Oilfield Produced Water Treatment Filter Tank Air-Water Backwash Regeneration Process

A technology of backwashing and filter tanks, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve problems such as increasing backwashing intensity, affecting water quality, and cracking of filter cake layer, and achieves simple process Practical, clean and thorough regeneration, great benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing:

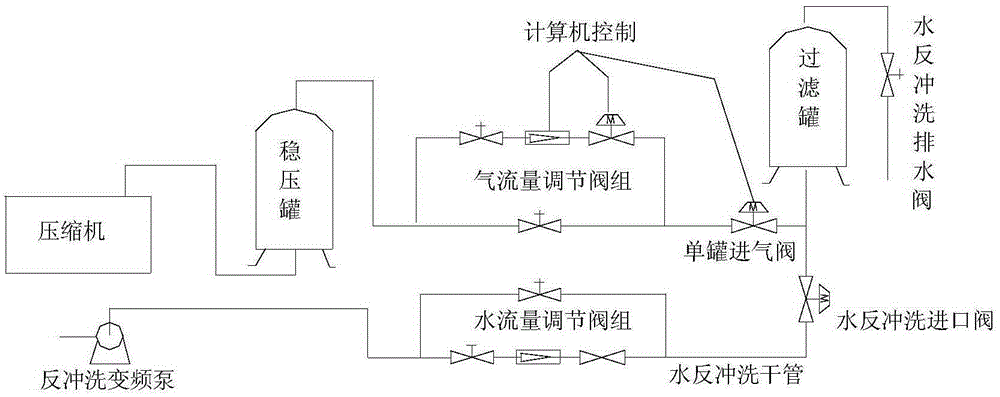

[0012] Such as figure 1 As shown, the gas-water backwash regeneration process of the oilfield produced water treatment filter tank includes the air washing process and the water washing process. Carry out the water backwash of the water volume of 1 gradient to the filter material in the filter tank;

[0013] First, use the air compressor→air pressure tank→air flow control valve group→single tank intake switch valve→air into the filter tank→backwash drain valve→low recovery pool to wash the filter material with two gradient air volumes;

[0014] The process flow of the above water washing is: backwashing frequency conversion water pump → water flow regulating valve group → single tank backwashing water inlet switch valve → water enters the filter tank → backwashing drain valve → backwashing recovery water tank for one filter material Gradient water flushing, the whole proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com