Patents

Literature

343results about How to "Effective compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

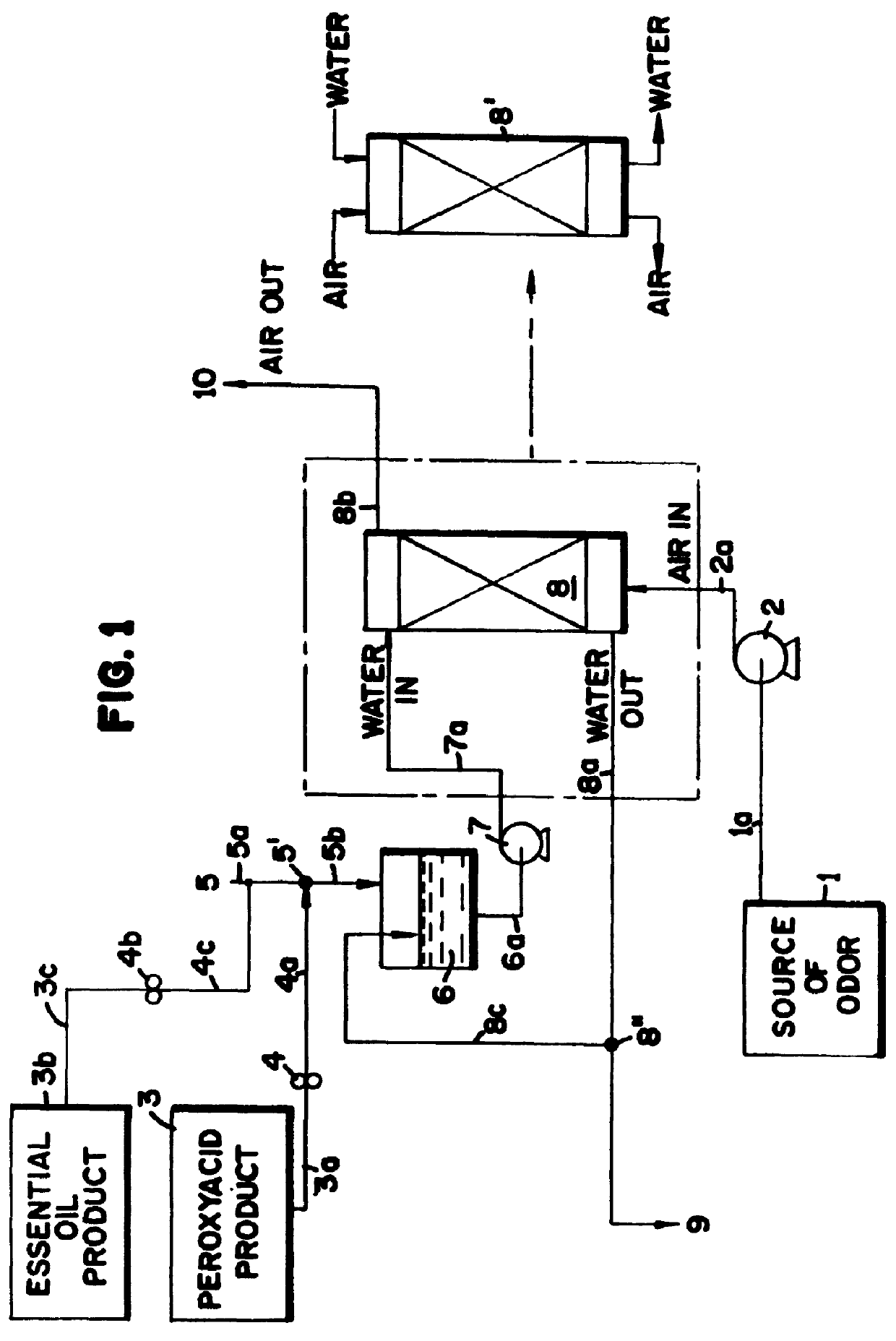

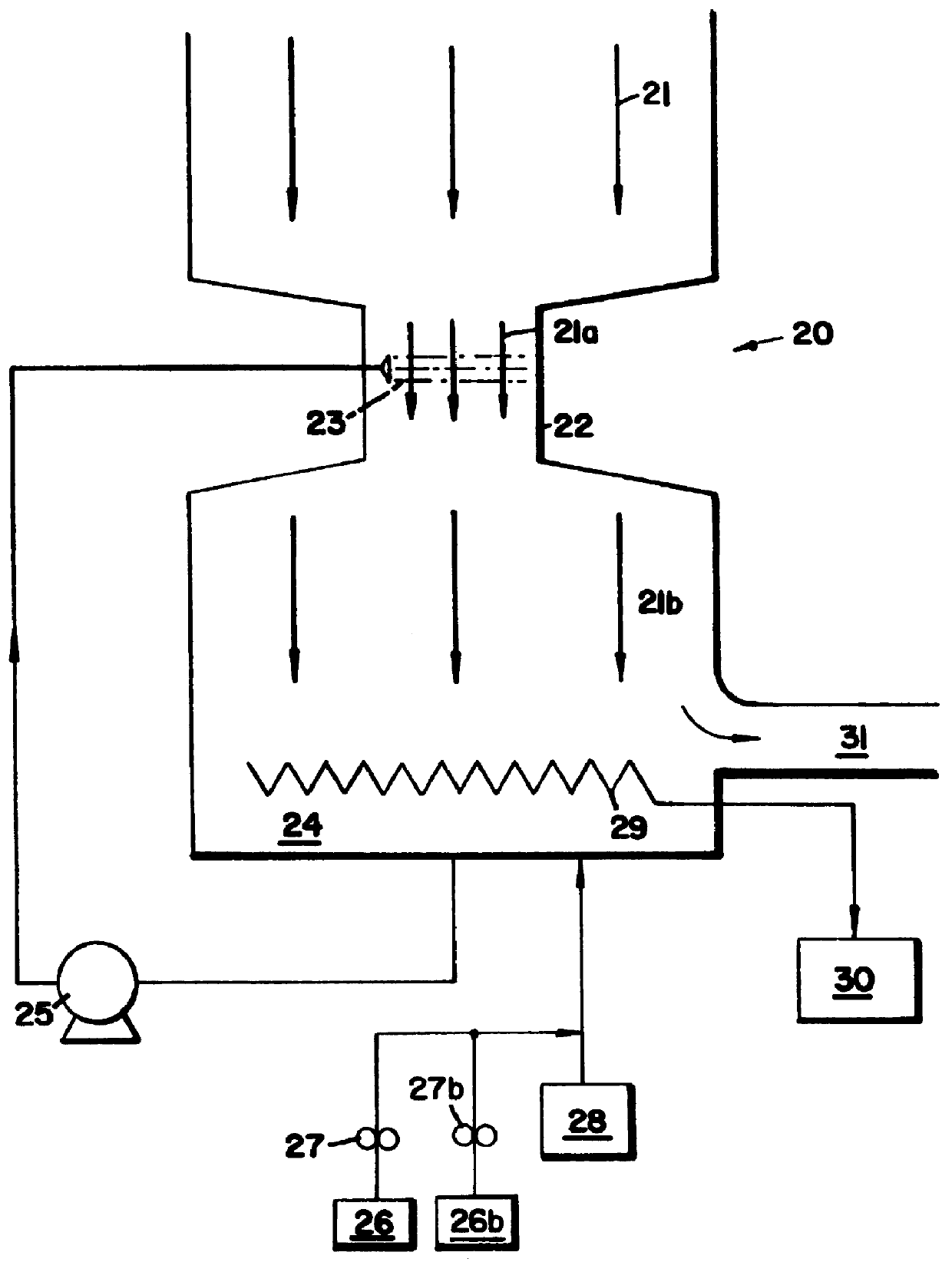

Peroxyacid compound use in odor reduction

InactiveUS6015536AReduce concentrationLess objectionable odor levelUsing liquid separation agentChemical/physical processesGas phasePeroxy acid

Disclosed is a process for the treatment of a plant fluid effluent containing odor compounds including an alkyl mercaptan or an alkyl thiol, an amine compound, ammonia, hydrogen sulfide and mixtures thereof by contacting the plant effluent in either a counterflow or cocurrent flow process. In the process, the effluent is contacted with an aqueous solution comprising a peracid compound. When contacted with the peracid, odor compounds in the effluent are oxidized and converted from the gaseous phase into a chemically modified highly aqueous soluble phase in the aqueous treatment. In this way, odor removal from the gas is preferred and odor compounds are efficiently transferred into the aqueous treatment solution. The use of such a process produces a significant improvement in odor quality index as measured by a conventional process using an expert panel when compared to conventional treatment methods.

Owner:ECOLAB USA INC

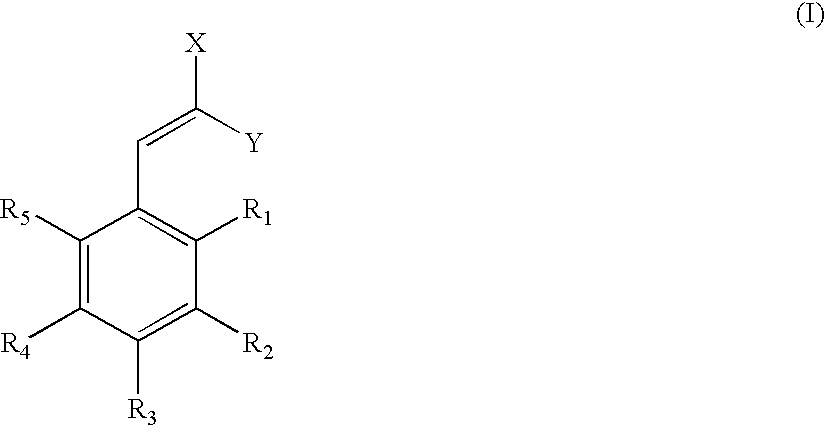

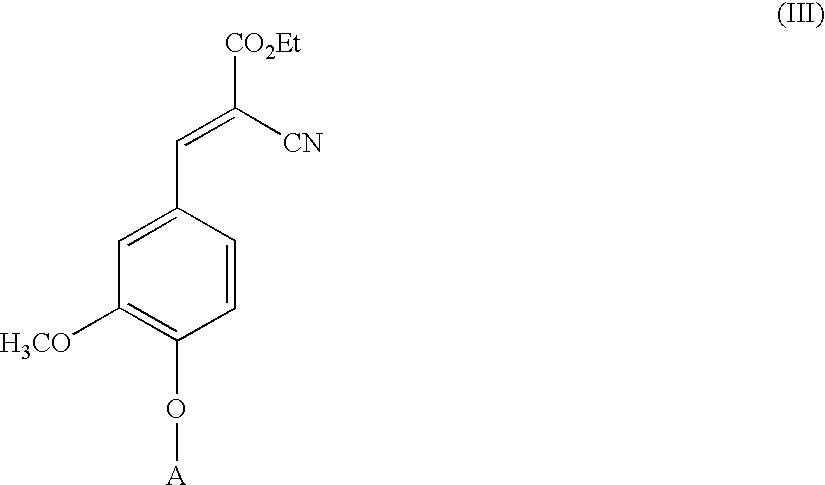

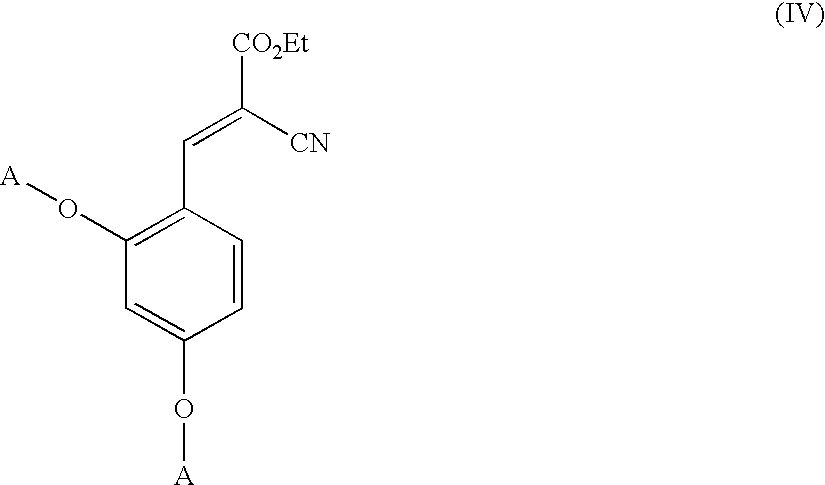

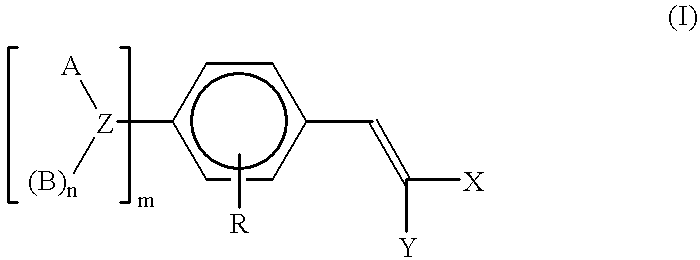

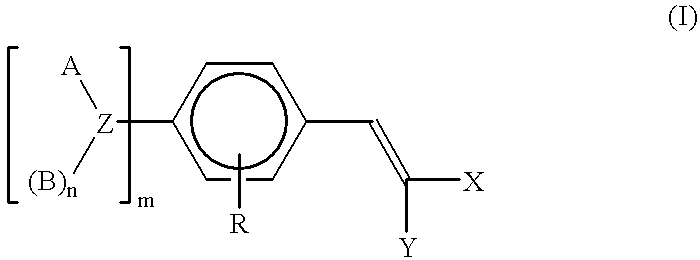

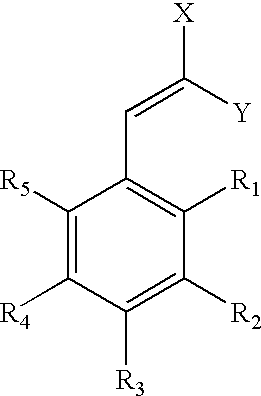

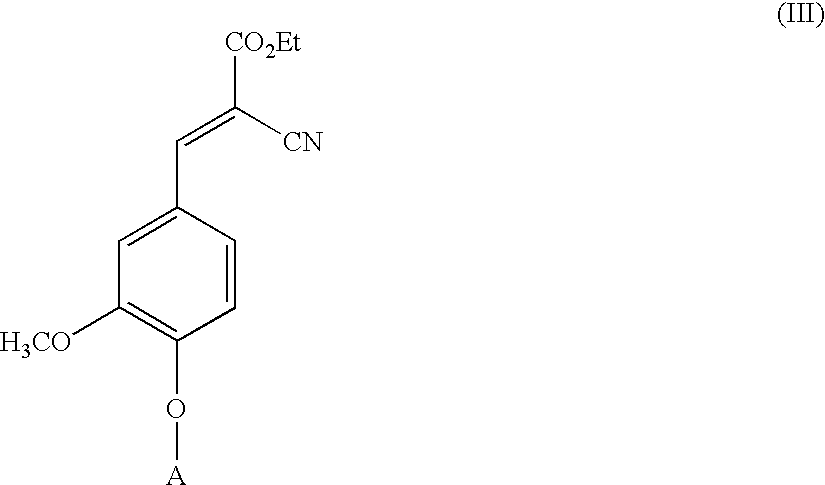

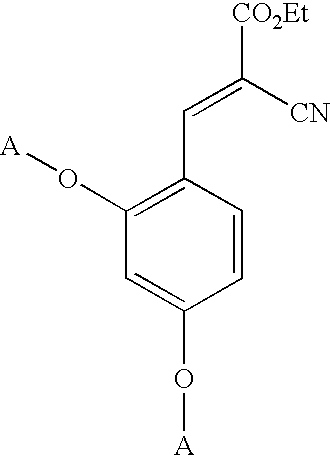

Low-color ultraviolet absorber compounds and compositions thereof

InactiveUS6559216B1Brighter clarityEffective compoundOrganic chemistryOrganic compound preparationThermoplasticChain length

Novel ultraviolet absorbing compounds that are liquid in nature, are extremely low in color (and thus permit use without the concomitant necessity of adding large amounts of other coloring agents to combat such discoloring), and are highly effective in providing protection in wavelength ranges for which previous attempts at low-color ultraviolet absorbers have failed are provided herein. Such compounds provide such excellent, inexpensive, and beneficial protection from ultraviolet exposure within various media, including, but not limited to, clear thermoplastics. The particular compounds are generally polymeric in nature including various chain lengths of polyoxyalkylenes thereon and are liquid in nature to facilitate handling and introduction within the target media. In addition, such ultraviolet absorbers also exhibit extremely low migratory properties thereby providing long-term protective benefits to the target media as well. This invention also concerns the end products, specific broadly defined types of compounds providing such beneficial characteristics, methods of making such low-color compounds, and methods of producing such clear, UV protected end products.

Owner:MILLIKEN & CO

Polymeric methine ultraviolet absorbers

This invention relates to novel ultraviolet absorbing methine-based compounds comprising polyoxyalkylene moieties. Such compounds provide excellent, inexpensive, protection from ultraviolet exposure within various media, including, but not limited to, thermoplastics. The presence of polyoxyalkylene chains on the methine backbone permits such an introduction within thermoplastics while simultaneously providing very low degrees of migration from the target substrate. This invention also concerns methods of making the aforementioned ultraviolet absorbing thermoplastic compositions.

Owner:MILLIKEN & CO

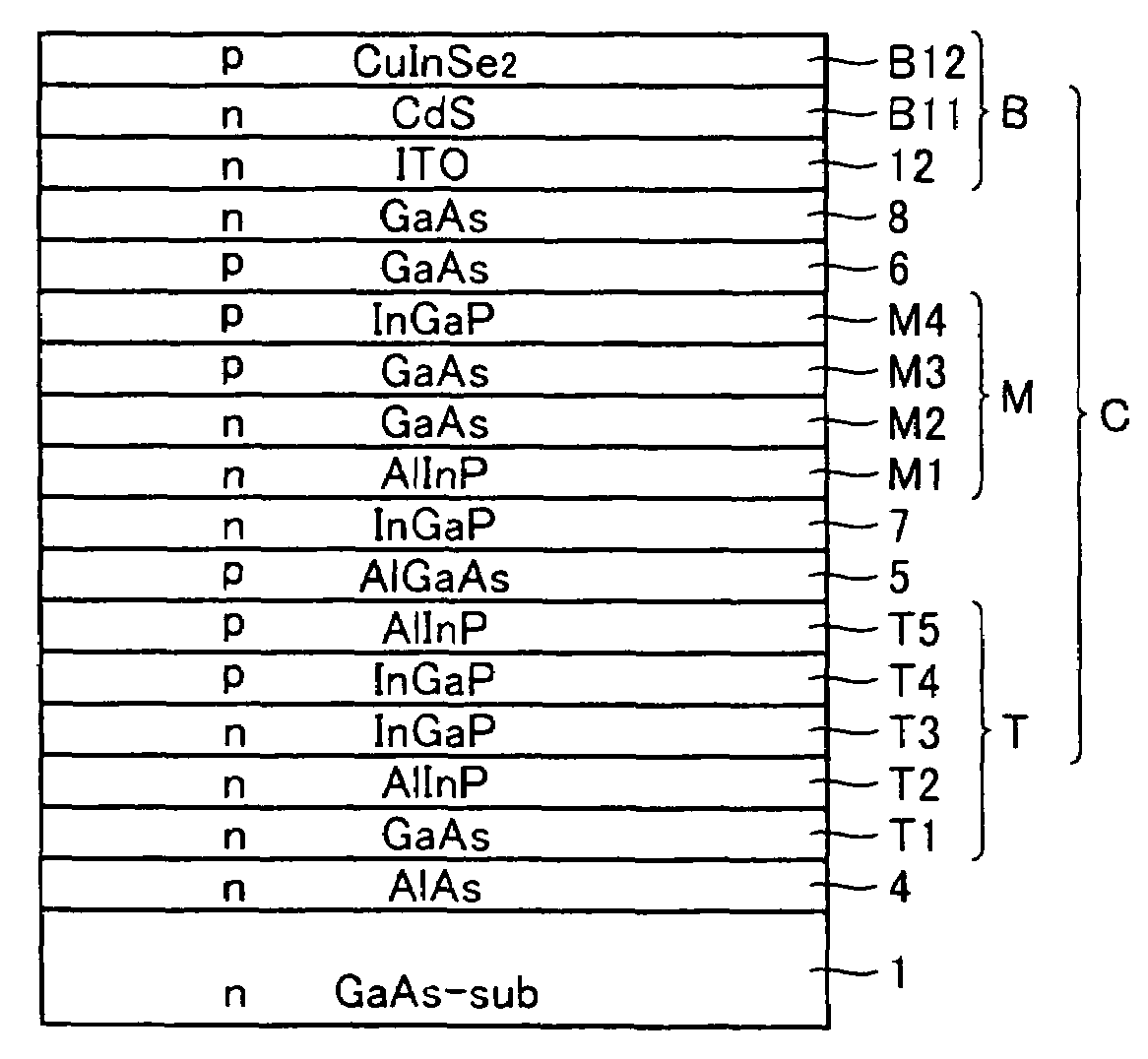

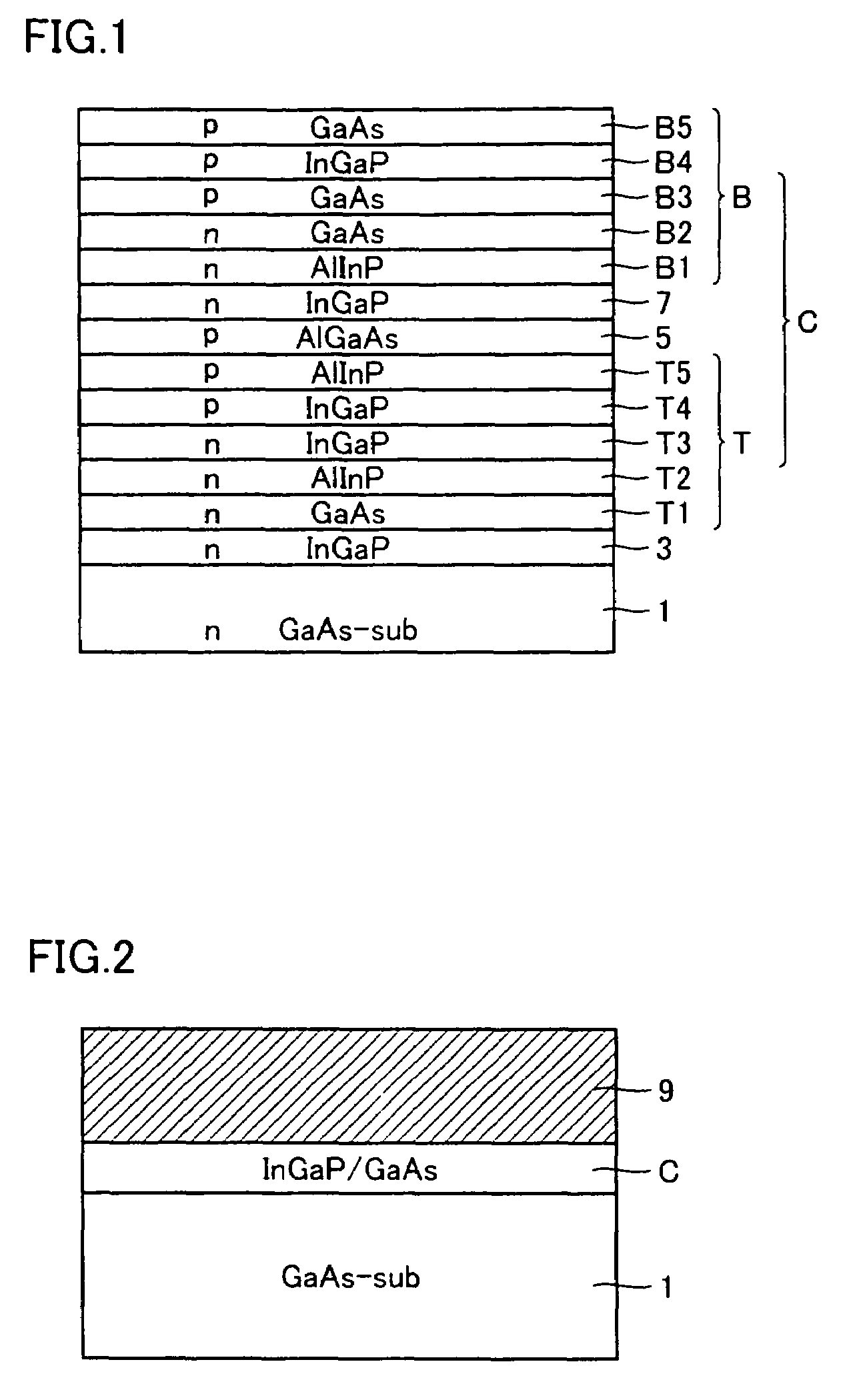

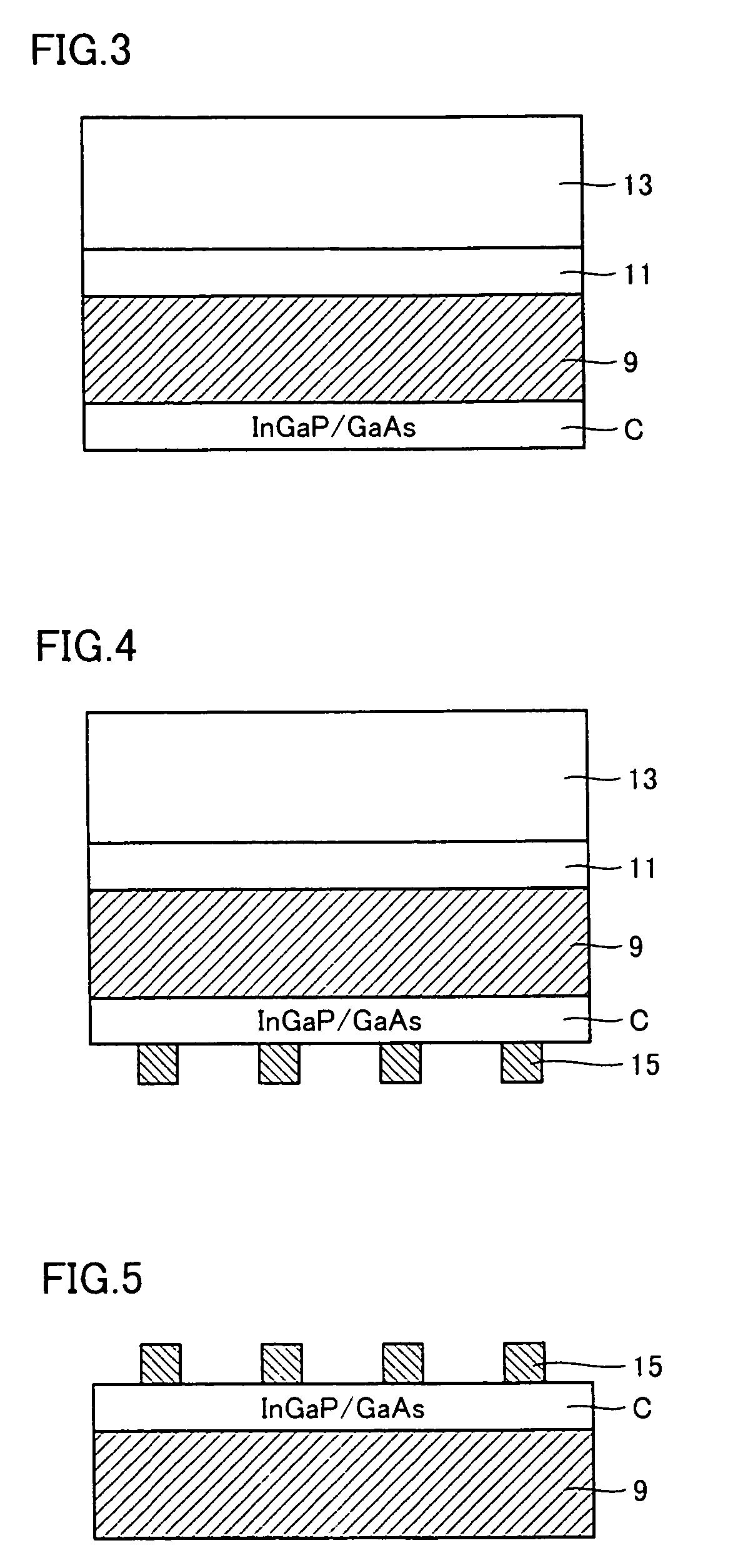

Compound solar battery and manufacturing method thereof

InactiveUS7488890B2Improve efficiencyImprove lighting effectsFinal product manufactureSemiconductor/solid-state device manufacturingWaxSolar battery

On a surface of a GaAs substrate, layers to be a top cell are formed by epitaxial growth. On the top cell, layers to be a bottom cell are formed. Thereafter, on a surface of the bottom cell, a back surface electrode is formed. Thereafter, a glass plate is adhered to the back surface electrode by wax. Then, the GaAs substrate supported by the glass plate is dipped in an alkali solution, whereby the GaAs substrate is removed. Thereafter, a surface electrode is formed on the top cell. Finally the glass plate is separated from the back surface electrode. In this manner, a compound solar battery that improves efficiency of conversion to electric energy can be obtained.

Owner:SHARP KK

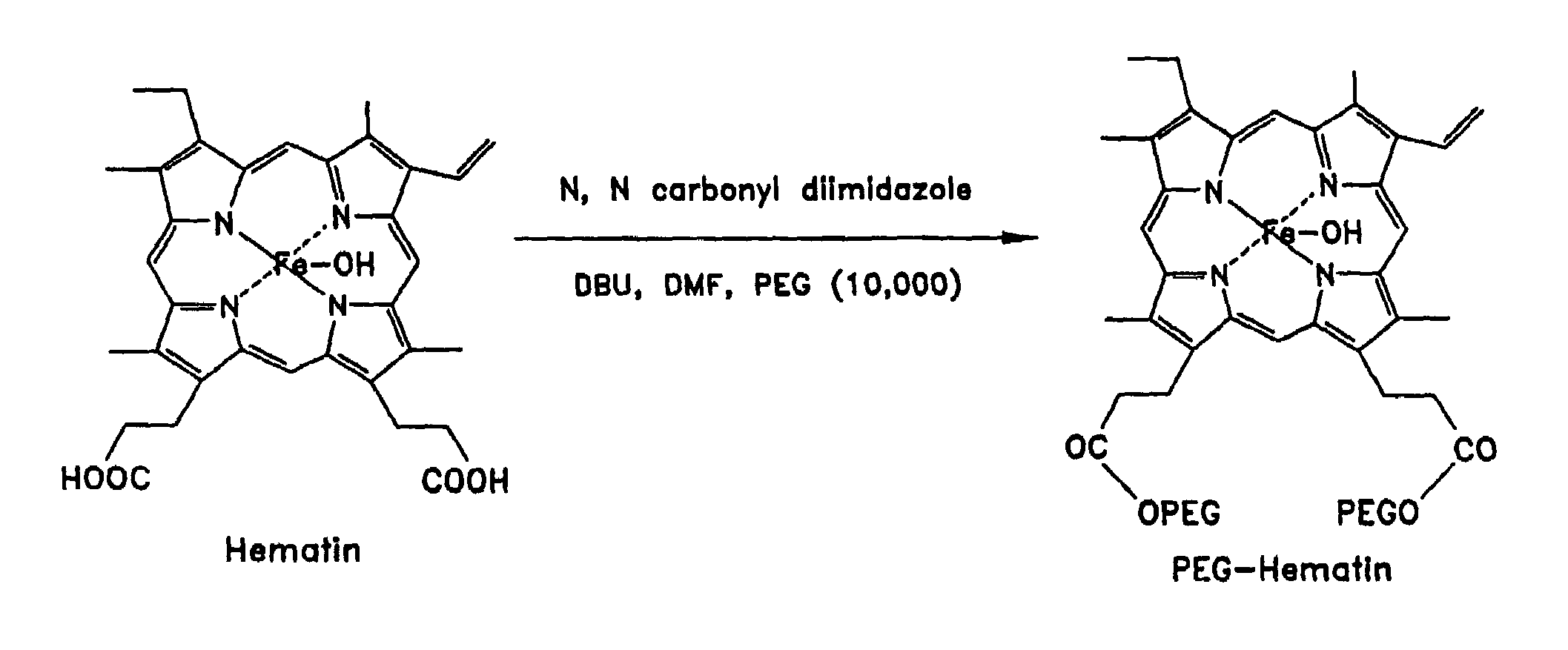

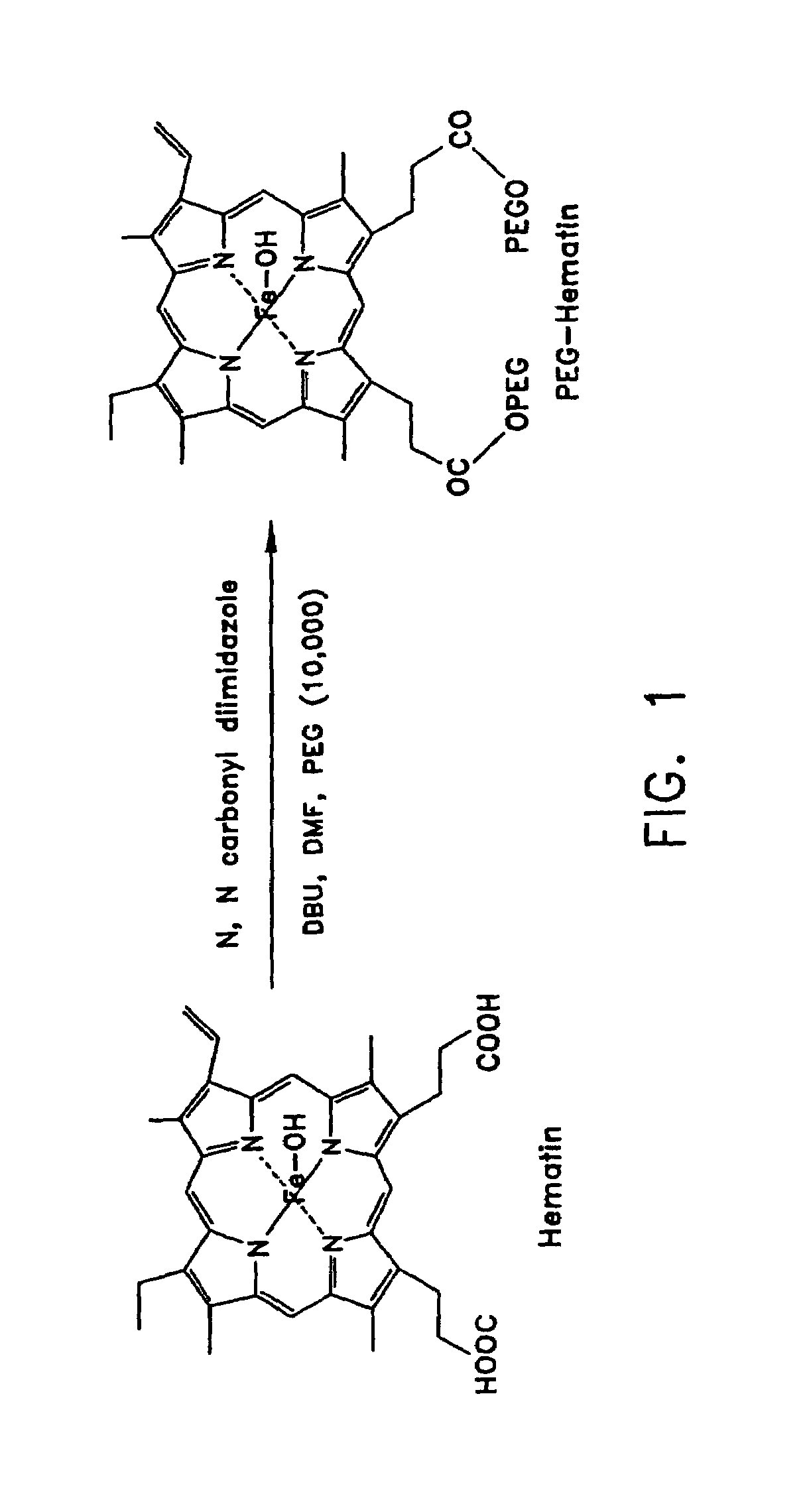

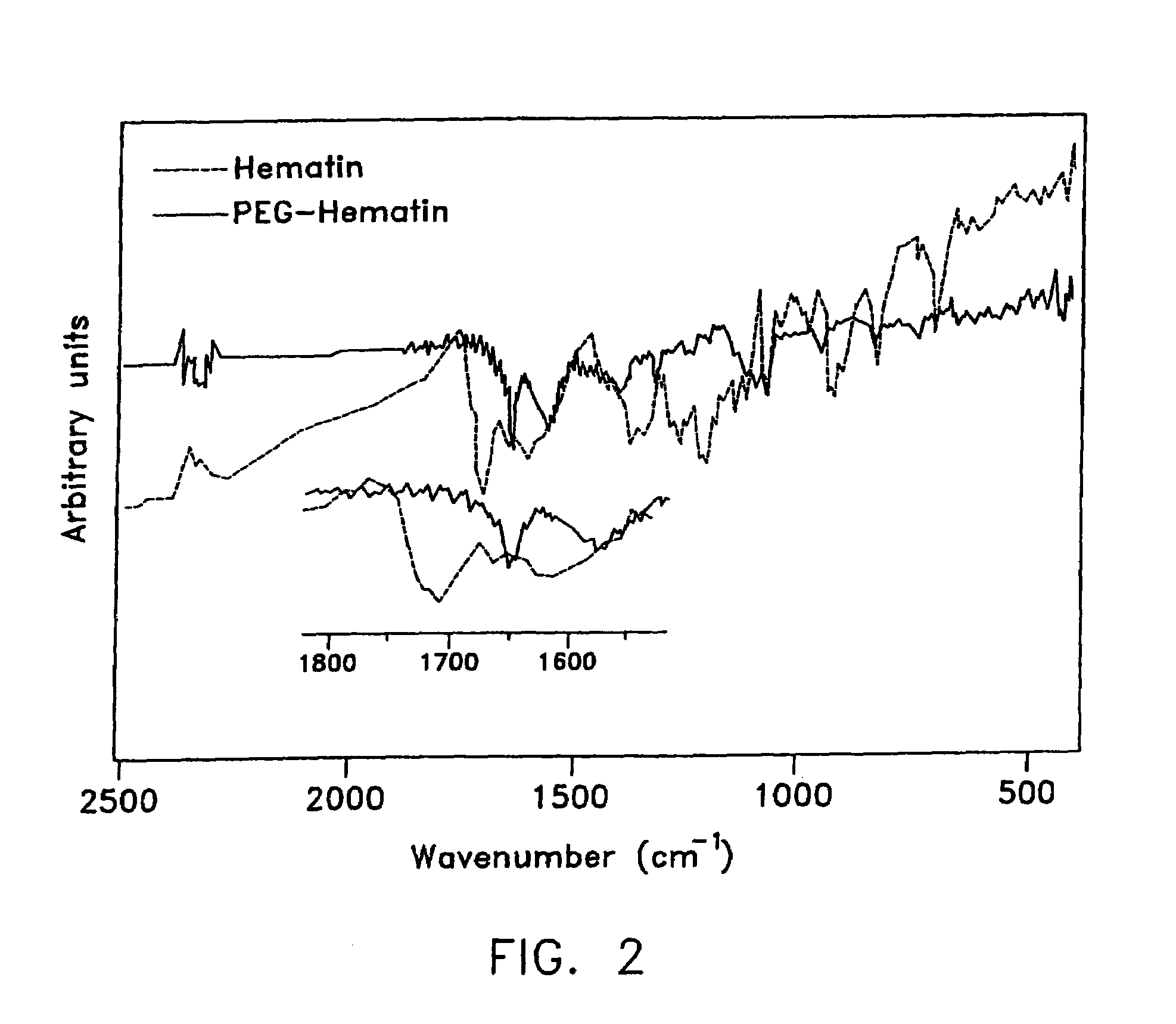

Methods for polymerization of electronic and photonic polymers

InactiveUS7186791B2Electrical and chemical stabilityEasy to processOrganic chemistryPhotonicsMonomer

A method for polymerizing electronic and photonic polymers, wherein an aromatic monomer is combined with a hematin catalyst derivatized with at least one non-proteinaceous amphipathic group, and a peroxide initiator, and employing a template, wherein the aromatic monomer aligns along the template and polymerizes to form a complex comprising the polymerized monomer and the template.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Conductive silicone rubber composition and low-resistance connector

InactiveUS6309563B1Stable resistivityInhibition of agglomerationLayered productsConductive materialPolymer scienceSpherical form

A conductive silicone rubber composition comprising (A) an organopolysiloxane having at least two aliphatic unsaturated groups, (B) a conductive powder comprising a silver powder premixed with 0.2-5% by weight of fine powder selected from the group consisting of inorganic fillers and spherical organic resins, and (C) a curing agent has a stable volume resistivity.

Owner:SHIN ETSU CHEM IND CO LTD +1

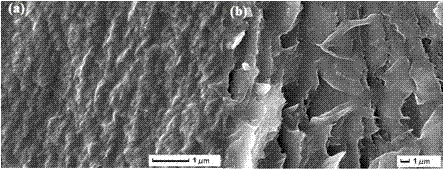

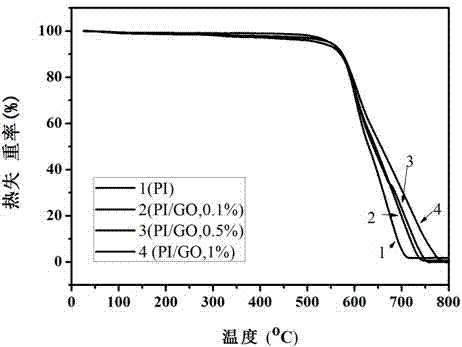

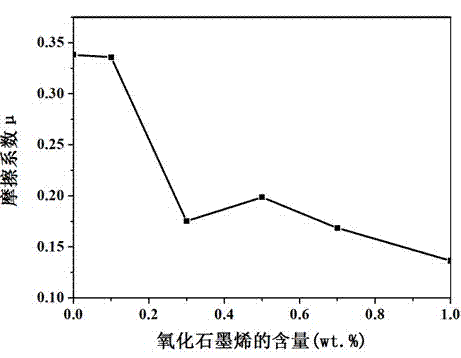

Preparation method for polyimide/oxidized graphene nanocomposite film

InactiveCN103589152ASolve the shortcomings of poor wear resistanceSolving Dispersion ProblemsPolyamideDissolution

The invention relates to a preparation method for a polyimide / oxidized graphene nanocomposite film, and belongs to the technical field of preparation of functional polymer materials. The preparation method comprises the following steps: performing ultrasonic even dispersion on the oxidized graphene in an organic solvent to obtain an oxidized graphene sheet suspension, wherein per ml of the oxidized graphene sheet suspension contains 1.3*10<-5>-1.3*10<-4>g oxidized graphene sheets; introducing nitrogen for carrying out deoxidization protection, adding diamine monomers into the suspension, mechanically stirring until full dissolution is achieved, adding dianhydride monomers, the moles of which are equal to that of the diamine monomers, in batches, and mixing for one to six hours under the ice bath conditions, so as to obtain polyamide acid / oxidized graphene composite solution; pouring the polyamide acid / oxidized graphene composite solution onto a die, removing the organic solvent, performing gradient temperature rise within 100-300DEG C, and carrying out thermal imidization to obtain the polyimide / oxidized graphene nanocomposite film.

Owner:JIANGSU UNIV

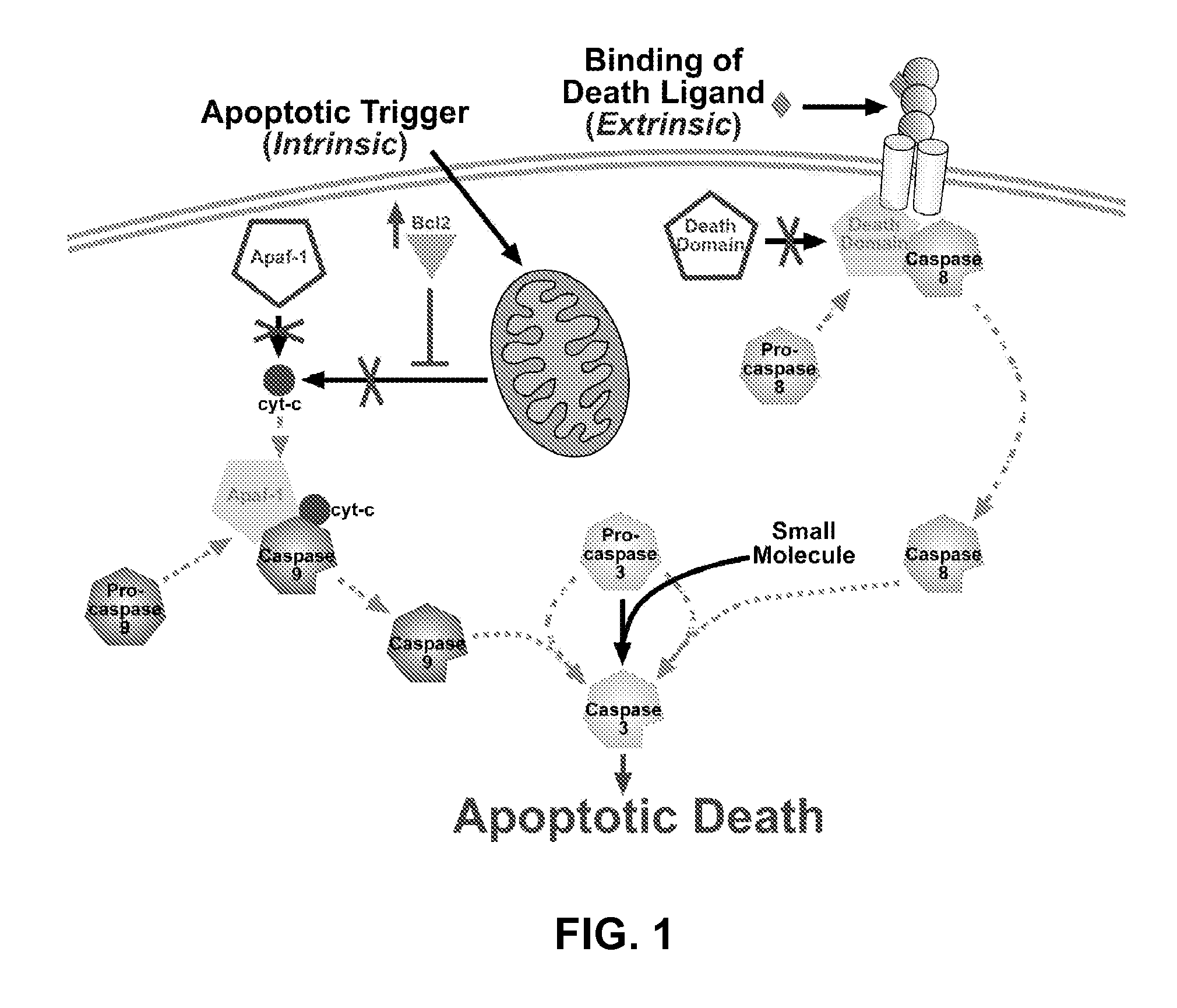

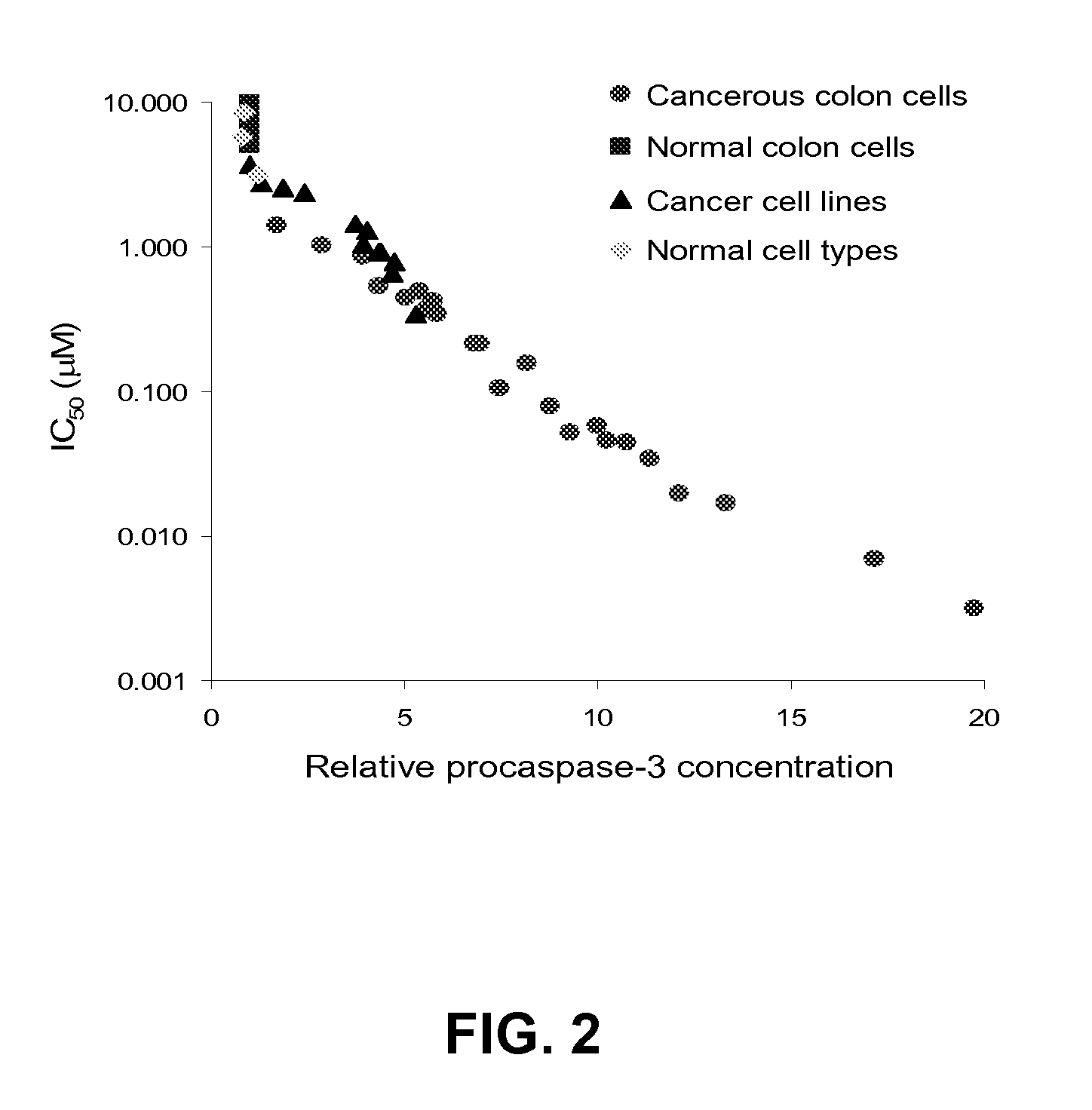

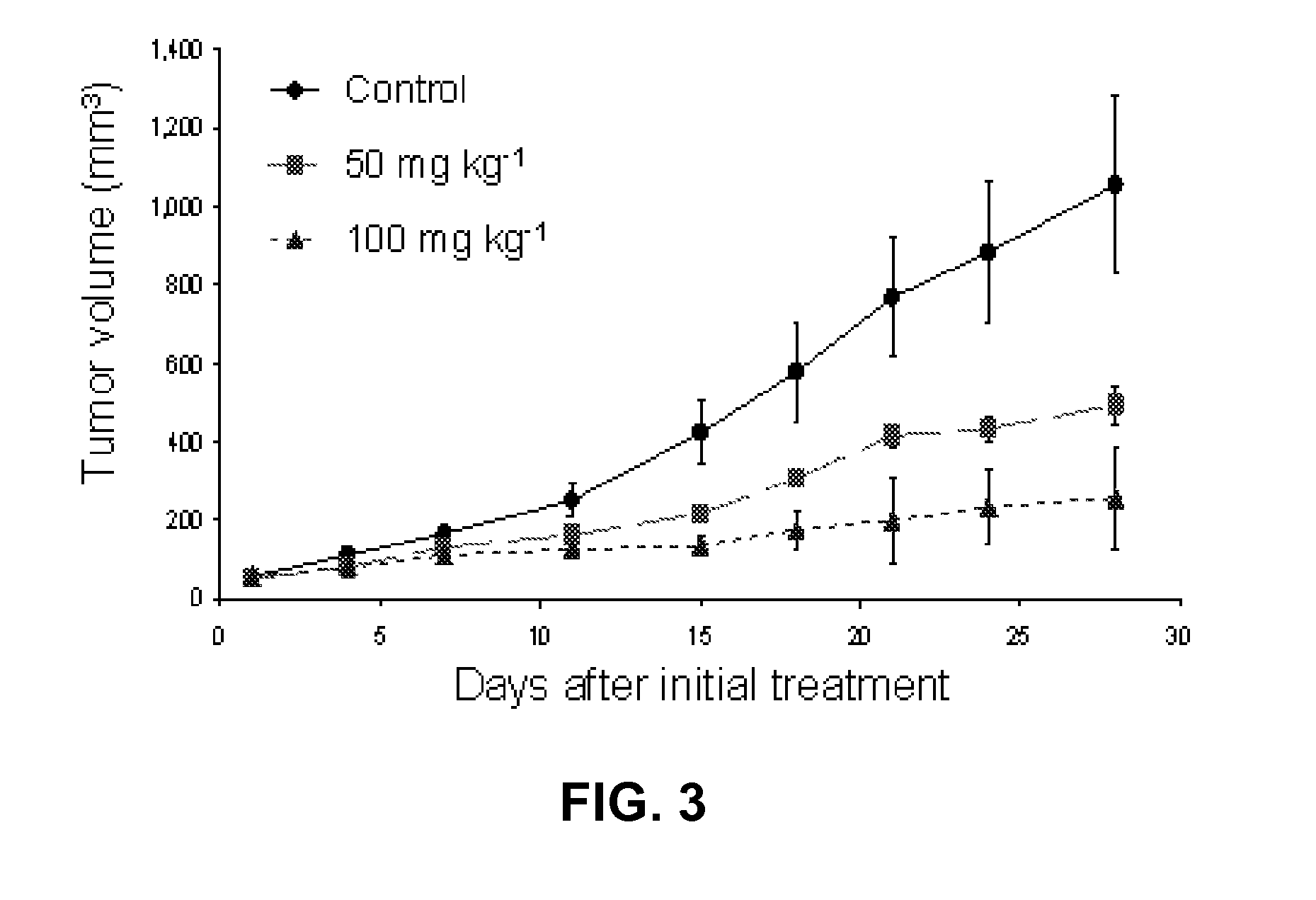

Design, synthesis and evaluation of procaspase activating compounds as personalized Anti-cancer drugs

ActiveUS20120040995A1Reduce adverse reactionsEffective compoundOrganic active ingredientsOrganic chemistryAnti cancer drugsNeurotoxic effect

Compositions and methods are disclosed in embodiments relating to induction of cell death such as in cancer cells. Compounds and related methods for synthesis and use thereof, including the use of compounds in therapy for the treatment of cancer and selective induction of apoptosis in cells are disclosed. Compounds are disclosed that have lower neurotoxicity effects than other compounds.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

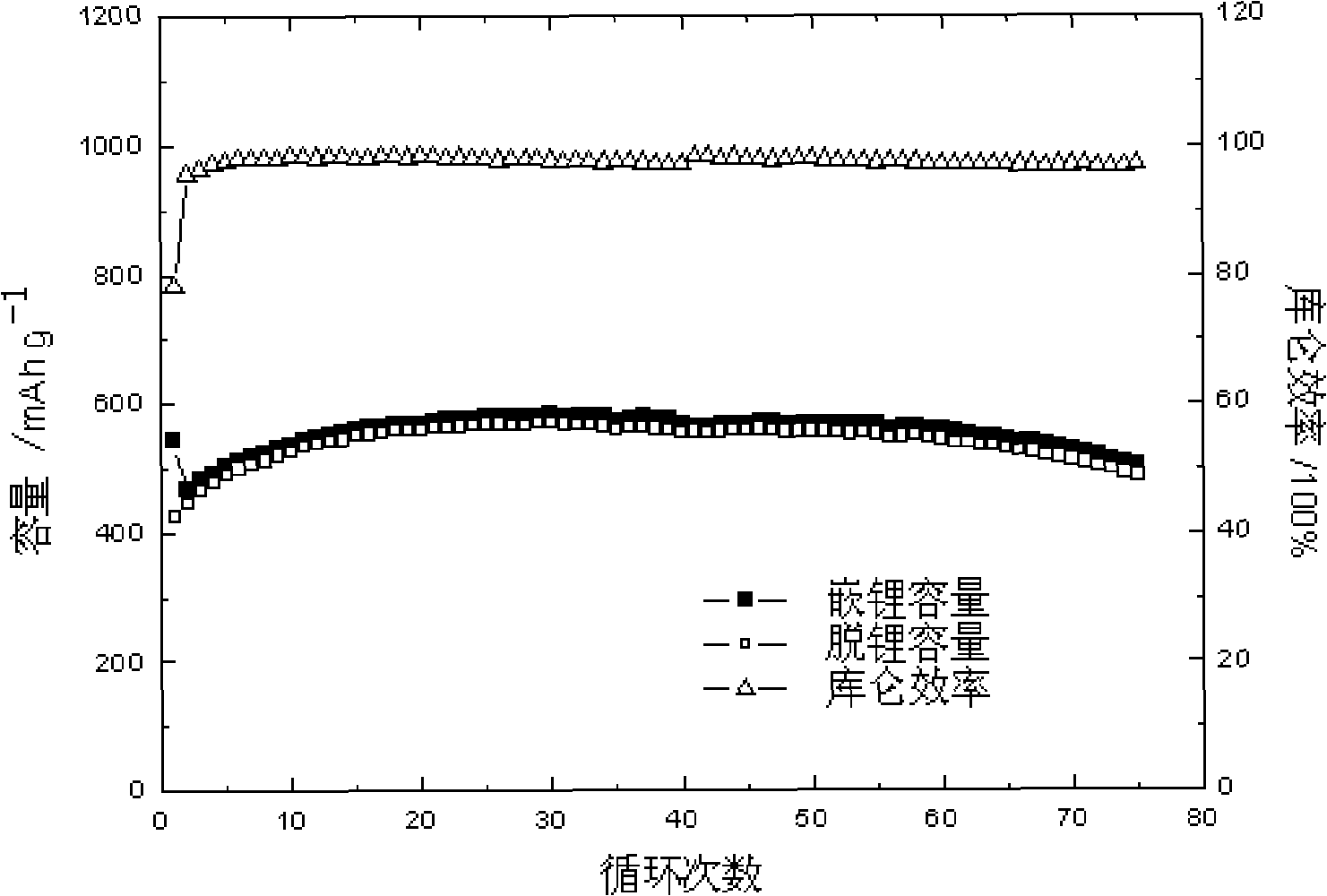

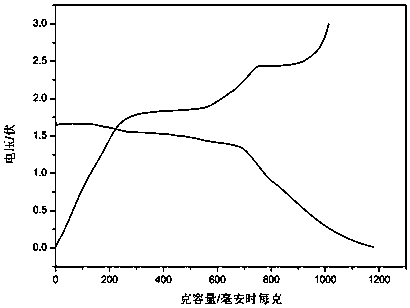

Composite cathode material for lithium ion cell and preparing method thereof

ActiveCN101286560AEvenly dispersedWell mixedElectrode manufacturing processesChemical/physical/physico-chemical processesComposite cathodeGraphite

The invention relates to a lithium ion battery composite cathode material and a preparation method thereof, which belongs to the technical field of lithium ion battery. The invention aims at improving the cycle performance of silicon cathode material at the same time when keeping the high ratio volume of lithium ion battery silicon cathode material. The proposal of the invention is that silica-based material coated by disordered carbon is treated with surface modification processing by utilizing lithium salt, namely, the lithium salt is coated on the surface of Si / G / DC (silicon / graphite / disordered carbon) to be prepared into the composite cathode material, therefore, the lithium-embedding and removing depth of the silicon can be effectively controlled, and the material is the lithium ion battery composite cathode material which has high specific capacity and good cyclical stability; furthermore, the material is safe and pollution-free, and presents higher thermal stability in various lithium salt electrolytes and solvents.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

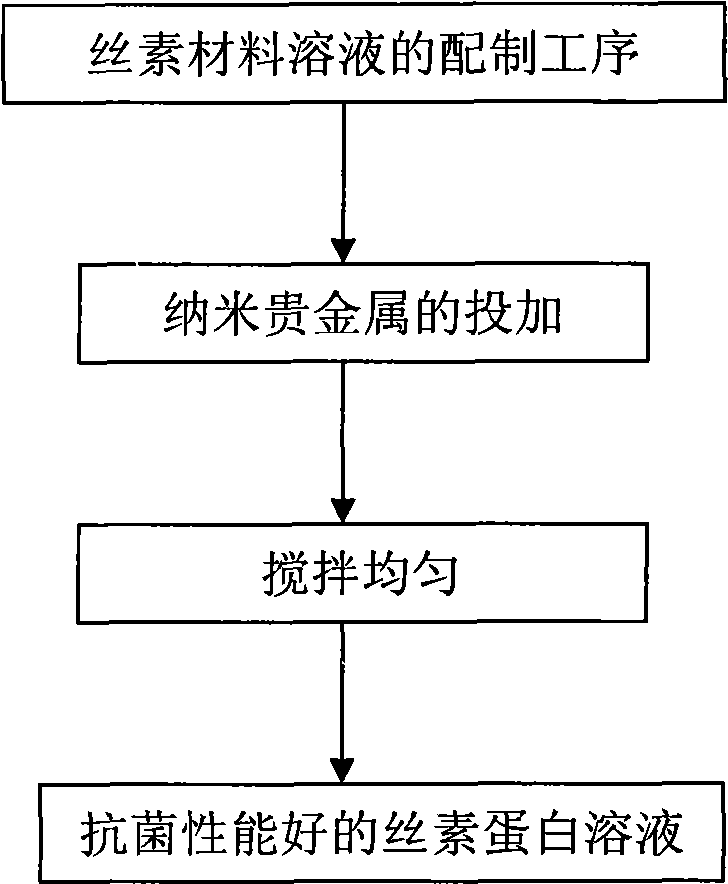

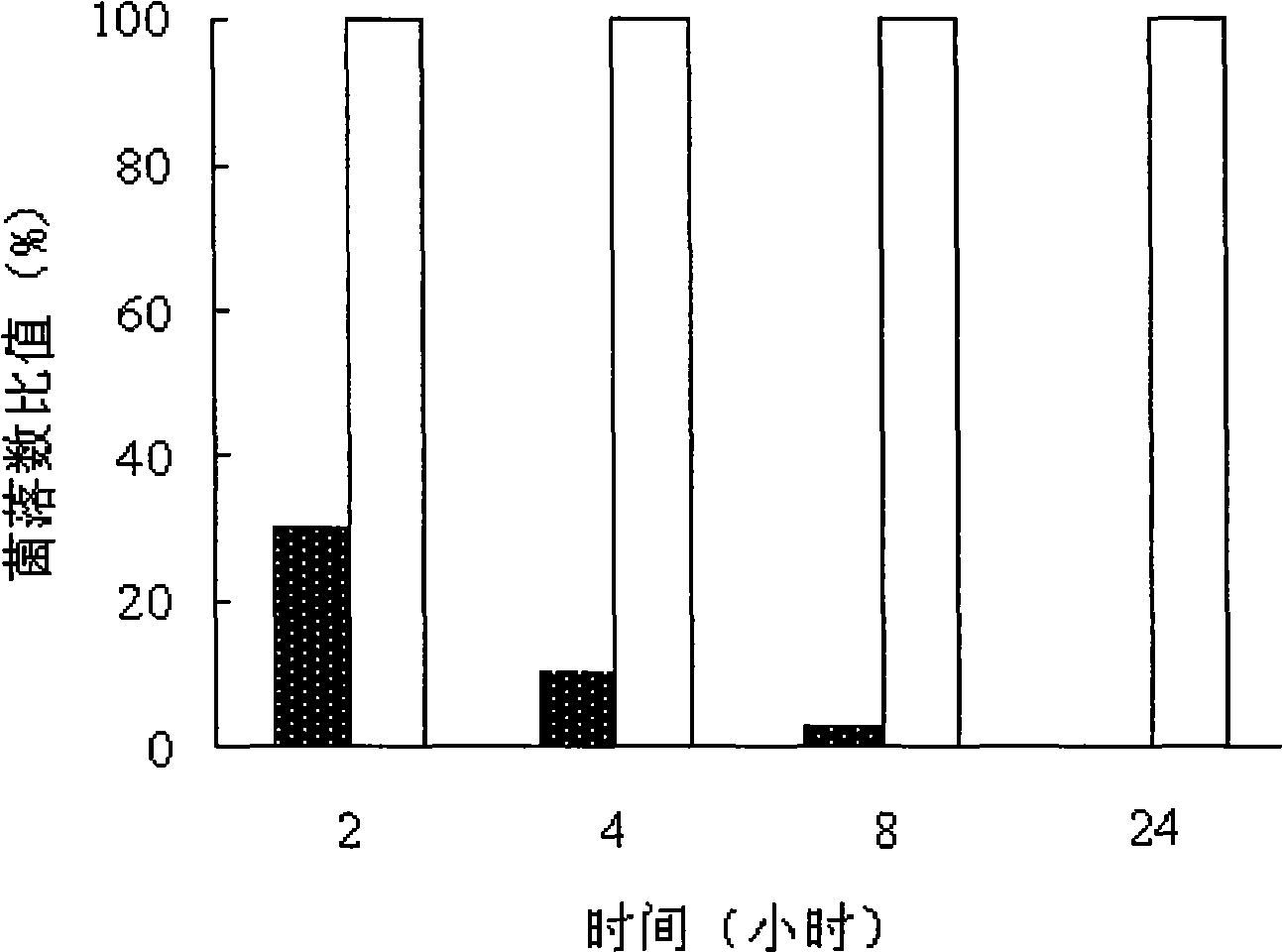

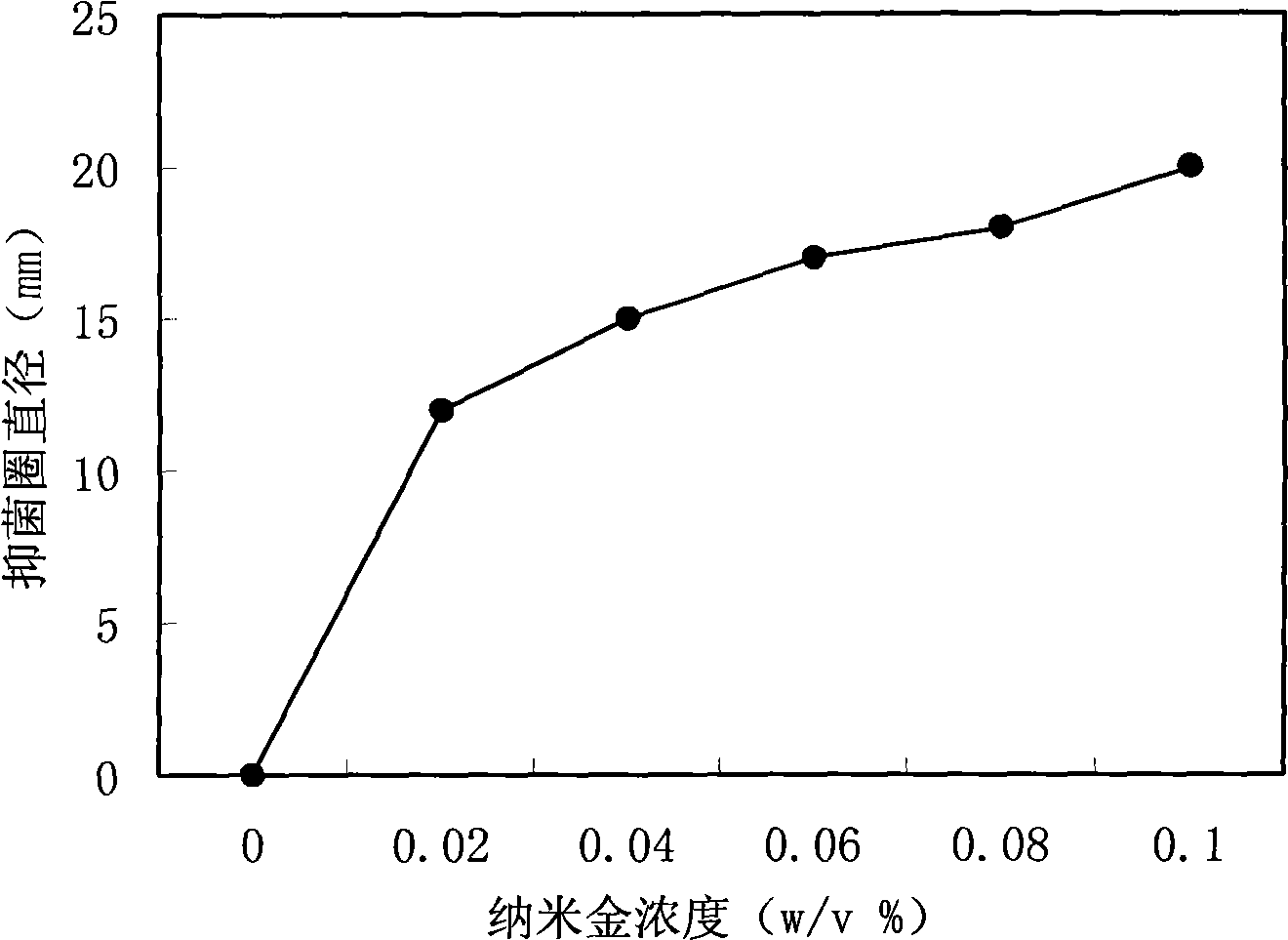

Method for improving antibiosis of silk fibroin material

InactiveCN101498061AEasy to get materialsUniform and effective releaseMonocomponent fibroin artificial filamentArtifical filament manufactureAntibiosisEngineering

The invention relates to a method of improving the bacterinertness of a silk fibroin solution. Silk fibroin material has favorable prospects when applied in biomedicine aspect, and thus the search of a method of improving the bacterinertness of silk material is meaningful. The invention comprises a silk fibroin solution preparing working procedure which adopts silk fibroin to prepare the silk fibroin solution and is characterized by also comprising a nanometer noble metal feeding working procedure by selecting nanometer noble metal with the grain diameter between 5 nanometers to 100 nanometers. When a temperature is between 0 DEG C to 50 DEG C, the nanometer noble metal is fed to a stand-by silk fibroin solution and is stirred at a rotating speed of 100-400 round / min to obtain the silk fibroin solution comprising the nanometer noble metal; the concentration of the silk fibroin is 0.5-15w / v percent, and the concentration of the nanometer noble metal is 0.005-0.2w / v percent. The invention can favorably improve the antibiotic performance of the silk fibroin solution so that the silk fibroin can be more widely applied to biological material.

Owner:ZHEJIANG UNIV

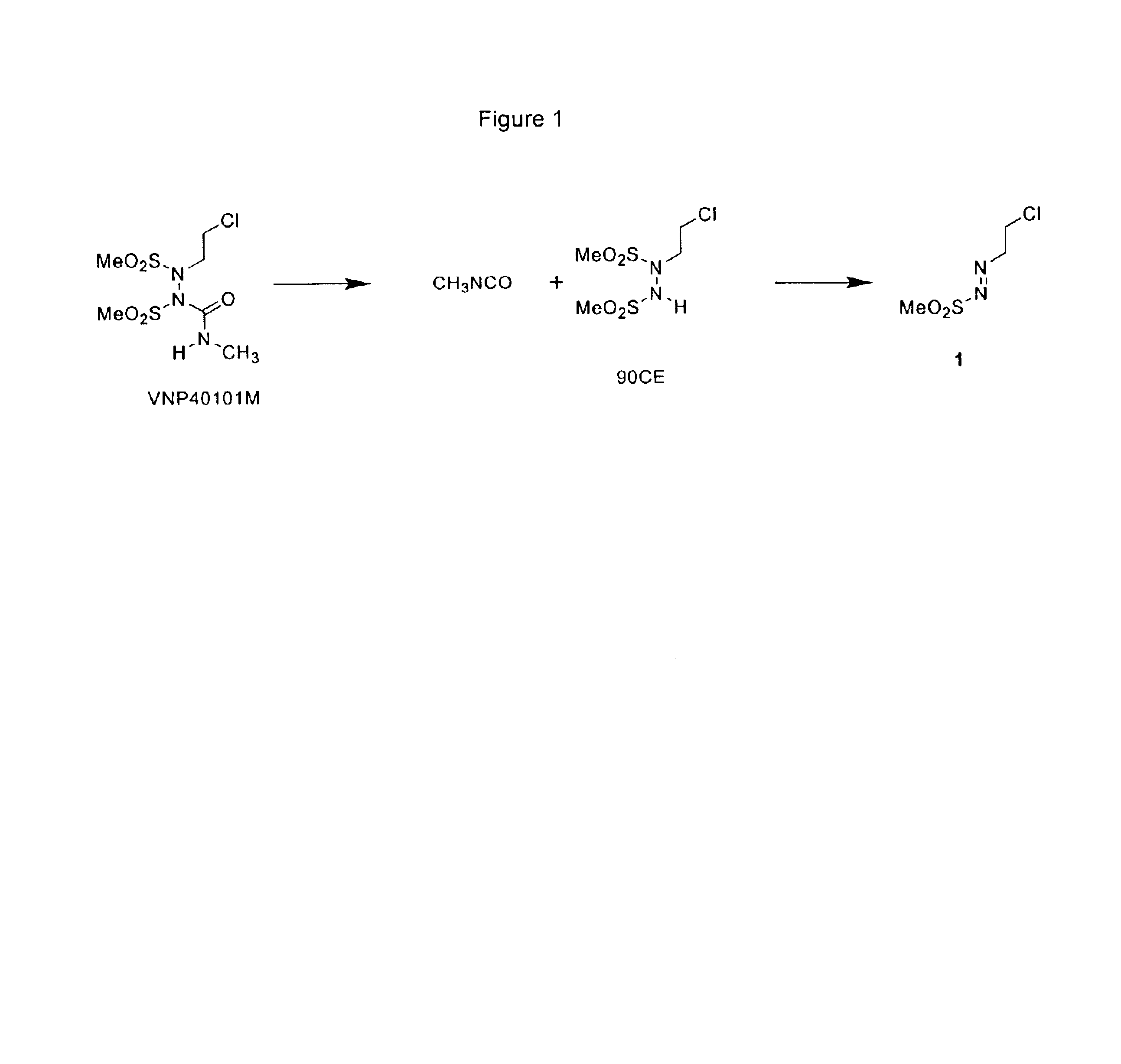

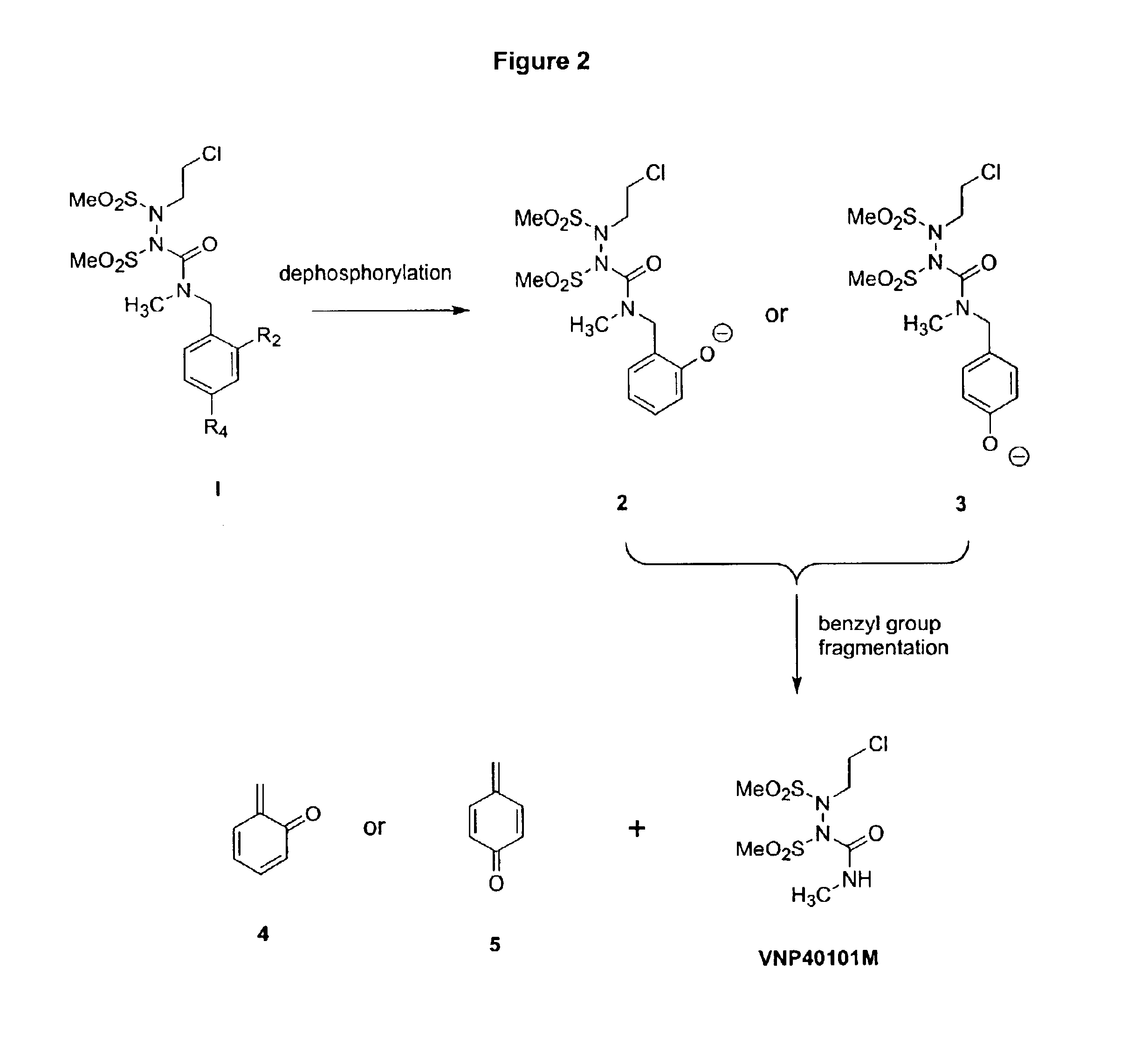

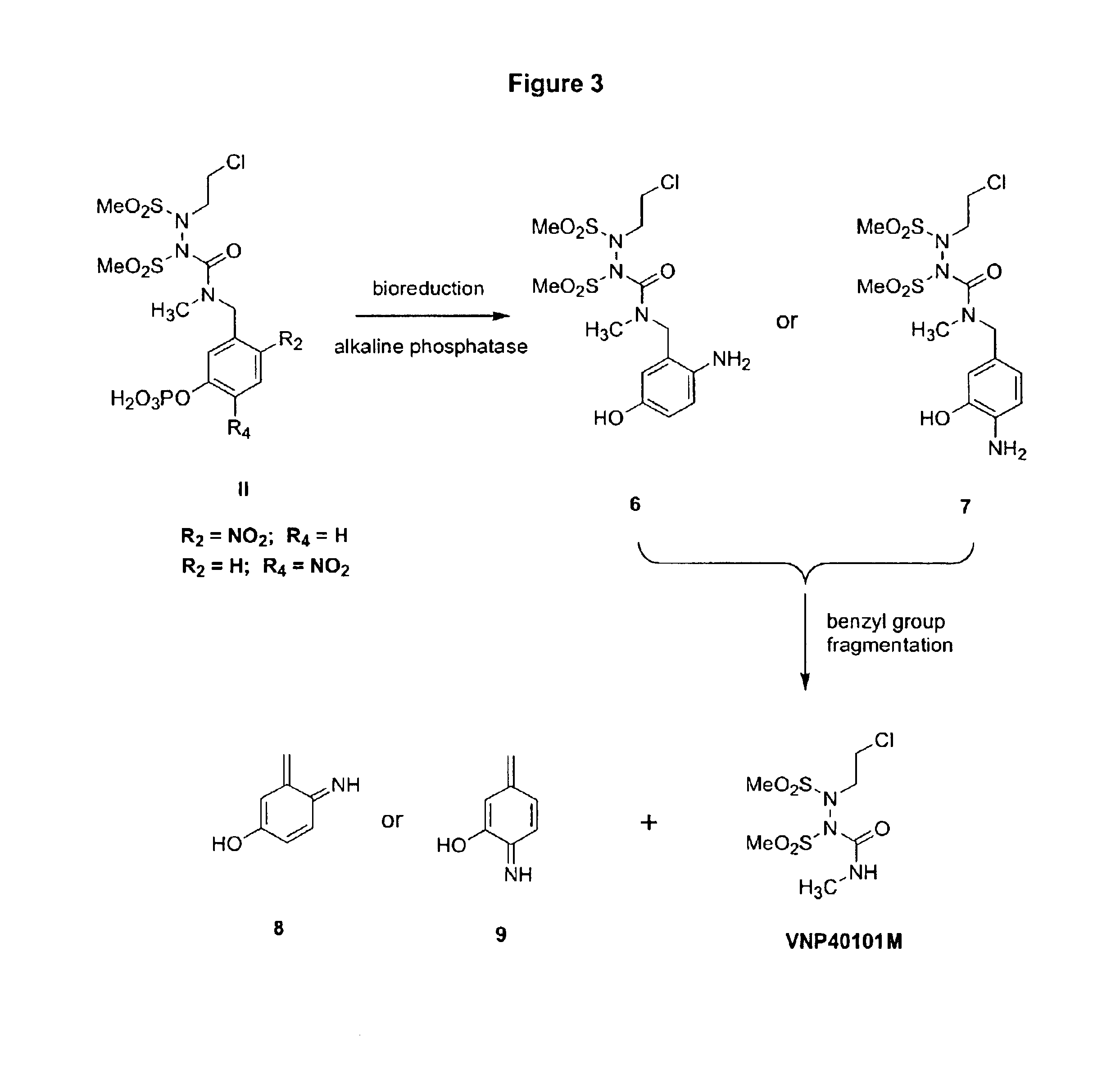

Water-soluble SHPs as novel alkylating agents

InactiveUS6855695B2Favorable enhanced characteristicLow toxicityOrganic active ingredientsBiocidePhosphoric acidWater soluble

Owner:NANOSHIFT LLC

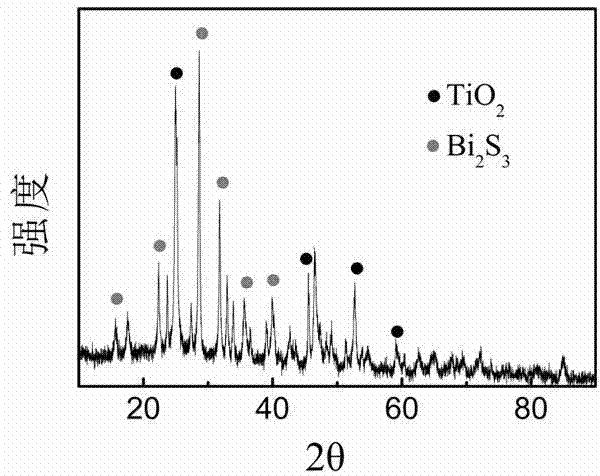

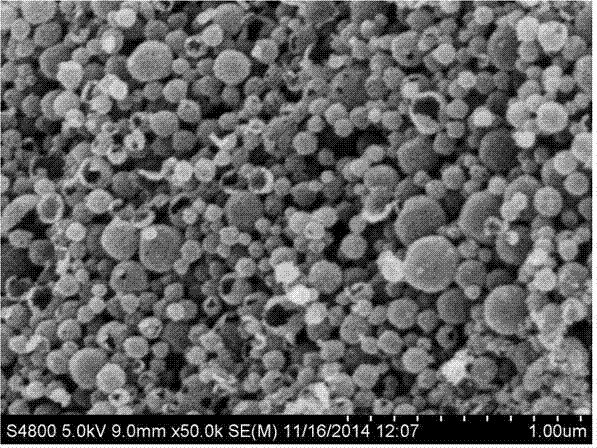

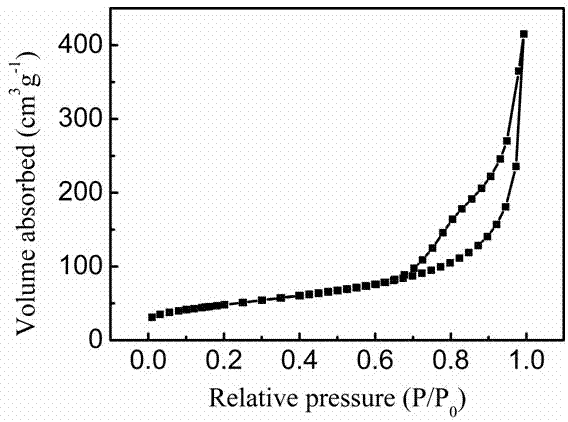

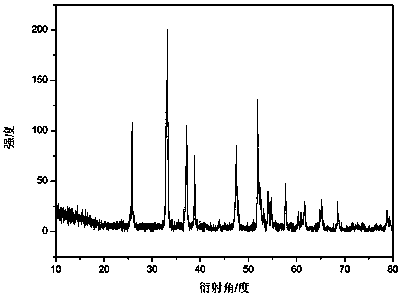

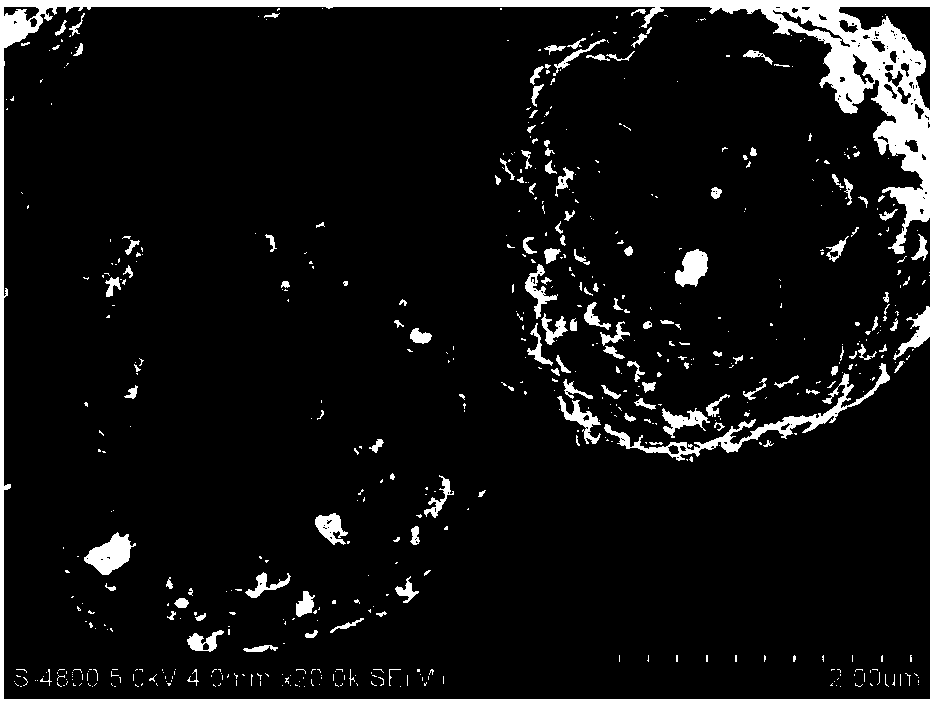

Metallic oxide/metal sulfide hollow nanospheres as well as preparation method and application thereof

ActiveCN104492460AEffective compoundAvoid recombinationPhysical/chemical process catalystsHeterojunctionPhysical chemistry

The invention discloses a metallic oxide / metal sulfide core-shell heterojunction hollow nanosphere. The inner layer of the spherical shell is a metallic oxide polycrystalline layer; the outer layer of the spherical shell is a metal sulfide polycrystalline layer; a heterojunction is formed between the metallic oxide polycrystalline layer and the metal sulfide polycrystalline layer; the thickness of each layer is 10 nanometers or below; and the diameter of the hollow sphere is 100-600 nanometers. The preparation method comprises the following steps: utilizing a template adsorption method, performing stepped adsorption and subsequent hydrothermal sulfuration, thereby preparing the metallic oxide / metal sulfide core-shell heterojunction hollow nanosphere. The metallic oxide / metal sulfide core-shell heterojunction hollow nanosphere disclosed by the invention is regular in structure, the thickness of the spherical shell is controllable, the grain size of the metallic oxide and metal sulfide is 10nm or below, the crystal quality is high, and the specific surface area is larger than 200m<2> / g. The method disclosed by the invention is simple and low in cost, has extremely wide range on selection of types of metallic oxides and selection of metal sulfides and contributes to industrialized application.

Owner:ZHEJIANG UNIV

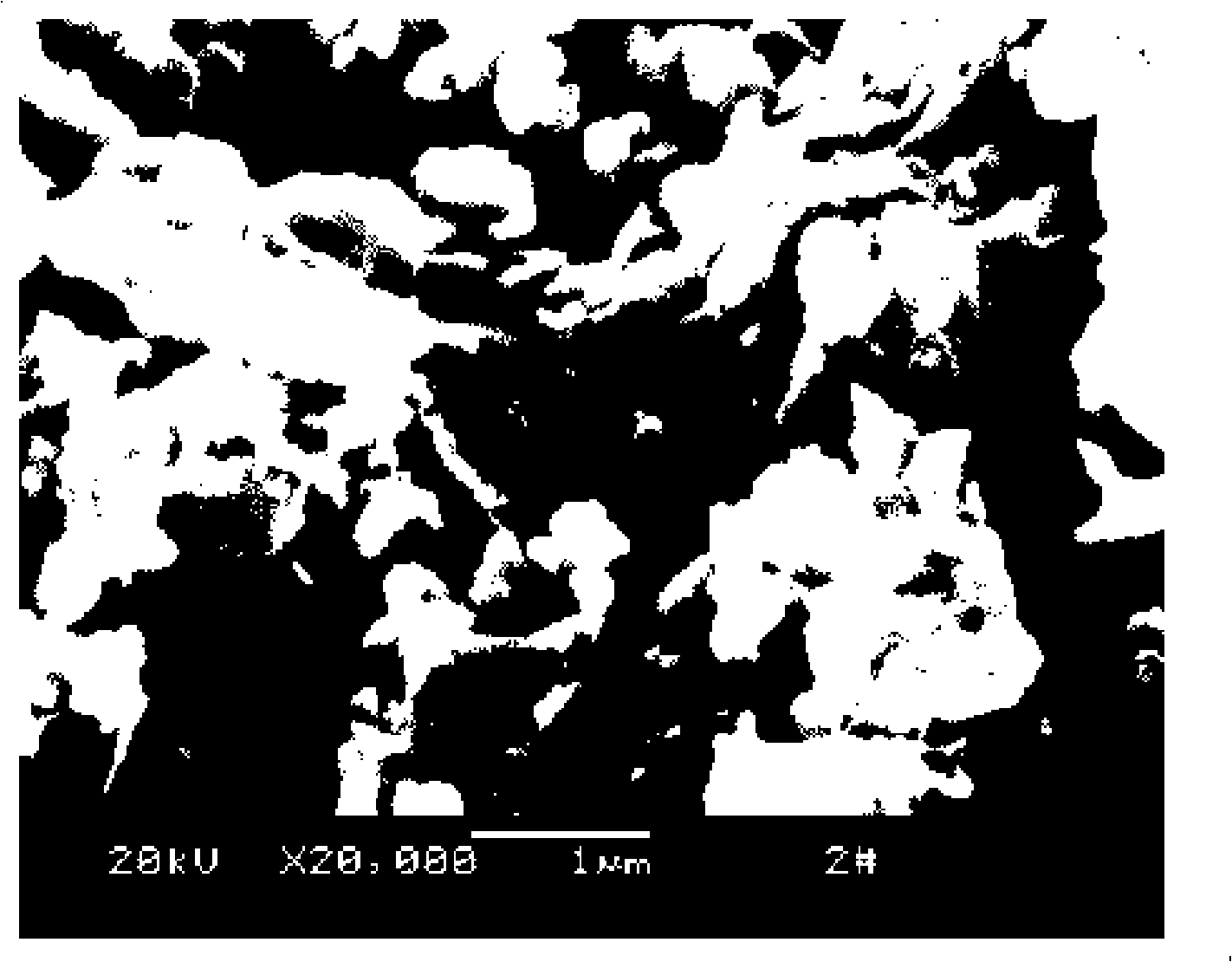

Preparation method of flaky nanometer FeS2/C negative electrode material

ActiveCN107611409AImprove ionic conductivityFast ion conductivityMaterial nanotechnologyCell electrodesMass ratioSolvent

The invention discloses a preparation method of a flaky nanometer FeS2 / C negative electrode material. The preparation method comprises the following steps: (1) dissolving an iron source and an organicligand into a solvent I, and stirring uniformly to obtain a homogeneous solution; (2) performing a hydrothermal reaction on the homogeneous solution obtained in the step (1), naturally cooling to room temperature, filtering, washing, depositing and drying to obtain yellow or red powder; (3) dispersing the yellow or red powder obtained in the step (2) and a sulfur source compound in a solvent II in the mass ratio of 1:(3 to 4), performing a hydrothermal reaction on mixed solution, natural cooling to room temperature, filtering, washing, precipitating and drying to obtain black powder; and (4)calcining the black powder obtained in the step (3) in a protective atmosphere, and cooling to room temperature to obtain the flaky nanometer FeS2 / C negative electrode material. The obtained flaky nanometer FeS2 / C negative electrode material is uniform in shape and size. A carbon material can be effectively compounded with ferrous sulfide, so that the ionic conductivity and electronic conductivityof the material are increased. The two-dimensional structure has the characteristics of shorter diffusion distance of lithium ions, high transmission rate, high specific surface area, high conductivity, high ion transmission speed and the like.

Owner:CENT SOUTH UNIV

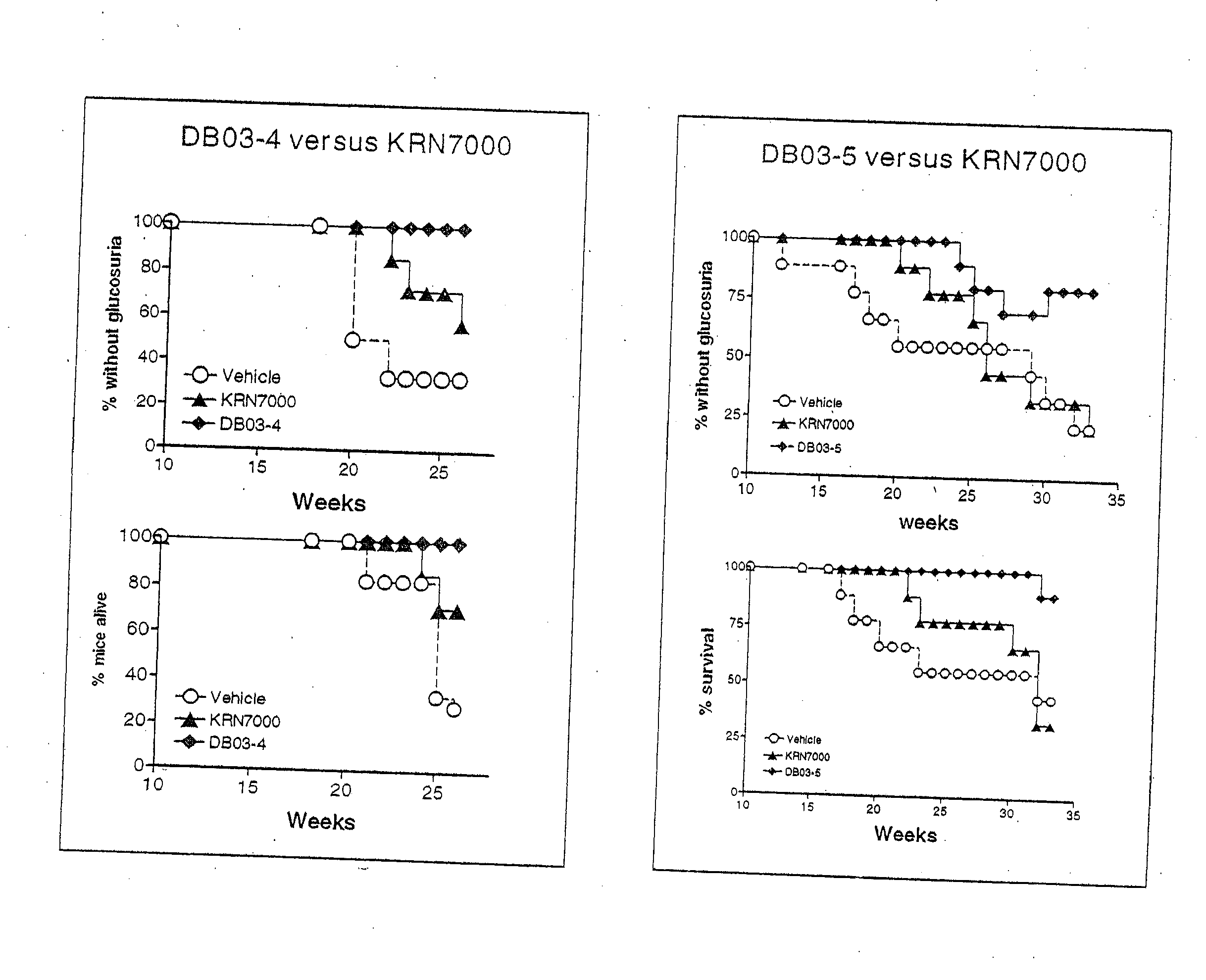

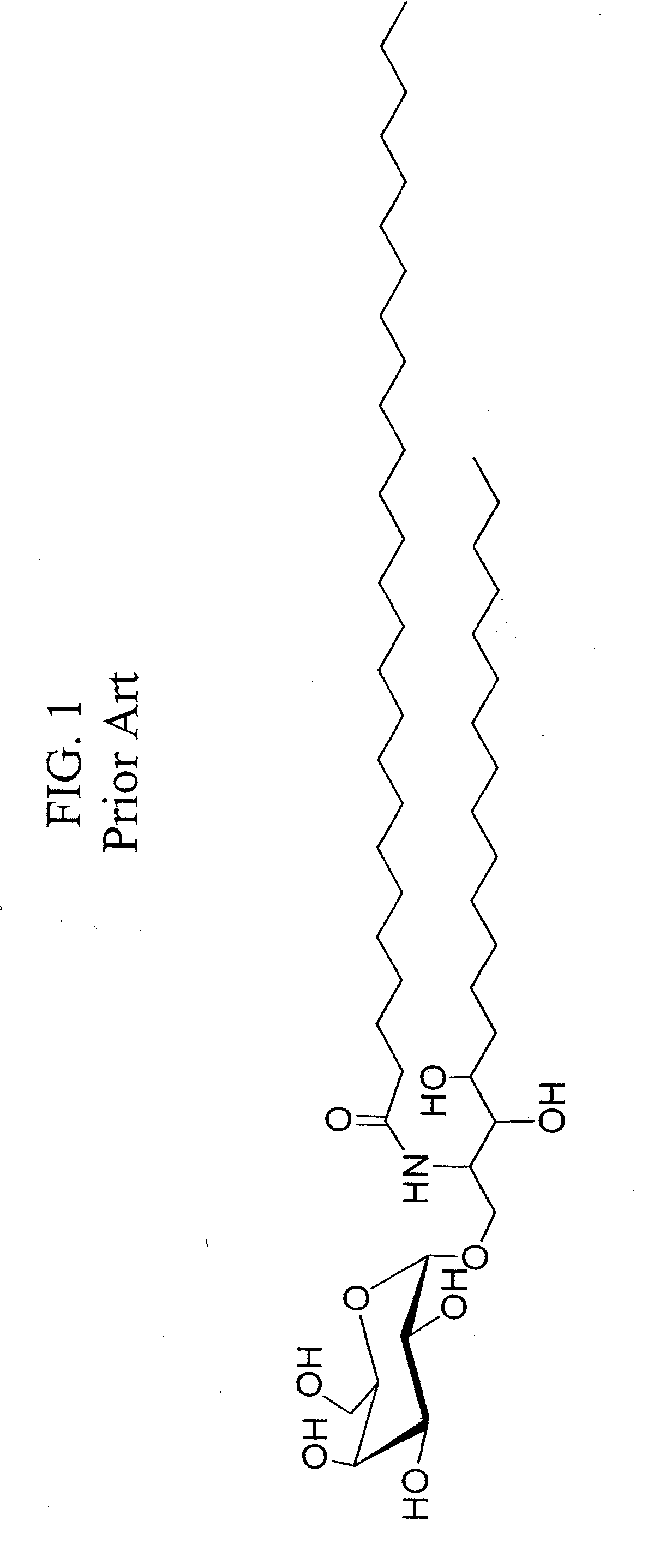

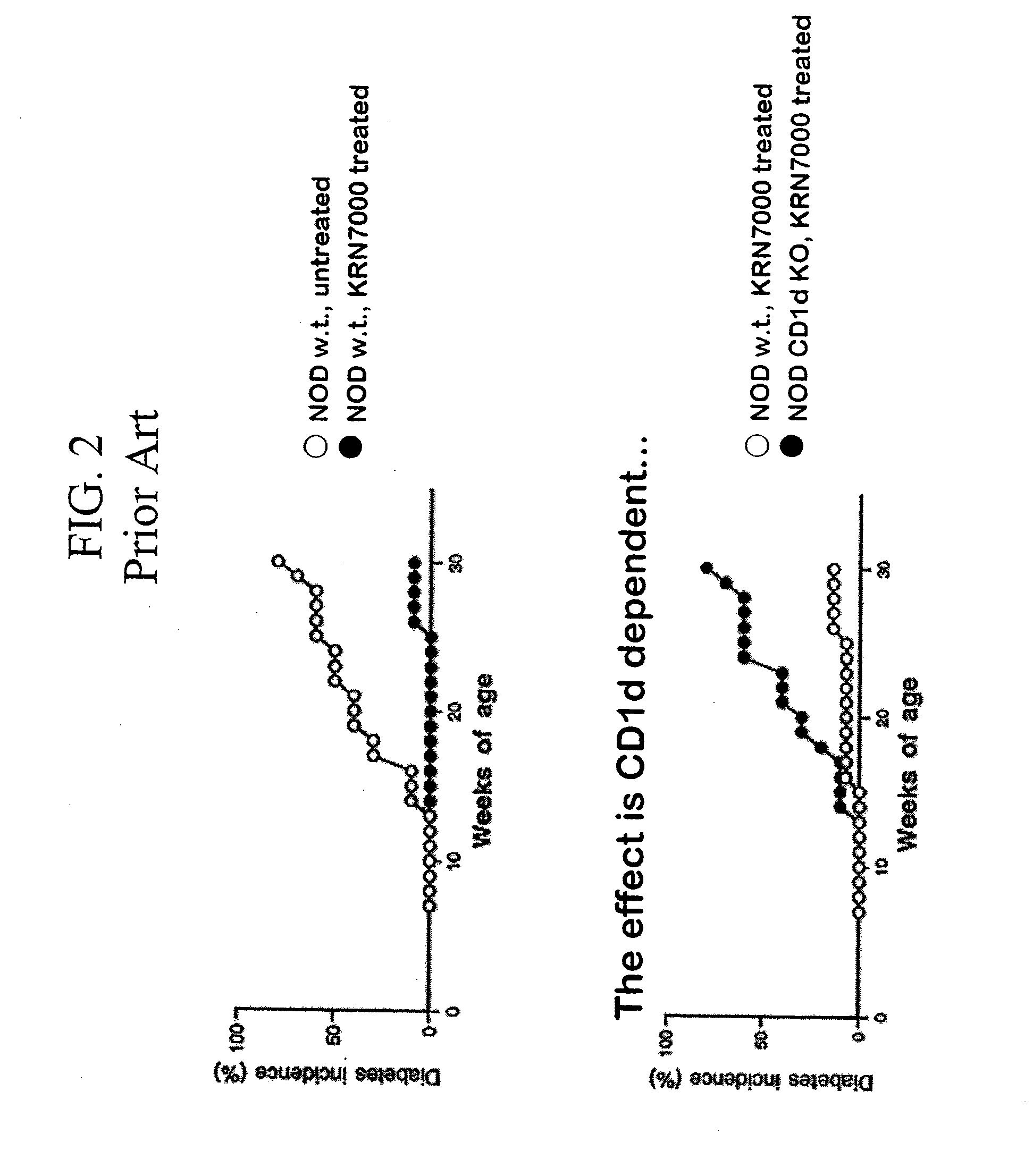

Ceramide derivatives as modulators of immunity and autoimmunity

α-Galactosylceramides and glycosylceramides (“ceramide-like glycolipids”) that modulate NK T cells. The ceramide-like glycolipids vary in the cytokines induced in NK T cells and vary in the antigen-presenting cells that are capable of efficiently presenting the compounds to NK T cells. Pharmaceutical compositions of the ceramide-like glycolipids are provided, as are pharmaceutical compositions of the ceramide-like glycolipids combined with dendritic cells. Methods utilizing the ceramide-like glycolipids in vaccines, to activate NK T cells, to stimulate the immune system, and to treat mammals are also provided. The invention also provides methods of evaluating a compound for its ability to activate an NK T cell in the presence of a cell expressing a CD1d protein.

Owner:ALBERT EINSTEIN COLLEGE OF MEDICINE OF YESHIVA UNIV

Method of treating peripheral neuropathies and motor neuron diseases

InactiveUS20170071972A1Effective compoundSufficient amountOrganic active ingredientsNervous disorderNervous systemMedicine

A composition comprising a molecule for use in the delivery of the molecule to the peripheral nervous system (PNS) and / or to the central nervous system (CNS), wherein the composition is administered by regional infusion.

Owner:GENETHON +1

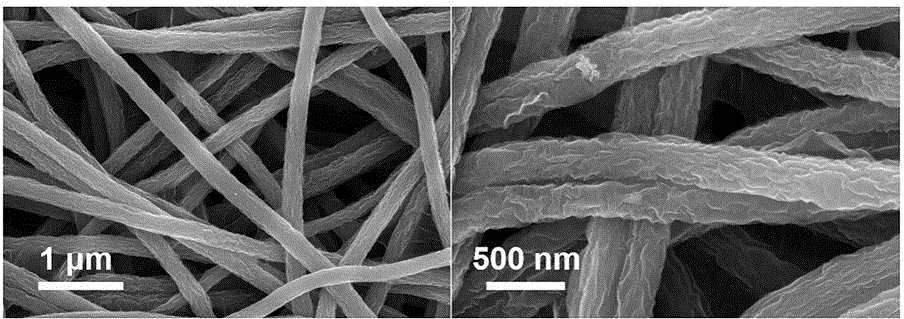

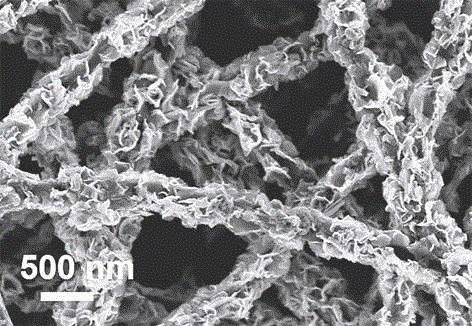

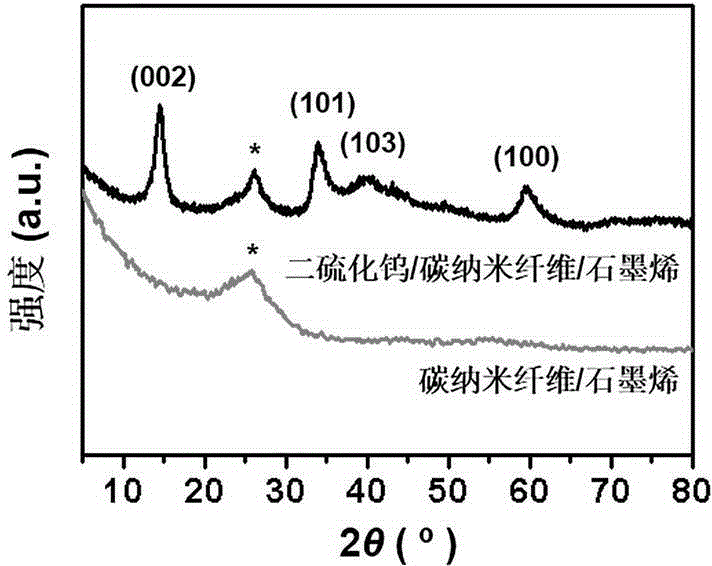

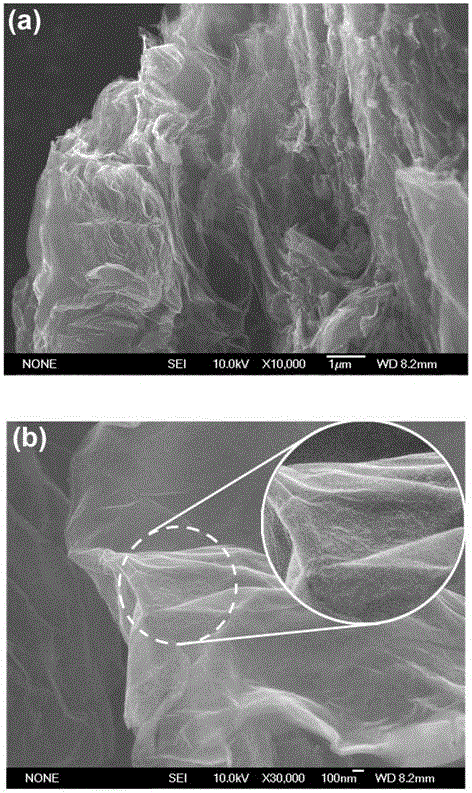

Tungsten disulfide/carbon nanofiber/graphene composite material and preparation method thereof

InactiveCN105322147AEasy to prepareEasy to operateMaterial nanotechnologyCell electrodesCarbon nanofiberNanofiber

The invention belongs to the technical field of transitional metal sulfide-carbon materials, and particularly relates to a tungsten disulfide / carbon nanofiber / graphene composite material and a preparation method thereof. The preparation method comprises the following steps: preparing a polyacrylonitrile nanofiber membrane in an electrostatic spinning manner; wrapping a polyacrylonitrile nanofiber with a graphene oxide through a solution immersion method; preparing a carbon nanofiber / graphene composite membrane through a high-temperature carbonization; and finally growing a tungsten disulfide nanosheet on the carbon nanofiber / graphene in situ through a one-step solvothermal method. The prepared tungsten disulfide / carbon nanofiber / graphene composite material has the advantages of stable chemical property, good conductivity, excellent mechanical property and the like, and can be used as an ideal high-performance electric catalytic material and an electrode material for new energy devices of a lithium-ion battery, a solar battery and the like.

Owner:FUDAN UNIV

Antimicrobial Peptides and Methods of Use

ActiveUS20090005300A1High activityStrong specificityAntibacterial agentsBiocideAntimicrobial peptidesAntibiotic Y

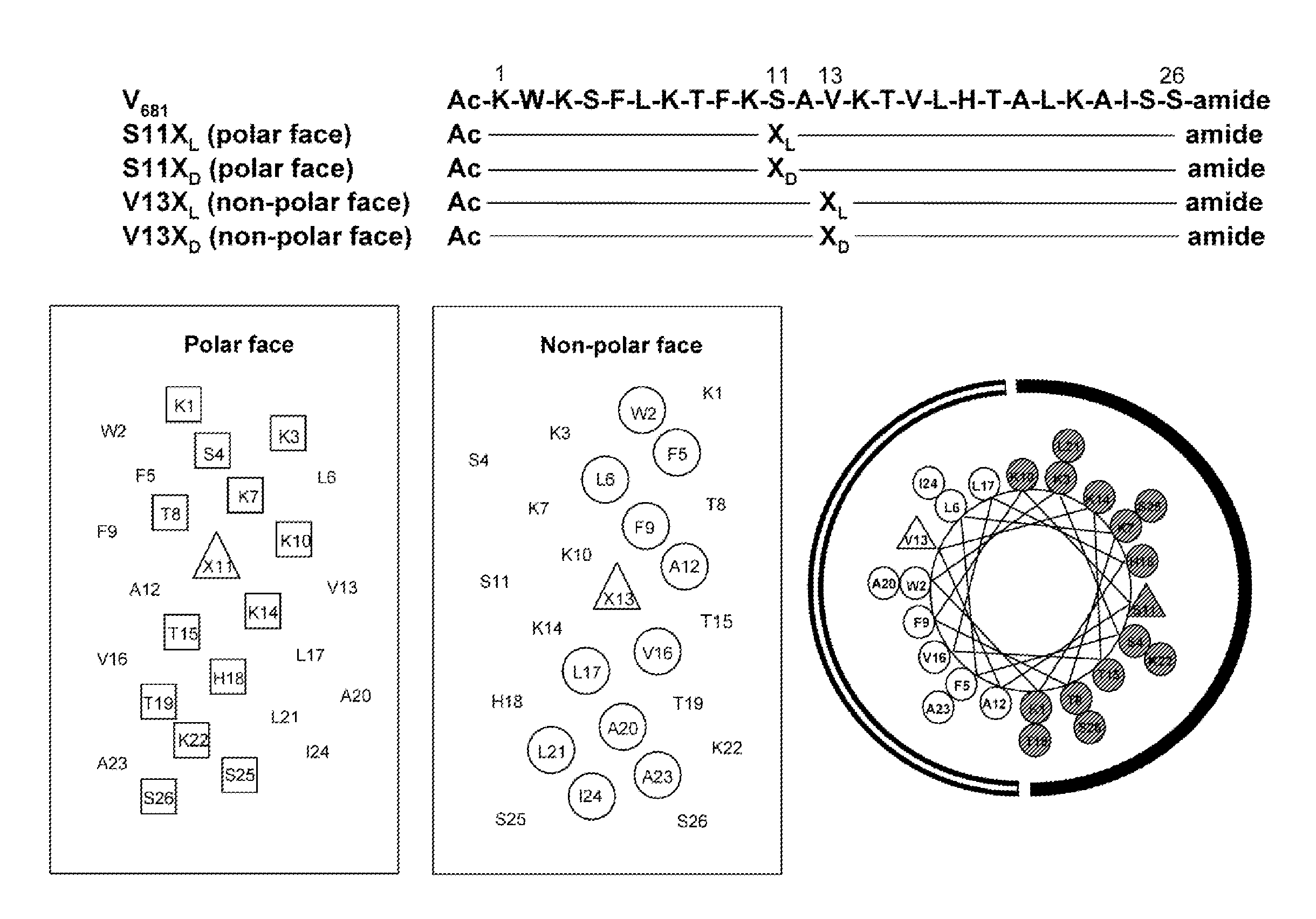

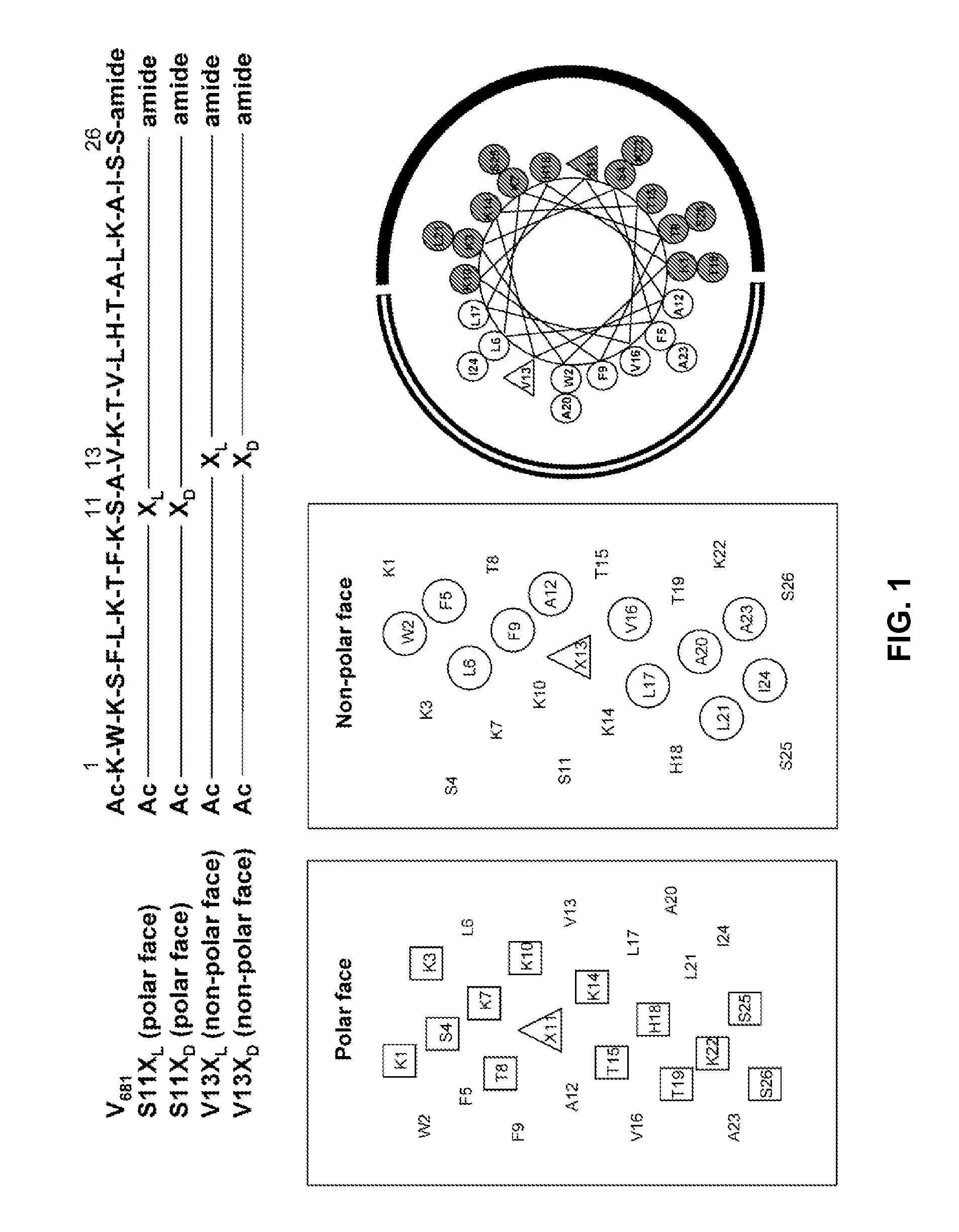

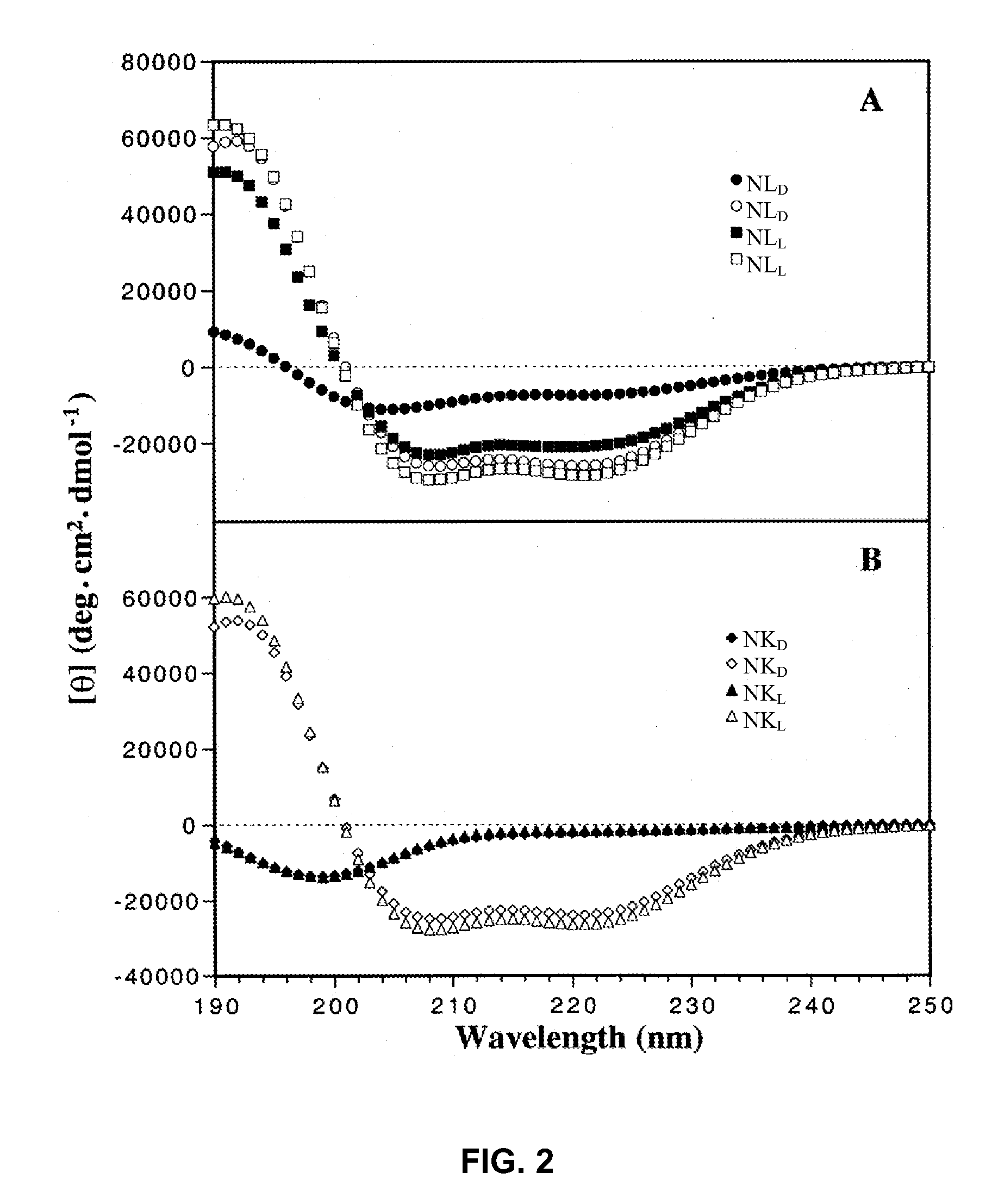

Disclosed herein are novel antimicrobial peptides with useful, improved, or superior properties such as antimicrobial activity, desirable levels of hemolytic activity, and therapeutic index against a broad range of microorganisms including gram-negative and gram-positive bacteria and other organisms having a cellular or structural component of a lipid bilayer membrane. Also provided are methods of making and using such peptides to control microbial growth and in pharmaceutical compositions for treatment or prevention of infections caused by such microorganisms. Certain peptides are disclosed utilizing a structure-based rational design relating to an antimicrobial peptide, V681, with single D- / L-amino acid substitutions or charged residue substitutions in or near the center of the peptide on the nonpolar or polar face. Also disclosed are peptides with one or more amino acids in the D configuration, including peptides with all amino acids in the D configuration. Modified peptide analogs herein can demonstrate one or more properties such as improved antimicrobial activity, specificity, and resistance to degradation. Compositions disclosed herein have useful clinical potential as antibiotics including broad spectrum antibiotics.

Owner:UNIV OF COLORADO THE REGENTS OF

Robust pellet

ActiveUS20050037071A1Improve solubilityImprove solubility and absorptionAntibacterial agentsOrganic chemistrySolubilityPharmacology

Compositions and methods for making robust pellets that contain a high percentage, by weight, of active drug agent, and which also contain additional components that enhance the absorption and solubility of the active drug agent within the gastrointestinal tract (GI tract) without diminishing the robust nature of the pellet, are disclosed.

Owner:SHIONOGI INK

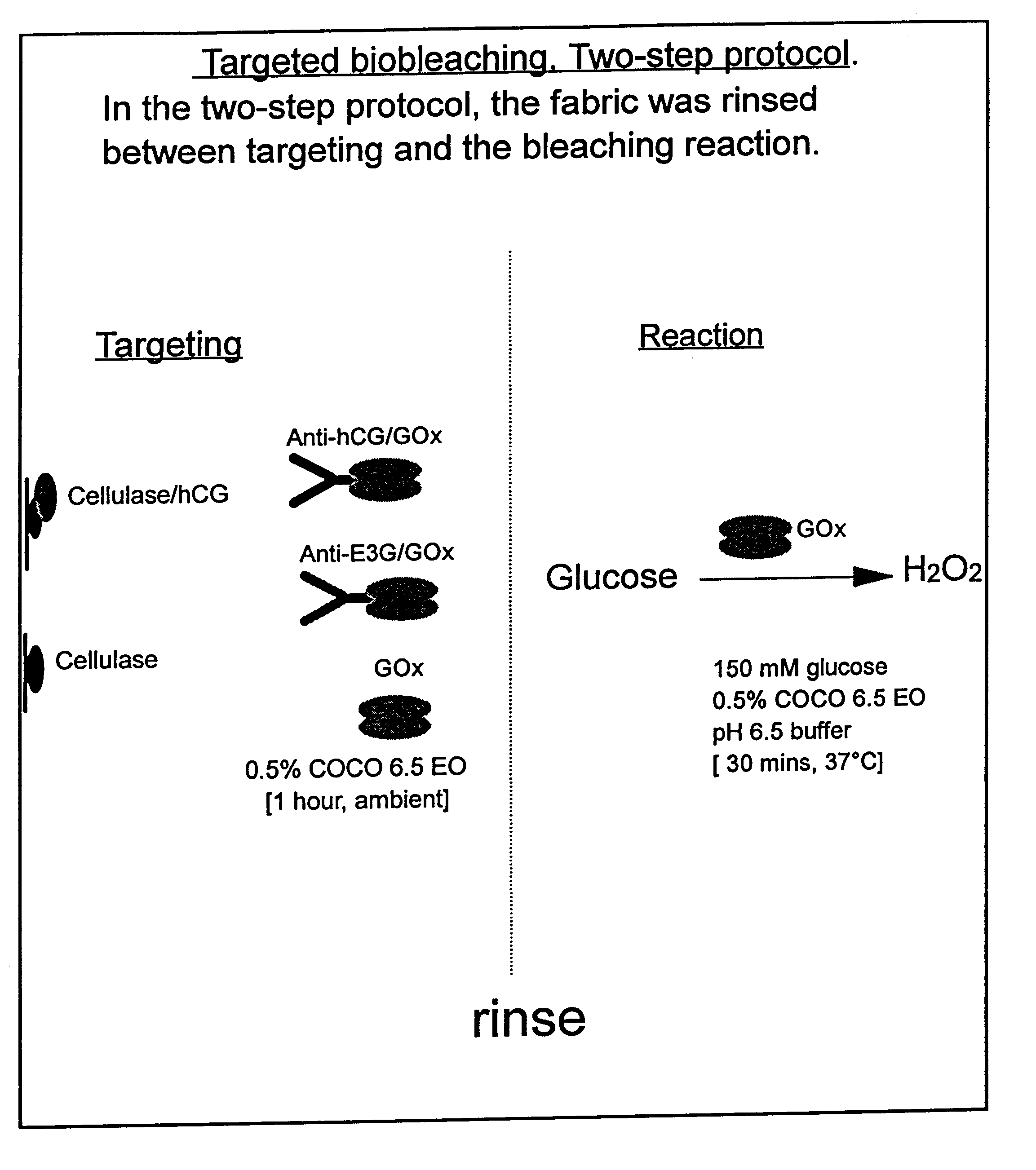

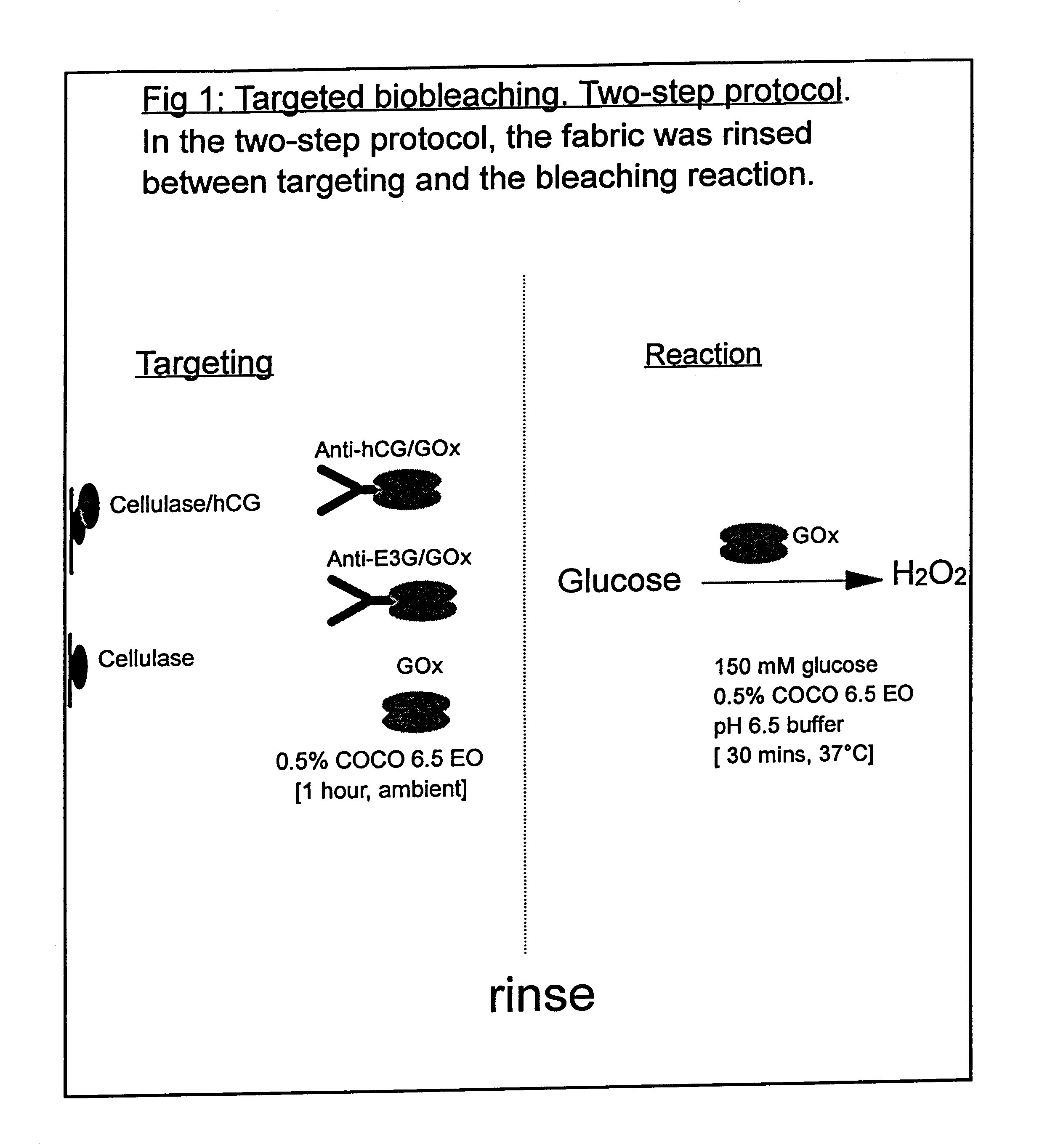

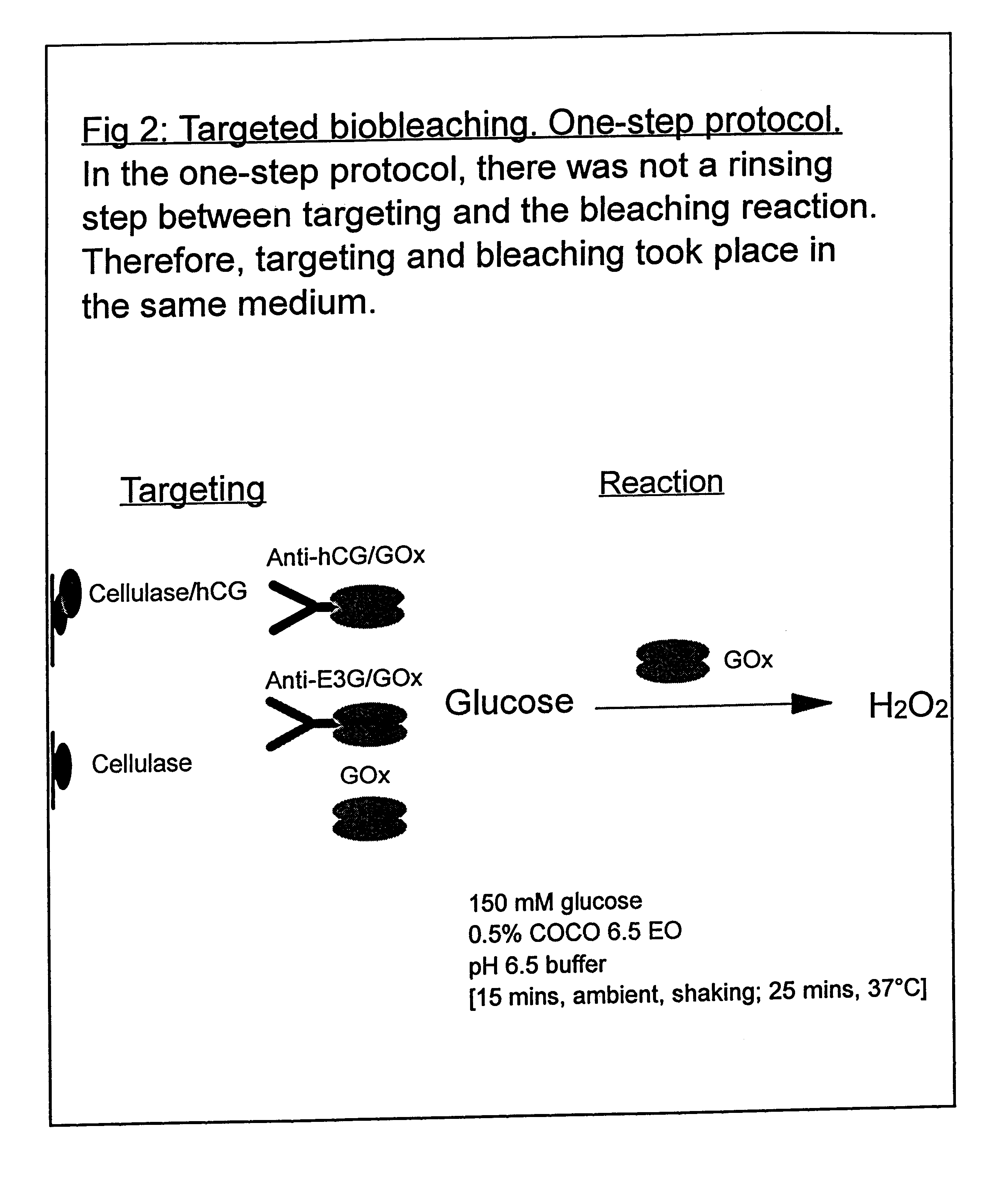

Bleaching enzymes

InactiveUS6218350B1High selectivitySmall amount of compoundOrganic detergent compounding agentsPeptide/protein ingredientsSURFACTANT BLENDEnzyme

There is provided a bleaching enzyme capable of generating a bleaching chemical and having a high binding affinity for stains present on fabrics. Furthermore, there is provided an enzymatic bleaching composition comprising the bleaching enzyme and a surfactant and a process for bleaching stains present of fabrics.

Owner:LEVER BROTHERS

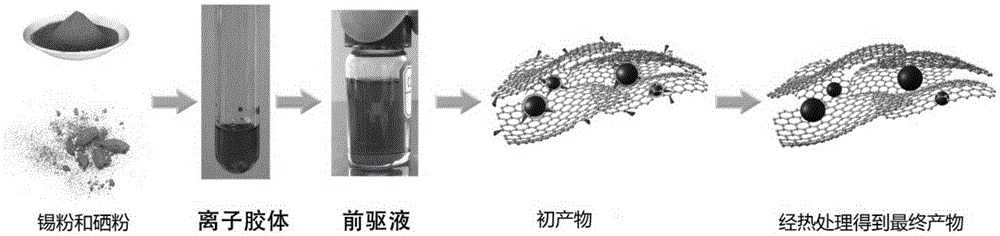

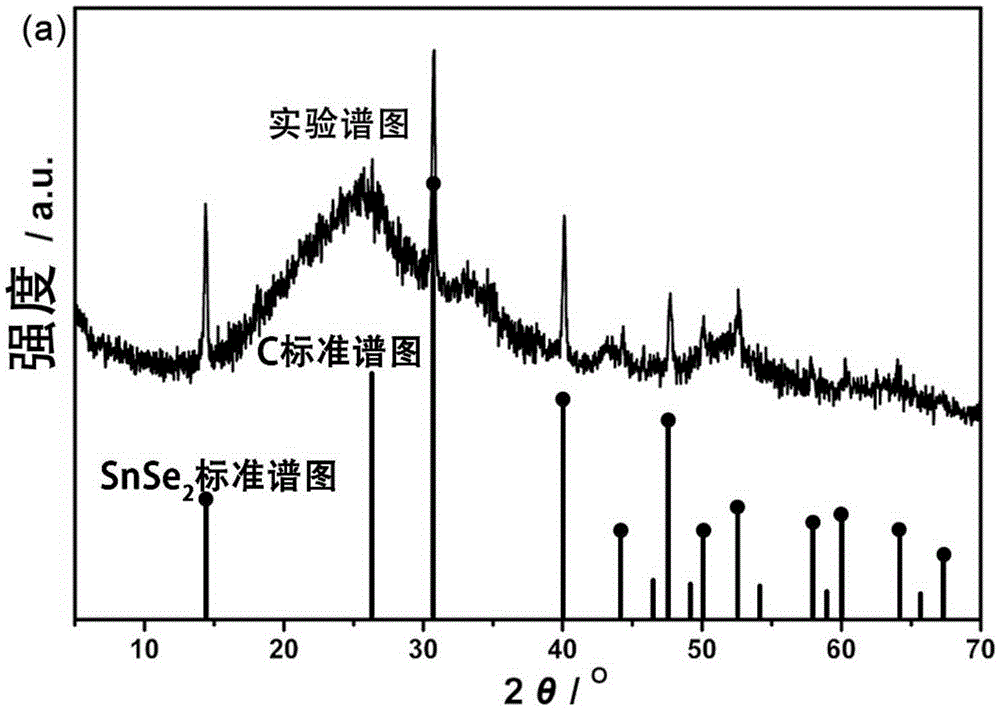

Nanometer tin diselenide/graphene composite material and its preparation method and use

ActiveCN105304878AUniform particle sizeHigh bonding strengthMaterial nanotechnologyCell electrodesSodium-ion batteryNanostructure

The invention discloses a nanometer tin diselenide / graphene composite material. The nanometer tin diselenide / graphene composite material is characterized in that tin diselenide particles with the average particle size of 3-10nm grow on the graphene surface. Nanometer tin diselenide and graphene have high binding strength, tin diselenide nanometer particles have good crystallization structures, graphene slice layers are disorderedly stacked to form a 3D skeleton, and nano-scale tunnels and a good charge transmission network are provided. The nanometer tin diselenide / graphene composite material is used as a cell cathode material and has good charge and discharge performances and stability. The invention also discloses a preparation method of the nanometer tin diselenide / graphene composite material. In synthesis, an ionic liquid is used and through improvement of binding strength of a metal sulfur nanometer structure and a carbon material, effective compounding of the carbon material and tin diselenide is realized and a high-performance lithium ion battery and sodion battery cathode material is obtained.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

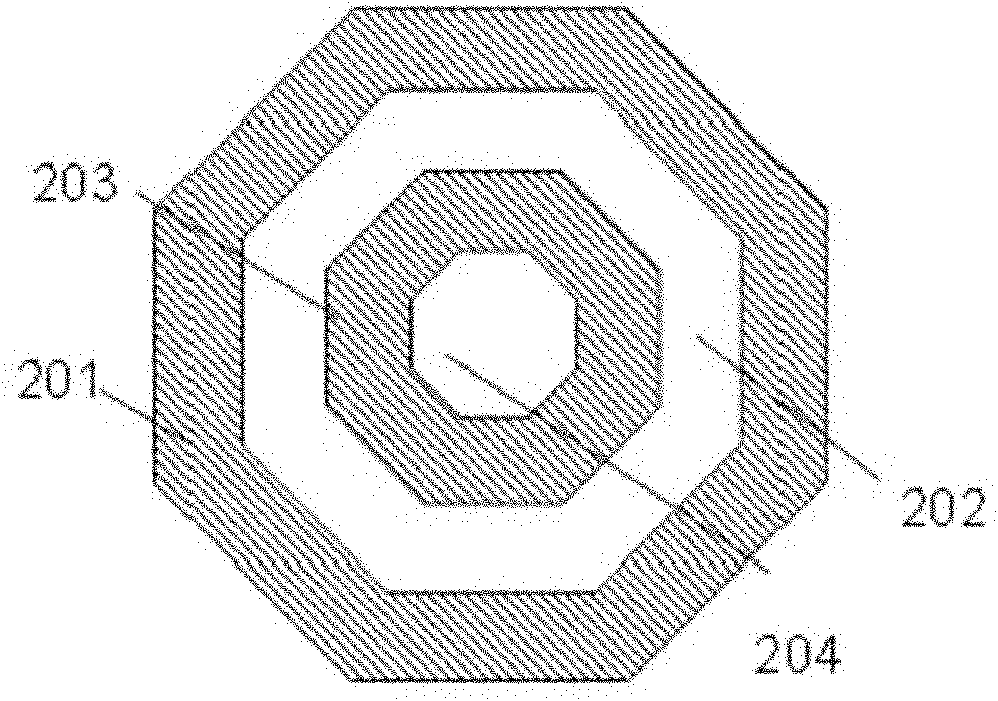

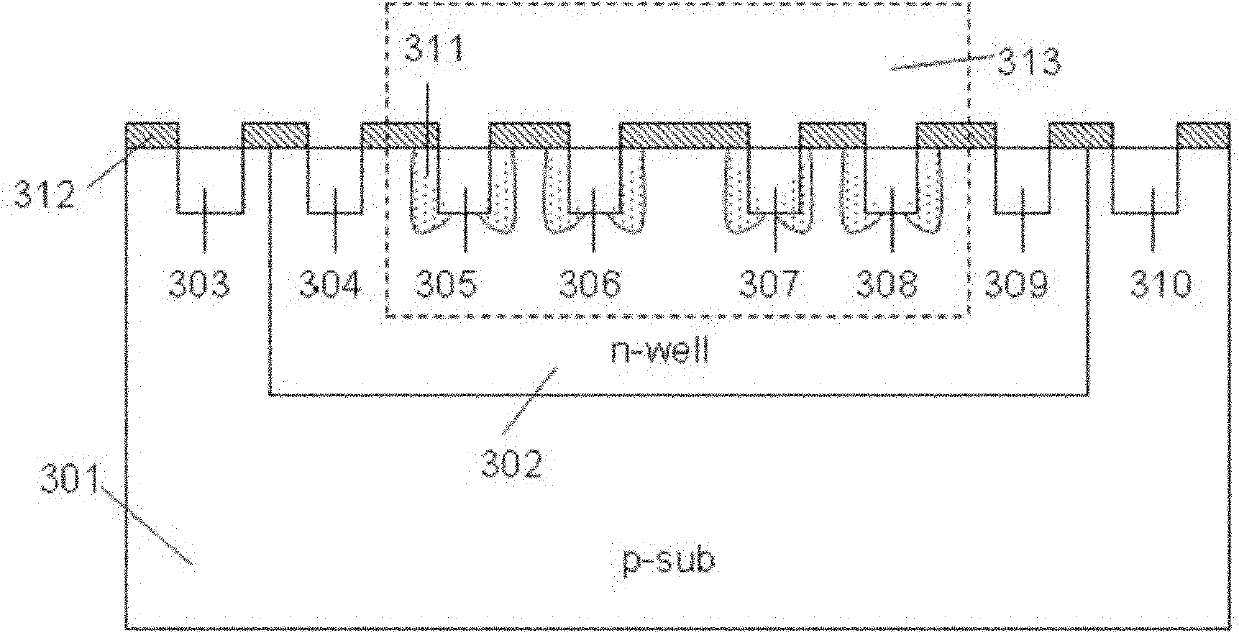

High-speed enhanced ultraviolet silicon selective avalanche photodiode and manufacturing method thereof

The invention discloses a high-speed enhanced ultraviolet silicon selective avalanche photodiode and a manufacturing method thereof. The photodiode comprises a P-type substrate, wherein an n well is arranged on the P-type substrate; a photosensitive window on the n well is a regularly octagonal concentric ring or is in array arrangement of a plurality of regularly octagonal concentric rings; and the doped types of the concentric rings are an n type and a p type at intervals. The photodiode has the advantages of high sensitivity, high responsiveness and high selectivity.

Owner:SHENZHEN AIXIESHENG TECH CO LTD

Low-color vanillin-based ultraviolet absorbers and methods of making thereof

Novel ultraviolet absorbing compounds that are liquid in nature, are extremely low in color (and thus permit use without the concomitant necessity of adding large amounts of other coloring agents to combat such discoloring), and are highly effective in providing protection in wavelength ranges for which previous attempts at low-color ultraviolet absorbers have failed are provided herein. Such compounds provide such excellent, inexpensive, and beneficial protection from ultraviolet exposure within various media, including, but not limited to, clear thermoplastics. The particular compounds are generally polymeric in nature including various chain lengths of polyoxyalkylenes thereon and are liquid in nature to facilitate handling and introduction within the target media. In addition, such ultraviolet absorbers also exhibit extremely low migratory properties thereby providing long-term protective benefits to the target media as well. This invention also concerns the end products, specific broadly defined types of compounds providing such beneficial characteristics, methods of making such low-color compounds, and methods of producing such clear, UV protected end products.

Owner:MILLIKEN & CO

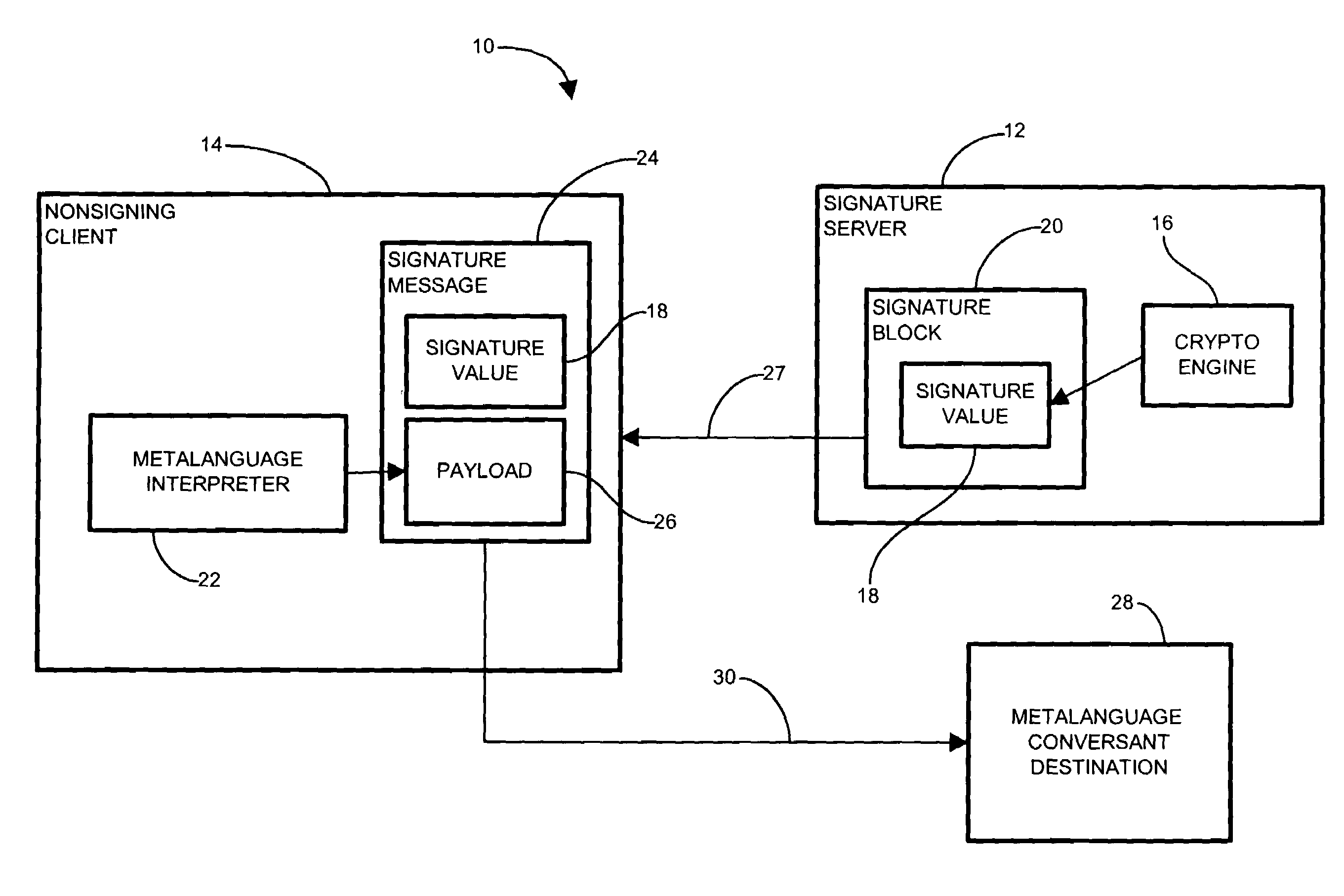

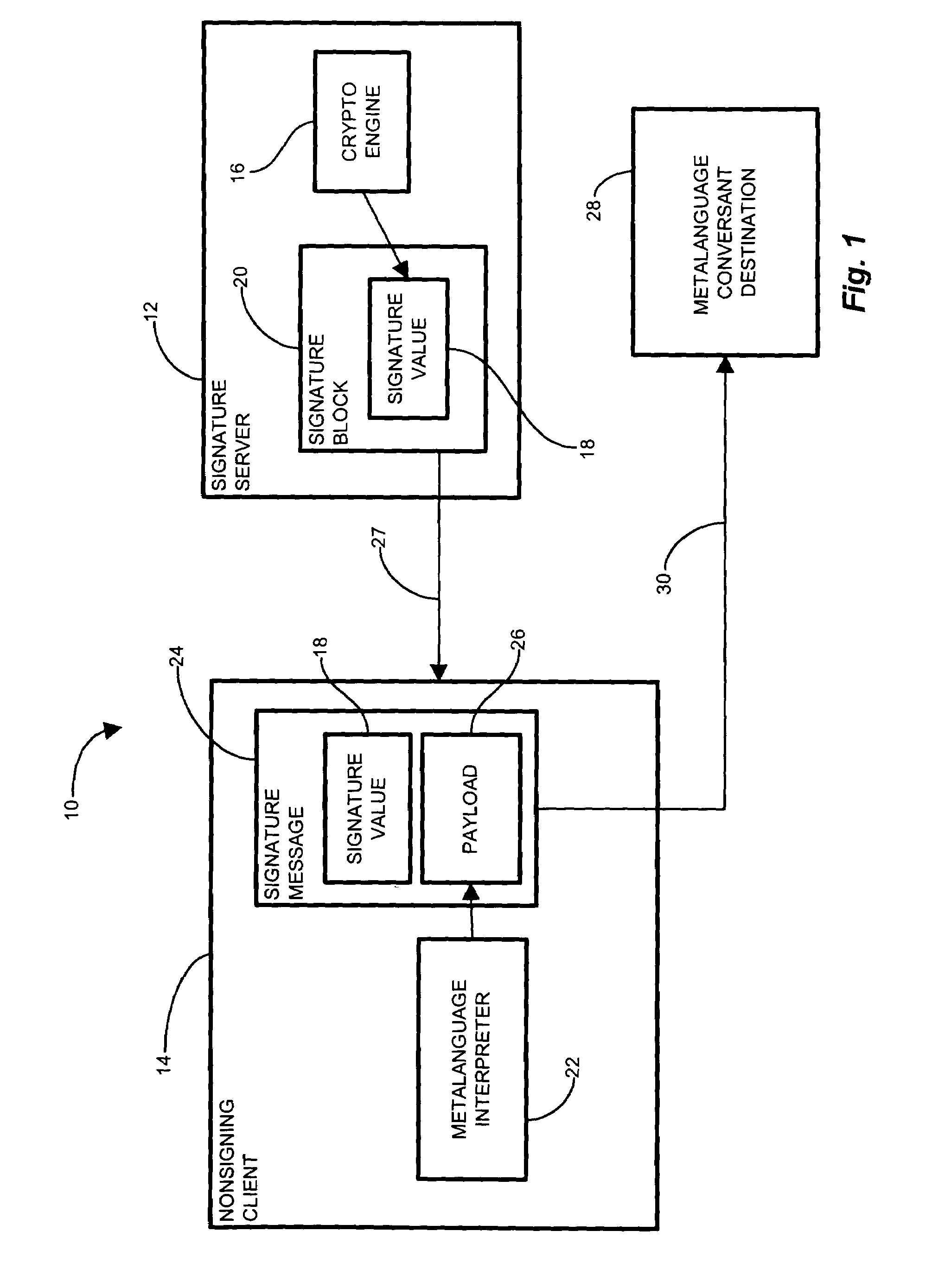

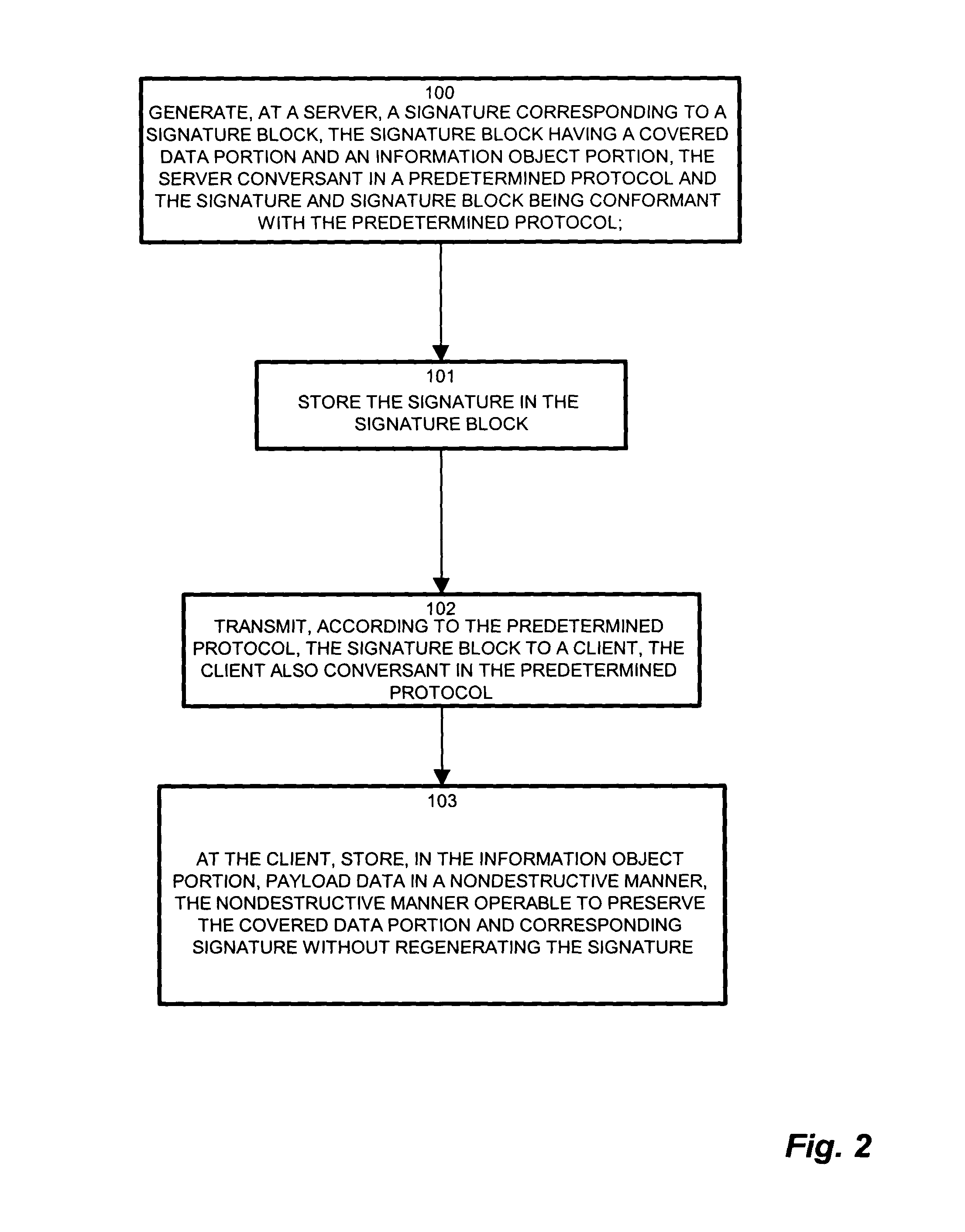

System and methods for using a signature protocol by a nonsigning client

ActiveUS7539869B1Effective compoundIncreased complexityKey distribution for secure communicationDigital data processing detailsMetalanguageClient-side

In a networked computer environment, a client is unencumbered from signature generating components, yet conversant to transmit signature-based documents in a signature-based metalanguage such as XML. The nonsigning client / user invokes a signature from a signature server to send a payload of data in a signed message format to a recipient also conversant in the metalanguage, according to the metalanguage format. The nonsigning client receives a signature block including a signature value from the server. The client identifies a payload for transmission according to the metalanguage. Employing the metalanguage interpreter in client, the client stores the payload data in the signature block without disrupting the signature and the data it covers in the signature block. The nonsigning client the sends the resulting signature message including the payload data and the signature value, in the metalanguage format, to the recipient destination conversant in the metalanguage. Accordingly, the nonsigning client employs signature-based messages without the encumbrance of cryptographic components.

Owner:ORACLE INT CORP

High-capacity silicon carbon negative electrode material, and preparation method and applications thereof

InactiveCN108539186AGood dispersionEasy to operateMaterial nanotechnologySecondary cellsCarbon compositesSURFACTANT BLEND

The invention discloses a high-capacity silicon carbon negative electrode material, and a preparation method and applications thereof. According to the preparation method, ball milling, surfactant treatment, ultrasonic wave treatment, spray drying, and the like are adopted, and related technological parameters are optimized for effective dispersion and combination of nanometer silicon and a carbonmaterial to prepare the silicon carbon composite material with a high specific capacity ranging from 1000 to 1700mAh / g and long cycle life. The preparation method is simple; cost is low; industrialized production is convenient to realize; and the silicon carbon composite material high in specific capacity and long in cycle life is prepared through ball milling, surfactant treatment, ultrasonic wave treatment, spray drying, and the like, and based on optimized related technological parameters.

Owner:SHAANXI COAL & CHEM TECH INST

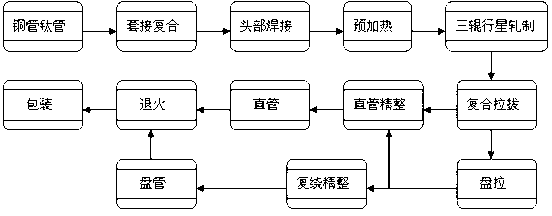

Production method for copper-titanium composite tube

The invention provides a production method for a copper-titanium composite tube. The method comprises the following steps: (1) sleeving a processed titanium tube in a copper tube and welding one end of the titanium tube and one end of the copper tube so as to form a composite tube blank; and (2) rolling the composite tube blank and carrying out composite drawing and annealing. According to the production method for the copper-titanium composite tube, ends of the two materials to be composited are welded before sleeve connection and rolling, so relative movement of the interior and exterior tubes during rolling is avoided; only one end of each tube are welded, so it is guaranteed that air between composite surfaces is effectively exhausted during rolling; because percentages of elongation of the two materials are different, lengths of the two materials may not be identical after rolling, so one-end welding allows free extension of metals along a length direction in the process of rolling to be realized and effective compositing of the two materials to be guaranteed.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

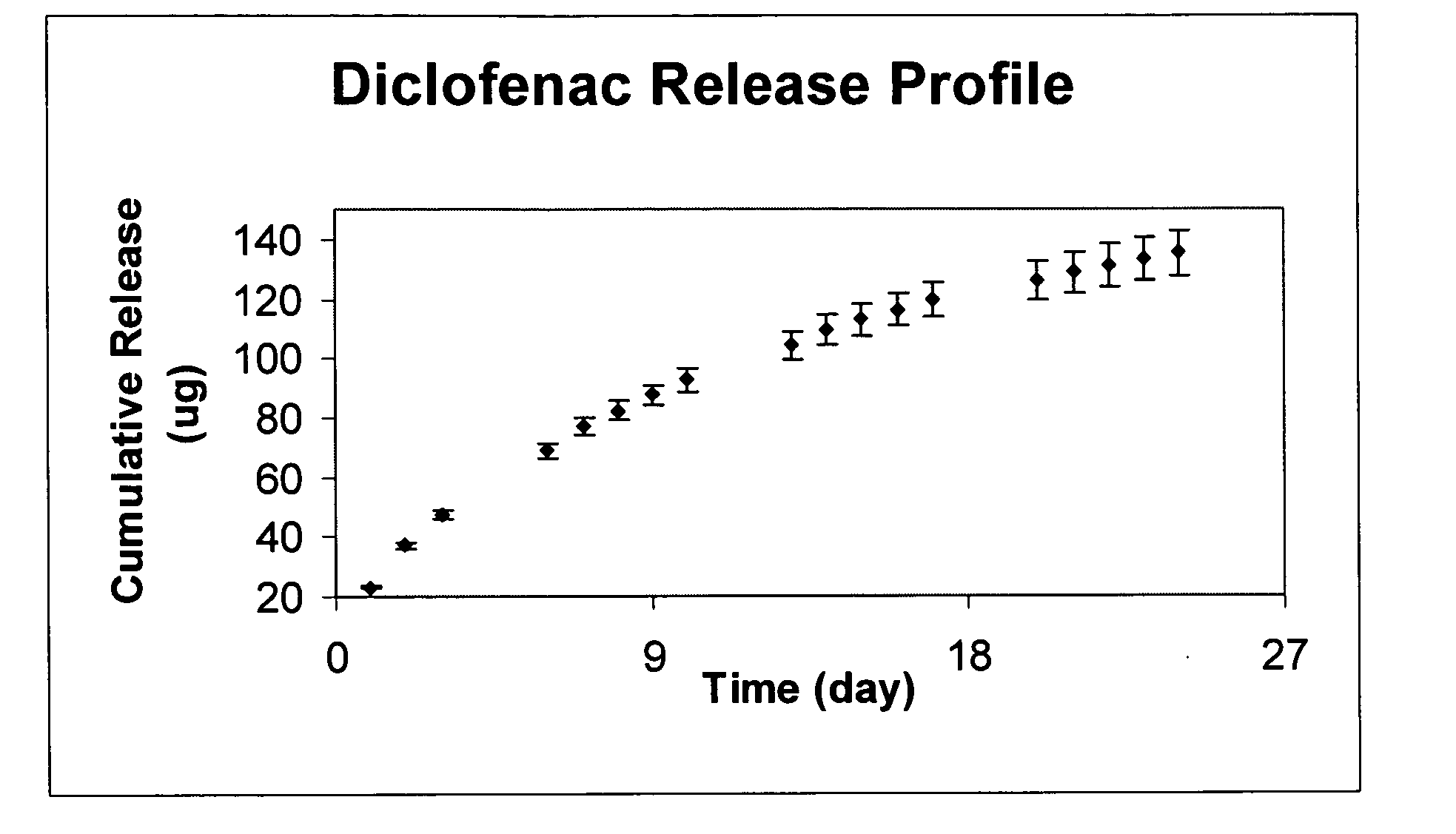

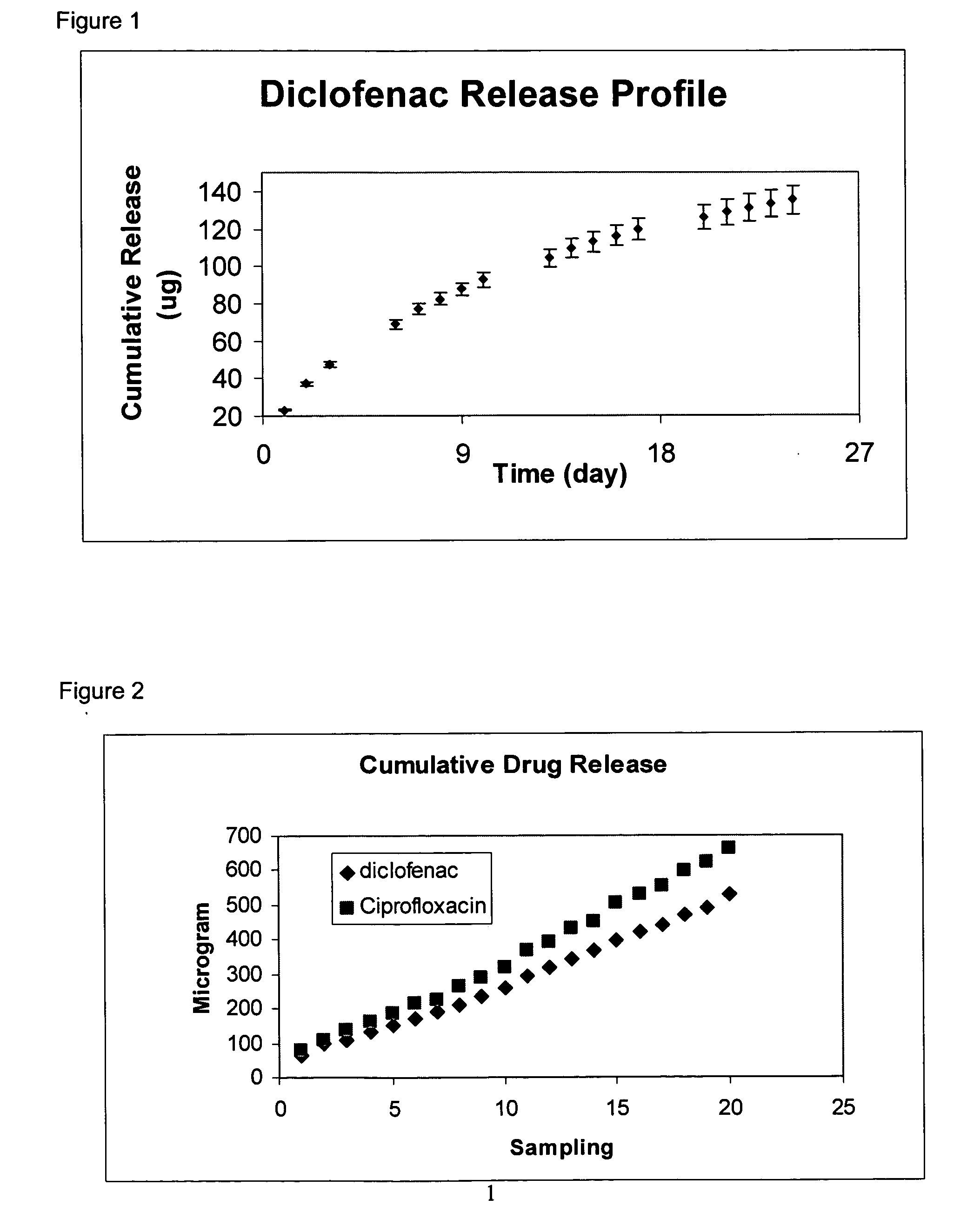

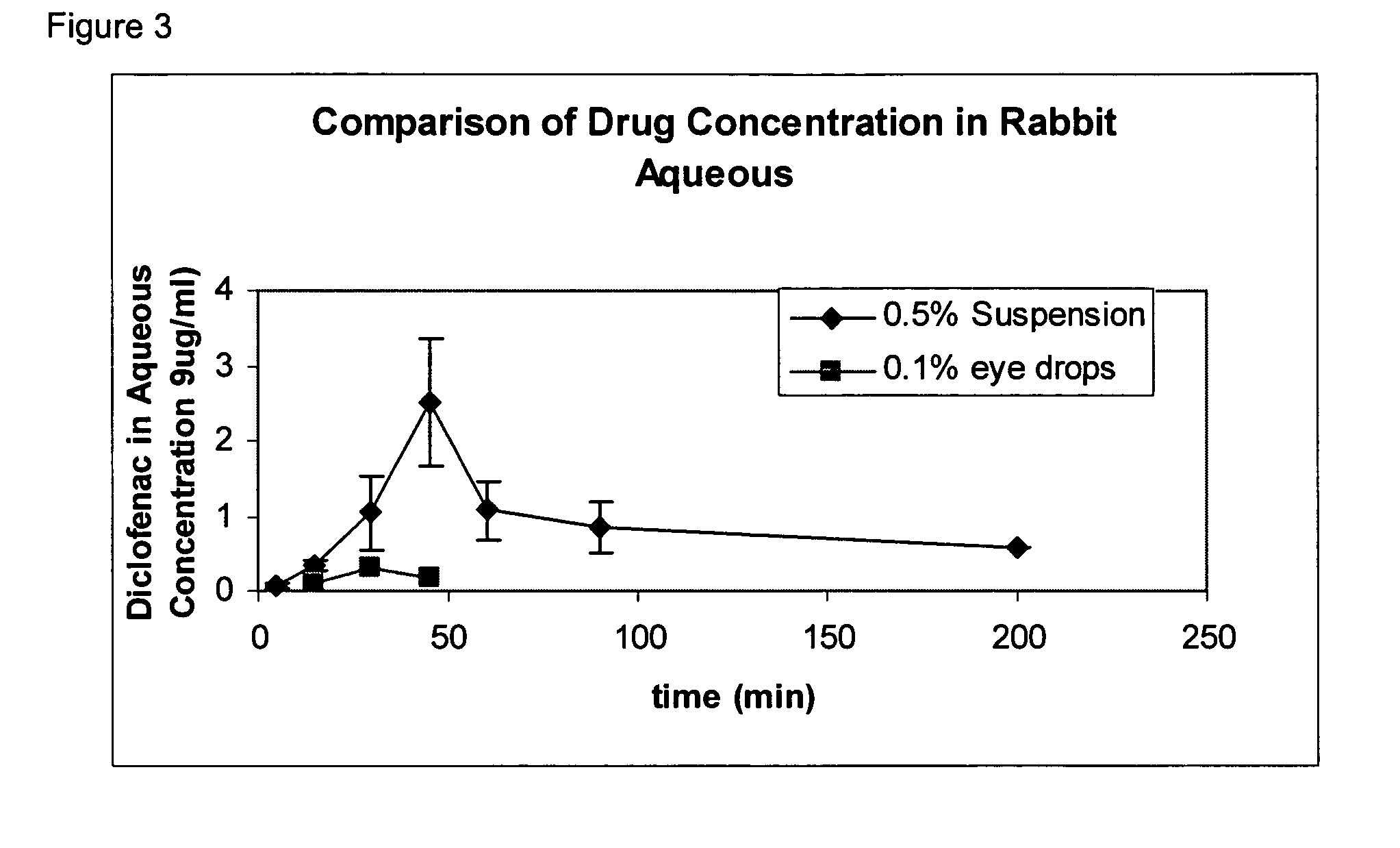

Compositions and methods for delivering a biologically active agent

InactiveUS20050008695A1Increase productionImprove physiological deliveryOrganic active ingredientsPill deliveryActive agentMedicine

The invention relates to codrugs having improved properties, methods for preparing and administering them, and methods of formulating and administering the codrugs as pharmaceutical preparations. In certain embodiments, the codrugs can be locally administered to deliver the constituent biologically active compound in a sustained-release fashion, reducing systemic concentrations of the biologically active compound.

Owner:CONTROL DELIVERY SYST

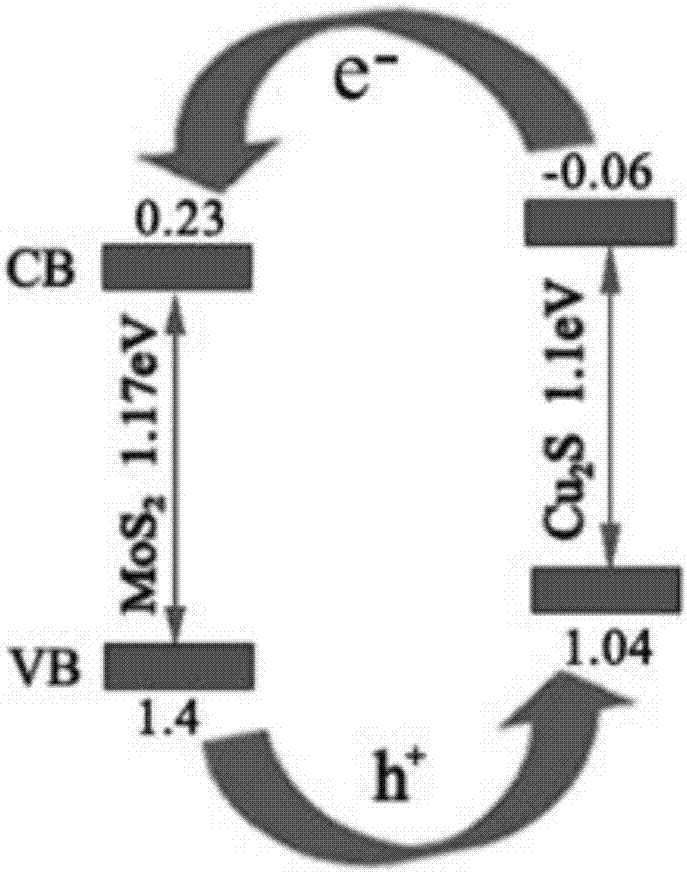

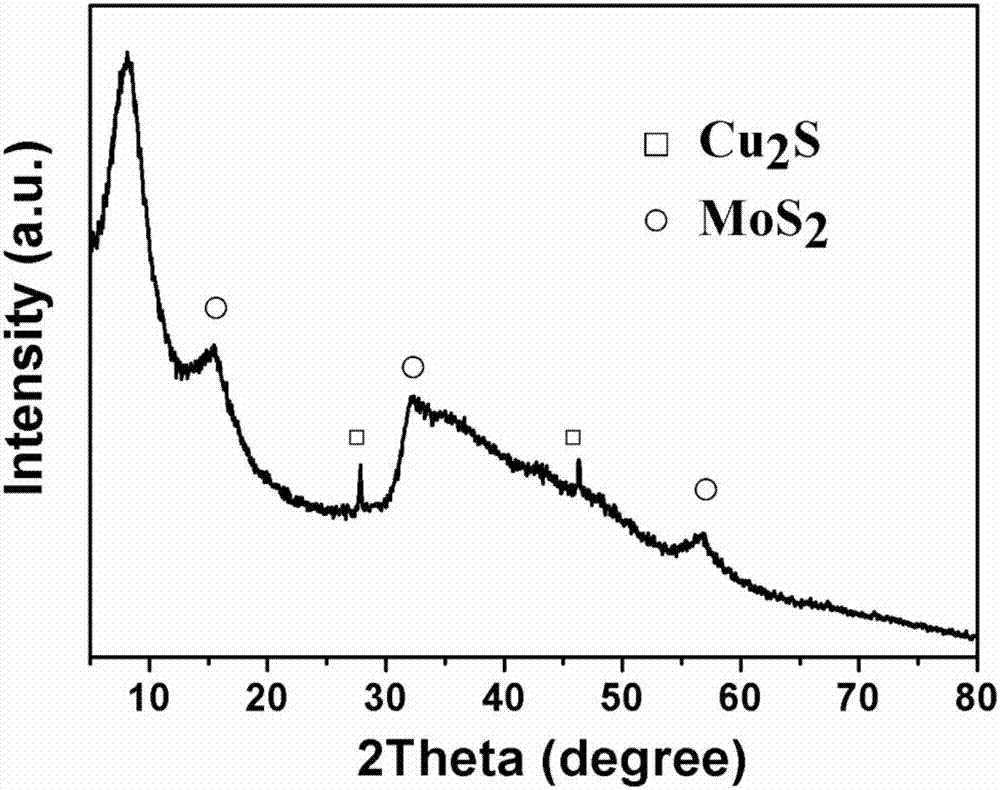

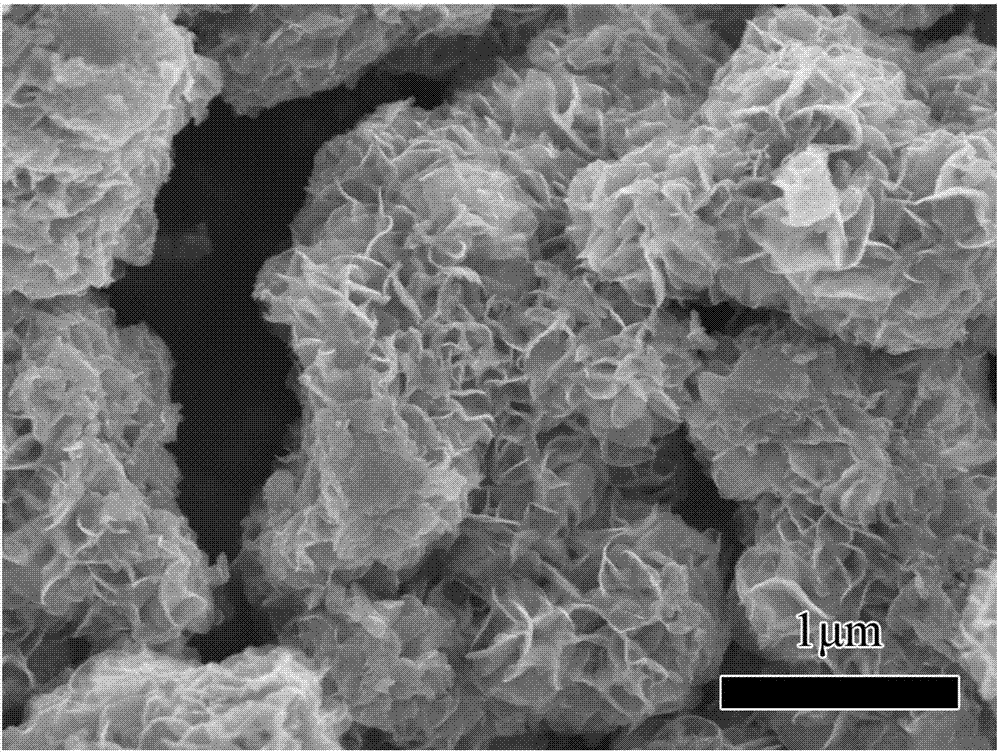

Hierarchy MoS2/Cu2S composite material and preparation method thereof

InactiveCN107262116AEffective compoundGood photocatalysisMaterial nanotechnologyCatalyst activation/preparationElectricityMicro nano

The invention discloses a hierarchy MoS2 / Cu2S composite material. The hierarchy MoS2 / Cu2S composite material is a micro-nano sphere with a flower-like structure formed by assembling MoS2 nanosheets and Cu2S nanosheets and is obtained by carrying out hydrothermal reaction on a molybdenum source, a sulfur source, a copper source and a reducing agent which serve as raw materials. The MoS2 / Cu2S composite material disclosed by the invention is prepared by using a hydrothermal method, and has the advantages of wide source of the related raw materials, low cost, simple and feasible technology and high yield; the difficult point that MoS2 is difficultly compounded with other materials at present can be solved; besides, the problem of low conductivity of the MoS2 in the catalytic reaction process also can be solved; the obtained composite material shows excellent photocatalytic performance and excellent electrocatalytic performance and is suitable for being popularized and applied.

Owner:WUHAN UNIV OF TECH

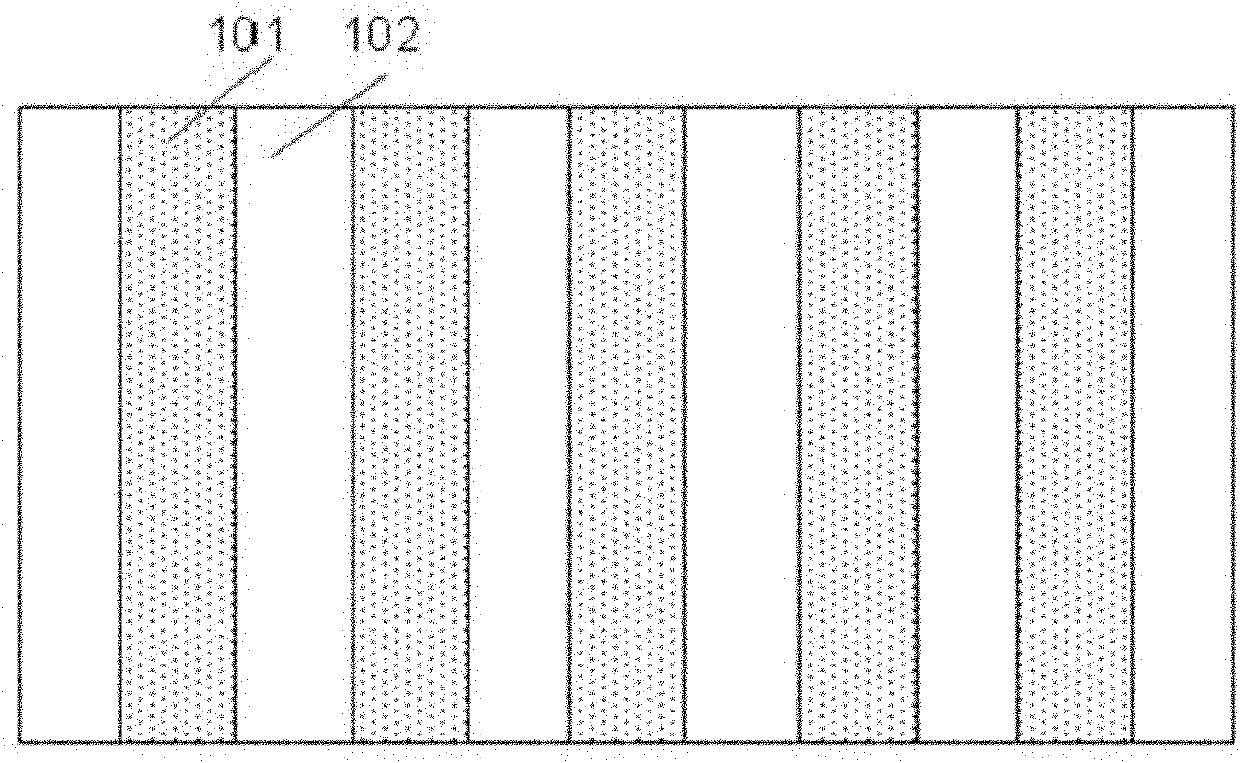

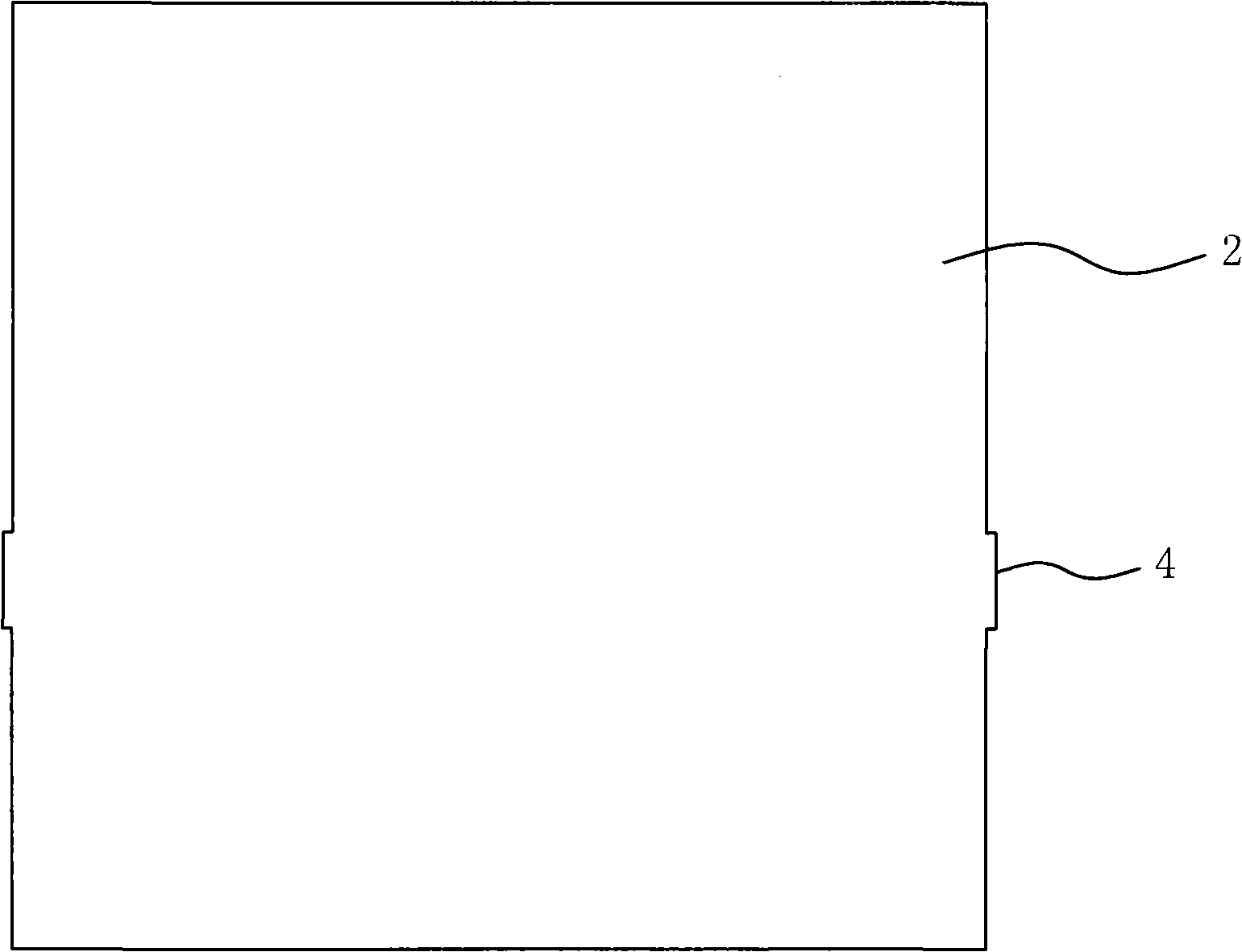

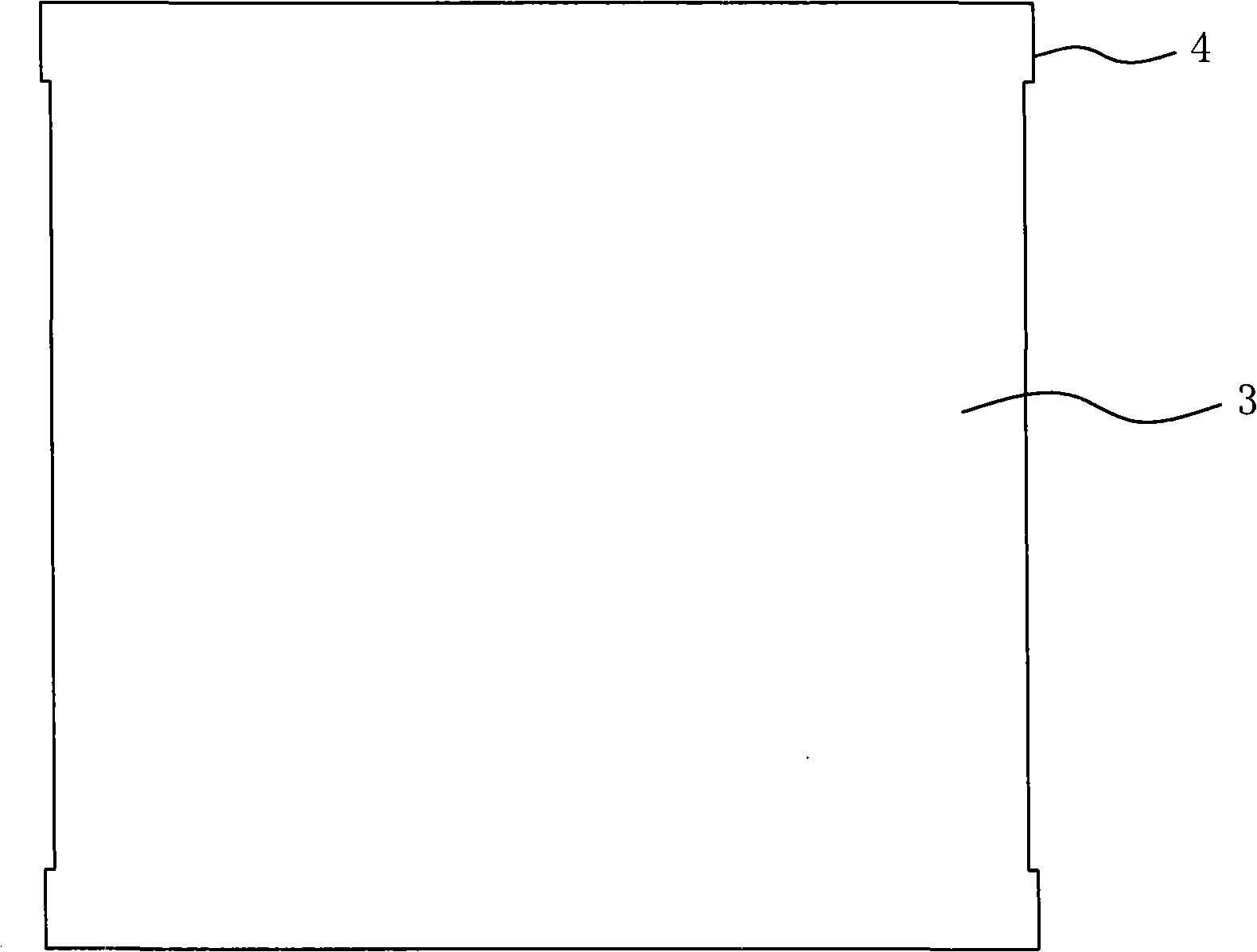

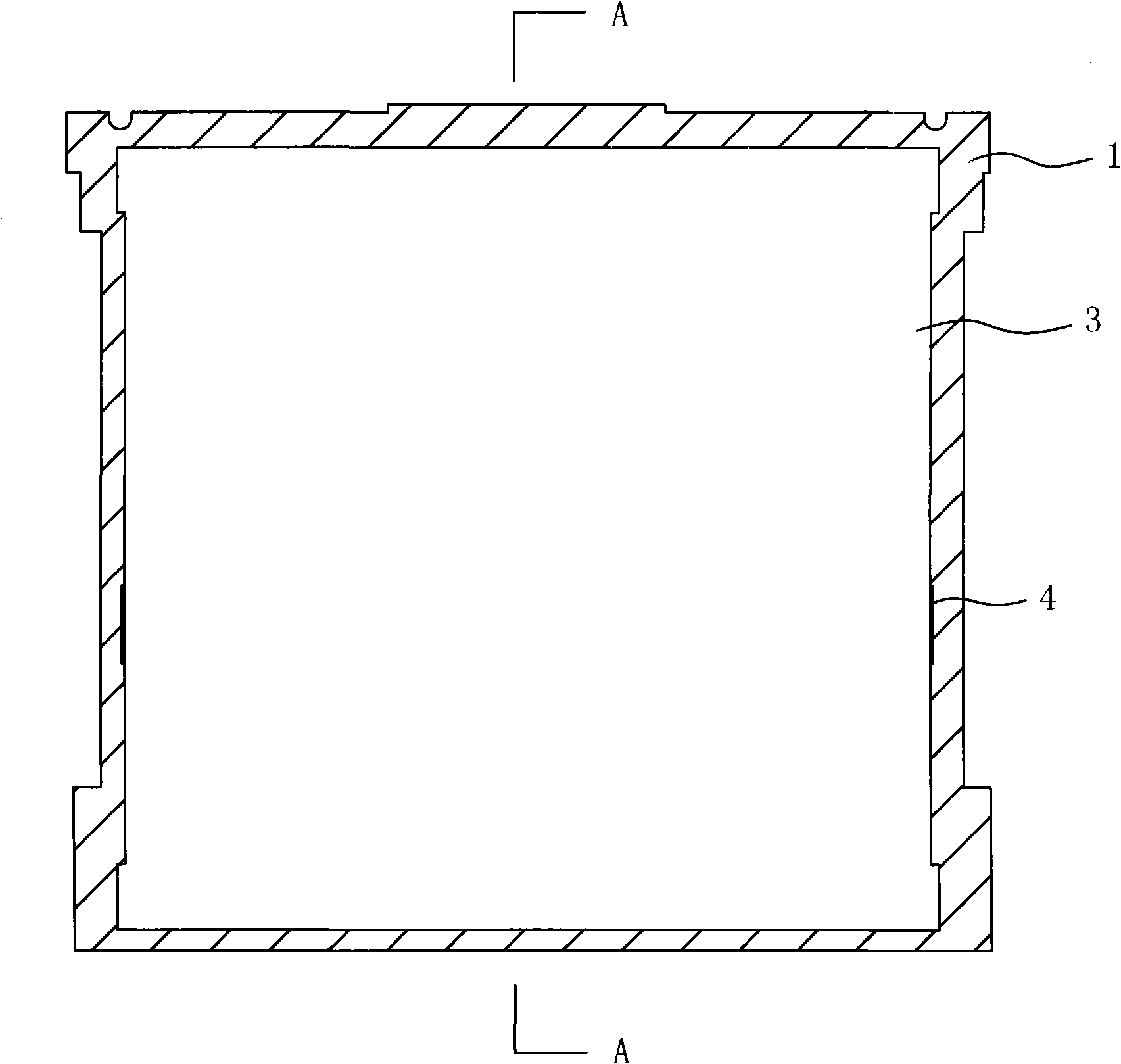

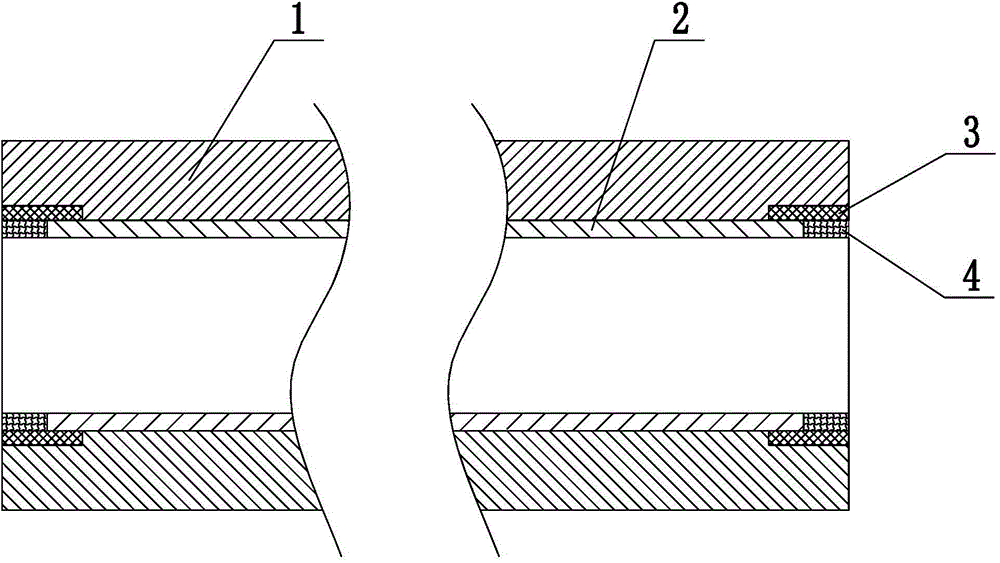

Three-layer combined optical film piece

InactiveCN101271222ASimple production operationReduce defective rateLayered productsNon-linear opticsAutomatic processingOptoelectronics

The invention discloses a composite optical membrane which comprises protecting films, optical membrane layers and a shading double-side adhesive tape layer, and the surrounding of the shading double-side adhesive tape layer is an annular stickiness part with the middle forming a transparent part. The invention is characterized in that: the hierarchical structure of the composite optical membrane consists of a first protecting film, the shading double-side adhesive tape layer, a first optical membrane layer, a second optical membrane layer and a second protecting film which are orderly overlapped. The first optical membrane layer is larger than the transparent part but less than the second optical membrane layer; and the surrounding is jointed with the stickiness part. The second optical membrane layer is less than the shading double-side adhesive tape layer, and the surrounding part of the second optical membrane layer exceeding the first optical membrane layer is jointed with the stickiness part of the shading double-side adhesive tape layer. The invention uses the stickiness of the shading double-side adhesive tape layer to directly compound each layer of membrane together by an automatic processing device, which is different from prior complex production process, ensures the more reliable performance of a backlight module and improves the production efficiency.

Owner:普胜科技电子(昆山)有限公司

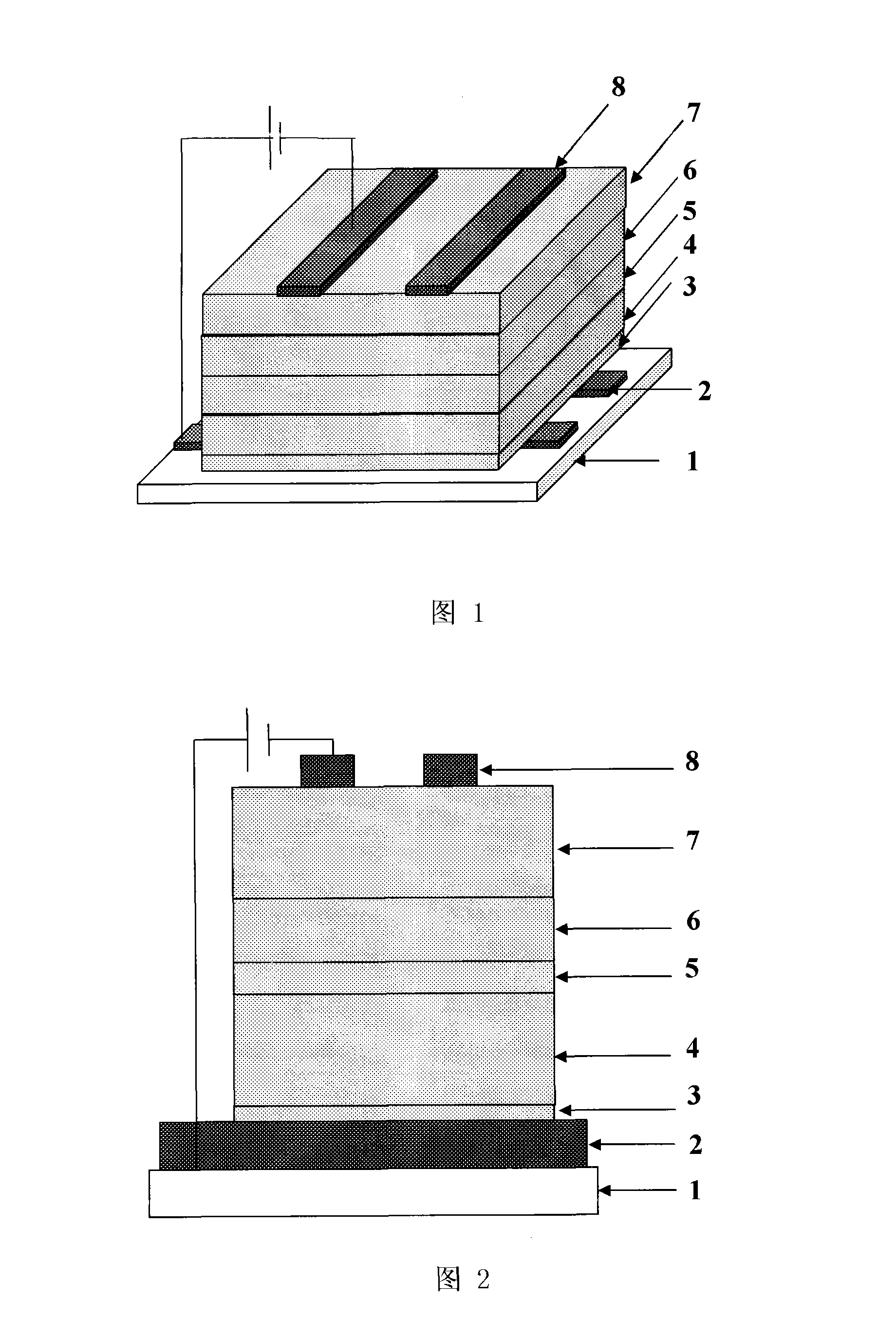

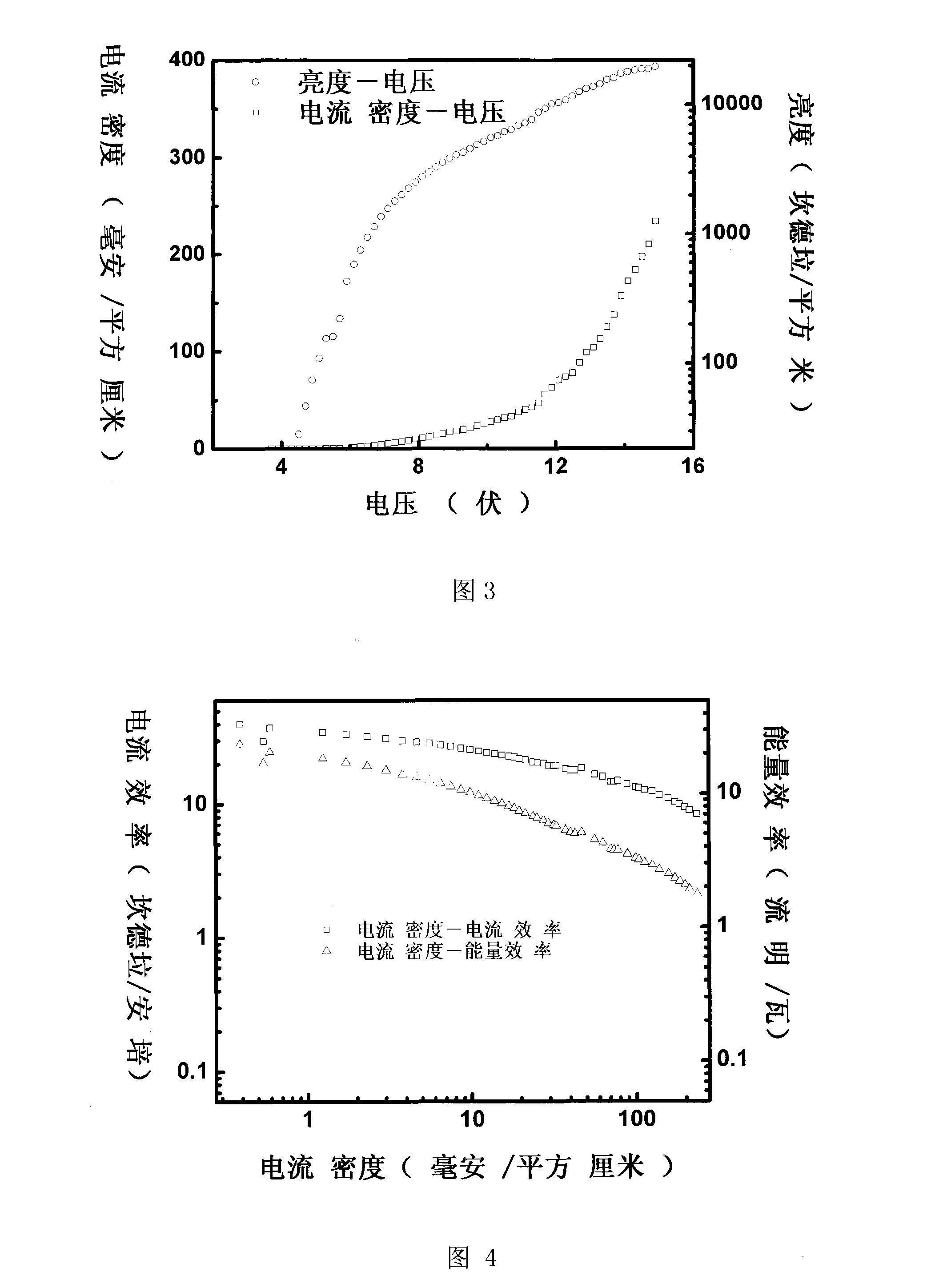

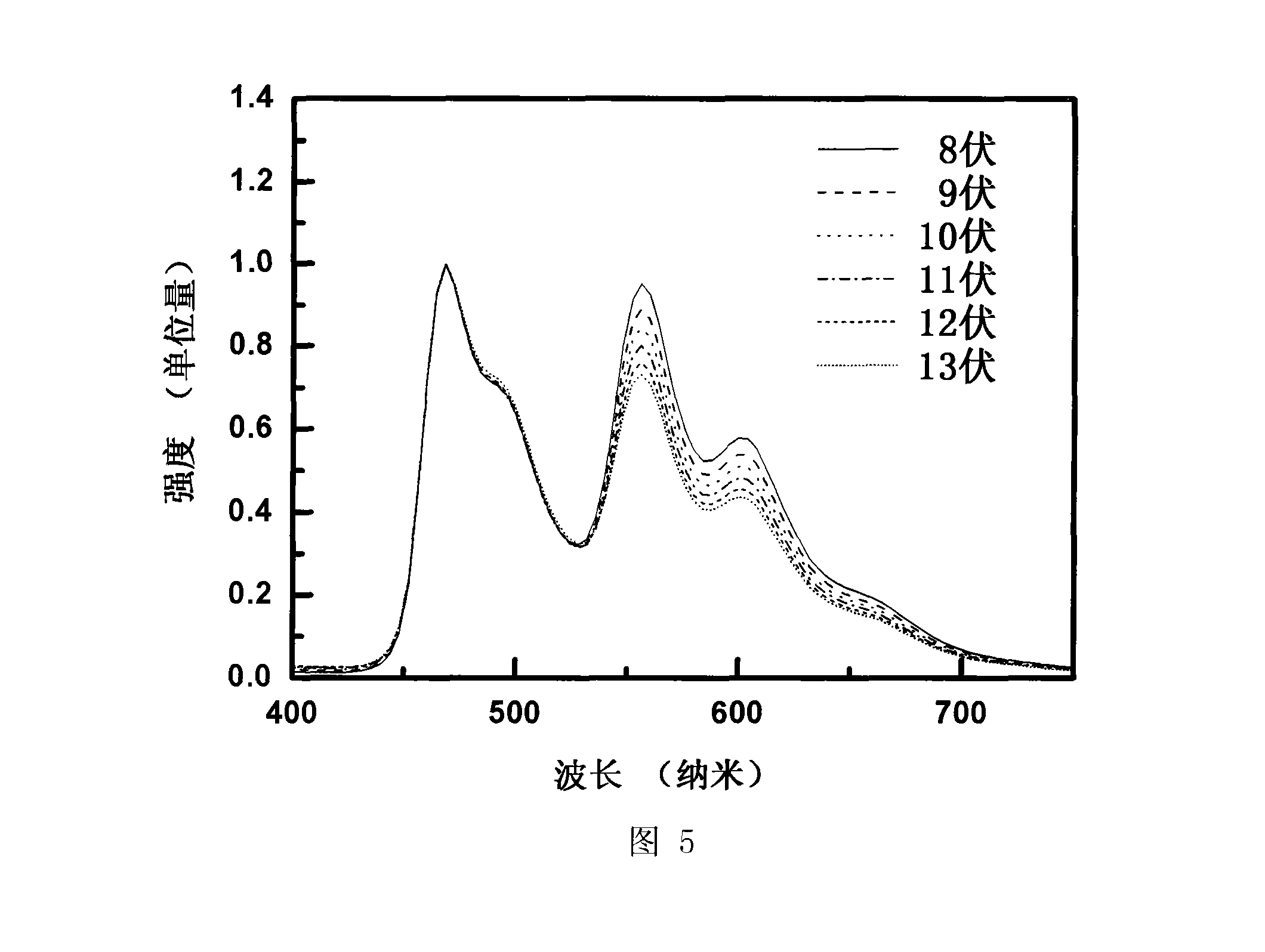

Double phosphorescent coloring agent common adulterate white light organic electroluminescent device and method for fabricating the same

InactiveCN101179116AGood white light emissionAchieving Internal Quantum EfficiencySolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionHole transport layer

The invention pertains to double phosphorescent dyes co-doped white organic light-emitting device and discloses the preparation method. The invention adopts sandwich structure and intermingles the two high-efficient phosphorescent dyes together in the wide band gap body; and also takes use of the energy difference between emission layer and its bilateral function layers to form a structure of energy sink type; restricts exaction within the structure completely, thereby realizing composite luminescence. The structure of the device is indium tin oxide (ITO) / metal oxide / hole-transporting layer / electron blocking layer / emission layer composed of the co-doped blue and orange light phosphorescent dyes / electron transporting(hole blocking)layer / metal cathode. The prepared devices are driven by direct voltage and obtain high-efficient white light emission. The maximum electroluminescence current efficiency is 52.8cd / A; the maximum electroluminescence (EL) power efficiency is 42.5lm / W; the maximum luminance is19500 cd / m2. The devices show simultaneous emission of complementary colors of orange and blue and stable spectrum when at work. The device has simple manufacturing process, low cost and excellent stability.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Bimetal composite pipe and manufacturing process thereof

ActiveCN104019288AEffective compoundGuarantee the quality of welding constructionRigid pipesWorkpiece edge portionsArchitectural engineeringMetal

The invention discloses a bimetal composite pipe which comprises a base pipe and a lining pipe installed on the inner side of the base pipe in a sleeved mode. The lining pipe is shorter than the base pipe, the inner walls of the two ends of the base pipe are respectively provided with an annular groove, each annular groove is internally provided with a first surfacing layer in a welded mode, the internal diameter of each first surfacing layer is the same as that of the base pipe, a second surfacing layer is welded to the inner wall of each first surfacing layer and located at the end of the lining pipe, the ends of the second surfacing layers are flush with the end of the base pipe, and the internal diameter of each second surfacing layer is the same as that of the lining pipe. The invention further discloses a manufacturing process of the bimetal composite pipe. According to the bimetal composite pipe, the annular grooves are formed in the inner walls of the two ends of the base pipe and the first surfacing layers are welded to the annular grooves, the end of the base pipe and the end of the lining pipe can be compounded effectively, and it is ensured that the lining pipe of the bimetal composite pipe is not affected by the base pipe in the circular welding process.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com