Patents

Literature

34results about How to "Same capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

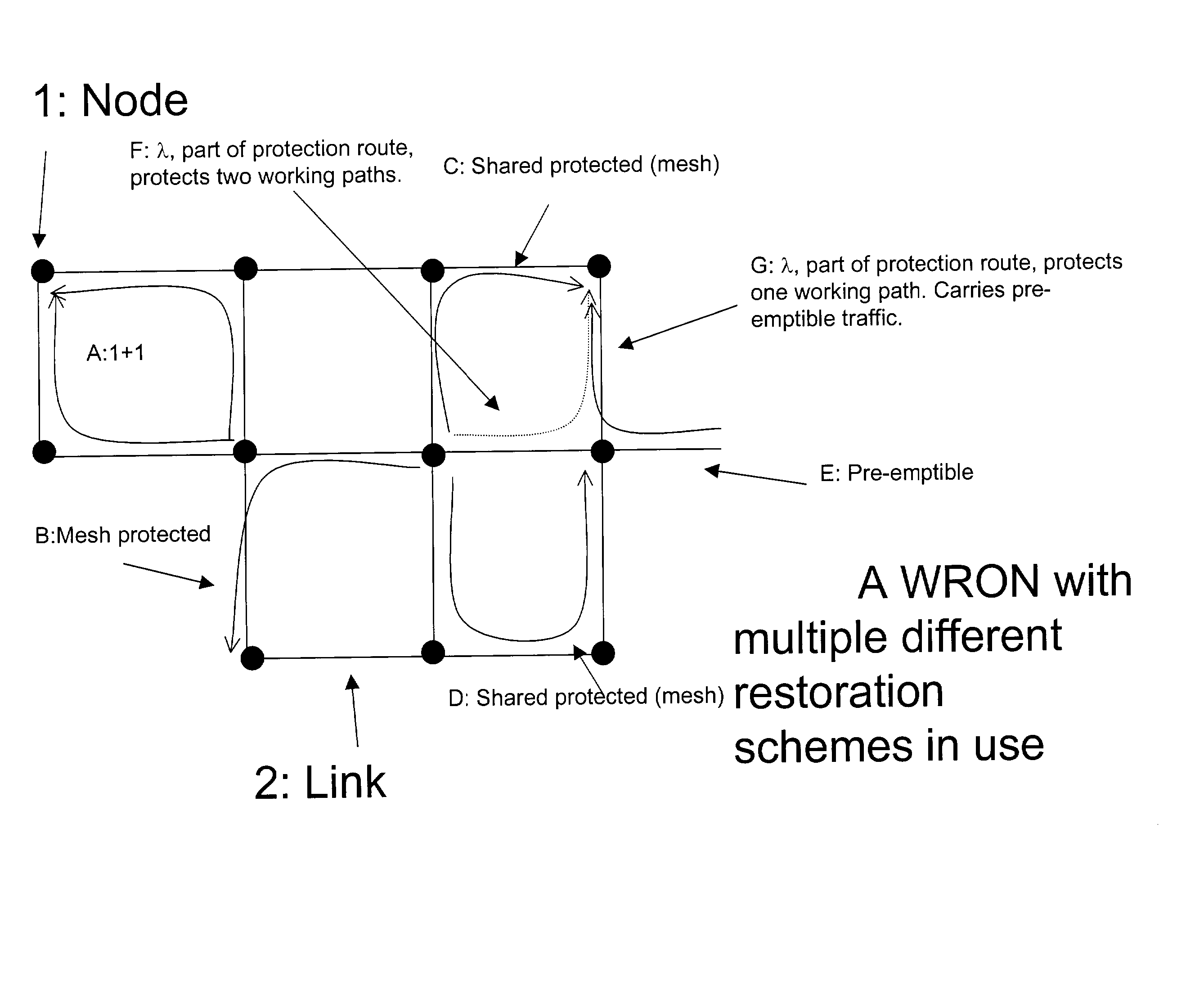

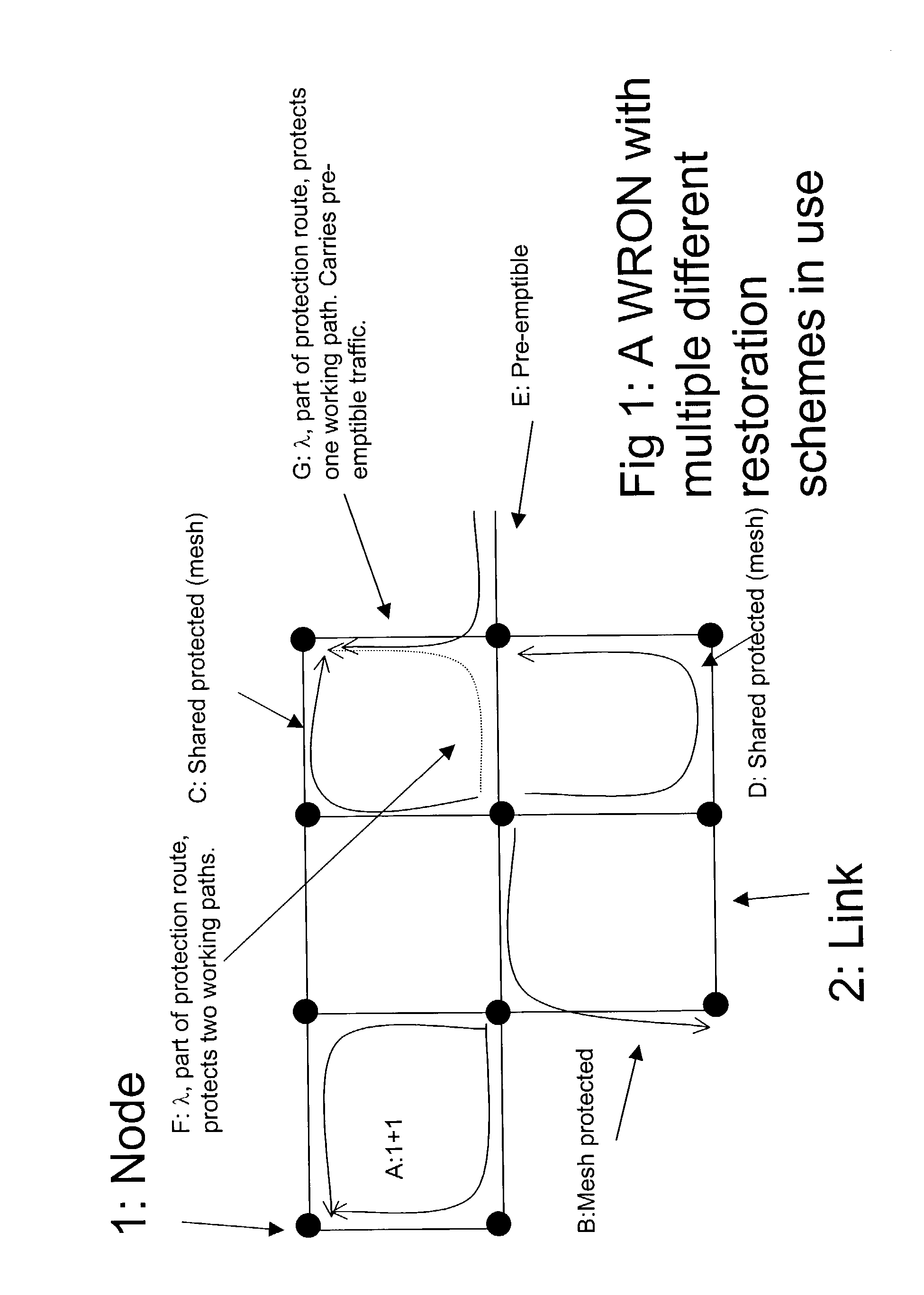

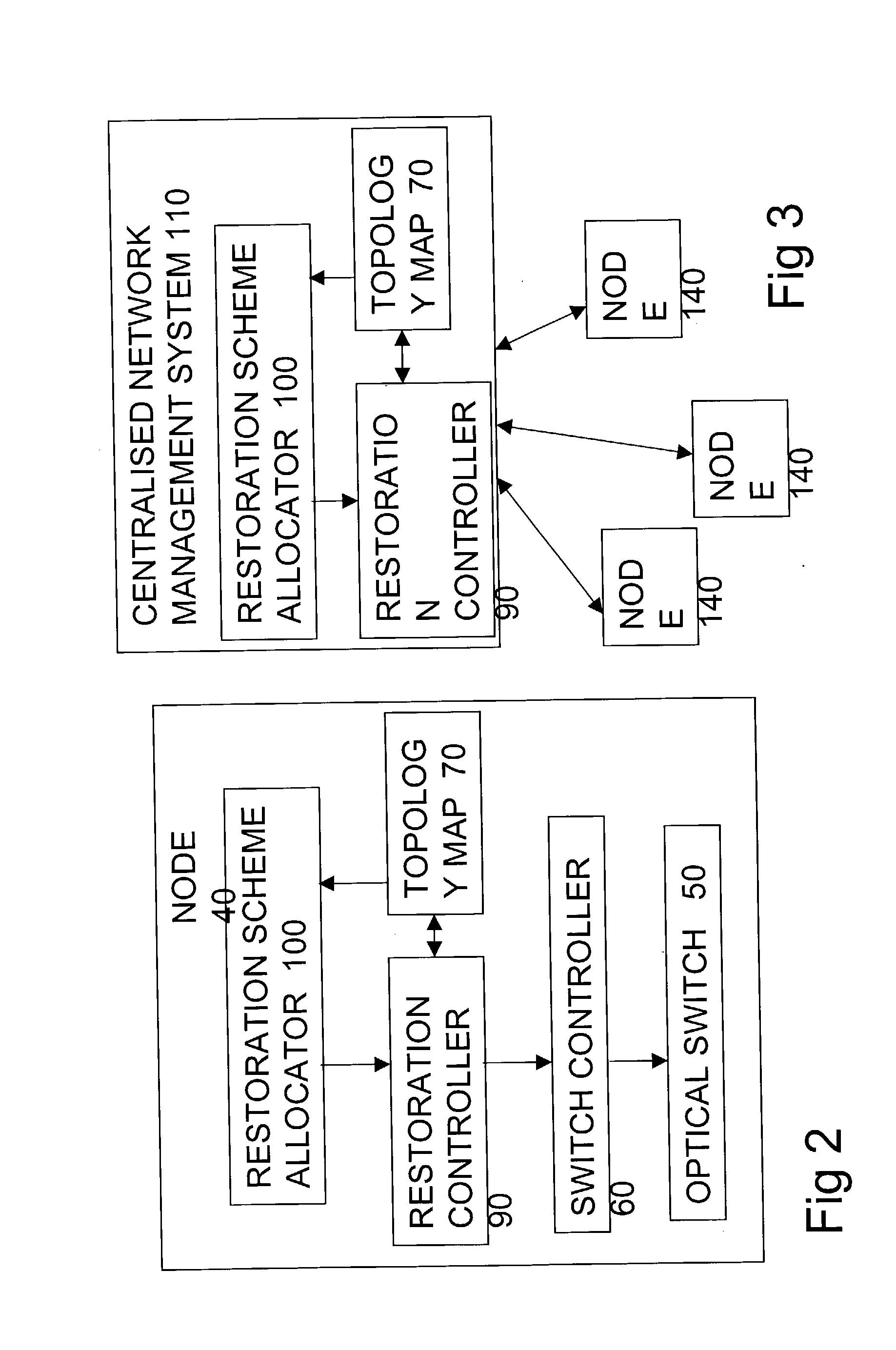

Differentiated resilience in optical networks

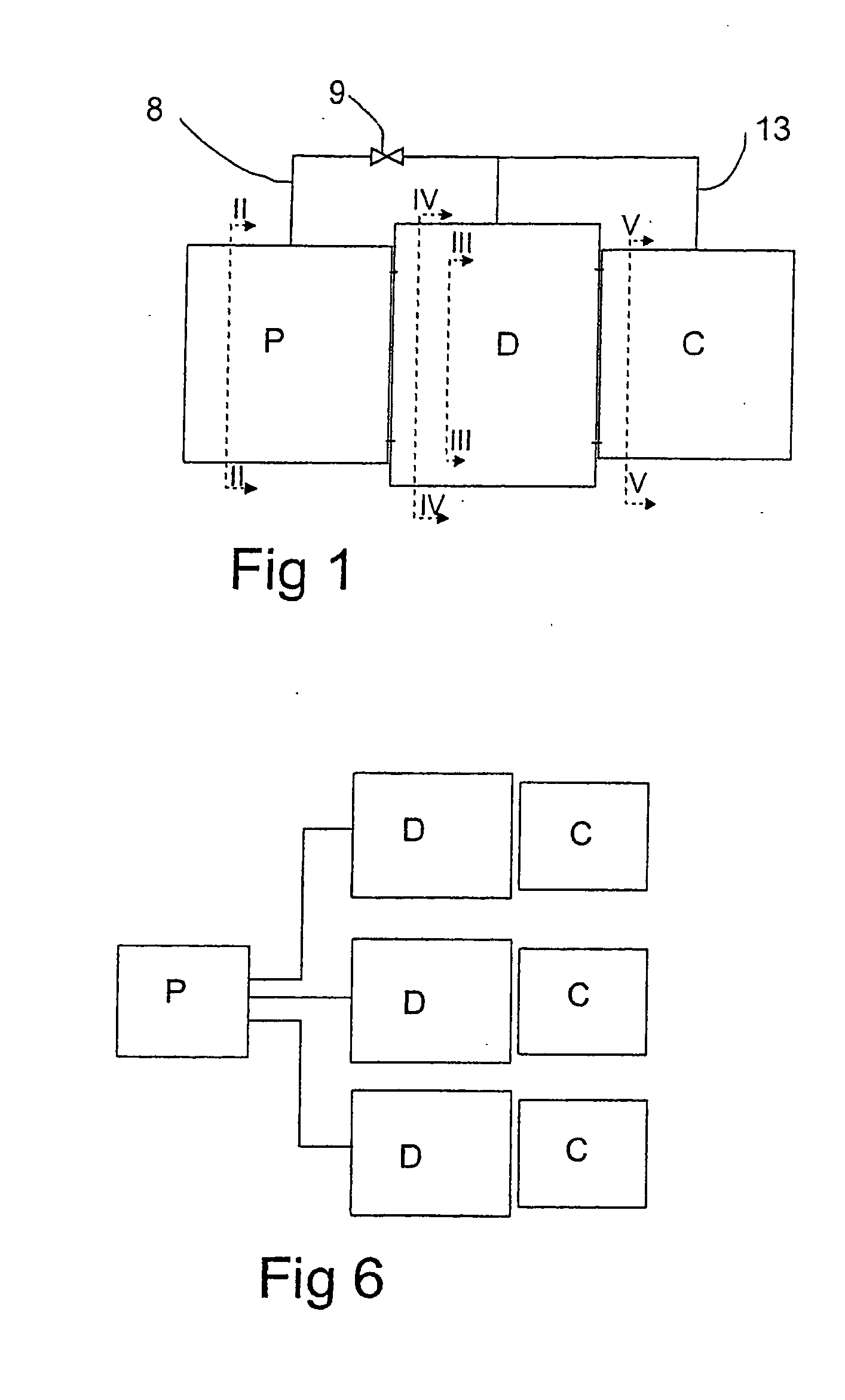

InactiveUS20040120705A1Easy to useSame capacityLaser detailsWavelength-division multiplex systemsTraffic capacityDifferentiated service

A transparent wavelength routed optical network has two or more different optical layer restoration schemes to provide different levels of resilience, and a restoration allocator arranged to allocate the optical layer restoration schemes, to different parts of the traffic. This can enable similar capacity for high resilience traffic as a single resilience level network, and provide additional capacity for lower resilience level traffic, which can reflect the value of the traffic. The allocator can be located centrally in a network manager, or in distributed fashion at each node, and can depend on a translation of a parameter requested by the customer. Nodes have message processors for receiving a message for reserving a path, determining if the path has become unavailable, and if so, sending a second message to collect information about any other paths still available on the same route.

Owner:NORTEL NETWORKS LTD

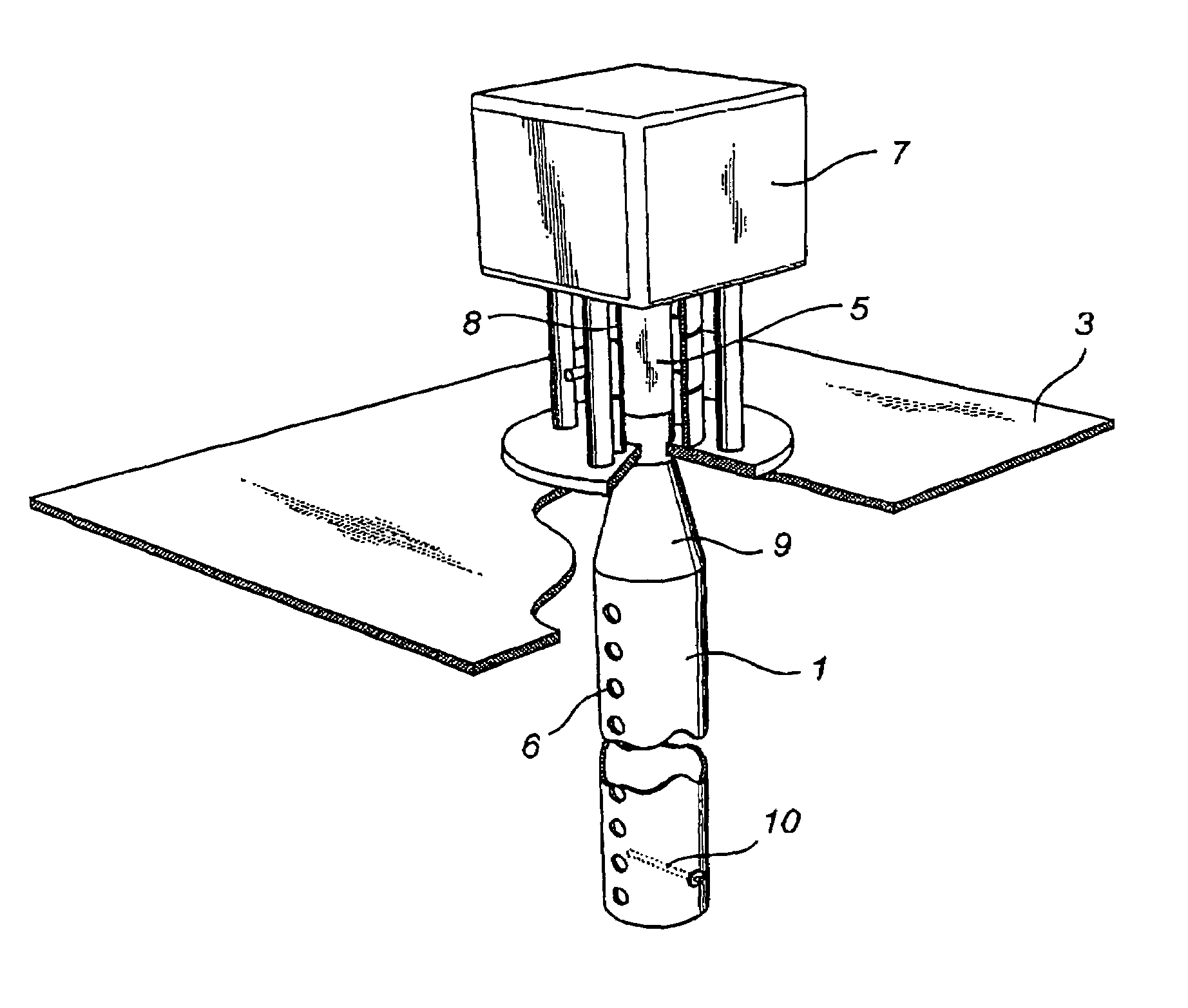

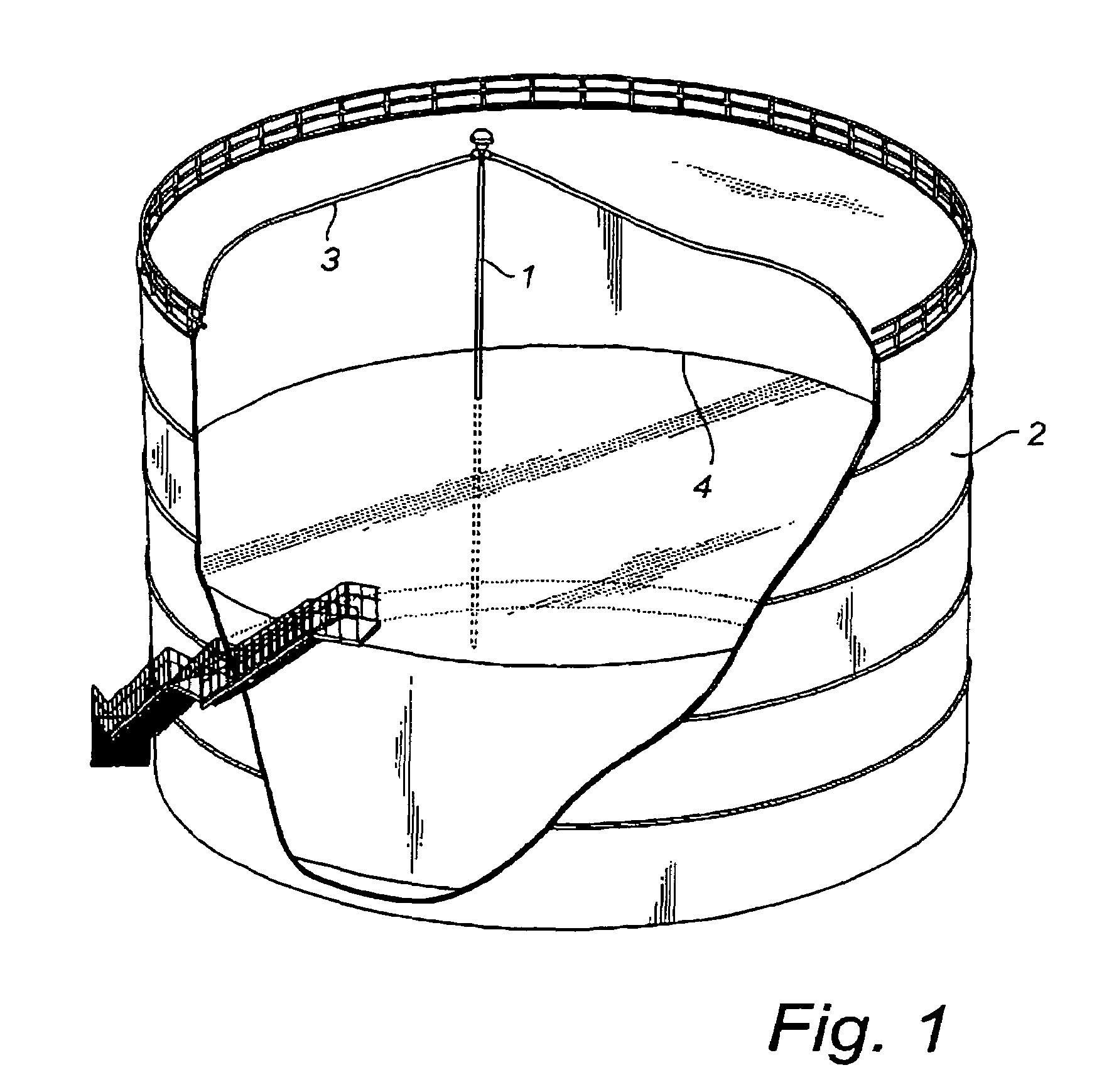

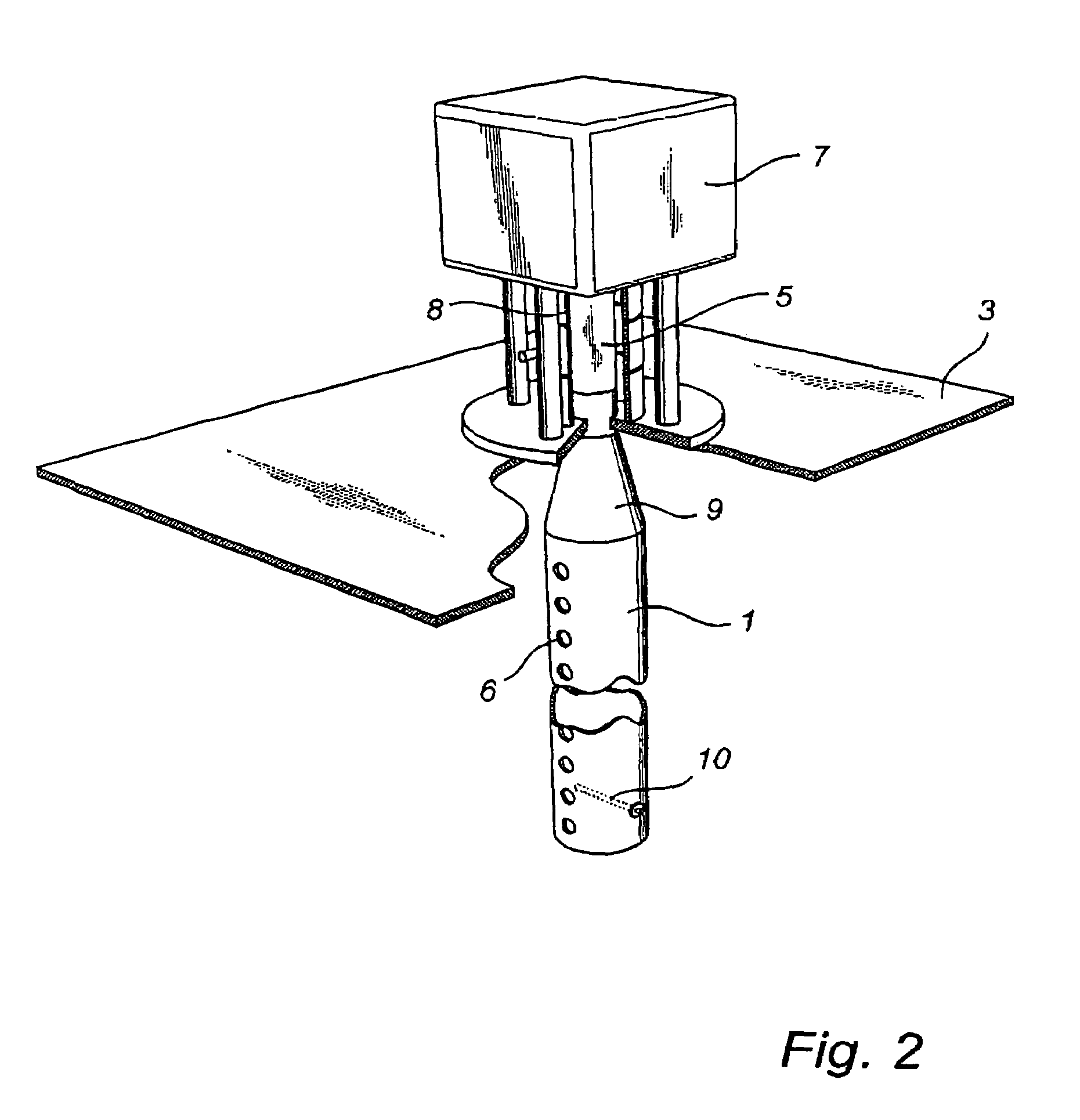

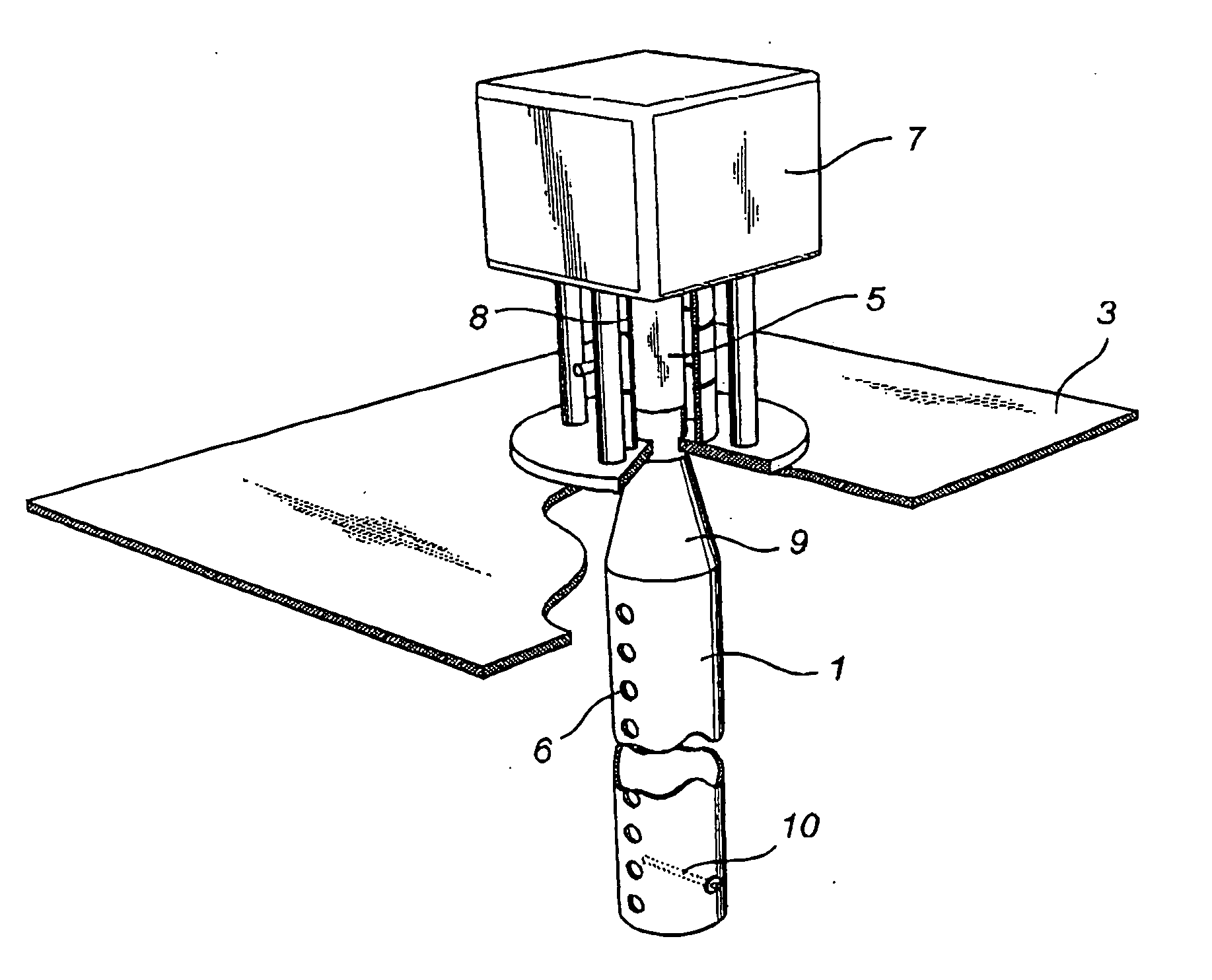

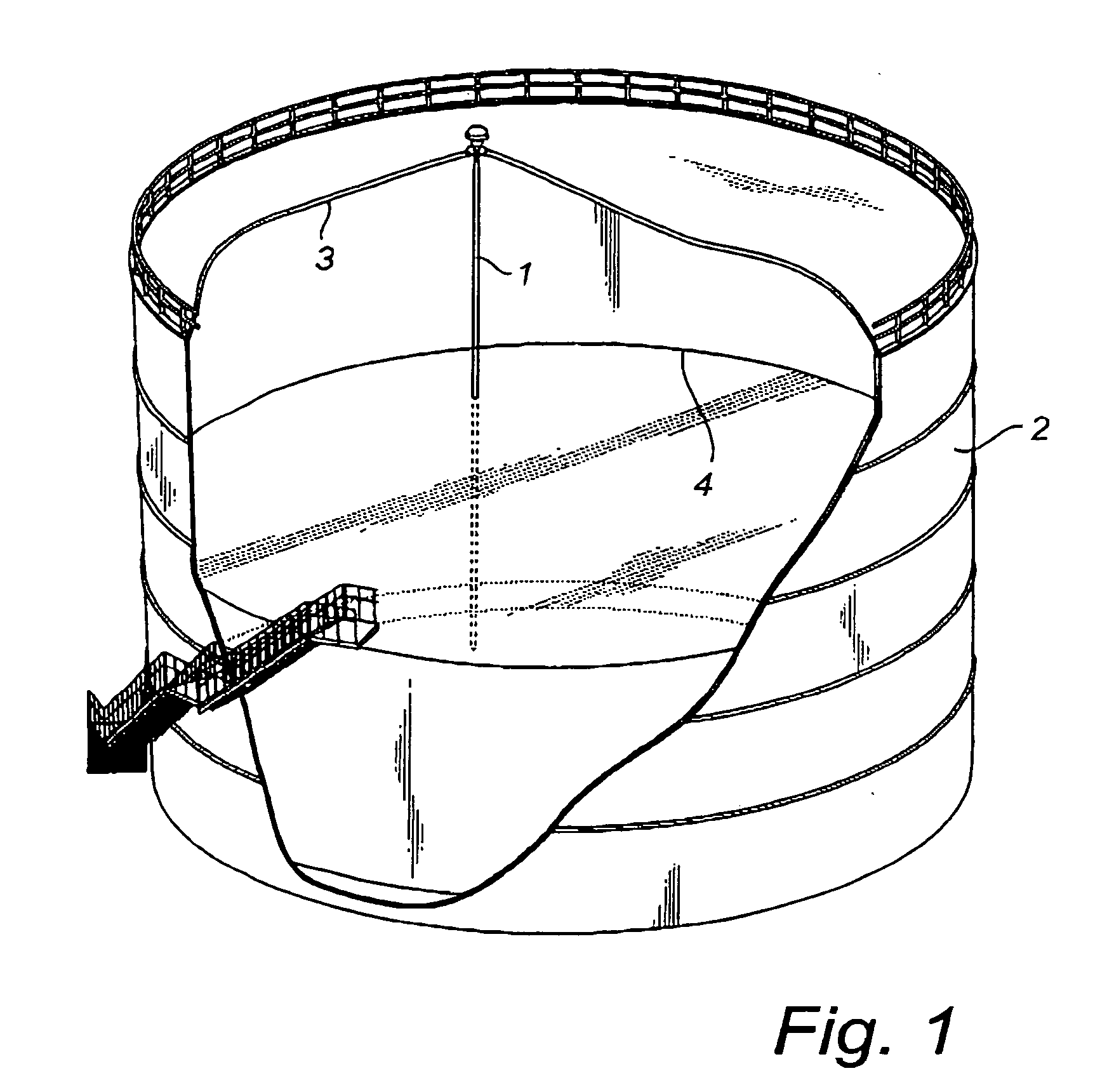

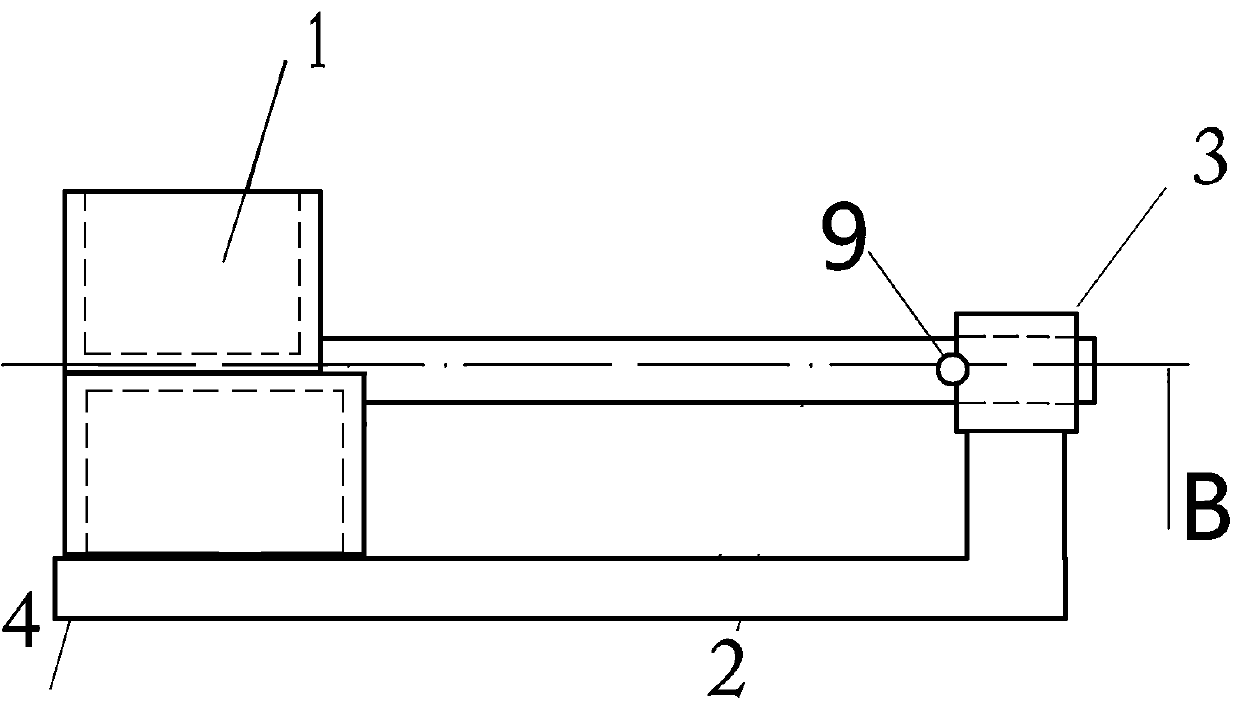

Two-mode radar level gauge system

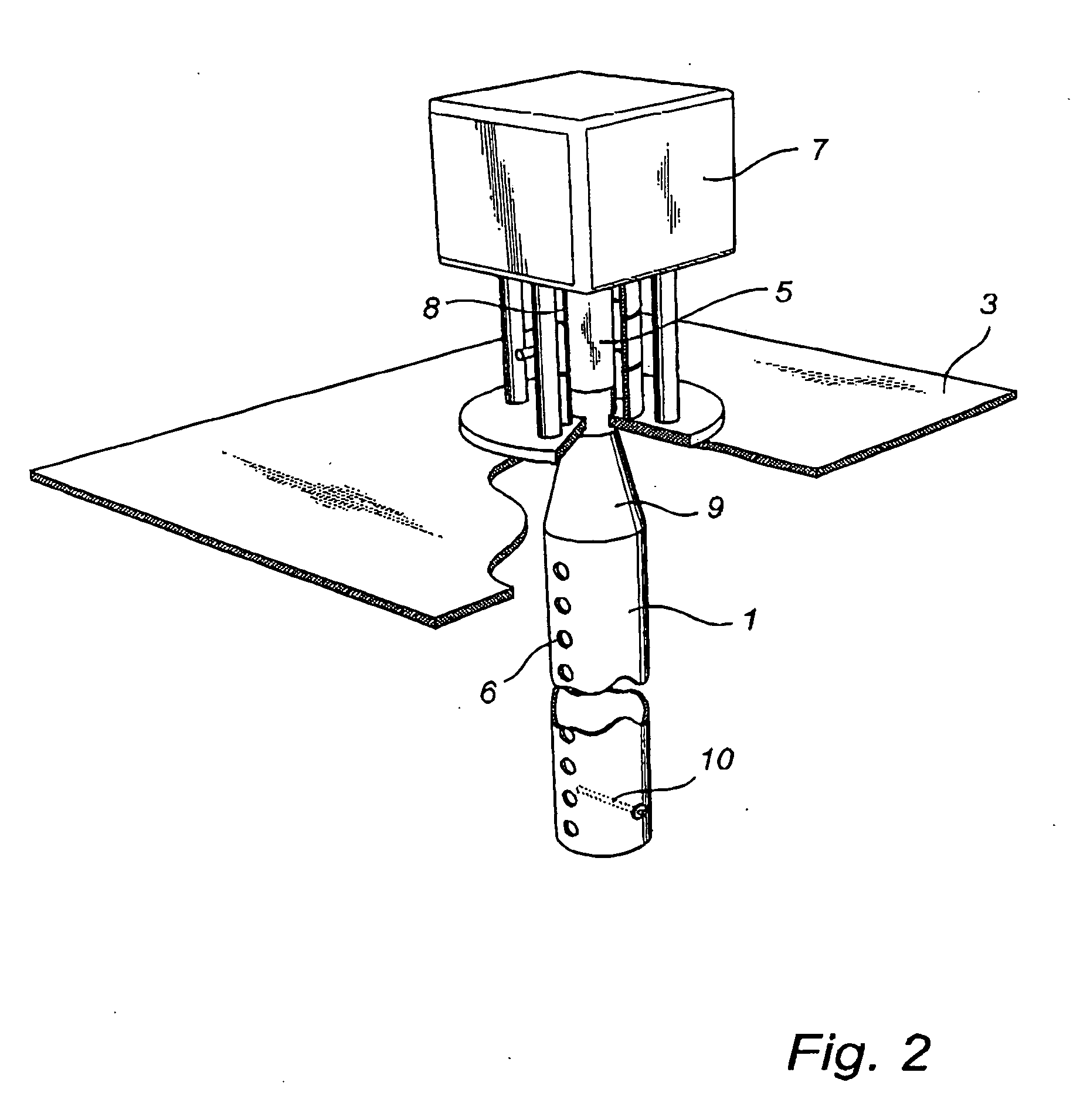

ActiveUS7345622B2Simplified feeding meanSame capacityLevel indicatorsAntenna detailsRadarFilling materials

A radar level gauge system for gauging the level of a filling material in a container is disclosed. The system comprises a waveguide extending towards the surface of said filling material; a transmitter for transmitting a microwave signal of a first mode of propagation in the waveguide; and a receiver for receiving the microwave signal reflected against the surface of the filling material and propagating back through the waveguide. Further, it comprises a processing circuitry for determining the filling level of the container based on the reflected microwave signal; and a transition element connecting the waveguide and the transmitter, wherein the transition element is configured to allow a part of the transmitted microwave signal to leak into a second mode of propagation. The first and second modes of propagation are within a frequency band which admits propagation of said microwave signal in the two different modes of propagation in the waveguide, wherein the receiver is arranged to receive the microwave signal in the at least two different modes of propagation.

Owner:ROSEMOUNT TANK RADAR

Two-mode radar level gauge system

ActiveUS20070085729A1Simplified feeding meanSame capacityLevel indicatorsAntenna detailsRadarFilling materials

A radar level gauge system for gauging the level of a filling material in a container is disclosed. The system comprises a waveguide extending towards the surface of said filling material; a transmitter for transmitting a microwave signal of a first mode of propagation in the waveguide; and a receiver for receiving the microwave signal reflected against the surface of the filling material and propagating back through the waveguide. Further, it comprises a processing circuitry for determining the filling level of the container based on the reflected microwave signal; and a transition element connecting the waveguide and the transmitter, wherein the transition element is configured to allow a part of the transmitted microwave signal to leak into a second mode of propagation. The first and second modes of propagation are within a frequency band which admits propagation of said microwave signal in the two different modes of propagation in the waveguide, wherein the receiver is arranged to receive the microwave signal in the at least two different modes of propagation.

Owner:ROSEMOUNT TANK RADAR

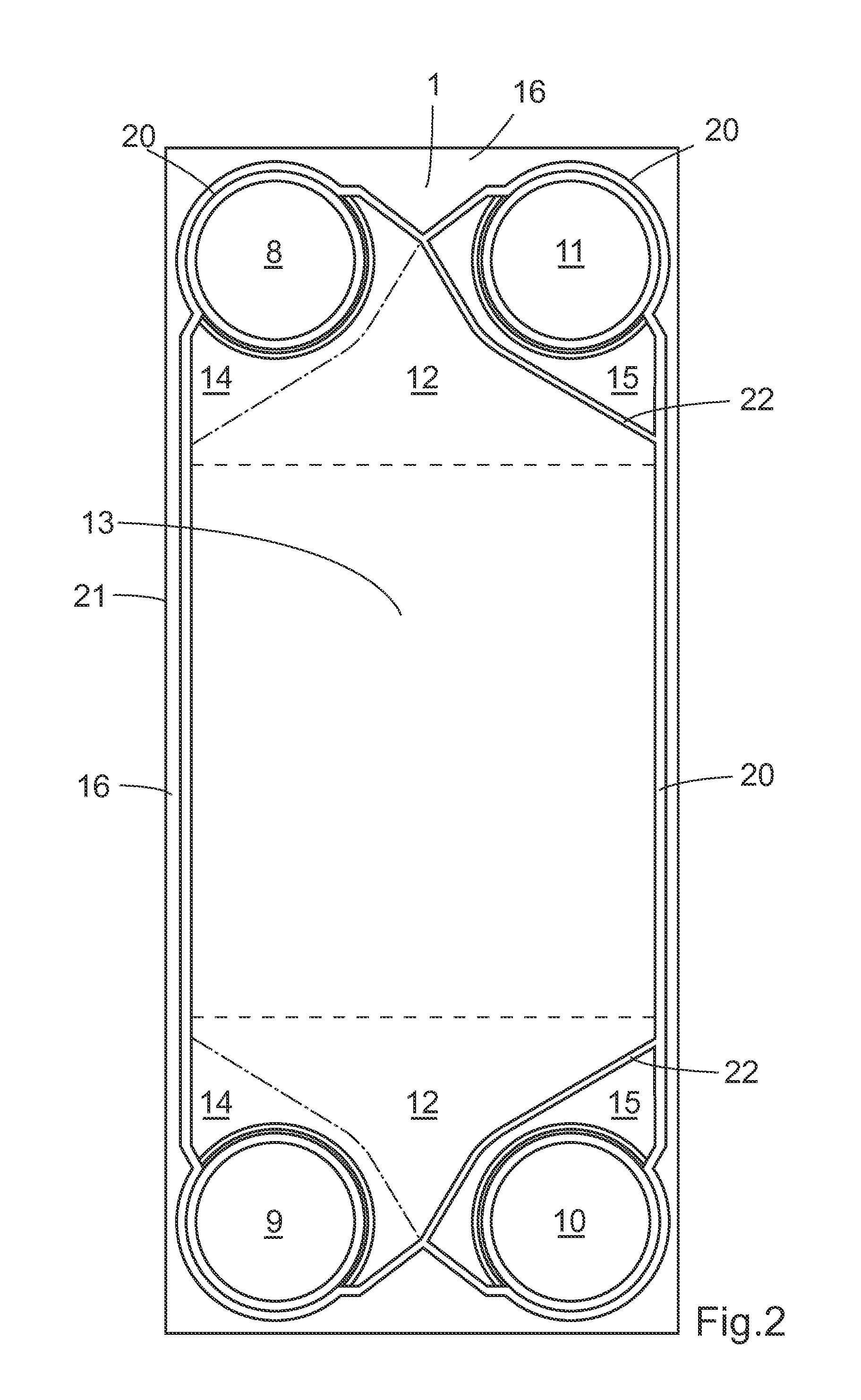

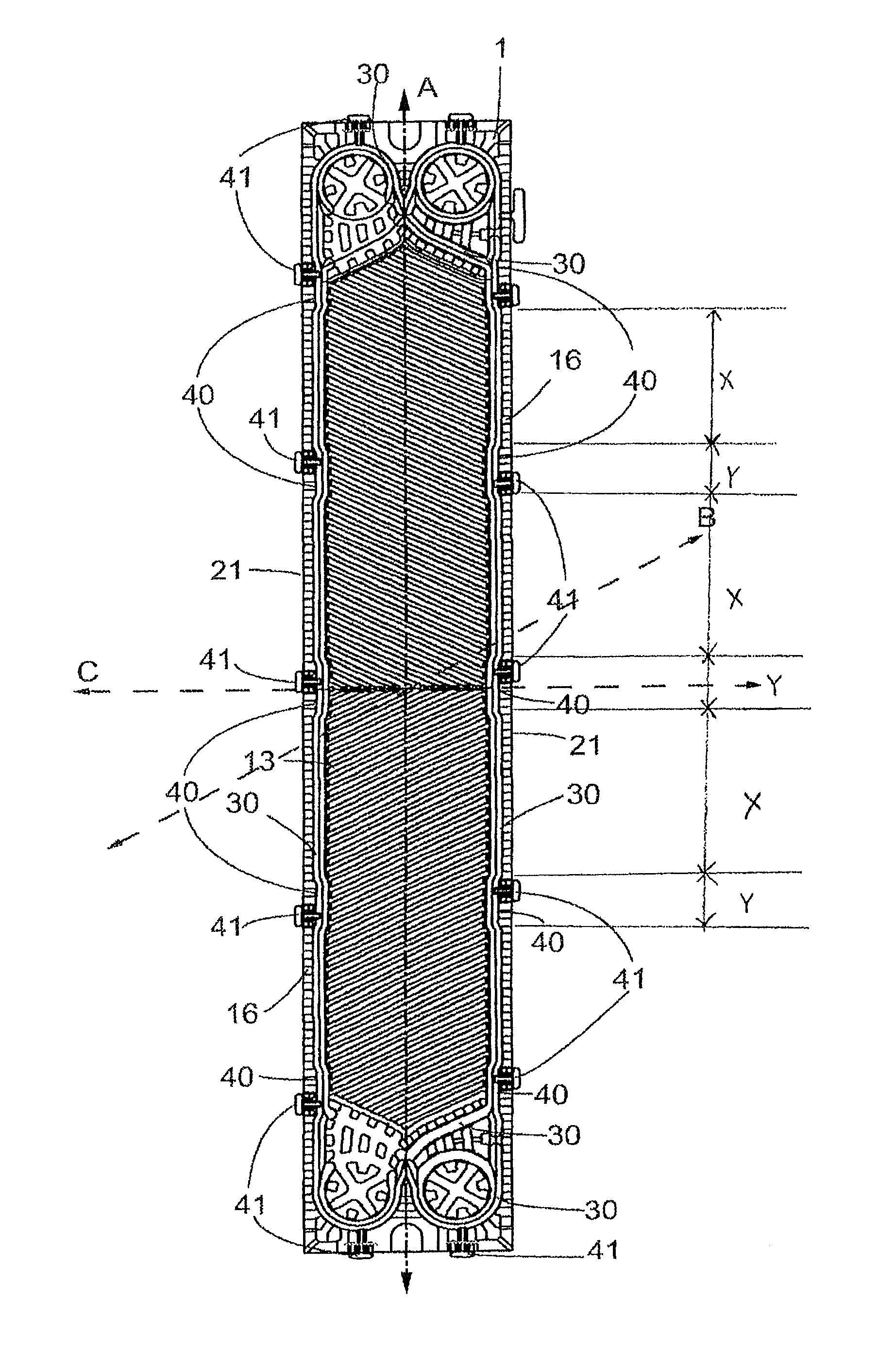

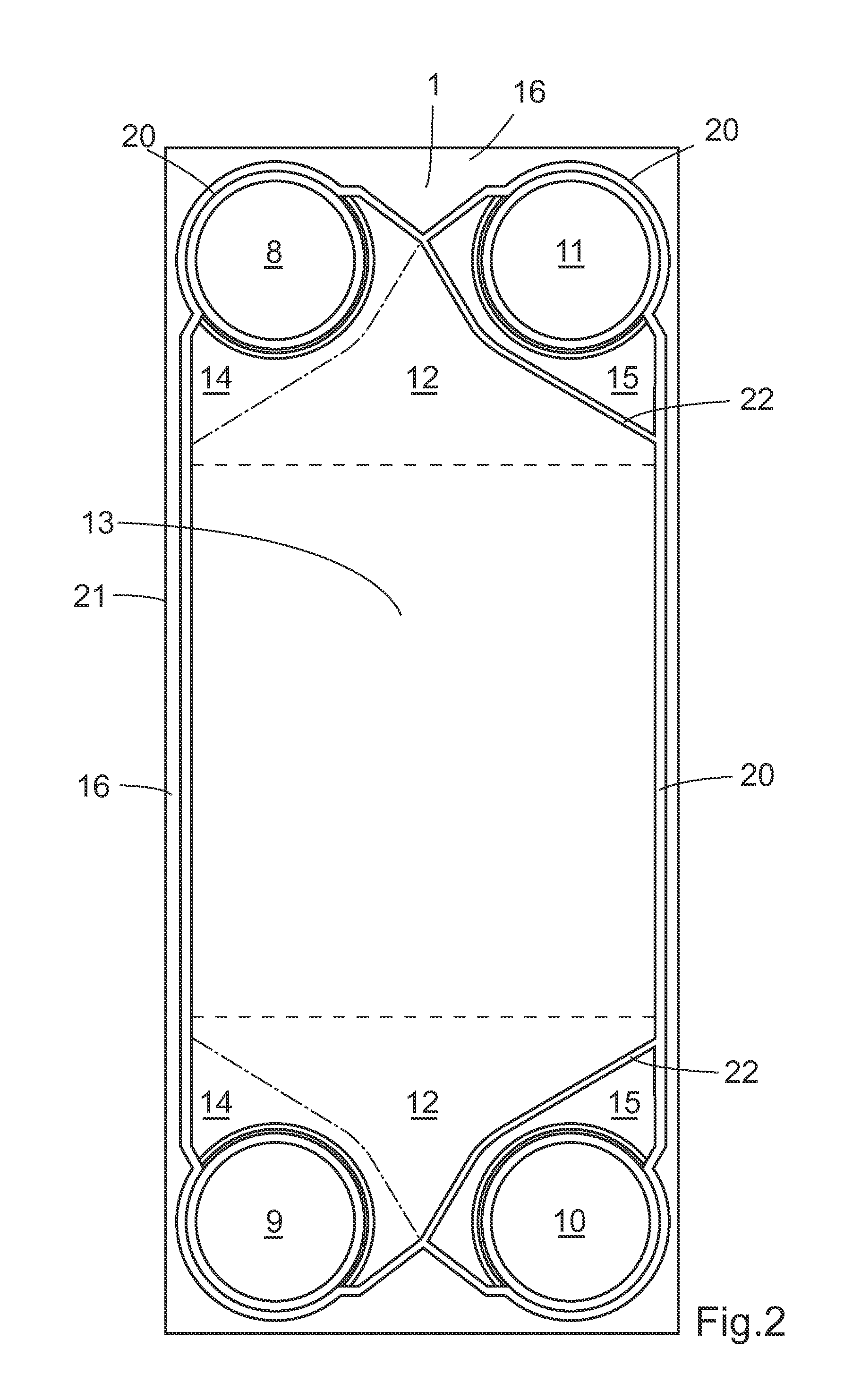

Plate and gasket for plate heat exchanger

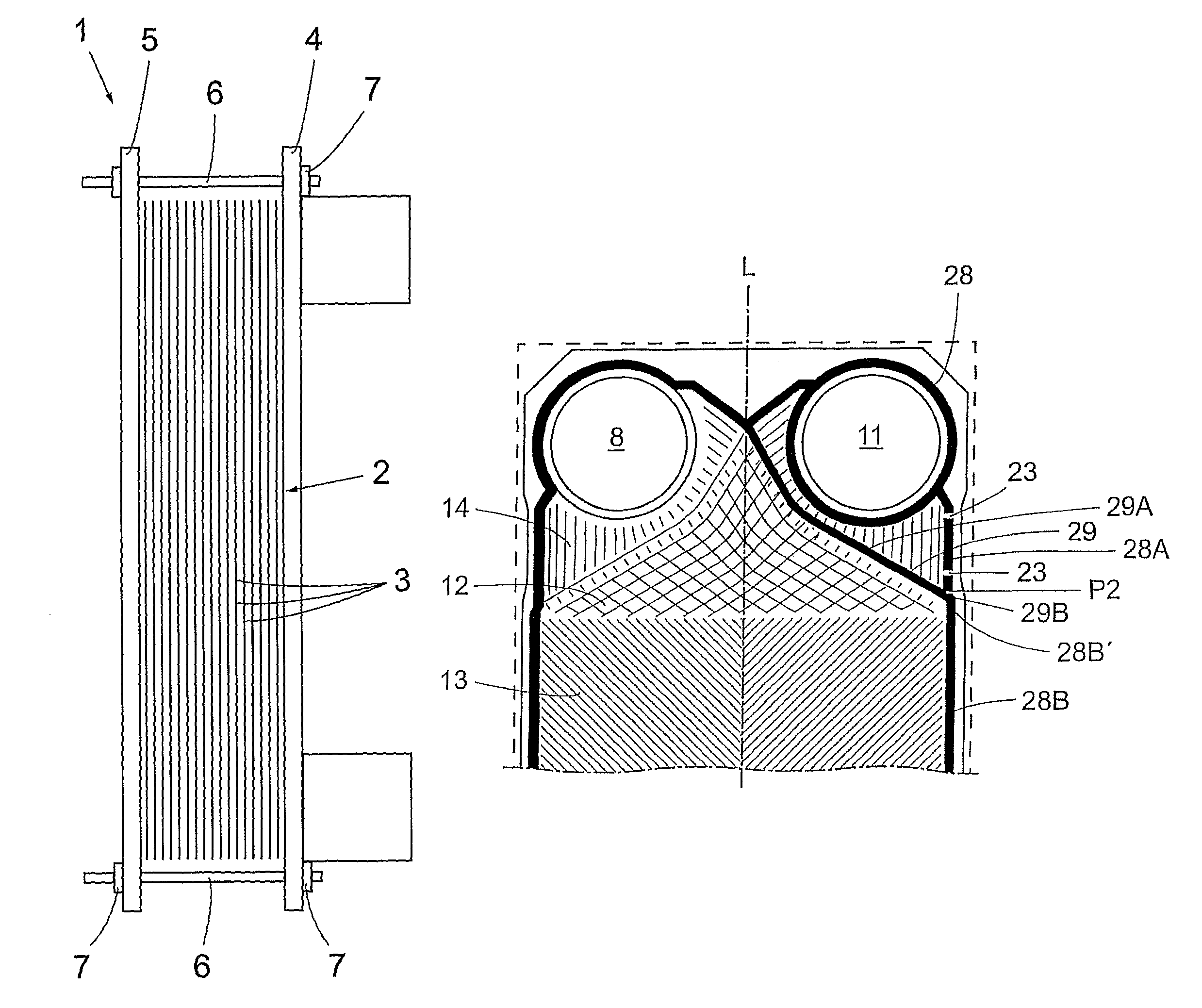

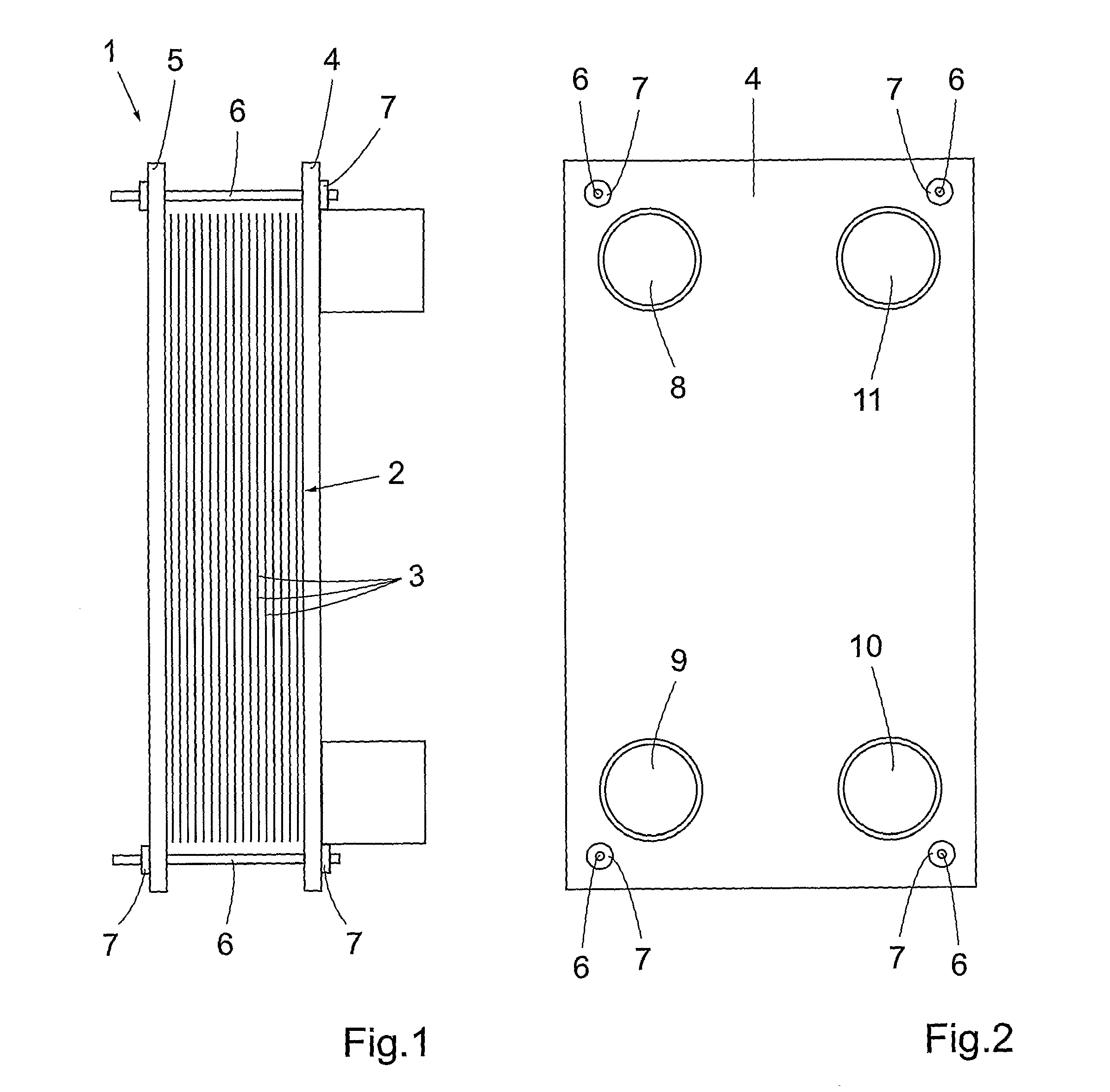

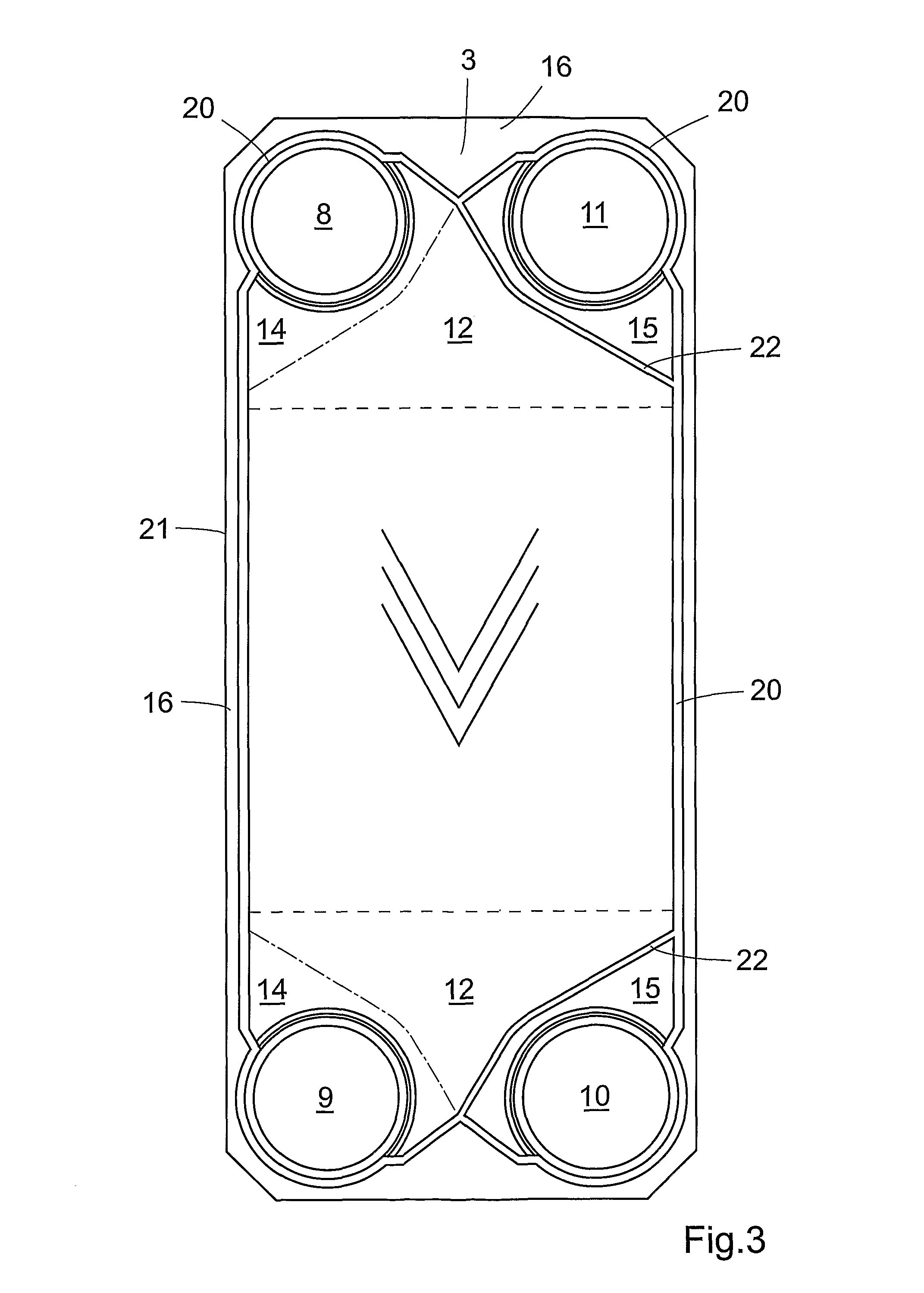

ActiveUS8646517B2Optimal utilisationImprove performanceHeat exhanger sealing arrangementHeat exchanger casingsPlate heat exchangerEngineering

The invention relates to a heat exchanger plate for a plate heat exchanger, which plate has a number of ports, a distribution region, a heat transfer region, a first adiabatic region, a second adiabatic region and an edge area that extends outside the ports and the regions, which plate has a first gasket groove extending in the edge area outside the regions and around the ports, and a second gasket groove extending between the adiabatic region and the adjacent distribution region, whereby the gasket grooves are connected together to accommodate a gasket for sealing abutment against an adjacent heat exchanger plate in the plate heat exchanger. The invention further relates to a gasket for a heat exchanger plate and a plate heat exchanger having a package of heat exchanger plates and gaskets.

Owner:ALFA LAVAL CORP AB

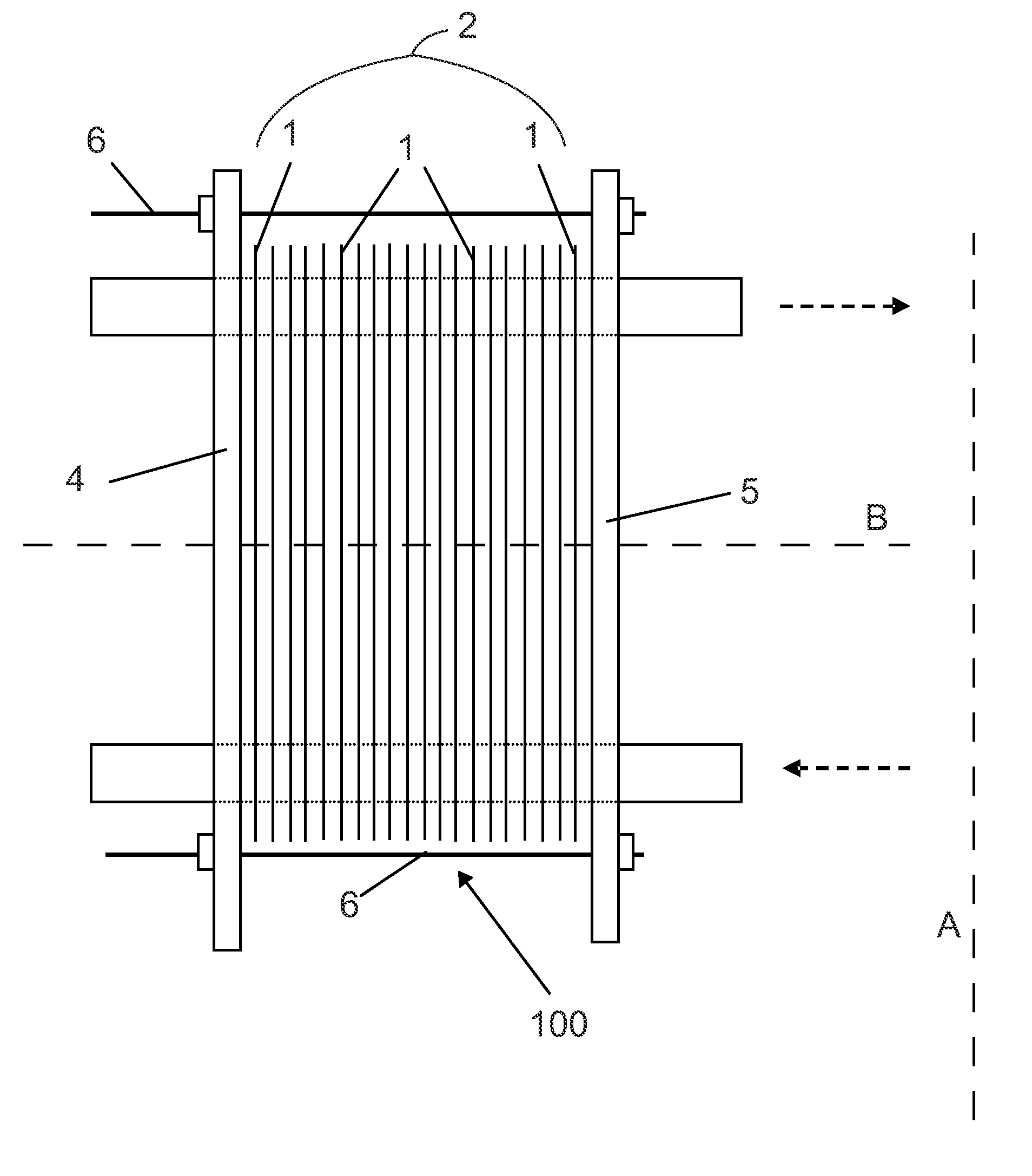

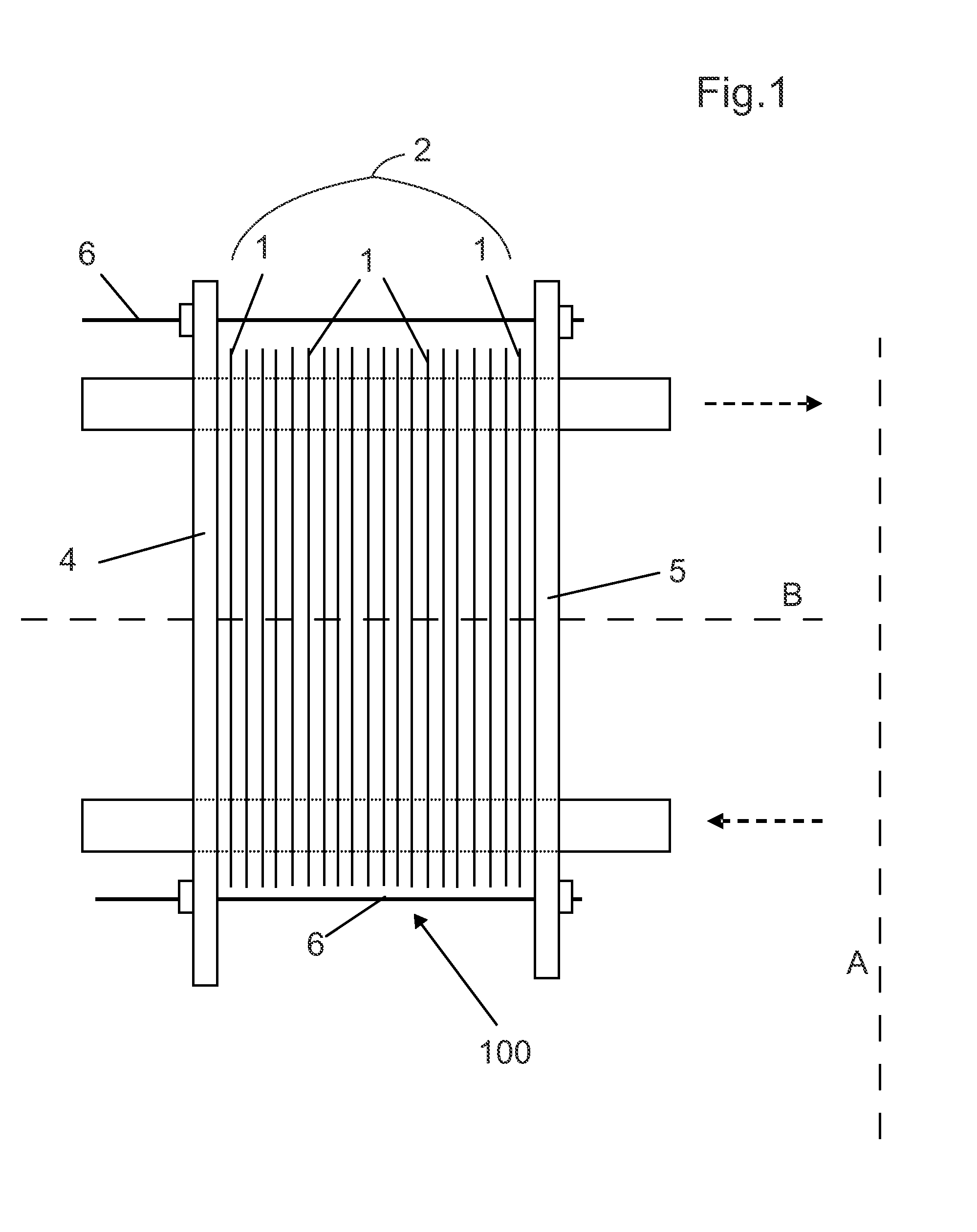

Filter apparatus

ActiveUS20140366493A1Simple structureImprove backwash efficiencyDispersed particle filtrationTransportation and packagingFiltrationEngineering

A filter apparatus including: a casing including, in a sealed space provided therein, a fluid inflow chamber, a filtration chamber and a drain chamber; a filter element provided inside the filtration chamber to let a fluid pass therethrough from inside to outside to perform filtration; a backwash slide member movably provided inside the filter element and removing trapped matter adhering to an inner circumferential surface of the filter element by an inward flow generated by a difference in pressure inside and outside the filter element at the time of backwashing; a backwash pipe that lets the inward flow flow toward the drain chamber; an actuation cylinder that lets the fluid from the backwash pipe flow toward the drain chamber; and a fluid flowing unit allowing a fluid to flow, enabling a piston member to move inside the actuation cylinder.

Owner:FUJI FILTER MFG

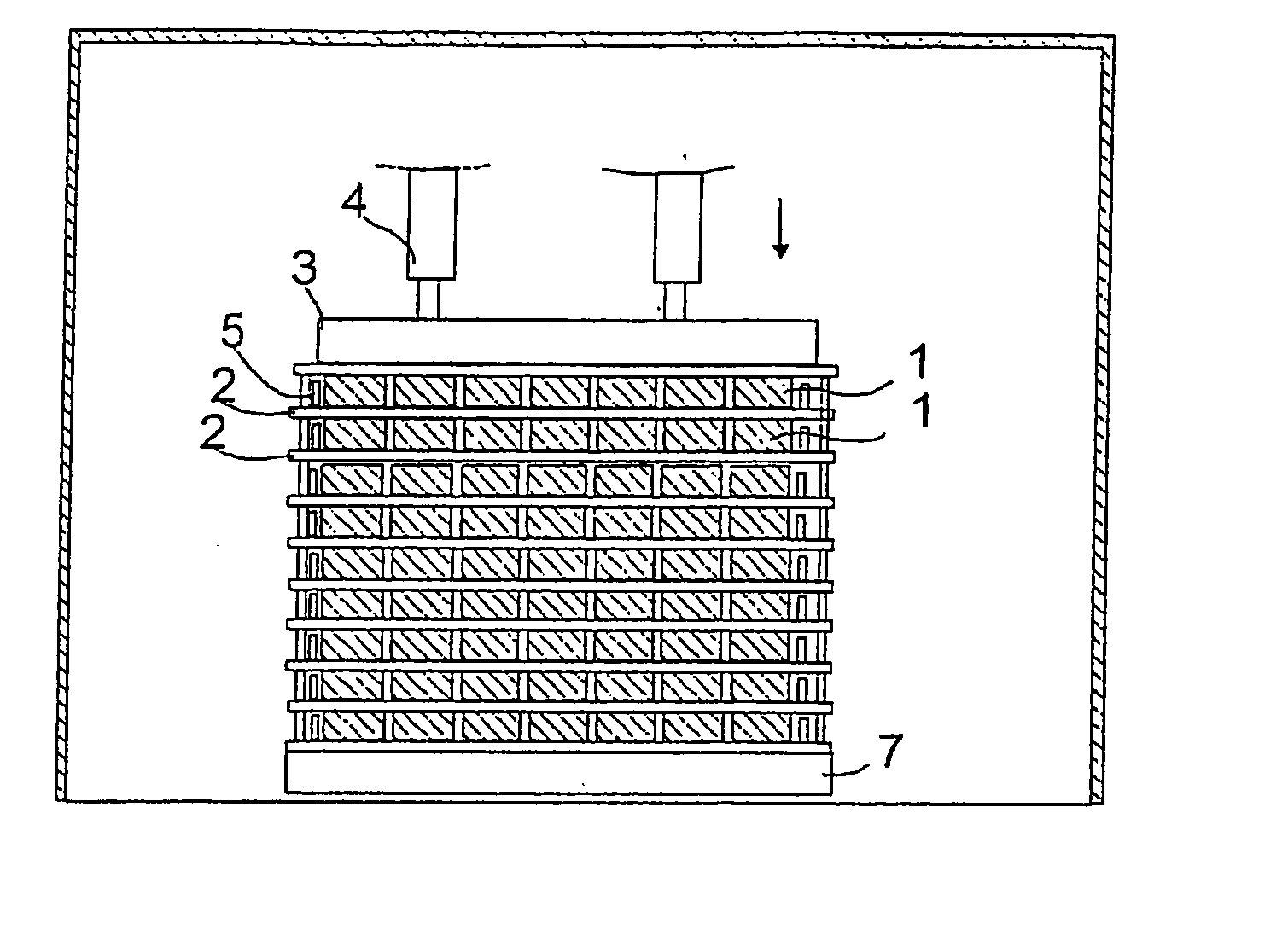

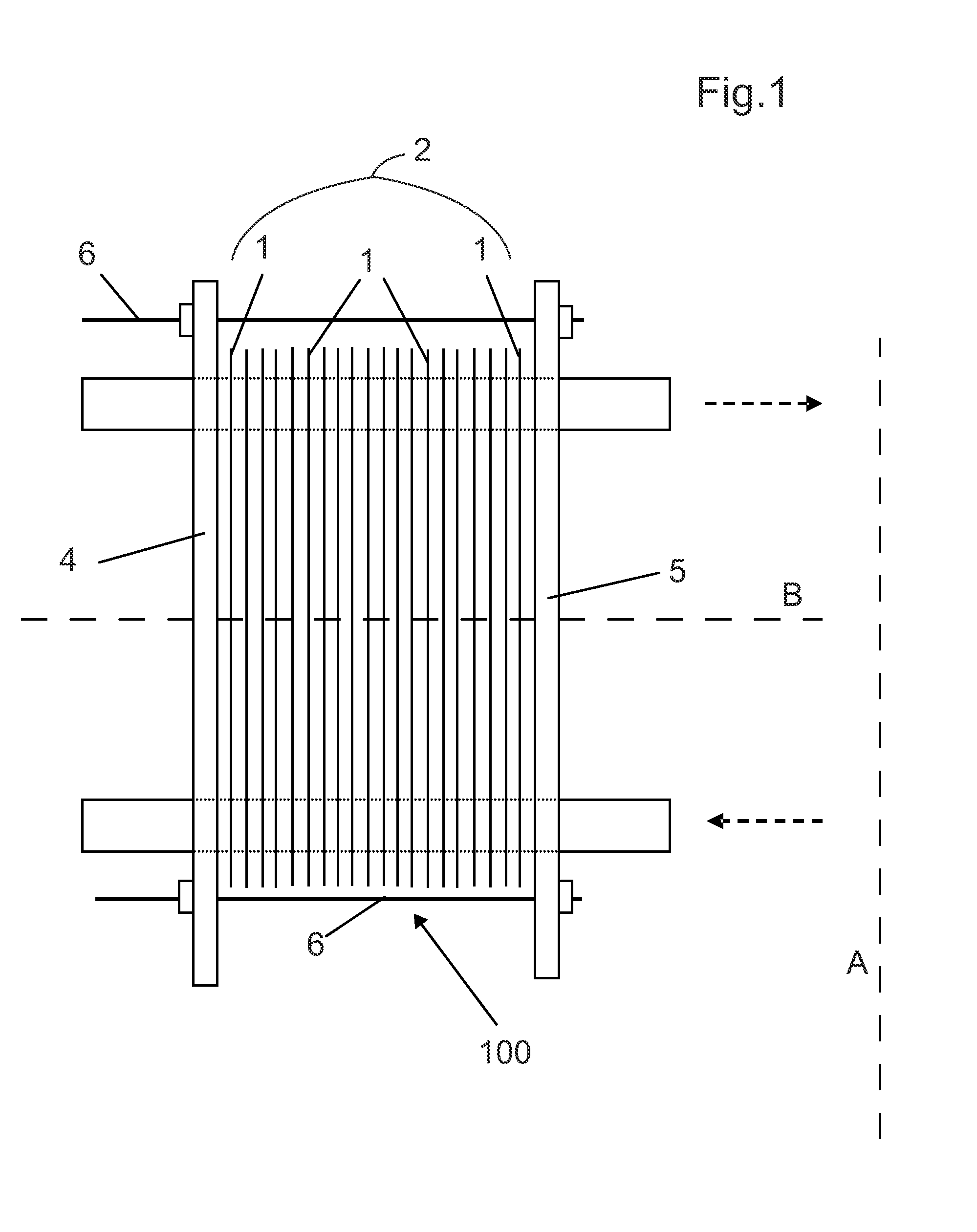

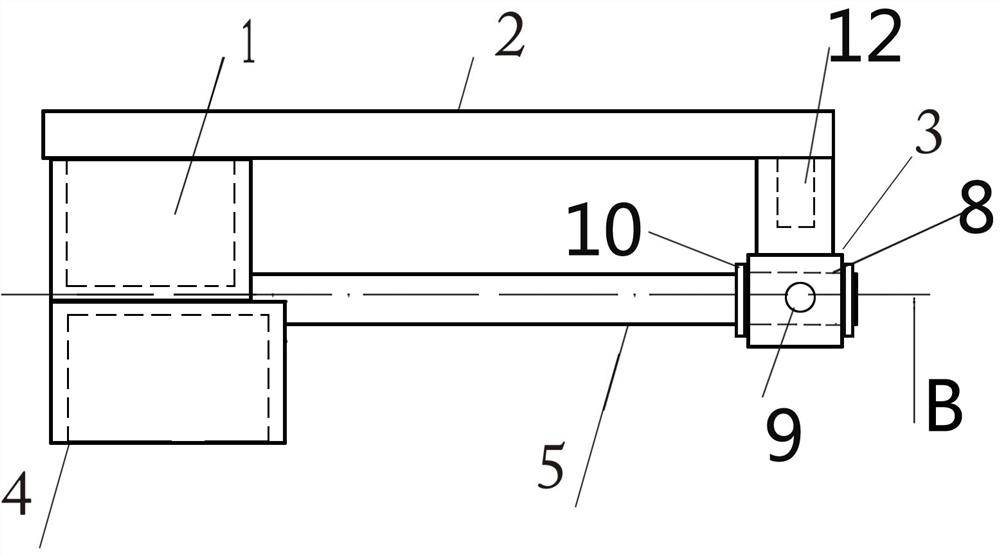

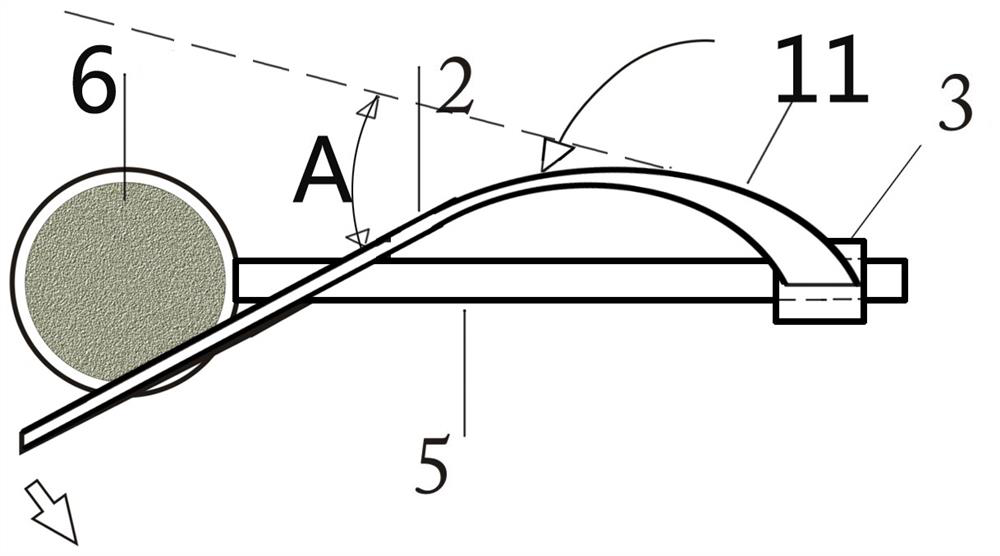

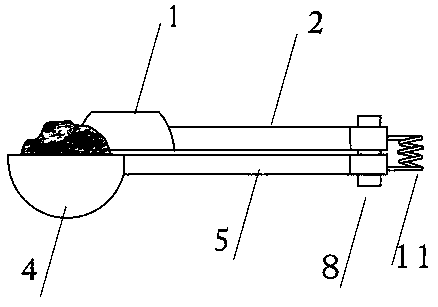

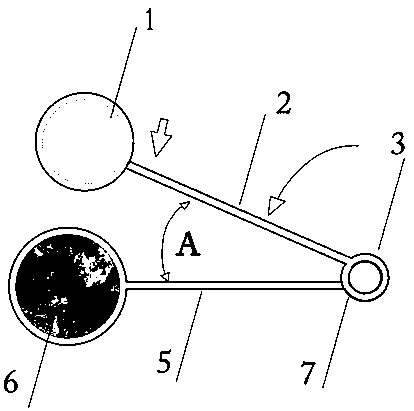

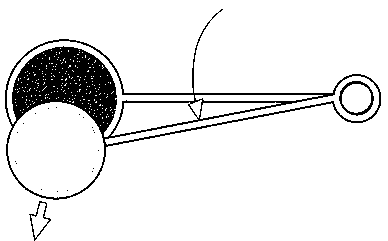

Method and apparatus for the treatment of wood or wood products

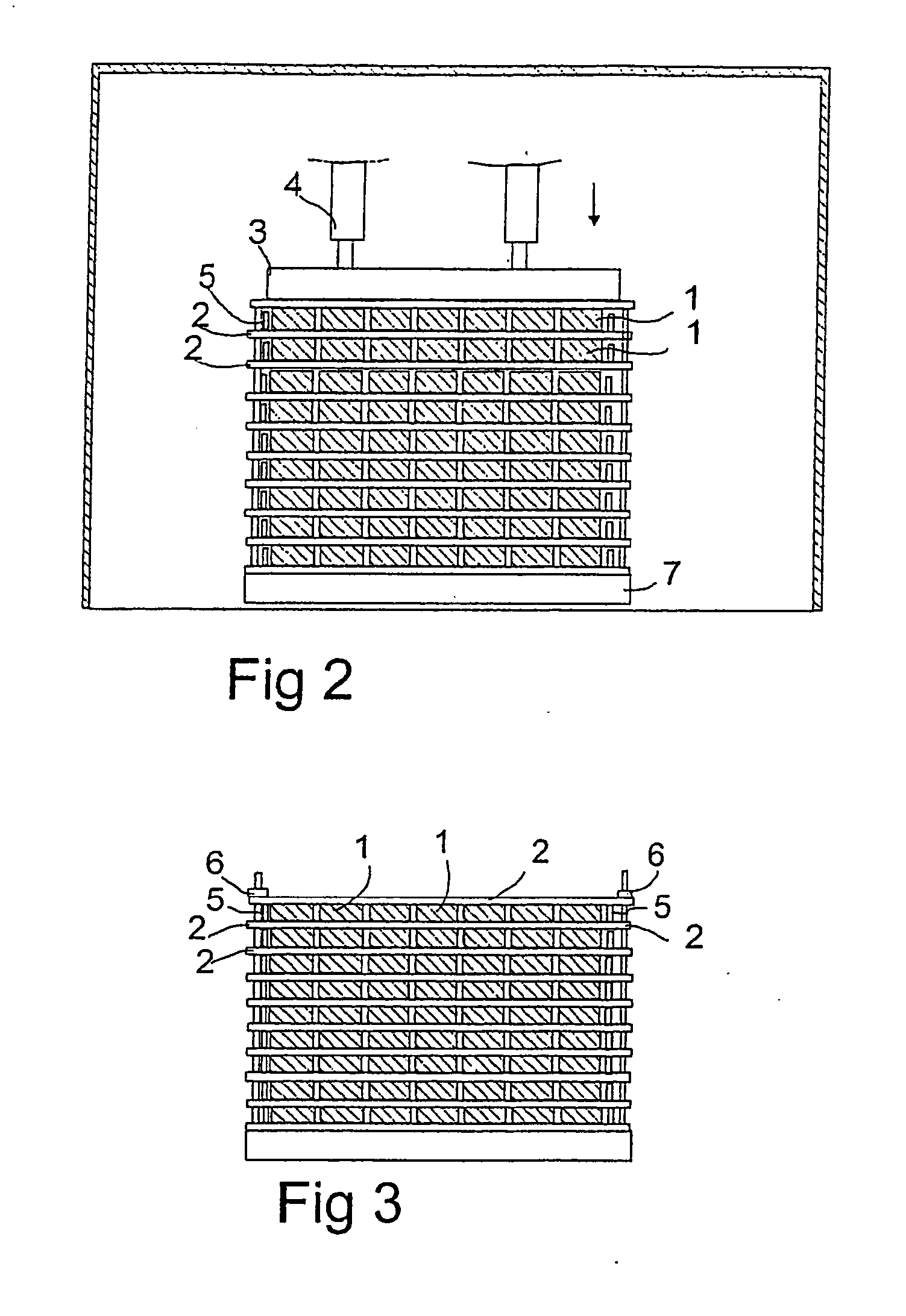

InactiveUS20060278336A1Avoid large amounts of heatSave energyDrying using combination processesPlywood pressesPulp and paper industryWood product

A method for the treatment of wood or wood products, in which method moist wood or wood products (1) are dried by first pressing and further by heating so that a desired degree of dryness is reached. In a first stage, the wood or wood products (1) arranged between treating elements (2) are pressed between the treating elements (2) so that a considerable amount of water is removed from the wood being treated, next the treating elements (2) are locked so that the wood or wood products (1) remain compressed between the treating elements (2), and the combination of treating elements (2) and wood or wood products (1) between them thus formed is moved into a drying chamber (D), where the wood or wood products are dried further by applying heat. The invention also relates to an apparatus.

Owner:TEKNOCOMP

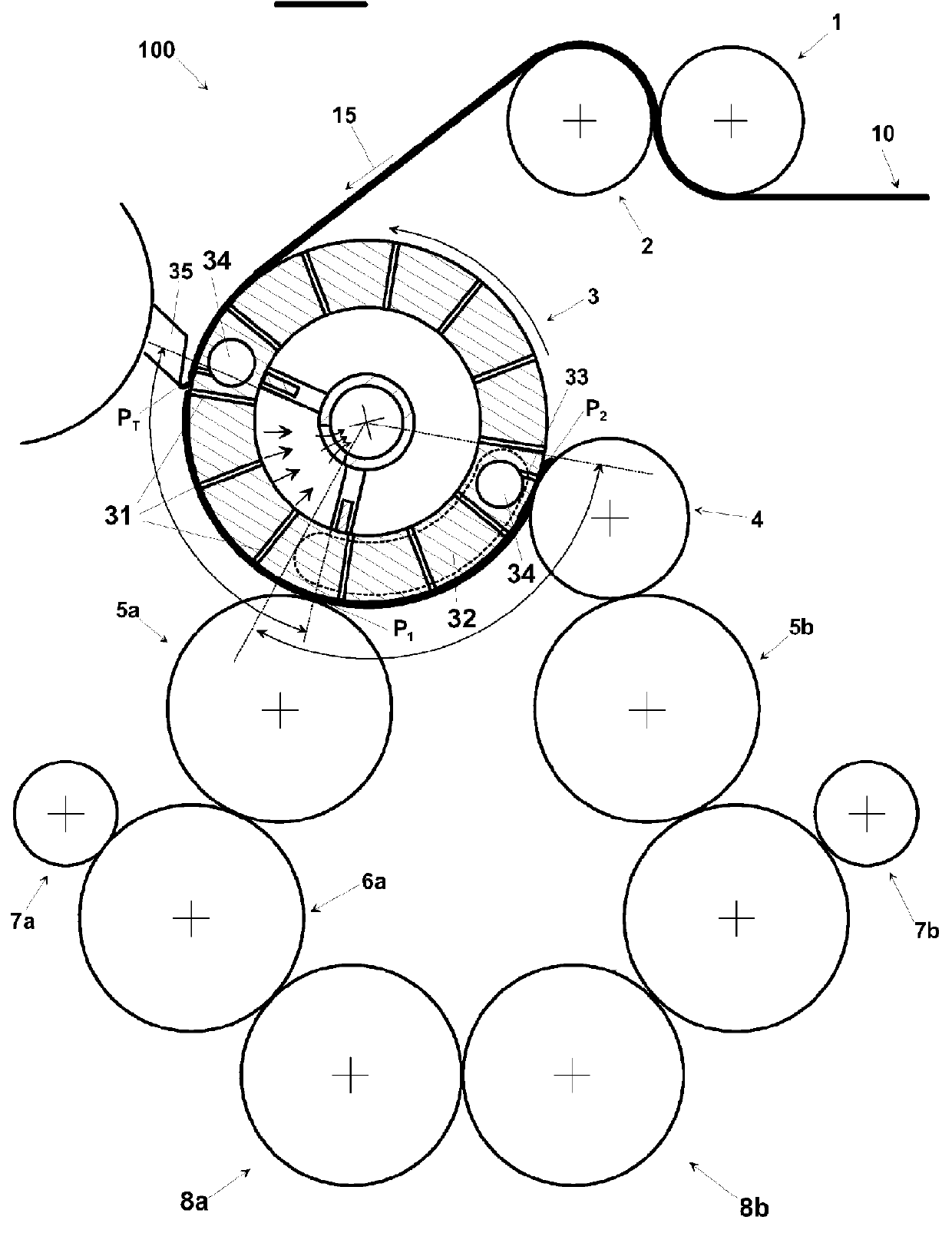

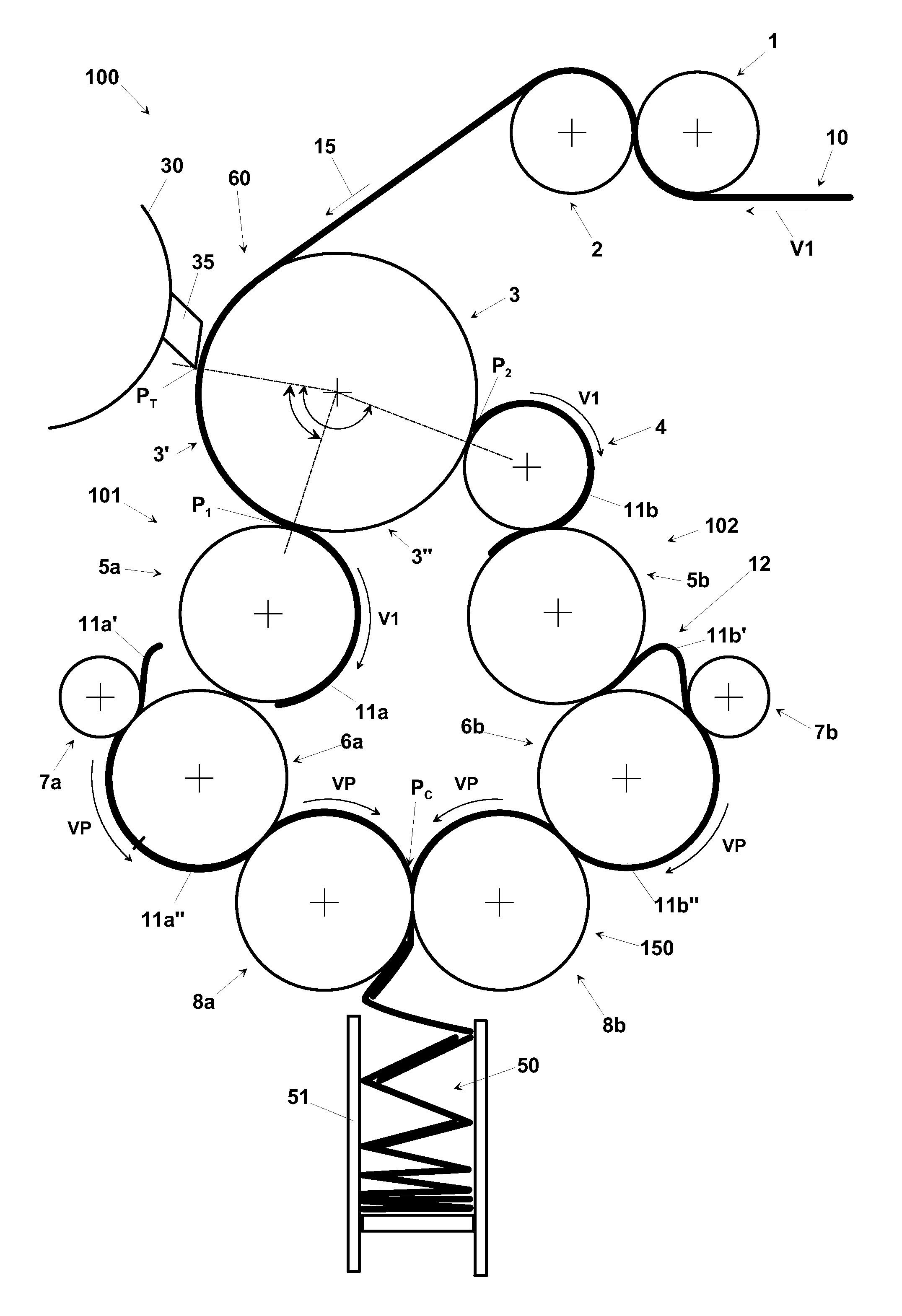

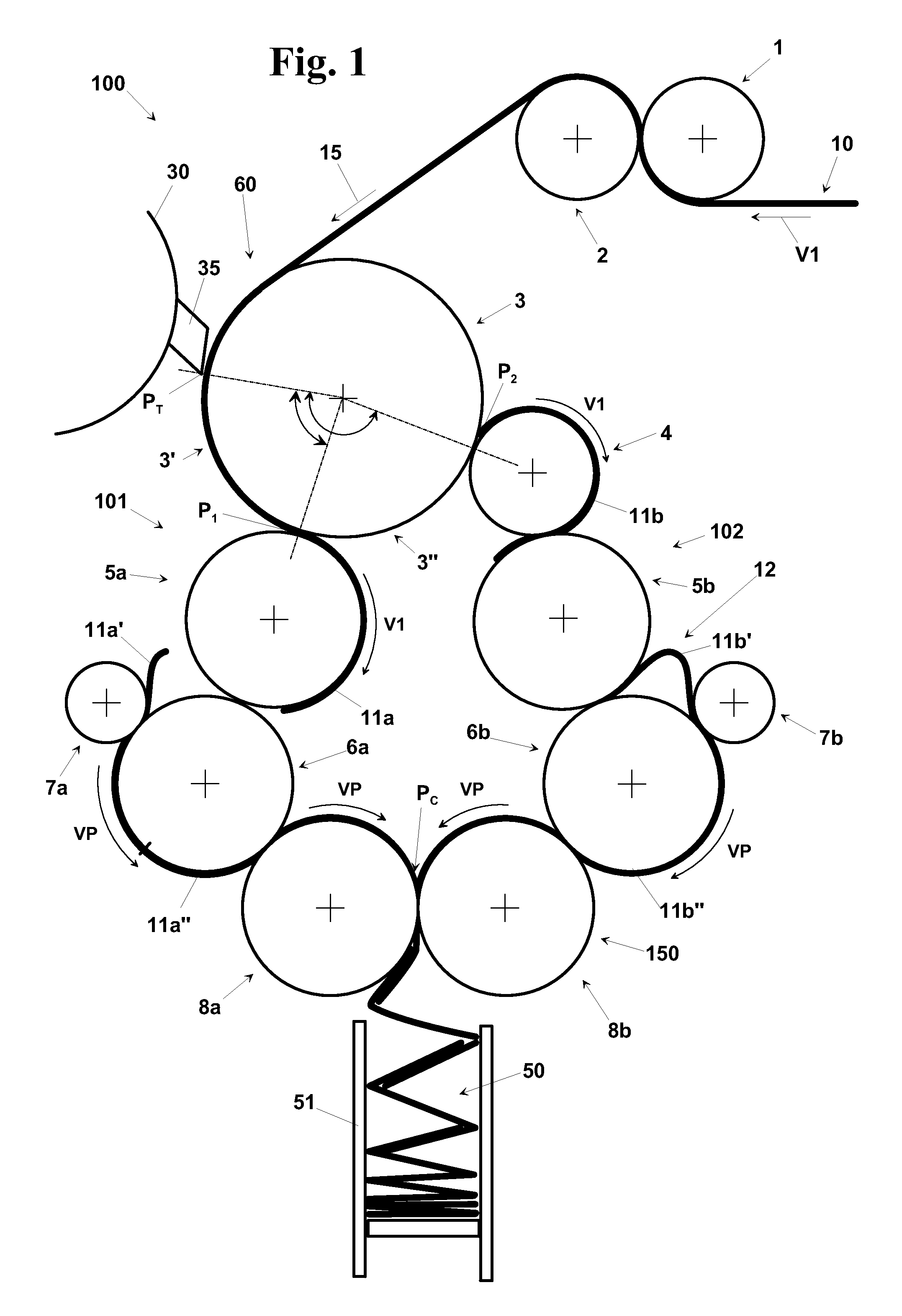

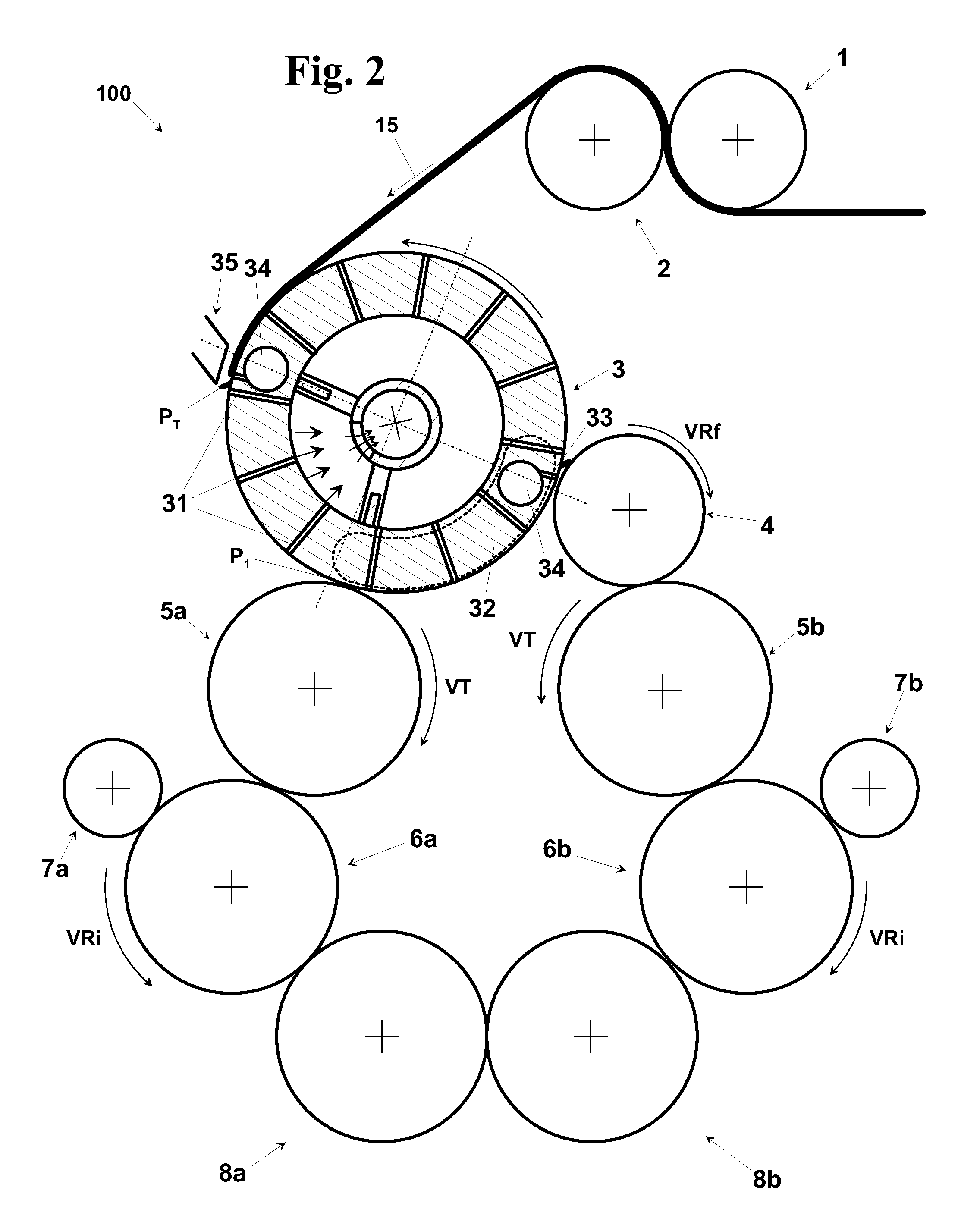

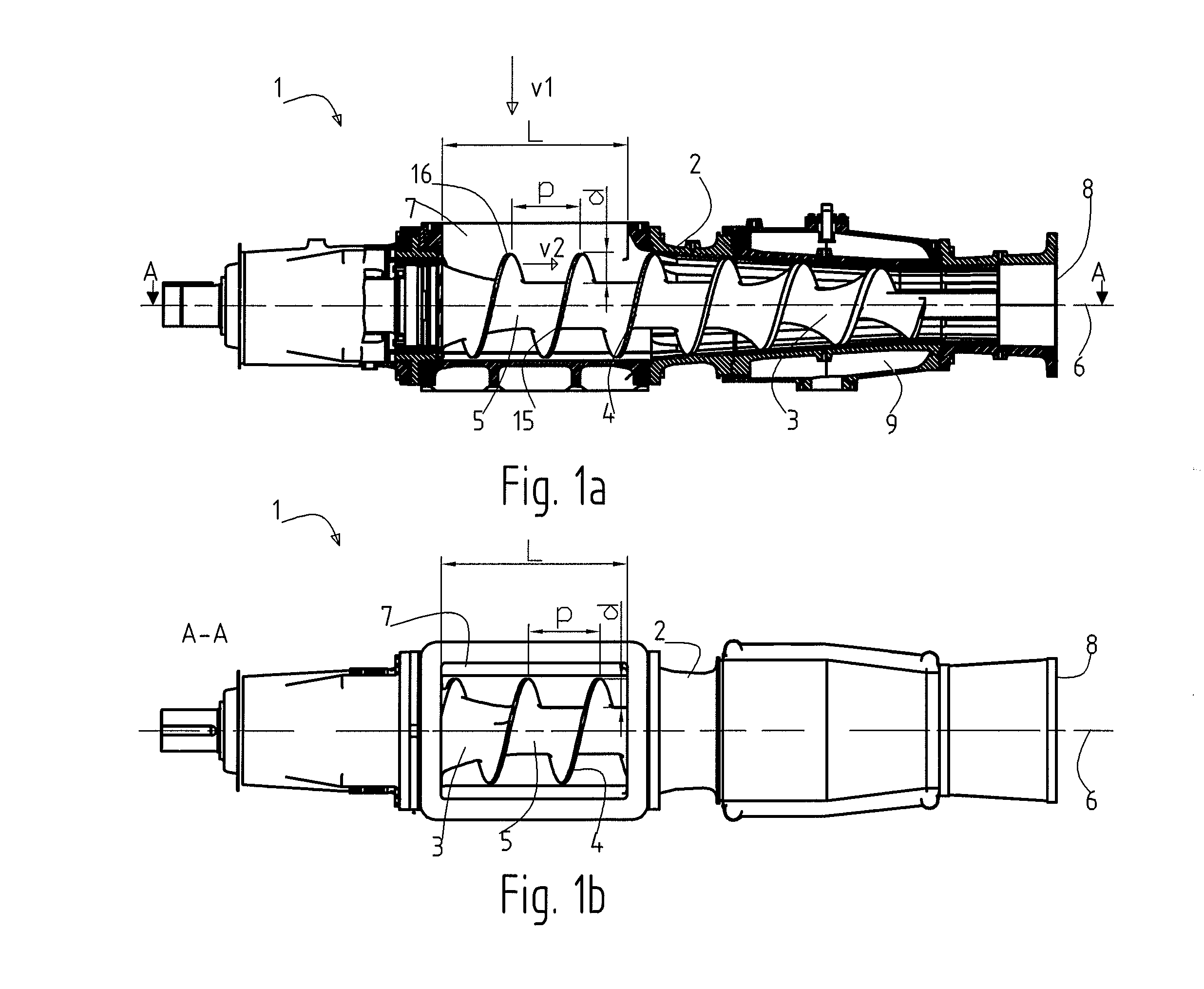

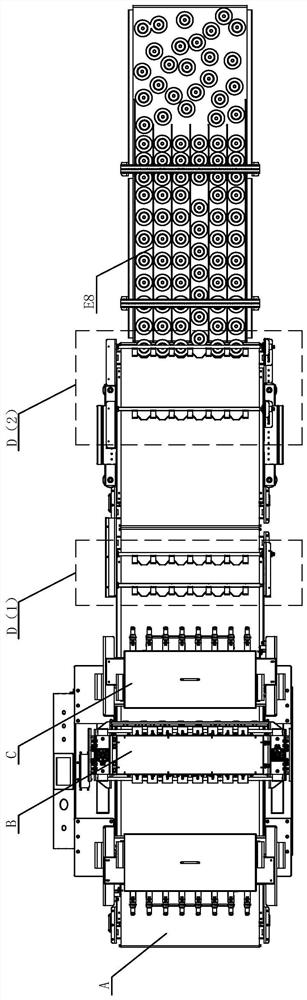

Structure of multipurpose sheet folding and stacking machine

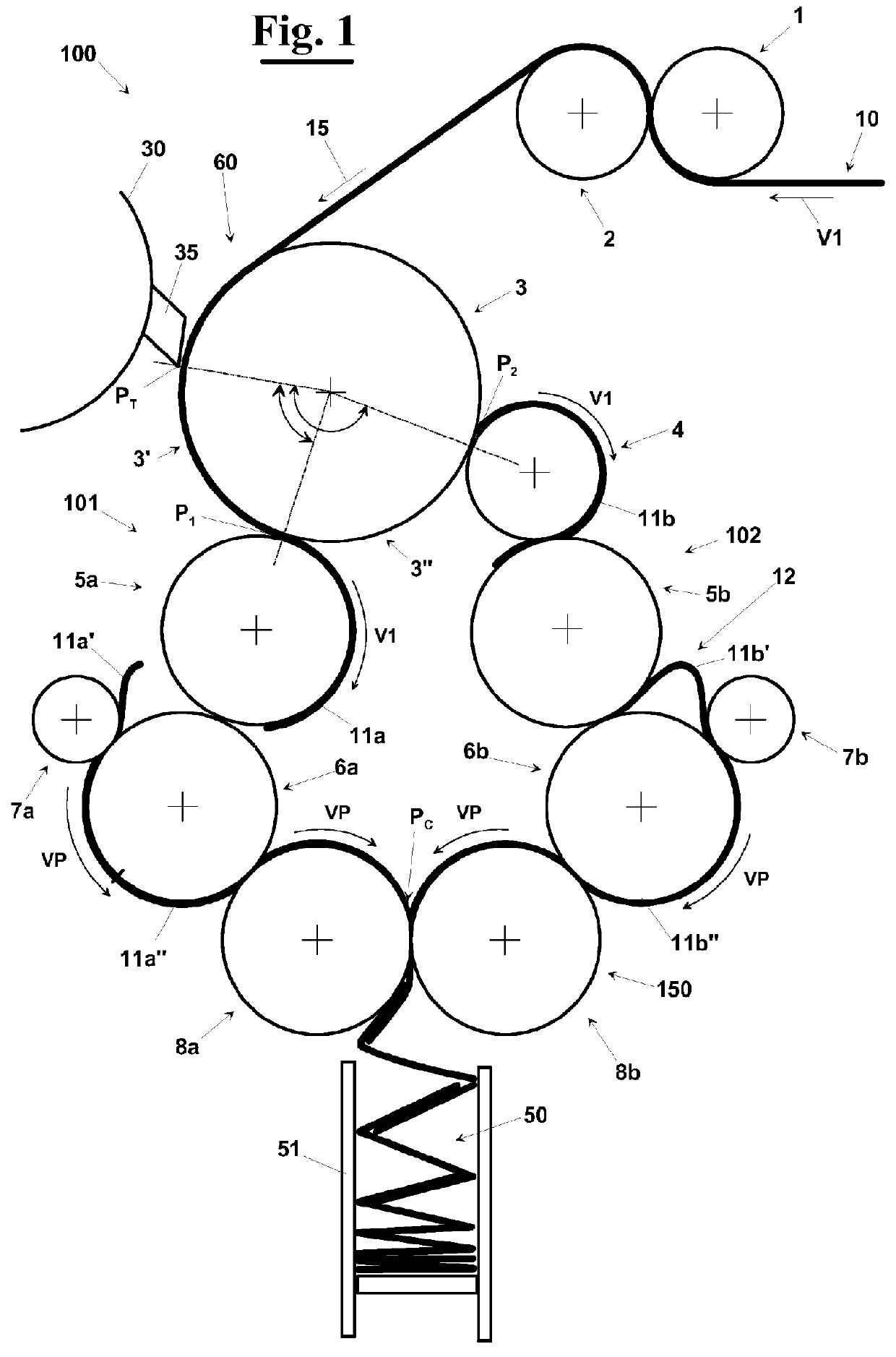

ActiveUS20120202670A1Less cumbersomeChange lengthMechanical working/deformationFolding thin materialsEngineeringFace sheet

A folding and stacking machine of a web of paper has first and second feed lines. The machine also has a folding section with folding rollers having a linear folding speed, VP. The folding rollers are adapted to receive a plurality of sheets of length L that can overlap each other for a fraction Y of their length L and to fold them into a plurality of panels P. The machine also has rollers adapted to feed at the folding speed VP the series of cut sheets but not yet folded towards the folding rollers. The rollers are located at the confluence of the two sheet feeding lines. Upstream of the first and feed lines a single cutting section is provided to cut a web of paper that proceeds along a direction of movement at a speed V(1).

Owner:MTC MACCINE TRASFORMAZIONE CARTA SRL

Plate and gasket for a plate heat exchanger

ActiveUS20110259561A1Speed up heat exchangeOptimal utilisationHeat exchanger fasteningLaminated elementsPlate heat exchangerEngineering

The invention relates to a heat exchanger plate for a plate heat exchanger, whereby the heat exchanger plate has a number of ports, distribution regions, adiabatic regions, a heat transfer region, and an edge region which extends outside the ports and the regions, whereby the heat exchanger plate includes a gasket groove extending in the edge region outside the regions and round the ports, whereby the gasket groove accommodates a gasket for sealing abutment against an adjacent heat exchanger plate in the plate heat exchanger where the gasket groove creates at least a recess of the heat transfer region along each side of the heat transfer region and that the recess enables a clip-on tab to be securely fastened to an edge region of the heat exchanger plate at the recess.

Owner:ALFA LAVAL CORP AB

Structure of multipurpose sheet folding and stacking machine

ActiveUS9388016B2Change lengthSame capacityMechanical working/deformationFolding thin materialsStack machineEngineering

A folding and stacking machine of a web of paper has first and second feed lines. The machine also has a folding section with folding rollers having a linear folding speed, VP. The folding rollers are adapted to receive a plurality of sheets of length L that can overlap each other for a fraction Y of their length L and to fold them into a plurality of panels P. The machine also has rollers adapted to feed at the folding speed VP the series of cut sheets but not yet folded towards the folding rollers. The rollers are located at the confluence of the two sheet feeding lines. Upstream of the first and feed lines a single cutting section is provided to cut a web of paper that proceeds along a direction of movement at a speed V(1).

Owner:MTC MACCINE TRASFORMAZIONE CARTA SRL

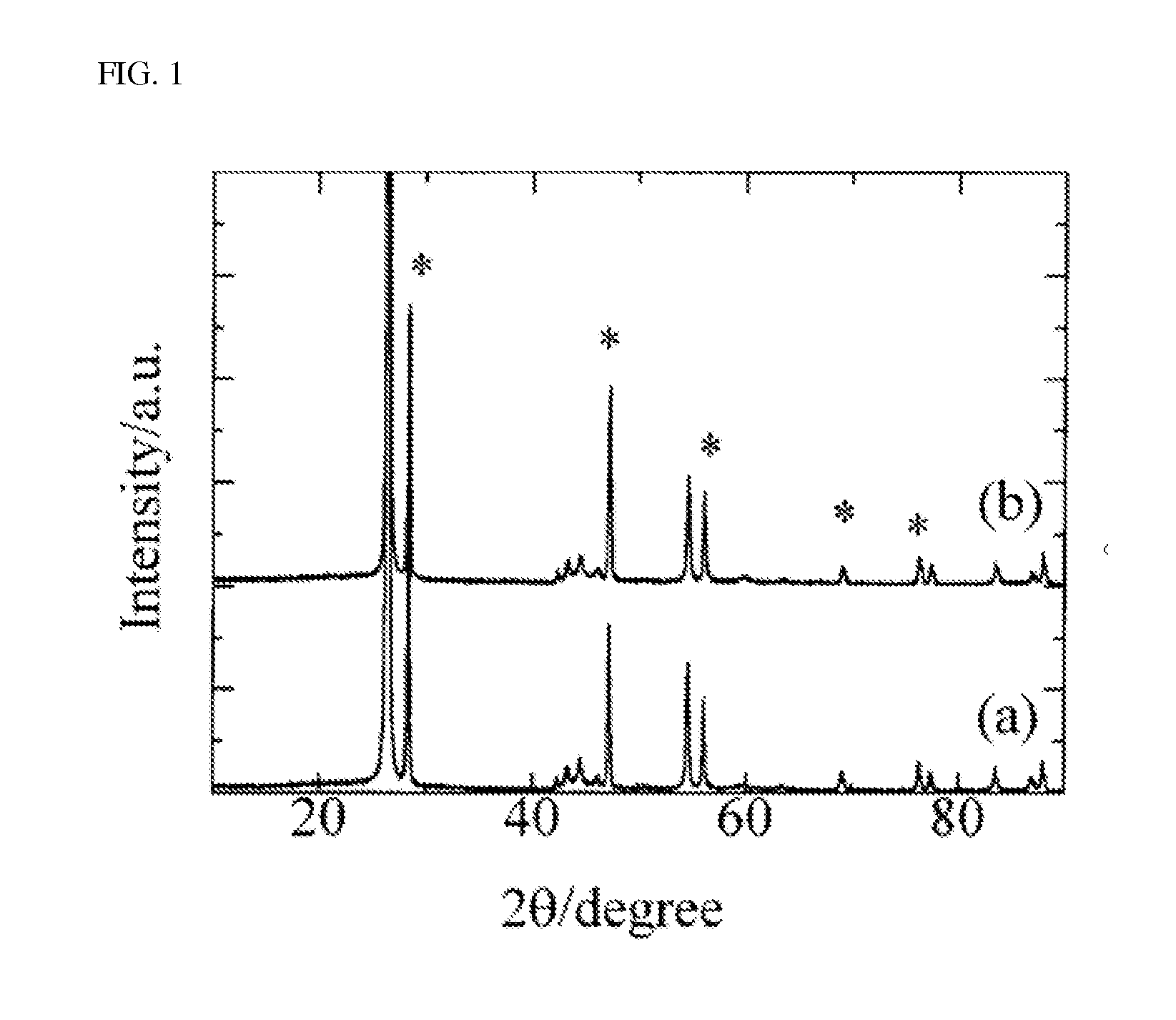

Lithium secondary battery of high power property with improved high energy density

ActiveUS20140120425A1Same capacityEnhanced high-output characteristic and long lifespan characteristicNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithiumHigh energy

Disclosed is a high-output lithium secondary battery including: a cathode that includes, as cathode active materials, a first cathode active material represented by Formula 1 below and having a layered structure and a second cathode active material represented by Formula 2 below and having a spinel structure, wherein the amount of the second cathode active material is between 40 and 100 wt % based on the total weight of the cathode active materials; an anode including crystalline graphite having a specific surface area (with respect to capacity) of 0.005 to 0.013 m2 / mAh as an anode active material; and a separator.

Owner:LG ENERGY SOLUTION LTD

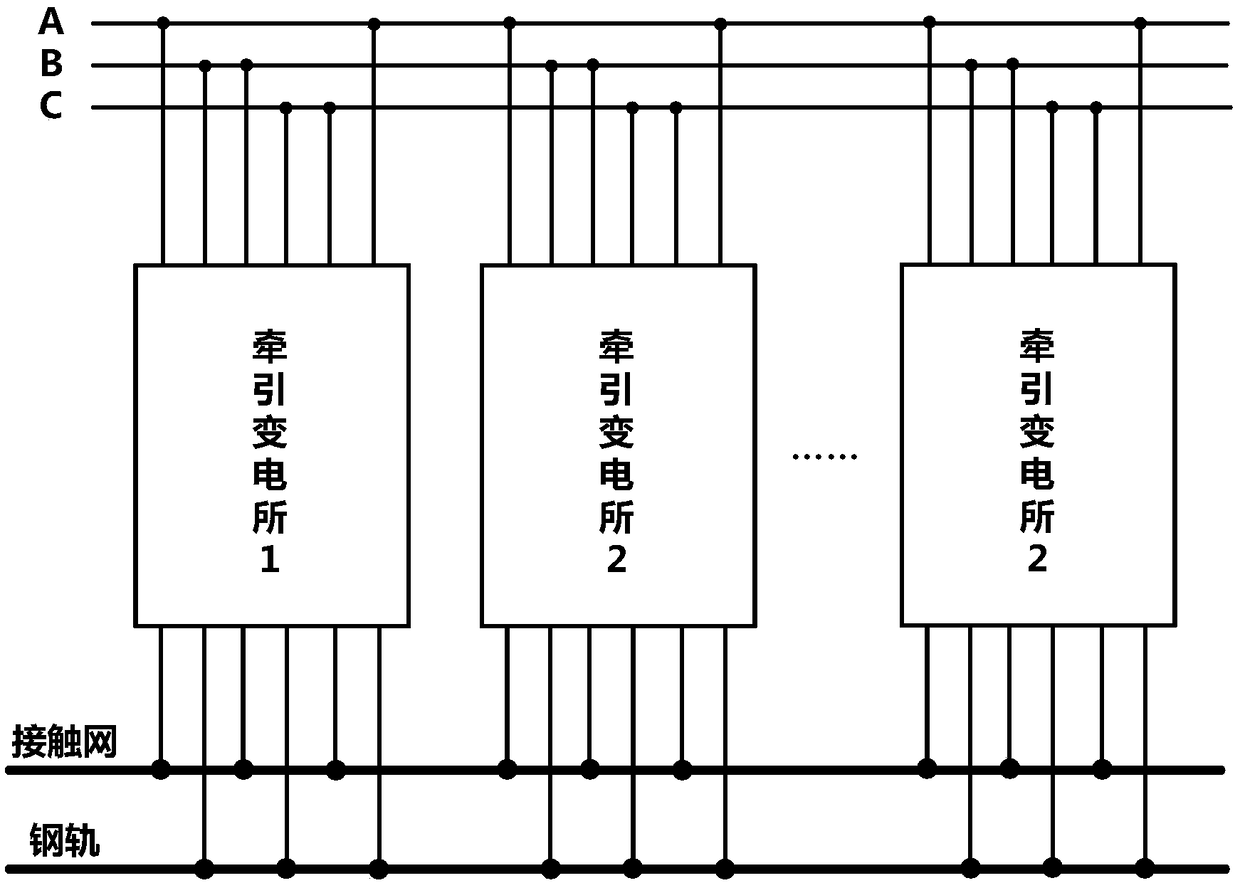

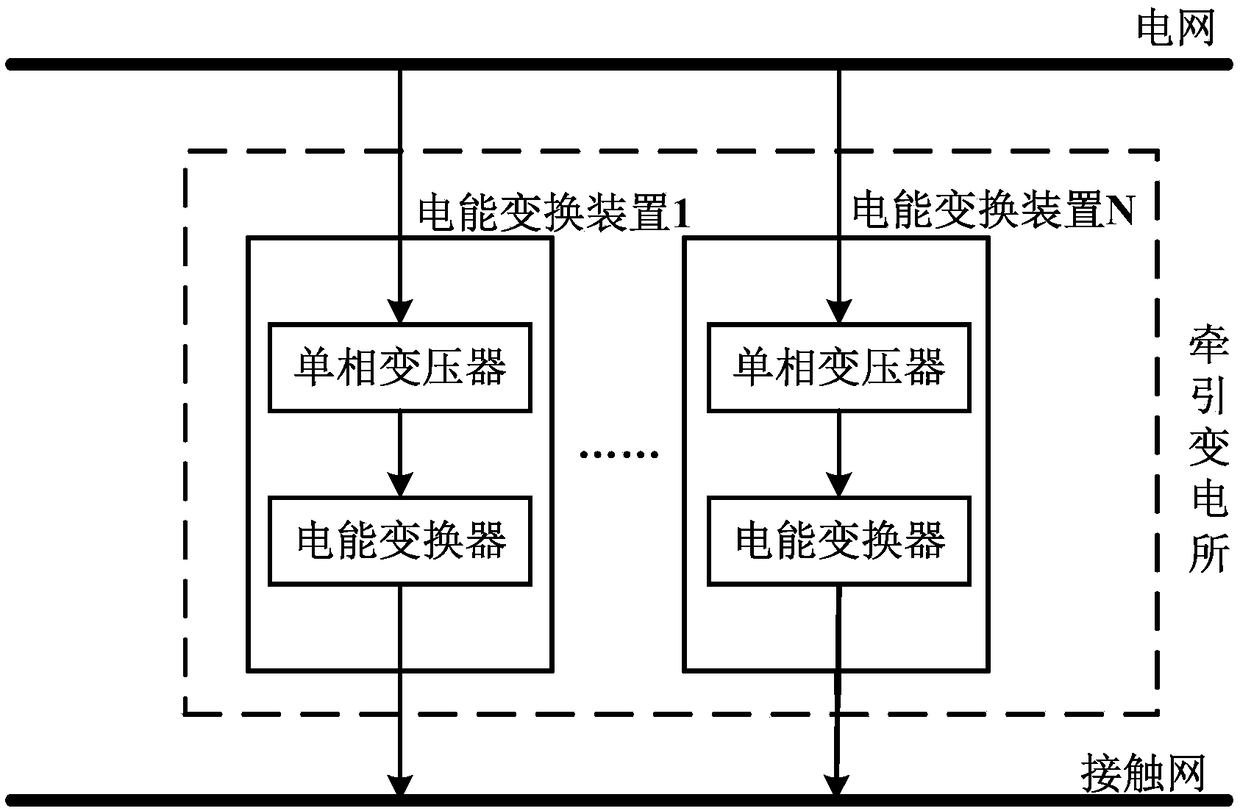

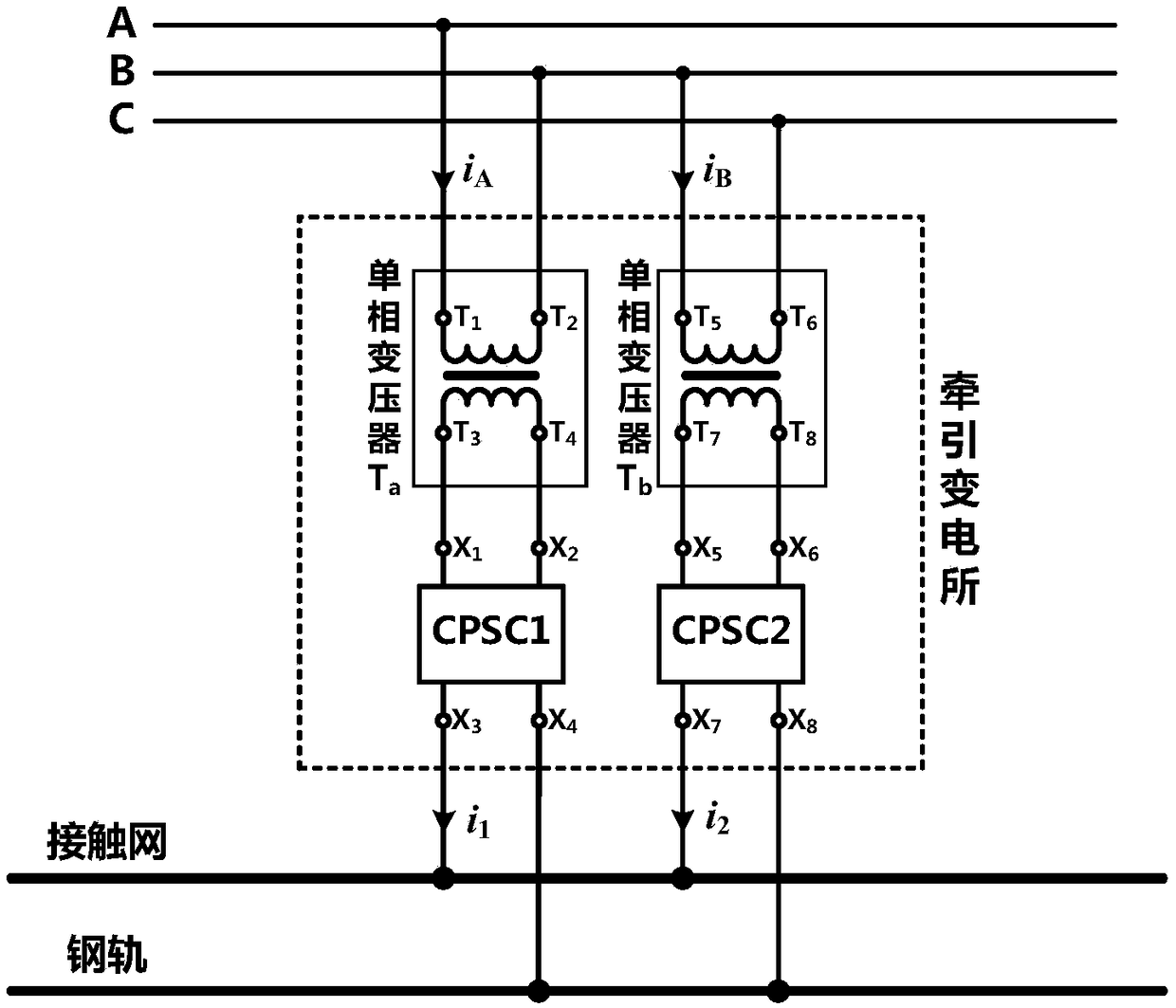

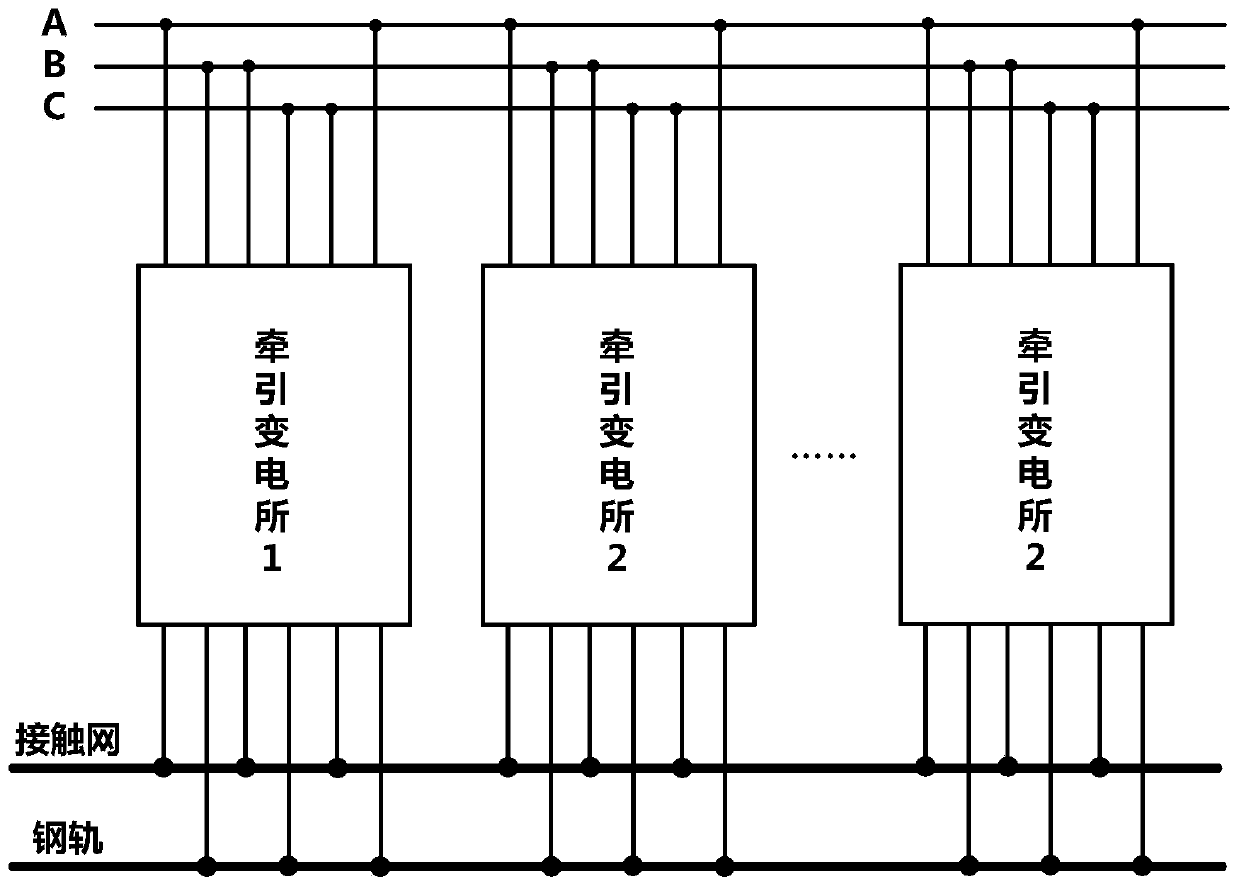

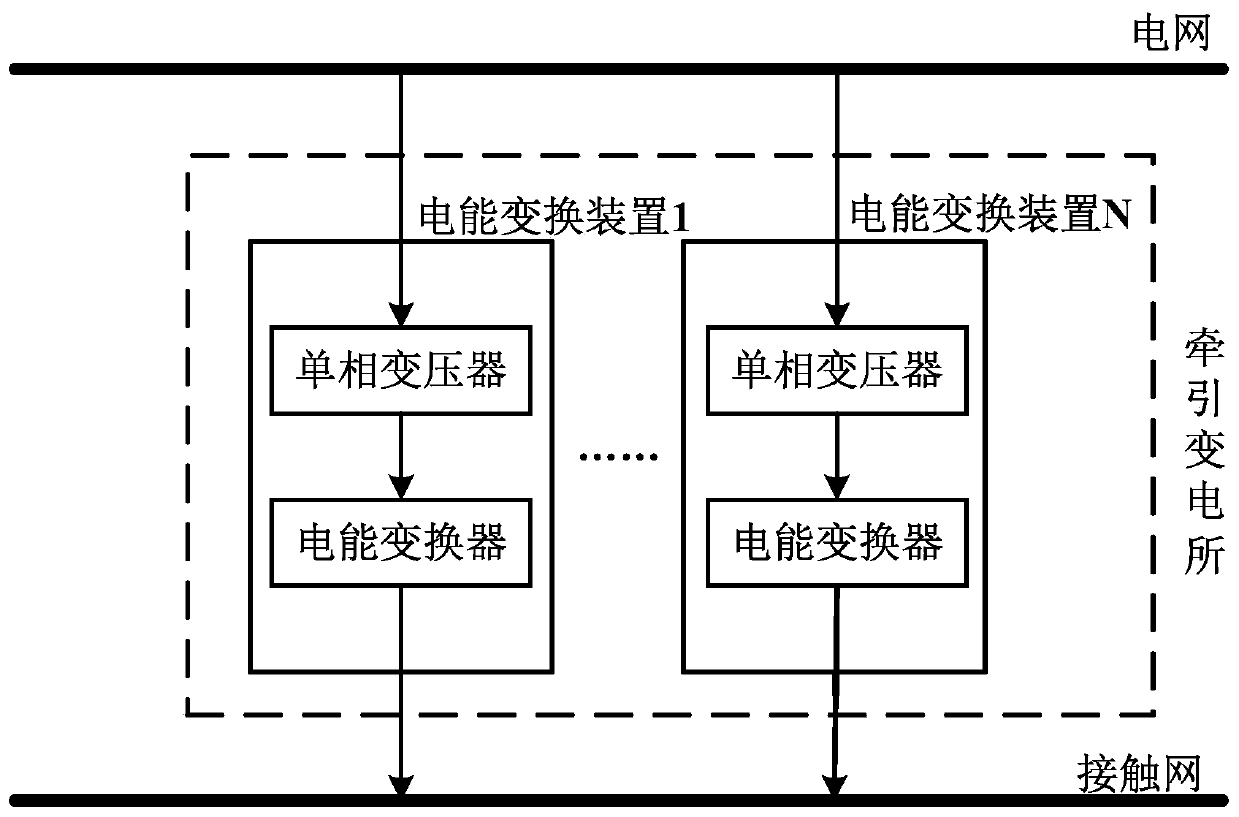

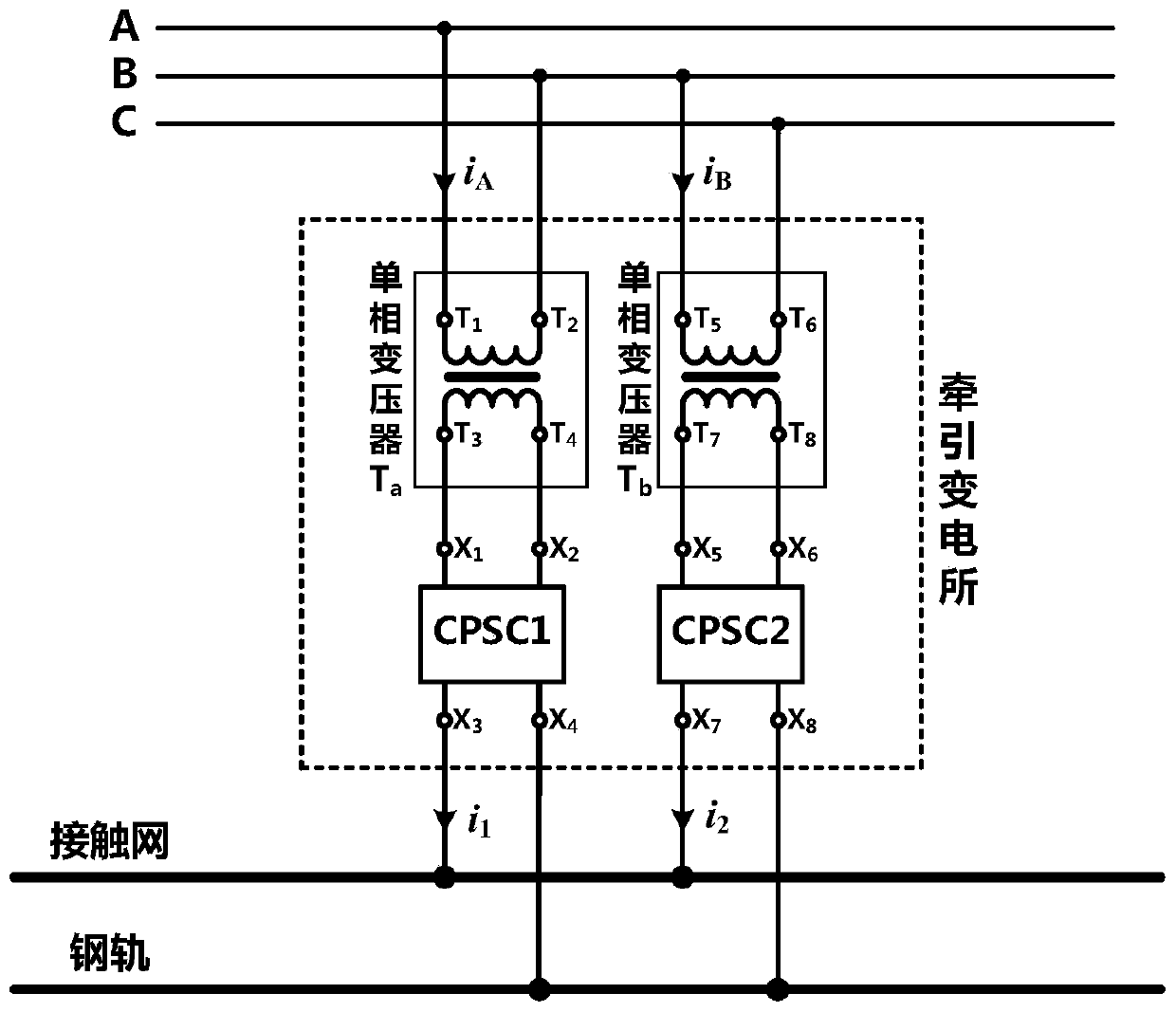

Connecting-type in-phase traction pow supply system, traction substation and power supply control method thereof

ActiveCN109050352AImprove power supply reliabilitySame capacityPower supply linesLow voltageEngineering

The invention relates to the technical field of electric power control, in particular to a through-type in-phase traction power supply system, a traction substation and a power supply control method thereof, aiming at solving the technical problem of how to reliably supply power to an electric locomotive. To this end, the present invention provides a traction substation comprising a plurality of electrical energy conversion devices. In particular, the electric energy conversion device comprises a single-phase transformer and an electric energy converter, The high-voltage winding of each single-phase transformer is respectively connected with two different phase wires in a preset power network, the low-voltage winding of each single-phase transformer is connected with an input side port ofa corresponding electric energy converter, and the output side port of each electric energy converter is respectively connected with a preset contact line and a preset rail. Based on the structure, the traction substation can also rely on other electric energy conversion devices to continuously supply a continuous supply voltage to the catenary with a constant voltage amplitude and phase when partof the electric energy conversion device fails. The power supply system of the present invention comprises the traction substation.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +2

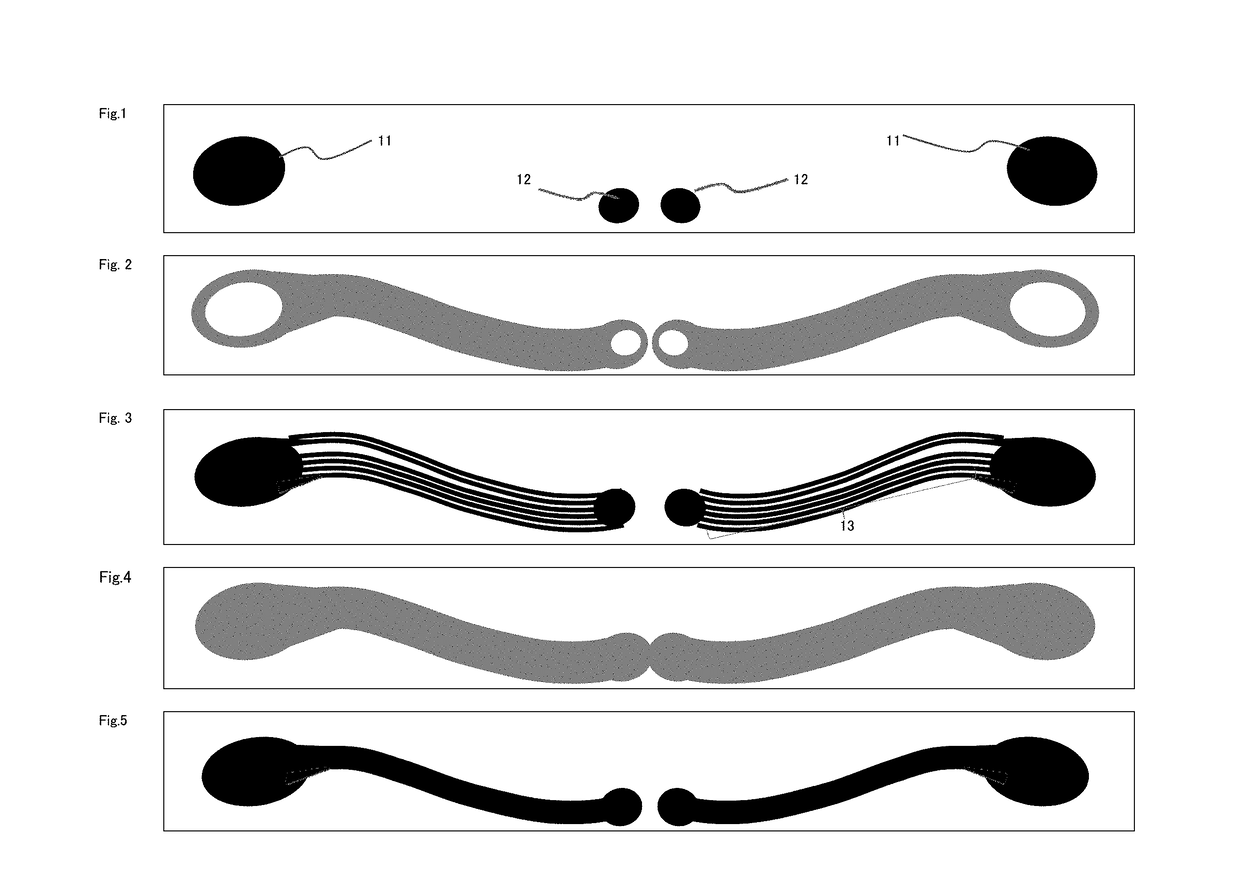

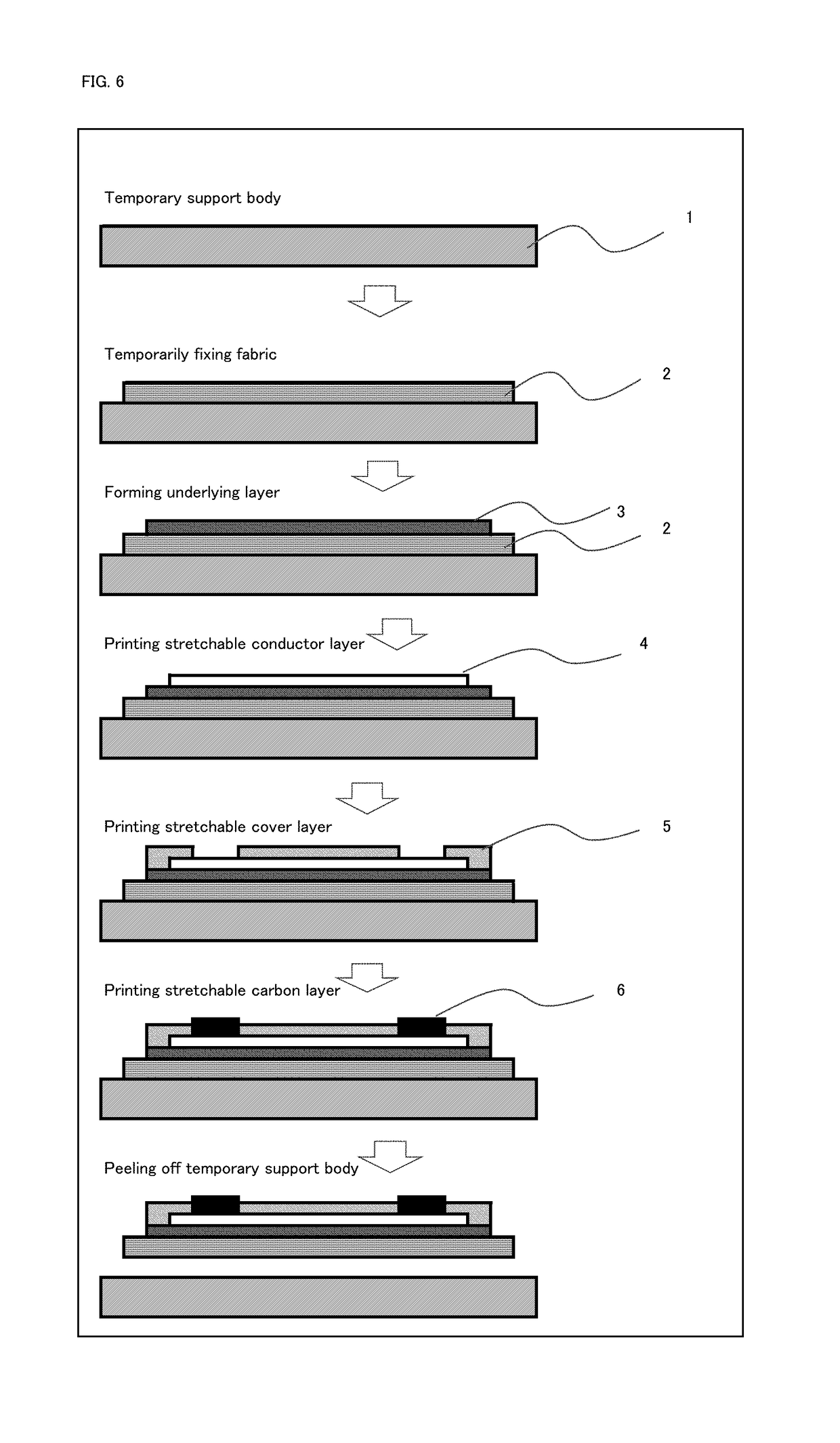

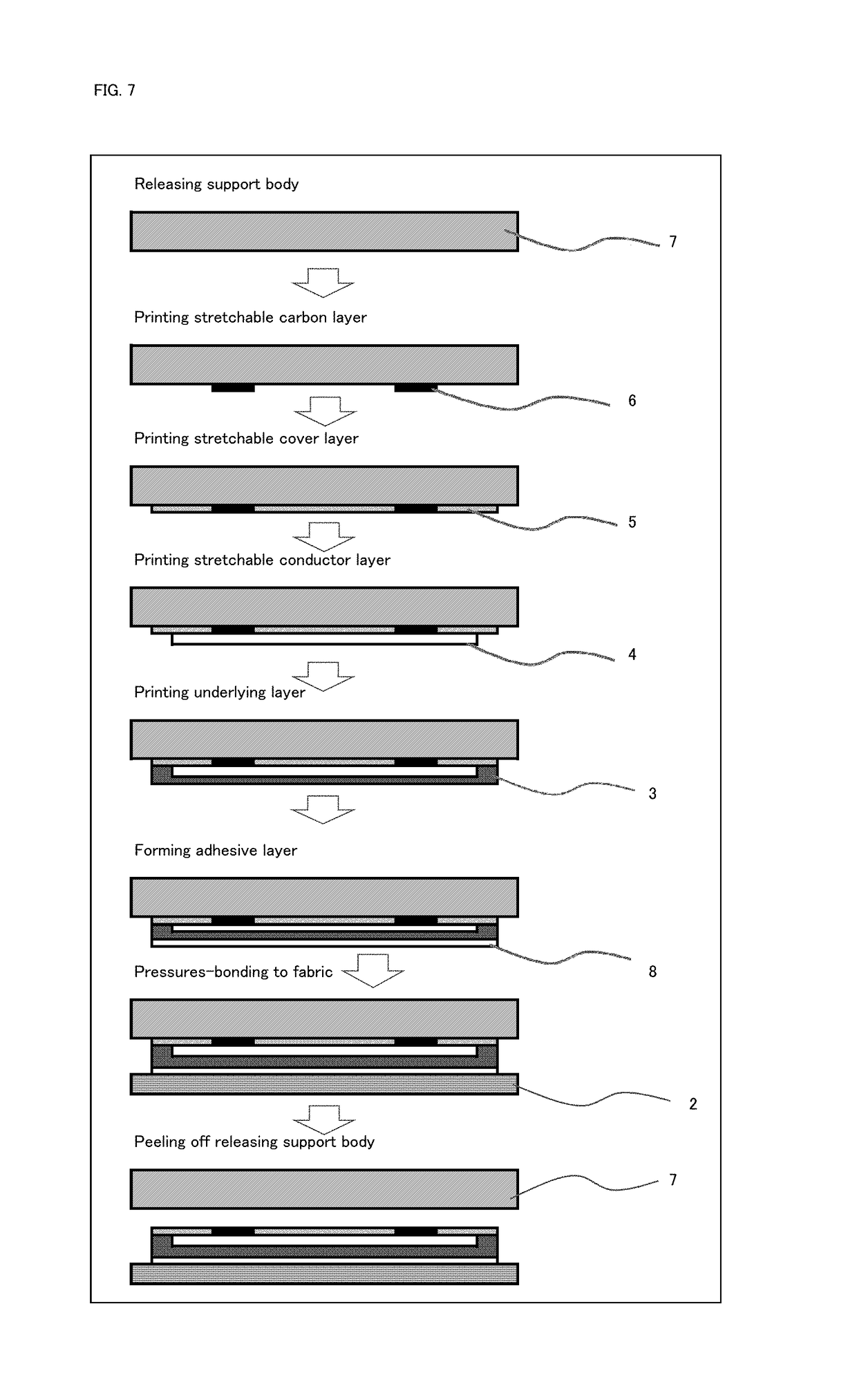

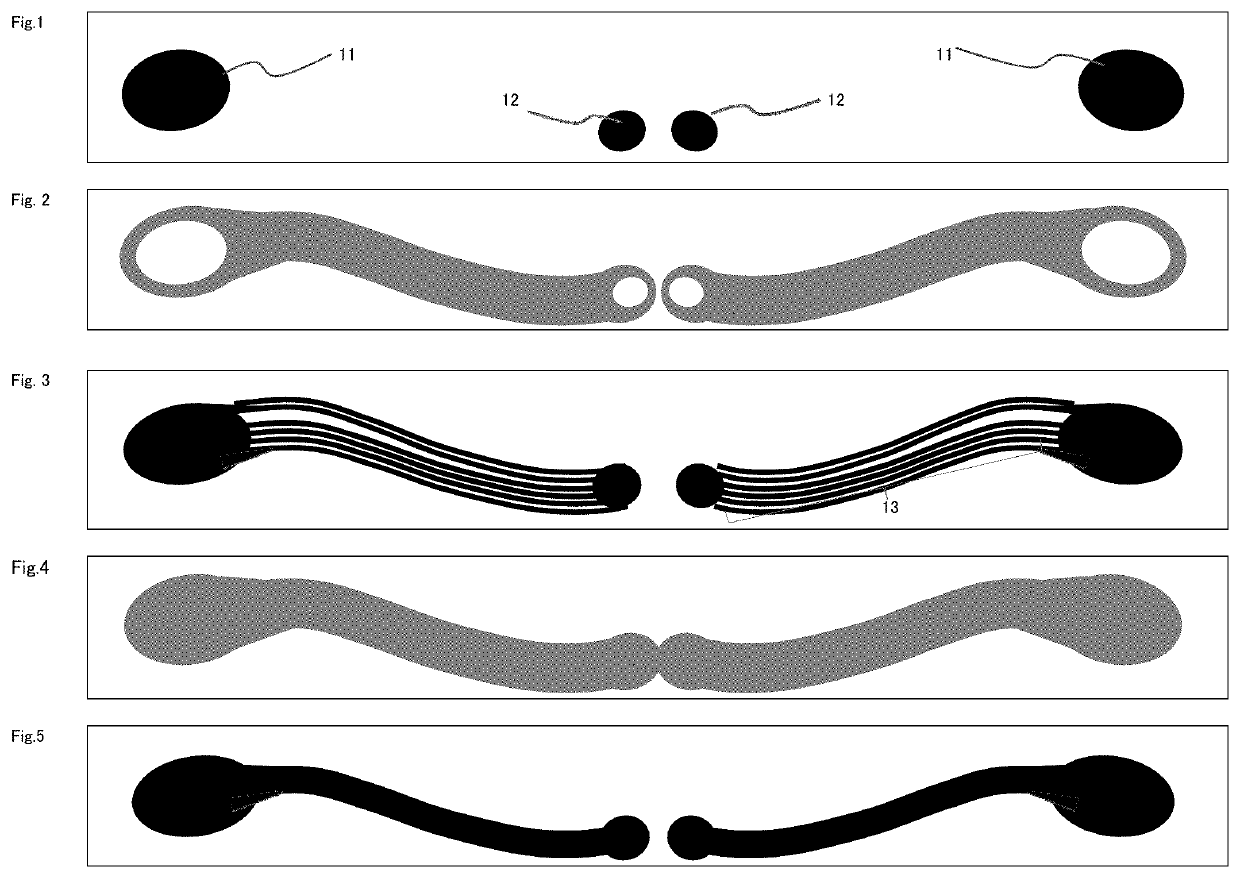

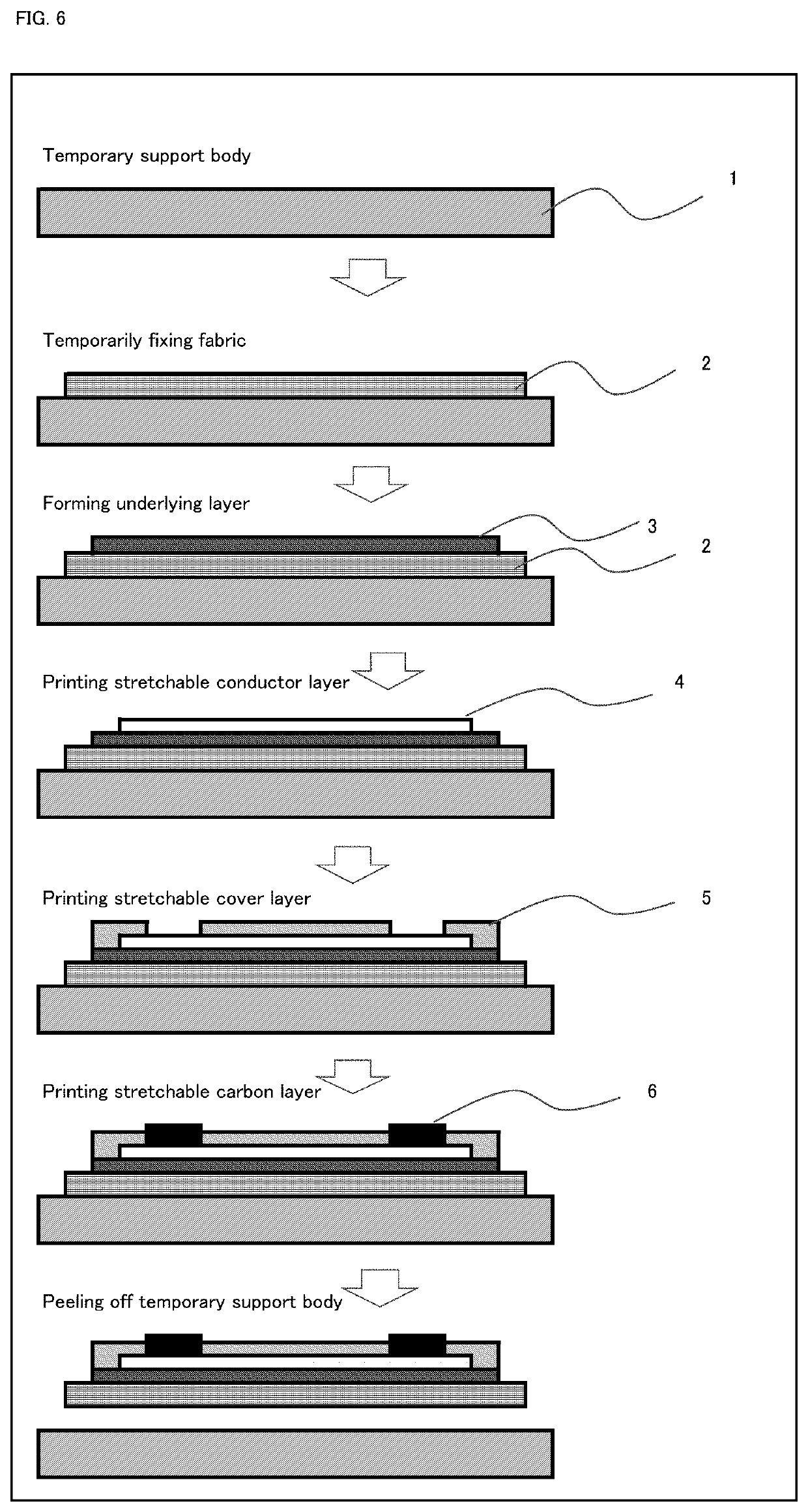

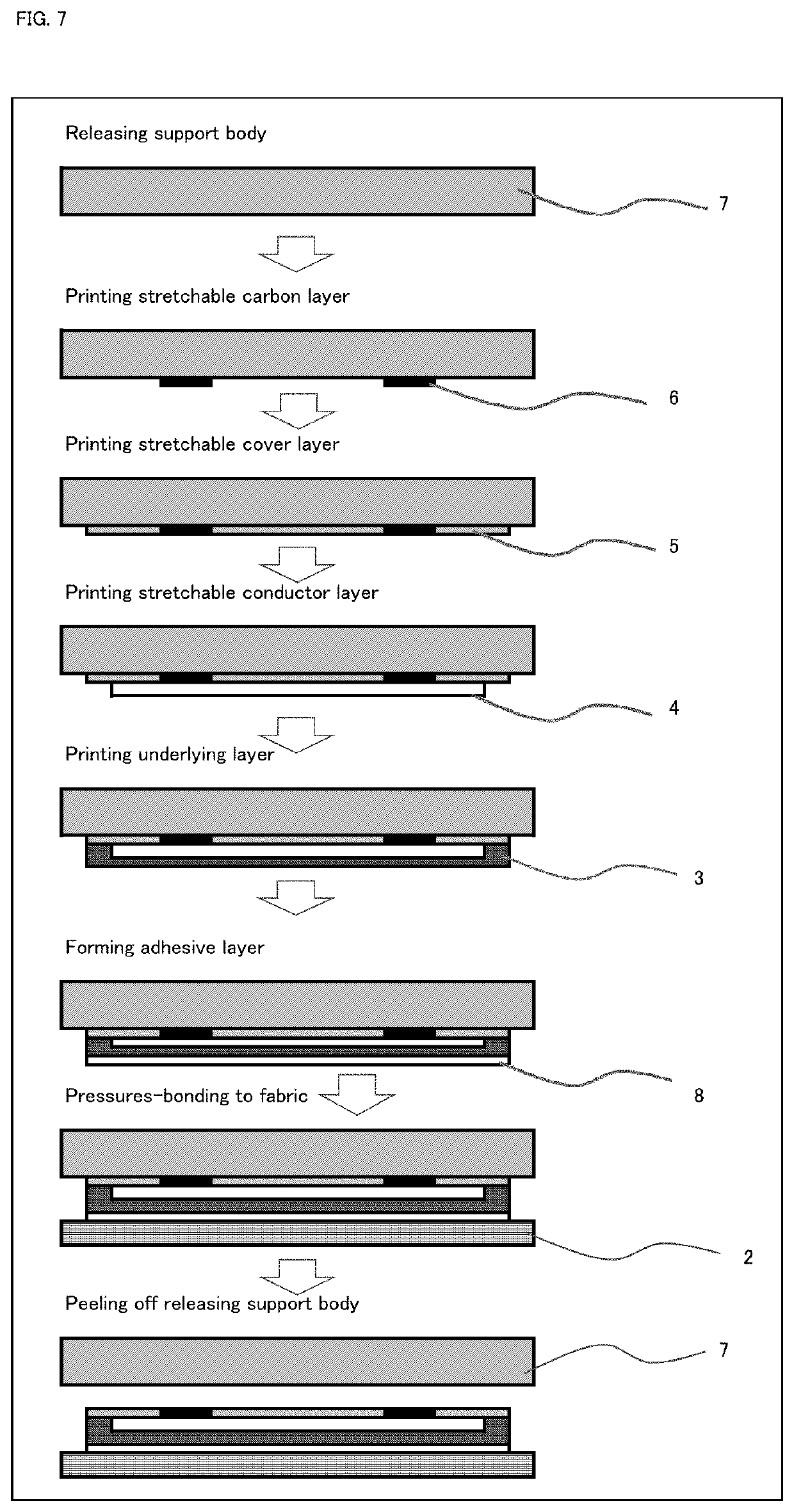

Wearable smart device

ActiveUS20190053546A1Reduce conductivitySame capacityCircuit bendability/stretchabilityNon-conductive material with dispersed conductive materialEngineeringElectrical conductor

The present invention provides to a wearable smart device having electrical wiring comprising a stretchable conductive composition having excellent in durability such as repeated bending properties and repeated twisting properties, a material for realizing the wearable smart device, and a method for producing the wearable start device.An electrical wiring including a fine line having an electrical line interval of 1 mm or less, preferably the line width of less than 1 mm, is formed by printing a paste for forming a stretchable conductor containing metal-based conductive particles and a non-crosslinked elastomer, and further dried and cured at a low temperature condition of 120° C. for 30 minutes. As a result, the wearable smart device having electrical wiring constituted by fine lines without sagging of the edge is obtained.

Owner:TOYO TOYOBO CO LTD

Plate and gasket for a plate heat exchanger

ActiveUS9212854B2Speed up heat exchangeOptimal utilisationHeat exchanger fasteningLaminated elementsPlate heat exchangerEngineering

The invention relates to a heat exchanger plate for a plate heat exchanger, whereby the heat exchanger plate has a number of ports, distribution regions, adiabatic regions, a heat transfer region, and an edge region which extends outside the ports and the regions, whereby the heat exchanger plate includes a gasket groove extending in the edge region outside the regions and round the ports, whereby the gasket groove accommodates a gasket for sealing abutment against an adjacent heat exchanger plate in the plate heat exchanger where the gasket groove creates at least a recess of the heat transfer region along each side of the heat transfer region and that the recess enables a clip-on tab to be securely fastened to an edge region of the heat exchanger plate at the recess.

Owner:ALFA LAVAL CORP AB

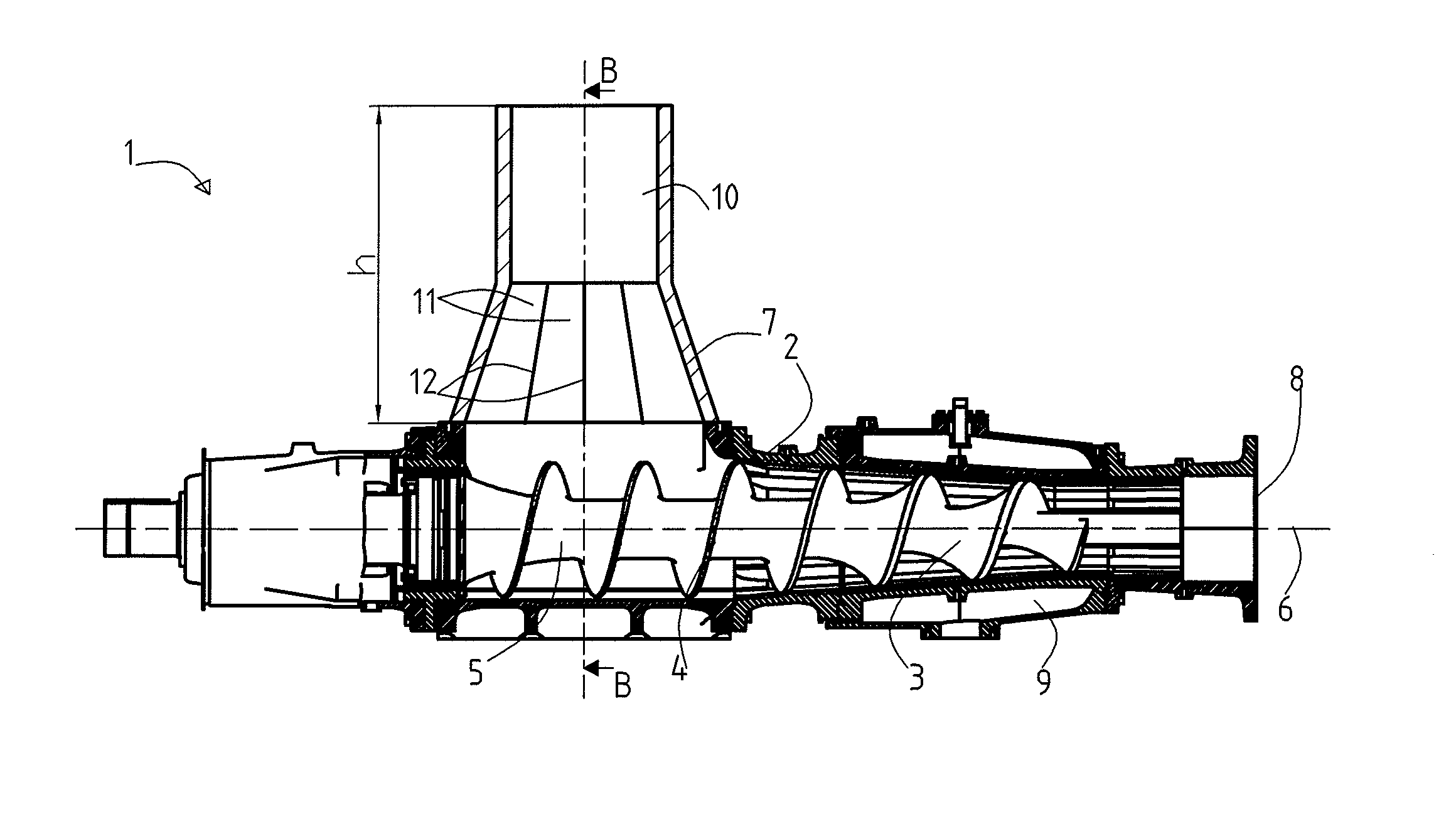

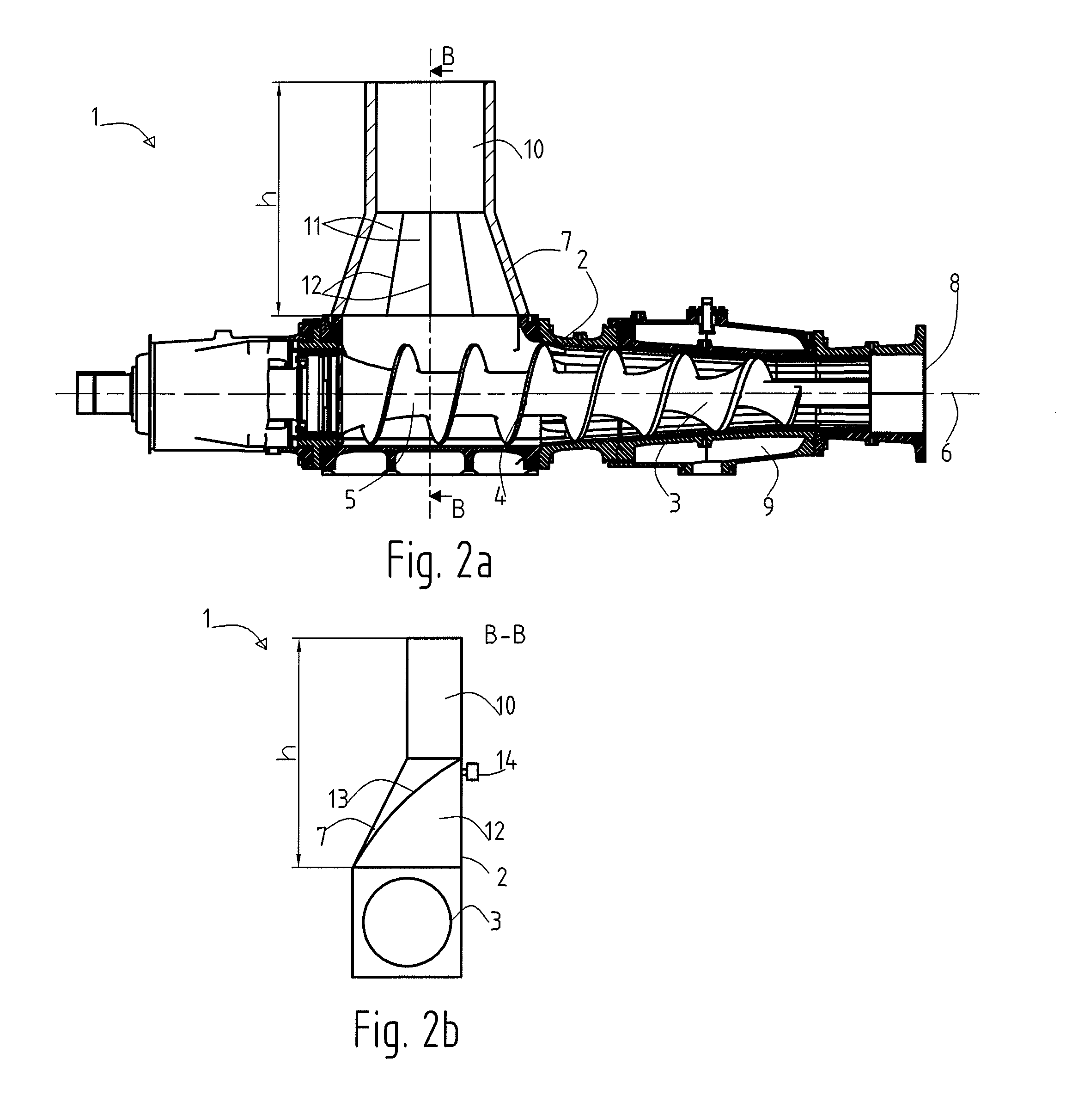

Screw conveyor for lignocellulose-containing material

ActiveUS9434551B2Equally distributedIncrease productionDigestersPulp de-wateringEngineeringScrew thread

A screw conveyor for transporting lignocellulose-containing material, including a housing containing a screw for transporting the lignocellulose-containing material from the inlet to the outlet of the housing, the screw including a screw core disposed along the screw axis and a screw thread surrounding the screw core, the screw thread including a screw depth defined by the distance between the periphery of the screw and the screw core, the inlet including at least one transverse plate dividing the inlet into at least two axial compartments for evenly distributing the lignocellulose-containing material at the inlet. A method for transporting lignocellulose-containing material by the screw conveyor, in which the axial length of the screw inlet being equal to or greater than the screw depth times the quotient between the axial speed of the screw and the incoming speed of the lignocellulose-containing material at the inlet.

Owner:VALMET AB

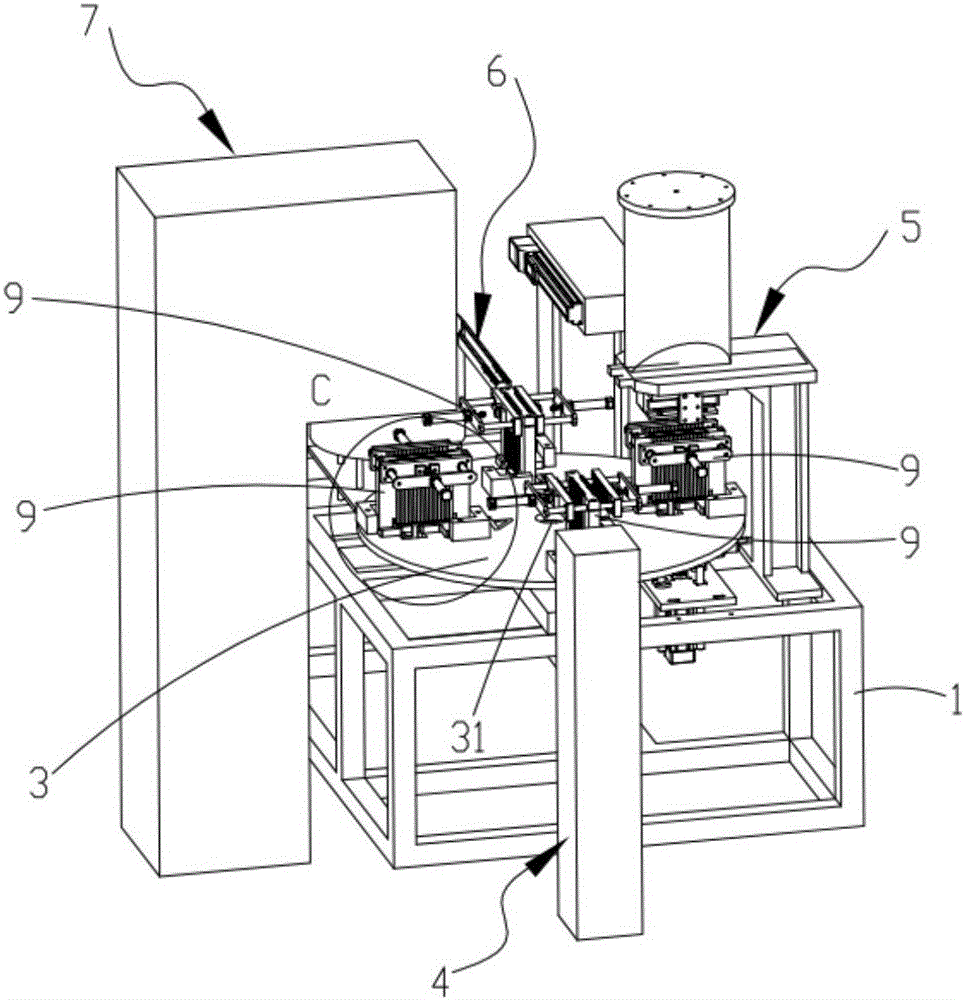

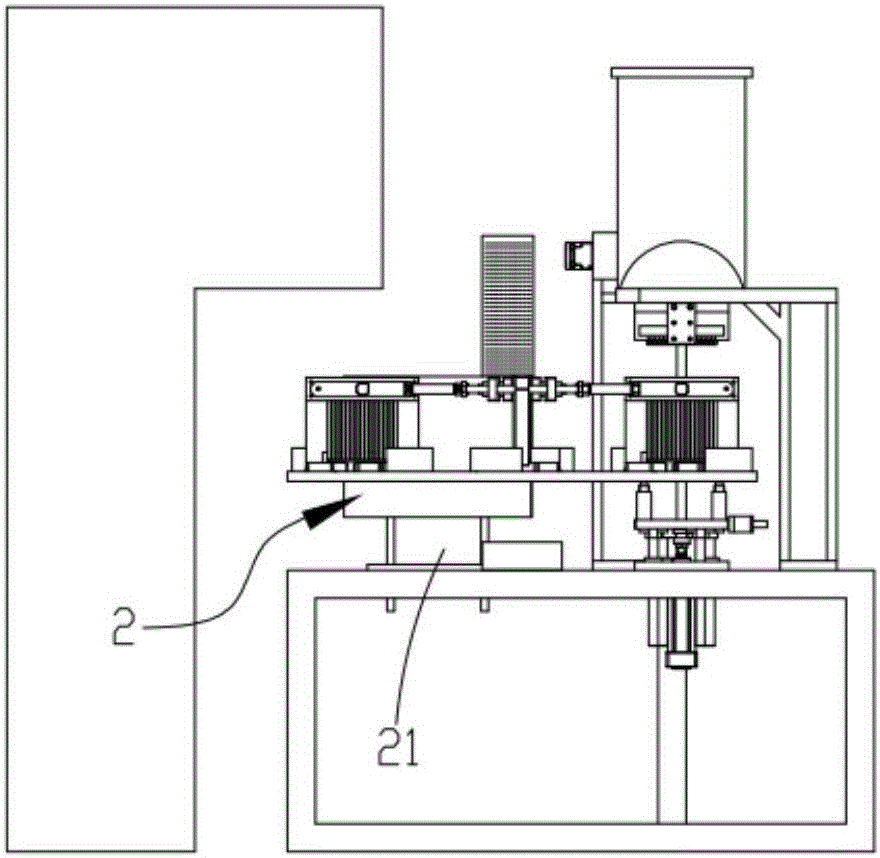

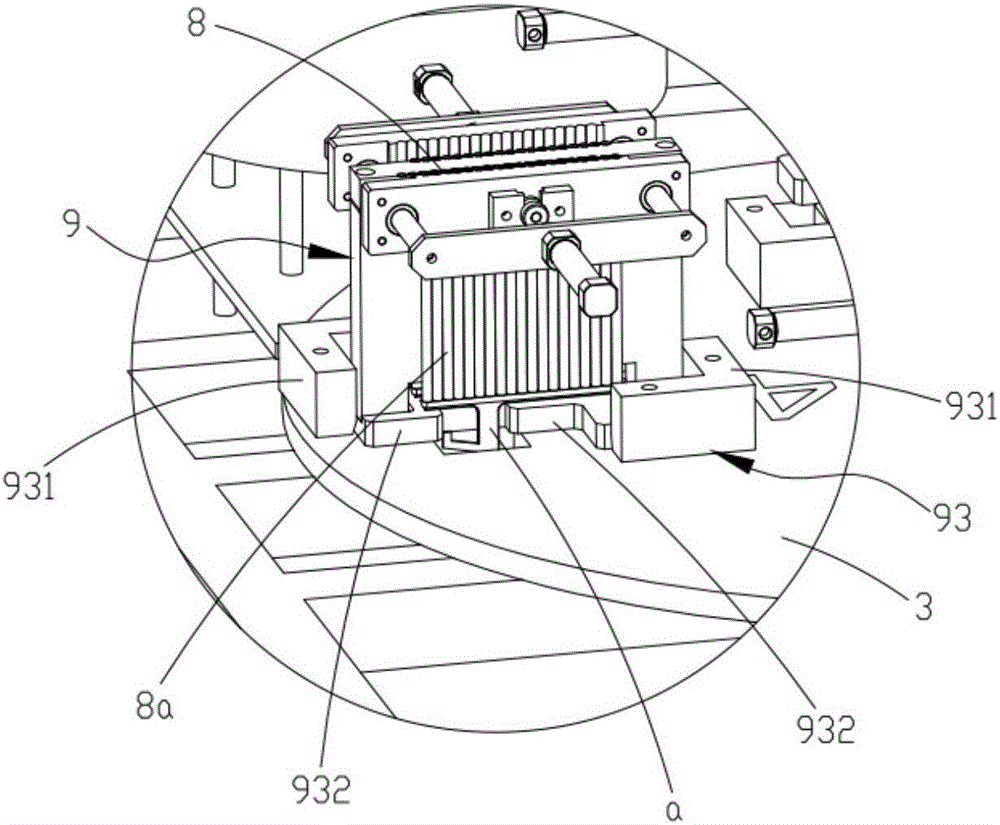

Full-automatic continuous processing device for tubular battery plate

ActiveCN105977451AFully automaticReduce processing timeLead-acid accumulator electrodesRotating discEngineering

The invention relates to a full-automatic continuous processing device for a tubular battery plate. The full-automatic continuous processing device comprises a stander and a rotating disc mounted on the stander, wherein a loading mechanism, a plaster filling mechanism, a cover sealing mechanism and a welding mechanism are sequentially arranged on the stander, clamps which are used for clamping sleeves internally inserted with grids and are arranged in up-down correspondence with the loading mechanism, the plaster filling mechanism, the cover sealing mechanism and the welding mechanism are uniformly distributed on the rotating disc; and the sleeves are driven by the rotation of the rotating disc to be sorted and fixed by the loading mechanism, the insides of the sleeves are automatically filled with lead plaster by the plaster filling mechanism, an upper sealing cover matched with the sleeves is automatically pressed and sealed with openings of the sleeves by the cover sealing mechanism, and the upper sealing cover is fixedly connected with the sleeves by the welding mechanism, thus realizing the continuous assembling and processing of the battery plates. According to the full-automatic continuous processing device, four stations are uniformly arranged around the rotating disc, the clamp for clamping the sleeves inserted with the grids is correspondingly arranged on each station, and the sleeves are sequentially conveyed among the four stations by virtue of the 360-degree rotation of the rotating disc, thereby realizing the full-automatic continuous assembling and processing of the battery plates.

Owner:ZHEJIANG DOULAN INTELLIGENT EQUIP CO LTD

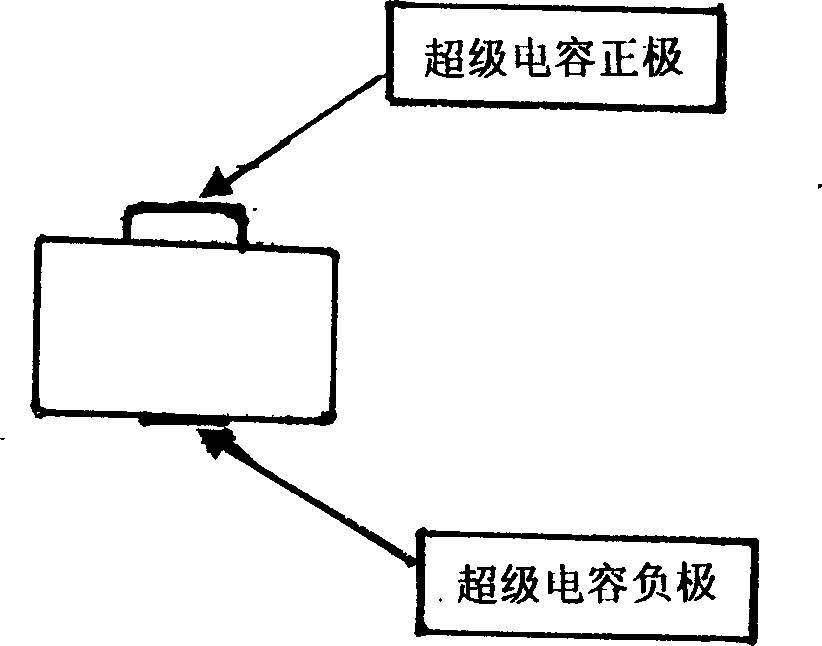

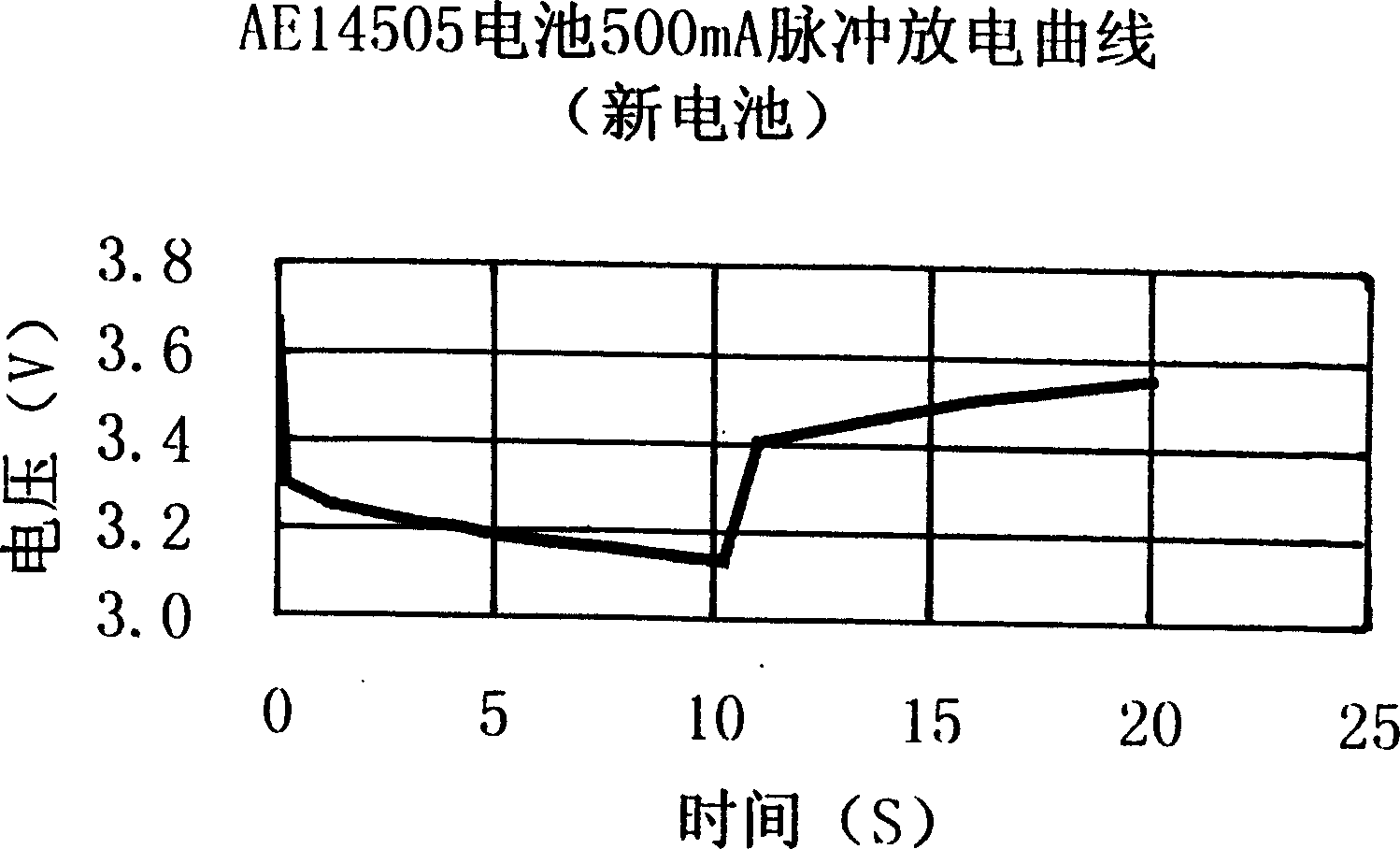

Method for preparing hysteresis-less lithium-thionye chloride cell

ActiveCN1710745ASame capacitySame large pulse current capabilityFinal product manufactureSecondary cellsCapacitanceHysteresis

First, a traditional lithium-thioyl chloride cell is fabricated. Then, a super capacitor able to supply larger current impulse is so prepared that a case body is as positive pole and center of bottom is as negative pole. Positive pole of lithium-thioyl chloride cell is connected to positive pole of the super capacitor through wire, and negative pole of lithium-thioyl chloride cell is connected to negative pole of the super capacitor through wire. The super capacitor is placed above the lithium-thioyl chloride cell and lined up, and resin glue is filled to connection part so as to form an integral body. Positive pole of the super capacitor and negative pole of lithium-thioyl chloride cell are utilized as positive pole and negative pole of the integral body for connecting to outside. Obtaining same power, capability of large pulse current and same safety with performances of capacity type cell, the disclosed cell has no hysteresis of voltage.

Owner:ABLE NEW ENERGY CO LTD

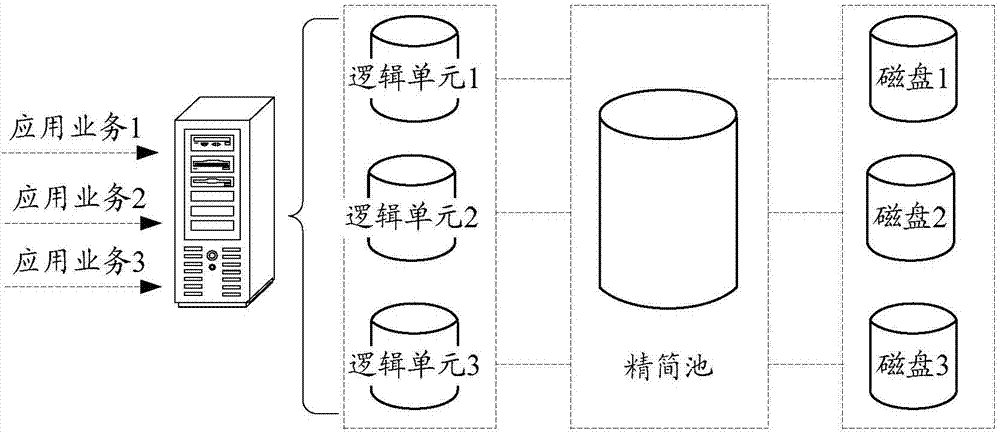

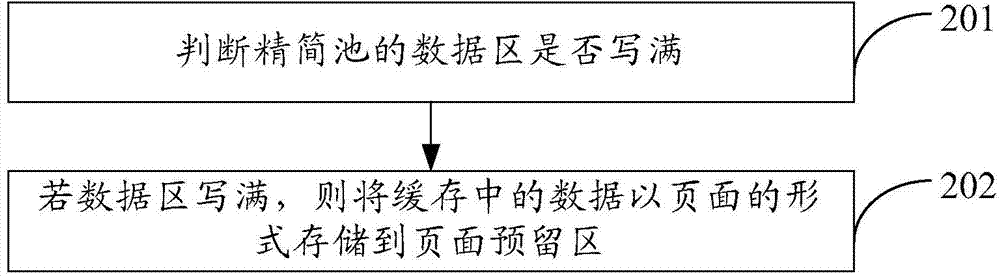

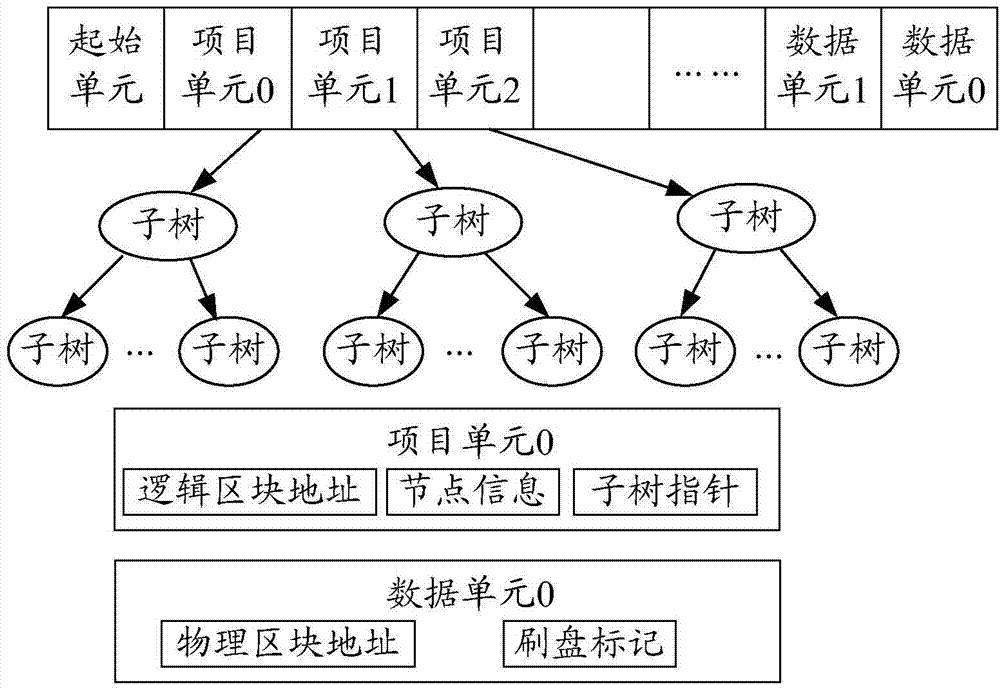

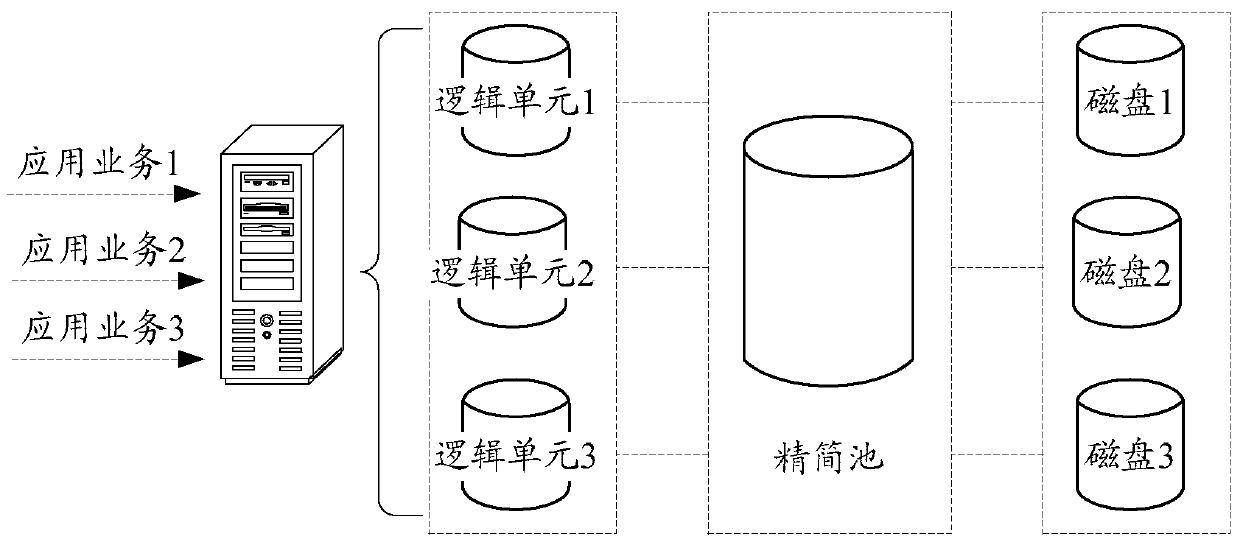

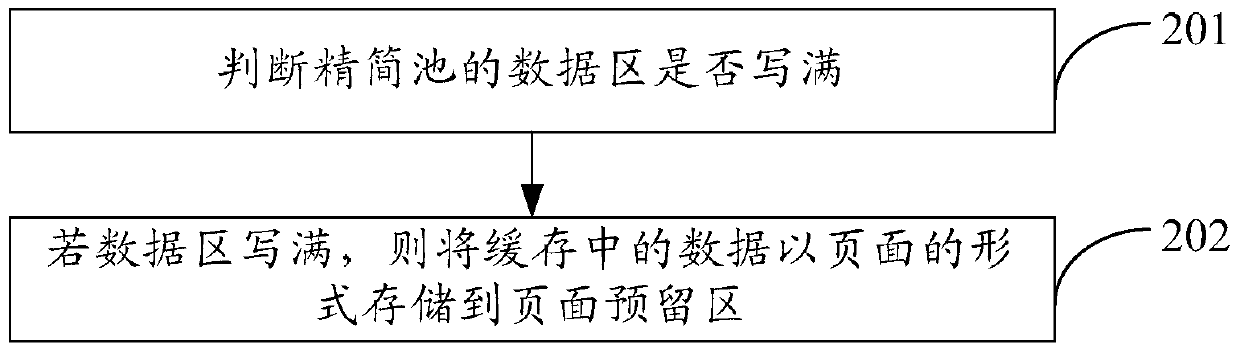

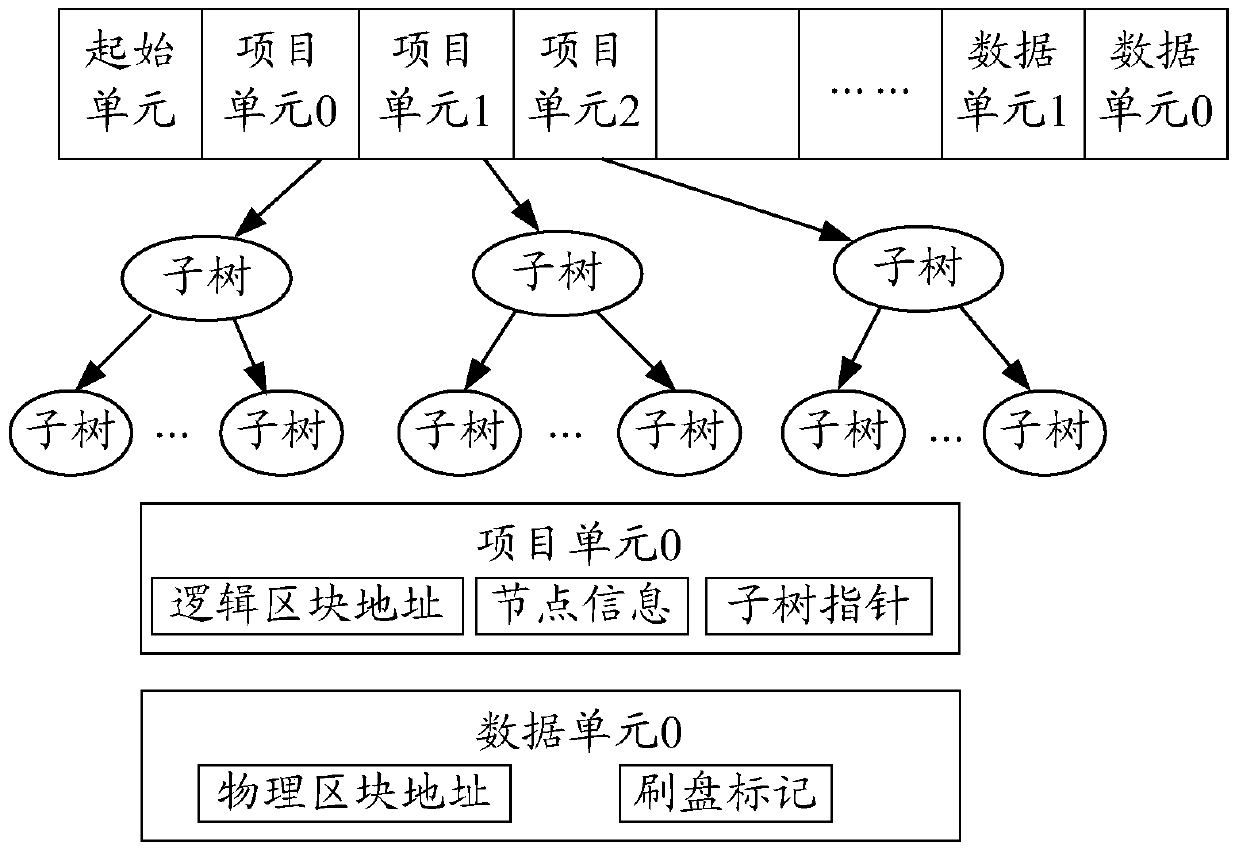

Method and device for processing data

ActiveCN103488584AReduce the risk of lossImprove securityInput/output to record carriersMemory adressing/allocation/relocationComputer hardwareSoftware engineering

An embodiment of the invention discloses a method and a device for processing data, and relates to the field of information technologies. By the aid of the method and the device, the problem that data can be lost easily when a thin pool is fully written can be solved. The particular scheme includes that the method comprises judging whether a data area of a thin pool is fully written or not; storing data in a cache into a page reservation area in a page form if the data area is fully written. The method and the device are used for processing the data.

Owner:HUAWEI TECH CO LTD

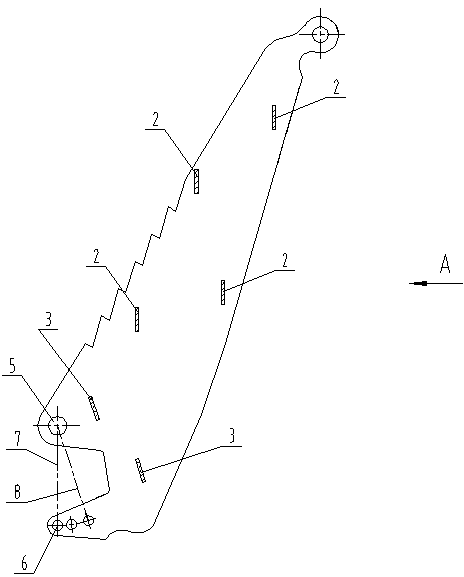

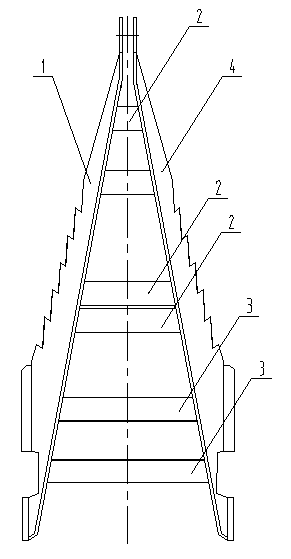

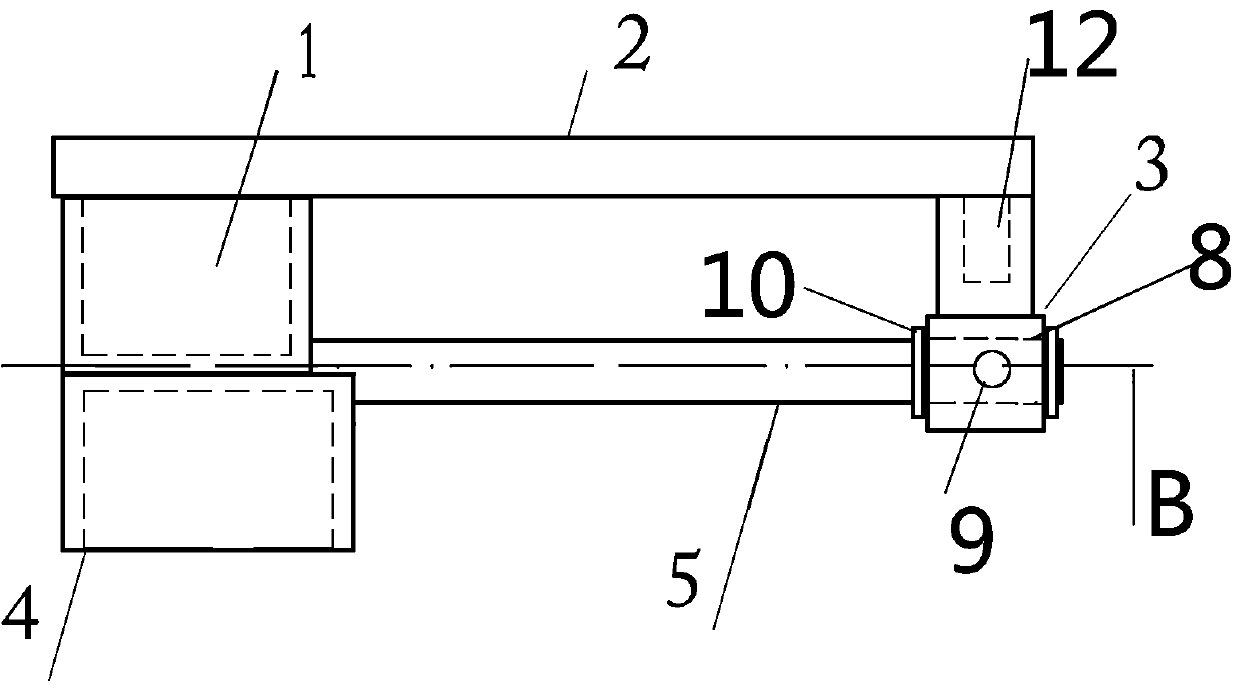

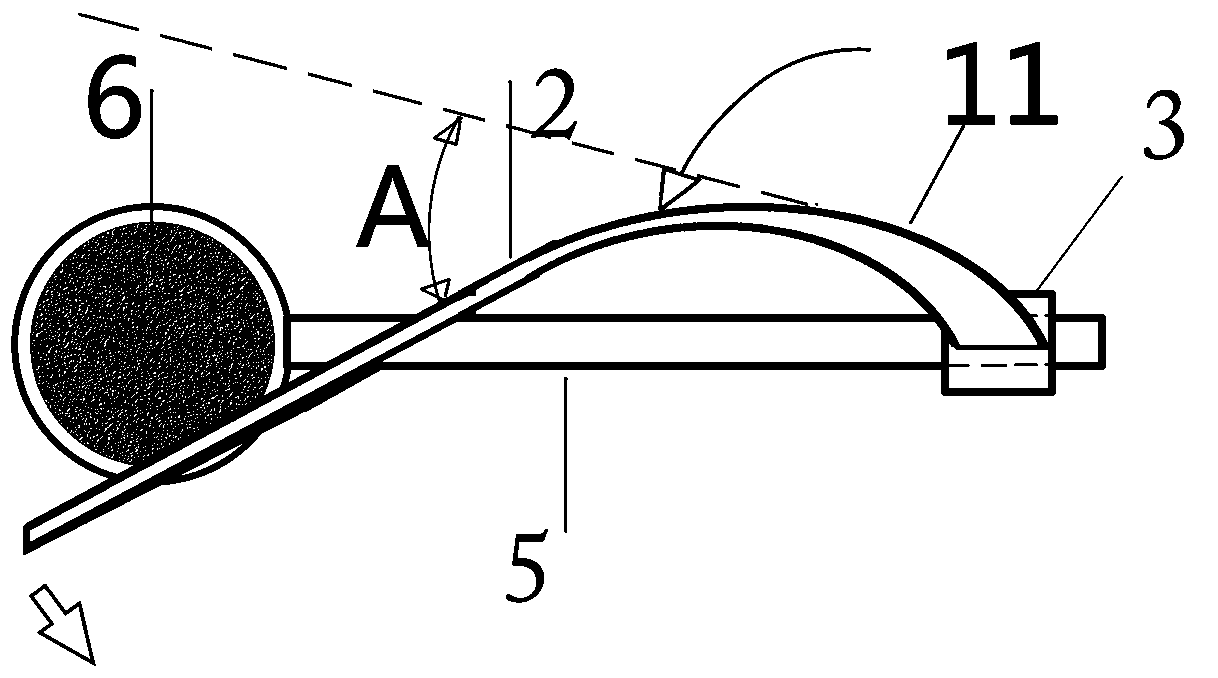

Reinforced high holding power anchor shaft

The invention discloses a reinforced high holding power anchor shaft which is of a symmetrical frame structure with the vertical axis as the symmetric axis. The reinforced high holding power anchor shaft comprises a left side plate, a right side plate and transverse ribs, wherein the left side plate and the right side plate are connected through the transverse ribs, the lower end of the left side plate and the lower end of the right side plate are respectively provided with a notch facing outwards, pin holes are formed above the notches, three positioning holes which are formed below each notch are distributed in an arc with the corresponding pin hole as the center, and the transverse ribs are parallel to the connection lines between the centers of the pin holes above the notches in the left side plate and the right side plate and the centers of the leftmost positioning holes below the notches; transverse ribs in another direction are further arranged on the left side plate and the right side plate, and the transverse ribs are parallel to the connection lines between the centers of the pin holes above the notches in the left side plate and the right side plate and the centers of the rightmost positioning holes below the notches. According to the reinforced high holding power anchor shaft, due to the fact that the transverse ribs in the two directions are arranged, the bearing capacities of the high holding power anchor shaft when the high holding power anchor shaft works at three different angles are almost the same, the strength of the high holding power anchor shaft is improved, and positioning requirements of different geological sea floors are met.

Owner:江苏扬远重工科技有限公司

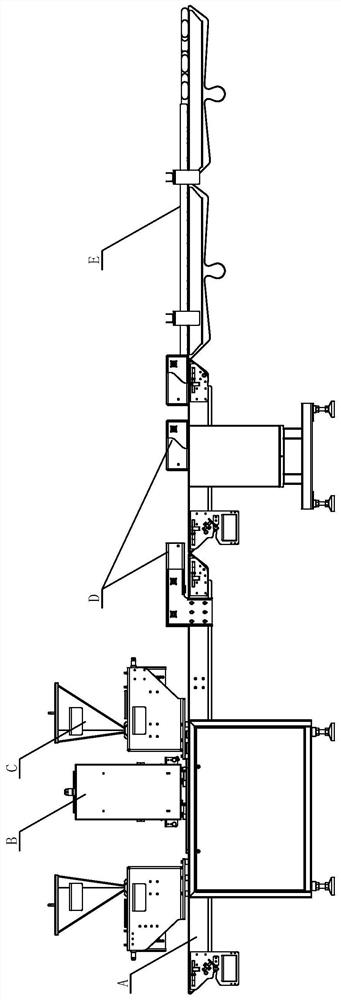

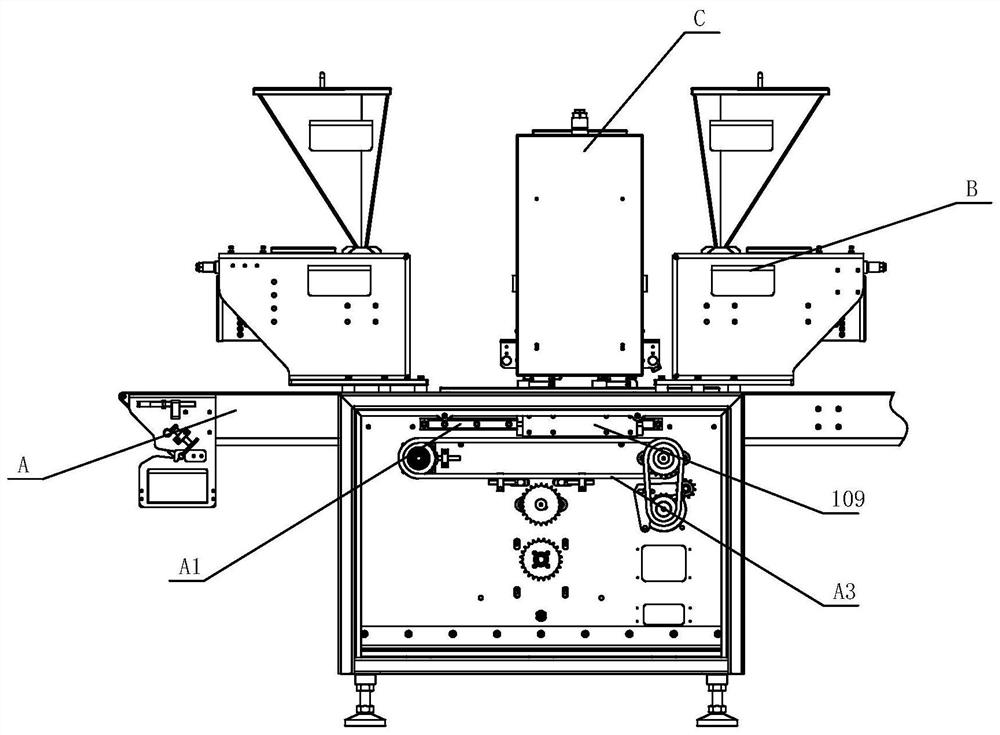

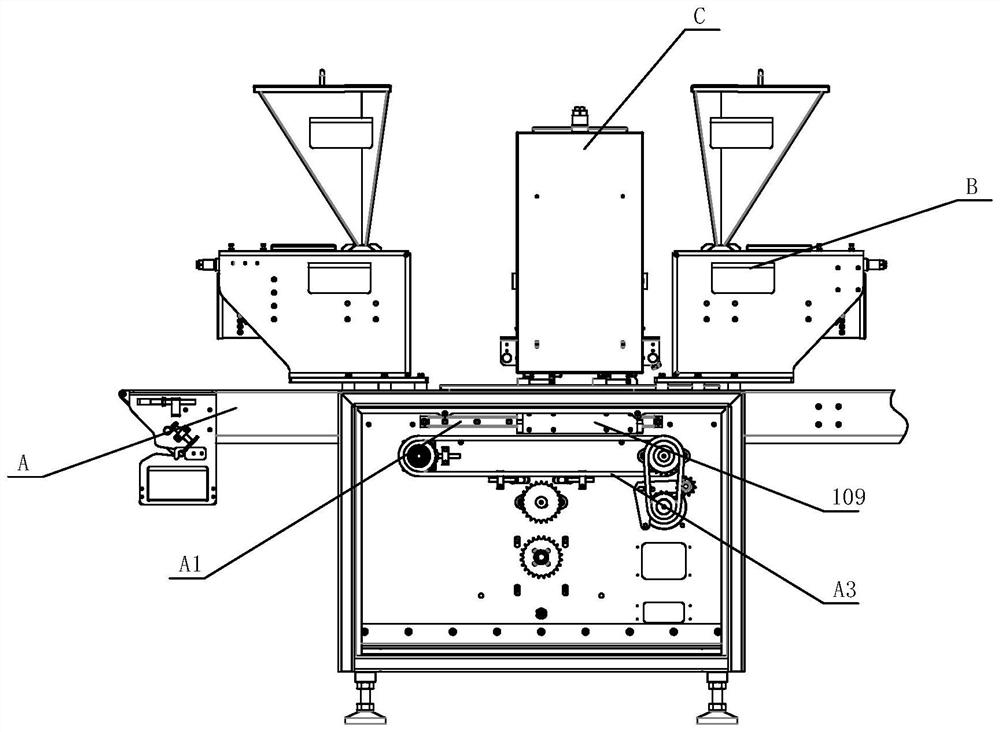

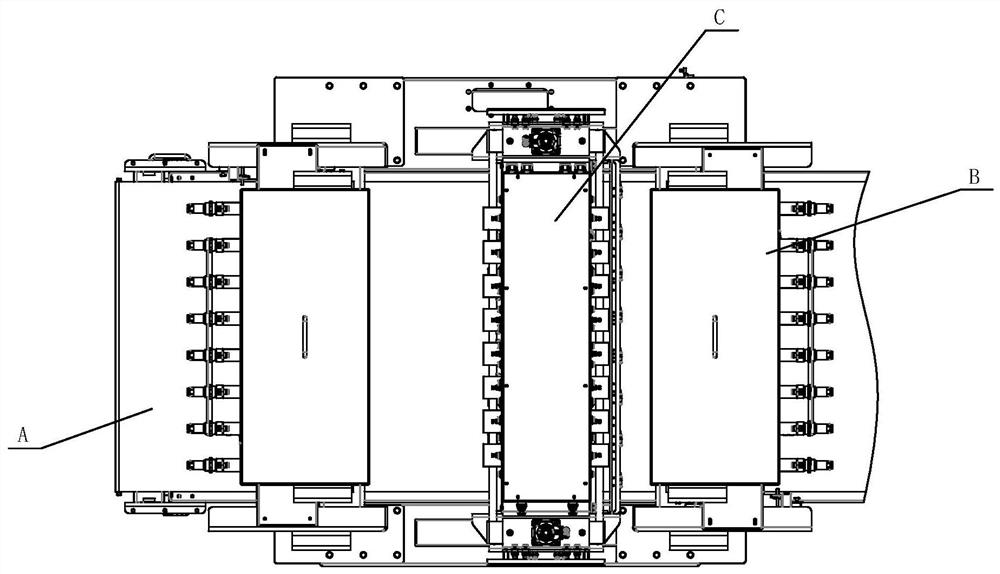

Fully automatic multiple adjustable fluid filler injecting production equipment and filler injecting technology

InactiveCN111670924AImprove machining accuracyHigh degree of automationFood coatingProgramme control in sequence/logic controllersProcess engineeringMechanical engineering

The invention discloses fully automatic multiple adjustable fluid filler injecting production equipment and a filler injecting technology. The filler injecting production equipment comprises a longitudinal queue material adjusting device, a horizontal queue material adjusting device and a filler injecting machine from an input end to an output end, wherein the longitudinal queue material adjustingdevice comprises a dividing device for dividing fed foods into longitudinal queues to be conveyed, the horizontal queue material adjusting device comprises a dividing device for dividing the foods ineach longitudinal queue to enable the foods to be aligned horizontally with the foods in the adjacent longitudinal queues, the filler injecting machine comprises a conveying table of the filler injecting machine, a food filler pumping device, and a food filler injecting device, the conveying table is used for conveying foods to be processed, the food filler pumping device pumps out a filler in the hopper and supplies the filler to the food filler injecting device, and the food filler injecting device is arranged on the conveying table for filler injection on the foods; and the food filler injecting device is provided with a movable driving device for driving the food filler injecting device to simultaneously move along with the conveyer belt of the conveying table while performing fillerinjecting. Full automation is adopted for filler injection on the conveyed foods, so that the working precision and the working efficiency can be improved.

Owner:嘉兴恒匠智能技术有限公司

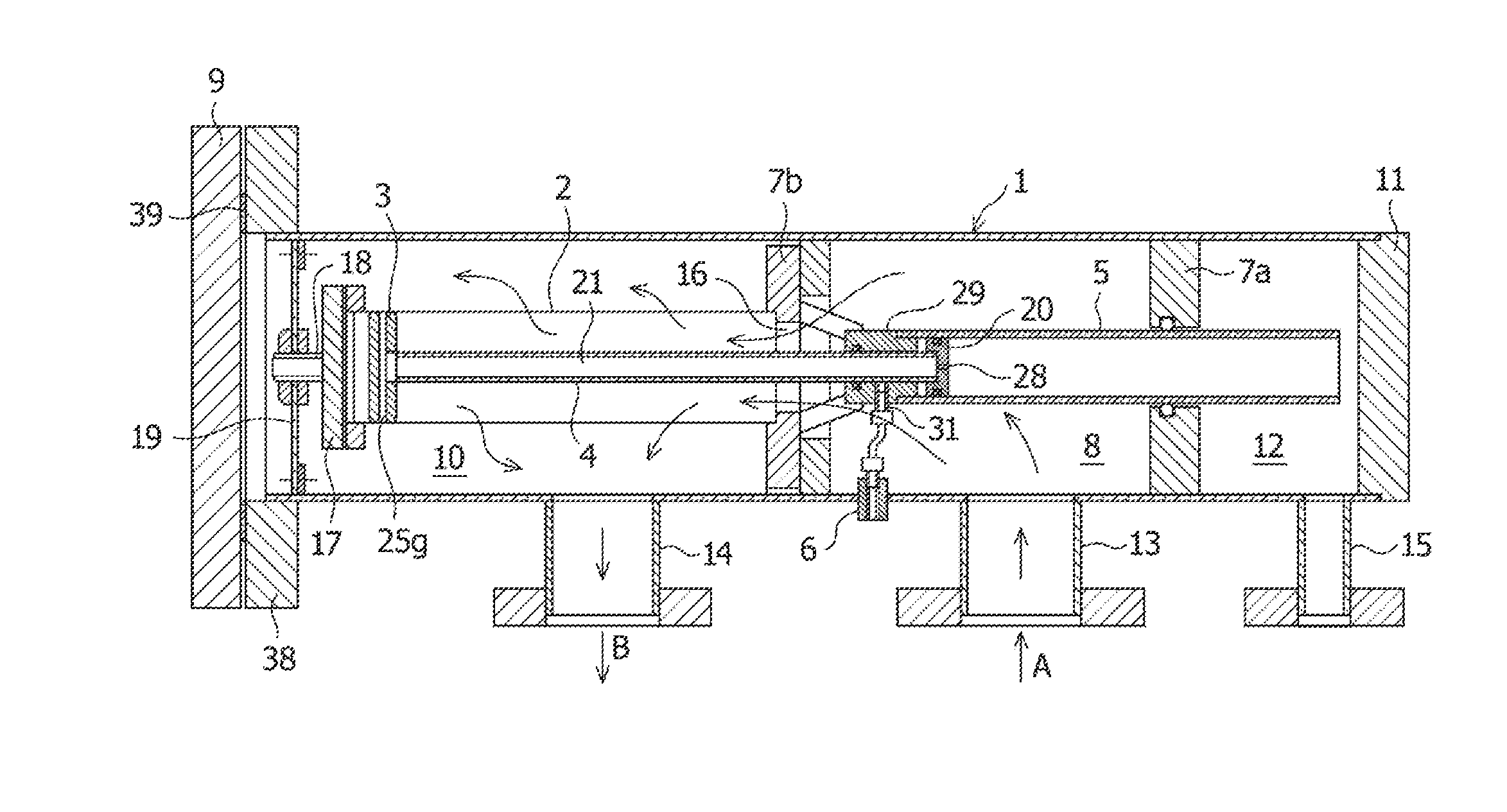

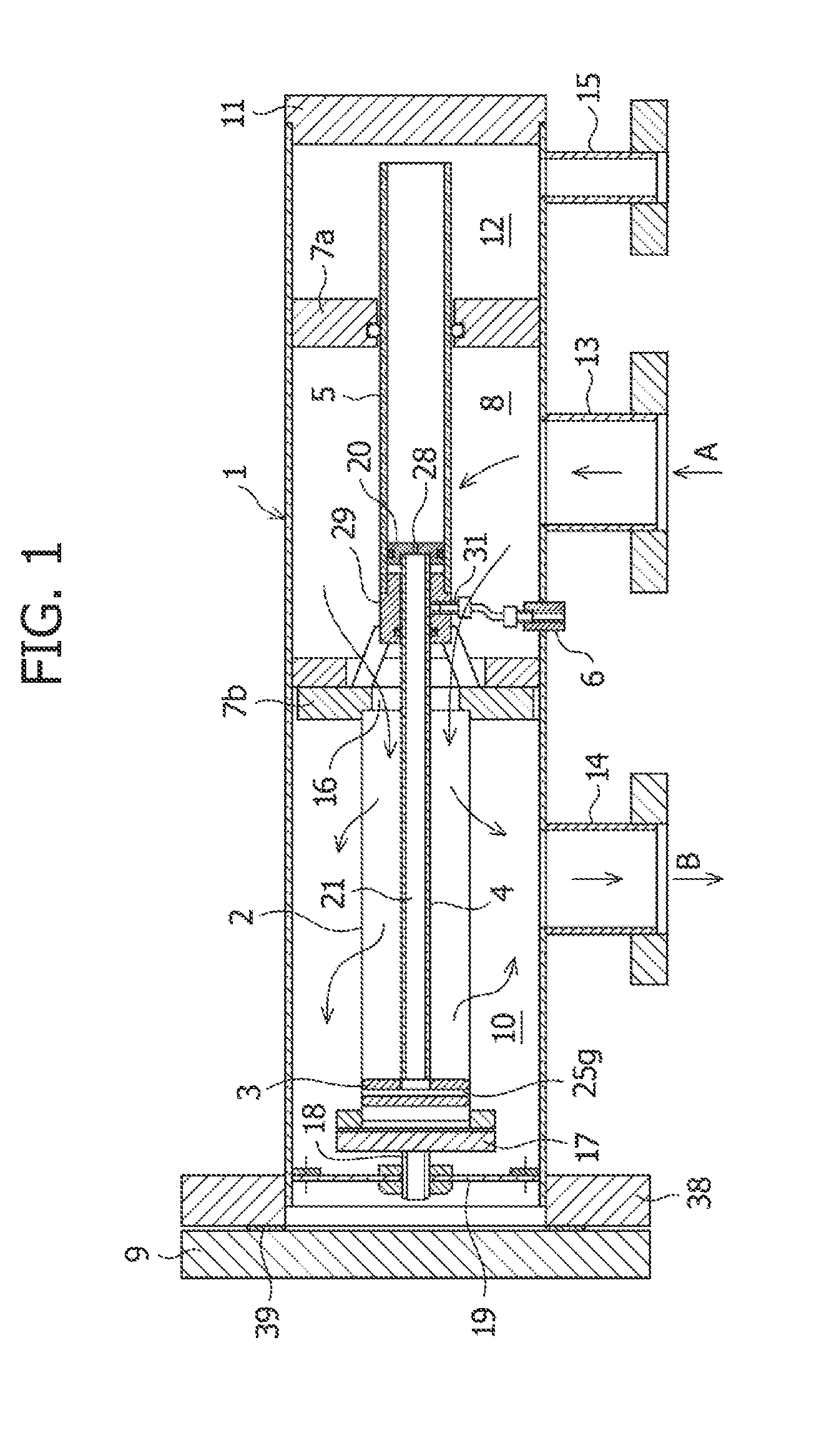

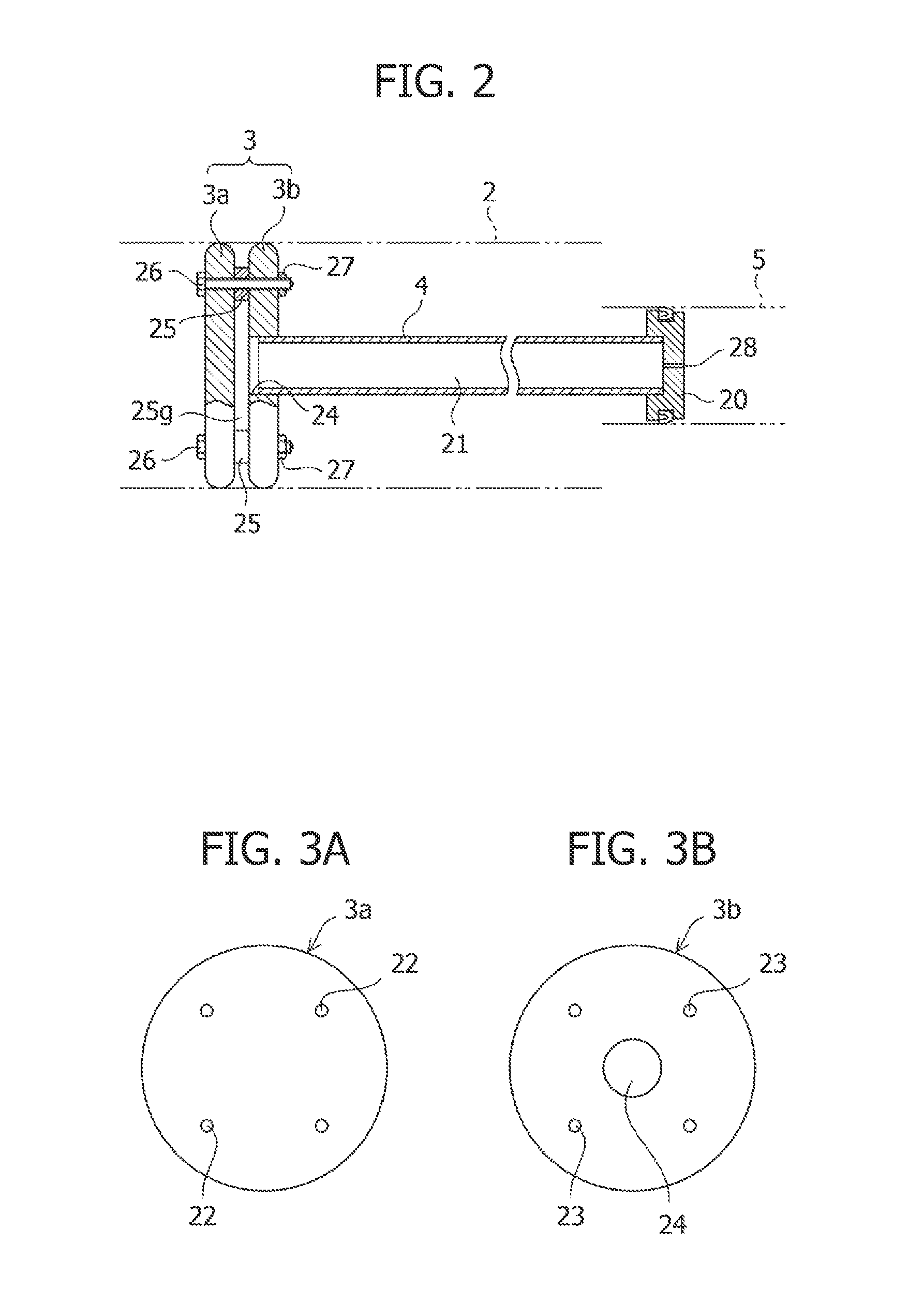

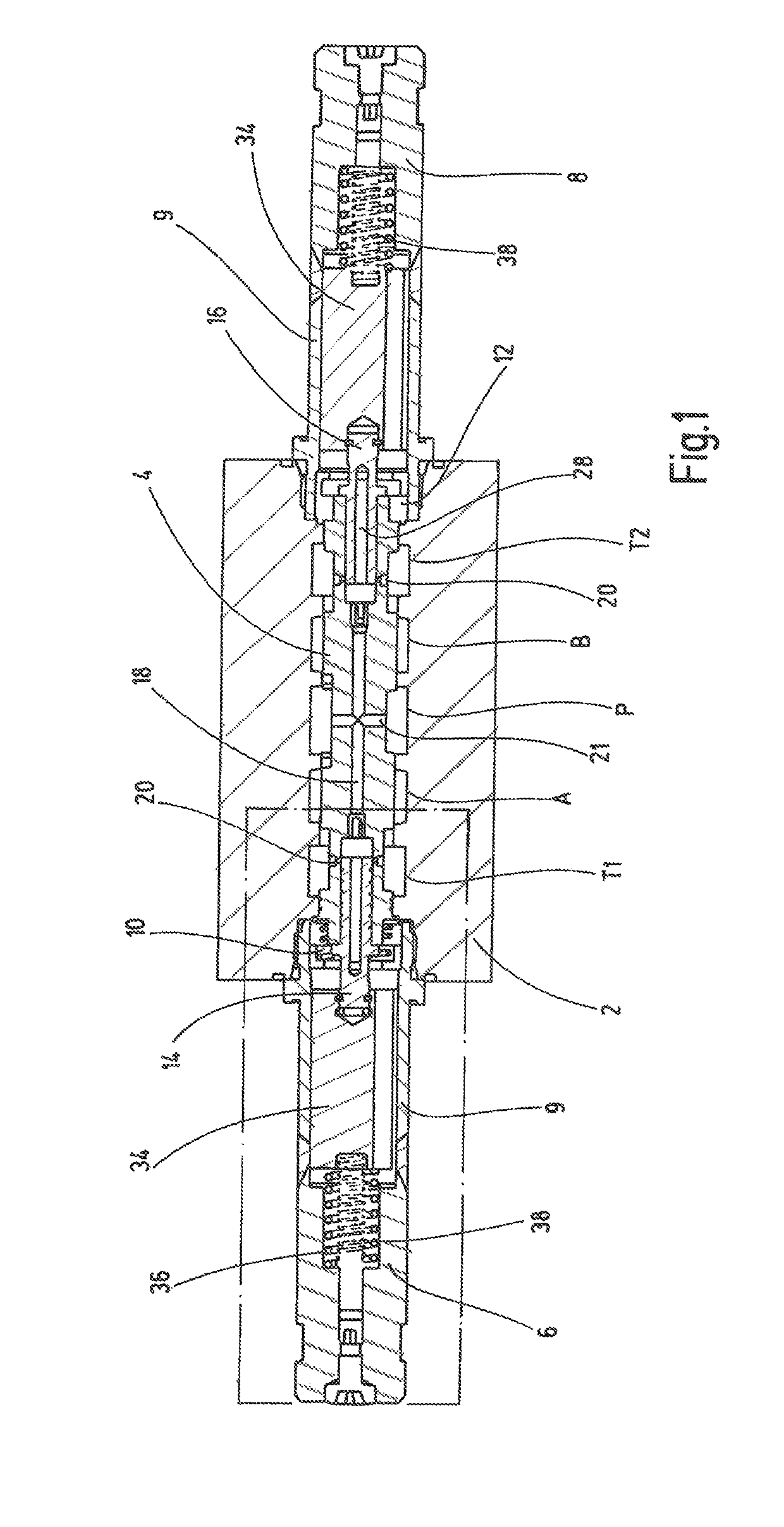

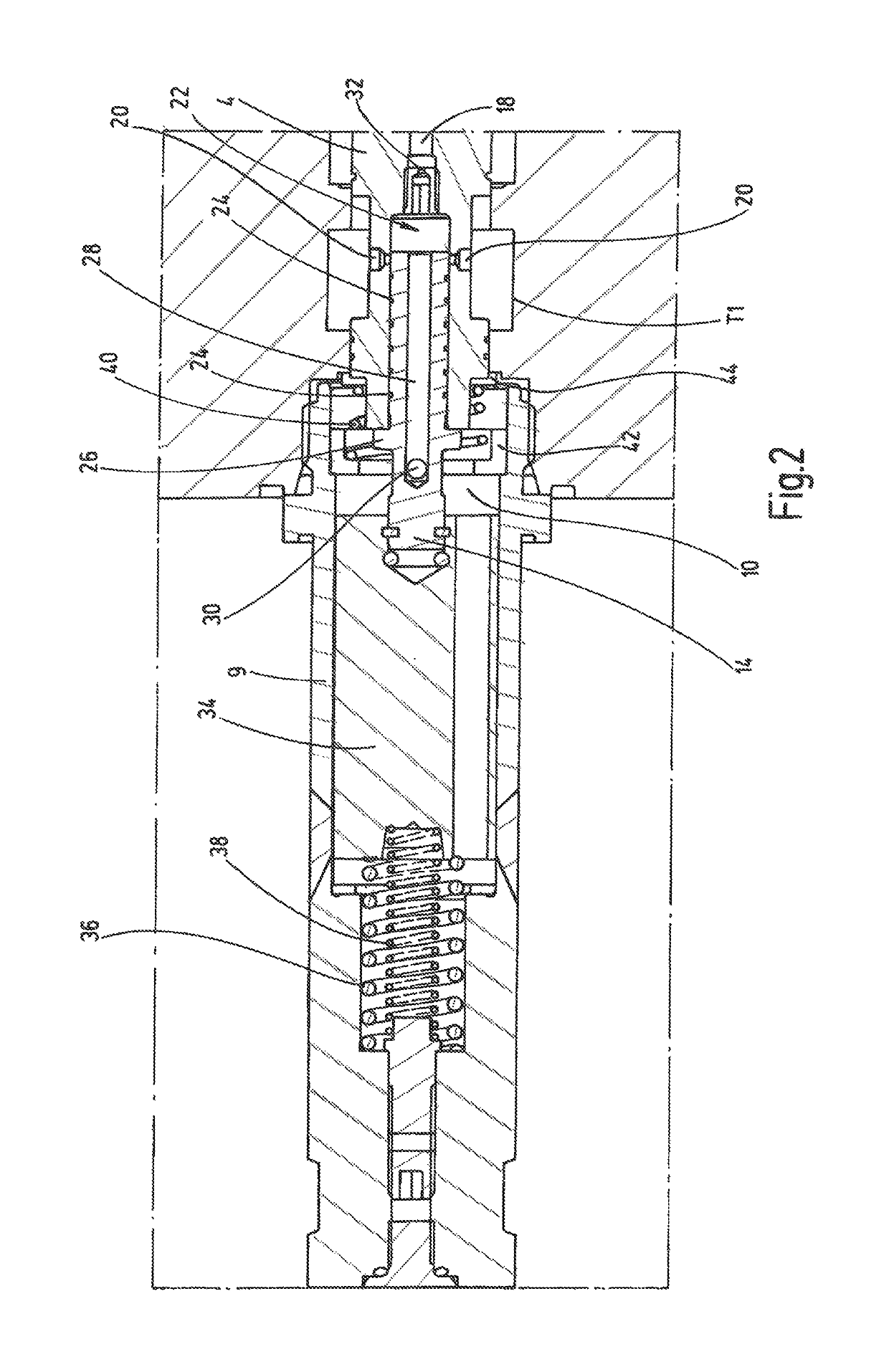

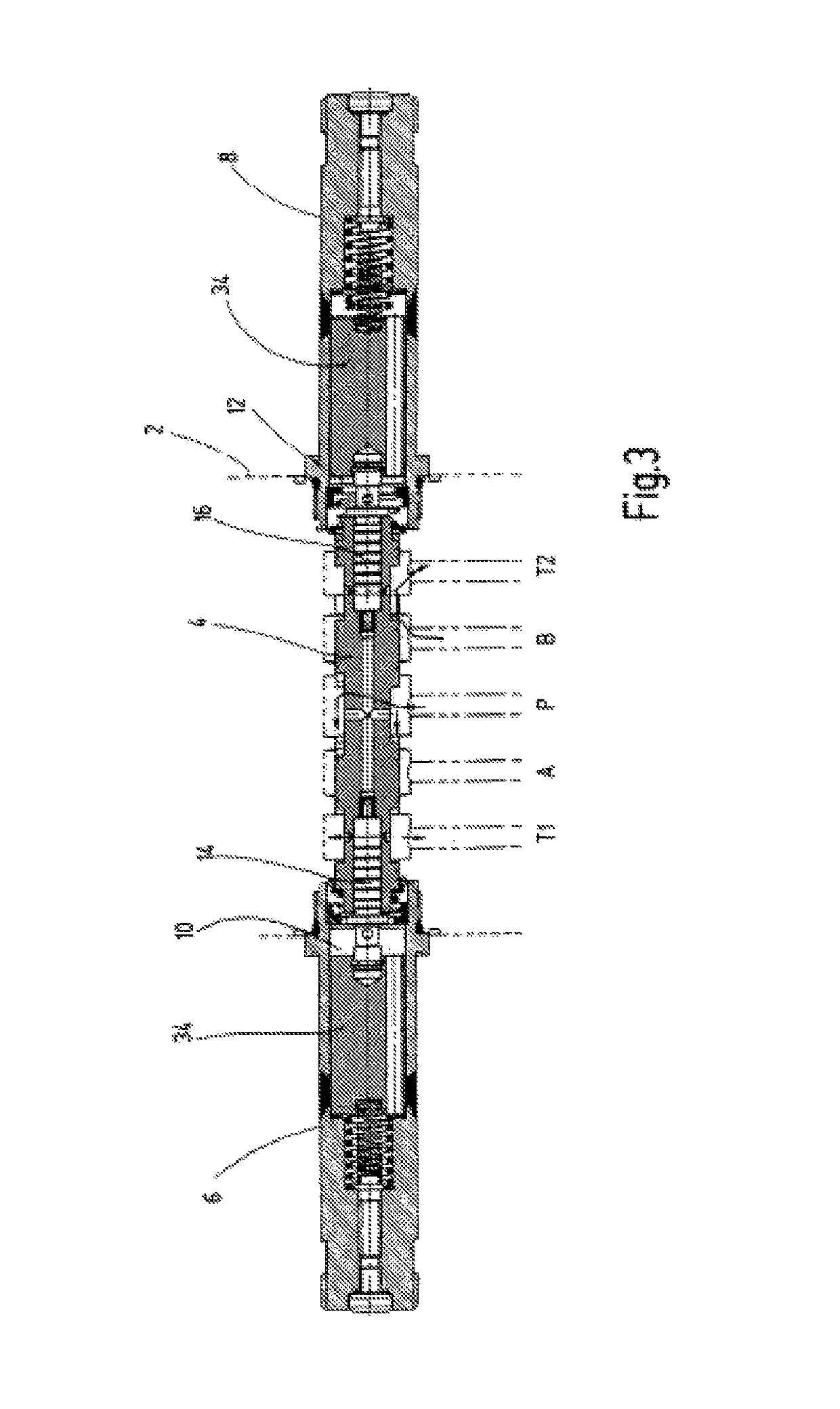

Valve device

ActiveUS10458556B2Improve performanceReduce design sizeOperating means/releasing devices for valvesMultiple way valvesFuel tankEngineering

A valve device has a valve housing and a main piston (4) arranged in an axially slidable manner in a piston bore of the valve housing (2). A first consumer connection (A) and a second consumer connection (B) can be alternately connected to a pressure connection (P) and a tank connection (T1, T2) by the action of a first magnetic actuating system (6) and a second magnetic actuating system (8) with two pilot pistons (14, 16). In an actuated state of the respective pilot piston (14, 16), the main piston (4) follows the movement of the pilot piston (14, 16) due to the force ratio adjusting itself to actuate the fluid-carrying connection between the pilot chamber (10, 12) of the pilot piston (14,16) and the assignable tank connection (T1, T2) such that pilot oil flows.

Owner:HYDAC FLUITECHNIK GMBH

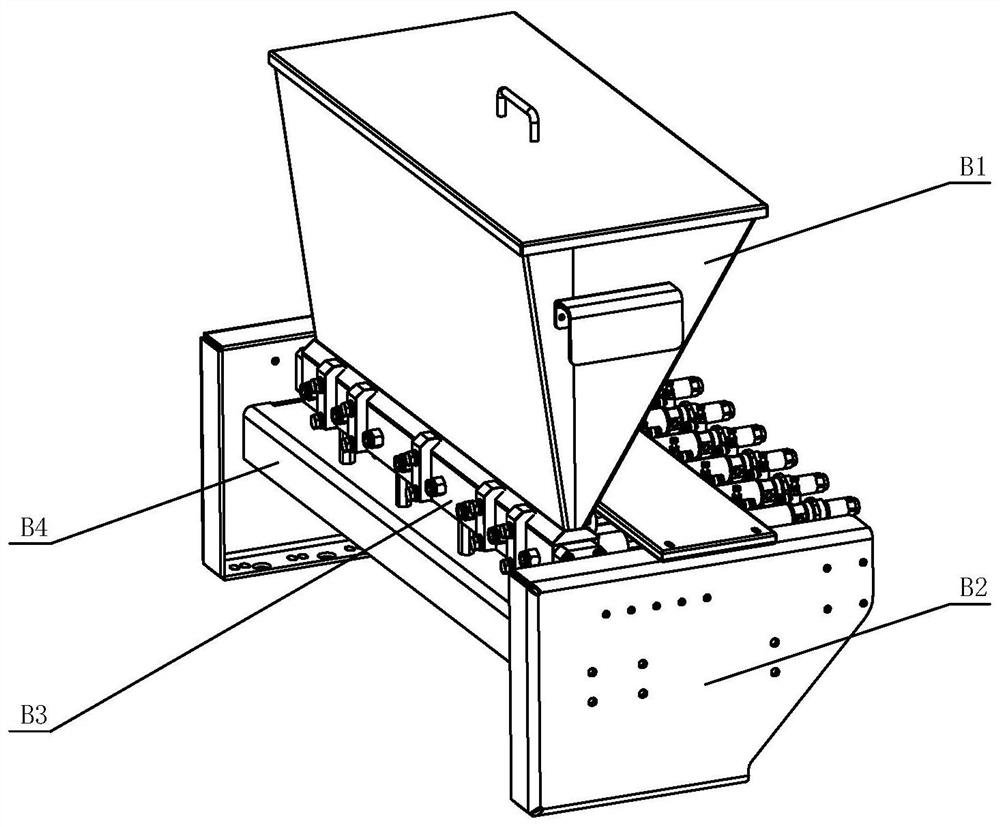

Multigang adjustable fluid filling machine and filling technology

InactiveCN111671114AImprove machining accuracyHigh degree of automationFood coatingDough processingBiotechnologyEngineering

The invention discloses a multigang adjustable fluid filling machine and a filling technology. The multigang adjustable fluid filling machine comprises a conveyer table, food filling extraction devices and a food filling device, wherein the multigang adjustable fluid filling machine is characterized in that the conveyer table is used for conveying to-be-processed food; the food filling extractiondevices extract fillings in a hopper and supply the fillings to the food filling device; the food filling device is arranged at the upper part of the conveyer table to fill the food; the food fillingdevice is provided with a mobile drive device; and the mobile drive device drives the food filling device to follow a conveyer belt of the conveyer table to synchronously move while filling. Accordingto the multigang adjustable fluid filling machine, an automation form is adopted, the food filling extraction devices extract the fillings in the hopper and push the fillings into the food filling device by adopting an extract-push mode, and automatic filling work is carried out on the conveyed food, so that the working accuracy and the working efficiency are improved.

Owner:嘉兴恒匠智能技术有限公司

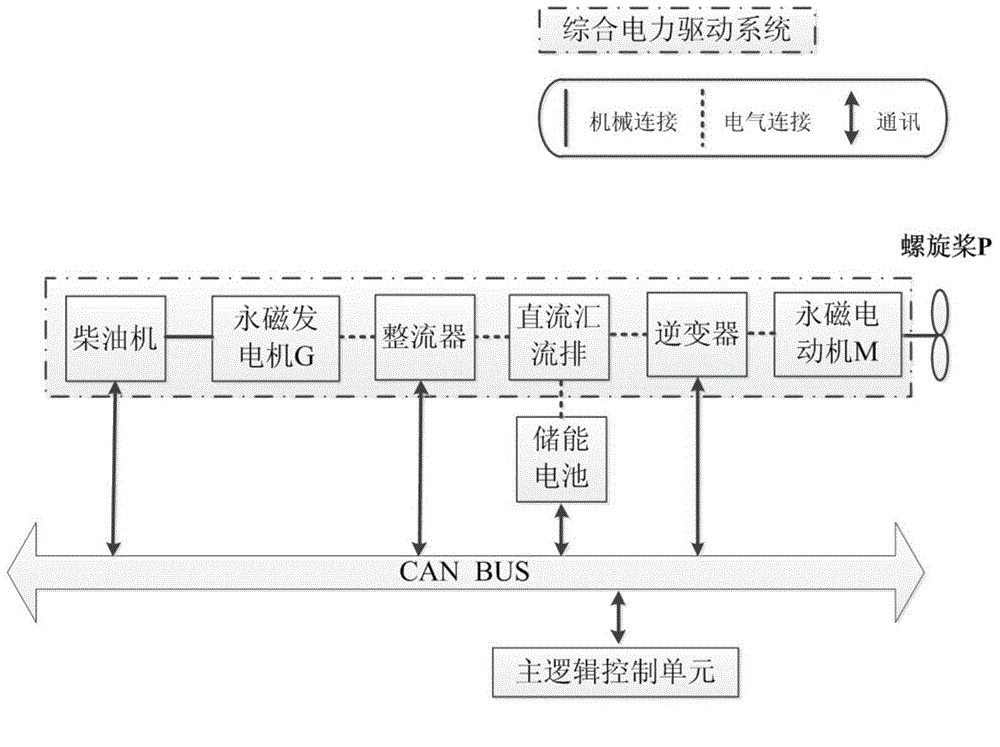

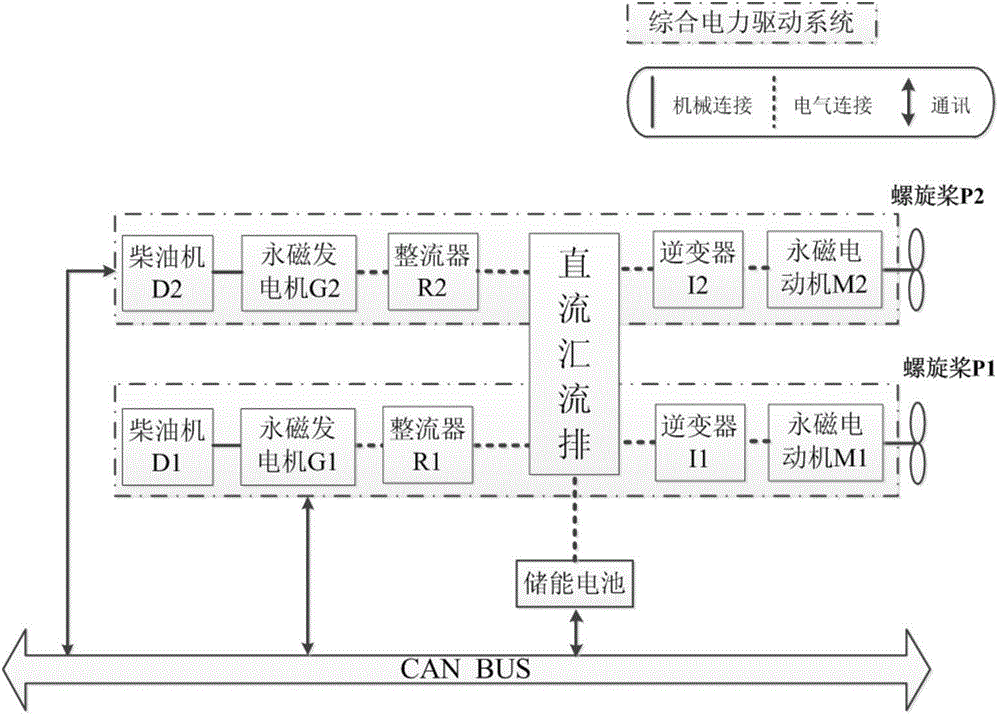

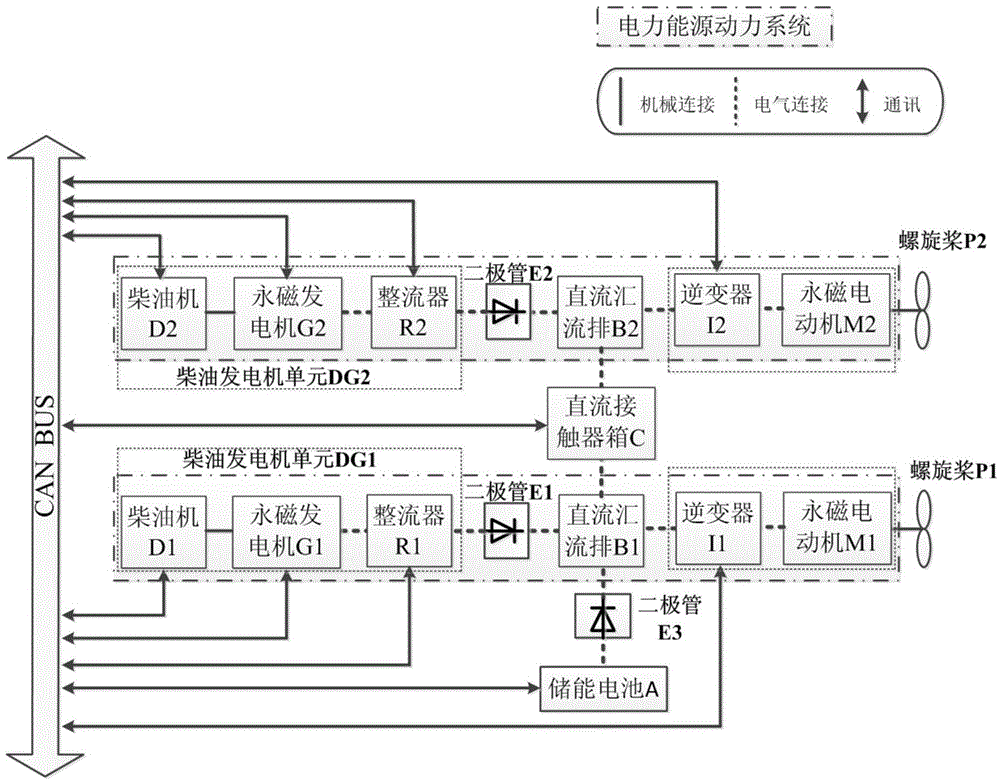

Electric energy power system for full electric propulsion ship

InactiveCN104890848AImprove operational efficiencyImprove operational reliabilityPropulsion power plantsPropulsive elementsBusbarElectrical battery

The invention discloses an electric energy power system for a full electric propulsion ship. The system comprises two single-machine energy power systems and a direct-current contact box (C), wherein the two single-machine electric energy power systems share one energy storage battery (A); the energy storage battery (A) is connected with a first direct-current confluence busbar (B1) of the first single-machine energy power system in parallel; the positive pole of the first direct-current confluence busbar (B1) is connected with the input end of a direct-current contactor (C); the output end of the direct-current contactor (C) is connected with the positive pole of a second direct-current confluence busbar (B2) of the second single-machine energy power system; and the negative pole of the first direct-current confluence busbar (B1) is connected with the negative pole of the second direct-current confluence busbar (B2) to form a double-machine parallel system.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Through-type same-phase traction power supply system, traction substation and power supply control method thereof

ActiveCN109050352BImprove power supply reliabilitySame capacityPower supply linesPower gridTraction power supply

The invention relates to the technical field of electric power control, in particular to a through-type in-phase traction power supply system, a traction substation and a power supply control method thereof, aiming at solving the technical problem of how to reliably supply power to an electric locomotive. To this end, the present invention provides a traction substation comprising a plurality of electrical energy conversion devices. In particular, the electric energy conversion device comprises a single-phase transformer and an electric energy converter, The high-voltage winding of each single-phase transformer is respectively connected with two different phase wires in a preset power network, the low-voltage winding of each single-phase transformer is connected with an input side port ofa corresponding electric energy converter, and the output side port of each electric energy converter is respectively connected with a preset contact line and a preset rail. Based on the structure, the traction substation can also rely on other electric energy conversion devices to continuously supply a continuous supply voltage to the catenary with a constant voltage amplitude and phase when partof the electric energy conversion device fails. The power supply system of the present invention comprises the traction substation.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI +2

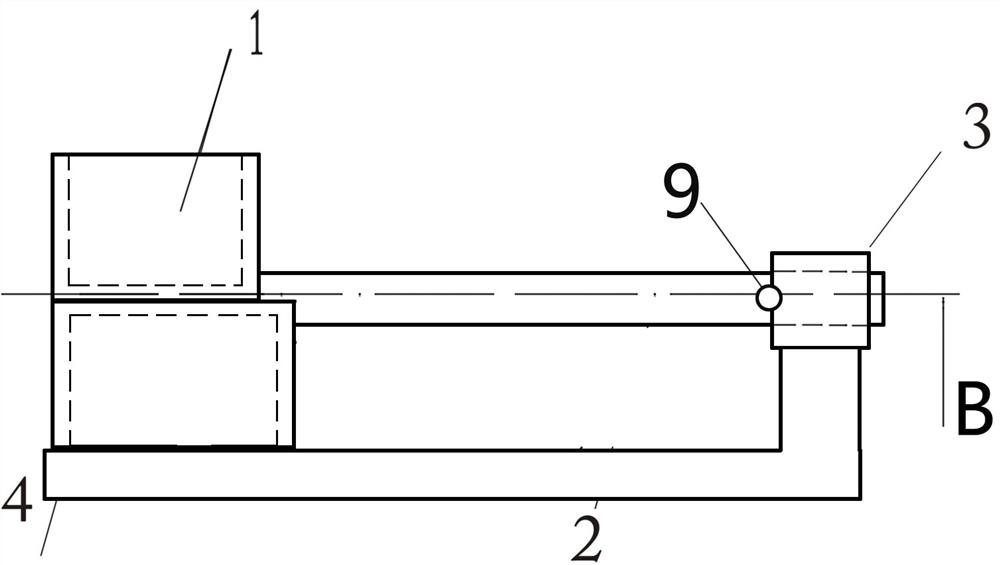

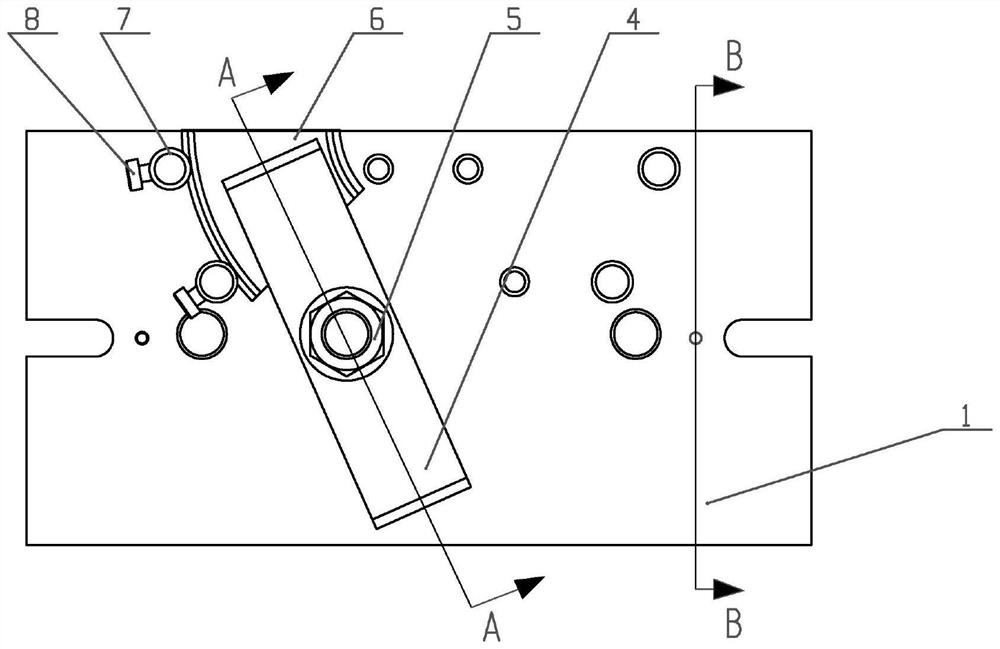

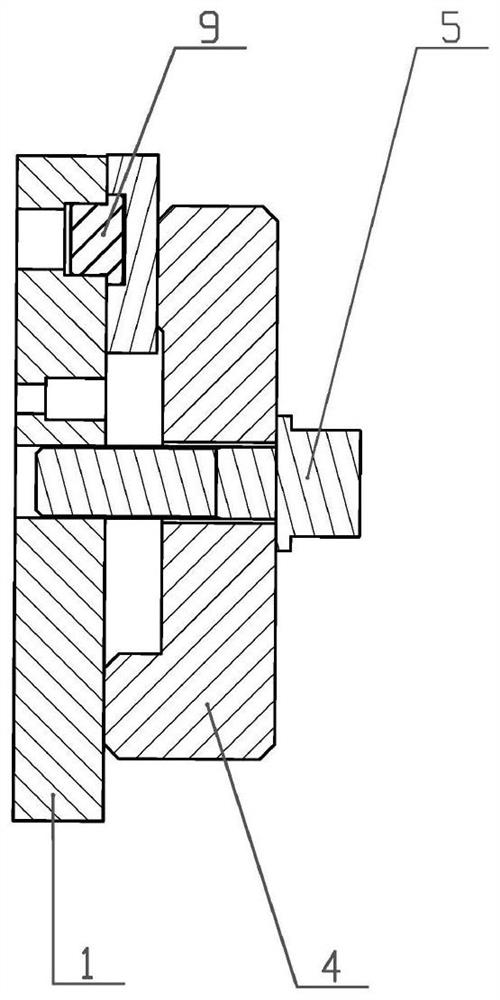

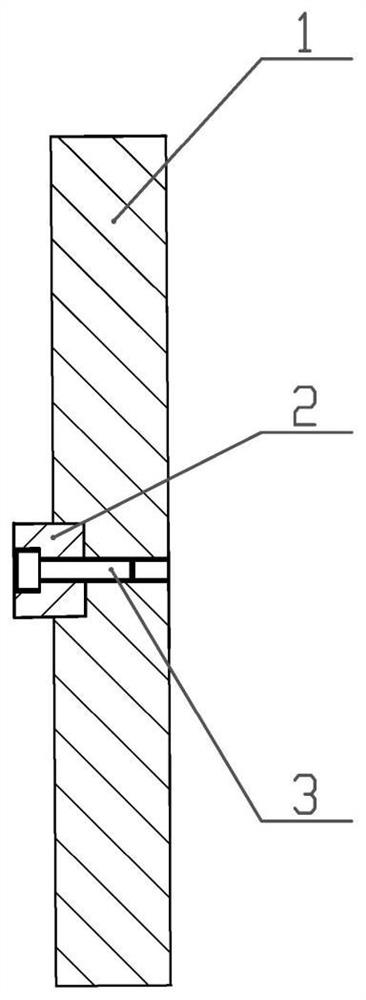

Measuring Method of Balanced Measuring Container

ActiveCN111272253BRealize the use of different capacitiesSame capacityVolume measurement apparatus/methodsControl engineeringMechanical engineering

Owner:周林斌

Processing technology of thrust pad base of shield motor

PendingCN114309739AMeet assembly needsGuaranteed uptimeMeasurement/indication equipmentsMilling equipment detailsElectric machineryEngineering

The invention relates to a machining process for a thrust pad base of a shielding motor, which comprises the following steps of: positioning and clamping the thrust pad base by adopting a positioning tool, machining a plane on one side, adjusting the position of the thrust pad base after machining the plane on one side, re-positioning the position of the clamping tool, and machining the plane on the other side. Thrust pad base space angle size machining is completed on the same clamping mould. The thrust pad base can be machined on the same positioning fixture, the angle size and tolerance required by a drawing are guaranteed, the subsequent assembly problem caused by the fact that the space size cannot be measured is avoided, and meanwhile the problem that alignment cannot be achieved after clamping is solved.

Owner:HARBIN ELECTRIC POWER EQUIP

Metering method of metering container

InactiveCN111426362ARealize the use of different capacitiesConsistent capacityContainer/cavity capacity measurementMechanical engineeringIndustrial engineering

The invention provides a metering method of a metering container. The metering container comprises two capacity parts with different sizes and handles, and two capacity part openings which are swept to be flat are formed. The metering method comprises the steps of enabling openings of two capacity parts to transversely sweep each other: correspondingly arranging openings of the two capacity partsin a staggered manner, wherein handles are arranged on the peripheries of the two capacity parts, the handles are elastically connected to achieve relative transverse sweeping movement of openings ofthe two capacity parts; and generating capacity consistency of the capacity parts: sweeping accumulated objects at the openings of the lower capacity parts to be flat at the upper capacity part, so that the volumes of the accumulated objects at the lower capacity part are consistent each time; and setting different capacities of the capacity parts: respectively setting different capacities of thefirst capacity part and the second capacity part, wherein the openings of the first capacity part and the second capacity part are used in two directions facing upwards or downwards for different capacities. The two different capacity parts are additionally arranged to achieve the effect of respective use, and the working efficiency of the product is improved.

Owner:周林斌

Wearable smart device

ActiveUS10959467B2Reduce conductivitySame capacityCircuit bendability/stretchabilityNon-conductive material with dispersed conductive materialElectrical conductorEngineering

The present invention provides to a wearable smart device having electrical wiring comprising a stretchable conductive composition having excellent in durability such as repeated bending properties and repeated twisting properties, a material for realizing the wearable smart device, and a method for producing the wearable start device.An electrical wiring including a fine line having an electrical line interval of 1 mm or less, preferably the line width of less than 1 mm, is formed by printing a paste for forming a stretchable conductor containing metal-based conductive particles and a non-crosslinked elastomer, and further dried and cured at a low temperature condition of 120° C. for 30 minutes. As a result, the wearable smart device having electrical wiring constituted by fine lines without sagging of the edge is obtained.

Owner:TOYOBO CO LTD

Metering method of balance metering container

ActiveCN111272253ASame capacitySimple structureVolume measurement apparatus/methodsControl engineeringMechanical engineering

According to the metering method of the balance metering container. The balance metering container comprises a first capacity part and a second capacity part, openings of the first capacity part and the second capacity part are oppositely arranged up and down, and a rotating transverse sweeping component is arranged on a handle on the periphery of the capacity parts. The metering method comprisesthe steps that: a transverse sweeping component is positioned at openings of two capacity parts; a rotating transverse sweeping part is arranged on the handle, the transverse sweeping component is rotationally connected with the transverse axis of the handle, the transverse sweeping component switches the positions of the two capacity part openings back and forth, and the capacity part capacity consistency step is generated, specifically, the transverse sweeping component sweeps upward capacity part opening accumulated objects to be flat, so that the volumes of the capacity part accumulated objects are consistent each time, wherein the capacities of the first capacity part and the second capacity part are different, the openings of the first capacity part and the second capacity part are used in two directions with different capacities upwards or downwards, the two different capacity parts are additionally arranged to achieve the effect of respective use, and the working efficiency ofthe product is improved.

Owner:周林斌

A data processing method and device

ActiveCN103488584BSame capacityReduce the risk of lossInput/output to record carriersMemory systemsData miningData loss

The embodiment of the invention discloses a data processing method and device, relates to the field of information technology, and solves the problem that data is easily lost when the thin pool is full. The specific solution is: judge whether the data area of the thin pool is full, and if the data area is full, store the data in the cache in the page reserved area in the form of pages. The invention is used for data processing.

Owner:HUAWEI TECH CO LTD

Lithium secondary battery of high power property with improved high energy density

ActiveUS9385372B2Same capacityEnhanced high-output characteristic and long lifespan characteristicActive material electrodesLi-accumulatorsElectrical batteryHigh energy

A high-output lithium secondary battery is provided. In some embodiments, the lithium secondary battery includes a cathode having a first cathode active material having a layered structure and. a second cathode active material having a spinel structure, wherein the-amount of the second cathode active material is between 40 and 100 wt % based on the total weight of the cathode active materials, an anode including crystalline graphite having a specific surface area (with respect to capacity) of 0.005 to 0.013 m2 / mAh as an anode active material, and a separator.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com