Patents

Literature

174results about How to "Improve adding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special effect processing method, computer equipment and computer storage medium

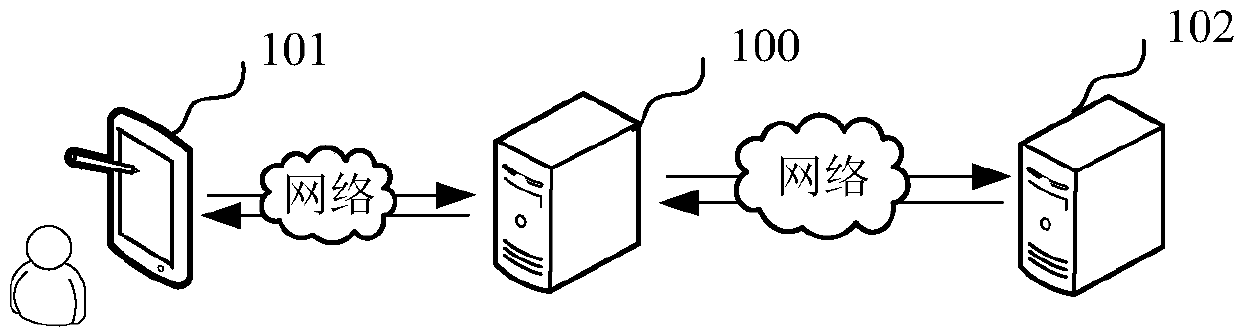

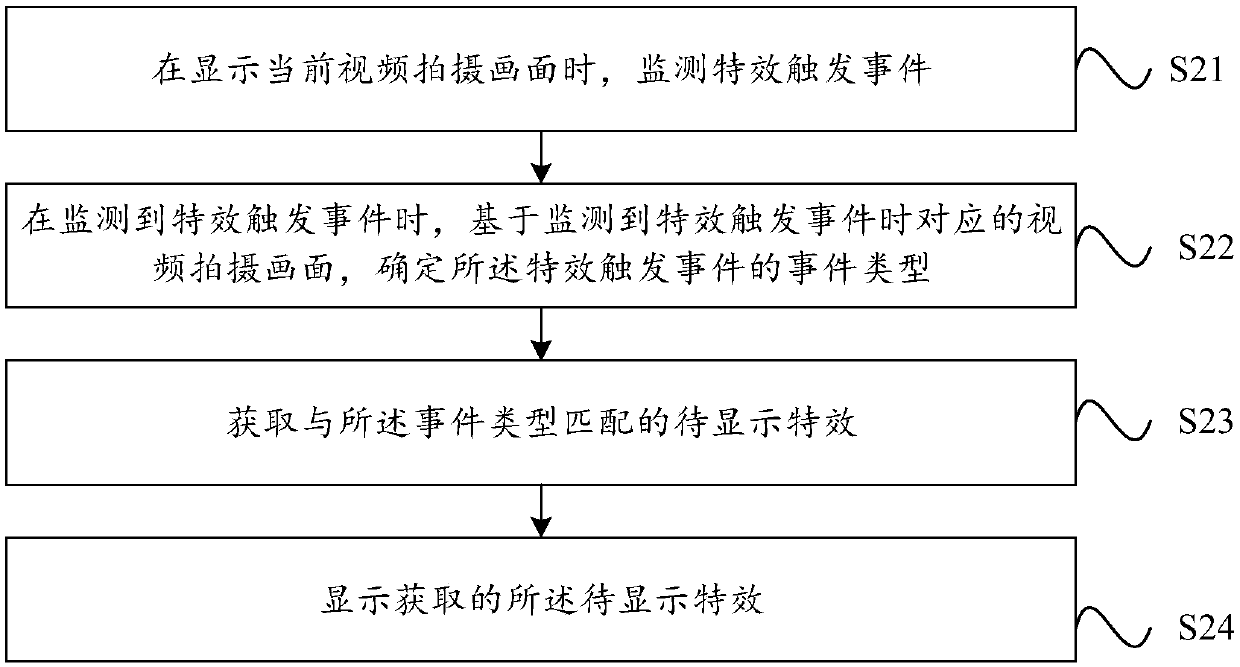

ActiveCN110611776AImprove adding efficiencyImprove display efficiencyTelevision system detailsImage enhancementEvent typeSpecial effects

The invention discloses a special effect processing method, computer equipment and a computer storage medium, and the method in one embodiment comprises the steps: monitoring a special effect triggering event when a current video photographing image is displayed; when a special effect triggering event is monitored, determining an event type of the special effect triggering event based on a corresponding video shooting picture when the special effect triggering event is monitored; acquiring a to-be-displayed special effect matched with the event type; and displaying the obtained special effectto be displayed. According to the method of the embodiment, in the process of playing the video picture, the display of the matched special effect is triggered based on the special effect triggering event, so that the special effect adding and displaying efficiency is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

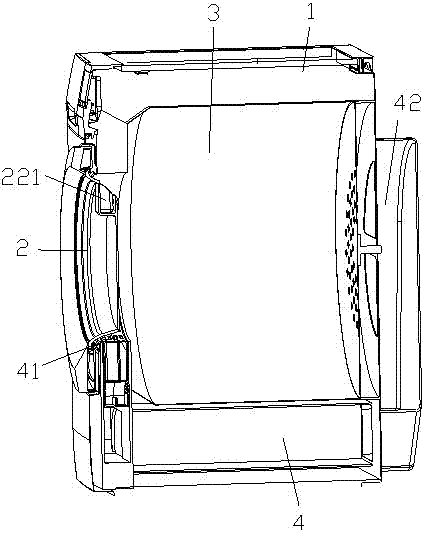

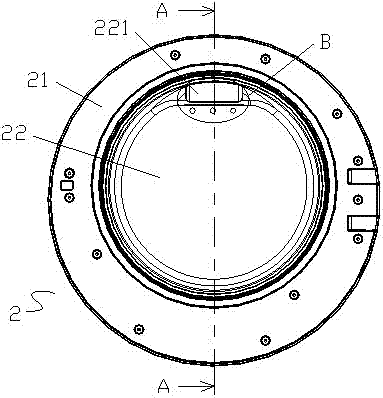

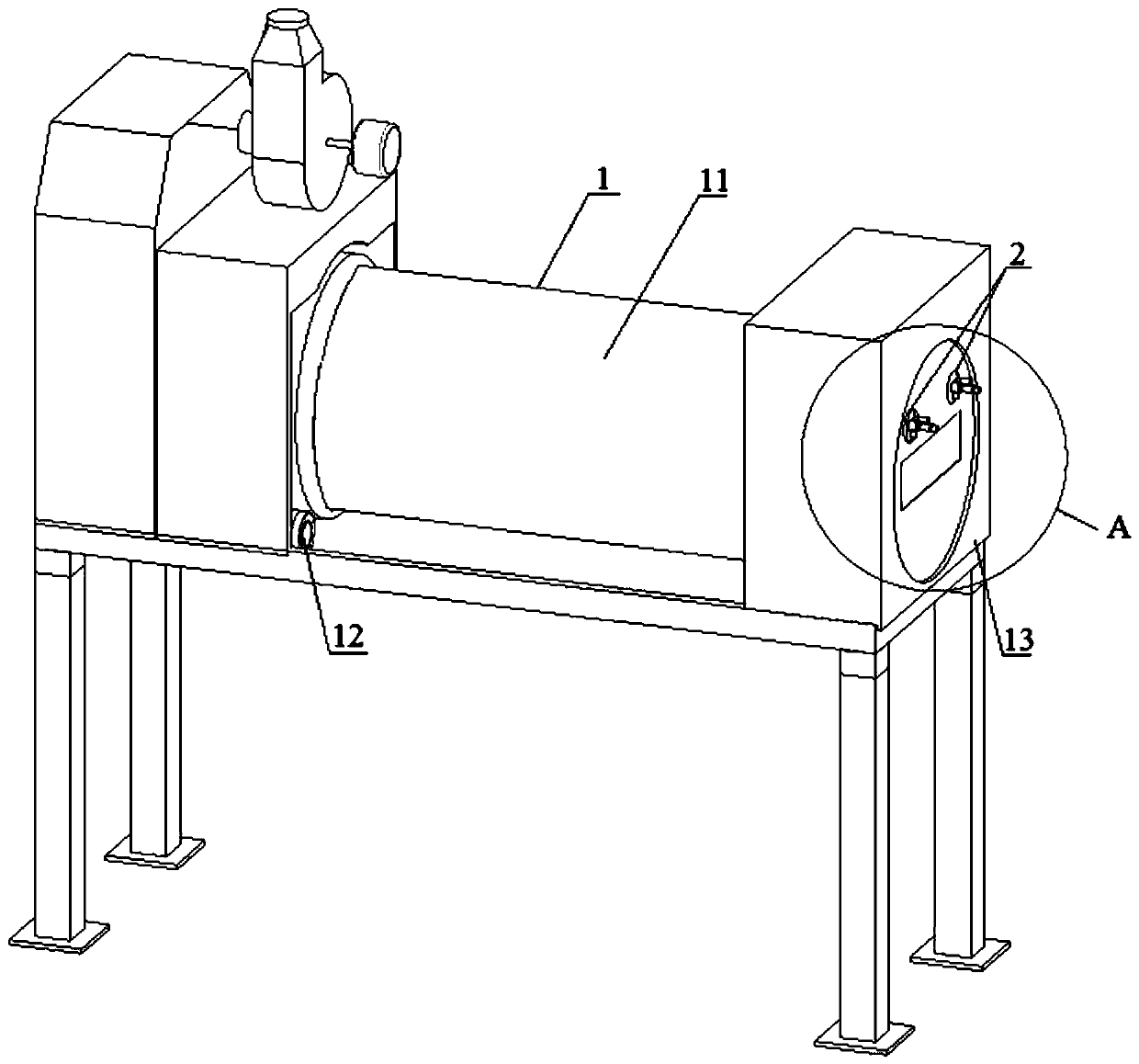

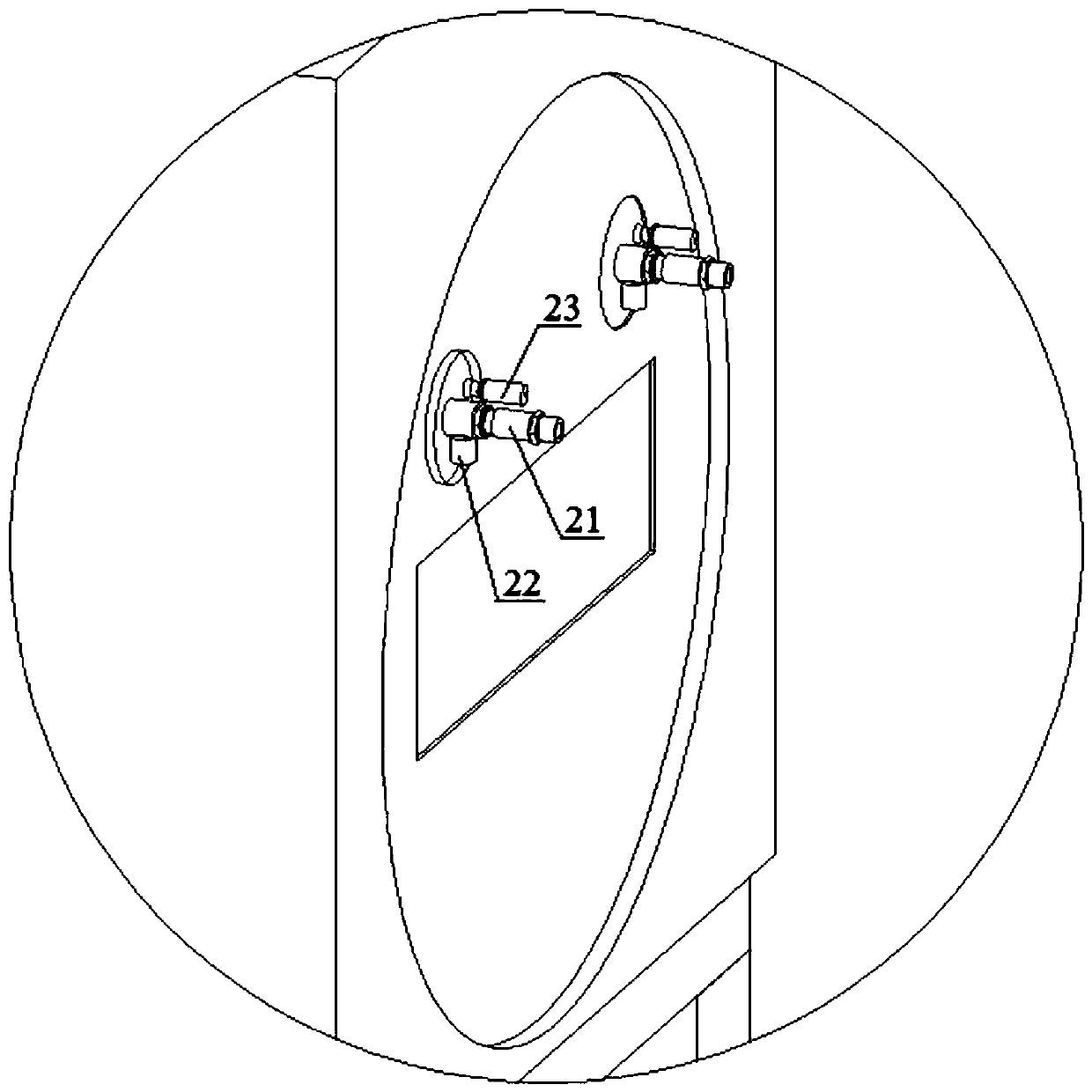

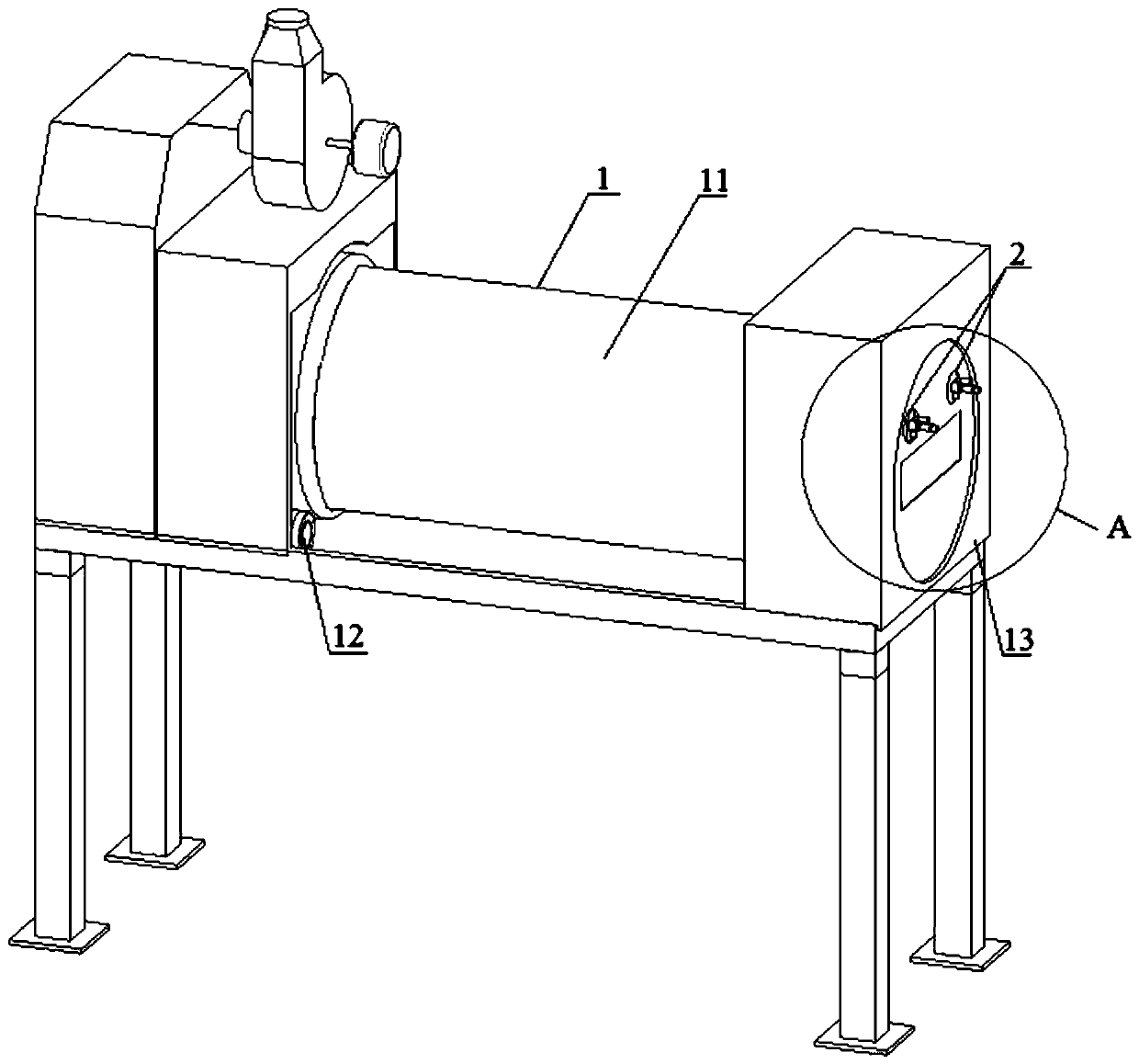

Clothes dryer with perfume adding structure and clothes drying method

The invention provides a clothes dryer with perfume adding structure and a clothes drying method. The clothes dryer comprises a box and a roller, wherein a door body capable of being opened and closed is hinged to the box, a door frame and an observing window protruding backwards are arranged on the door body, and a groove for containing an aroma agent is formed in the observing window; the roller is rotationally installed in the box and used for containing clothes. The groove for containing the aroma agent is formed in the observing window, and a part of airflow blown into the roller through an air outlet of an air flue can reach the groove, which is beneficial for accelerating aroma agent volatilization, increasing the concentration of the aroma agent in the airflow and promoting the aroma effect; the airflow reaching the groove forms vortexes and lingers in the roller space instead of directly flowing into an air inlet of the air flue, which is beneficial for further aroma treatment on the clothes, and it is avoided that as the aroma agent volatilized newly flows through the air flue first, smell of the aroma agent is absorbed to a certain degree.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

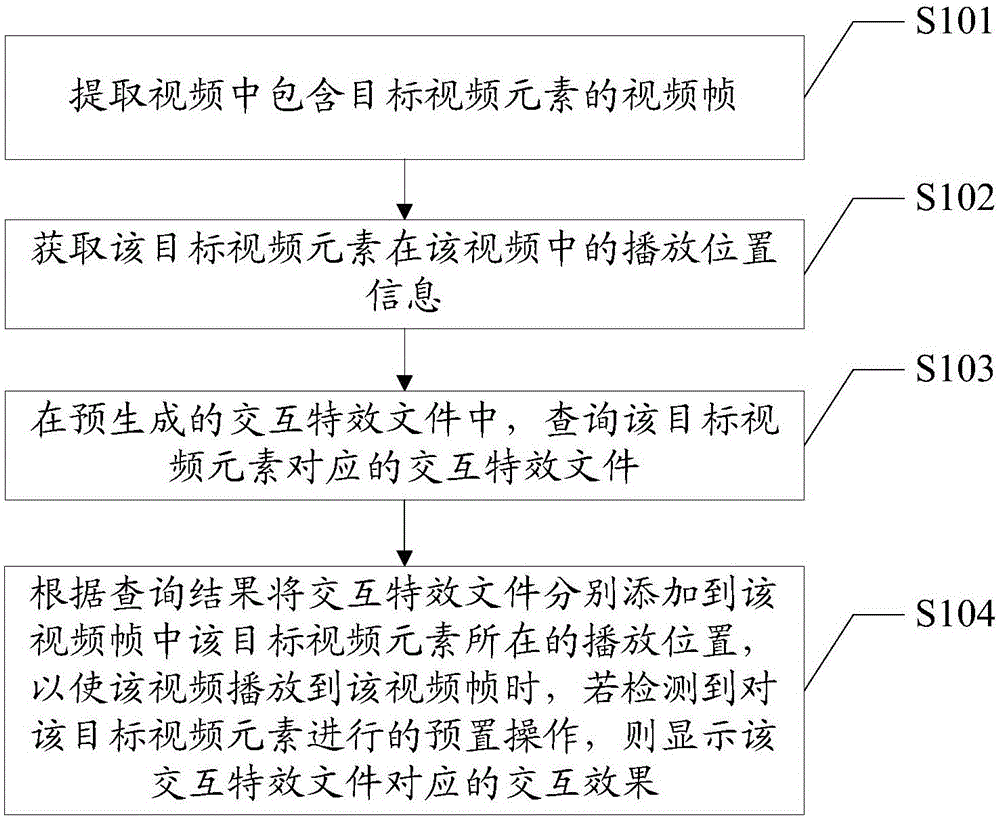

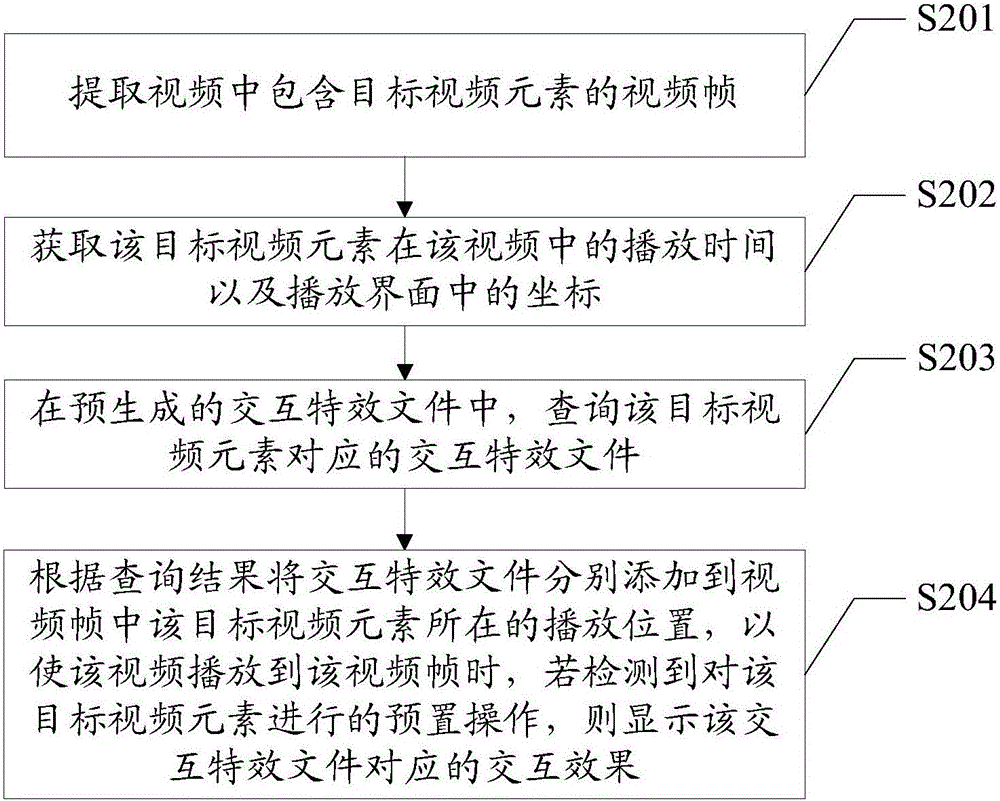

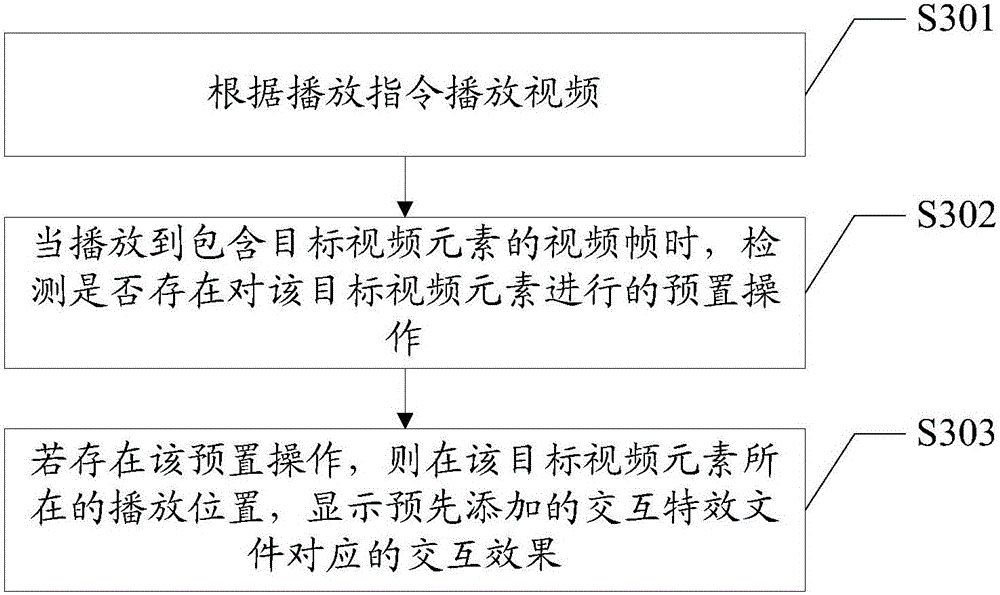

Video interaction method and device

InactiveCN106096062AImprove adding efficiencyVideo data indexingSpecial data processing applicationsTime costHuman–computer interaction

The invention discloses a vide interaction method and device. The method comprises the following steps: extracting a video frame which contains a target video element in a video, obtaining the playing position information of the target video element in the video, inquiring an interaction special effect file corresponding to the target video element in a pre-generated interaction special effect file, and independently adding the interaction special effect file onto a playing position where the target video element is positioned according to a query result to display an interaction effect corresponding to the interaction special effect file if a preset operation carried out on the target video element is detected when the video frame is played by the video. According to the method, adding efficiency can be improved, and time cost can be saved.

Owner:LETV HLDG BEIJING CO LTD +1

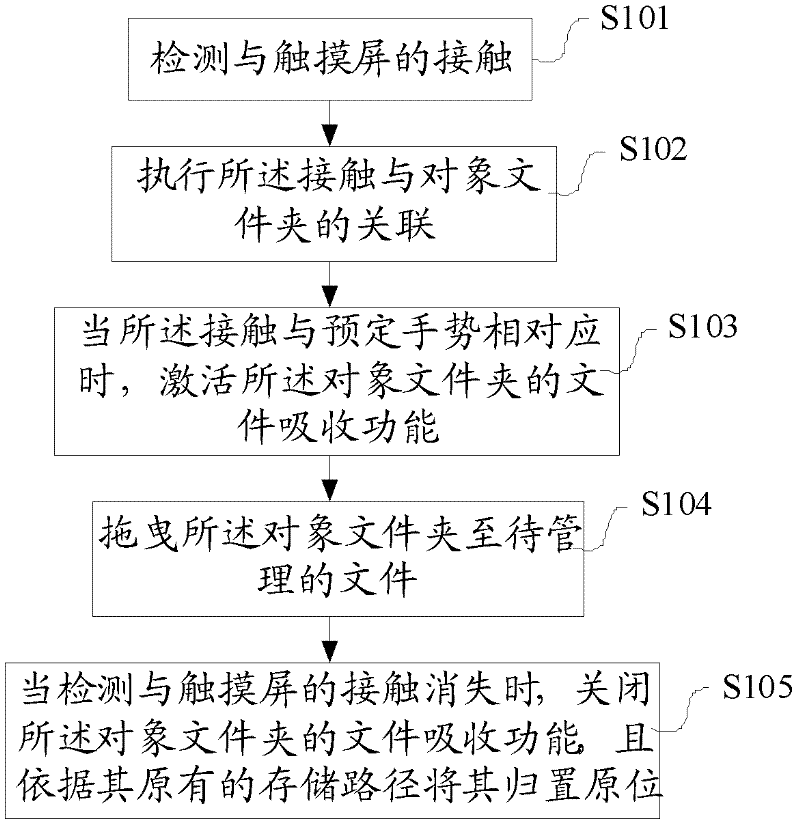

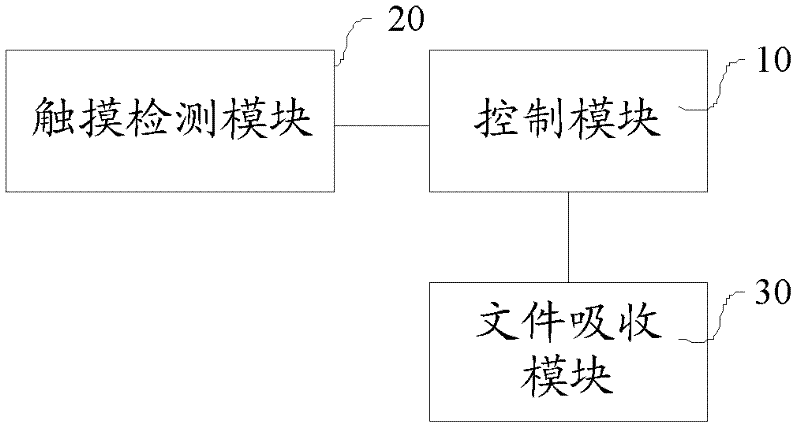

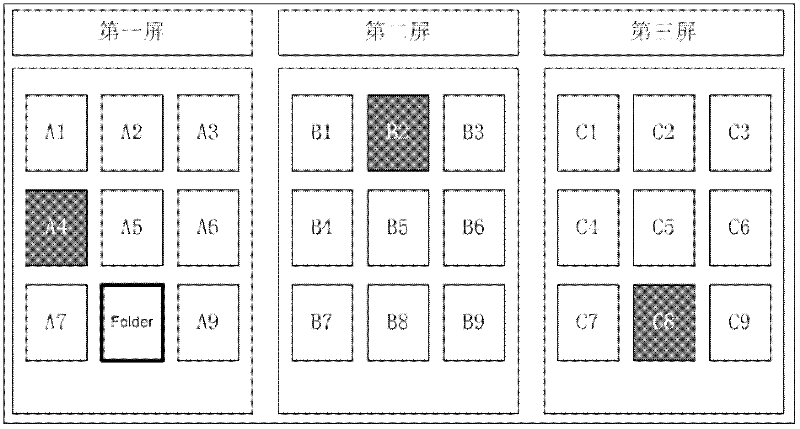

File management method and device for electronic equipment with touch screen, and electronic equipment

ActiveCN102368199AImprove experienceImprove adding efficiencySpecial data processing applicationsInput/output processes for data processingTouchscreenElectric equipment

The invention discloses a file management method and device for electronic equipment with a touch screen, and the electronic equipment. The method comprises the following steps of: detecting contact with the touch screen; executing association between the contact and a target folder; when the contact corresponds to a preset gesture, activating a file absorption function of the target folder; and dragging the target folder to a file to be managed. According to the method provided for a user of the electronic equipment with the touch screen in the invention, a plurality of files to be managed can be conveniently added to the target folder, and in the addition process of the files to be managed, reciprocation among a plurality of screens for many times is not required, thereby reducing moving paths of fingers or other touch equipment; and by the method, the device and the electronic equipment, the file addition efficiency of the user can be improved, and user experiences can be improved.

Owner:ZTE CORP

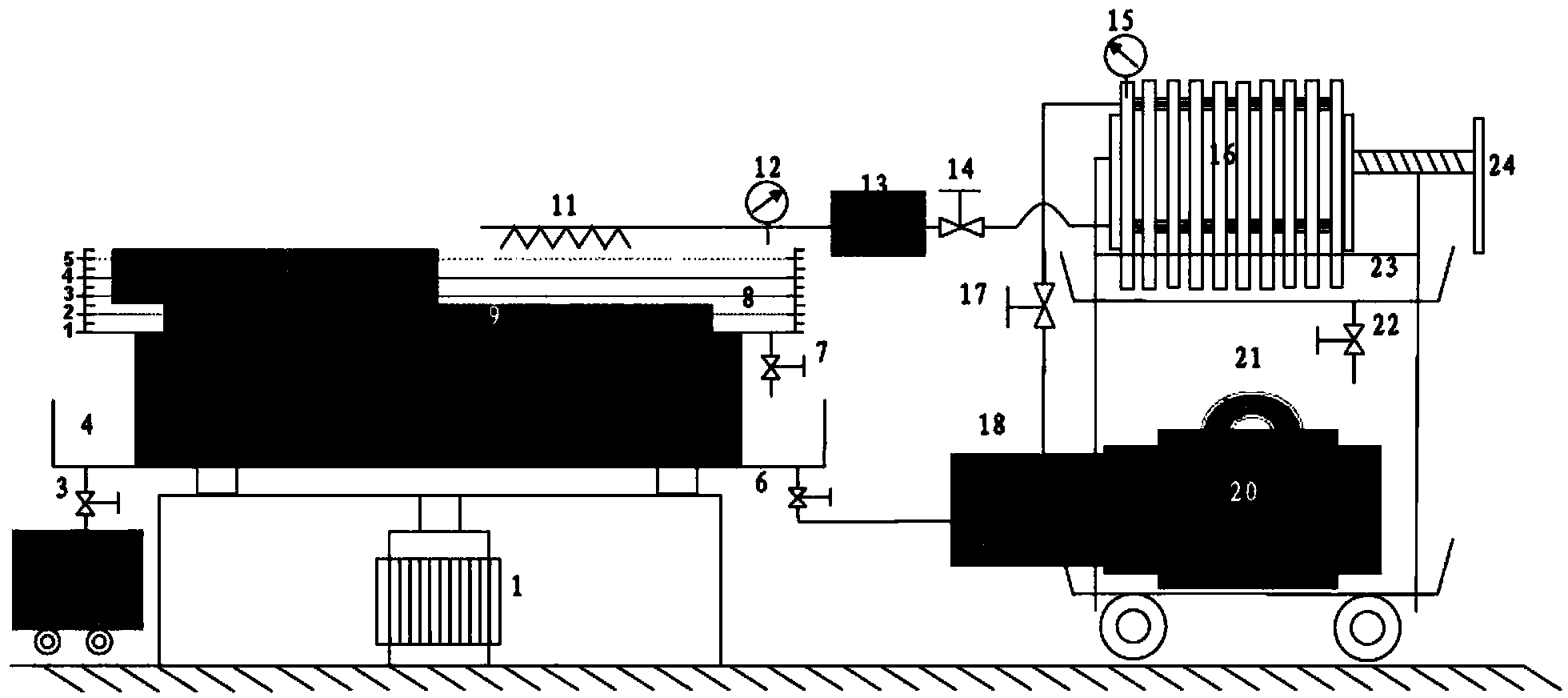

Large immersion type ring polishing machine

ActiveCN103372805AGrain size parameters are stableImprove machining accuracyPolishing machinesSurface roughnessProcess engineering

A large immersion type ring polishing machine mainly comprises a marble polishing disc, a large liquid storage groove, a polishing solution storage tank, a magnetic stirrer, an electric pump, a polishing solution filtering device, a spraying nozzle device and the like. The magnetic stirrer is arranged in the polishing solution storage tank and performs continuous stirring. The polishing solution filtering device adopts a multilayer filtering film type filtering device and can perform multilayer grading filtering according to needs. By means of the large immersion type ring polishing machine, immersion type polishing processing of the large immersion type ring polishing machine is achieved, temperature balance performance is good, polishing surface shape errors caused by uneven polishing temperature are reduced, surface shape precision and surface roughness of a large-caliber plane optical element are improved, and surface defects of elements can be effectively controlled. Furthermore, the immersion type ring polishing machine adopts a mode of cyclic utilization of polishing solution, so that consume of the polishing solution can be greatly reduced, and processing cost is reduced.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

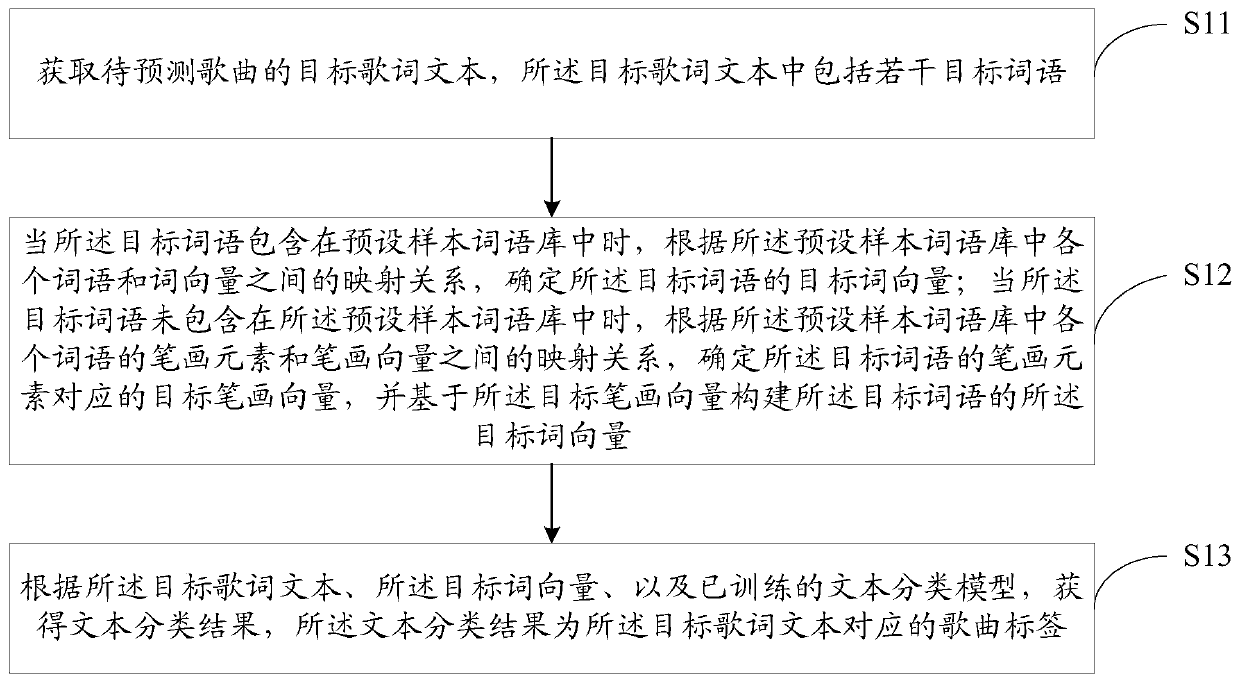

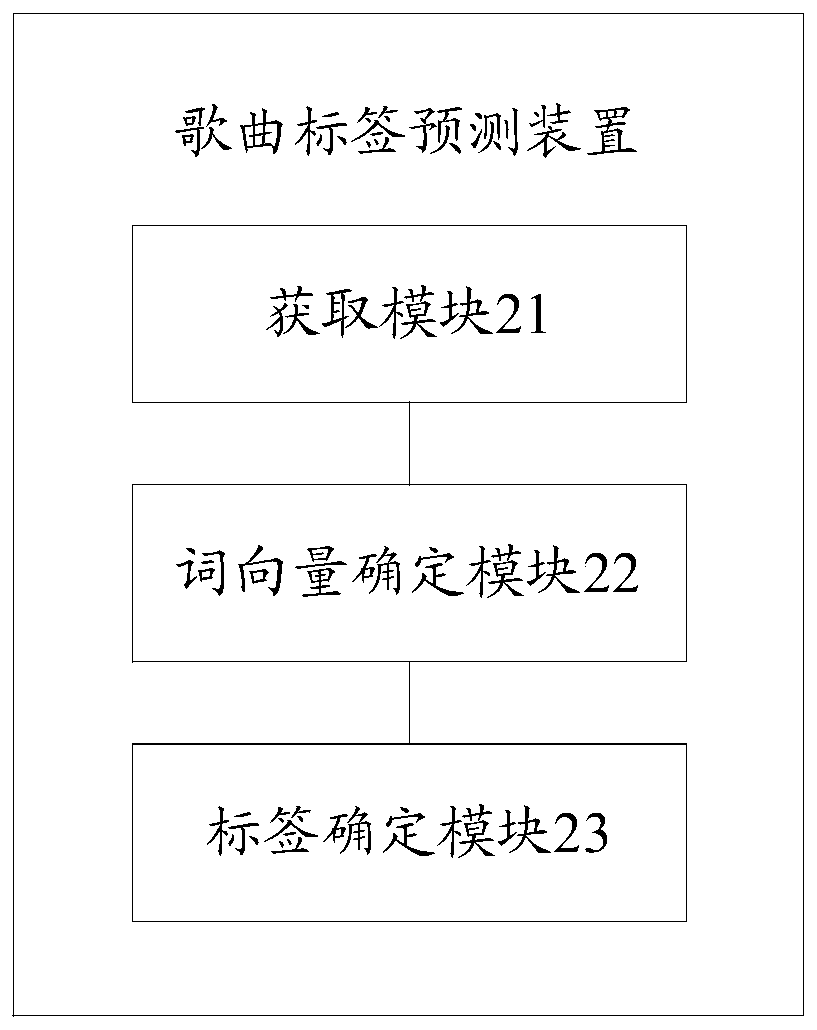

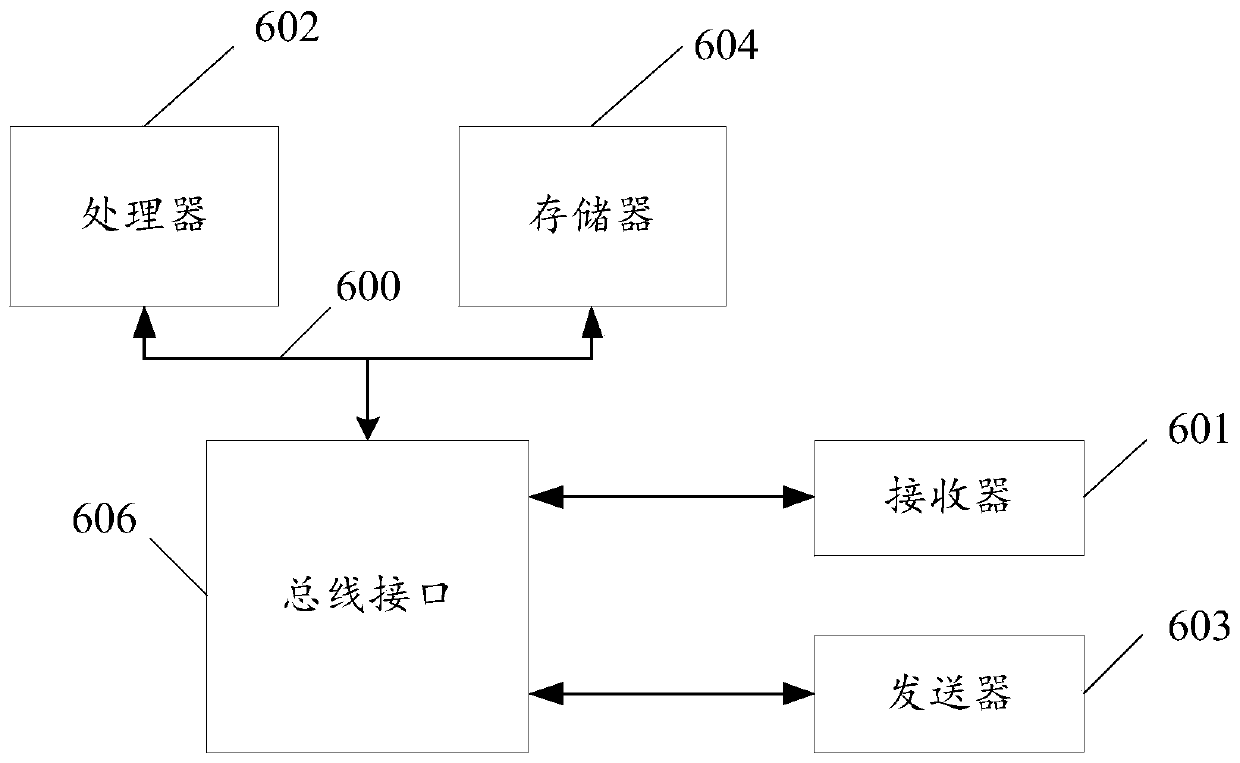

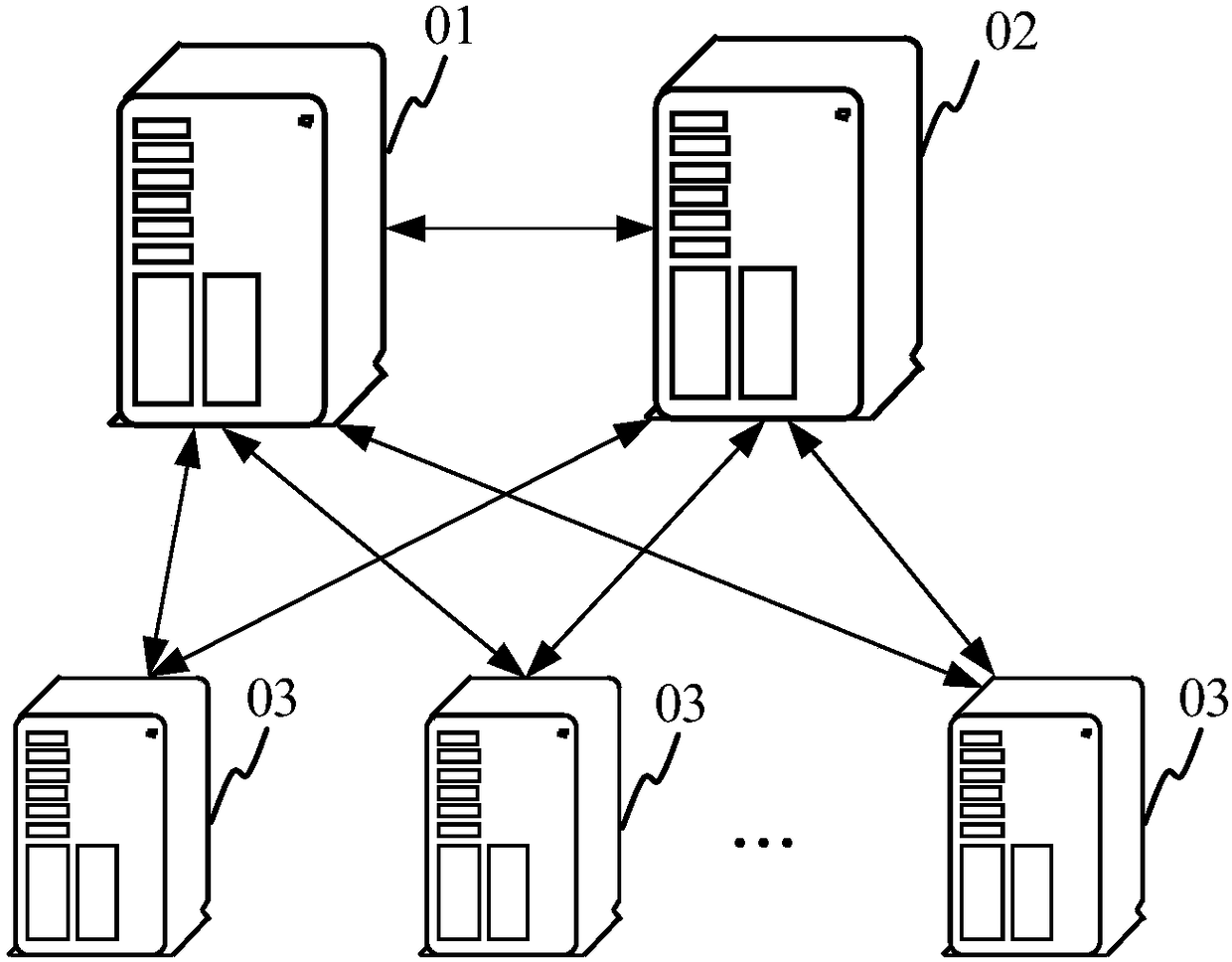

Song tag prediction method and device, server and storage medium

ActiveCN109933686AImprove adding efficiencyImprove accuracySpecial data processing applicationsAudio data clustering/classificationPredictive methodsAlgorithm

The invention discloses a song tag prediction method and device, a server and a storage medium, and the method comprises the steps: obtaining a target lyric text of a song to be predicted, the targetlyric text comprising a plurality of target words; determining a target word vector of the target word according to a mapping relationship between each word and a word vector in the preset sample wordlibrary and a mapping relationship between stroke elements and stroke vectors of each word in the preset sample word library; and obtaining a text classification result according to the target lyrictext, the target word vector and a trained text classification model, the text classification result being a song tag corresponding to the target lyric text. According to the scheme, the target word vector of each target word in the target lyric text can be acquired, so that the meaning of each target word in the lyric text can be comprehensively considered during label prediction, and the label prediction accuracy of songs is improved.

Owner:ADVANCED NEW TECH CO LTD

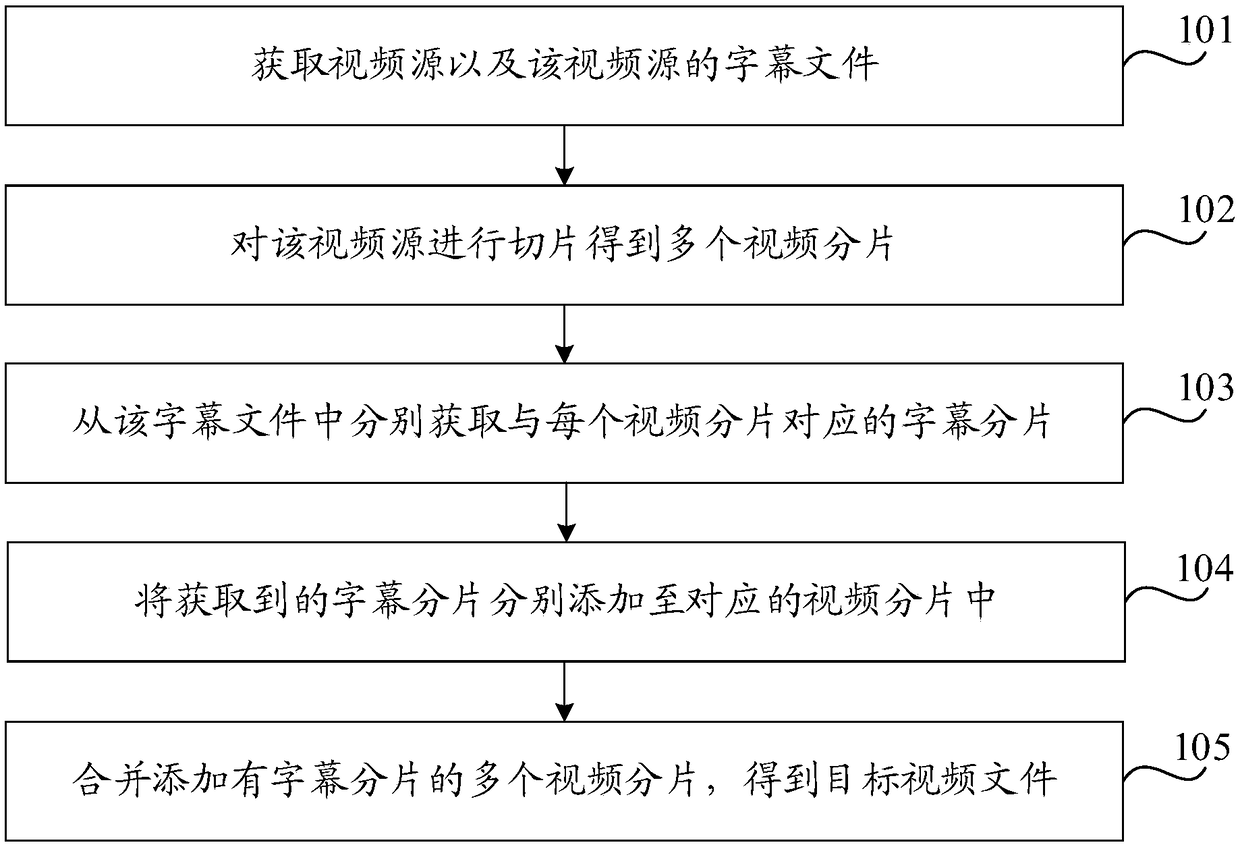

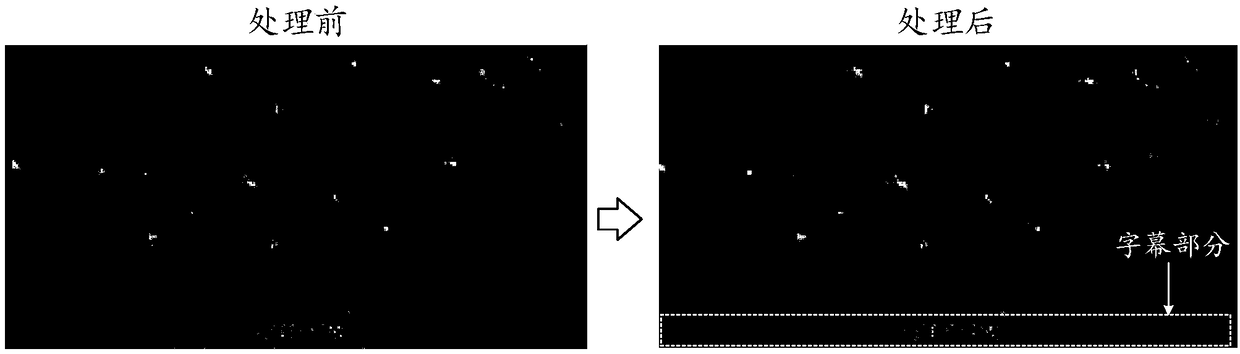

Subtitle adding method and device

ActiveCN108449651AImplement distributed additionImprove adding efficiencySelective content distributionPattern recognitionVideo processing

The application discloses a subtitle adding method and device, and belongs to the field of audio and video processing. The method comprises the following steps: acquiring a video source and a subtitlefile of the video source; slicing the video source to obtain a plurality of video fragments; acquiring subtitle fragments corresponding to the video fragments from the subtitle file respectively, wherein a subtitle fragment corresponding to at least one of the plurality of video fragments includes M subtitles, the duration of each of the m subtitles in the video source intersects with the duration of the corresponding video fragments in the video source, and m is a positive integer; and adding the acquired subtitle fragments into the corresponding video fragments respectively, and merging theplurality of video fragments added with the subtitle fragments to obtain a target video file. Through adoption of the subtitle addition method provided in the application, distributed subtitle addition can be realized, and the subtitle addition efficiency is increased.

Owner:TENCENT TECH (SHENZHEN) CO LTD

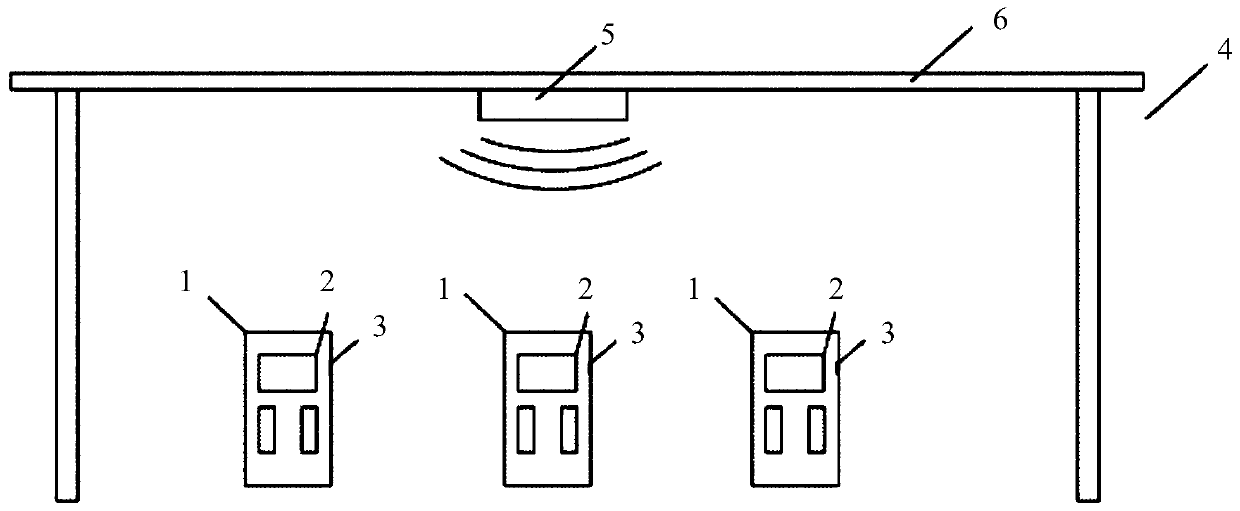

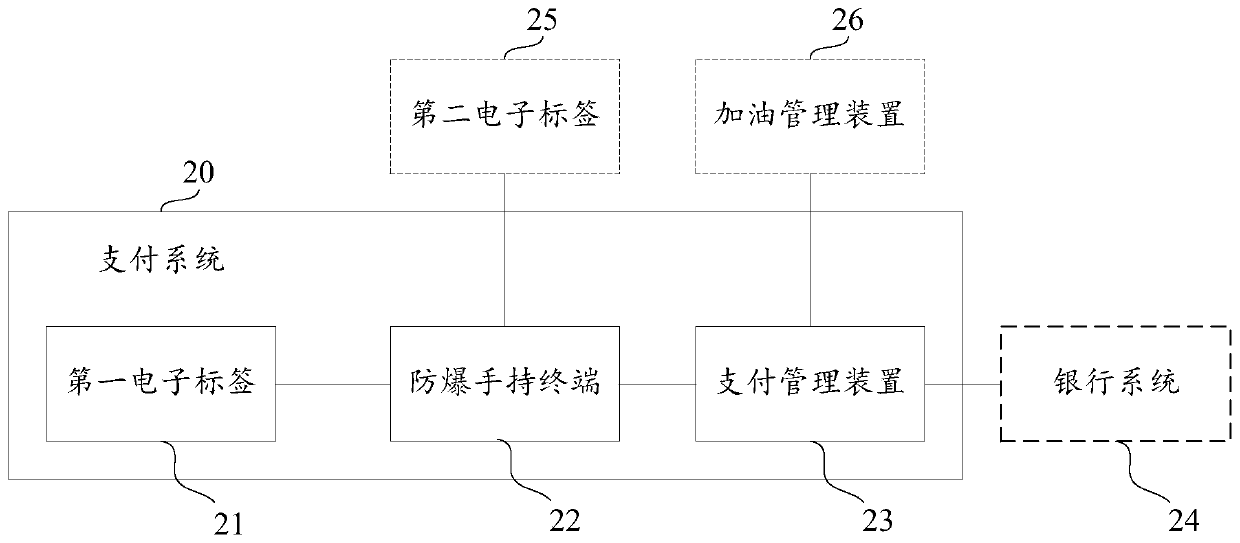

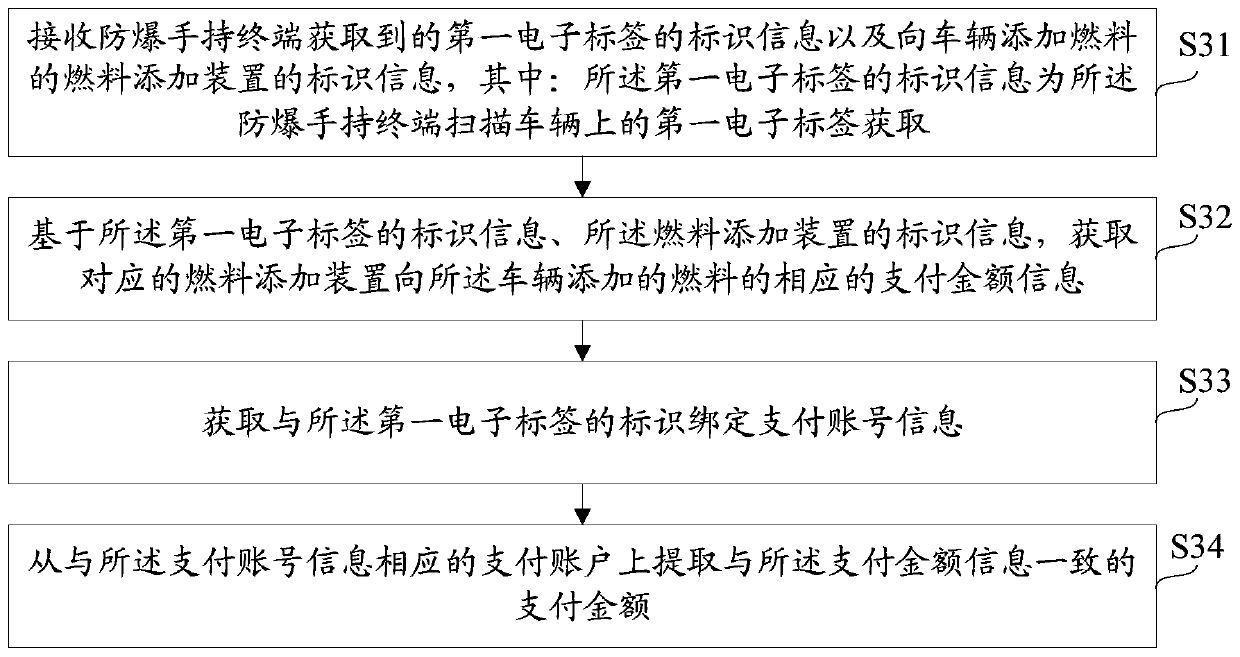

Payment method, system, payment management device, explosion-proof handheld terminal and medium

PendingCN110992015ALow costImprove payment efficiencyCo-operative working arrangementsPayment architectureComputer networkEmbedded system

The invention discloses a payment method, a payment system, a payment management device, an explosion-proof handheld terminal and a medium. The method is suitable for the payment management device. The payment management device is deployed outside a vehicle fuel adding area. The method comprises the following steps that: the identification information of a first electronic tag acquired by an explosion-proof handheld terminal and the identification information of a fuel adding device for adding fuel to a vehicle are received, wherein the identification information of the first electronic tag isacquired by scanning the first electronic tag on the vehicle by the explosion-proof handheld terminal; based on the identification information of the first electronic tag and the identification information of the fuel adding device, corresponding payment amount information of the fuel added to the vehicle is obtained by the corresponding fuel adding device; payment account information bound withthe identifier of the first electronic tag is acquired; and a payment amount consistent with the payment amount information is extracted from a payment account corresponding to the payment account information. With the method provided by the technical schemes of the invention adopted, implementation cost can be decreased.

Owner:连全俊

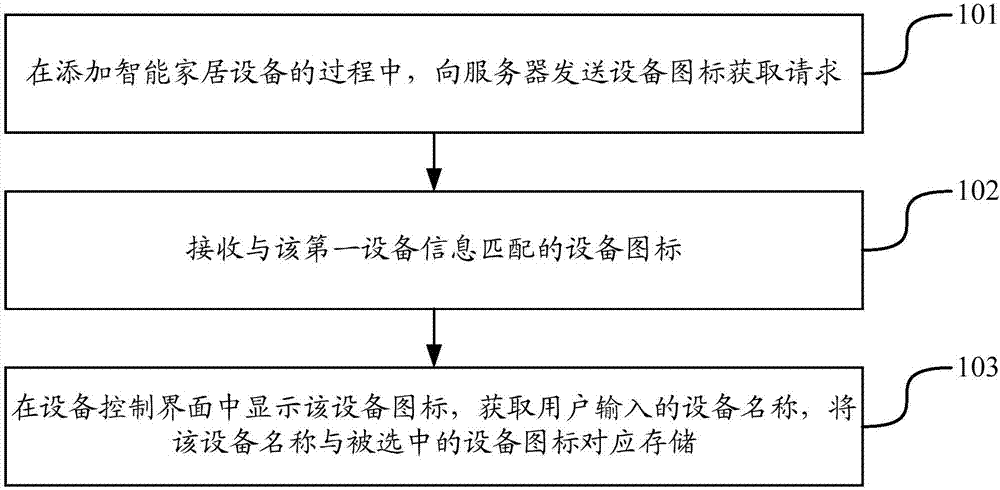

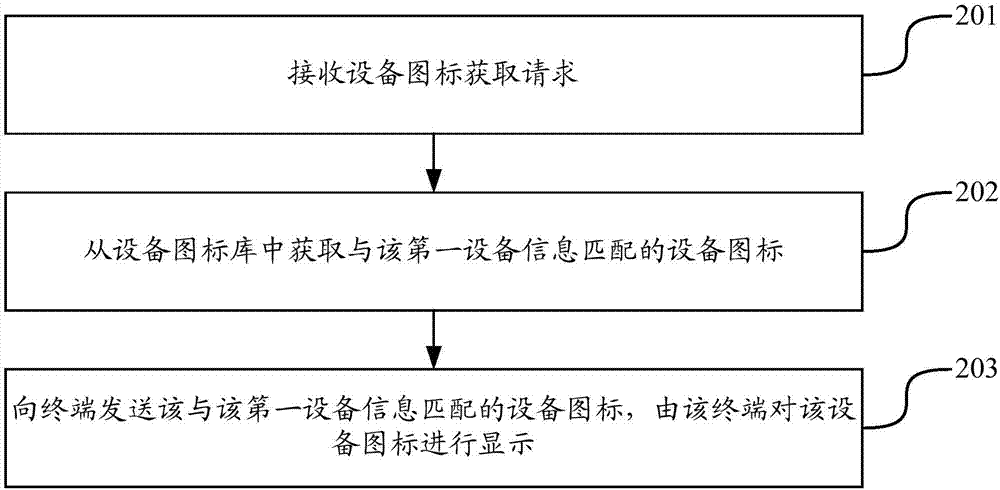

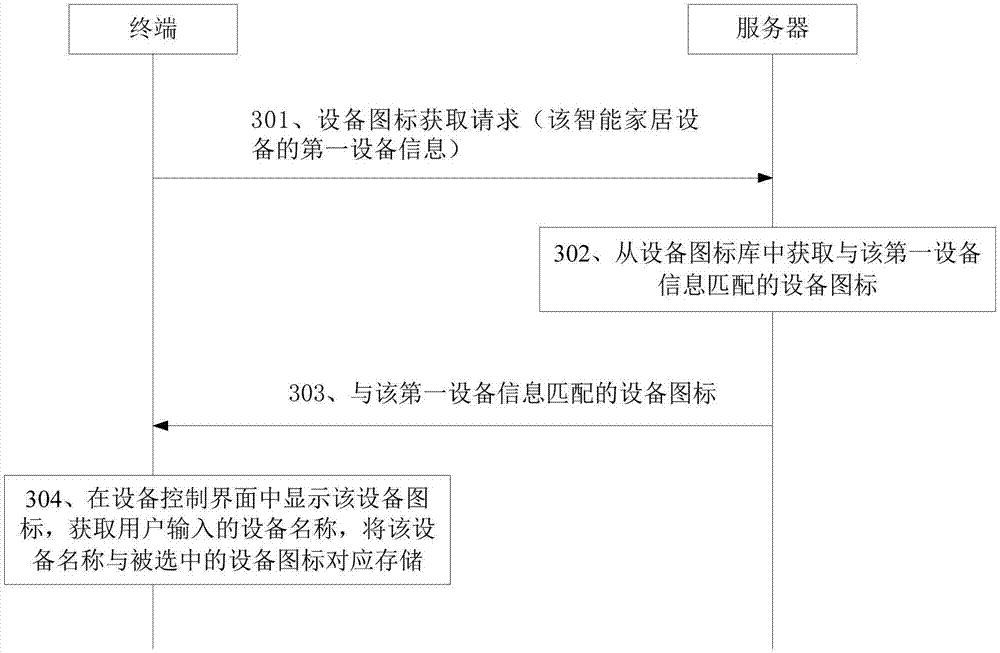

Smart home equipment adding method and device

ActiveCN106953785AImprove adding efficiencyQuick modificationComputer controlHome automation networksUser inputEmbedded system

The invention discloses a smart home equipment adding method and device, and belongs to the field of smart home. The smart home equipment adding method comprises the steps that an equipment icon acquisition request is sent to a server; an equipment icon matched with first equipment information is received; and the equipment icon is displayed in an equipment control interface, an equipment name inputted by a user is acquired, and the equipment name and the selected equipment icon are stored in a corresponding manner. According to the invention, an equipment icon matched with the actual appearance of smart home equipment is acquired from the server, and the equipment icon is displayed in the equipment control interface, so that the user is enabled to accurate differentiate the same kind of smart home equipment through the equipment icon. The user can modify the equipment name of the smart home equipment rapidly by only performing a simple input operation so as to complete the smart home equipment adding process. The smart home equipment adding method and device are conducive to improving the smart home equipment adding efficiency.

Owner:HISENSE

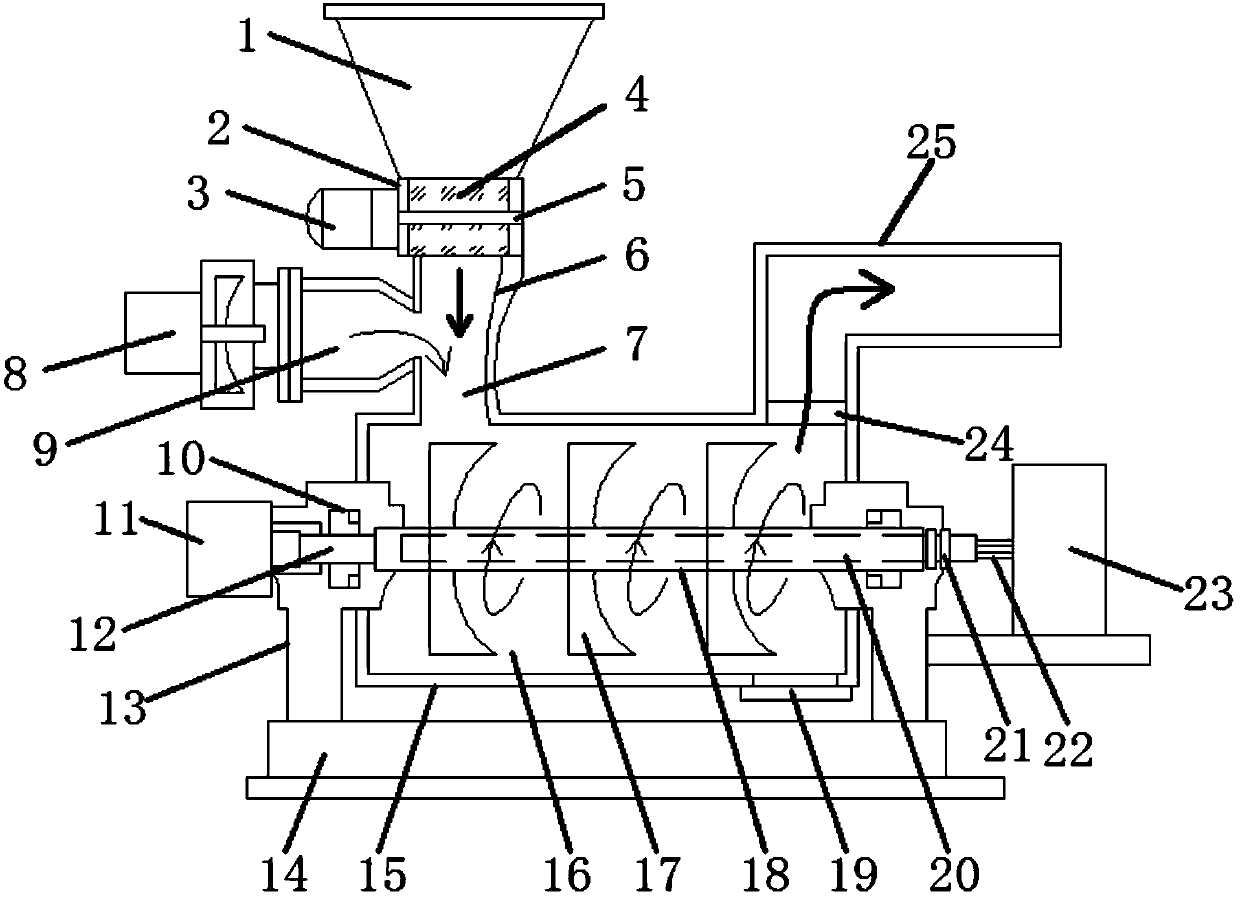

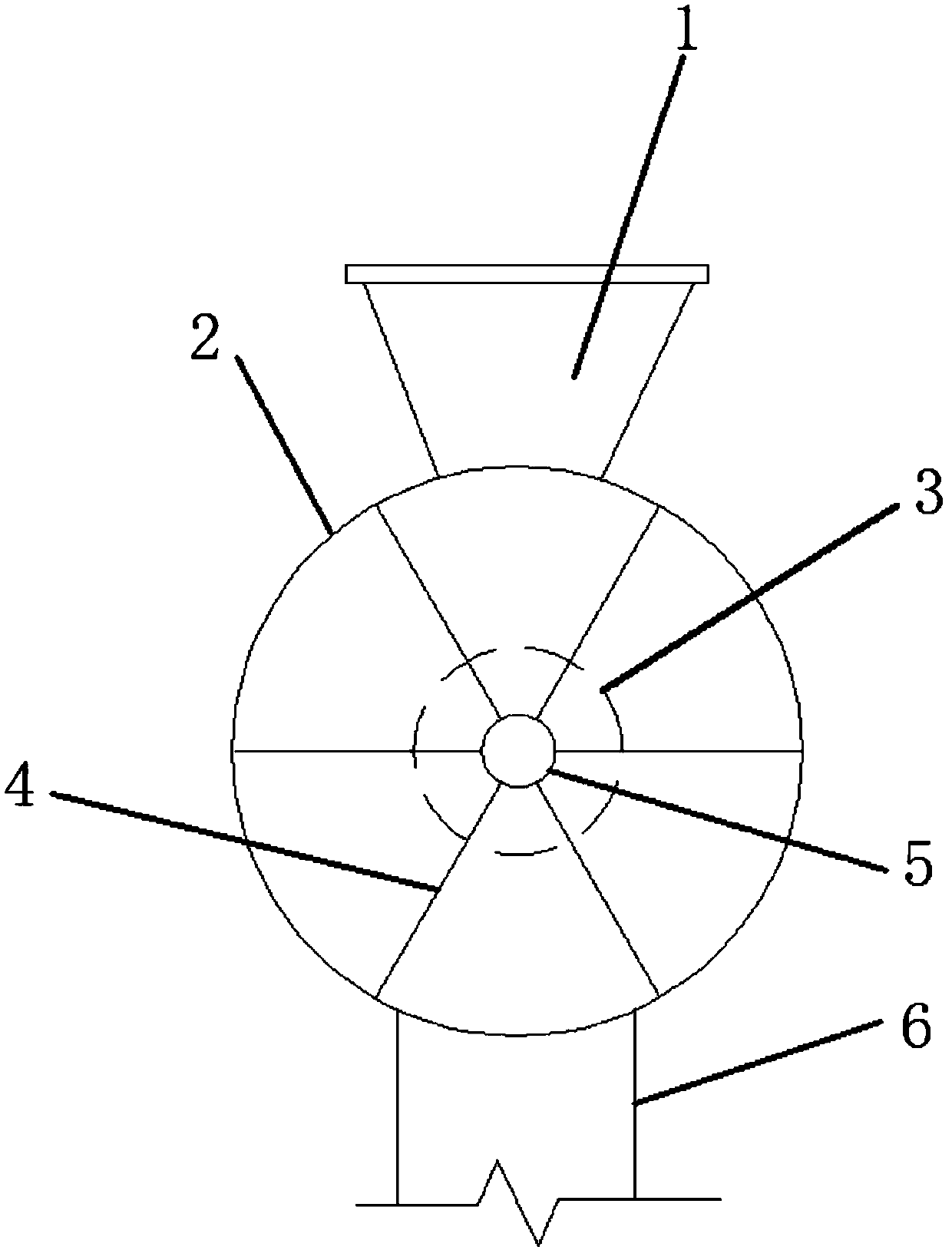

Horizontal feed crushing and blowing device with iron removal function

InactiveCN107552155AImprove sufficiencyEasy dischargeMagnetic separationGrain treatmentsGastric tube feedingScrap

The invention discloses a horizontal iron-removing feed crushing and blowing device, which comprises a feeding hopper, a quantitative feeder, an air inlet pipe, a crushing cylinder, a crushing blade, a crushing shaft and an iron adsorption plate. A quantitative feeder is installed at the bottom and communicates with the upper part of the quantitative feeder. A pusher is installed inside the quantitative feeder. The pusher is welded on the rotating shaft of the material, and one end of the rotating shaft passes through the barrel of the quantitative feeder. The body is connected to the feeding motor; the bottom end of the quantitative feeder is connected to the feeding pipe, and the bottom end of the feeding pipe is welded with a mixed-flow adding pipe, which is connected to the upper left end of the crushing cylinder; it is convenient to control feed addition and improve the efficiency of feed addition. Efficiency and avoiding the clogging of feed addition, it is convenient to crush the crushed material in the crushing cavity, which improves the adequacy of feed crushing and facilitates the discharge of crushed feed; when the coil in the crushing blade is connected to the coil, a magnetic field is generated to magnetize the iron core, which improves the crushing efficiency. The effect of removing iron impurities in feed.

Owner:储昭汉

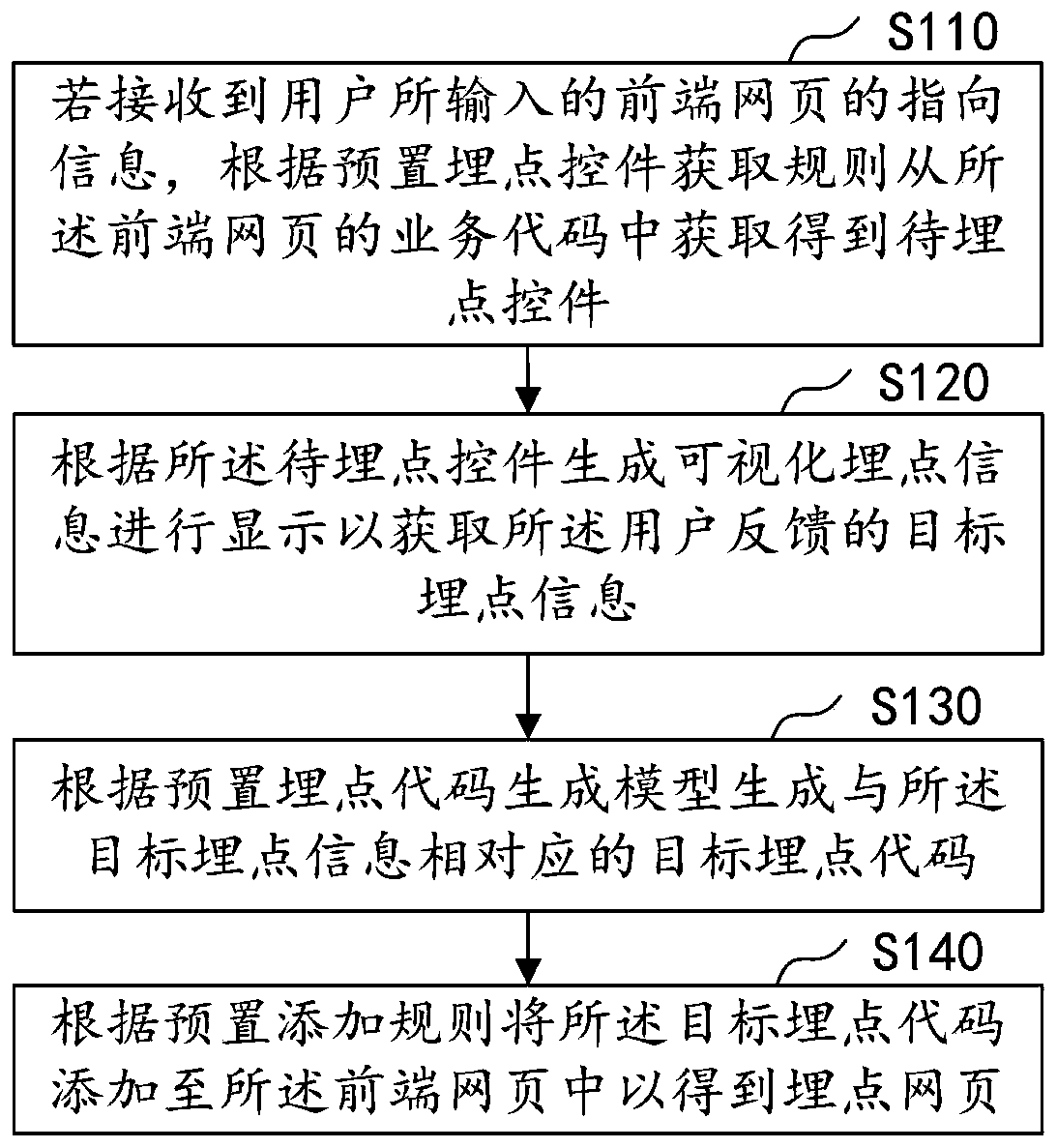

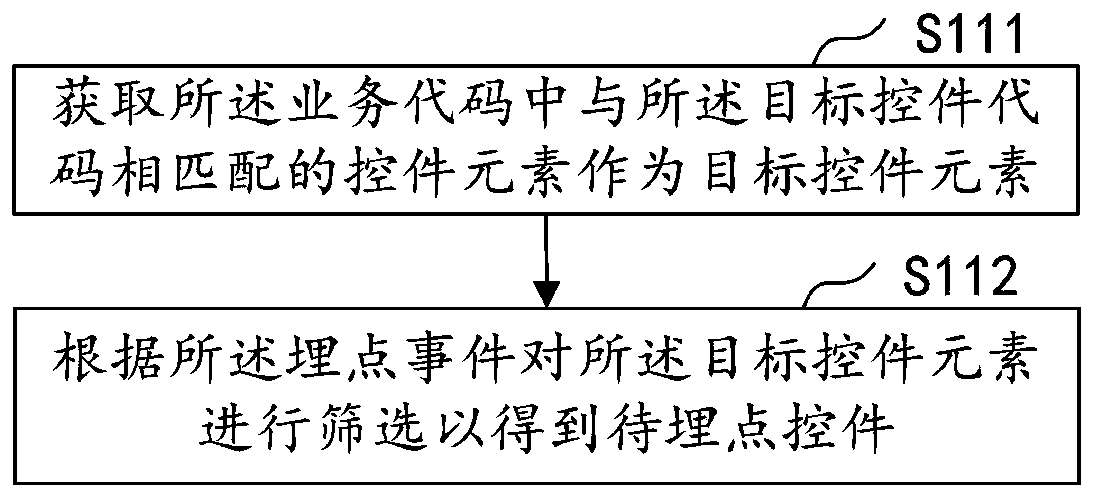

Webpage burying point code adding method and device, computer equipment and storage medium

PendingCN111241444AImprove production efficiencyImprove adding efficiencyWebsite content managementSpecial data processing applicationsCode generationWeb page

The invention discloses a webpage burying point code adding method and device, computer equipment and a storage medium. The method comprises the steps: if pointing information, input by a user, of a front-end webpage is received, obtaining a to-be-buried point control from a service code of the front-end webpage according to a preset buried point control obtaining rule; generating visual burying point information according to the to-be-buried point control, and displaying the visual burying point information to obtain target burying point information fed back by the user; generating a target burying point code corresponding to the target burying point information according to a preset burying point code generation model; and adding the target burying point code into the front-end webpage according to a preset adding rule to obtain a burying point webpage. Based on the development assisting technology, the buried point code generating and adding efficiency can be improved, the situationthat bugs are generated in a webpage due to misoperation of manual buried point code adding is avoided, the buried point code adding efficiency and reliability are ensured, and a good technical effect is achieved in the actual application process.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

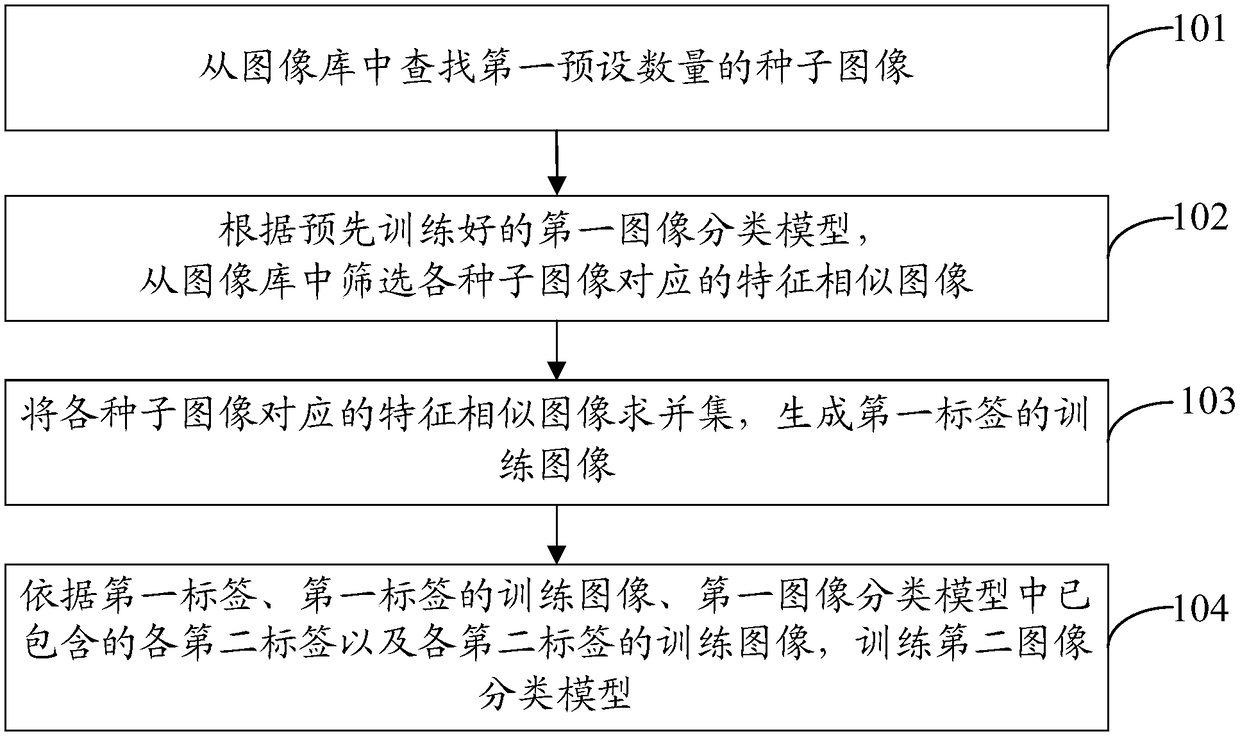

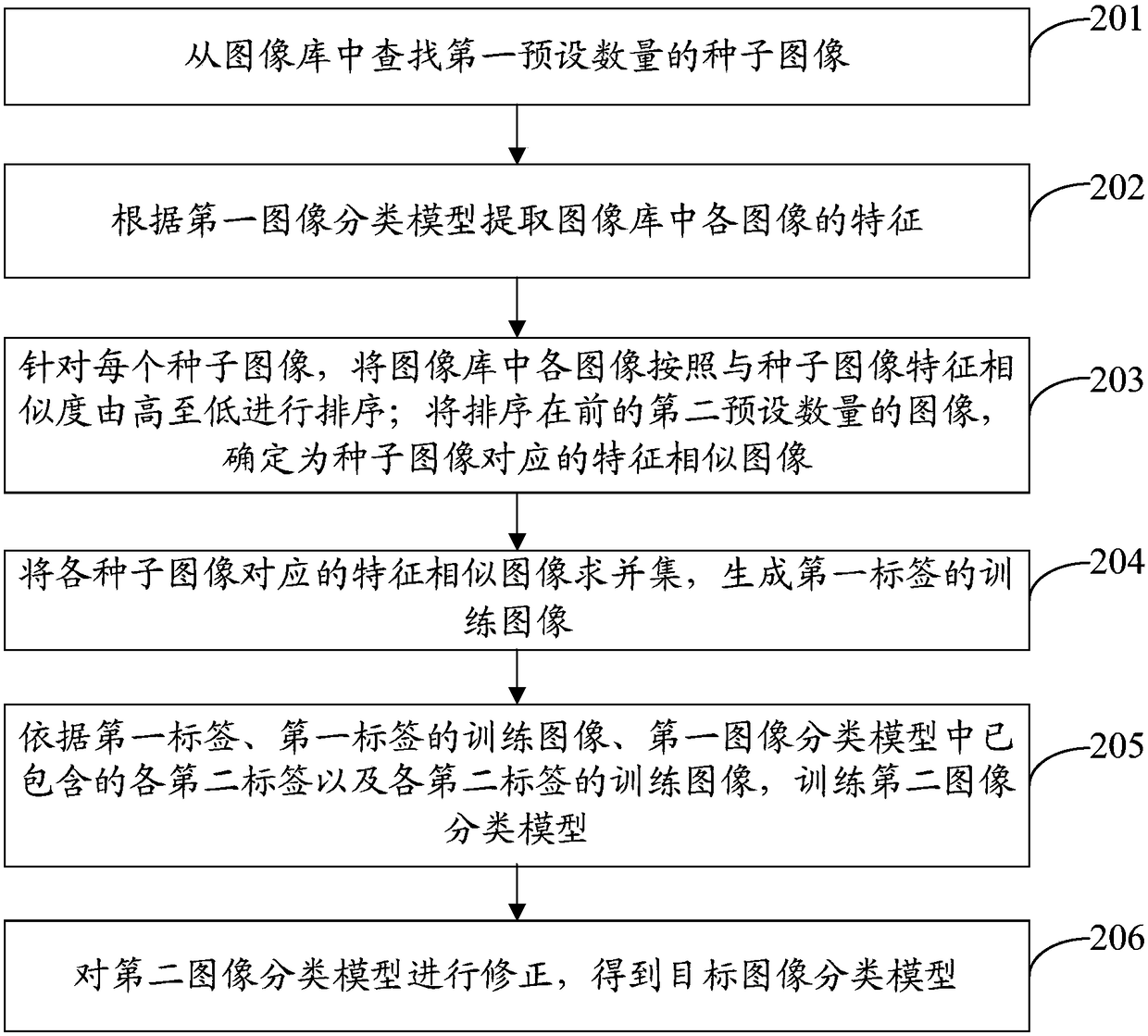

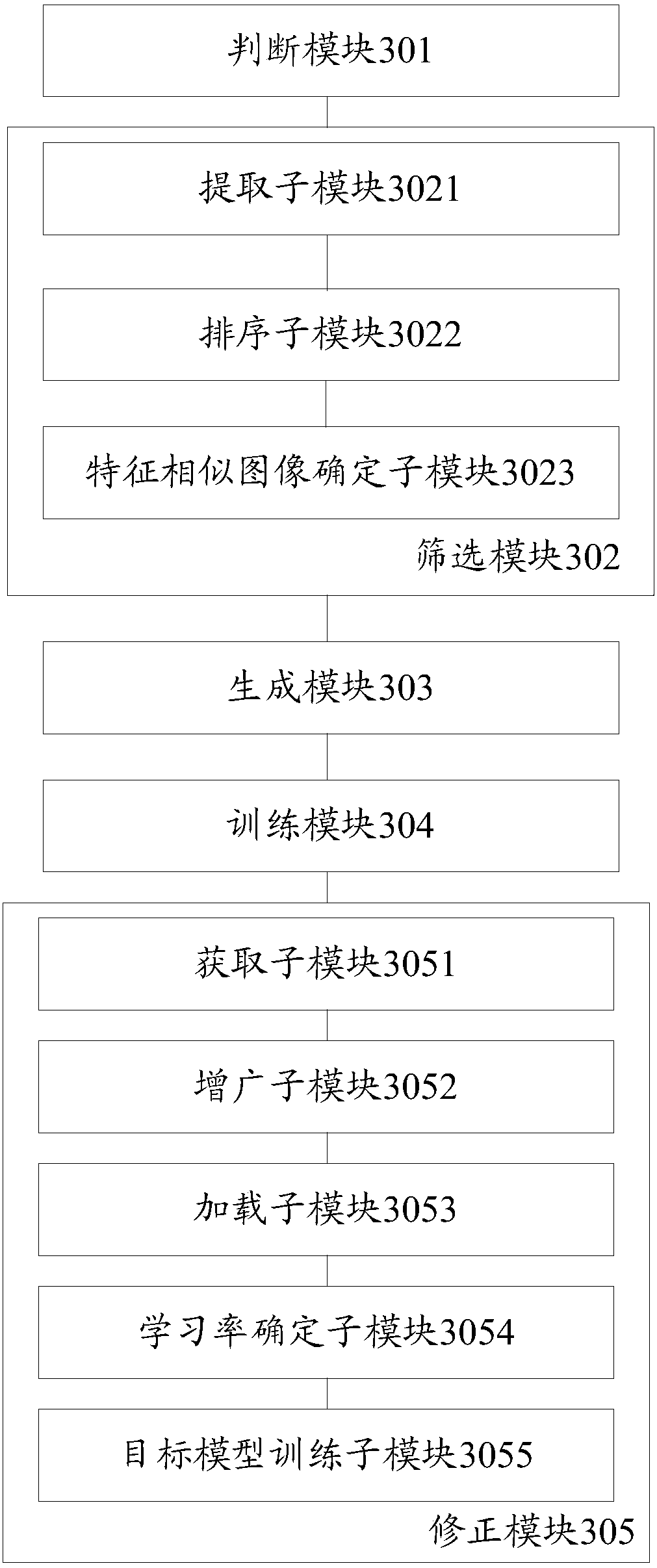

Label adding method and device and terminal

InactiveCN108563683AImprove adding efficiencyEasy to operateCharacter and pattern recognitionSpecial data processing applicationsPattern recognitionCategorical models

Embodiments of the invention provide a label adding method and device and a terminal. The method comprises the following steps of: searching a first preset quantity of seed images from an image library, wherein the seed images are matched with a to-be-added first label; screening feature similar images corresponding to the seed images from the image library according to a pre-trained first image classification model; summarizing the feature similar images corresponding to the seed images to generate a training image of the first label; and training a second image classification model accordingto the first label, the training image of the first label, second labels included in the first image classification model and training images of the second labels. Through the label adding method provided by the invention, users do not need to train image signs in batches, and only need to manually screen the first preset quantity of seed images, so that the operation is convenient, the consumedtime is short, the human resources can be saved and the label adding efficiency can be enhanced.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

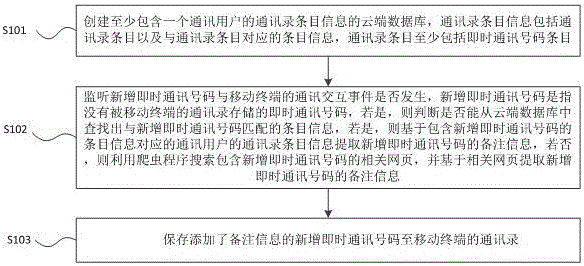

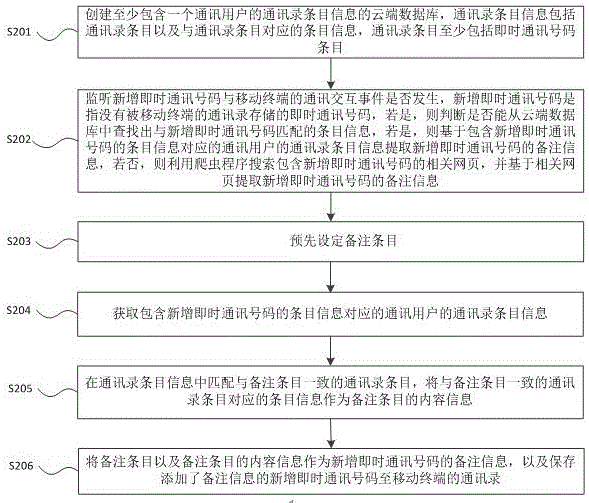

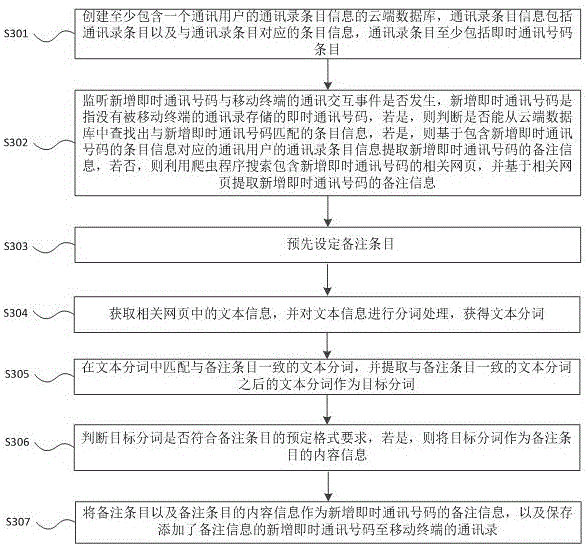

Method and device for automatically adding remark information to newly-increased instant messaging number

InactiveCN105049341AImprove adding efficiencyImprove experienceMessaging/mailboxes/announcementsData switching networksWeb pageInstant messaging

The invention discloses a method and a device for automatically adding remark information to a newly-increased instant messaging number. The method comprises the steps as follows: monitoring whether a communication interactive event of the newly-increased instant messaging number with a mobile terminal is happened by creating at least one cloud database comprising address list item information of a communication user; judging whether the item information matched with the newly-increased instant messaging number could be searched from the cloud database if the interactive event is happened; extracting the remark information of the newly-increased instant messaging number based on the address list item information of the communication user corresponding to the item information comprising the newly-increased instant messaging number if the item information matched with the newly-increased instant messaging number could be searched from the cloud database, otherwise, using a crawler to search the related webpage comprising the newly-increased instant messaging number, and extracting the remark information of the newly-increased instant messaging number based on the related webpage. The method and the device of the invention solve the technical problem of tedious operation and low efficiency brought by manually adding the remark information to the newly-increased instant messaging number, thereby improving adding efficiency of the remark information and user experience.

Owner:陈包容

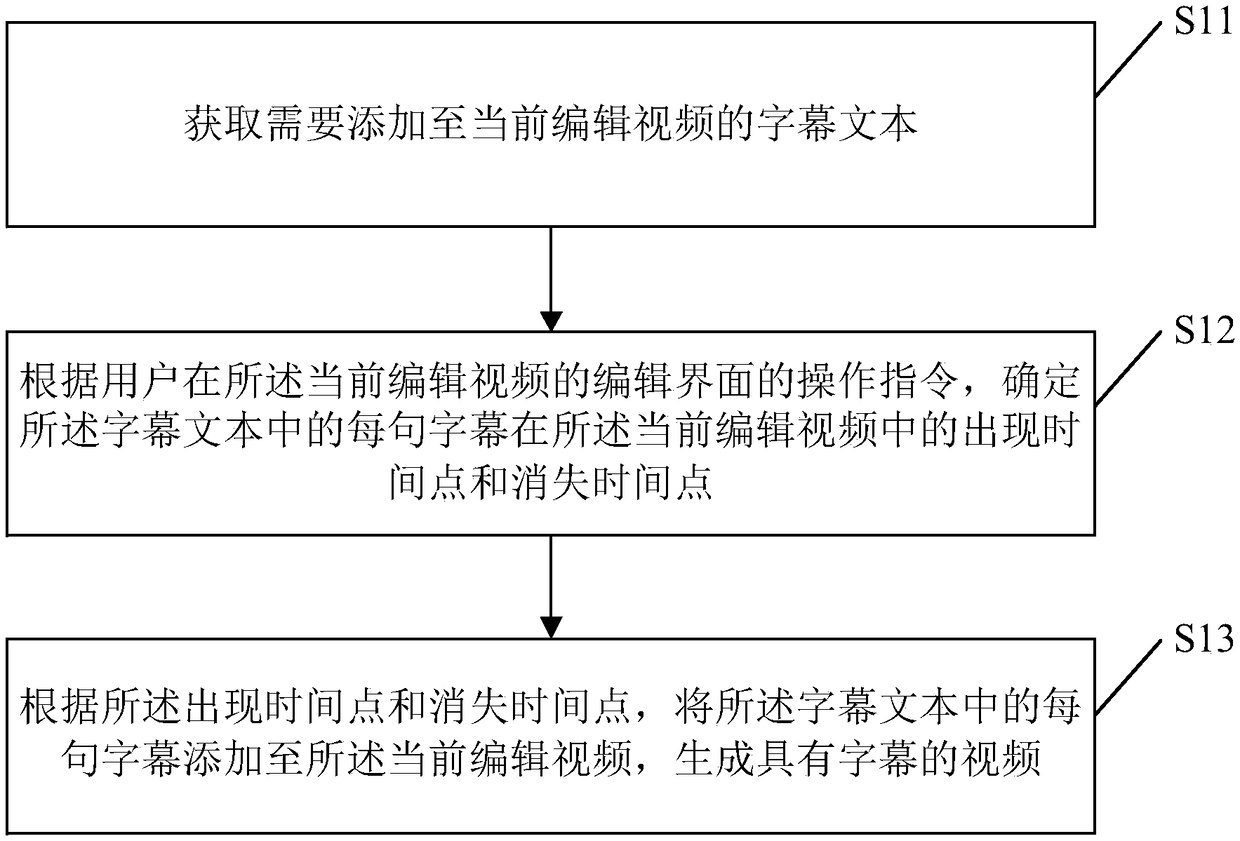

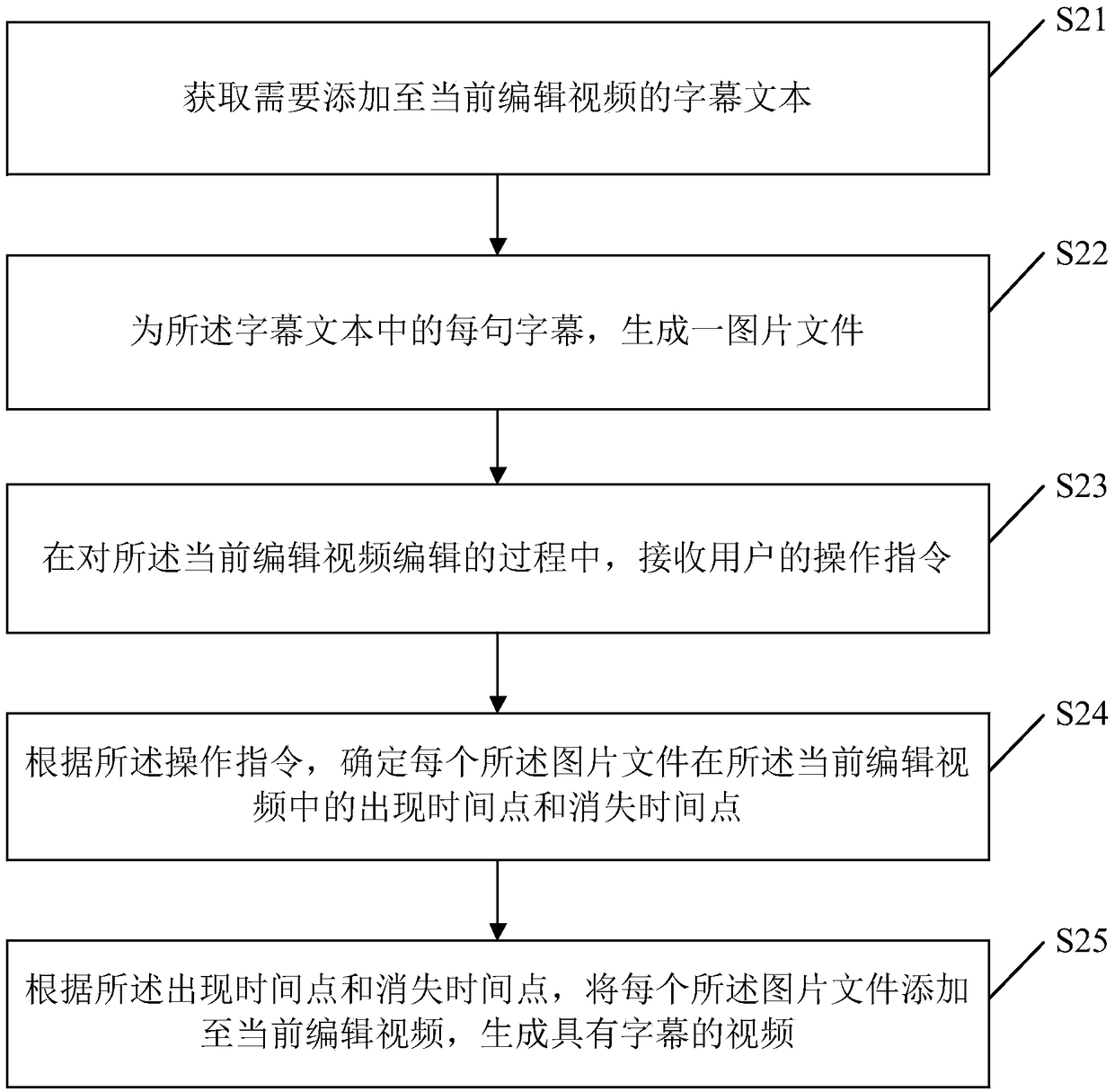

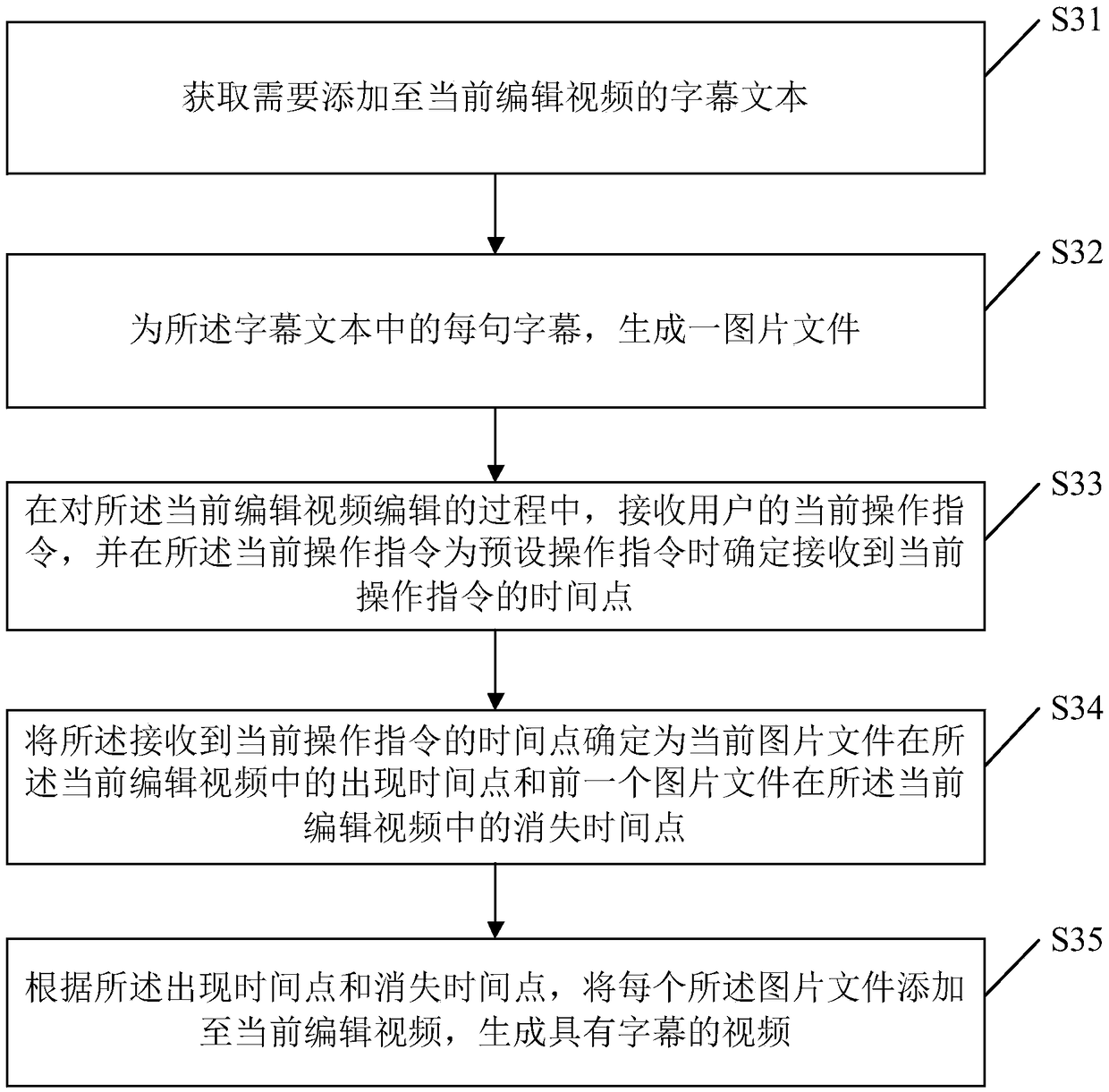

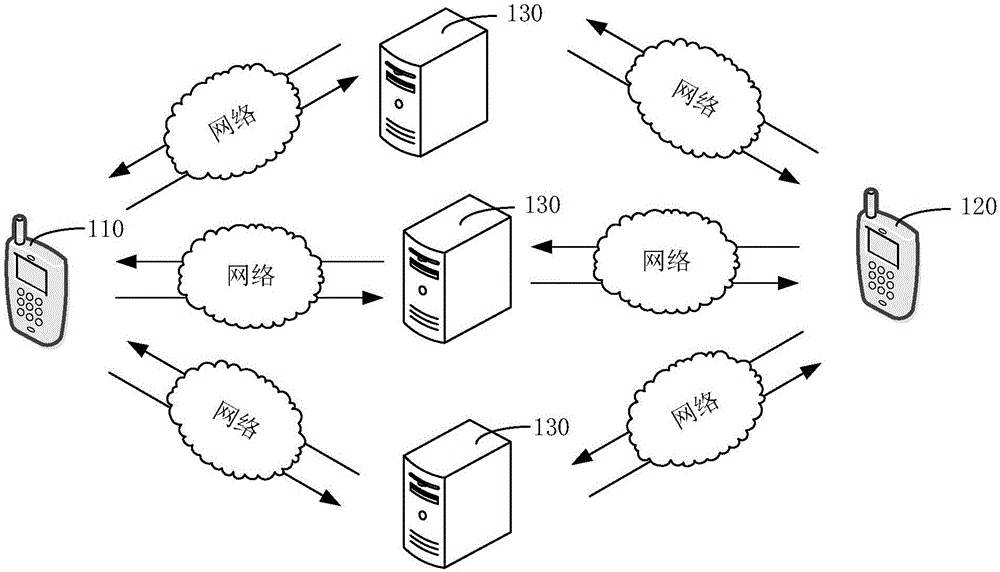

Video editing method and device as well as electronic equipment and storage medium

ActiveCN109413478AEasy to operateImprove adding efficiencySelective content distributionComputer scienceElectric equipment

The embodiment of the invention provides a video editing method and device as well as electronic equipment and a storage medium. The video editing method comprises the following steps: acquiring a caption text required to be added to the currently edited video; according to an operation instruction of a user on an editing interface of the currently edited video, determining an appearing time pointand a disappearing time point of each sentence of the caption text in the currently edited video; and according to the appearing time points and the disappearing time points, adding each sentence ofthe caption text into the currently edited video, so that a video with captions is generated. The embodiment of the invention does not need the user to input the captions sentence by sentence any longer and sets corresponding appearing time points and disappearing time points, the whole caption text can be directly obtained and added into the video, so that operation of the user is simplified, andcaption adding efficiency of the caption is improved.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

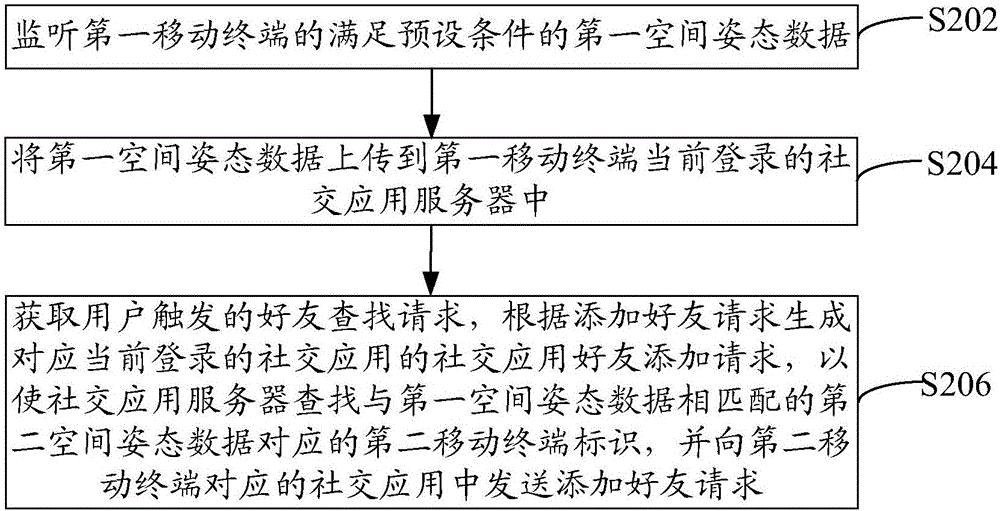

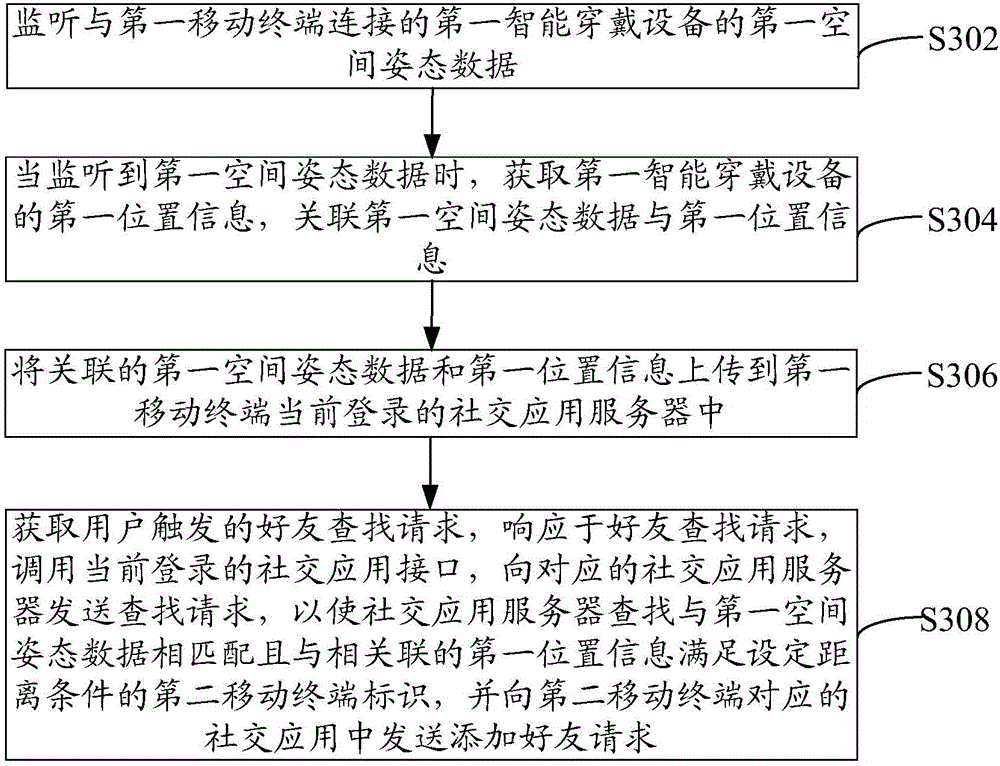

Friend adding method and apparatus

InactiveCN106411716AEasy to addImprove adding efficiencyData switching networksData matchingApplication server

The invention relates to a friend adding method. The method comprises the following steps: monitoring first space attitude data of a first mobile terminal; uploading the first space attitude data to a social application server which the first mobile terminal currently logs in; and obtaining a friend search request triggered by a user, and according to the friend search request, generating a social application friend adding request corresponding to a current login social application so as to enable the social application server to search for a second mobile terminal identification corresponding to second space attitude data matching the first space attitude data and send a friend adding request to a social application corresponding to a second mobile terminal. By use of the method, friends can be added more conveniently. Besides, the invention further provides an apparatus.

Owner:MEIZU TECH CO LTD

New energy automobile motor copper wire automatic molding equipment

PendingCN108889884APrevent fallingImprove securityWire articlesElectric machinesNew energyCopper wire

The invention discloses a new energy automobile motor copper wire automatic molding integrated equipment, comprises an assembly slide rail, wherein one end of the assembly slide rail is provided witha copper wire coiling and uncoiling device and the other end is provided with a copper wire molding device, and a copper wire stripping device, a copper wire traction device, a copper wire cutting device and an automatic copper wire clamping device are sequentially arranged from left to right between the copper wire coiling and uncoiling device and the copper wire molding device. The device automatically unwinds the copper wire, and uninterrupted conveying is realized by the traction device, in this convey process, As that paint strip device travels with the cop wire, and finish stripping thecopper wire in the course of traveling, A thread cutting device is also arranged after the paint stripping operation, The copper wire cutting is completed, and the copper wire is conveyed to the copper wire molding device by an automatic clamping device to complete the molding operation, and in the operation, the paint stripping device, the wire cutting device and the automatic clamping device alltravel together with the copper wire, so that the paint stripping, the cutting and the molding are automatically completed when the copper wire is uninterruptedly conveyed.

Owner:JULI AUTOMATION EQUIP ZHEJIANG CO LTD

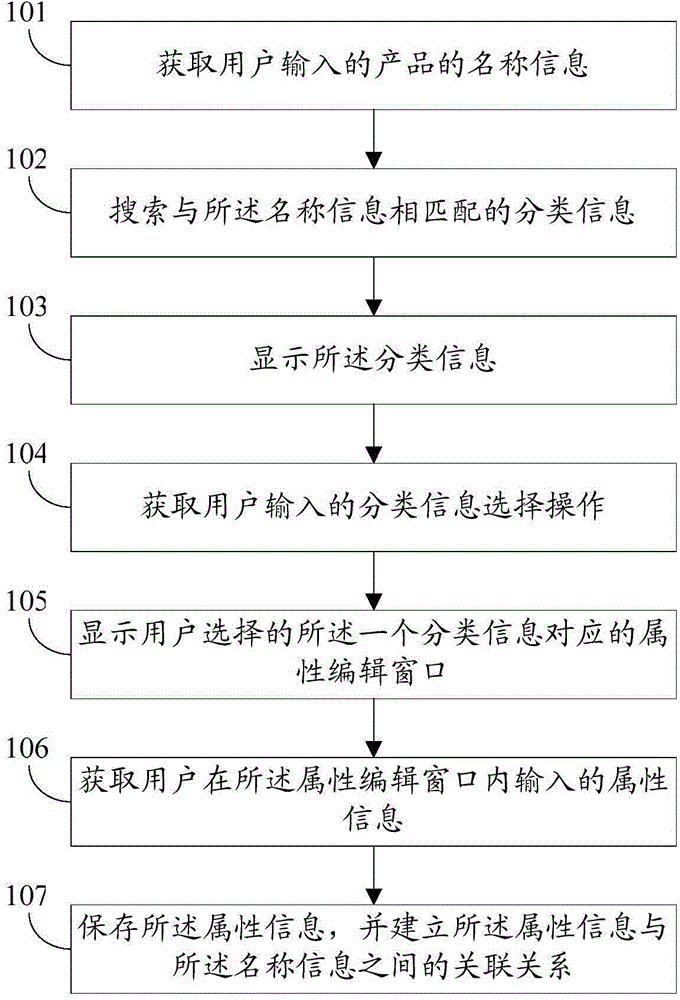

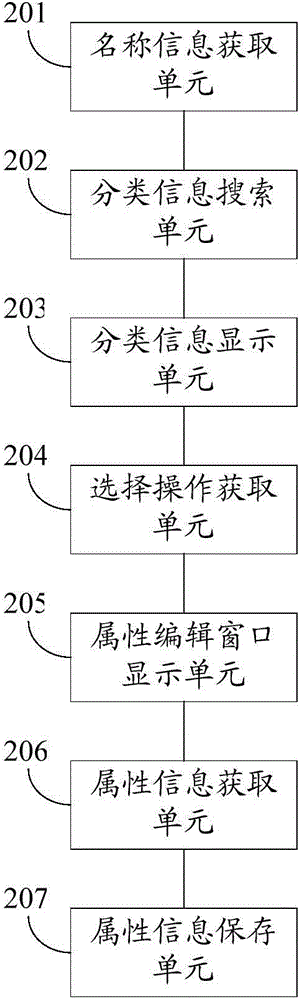

Product attribute information adding method and system

ActiveCN104615774AReduce workloadImprove adding efficiencyWeb data indexingSpecial data processing applicationsClassified informationUser input

The invention discloses a product attribute information adding method and system. The method includes: acquiring name information of a product inputted by a user; searching classified information matched with the name information; displaying the classified information; acquiring classified-information selection operation inputted by the user; displaying an attribute editing window corresponding to the classified information selected by the user, wherein the corresponding relation of the classified information and the attribute editing window is preset; acquiring the attribute information inputted in the attribute editing window by the user; storing the attribute information and establishing the association relation between the attribute information and the name information. By the production attribute information adding method and system, workload spent in adding the attribute information of the product is reduced, and adding efficiency is improved.

Owner:ZHENGZHOU XIZHI INFORMATION TECH

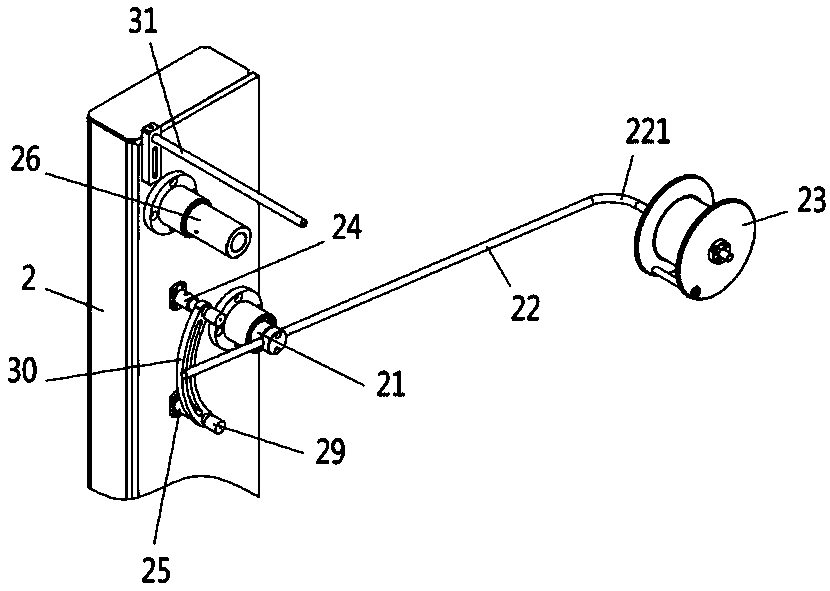

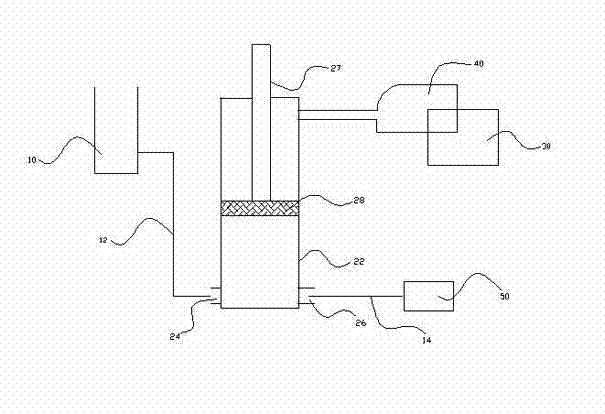

Adding device of paper pulp moulding assistant

InactiveCN102230303AImprove uniformityPrevent dispersion failurePulp material addition processesPulp and paper industryControl unit

The invention provides an adding device of a paper pulp moulding assistant, comprising a storing unit for storing an assistant, an adding unit for adding the assistant, an input pipe for connecting the storing unit with the adding unit, an output pipe connected with the adding unit, a control unit for controlling the adding unit, an assistant dispersing pipe for evenly dispersing the assistant ina pulp injecting pipe and a stirring and blending unit for evenly mixing the assistant with pulp in the pulp injecting pipe. The intermittent adding of the assistant in the pulp is realized by regulating the pressure and the air quantity of a pneumatic unit in the invention; the assistant is evenly dispersed in the pulp injecting pipe by the assistant dispersing pipe; the assistant and the pulp in the pulp injecting pipe are evenly mixed by the stirring and the mixing of the stirring and blending unit, so that the uniformity and the adding efficiency of the assistant for paper pulp moulding are largely improved; the dispersing failure of the assistant for a long time is effectively prevented; and the invention has important significance on the improvement of the quality and the productivity of paper pulp moulding products.

Owner:佛山市昆保达模塑科技有限公司

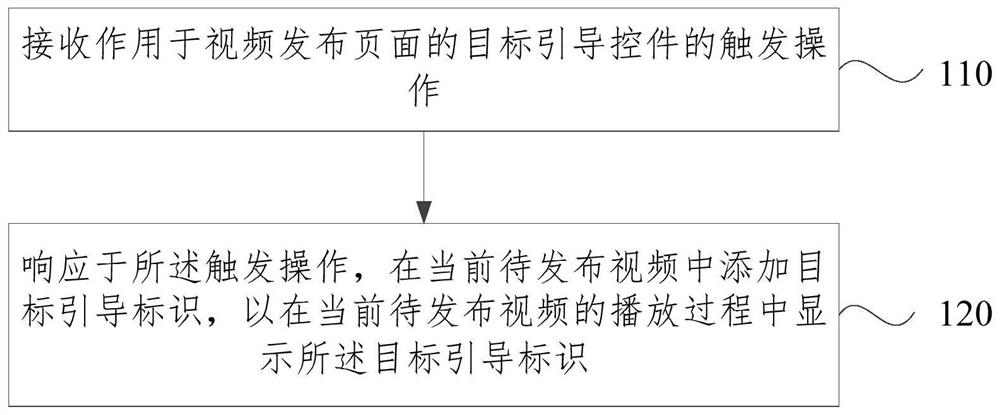

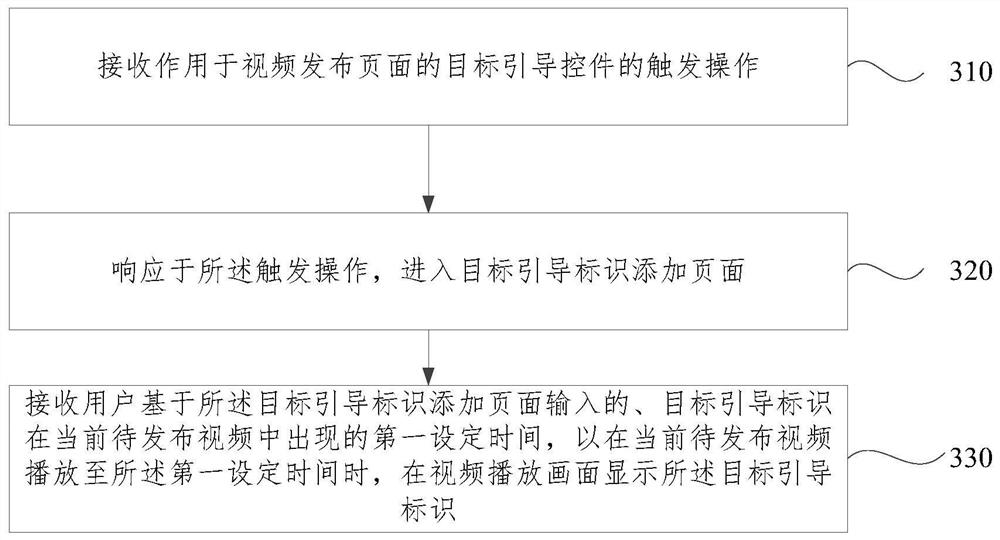

Video processing method and device, electronic equipment and storage medium

PendingCN113038236ASimplified processing operation pathImprove experienceSelective content distributionVideo processingEngineering

The invention relates to a video processing method and device, electronic equipment and a storage medium. The method comprises the following steps: receiving a trigger operation acting on a target guide control of a video release page; in response to the trigger operation, adding a target guide identifier in the current to-be-published video so as to display the target guide identifier in the playing process of the current to-be-published video. Through the technical scheme of the embodiment of the invention, the purpose of conveniently adding the target guide identifier in the video is realized, so a video author can conveniently add the target guide identifier without skipping to other applications in the process of publishing the video.

Owner:BEIJING ZITIAO NETWORK TECH CO LTD

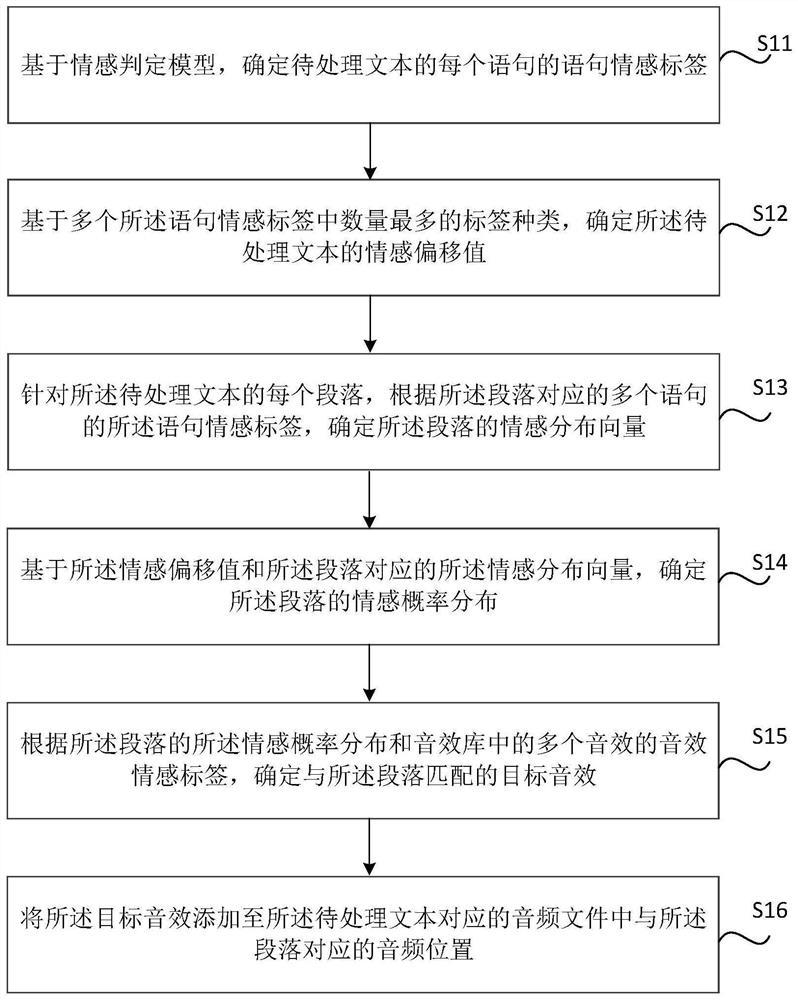

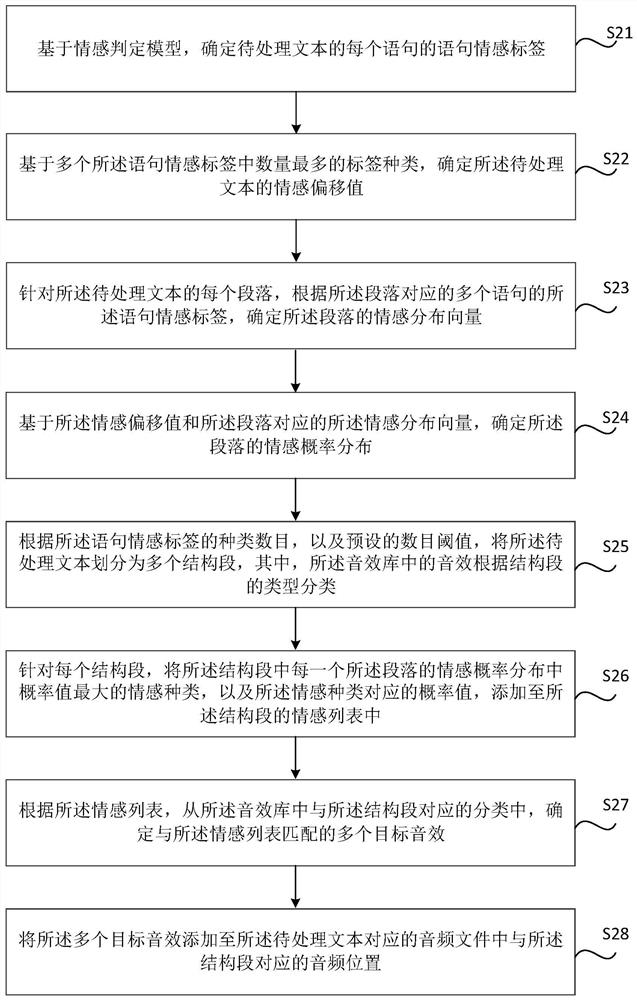

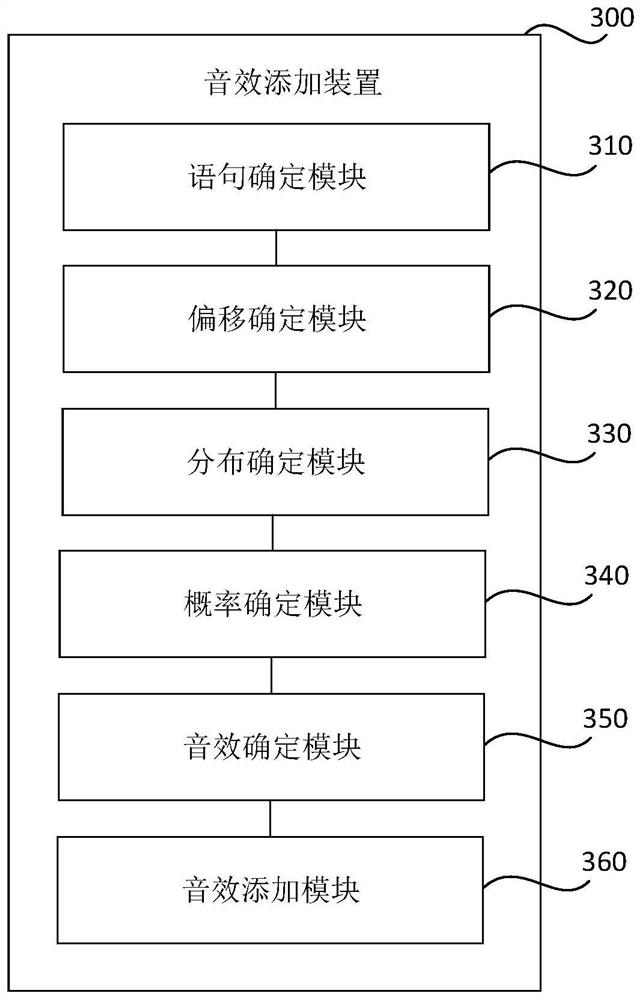

Sound effect adding method and device, storage medium and electronic equipment

PendingCN111767740AImprove adding efficiencyIncrease the atmosphereSemantic analysisSpeech analysisAudio frequencyParagraph

The invention relates to a sound effect adding method and device, a storage medium and electronic equipment, and the method comprises the steps: determining a statement emotion label of each statementof a to-be-processed text based on an emotion judgment model; determining an emotion offset value of the to-be-processed text based on the label type with the largest number in the plurality of statement emotion labels; for each paragraph of the to-be-processed text, determining an emotion distribution vector of the paragraph according to the statement emotion tags of the plurality of statementscorresponding to the paragraph; determining emotion probability distribution of the paragraph based on the emotion offset value and the emotion distribution vector corresponding to the paragraph; determining a target sound effect matched with the paragraph according to the emotion probability distribution of the paragraph and sound effect emotion labels of a plurality of sound effects in a sound effect library; and adding the target sound effect to an audio position corresponding to the paragraph in an audio file corresponding to the to-be-processed text.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

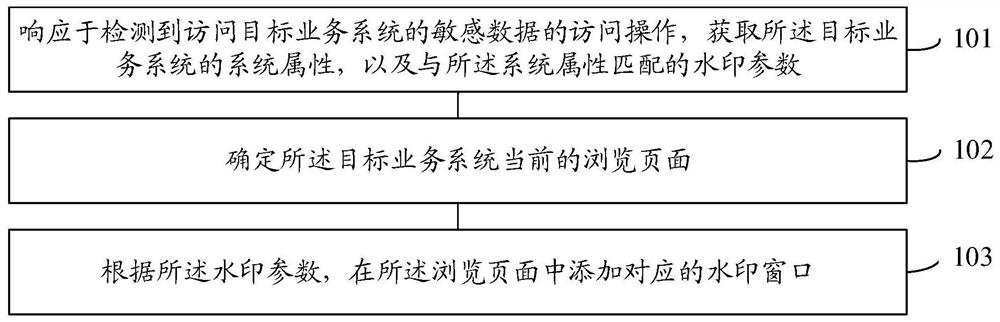

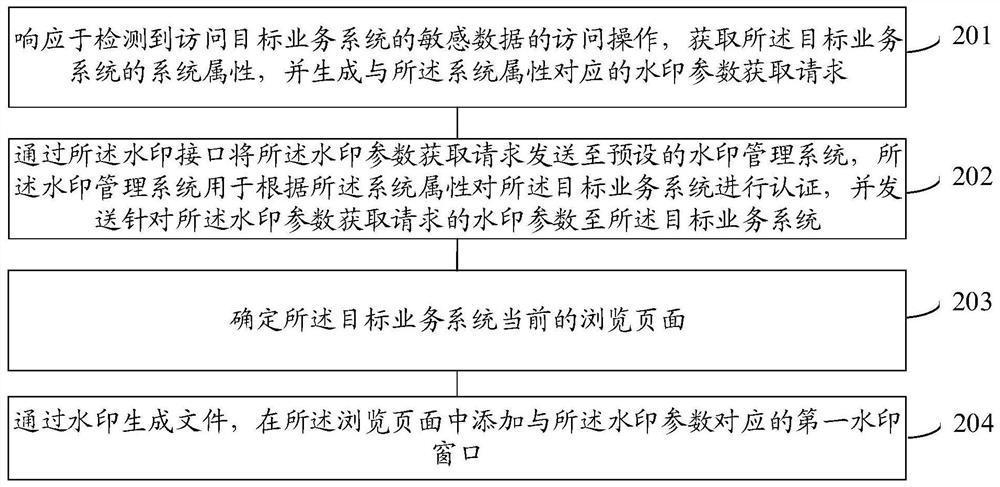

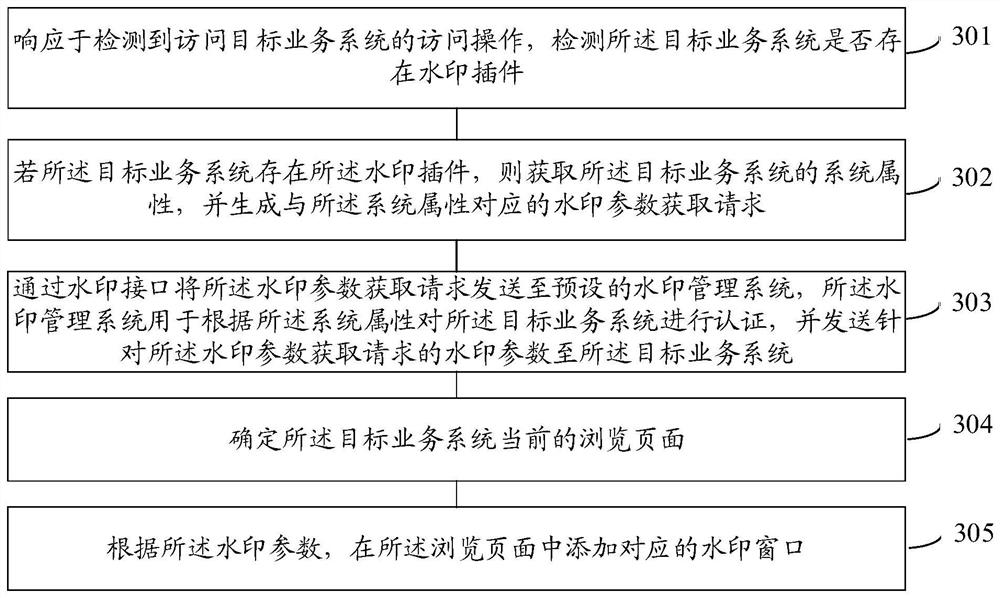

Watermark adding method and device

PendingCN111931135AEnsure safetyImprove universalityProgram/content distribution protectionWatermarkReliability engineering

The embodiment of the invention provides a watermark adding method and device which can be applied to a user terminal, the user terminal can comprise at least one different service system. If so, theuser terminal can respond to the detected access operation of accessing the sensitive data of the target service systemto acquire system attributes of the target service system and the watermark parameters matched with the system attributes, determines a browsing page corresponding to the current sensitive data, and adds a corresponding watermark window in the browsed page according to watermark parameters; therefore, the user terminal can perform watermark matching and add different watermarks according to different service systems, the problem that the watermarks and the service systems cannot be dynamically combined is solved, the universality of watermark adding is improved, the data security is ensured, the watermark adding process is simplified, and the watermark adding efficiency isimproved.

Owner:北京明朝万达科技股份有限公司

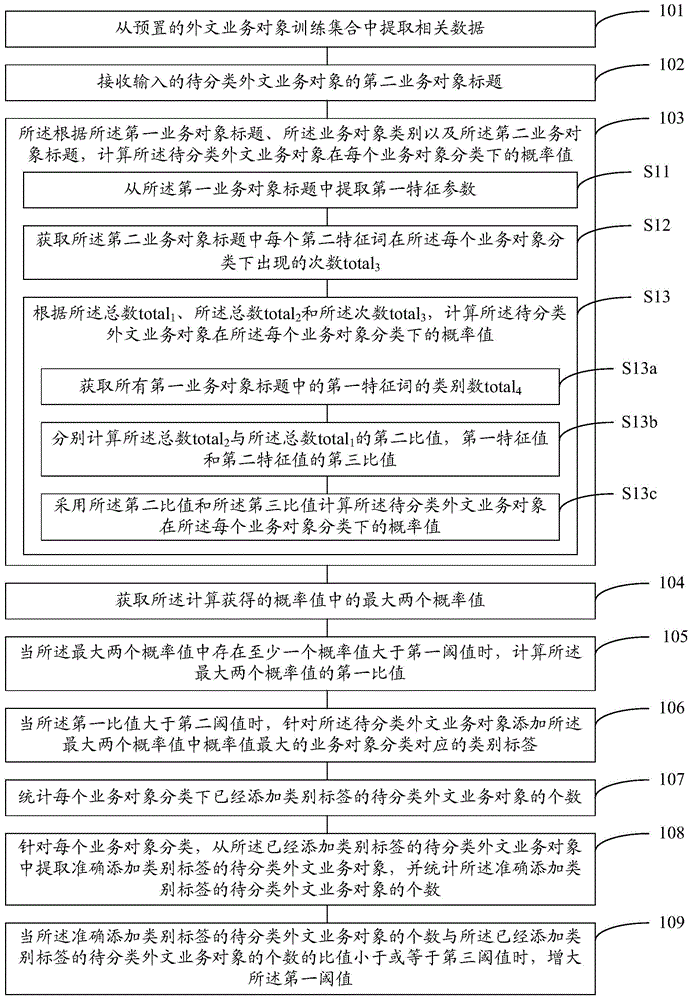

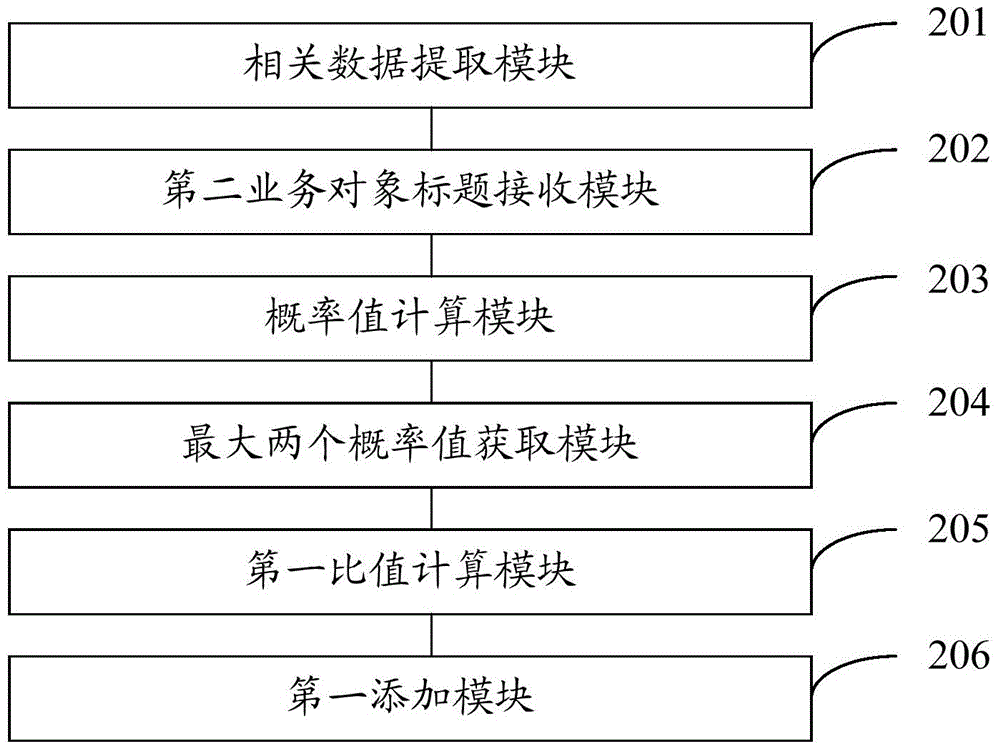

Method and device for adding foreign language business object category labels

InactiveCN104915377AAvoid repeated confirmation operationsImprove adding efficiencySpecial data processing applicationsData miningAlgorithm

The invention discloses a method and device for adding foreign language business object category labels. The method comprises the steps that relevant data are extracted from a preset foreign language business object training set; input second business object titles of foreign language business objects to be classified are received; according to first business object titles, business object categories and the second business object titles, the probability values of the foreign language business objects to be classified under business object classes are calculated; the two maximum probability values in the probability values obtained through calculation are obtained; when at least one of the two maximum probability values is larger than a first threshold value, a first specific value of the two maximum probability values is calculated; when the first specific value is larger than a second threshold value, category labels corresponding to the business object classes with the maximum probability value in the two maximum probability values are added to the foreign language business objects to be classified. According to the method, the accuracy for adding the foreign language business object category labels can be ensued, and the efficiency for adding the category labels can be improved.

Owner:亿赞普(北京)科技有限公司

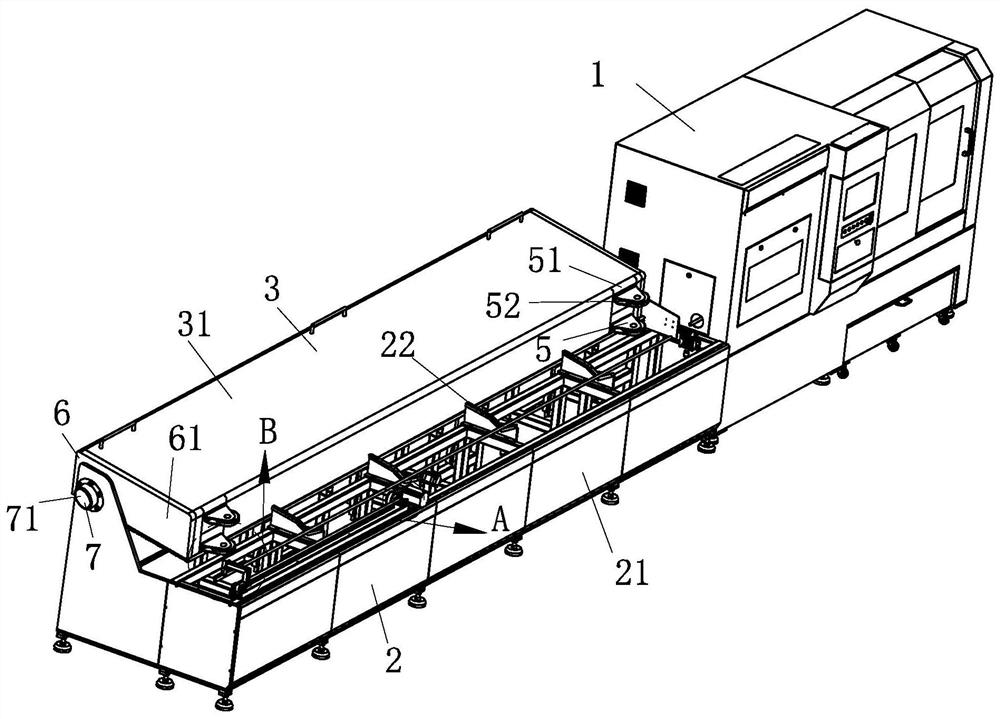

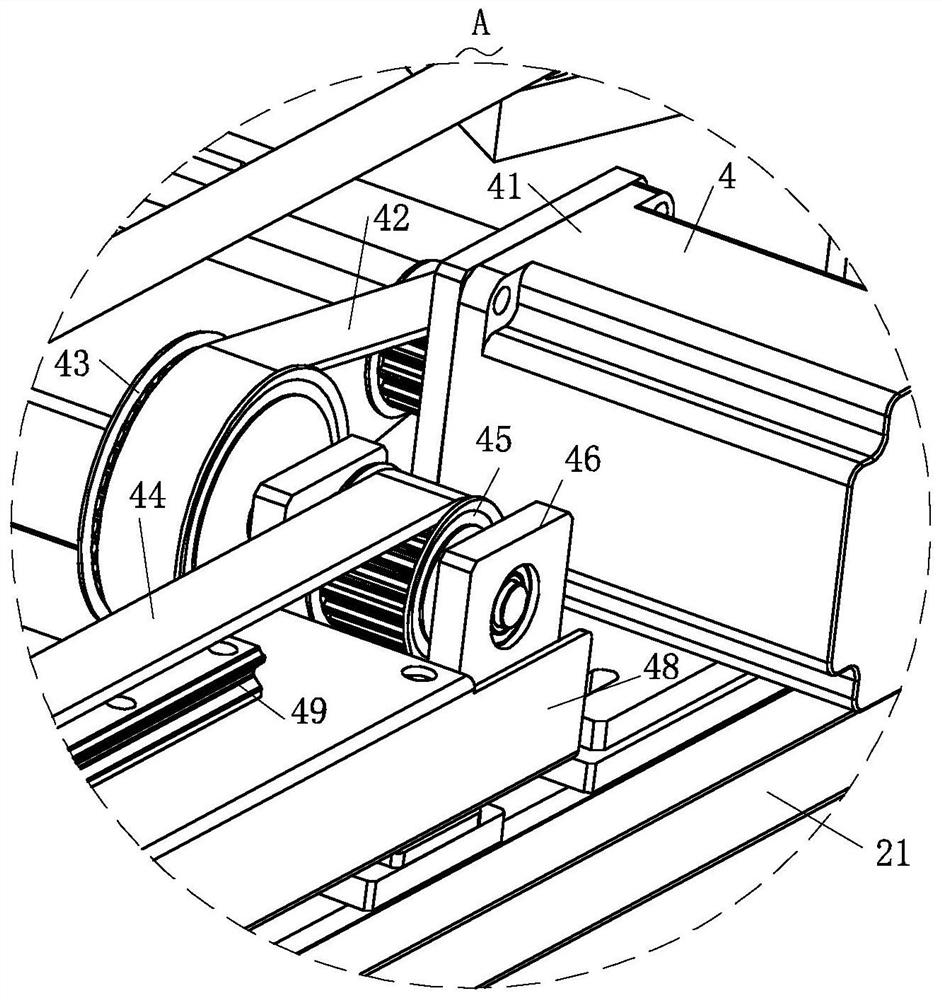

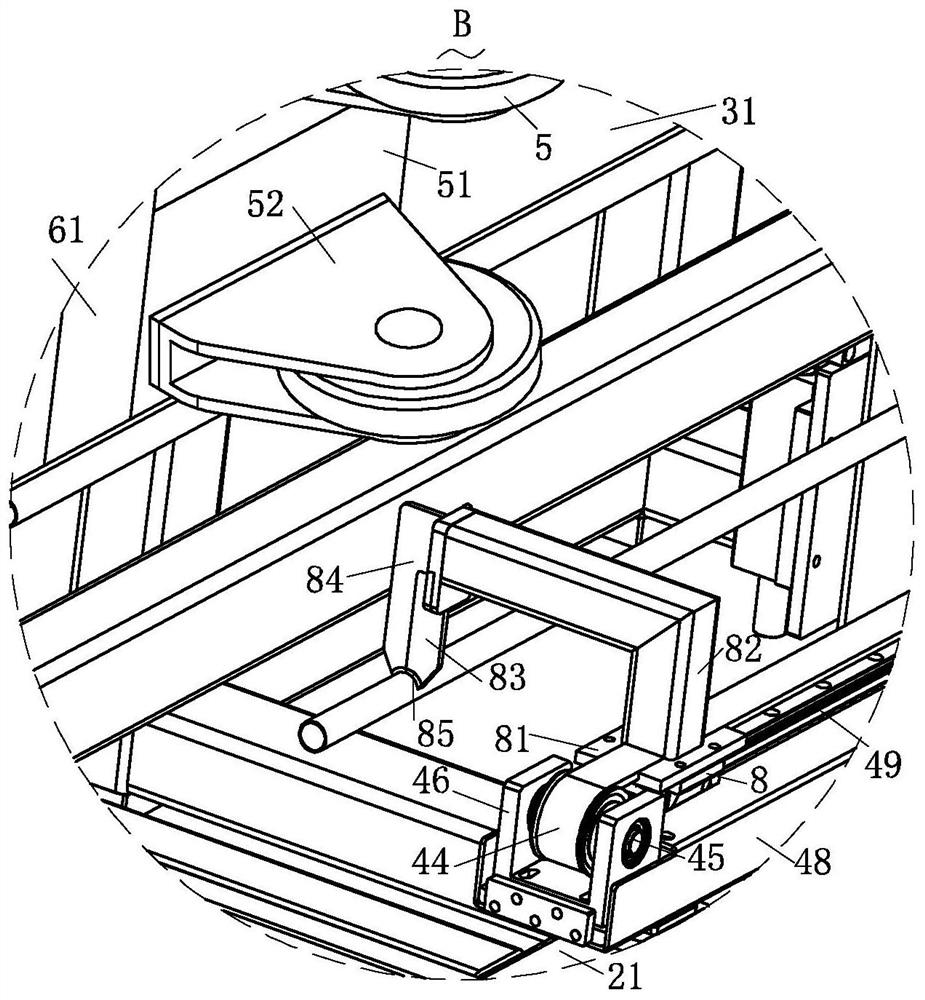

Round tube laser cutting machine convenient for adding materials

ActiveCN113732524AImprove the effect of addingImprove stabilityLaser beam welding apparatusEngineeringLaser cutting

The invention relates to the technical field of laser cutting, in particular to a round tube laser cutting machine convenient for adding materials. The machine comprises a laser cutting machine body, and one side of the laser cutting machine body is connected with a supporting structure for storing round tube materials; an angle adjusting structure is arranged on the supporting structure, the angle adjusting structure is connected to an arrangement structure, the arrangement structure is connected to a storage structure used for storing round tube materials, and the arrangement structure is in linkage with a moving structure used for moving on the storage structure; and the round tube materials are conveniently stored through the storage structure and then moved through the moving structure, then the arrangement structure abuts against the angle adjusting structure, the angle adjusting structure drives the arrangement structure, the storage structure on the arrangement structure is turned over to the top end of the supporting structure, then the round tube materials are more conveniently and rapidly added, secondary carrying of the round pipe materials is effectively avoided, meanwhile, temporary replacement of different materials is facilitated, and then the laser cutting efficiency and quality are greatly improved.

Owner:浙江沪云光电设备股份有限公司

Nano-porous thermal insulation ceramic coil and production method thereof

The invention discloses a nano-porous thermal insulation ceramic coil and a production method thereof. The coil adopts a high temperature-resistant fiber felt as a reinforcing material, nano-porous mullite ceramic in situ formed by nano-silica and nano-alumina as a substrate and a high-temperature infrared shielding material as an auxiliary material, and the obtained nano-porous thermal insulationceramic coil has a good flexibility, a thermal conductivity at 25 DEG C of 0.015 W / (m.K) or less and a thermal conductivity at 1000 DEG C of 0.040 W / (m.K) or less. The coil can be cut at will, is convenient to construct, and can be widely used in the thermal insulation, energy saving and protection of supersonic aircrafts, military ships, metal melting, ceramic sintering and other high-temperature fields.

Owner:响水华夏特材科技发展有限公司

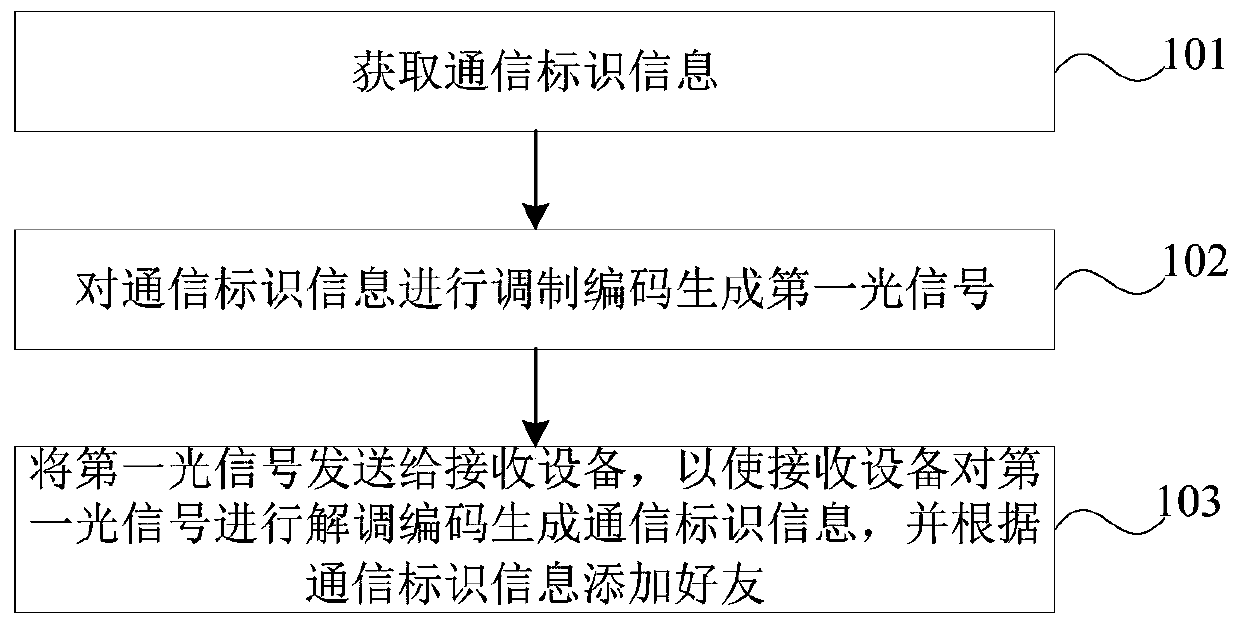

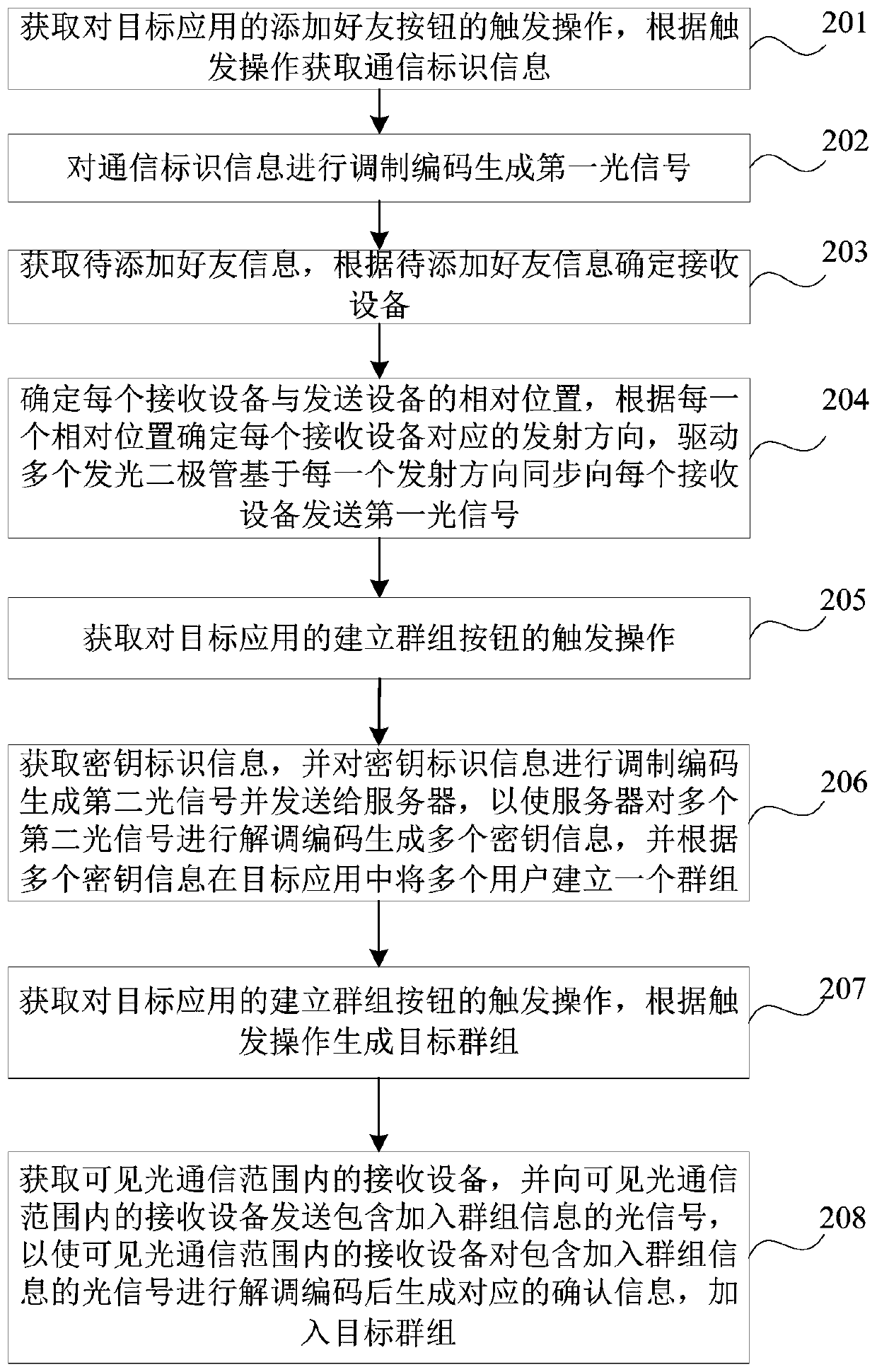

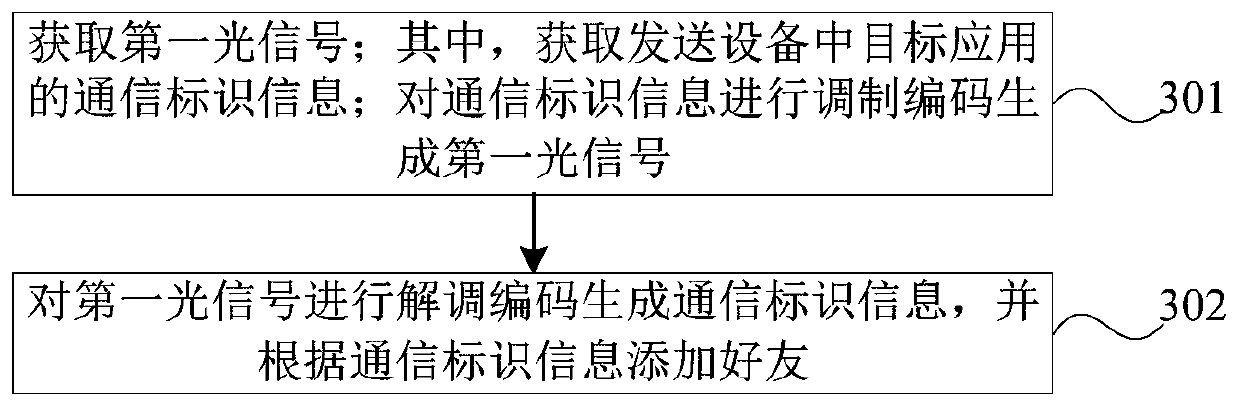

Friend adding method and device based on visible light communication and mobile terminal

ActiveCN110492936AAdd automatic fastImprove adding efficiencyClose-range type systemsData switching networksComputer terminalModulation coding

The invention provides a friend adding method and device based on visible light communication and a mobile terminal. The method comprises steps of obtaining communication identification information; modulating and encoding the communication identification information to generate a first optical signal; and sending the first optical signal to a receiving device, so that the receiving device demodulates and encodes the first optical signal to generate communication identification information, and adds friends according to the communication identification information. The problem of single friendadding mode in the prior art is solved; tedious technical problem, communication identification information is converted into an optical signal to be sent; therefore, the friends can be added throughthe communication identification information by analyzing the received optical signals, the friends can be automatically and quickly added, multiple optical signal analyses can be obtained at a time,the friends can be added, the friend adding efficiency is improved, one-key friend making is achieved, and the user experience is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

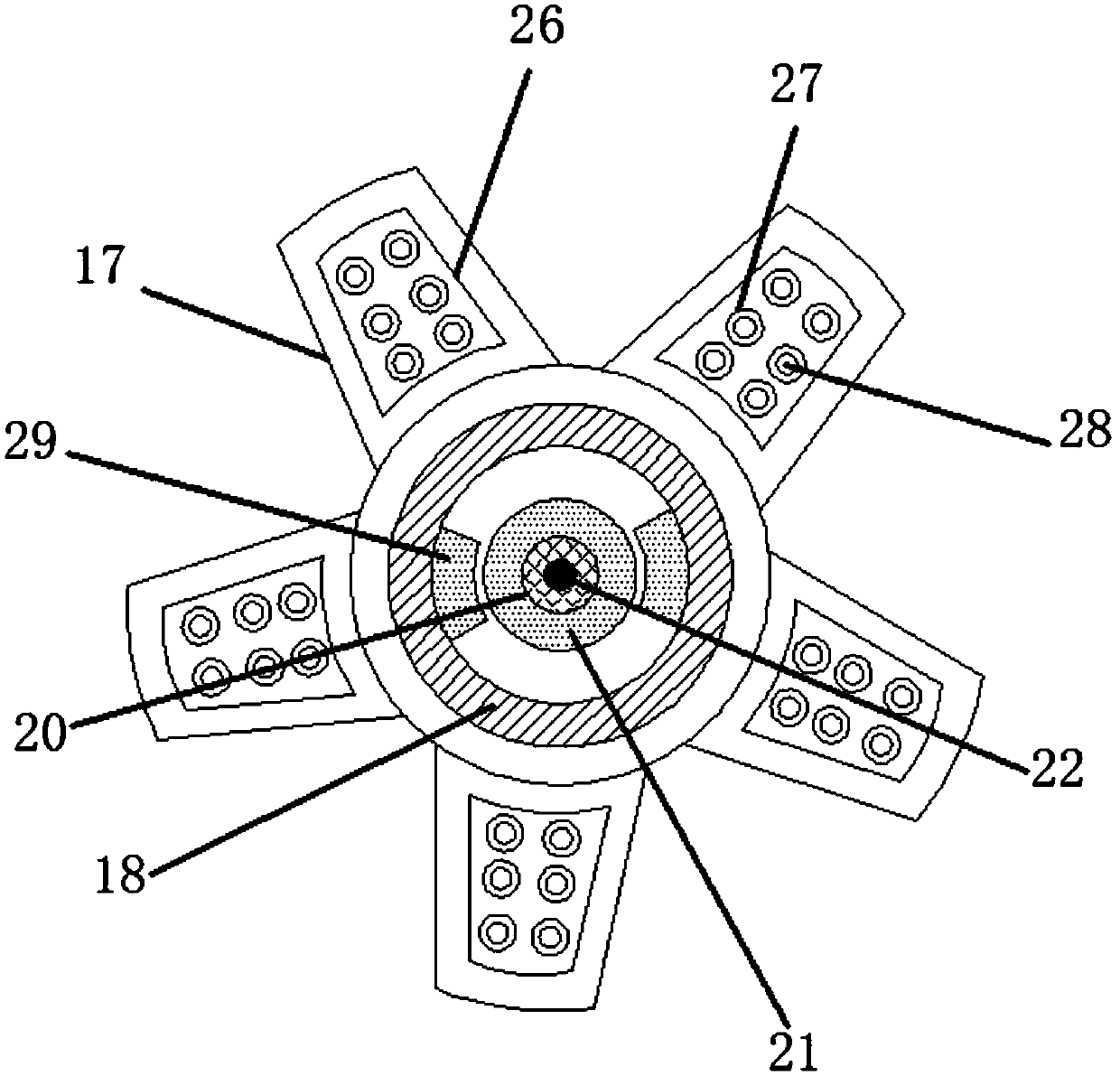

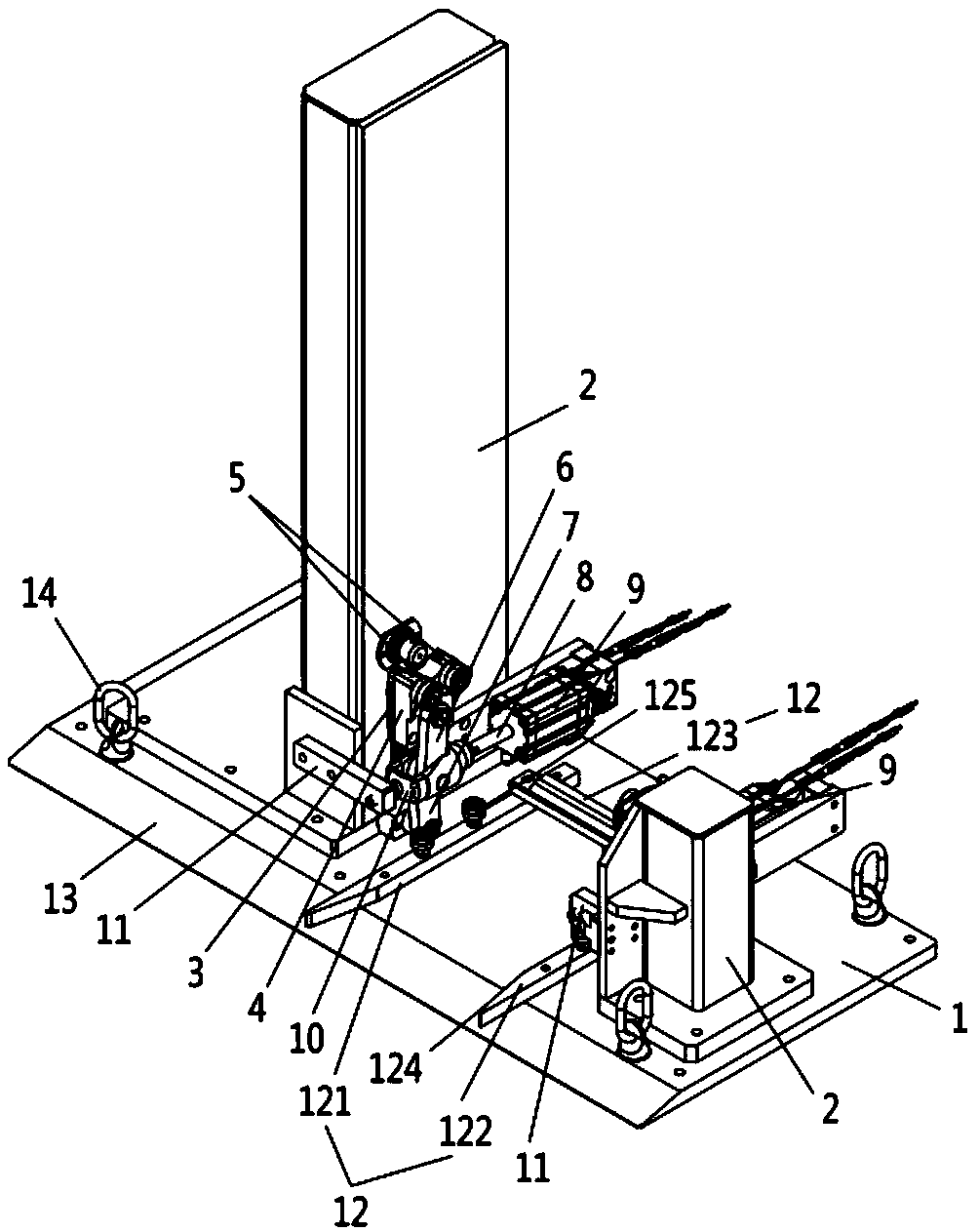

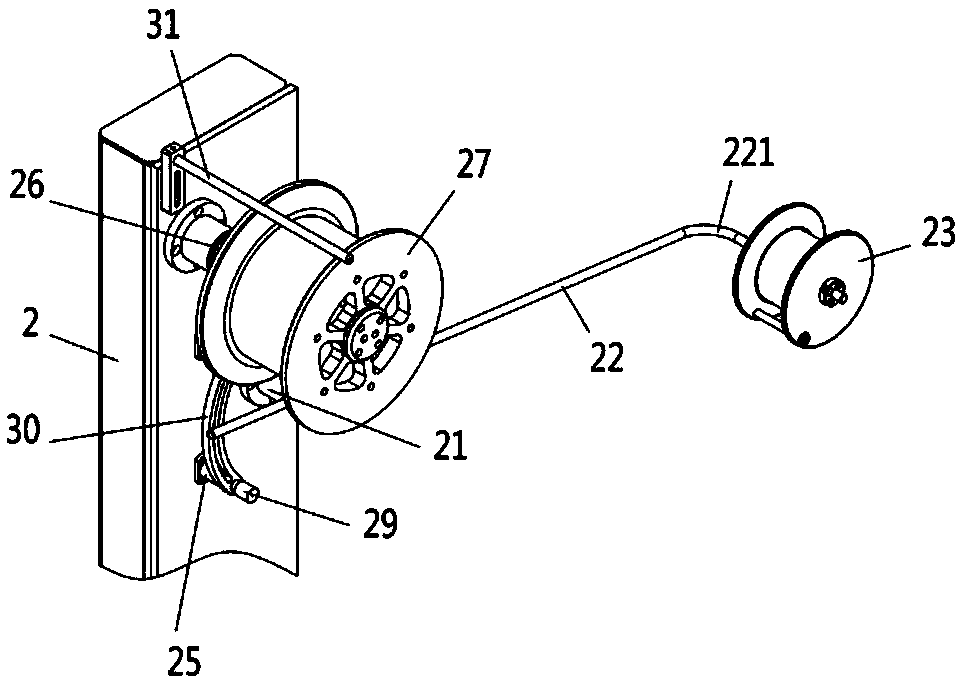

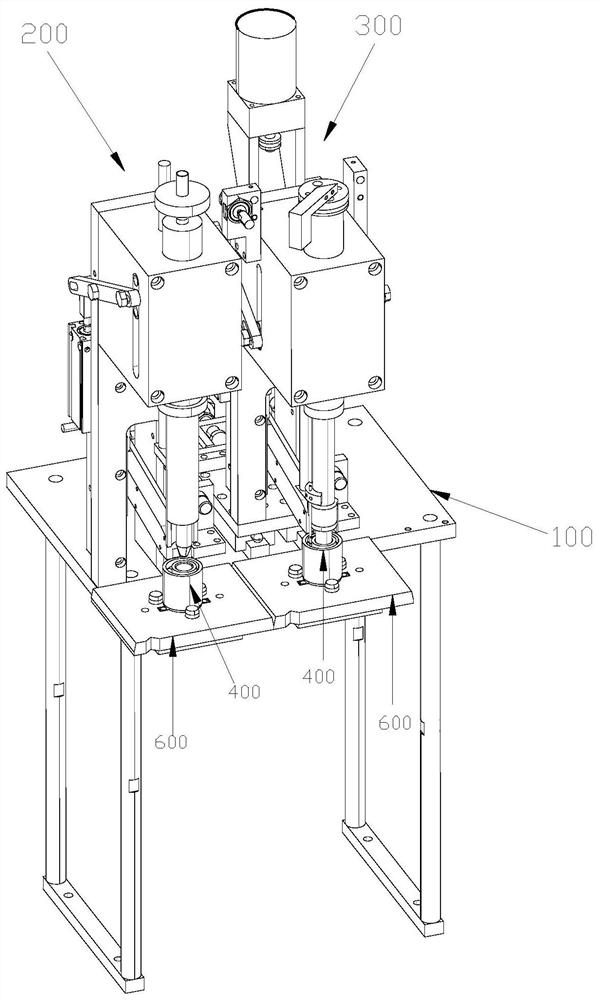

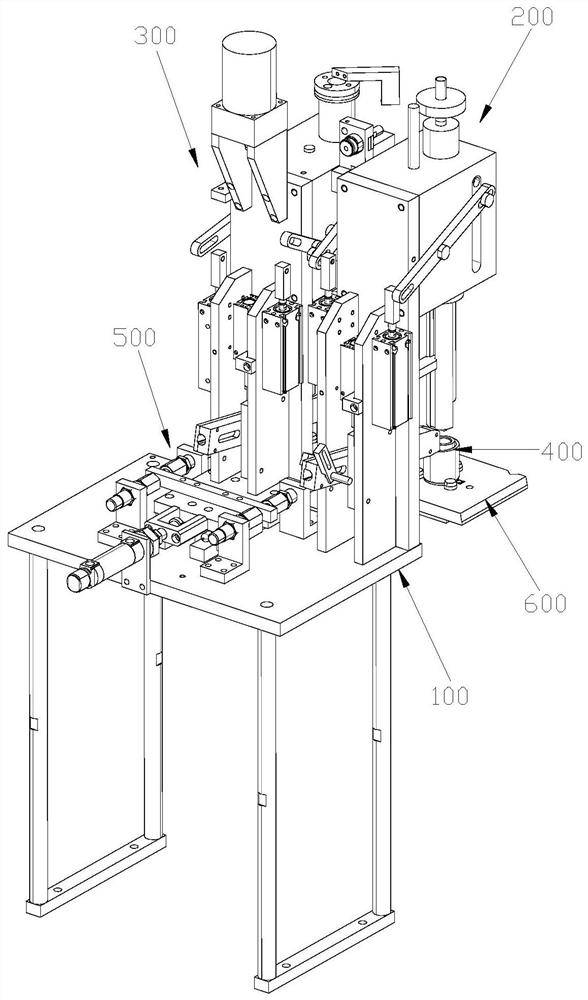

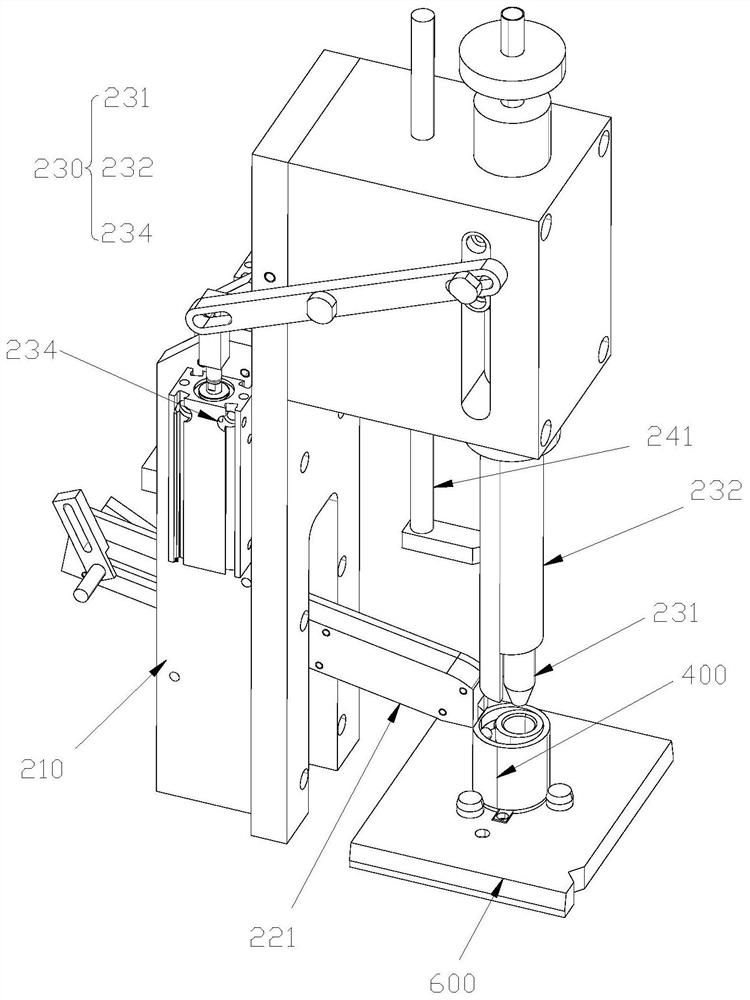

Ball adding device for two-row ball bearing

The invention relates to the technical field of bearing assembling and discloses a ball adding device for a two-row ball bearing. The ball adding device comprises a worktable, wherein a first ball adding mechanism and a second ball adding mechanism are successively arranged on the worktable along a transmission direction of the two-row ball bearing, and the first ball adding mechanism is configured to fill a first channel of the two-row ball bearing with steel balls; the second ball adding mechanism is configured to fill a second channel of the two-row ball bearing with steel balls; a push-pull mechanism is further arranged on the worktable and is configured to push-pull the second ball adding mechanism to drive the second ball adding mechanism to drive an inner ring of the two-row ball bearing to translate relative to an outer ring. The first ball adding mechanism and the second ball adding mechanism can fill the first channel and the second channel of the two-row ball bearing with the steel balls separately and simultaneously. After the balls are added, the second ball adding mechanism is pulled by the push-pull mechanism, so that the inner ring and the outer ring of the two-rowball bearing after the balls are added are located in a same axis to keep corresponding steel balls in corresponding first channel and second channel, and therefore, the ball adding device is high inball adding efficiency.

Owner:KUNSHAN AODELU AUTOMATION TECH

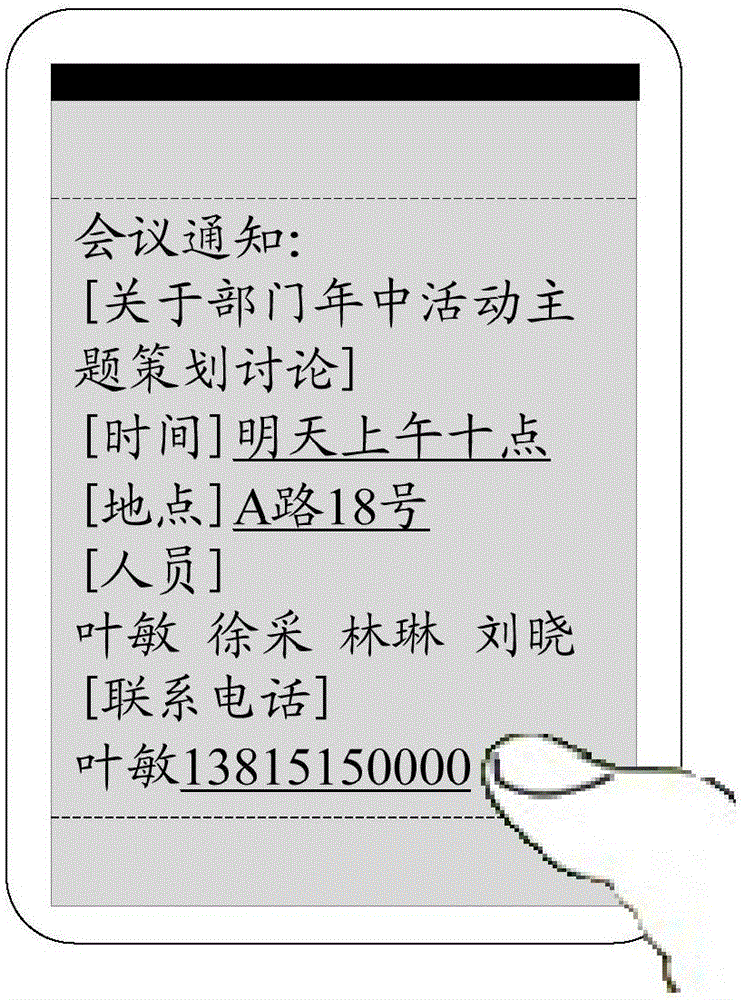

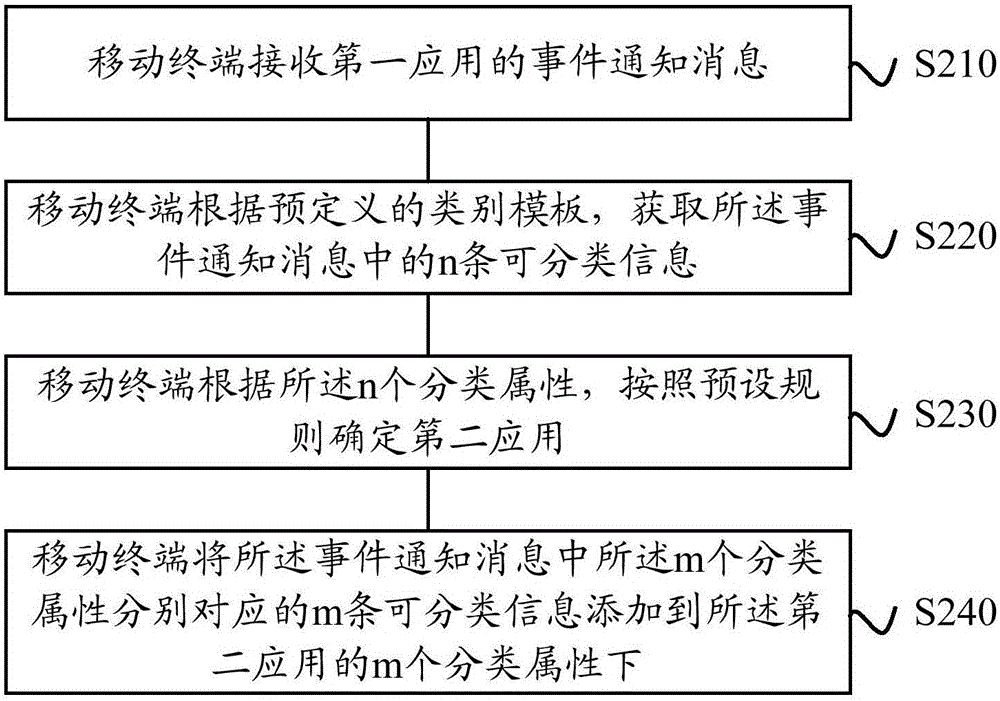

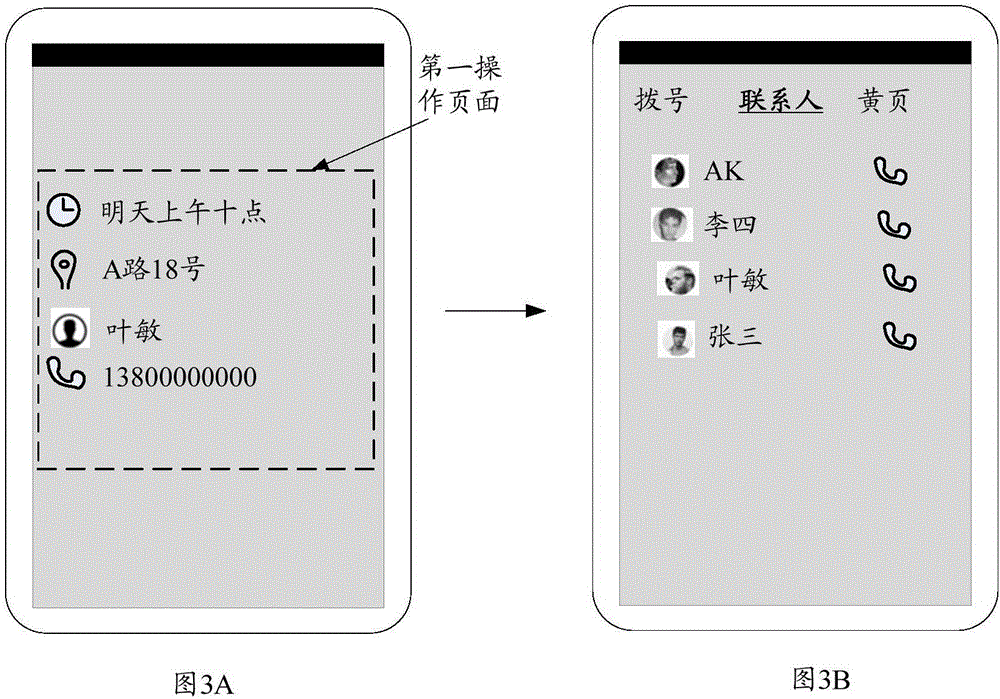

Mobile terminal and method for acquiring event information on mobile terminal

ActiveCN106686240AAutomatically addedImprove adding efficiencyInterprogram communicationServices signallingComputer terminalReal-time computing

Owner:HUAWEI MACHINERY

Dual spice adding system

The invention discloses a dual spice adding system. The dual spice adding system comprises nozzles for spraying spice liquid into a perfuming barrel, the perfuming barrel used for containing a material and mixing the material and the spice liquid, a first feeding device and a second feeding device, wherein the perfuming barrel and the nozzles are arranged in a relatively rotating manner, so that the mixing of the material and the spice liquid is realized by utilizing the rotation speed difference of the perfuming barrel and the nozzles; and the nozzles comprise a first nozzle and a second nozzle, the first nozzle is connected with the first feeding device, and the second nozzle is connected with the second feeding device. The dual spice adding system provided by the invention is provided with the two nozzles and the two sets of feeding devices, so that the two spices with different solubilities can be dissolved in the two sets of feeding devices respectively, the obtained liquid is conveyed into the nozzles, further, the spice liquid is sprayed into the perfuming barrel through the two nozzles, and meanwhile, the spice liquid is sufficiently mixed with the material by utilizing therotation speed difference between the nozzles and the perfuming barrel. Compared with the prior art, the system provided by the invention has the advantages that the processing time is greatly shortened, the production efficiency is improved, and the simultaneous adding of the two spices with different solubilities is realized.

Owner:CHINA TOBACCO GUANGDONG IND

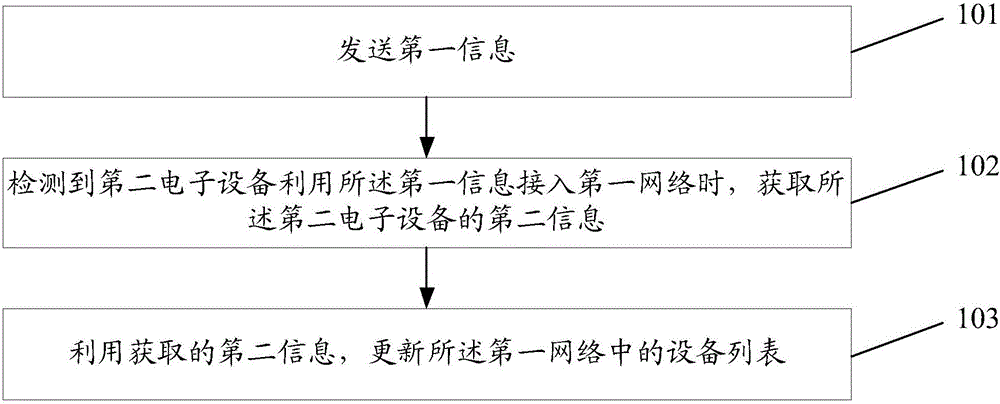

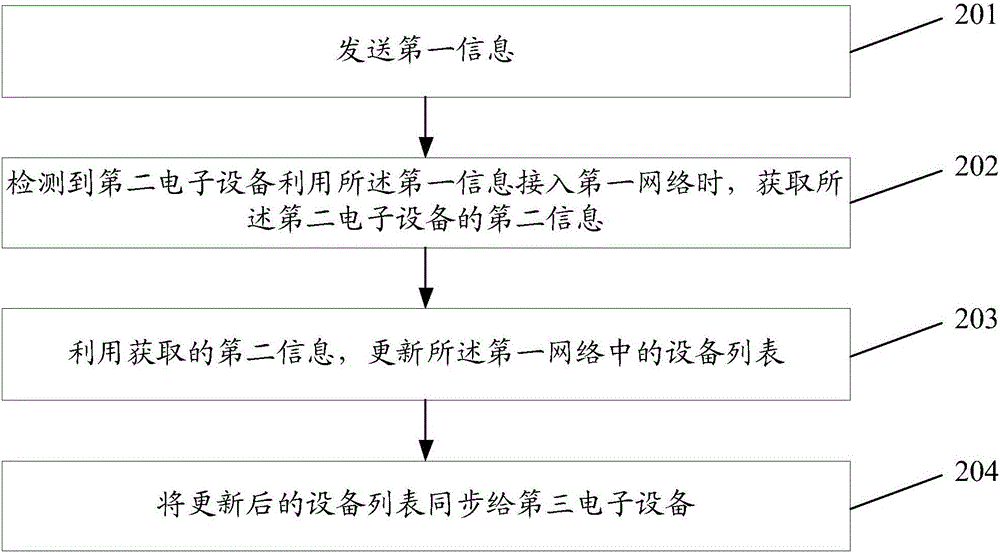

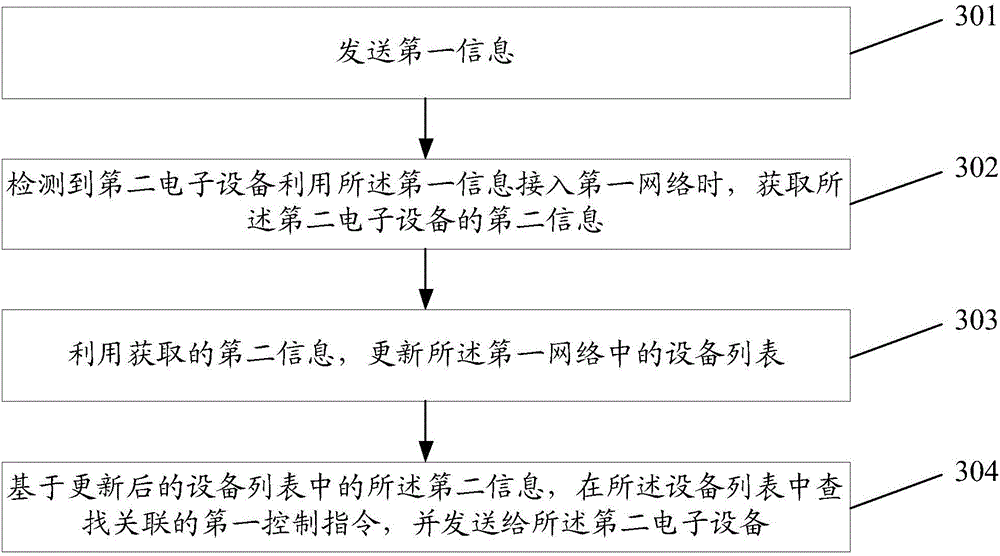

Information processing method and electronic equipment

ActiveCN105979002AImprove adding efficiencyAssess restrictionTransmissionInformation processingComputer science

The invention discloses an information processing method and electronic equipment. The method comprises the following steps: transmitting first information by first electronic equipment, wherein the first information represents authentication information for accessing a first network; acquiring second information of second electronic equipment when that the second electronic equipment accesses the first network by using the first information is detected, wherein the second information represents the attribute of the second electronic equipment; and updating an equipment list in the first network by using the acquired second information, wherein the first electronic equipment can control running of the second electronic equipment according to the second information in the updated equipment list.

Owner:LENOVO (BEIJING) LTD

Data processing method and device, equipment and storage medium

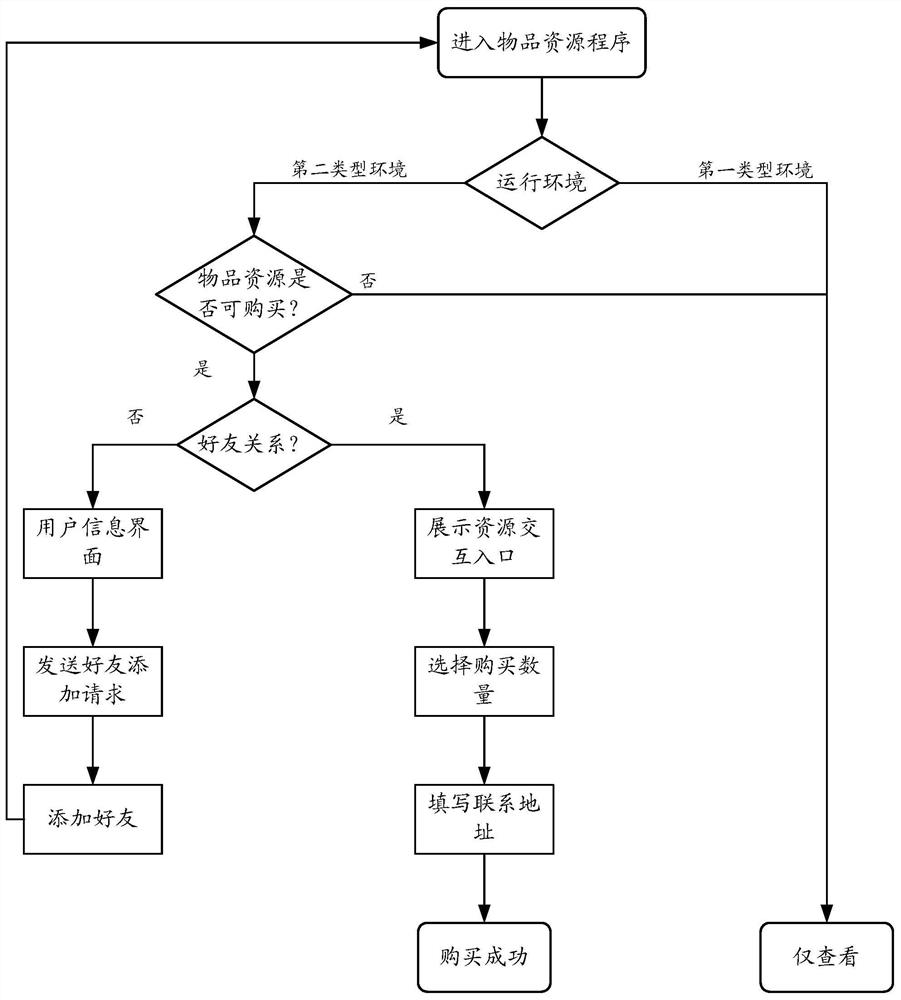

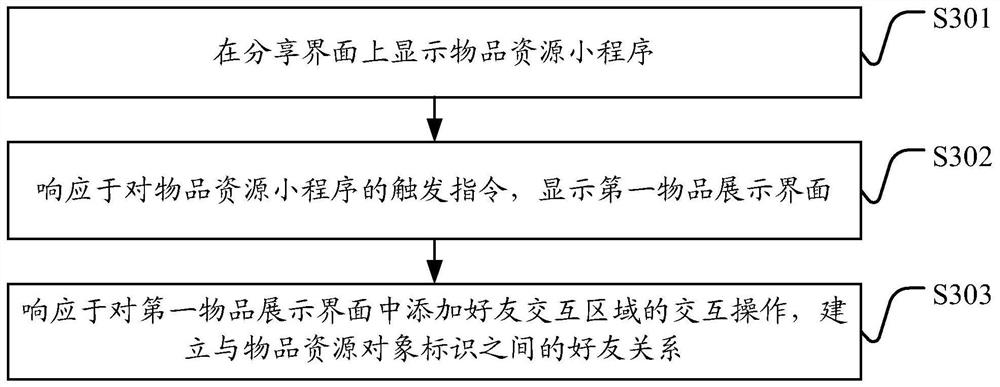

PendingCN112150256AImprove adding efficiencyBuying/selling/leasing transactionsPayment circuitsHuman–computer interactionObject identifier

The embodiment of the invention provides a data processing method and device, equipment and a storage medium. The method comprises the following steps: displaying an article resource applet on a sharing interface; in response to a triggering instruction for the article resource applet, displaying a first article display interface; and in response to an interaction operation of adding a friend interaction area to the first article display interface, establishing a friend relationship with the article resource object identifier. By adopting the embodiment of the invention, the users of the two parties of commodity transfer can be visually and conveniently guided to establish the friend relationship based on the article resource applet displayed on the sharing interface, and the friend addingefficiency is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com