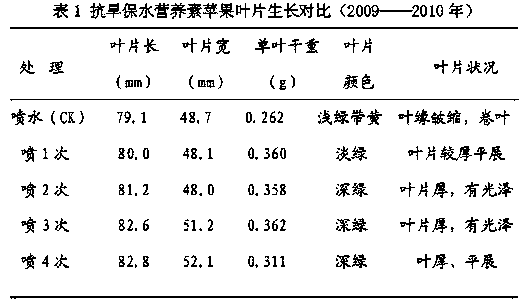

Patents

Literature

31 results about "Glauconite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glauconite is an iron potassium phyllosilicate (mica group) mineral of characteristic green color which is very friable and has very low weathering resistance. It crystallizes with a monoclinic geometry. Its name is derived from the Greek glaucos (γλαυκος) meaning 'blue', referring to the common blue-green color of the mineral; its sheen (mica glimmer) and blue-green color presumably relating to the sea's surface. Its color ranges from olive green, black green to bluish green, and yellowish on exposed surfaces due to oxidation. In the Mohs scale it has hardness of 2. The relative specific gravity range is 2.4 - 2.95. It is normally found in dark green rounded brittle pellets, and with the dimension of a sand grain size. It can be confused with chlorite (also of green color) or with a clay mineral. Glauconite has the chemical formula – (K,Na)(Fe³⁺,Al,Mg)₂(Si,Al)₄O₁₀(OH)₂.

Agate-containing dark green glaze for ru-porcelain, processing method of glaze as well as ru-porcelain and firing method thereof

The invention relates to agate-containing dark green glaze for ru-porcelain, a processing method of the glaze as well as the ru-porcelain and a firing method thereof and relates to the technical field of silicate ceramics. The agate-containing dark green glaze for the ru-porcelain is prepared from components in parts by weight as follows: 6-20 parts of ru jade, 1-15 parts of agate, 10-70 parts of feldspar, 2-8 parts of calcite, 1-20 parts of wollastonite, 0-2 parts of talc, 0-15 parts of chest wood ash, 1-8 parts of ammolite and 1-20 parts of black bluestone. The enamel of the ru-porcelain fired with the adoption of the agate-containing dark green glaze for the ru-porcelain takes dark green as a base, can present the deep and full sky blue, azure, light greenish blue, bluish white, pale blue and bright green and can present bright and transparent pea green and onion green color. The ru-porcelain adopting the agate-containing dark green glaze for the ru-porcelain has good jade sense and opalescence effects and has a smoother glaze surface, higher mechanical strength, lower water absorption rate and high firing qualification rate.

Owner:郭秀贞

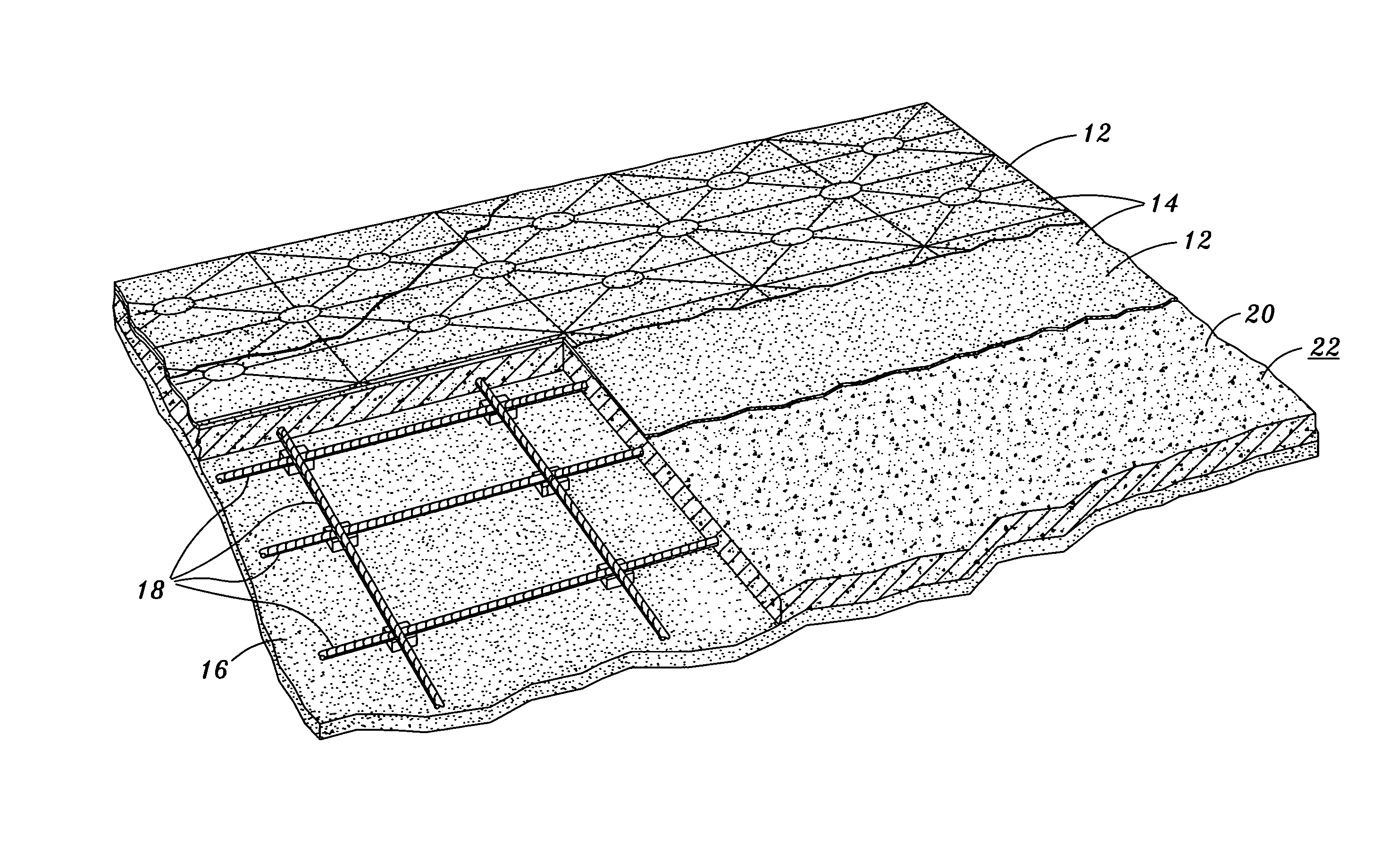

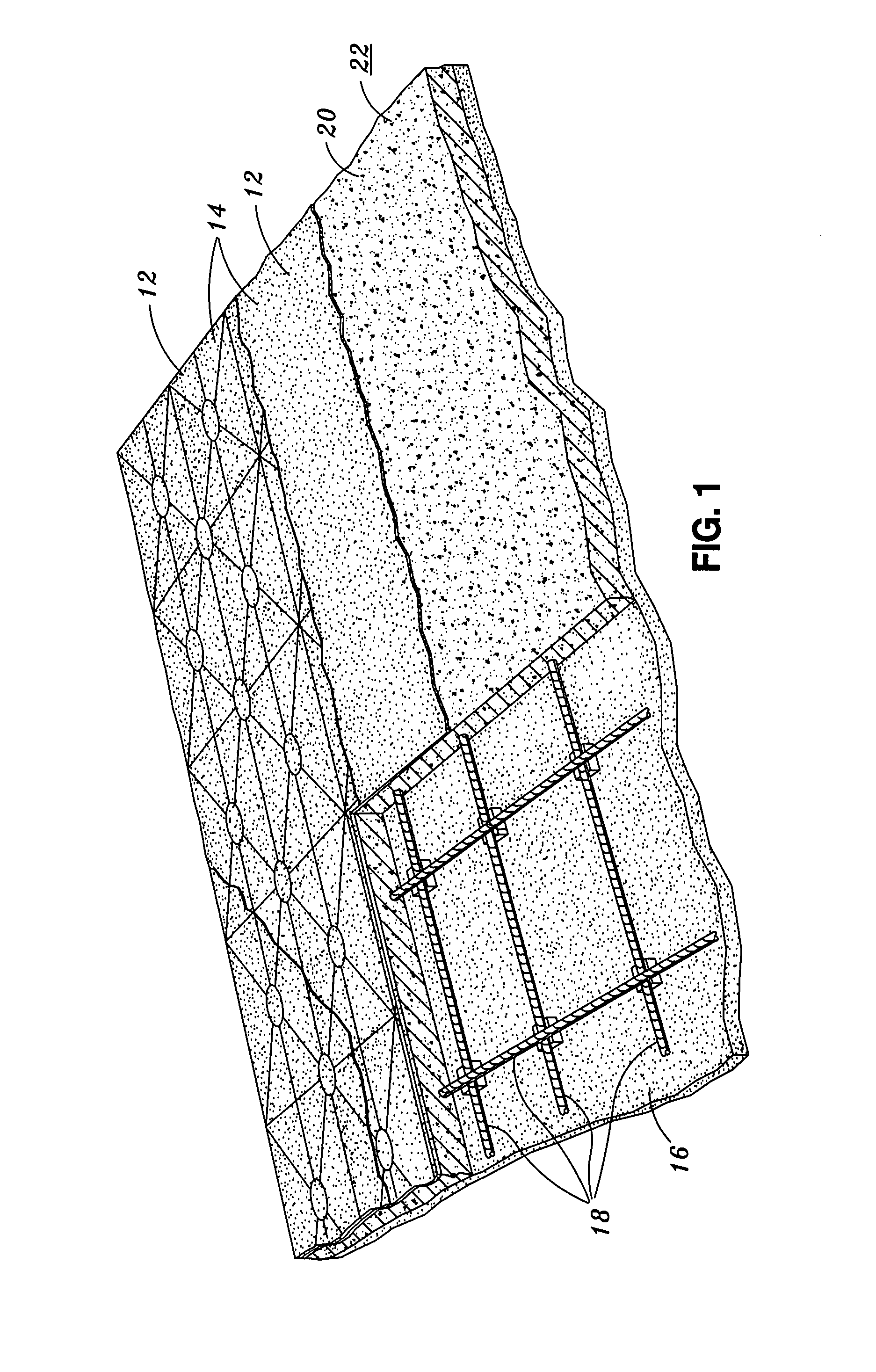

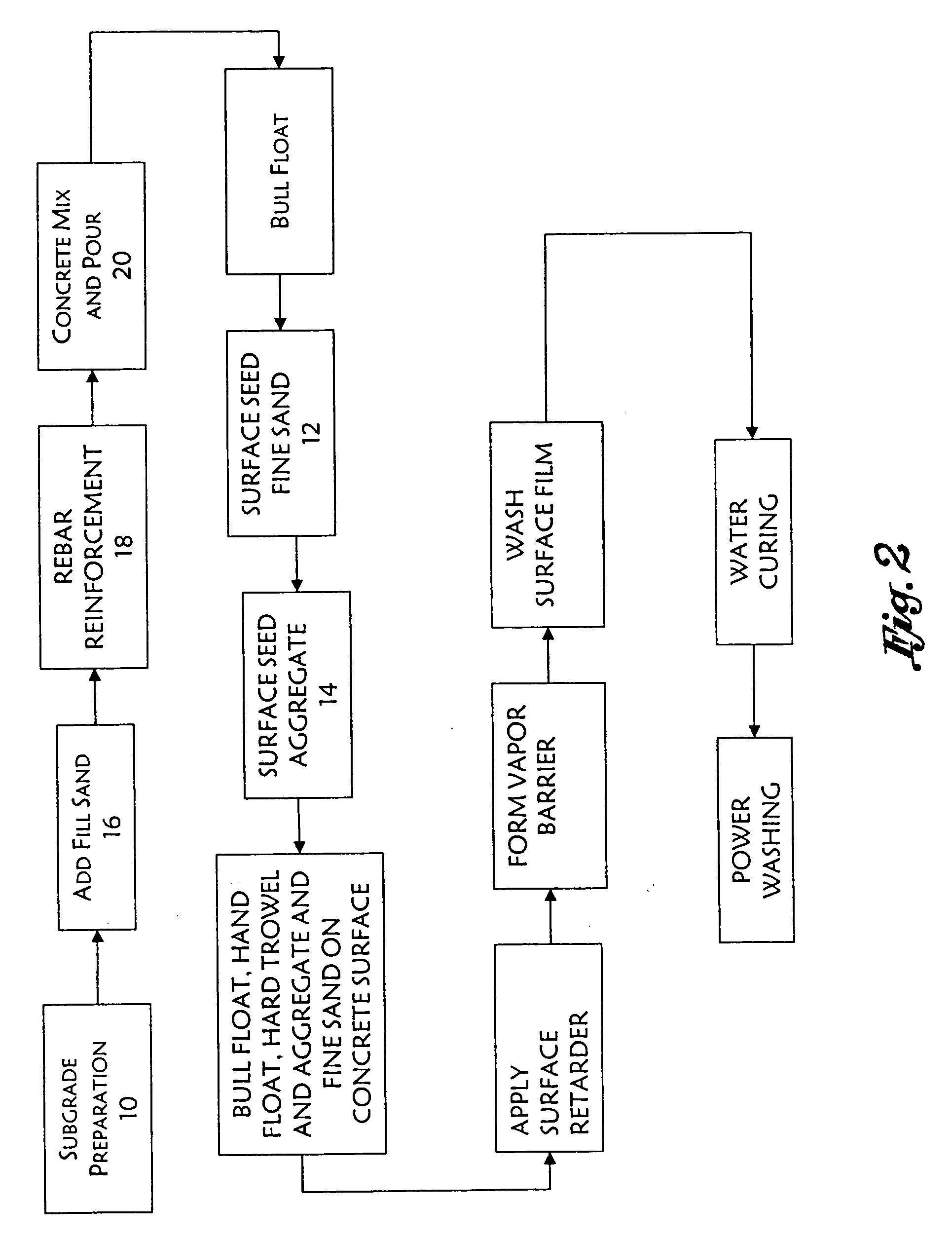

Surface seeded fine aggregate concrete simulating quarried stone

A method and a surface seeded exposed aggregate concrete product are provided that precisely simulate the appearance and qualities of various types of natural quarried stone, such as granite, marble, rhinestone, bluestone, and brownstone, to name a few. Implementations of the present invention are characterized by the use of fine sand and aggregate broadcast over the exposed surface of poured concrete, which surface has been prepared to receive the same. Subsequently, a surface retarder and finishing steps are performed to produce the concrete product which assimilates the characteristics and colors of natural quarried stone, such as speckles, inclusions, flecks, graining, fractures, joints, knots, crystallization patterns, streaks, weathering, etc.

Owner:SHAW CRAFTSMEN CONCRETE LLC

Glaze of purple-sand tea sets and glazing technology

A glazing technology for purple-sand tea sets relates to the technical field of purple sand and comprises the following technological steps: 1) preparing a green body, specifically taking purple sand at Huainan area of Anhui province of China as a main material to prepare the green body; 2) taking out the green body, baking to dry at a room-temperature environment, so as to prevent deformation of the green body; 3) sintering the green body, specifically for first sintering in a kiln, employing reduction flame for sintering, heating to 950-1050 DEG C, and sintering for 16-18 h, so as to mainly eliminate humidity and remove alkali in the green body; 4) keeping warm for 10-20 min, naturally cooling and discharging from the kiln; 5) uniformly glazing the surface of the green body; and 6) sintering the glazed green body, specifically for secondary sintering in a kiln, employing reduction flame for sintering, sintering at 130 DEG C for 20 h, keeping warm for 10-20 min, and naturally cooling and discharging out of the kiln. The technology is simple, and by adding compositions such as shells, bluestone and the like, the sintered tea set has spots on the surface and has beautiful color.

Owner:卢群山

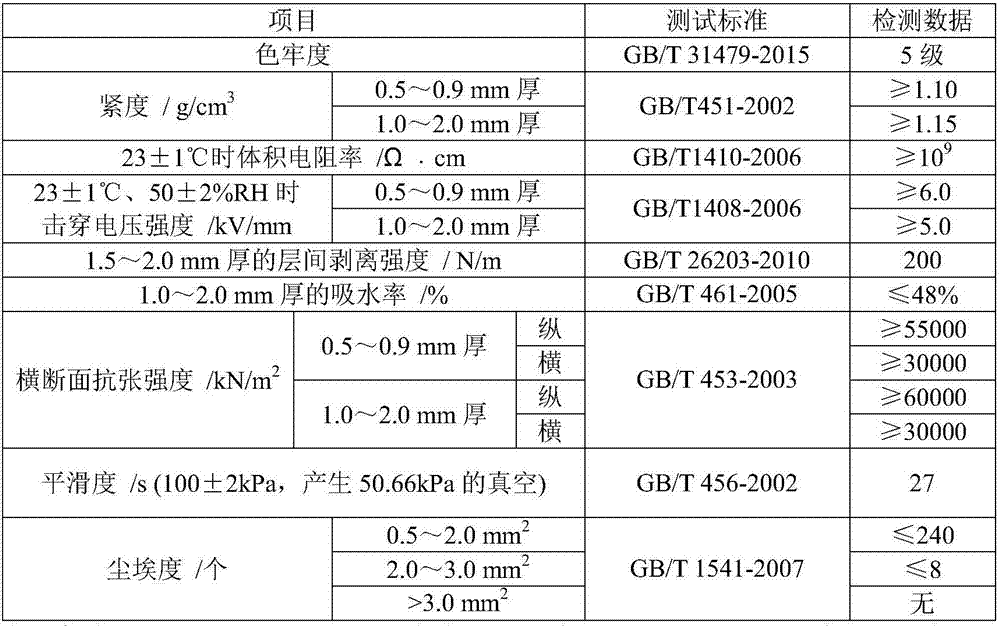

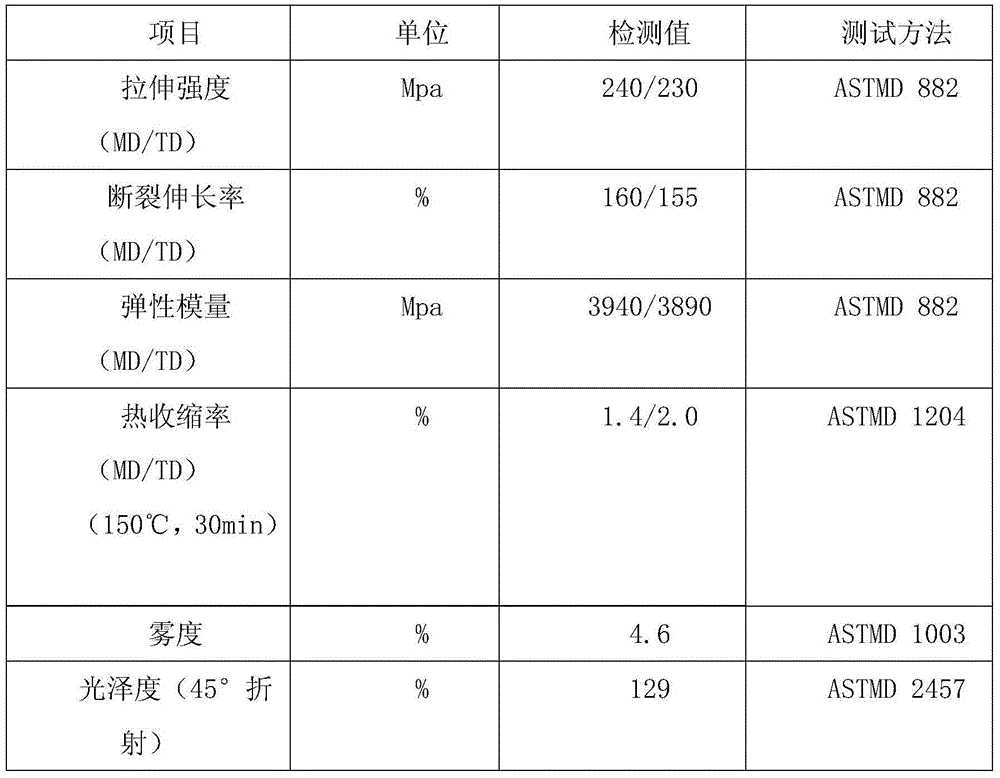

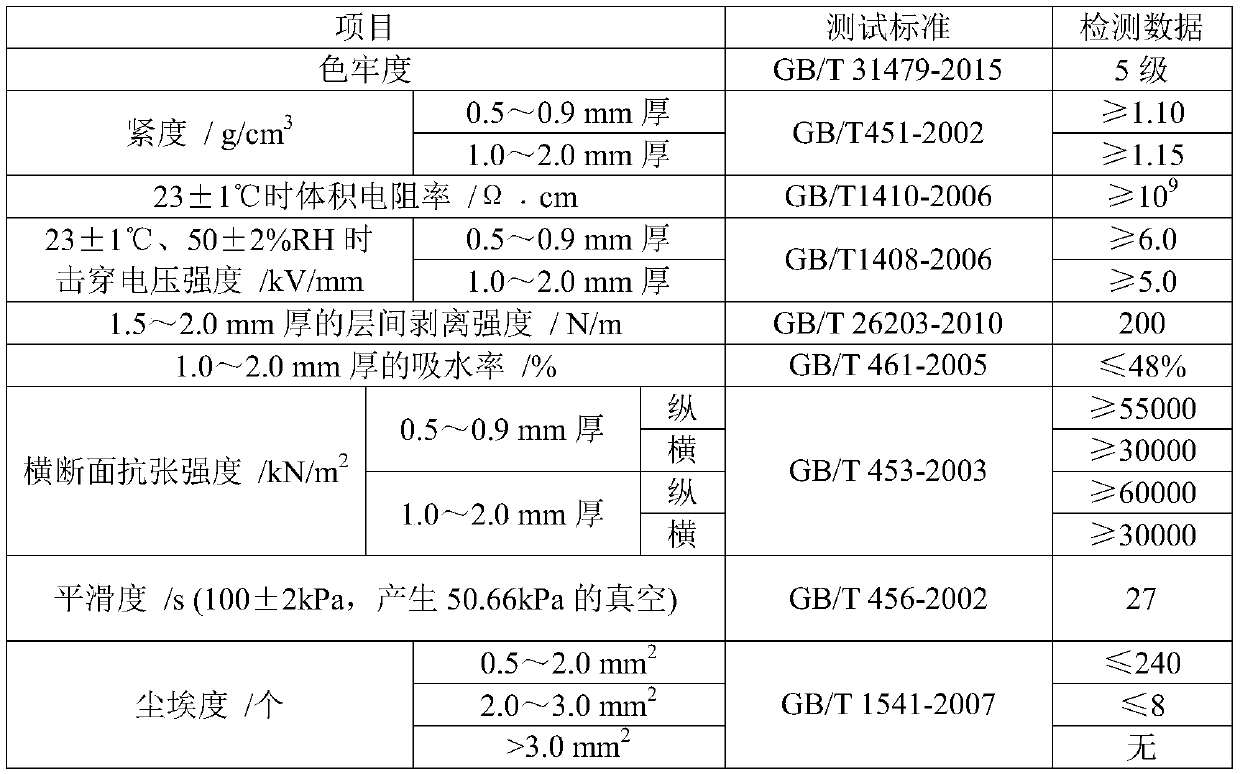

High-tinting-strength green vulcanized paper for abrasive discs

ActiveCN107419591AGood surface finenessStrong coloring powerSpecial paperPaper coatingCelluloseCobalt green

The invention belongs to the technical field of vulcanized paper and particularly discloses high-tinting-strength green vulcanized paper for abrasive discs. The high-tinting-strength green vulcanized paper is prepared from, by weight, 100-120 parts of cotton fibers, 40-70 parts of wood pulp cellulose, 4-12 parts of an inorganic composite pigment, 0.8-1.2 parts of a dispersing agent, 2-4 parts of water-soluble chitosan, 2-6 parts of an insulation reinforcing agent, 3-7 parts of a heatproof reinforcing agent and 1-3 parts of a setting agent. The inorganic composite pigment is prepared from glauconite, green serpentine and a cobalt green pigment, a particle size range of glauconite and green serpentine is 0.1-1nm, and glauconite and green serpentine are calcined for 2-3h at 500-600DEG C before use. The green vulcanized paper for the abrasive discs is high in tinting strength, less prone to fading, moisture absorption and deformation, great in heatproof performance, insulating, flame retardant and long in service life, and prepared abrasive discs are high in processing precision due to great surface fineness of the green vulcanized paper.

Owner:杭州特种纸业有限公司

Production method for dry-joint sticking clay of Nixing pottery

InactiveCN104944913ASmall humidity gradientReduce the chance of crackingClaywaresCordieritesGlauconite

The invention provides a production method for dry-joint sticking clay of Nixing pottery. The production method for the dry-joint sticking clay of the Nixing pottery comprises the following steps that 1 raw materials of, by weight, 3 to 4 parts of east clay, 3 to 4 parts of west clay, 1 to 2 parts of cordierite, 1 to 2 parts of mineral powders and 0.5 to 1 part of feldspar are weighted; 2 the east clay and the west clay are mixed and are ground into mud through a ball mill, filtering is conducted, clay laths are formed in a suppressed mode, vacuum pugging is conducted, decaying is conducted, and A clay material is obtained; 3 the cordierite, the mineral powders and the feldspar are mixed and are mixed into mud through the ball mill, filtering is conducted, the clay laths are formed in a suppressed mode, vacuum pugging is conducted, decaying is conducted, and B clay material is obtained; 4 the A clay material and the B clay material are mixed to the dry-joint sticking clay, and the water content of the dry-joint sticking clay is 10 to 15 percents. According to the production method for the dry-joint sticking clay of the Nixing pottery, the dry-joint sticking clay still has comparatively good liquidity under the condition that the water content is comparatively low, the adhesive strength is strong, the figurability is comparatively good, and moulding body drying and burning crazing can be reduced greatly.

Owner:QINZHOU UNIV

Pot flower slow-release coated fertilizer and preparation method thereof

InactiveCN106083306APromote growthHigh activityAnimal corpse fertilisersExcrement fertilisersPeatNatural mineral

The invention discloses a pot flower slow-release coated fertilizer and a preparation method thereof. The pot flower slow-release coated fertilizer is prepared from the following raw materials (in parts) by weight: a 4-6wt% HCl solution, zinc oxide powder, humic acid powder, maleic anhydride, glauconite, shells, micalex, moss soil, titanium dioxide, indoleacetic acid, chitosan, sodium selenite, zinc chloride, peat, potassium sulfate, cellulose homogenate and water. Generally, pot flowers do not need too much soil, or else root system breath and water content can be affected; as mineral-enriched stone is calcined and the calcined material is crushed into powder, the stone powder contains a great amount of minerals, and the minerals can be easily dissolved out after being quenched and are natural minerals, the content of inorganic trace elements in the fertilizer disclosed by the invention can be reduced, and flowers can be promoted to grow and can be kept vigorous.

Owner:HUAINAN SONGWANG HIGH QUALITY GRAIN PLANTING FARMERS SPECIALIZED COOPERAIVE

Raw material composition and preparation method of a slow-release drought-resistant and water-retaining nutrient

The invention relates to a raw material composition and preparation method of a sustained-release drought-resistant water-retention nutrient. The drought-resistant water-retention nutrient provided by the invention is prepared from the following raw materials in parts by weight: 550-700 parts of HA35% ammonium phytate, 80-200 parts of N64% coated urea, 60-150 parts of P14 phosphate fertilizer, 60-150 parts of N17 and P44 ammonium phosphate, 20-35 parts of chitin, 3-30 parts of 80-mesh kushenin and 20-50 parts of glauconite. The sustained-release drought-resistant water-retention nutrient prepared by the preparation method provided by the invention has the characteristics of synchronous plant absorption and sustained release, high water absorption capability, good stress resistance and water retention properties, entire nutrients, rich bioactive substances and soil activation, can improve leaf photosynthesis, prevent bacteria infection and alleviate drought-induced plant physiological damage, has significant effects in greenness, environment friendliness and quality and efficiency improvement, is especially suitable for production of food economical crops, and has persistency and controllability on the drought resistance and nutrient supply.

Owner:武兴战

Bacteriostatic and antibacterial ceramic filter element and preparation method therefor

ActiveCN105060869AImprove filtering effectStable chemical propertiesBiocideTreatment involving filtrationSodium bicarbonateEpoxy

The present invention discloses a bacteriostatic and antibacterial ceramic filter element and a preparation method therefor. The bacteriostatic and antibacterial ceramic filter element is mainly prepared from glauconite, bryozoatum, bentonite, nano white metal charcoal, rice husk powder, razor king shell powder, limonite, sodium bicarbonate, acrylic emulsion, cane molasses, palm fibers, corn flour, phenolic resin, epoxy soybean oil, beeswax, and bacteriostatic additives. The ceramic filter element disclosed by the invention uses glauconite and bryozoatum as the main raw material; the raw materials such as nano white metal charcoal, rice husk powder, razor king shell powder, limonite and the like are added to ensure good filtering performance of the ceramic filter element, so that hazardous substances such as heavy metals and the like can be effectively adsorbed, and chemical stability and good water resistance can be achieved; hokutolite and crystal gravel contained in the antibacterial additives can release a great number of negative ions to exert good bactericidal antimicrobial effect; and natural manganese sand, nano silver carbon molecular sieve, and nano-zinc oxide contained in the antibacterial additives interact with each other to achieve good adsorption filtration performance, and good bactericidal properties.

Owner:JIAN CITY QINGYUAN DISTRICT QINGFENG FILTER EQUIP MATERIAL

Water-resistant moisture-proof refractory brick and preparation method thereof

InactiveCN106518105AImprove fire resistanceImprove performanceCeramic materials productionClaywaresSludgeFlexural strength

The invention discloses a water-resistant moisture-proof refractory brick and a preparation method thereof. The refractory brick is prepared from the following raw materials by weight: 33-41 parts of petroleum refined waste oil sludge, 17-29 parts of bauxite tailings, 14-22 parts of glauconite, 15-20 parts of natural colored sand, 16-28 parts of natural zeolite, 4-7 parts of sodium alginate, 10-15 parts of alunite, 12-19 parts of coal-fired boiler ash, 3-6 parts of ferric chloride, 5-10 parts of acrylic nuclear glycan, 7-12 parts of polymethylsilsesquioxane spherical micropowder, 5-10 parts of spherical calcium chloride dihydrate, 20-30 parts of waste mortar, and 13-21 parts of quick lime. The method provided by the invention employs natural colored sand, alunite, petroleum refined waste oil sludge, ferric chloride, acrylic nuclear glycan, polymethylsilsesquioxane spherical micropowder, spherical calcium chloride dehydrate and other raw materials for mutual compounding, greatly reduces the water absorption of the refractory brick, and does not affect the flexural strength, compressive strength and refractoriness of the refractory brick. The refractory brick provided by the invention has the advantages of excellent water resistance and moisture proofness, and high refractoriness, and is suitable for wall building under a moist environment.

Owner:MAANSHAN BAOLONG NEW BUILDING MATERIALS

High-strength and high-temperature-resistance molding sand and preparation method thereof

InactiveCN105478654AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresBrickCalcium formate

The invention discloses high-strength and high-temperature-resistance molding sand and a preparation method thereof. The high-strength and high-temperature-resistance molding sand is prepared by the following raw materials in parts by weight: 14-22 of allophane, 24-38 of attapulgite, 12-18 of obsidian, 10-15 of baddeleyite, 8-14 of waste brick chips, 5-10 of refining slag, 16-24 of emery, 9-16 of glauconite, 7-11 of calcium formate, 5-10 of nanometer magnesium titanate, 4-7 of polyethylenimine, and 270-330 of modifying agents. The molding sand, prepared with allophane, obsidian, baddeleyite, waste brick chips, refining slag, emery and the like as main raw materials, is better in thermal stability and higher in refractoriness, and is added with calcium formate, nanometer magnesium titanate, polyethylenimine and the like to improve the green compression strength and the wet tensile strength. The prepared molding sand is excellent in breathability, fluidity, strength, collapsibility and high-temperature resistance; and a casting produced by the molding sand is smooth in surface and low in rejection rate.

Owner:安徽创奇乐智能游乐设备有限公司

Antibacterial ceramic filter element and preparation method thereof

InactiveCN107899303AImprove filtering effectStable chemical propertiesBiocideOther chemical processesSodium bicarbonateSodium Bentonite

The invention discloses an antibacterial ceramic filter element and a preparation method thereof. The antibacterial ceramic filter element is mainly prepared from glauconite, bryozoatum, bentonite, nano black ebony carbon, rice hull powder, razor clam king shell powder, hollow stone, sodium bicarbonate, an acrylic emulsion, cane molasses, a palm fiber, corn flour, a phenolic resin, epoxidized soybean oil, beewax and antibacterial additives. Due to adoption of glauconite and bryozoatum as main raw materials, and together with raw materials such as nano black ebony carbon, rice hull powder, razor clam king shell powder and hollow stone, the ceramic filter element is very good in filtration performance, capable of effectively adsorbing harmful substances such as heavy metals, in addition stable in chemical property and good in water resistance; as a great deal of anion is released from radiobarite and crystal macadam in the antibacterial additives, a very good antibacterial function is achieved; due to cooperation of natural manganese sand, a nanosilver molecular sieve and nano zinc oxide, not only is good filtration and adsorption performance achieved, but also very good sterilization performance is achieved.

Owner:张琴

Purple sand clay-containing colored glaze

The invention discloses purple sand clay-containing colored glaze. The purple sand clay-containing colored glaze is characterized by comprising the following components in parts by mass: 90-110 parts of purple sand clay, 4-12 parts of sodium nitrate, 16-20 parts of cuprous oxide, 17-25 parts of lead dioxide, 10-12 parts of sodium chloride, 12-16 parts of small bluestone, 6-10 parts of calcium carbonate antimony oxide, 15-22 parts of talcum, 6-10 parts of lithium carbonate, 2-4 parts of explosion-proof fiber, 1-8 parts of starch, 1-8 parts of charcoal powder, 4-8 parts of potassium feldspar, 2-16 parts of magnesium carbonate, 1-5 parts of phenol-formaldehyde resin, 17-22 parts of quartz sand, 9-11 parts of aluminum sesquioxide, 5-9 parts of cerium dioxide, 20-30 parts of ferric oxide yellow, 4-8 parts of zirconium oxide, 2-4 parts of TEOS and 3-6 parts of polytetrafluoroethylene. The invention provides the purple sand clay-containing colored glaze which is good in glaze gloss, non-fading and more environmentally friendly; the production process is simplified, the efficiency is improved, the process time is shortened, and the production cost is reduced.

Owner:太仓市科教新城琉璃艺术策划中心

Mineral middle element fertilizer and production method thereof

InactiveCN106588363ALow costSimple processCalcareous fertilisersMagnesium fertilisersSodium metasilicateTrace element

The invention in particular relates to a middle element fertilizer by using minerals as raw materials and a production method thereof. The technical problem to be solved by the invention is that the middle element fertilizer has low middle element content, single nutrient, low utilization rate, cumbersome application and so on. A technical scheme adopted in the invention is as below: the mineral middle element fertilizer comprises the following raw materials by weight: 300 to 500 parts of calcined glauconite, 30 to 50 parts of sodium metasilicate, 150 to 300 parts of plant ash, 120 to 240 parts of quicklime, 140 to 220 parts of magnesium sulfate monohydrate and 8 to 15 parts of trace element fertilizer, wherein the calcined glauconite is made by calcining glauconite of which the silicon oxide content is 50 to 75 wt% at high temperature of 3500 to 4500 DEG C, and the trace element fertilizer is a mixture of fertilizers containing four trace elements such as B, Zn, Mo and Fe, respectively. The middle element fertilizer provided by the invention has the advantages of benefiting a whole year though one-time fertilization, being convenient for fertilization, and saving manpower, material and financial resources.

Owner:山西中农化生物技术股份有限公司

Glaze and Glazing Technology of Zisha Tea Set

A glazing technology for purple-sand tea sets relates to the technical field of purple sand and comprises the following technological steps: 1) preparing a green body, specifically taking purple sand at Huainan area of Anhui province of China as a main material to prepare the green body; 2) taking out the green body, baking to dry at a room-temperature environment, so as to prevent deformation of the green body; 3) sintering the green body, specifically for first sintering in a kiln, employing reduction flame for sintering, heating to 950-1050 DEG C, and sintering for 16-18 h, so as to mainly eliminate humidity and remove alkali in the green body; 4) keeping warm for 10-20 min, naturally cooling and discharging from the kiln; 5) uniformly glazing the surface of the green body; and 6) sintering the glazed green body, specifically for secondary sintering in a kiln, employing reduction flame for sintering, sintering at 130 DEG C for 20 h, keeping warm for 10-20 min, and naturally cooling and discharging out of the kiln. The technology is simple, and by adding compositions such as shells, bluestone and the like, the sintered tea set has spots on the surface and has beautiful color.

Owner:卢群山

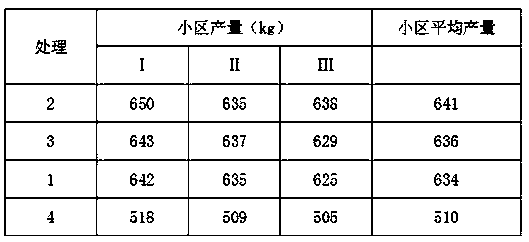

Special medicinal rhubarb organic fertilizer and manufacturing method thereof

InactiveCN109456124APromote growthImprove water retentionCalcareous fertilisersBio-organic fraction processingDiseaseGuano

The invention discloses a special medicinal rhubarb organic fertilizer and a manufacturing method thereof, and belongs to the technical field of fertilizers. The organic fertilizer is prepared from, by weight, 30-40 parts of cow dung, 5-10 parts of bamboo charcoal, 2-5 parts of fulvic acid, 1-3 parts of nicotinic acid amide, 20-30 parts of chicken manure, 10-15 parts of chimney ash, 1-5 parts of attapulgite powder, 20-30 parts of bran, 20-25 parts of fish bone meal, 20-30 parts of salt, 10-15 parts of sodium carbonate, 20-25 parts of guano, 15-20 parts of sunflower straw ash, 5-7 parts of medical stone powder, 5-10 parts of carnallite, 3-7 parts of polyterpene bacillus agents, 5-8 parts of actinomycete agents, 5-7 parts of glauconite, 10-15 parts of seaweed, 5-10 parts of fatty acid, 3-10parts of dolomite, 1-3 parts of zeolite, 2-5 parts of oxalic acid and 5-8 parts of potassium salt. According to the organic fertilizer, stress resistance of medicinal rhubarb can be effectively improved, reproduction of harmful and pathogenic microorganisms in soil can be effectively restrained, the acre yield of the medicinal rhubarb can reach 742kg or more after the organic fertilizer is applied, and the incidence rate of root rot diseases of the medicinal rhubarb is lower than 27%.

Owner:陇南远大生物科技有限公司

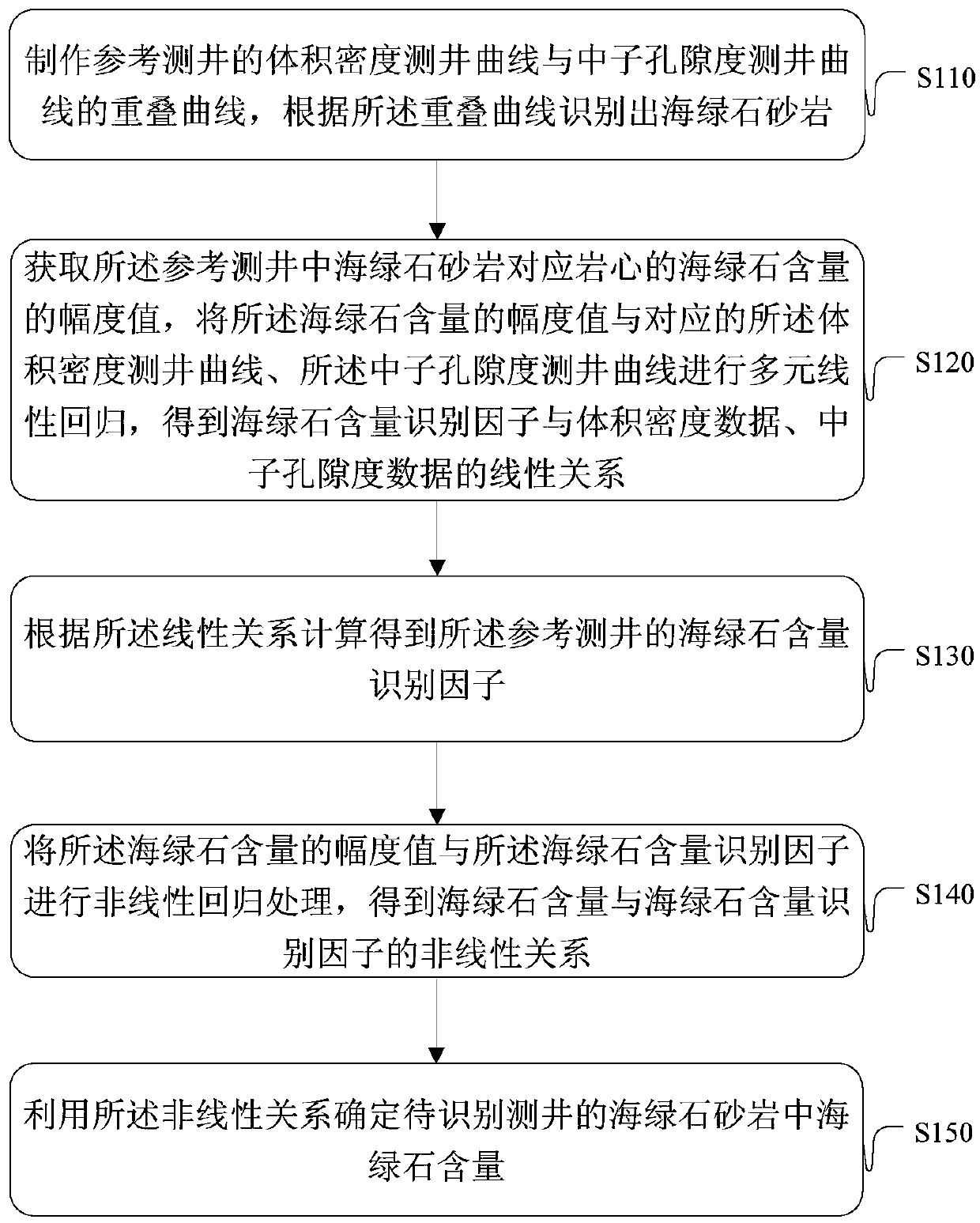

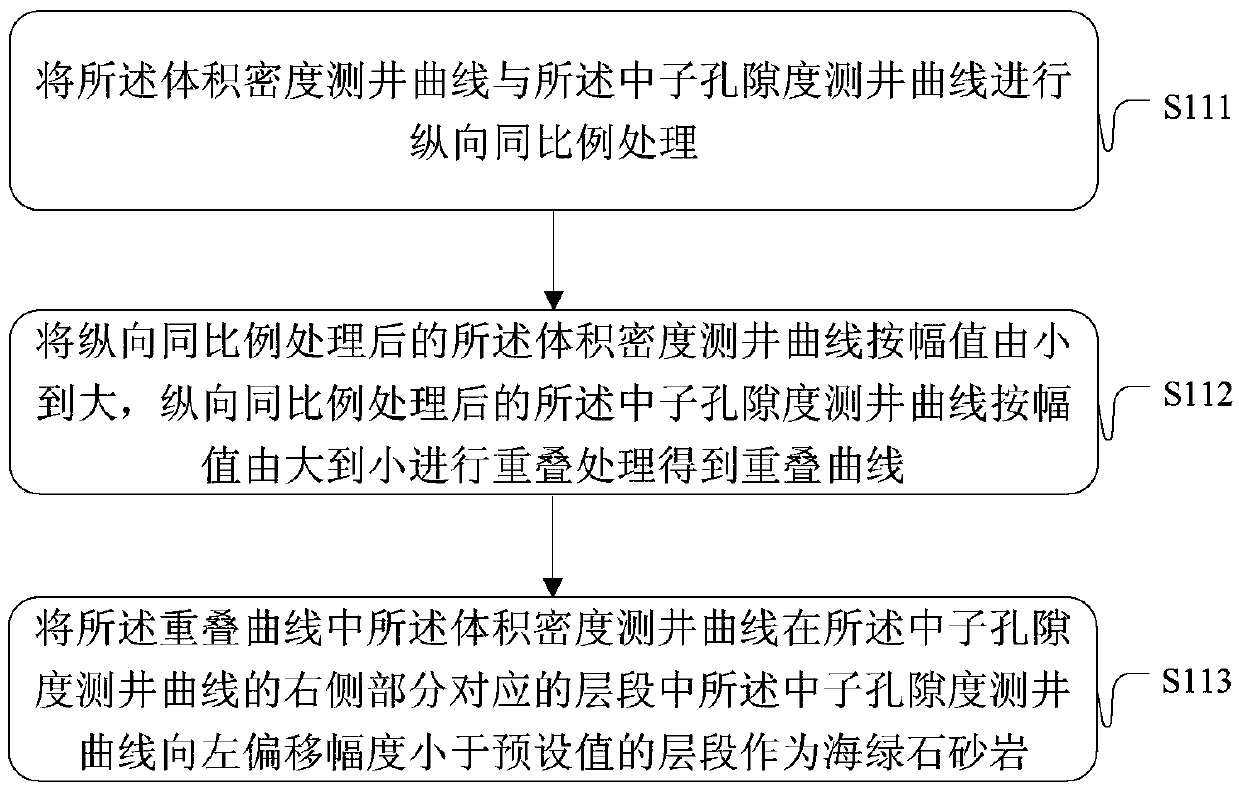

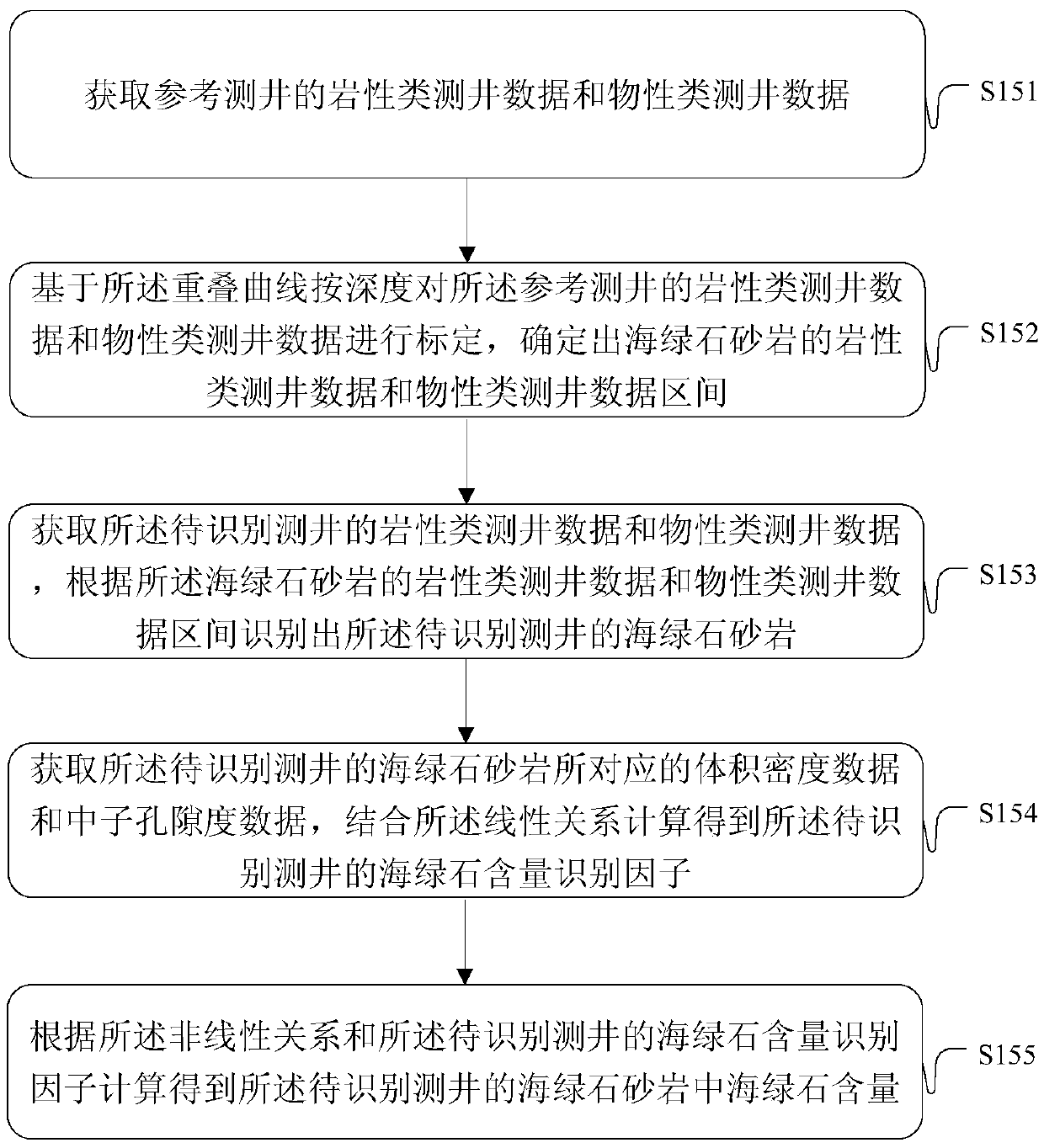

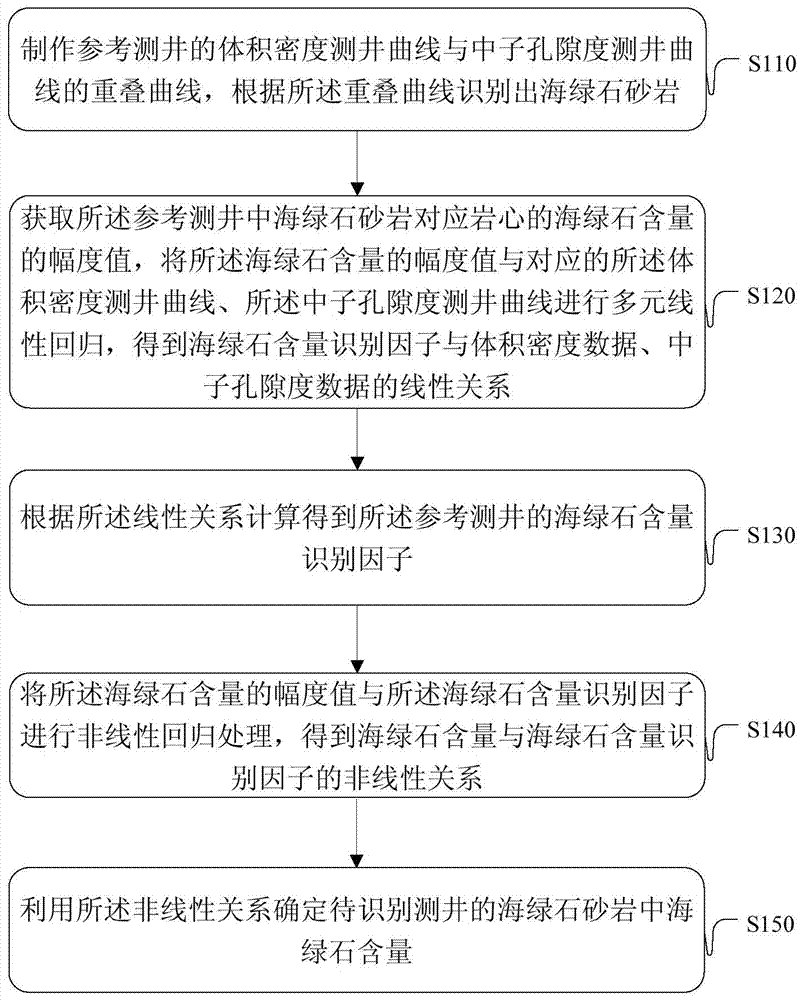

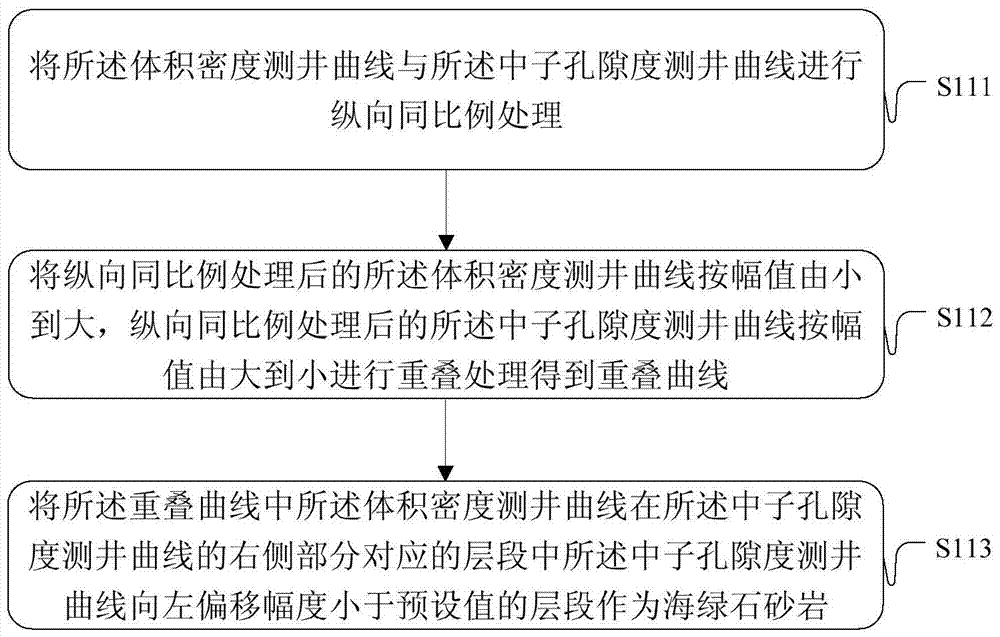

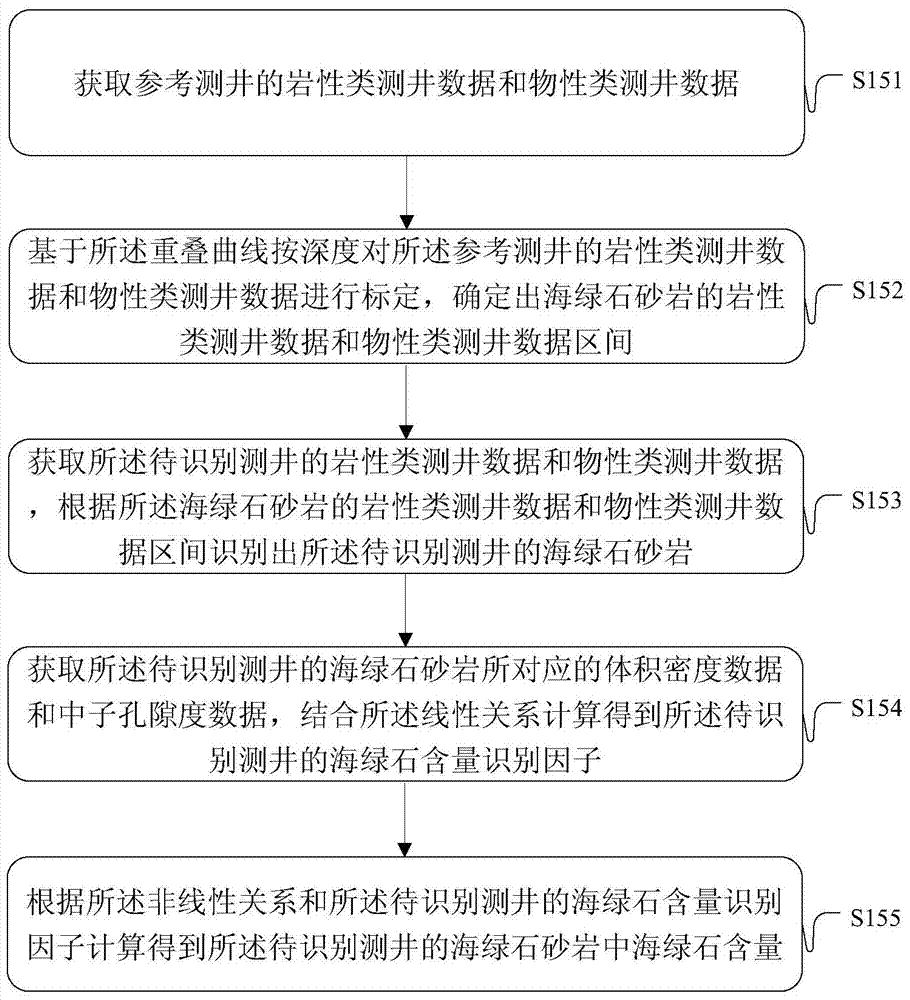

Method and device for determining content of glauconite in glauconite sandstone

The embodiment of the invention provides a method and device for determining the content of glauconite in glauconite sandstone. The method comprises steps of: making a superposed curve of a volume density logging curve and a neutron porosity logging curve of a reference logging, and identifying the glauconite sandstone; subjecting a glauconite content amplitude value acquired from core data, the corresponding volume density logging curve, and the corresponding neutron porosity logging curve to multivariate linear regression in order to obtain a linear relation among a glauconite content identification factor, the volume density data, and the neutron porosity data; computing a glauconite content identification factor of the reference logging according to the linear relations; subjecting the glauconite content amplitude value and the glauconite content identification factor to nonlinear regression to obtain a nonlinear relation between the glauconite content and the glauconite content identification factor; and determining the content of glauconite in glauconite sandstone of a logging to be identified according to the nonlinear relation. The method and the device may accurately determine the content of glauconite in glauconite sandstone.

Owner:PETROCHINA CO LTD

Solvent resistant and weather-proofing glass bead for reflective membrane and preparation method of solvent resistant and weather-proofing glass bead

The invention discloses a solvent resistant and weather-proofing glass bead for a reflective membrane and a preparation method of the solvent resistant and weather-proofing glass bead. The solvent resistant and weather-proofing glass bead is prepared from the following raw materials by weight: 34-46kg of silica sand, 27-39kg of glauconite, 18-34kg of talcum, 16-28kg of iolite, 24-38kg of metallurgy slag, 12-18kg of silicon boride, 10-15kg of molybdenum carbide, 8-16kg of zirconium sulfate, 5-10kg of potassium dihydrogen phosphate, 5-10kg of sodium nitrate, 4-8kg of dioctyl sodium sulfosuccinate, 3-6kg of sodium dodecyl sulfate, 2-4kg of coconut diethanolamide, 3-5kg of glycosaminoglycans, and 7-13kg of additives. Through the adding of glauconite, talcum, iolite, and metallurgy slag, the light aging and heat aging properties of the glass bead are significantly improved, and through the adding of the silicon boride, molybdenum carbide, and zirconium sulfate, the solvent resistant and wearing properties and the chemical stability of the glass bead can be improved while the mechanical strength of the glass bead can be improved. The prepared glass bead is good in solvent resistant property and weather-proofing property, high in refractive index, good in reflection effect, long in service life, and wide in application.

Owner:HEFEI DINGLIANG OPTICAL TECH

Organic bio-fertilizer

InactiveCN105111006ARecovery pelletsAvoid churnBio-organic fraction processingOrganic fertiliser preparationDiseaseContinuous use

The invention discloses an efficient organic bio-fertilizer, which comprises the following components by weight: 4-8 parts of ground phosphate rock, 2-6 parts of glauconite, 3-7 parts of shale, 1-4 parts of potash feldspar, 3-6 parts of nitre, 0.5-1.5 parts of boron, 1.3-3.7 parts of a production strain, 4-9 parts of soybean cake, 40-65 parts of dried chicken manure, 2-7 parts of blood meal, and 4-8 parts of raw bone meal. The fertilizer can improve soil, raise soil fertility, restore soil aggregate, prevent water and soil loss, eliminate diseases and pests in soil, and promote early ripening of crops by 7-10 days, even under serious drought conditions, because of the hydrophility of the fertilizer itself, crops still can get sufficient water, and through continuous use, soil can be restored to an original soil state, the crop produced under the soil condition has a very significant effect on human health, and compared with traditional fertilizers, the bio-fertilizer provided by the invention can increase the crop yield by 5%-15%.

Owner:安宝祥

Raw material composition and preparation method of sustained-release drought-resistant water-retention nutrient

The invention relates to a raw material composition and preparation method of a sustained-release drought-resistant water-retention nutrient. The drought-resistant water-retention nutrient provided by the invention is prepared from the following raw materials in parts by weight: 550-700 parts of HA35% ammonium phytate, 80-200 parts of N64% coated urea, 60-150 parts of P14 phosphate fertilizer, 60-150 parts of N17 and P44 ammonium phosphate, 20-35 parts of chitin, 3-30 parts of 80-mesh kushenin and 20-50 parts of glauconite. The sustained-release drought-resistant water-retention nutrient prepared by the preparation method provided by the invention has the characteristics of synchronous plant absorption and sustained release, high water absorption capability, good stress resistance and water retention properties, entire nutrients, rich bioactive substances and soil activation, can improve leaf photosynthesis, prevent bacteria infection and alleviate drought-induced plant physiological damage, has significant effects in greenness, environment friendliness and quality and efficiency improvement, is especially suitable for production of food economical crops, and has persistency and controllability on the drought resistance and nutrient supply.

Owner:武兴战

Modified glauconite, and preparation method and applications thereof

The invention relates to a modified glauconite, and a preparation method and applications thereof. The modified glauconite is obtained through steps of heating, crushing, dedusting, and magnetic selection. The modified glauconite is taken as a main component in sewage treatment, and the sewage treatment effect of the modified glauconite is better than that of glauconite raw sand.

Owner:崔凡

Non-caking absorbable high-efficiency medium for agaricus blazei murill and preparation method thereof

InactiveCN105000978AGuaranteed water absorptionGuaranteed loose and non-caking performanceFertilizer mixturesFiberNiobium

The invention discloses a non-caking absorbable high-efficiency medium for agaricus blazei murill. The medium is characterized by comprising the following components, by weight, 1-2 parts of 3-Hydroxy-4-(trimethylammonio)butanoate, 5-8 parts of chitosan, 10-20 parts of 80-mesh kushenin, 3-8 parts of glauconite powder, 1-2 parts of shell powder, 2-3 parts of niobium ore powder, 30-40 parts of bran, 4-6 parts of silicon nitride ultrafine powder, 3-7 parts of chitin fiber, 50-80 parts of sorghum straw, 60-70 parts of brown rice grain, 2-3 parts of yeast, 8-10 parts of decomposed coal, 1-2 parts of ardealite and a proper amount of water. By the use of modified kushenin, various mineral powders, shell powder and decomposed coal, water absorption and loose and non-caking properties of the medium are guaranteed. Meanwhile, ultramicro silicone powder-loaded chitin fiber is used. As ultramicro silicone powder promotes nutrient absorption of agaricus blazei murill and chitin fiber constantly adsorbs and enriches nutrients, growth of agaricus blazei murill is promoted.

Owner:HEFEI FUQUAN MODERN AGRI SCI & TECH

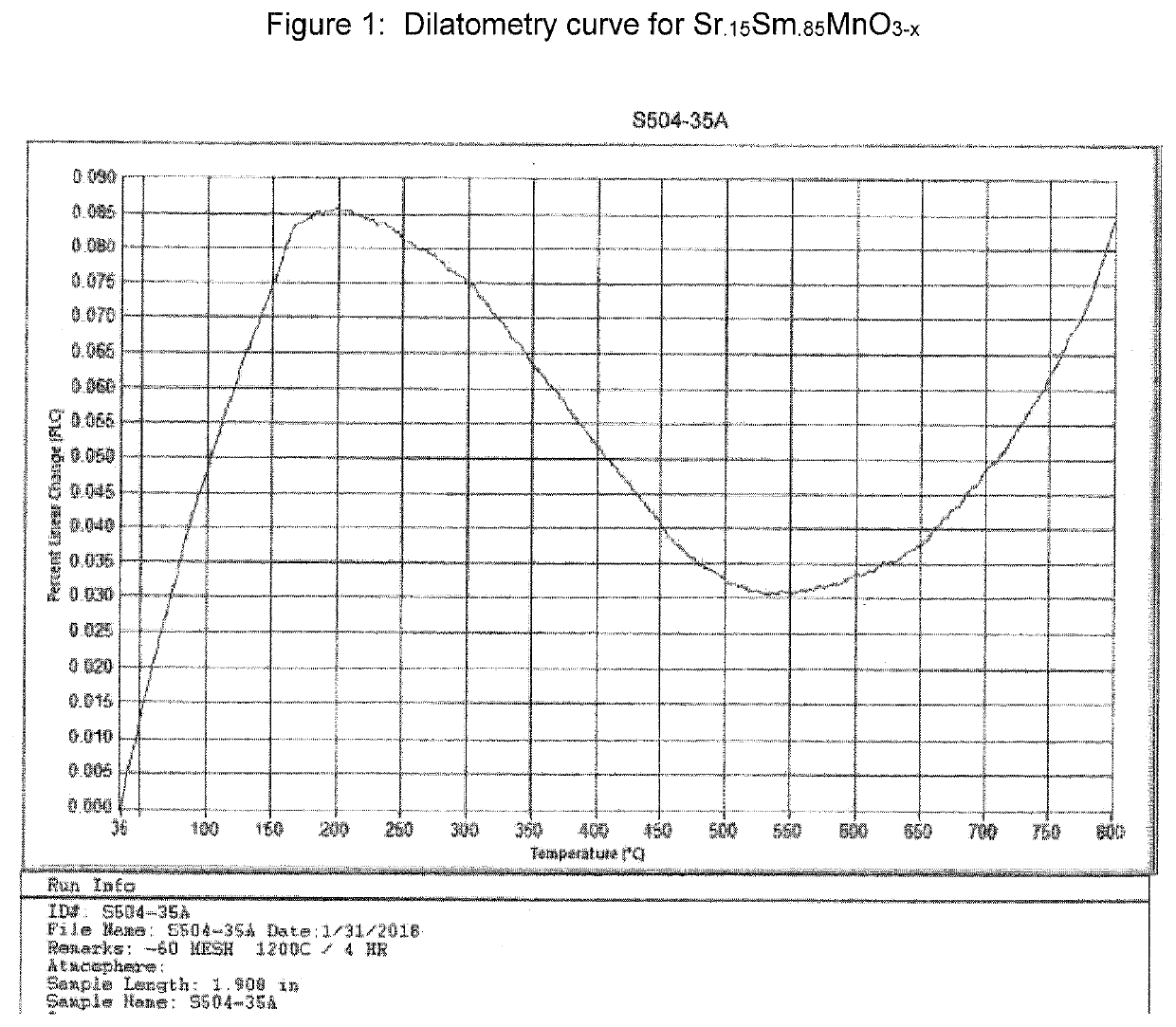

Dark-Colored, Low-Expansion Fillers

Colored CTE modifiers may be added to a glass frit system to modify the CTE of a resulting fired enamel. The CTE modifier is colored. The colored CTE modifier may include a modified Pseudo-Brookite type material having a formula Al2TiO5, where Al and / or Ti are partially substituted with one or more coloring ions including Fe, Cr, Mn, Co, Ni, and Cu; a modified Cordierite type material having a formula Mg2Al4Si5O18, wherein Mg and / or Al is partially substituted with one or more of the coloring ions; a Perovskite type material having a formula Sm1−xSrxMnO3−δ, where x=0.0-0.5 and δ=0.0-0.25, or a modified version of the Perovskite type material wherein Sr is partially substituted with Ba and / or Ca; a modified magnesium pyrophosphate type material having a formula Mg2P2O7 wherein Mg is substituted with Co and / or Zn ions; or combinations thereof.

Owner:FERRO CORP

A method and device for determining glauconite content in glauconite sandstone

Owner:PETROCHINA CO LTD

Culture medium for large-scale culture of chlorella and culture method of culture medium

InactiveCN112111406AEasy to makeSimple and convenient cultivation methodUnicellular algaeMicroorganism based processesBiotechnologyMicrobiology

The invention discloses a culture medium for large-scale culture of chlorella and a culture method of the culture medium. The culture medium comprises the following components: CH4N2O, K2HPO4, MgSO4.7H2O, CaCl2.2H2O, citric acid, ferric citrate, EDTANA2, glauconite, H3BO4, MnCl2.4H2O, ZnSO4.7H2O, Na2MoO4.2H2O, CuSO4.5H2O and C4H6CoO4.4H2O. The culture method comprises the following steps: inoculating the chlorella into the culture medium, wherein the initial inoculation amount is 3*10<6>-5*10<6> cell / mL; inflating the chlorella liquid for 60-120 minutes at 9 o'clock, 12 o'clock and 3 o'clock every day in ordinary sunny days at the temperature of 20-35 DEG C to prevent the chlorella cells from sinking to the bottom; and when the chlorella cell density reaches 5*10<7>-1*10<8> cell / mL, finishing the culture. The culture medium is different from a common chlorella culture medium, and is low in cost, and the growth and reproduction speed of the chlorella can be remarkably increased, so thatthe chlorella cell density is remarkably increased within a short time, and the culture period is short. In combination with the culture method disclosed by the invention, a large-scale high-densityculture mode of the chlorella can be quickly realized.

Owner:ANHUI TECH BANK BIO TECH

Clay green sand applied to carbon steel castings and preparation method of clay green sand

InactiveCN105537504AImprove liquidityImprove breathabilityFoundry mouldsFoundry coresSludgeMonopotassium phosphate

Owner:WUHU JINMAO FLUID TECH CO LTD

Adsorbent for treating lead-containing wastewater and preparation method thereof

InactiveCN106140115BReduce manufacturing costEasy to useOther chemical processesAlkali metal oxides/hydroxidesSilanesSorbent

The invention discloses an adsorbent for treating lead-containing wastewater and a preparation method thereof. The adsorbent is mainly composed of, by weight, 1-8 parts of brown alga powder, 3-10 parts of glauconite powder, 3-5 parts of magnesite powder, 3-15 parts of bauxite, 0.6-4 parts of (3-mercaptopropyl) triethyoxy silane, 1-10 parts of chitosan, 1-4 parts of modified polycarboxylate, 2-10 parts of barite powder, 10-50 parts of polymer binder, 60-100 parts of quartz wool, 5-20 parts of buckwheat powder and 0.3-5 parts of titanium isopropanol. When adsorbent granules prepared from brown alga powder, glauconite powder, magnesite powder, bauxite, (3-mercaptopropyl) triethyoxy silane, chitosan,,polymer binder, buckwheat powder and titanium isopropanol are put into lead-containing water, the adsorbent granules can effectively adsorb lead and are free of environment pollution; the adsorbent is low in manufacturing cost and convenient to use.

Owner:BEIJING SOUND ENVIRONMENTAL ENG

A green abrasive steel paper with strong tinting strength

ActiveCN107419591BGood surface finenessStrong coloring powerSpecial paperPaper coatingCellulosePolymer science

Owner:杭州特种纸业有限公司

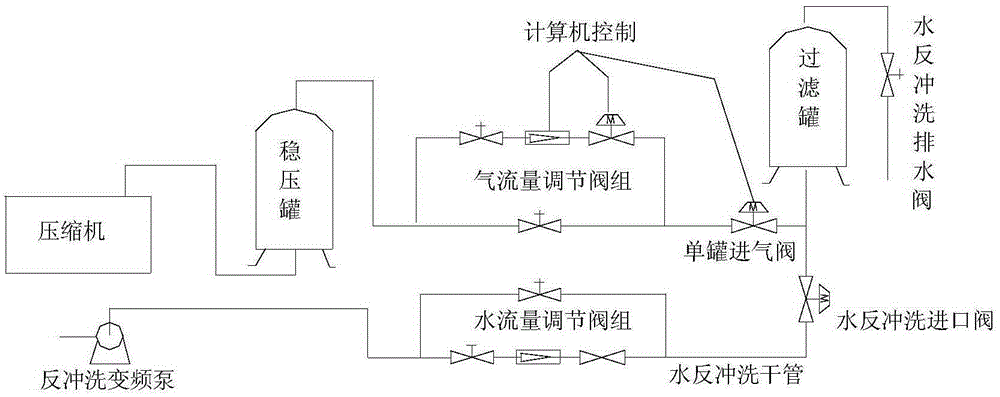

Oilfield Produced Water Treatment Filter Tank Air-Water Backwash Regeneration Process

ActiveCN103520968BRegeneration is clean and thoroughAchieve regenerationLoose filtering material filtersGravity filtersParticulatesWater discharge

The invention relates to an oil field produced water treatment filtration tank gas-water backwash regeneration process. The process comprises a gas washing process and a water washing process. First, the filtering material in the filtration tank is subjected to gas backwash with 2 gas gradients according to a gas washing process, and the filtering material in the filtration tank is subjected to water backwash with 1 water gradient. The gas washing process sequentially adopts an air compressor, an air pressure regulation tank, a gas flow rate controlling valve set, a single-tank gas inlet switching valve, the filtration tank, a backwash water discharge valve, and a low-level recovery water tank. The water washing process sequentially adopts a backwash variable-frequency water pump, a water flow rate regulation valve set, a single-tank backwash water inlet switch valve, the filtration tank, a backwash water discharge valve, and a backwash recovery water tank. With the process, regeneration of particulate filtering materials in single-layer quartz filtration tank, single-layer magnetite filtration tank, quartz-magnetite double-layer filtering material filtration tank, glauconite-magnetite double-layer filtering material filtration tank, and the like in oil field produced water treatment processes can be effectively realized.

Owner:PETROCHINA CO LTD +2

Organic modified layering silicate and preparation method thereof

InactiveCN109456621AIncrease layer spacingSimple structureNon-macromolecular adhesive additivesPigment treatment with non-polymer organic compoundsAdhesiveSolvent

The invention relates to a preparation method of organic silicate. The method comprises the following steps: pretreating the silicate by adopting a comprehensive means of heat activation, acid treatment and lithium nitrate intercalation modification to obtain lithium-based silicate, performing intercalation reaction for an organic intercalation agent and lithium-based montmorillonoid in a solventat the temperature of 80 to 180 DEG C, then purifying an organic silicate aqueous solution to obtain the organic modified silicate. The organic intercalation agent is an organic compound shown in thestructural general formula of R(CH2)12 to 18N(CH3)3R, and the R in the general formula is chlorine atoms or bromine atoms. The layered silicate is white mica subtribe and black mica subtribe and comprises sodium mica, white mica, glauconite, gold mica, black mica, iron-lithium mica and lithium mica. By adopting the method of the invention, in the preparation process, not only can the effective swelling of a space among silicate layers be realized, but also the active functional group is introduced among the layered silicate layers, the obtained organic modified layered silicate is loose, easyto break, suitable for a high-temperature polyimide adhesive / layered silicate nano composite material, and wide in application prospect.

Owner:CENT SOUTH UNIV

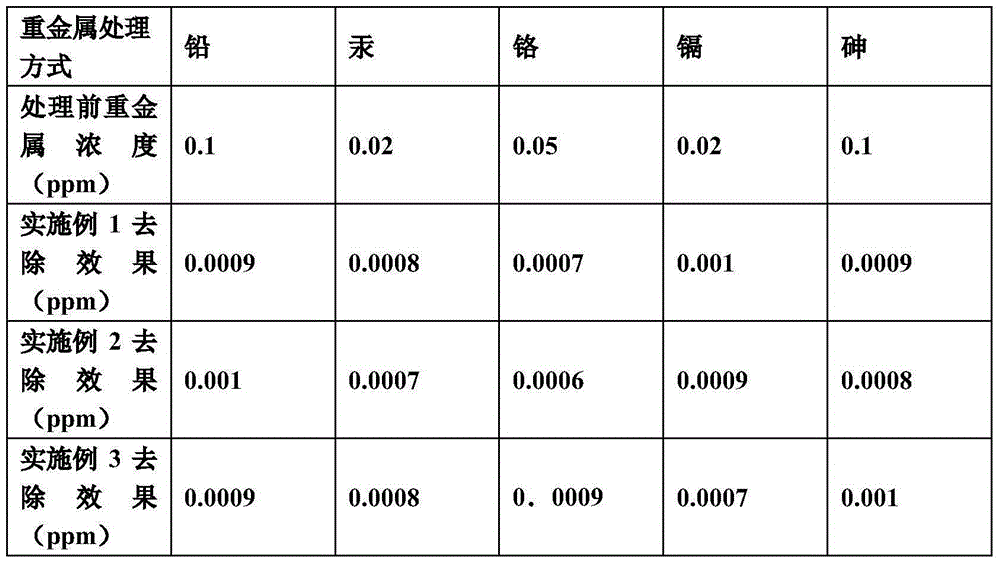

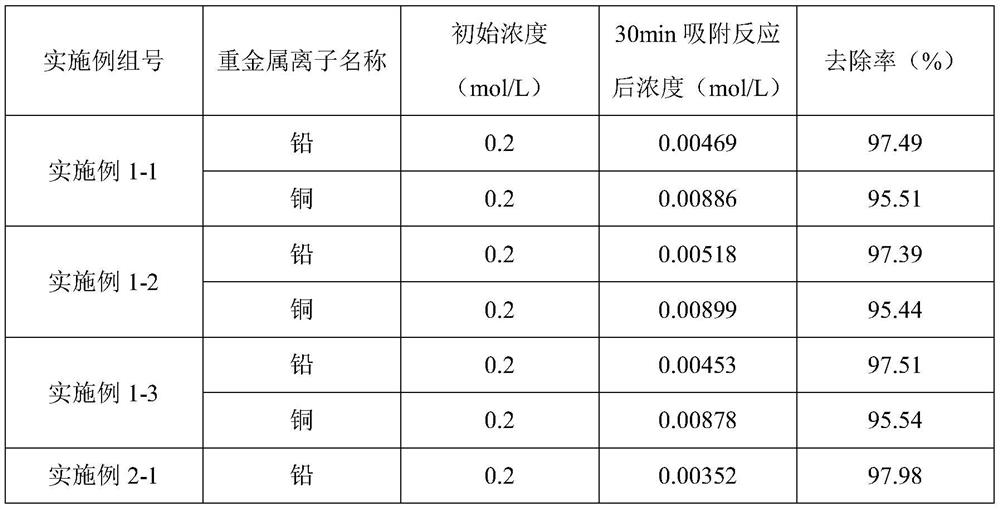

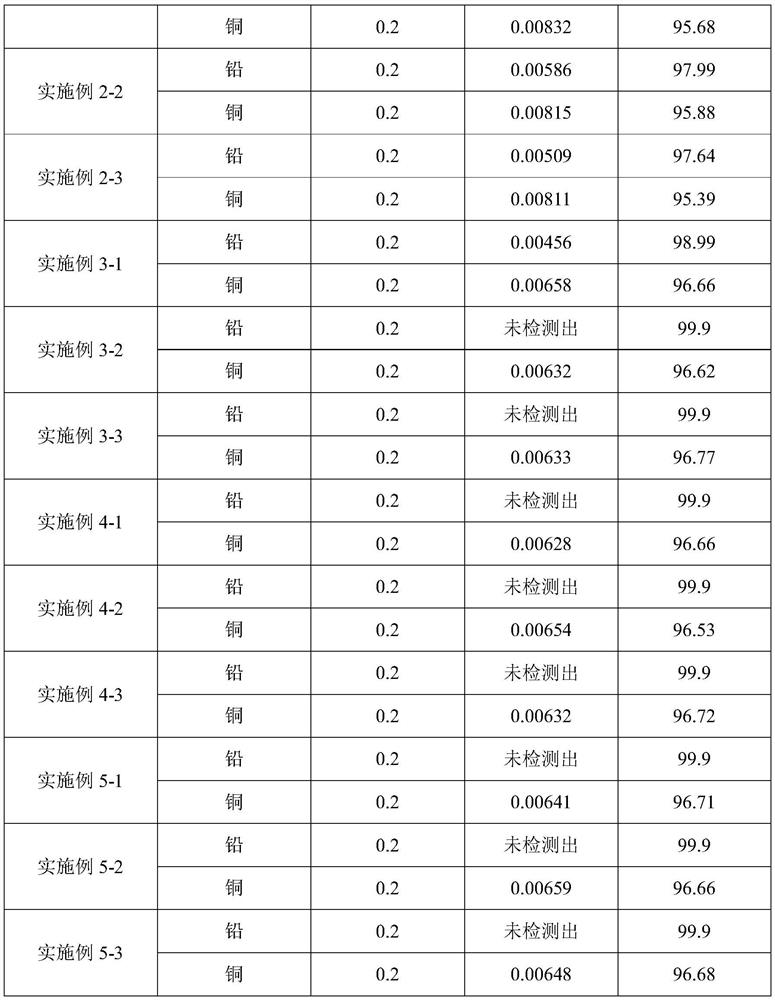

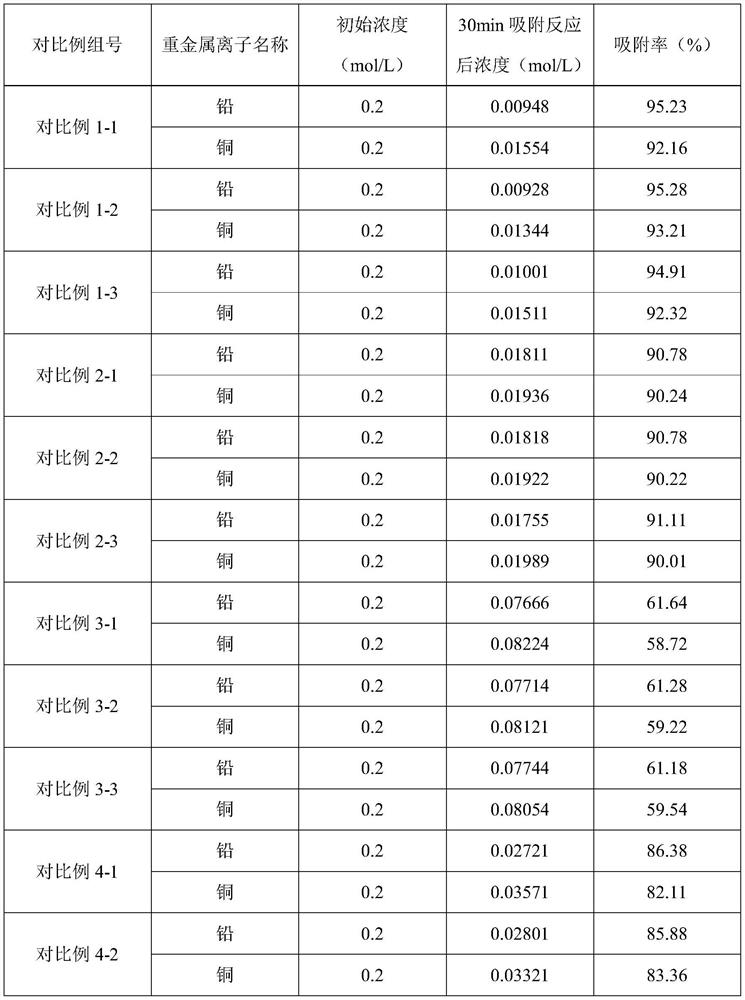

Glauconite-based composite heavy metal wastewater treatment porous material as well as preparation method and application thereof

PendingCN113797887AGood removal effectOther chemical processesAluminium silicatesSodium BentoniteGlauconite

The invention discloses a glauconite-based composite heavy metal wastewater treatment porous material as well as a preparation method and an application thereof. The porous material is prepared from the following raw materials in parts by weight: 23-32 parts of glauconite, 15-21 parts of deacetylated chitin, 13-18 parts of sodium bentonite, 8-15 parts of a pore-forming agent, 4-10 parts of graphene oxide and 2-9 parts of sodium hydroxide. The composite powder is firstly obtained and then pressed into the pressed blank through CIP, the pressed blank is subjected to a solid-phase sintering process under the action of the pore-forming agent, and the sintering process is controlled to be finished in the sintering middle stage, so that the porous material generates a large number of pores and meets the porosity requirement while the matrix strength is guaranteed, a self-bearing structure is obtained, and the requirement for renewable utilization is met; the product is used for adsorbing and removing lead and copper in heavy metal wastewater, and has an excellent adsorption and removal effect.

Owner:长沙工研院环保有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com