Polishing pad, polishing apparatus, and polishing method

a polishing apparatus and polishing pad technology, applied in the direction of grinding/polishing apparatus, grinding machines, manufacturing tools, etc., can solve the problems that the polishing pad as above-mentioned cannot solve the polishing apparatuses, and the production cost of the polishing pad is high, so as to reduce the surface of the polishing pad, prevent the increase of the polishing resistance, and facilitate the removal of work from the polishing pad.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

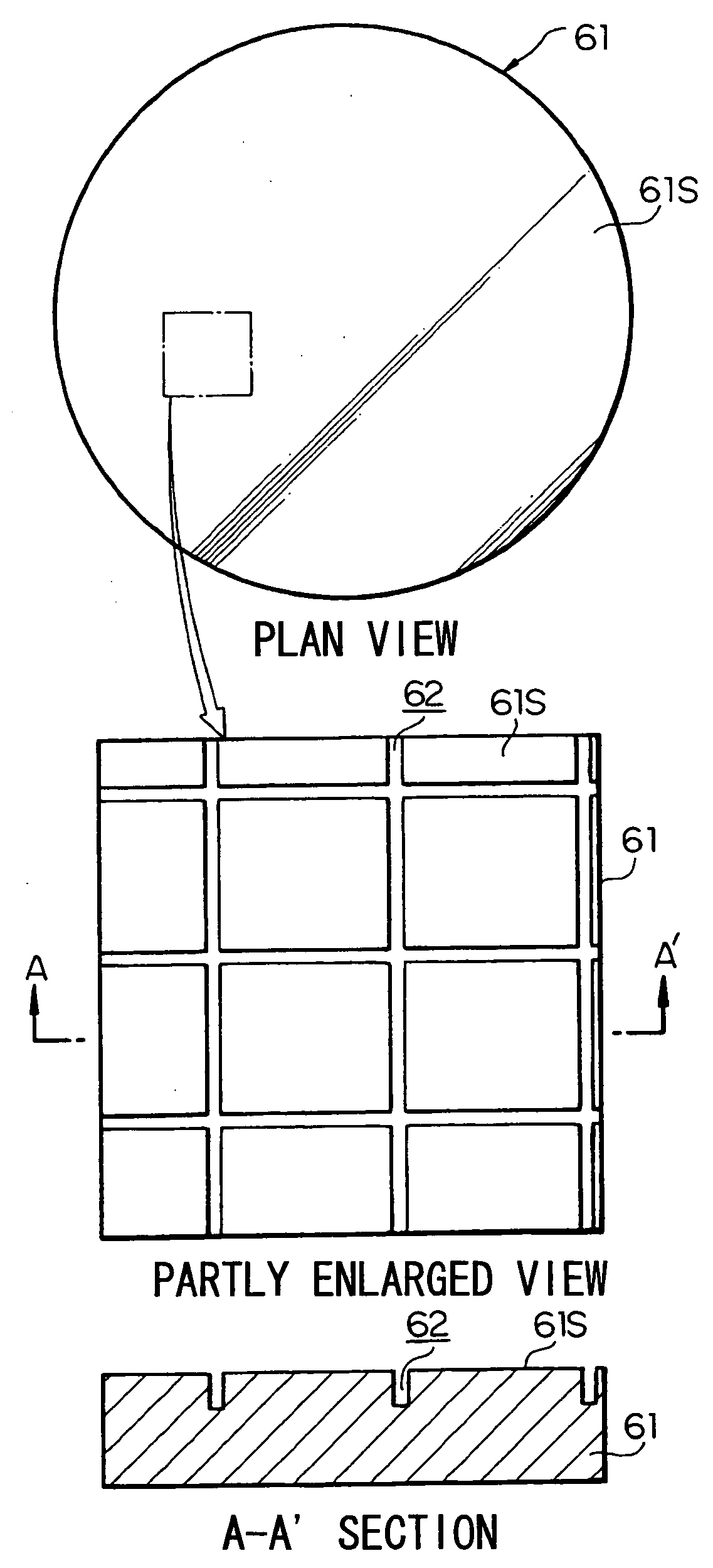

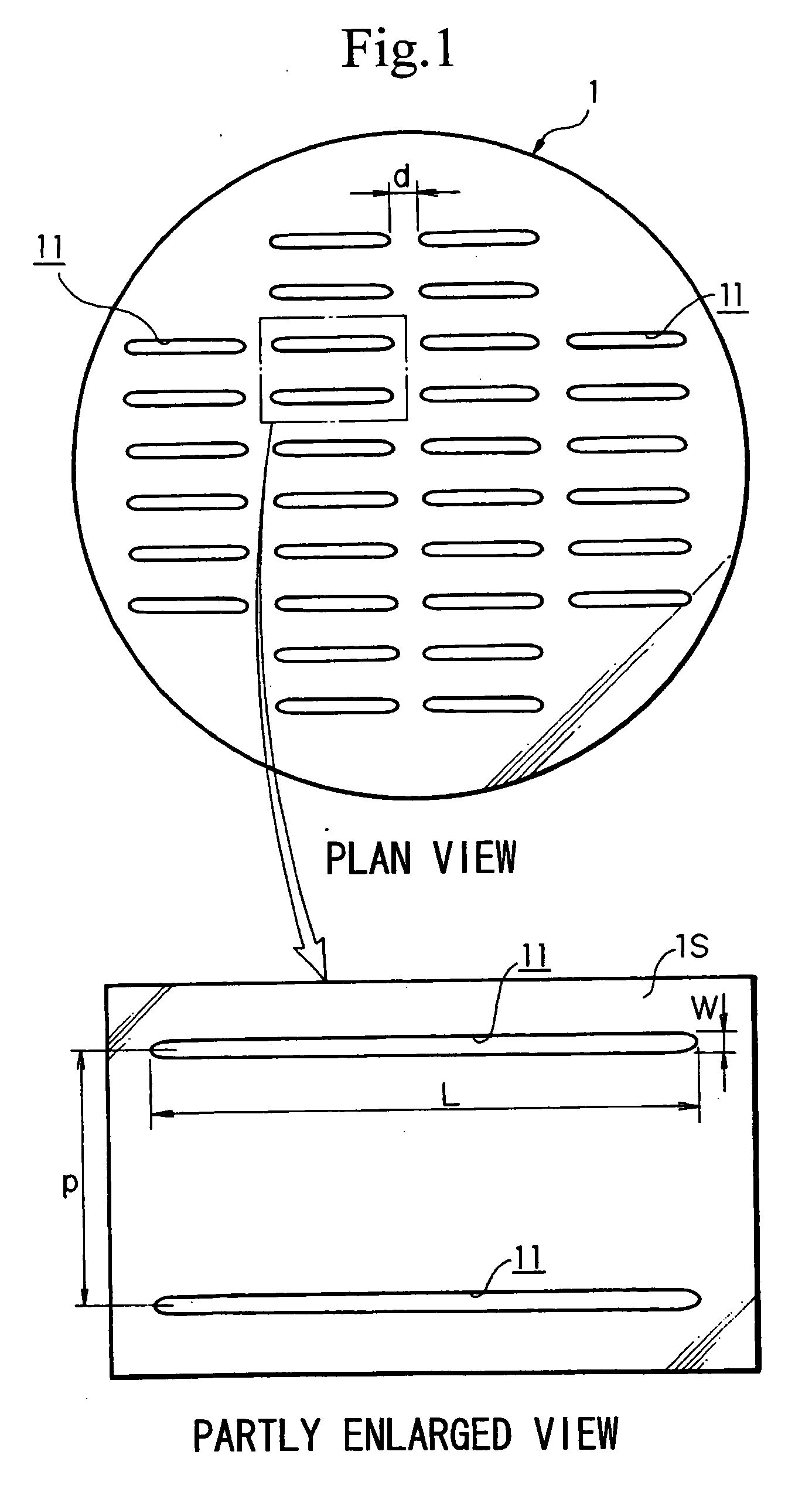

[0037] the first polishing pad according to the present invention will be described referring the plan view and the partly enlarged view shown in FIG. 1.

[0038] As shown in FIG. 1, the first polishing pad 1 is provided with a plurality of slots 11 piercing through the polishing pad 1 in the thickness direction, the slots 11 being aligned in the row direction and the column direction. The polishing pad 1 is formed of a resin, for example, foamed polyurethane or urethane. Its thickness is comparable to those of ordinary polishing pads, and is, for example, about 0.5 to 3.0 mm. The slots 11 are so formed as to be included in the polishing pad 1, and their length L in the longitudinal direction is not less than 20 mm. In addition, the slots 11 are formed at a pitch p which is not less than twice the length in the transverse direction (hereinafter referred to as the width) W thereof and is less than 100 mm. Incidentally, the spacing d in the longitudinal direction of the slots 11 is appro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com