Patents

Literature

108results about How to "Improve backwash efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

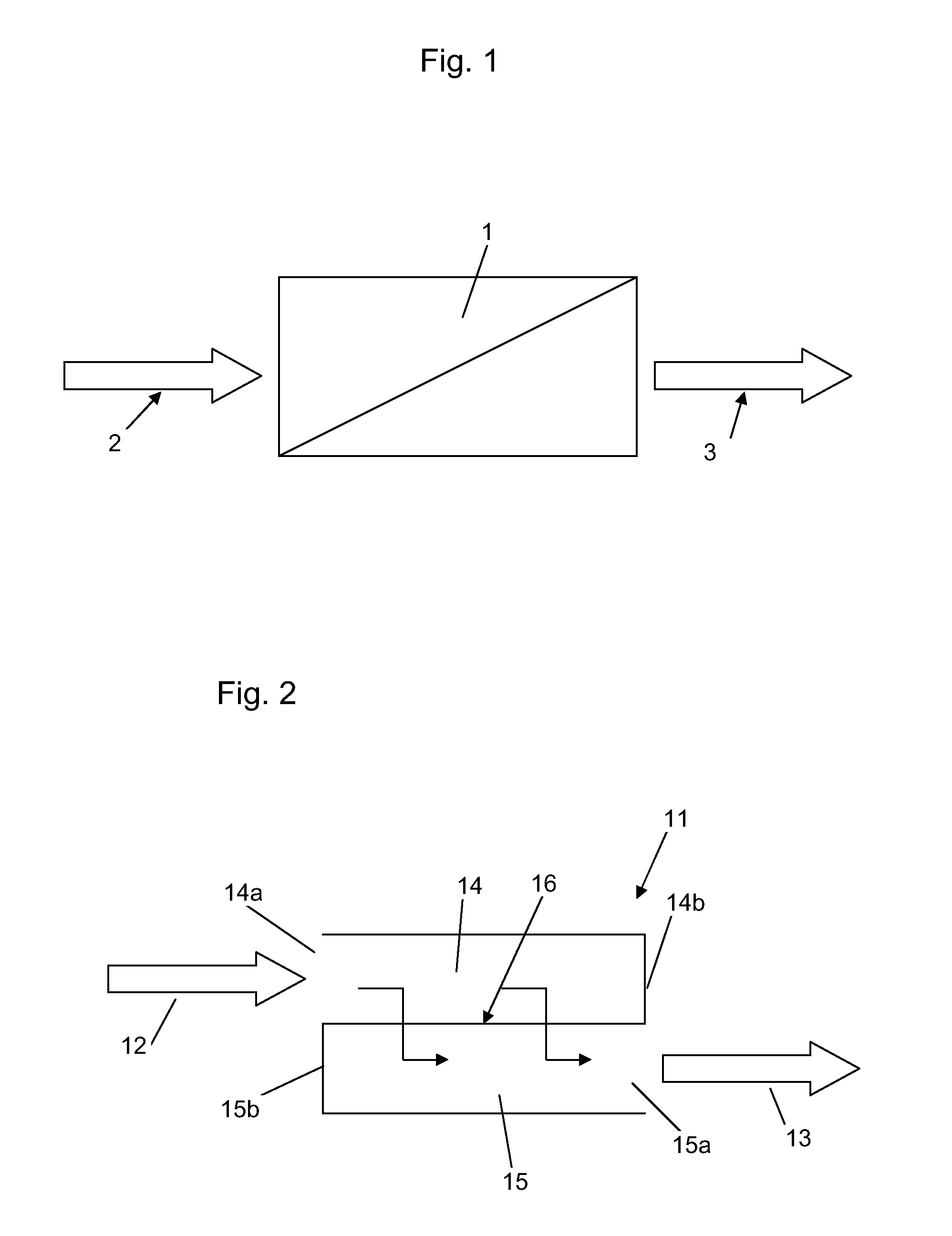

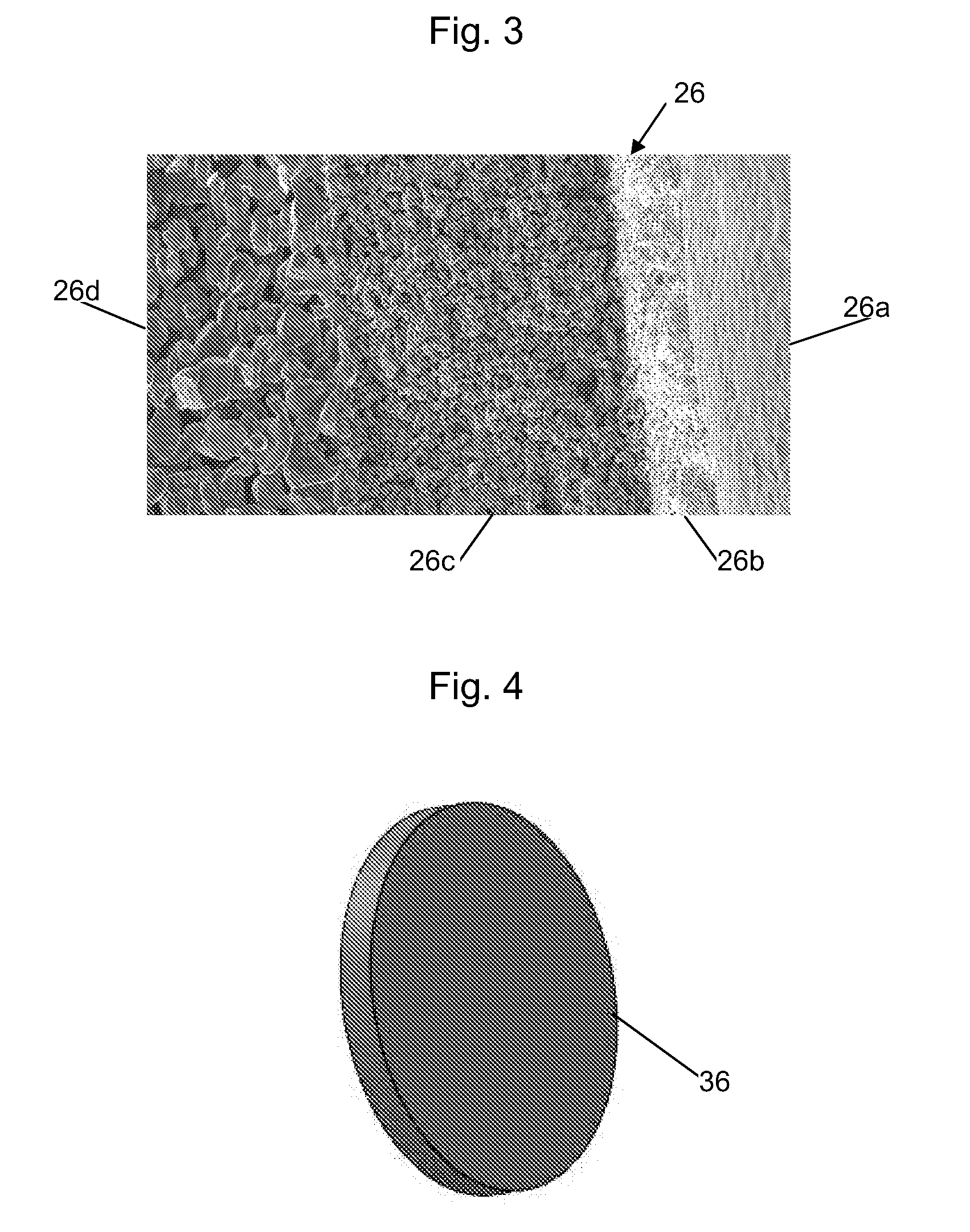

Ceramic dead-end filter, a filter system, a method of filtering and a method of producing a ceramic dead-end filter

InactiveUS20110100910A1Improve backwash efficiencyHigh liquid fluxSemi-permeable membranesMembranesMetallurgyHigh flux

The invention relates to a ceramic dead-end filter for filtration of liquid. The ceramic dead-end filter comprises at least one ceramic filter membrane having a first side with a front surface and a second side. The ceramic membrane comprises a selective front layer providing said front surface and the selective front layer comprises a maximum pore size diameter of about μm or smaller, for example between about 0.5 nm and about 25 μm. The ceramic dead-end filter of the invention provides an effective filtration with a high flux and a long durability. The filter can furthermore be regenerated in a simple way. The invention also relates to filtration system comprising such ceramic dead-end filter, a method of performing the filtration process as well as a method of producing the filter.

Owner:COMETAS

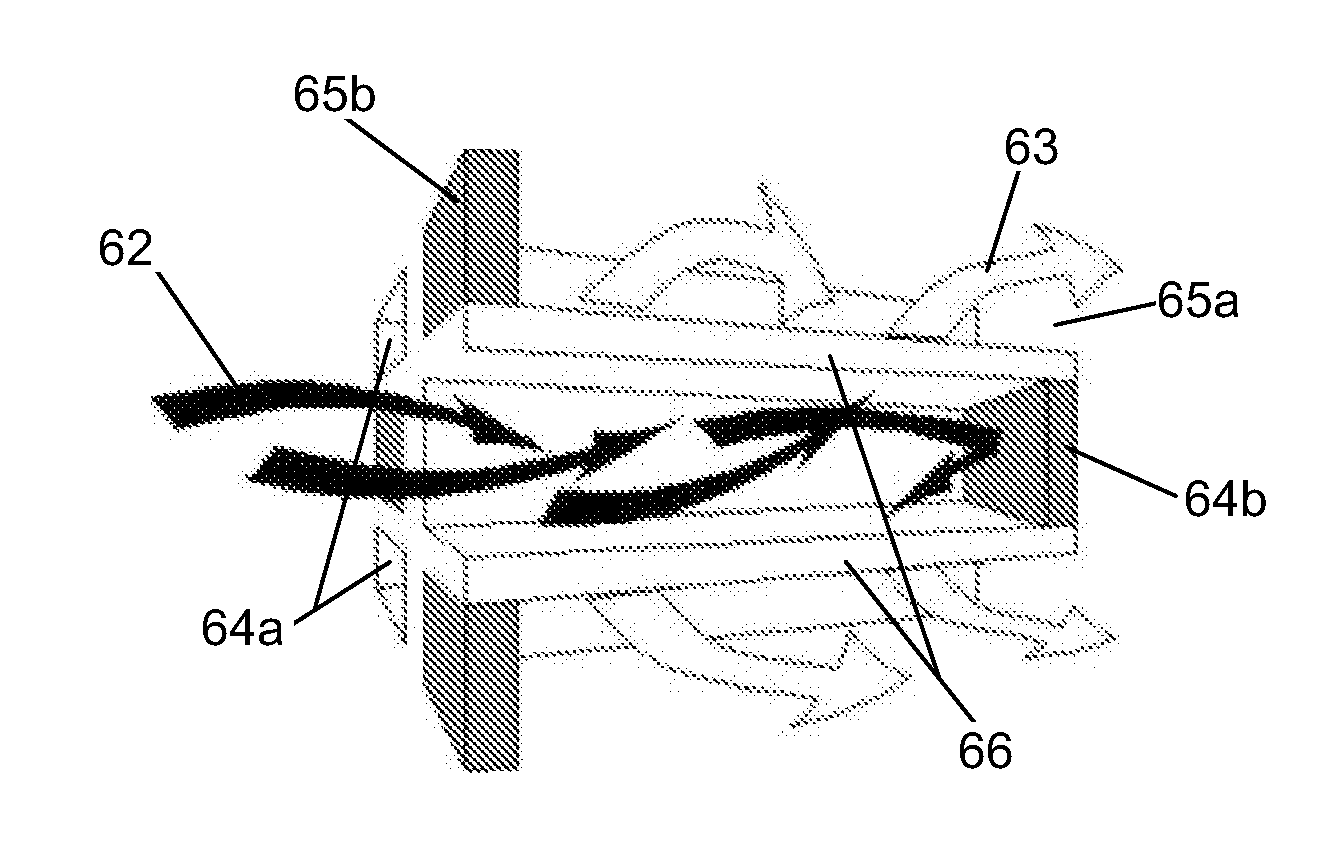

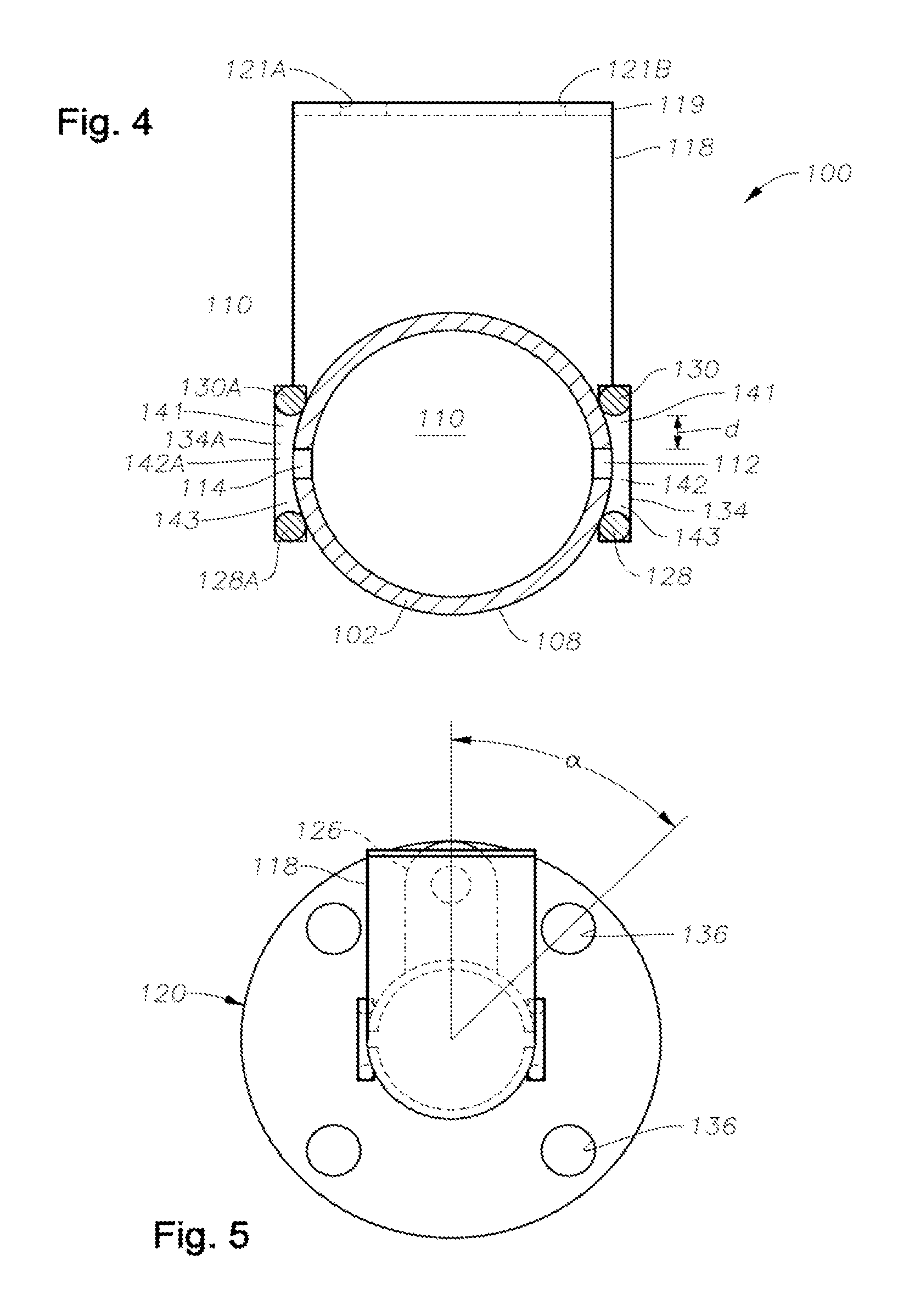

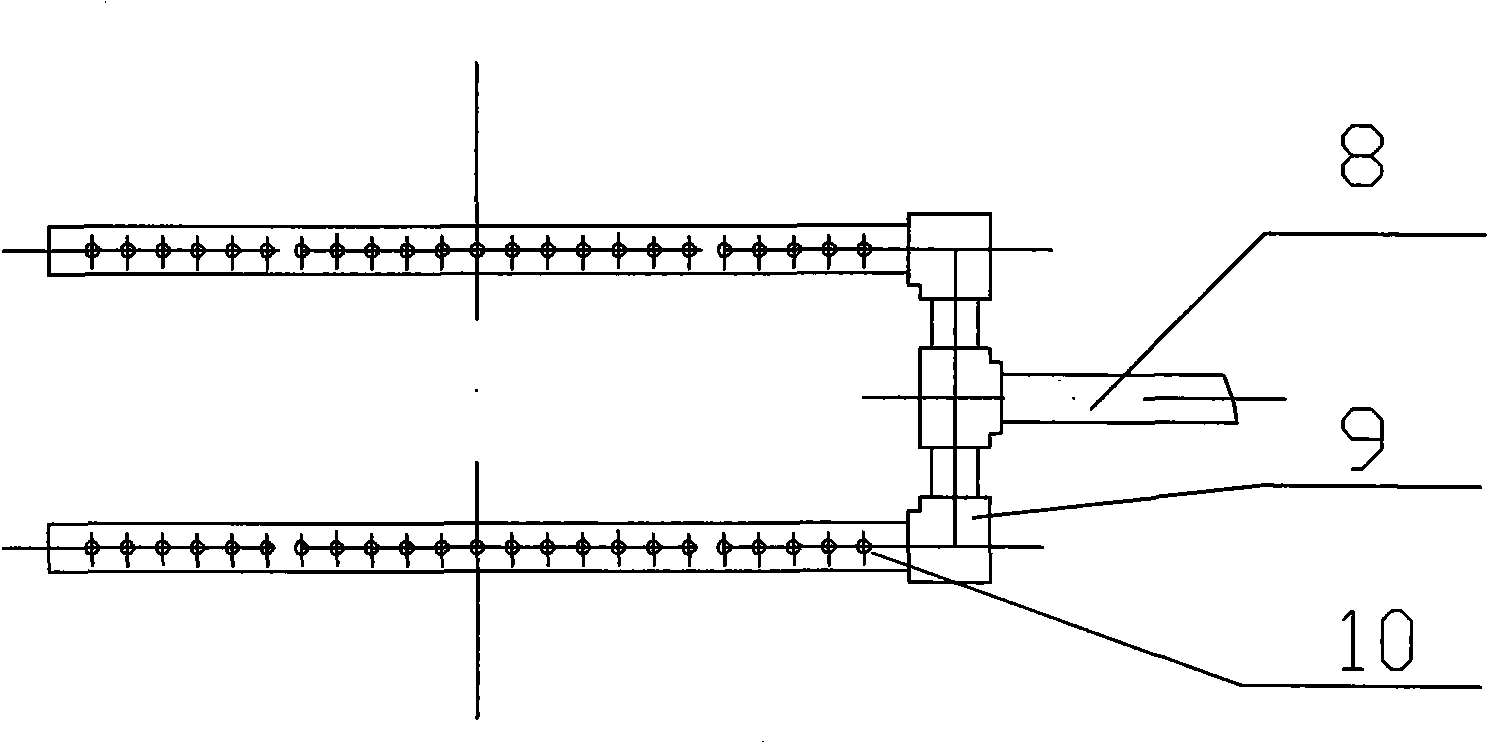

Methods and apparatus for treating water and wastewater employing a cloth disk filter

ActiveUS20130105415A1Reduce and overcome deficiencyImprove backwash efficiencyWater/sewage treatmentMembrane filtersWastewaterEngineering

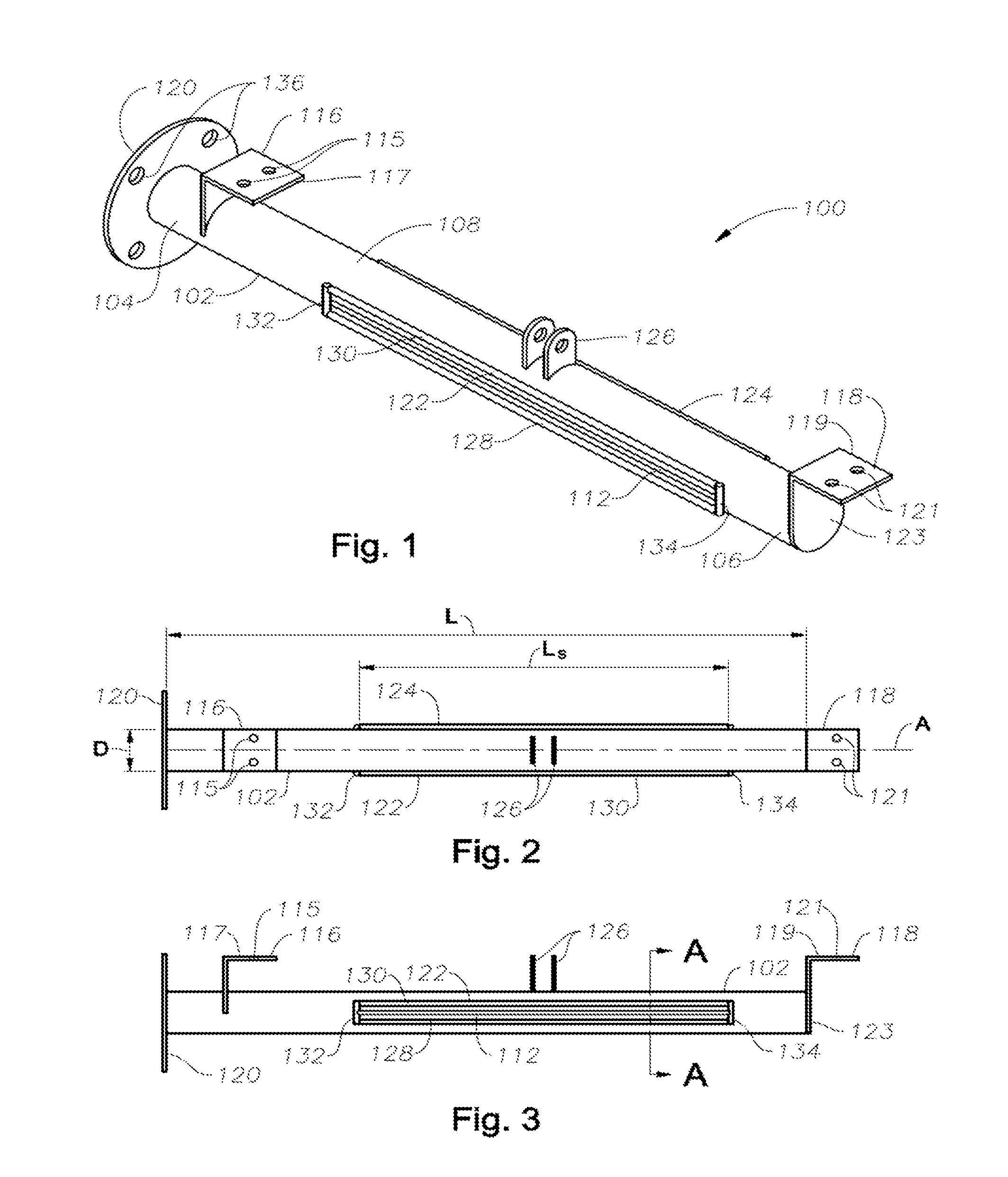

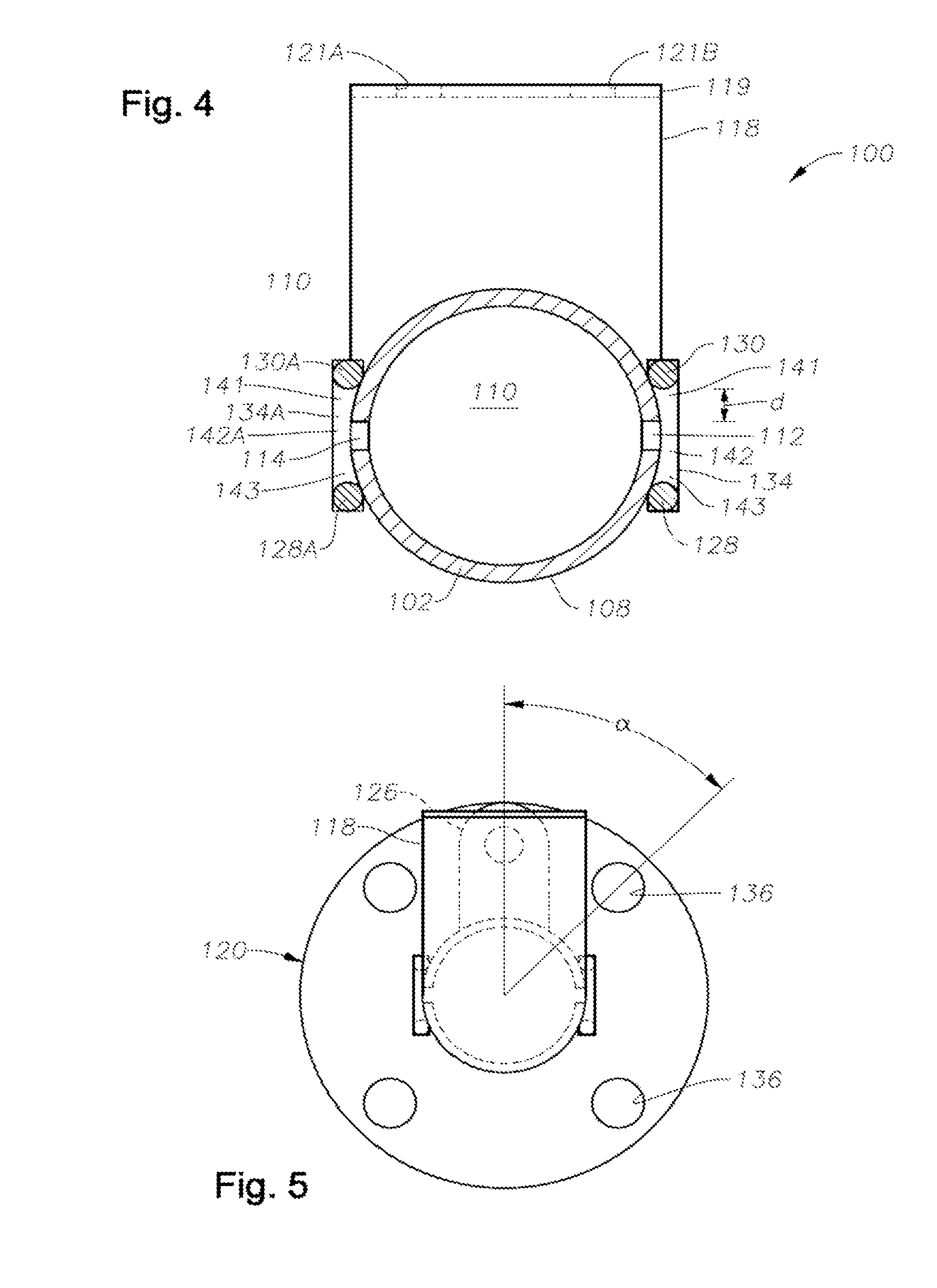

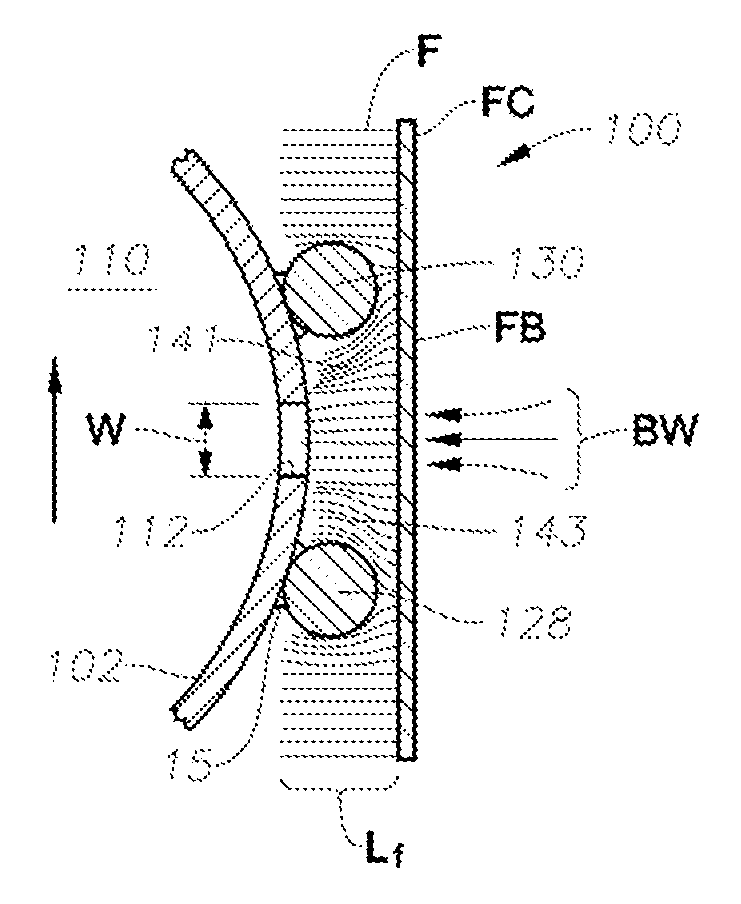

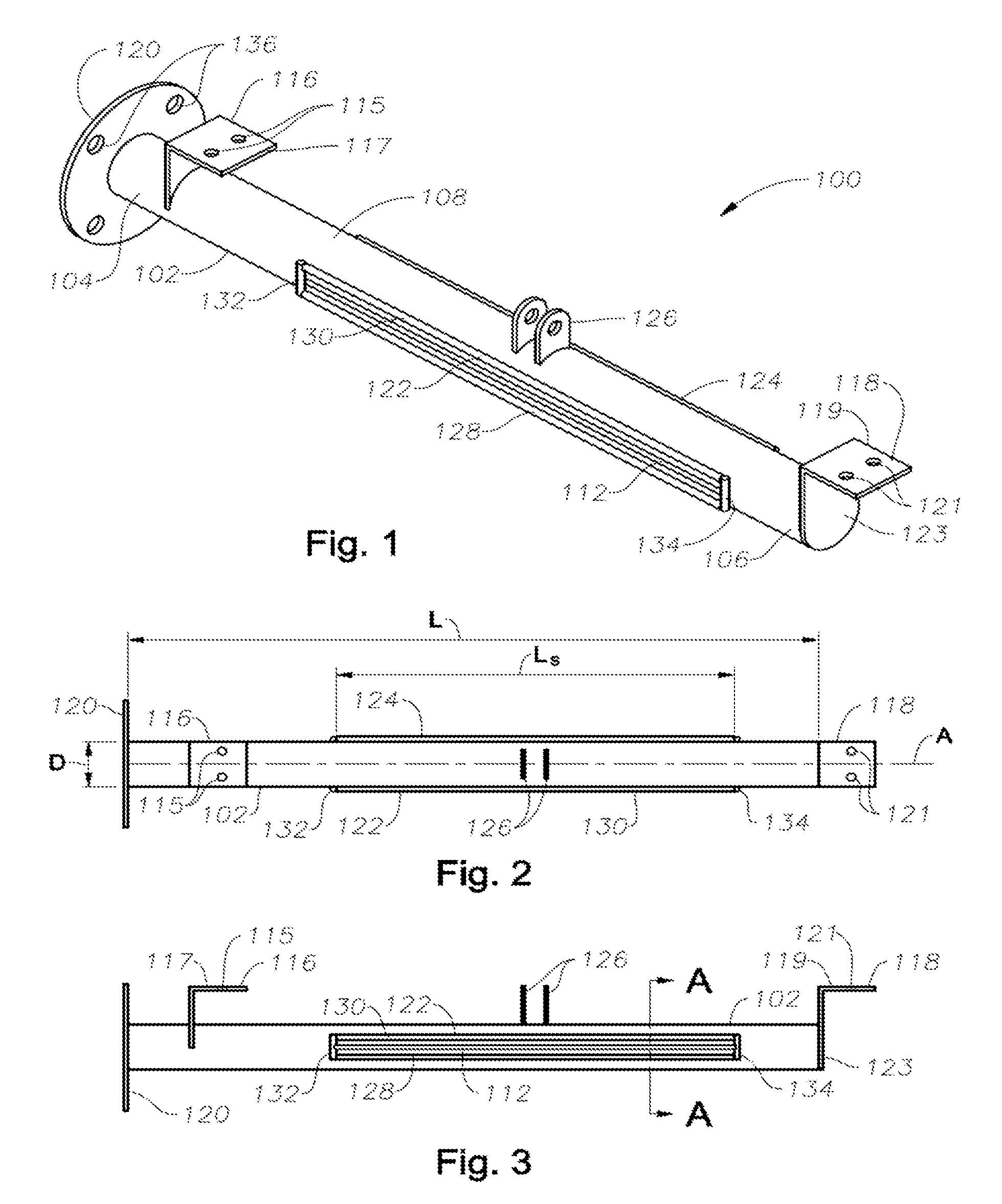

A backwash header for a cloth filter disk includes a body having a length a diameter, first and second ends, a longitudinal axis, and an exterior surface, the body defining at least one internal cavity. The body includes at least one suction slot configured to allow fluids and solids to enter the internal cavity from outside of the exterior surface. A structure is attached to a portion of the exterior surface of the body around and extending away from the suction slot to form a chamber defined by the structure and a portion of the exterior surface near the suction slot. The structure is configured to allow fluids and solids to enter the chamber and then the suction slot and cavity from a material being cleaned. Cloth disk filters and methods of treating water and wastewater using the backwash headers and cloth disk filters.

Owner:ALFA LAVAL CORP AB

Methods and apparatus for treating water and wastewater employing a cloth disk filter

ActiveUS8852445B2Reduce and overcome deficiencyImprove backwash efficiencyWater/sewage treatmentMembrane filtersWastewaterEngineering

A backwash header for a cloth filter disk includes a body having a length a diameter, first and second ends, a longitudinal axis, and an exterior surface, the body defining at least one internal cavity. The body includes at least one suction slot configured to allow fluids and solids to enter the internal cavity from outside of the exterior surface. A structure is attached to a portion of the exterior surface of the body around and extending away from the suction slot to form a chamber defined by the structure and a portion of the exterior surface near the suction slot. The structure is configured to allow fluids and solids to enter the chamber and then the suction slot and cavity from a material being cleaned. Cloth disk filters and methods of treating water and wastewater using the backwash headers and cloth disk filters.

Owner:ALFA LAVAL CORP AB

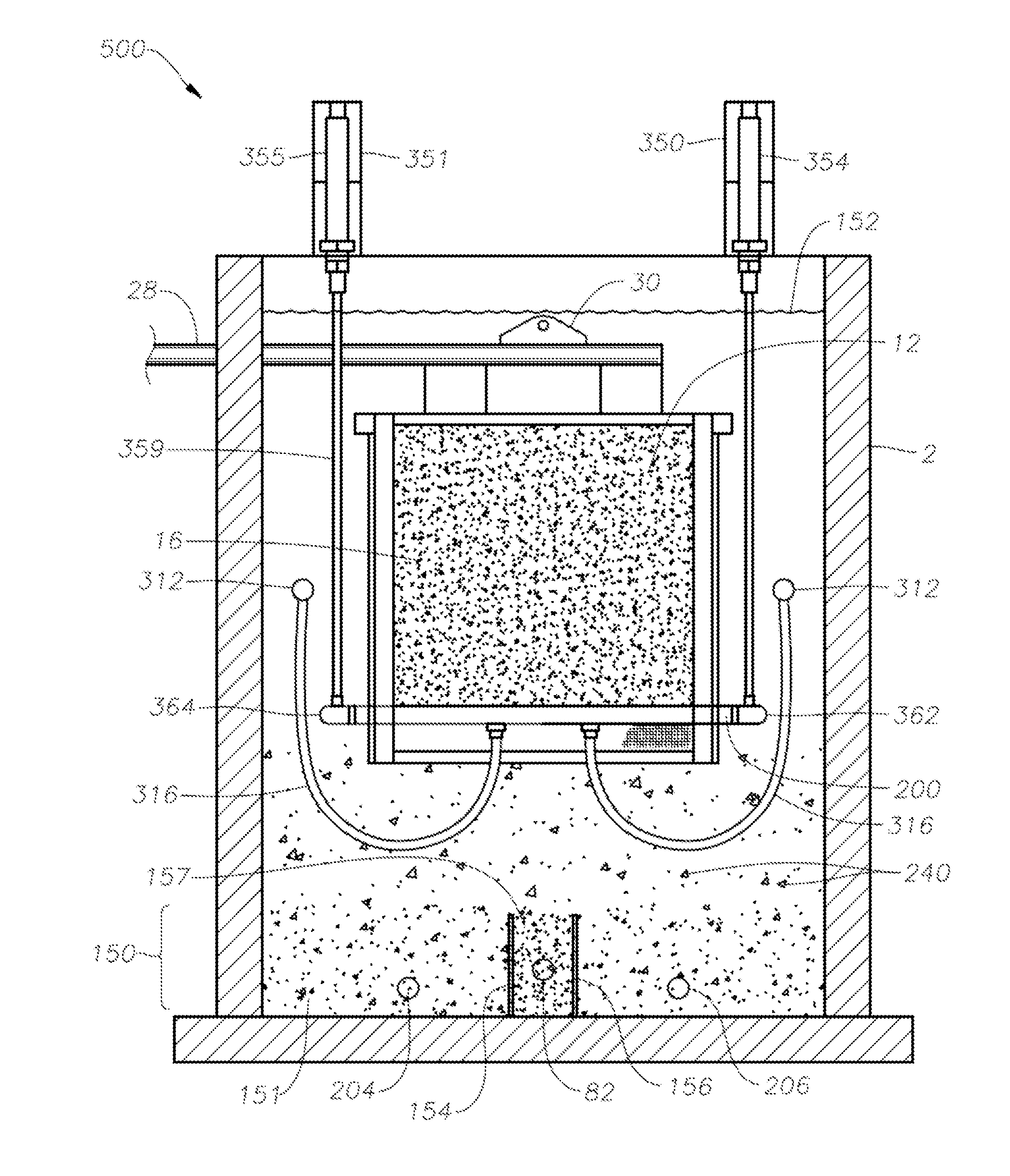

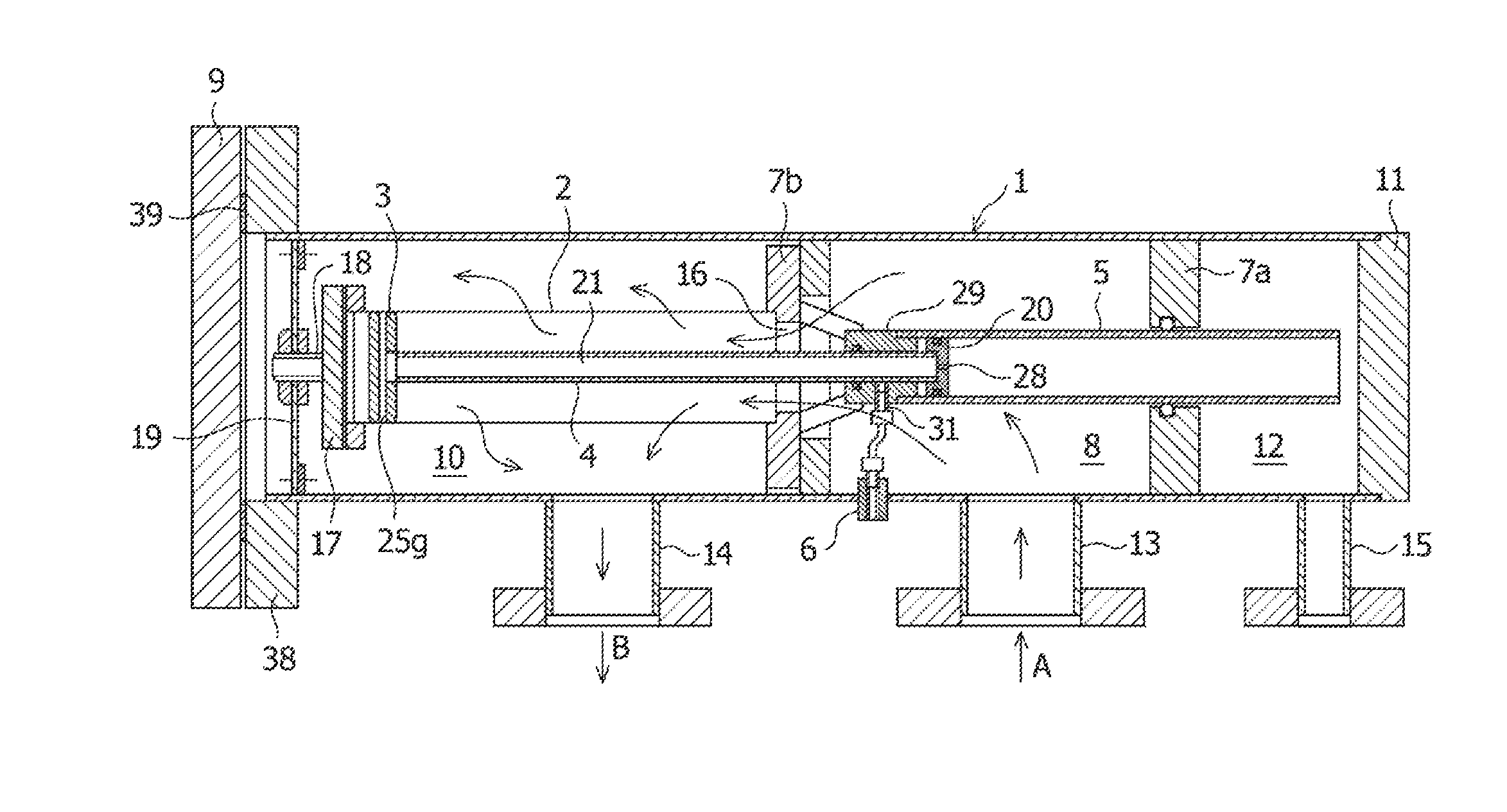

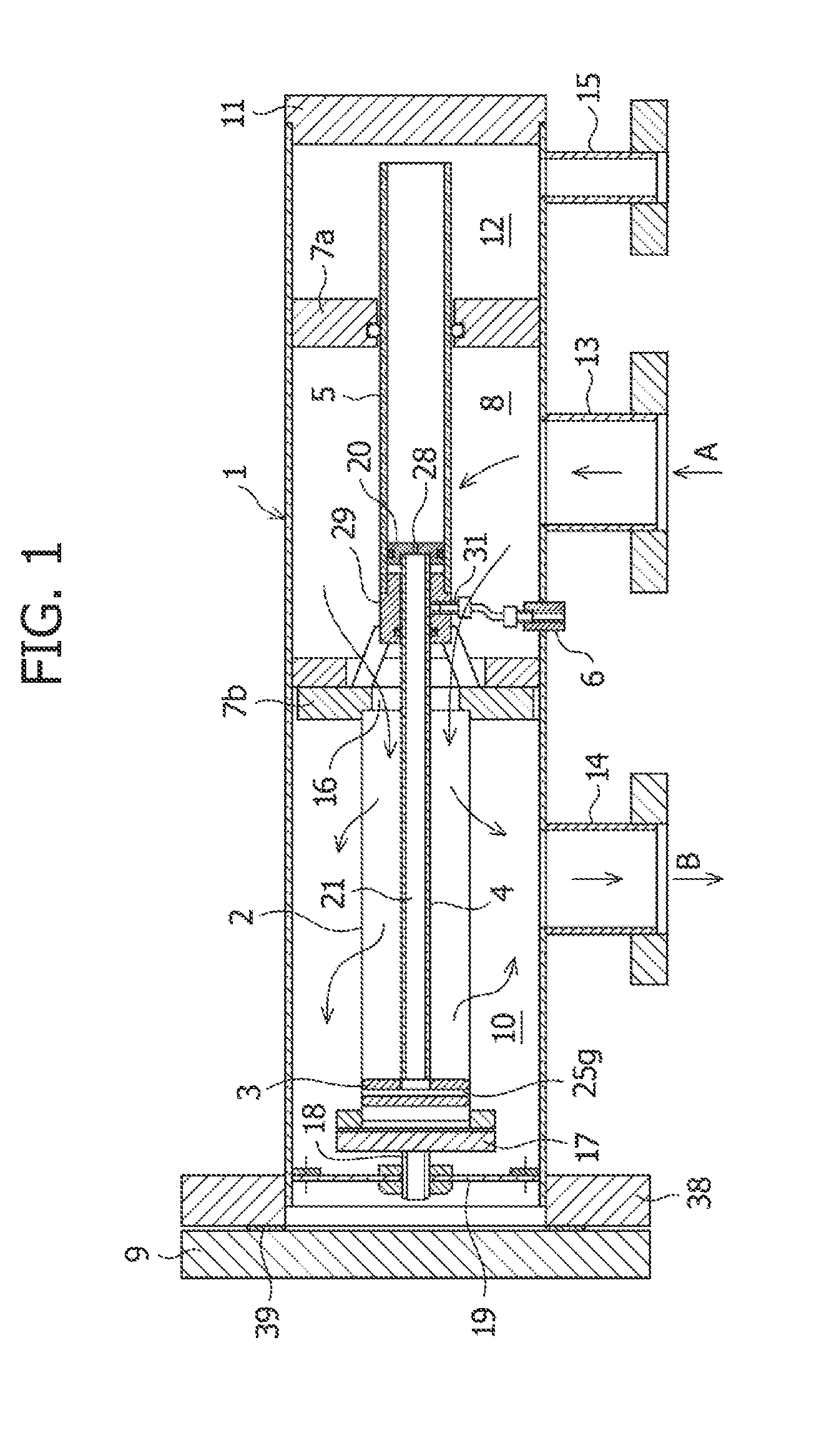

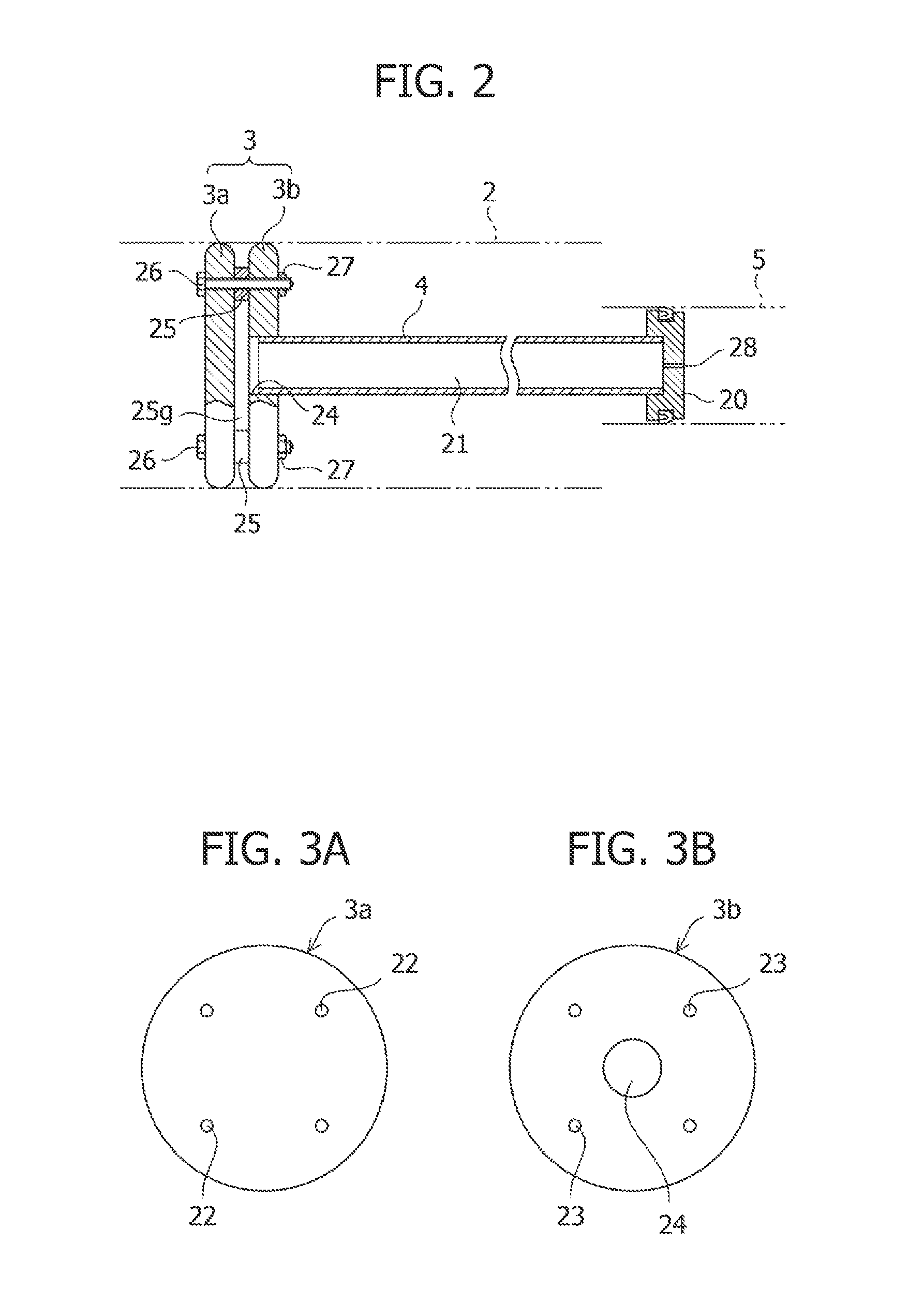

Filter apparatus

ActiveUS20140366493A1Simple structureImprove backwash efficiencyDispersed particle filtrationTransportation and packagingFiltrationEngineering

A filter apparatus including: a casing including, in a sealed space provided therein, a fluid inflow chamber, a filtration chamber and a drain chamber; a filter element provided inside the filtration chamber to let a fluid pass therethrough from inside to outside to perform filtration; a backwash slide member movably provided inside the filter element and removing trapped matter adhering to an inner circumferential surface of the filter element by an inward flow generated by a difference in pressure inside and outside the filter element at the time of backwashing; a backwash pipe that lets the inward flow flow toward the drain chamber; an actuation cylinder that lets the fluid from the backwash pipe flow toward the drain chamber; and a fluid flowing unit allowing a fluid to flow, enabling a piston member to move inside the actuation cylinder.

Owner:FUJI FILTER MFG

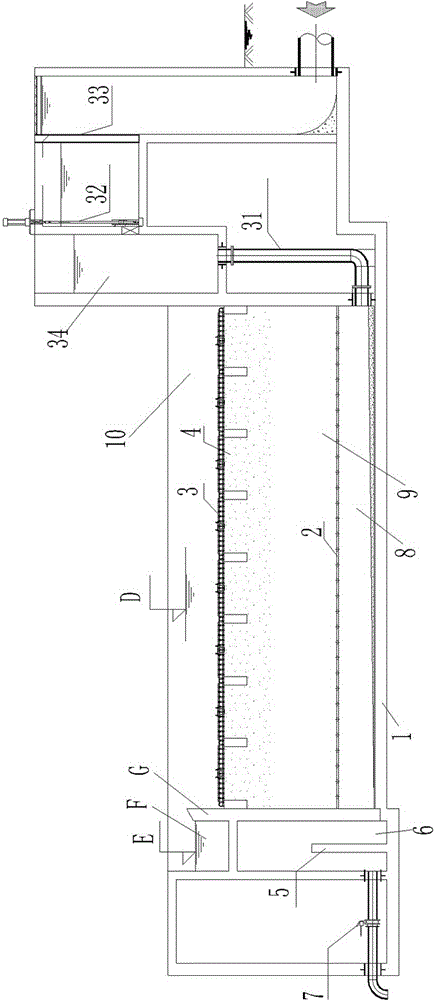

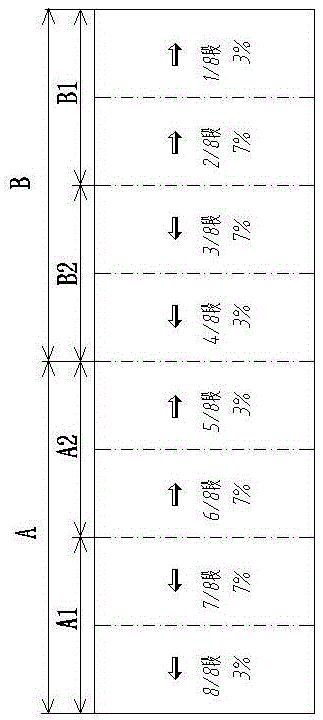

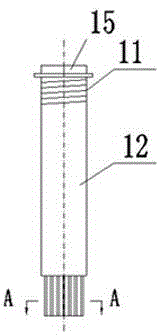

Suspended filtering system

ActiveCN103977611AIncrease disturbanceIncrease frictionLoose filtering material filtersGravity filtersSuspended particlesFilter system

The invention relates to a suspended filtering system. The suspended filtering system comprises a filtering pool body, wherein the filtering pool body is divided into three areas by an upper filtering plate and a top plate of a water distribution channel from top to bottom; the area above the upper filtering plate is a clean water storage area; the area under the top plate of the water distribution channel is provided with a raw water distribution channel communicated with raw water; the area between the upper filtering plate and the top plate of the water distribution channel is a filtering area; a suspended particle filtering material with preset thickness is contained in the filtering area; filtering head installing holes are distributed in the upper filtering plate and are internally provided with filtering heads; water distribution holes are distributed in the top plate of the water distribution channel. Compared with a traditional forward-flow filtering process, a backward-flow filtering process of the filtering system has the advantages that the water head loss is as less as about 0.6m and is only 1 / 4 of that of conventional filtering; in addition, during back washing, a water head after upper filtering can be utilized, the back washing is realized by means of the gravity action of a water body, and energy consumption is not needed in the back-washing process, so that huge facility investments and operating costs are saved.

Owner:YELLOW RIVER ENG CONSULTING

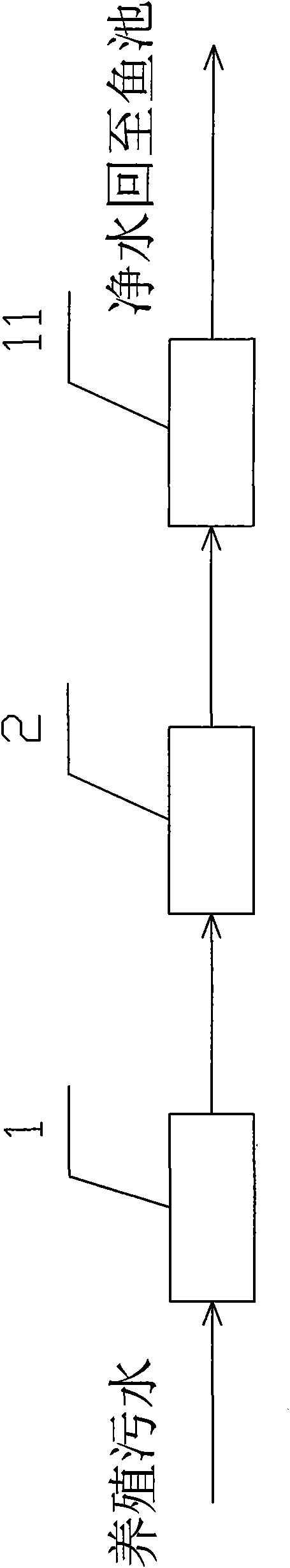

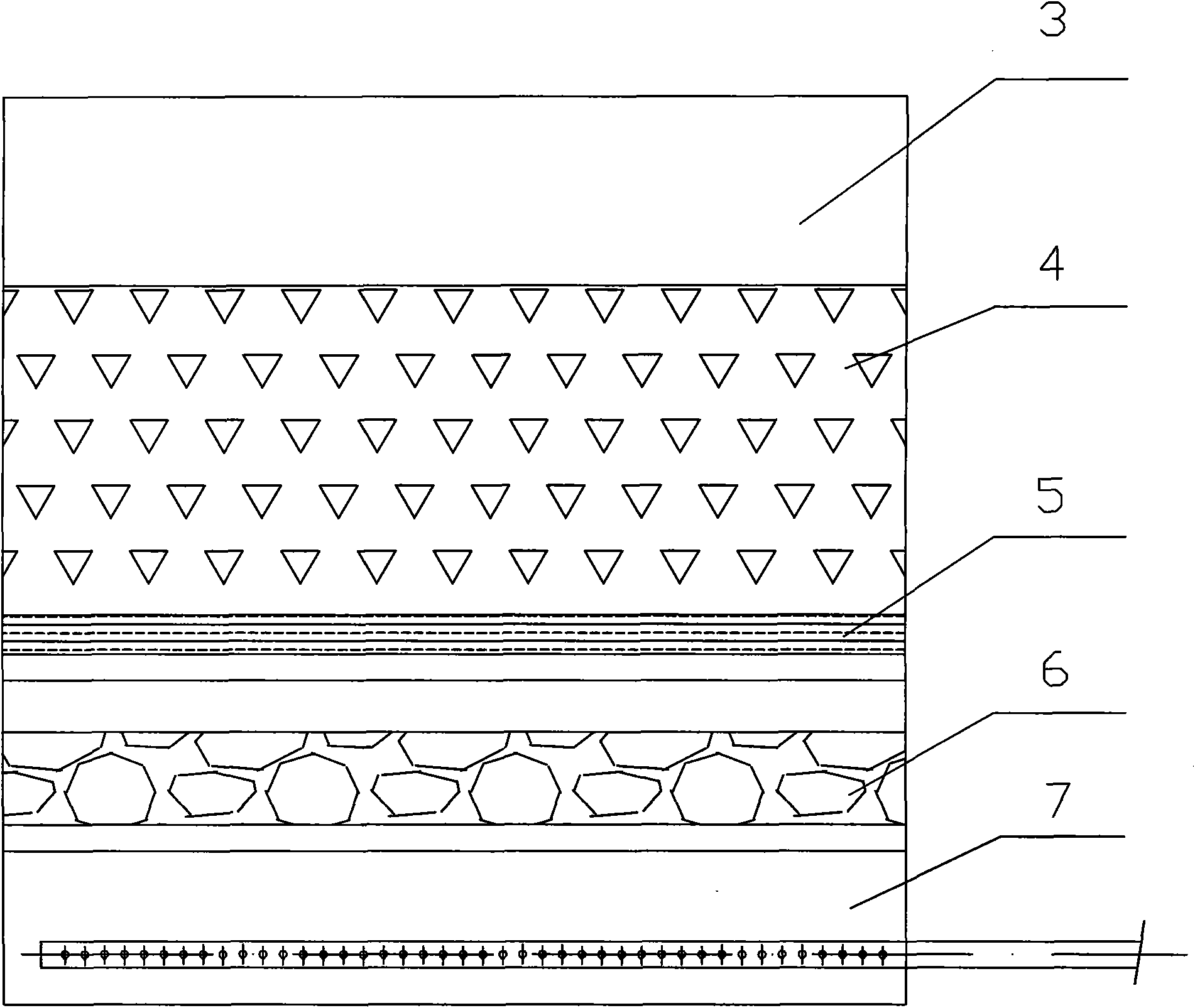

Claystone-activated carbon fiber water purification and filtration system

InactiveCN102040291AReduce use costEasy to handleMultistage water/sewage treatmentWater/sewage treatment by sorptionChemistryActivated carbon

The invention relates to a claystone-activated carbon fiber water purification and filtration system. The claystone-activated carbon fiber water purification and filtration system comprises a water conveying device, a water draining main pipe and a claystone-activated carbon fiber filtering device, wherein the water conveying device is communicated with the claystone-activated carbon fiber filtering device; the claystone-activated carbon fiber filtering device is communicated with the water draining main pipe; the claystone-activated carbon fiber filtering device is provided with a claystone-activated carbon fiber medium layer and an air-distributing structure layer respectively; the claystone-activated carbon fiber medium layer comprises three filtering layers, namely a modified bentonite filtering layer, an activated carbon fiber filtering layer and a zeolite filtering layer, which are arranged from top to bottom sequentially; a certain space is reserved above the modified bentonite filtering layer and the zeolite filtering layer; and the air-distributing structure layer is positioned on the lower part of the claystone-activated carbon fiber medium layer and is communicated with the claystone-activated carbon fiber medium layer. After breeding organic sewage is treated by the claystone-activated carbon fiber water purification and filtration system, the result shows that the removal rate of ammonia nitrogen is 42 to 48 percent, the decoloration rate is 64 to 68 percent, and good water purification effect is achieved.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

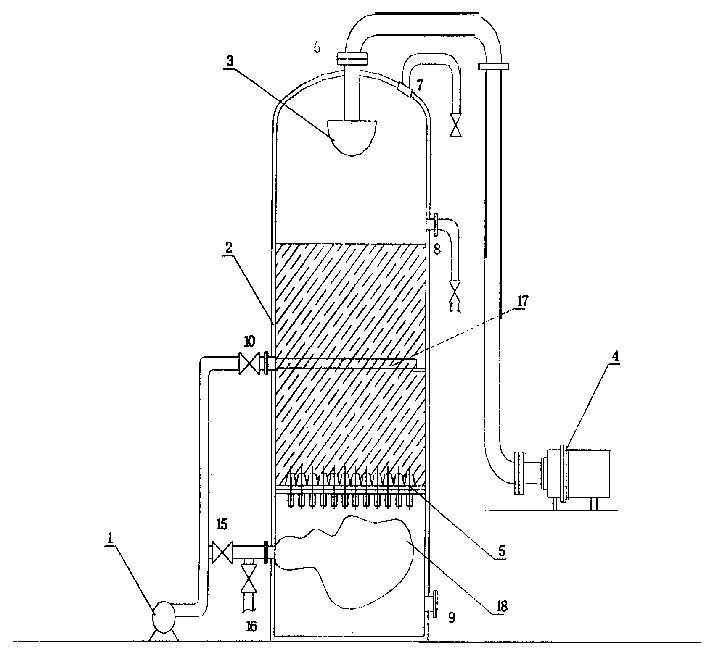

Pressure sand filter and reverse flushing method

InactiveCN1424129AIncrease profitLess investmentLoose filtering material filtersGravity filtersAir pumpWater quality

A pressure sand filter is composed of cylindrical body, raw water pump and air pump. Said cylindrical body contains a lower air bag in water collecting chamber. The water collecting chamber also plays the role of back washing box and the blower plays the role of back washing pump. Its advantages are less water consumption, low cost and high water utilization rate.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

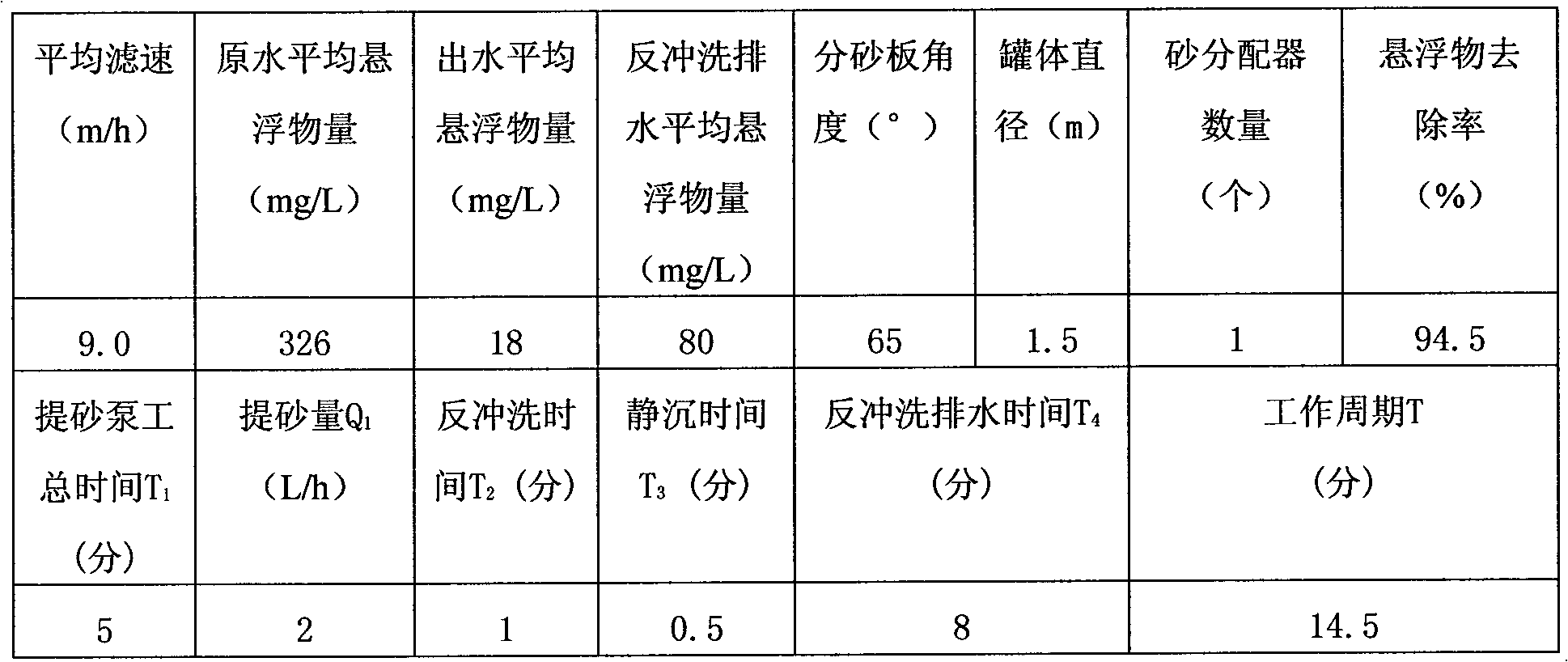

Water treatment method and device for synchronously realizing filtering and back washing

InactiveCN102847352AImprove pollution interception effectImprove work efficiencyLoose filtering material filtersGravity filtersWater dischargeWastewater

The invention discloses a water treatment device and method for synchronously realizing filtering and back washing. A filtering tank is installed on a supporting support, and the device is characterized in that the lower part of the filtering tank is connected with a water inlet tube and a water distribution device; a sand distribution device is arranged below the water distribution device; filter materials are placed in the filtering tank; a water outlet groove and a water discharge tube are arranged on the upper part of the filtering tank; a sand storage hopper is arranged at the bottom of the filtering tank; the sand storage hopper is externally connected with a sand transportation tube and a sand extraction pump; a back washing chamber is installed on the upper part of the filtering tank; the sand transportation tube is connected with the back washing chamber; sand-water separation is carried out on back washing water and inlet gas, clean sand enters a sand cleaning chamber and falls down a filter material layer; and separated back washing sewage is discharged out of the filtering tank from a back washing tube. A mode that waste water flows upwards is adopted, the filter material with the maximum sewage cutting amount in the filtering tank is located on the lower part of the whole filtering layer, sand in a lower layer falls down, replacement and changing are convenient through sand lifting, filtering and back washing can be synchronously operated, continuous operation of a filtering device is achieved, filtering layer sewage cutting capacity and work efficiency are improved, and the energy consumption and cost are reduced.

Owner:HUBEI ZHONGBI ENVIRONMENTAL PROTECTION TECHCO

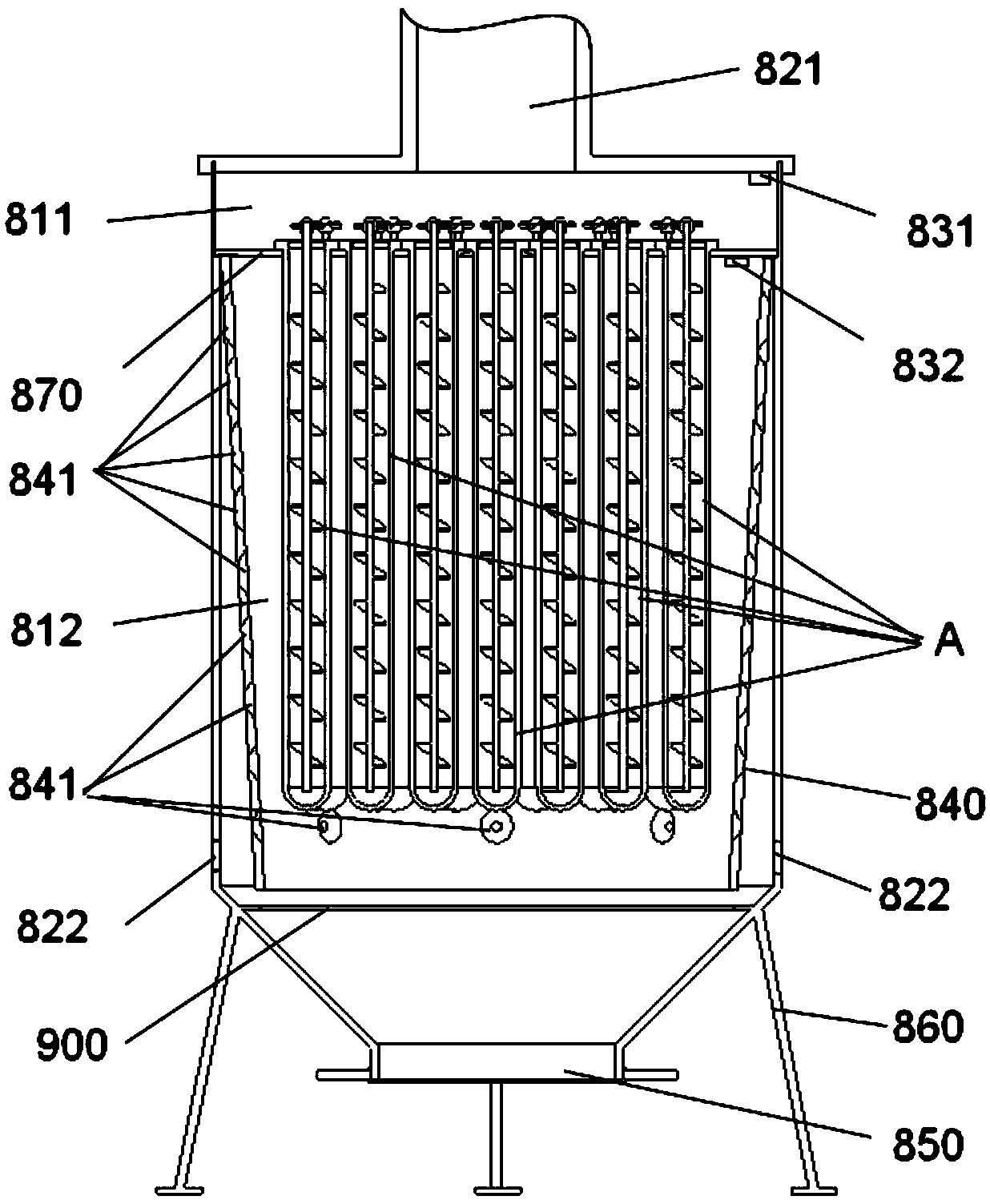

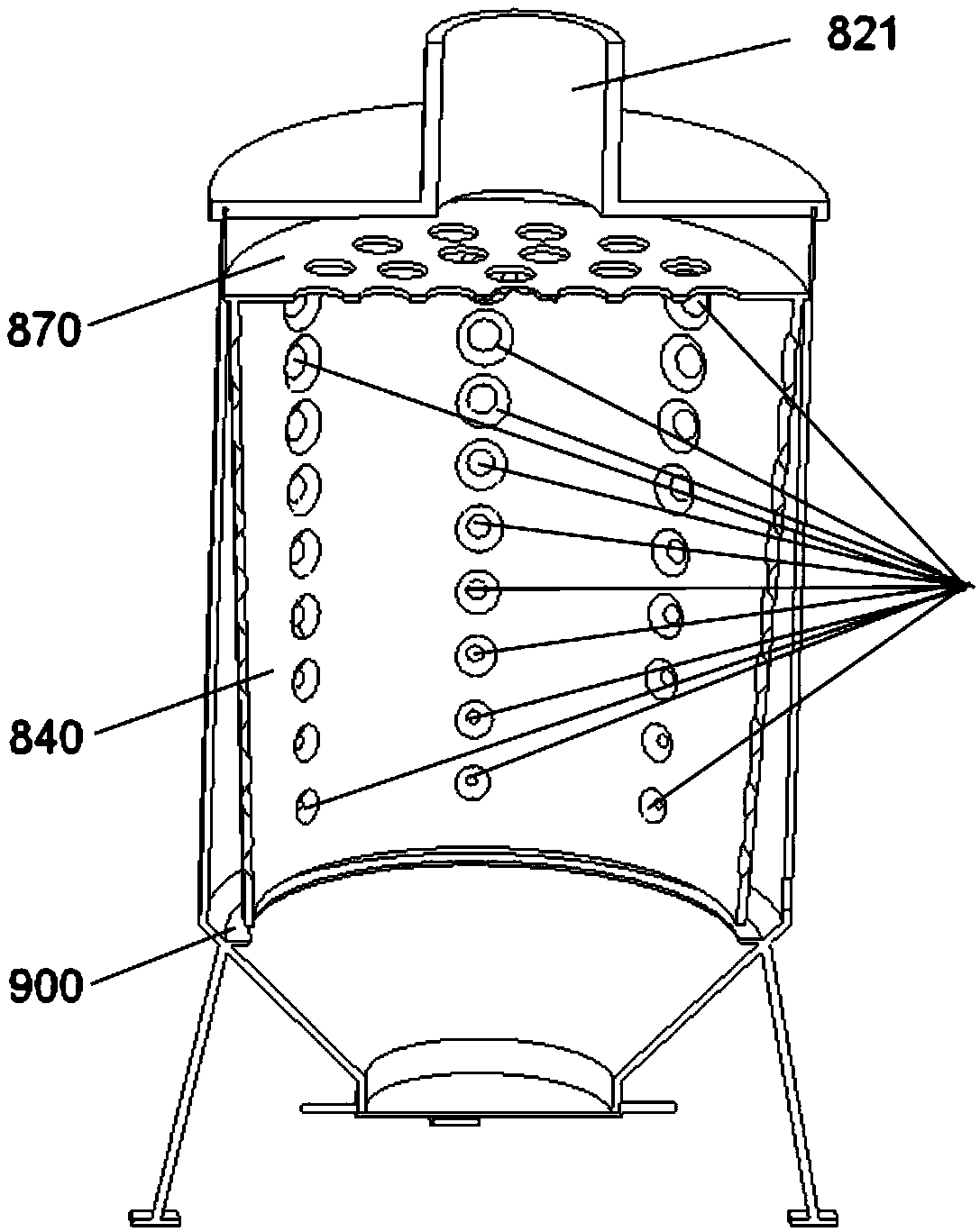

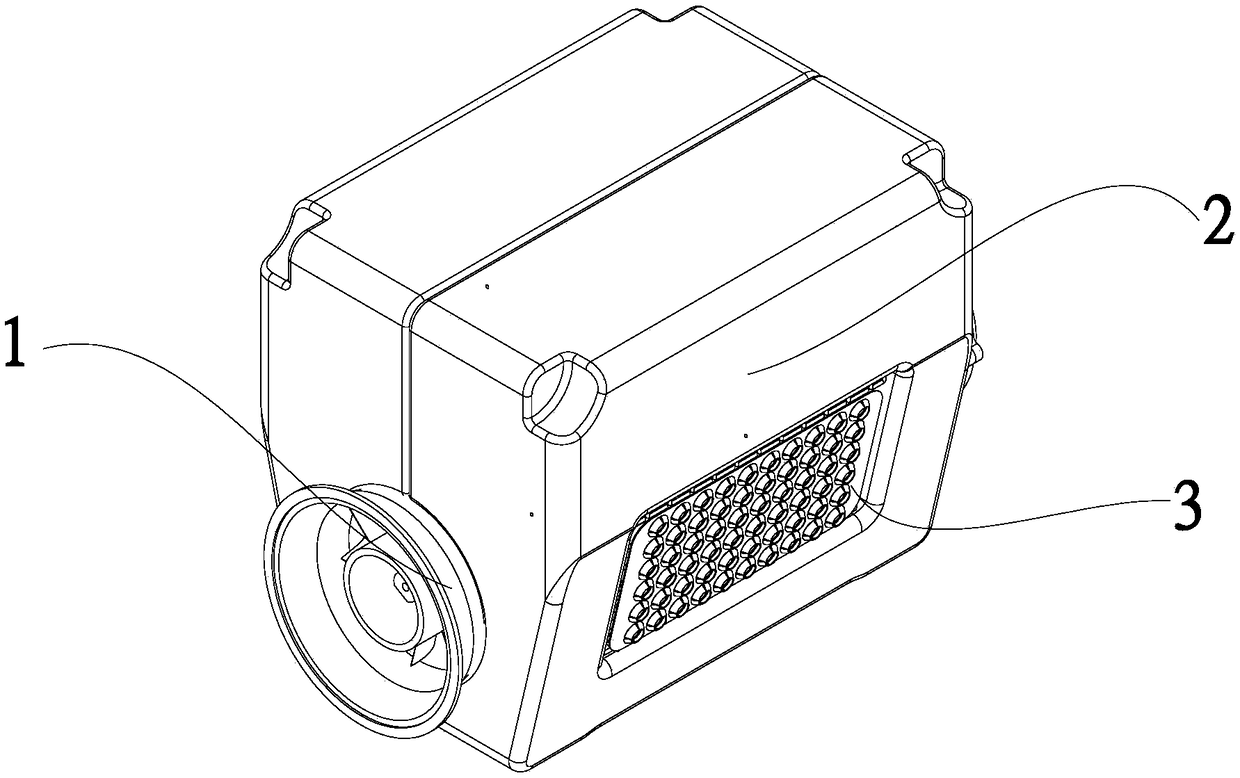

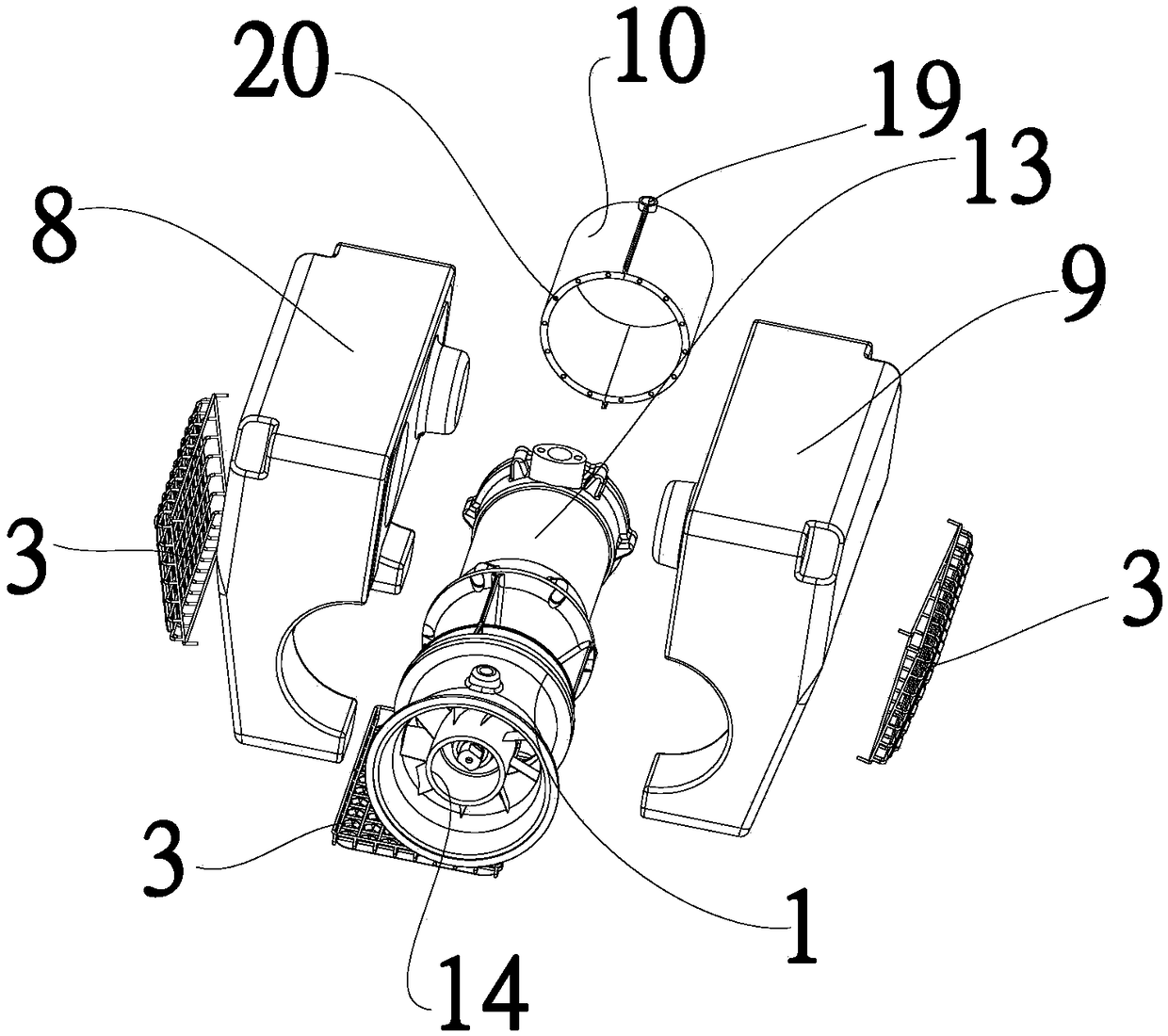

Dust removal device and high-temperature waste gas treatment equipment

ActiveCN109289375ABalanced utilizationIncreasing the thicknessDispersed particle filtrationTransportation and packagingFiberFiltration

The invention relates to a dust removal device, which comprises a hollow shell and a partition disposed in the shell. The partition at least divides the shell into a first chamber and a second chamber. Several ceramic filter pipes are vertically arranged side by side on the partition. The dust removal device is designed as follows: the gas flows from the first chamber to the second chamber or fromthe second chamber to the first chamber and must be filtered through a ceramic filtering structure. The ceramic filtering structure comprises the ceramic filter pipes, which comprises ceramic fiber pipes used for filtration. The two-way air passage between the inside of the pipes and the outside of the pipes is realized through several air vents on the pipe wall of the pipes. The dust removal device is arranged according to the following mode: the filtered gas that enters the second chamber can flow from at least two different levels to the several ceramic filter pipes. According to the dustremoval device, the filter resources of the ceramic filter pipes can be more fully and evenly utilized, thus enhancing the filter efficiency and being helpful for improving the backwash efficiency.

Owner:BGT GRP CO LTD

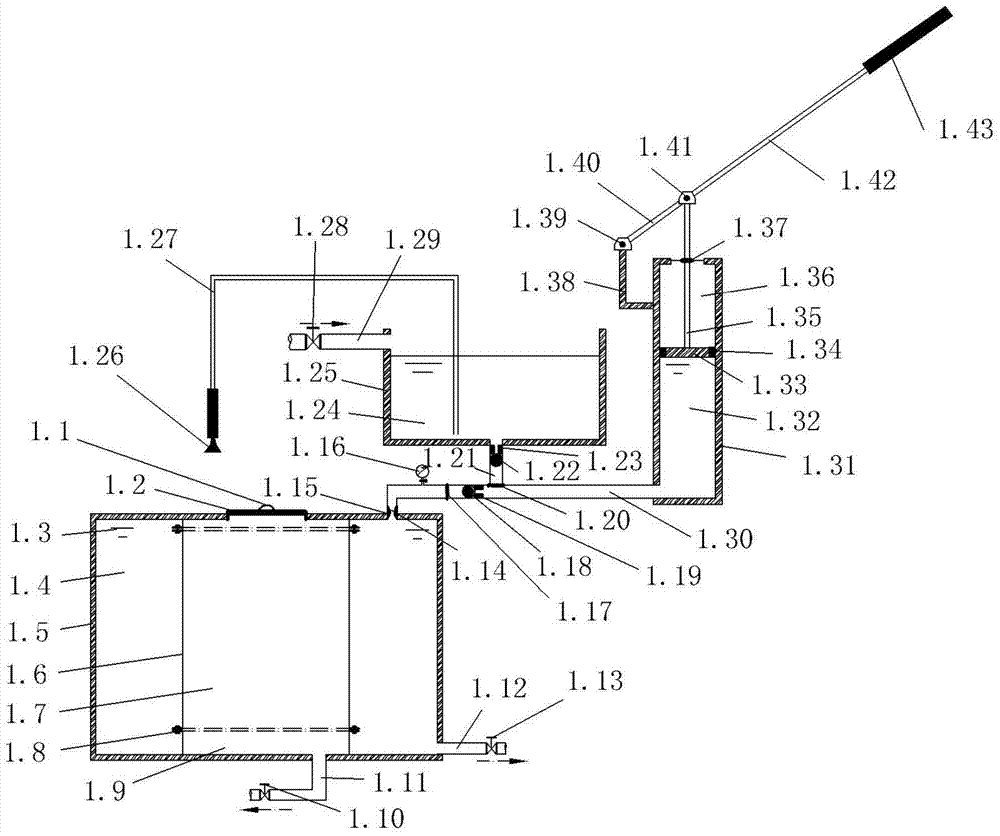

Ultrafiltration back flushing device for rural domestic sewage

InactiveCN103657426AReduce energy consumptionSolve cleaningUltrafiltrationWater/sewage treatment bu osmosis/dialysisHigh energyUltrafiltration

The invention discloses an ultrafiltration back flushing device for rural domestic sewage, belongs to sewage treatment (C02F), and mainly aims to solve the problems of high energy consumption, incomplete cleaning, poor flux recovery, short running period, complexity in operation management, easiness in damaging ultrafiltration assemblies and the like existing in the conventional tubular ultrafiltration back flushing device. A manual hydraulic pump is used for supplying power to the ultrafiltration back flushing device, so that a low-power and low-energy-consumption effect is achieved; moreover, a two-stage flushing mode consisting of high-level boosting manual flushing and manual hydraulic pump boosting back flushing is adopted for completely flushing a membrane tube, so that the membrane flux recovery degree is increased effectively, and the running period of a membrane assembly is prolonged. The ultrafiltration back flushing device has the advantages of low energy consumption, completeness in cleaning, good flux recovery, easiness in operation management, low investment and running costs and the like, and can be used by being matched with an ultrafiltration device.

Owner:CHENGDU UNIV

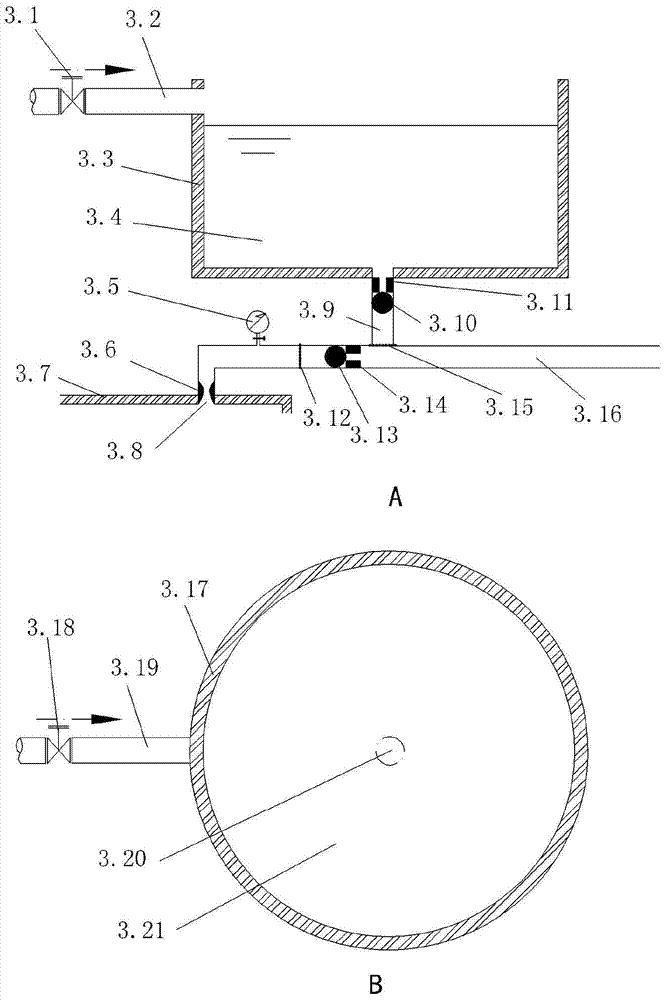

Helical flow dephosphorization reactor

ActiveCN104478121AEnhanced plug flowImprove performanceWater contaminantsTreatment involving filtrationWater dischargeEnvironmental engineering

The invention provides a helical flow dephosphorization reactor. The helical flow dephosphorization reactor comprises a pre-backwashing zone, a gas stripping lifting zone, a water discharging zone, a filtering zone, a water feeding zone, a backwashing zone and a solid-liquid separation zone from bottom to top; the pre-backwashing zone comprises an inverted bench body, and an escape tube is arranged below the inverted bench body; the gas stripping lifting zone comprises a gas stripping tube, and the lower end of the gas stripping tube is provided with a gas stripping gas inlet tube; the water discharging zone comprises a filtered water collecting tube, and the filtered water collecting tube is coaxially arranged outside the gas stripping tube; the filtering zone comprises a lower cylinder, and the lower cylinder is coaxially arranged outside the filtered water collecting tube; the water feeding zone comprises a water feeding tube, and the water feeding tube is connected with the upper end of the lower cylinder; the backwashing zone comprises a backwashing air tube, the backwashing air tube is connected with the upper end of the gas stripping tube, and an efficient stripping tube is connected with the top of the gas stripping tube; and the solid-liquid separation zone comprises an upper cylinder, and the upper cylinder is connected with the top of the lower cylinder. The reactor has the advantages of continuous running, tending towards a laminar flow state, small dead zone area, high filtering and backwashing efficiency, reasonable and concise structure, convenient processing and convenient popularization application.

Owner:浙江沃乐科技有限公司

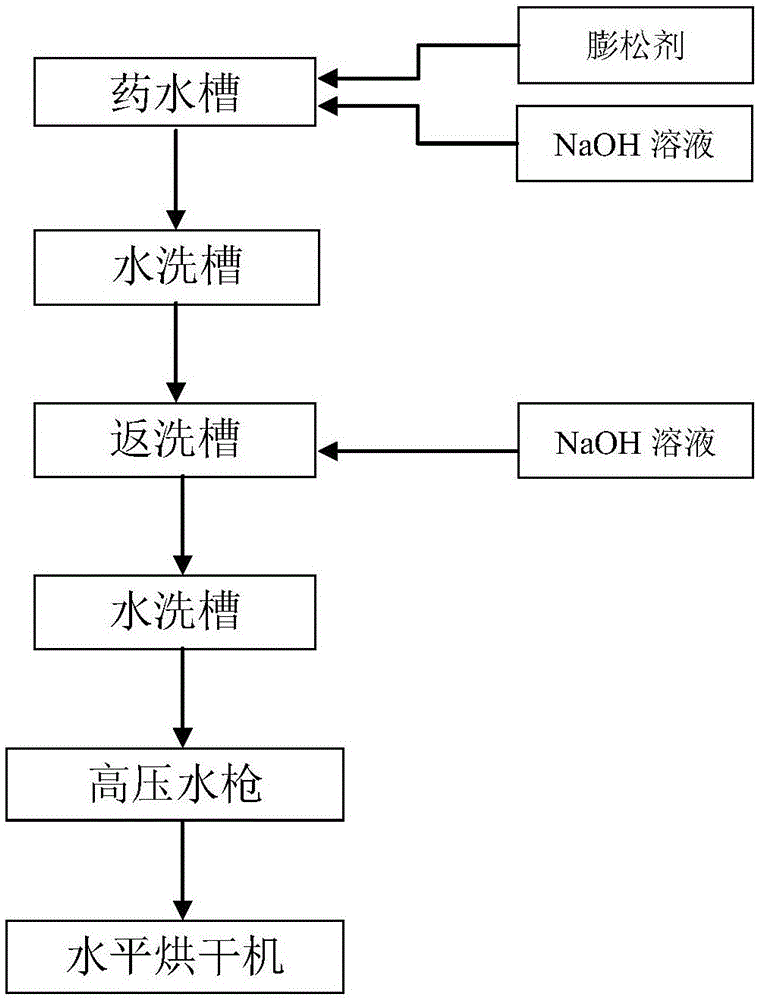

Method for re-washing solder resist plug hole

InactiveCN106413276AEasy to cleanAvoid blushingPost-manufacturing circuit processesNon-metallic protective coating applicationResistPrinting ink

The invention discloses a method for re-washing a solder resist plug hole, belonging to the technical field of manufacturing of circuit boards. The method comprises the following steps of: (a), putting a plug hole board to be re-washed in a liquid medicine groove containing a swelling agent to immerse and perform swelling treatment; (b), putting the plug hole board immersed by the swelling agent in a water washing groove to wash, and removing the swelling agent on the surface of the board; (c), putting the plug hole board in a re-washing groove containing NaOH solution to immerse; (d), putting the plug hole board processed in the step (c) in the water washing groove to wash; and (e), washing the fetched plug hole board by using a high-voltage water gun, and removing printing ink and NaOH solution on the surfaces of the plug hole and the board. By means of the method disclosed by the invention, solder resist printing ink in the hole of the plug hole board can be effectively removed; and thus, the quality problem that printing ink in small holes cannot be re-washed cleanly after solder resist solidification can be thoroughly solved.

Owner:珠海杰赛科技有限公司

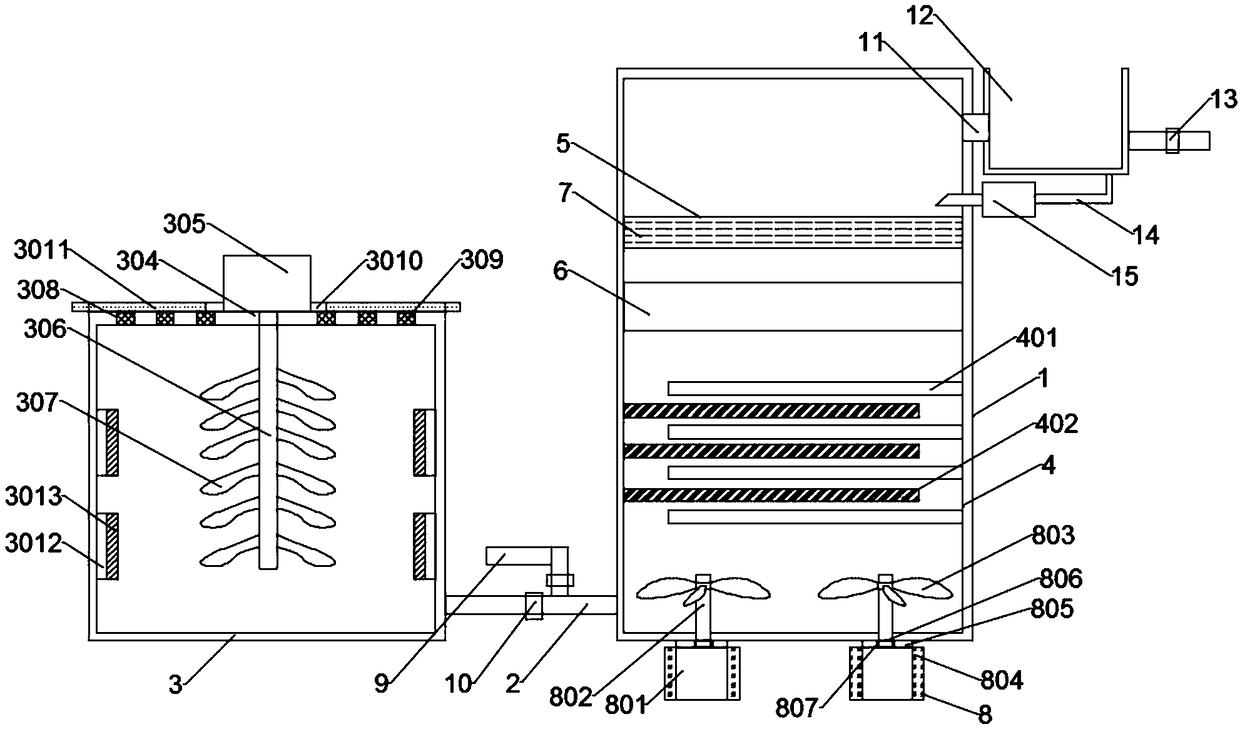

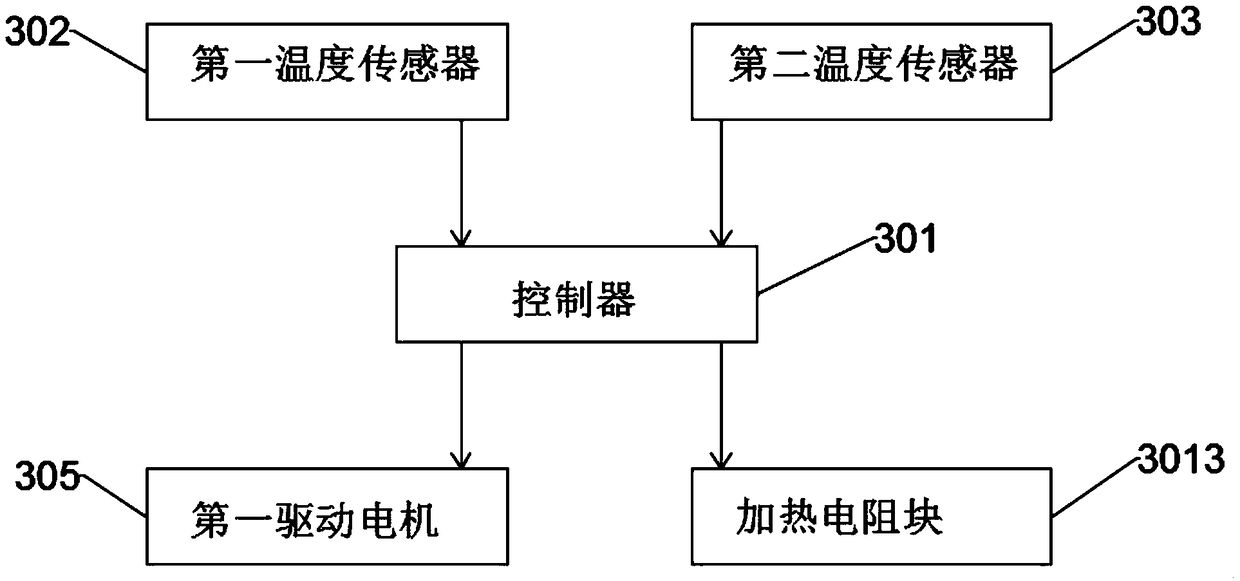

Multifunctional biological aerated filter for sewage treatment

InactiveCN108996673AFilter in timeAvoid damageWater treatment parameter controlTreatment involving filtrationFiltration membraneWater flow

The invention discloses a multifunctional biological aerated filter for sewage treatment. The multifunctional biological aerated filter comprises a treating tank body, wherein a water inlet is formedin the lower end of the treating tank body; the water inlet is connected with a constant-temperature tank; a buffering and flow-stabilizing zone and a plurality of filtering mounting plates are arranged inside the treating tank body; an aerobic filter material layer and a hypoxic filter material layer are arranged inside the filtering mounting plates; accelerating backwashing mechanisms are further arranged inside the buffering and flow-stabilizing zone; a filtering and flow-slowing mechanism mounted on the side wall of the treating tank body is arranged inside the buffering and flow-stabilizing zone; the filtering and flow-slowing mechanism comprises a plurality of primary filter plates and a plurality of secondary filter plates which are uniformly fixed to two parallel side surfaces of the treating tank body; the primary filter plates and the secondary filter plates are arranged in a staggered manner; an S-shaped water flow passage is formed between the primary filter plates and thesecondary filter plates. The multifunctional biological aerated filter can filter suspended solids in sewage in time, so that the service life of a biological filtration membrane is prolonged; throughsewage water temperature pretreatment, the activity of the biological membrane is improved and the sewage treatment effect is improved.

Owner:JIXI YUANDAO AGRI IND TECH

Sewage three-level effluent advanced treatment device and treatment method

InactiveCN104150657ADurable and safe disinfection and degradationIncrease concentrationMultistage water/sewage treatmentThree levelUltrafiltration

The invention relates to a sewage three-level effluent advanced treatment device. The device mainly comprises a coagulating basin, wherein the upper end of the coagulating basin is connected with a chemical dosing device, the water outlet of the coagulating basin is connected with a surface turbulence filtering device, the water outlet of the surface turbulence filtering device is connected with a photocatalytic degradation reaction device, the water outlet of the photocatalytic degradation reaction device is connected with a secondary nanometer aeration advanced oxidation device, and the water outlet of the secondary nanometer aeration advanced oxidation device is connected with an ultrafiltration device. The invention also discloses a sewage three-level effluent advanced treatment method.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Clogging prevention control method of floating water pump

ActiveCN109236676APlay the role of isolating sundriesAvoid cloggingPump componentsPump controlStopped workFiltration

The invention belongs to the technical field of water pumps, and particularly relates to a clogging prevention control method of a floating water pump. The clogging prevention control method of the floating water pump includes the following steps that 1, the power of a drive motor of a pump body is monitored; 2, the monitored power of the drive motor is compared with preset power and maximum application power of the drive motor; 3, according to comparison results in step 2, the pump body is controlled to make the floating water pump rotate faster, or the pump body stops working, and when the pump body stops working, water in the floating water pump and water in a water pipe are subjected to back flush. During running of the floating water pump, the flow of the floating water pump is reduced, when the power of the floating water pump increases to be within a preset range, the rotation speed of the floating water pump is moderately increased through a control cabinet, and water flow needed by a customer is ensured; when filter screen clogging becomes more serious and the maximum application power of the floating water pump motor is reached, a back flush command is started; a gap withpreset width exists between the periphery of a filter screen and a floating ring, it is convenient to flush junk inside the floating ring and at the inner sides of filtration pores to the external ofthe floating ring, the situation is avoided that the junk deposits at the inner sides of the filtration pores, and the back flush efficiency can be greatly improved.

Owner:长沙迪沃机械科技有限公司

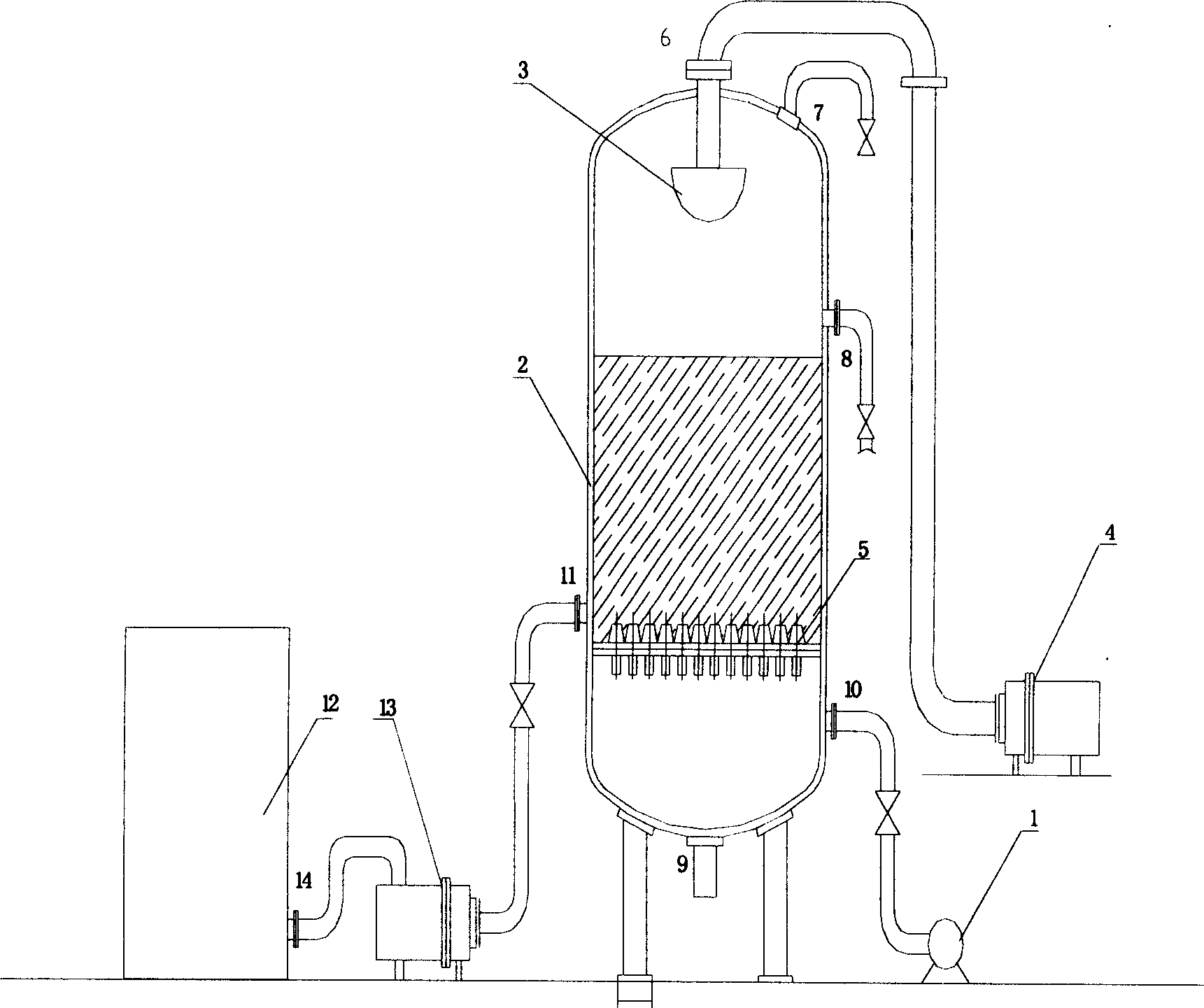

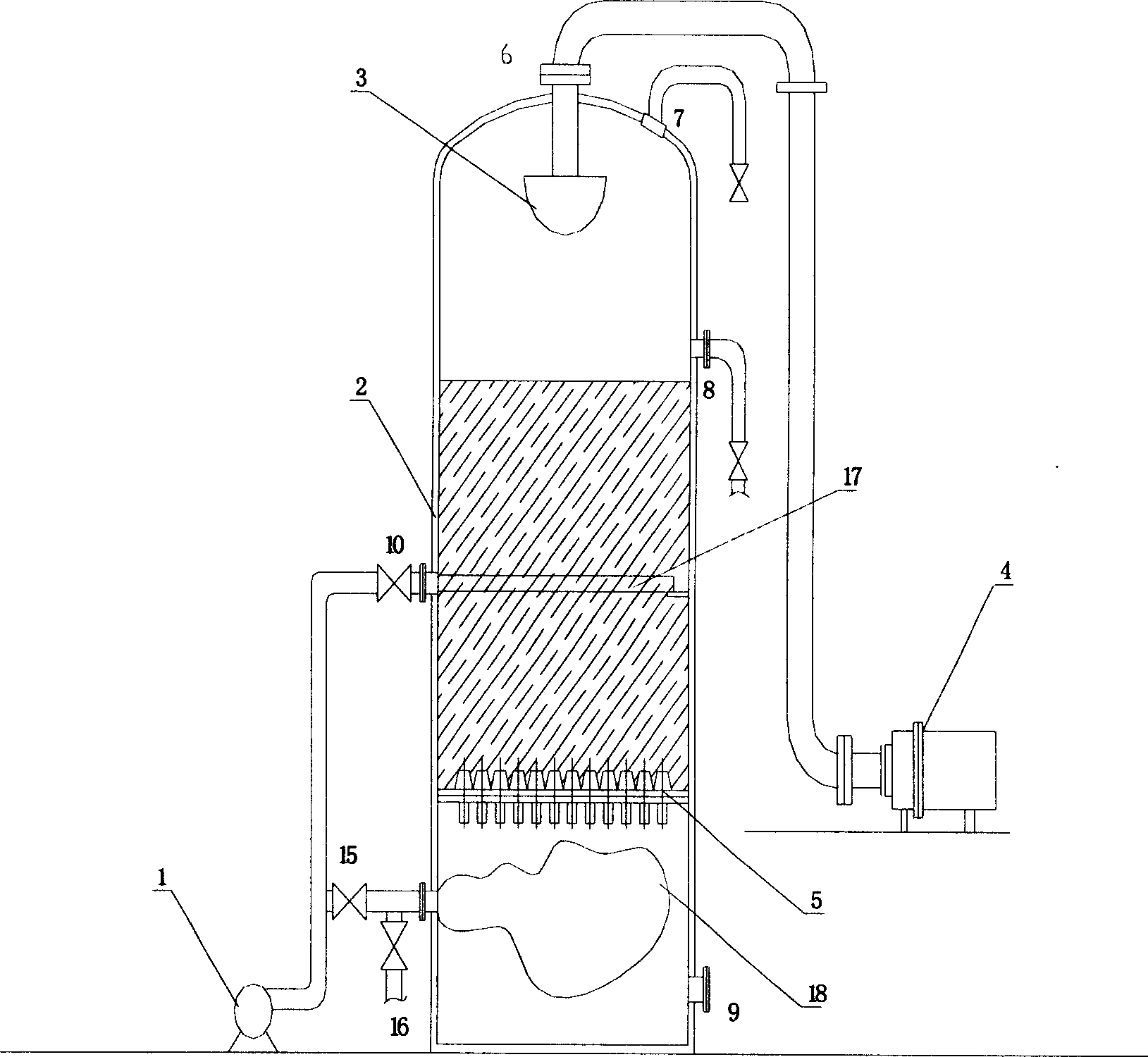

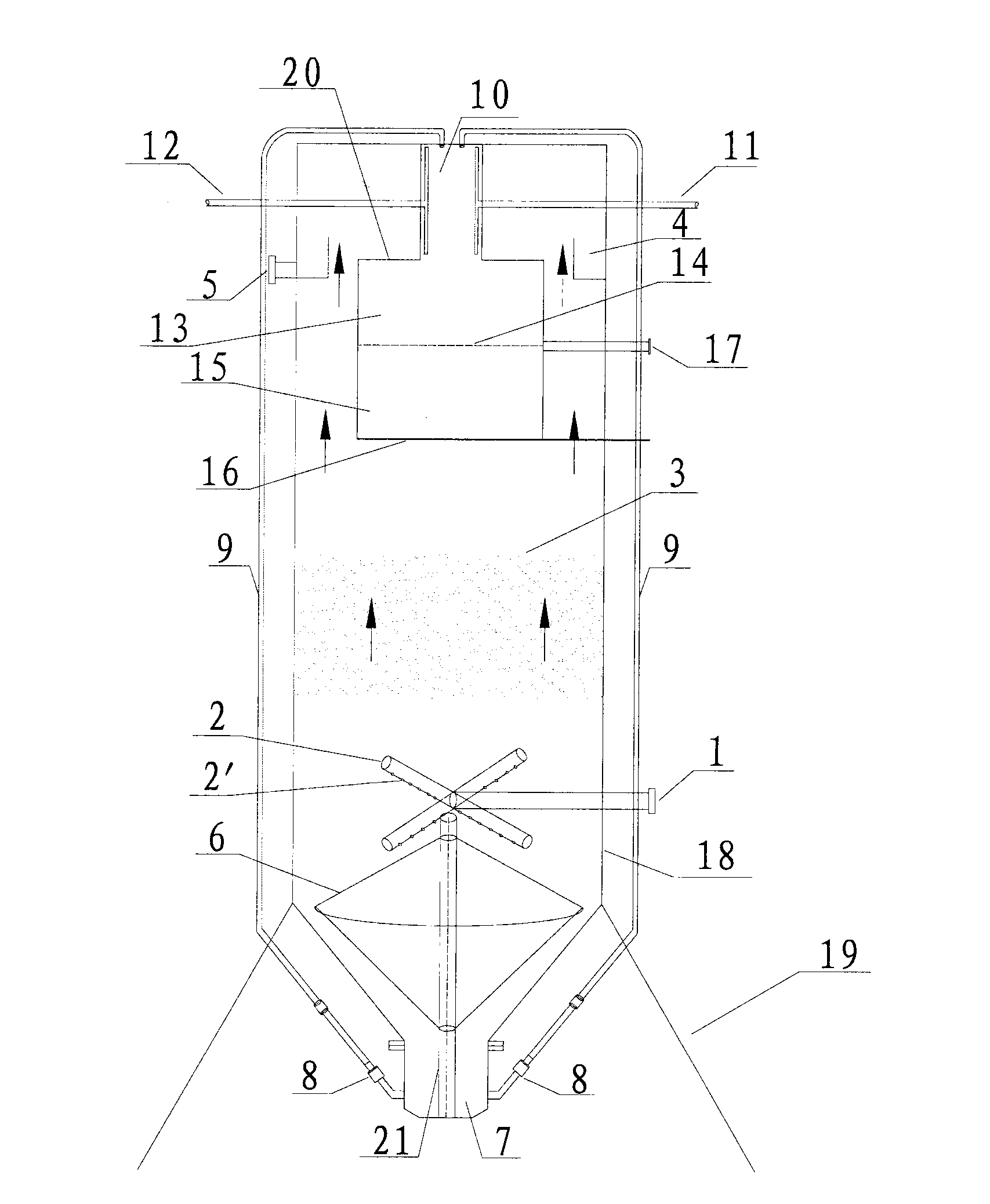

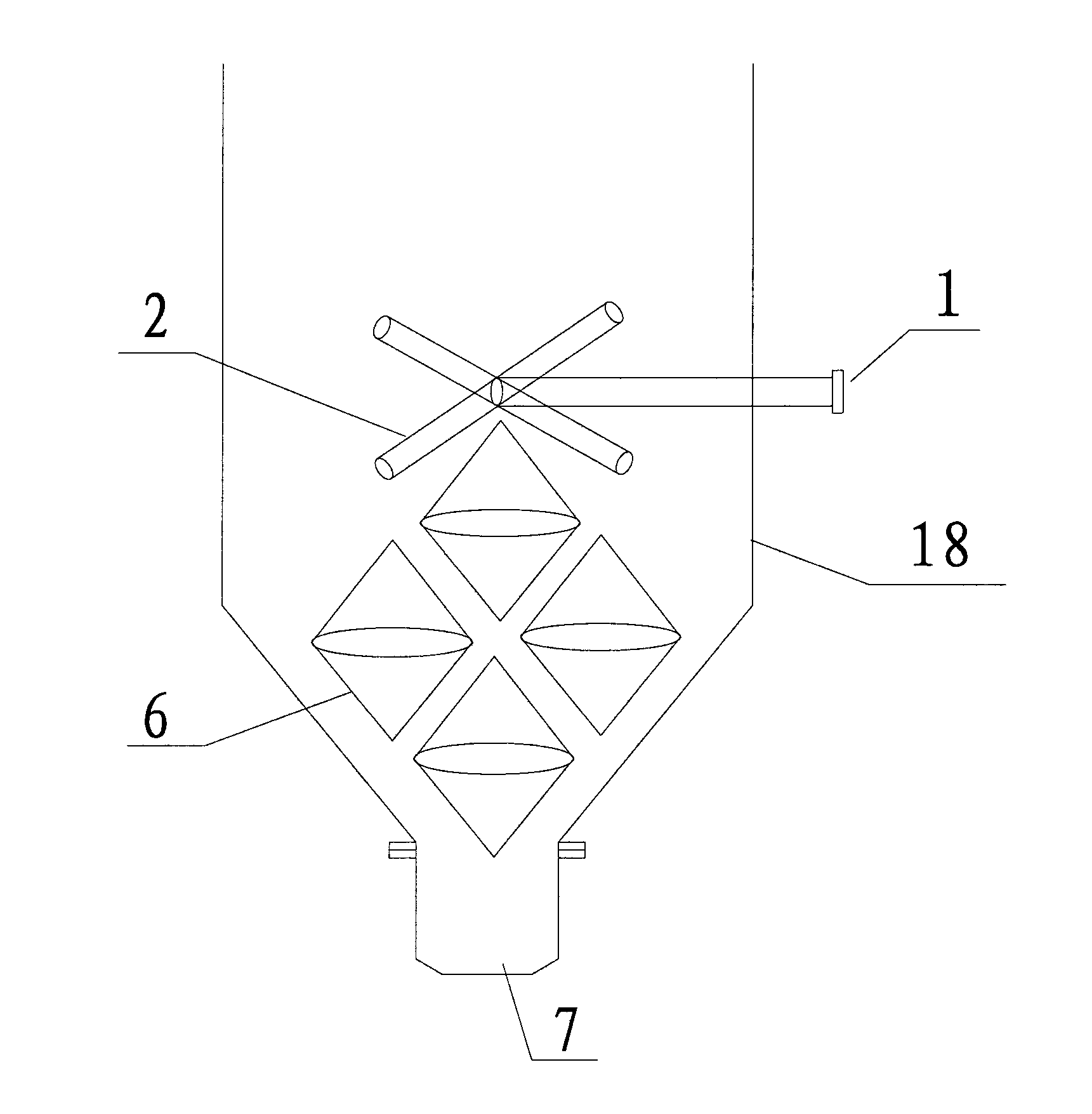

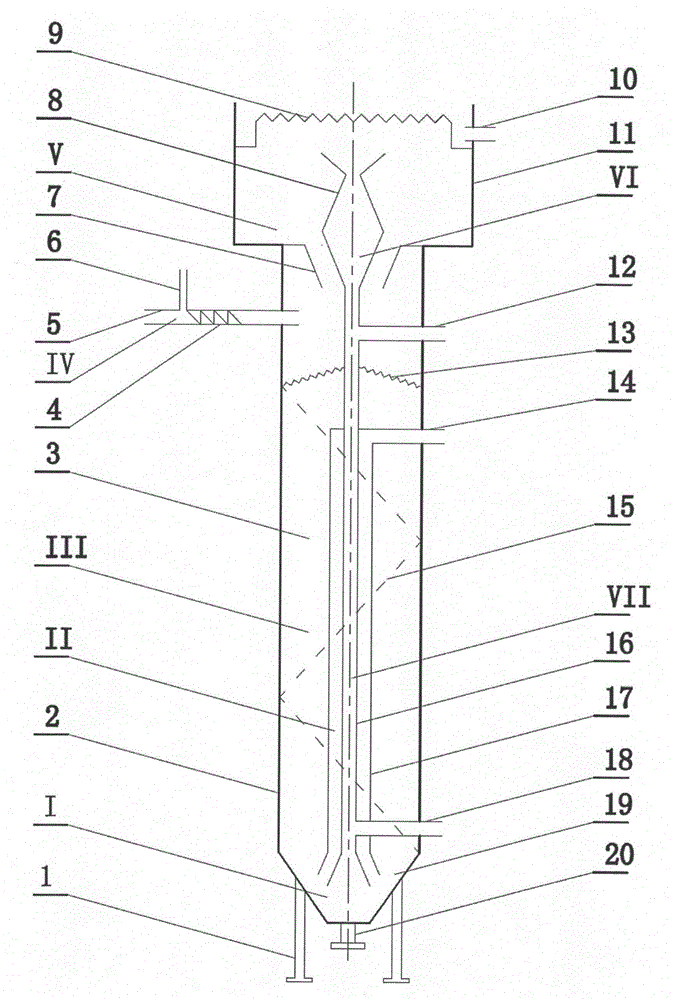

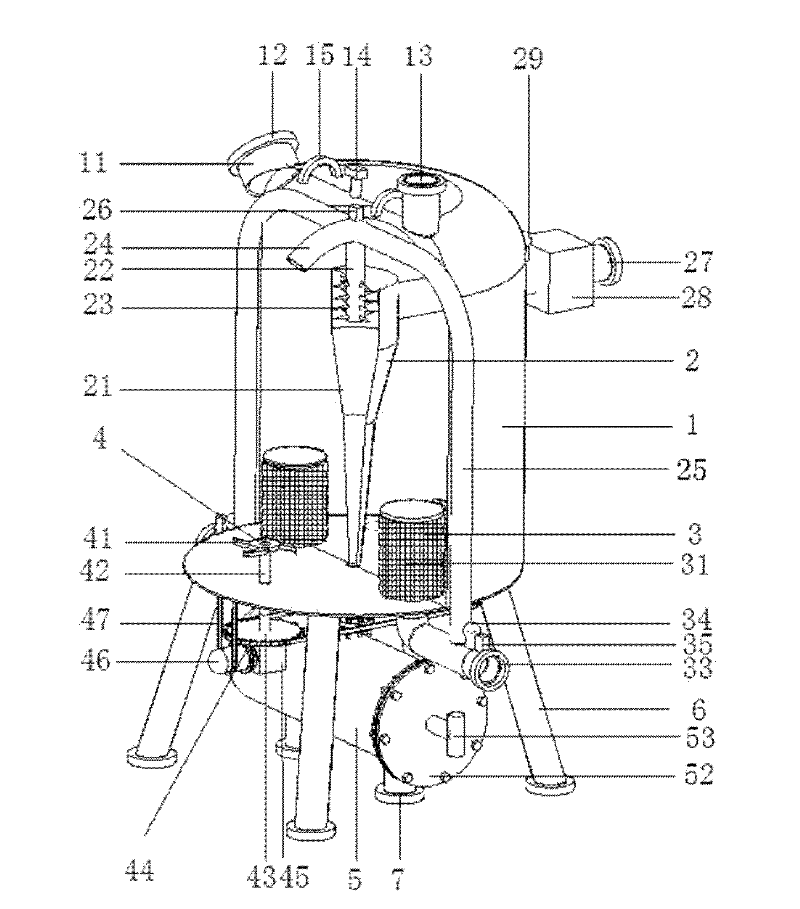

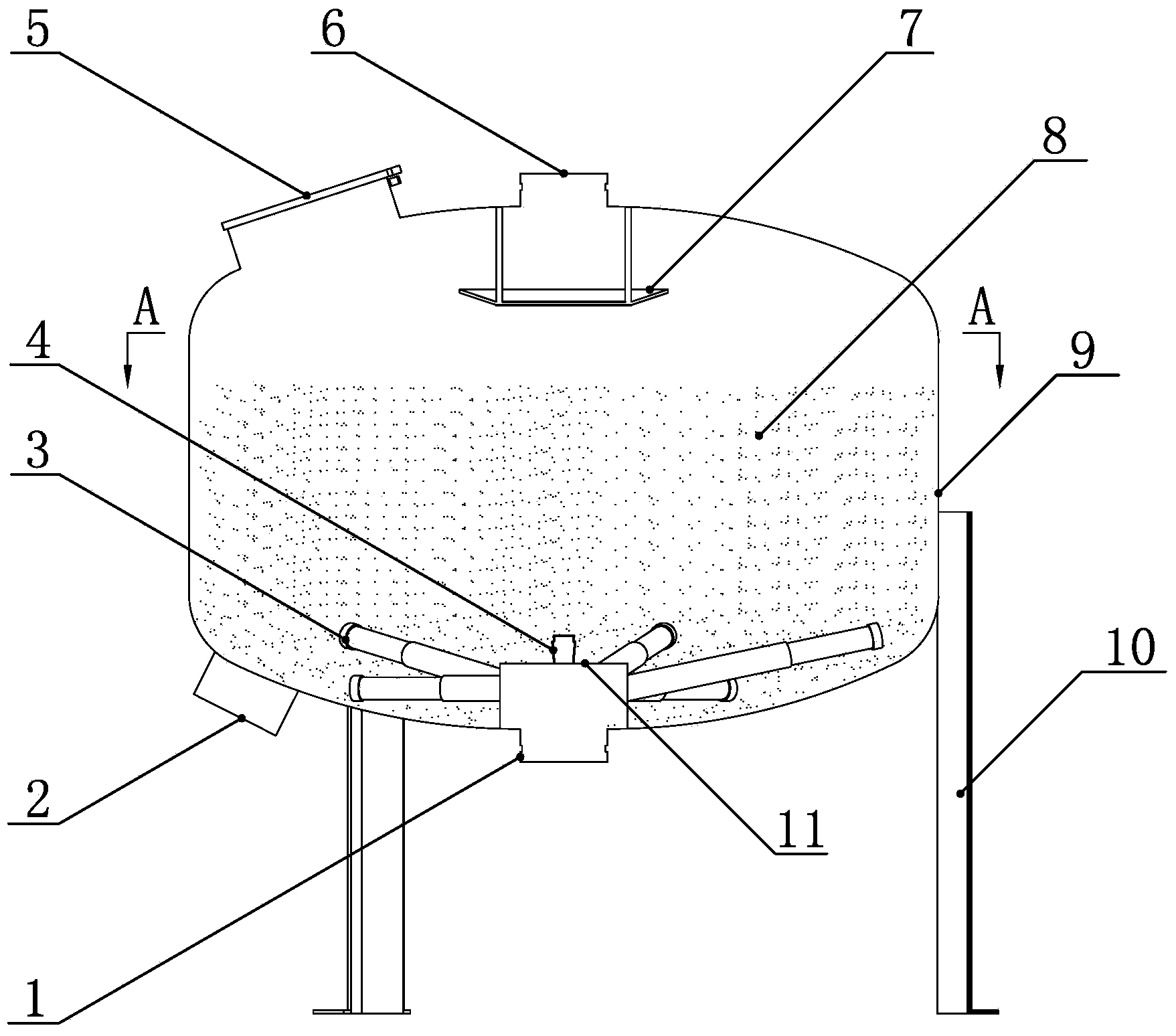

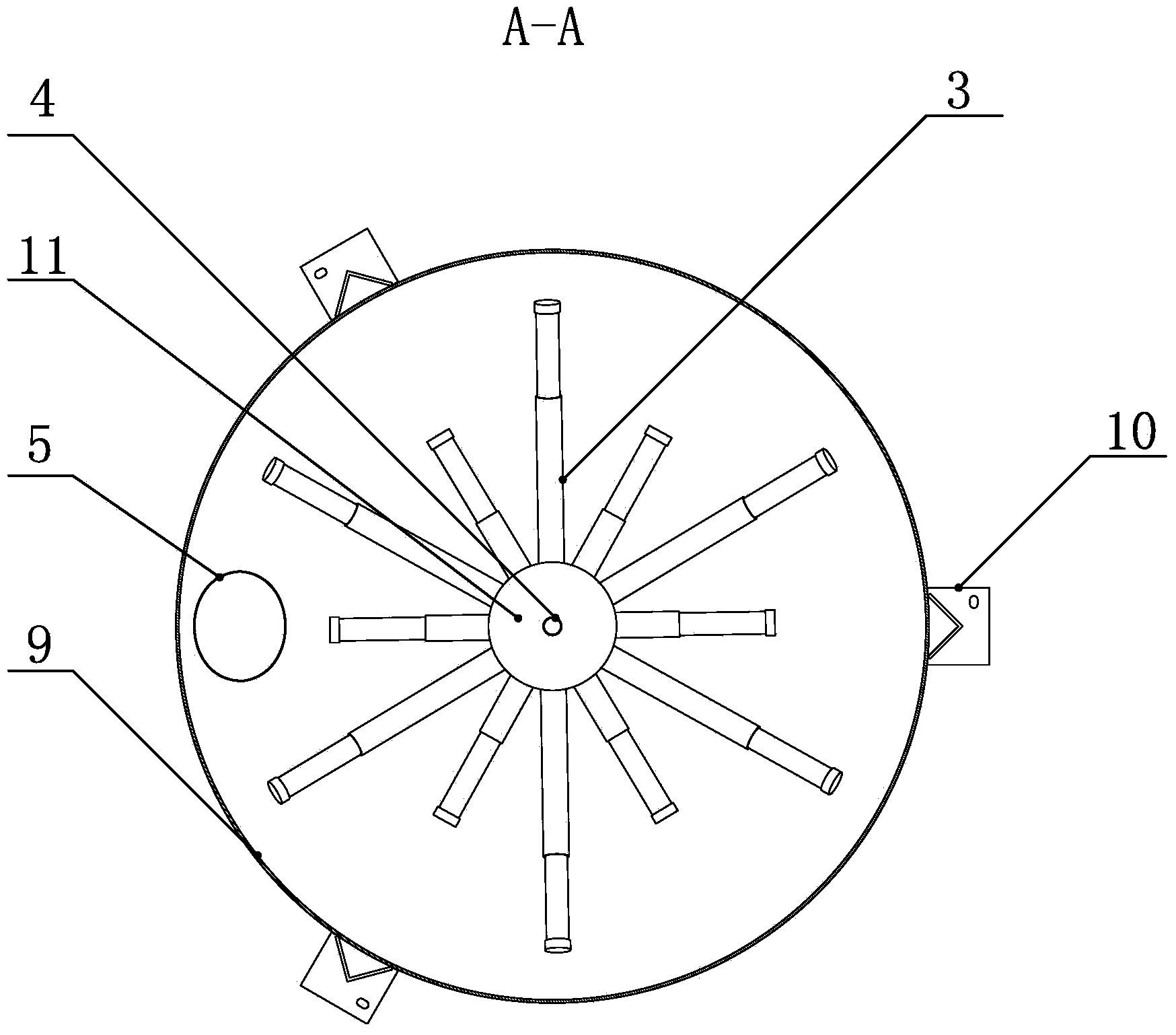

Biofilm active sand reactor and wastewater treatment method thereof

InactiveCN103803698ASmall footprintImprove backwash efficiencyBiological water/sewage treatmentChemical oxygen demandTurbidity

The invention discloses a biofilm active sand reactor and a wastewater treatment method thereof. The biofilm active sand reactor comprises a main body, a water inlet pipe, an effluent weir, a filter material, a water distributor, a sand guide cone, an air lifting pump, a sand lifting air nozzle, a sand lifting pipe, a sand washer, a sand washing water outlet and an electric control system. The wastewater enters through the water inlet pipe and is uniformly distributed by the water distributor; the wastewater goes adversely from bottom to top and goes through the filter material; impurities in the wastewater are filtered, and the turbidity and chroma in the wastewater are effectively removed. By adopting the reactor and method disclosed by the invention to treat wastewater, the reactor covers a small area, the backwashing efficiency of a filter material is high, and the filter material is not hardened; by wrapping the filter material with a biofilm, an effect of removing organic pollutants in the wastewater is realized; moreover, the chroma and turbidity removal effect of the whole system is more remarkable due to microorganisms. After the treatment, the COD (chemical oxygen demand), turbidity and chroma in the water reach or exceed the first-class A standard of the Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002).

Owner:宜兴市金德环保设备有限公司

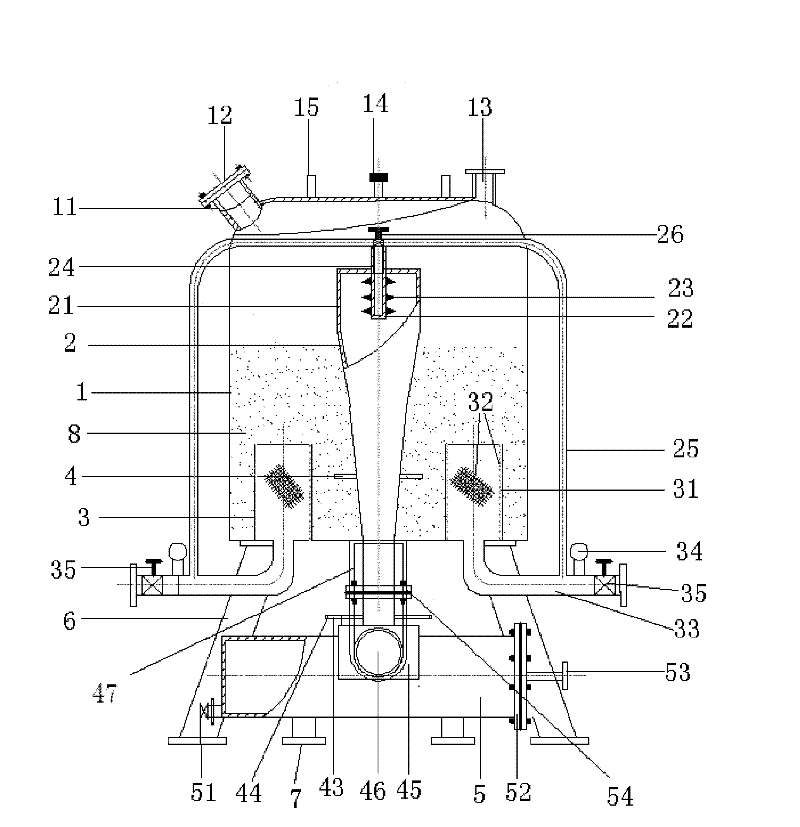

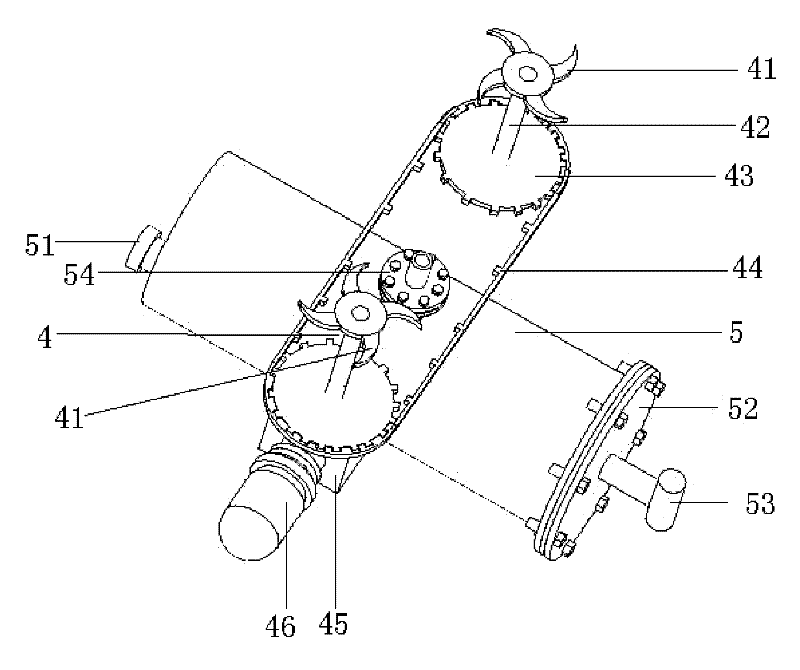

Automatic back-washing combined filter

ActiveCN102512870AFast water and sand separationImprove efficiencyFiltration circuitsImpellerWater sediment

The invention relates to an automatic back-washing combined filter which is characterized by comprising a sediment filter tank body; a sediment inlet, a back-washing water outlet and an air inlet / exhaust valve are arranged at the top of the sediment filter tank body; a water-sediment swirler is arranged in the sediment filter tank body; an outlet opening at the bottom of the sediment filter tank body passes out of the baseplate of the sediment filter tank body and is connected with a sand tank; one end of an overflow pipe connected with the water-sediment swirler extends into a water-sediment swirler tank body, and the other end of the overflow pipe is connected with the junction between the outflow pipe and a back-washing drainage pipe; an electromagnetic three-way valve is arranged at the junction; two ends of the outflow pipe are arranged in the sediment filter tank body; a water inlet tube passing out of the sediment filter tank body is connected on the water-sediment swirler tank body; drain pipes passing out of the bottom plate of the sediment filter tank body are connected with the bottoms of two mesh gauze filters arranged in the sediment filter tank body; two ends of the back-washing drainage pipes pass out of the sediment filter tank body and are correspondingly connected on the drain pipes; an impeller is arranged in the sediment filter tank body; and the motor fixed on the sediment filter tank body provides power for the impeller.

Owner:德邦大为(芜湖)农机有限公司

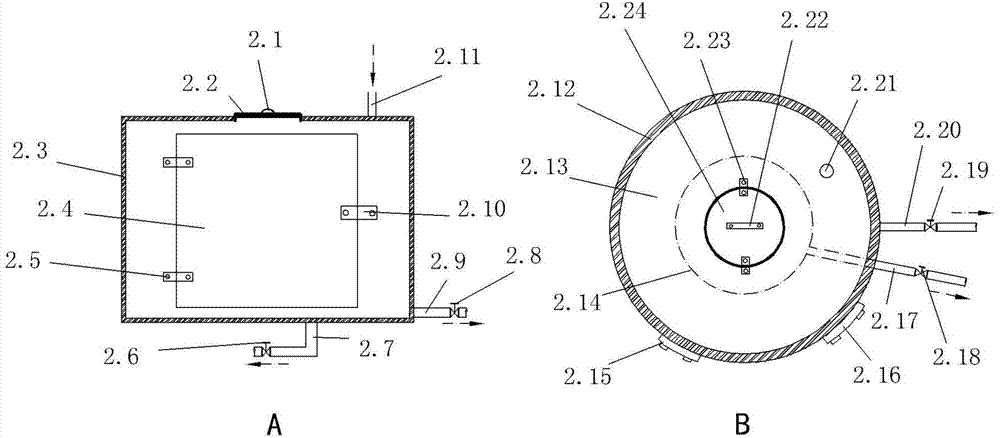

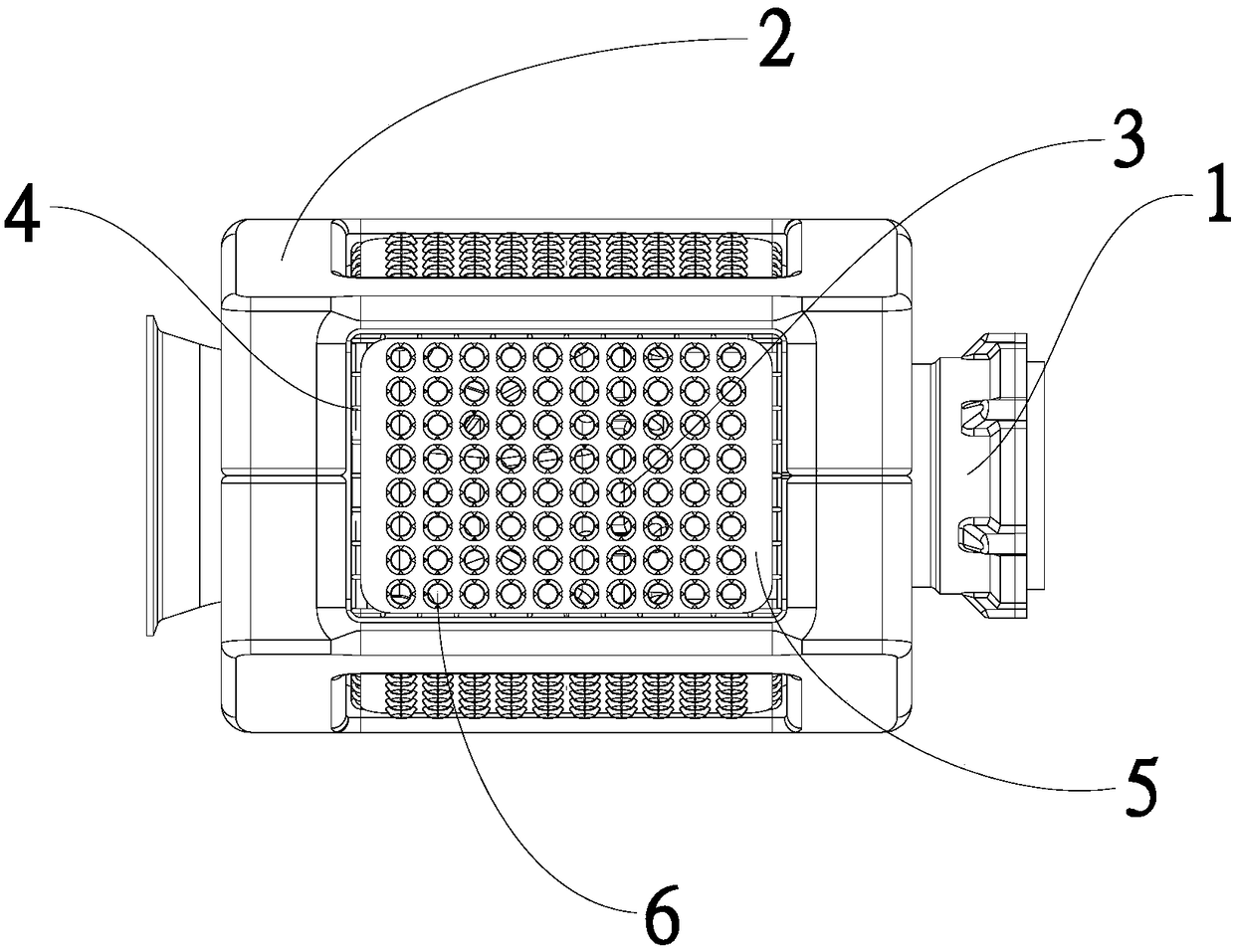

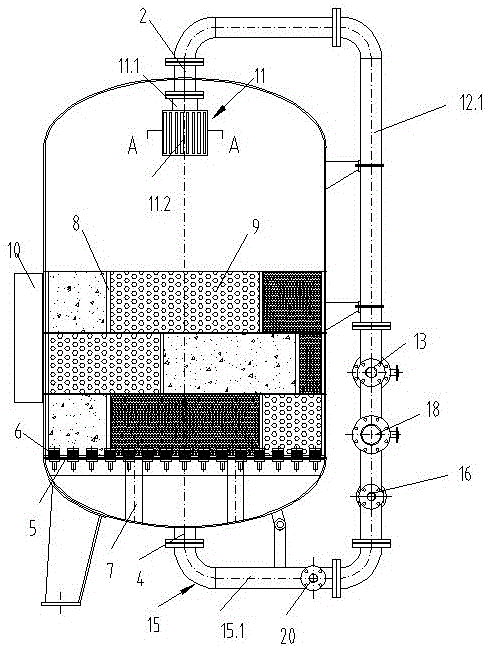

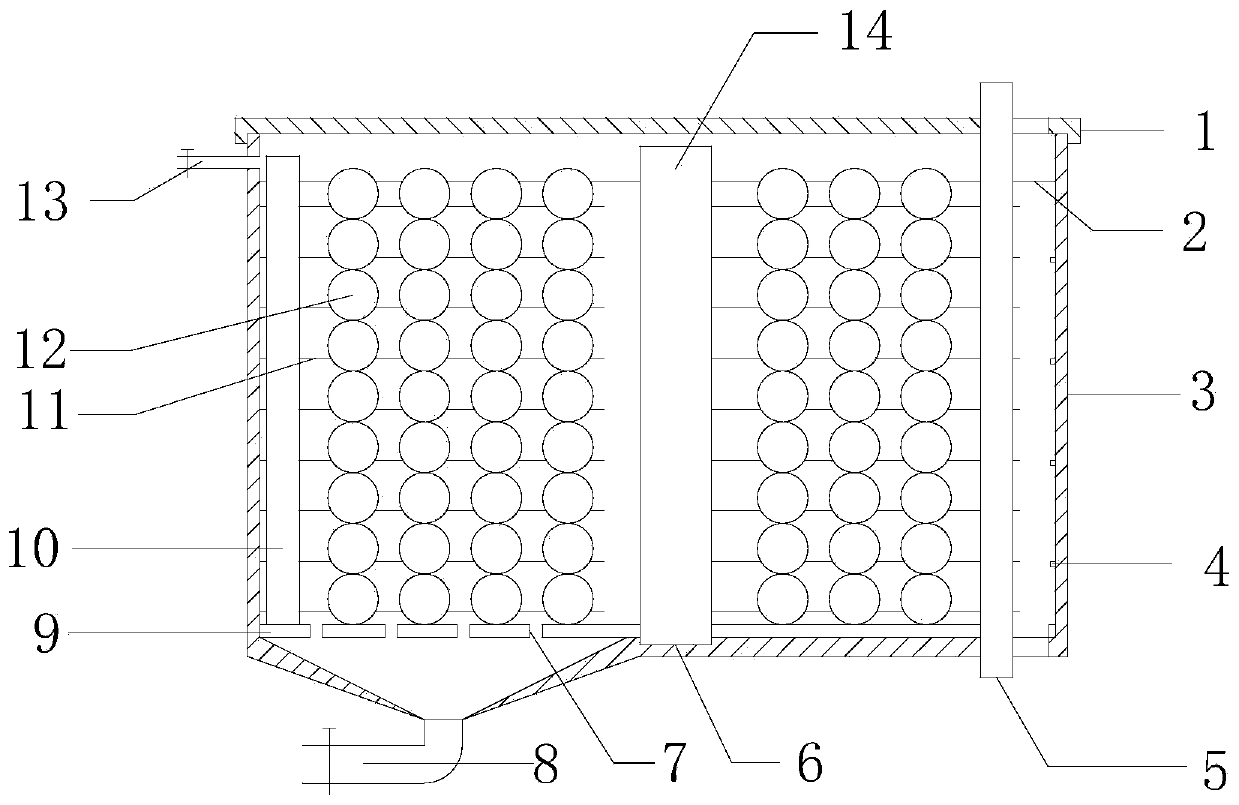

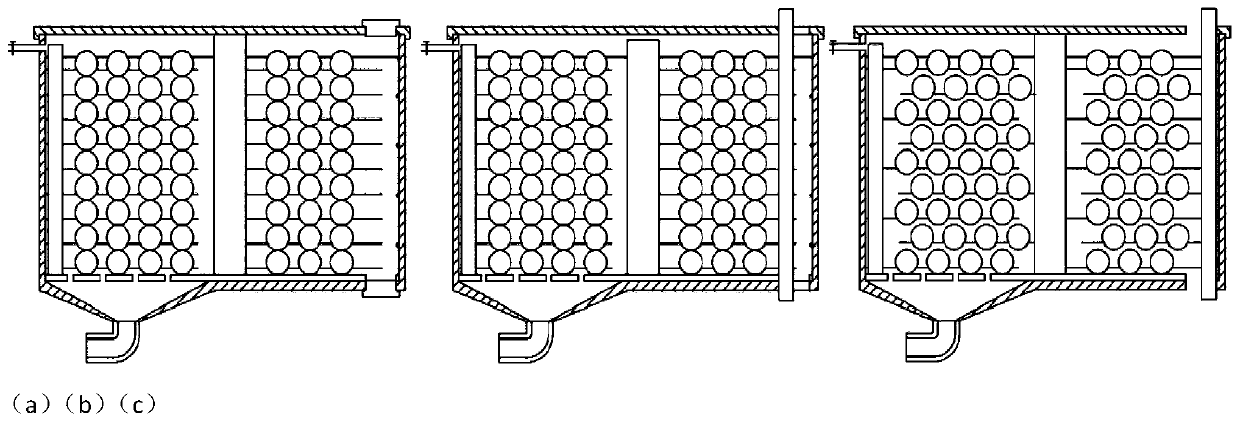

Multi-medium filter

InactiveCN105964022AImprove backwash efficiencyImprove filtration efficiencyLoose filtering material filtersGravity filtersActivated carbonFiltration

A multi-medium filter comprises a tank body, a water inlet pipe formed at the top end of the tank body, an exhaust pipe formed at one side of the water inlet pipe, and a water drainage outlet formed at the bottom end of the tank body; a filtration screen board is arranged close to the bottom end in the tank body; water drainage caps are arranged on the filtration screen board, a plurality of support tubes are arranged at the bottom end of the filtration screen board, bottom ends of the support tubes are connected with the tank body, a plurality of layers of mutually stacked filtering material screen racks are arranged above the filtration screen board, the filtering material screen racks comprise disc-shaped brackets and grille-shaped supports perpendicular to the disc-shaped brackets, the grille-shaped supports comprise a plurality of staggered plate bodies, top ends of the plat bodies are zigzag, each space separated by the grille-shaped supports of the filtering material screen racks are filled with a filtering material, and the filtering material includes quartz sand, activated carbon or anthracite.

Owner:JIANGSU ZHONGCHAO ENVIRONMENTAL PROTECTION

Novel sand and rock filter

InactiveCN104069680AImprove filtering effectPrevent impurities from passing throughFiltration circuitsEnvironmental geologySewage treatment

The invention provides a novel sand and rock filter, relates to a filter for surface water filtering and sewage treatment, and aims to provide a novel sand and rock filter which is simple in structure, low in use and maintenance cost, and complete in filtering and cleaning. The novel sand and rock filter comprises a tank body; a water inlet and a sand filling opening are formed in the upper part of the tank body; a water outlet and a sand digging opening are formed in the lower part of the tank body; a plurality of brackets are mounted below the tank body; a single buffering baffle is arranged under the water inlet; the edge part of the buffering baffle is arranged upwards in an inclined manner; a filter element base is mounted above the water outlet; a back washing valve and a plurality of filter elements are arranged on the filter element base; each filter element comprises a framework and a wrapping wire wound on the framework; the cross section of the wrapping wire is trapezoidal; the bottom surface, corresponding to the longer bottom edge, of the trapezoidal cross section is in contact with the framework; a V-shaped clearance is defined by two adjacent circles of the wrapping wire on the framework; a sand and rock mixing layer is arranged in the tank body; the top surface of the sand and rock mixing layer is higher than the upper surfaces of the filter elements.

Owner:东方智感(浙江)科技股份有限公司

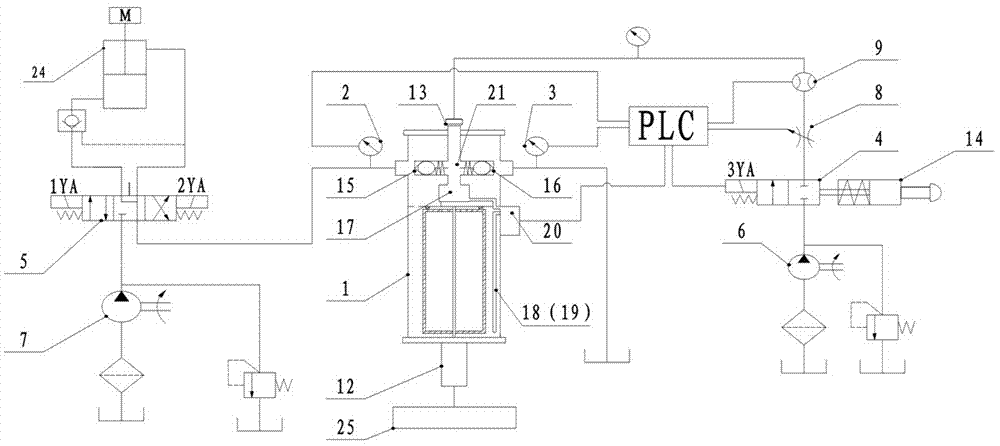

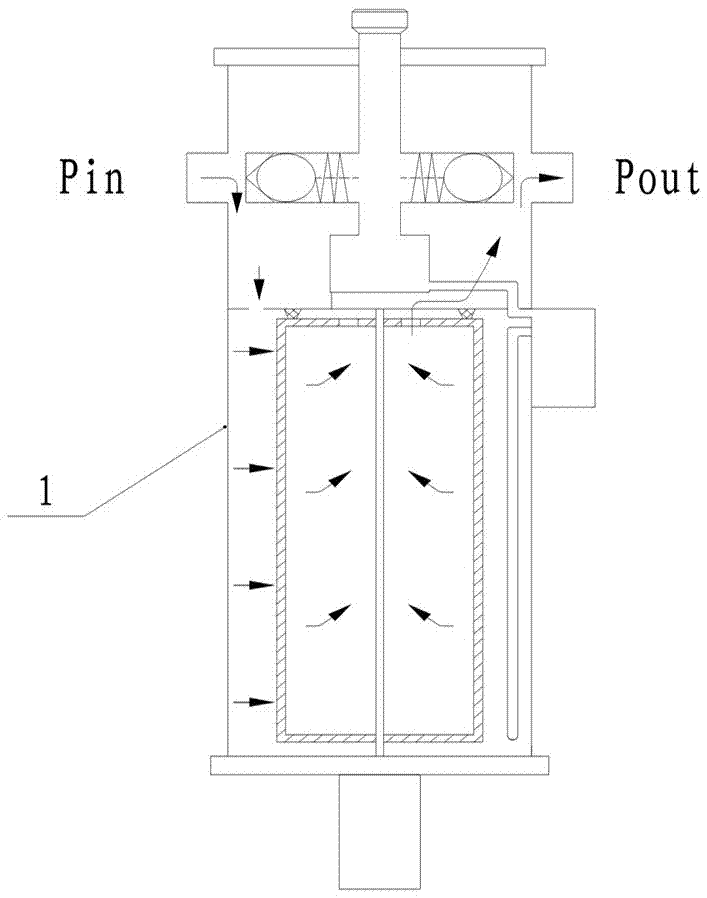

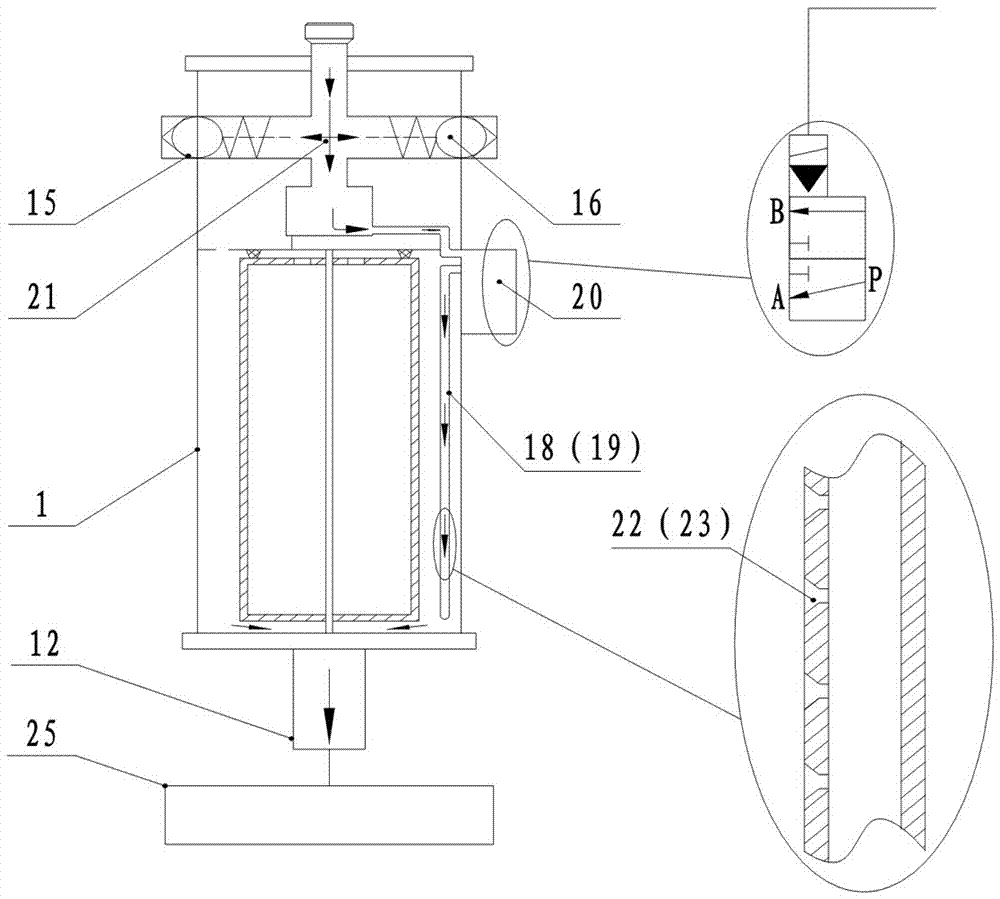

High water base filtration system back washing apparatus based on fluid-solid coupling vibration, and back washing method thereof

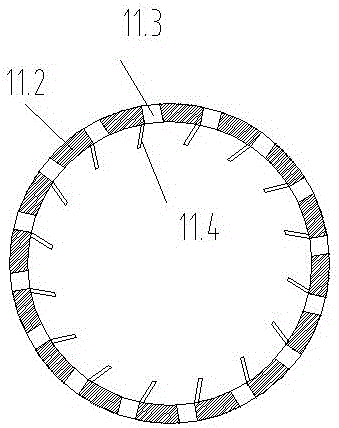

InactiveCN107158782ASimple structureImprove backwash efficiencyMembrane filtersMoving filtering element filtersWater basedJet flow

The invention belongs to the technical field of coal mine fully-mechanized mining work surface filters, and provides a high water base filtration system back washing apparatus based on fluid-solid coupling vibration, and a back washing method thereof. The high water base filtration system back washing apparatus comprises a filtration core arranged in a filter, a jet flow liquid storage chamber, a drainage member, a clockwise jet flow pipe and a counterclockwise jet flow pipe, wherein a flow meter and a throttle valve are arranged between a high water base hydraulic pump and the first channel of the drainage member, the second channel of the drainage member is communicated to the liquid inlet P of an insertion-installation valve through the jet flow liquid storage chamber, the liquid outlet A and the liquid outlet B of the insertion-installation valve are respectively communicated to the clockwise jet flow pipe and the counterclockwise jet flow pipe, the clockwise jet flow pipe and the counterclockwise jet flow pipe are respectively provided with a plurality of clockwise jet flow holes and counterclockwise jet flow holes obliquely intersecting with the cross section circumference of the filtration core, and the control ends of the insertion-installation valve and the throttle valve, and the output end of the flow meter are connected to a PLC controller. According to the present invention, with the apparatus and the method, the back washing effect is improved, the back washing control process is simple, and the apparatus and the method can be widely used in coal mine fully-mechanized mining work surface.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

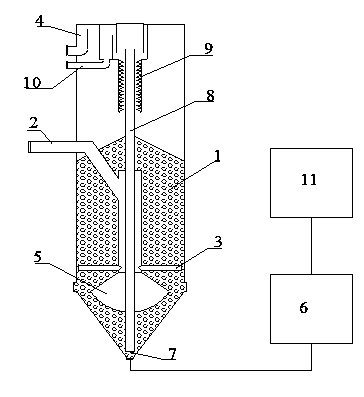

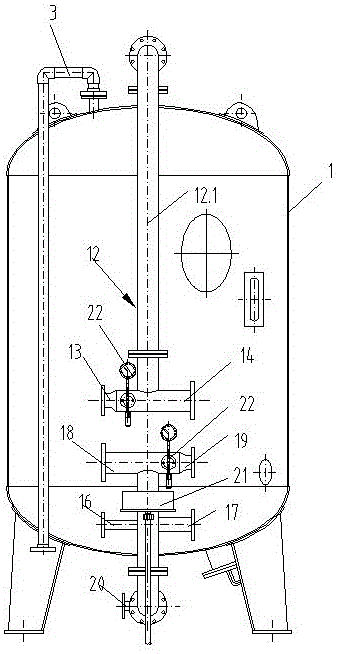

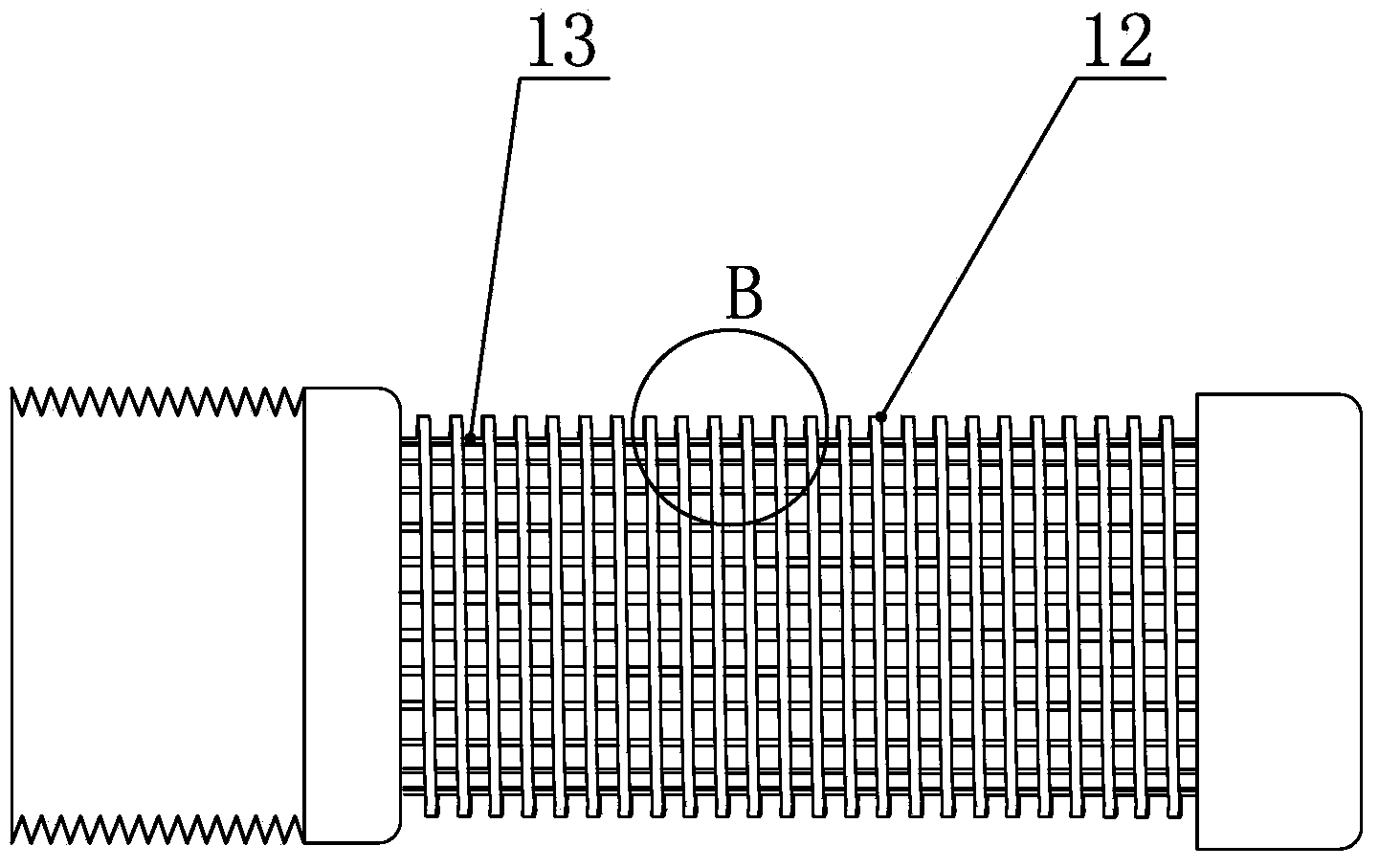

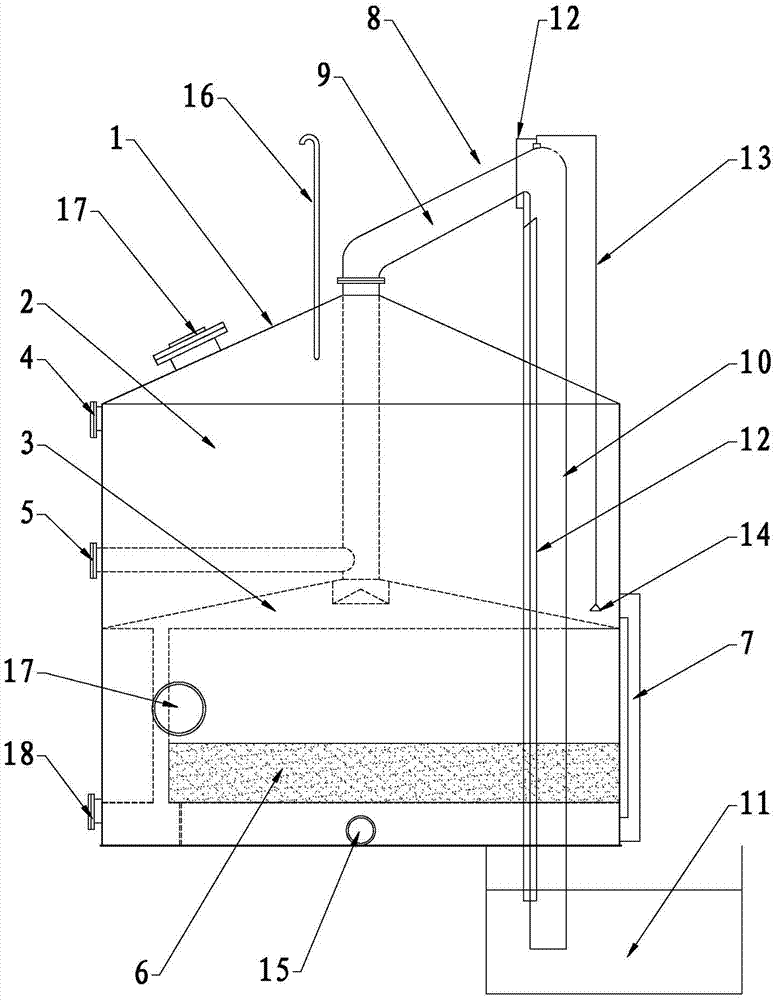

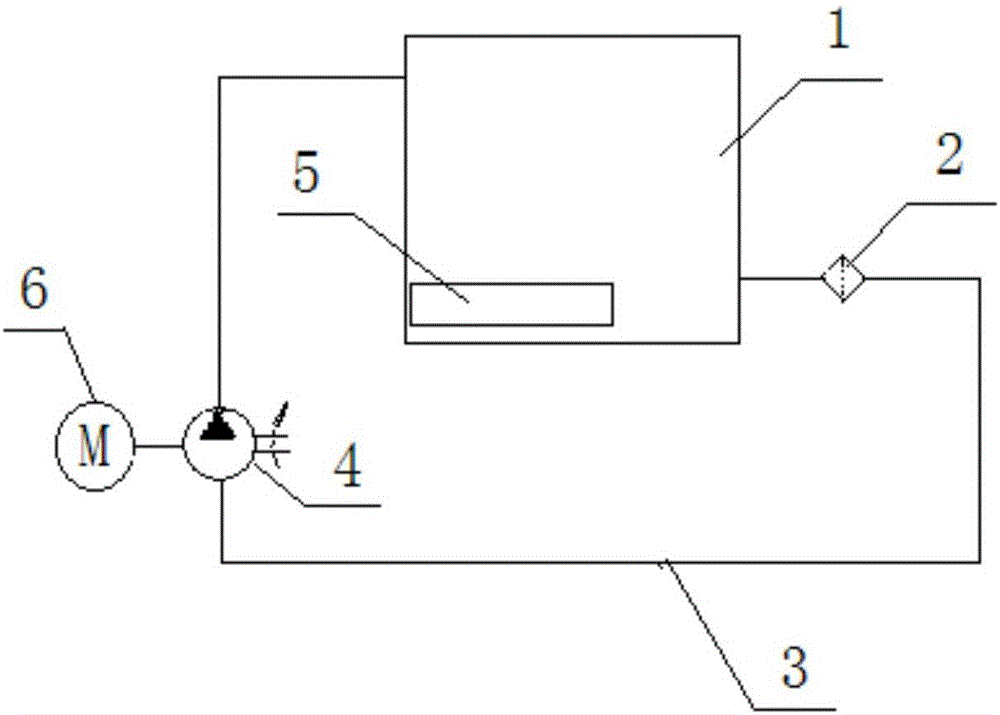

Siphon type valveless filtering pool

InactiveCN103239905ASimple structureSimple operation and maintenanceLoose filtering material filtersGravity filtersSiphonEngineering

The invention discloses a siphon type valveless filtering pool comprising a pool body (1), a clean water tank (2), a filtering water chamber (3), a water outlet (4), a water inlet pipe (5), a filtering layer (6) and a closed pipe (7), wherein the pool body (1) is provided with a siphon pipe (8) which is communicated with an outlet end of the water inlet pipe (5); the siphon pipe (8) comprises a siphon ascending pipe (9) and a siphon descending pipe (10); the lower end and the upper end of the siphon ascending pipe (9) are respectively connected with the outlet end of the water inlet pipe (5) and the upper end of the siphon descending pipe (10); the lower end of the siphon descending pipe (10) is immersed into a water seal tank (11) located at the lower side of the pool body (1); and the lower wall of the upper end of the siphon ascending pipe (9) is provided with a siphon assisting pipe (12) and the upper wall of the top end of the siphon pipe (8) is provided with a siphon damaging pipe (13) with the lower end located at the bottom of the clean water tank (2). According to the siphon type valveless filtering pool disclosed by the invention, the backwashing speed is high, the efficiency is high and the backwashing is complete, so that the siphon type valveless filtering pool is suitable for being popularized and used.

Owner:JIANGSU RUISHENG WATER TREATMENT

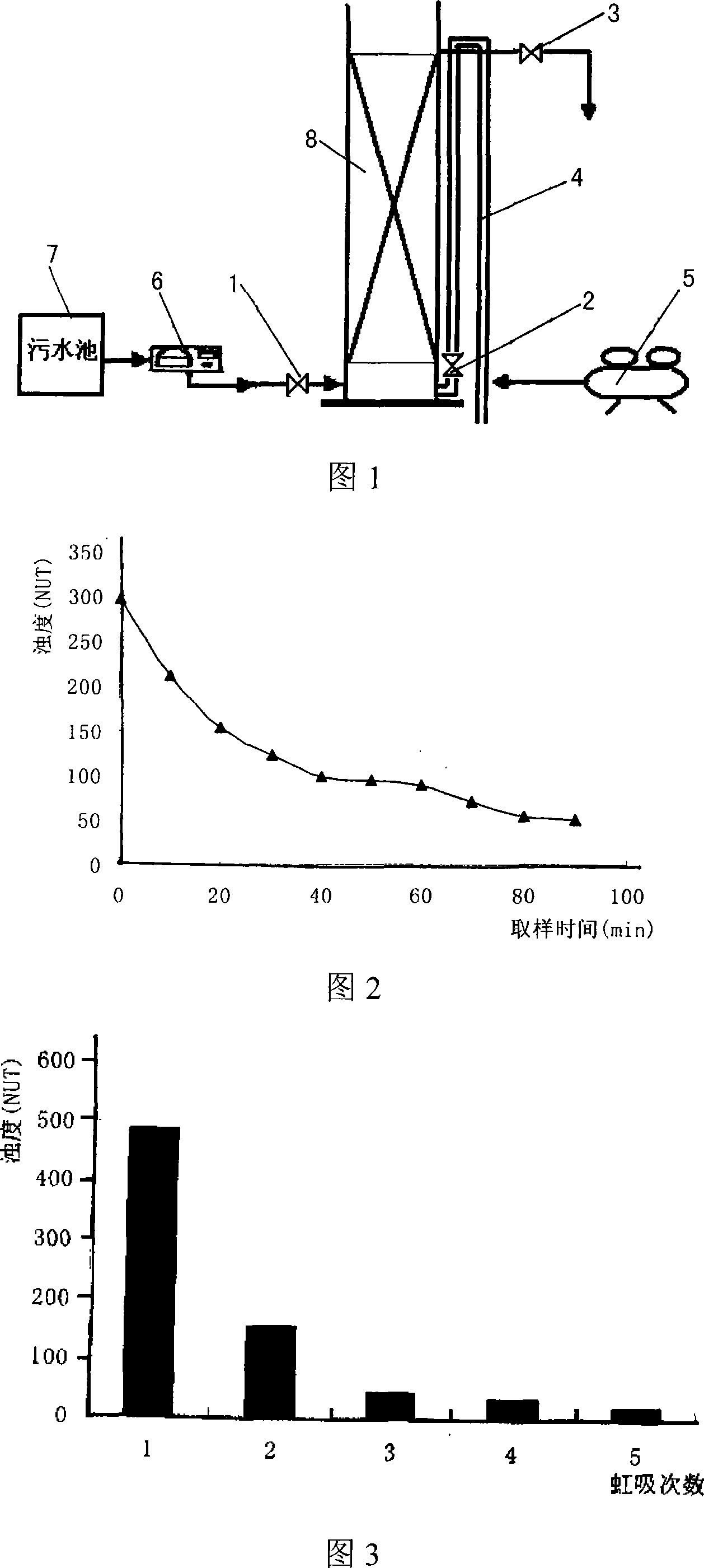

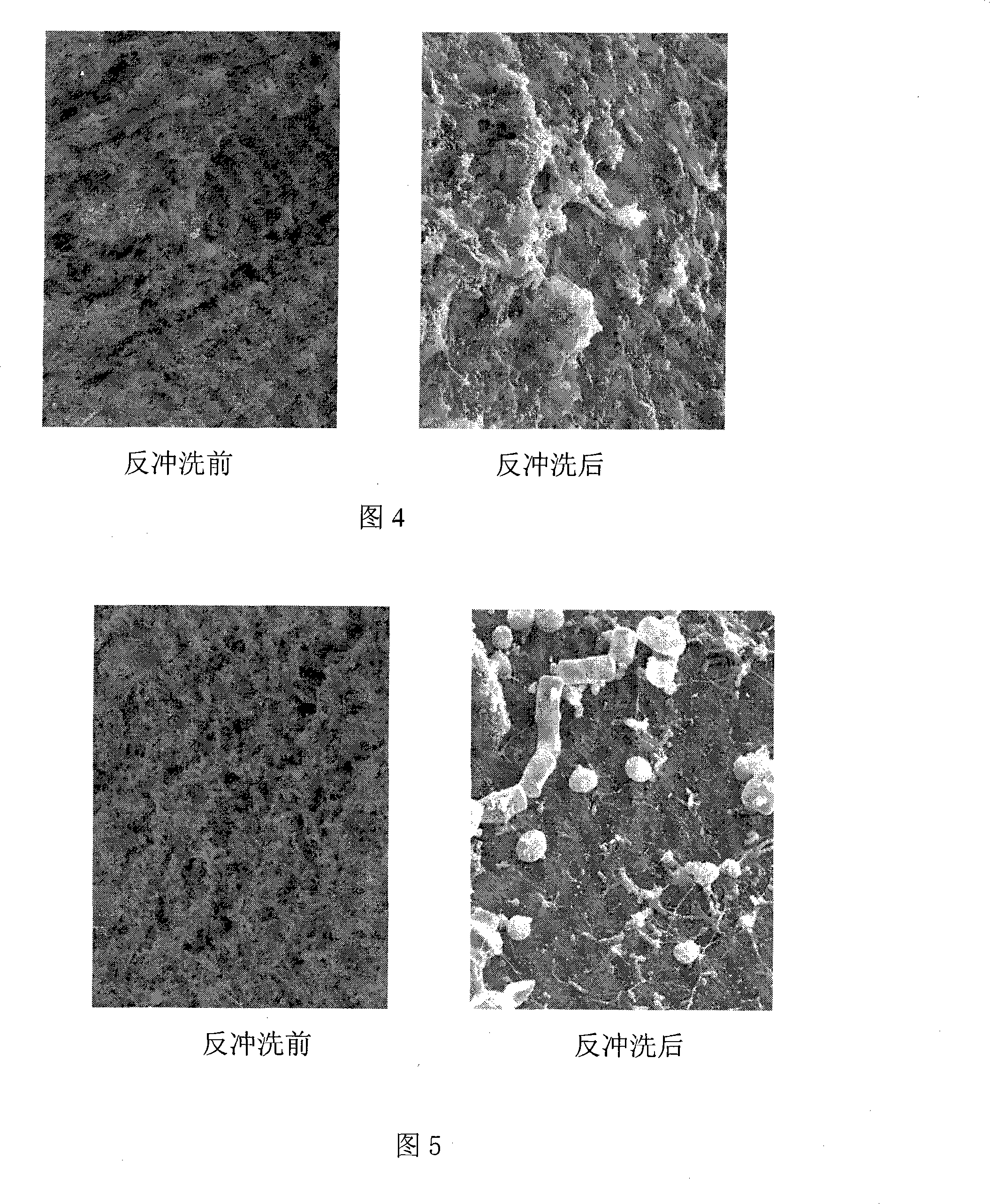

Back-flushing operation method of dynamic membrane bioreactor

InactiveCN1843971AReduce damageDoes not affect operationTreatment using aerobic processesSustainable biological treatmentMembrane bioreactorHigh pressure

The invention discloses a backwash operating mode of dynamic flim bioreactor, which belongs to the technical sphere of sewage disposal. Setting Film assembly made from bolting silk on the middle of the reaction, installing aeration device on its bottom, filtering by dynamic flim, making aeration device below film assembly, both supply oxygen for upper miscible liquids and accelerate the flow of miscible liquids, by the flow of bubble and miscible liquids, enhancing scouring and disturbance to dynamic flim; during the operation of dynamic flim bioreactor, when backwash needed, closing water outlet, opening backwash aeration pipe, supplying gas of 1.6- 8.0m3 / (m2*h) by backwash gas pump. The invention, greatly improves backwash efficiency, reduces aeration intensity and aeration time and cuts operating cost dowm; compared with cleaning with water under high pressure, it can proceedis on line, don't effect the operation of reaction, reduces the damage degree to dynamic flim, and shoertens the recovery time of dynamic flim.

Owner:SHANDONG UNIV

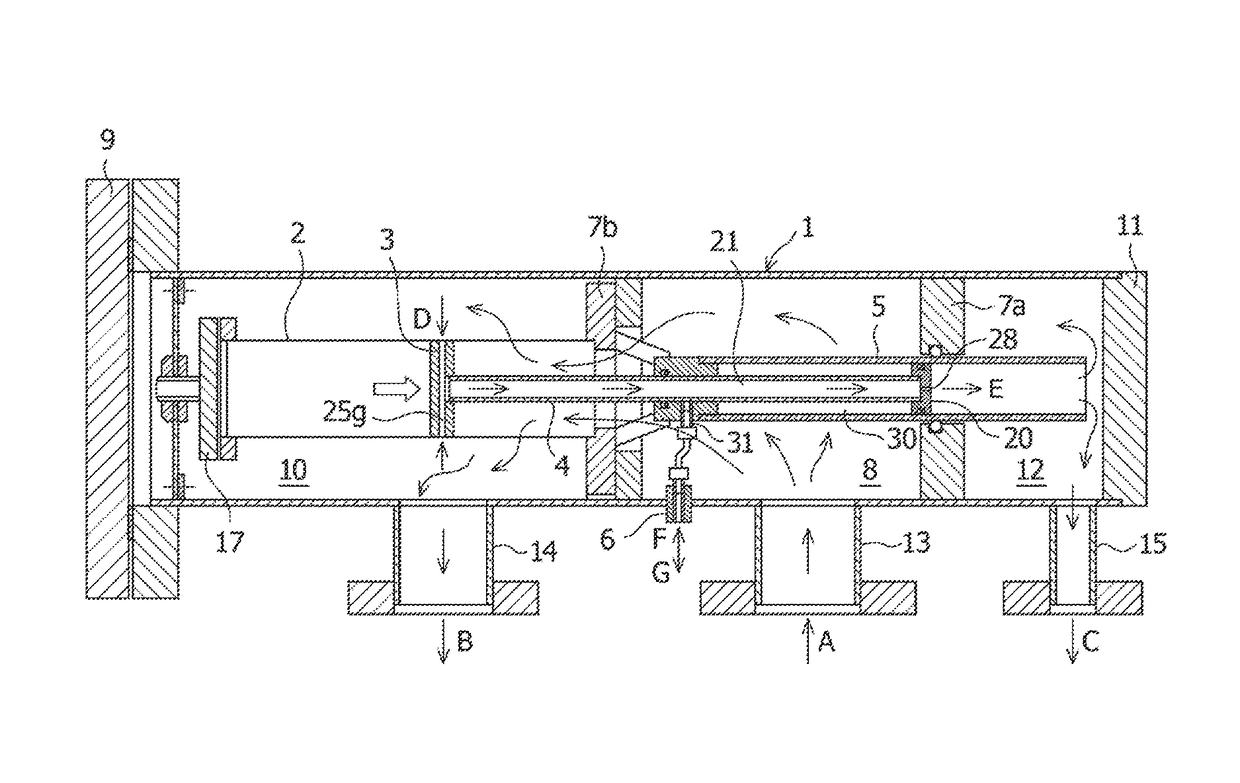

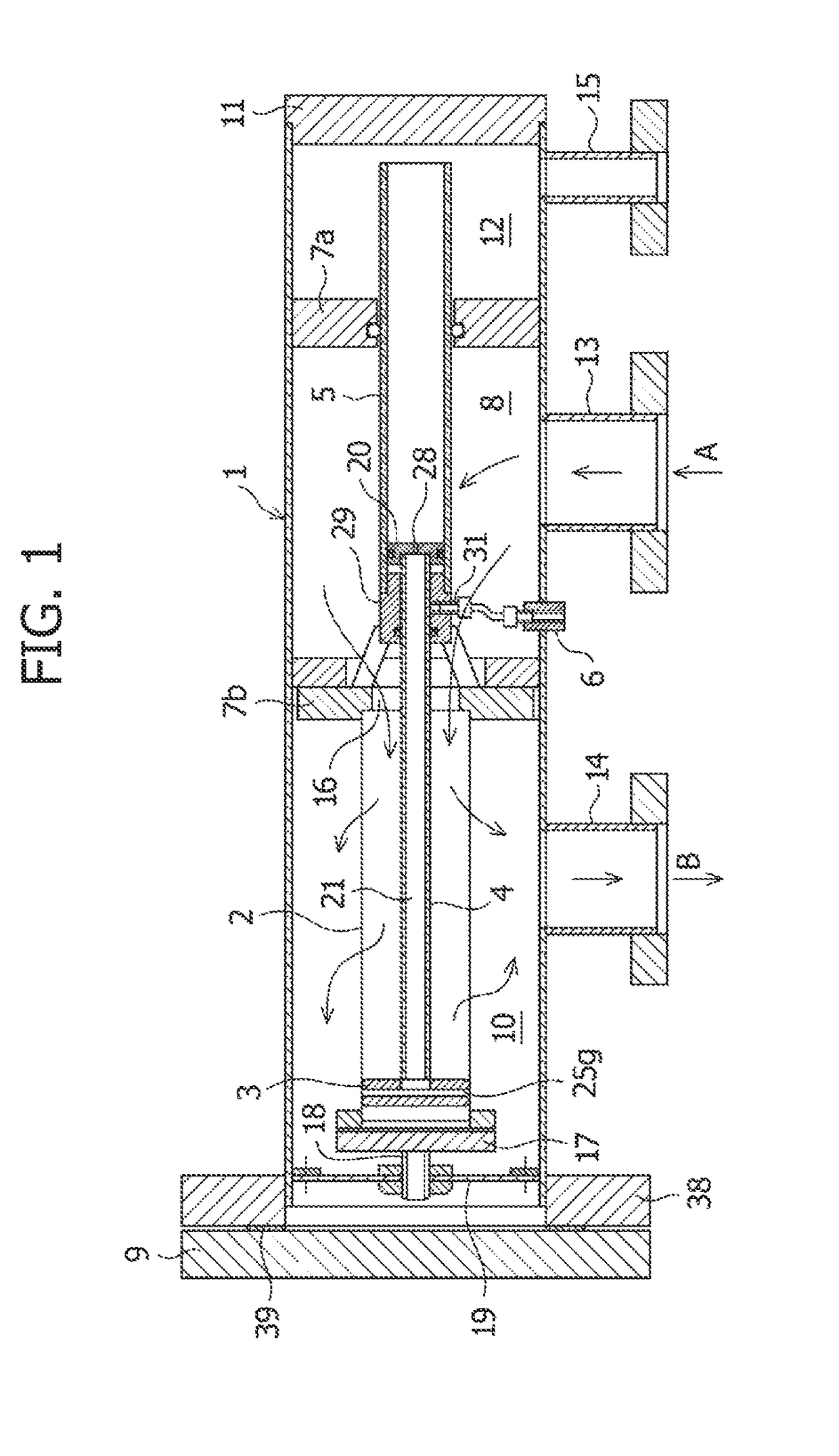

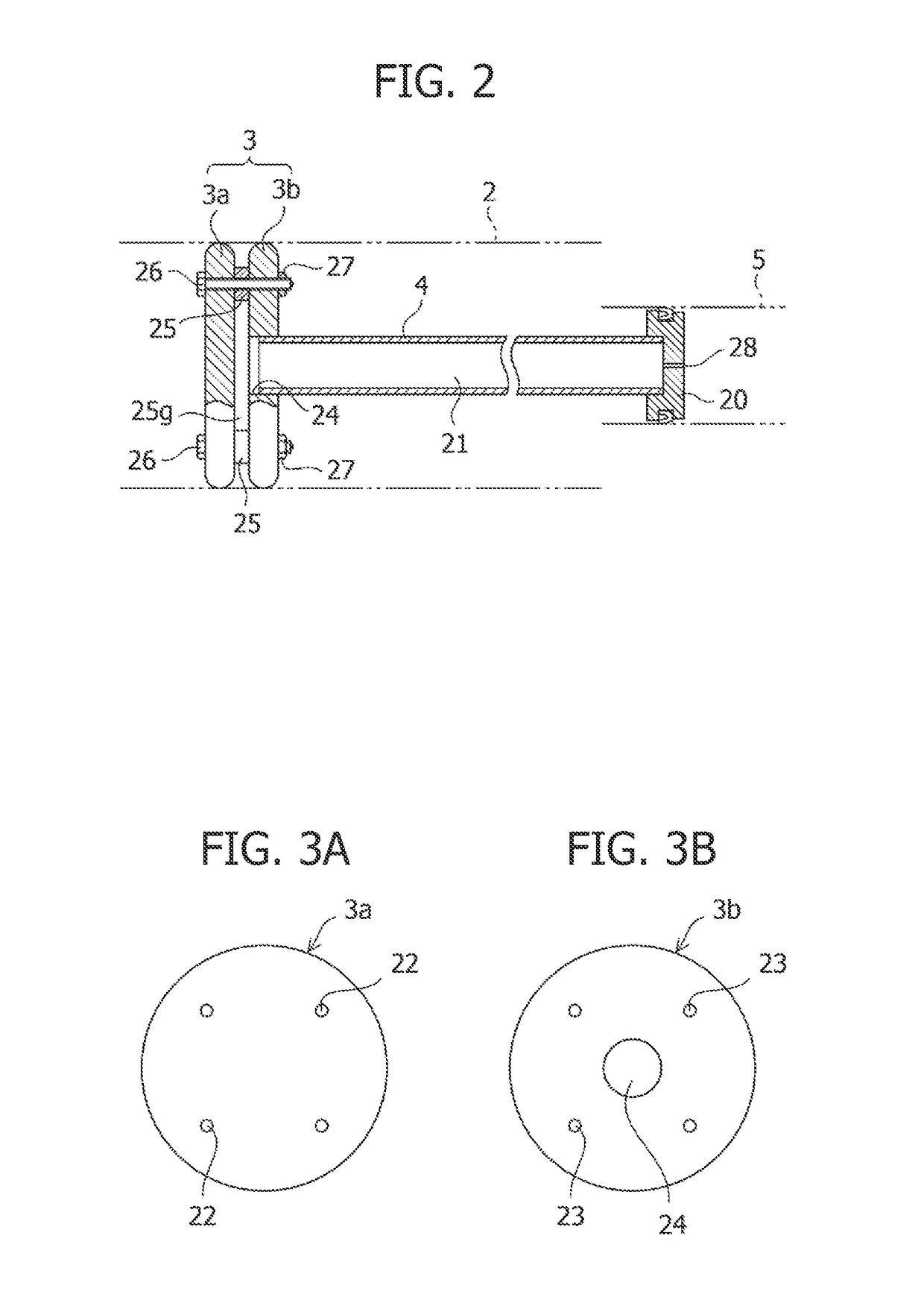

Filter apparatus

ActiveUS9669335B2Improve backwash efficiencyReduce in quantityDispersed particle filtrationTransportation and packagingFiltrationEngineering

A filter apparatus including: a casing including, in a sealed space provided therein, a fluid inflow chamber, a filtration chamber and a drain chamber; a filter element provided inside the filtration chamber to let a fluid pass therethrough from inside to outside to perform filtration; a backwash slide member movably provided inside the filter element and removing trapped matter adhering to an inner circumferential surface of the filter element by an inward flow generated by a difference in pressure inside and outside the filter element at the time of backwashing; a backwash pipe that lets the inward flow flow toward the drain chamber; an actuation cylinder that lets the fluid from the backwash pipe flow toward the drain chamber; and a fluid flowing unit allowing a fluid to flow, enabling a piston member to move inside the actuation cylinder.

Owner:FUJI FILTER MFG

Complex pipe cavity part reverse flushing equipment and reverse flushing process thereof

ActiveCN106583333ASmall footprintSave spaceHollow article cleaningCleaning using liquidsFuel tankSmall footprint

The invention discloses complex pipe cavity part reverse flushing equipment and a reverse flushing process. The reverse flushing equipment comprises an opening container, a gear pump and a motor; the motor is connected with the gear pump; the opening container and the gear pump are connected through an oil outlet pipe; a ultrasonic generator is mounted in the opening container; and the oil outlet pipe is provided with a filter at an outlet end of the opening container. The reverse flushing process comprises the following steps; the reverse flushing equipment and the reverse flushing process guarantee the cleanness of inner cavities of parts; the reverse flushing process can satisfy the reverse flushing requirements of any complex pipe cavity parts, and is simple and flexible in operation, high in efficiency, excellent in reverse flushing effect and high in safety coefficient; as a reverse flushing container and an oil collecting tank are integrated, the floor area is small, and the space is saved; and as the gear pump is used, the reverse flushing equipment is low in noise during working.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

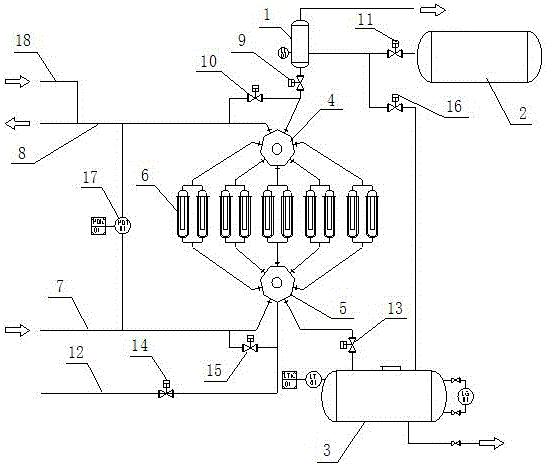

Full-automatic back-flush filtering system

InactiveCN106731168AImprove backwash efficiencyHigh degree of automationFiltration separationDifferential pressureFluid infusion

The invention discloses a full-automatic back-flush filtering system which comprises an emptying tank, a nitrogen tank, a pollution receiving tank, a first multi-channel rotating valve, a second multi-channel rotating valve and a plurality of filters, wherein the bottoms of the plurality of filters are communicated with a filtrate inlet pipe through the second multi-channel rotating valve; the tops of the plurality of filters are communicated with a filtrate outlet pipe through the first multi-channel rotating valve; the first multi-channel rotating valve is connected with the emptying tank through a coupling valve; a filtered coupling valve connected with the first multi-channel rotating valve in parallel is arranged between the coupling valve and the filtrate outlet pipe; the emptying tank is connected with the nitrogen tank; the second multi-channel rotating valve is connected with a soaking inlet pipe and the pollution receiving tank; a fluid infusion filtering valve connected with the second multi-channel rotating valve in parallel is arranged between the soaking inlet pipe and the filtrate inlet pipe; the pollution receiving tank is communicated with the emptying tank; a differential pressure transmitter is arranged between the filtrate outlet pipe and the filtrate inlet pipe. According to the system disclosed by the invention, the back-flushing efficiency can be improved, the degree of automation is high, centralized monitoring is facilitated, and unattended full-automatic operation can be realized.

Owner:QIDONG CITY FEIHONG AUTOMATION EQUIP

Air-water combined siphonage bidirectional backwash technique and device

InactiveCN101172696ADoes not affect activityLong cycleTreatment using aerobic processesSustainable biological treatmentSiphonFluidized bed

The invention discloses a gas-water united siphon bi-directional backwash art and the device thereof, belonging to the backwash field of the sewage treating art. The invention relates to establish a new backwash art in a fluidized bed system for treating sewage, and names the art as a gas-water united siphon bi-directional backwash art. The invention has the characteristics that the bottom aeration is adopted; when the lower part has inflow and reaches the siphon water level, the siphon at the lower part automatically discharges backwash water. The new backwash art has the advantages of time and water conservation, short recover period after the backwash, prolonged backwash period and so on when being compared with the commonly adopted gas-water united unilateral backwash art and the single pure water backwash art at present.

Owner:CHINA AGRI UNIV

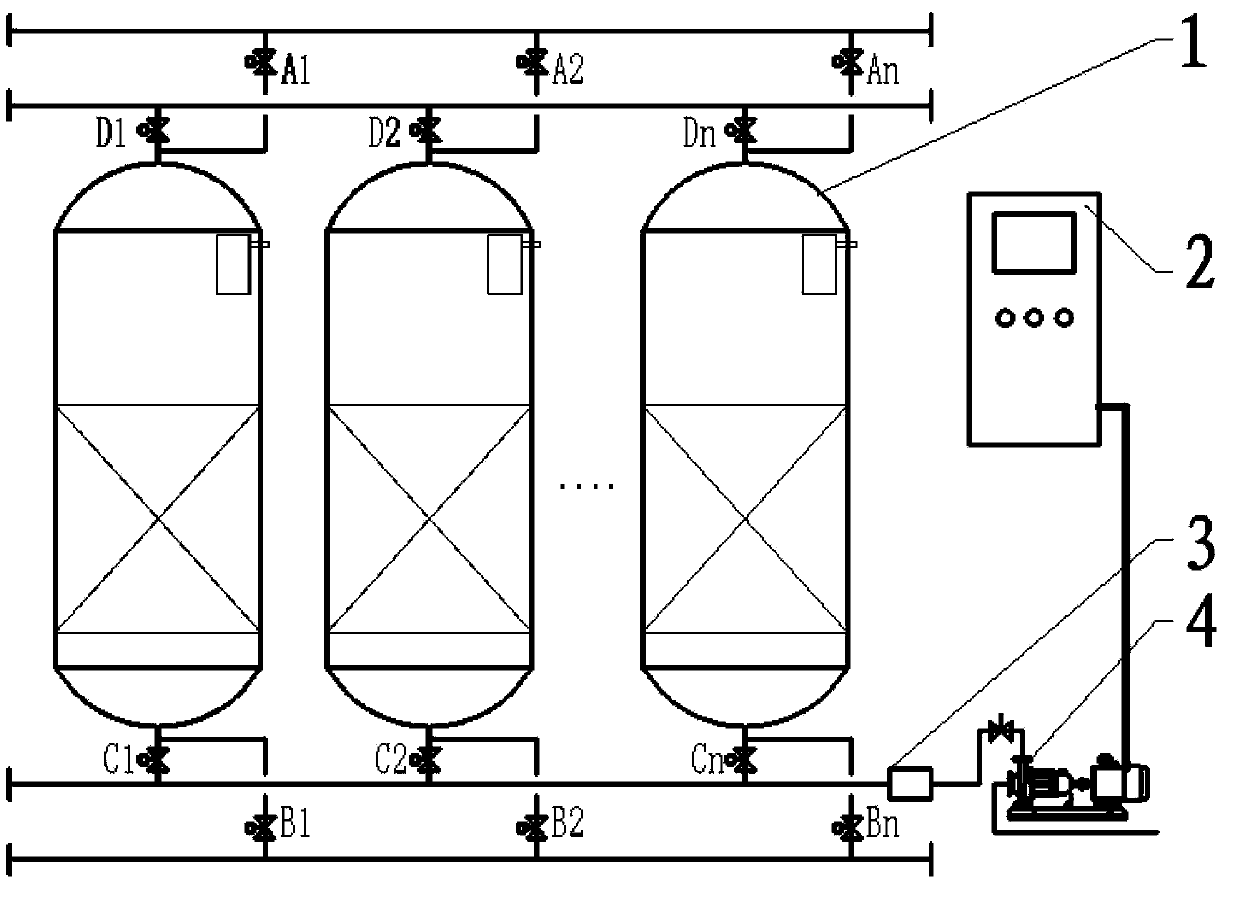

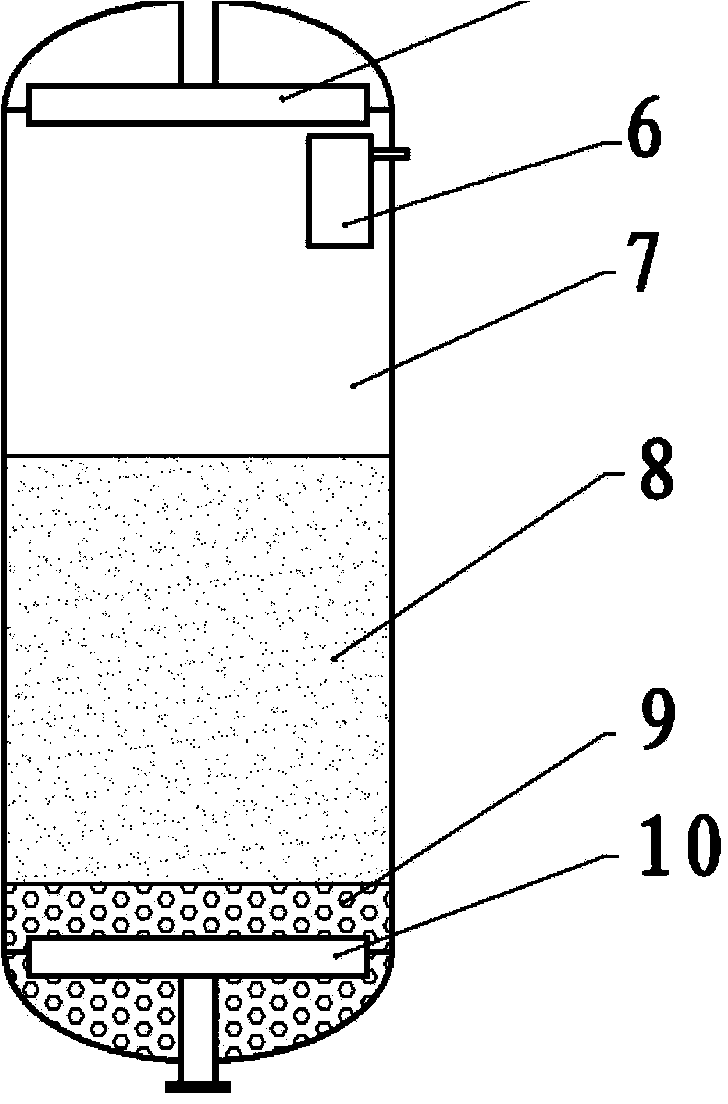

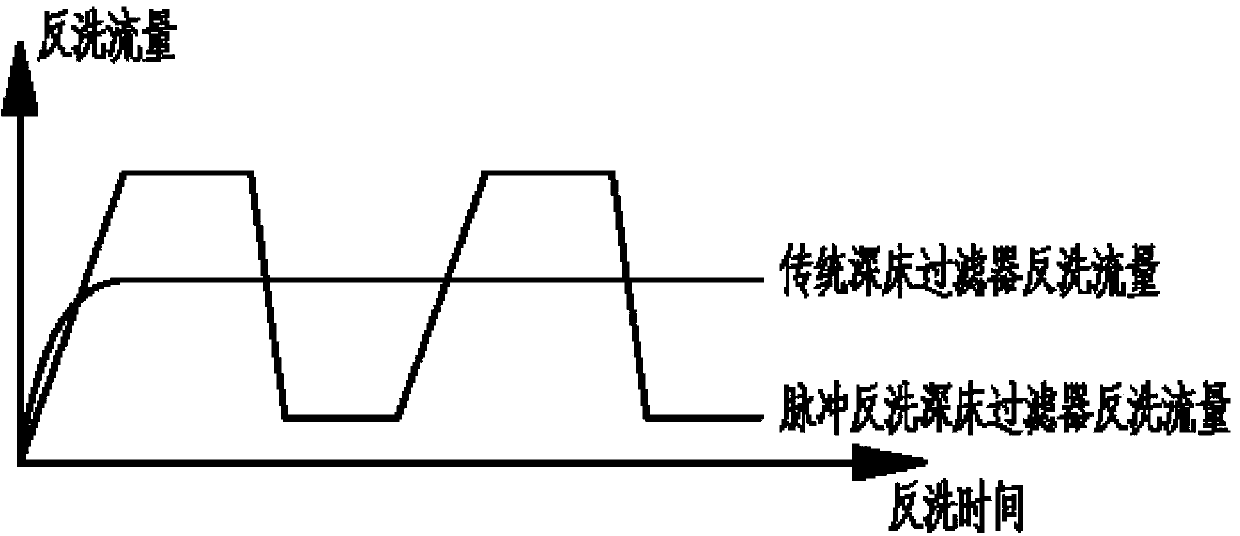

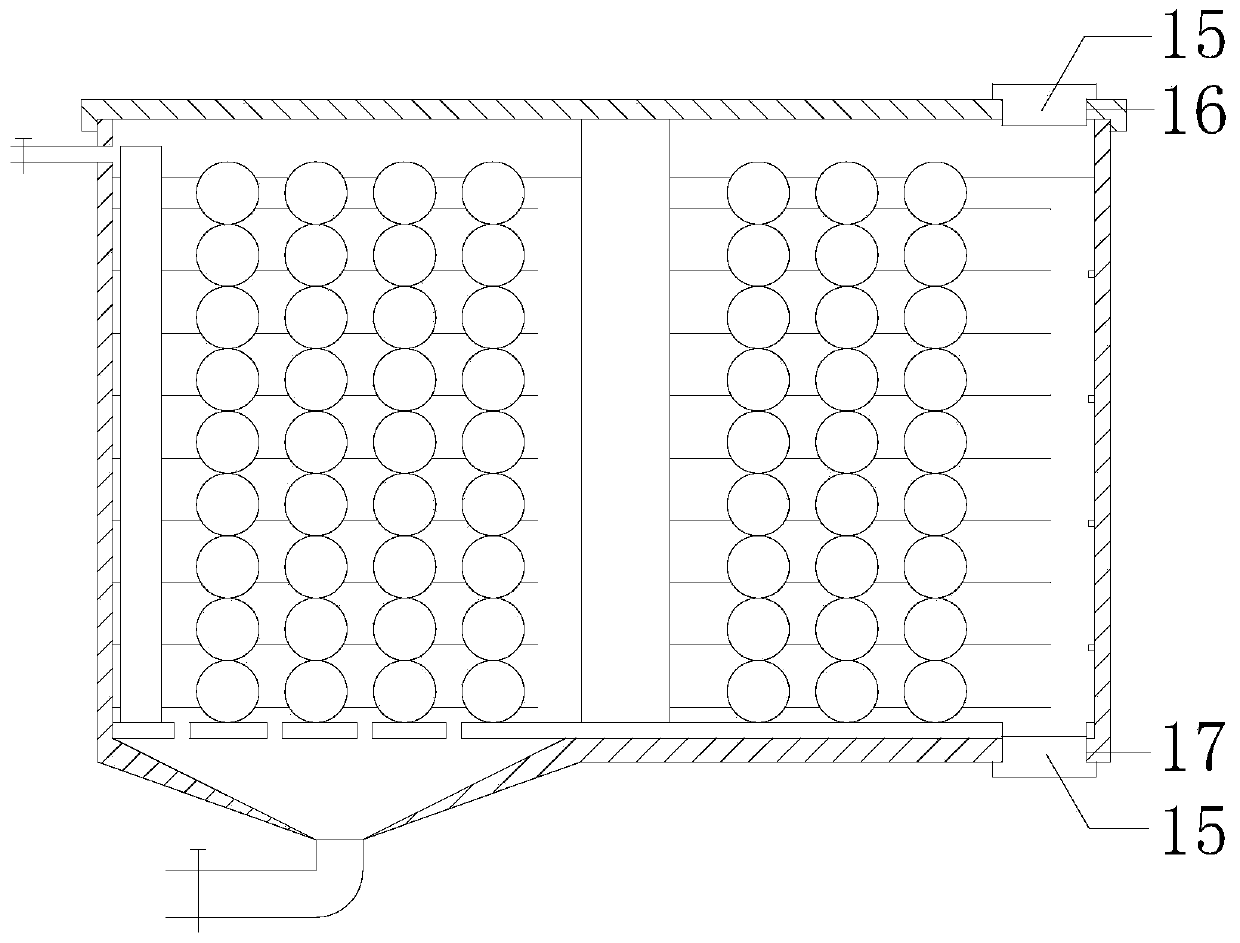

Pulse backwashing deep bed filter device and method

ActiveCN104208928AAlleviate the momentary shockEasy to desorbLoose filtering material filtersGravity filtersWater savingFrequency changer

The invention discloses a pulse backwashing deep bed filter device and a method, and belongs to the technical field of automatic control. A set of device may be provided with 1, 2.....n pulse backwashing deep bed filters; the pulse backwashing deep bed filter comprises a casing, a water collection mechanism arranged on the lower part of the casing and a connecting tube thereof, a water distributing mechanism arranged on the upper part of the casing and a connecting tube thereof, a filter material cushion layer arranged on the lower part of the casing, a filter material arranged in the middle part of the casing, and a filter material height detection device arranged on the upper part of the casing; a backwashing pump is a centrifugal pump, the rotating speed of an arranged motor can be regulated in variable frequency; a flow detection device is arranged on a main backwashing pipeline of a backwashing pump outlet; a control cabinet is provided with a PLC (programmable logic controller), and also provided with a frequency converter for regulating the rotating speed of the backwashing pump; the flow detection device and the filter material height detection device are provided with detection signal output ends which are connected with signal acquisition ends of the PLC. The effect of the pulse backwashing deep bed filter device is that: water-saving high-efficiency cleaning of a filtering layer can be performed by used of backwash water producing flow fluctuation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Electrostatic separator capable of changing packing stacking mode and cleaning method thereof

ActiveCN111349456AAchieve purificationEasy to fillRefining by electric/magnetic meansCleaning using liquidsElectrostatic separationStructural engineering

The invention provides an electrostatic separator capable of changing a packing stacking mode and a cleaning method thereof, the packing stacking mode can be conveniently changed in the electrostaticseparator without disassembly; the technical problem of backwashing of a packing is insufficient, the backwashing efficiency is low, and the packing is difficult to dry in the prior art are solved. The electrostatic separator comprises a cylinder body; a plurality of packing plates are arranged among an electrode column, an inner electrode and the cylinder body which are coaxial, each packing plate is provided with an assembly column insertion hole, a fixed column insertion hole, a movable column insertion hole, an electrode hole and a packing placement hole, packing is arranged on the packingplates, odd-numbered plates are fixed through fixed columns, and horizontal movement of even-numbered plates is controlled through movable columns to change the packing stacking mode.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

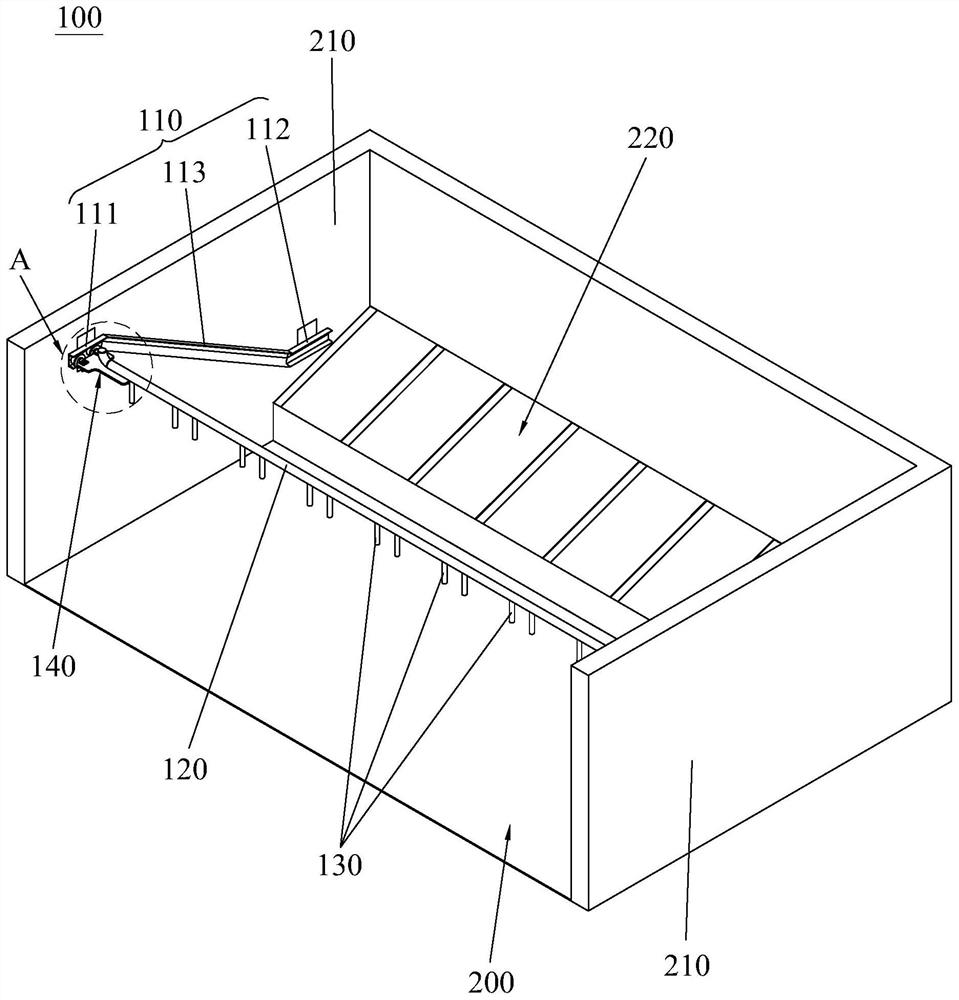

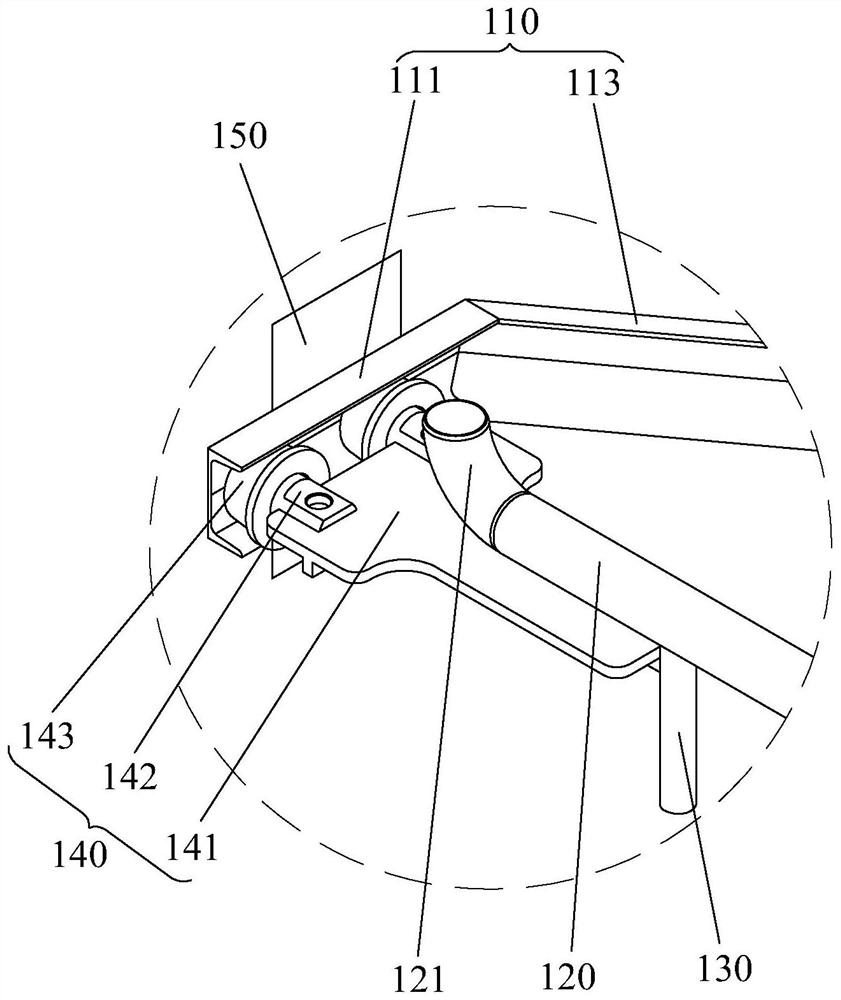

Movable drum-shaped filter screen flushing device

PendingCN114432769AAchieving full cross-section flushingImprove backwash efficiencyStationary filtering element filtersForeign matterAccident risk

The invention discloses a movable drum-shaped filter screen flushing device. The movable drum-shaped filter screen flushing device comprises two guide rails, a main pipeline and a plurality of spraying branch pipe assemblies, the two guide rails are arranged in parallel; the two ends of the main pipeline are slidably connected to the two guide rails, the main pipeline moves between a first position away from the drum-shaped filter screen and a second position located above the drum-shaped filter screen along the guide rails, and at least one end of the main pipeline is provided with a water inlet; and the spraying branch pipe assemblies are connected to the main pipeline at intervals and convexly extend towards the drum-shaped filter screen. When flushing is not needed, the main pipeline slides to be away from the drum-shaped filter screen, flushing is needed, the main pipeline slides to the position above the drum-shaped filter screen, total cross-section flushing of the drum-shaped filter screen is achieved, the back flushing efficiency of the drum-shaped filter screen is greatly improved, and compared with an existing mode that a fire gun is manually held by hand for flushing, a large amount of manpower can be saved; and personnel or foreign matters can be prevented from falling to the bottom of the drum net, the reliability of the cold source of the power plant is greatly improved, and personnel accident risks can be effectively avoided.

Owner:YANGJIANG NUCLEAR POWER +2

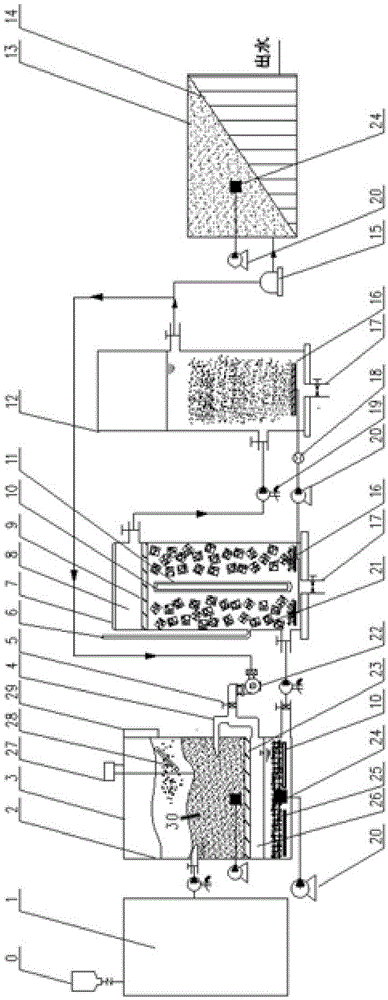

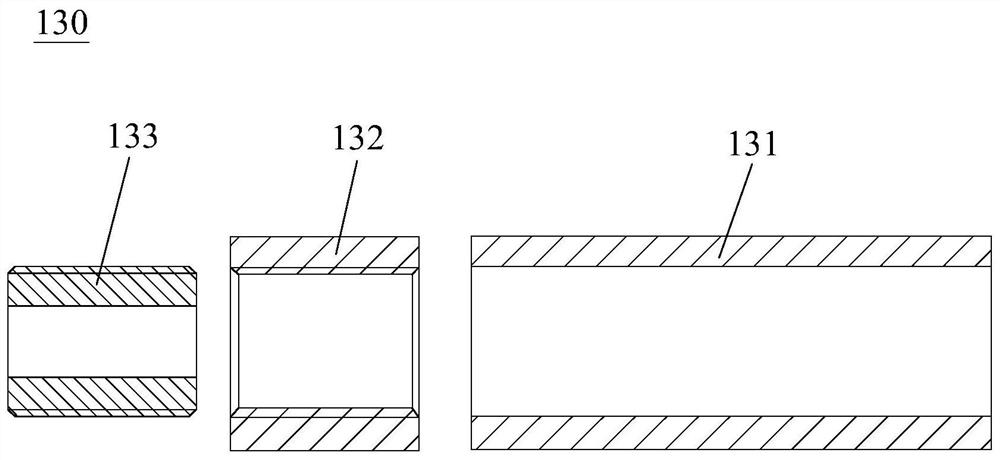

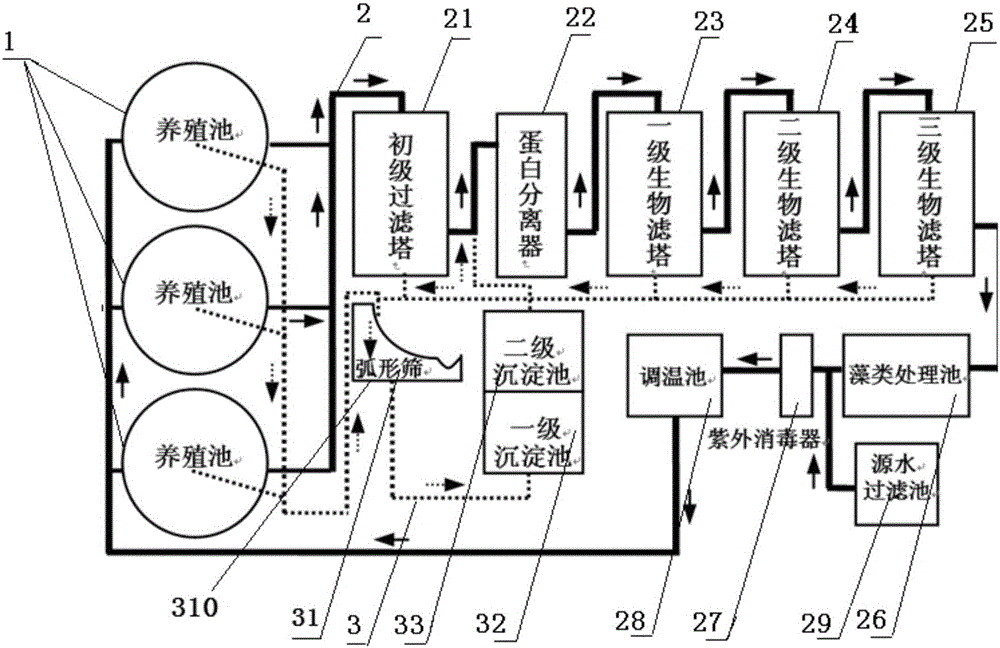

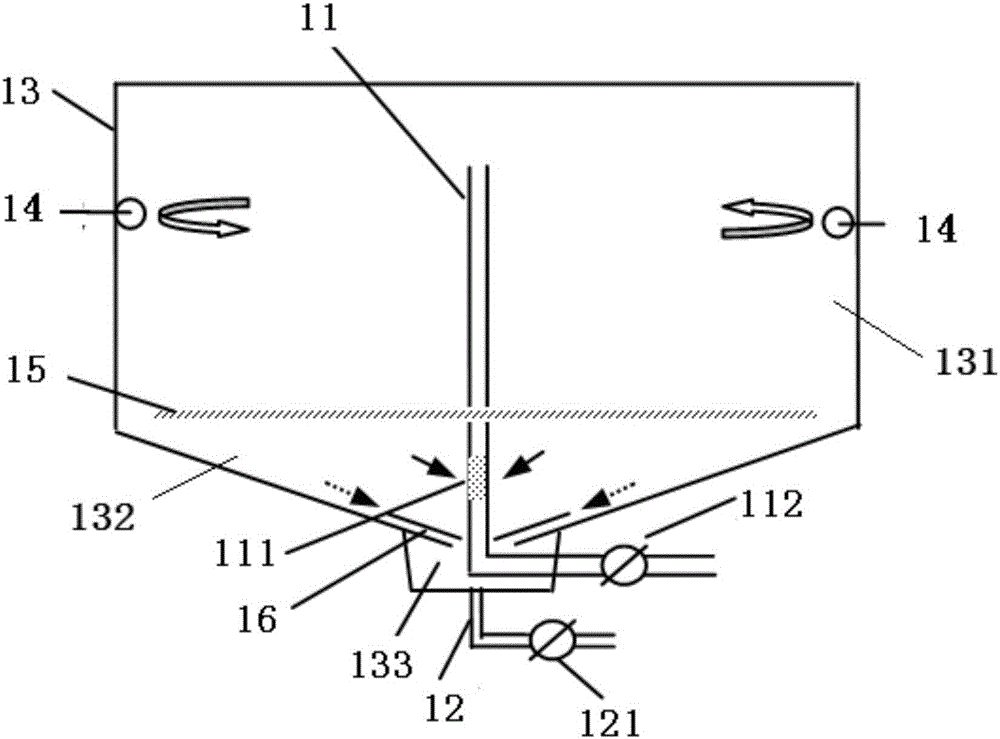

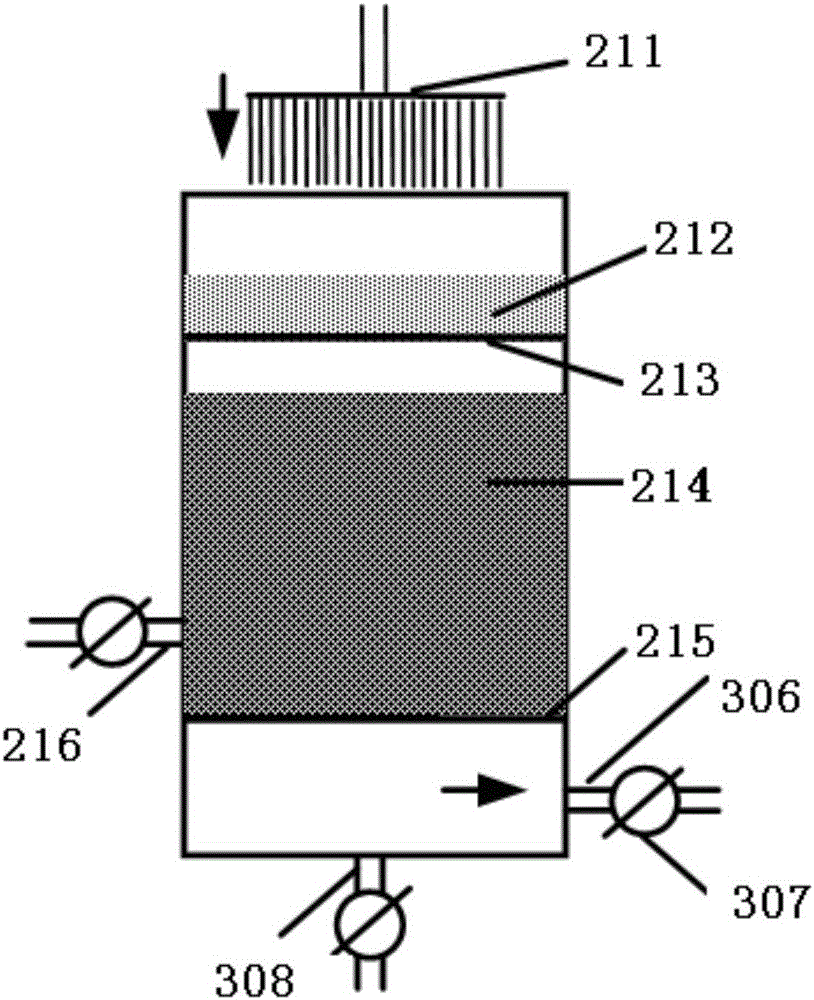

An ecological type seawater rare fish factory circulating aquaculture system

InactiveCN102742536BHas economic valueCover costsPisciculture and aquariaResource utilizationBiological filter

The invention discloses an ecological seawater rare fish factorization circulating water aquaculture system which comprises an aquaculture pond, a primary filter tower, an albumen segregator, a primary biological filter tower, a secondary biological filter tower, a tertiary biological filter tower, an algae treating pond, a source water filter pond, a UV (Ultraviolet) sterilizer, a temperature adjusting pond, an arc-shaped sieve, a primary sedimentation pond and a secondary sedimentation pond. A bidirectional drainage system is adopted by the aquaculture pond, the water containing less smaller particles at the lower part of the pond and the water containing more larger particles at the bottom of the pond are respectively drained and then input into different processing units for recycle. Molluscs, sea cucumbers and algae are drawn into aquaculture waste, wastewater disposal and resource utilization by the circulating water aquaculture system, so that the circulating water aquaculture system has an obvious ecological characteristic. The ecological seawater rare fish factorization circulating water aquaculture system has the advantages of high treatment efficiency of aquaculture wastewater and rubbish, simpler equipment, low energy consumption, high backwash efficiency, resource utilization of aquaculture wastewater and rubbish, less circulation supplement water, high treatment efficiency of inorganic nutrient salt in the water and high economic additional value.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com