Device and process for recycling volatile organic gas in adsorption-desorption manner

An organic gas and desorption technology, which is used in the desorption process, industrial organic waste gas (VOCS) adsorption-desorption recovery, and adsorption of activated carbon fiber adsorption towers, which can solve secondary pollution, long desorption time, and water vapor consumption. Large and other problems, to achieve the effect of high recovery rate, avoid secondary pollution, and fast regeneration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

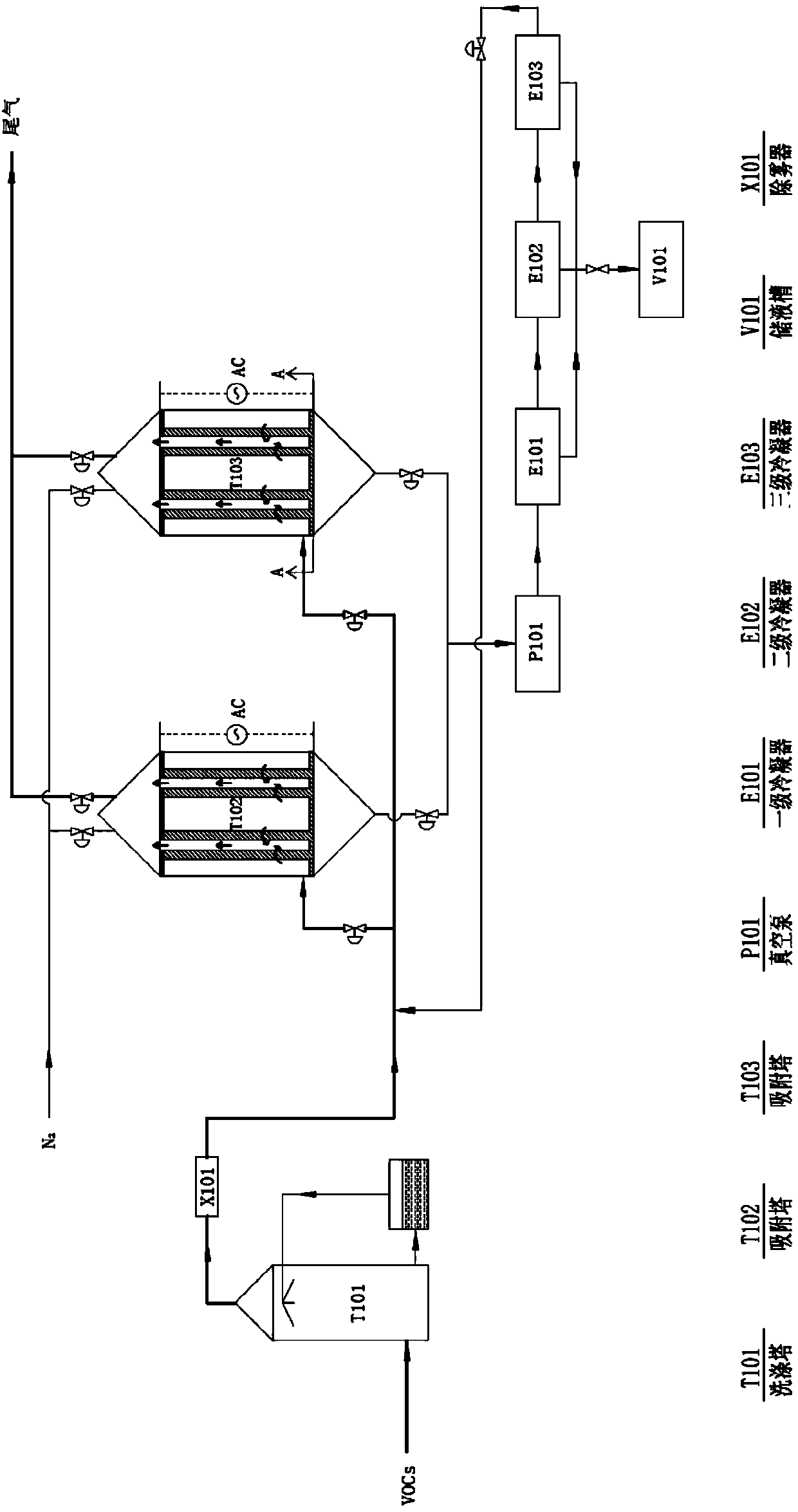

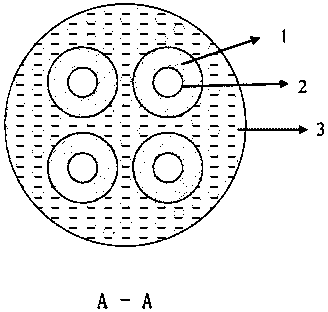

[0040] Refer below figure 1 with figure 2 Provide the device system and flow diagram of the process technology of the present invention, the device of the present invention includes two activated carbon fiber adsorption towers, respectively the first activated carbon fiber adsorption tower T102, the second activated carbon fiber adsorption tower T103; and vacuum pump P101, one-stage condensation E101, secondary condenser E102, tertiary condenser E103, liquid storage tank V101, washing tower T101, demister X101, the first activated carbon fiber adsorption tower T102 and the second activated carbon fiber adsorption tower T103 are equipped with activated carbon fiber adsorption column, an upper fixing frame and a lower fixing frame for fixing the activated carbon fiber adsorption column. Composed of cloth 2, the side wall of the insulating hollow tube 1 is distributed with air holes, the opening rate is 70%, and the aperture size is 5mm. The side wall of the insulating hollow t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com