Manufacturing method of full-stamped and stretched stainless steel water tap

A technology of stamping and stretching and manufacturing methods, which is applied in the field of manufacturing stainless steel faucets, can solve problems such as unguaranteed quality, lack of competitiveness, and long processing cycles, so as to improve surface quality and production efficiency, improve polishing efficiency, and shorten processing cycles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

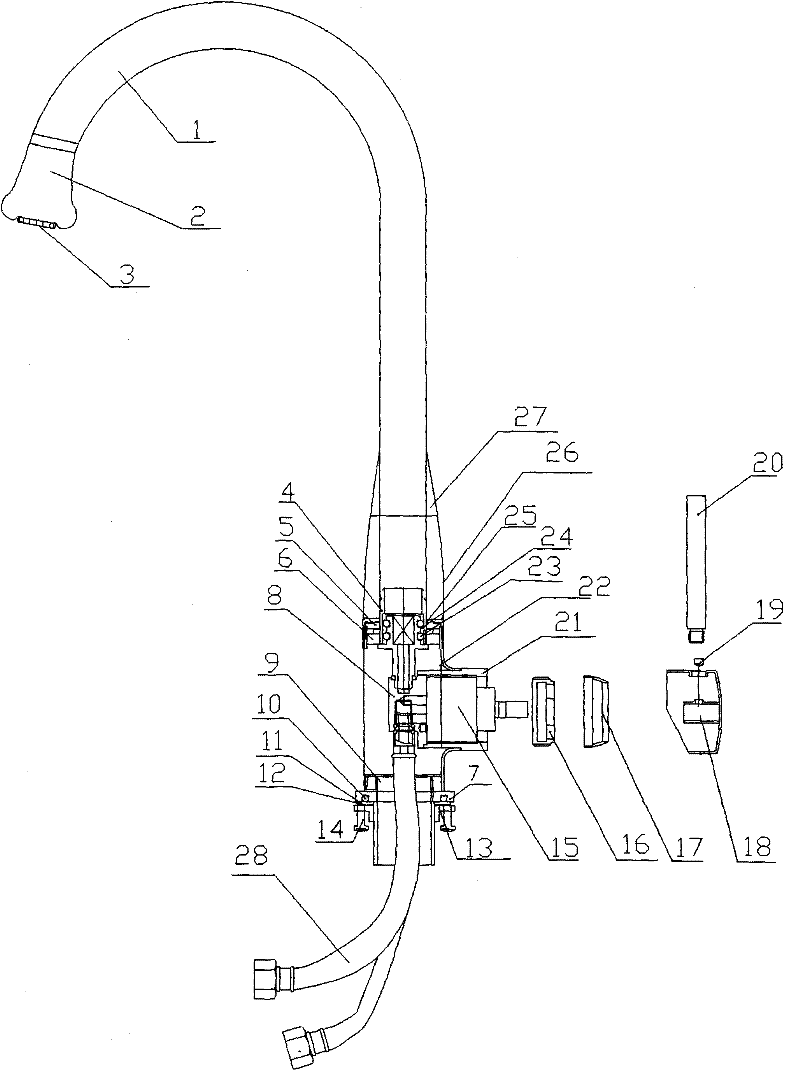

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] Such as Figure 1 to Figure 4b Shown, a kind of manufacturing method of full stamping drawn stainless steel faucet comprises the following process steps:

[0034] A. First make such as figure 1 Stainless Steel Faucet Body Shown:

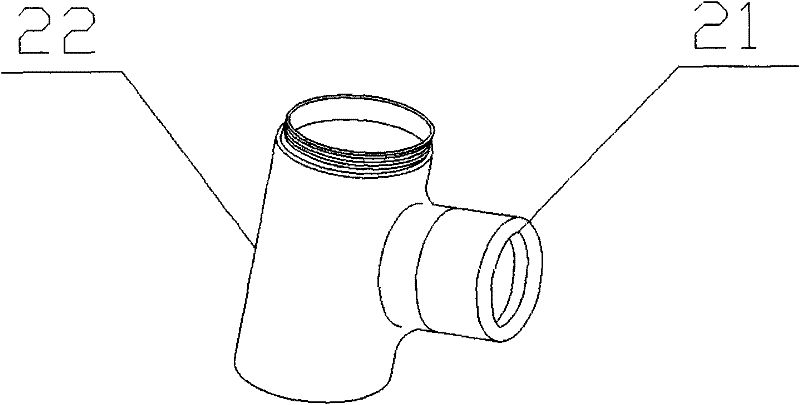

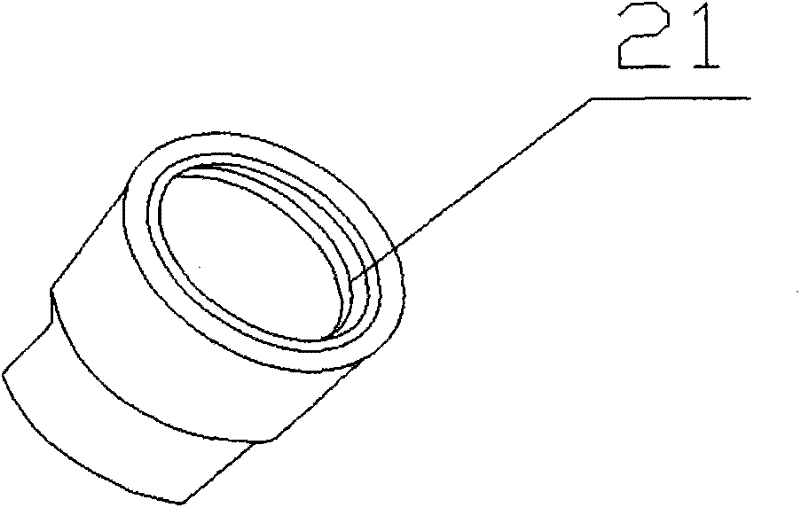

[0035] (1) Put the stainless steel tube into the punching die and punch the pre-hole to make the main body shell 22. The stainless steel tube described in the present embodiment is preferably a round tube;

[0036] (2) Put the main body shell 22 in the boss drawing die to stretch out the boss, stretch and reshape again, shrink the port portion, and reach the required size; the main body shell 22 of the present invention stretches the boss mode It can also be stretched in the form of water swelling or stretched in other forms;

[0037] (3) process the boss plane with a lathe, a cutting machine, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com