Pulse backwashing deep bed filter device and method

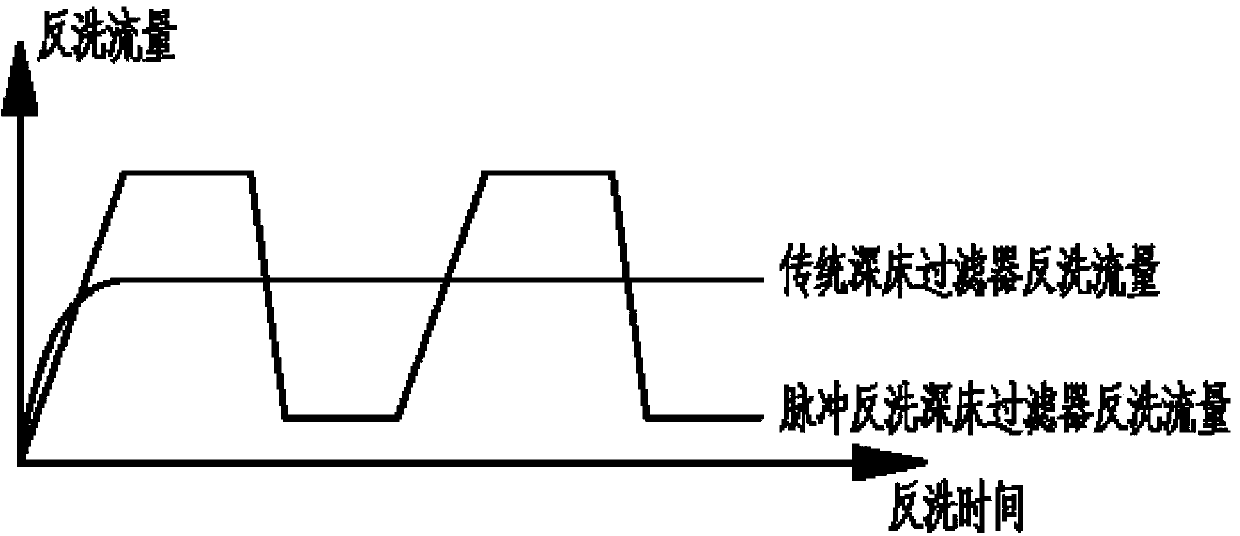

A deep bed and pulse technology, which is applied in the field of pulse backwash deep bed filter device, can solve the problems of low backwash efficiency, increase of maximum backwash flow, severe collision and friction of filter material particles, etc., and achieve high backwash efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

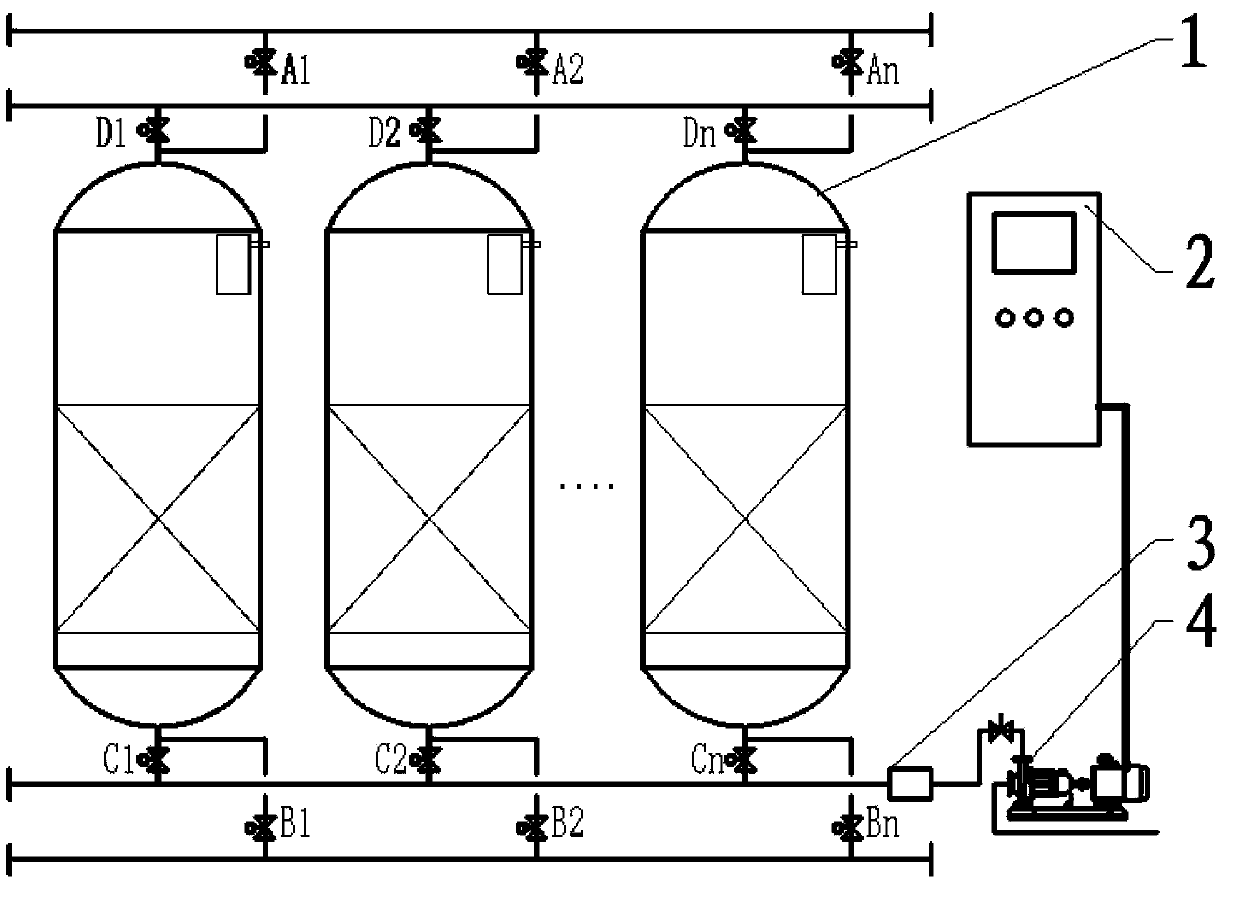

[0027] Embodiment 1: as figure 1 , figure 2 , image 3 as shown,

[0028] The invention is a set of pulse backwashing deep bed filter device with automatic control. The whole device consists of backwash pump 4 with frequency conversion adjustment, control cabinet 2 with frequency converter and PLC controller, backwash water flow detection device 3, deep bed filter 1, filter material height detection device 6, with automatic control pulse feedback It is composed of washing and processing filter material height signal and backwashing flow control program.

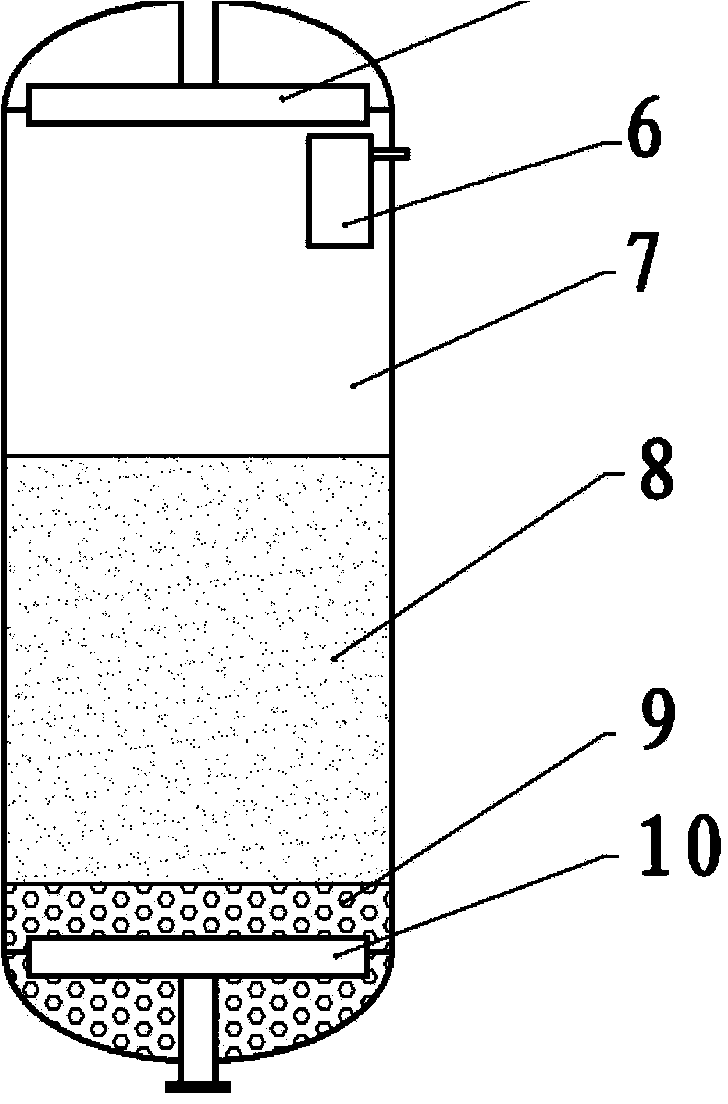

[0029] There can be 1, 2...n sets of deep bed filters 1 in a set of devices. The deep bed filter 1 consists of a housing 7, a water collecting mechanism 10 arranged at the lower part of the housing and its connecting pipe, a water distribution mechanism 5 arranged at the upper part of the housing and its connecting pipe, a filter material cushion 9 arranged at the lower part of the housing, The filter material 8 arrange...

Embodiment 2

[0031] Embodiment 2: as figure 1 , figure 2 As shown, a pulse backwash deep bed filter device includes a deep bed filter, a backwash pump and a flow detection device. The deep bed filter has a shell, and a water collection mechanism and its connecting pipe are arranged at the bottom of the shell. The upper part is equipped with a water distribution mechanism and its connecting pipe, the filter material cushion is set in the lower part of the shell, the filter material is set in the middle of the shell, and the filter material height detection device is set in the upper part of the shell; the backwash pump is a centrifugal pump, and the backwash pump is connected to the deep bed filter; the flow detection device is installed on the main backwash pipeline at the outlet of the backwash pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com