Back-flushing operation method of dynamic membrane bioreactor

A technology of bioreactor and operating method, which is applied in the field of sewage treatment, can solve the problems of long time required for dynamic membrane recovery, large aeration volume and aeration time, low efficiency of aeration and backwashing, etc., to reduce the degree of damage, The effect of shortening time and reducing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

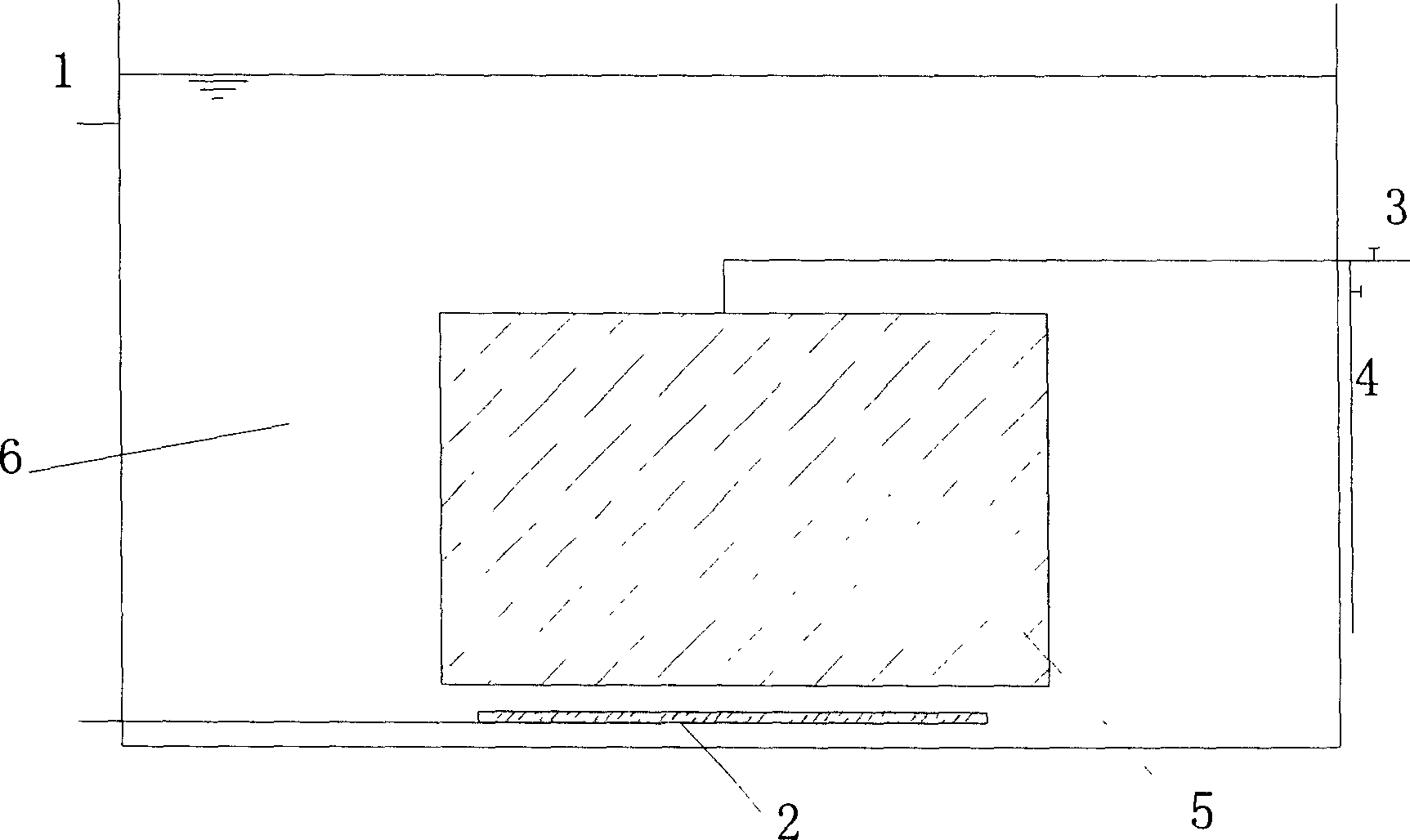

[0012] The structure is shown in the attached figure. The dynamic membrane bioreactor adopts constant flux filtration. The MLSS of the reactor is 5000mg / L, the DO is 2.0-4.0mg / L, the influent COD is 200mg / L, and the influent ammonia nitrogen is 50mg / L. During operation, when the gas-water ratio is 60:1, the effluent COD is 25mg / L, the effluent ammonia nitrogen is 1.0mg / L, and the turbidity of the effluent is 4NTU. After the reactor runs stably for 60 days, the head of the effluent water reaches 12cm, requiring backwashing . The backwash intensity is 3.2m 3 / (m 2 *h), backwashing time is 5min. 60 minutes after backwashing, the quality of the effluent from the reactor decreased to the level before backwashing and tended to be stable, the dynamic membrane was fully restored, and the head of the effluent from the reactor dropped to 1.5cm.

Embodiment 2

[0014] Reactor operating conditions and influent water quality are basically the same as in Example 1. During the operation, the gas-water ratio is 60:1. After 60 days of stable operation of the reactor, the head of the effluent reaches 12 cm, and backwashing is required. The backwash intensity is 3.2m 3 / (m 2 *h), backwashing time is 20min. After 90 minutes of backwashing, the effluent from the reactor was stable, the dynamic membrane was fully recovered, and the head of the effluent from the reactor was reduced to 0.7cm.

Embodiment 3

[0016] The operating conditions of the reactor and the quality of the influent and effluent water are basically the same as in Example 1. During the operation, the gas-water ratio is 60:1. After 60 days of stable operation of the reactor, the head of the effluent reaches 12 cm, and backwashing is required. The backwash intensity is 3.2m 3 / (m 2 *h), backwashing time is 12min. After 75 minutes of backwashing, the effluent from the reactor reached stability, the dynamic membrane was fully restored, and the head of the effluent from the reactor was reduced to 1.0 cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com