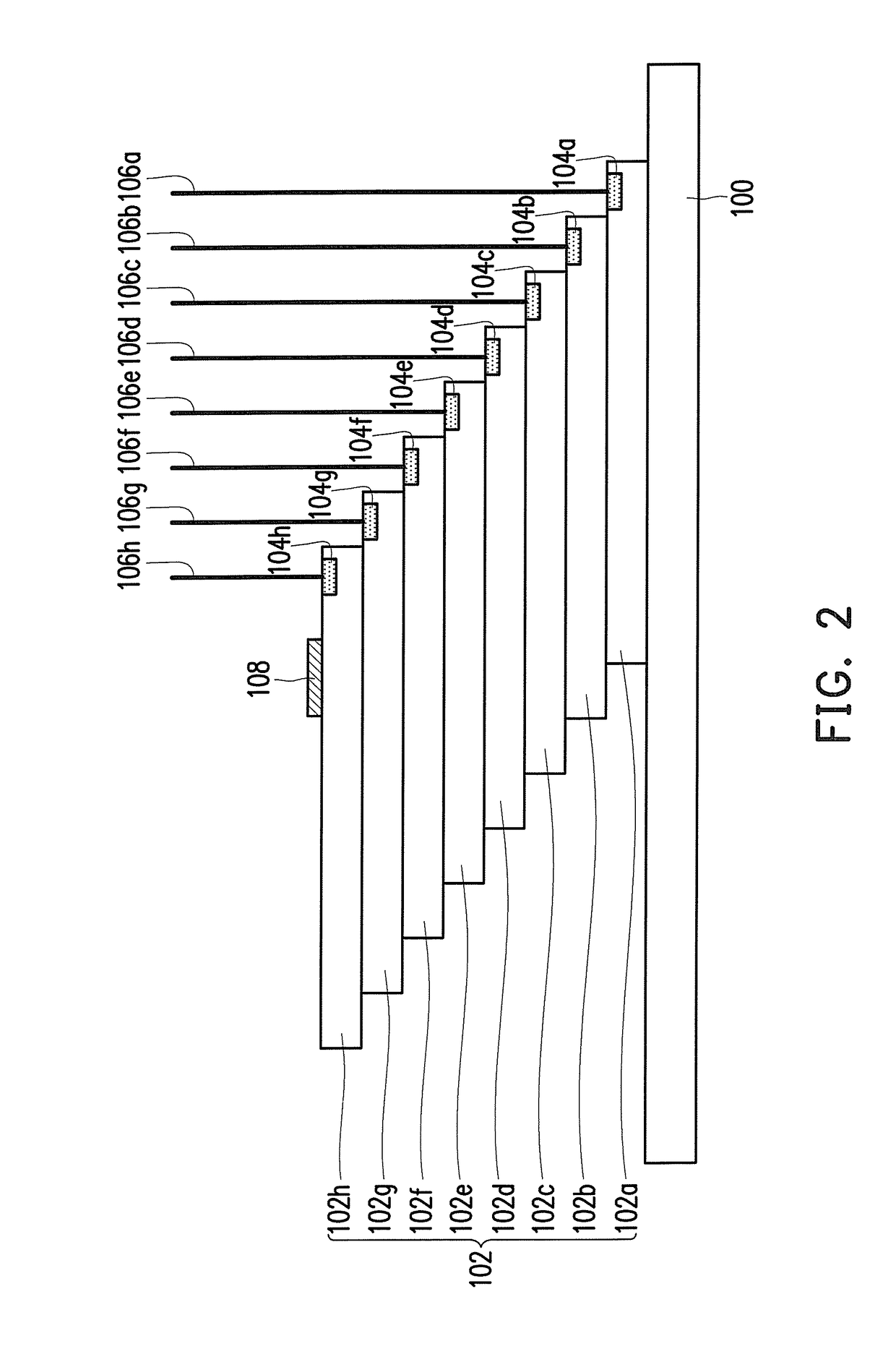

Substrate polishing apparatus, substrate polishing method, and apparatus for regulating temperature of polishing surface of polishing pad used in polishing apparatus

ActiveUS20110159782A1Polishing rate can be optimizedShorten polishing timeSemiconductor/solid-state device manufacturingLapping machinesTemperature controlEngineering

Owner:EBARA CORP

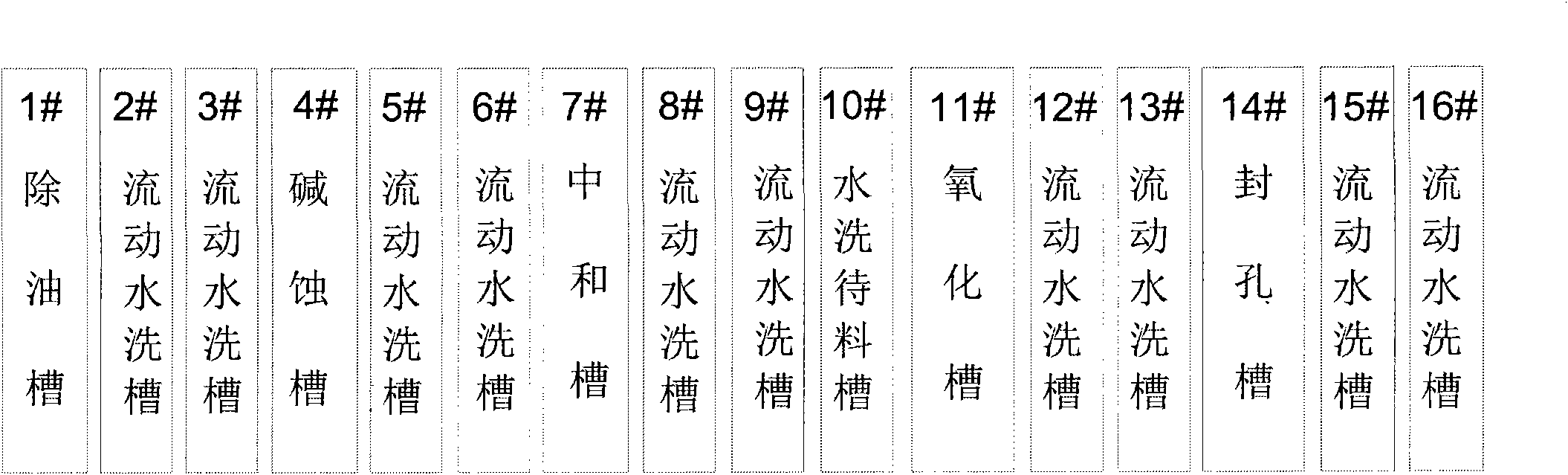

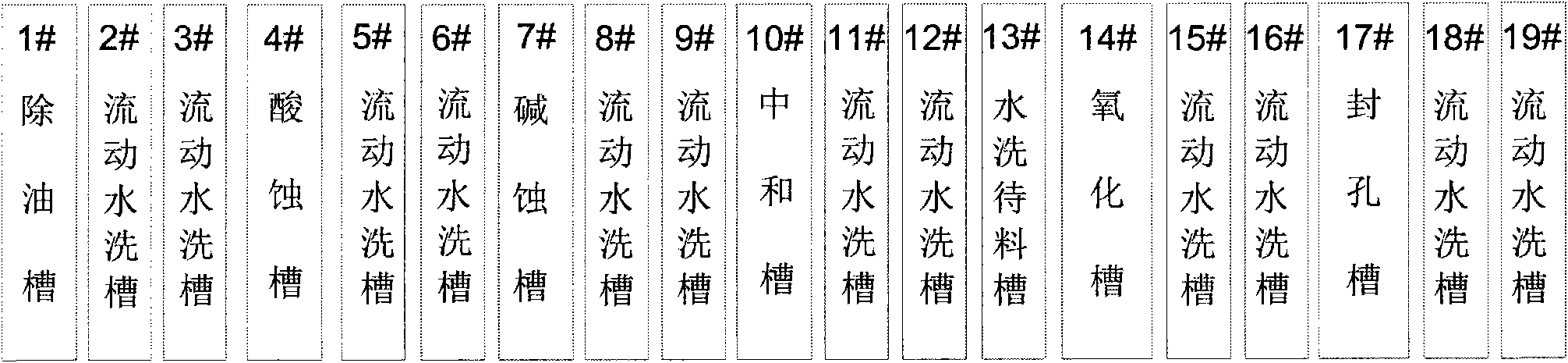

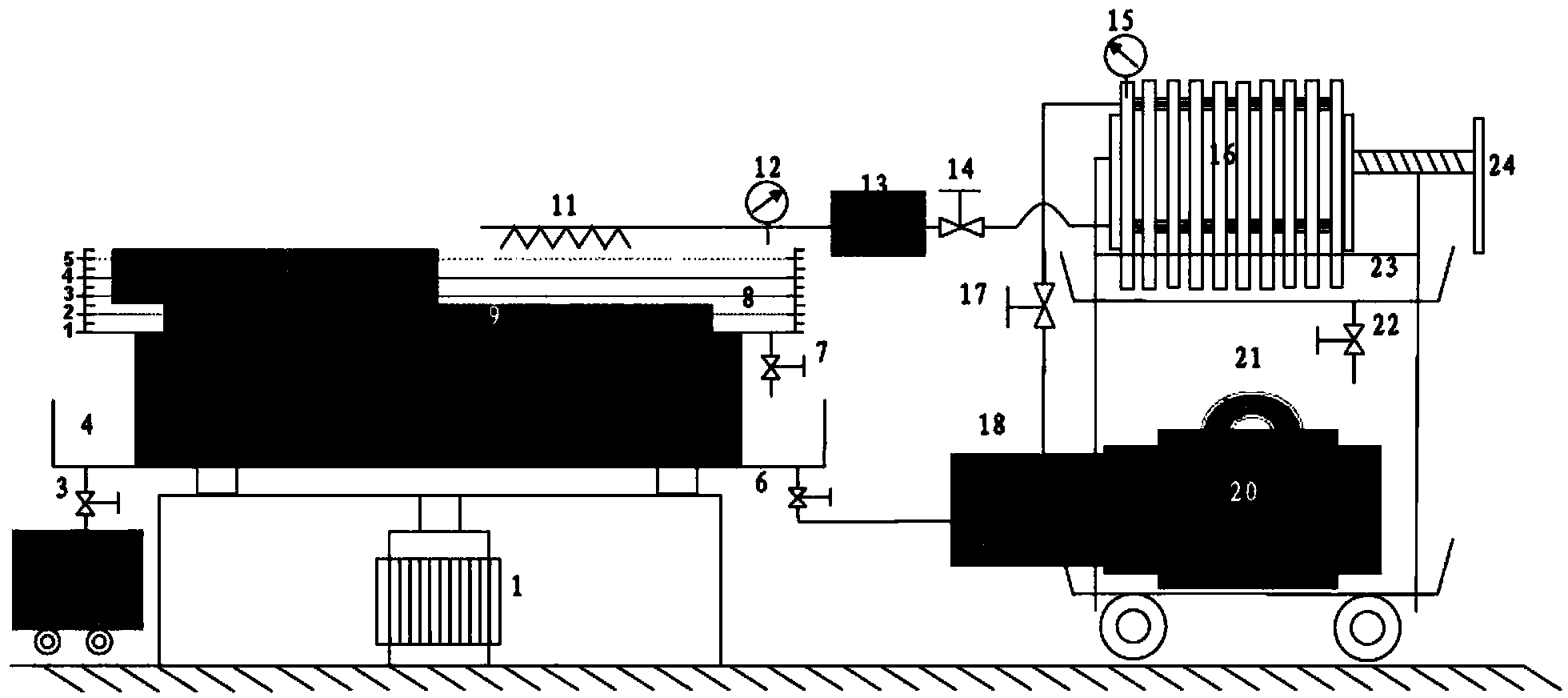

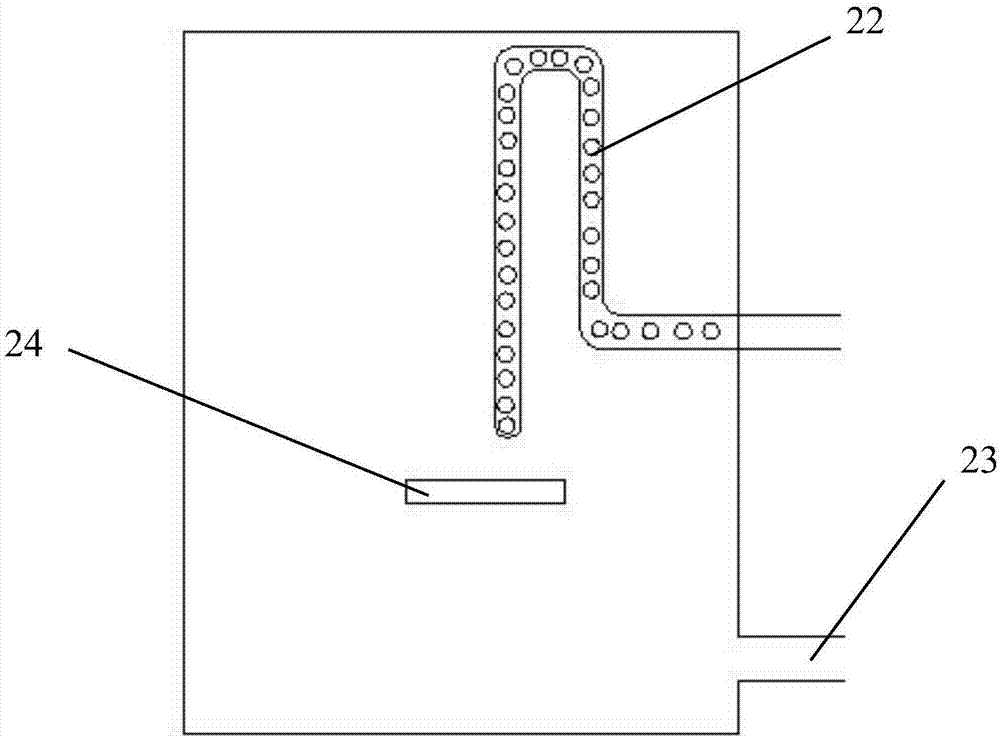

Surface pre-treatment system combining four aluminum alloy working grooves into whole for full recovery of medicament and zero emission of wastewater

The invention relates to a surface pre-treatment system combining four aluminum alloy working grooves into a whole for full recovery of medicament and zero emission of wastewater. The surface pre-heated system comprises a No.1 four-in-one sand surface groove, a No.2 matte tank, a No.3 water washing interception groove, a No.4 water washing interception groove, a No.5 water washing interception groove, a No.6 water washing material waiting groove, a No.7 oxidation groove and a No.8 water washing interception groove, as well as a matching slag pumping system, a medicament recovery system, a water circulation purification processing system and a reverse water replenishing neutralization system. As the four working grooves are combined into a whole, and the technical scheme is simultaneously equipped with the full recovery of the medicament and the zero emission of the wastewater, the pollution of fluorine and ammonium in the oxidation pre-treatment of an aluminum alloy anode can be effectively solved, the full recovery of the wastewater in the aluminum alloy surface pre-treatment can be realized, the pollution control of a company can be greatly reduced, and the production cost can be reduced.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

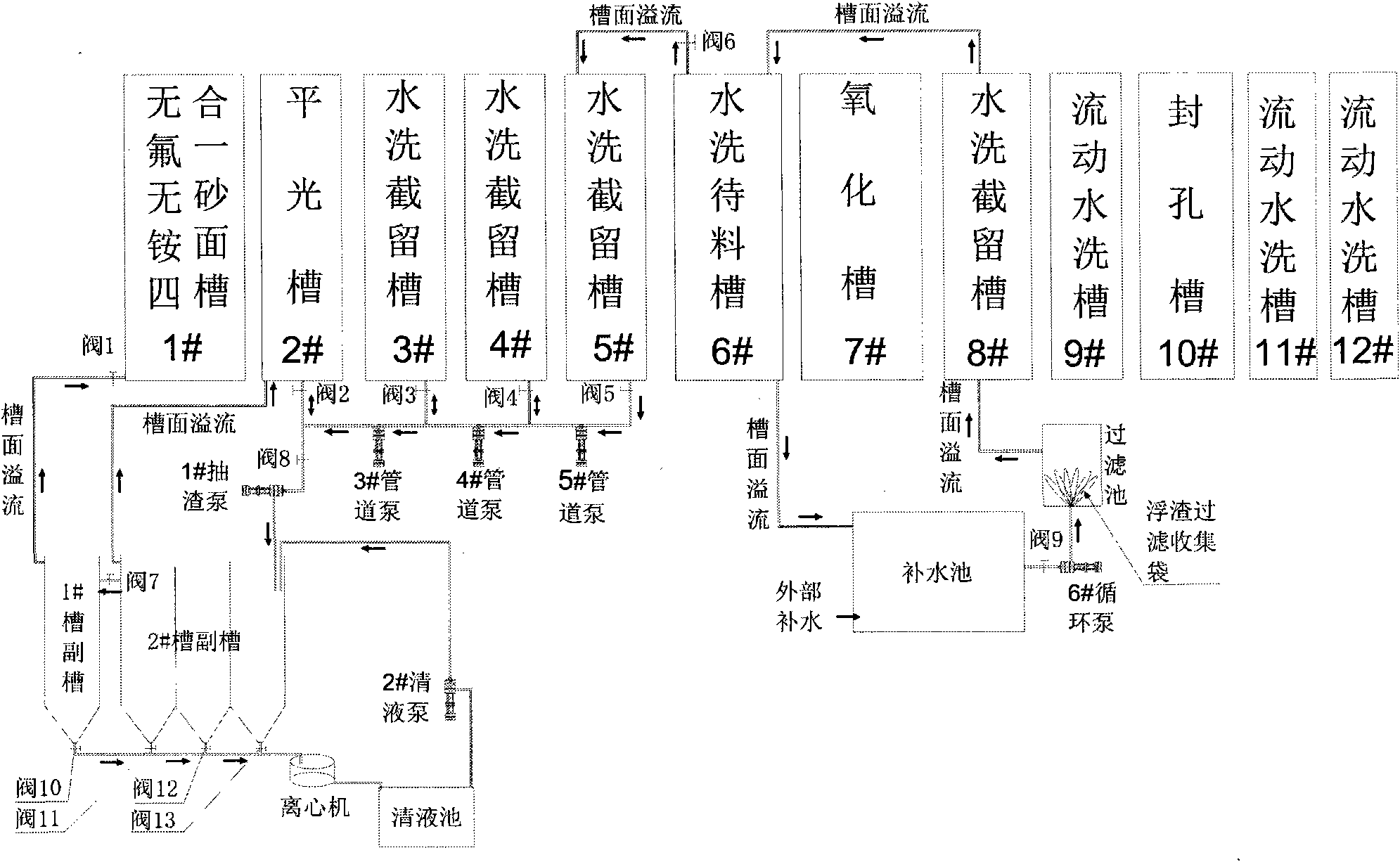

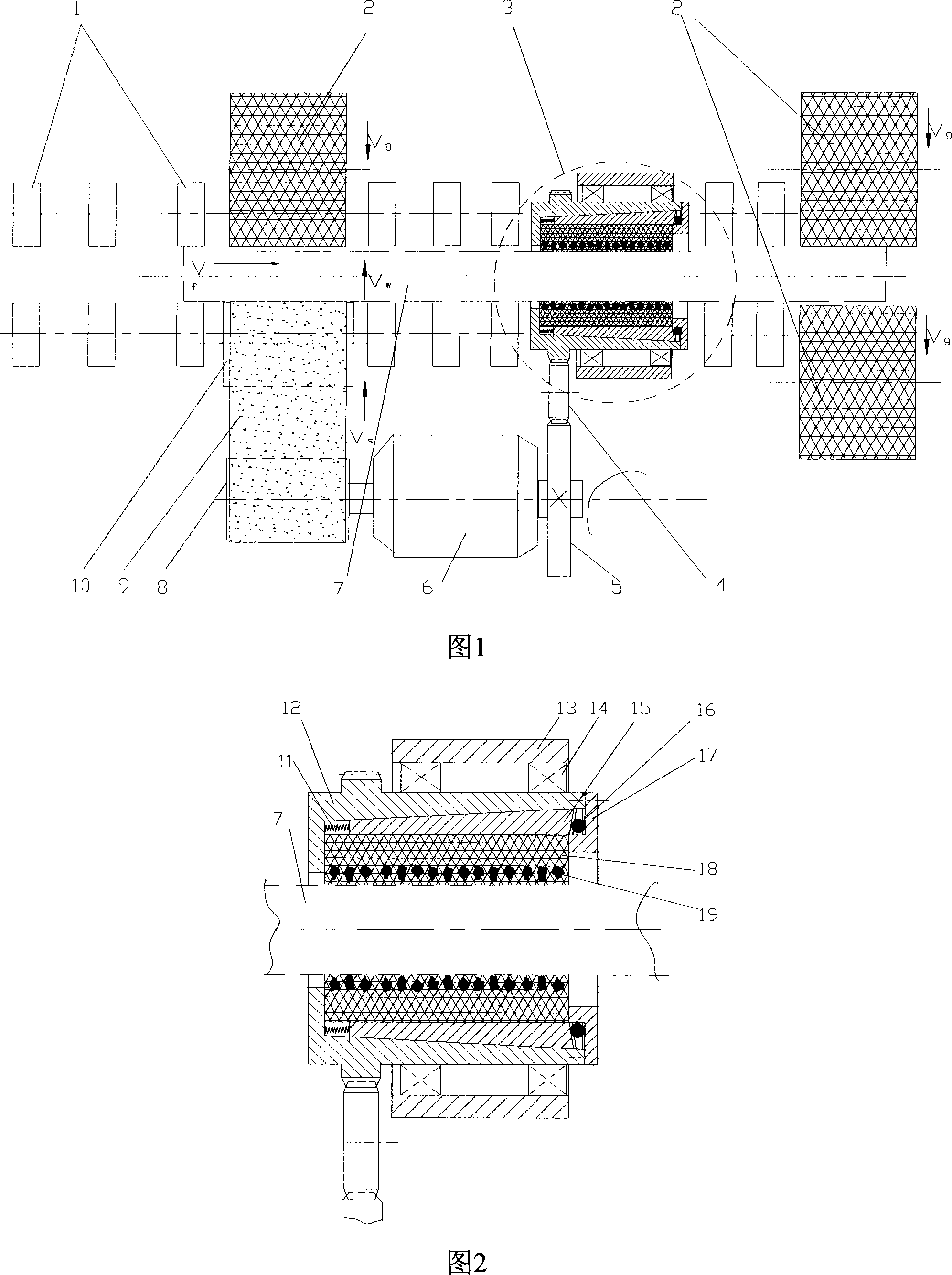

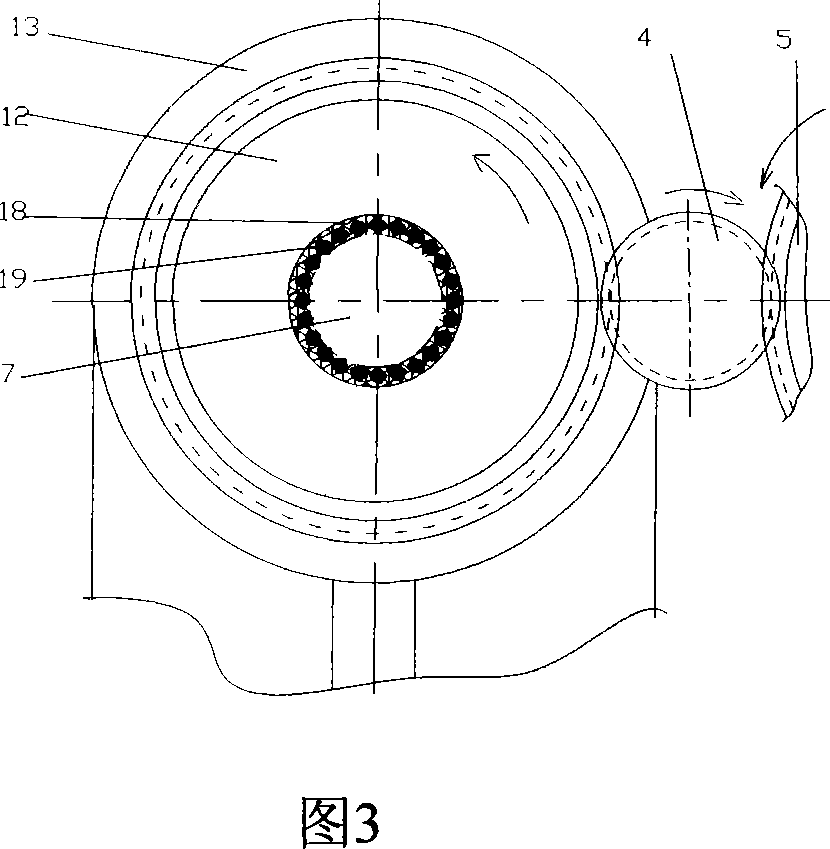

Wide/fine machining integrated processing device for emery belt centerless grinding and polishing

InactiveCN101195205AImprove grinding efficiencyImprove securityPolishing machinesBelt grinding machinesDrive wheelGear wheel

The invention discloses a process device with the combination of rough machining and fine machining of centreless grinding and lapping and polishing of an abrasive belt. The device comprises a piece riding wheel, a guide wheel, an abrasion head, a transition gear, a fixing gear, a two-shaft motor, a centreless abrasive head of the abrasive belt, and a supporting member of the piece riding wheel, wherein the centreless abrasive head of abrasive belts is composed of an abrasion head driving gear, the abrasive belt and an abrasive head contacting gear, and the abrasion head driving gear is connected with the abrasive head contacting gear via the abrasive belt. One end of the two-shaft motor is in fixed connection with the abrasive head driving gear, and the other end is connected with a fixed gear which is matched with the transition gear. The transition gear is matched and connected to the abrasive head. The device resolves the problems of poor rigidity, a lot of process procedures, a plurality of devices, much transport, complex operation, inconvenient installation and the like in the prior art of the coarse grinding, fine grinding, polishing and the like of the outer circle with elongated circular rods. The device increases the integral efficiency, reduces manufacture cost, enlarges the manufacture range and combines the rough process, semi-fine process, fine process, lapping and polishing.

Owner:GUANGDONG IND TECHN COLLEGE

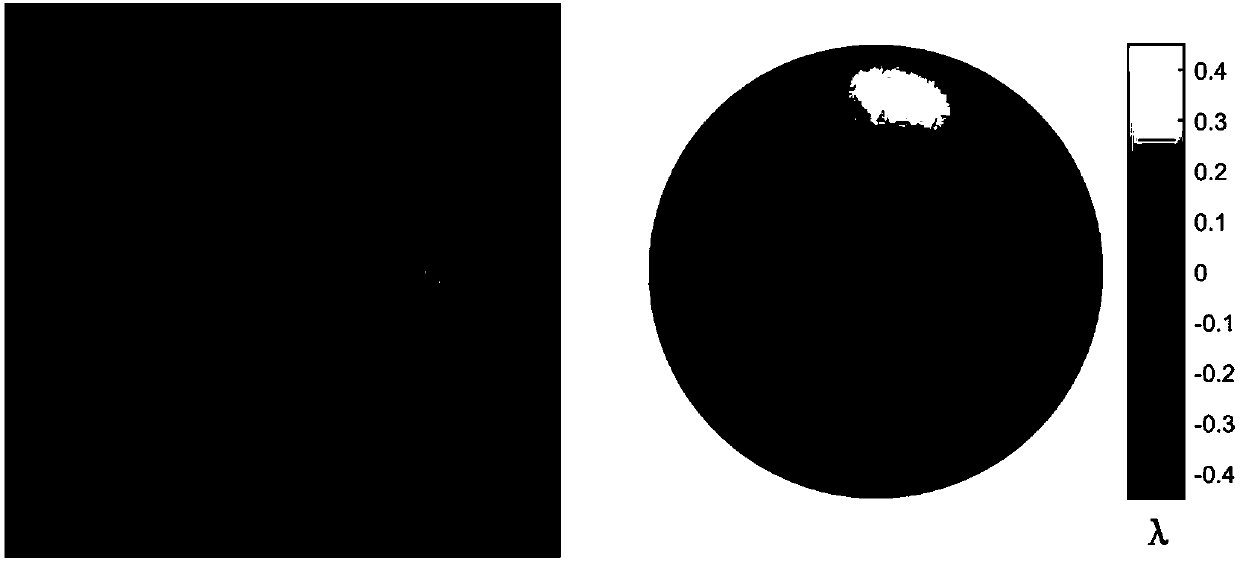

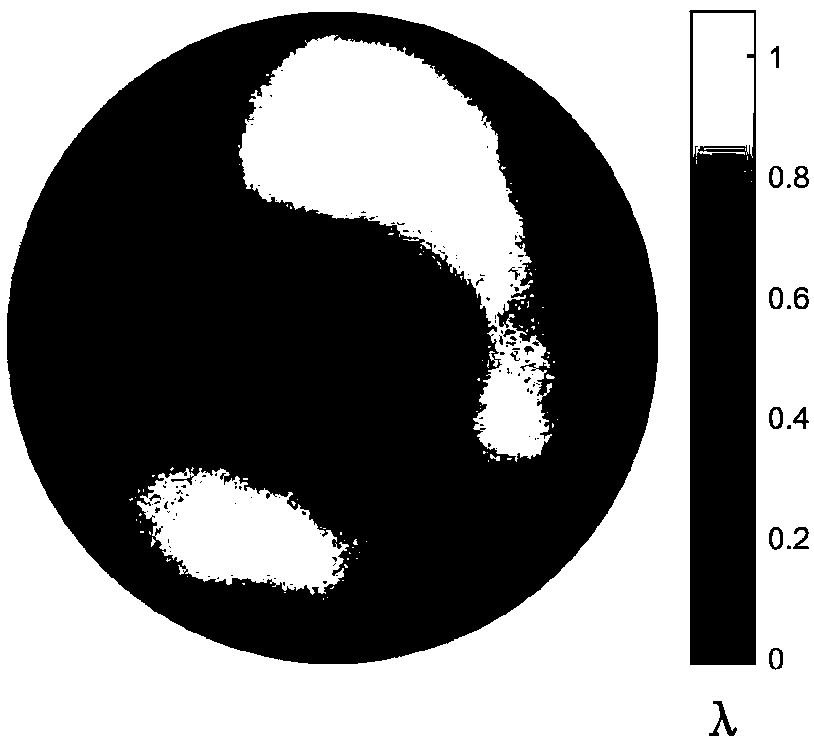

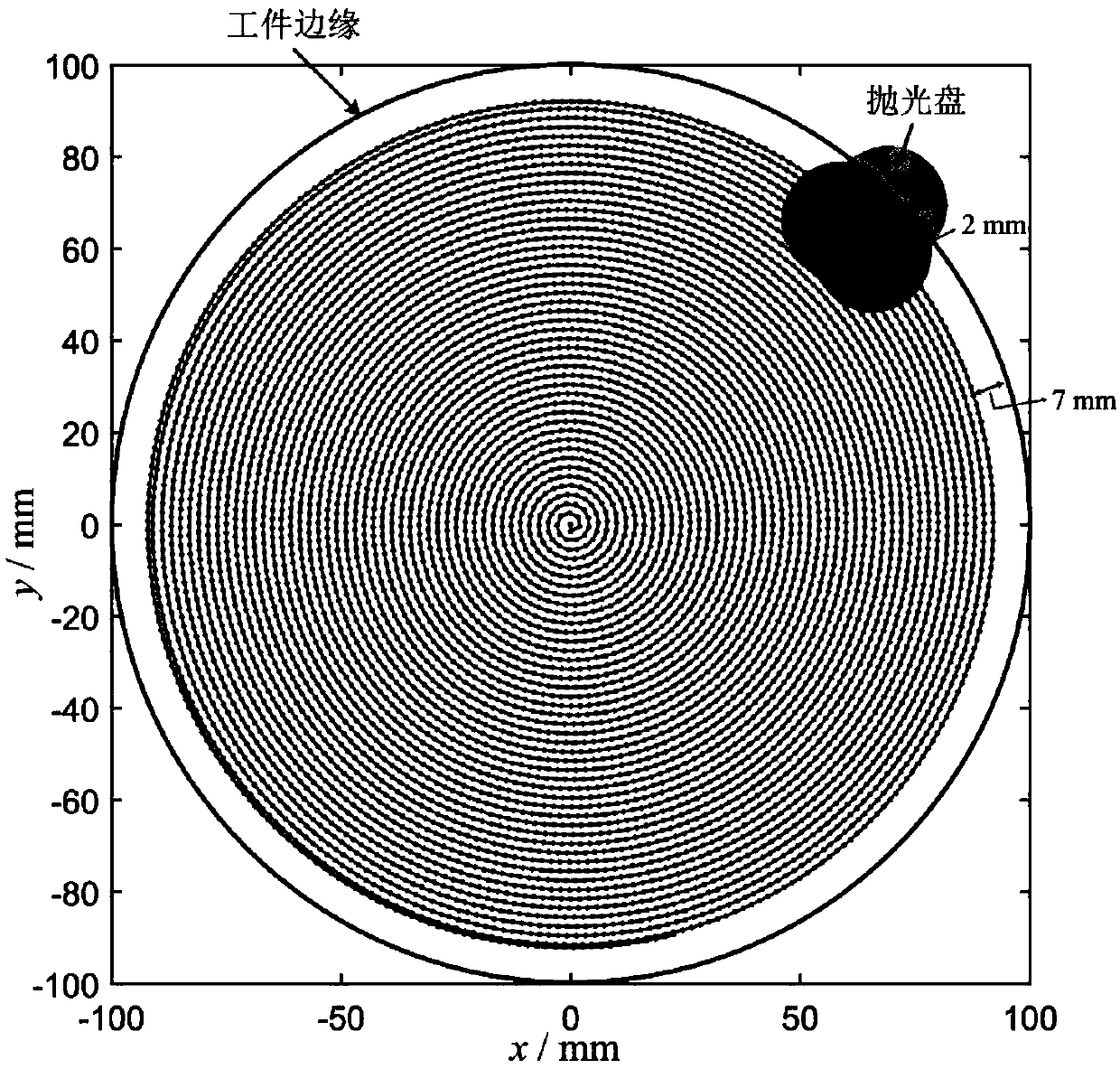

Edge error control method in optical lens small grinding head optical machining

ActiveCN108555729AReduced control accuracyReduce polishing costsOptical surface grinding machinesAutomatic grinding controlOptical processingSurface shape

The invention belongs to the technical field of optical element machining, and particularly discloses an edge error control method in optical lens small grinding head optical machining. The edge errorcontrol method comprises specific steps that firstly, a workpiece is measured to obtain a surface shape error, an appropriate quadratic term is added to the surface removing amount for adjustment, and the edge machining difficulty is lowered; meanwhile, a polishing path is abstracted to discrete sampling points, and a removing function of each sampling point is calculated according to a removingfunction model; then, the residence time is solved through a space variation deconvolution algorithm; and finally, a control program is generated according to the polishing path and the residence time, and polishing is carried out on the workpiece. The removing function changing along with the position is adopted to solve the residence time, and the removing amount of the edge part can be precisely controlled; the non-linear deconvolution algorithm can adapt to the shifting removing function; and by means of the surface shape adjusting technology, the convergence difficulty of the edge error is lowered to the maximum extent. According to the edge error control method, the requirement for the control precision of a polishing system is relatively low, and therefore the small grinding head polishing cost can be reduced, and the machining efficiency is improved.

Owner:FUDAN UNIV

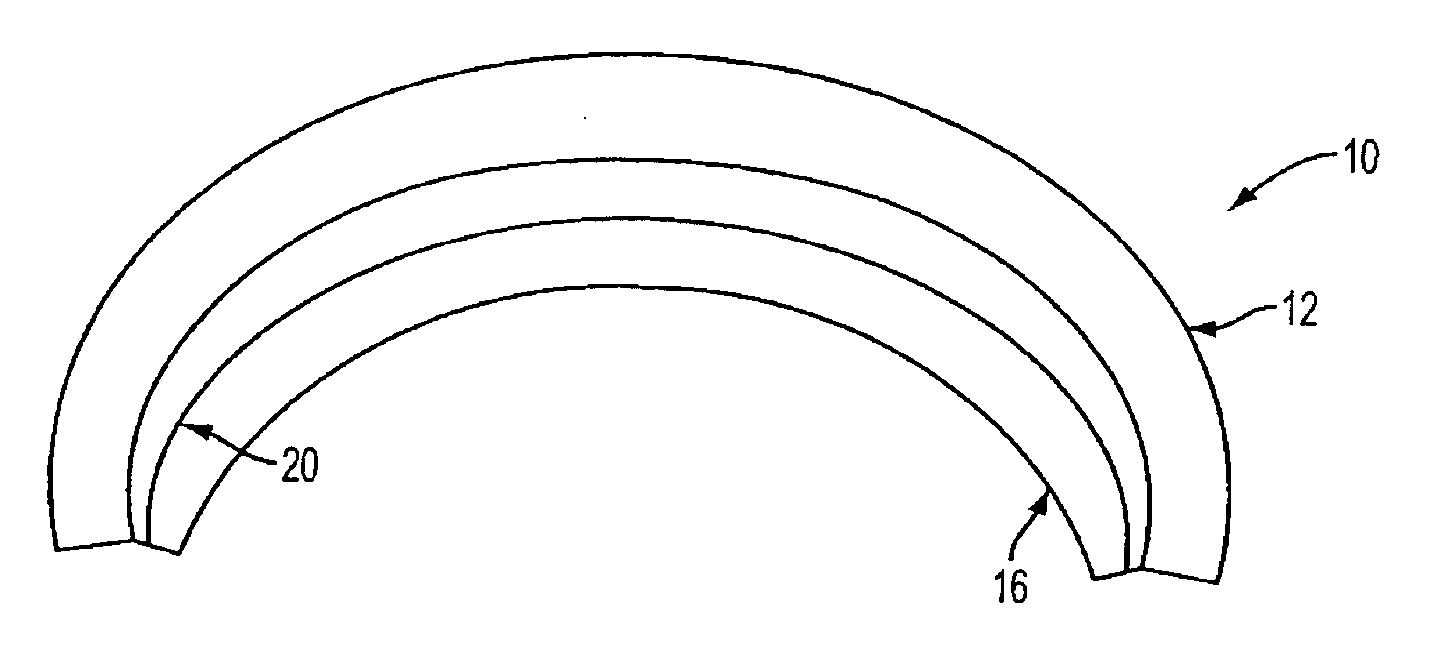

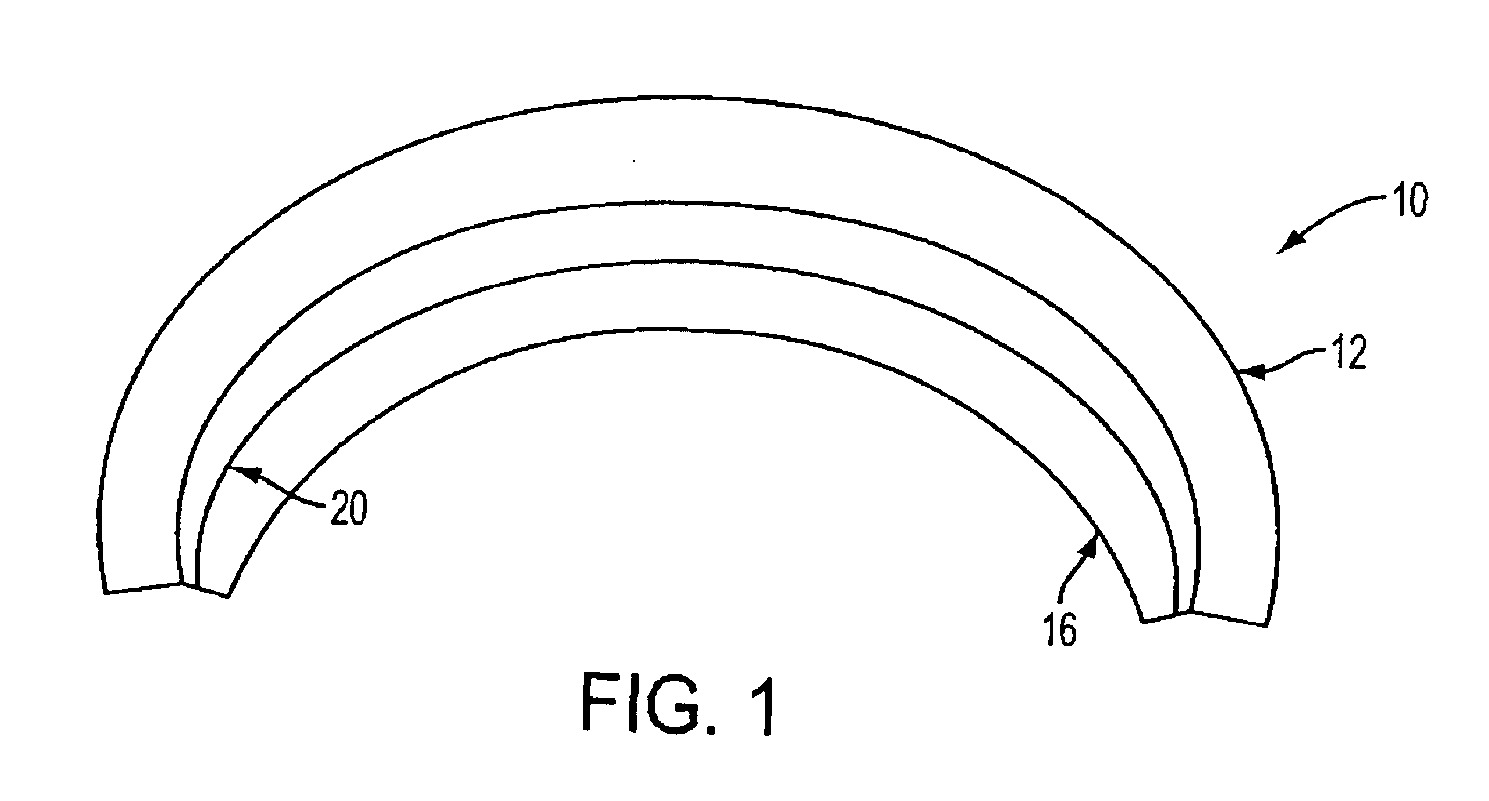

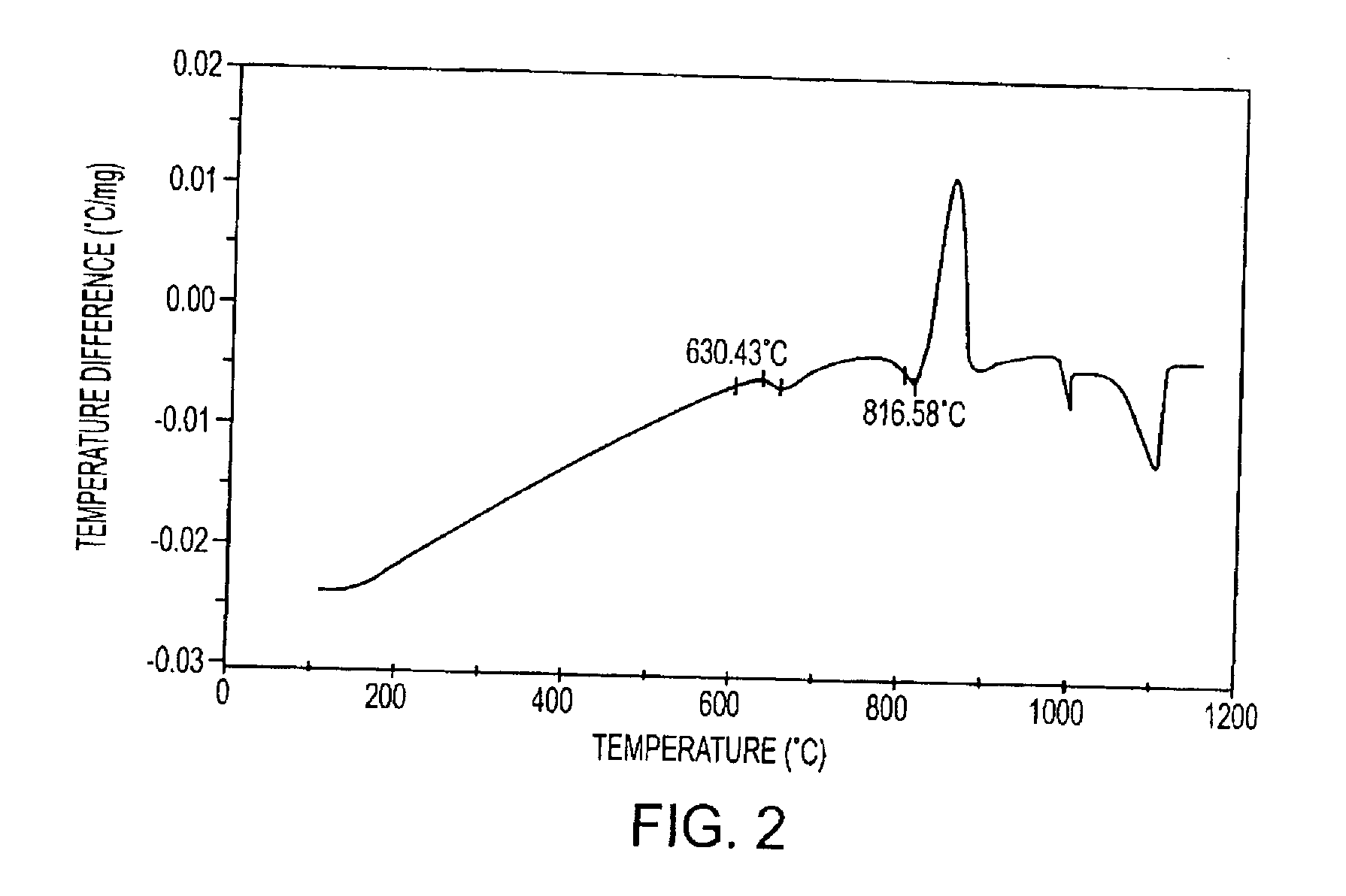

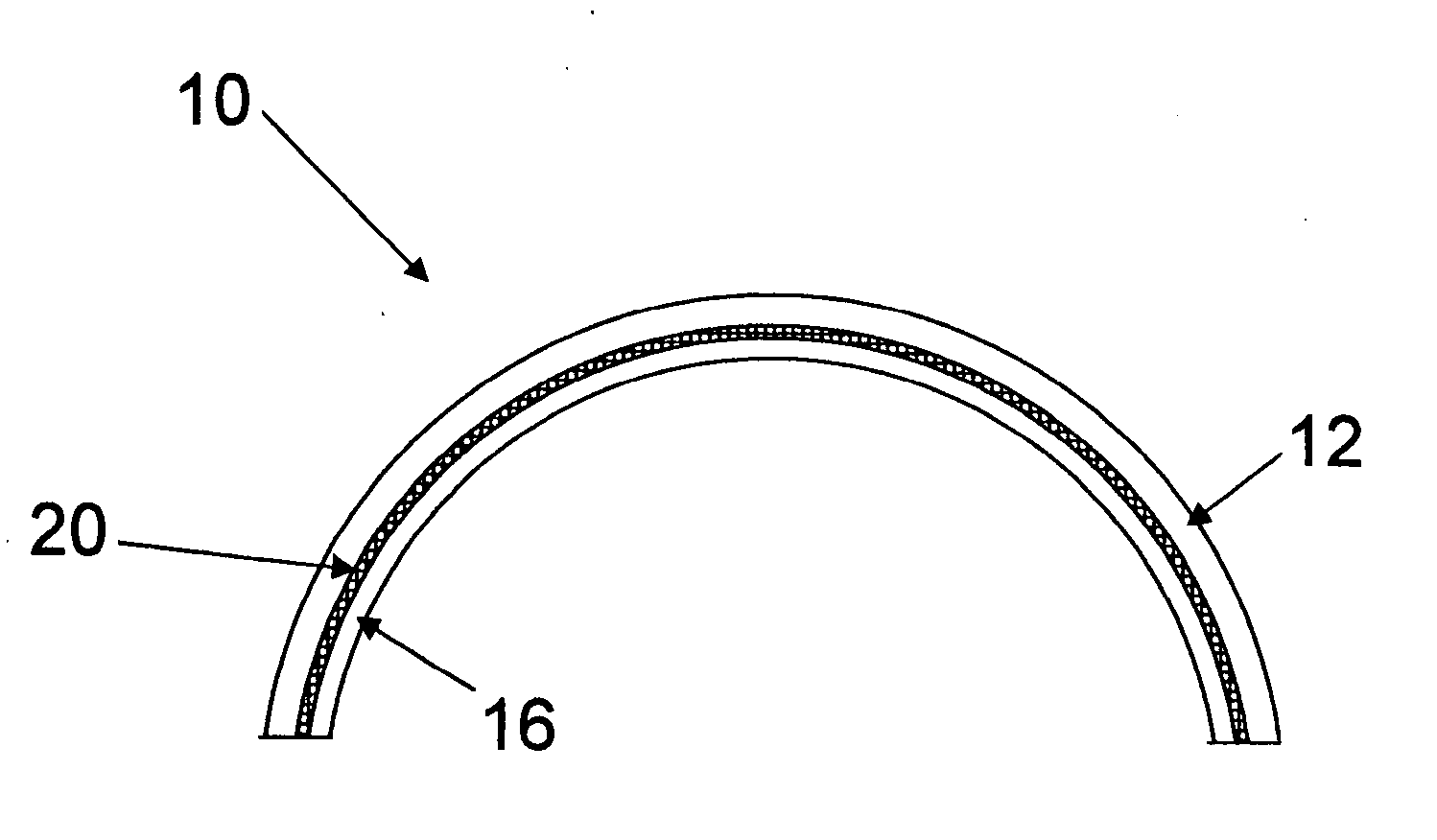

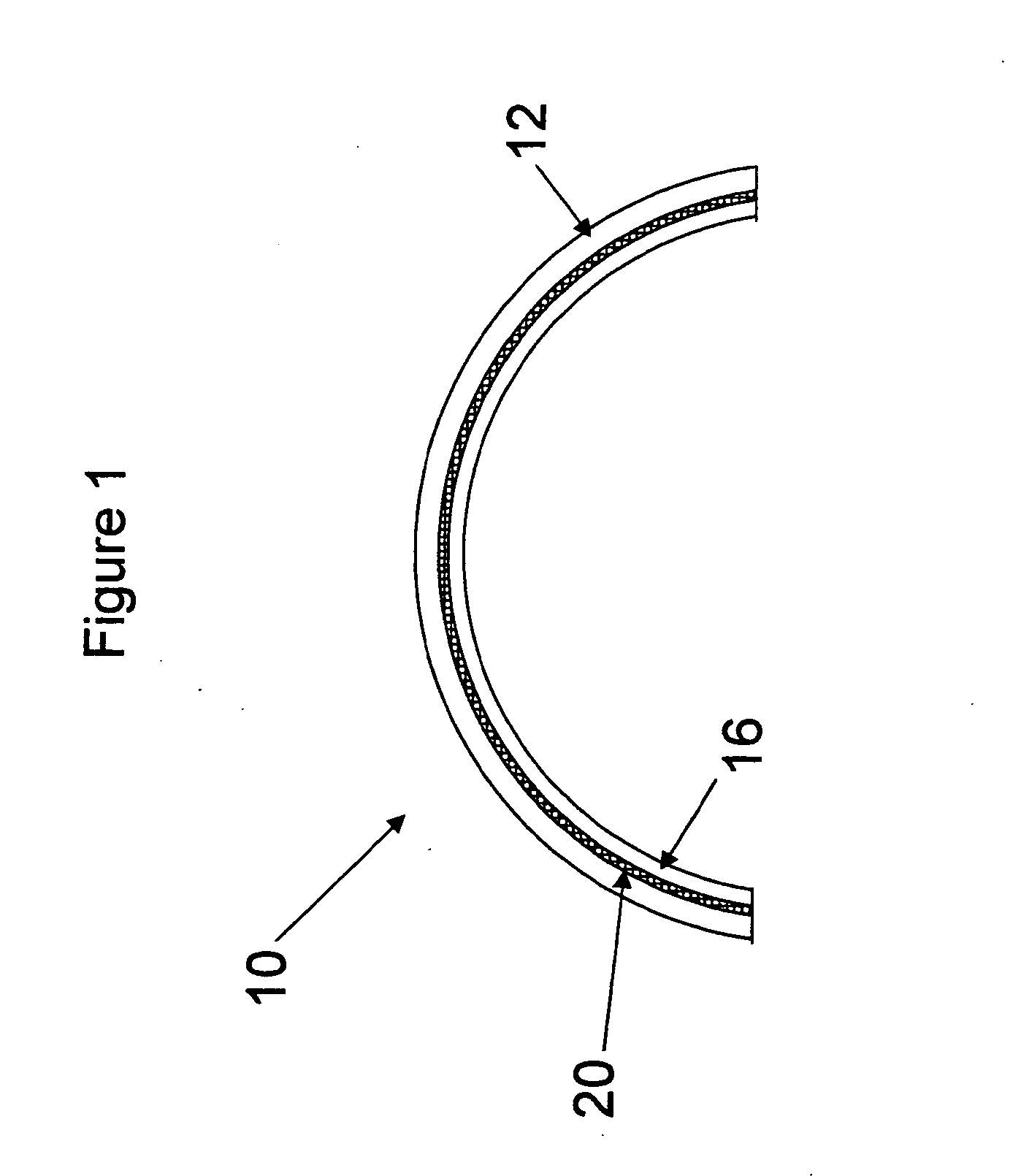

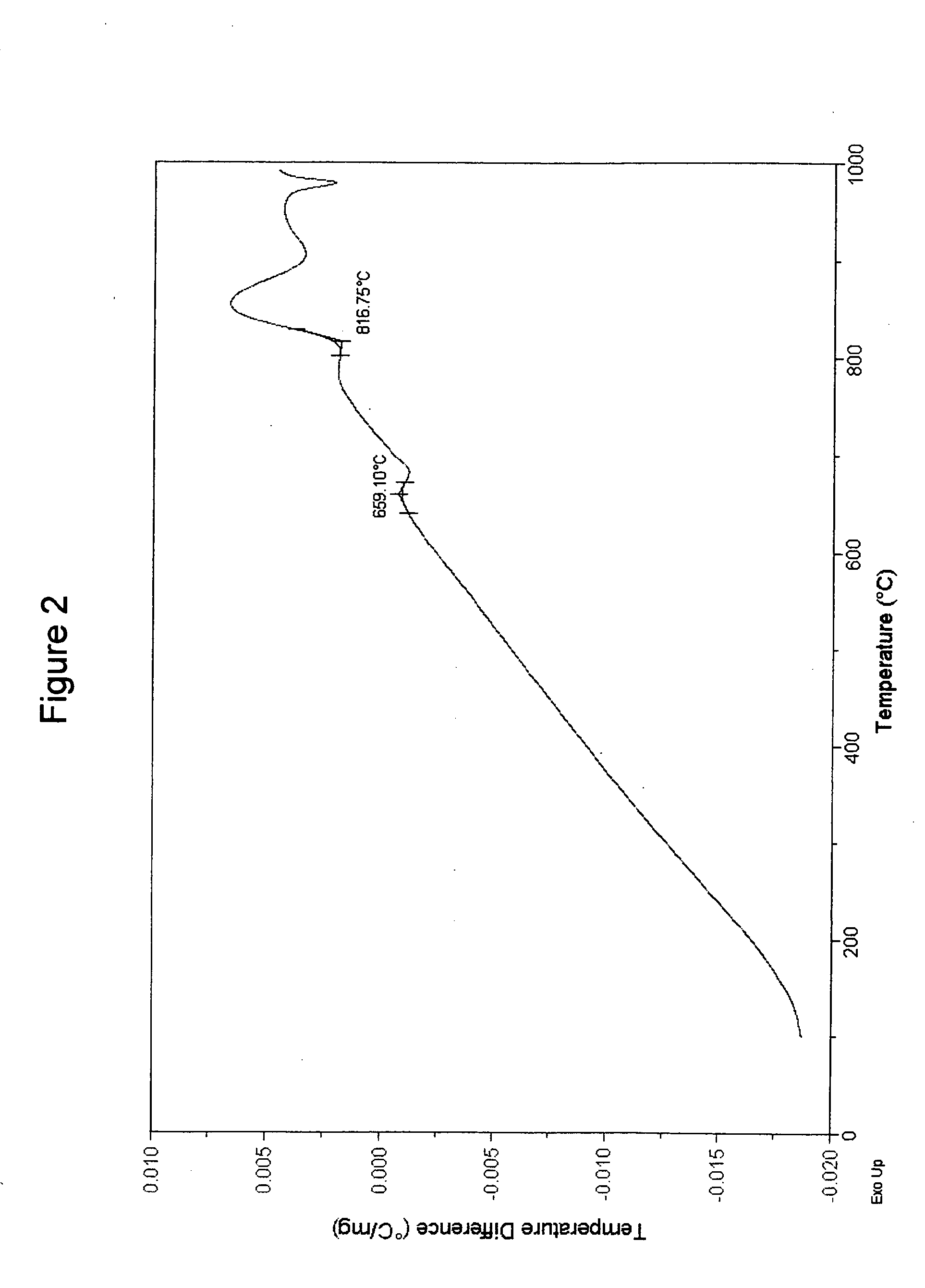

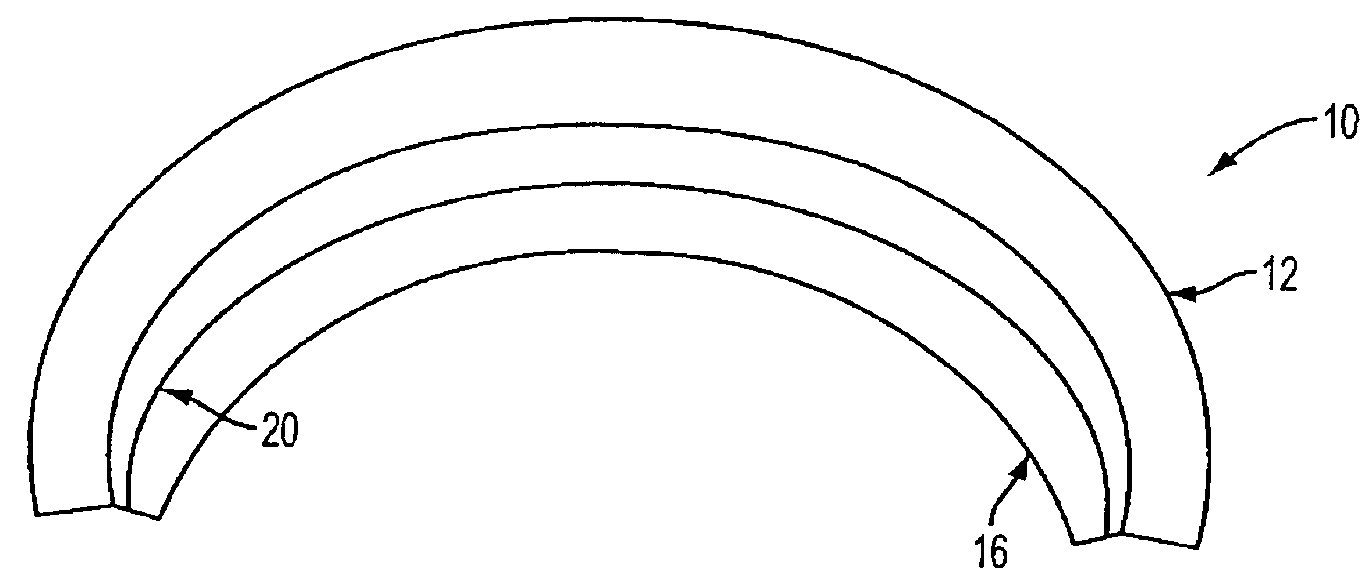

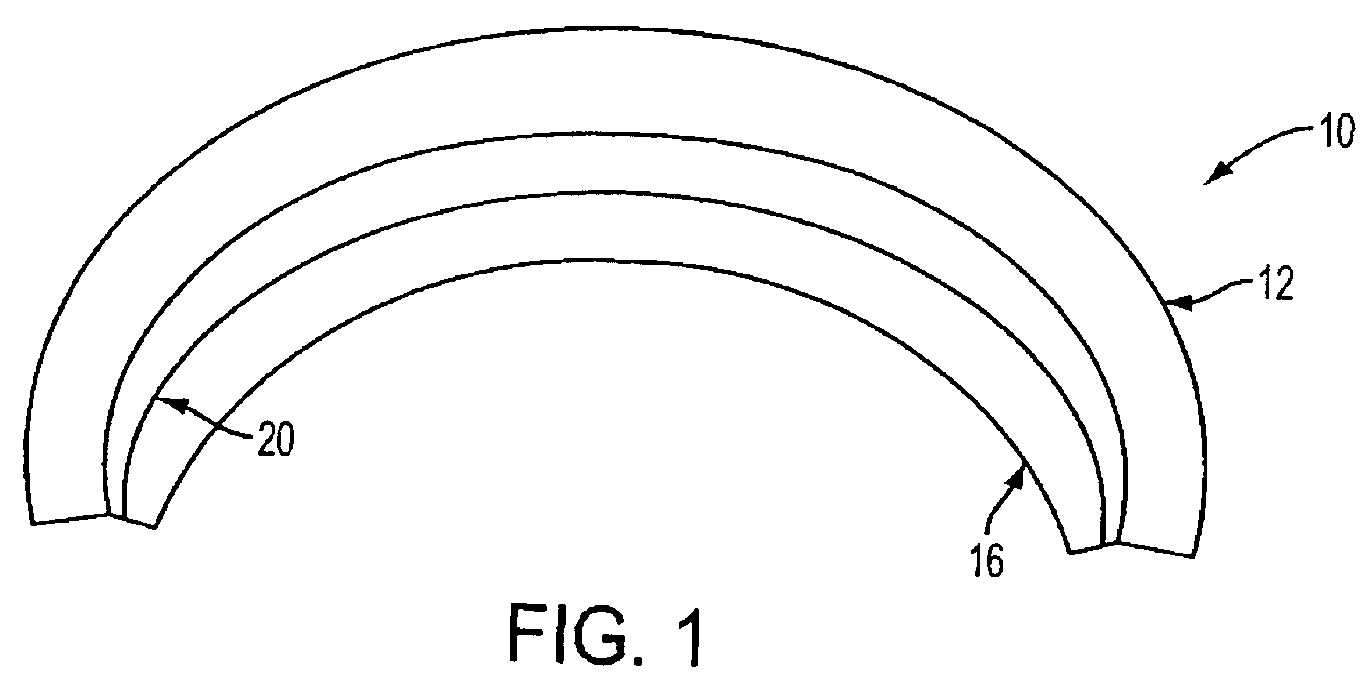

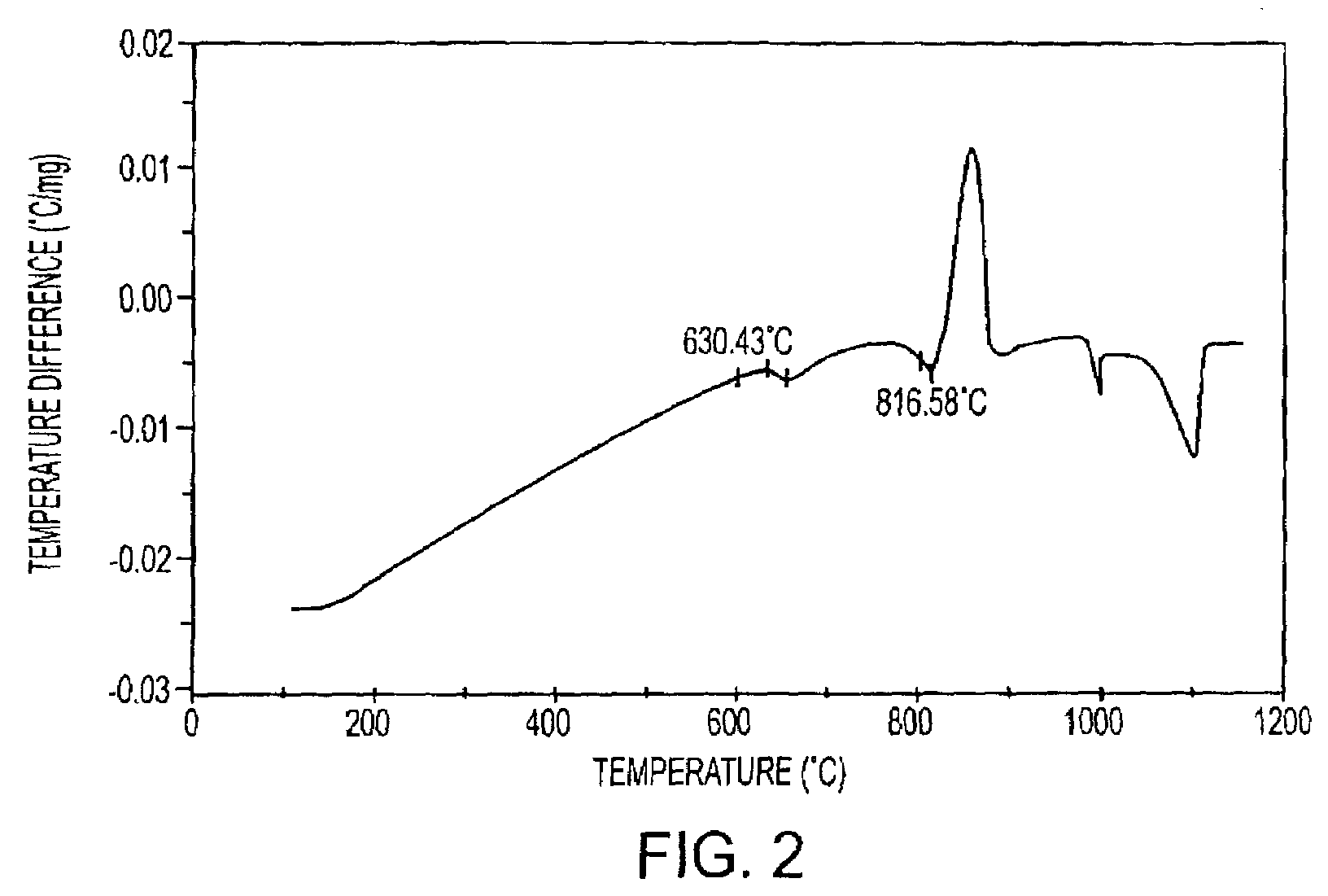

Low loss visible-IR transmitting glass-ceramic spinel composites and process

ActiveUS20070087204A1Conserve costReduce polishing costsGlass/slag layered productsNatural mineral layered productsTransmittanceSpinel

This invention pertains to a composite of Spinel and BGG glass substrates and to process for bonding Spinel to BGG glass. The composite includes a Spinel and a BGG glass bonded together and having transmission in the visible and mid-infrared wavelength region. The process includes the step of heating them together above the softening temperature of the BGG glass, the composite having excellent, i.e., typically in excess of about 80%, transmission in the 0.5-5 wavelength region.

Owner:NAVY U S A AS REPRESENTED BY THE SEC OF THE THE

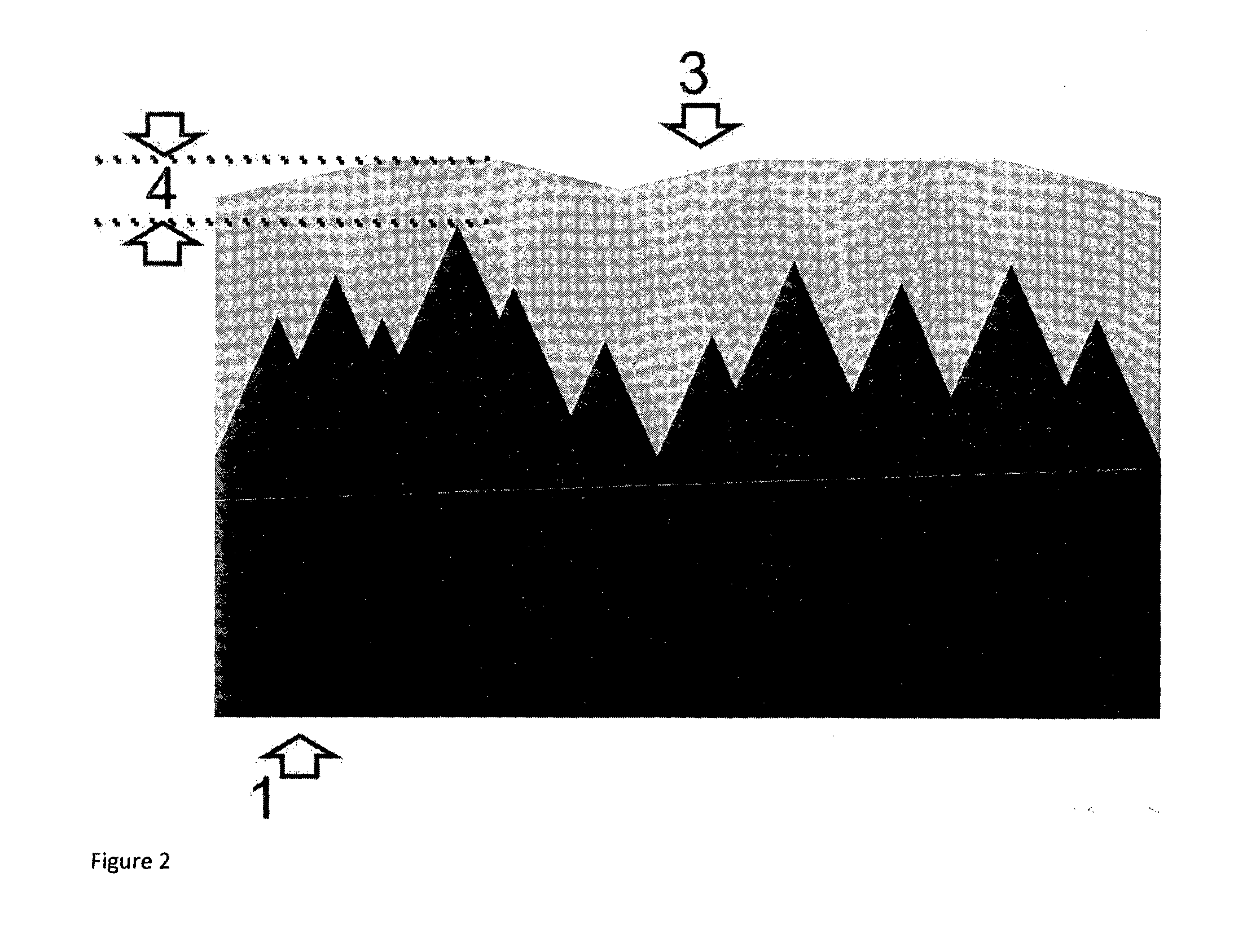

Spin-on-glass assisted polishing of rough substrates

InactiveUS20150197455A1Reduce polishing costsImprove the quality of anticorrosionDecorative surface effectsVacuum evaporation coatingOptical radiationPolymer science

A method produces a smooth surface on a rough substrate. The rough substrate is coated with a film or particles of spin-on-glass (SOG) dissolved in a solvent using spin coating, spray coating or dip coating. The SOG is made to reflow by using thermal melting and solvent thinning. The reflow is done in an atmosphere containing a partial pressure of the solvent. The reflow allows the SOG to partially melt and to decrease the surface roughnesss of the film. The SOG is cured by thermal curing or UV exposure radiation curing into a hard durable and chemical inert silicon dioxide film. The SOG can be hydrogen silsesquioxane or methyl silsesquioxane dissolved in either methyl isobutyl ketone or volatile methyl siloxanes. The method can include embossing, chemical mechanical polishing, etching and functionalizing the surface. The substrate can be a cast, mould or form for producing a polymer or a glass replica.

Owner:INMOLD BIOSYST

Low loss visible-IR transmitting glass-aluminum oxynitride composites and process

InactiveUS20070087203A1Reduce polishing costsFacilitate transmissionGlass/slag layered productsMetal layered productsTransmittanceMid infrared

This invention pertains to a composite of AlON and a germanate glass, and to a process for bonding AlON to the glass. The composite includes AlON and glass bonded together and having transmission in the visible and mid-infrared wavelength region. The process includes the step of heating them together above the softening temperature of the glass, the composite having excellent, i.e., typically in excess of about 60%, transmission in the 0.4-5 wavelength region.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

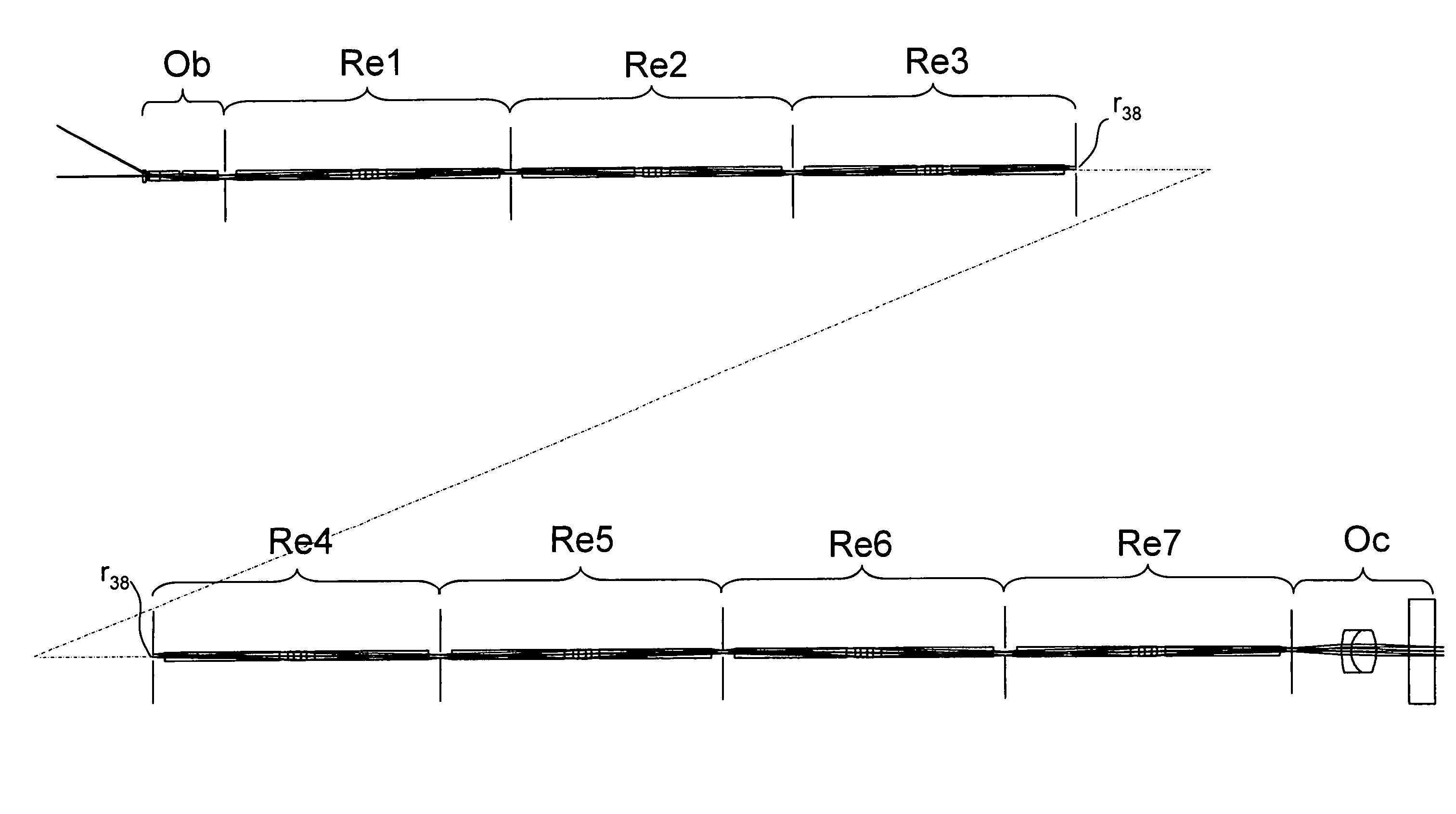

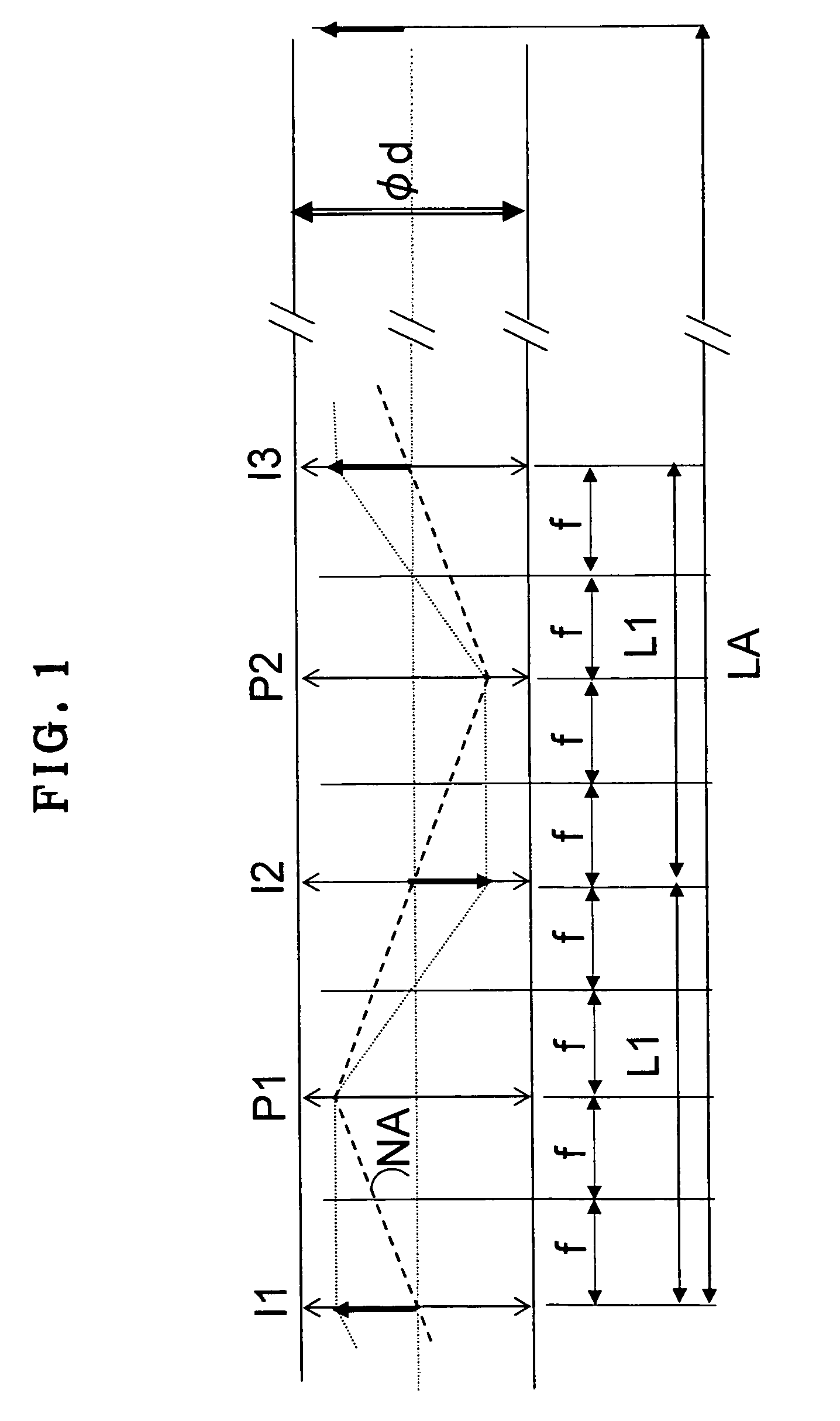

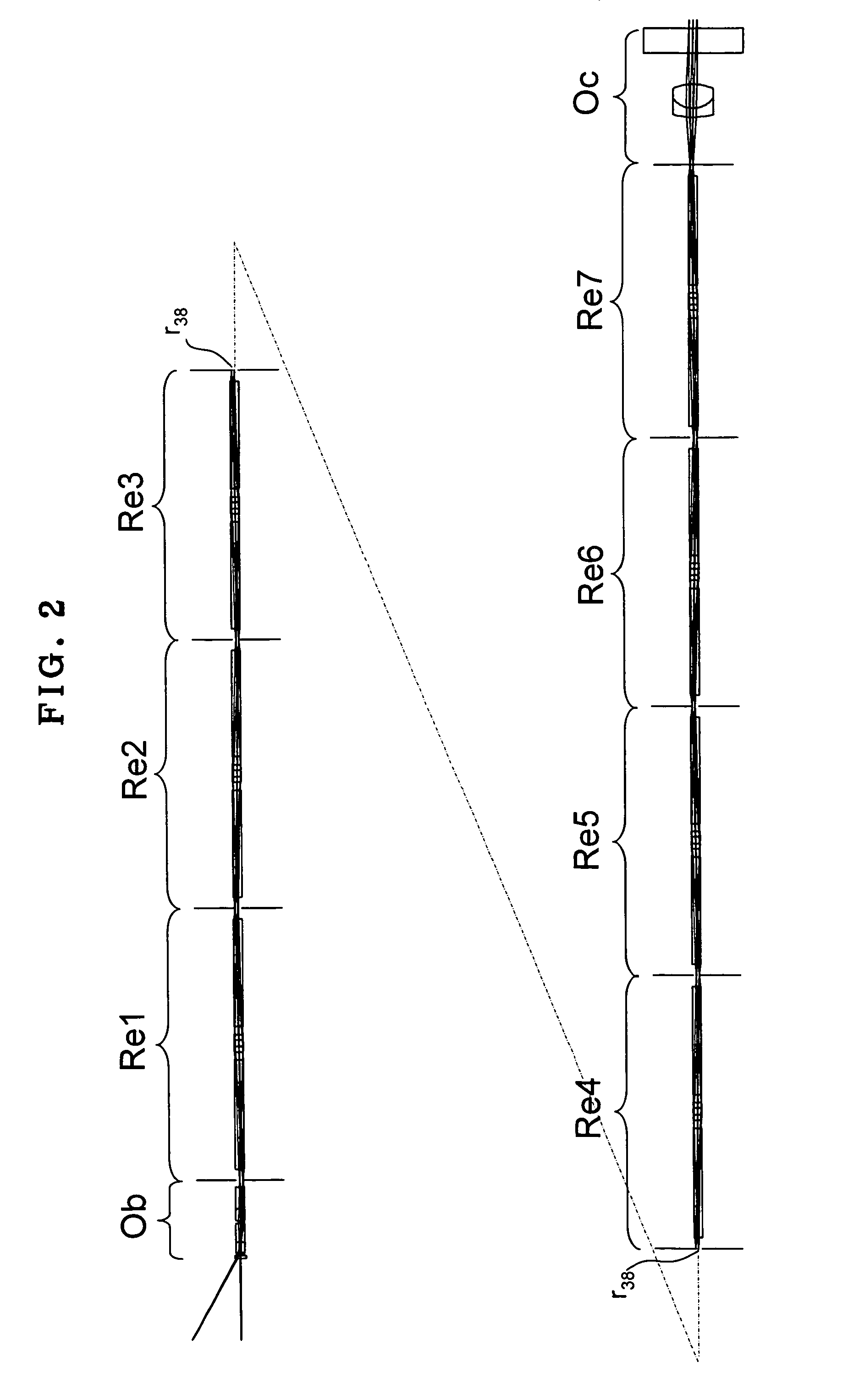

Rigid endoscope

ActiveUS7724430B2Low costShorten the counting processSurgeryEndoscopesImage transferRefractive index

Owner:OLYMPUS CORP

Method for recycling cerium oxide abrasive

ActiveCN102189489AEfficient recyclingExtend update cycleOther chemical processesPolishing compositions with abrasivesSlurrySodium fluoride

Disclosed is a method for recycling a cerium oxide abrasive. The method may include adding a strong alkali solution to a slurry waste of the cerium oxide abrasive, adding sodium fluoride to the slurry waste, and separating a cerium oxide particle included in the slurry waste from other kinds of particles.

Owner:LG CHEM LTD

Large immersion type ring polishing machine

ActiveCN103372805AGrain size parameters are stableImprove machining accuracyPolishing machinesSurface roughnessProcess engineering

A large immersion type ring polishing machine mainly comprises a marble polishing disc, a large liquid storage groove, a polishing solution storage tank, a magnetic stirrer, an electric pump, a polishing solution filtering device, a spraying nozzle device and the like. The magnetic stirrer is arranged in the polishing solution storage tank and performs continuous stirring. The polishing solution filtering device adopts a multilayer filtering film type filtering device and can perform multilayer grading filtering according to needs. By means of the large immersion type ring polishing machine, immersion type polishing processing of the large immersion type ring polishing machine is achieved, temperature balance performance is good, polishing surface shape errors caused by uneven polishing temperature are reduced, surface shape precision and surface roughness of a large-caliber plane optical element are improved, and surface defects of elements can be effectively controlled. Furthermore, the immersion type ring polishing machine adopts a mode of cyclic utilization of polishing solution, so that consume of the polishing solution can be greatly reduced, and processing cost is reduced.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Polishing method for irregular marble surface

ActiveCN102765013AAchieve mechanized polishingImprove polishing efficiencyPolishing machinesPolishingGrinding mill

The invention discloses a polishing method for an irregular marble surface. The method is as follows: placing marble blank and abrasive in a vibration grinding machine, followed by coarse grinding and fine grinding so as to obtain stones with a better polishing effect. The polishing method has excellent polishing effect. Due to the adoption of the method, the marble polishing surface has various art visual effects rather than single mirror smoothing effect in the prior art; the mechanical polishing of the marble, particularly, the irregular marble, is realized; the polishing efficiency of the irregular marble is greatly improved, and the polishing cost of irregular marble material can be greatly reduced, and is only tens of times less than the polishing cost of the traditional method; and the irregular polishing stone products can possibly become popular building material products, and expression forms of the irregular marble products and building decoration marble are enriched.

Owner:GAOYAO CITY DONGYING STONEMASONRY

Manufacturing method of full-stamped and stretched stainless steel water tap

The invention discloses a manufacturing method of a full-stamped and stretched stainless steel water tap and relates to a manufacturing method of a stainless steel water tap. The manufacturing method comprises the following steps: (1) processing a main body: punching a reserved hole, stretching a boss, processing the plane of the boss, machining a valve core seat, drilling a water inlet and outlet hole, tapping a thread of the water inlet and outlet hole, chamfering the hole, turning a shell of the valve core seat, assembling the valve core seat and the shell, assembling the main body of the water tap, polishing, testing water and testing pressure; (2) processing a bent pipe; and (3) assembling the whole of the water tap. Compared with the existing precision casting method, the manufacturing method has the advantages of short processing cycle, high primary qualification rate, no sand air holes on the surface and the like, and belongs to the environmentally-friendly industry with low energy consumption, no electroplating and low pollution, mirror light can be polished on the surface, and the lead content is further below 0.025% and can achieve the requirements of American AB1953 bill, thereby being more environmentally-friendly.

Owner:FOSHAN SHUNDE DISTRICT JIANJI ELECTRIC APPLIANCE IND

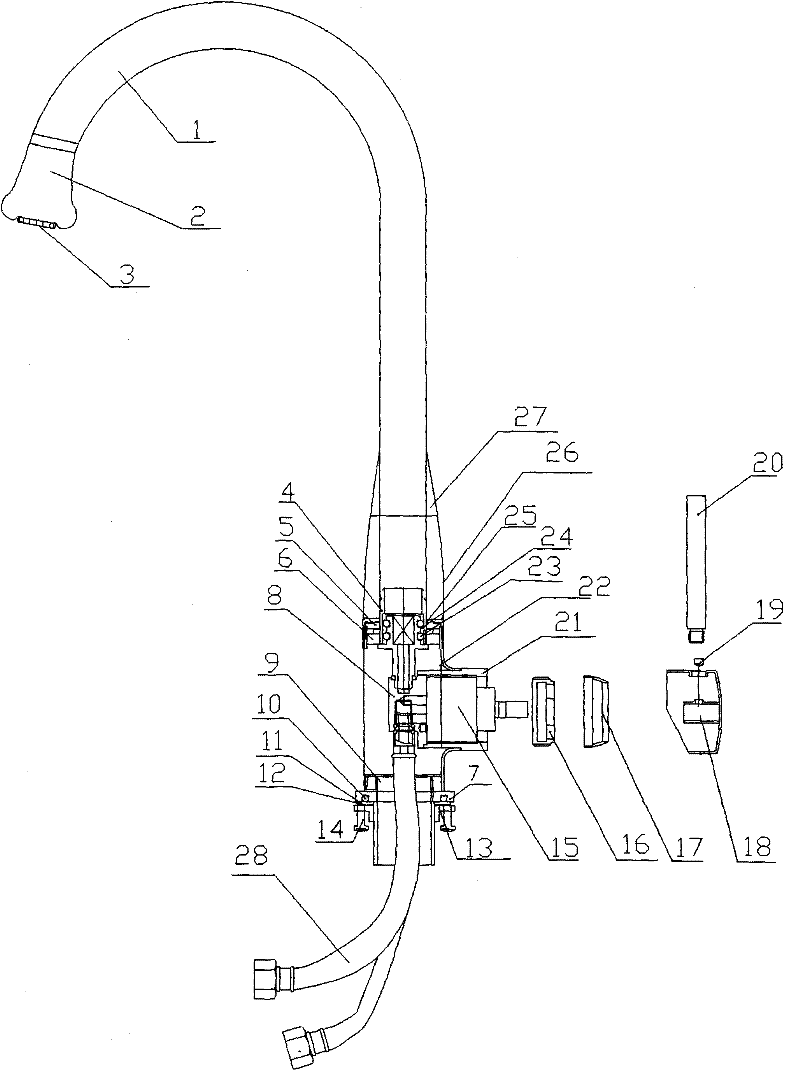

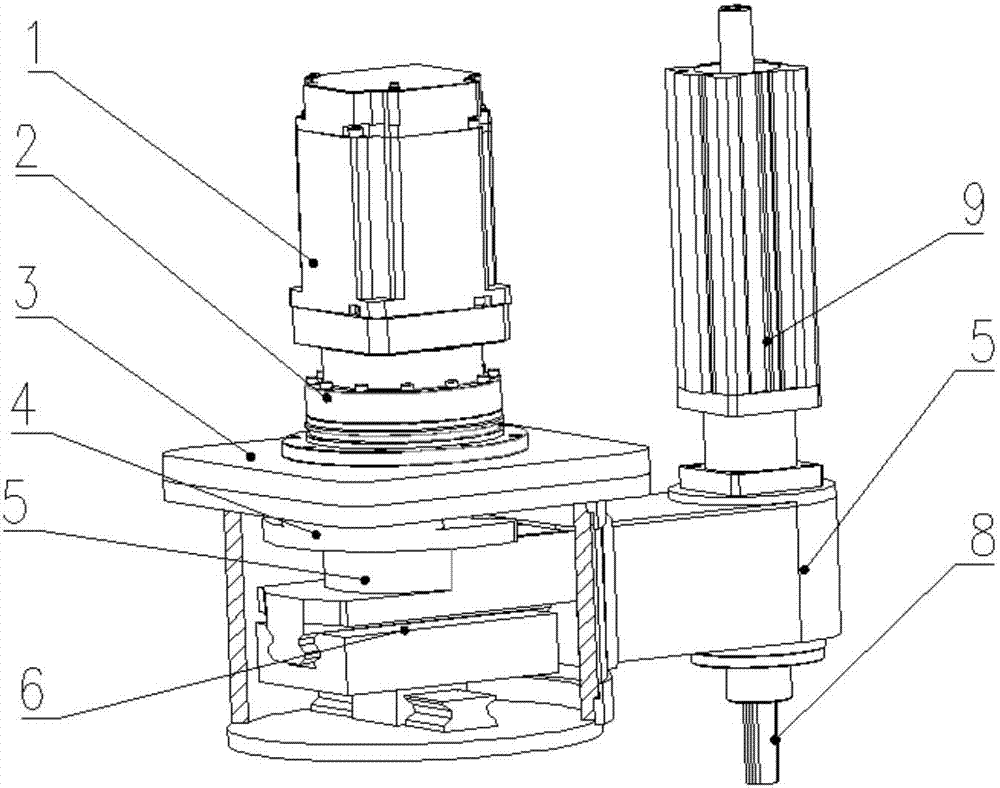

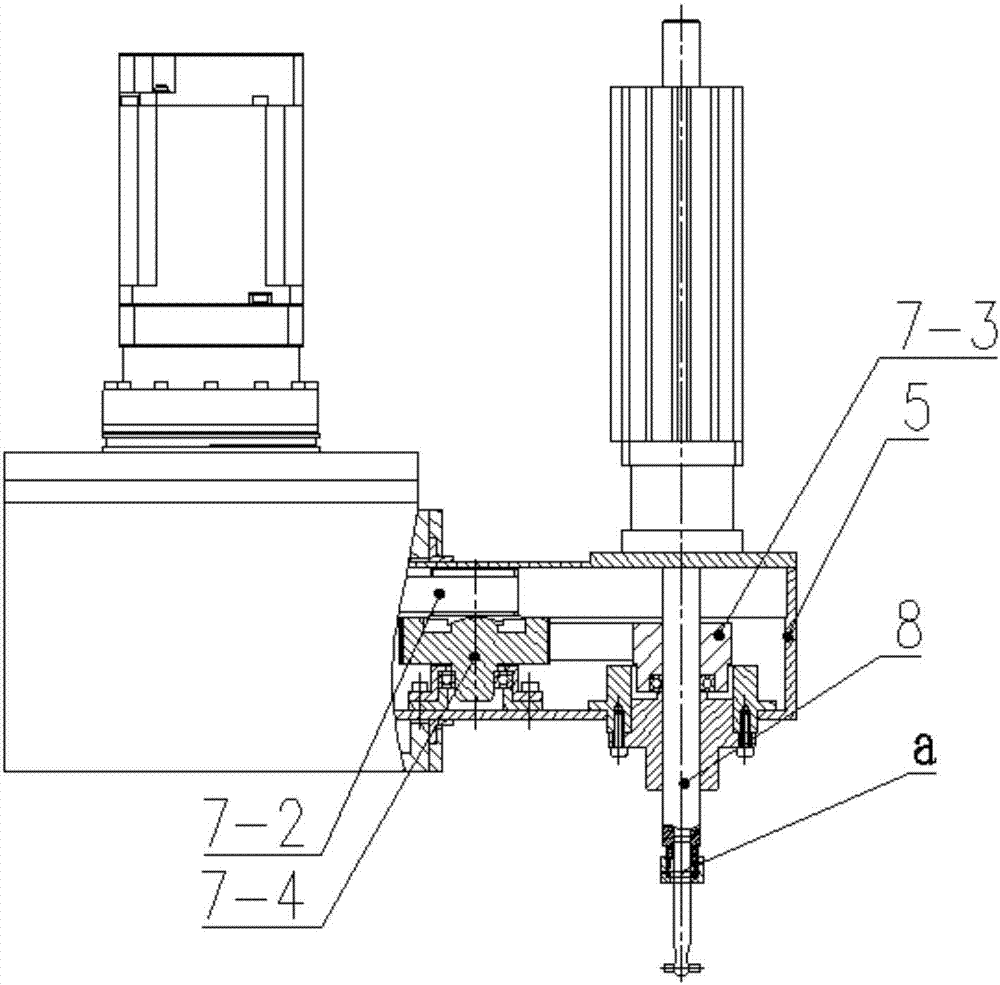

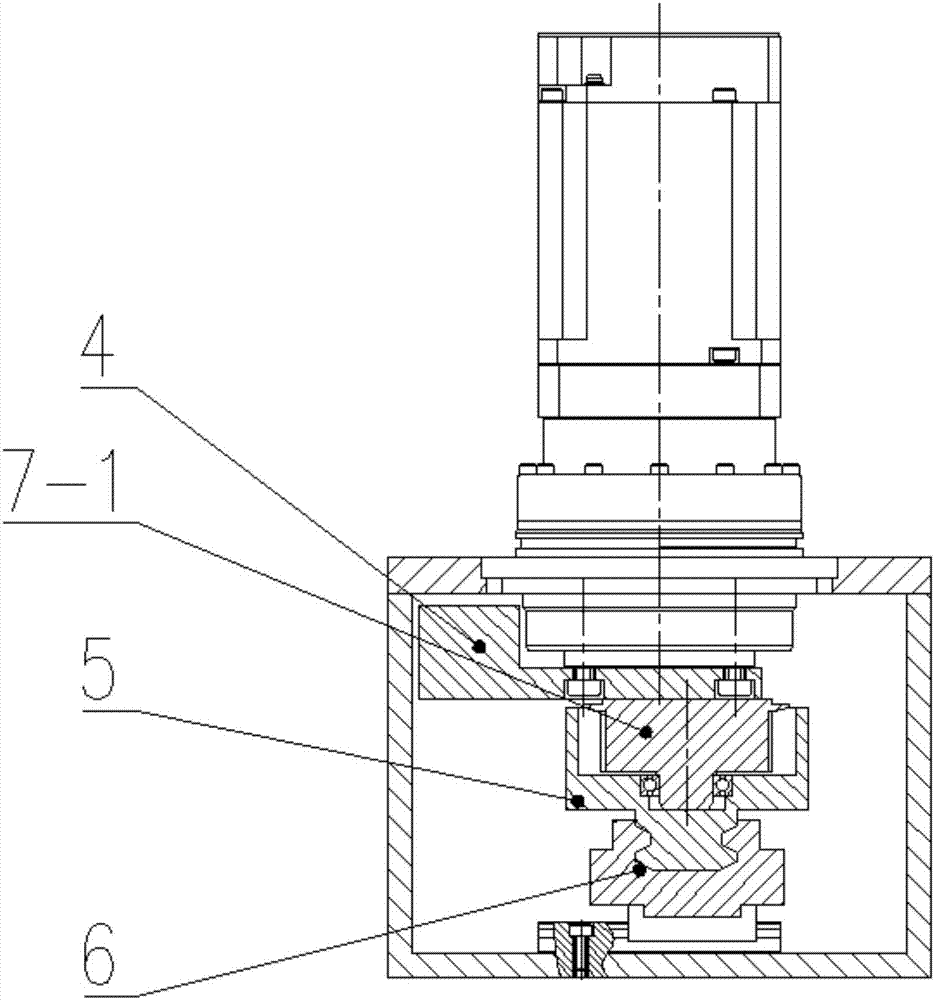

Eccentric planetary polishing device of large-caliber aspheric robot

InactiveCN107414631ASmall sizeReduce weightOptical surface grinding machinesGrinding drivesDynamic balanceFriction force

The invention discloses an eccentric planetary polishing device of a large-caliber aspheric robot. The main structure of the eccentric planetary polishing device is composed of an eccentric planetary transmission mechanism and a polishing shaft assembly. The eccentric planetary transmission mechanism achieves revolution motion and rotation motion of end execution of the polishing device at the same time through the same motor and comprises a planetary transmission mechanism body and a mass center balance mechanism, and dynamic balance stability during mechanism operating can be achieved. The polishing shaft assembly is composed of a low-friction air cylinder, a rotary ball spline and a polishing hollow shaft. The polishing hollow shaft can inject a polishing solution to a polishing disc during polishing, and therefore dynamic-pressure and static-pressure polishing is achieved. The influence of friction force on the polishing shaft of a pure rolling connection manner under pressure control is low, and therefore high control precision is achieved.

Owner:TIANJIN UNIV

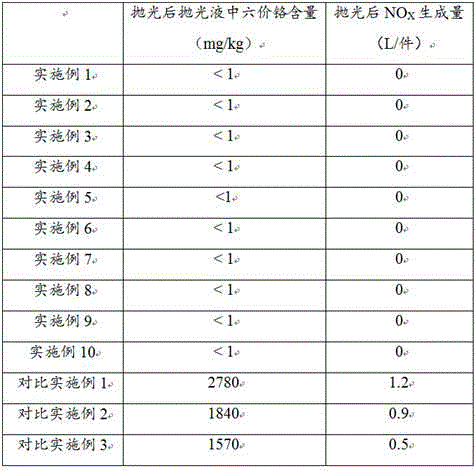

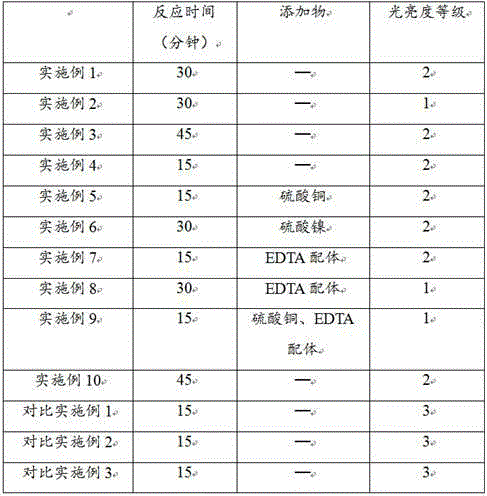

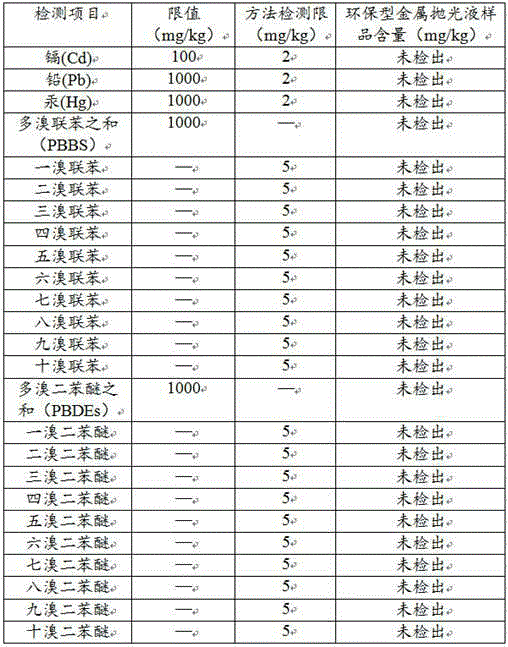

Preparation of environment-friendly metal polishing solution

The invention relates to the field of application of a metal polishing solution. A preparation method of the metal polishing solution comprises the following steps: uniformly mixing 8-15 part of organic acid and 4-7 parts of organic alkali by weight, adding 2-5 parts of surfactant, 0.2-1 part of water-soluble organic bright assistant and 1-3 parts of inorganic salt by weight in the mixture, and adding water to stir so as to obtain the metal polishing solution, wherein the metal polishing solution mainly comprises the surfactant, the organic acid, the organic alkali, the water-soluble organic bright assistant and the inorganic salt and has the pH of 6-8. The adding of all the components and the polishing operating process are carried out according to the strict sequence. The surface brightness and definition of a metal workpiece polished by adopting the metal polishing solution reach the mirror plane effect, so that the production cost is greatly reduced. The safety protection requirements to employees during the production process are low, the corrosion to equipment is small, and the environmental pollution is greatly reduced by adopting the metal polishing solution.

Owner:ZHEJIANG HUMO POLISHING GRINDER MFG

Rigid endoscope

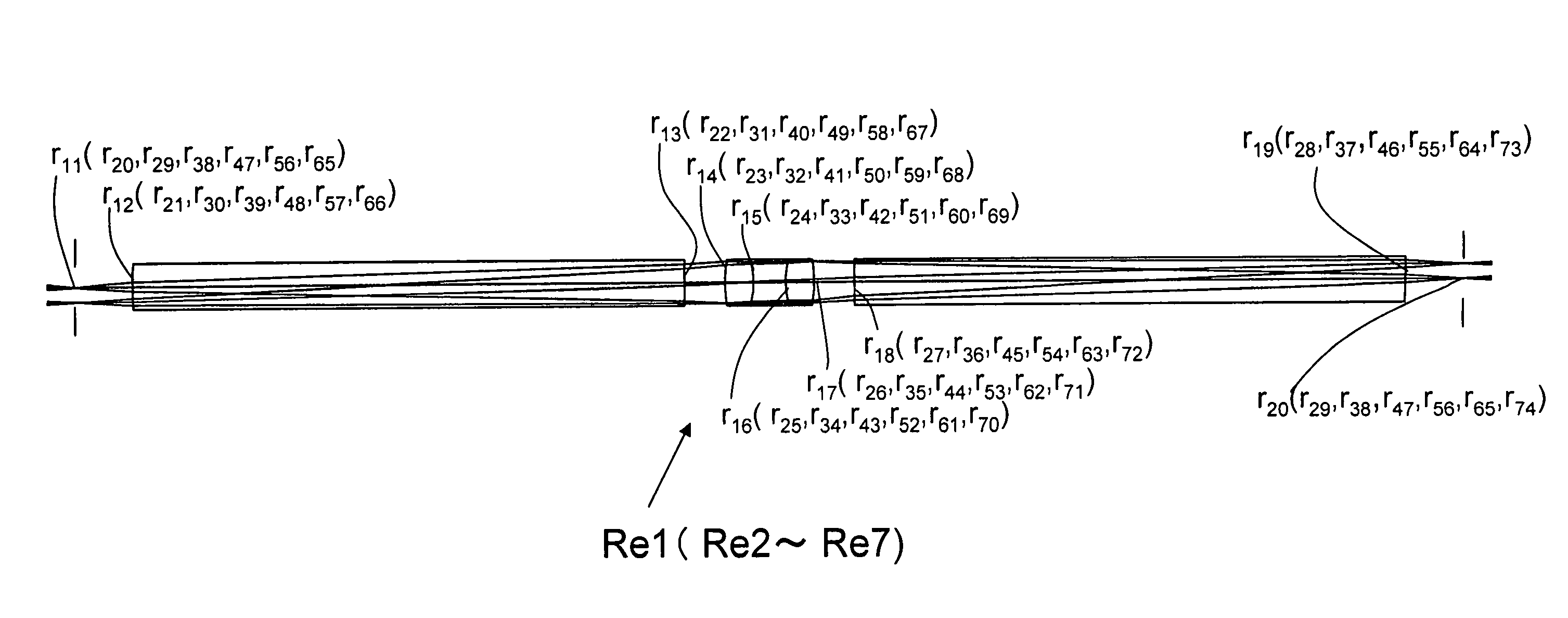

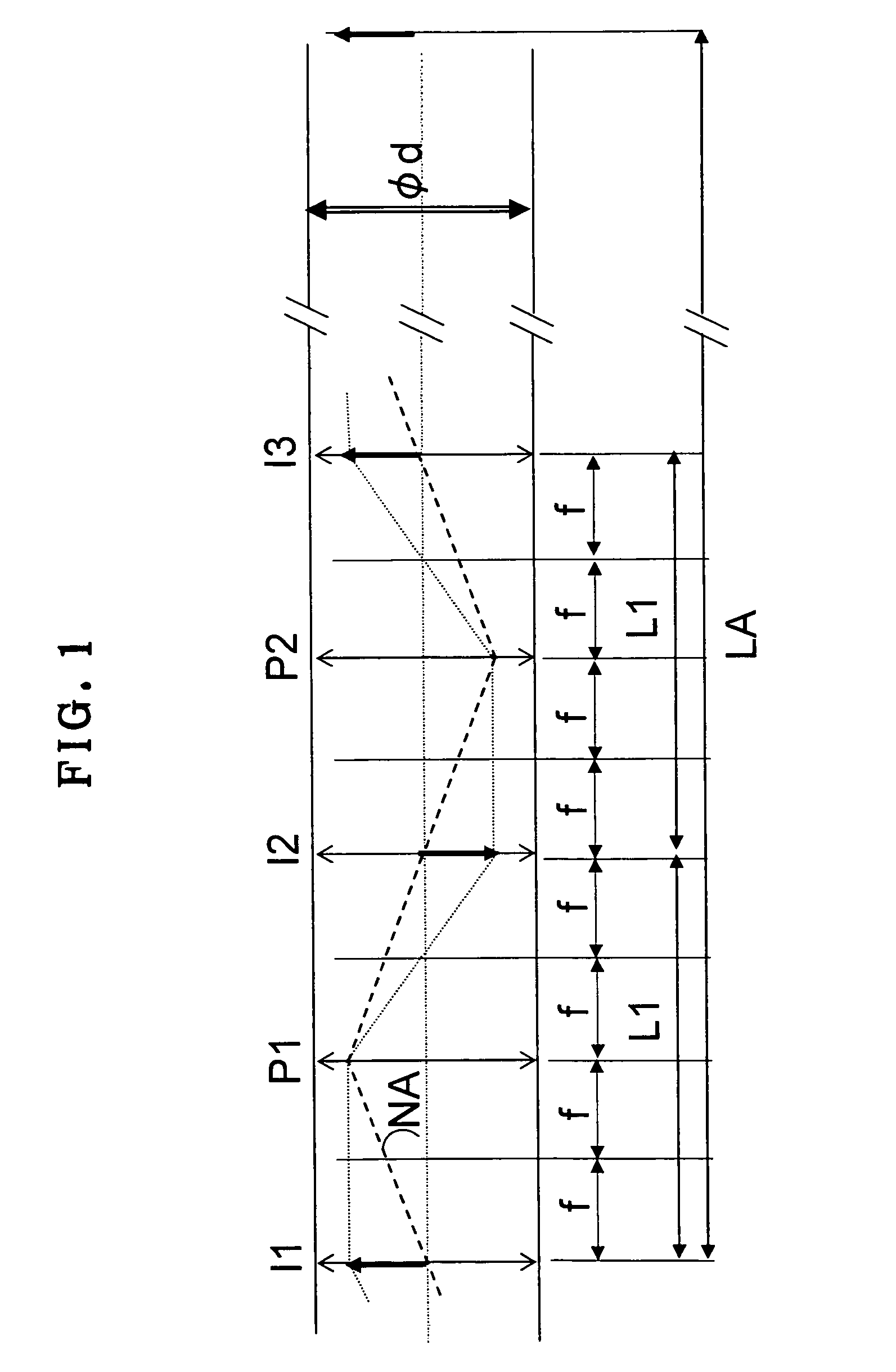

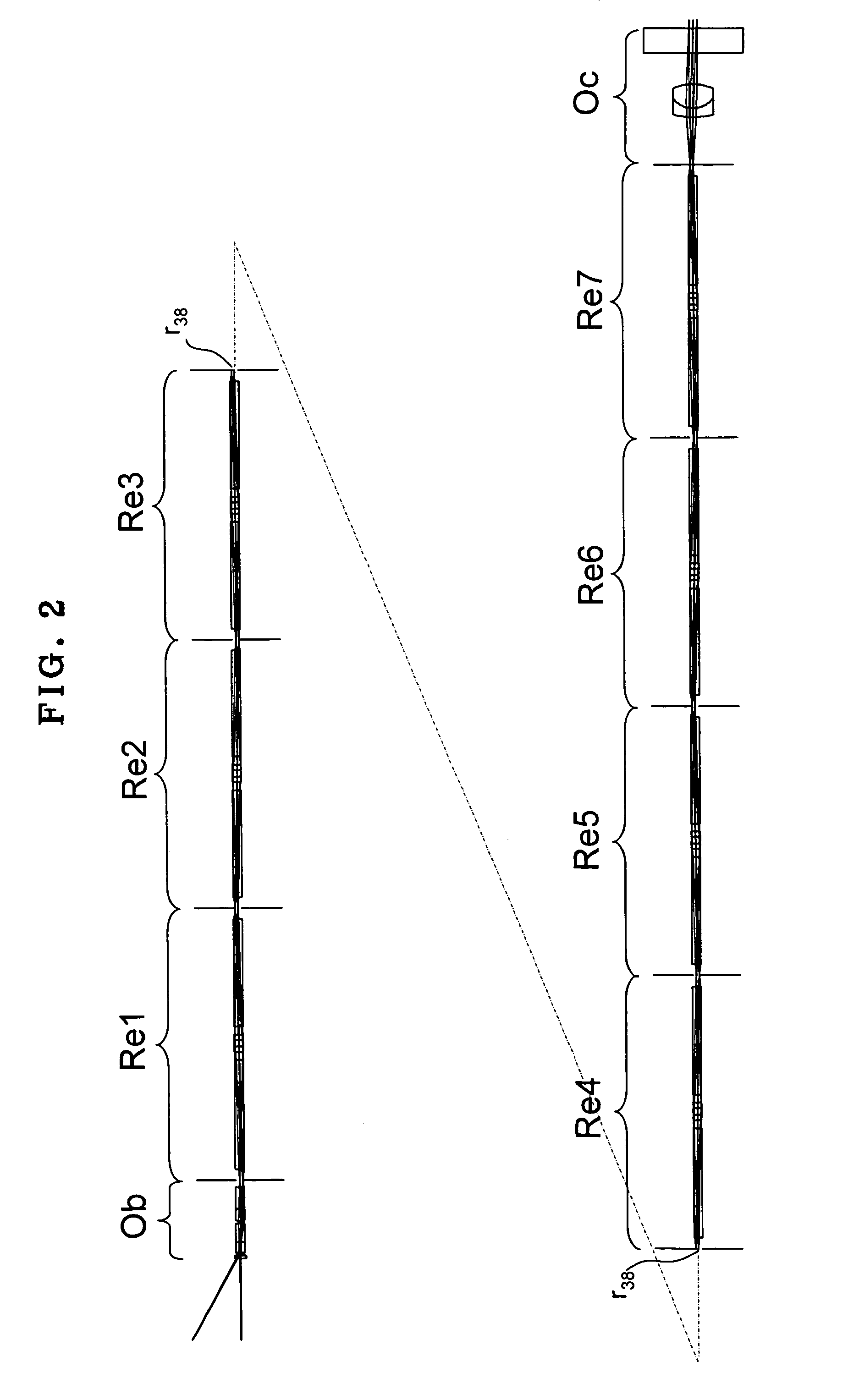

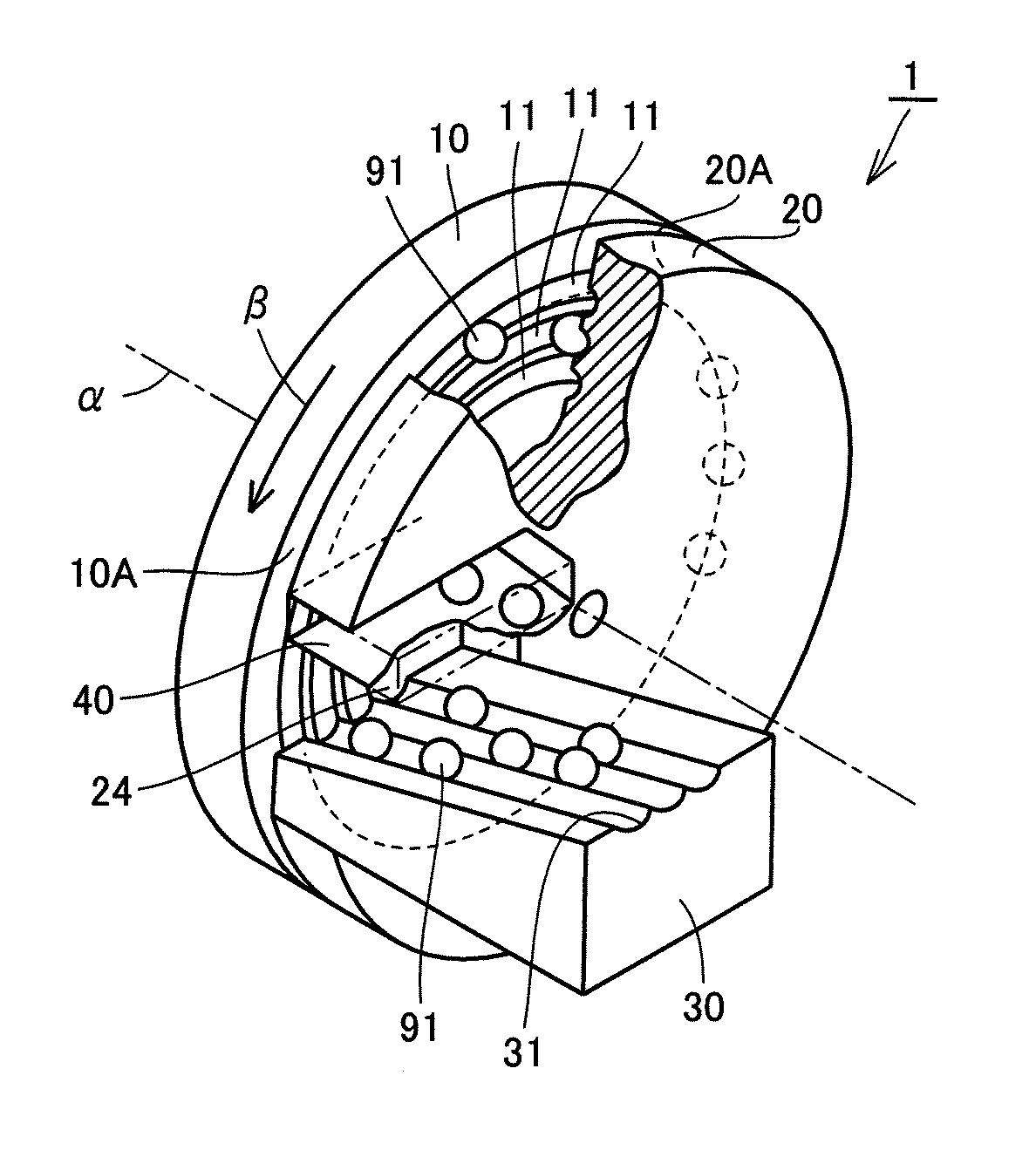

The invention provides a rigid endoscope relay optical system that can be fabricated at lower costs while its brightness is kept intact by reducing parts count. The rigid endoscope optical system has an elongate insert and is adapted to implement image transfer using relay lenses Re1 to Re7. The relay lenses Re1 to Re7 each have at least two rod lenses and satisfy nd>2, where nd stands for the refractive index on d-line basis of each rod lens in the relay lens.

Owner:OLYMPUS CORP

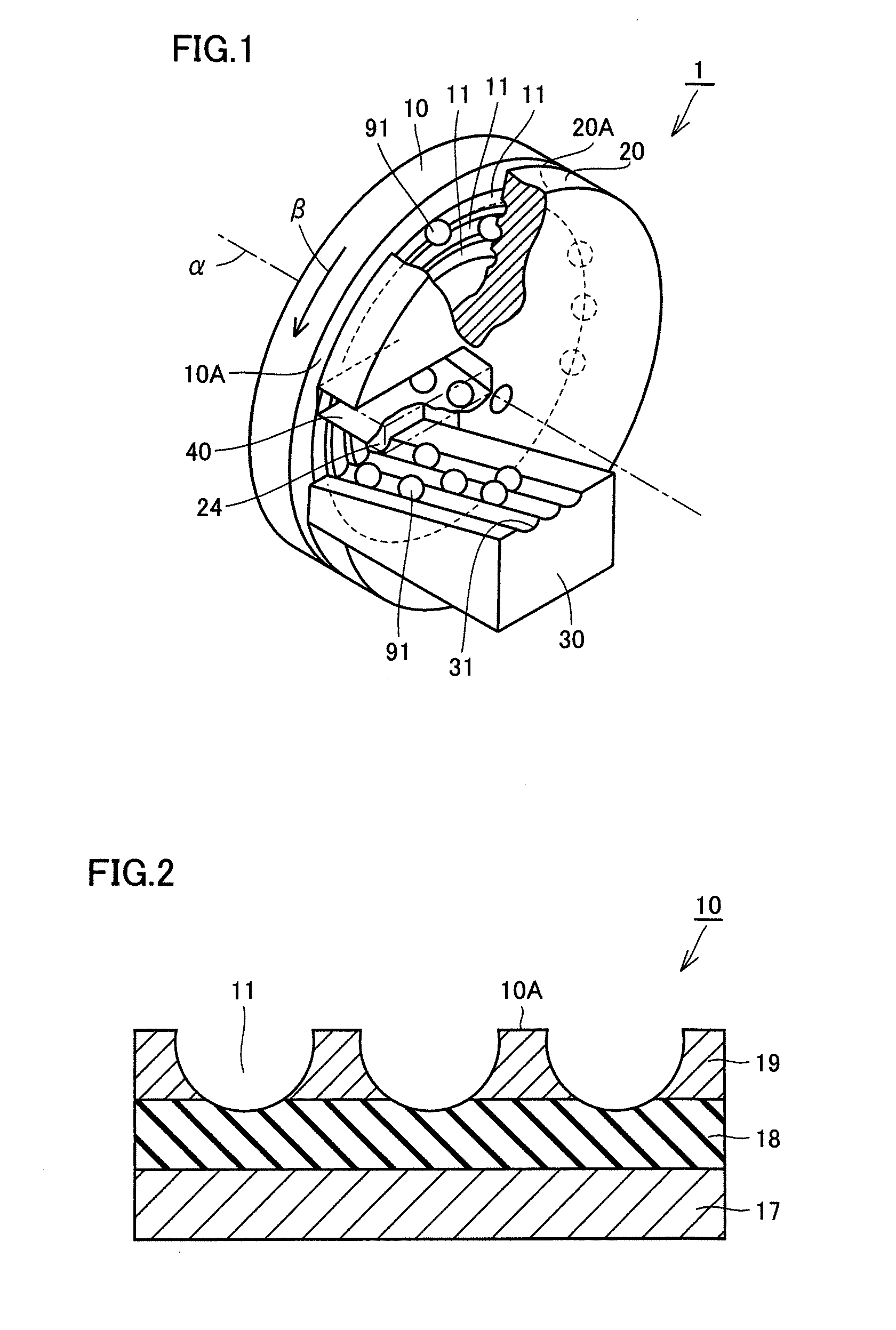

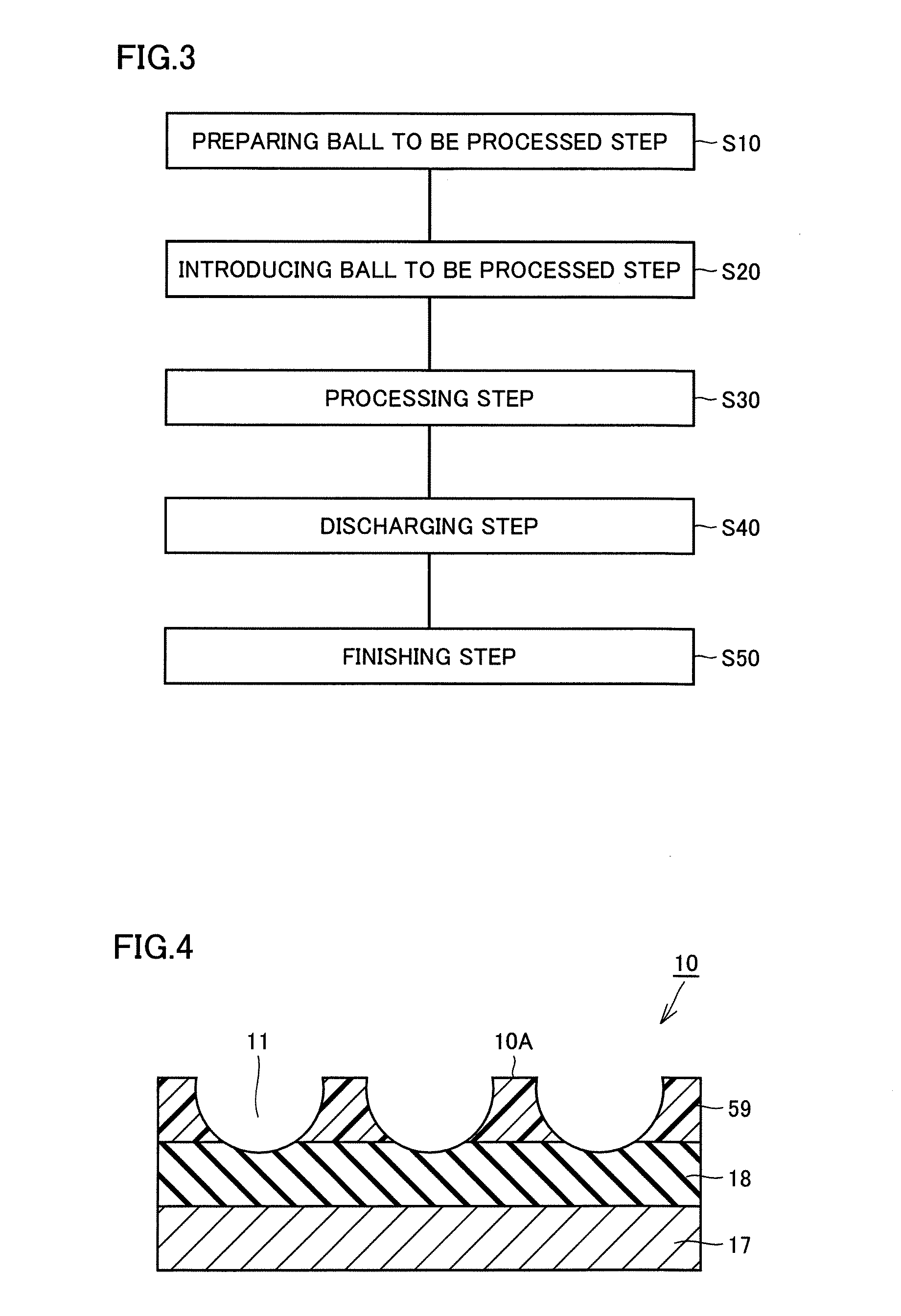

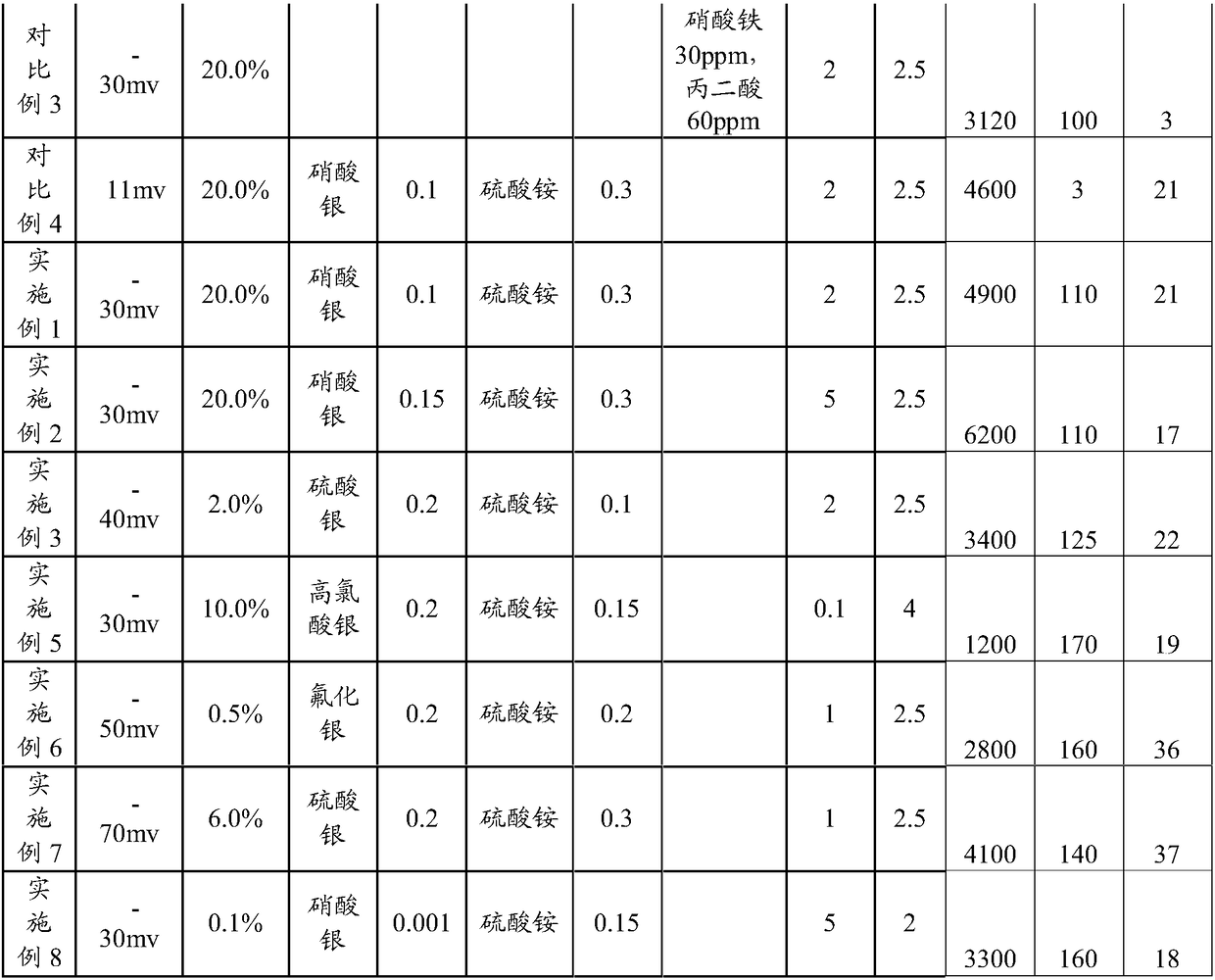

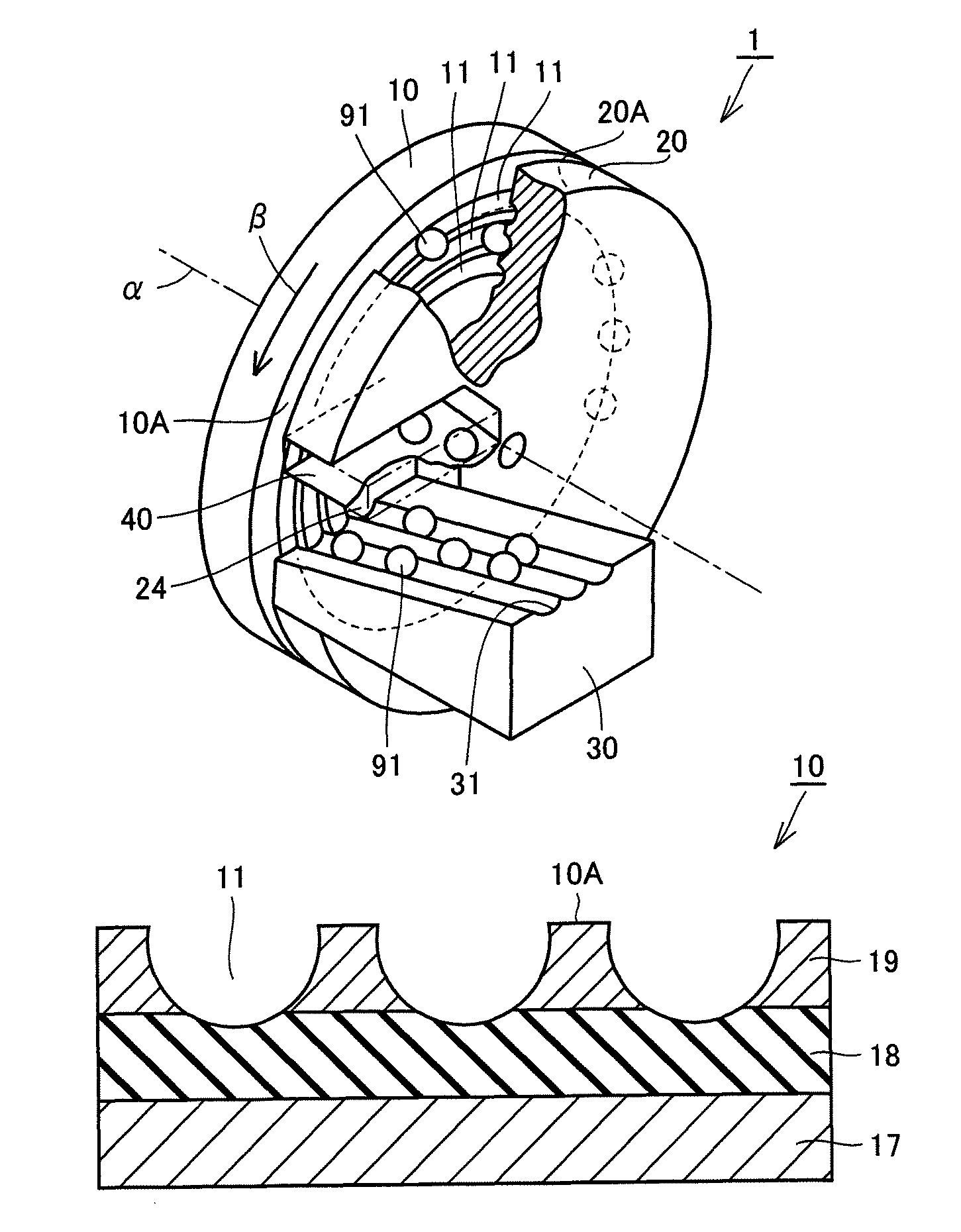

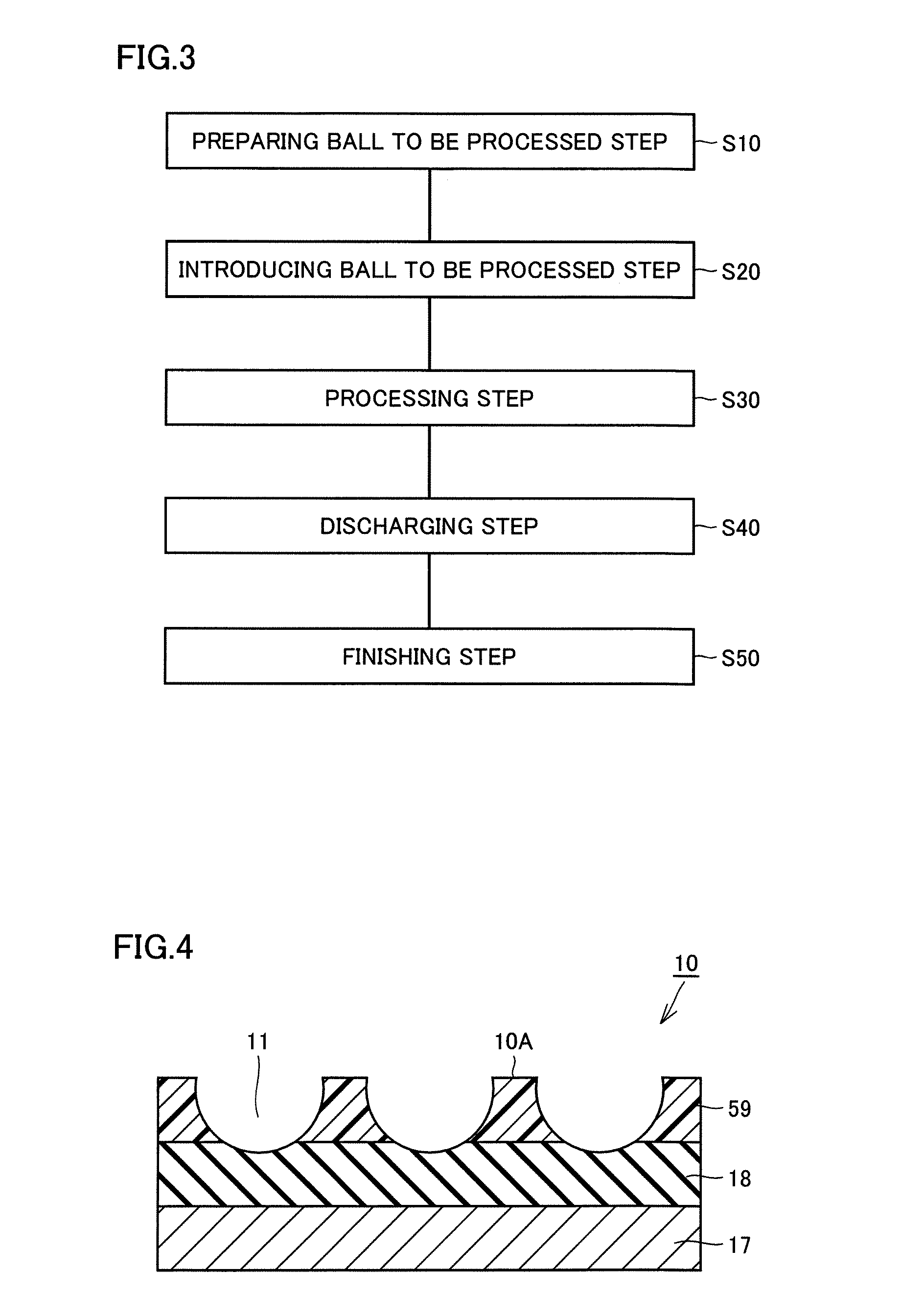

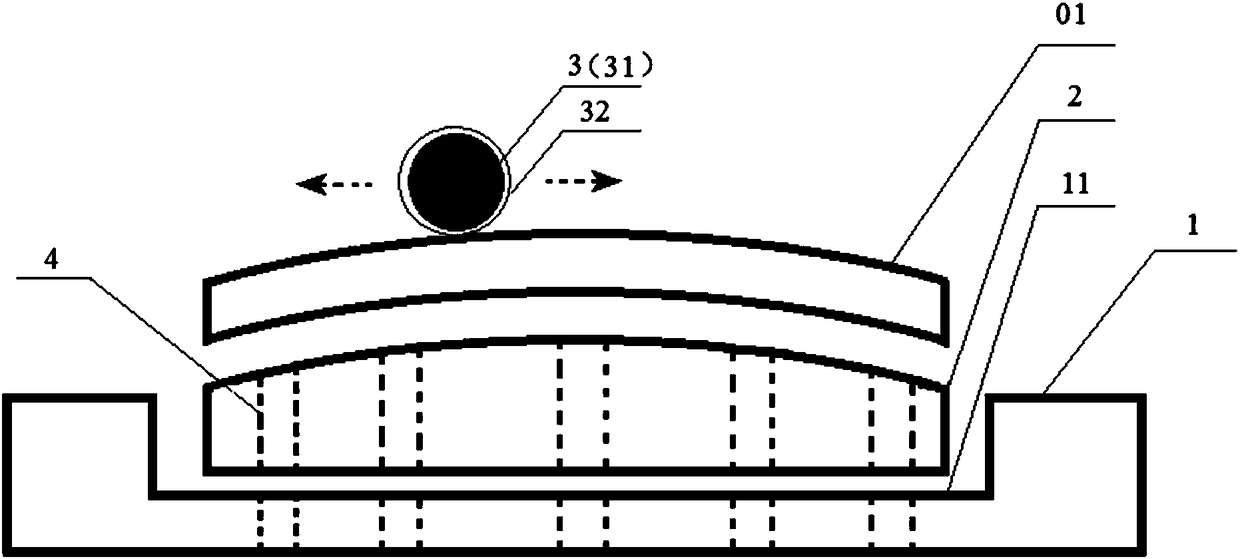

Spherical body polishing apparatus, method for polishing spherical body and method for manufacturing spherical member

InactiveUS20110177760A1Reduce polishing costsEdge grinding machinesSpherical surface grinding machinesEngineeringHardness

A spherical body polishing apparatus capable of reducing polishing costs includes a rotating disk having a rotating disk polishing surface and a fixed disk having a fixed disk polishing surface opposed to the rotating disk polishing surface. The rotating disk polishing surface is capable of relative rotation while keeping being opposed to the fixed disk polishing surface. The rotating disk polishing surface has a groove portion formed therein and extending circumferentially along the rotation. The rotating disk having the groove portion therein includes an abrasive grain layer having a higher hardness than that of a material ball which is a spherical body and a holding layer formed on the abrasive grain layer and having a lower hardness than that of the abrasive grain layer. The groove portion is formed to penetrate the holding layer in a depth direction and to reach the abrasive grain layer.

Owner:NTN CORP

Production method for mixed grinding material

ActiveCN102241959AReduce surface damageImprove surface finish qualityOther chemical processesSiphonHybrid type

The invention relates to a novel production method for a mixed grinding material. The method comprises the following steps: mixing zirconium silicate and alumina; carrying out ball milling on the mixture so as to obtain mixed micro-powder; putting the mixed micro-powder, water and a dispersant into a sorting barrel and standing the mixture for settlement after stirring; carrying out sorting, wherein two sub-steps are included, namely, a) sucking out a slurry on the upper layer of the sorting barrel with a siphon, adding clear water to the sorting barrel until the mixture reaches the initial liquid level before siphoning, and carrying out stirring, settling and siphoning so as to obtain particles of a grade, and b) adding the dispersant and clear water into the sorting barrel until the mixture reaches the initial liquid level before siphoning and repeating the steps of stirring, settling and siphoning so as to obtain particles of another grade; drying the obtained particles with different grades so as to obtain a finished product. The mixed grinding material produced in the invention enables damage of micro-powder to the surface of a ground material in grinding to be substantially reduced and plays a very critical role in improving the quality of surface polishing of an object and in reducing polishing cost.

Owner:无锡成旸科技股份有限公司

Stainless steel material polishing agent and preparation method thereof

The invention relates to a polishing agent, in particular to a stainless steel material polishing agent and a preparation method thereof. Each liter of the polishing agent solution is composed of 5-9 g / L of ferric trichloride, 80-150 ml / L of concentrated hydrochloric acid, 30-60 ml / L of concentrated nitric acid, 18-26 g / L of emery, 20-40 ml / L of tetra-polyricinoleate, 12-18 ml / L of organic polymeric tribasic carboxylic acid, 5-12 ml / L of triethanolamine, 30-80 ml / L of ethylene glycol, 10-25 ml / L of composite additives, and the balance water. The polishing agent provided by the invention is environmentally friendly, efficient and convenient to use.

Owner:ANHUI HONGQIAO METAL MFG

Polishing head

The invention discloses a polishing head comprising a cover plate, a main diaphragm, a substrate, a flexible membrane and a retaining ring, wherein the main diaphragm is annular, has elasticity and is fixed on the lower surface of the cover plate; the substrate is fixed on the lower surface of the main diaphragm; the flexible membrane is fixed on the lower surface of the substrate, and the flexible membrane and the substrate limit a lower cavity communicated with the outside; the retaining ring is fixed on the lower surface of the substrate; and the area of the radial cross section of the retaining ring is gradually decreased from bottom to top. According to the polishing head of the embodiment disclosed by the invention, a wafer can be prevented from throwing in the chemical mechanical polishing process, and even and consistent effect can be obtained. In addition, the abrasion of the retaining ring can not lower polishing effect, and thus the retaining ring has longer service life soas to lower polishing cost.

Owner:HWATSING TECH

Aluminum section bar three acid polishing and leveling fog inhibitor for furniture and finishing method thereof

InactiveCN101457362AReduce wear and tearFlat and smooth surface appearancePotassium sulfidePhosphoric acid

The invention discloses a three acid polishing and flattening fog inhibitor used on a furniture aluminum section. The fog inhibitor is made from the following components by weight: 70-85% of phosphoric acid, 6-12% of sulfuric acid, 3-9% of nitric acid, 0.5-3% of boracic acid, 1-5% of potassium sulfide and 1-3% of magnesium oxide. The operation flow of the chemical polishing working procedures comprises the following steps: (1) removing oil stains from surfaces of an aluminum section according to the conventional oil removal working procedures; and (2) chemical polishing: at first, soaking and cleaning the aluminum section with hot water for 4-5min, then polishing in a chemical polishing and flattening fog inhibitor at the temperature of 105-110 DEG C for 4-5min, taking out and cleaning, then soaking and cleaning with 20% of dilute nitric acid by mass percent for 5-8min, and finally oxidizing and sealing holes according to the conventional procedures to obtain a finished product. The fog inhibitor avoids complex mechanical polishing working procedures, and is employed to directly perform three-acid chemical polishing on the aluminum section, which obtains the same process effect as that obtained by the mechanical polishing working procedures, reduces the aluminum section waste and environmental pollution and can significantly lower the production cost.

Owner:HUNAN XINMEIGE INNOVATORY DECORATIVE MATERIAL

Chemical polishing agent for stainless steel product surface polishing, preparation method and polishing method thereof

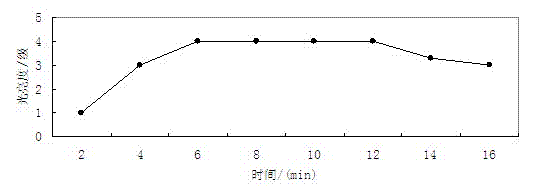

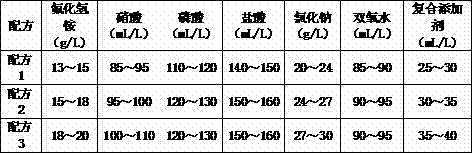

The invention relates to a chemical polishing agent for stainless steel product surface polishing, a preparation method and a polishing method thereof. The chemical polishing agent is prepared by adding 13-20 g / L of ammonium bifluoride, 85-110 mL / L of nitric acid, 110-130 mL / L of phosphoric acid, 140-160 mL / L of hydrochloric acid, 20-30 g / L of sodium chloride, 85-95 mL / L of hydrogen peroxide, and 25-40 mL / L of a composite additive to water, wherein the composite additive contains 4-6 g / L of hexamethylenetetramine, 10-15 g / L of polyethylene glycol, 10-12 g / L of urea, 5-7 g / L of sulfosalicylic acid, and 4-8 g / L of an OP emulsifying agent. According to the present invention, surface flatness and glossiness of a stainless steel work-piece are increased, consumption of a large amount of electric energy is not required, chromic anhydride toxic substances are not generated, and waste water treatment requirements are reduced.

Owner:GUANGXI LIUGONG MASCH CO LTD

Package structure and manufacturing method thereof

ActiveUS20170110439A1Reduce lengthReduce riskSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

Provided is a package structure including a substrate, N dies, N first pads, N vertical wires, and a second pad. The N dies are stacked alternatively on the substrate, so as to form a multi-die stack structure. The N dies include, from bottom to top, first to Nth dies, wherein N is an integer greater than 1. The first die is a bottom die, and the Nth die is a top die. The first pads are disposed on an active surface of the dies respectively. The vertical wires are disposed on the first pads respectively. The second pad is disposed on the top die.

Owner:POWERTECH TECHNOLOGY

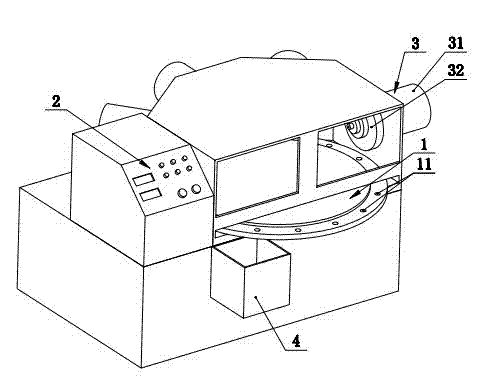

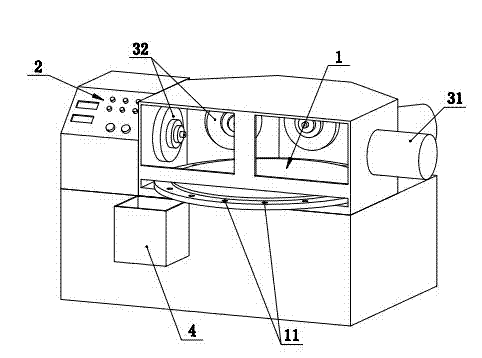

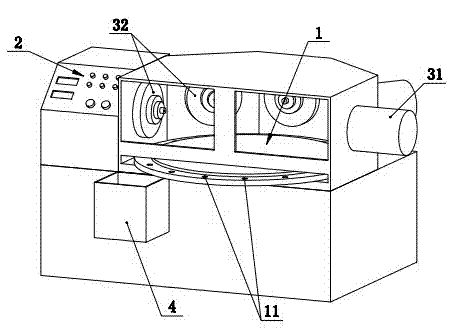

Disc multi-station automatic polishing machine

InactiveCN102335864AImprove processing efficiencyReduce polishing costsPolishing machinesElectric machineryEngineering

The invention discloses a disc multi-station automatic polishing machine. The machine comprises a disc-shaped worktable which can be controlled to rotate, wherein a plurality of machining stations for fixing a workpiece to be machined are uniformly distributed on the circumference on the worktable; a plurality of groups of polishing mechanisms are uniformly distributed on the circumference above the worktable corresponding to the machining stations; each polishing mechanism comprises a motor and a polishing wheel sleeved on an output shaft of the motor; and a plurality of polishing wheels in the plurality of groups of polishing mechanisms are polishing wheels made of different polishing materials. Due to the structure, the plurality of groups of polishing mechanisms are uniformly distributed on the circumference above the worktable corresponding to the machining stations, and the polishing materials of the plurality of polishing wheels in the plurality of groups of polishing mechanisms are distributed anticlockwise circumferentially from coarse to fine, so only the workpiece to be machined is needed to be fixed on any machining station on the worktable, the surface of the workpiece to be machined can be subjected to gradual machining from coarse grinding to fine grinding by rotating a circle of the circumference of the disc-shaped worktable, machining efficiency is high, and polishing cost can be effectively reduced.

Owner:苍南县灵泉抛光机床制造有限公司

Low loss visible-IR transmitting glass-ceramic spinel composites and process

ActiveUS7670685B2Conserve costReduce polishing costsGlass/slag layered productsNatural mineral layered productsMid infraredSpinel

This invention pertains to a composite of Spinel and BGG glass substrates and to process for bonding Spinel to BGG glass. The composite includes a Spinel and a BGG glass bonded together and having transmission in the visible and mid-infrared wavelength region. The process includes the step of heating them together above the softening temperature of the BGG glass, the composite having excellent, i.e., typically in excess of about 80%, transmission in the 0.5-5 wavelength region.

Owner:NAVY U S A AS REPRESENTED BY THE SEC OF THE THE

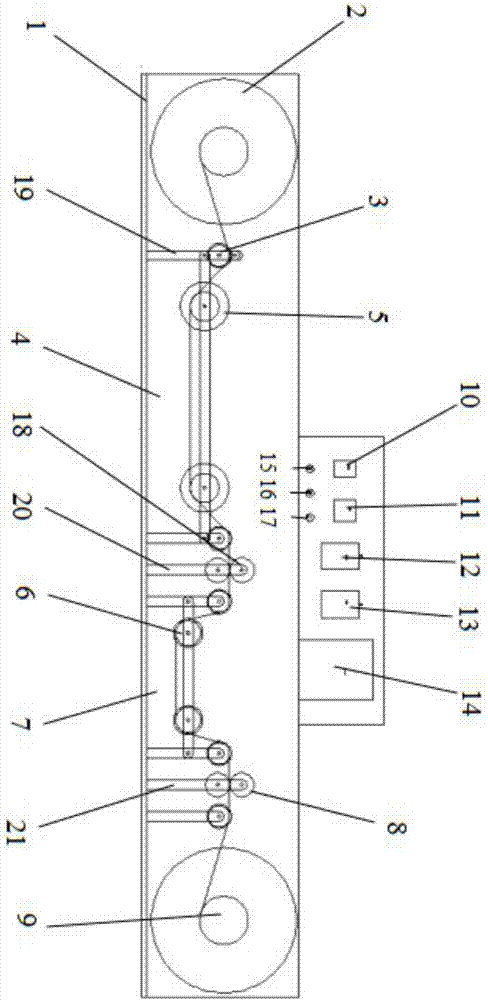

Strip polishing equipment

InactiveCN107971917AReduce polishing costsImprove polishing efficiencyEdge grinding machinesPolishing machinesEngineeringMechanical engineering

The invention discloses strip polishing equipment. The strip polishing equipment comprises tension motors, a polishing device, a cleaning device, wire winding motors and controllers, wherein the tension motors, the polishing device, the cleaning device and the wire winding motors are sequentially arranged along the transmission direction of a strip; the strip sequentially winds around the tensionmotors, the polishing device, the cleaning device and the wire winding motors; and the controllers are electrically connected with the tension motors and the wire winding motors. According to the strip polishing equipment, the strip with a long distance can be polished at one time, a polishing solution cannot be leaked externally, so that the damage to a human body and the pollution to the environment are reduced; and through the processes of polishing by the polishing liquid, cleaning and polishing by a felt wheel, the strip is efficiently polished, the polished strip is glossy and bright andis uniform in texture, the structures of all parts are simple, the machining efficiency is high and the cost is low.

Owner:北京鼎臣世纪超导科技有限公司

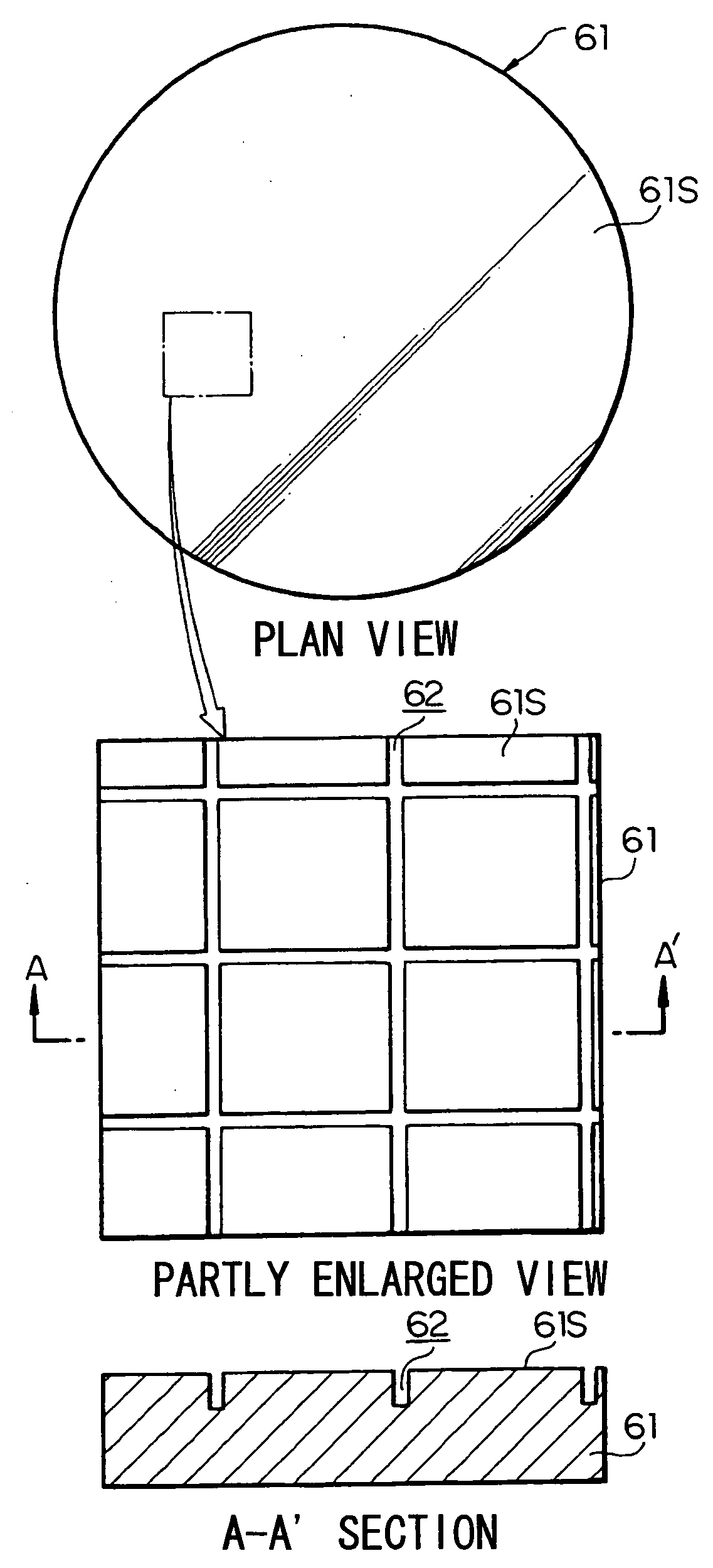

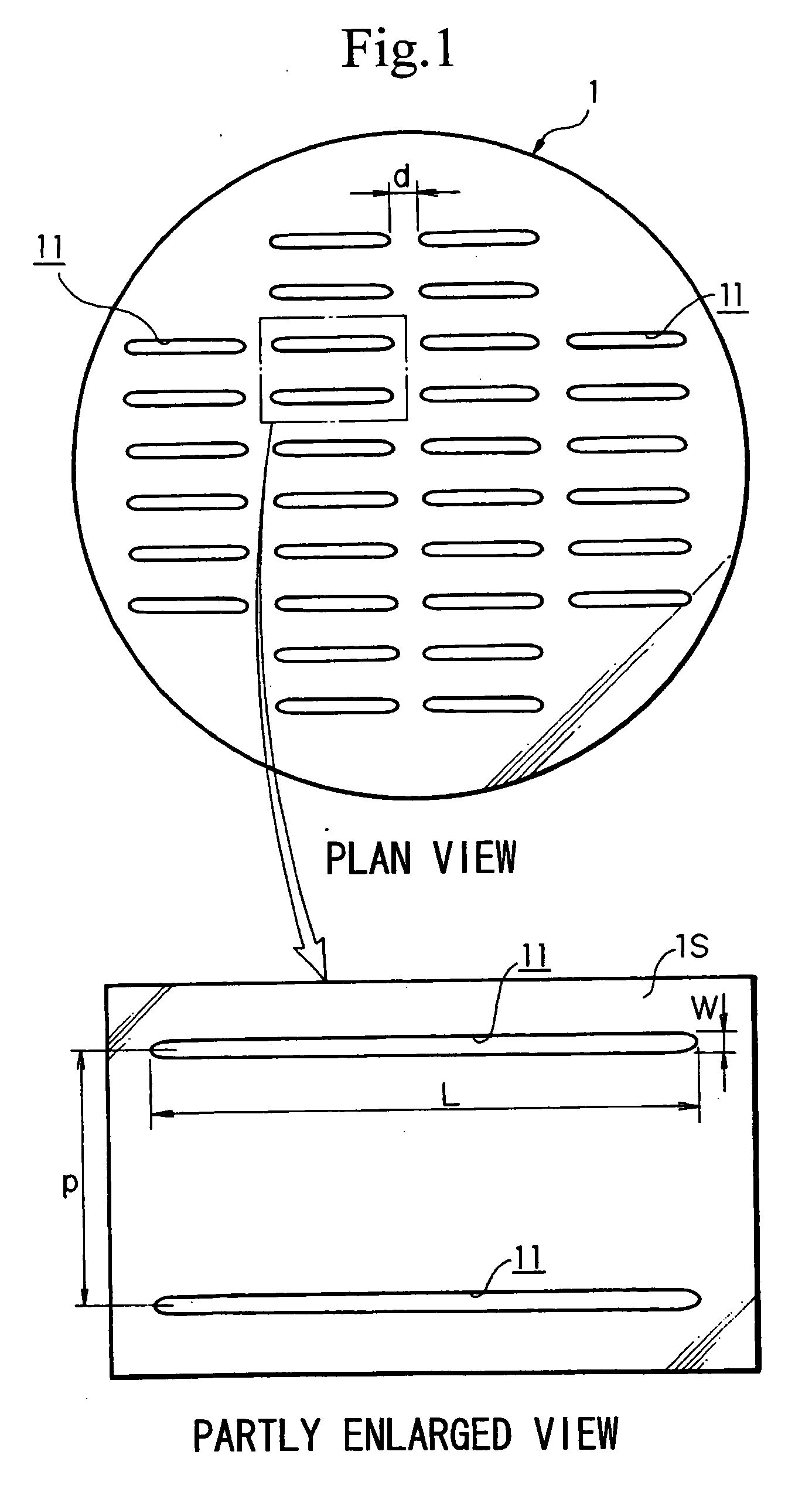

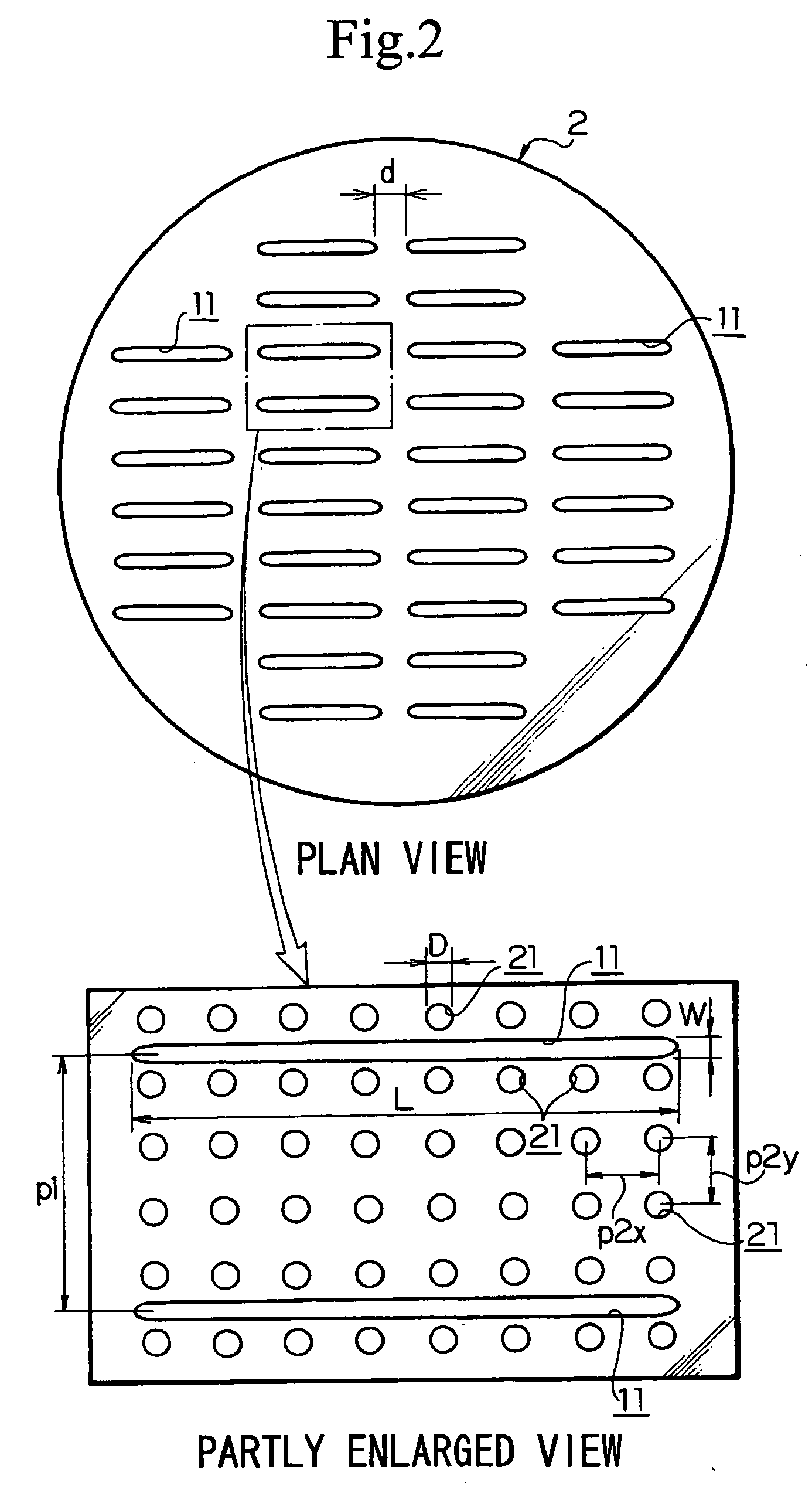

Polishing pad, polishing apparatus, and polishing method

InactiveUS20050153633A1Easy to disassembleIncrease resistanceAbrasion apparatusSemiconductor/solid-state device manufacturingEngineeringSmall hole

A polishing pad which ensures that a work can be easily removed from the polishing pad surface after polishing, the amount of a polishing liquid used for polishing can be reduced, and the production cost of the polishing pad can be lowered. A first polishing pad (1) for polishing a work is provided with a plurality of slots (11) piercing the first polishing pad (1) in a sa direction, the length in the longitudinal direction of the slots (11) being preferably not less than 20 mm, the pitch in the width direction of the slots (11) being preferably less than 100 mm, and small holes (not shown) may be provided in addition to the slots (11).

Owner:SONY CORP

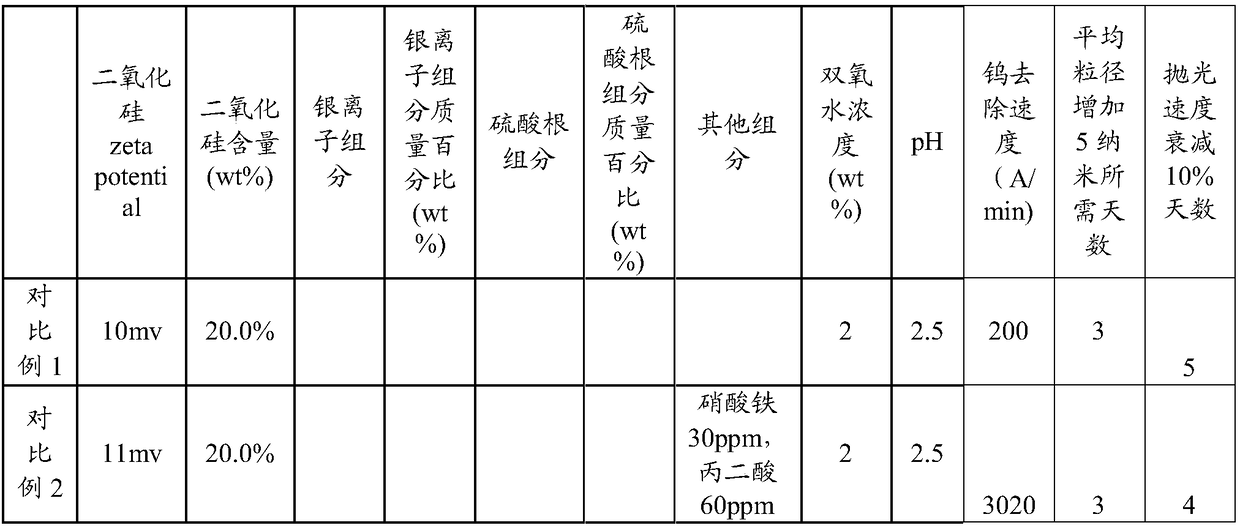

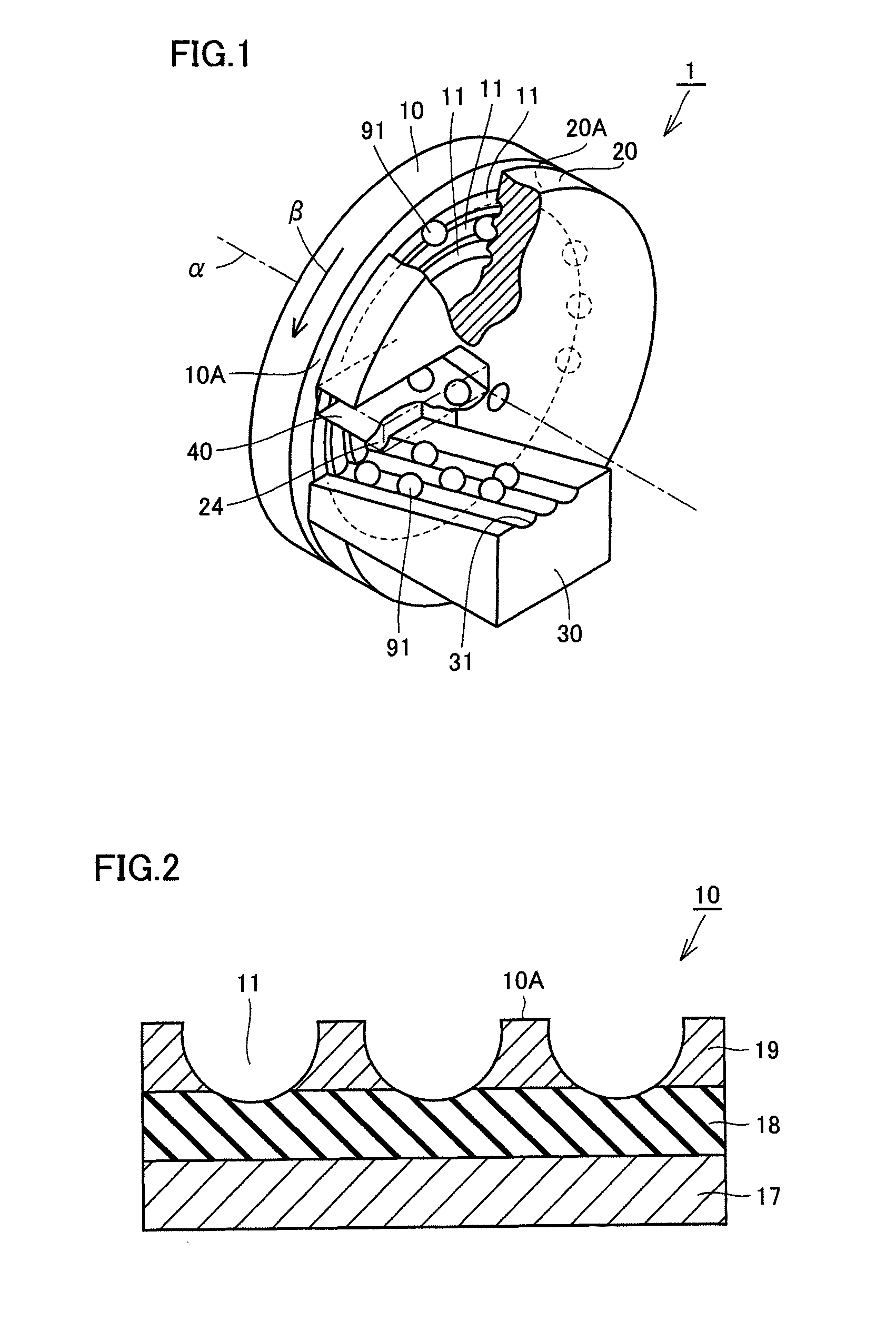

Chemical mechanical polishing liquid

InactiveCN108250976AImprove stabilityImprove polishing stabilityPolishing compositions with abrasivesCompound (substance)SULFATE ION

The invention provides a chemical mechanical polishing liquid, which contains water, abrasive particles with negative charges on the surface, a compound capable of producing silver ions, a compound capable of producing sulfate ions, and a peroxide. According to the present invention, by changing the charge on the surface of the silica abrasive particles, the stability of the polishing liquid is significantly improved, the polishing stability is further improved, the polishing efficiency is improved, and the polishing cost is reduced.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Spherical body polishing apparatus, method for polishing spherical body and method for manufacturing spherical member

InactiveUS9089947B2Reduce polishing costsEdge grinding machinesSpherical surface grinding machinesEngineeringHardness

A spherical body polishing apparatus capable of reducing polishing costs includes a rotating disk having a rotating disk polishing surface and a fixed disk having a fixed disk polishing surface opposed to the rotating disk polishing surface. The rotating disk polishing surface is capable of relative rotation while keeping being opposed to the fixed disk polishing surface. The rotating disk polishing surface has a groove portion formed therein and extending circumferentially along the rotation. The rotating disk having the groove portion therein includes an abrasive grain layer having a higher hardness than that of a material ball which is a spherical body and a holding layer formed on the abrasive grain layer and having a lower hardness than that of the abrasive grain layer. The groove portion is formed to penetrate the holding layer in a depth direction and to reach the abrasive grain layer.

Owner:NTN CORP

Processing making technology for gold plated brick

The invention discloses a processing making technology for a gold plated brick. The technology is characterized by comprising the following steps of: blank pressing, glazing, printing, microcrystalline glazing, roasting, gold plating, and polishing, thus obtaining a finished product. Through improvement, the invention can achieve the effects that: 1. the previous twice firing is changed into one time firing, one cubic meter natural gas energy can be saved in terms of each square meter (about 1.3m<3> of natural gas can be saved for per m<2> of tile, i.e. 3.2 yuan / m<2>); 2. the price difference between microcrystalline glaze and microcrystalline powder is about 6.5 yuan for per m<2> of tile; 3. in the process, microcrystalline glaze is improved into glaze pouring type glaze fling, the operation is very simple, and the microcrystalline powder has to be stacked by a machine, the process can be greatly affected by tiles, such as different brick blank thickness, varying brick blank flatness and the like, thereby seriously affecting quality; 4. compared with traditional technologies, 5 yuan can be saved by per m<2> of tile in terms of labor and electric charge; and 5. for the surface hardness, the firing temperature of microcrystalline glaze is at about 1200DEG C, so that the surface hardness is much higher than that of microcrystalline powder, with the firing temperature of microcrystalline powder being about 1020DEG C. Thus, the product is not easy to be worn away.

Owner:夹江县长城建陶厂

Polishing device and polishing method of 3D glass board

PendingCN108098556AEasy to debugHigh precisionPolishing machinesSupport wheelsEngineeringCircular surface

The invention provides a polishing device of a 3D glass board. The 3D glass board is a glass board with two ends in the length or with directions of a board surface bending towards the same direction.The polishing device comprises a high-molecular bottom board, a curved rubber board and a polishing rod. The device further comprises a vacuum air extraction passage used for fixing the 3D glass board during polishing. The high-molecular bottom board contains a cavity used for accommodating the curved rubber board and locating the 3D glass board. The curved rubber board comprises a bent top surface used for supporting the 3D glass board. The polishing rod comprises a cylinder steel core and soft grinding leather fixedly arranged on the external circular surface of the cylinder steel core. Thepolishing rod is arranged above the 3D glass board and drives the polishing rod to rotate through external force such that the soft grinding leather of the polishing rod contacts the 3D glass board in order to perform polishing operation. The polishing rod rotates while performing motion along the bending length direction or the width direction of the 3D glass board. The polishing yield rate of the 3D glass board is greatly increased so that polishing cost is greatly reduced.

Owner:LENS TECH CHANGSHA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com