Patents

Literature

68results about How to "Shorten the path of movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

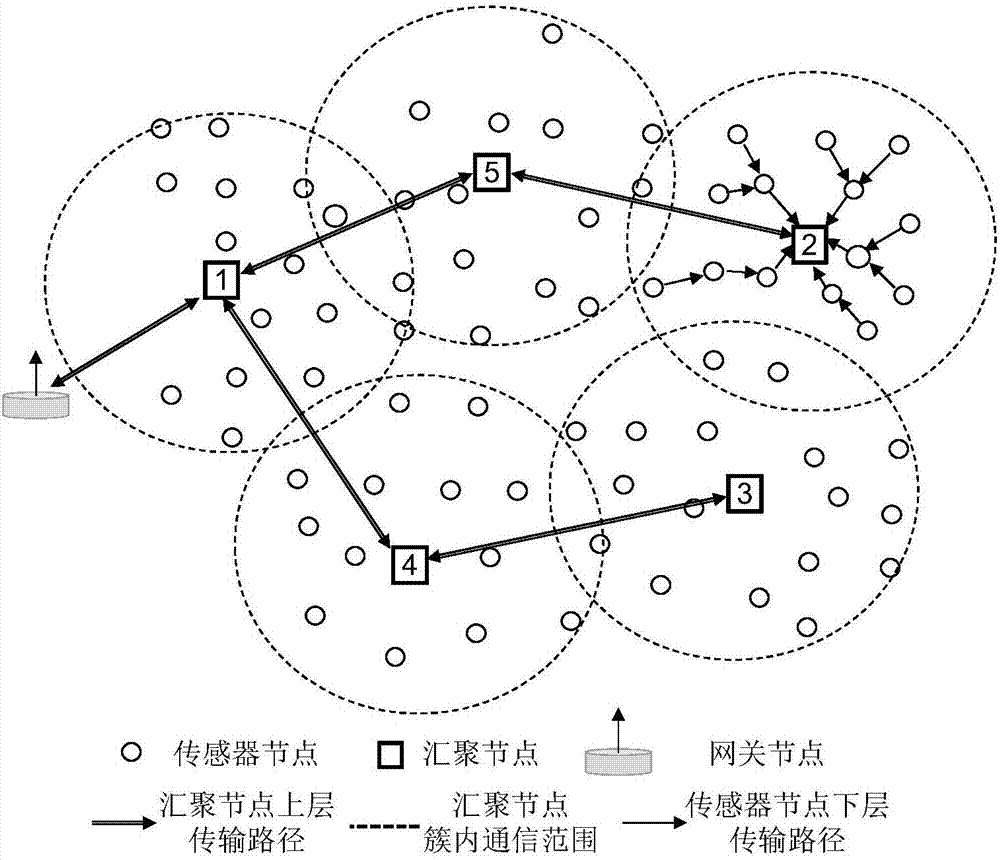

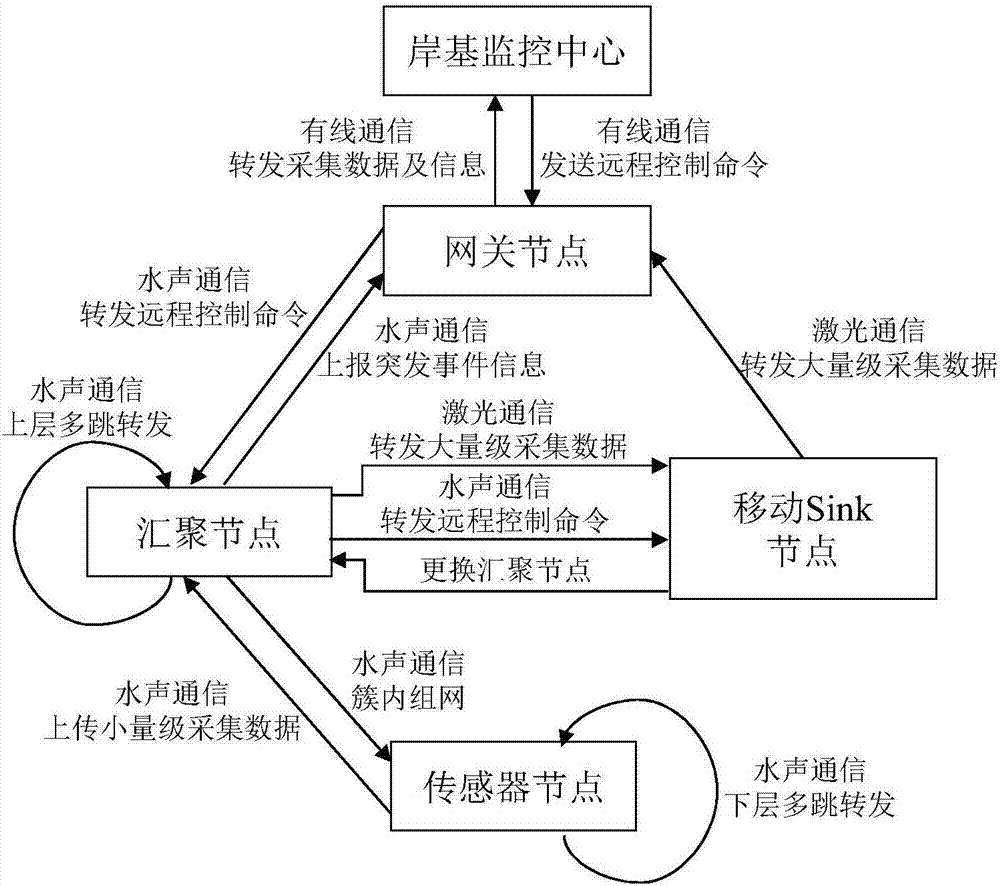

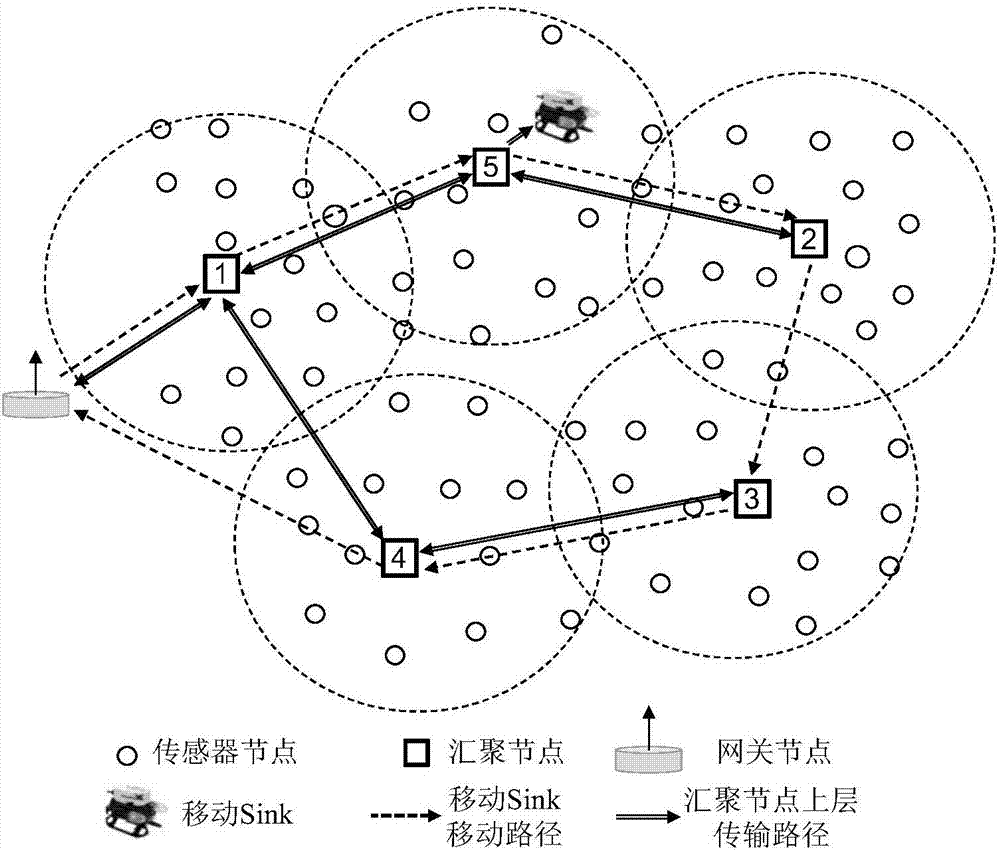

Mobile Sink path planning method for underwater heterogeneous sensor network

ActiveCN107994948AReduce energy consumptionReduce distanceNetwork topologiesElectromagnetic transmittersNetwork structurePlanning method

The invention discloses a mobile Sink path planning method for an underwater heterogeneous sensor network. The method comprises the following steps: a dual-layer topology network structure is established; an optimal aggregation node laying location is selected by adopting a fitness function and a grid method; a mobile Sink plans the shortest mobile path and mobiles to transverse all aggregation nodes; a shore-based monitoring center sends a remote control command to the mobile Sink in a multi-hop way through the aggregation node upper network; the mobile Sink changes the mobile path in real time according to the control command. The collection and transmission of the network monitoring data are realized through a multi-mode communication way of the underwater sound and laser communicationand the mobility of the mobile Sink, thereby effectively improving the bottleneck problem that the underwater communication rate and the distance are in conflict.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

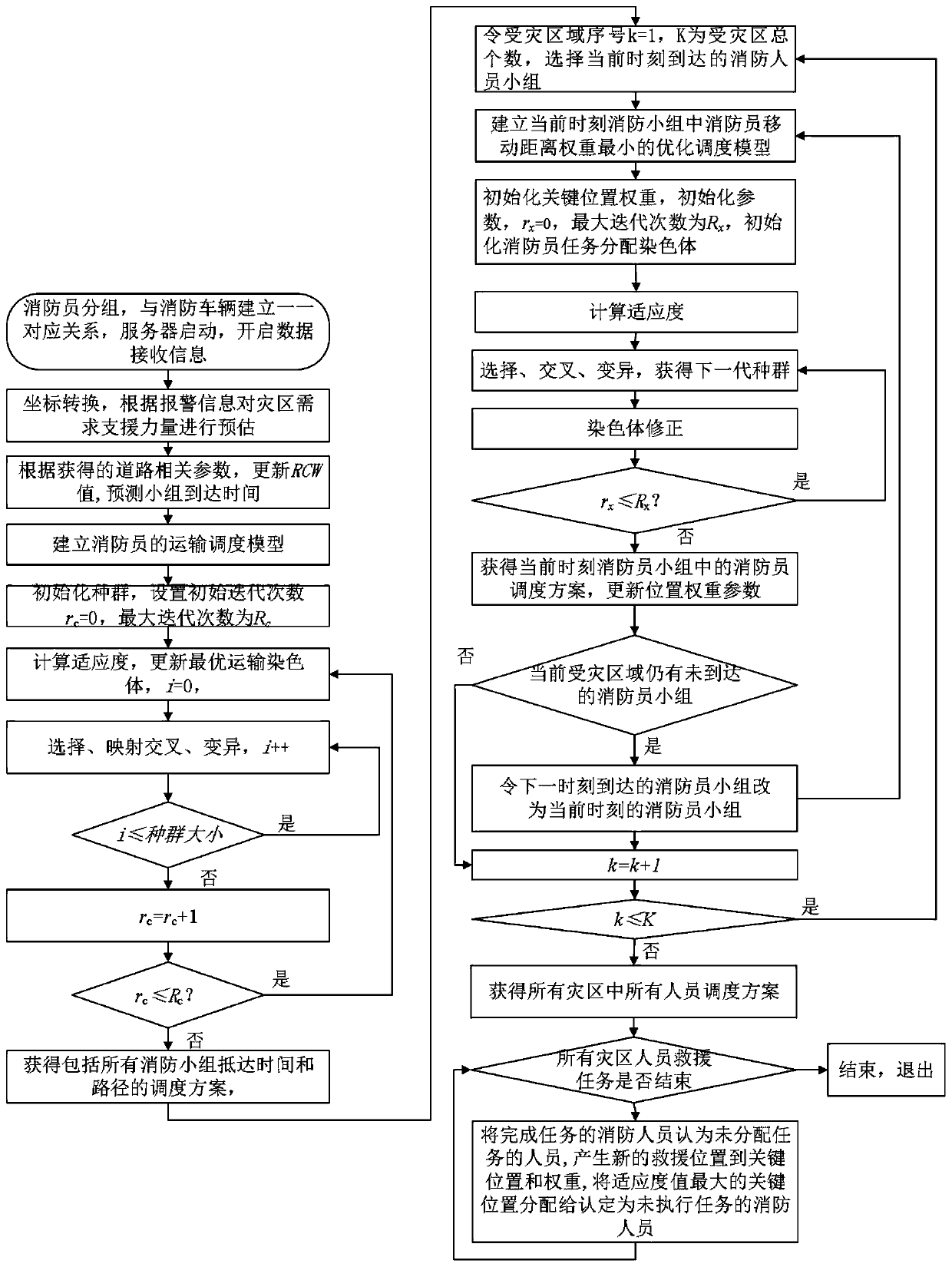

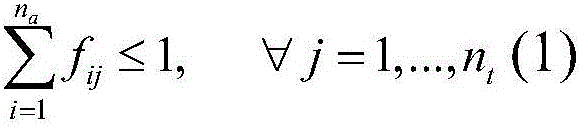

Firefighter rescue scheduling method adapting to fire dynamic changes

ActiveCN110197303ASolving Transportation Allocation ProblemsImprove arrival timeForecastingFire alarmsGenetic algorithmArrival time

The invention relates to a firefighter rescue scheduling method adapting to fire dynamic changes, which comprises the following steps: establishing an optimization model for balancing transportation time and fair distribution of a disaster-affected area, and solving the problems of short arrival time of firefighters and balancing personnel distribution of each disaster-affected area by adopting agenetic algorithm; according to the invention, dynamic changes of disaster situations are also considered; after the firefighters arrive at a disaster area, the rescue task can also be changed in realtime along with the change of the disaster situation; according to the method, rescue tasks are distributed to each firefighter reaching the disaster area in real time; a personnel movement distanceweight minimum optimization scheduling model is established; a genetic algorithm is adopted to reduce the moving rescue path of the firefighters reaching the disaster area and correct the distributionof the firefighters reaching the disaster area, so that the overall rescue efficiency is improved, and the rescue scheduling and distribution are more reasonable; and the method is an important change from traditional rescue to intelligent rescue, and precious time is saved for rescue.

Owner:ZHEJIANG SHUREN COLLEGE ZHEJIANG SHUREN UNIV

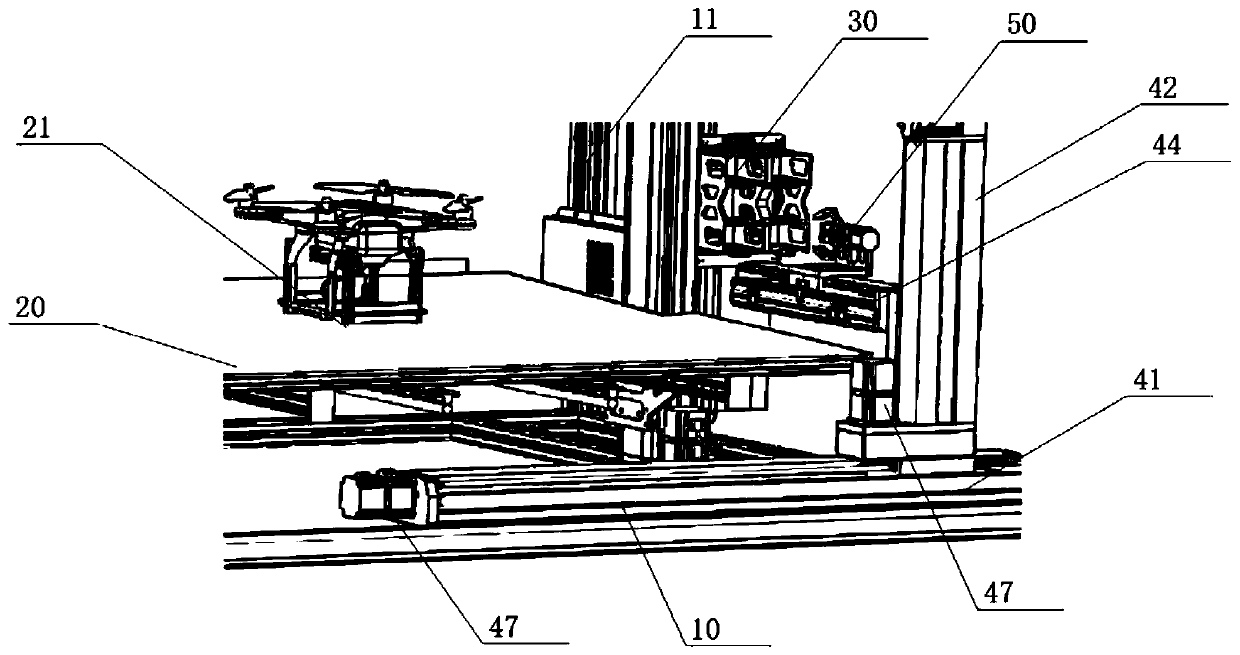

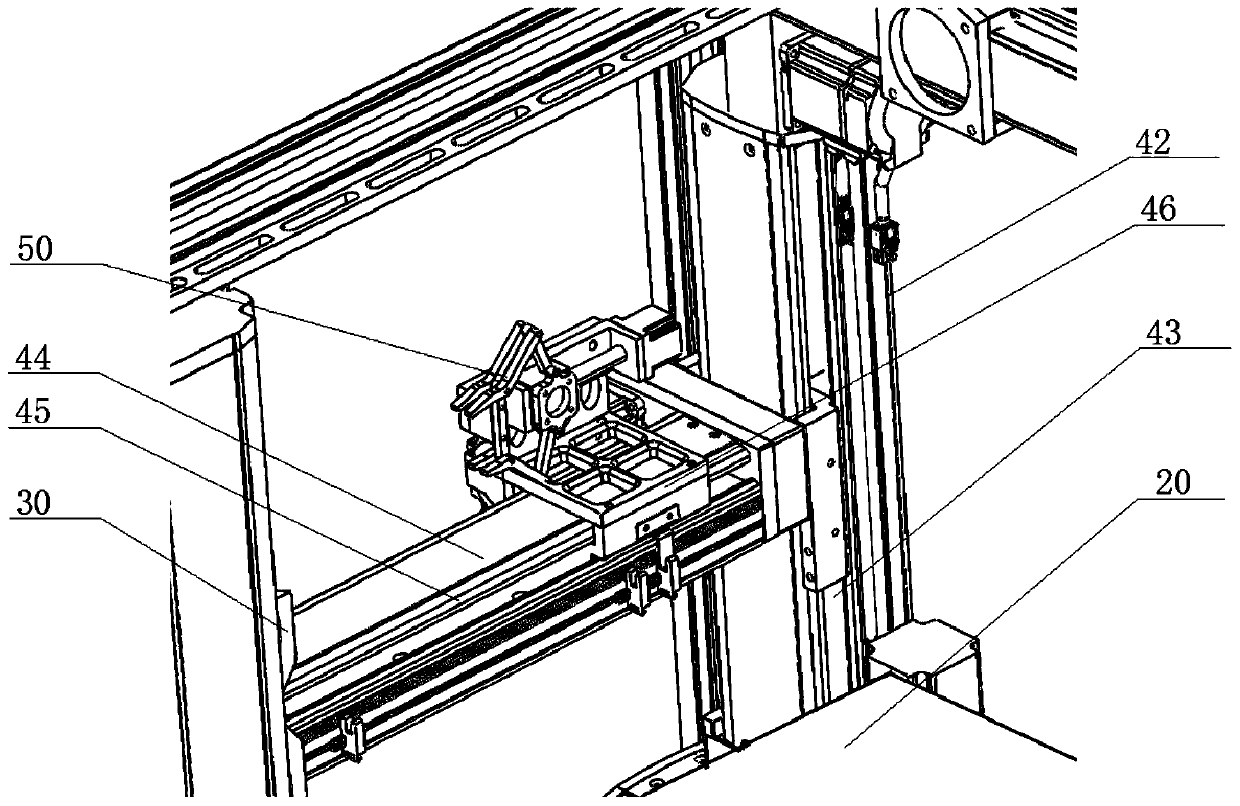

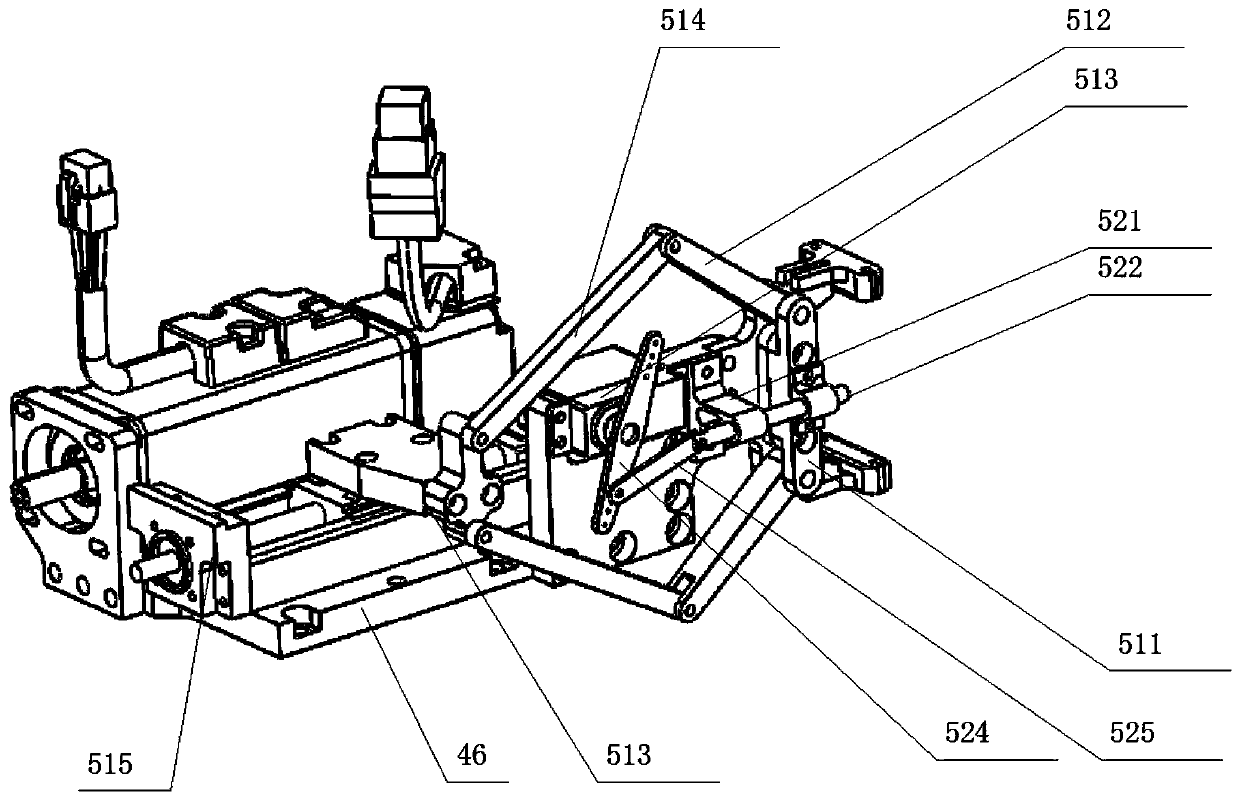

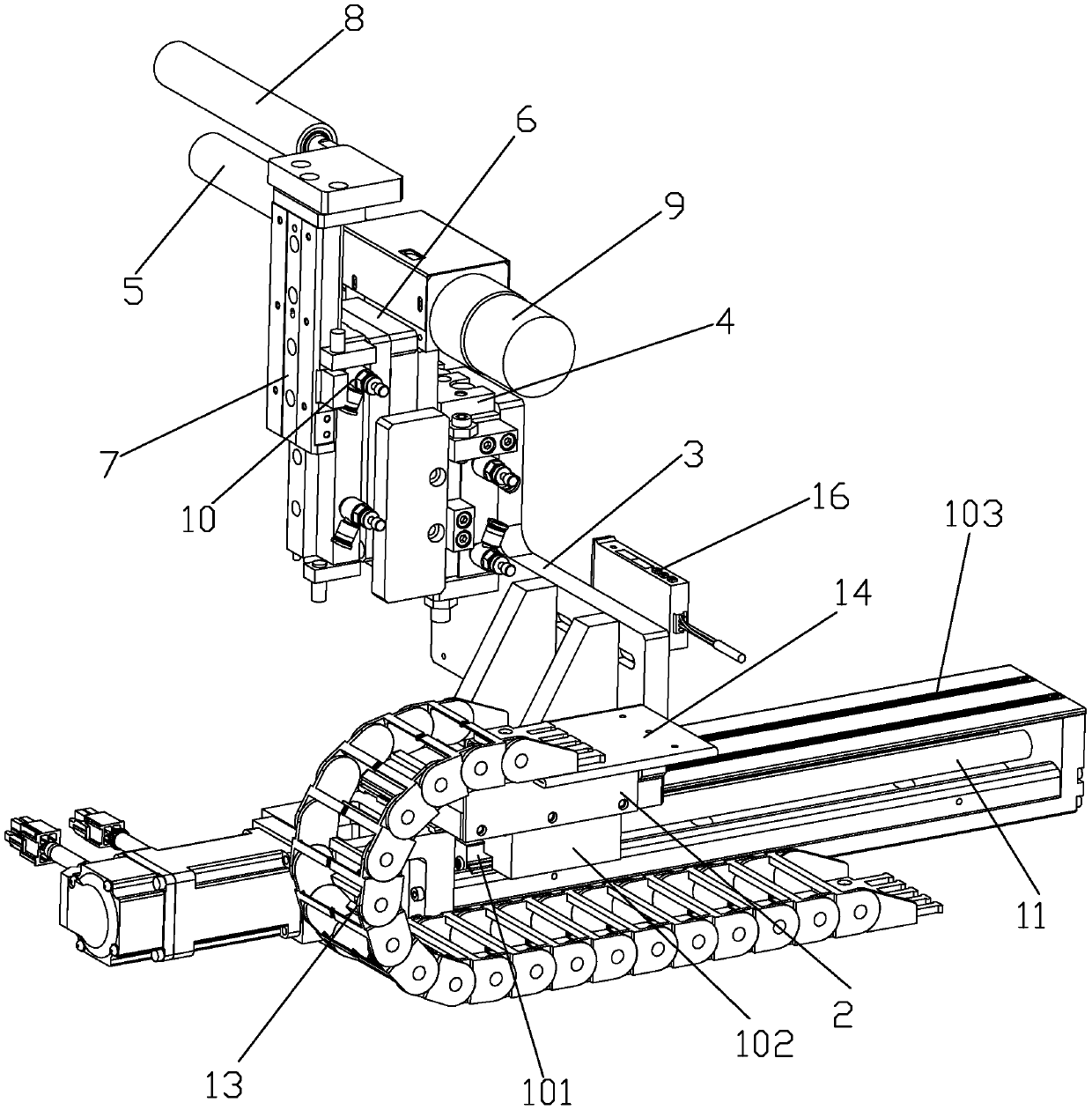

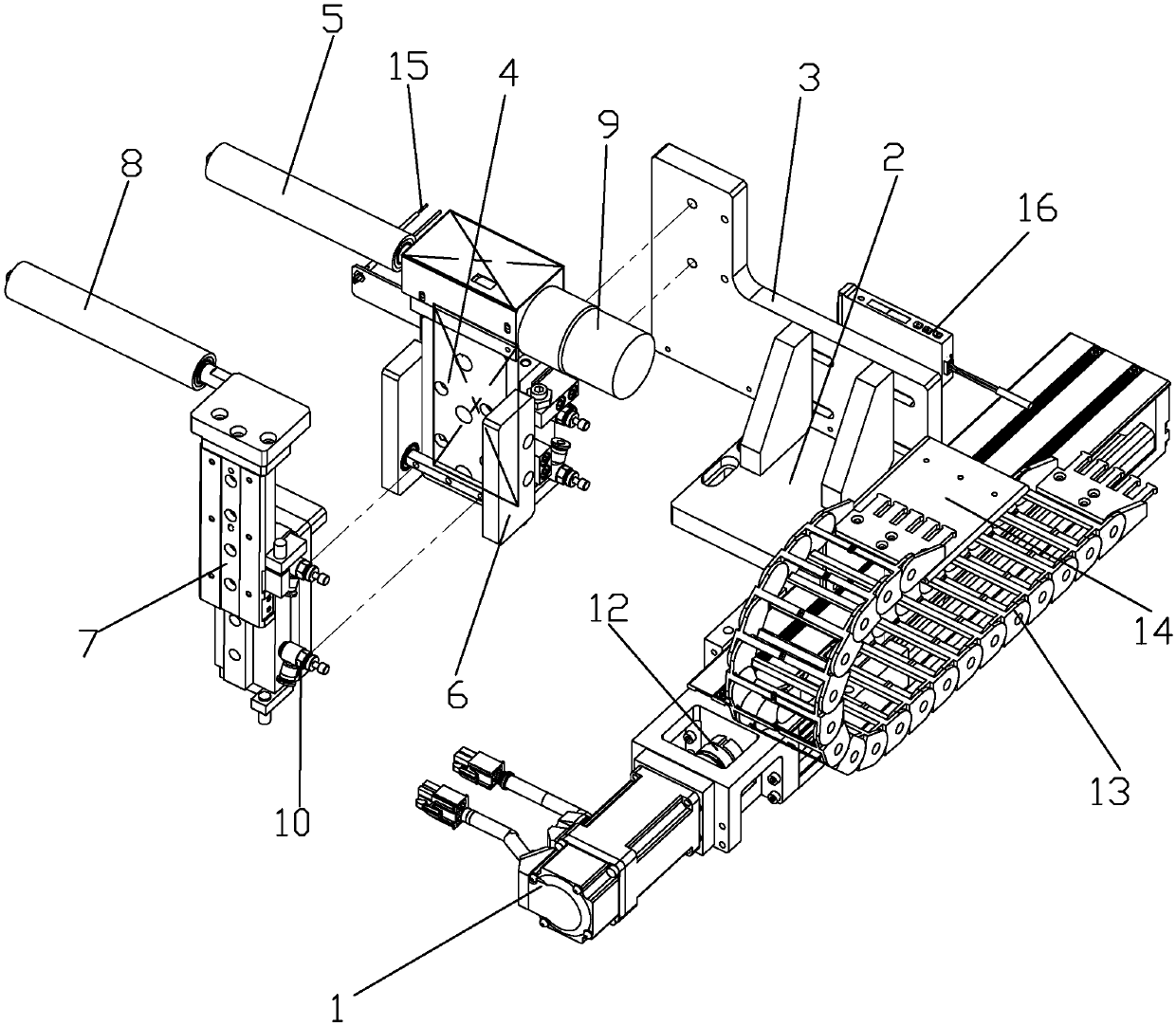

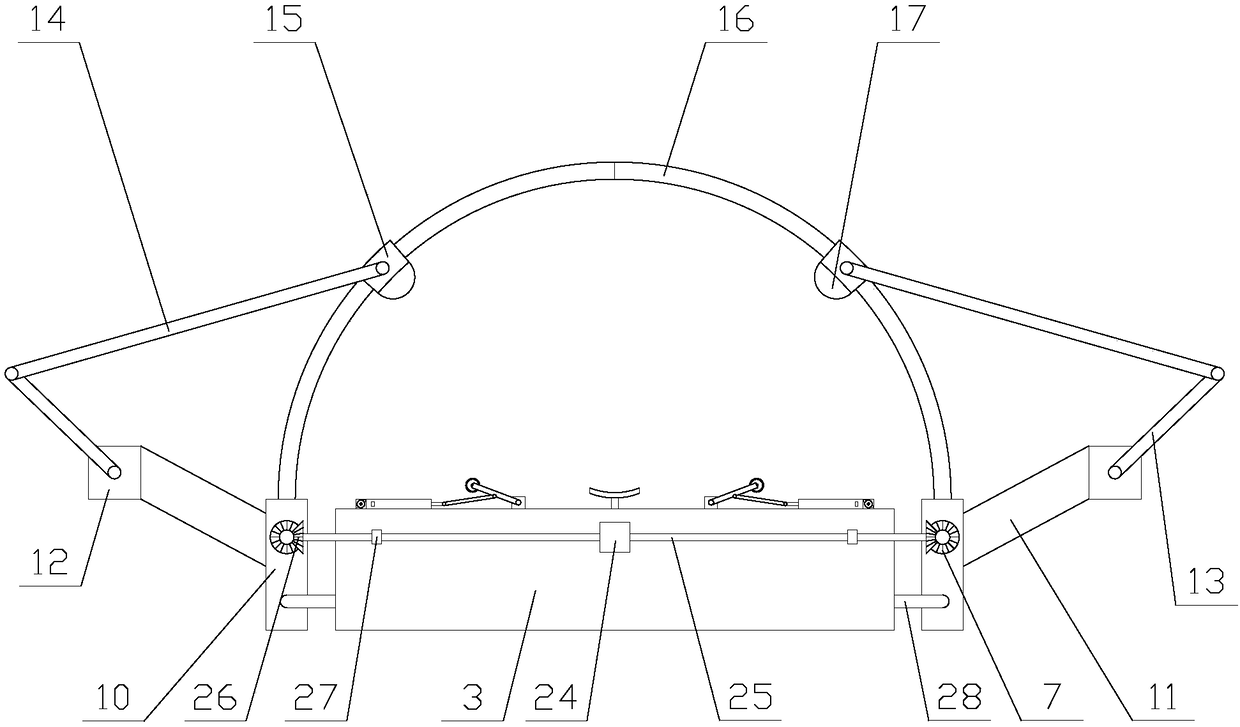

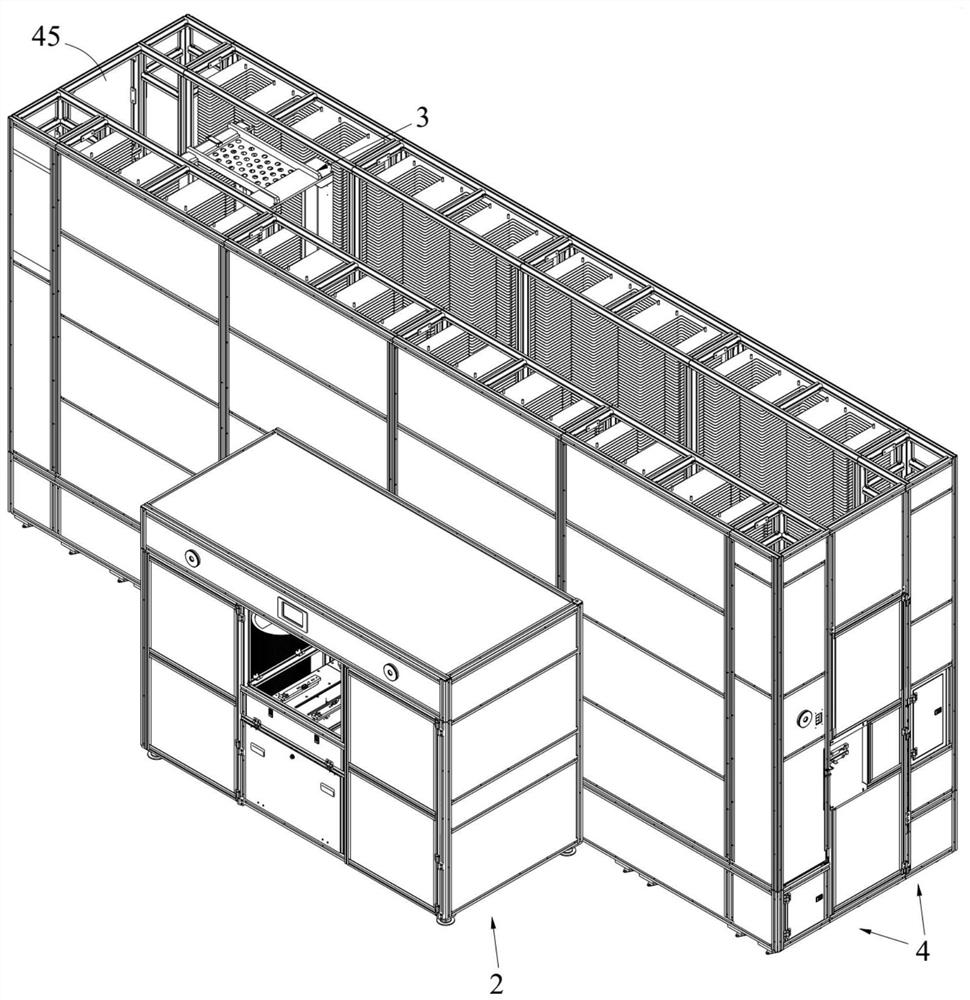

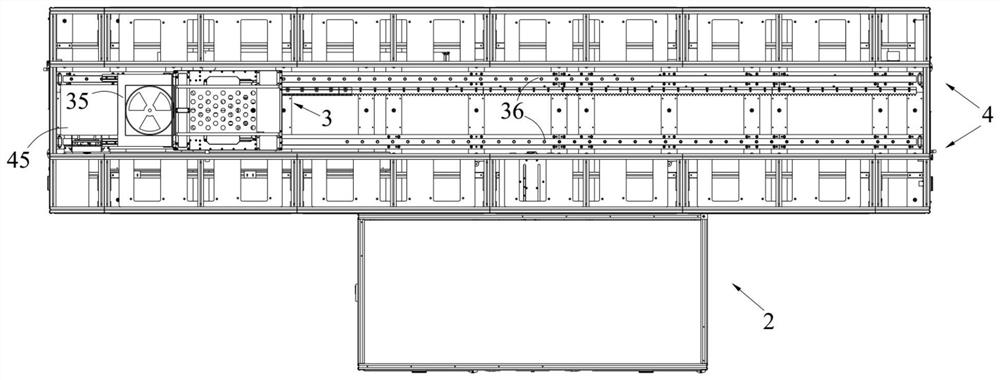

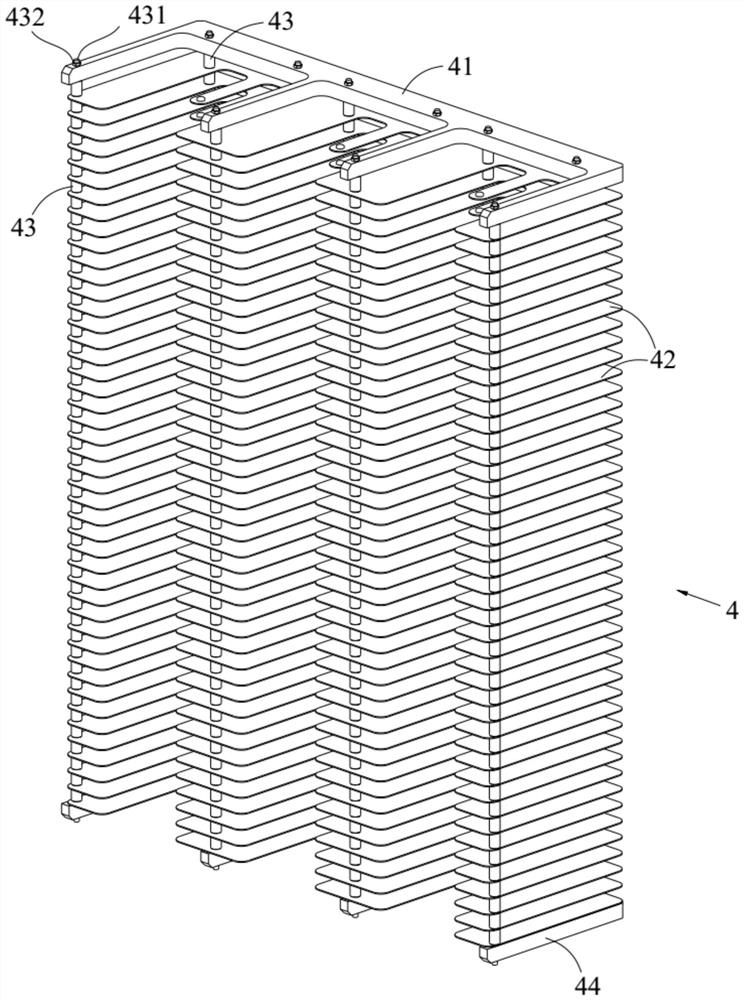

Unmanned aerial vehicle battery replacing equipment and unmanned aerial vehicle nest

ActiveCN111547255ALower barriers to useHigh degree of intelligenceCharging stationsGripping headsMarine engineeringUncrewed vehicle

The invention provides unmanned aerial vehicle battery replacing equipment. The unmanned aerial vehicle battery replacing equipment comprises a rack, a parking platform, a battery bin, a three-axis moving platform and a mechanical claw device. The parking platform, the battery bin and the three-axis moving platform are fixed to the rack, and the mechanical claw device is arranged on the three-axismoving platform. The three-axis moving platform drives the mechanical claw device to move to the battery bin and the parking platform, and the mechanical claw device takes out or places an unmanned aerial vehicle battery from the battery bin or the unmanned aerial vehicle. According to the unmanned aerial vehicle battery replacing equipment, the operation of replacing the battery of the unmannedaerial vehicle on the parking platform can be quickly carried out; intervention of professional operators is not needed, so that the use threshold of the unmanned aerial vehicle is reduced, the intelligent degree is improved, consumption of manpower and material resources is reduced, and the unmanned aerial vehicle is particularly suitable for some complex environments, and the working risk of theprofessional operators is reduced.

Owner:广州中科云图智能科技有限公司

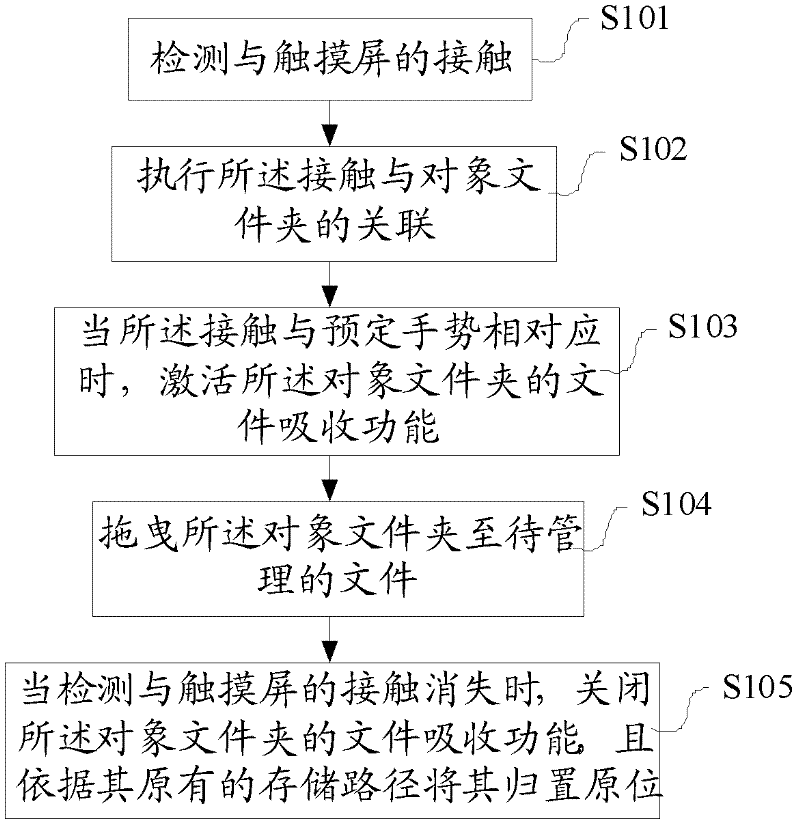

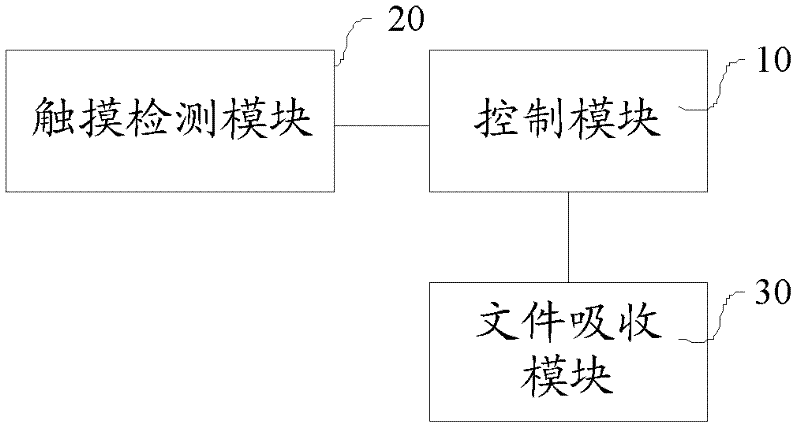

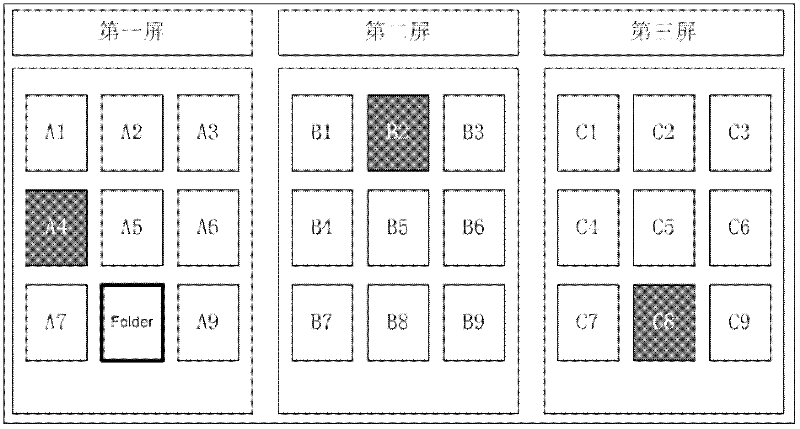

File management method and device for electronic equipment with touch screen, and electronic equipment

ActiveCN102368199AImprove experienceImprove adding efficiencySpecial data processing applicationsInput/output processes for data processingTouchscreenElectric equipment

The invention discloses a file management method and device for electronic equipment with a touch screen, and the electronic equipment. The method comprises the following steps of: detecting contact with the touch screen; executing association between the contact and a target folder; when the contact corresponds to a preset gesture, activating a file absorption function of the target folder; and dragging the target folder to a file to be managed. According to the method provided for a user of the electronic equipment with the touch screen in the invention, a plurality of files to be managed can be conveniently added to the target folder, and in the addition process of the files to be managed, reciprocation among a plurality of screens for many times is not required, thereby reducing moving paths of fingers or other touch equipment; and by the method, the device and the electronic equipment, the file addition efficiency of the user can be improved, and user experiences can be improved.

Owner:ZTE CORP

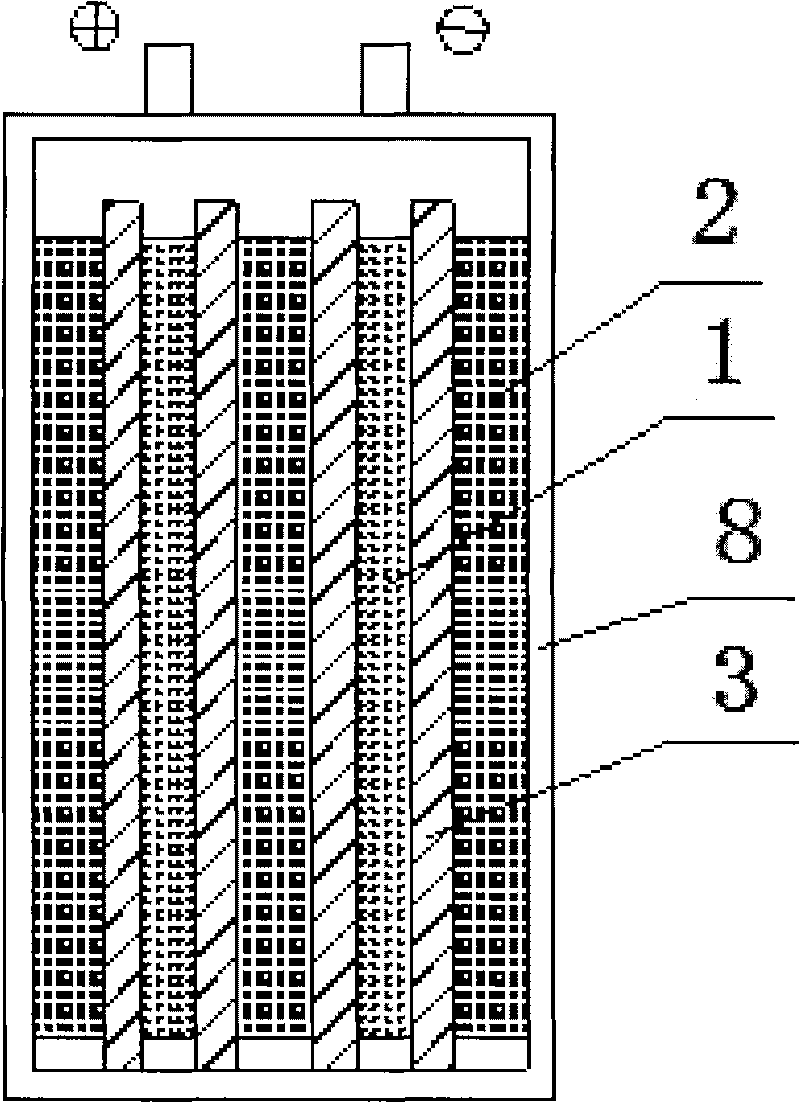

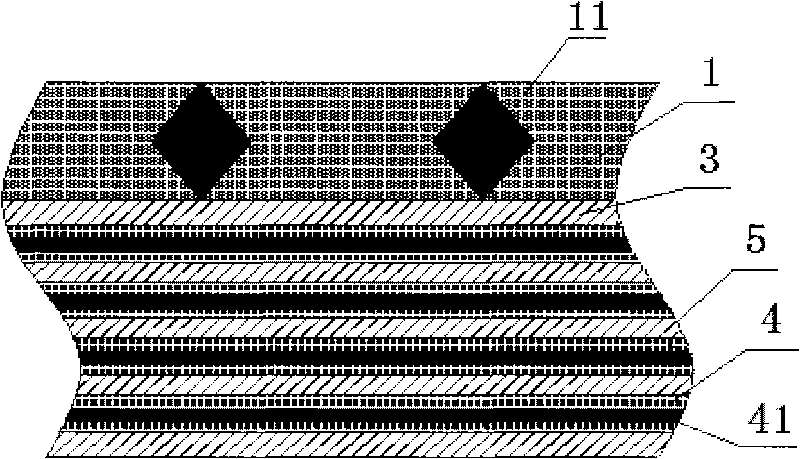

Hybrid electrochemical capacitor

ActiveCN101707143AReduced series resistanceShorten the path of movementHybrid capacitor electrodesDouble layer capacitorsCapacitanceElectrical battery

The invention discloses a hybrid electrochemical capacitor comprising a positive electrode, a negative electrode, clapboards and electrolyte, wherein the clapboards are arranged between the positive electrode and the negative electrode. The hybrid electrochemical capacitor is characterized in that the negative electrode is combined by more than two layers of thin carbon powder electrodes and negative clapboards arranged between two adjacent layers of thin carbon powder electrodes. Because an alternately configured combination of multi-layer thin carbon powder electrodes and the negative clapboards is adopted in the negative electrode, an equivalent series resistance in the negative electrode is reduced, moving paths of electrolyte ions are shortened, and specific capacitance and power density are increased. Compared with the traditional designed hybrid electrochemical capacitor, the invention not only has the traditional advantages of high power density and long circulation life of the hybrid electrochemical capacitor, but also has an remarkably improved power density of more than 20 Wh / kg, which can completely meet the requirements for both the power batteries of electric vehicle and hybrid electric vehicles and the energy storage components for solar power stations and wind power stations.

Owner:SUZHOU YOURBEST NEW TYPE MATERIALS

Electronic component detecting system

InactiveCN1828321AEasy to judgeAlignment stabilityImage analysisPhotogrammetry/videogrammetryEngineeringElectronic component

The invention relates to a testing system for electronic element, comprising: electronic element supply part; electronic element aligning part with no vibration transfer; glass disk for electronic element arrangement; electronic element position testing part, generating trigger signal and code; shooting part; shooting the four surfaces of electronic element; discharging part, discharging electronic element by injecting condensed air; controlling part, controlling said discharging part according to judgment about the qualification of electronic element got from trigger signal, code and shoot image. The said aligning part can align electronic element with no vibration; the judgment is made according to more than two times' shoot; the removal of inject nozzle shortens the moving route of condensed air, and so the answer speed for electronic element discharge is increased.

Owner:ウィンテックカンパニーリミテッド

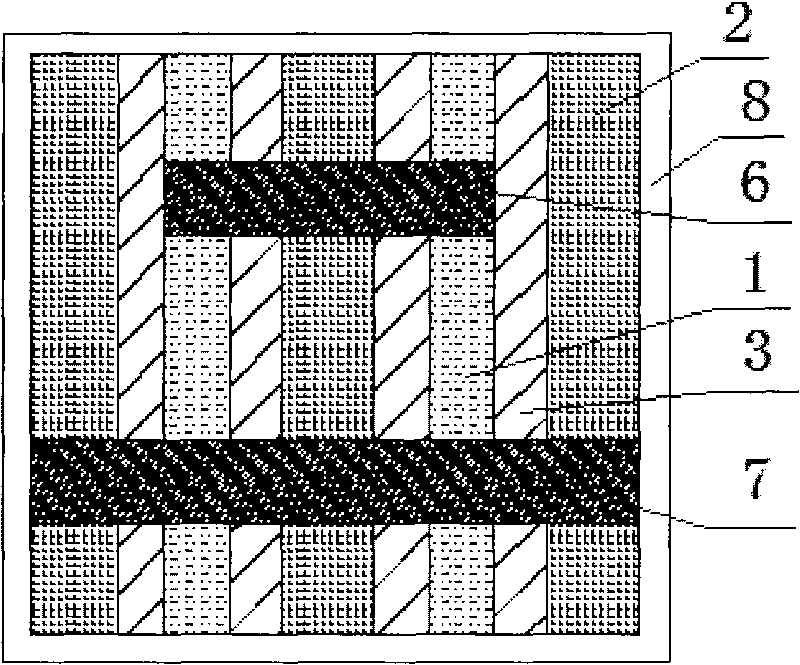

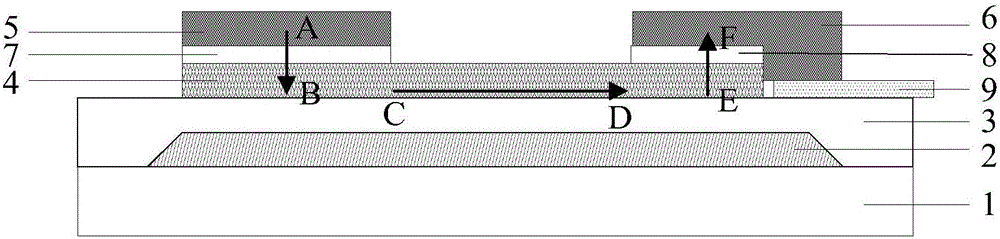

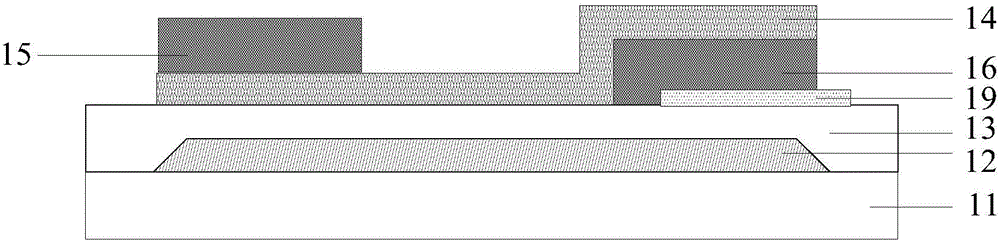

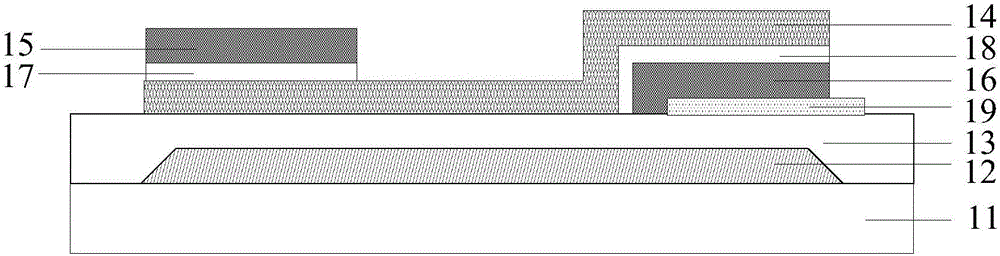

Thin film transistor, display substrate and liquid crystal display device

InactiveCN106024906AIncrease turn-on currentUniform distribution of electrons and holesTransistorSolid-state devicesLiquid-crystal displayEngineering

The present application provides a thin film transistor, a display substrate and a liquid crystal display device, so as to increase the turn-on current of the thin film transistor and reduce the turn-off current of the thin film transistor. The thin film transistor provided by the present application includes: a gate electrode, a gate insulating layer, and an active layer arranged on the substrate in sequence, and also includes: a source electrode arranged on the active layer, and an electrode arranged on the The drain between the gate insulating layer and the active layer.

Owner:BOE TECH GRP CO LTD +1

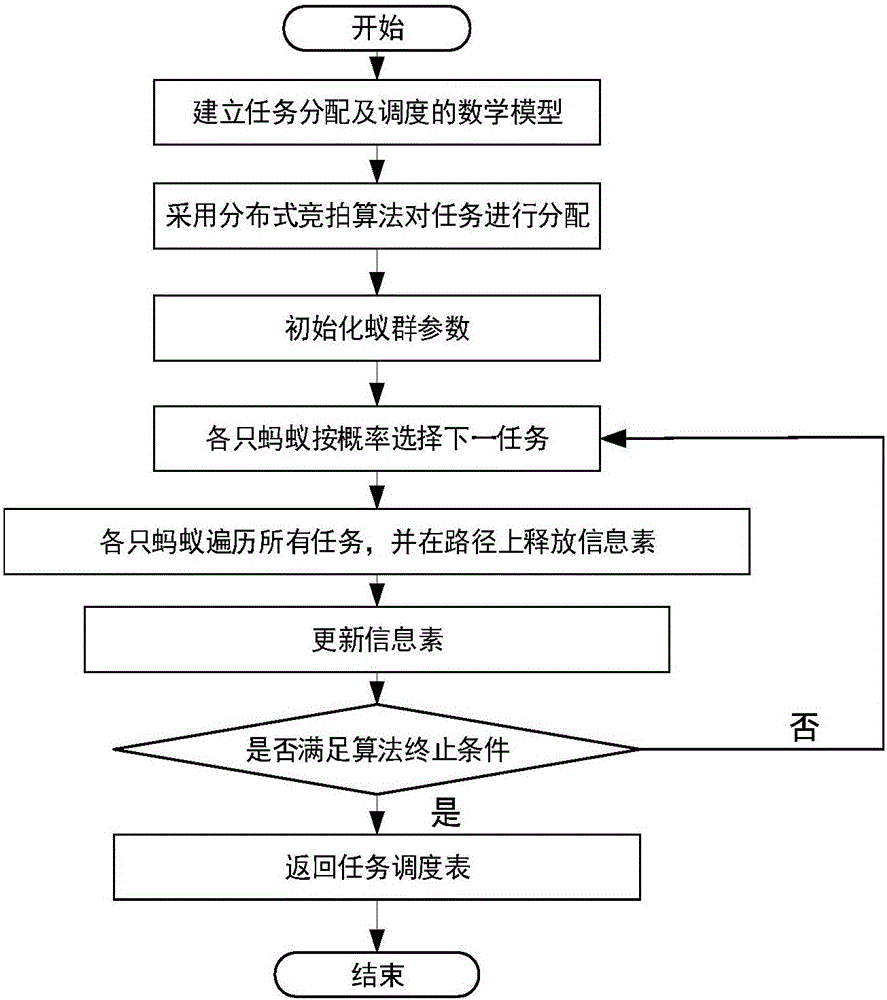

Ant-colony-algorithm-based task scheduling method of actuator in WSAN

InactiveCN106095555AShorten the path of movementLow number of retweetsProgram initiation/switchingArtificial lifeMathematical modelActuator

The invention discloses an ant-colony-algorithm-based task scheduling method of an actuator in a WSAN. The ant-colony-algorithm-based task scheduling method includes the following steps that 1, a mathematical model for cooperation task distribution and scheduling of the actuator is built; 2, tasks are distributed with a distributed auction algorithm; 3, an ant colony is initialized; 4, ants select next tasks according to the probability; 5, the ants carry out traversal on all the tasks, and pheromones are released; 6, the pheromones are updated; 7, if an algorithm ending condition is not met, the method returns to the step 4, and if the algorithm ending condition is met, the method returns to a task scheduling table which then is the optimal task scheduling table. By means of the method, the tasks in the WSAN are reasonably scheduled, the movement distance of nodes of the actuator is reduced, task completing time is shortened, and the energy consumption of the network is reduced.

Owner:HOHAI UNIV CHANGZHOU

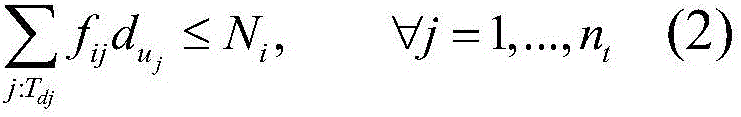

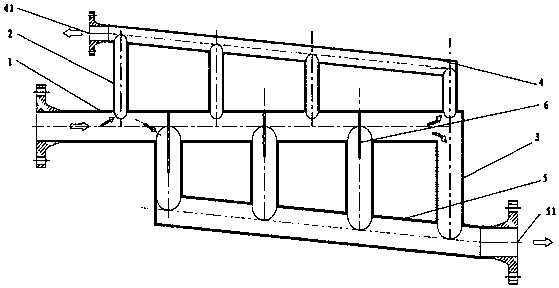

Tubular oil and water separation device

ActiveCN106517402AShorten the path of movementExtended stayWaste water treatment from quariesFatty/oily/floating substances removal devicesEngineeringOil phase

The invention relates to a tubular oil and water separation device. The device is characterized by comprising a communicating tube, an oil phase flotation tube group, a water phase sedimentation tube group, an oil collecting tube and a water collecting tube. An oil and water mixed liquid is under the gravity effect while moving in the communicating tube, graded separation is performed according to specific characteristics of the mixed liquid, the moving path of large-particle oil drops in equipment is shortened, the stay time of small-particle oil drops is prolonged, so that the higher separation effect is realized, and the purposes of reduction of the size of the equipment and decrease of the production cost of the equipment are achieved. All parts are made of conventional materials in the industry, special machining and production requirements are not needed, and all the parts are reliable in use performance and have lower requirements for treated materials, so that the equipment has the lower production requirement and is low in production cost and wider in application range. The device is reasonable in structure, convenient to operate and use and reliable in performance.

Owner:MORIMATSU (JIANGSU) HEAVY IND CO LTD

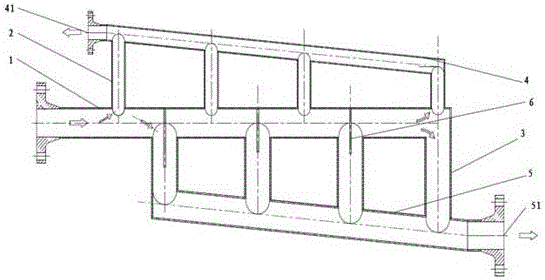

Film tearing mechanism of film sticking machine and film tearing method thereof

InactiveCN107585379AEasy tearing operationReduce manual labor intensityArticle unpackingEngineeringLinear motor

The invention discloses a film tearing mechanism of a film sticking machine, and relates to the field of electronic product machining. The film tearing mechanism comprises a jacking mechanism, a clamping mechanism and an advance and backstep mechansim, wherein the advance and backstep mechansim comprises a linear motor, an advance and backstep base and a main installation board, the linear motor comprises a mover base and an upper cover, the advance and backstep base is fixed to the mover base and located above the upper cover, the main installation board is fixed to the advance and backstep base and extends out of one side of the advance and backstep base to form a cantilever, the jacking mechanism comprises a jacking air cylinder, a jacking roller and an auxiliary installation board, thejacking air cylinder is vertically fixed to the main installation board, the auxiliary installation board is fixed to one side of the jacking air cylinder, the jacking roller is fixed to the top of the auxiliary installation board, the clamping mechanism comprises a clamping air cylinder and a clamping roller, the clamping air cylinder is vertically fixed to the auxiliary installation board, theclamping roller is fixed to the top of the clamping air cylinder and located above the jacking roller, a product with a film to be torn can be contained between the jacking roller and the clamping roller and the surface of the product sticking to the film faces downward. According to the film tearing mechanism, the precision is high, consumables are few, the cost is low, and the product is not likely to be damaged.

Owner:苏州威创达智能设备有限公司

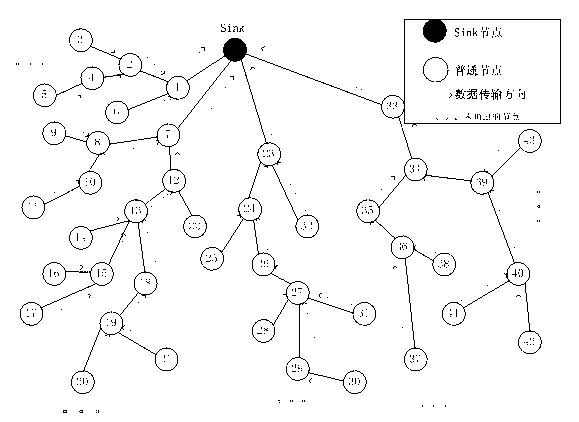

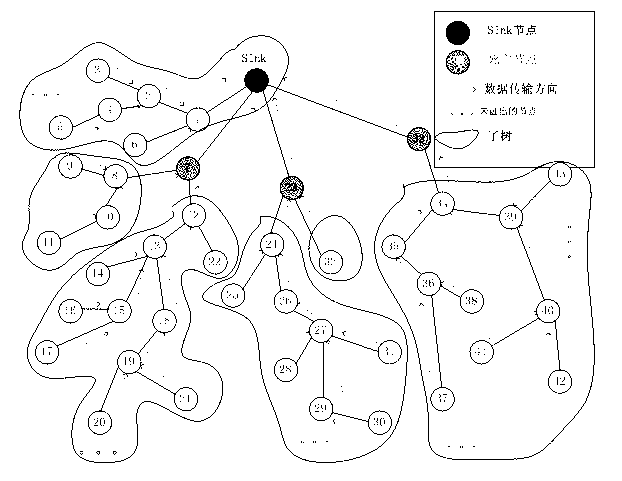

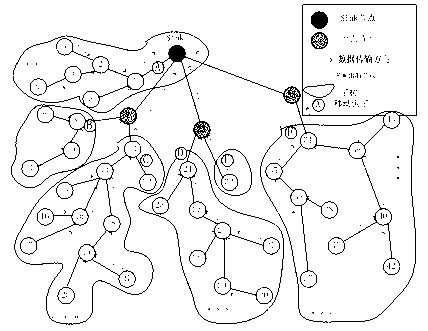

Wireless sensor network data acquisition method based on multiple mobile factors

InactiveCN103269505AExtend the life cycleReduce node energy consumptionNetwork topologiesHigh level techniquesWireless sensor networkingData acquisition

The invention discloses a wireless sensor network data acquisition method based on multiple mobile factors, and aims to save energy consumed by transmission of a large amount of data, effectively use network resources, prolong the service life of a network and balance a relation between multiple hops and cache overflow. The wireless sensor network data acquisition method comprises the following steps of 1, acquiring data by forming a tree-shaped structure by network self-organization; 2, informing node state information to a base station and a direct subsequent node by a low-electric-quantity node; 3, dispatching multiple mobile factors to respective sub-trees to finish corresponding acquisition tasks by the base station, wherein when the whole network is divided into a plurality of sub-trees, the nodes in the sub-trees acquire the data and forward the data to the mobile factors through one hop when the mobile factors dispatched by the base station reach a communication radius range instead of forwarding the data according to an original tree-shaped structure; 4, designing the optimal path of the mobile factors; and 5, cooperatively finishing data acquisition of the whole network by the mobile factors.

Owner:NANJING UNIV OF POSTS & TELECOMM

Method and device for moving object, intelligent equipment and storage medium

ActiveCN111230876AIncrease flexibilityImplement a phased moveProgramme-controlled manipulatorPinch gripControl engineering

The embodiment of the invention discloses a method and device for moving an object, intelligent equipment and a storage medium and belongs to the technical field of computers. The method comprises thesteps that a moving path of a gripper is determined according to the first position where the gripper is located, and the initial position and final position of the target object; according to the moving path, the gripper is controlled to move to the initial position from the first position to clamp the target object; the first target position of the gripper in the moving path is determined according to the initial position where the gripper is located, and the gripper is controlled to move to the first target position from the initial position; a second target position of the gripper in themoving path is determined according to the first position where the gripper is located, the gripper is controlled to move to the second target position from the first target position until the targetposition of the gripper in the moving path is determined as the final position, and the gripper is controlled to move the target object to the final position. A staged moving manner is adopted, and afoundation is laid for dealing with emergencies.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Electric pipe type oil-water separating device

InactiveCN107648884AShorten the path of movementExtended stayFatty/oily/floating substances removal devicesLiquid separationOil phaseLarge particle

The invention relates to an electric tube type oil-water separation device, which is characterized in that it comprises a connecting pipe, an oil phase flotation tube group, a water phase settling tube group, an oil collecting pipe and a water collecting pipe; Under the action of gravity, and according to the specific characteristics of the mixed liquid, it is classified and separated, shortening the moving path of large-particle oil droplets in the equipment, and increasing the residence time of small-particle oil droplets, so as to achieve a higher separation effect and reduce the size of the equipment. The purpose of reducing the size and cost of equipment; all components are conventional materials in the industry, and do not require special processing and manufacturing requirements. The cost is low and the application range is wide; the invention has reasonable structure, convenient operation and reliable performance.

Owner:南通旭越光电科技有限公司

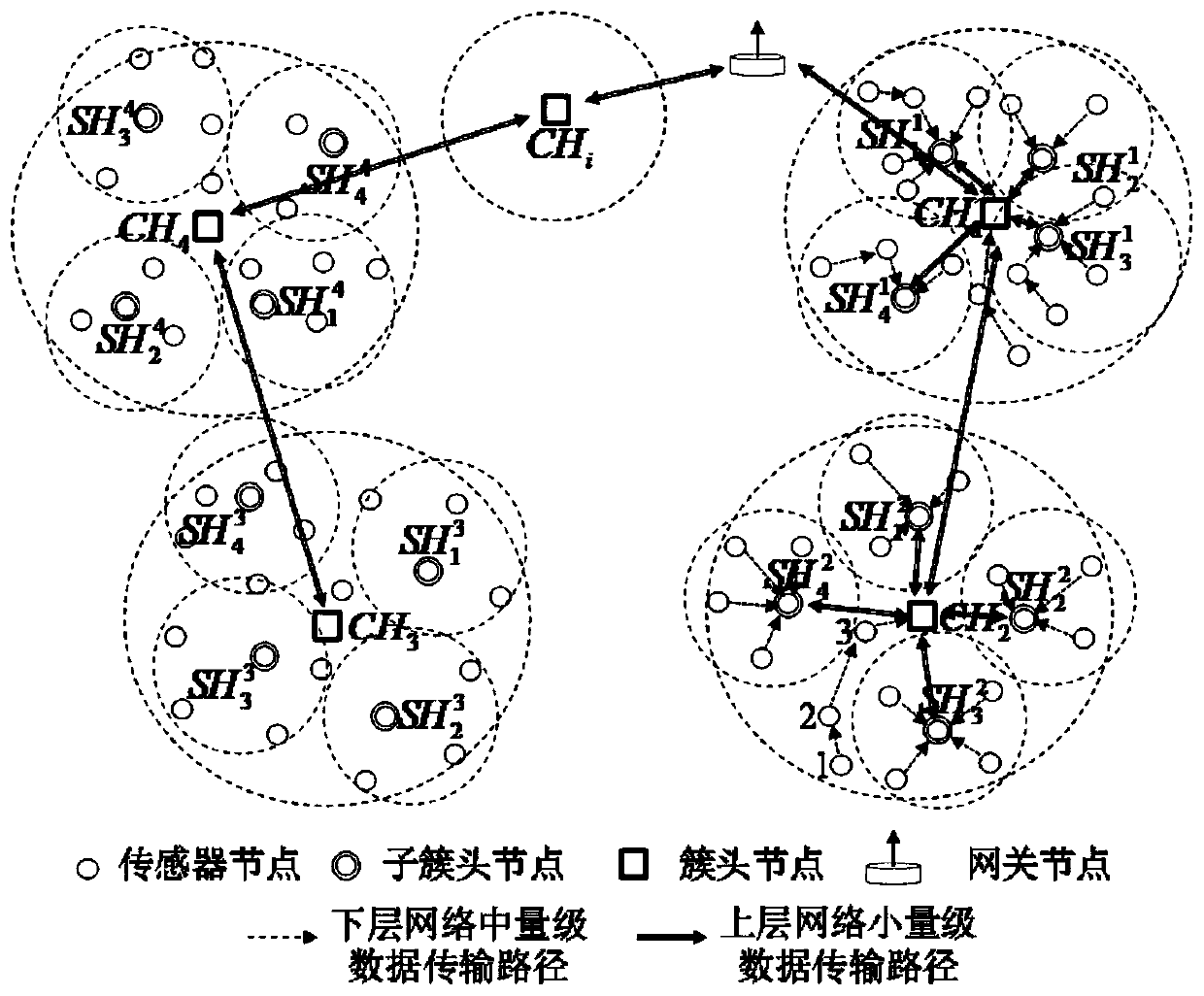

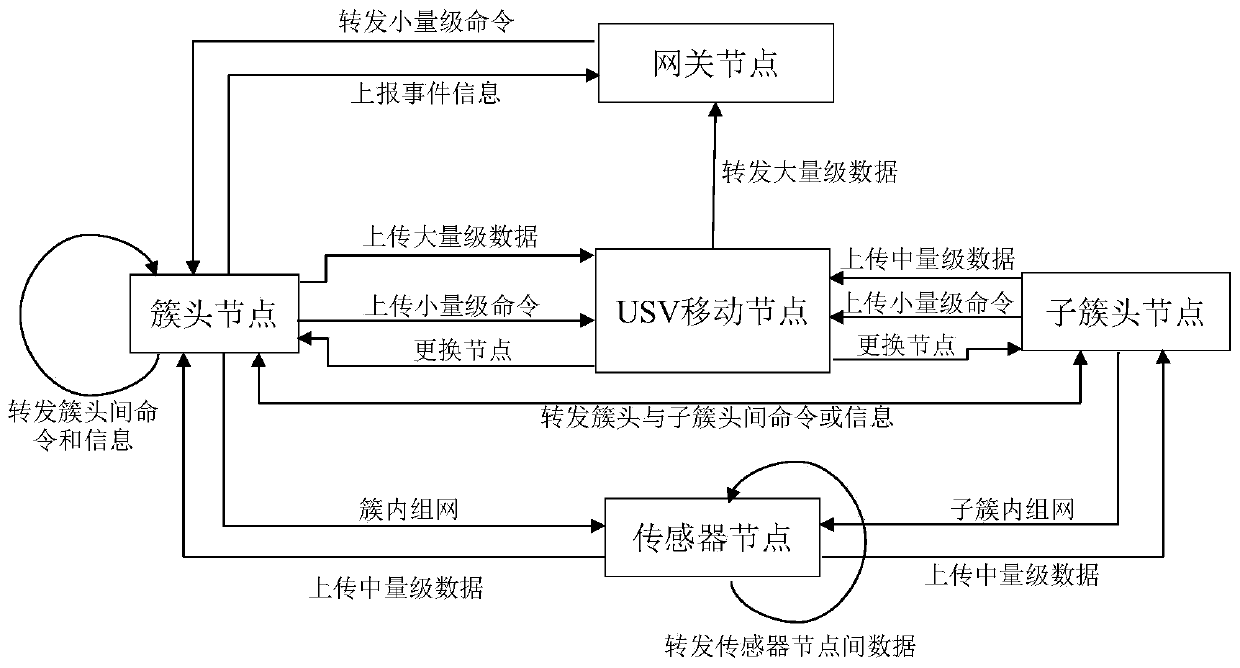

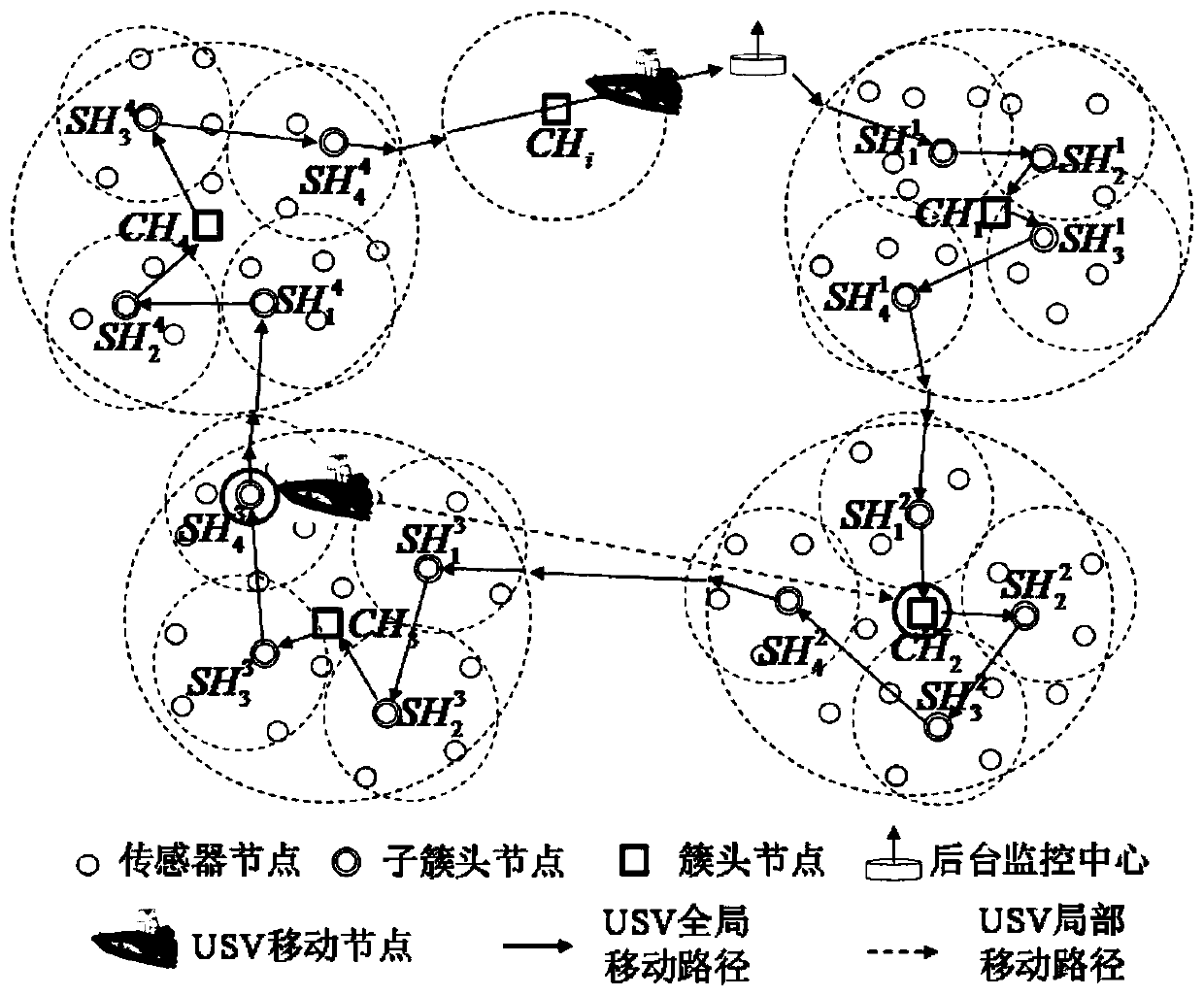

Heterogeneous node cooperative sensing system and method for offshore self-organizing network

InactiveCN110933641AReduce energy consumptionReduce the probability of packet lossPower managementNavigational calculation instrumentsDynamic monitoringEngineering

The invention discloses a heterogeneous node cooperative sensing system and method for an offshore self-organizing network, and the method comprises the steps: selecting an optimal sub-cluster head node through employing a fitness equation, and building a self-organizing network model of a three-layer cluster structure; planning a global shortest path of a USV and moving and traversing all clusterhead and sub-cluster head nodes; realizing USV local path planning through a multi-hop relay network formed by the cluster heads and the sub-cluster heads, and planning a USV moving path in real time, so that a heterogeneous node cooperative sensing system oriented to the offshore self-organizing network is established. Through the double-layer collection effect of the cluster heads and the sub-cluster head nodes and the USV global and local combined path planning method, energy consumption balance of the offshore self-organizing network and efficient maintenance and dynamic monitoring of thenetwork can be effectively achieved.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

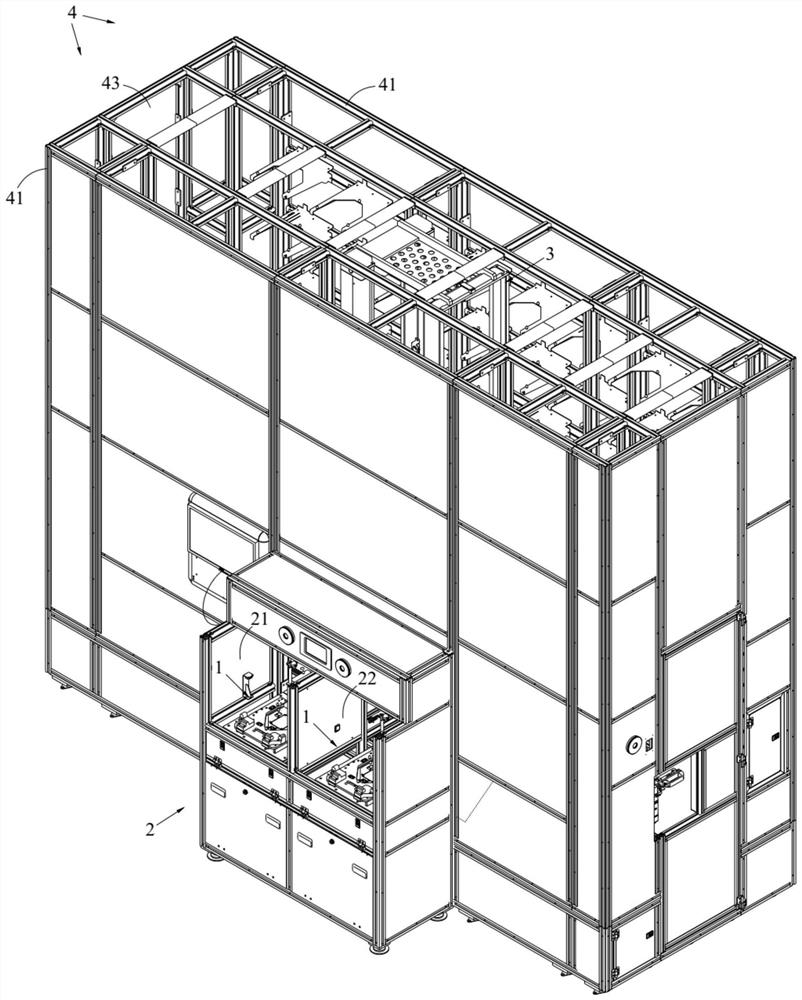

Automatic mold selecting system and control method thereof

ActiveCN111531758ARealize automatic replacementShorten the path of movementEngineeringMaterials processing

The invention relates to the technical field of composite material processing, and particularly relates to an automatic mold selecting system. The automatic mold selecting system comprises a pre-forming device, a support, a plurality of molds and a mold grabbing device, wherein the length direction of the pre-forming device is the same as the length direction of a long truss to be processed; the support is parallel to the pre-forming device; the plurality of molds are placed on the support, detachably fixed to the pre-forming device and used for forming the long truss; and the mold grabbing device is arranged on the support in a relatively movable mode, the moving direction of the mold grabbing device is parallel to the length direction of the pre-forming device, and the mold grabbing device is used for transferring the molds on the pre-forming device and the support. According to the automatic mold selecting system, the molds placed on the support are taken down and moved to the pre-forming device through the mold grabbing device, the molds on the mold grabbing device are automatically placed on the pre-forming device through a jacking piece arranged on the pre-forming device, andautomatic replacement of the molds is achieved. The invention further provides a control method of the automatic mold selecting system.

Owner:NEWTRY COMPOSITE

High-scanning efficiency anti-jitter intelligent face recognition device

InactiveCN108268848AGuaranteed accuracyPrevent rotationCharacter and pattern recognitionAir pumpControl engineering

The invention relates to a high-scanning efficiency anti-jitter intelligent face recognition device. The device comprises a fixing block and a recognition mechanism; the recognition mechanism comprises a scanning mechanism, a fixing mechanism and a detection mechanism; the scanning mechanism comprises a driving assembly and two scanning assemblies, wherein the scanning assembly comprises a first bevel gear, a screw rod, a bearing, a lifting block, a first motor, a first linking rod, a second linking rod, a slip ring, a slide rail and a camera; and the fixing mechanism comprises two fixing assemblies, wherein the fixing assembly comprises an air pump, an air cylinder, a piston, a supporting rod and a fixing rod. According to the high-scanning efficiency anti-jitter intelligent face recognition device of the invention, the head of a person to be detected is fixed through the fixing mechanism, so that the rotation or movement of the head of the user during a scanning process can be prevented, and therefore, the smooth proceeding of scanning can be ensured; and the two scanning assemblies in the scanning assembly operate simultaneously, and the moving path of the slip rings is shortened, and therefore, the scanning efficiency of the cameras can be improved, and the rapid scanning and face recognition of the device can be realized.

Owner:深圳市中科智诚科技有限公司

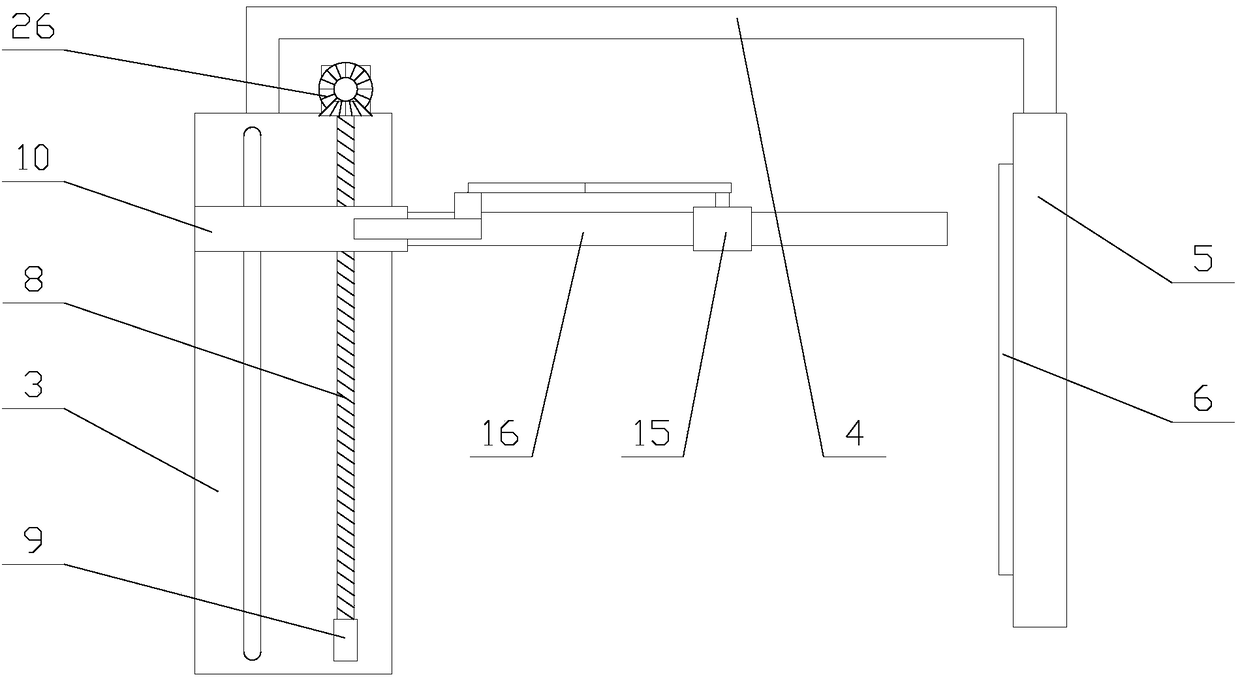

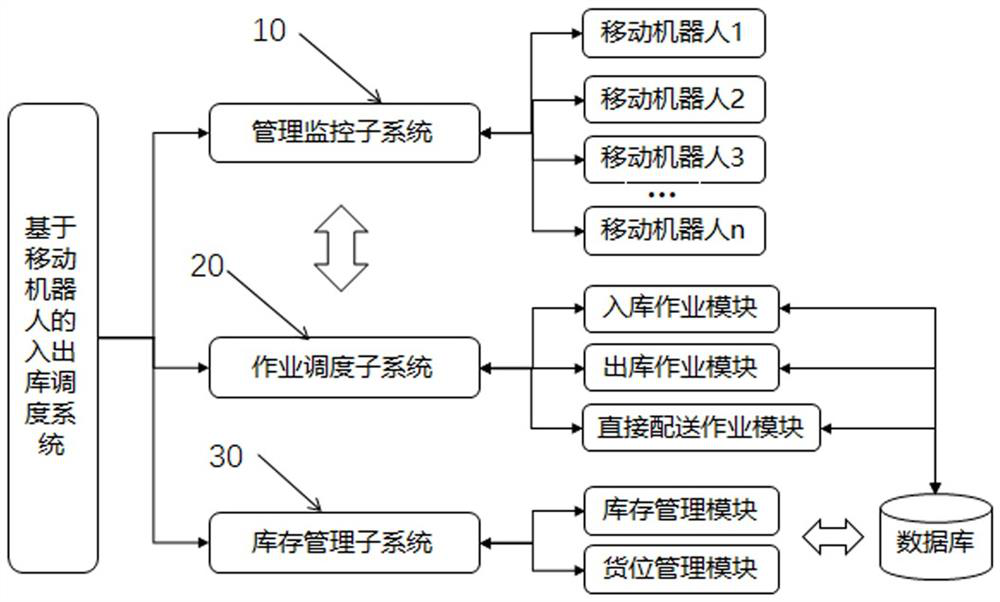

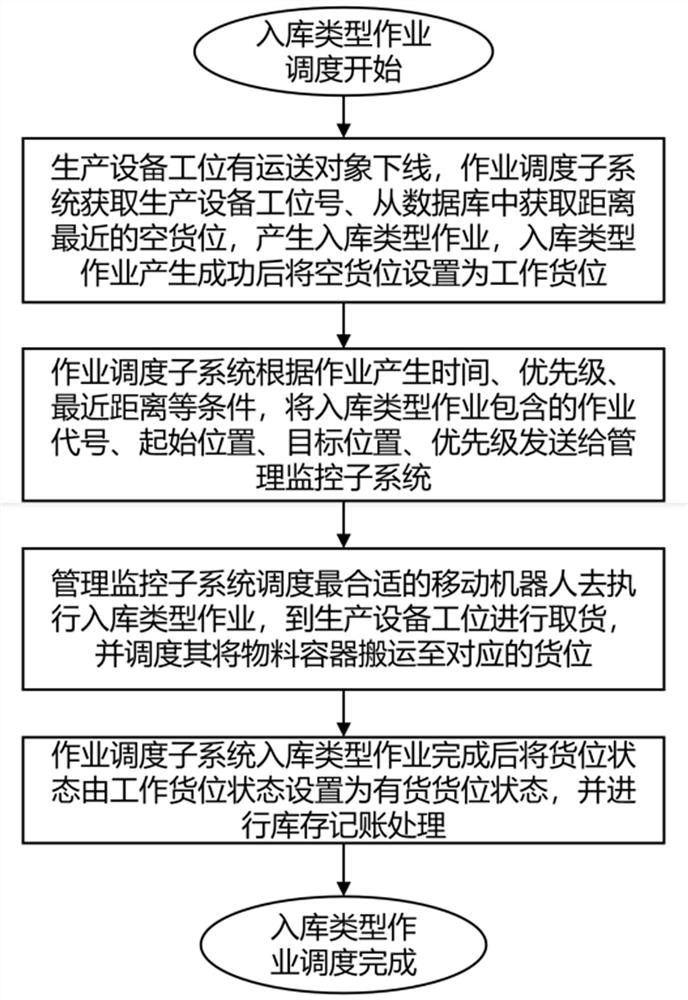

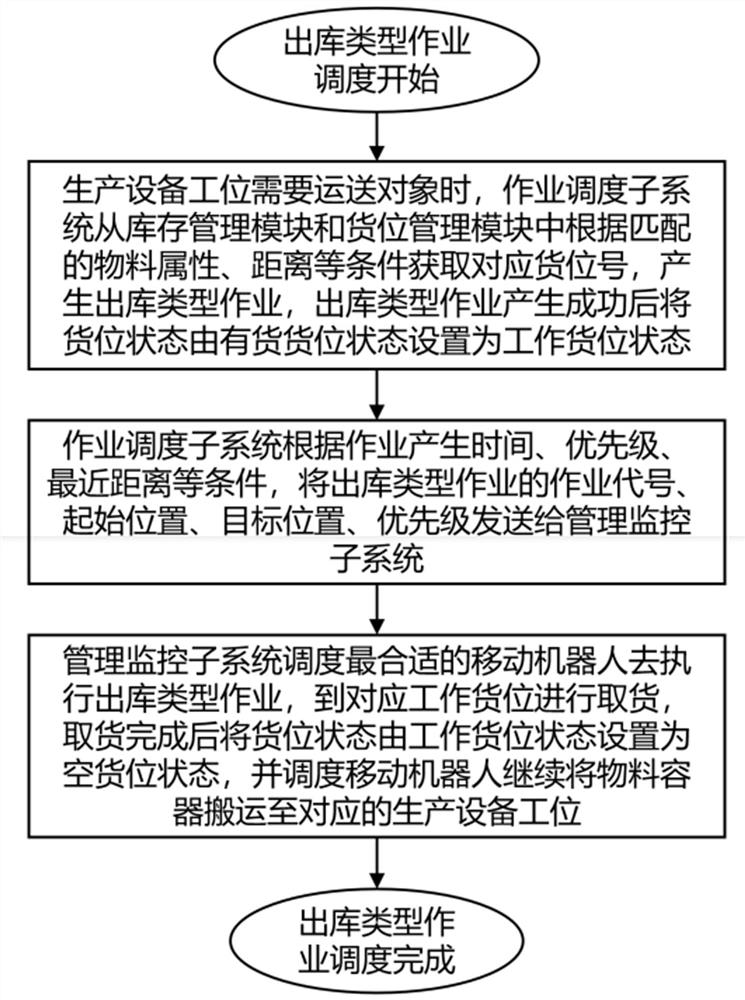

Warehouse-in and warehouse-out scheduling system based on mobile robot and optimized scheduling method thereof

ActiveCN114415617AShorten the path of movementPlay a role in streamliningTotal factory controlProgramme total factory controlOperation schedulingEngineering

The invention discloses a warehouse-in and warehouse-out scheduling system based on a mobile robot and an optimized scheduling method thereof, and the system comprises a job scheduling subsystem which is used for generating a scheduling job and transmitting the scheduling job information to a management monitoring subsystem; the management monitoring subsystem is used for scheduling the mobile robot to execute the scheduling operation according to the scheduling operation information sent by the operation scheduling subsystem so as to transport the transport object from the initial position of the scheduling operation to the target position through the mobile robot; and if the job scheduling subsystem simultaneously has the ex-warehouse type job and the in-warehouse type job, the job scheduling subsystem is used for integrating the ex-warehouse type job and the in-warehouse type job so as to integrate the ex-warehouse type job and the in-warehouse type job into a direct distribution type job. According to the invention, through warehouse-in and warehouse-out operation optimization scheduling, the intelligent scheduling level and the distribution efficiency of the mobile robot for field operation are improved; and the number of purchased mobile robots can be reduced for a final user, so that a large amount of economic cost is saved.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

Article moving method and intelligent equipment

ActiveCN111230877AIncrease flexibilityImplement a phased moveProgramme-controlled manipulatorPathPingControl engineering

The embodiment of the invention discloses an article moving method and intelligent equipment, and belongs to the technical field of computers. The method comprises the steps that a controller determines a moving path of a clamp holder according to a first position where the clamp holder is located as well as an initial position and a final position of a target object; the clamp holder is controlled to move from the first position to the initial position and then clamp the target object according to the moving path; a first target position of the clamp holder in the moving path is determined according to a second position where the clamp holder is located, and the clamp holder is controlled to move from the second position to the first target position; and a second target position of the clamp holder in the moving path is determined according to a third position where the clamp holder is located, the clamp holder is controlled to move from the third position to the second target position until a target position of the clamp holder in the moving path is determined to be a termination position, and the clamp holder is controlled to move the target object to the termination position. According to the article moving method, a staged moving mode is adopted, so that a foundation is laid for coping with emergencies, and accordingly flexibility of the intelligent equipment is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

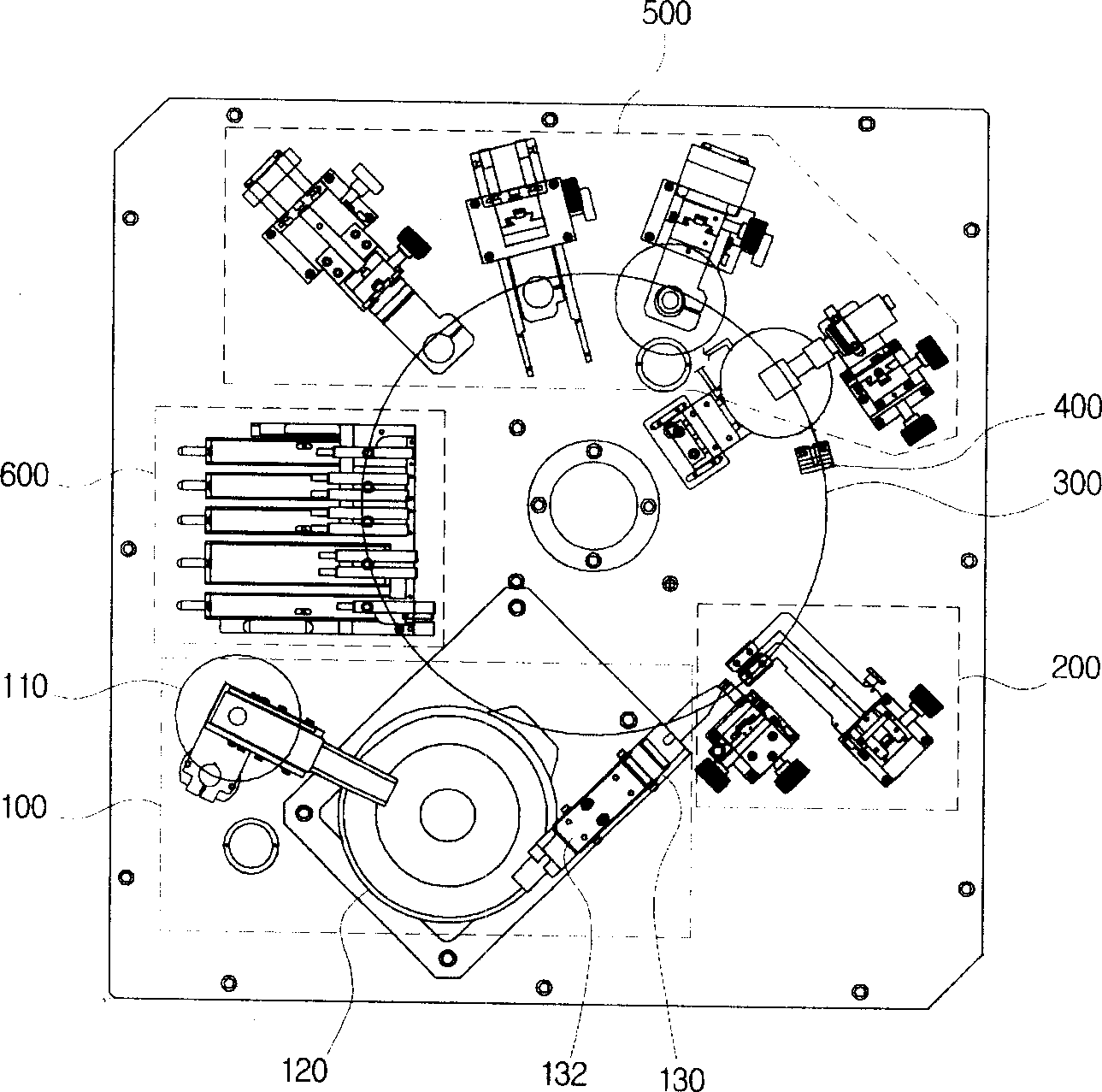

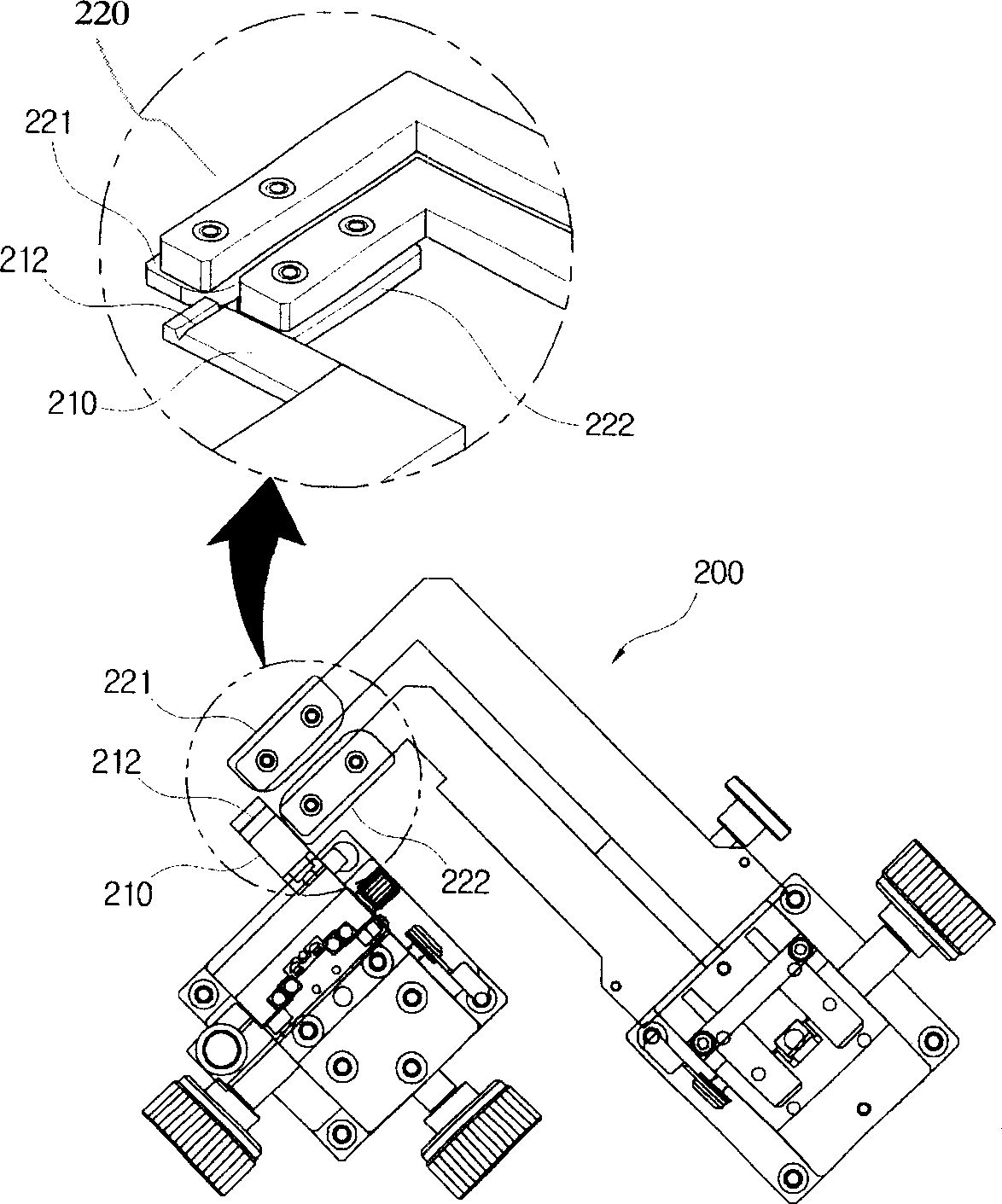

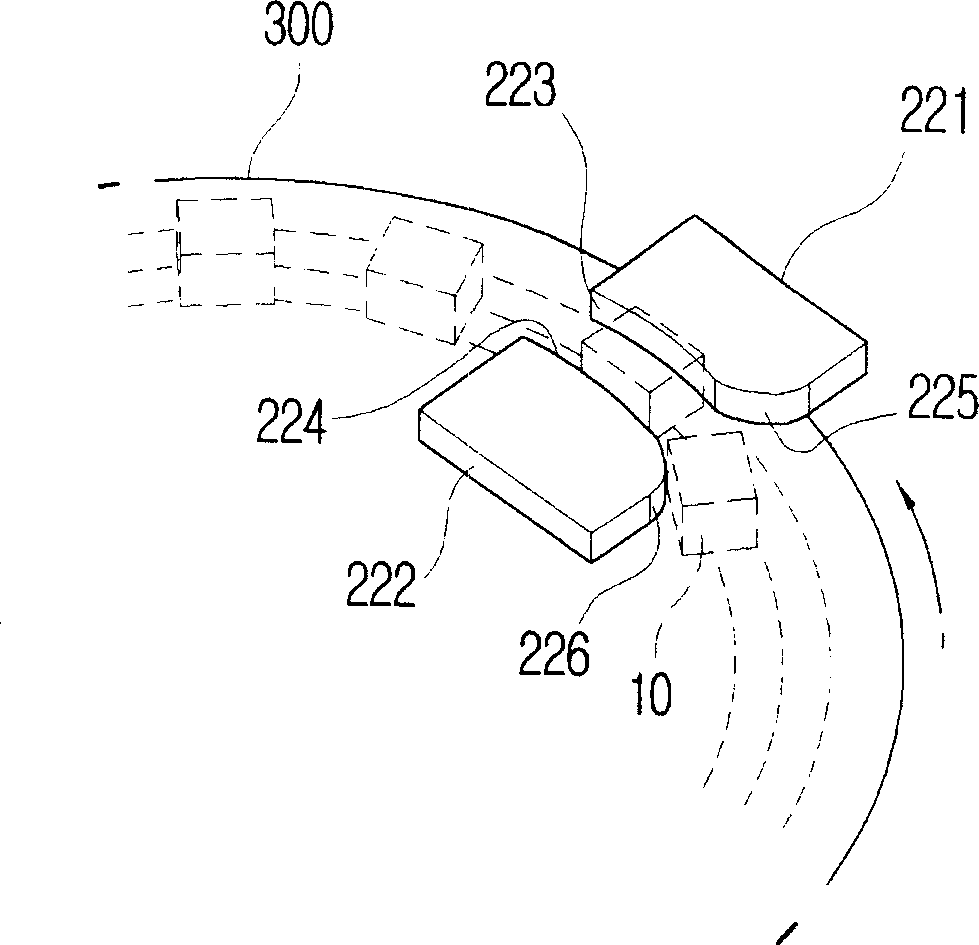

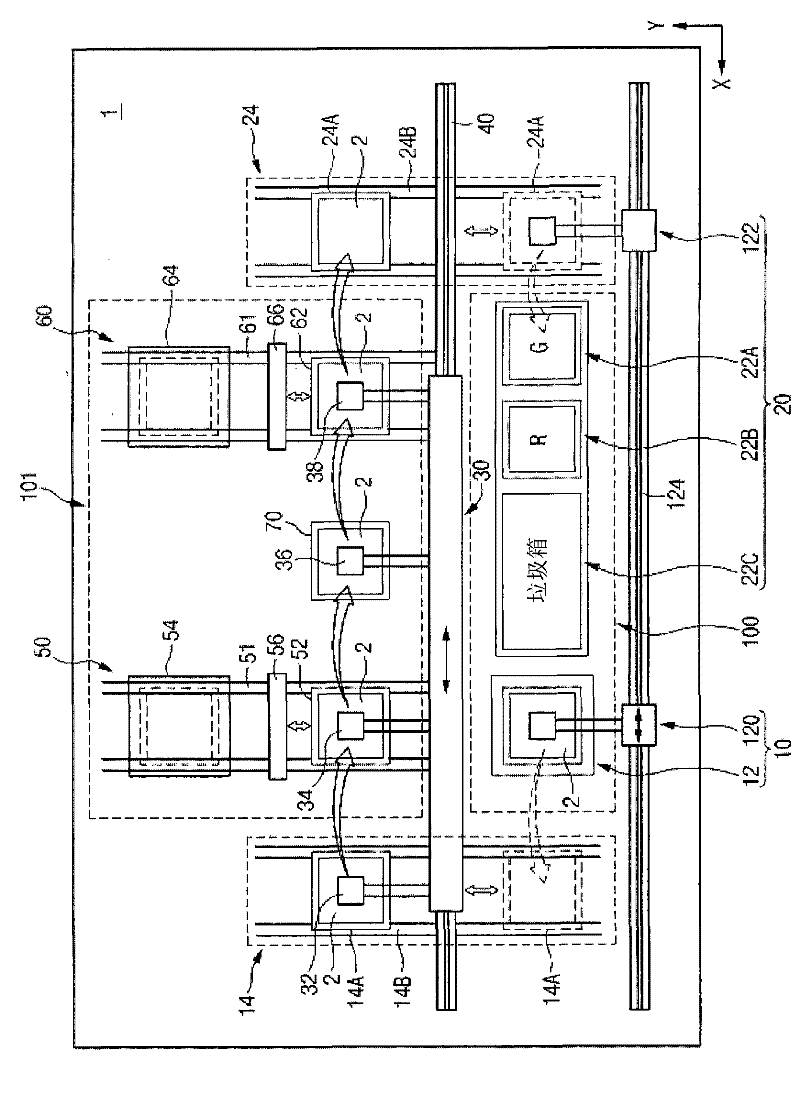

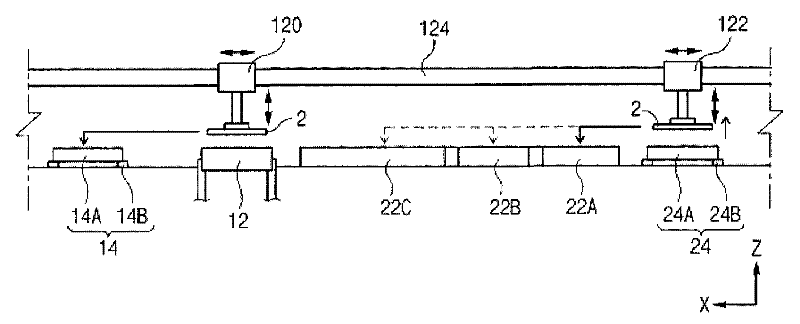

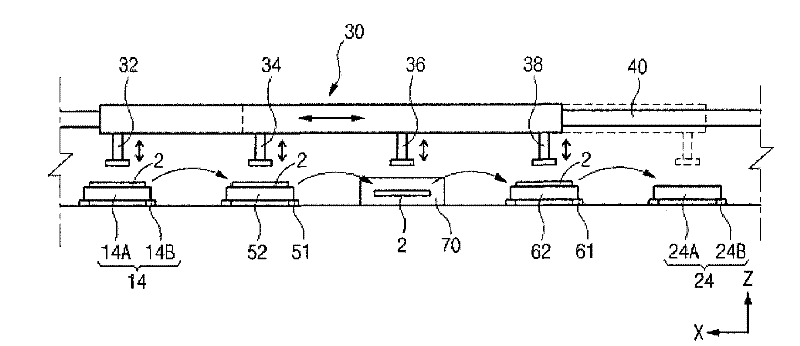

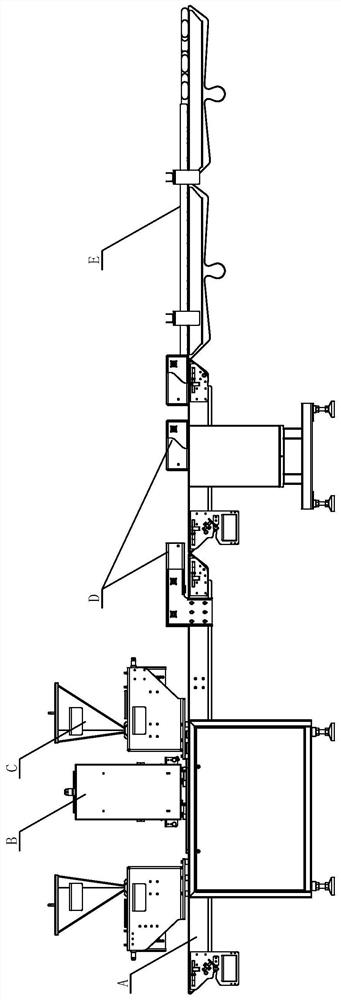

Vision inspection apparatus

InactiveCN101769874BIncrease productionShorten and simplify the path of movementOptically investigating flaws/contaminationContactless circuit testingVision inspectionVisual inspection

Disclosed is a vision inspection apparatus, and particularly, a capable of inspecting external appearance of an electronic component. The vision inspection apparatus includes a loading unit for loading at least one electronic component to be vision-inspected; a first vision inspection unit for performing first vision inspection with respect to the electronic component loaded by the loading unit; a second vision inspection unit for performing second vision inspection with respect to the electronic component; an inverting unit installed between the first and second vision inspection units, for inverting the electronic component having been completely first-vision inspected by the first vision inspection unit before the electronic component is transferred to the second vision inspection unit; an unloading unit for unloading the electronic component having been completely second vision-inspected by the second vision inspection unit; and a transfer tool for simultaneously transferring electronic components respectively in the first vision inspection unit, the inverting unit, and the second vision inspection unit to the next respective units.

Owner:JT

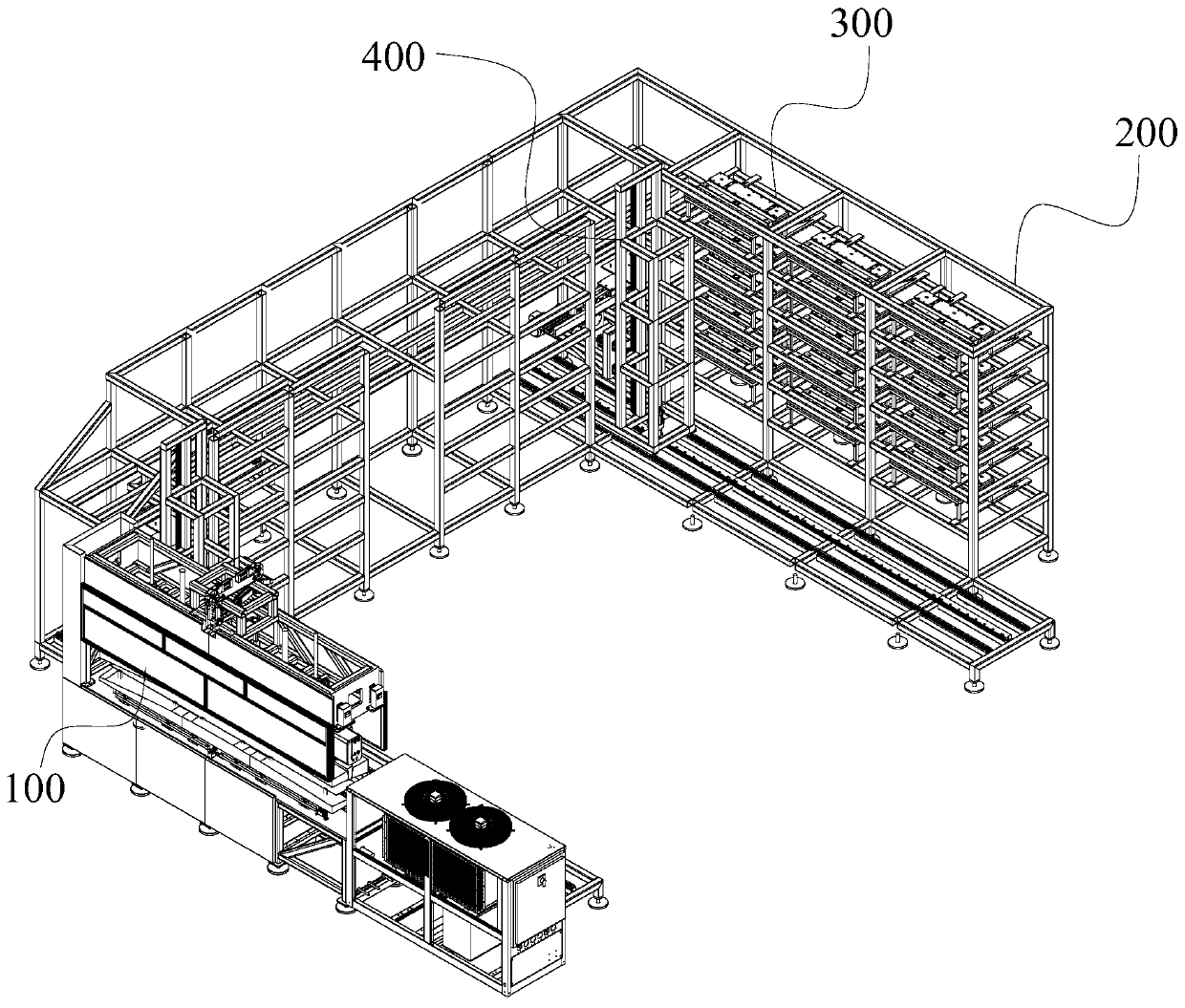

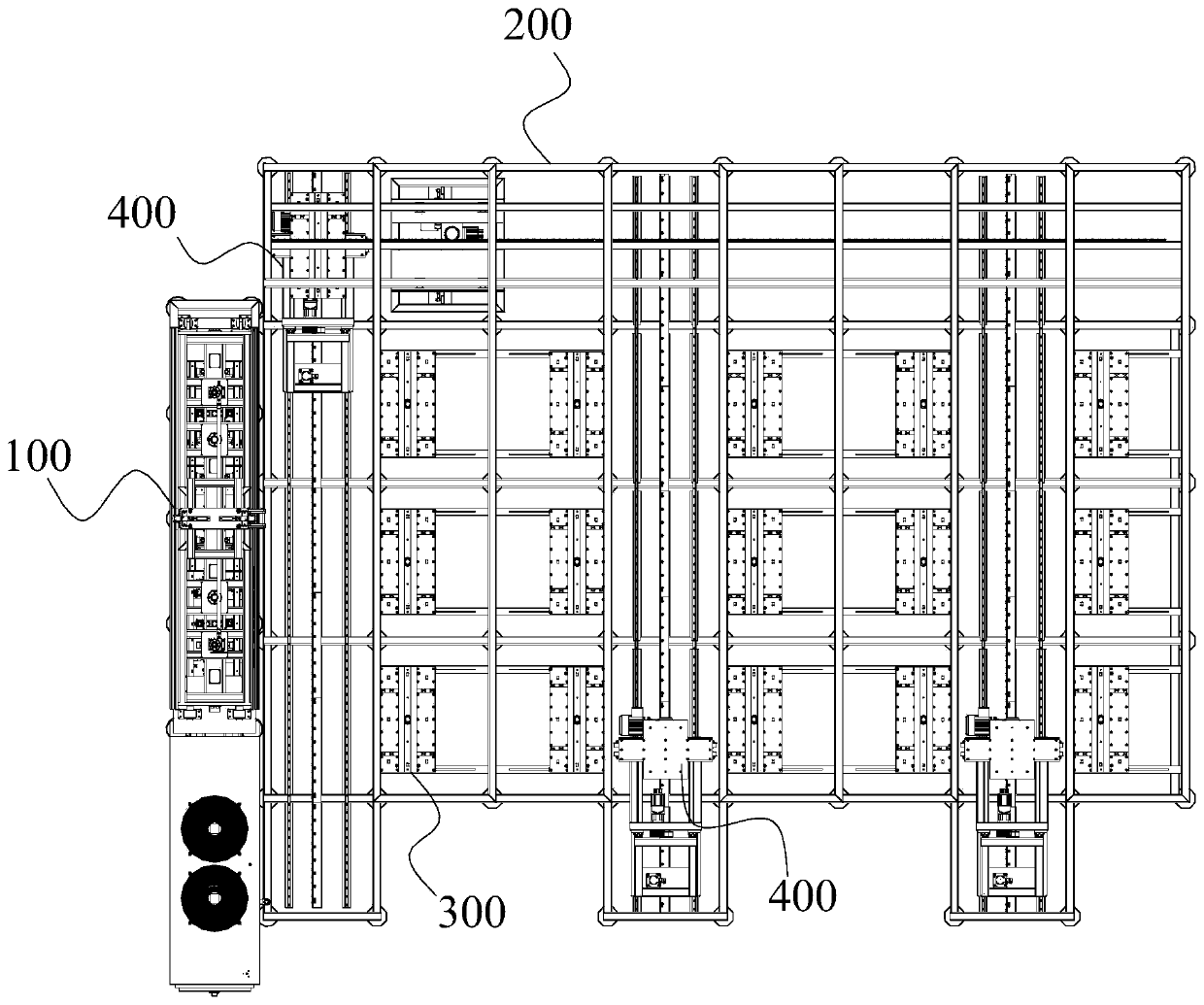

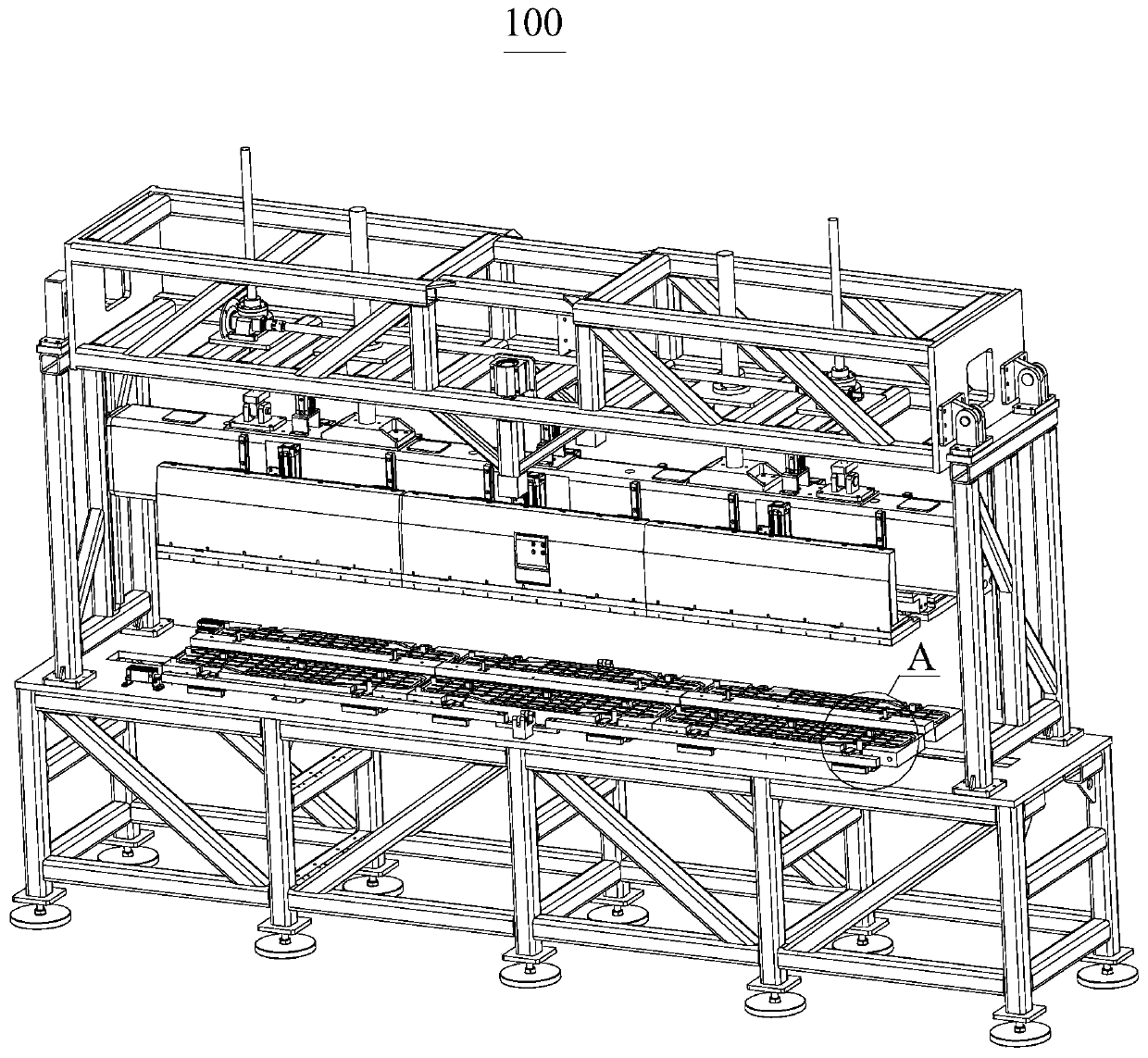

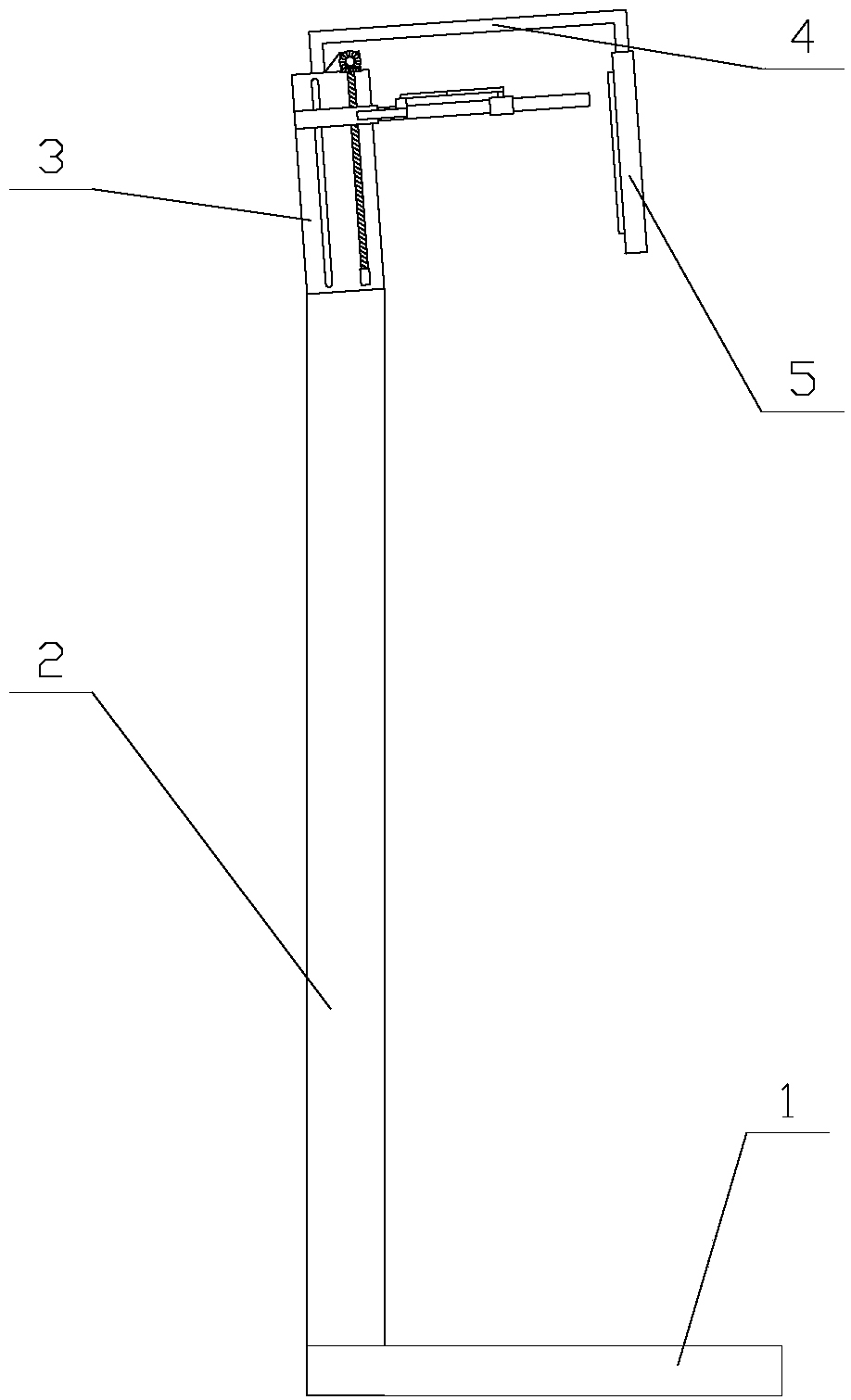

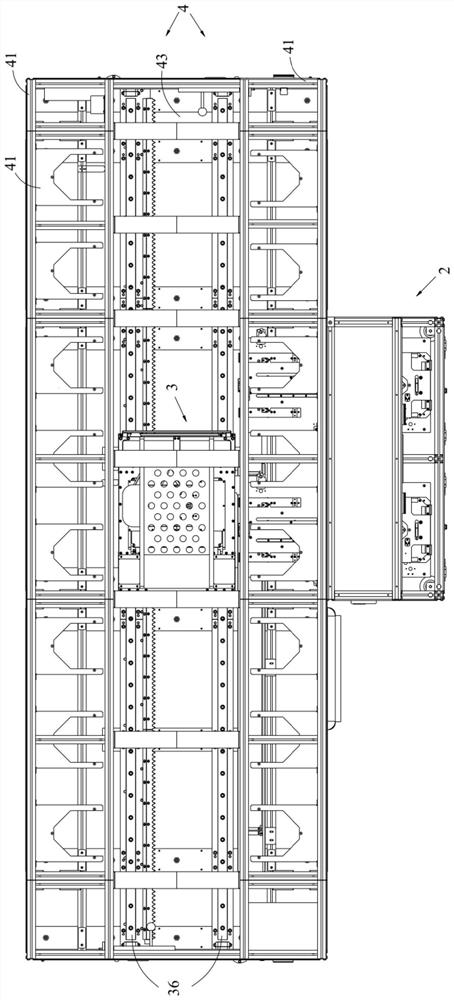

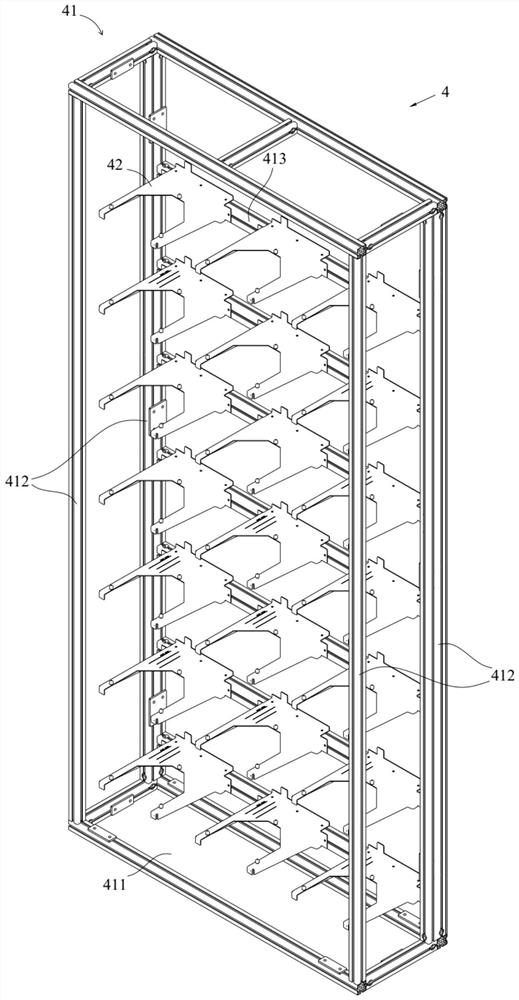

Automatic stereoscopic warehouse

InactiveCN112830141ATwo-way accessShorten the path of movementStorage devicesMechanical conveyorsAgricultural engineeringMechanical engineering

The invention discloses an automatic stereoscopic warehouse. The warehouse comprises two goods shelves arranged in parallel, a feeding and discharging support, two conveying mechanisms and a material taking and placing mechanism; the two goods shelves are arranged in a spaced mode to form a carrying channel located between the two sets of goods shelves, and one goods shelf is provided with a conveying channel communicating the interior and the exterior of the goods shelf; the feeding and discharging support is provided with a feeding channel and a discharging channel which are arranged in parallel in a spaced mode; the feeding channel and the discharging channel are each internally provided with one conveying mechanism; the material taking and placing mechanism comprises a horizontal guide rail arranged in the carrying channel, a lifting frame connected with the horizontal guide rail in a sliding mode and a temporary storage assembly connected with the lifting frame in a sliding mode. According to the warehouse, the structure is compact, the space utilization rate is high, bidirectional storage and taking of the materials can be achieved, the moving path of the stored and taken materials is reduced, the storage and taking efficiency is improved, and the storage and taking efficiency is further improved while the storage capacity of the stereoscopic warehouse is improved through bidirectional storage and taking of the materials.

Owner:成川科技(苏州)有限公司

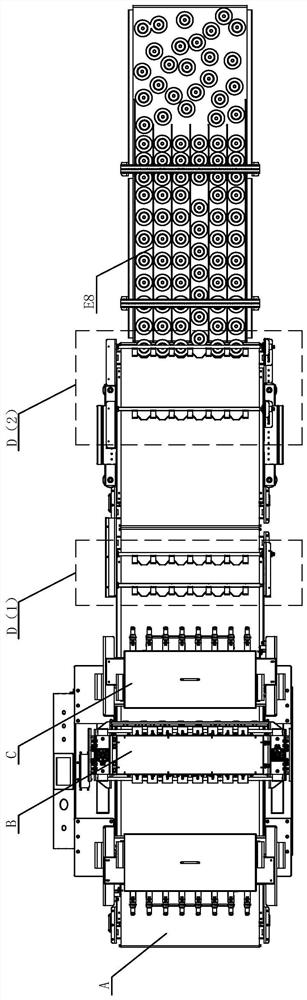

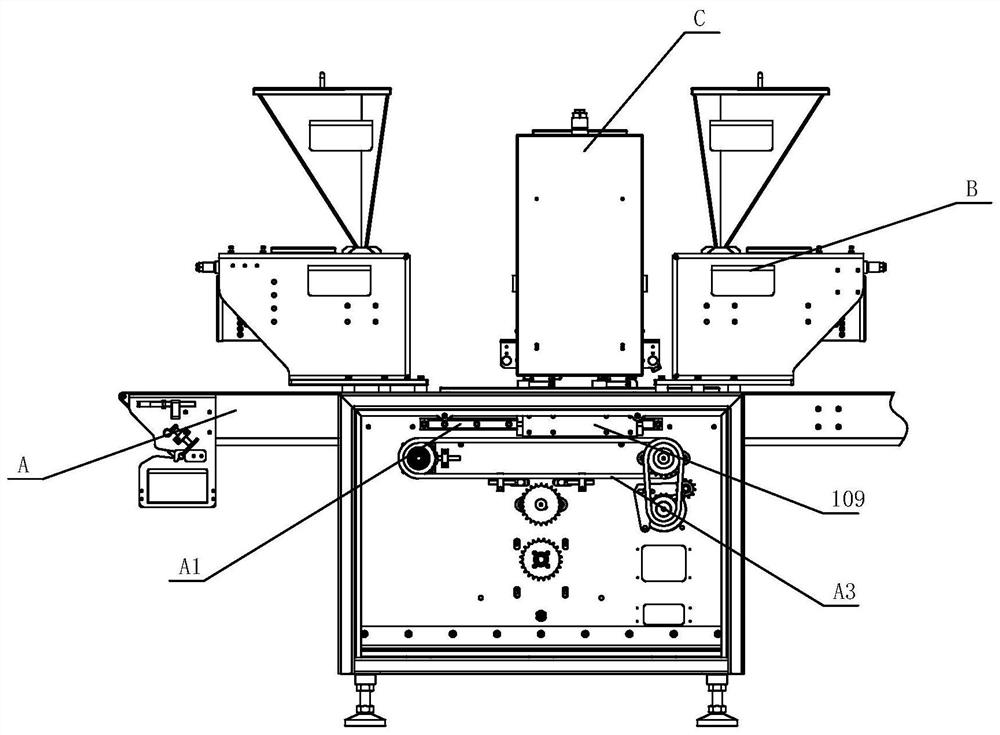

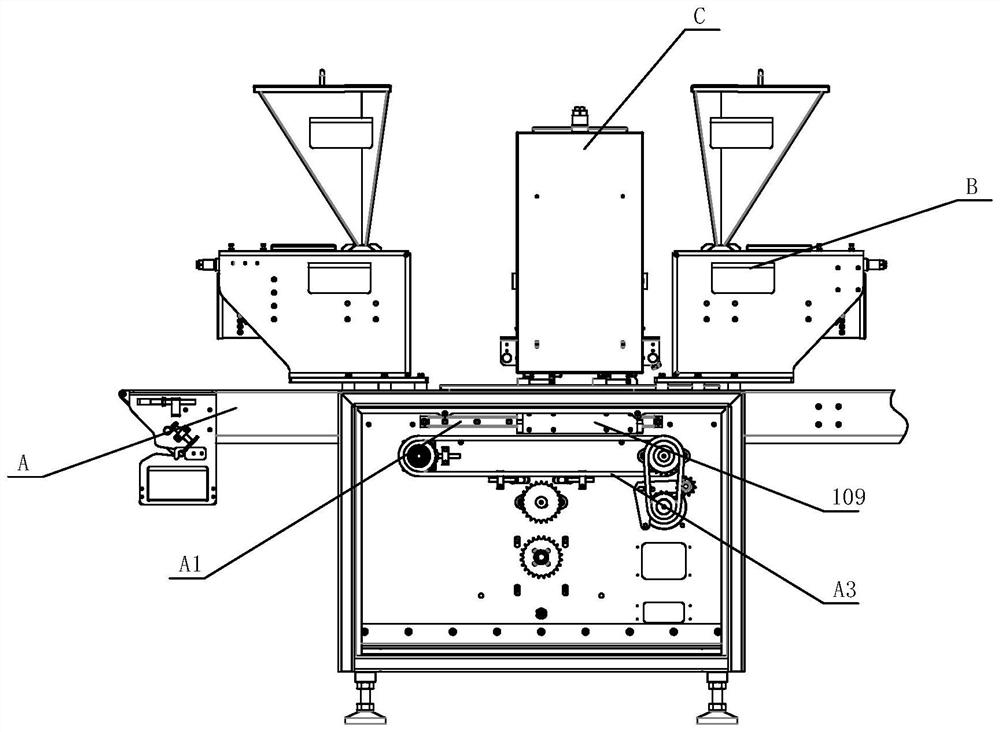

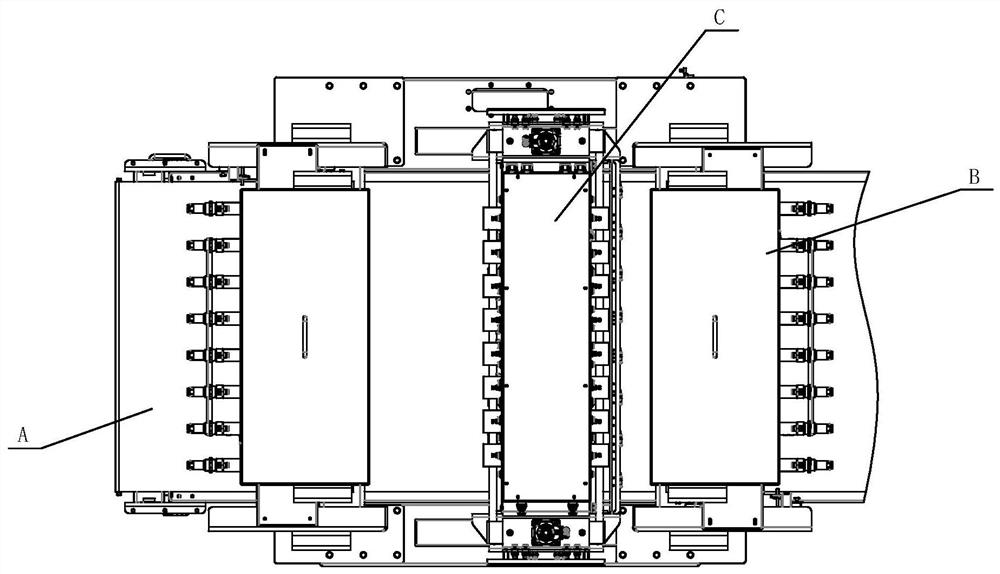

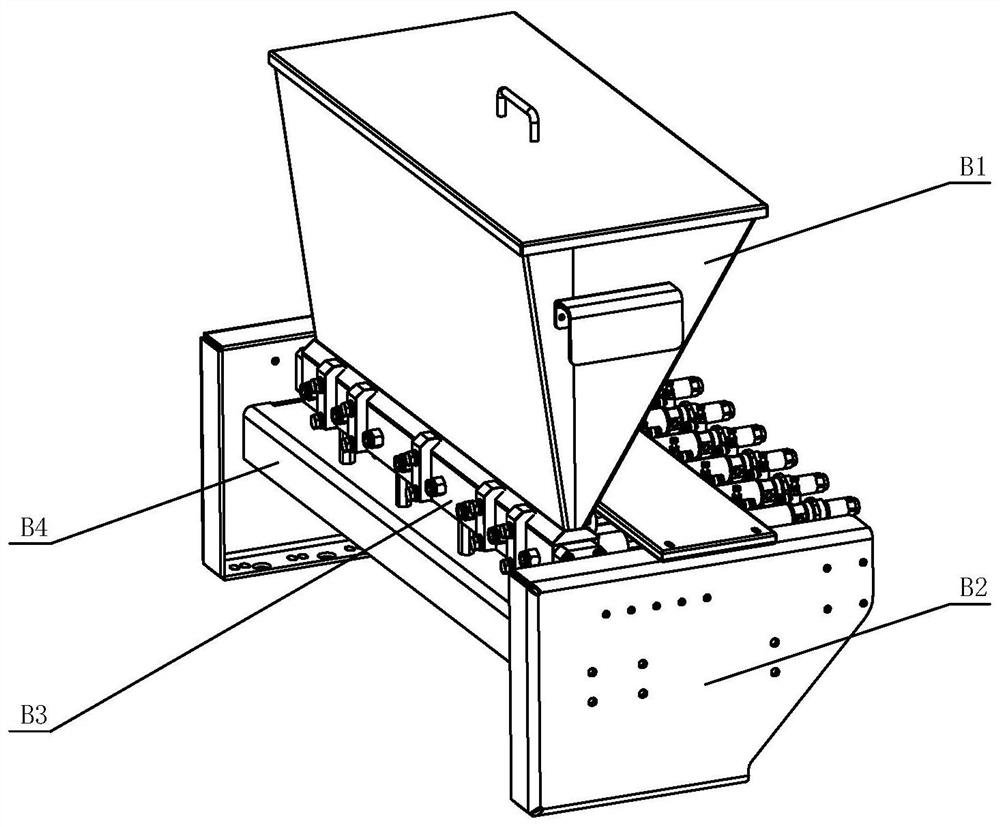

Fully automatic multiple adjustable fluid filler injecting production equipment and filler injecting technology

InactiveCN111670924AImprove machining accuracyHigh degree of automationFood coatingProgramme control in sequence/logic controllersProcess engineeringMechanical engineering

The invention discloses fully automatic multiple adjustable fluid filler injecting production equipment and a filler injecting technology. The filler injecting production equipment comprises a longitudinal queue material adjusting device, a horizontal queue material adjusting device and a filler injecting machine from an input end to an output end, wherein the longitudinal queue material adjustingdevice comprises a dividing device for dividing fed foods into longitudinal queues to be conveyed, the horizontal queue material adjusting device comprises a dividing device for dividing the foods ineach longitudinal queue to enable the foods to be aligned horizontally with the foods in the adjacent longitudinal queues, the filler injecting machine comprises a conveying table of the filler injecting machine, a food filler pumping device, and a food filler injecting device, the conveying table is used for conveying foods to be processed, the food filler pumping device pumps out a filler in the hopper and supplies the filler to the food filler injecting device, and the food filler injecting device is arranged on the conveying table for filler injection on the foods; and the food filler injecting device is provided with a movable driving device for driving the food filler injecting device to simultaneously move along with the conveyer belt of the conveying table while performing fillerinjecting. Full automation is adopted for filler injection on the conveyed foods, so that the working precision and the working efficiency can be improved.

Owner:嘉兴恒匠智能技术有限公司

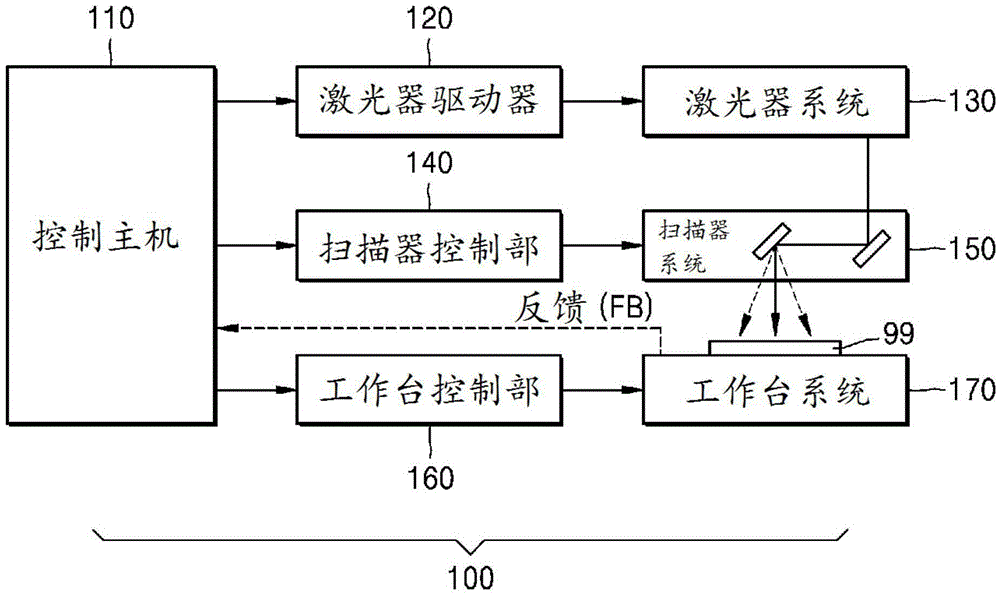

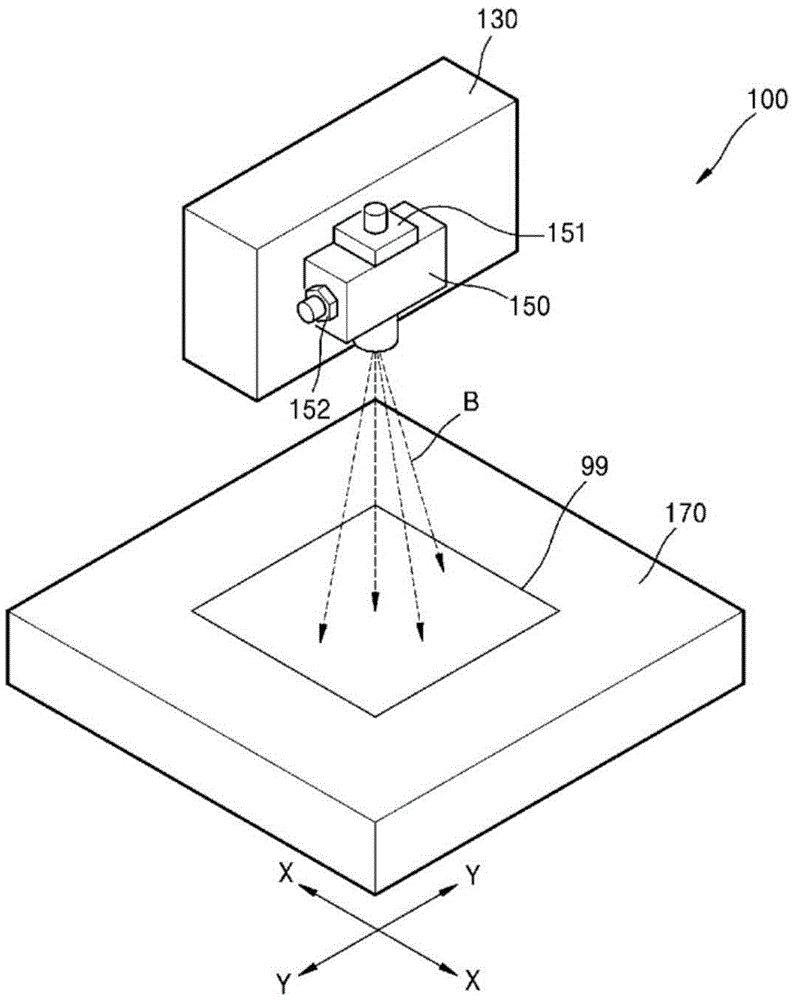

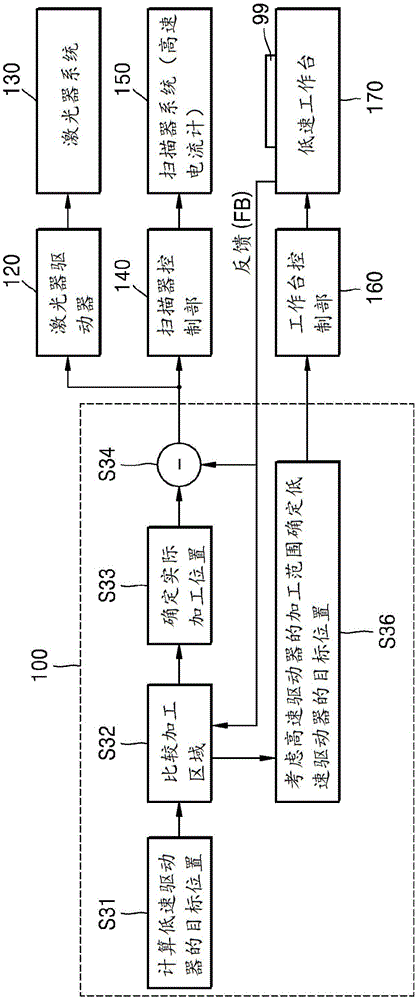

Method for continuous laser processing using multi-position control, and system employing same

ActiveCN105612022AMobile minimizeReduce processing timeLaser beam welding apparatusLaser processingLow speed

Disclosed are a laser processing method and a laser processing system employing the same. The laser processing method comprises: a first step of calculating the middle position of adjacent patterns from among a plurality of patterns to be processed; a second step of transferring a low-speed drive to the middle position; and a third step of processing the plurality of patterns by driving a high-speed drive at the middle position, wherein the laser processing for the plurality of patterns to be processed is performed by repeating the first to third steps.

Owner:TECHNICS

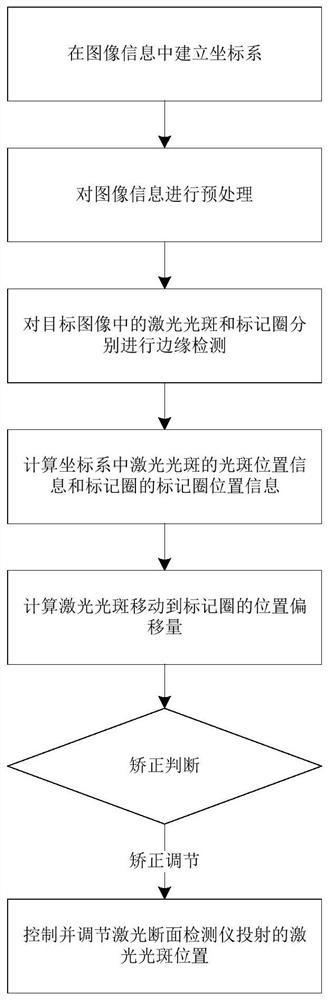

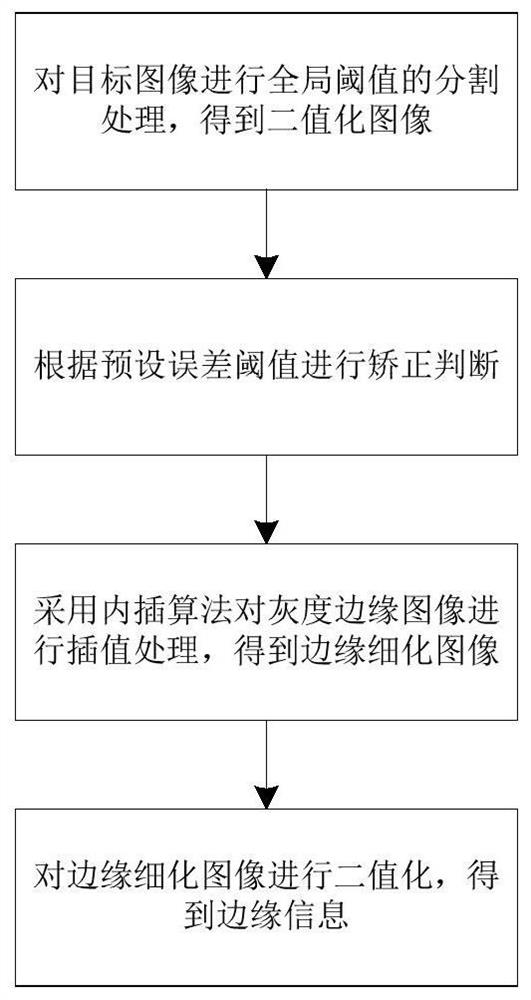

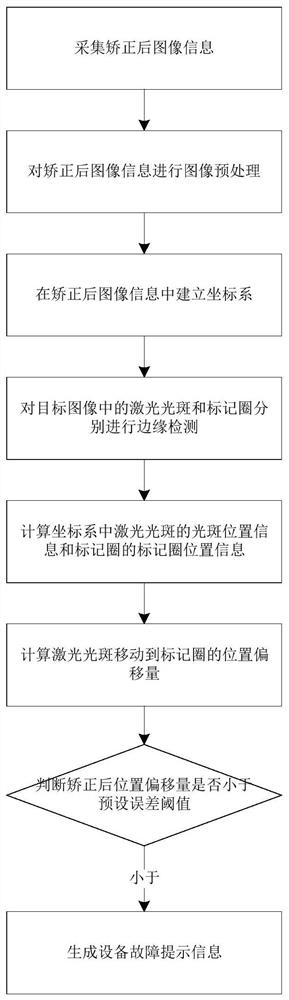

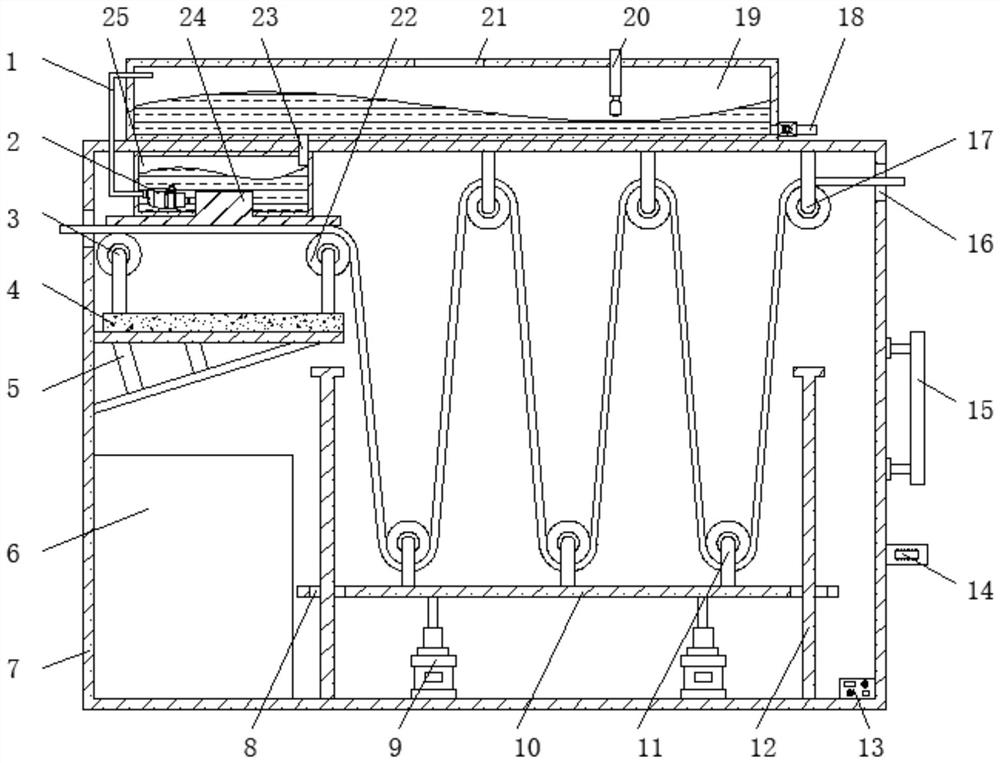

Sub-pixel edge detection method

PendingCN113129322AEasy fault detectionEasy alignmentImage enhancementImage analysisImaging processingLight spot

The invention relates to the technical field of image processing, and particularly discloses a sub-pixel edge detection method, which comprises the following steps: a coordinate system establishment step: establishing a coordinate system in collected image information; image preprocessing: performing image preprocessing on the image information to obtain a target image; an edge detection step: respectively carrying out edge detection on the laser spot and the marking ring in the target image to obtain spot edge information and marking ring edge information; a position calculation step: respectively calculating light spot position information of the laser light spot and marking ring position information of the marking ring in the coordinate system according to the light spot edge information and the marking ring edge information; an offset calculation step: calculating the position offset of the laser spot moving to the marking ring according to the spot position information and the marking ring position information; and a correction step: controlling and adjusting the position of the laser spot projected by the laser section detector according to the position offset. By adopting the technical scheme of the invention, the alignment precision of the laser spot and the marking ring is higher.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Cooling equipment for processing silica gel tent cloth

The invention discloses cooling equipment for processing silica gel tent cloth. The cooling equipment comprises a cooling outer box, wherein cloth through holes extending into an inner cavity of the cooling outer box are formed in the upper ends of the left side wall and the right side wall of the cooling outer box in a staggered mode, first air cylinders are symmetrically installed on the right side of the bottom of the inner cavity of the cooling outer box, and bearing plates are fixedly welded to the output ends of the tops of the two sets of first air cylinders; and second material guide rollers are fixedly welded to the tops of the bearing plates at equal intervals, a cooling inner box is fixedly welded to the left side of the bottom of the inner cavity of the cooling outer box, and abearing frame is fixedly welded to the position, located in the middle of the left side wall of the inner cavity of the cooling outer box, above the cooling inner box. According to cooling equipmentfor processing the silica gel tent cloth, the first air cylinders extend to drive the bearing plates to move upwards outside T-shaped limiting rods under action of limiting through holes, and the second material guide rollers are driven to move synchronously, so that vertical distances between the second material guide rollers and third material guide rollers and a fourth material guide roller arereduced, and a moving path of the silica gel tent cloth in the inner cavity of the cooling outer box is reduced.

Owner:安徽北极户外用品有限公司

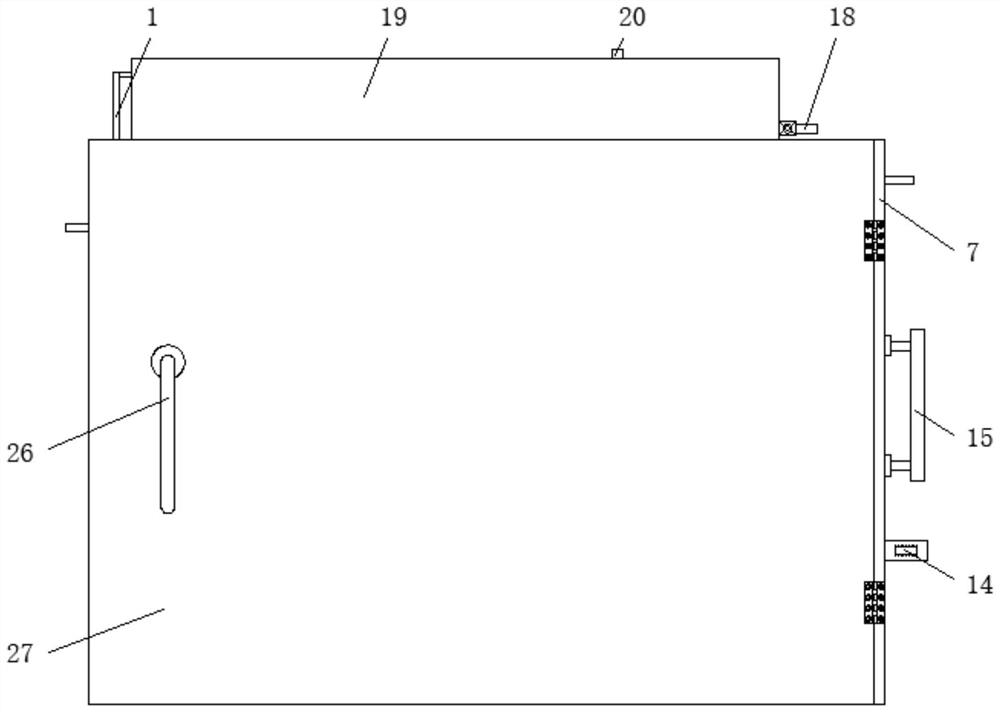

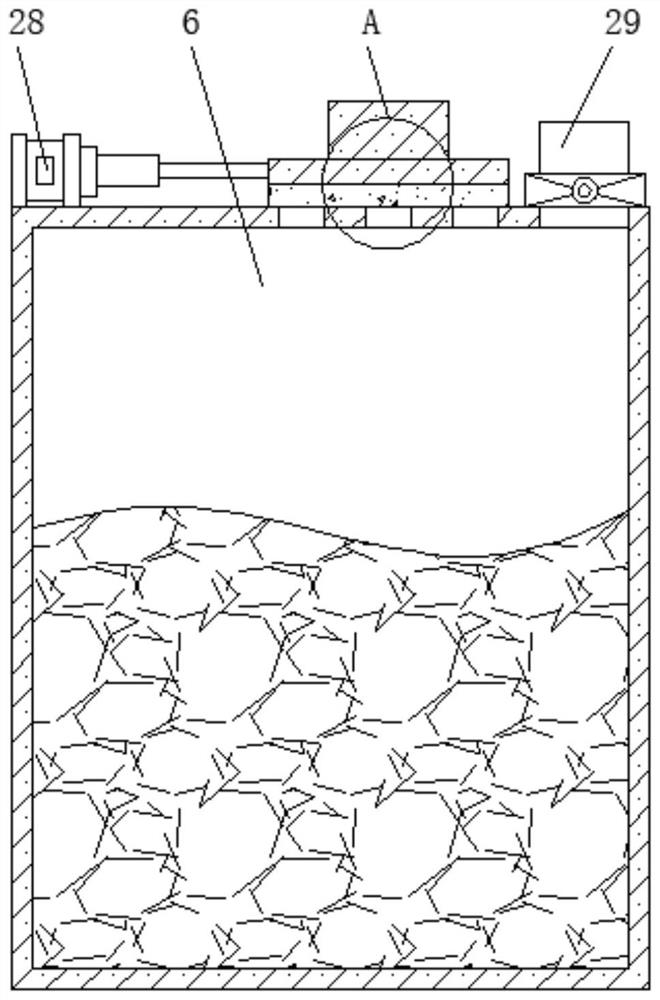

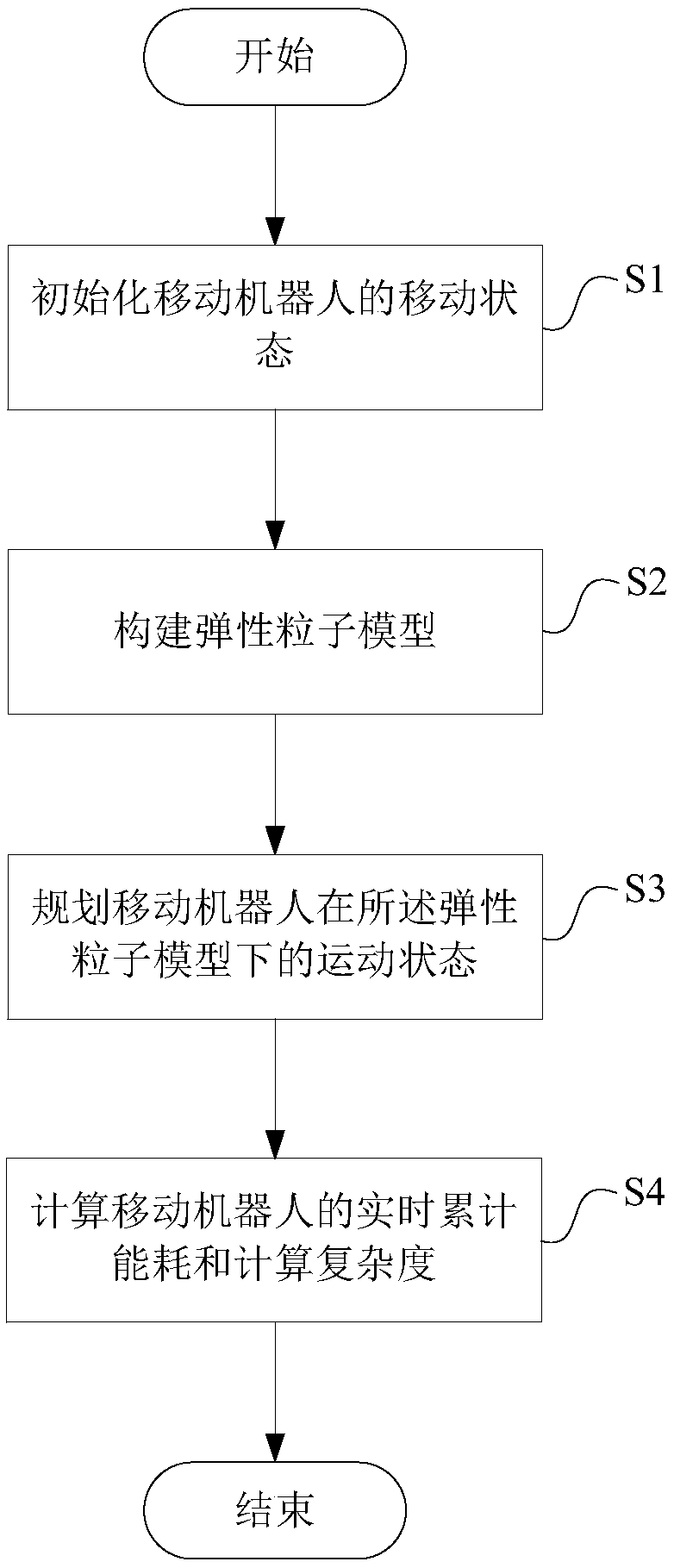

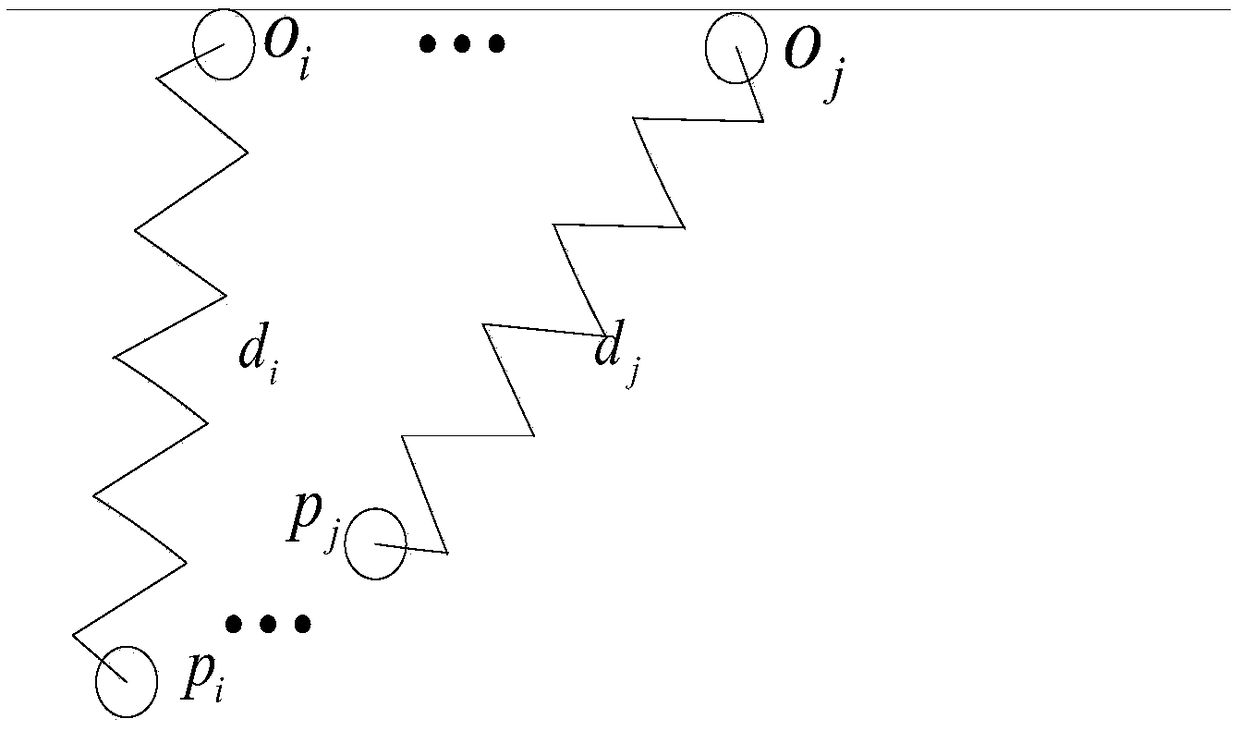

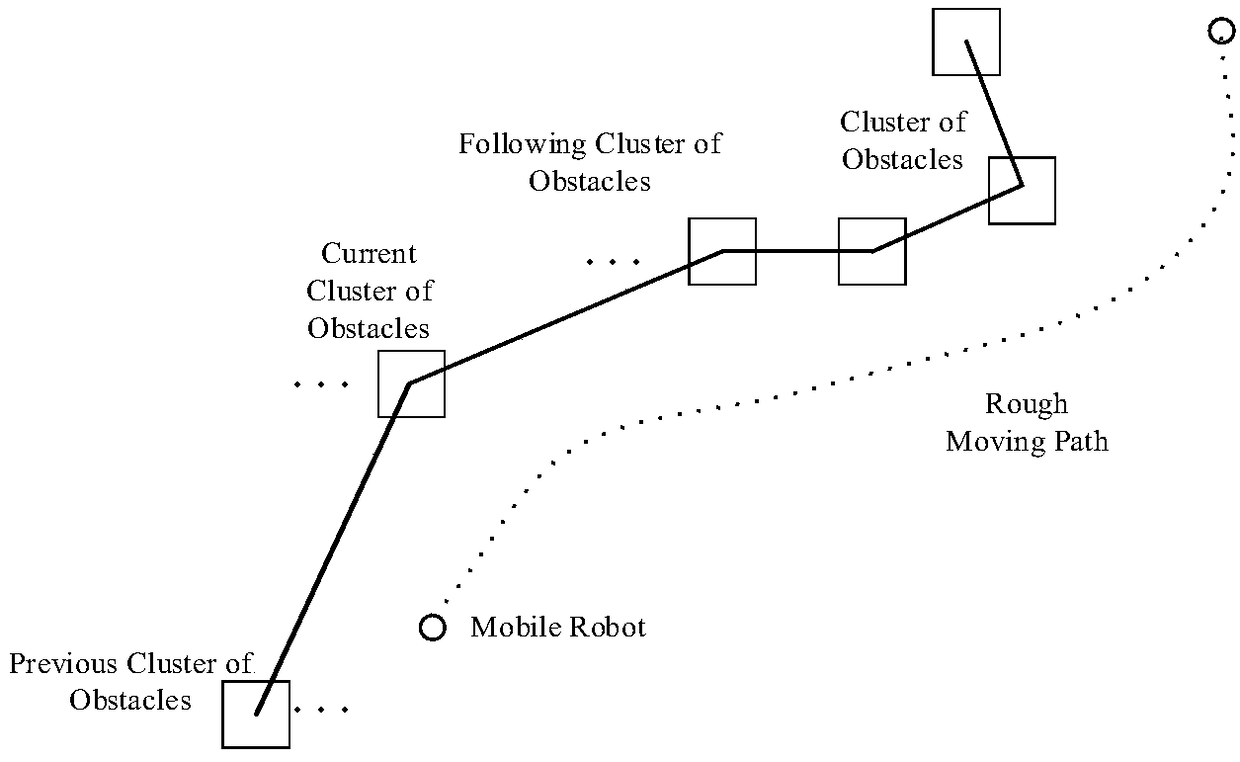

Path planning method for mobile robot

ActiveCN109358618AReduce energy lossFacilitate path planningPosition/course control in two dimensionsVehiclesSimulationMobile robots path planning

The invention discloses a path planning method for a mobile robot, comprising the following steps of: initializing the moving state of the mobile robot; constructing an elastic particle model; planning the motion state of the mobile robot under the elastic particle model; and calculating the real-time cumulative energy consumption and the complexity of the mobile robot. According to the path planning method for the mobile robot, the interaction force between the mobile robot and an obstacle is taken into consideration, so that the interaction with a distant object is avoided, and the mobile robot does not fall into a local equilibrium position, is high in initiative, and can be applied to any target position; meanwhile, the energy consumption of the mobile robot is effectively reduced, andthe path planning of the mobile robot is facilitated; and by means of the elastic particle model, the complexity of the real-time calculation of the path planning is effectively reduced, the moving path is shortened, and the energy consumption of the mobile robot is saved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Automatic stereoscopic warehouse used for buffering and storing semiconductor components

InactiveCN113023193AShorten the path of movementImprove storage effectStorage devicesMechanical conveyorsEngineeringTransfer mechanism

The invention discloses an automatic stereoscopic warehouse used for buffering and storing semiconductor components. The automatic stereoscopic warehouse comprises two sets of goods shelves arranged in parallel, a buffer-storing and feeding mechanism, a feeding and discharging transfer mechanism and a material taking and placement mechanism. The two sets of goods shelves are arranged in a spaced manner so as to form a transfer channel located between the two sets of goods shelves, and a butt joint channel communicating the inside and the outside of the goods shelves is formed in one set of goods shelves. The buffer-storing and feeding mechanism comprises a rack and a buffer-storing and carrying assembly arranged in the rack. The feeding and discharging transfer mechanism is arranged in the rack and located under the buffer-storing and carrying assembly. The material taking and placement mechanism comprises a horizontal guide rail arranged in the transfer channel, a lifting frame connected with the horizontal guide rail in a sliding manner and a taking and placement assembly connected with the lifting frame in a sliding manner. According to the automatic stereoscopic warehouse, the moving path for storing and taking materials is reduced, meanwhile, the materials can be stored and taken in two directions, and the storage and taking efficiency is improved while the storage capacity of the stereoscopic warehouse is improved.

Owner:成川科技(苏州)有限公司

Multigang adjustable fluid filling machine and filling technology

InactiveCN111671114AImprove machining accuracyHigh degree of automationFood coatingDough processingBiotechnologyEngineering

The invention discloses a multigang adjustable fluid filling machine and a filling technology. The multigang adjustable fluid filling machine comprises a conveyer table, food filling extraction devices and a food filling device, wherein the multigang adjustable fluid filling machine is characterized in that the conveyer table is used for conveying to-be-processed food; the food filling extractiondevices extract fillings in a hopper and supply the fillings to the food filling device; the food filling device is arranged at the upper part of the conveyer table to fill the food; the food fillingdevice is provided with a mobile drive device; and the mobile drive device drives the food filling device to follow a conveyer belt of the conveyer table to synchronously move while filling. Accordingto the multigang adjustable fluid filling machine, an automation form is adopted, the food filling extraction devices extract the fillings in the hopper and push the fillings into the food filling device by adopting an extract-push mode, and automatic filling work is carried out on the conveyed food, so that the working accuracy and the working efficiency are improved.

Owner:嘉兴恒匠智能技术有限公司

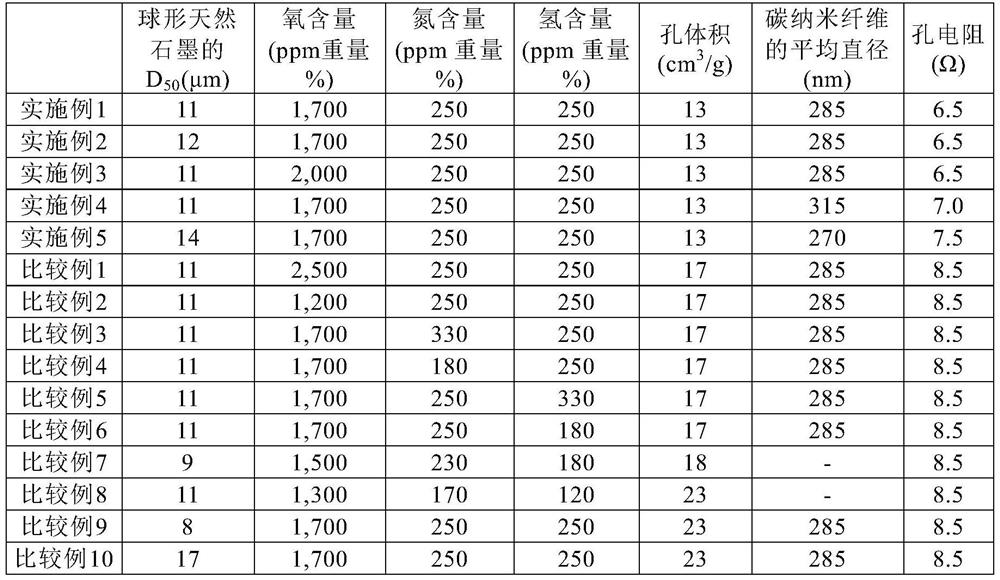

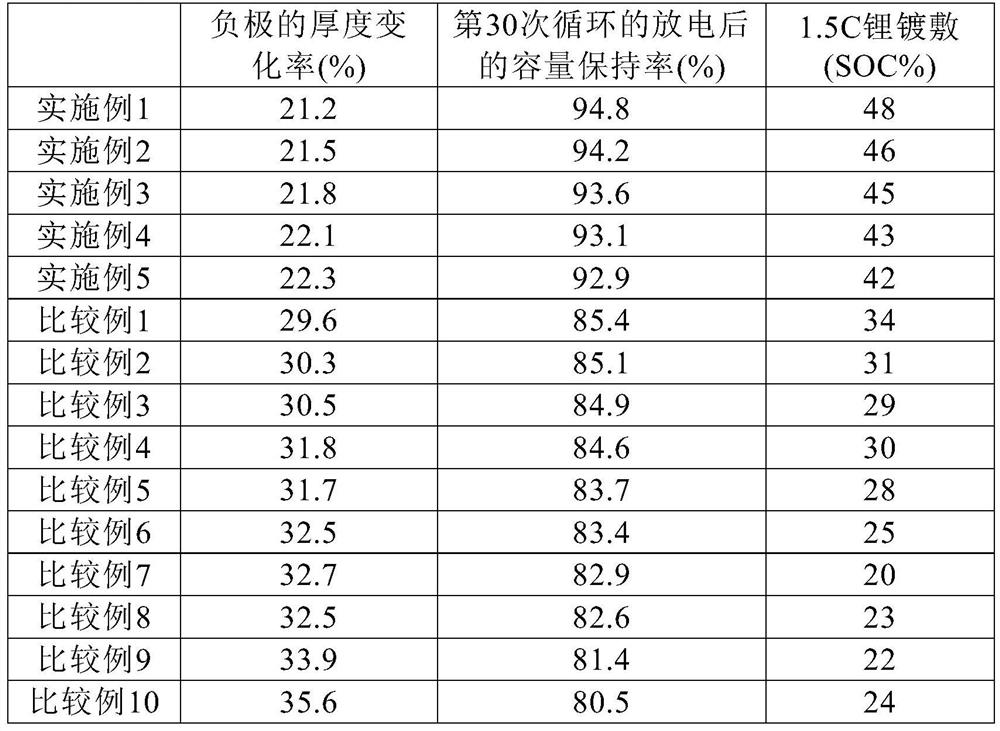

Anode and secondary battery comprising anode

PendingCN113646927AImprove adhesionImprove life performanceCell electrodesSecondary cellsCarbon layerElectrical battery

The present invention relates to an anode and a secondary battery, the anode comprising an anode active material layer including an anode active material, wherein the anode active material includes a core and a coating layer disposed on the core, the core comprises a natural graphite and an amorphous carbon layer, D50 of the natural graphite is 10 um to 14 um, and as confirmed through ONH analysis, the anode active material comprises 1,500 ppm wt% to 2,000 ppm wt% of oxygen, 200 ppm wt% to 300 ppm wt% of nitrogen, and 200 ppm wt% to 300 ppm wt% of hydrogen, and the coating layer comprises carbon nanofibers.

Owner:LG ENERGY SOLUTION LTD

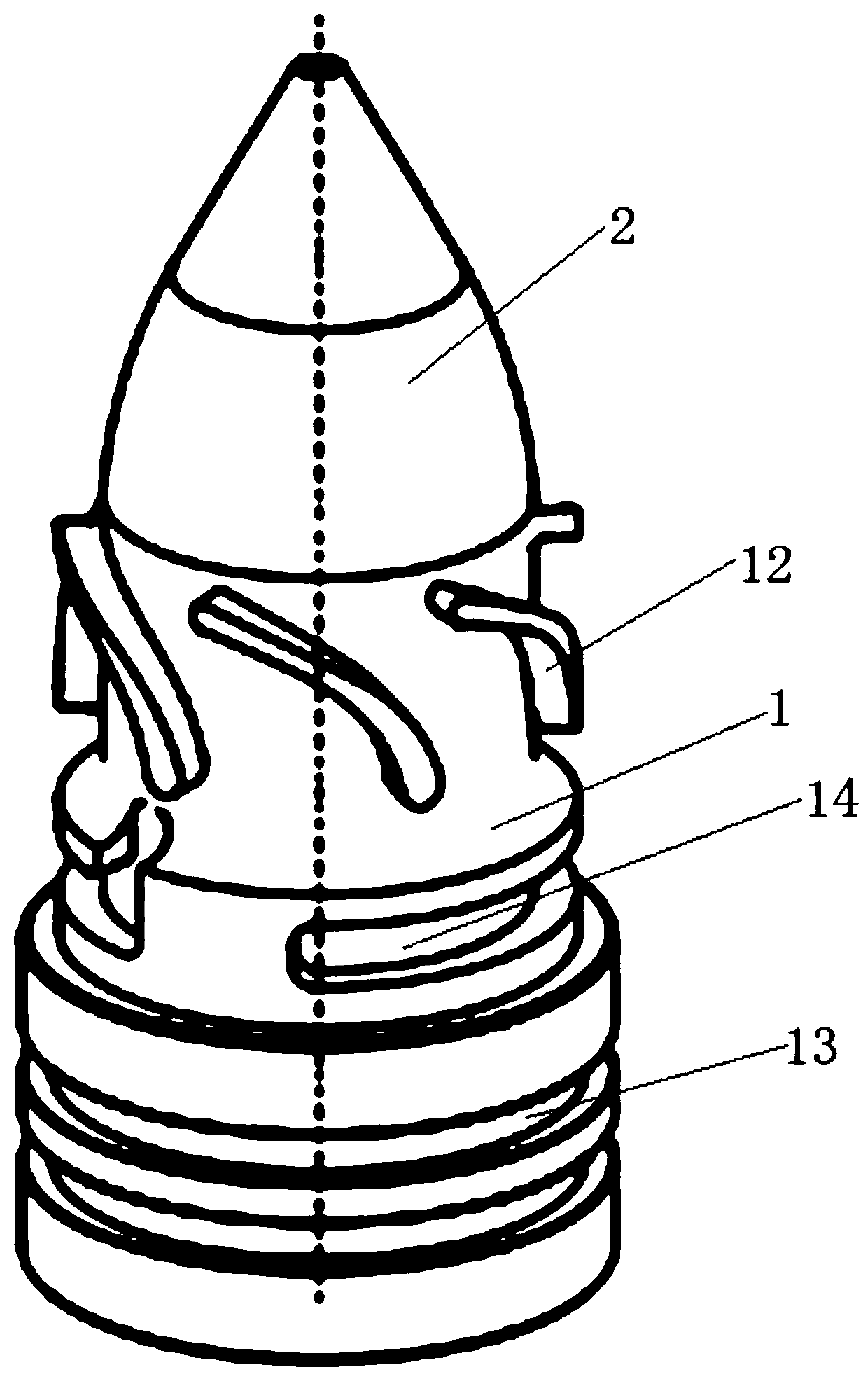

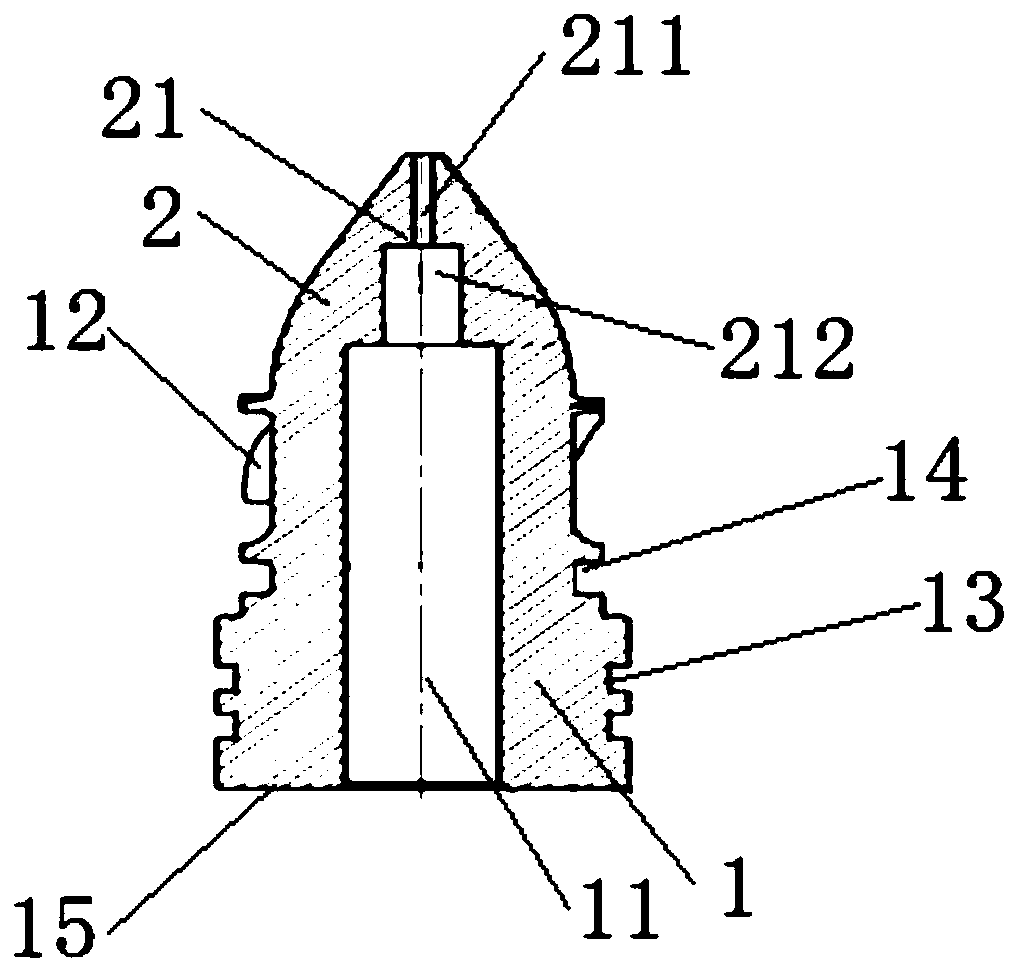

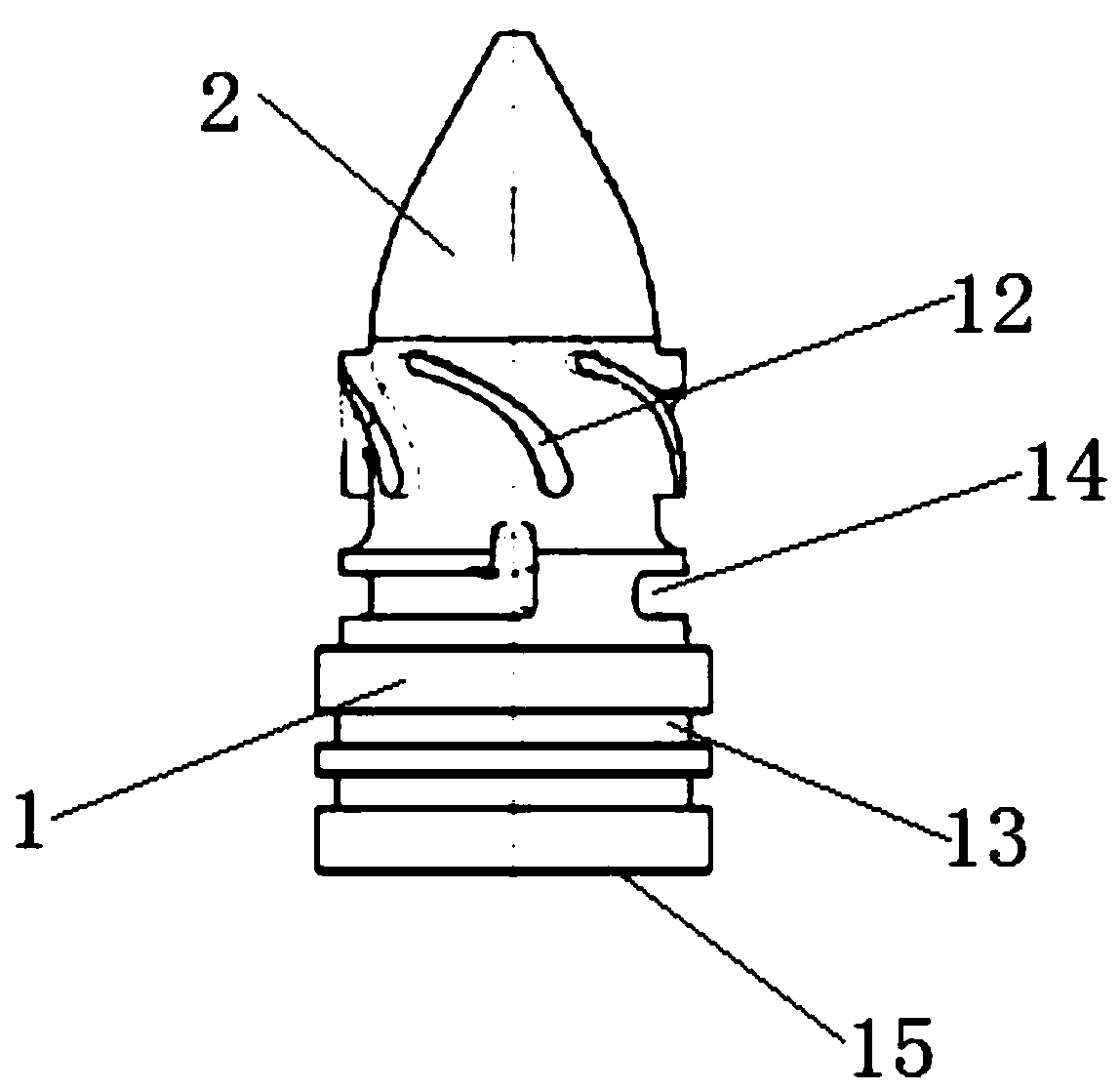

Complex structure reverse-flow valve core and numerical control processing method thereof

PendingCN111442132ATo solve the varietySolve the small batchValve arrangementsNumerical controlStructural engineering

The invention relates to a complex structure reverse-flow valve core and a numerical control machining method of the complex structure reverse-flow valve core, and belongs to the technical field of mechanical parts and machining. The complex structure reverse-flow valve core comprises a valve body and a valve head. The valve head is connected to the upper end of the valve body. A stepped through hole is formed in the valve head. A straight through hole is formed in the valve body. The stepped through hole communicates with the straight through hole. An irregular boss is arranged outside the valve body. Compared with the prior art, according to the complex structure reverse-flow valve core and the numerical control machining method, due to the adoption of area-based milling, cutter jumpingcaused by the existence of a boss is effectively avoided, and the moving path of a cutter is shortened. Layer-based milling is adopted by rough machining, so that the abrasion of the cutter is greatlyreduced, cutter breaking and burning are avoided, the service life of the cutter is prolonged, and the production cost is reduced. The pertinence and adjustability of the method are guaranteed through region drawing at a step three and an offset curve at a step five.

Owner:SHANGHAI JIAN QIAO UNIV +1

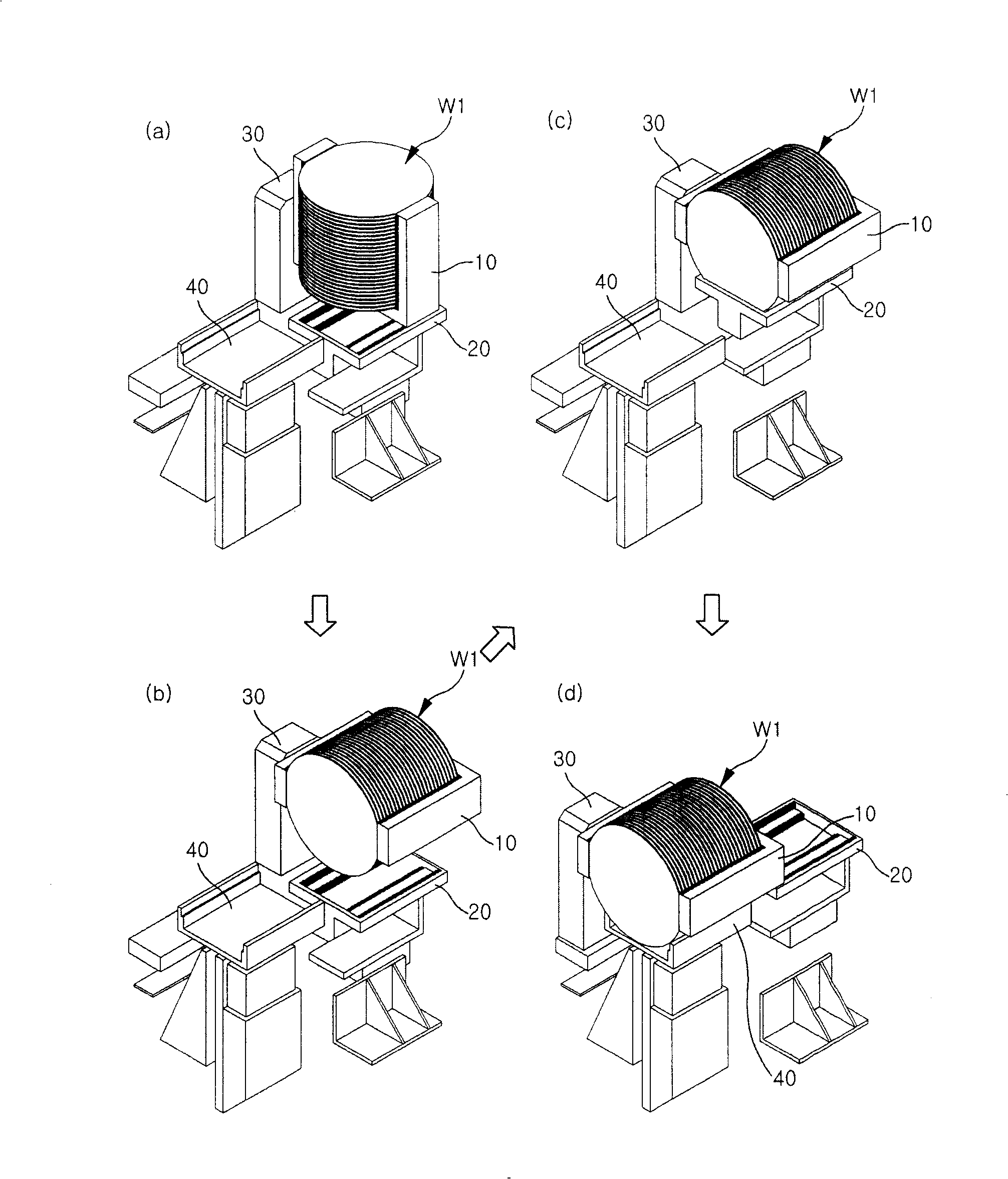

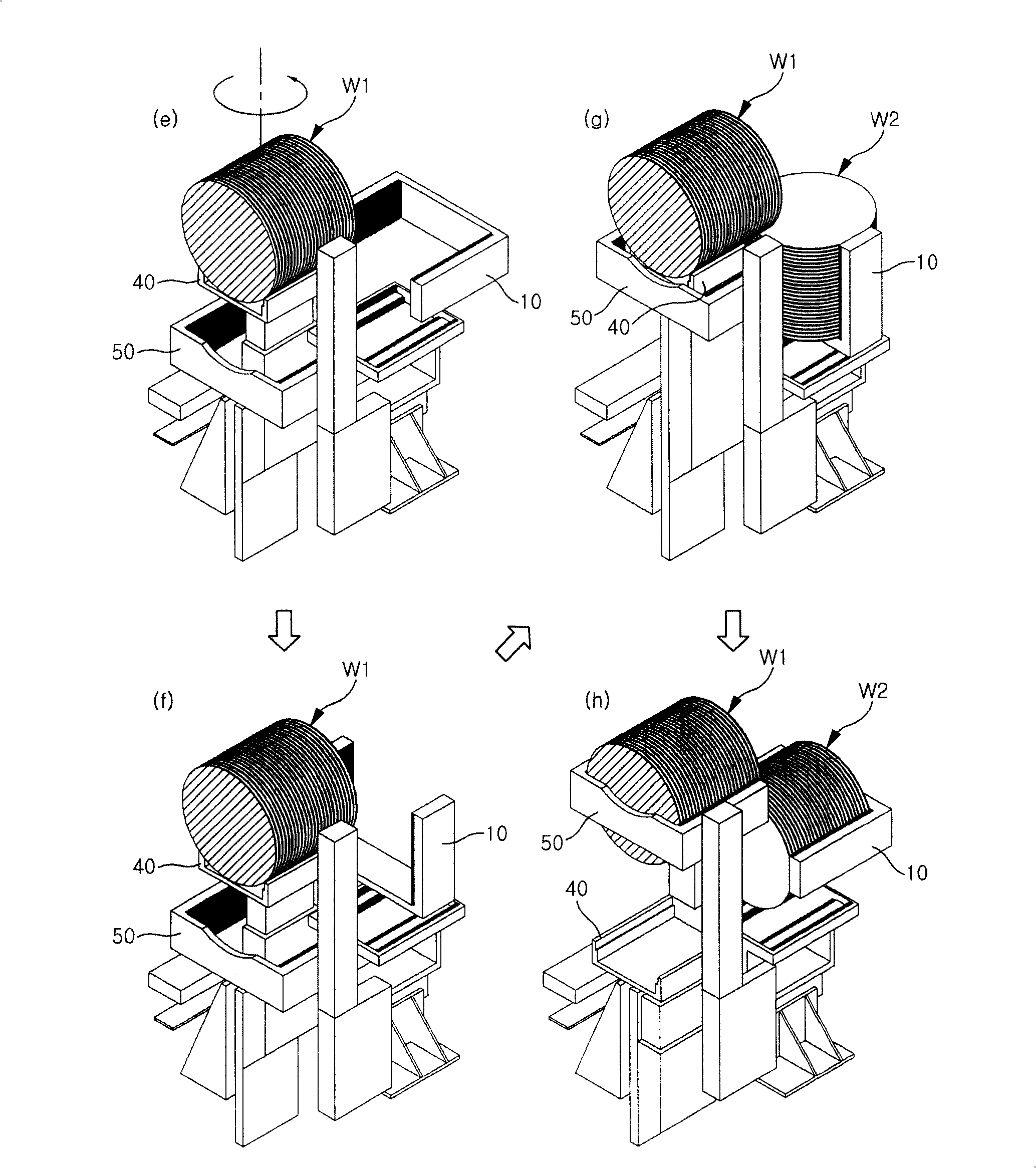

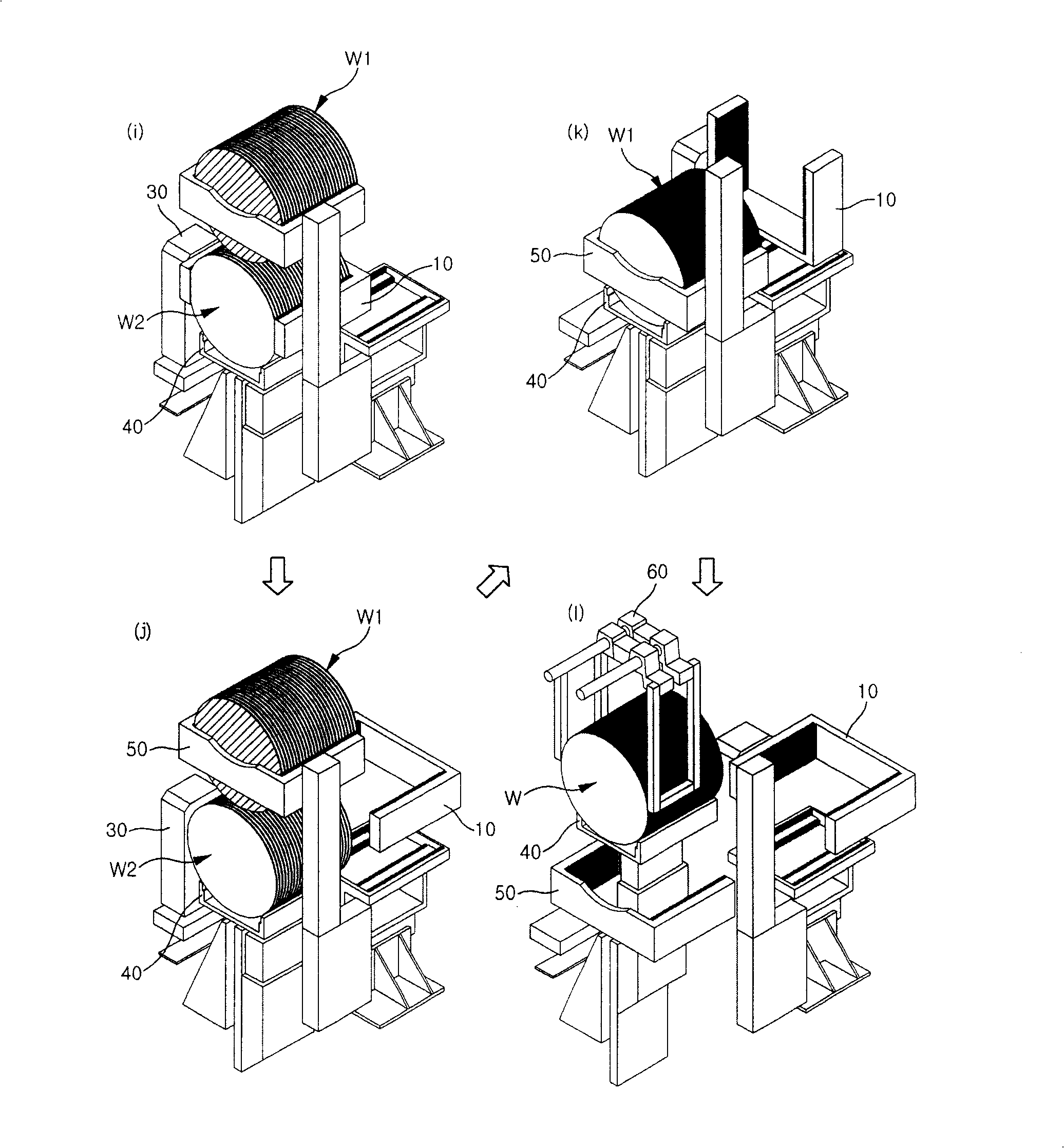

Wafer array apparatus and method for arraying wafer

ActiveCN100449725CSimple structureIncrease productionSemiconductor/solid-state device manufacturingCharge manipulationElectrical and Electronics engineering

The invention relates to a wafer array apparatus which makes opposite surfaces of a pair of adjacent wafers have a same property during a process of cleaning a plurality of wafers at one time by arraying wafers. The wafer array apparatus provided according to the invention includes a wafer receiving unit for receiving a first wafer group and a second wafer group composed of at least a wafer respectively in a horizontal state and arranging the wafer groups in a vertical state, and a delivering unit for orderly receiving the first wafer group and second wafer group of the vertical state and arranging the groups, and the wafer array apparatus further has a sturcture in which the wafers of the first wafer group and the second wafer group are alternately arrayed in opposite directions by the rotation of either the wafer receiving unit or the delivering unit.

Owner:K C TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com