Large immersion type ring polishing machine

A ring polishing machine, immersion technology, applied in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc. The effect of maintaining stable parameters, improving machining accuracy and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment, but should not limit the transformation scope of the present invention with this.

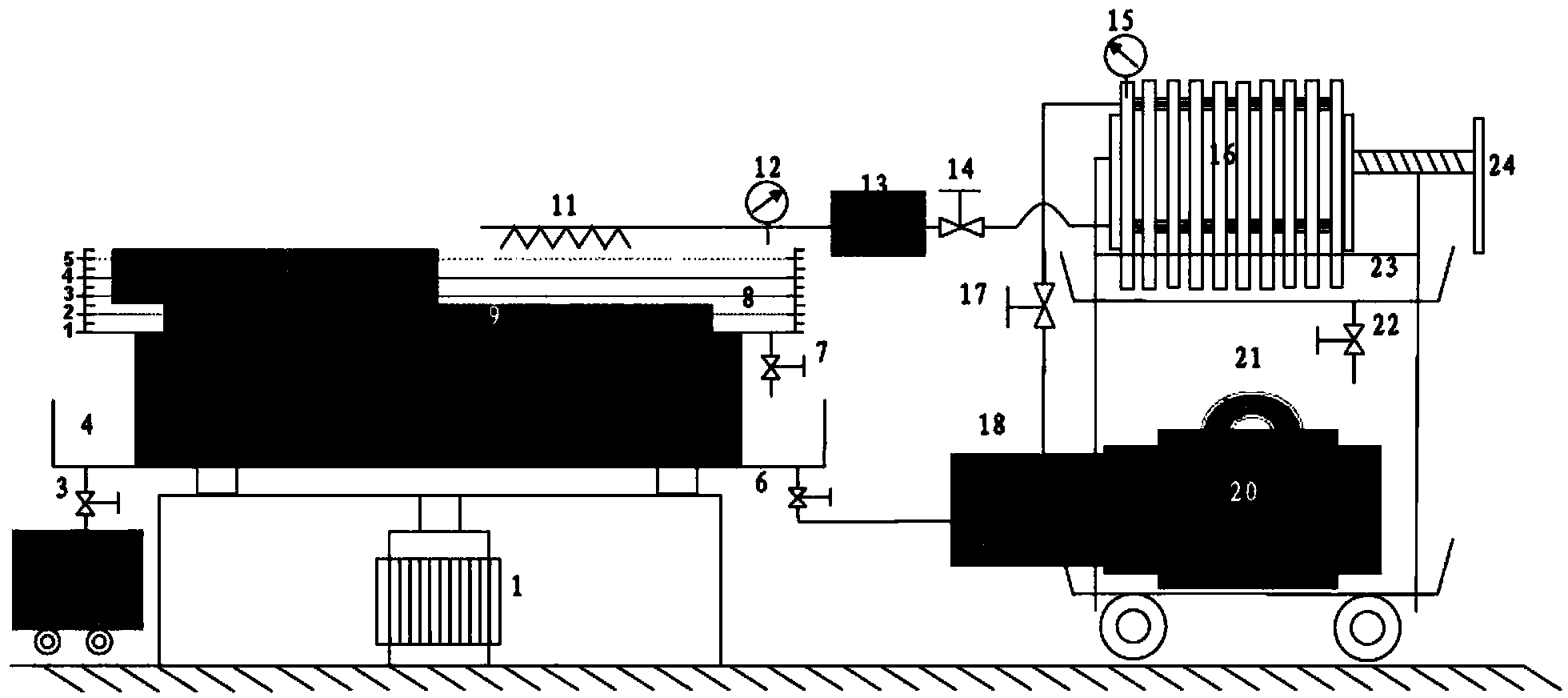

[0020] see first figure 1 , figure 1 It is a structural schematic diagram of the best embodiment of the large-scale submerged ring polishing machine of the present invention. As can be seen from the figure, the large-scale submerged ring polishing machine of the present invention includes a marble polishing disc 5 driven by a motor 1, and the upper surface of the polishing disc is poured One layer of uniform polishing rubber plate 9, a circular glass calibration plate 10 is placed on the polishing rubber plate, and both the polishing rubber plate 9 and the glass calibration plate 10 are placed in a large liquid storage tank 8; the liquid storage tank 8 is Annular groove, its inner circumference is fixed on the circumference of the outer edge of marble polishing disc 5 by fastening screws, and rotates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com