Wafer array apparatus and method for arraying wafer

A technology for arranging devices and arranging directions, which is applied to cleaning methods and utensils, chemical instruments and methods, and cleaning methods using liquids, etc., and can solve problems such as increasing devices, low output, and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

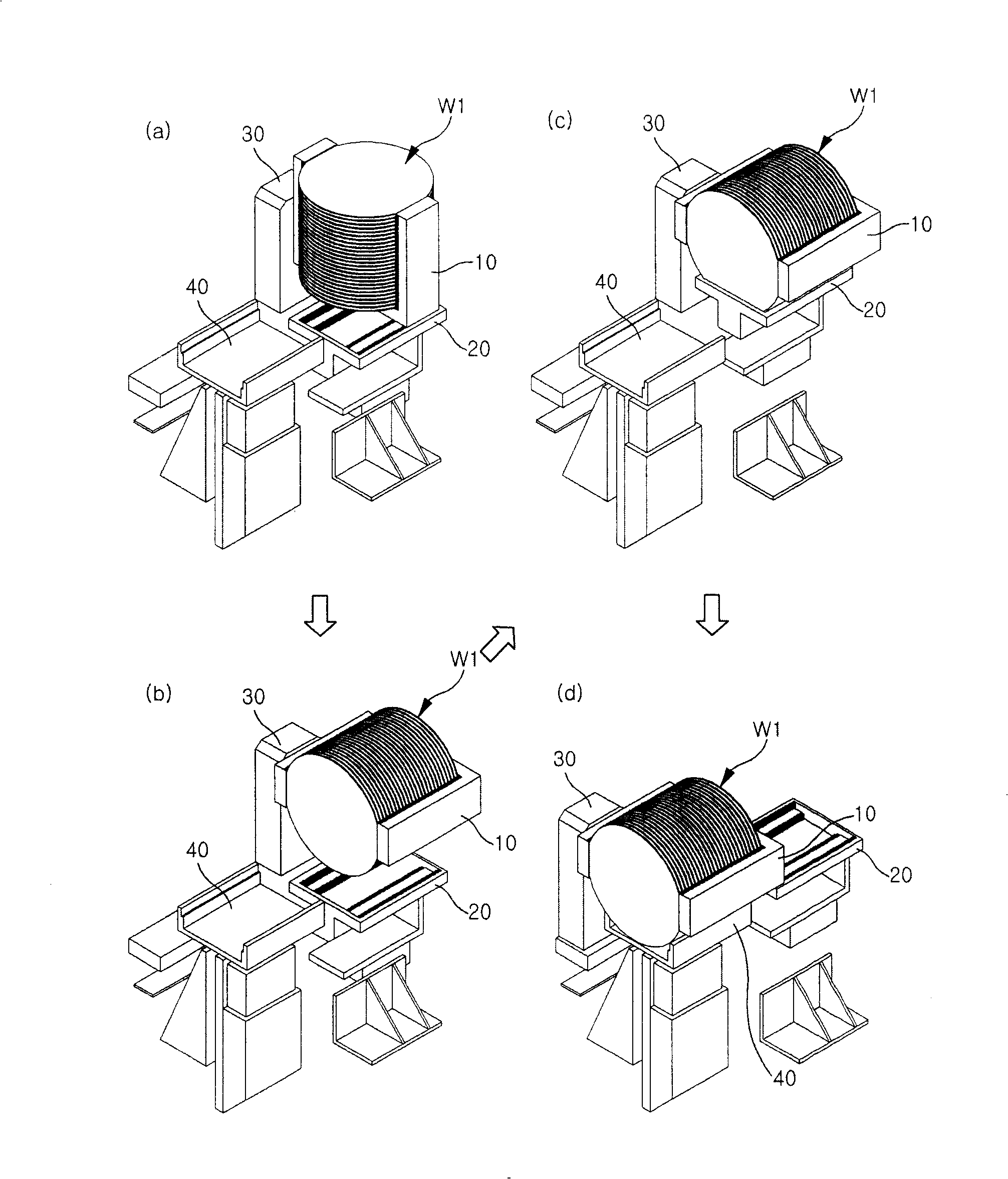

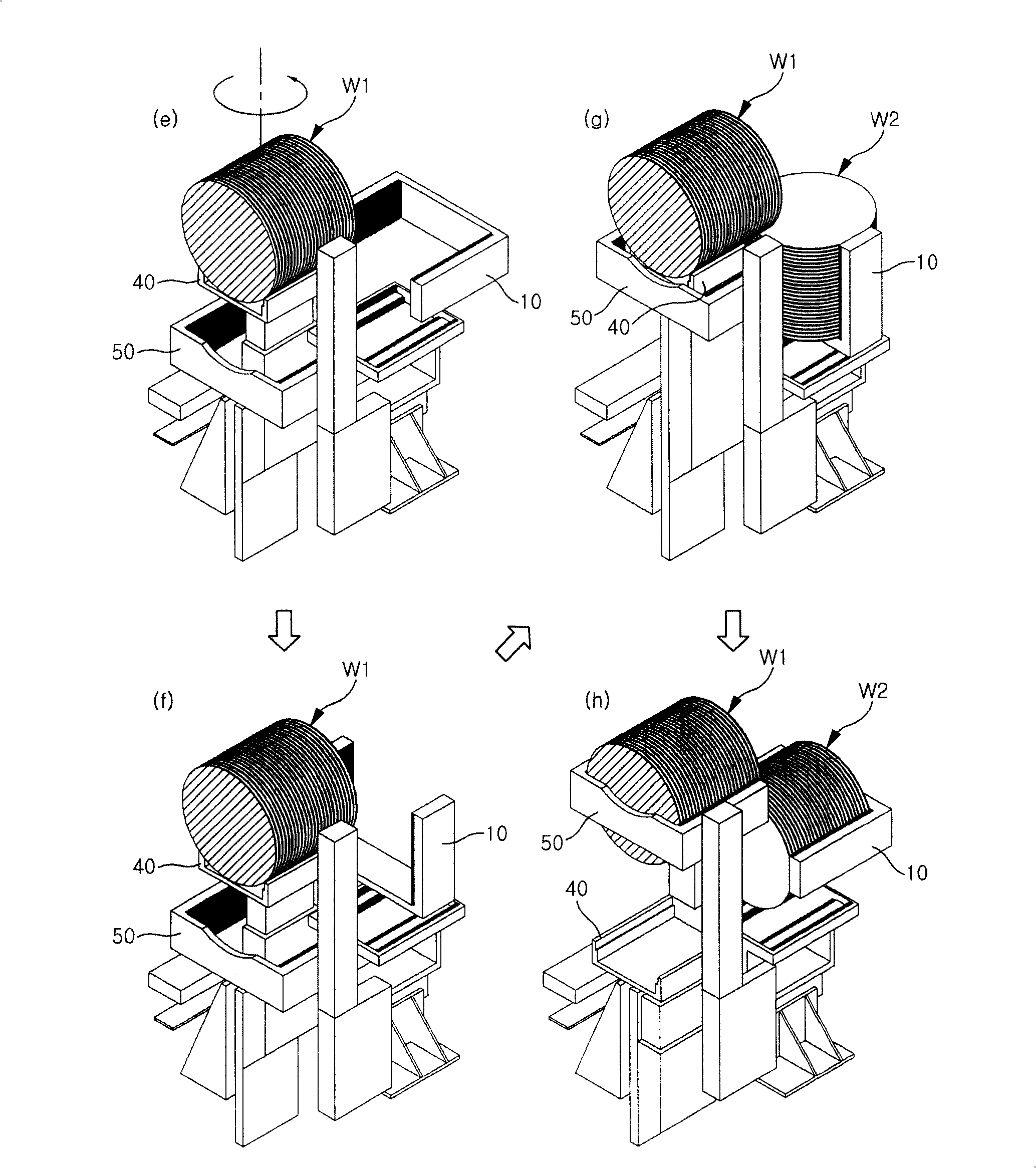

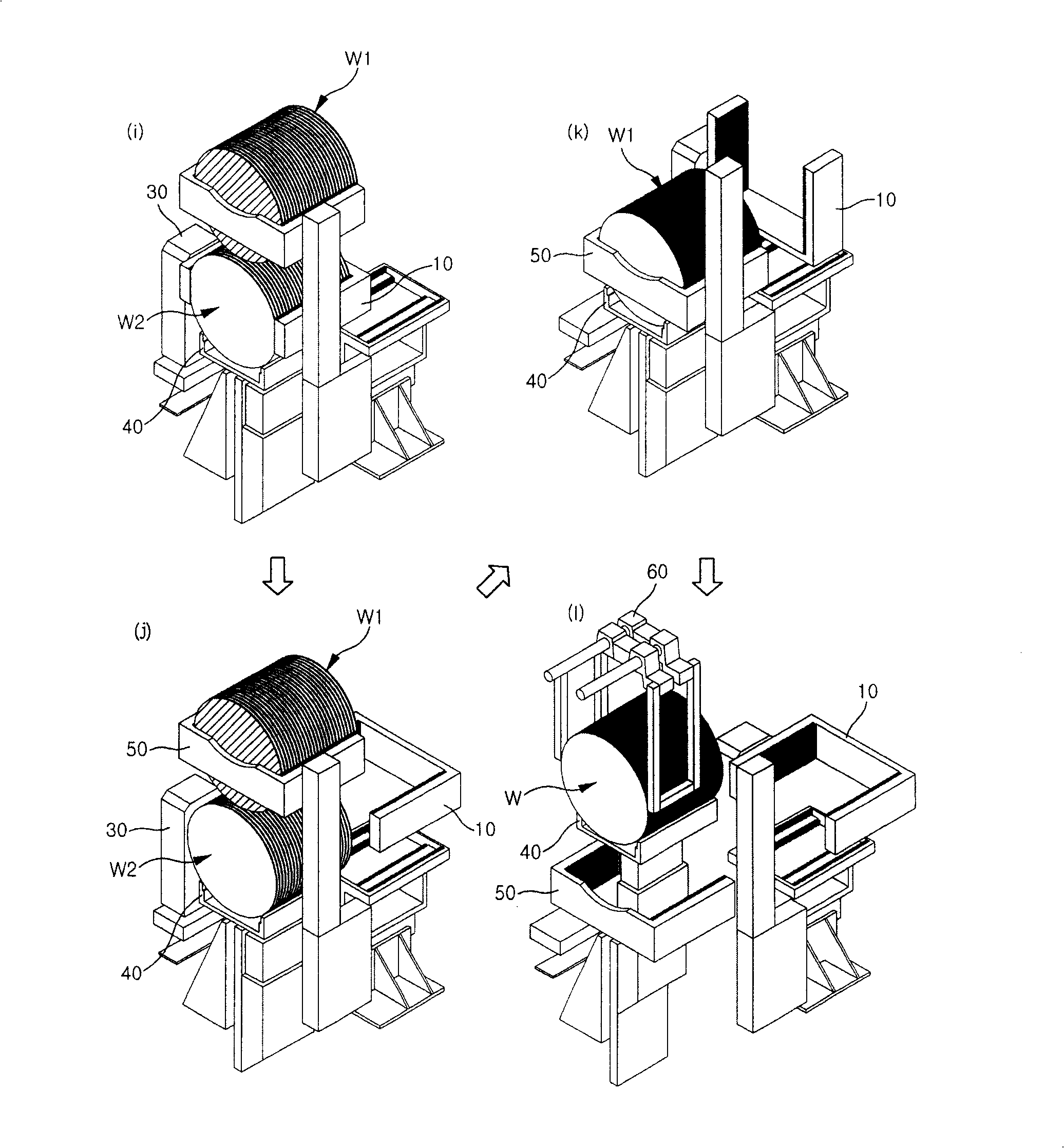

[0040] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0041] Figure 4 It is a side view of the first embodiment of the wafer alignment device provided by the present invention as a whole.

[0042] like Figure 4 As shown, the wafer alignment device provided by the present invention includes a wafer receiving unit 200 that rotates the wafer 90 degrees around the horizontal axis and a push unit 300 that rotates the wafer 180 degrees around the vertical axis. At this time, wafers are supplied from the robot 100 to the wafer receiving unit.

[0043] The robot 100 supplies a first wafer group and a second wafer group each composed of a plurality of wafers to the wafer receiving unit 200, respectively. At this time, the wafers of the first wafer group and the second wafer group are supplied to the wafer receiving unit 200 in a horizontal state.

[0044] Hereinafter, a case where the number of chips in each chip gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com