A calibration stand that avoids pinching the product

A technology for calibrating tables and products, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., and can solve problems such as ring locking, large error in placement angle, and blocked closing of the clamping arms on the side of the calibrating table, etc. , to achieve the effect of avoiding calibration and alleviating instantaneous impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the accompanying drawings.

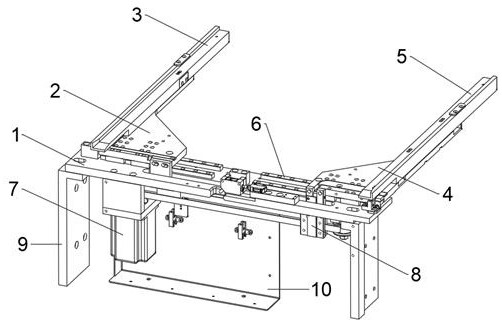

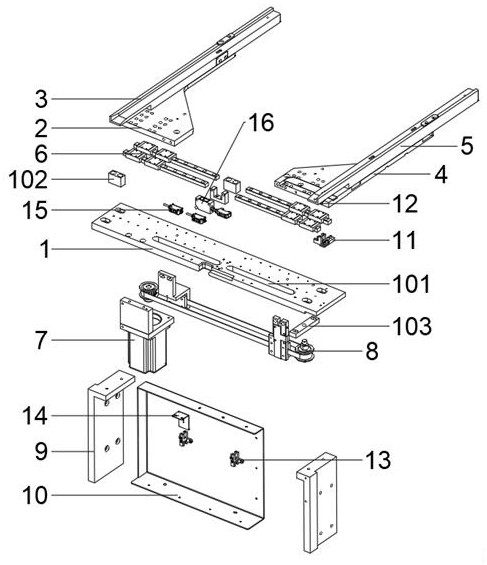

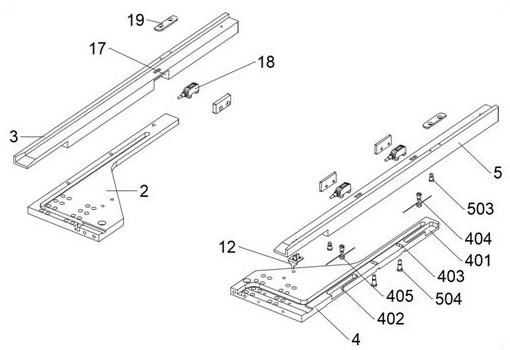

[0035] refer to Figure 1-Figure 8 , a calibration table to avoid pinching products, including base plate 1, left base plate 2, left clamp arm 3, right base plate 4, right clamp arm 5, elastic mechanism, linear sliding mechanism 6, motor 7, transmission mechanism 8, The error judgment photoelectric switch 11, the error judgment baffle 12, the fixed ends of the two linear sliding mechanisms 6 are assembled on the upper surface of the base plate 1, and the two linear sliding mechanisms 6 are symmetrical on the left and right, and the left base plate 2 and the right base plate 4 are respectively fixed and installed on the base plate 1. On the sliding ends of the two linear sliding mechanisms 6, the left clamp arm 3 is fixedly installed on the upper surface of the left base plate 2, the right clamp arm 5 is flexibly connected to the right base plate 4 through an elastic me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com