Fully automatic multiple adjustable fluid filler injecting production equipment and filler injecting technology

A production equipment, fully automatic technology, applied in control/regulation systems, baking, food science, etc., can solve problems such as low adjustment applicability, pollution of processing equipment, and lack of monolithic equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

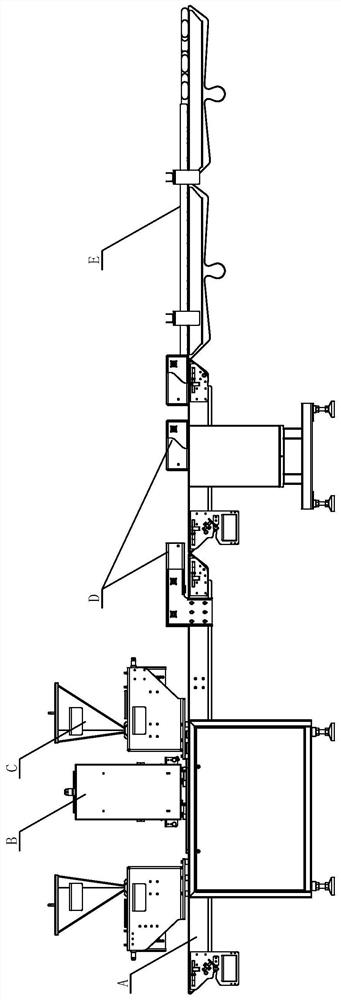

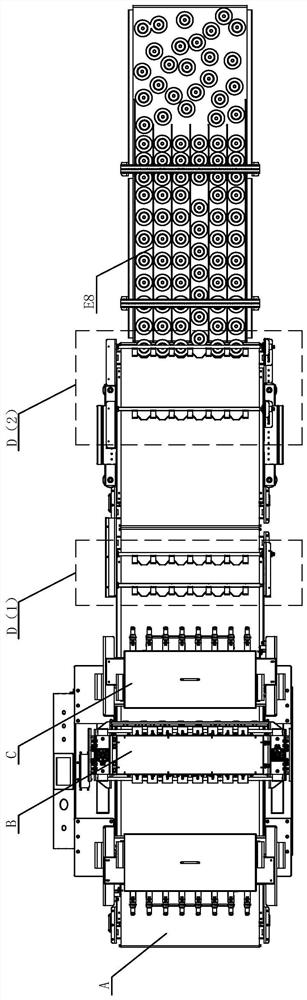

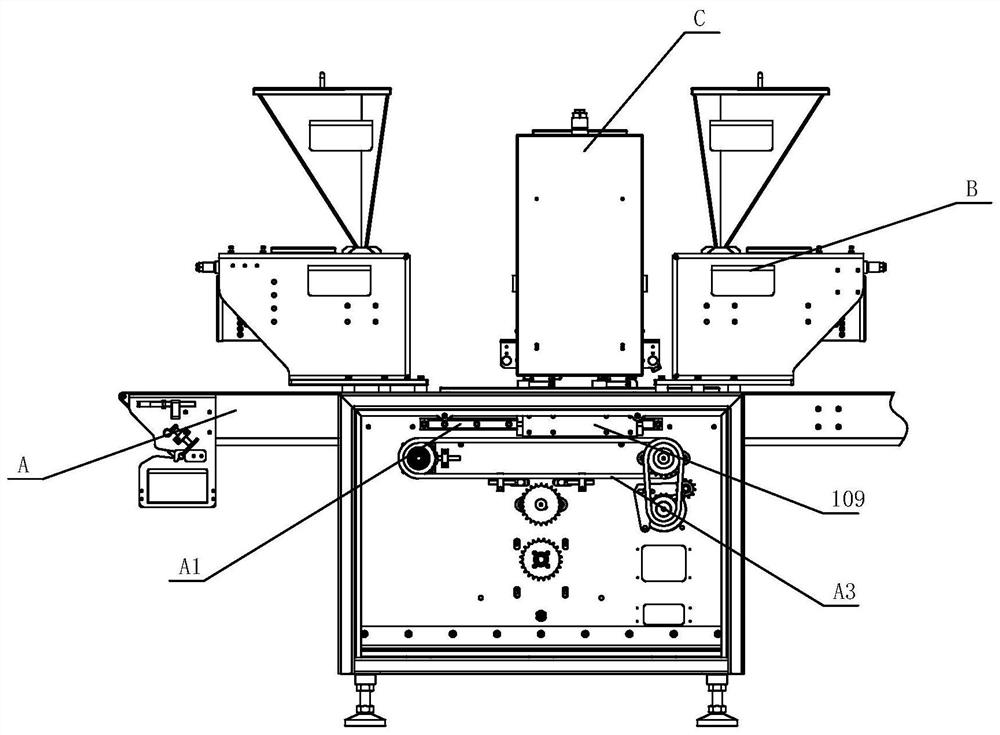

[0091] Such as Figure 1-3 As shown, a fully automatic multi-connected adjustable fluid stuffing production equipment, the whole fully automatic multi-connected adjustable fluid stuffing production equipment includes a longitudinal queue trimming device E, a horizontal queue trimming device D and a In the stuffing machine, the vertical queue whole material device E includes a partition device that divides the raw food into vertical queues for conveying, and the horizontal queue whole material device D includes separating the food in each vertical queue into the corresponding The food filling machine in the adjacent longitudinal queue is horizontally aligned. The stuffing machine includes a filling machine conveying platform A, a food stuffing device B, and a food filling device C. The conveying platform A transports the food to be processed, The food f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com