Equipment and method for treating organic waste water through electrocatalysis of cathode in combination with anode

An organic wastewater and electrocatalysis technology, applied in electrochemical water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of complex structure, limited practical application of wastewater treatment, weak electrocatalytic oxidation, etc., to achieve treatment efficiency High, overcome the decline of treatment effect, the effect of simple reactor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

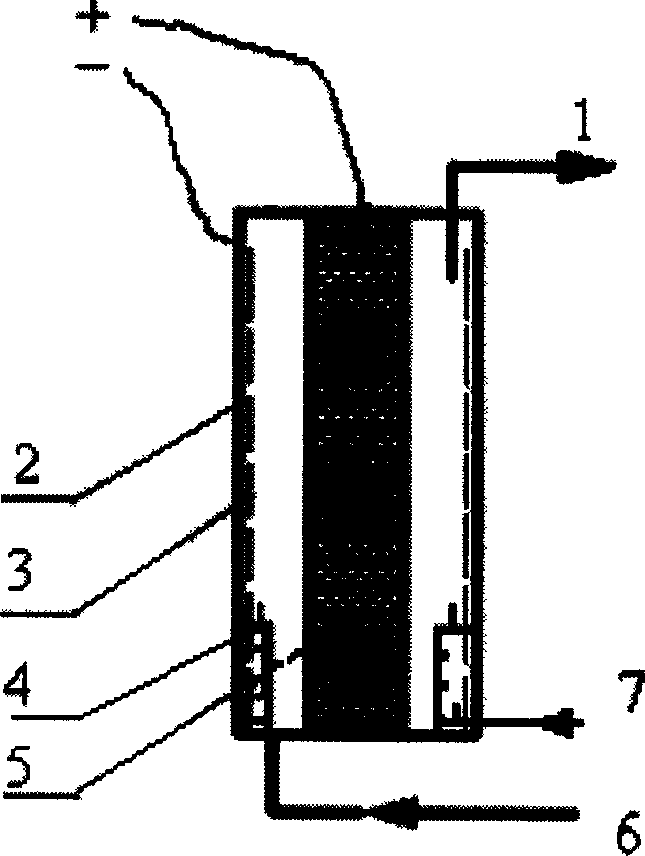

Image

Examples

Embodiment

[0032] The experiment compared the difference of the degradation rate of phenol under three ways of ferrous ion catalyzed cathodic and cathodic co-degradation (FeACE), cathodic co-degradation (ACE) and anodic oxidation reaction (AE).

[0033] (1) In the anodic oxidation (AE) process, the treatment condition is that the concentration of phenol in the wastewater is 100mg L -1 , pH3, current 0.25A, no aeration, no ferrous ion dosing;

[0034] (2) In the ACE process, the treatment condition is that the concentration of phenol in the wastewater is 100 mg L -1 , pH3, current 0.25A, aeration rate (air) of 6.7mL s -1 , no ferrous ion dosing;

[0035] (3) In the ferrous ion-catalyzed cathodic and cathodic co-degradation (FeACE) process, the treatment condition is that the concentration of phenol in the wastewater is 10 mg L -1 , pH3, current 0.25A, aeration rate (air) of 6.7mL s -1 , The dosage of ferrous ion is 0.50mM.

[0036] The results showed that the treatment effect: FeACE>...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com