Three-layer combined optical film piece

An optical film, composite technology, applied in optics, nonlinear optics, layered products, etc., can solve the problems of scrap, loss, waste and other problems of four films, and achieve reliable and stable quality, material saving, convenient production and operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

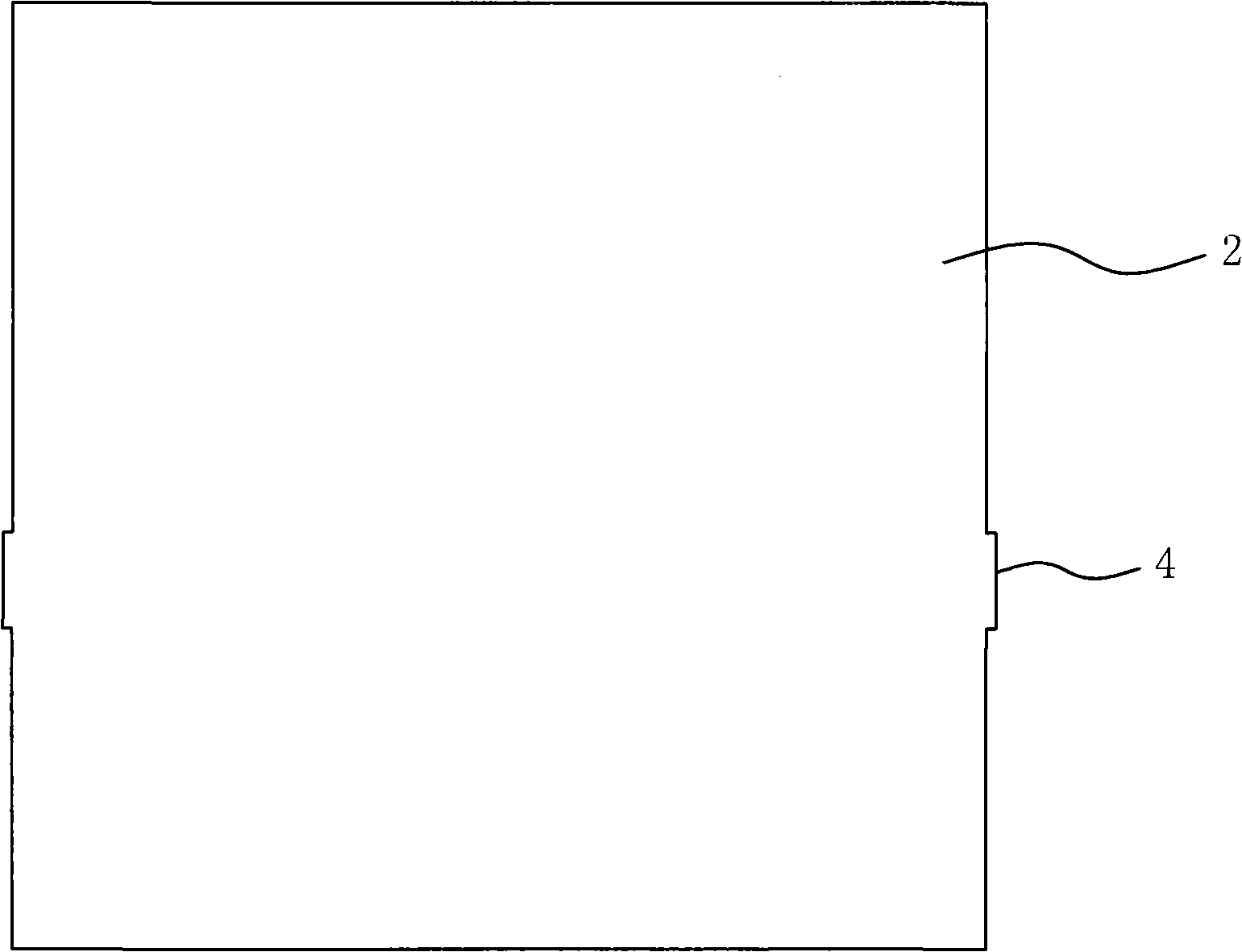

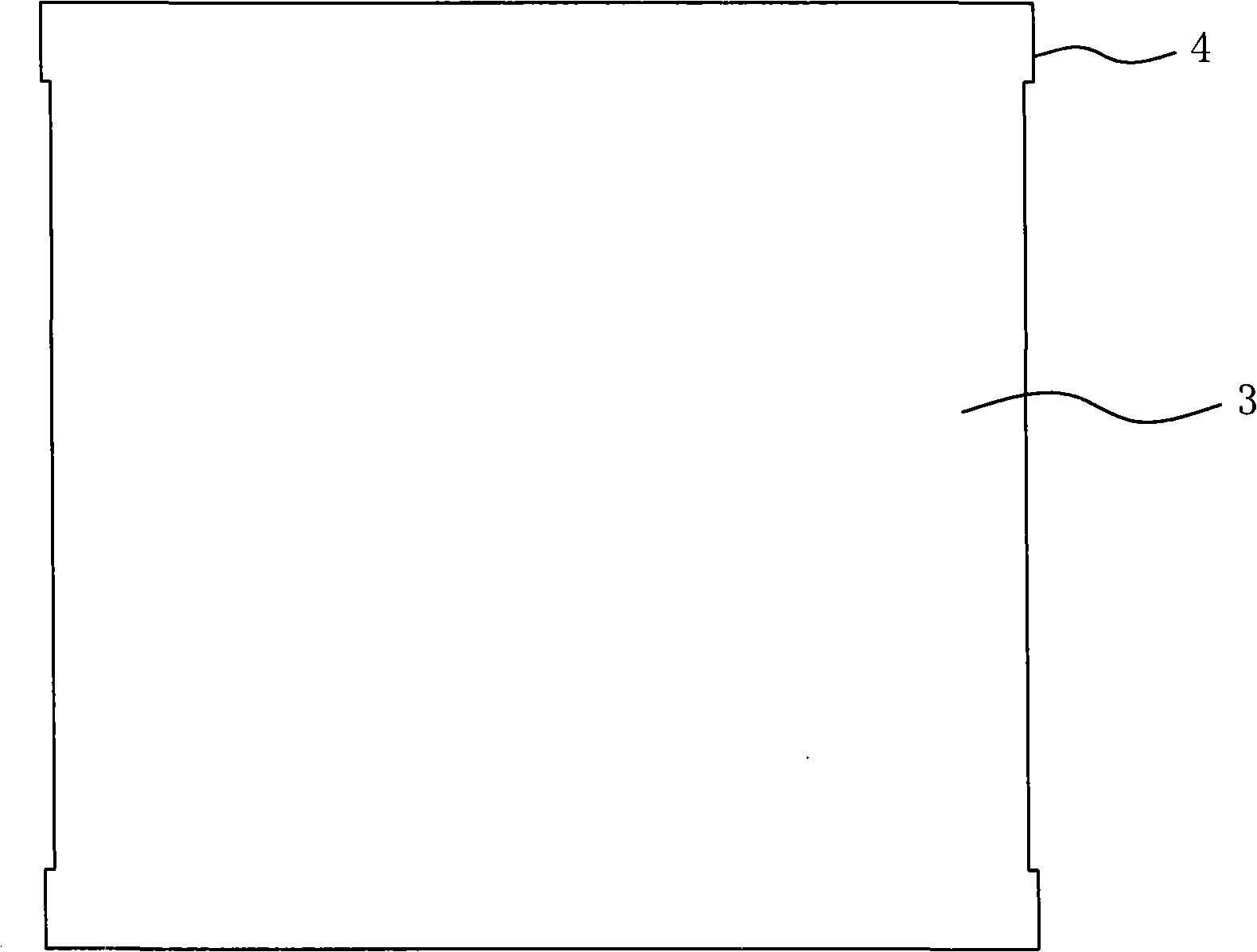

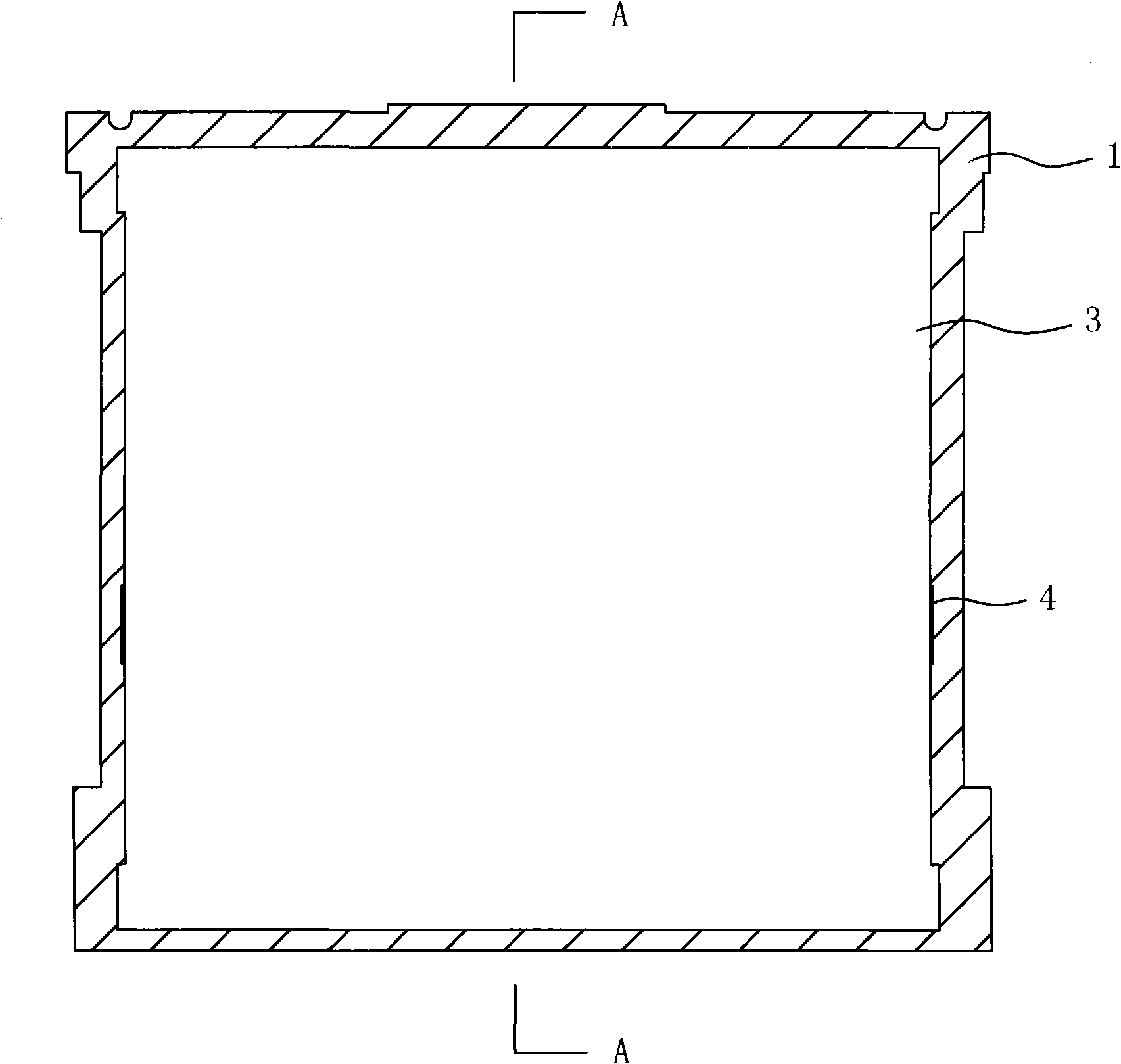

[0030] Embodiment one: see attached figure 1 To attach Figure 6 As shown, a three-layer composite optical film includes two layers of optical film layers, two layers of protective film 6 and a light-shielding double-sided adhesive layer 1, and the composite optical film is composed of the first protective film, the first protective film, The light-shielding double-sided adhesive layer, the first optical film layer 2, the second optical film layer 3 and the second protective film are sequentially stacked, and a light-transmitting part 5 is arranged in the middle of the light-shielding double-sided adhesive layer. The film layer is larger than the light-transmitting part but smaller than the second optical film layer, and the second optical film layer is larger than the first optical film layer but smaller than the light-shielding double-sided adhesive layer.

[0031] In the process of processing, the original three separate diaphragms are composited together by automatic equi...

Embodiment 2

[0032] Embodiment two: a kind of three-layer composite optical film, comprising two layers of optical film layers, two layers of protective film and light-shielding double-sided adhesive layer, the first optical film layer is a prism sheet, and the second optical film layer is Prism sheet. The composite optical film is composed of a first protective film, a light-shielding double-sided adhesive layer, a prism sheet, a prism sheet and a second protective film in sequence from outside to inside, and a light-transmitting part is opened in the middle of the light-shielding double-sided adhesive layer. The first optical film layer is larger than the light-transmitting part but smaller than the second optical film layer, and the second optical film layer is larger than the first optical film layer but smaller than the light-shielding double-sided adhesive layer.

Embodiment 3

[0033] Embodiment 3: The structure is similar to Embodiment 1, wherein the first optical film layer is a diffusion sheet, and the second optical film layer is a diffusion sheet.

[0034] Embodiment 3: The structure is similar to Embodiment 1, wherein the first optical film layer is a prism sheet, and the second optical film layer is a diffusion sheet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com