Production method of crop straw-based degradable polymer sheet

A technology of crop straw and polymer, applied in the field of straw recycling, can solve the problems of environmental pollution, insufficient recycling rate of straw resources, poor strength and quality, etc. The effect of using performance, avoiding pollution and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

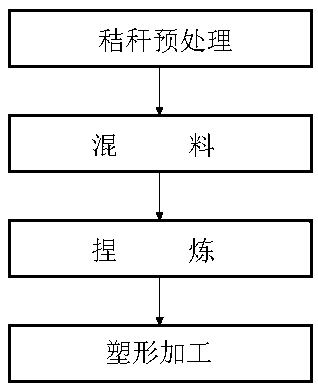

[0022] Such as figure 1 As shown, a method for preparing a degradable polymer sheet based on crop straw includes the following steps:

[0023] In the first step, straw pretreatment, the straw to be treated is soaked in deionized water at 30°C for 12 hours, then the soaked straw is freeze-dried, and the freeze-dried straw is crushed into 160 mesh powder for later use;

[0024] The second step is to mix materials. After the first step is completed, the prepared straw powder and waste plastic particles, 20-100 mesh calcium carbonate powder, silver oxide powder, polyvinyl chloride, kumquat powder, graphene fiber, carboxylate Methyl cellulose, polyethylene-propionic acid copolymer and antioxidant are mixed and stirred evenly. Among them, straw powder and waste plastic particles, 20-100 mesh calcium carbonate powder, silver oxide powder, polyvinyl chloride, kumquat powder, graphite The mass percentages of olefin fiber, carboxymethyl cellulose, polyethylene-propionic acid copolymer and a...

Embodiment 2

[0029] Such as figure 1 As shown, a method for preparing a degradable polymer sheet based on crop straw includes the following steps:

[0030] In the first step, straw pretreatment, the straw to be treated is soaked in deionized water at 50°C for 24 hours, then the soaked straw is freeze-dried, and the freeze-dried straw is crushed into 200 mesh powder for later use;

[0031] The second step is to mix the materials. After the first step is completed, the prepared straw powder and waste plastic particles, phenolic resin, titanium dioxide powder, vinyl acetate resin, lemon powder, organic fiber, carboxymethyl cellulose, and poly β— Hydroxybutyrate and antioxidant are mixed and stirred evenly, including straw powder and waste plastic particles, phenolic resin, titanium dioxide powder, vinyl acetate resin, lemon powder, organic fiber, carboxymethyl cellulose, poly β-hydroxybutyrate And the mass percentage of antioxidants: straw powder 10%-30%, phenolic resin 6%, titanium dioxide powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com