Patents

Literature

70 results about "Olefin fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Olefin fiber is a synthetic fiber made from a polyolefin, such as polypropylene or polyethylene. It is used in wallpaper, carpeting, ropes, and vehicle interiors. Olefin's advantages are its strength, colourfastness and comfort, its resistance to staining, mildew, abrasion, sunlight and its good bulk and cover.

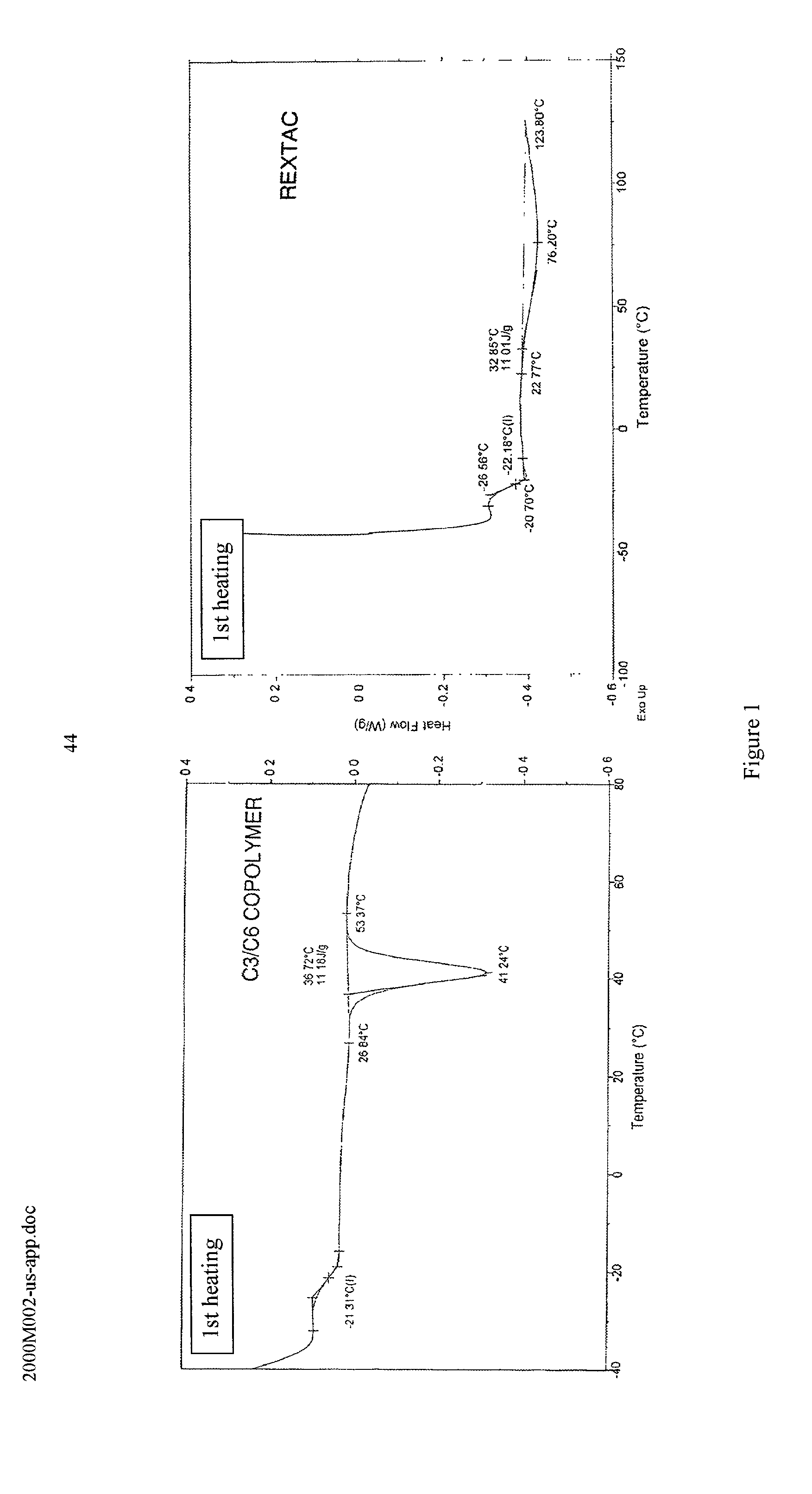

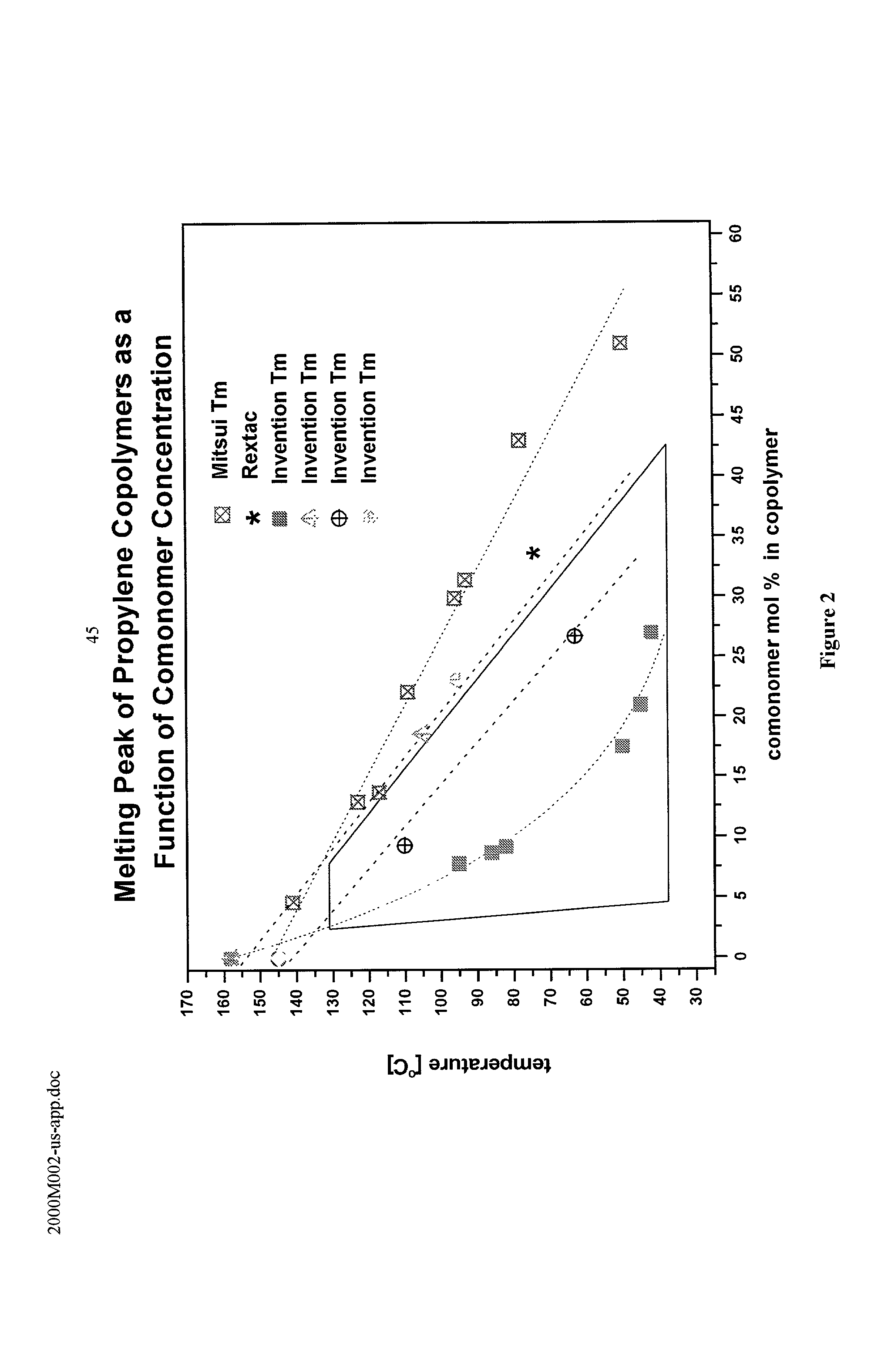

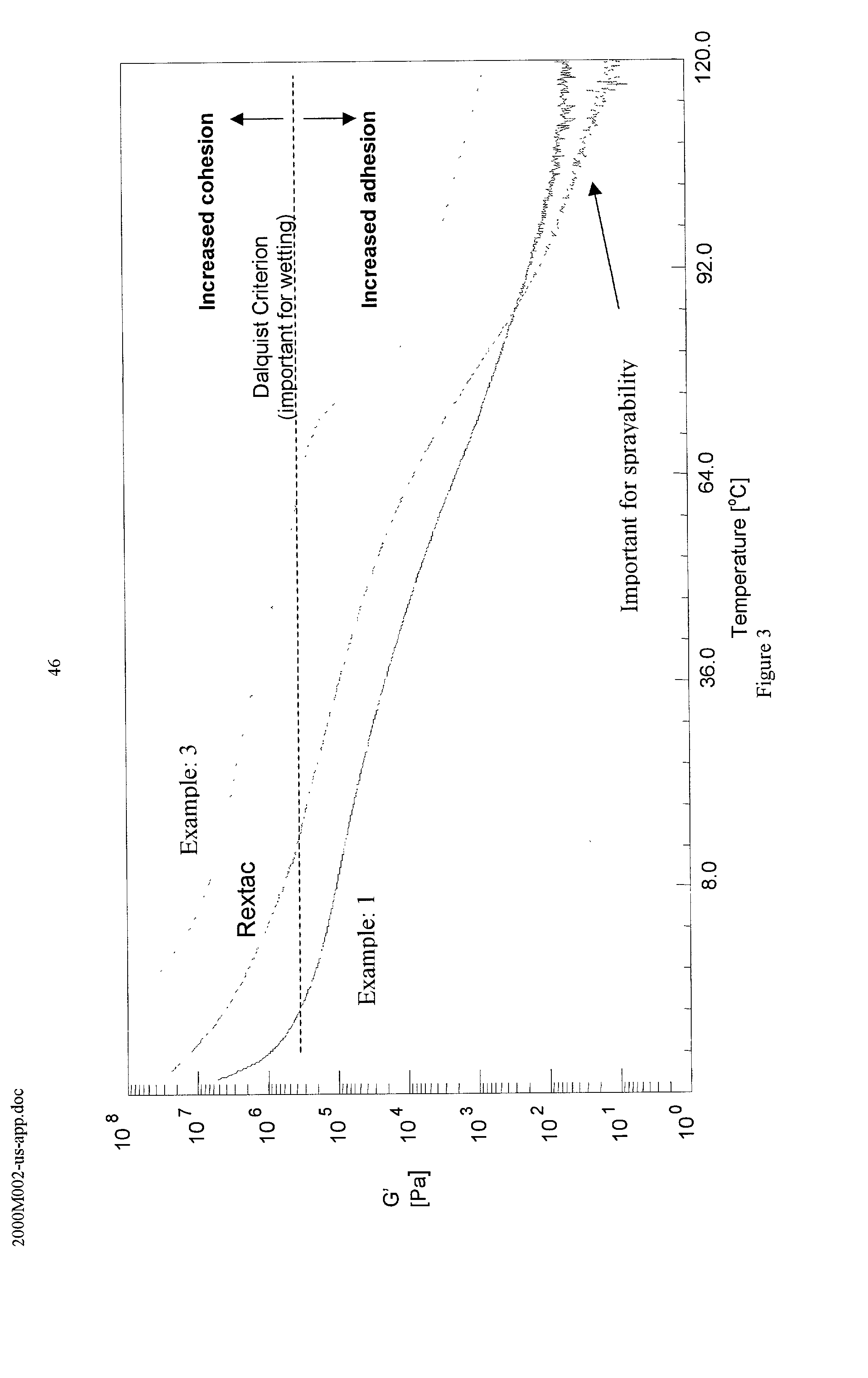

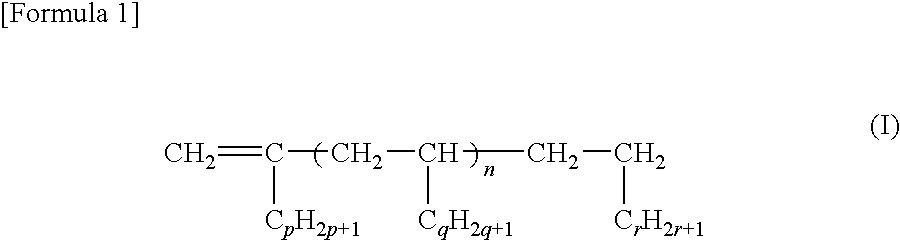

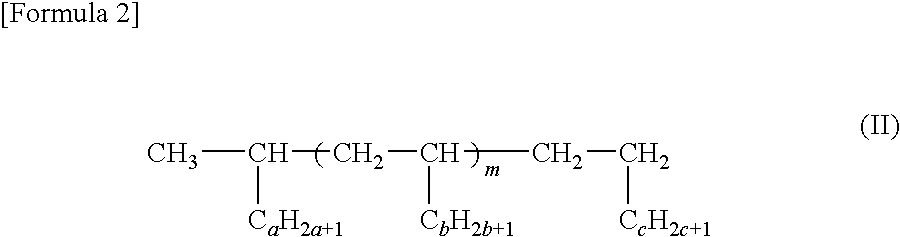

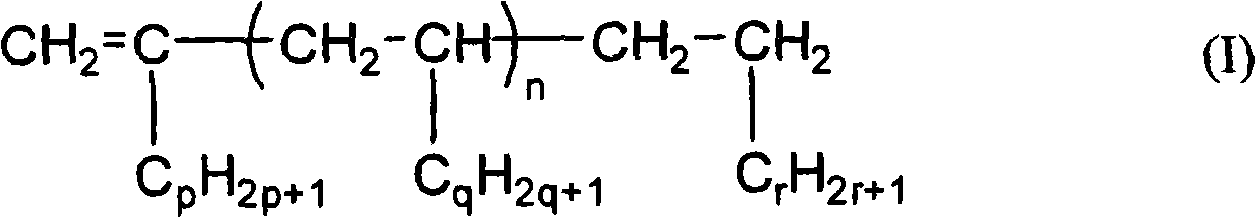

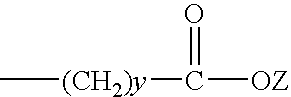

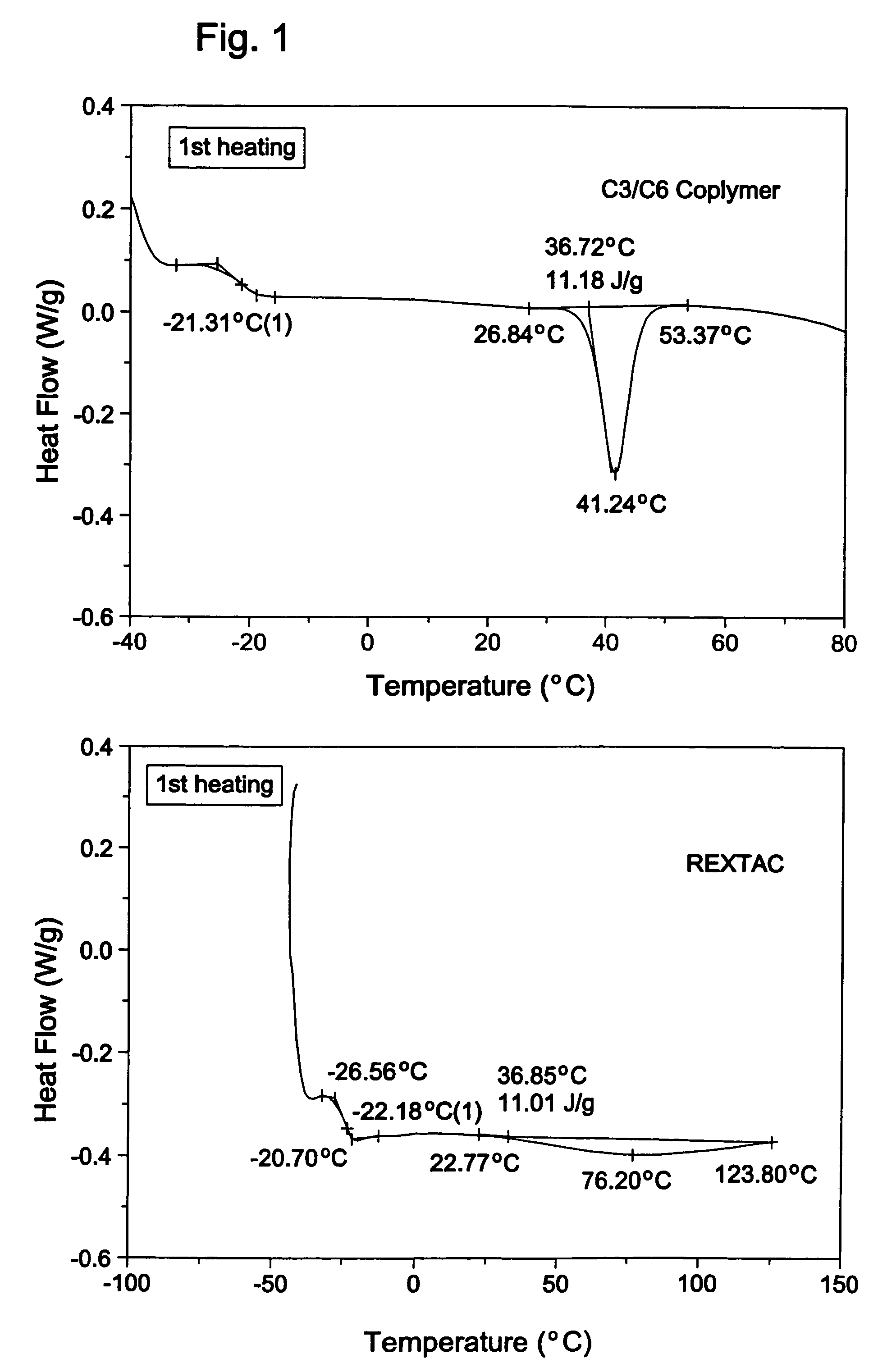

Adhesive alpha-olefin inter-polymers

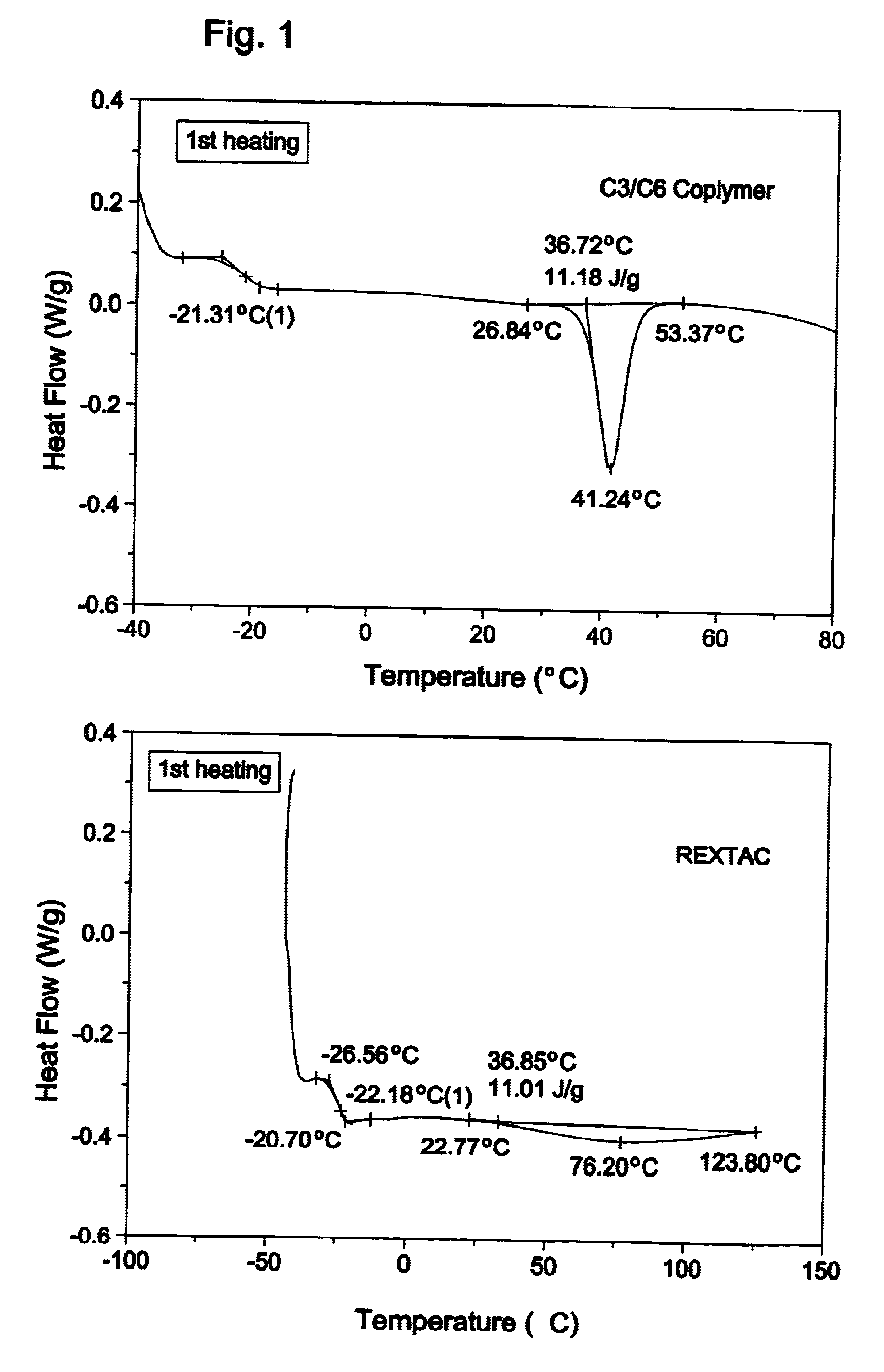

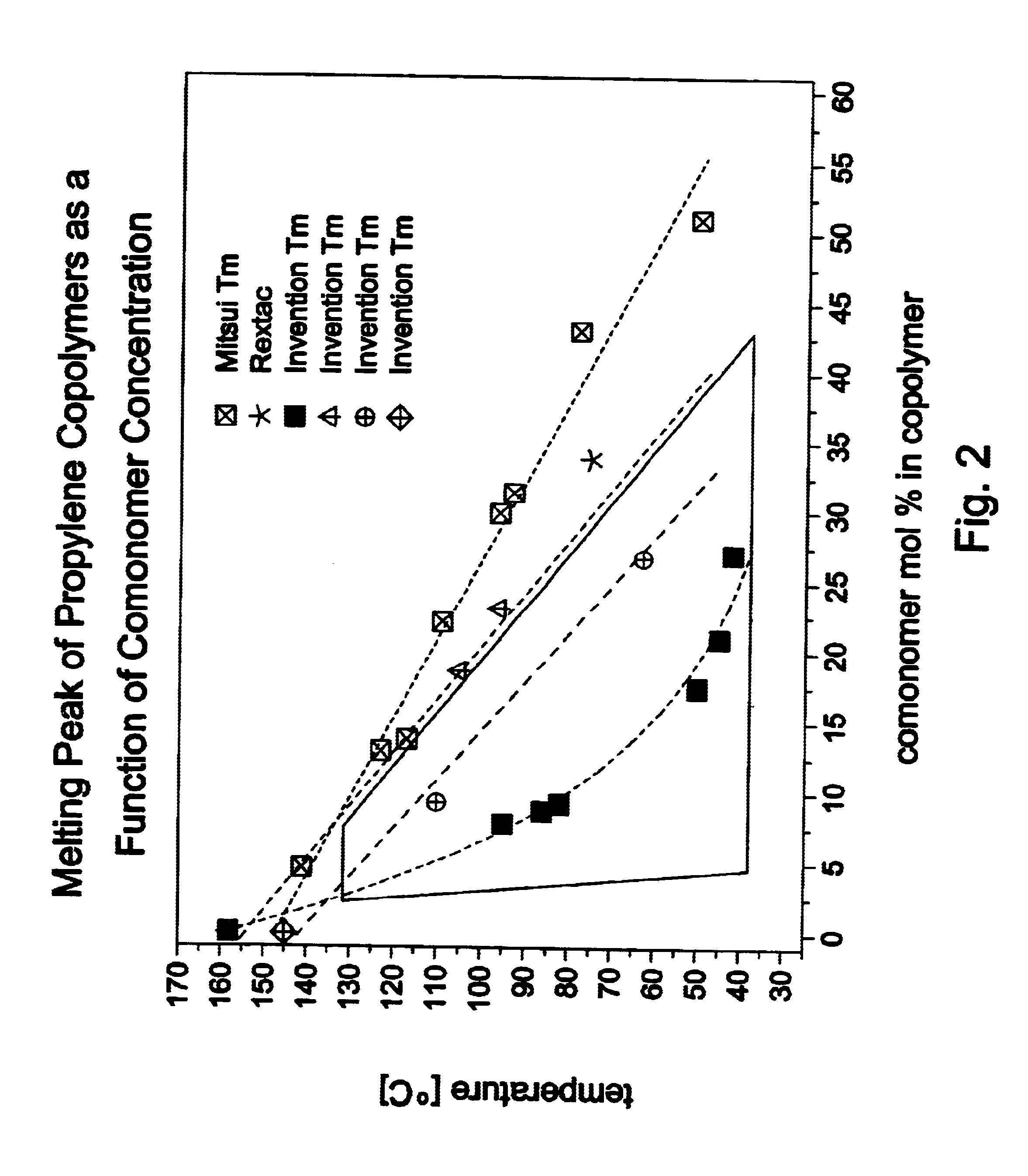

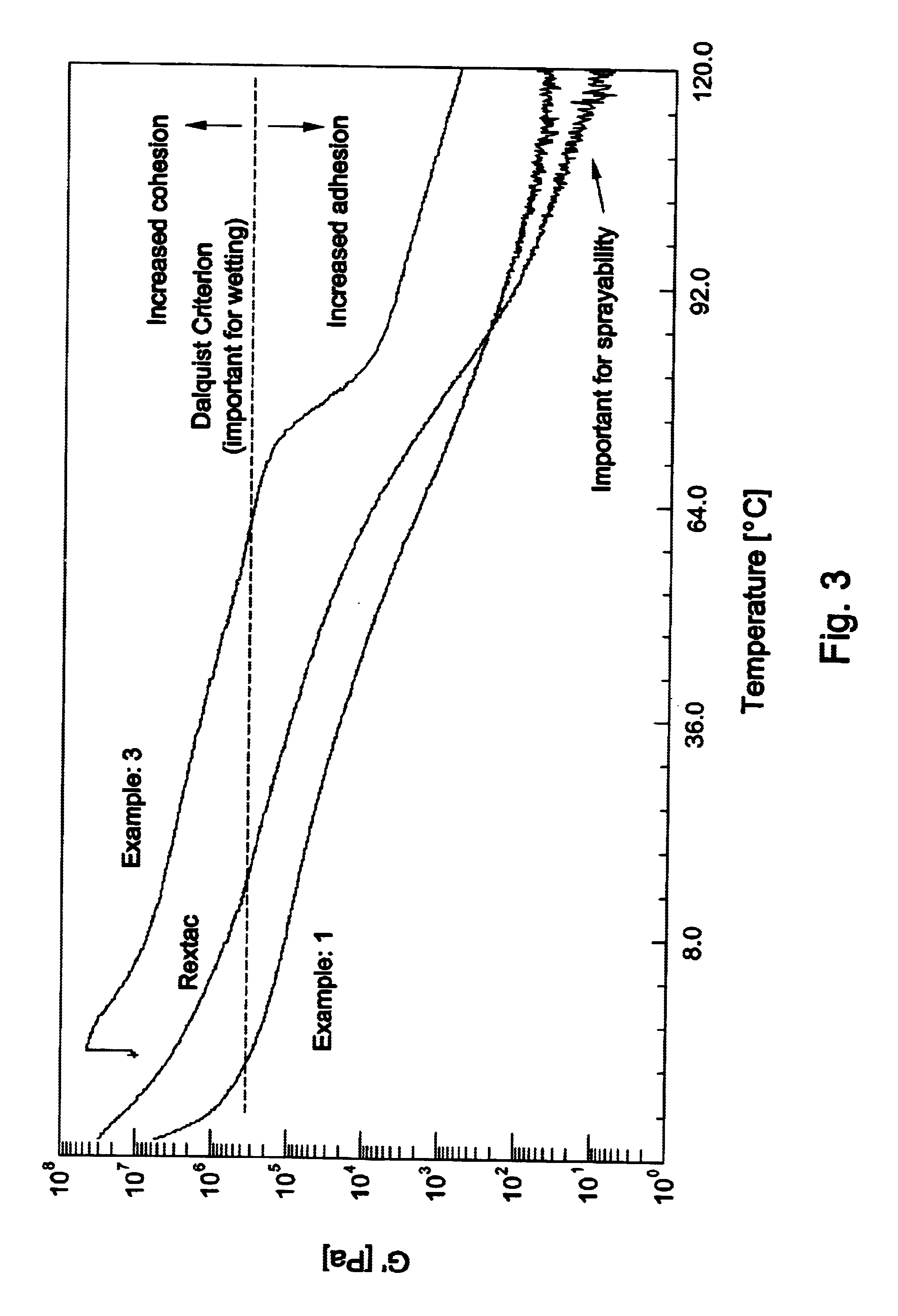

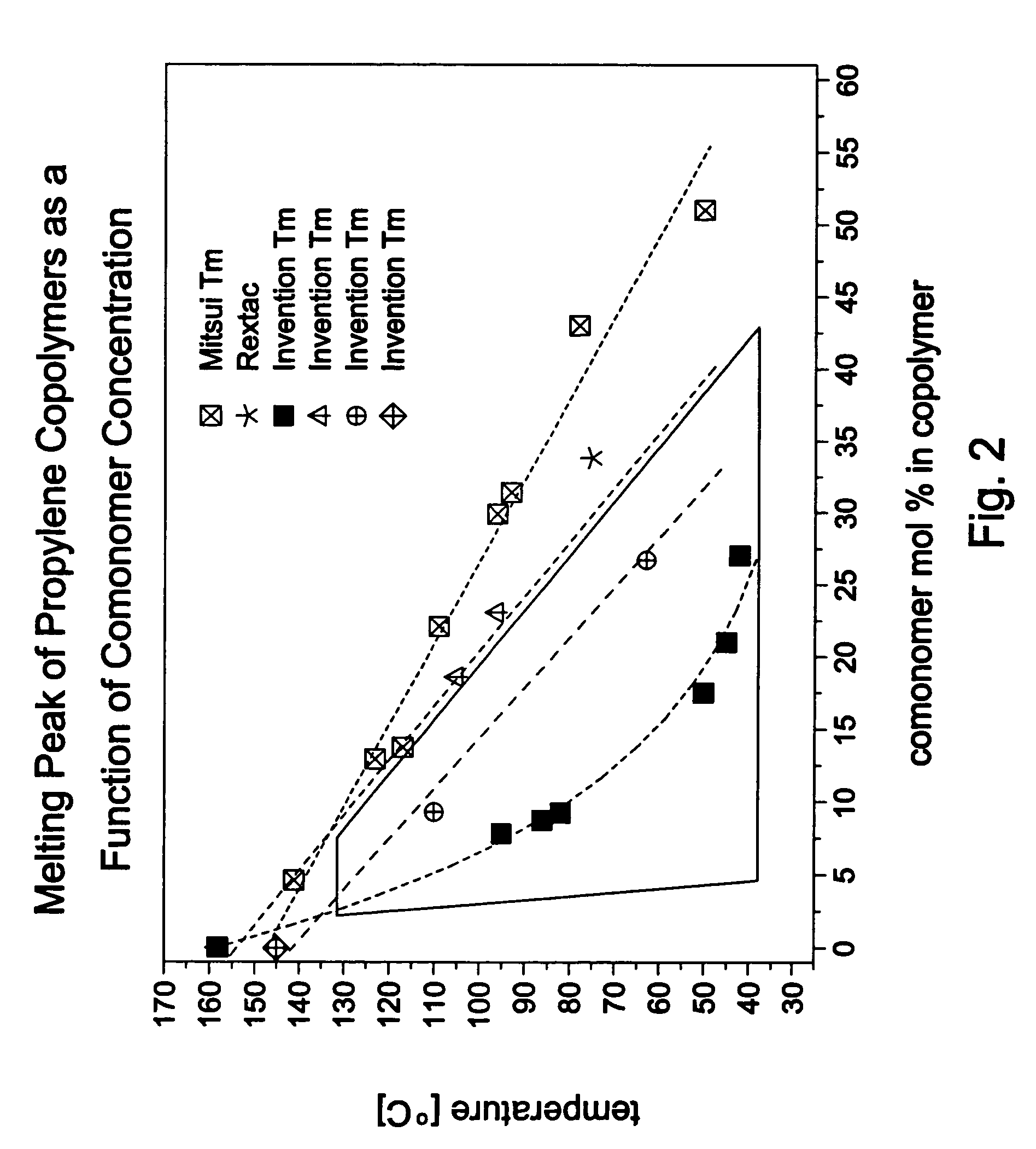

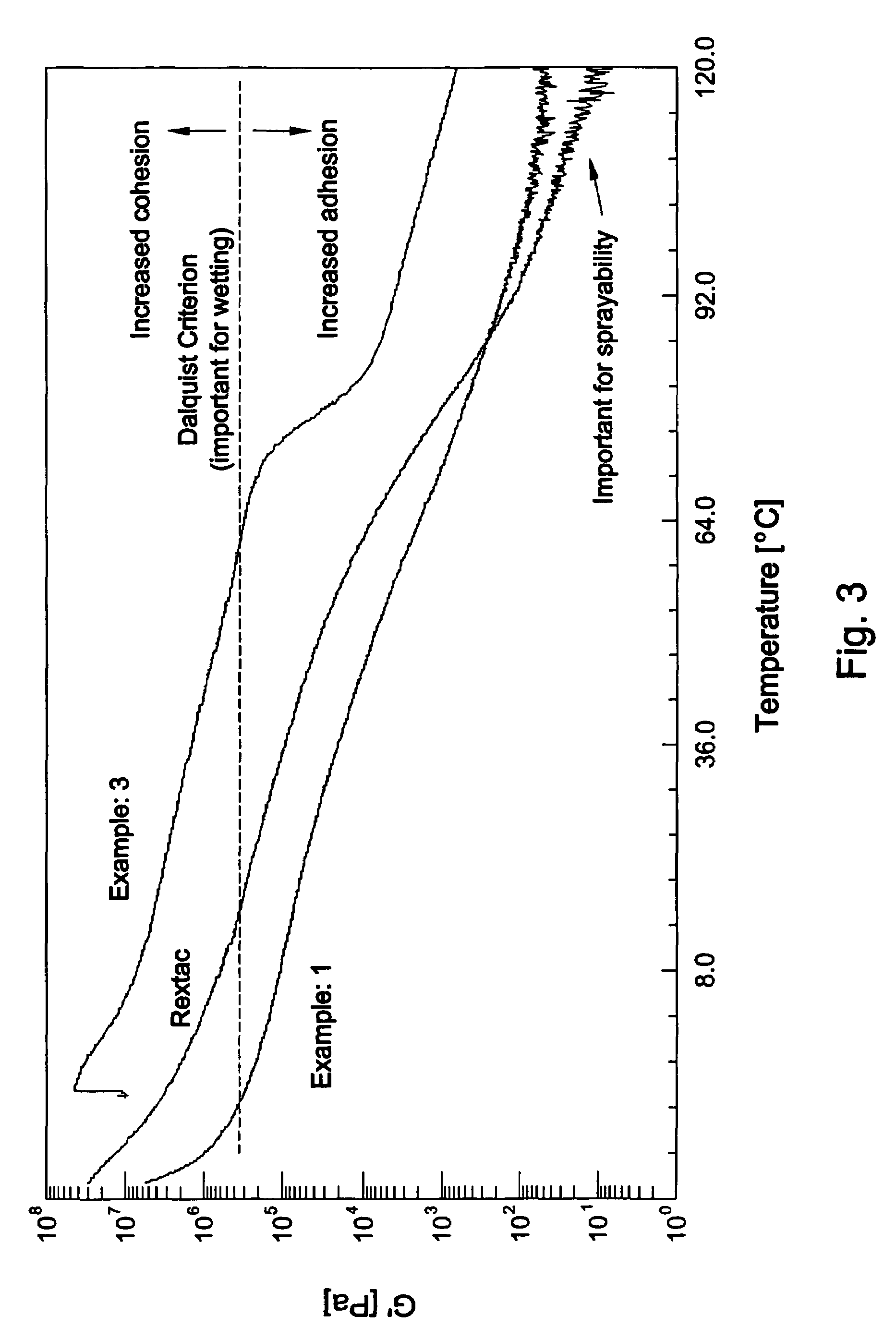

The invention relates to novel adhesive alpha-olefin inter-polymers which are largely amorphous and have a rheological behavior that makes them suitable for adhesive use, both without and with minimized amounts of tackifying resins. Specifically, the invention poly-alpha olefin inter-polymer may be composed of A) from 60 to 94 mol % of units derived from one alpha mono-olefin having from 3 to 6 carbon atoms and B) from 6 to 40 mol % of units derived from one or more other mono-olefins having from 4 to 10 carbon atoms and at least one carbon atom more than A); and C) optionally from 0 to 10 mol % of units derived from another copolymerizable unsaturated hydrocarbon, different from A) and B); the diad distribution of component A in the polymer as determined by <13>C NMR as described herein showing a ratio of experimentally determined diad distribution over the calculated Bernoullian diad distribution of less than 1.07; and the storage modulus G' of said polymer, determined upon cooling as described herein, intersecting a value of 3.10<5 >Pa at a temperature of less than 85° C. The invention also describes polymerization processes suitable for the manufacture of these adhesive alpha-olefin inter-polymers.

Owner:EXXONMOBIL CHEM PAT INC

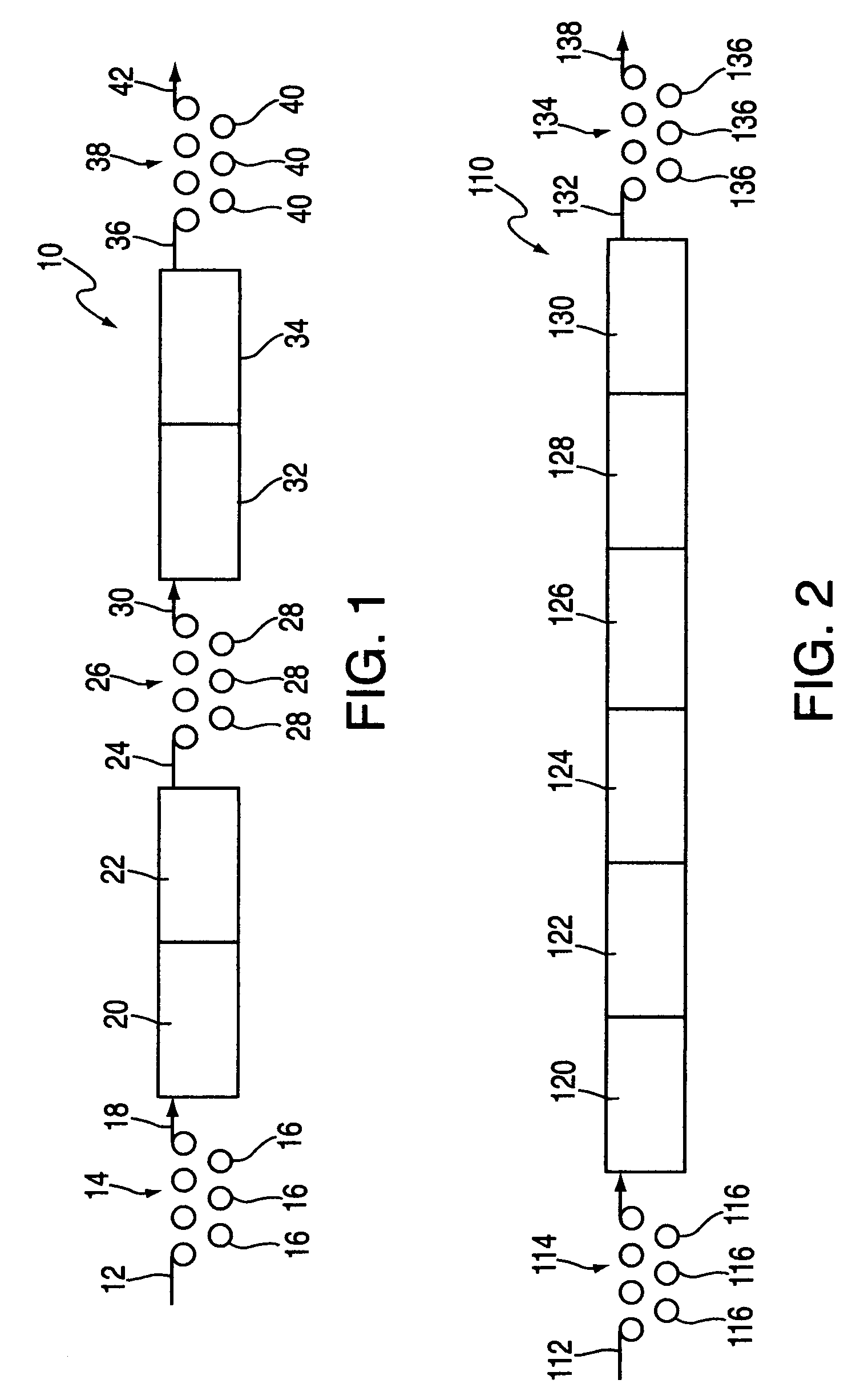

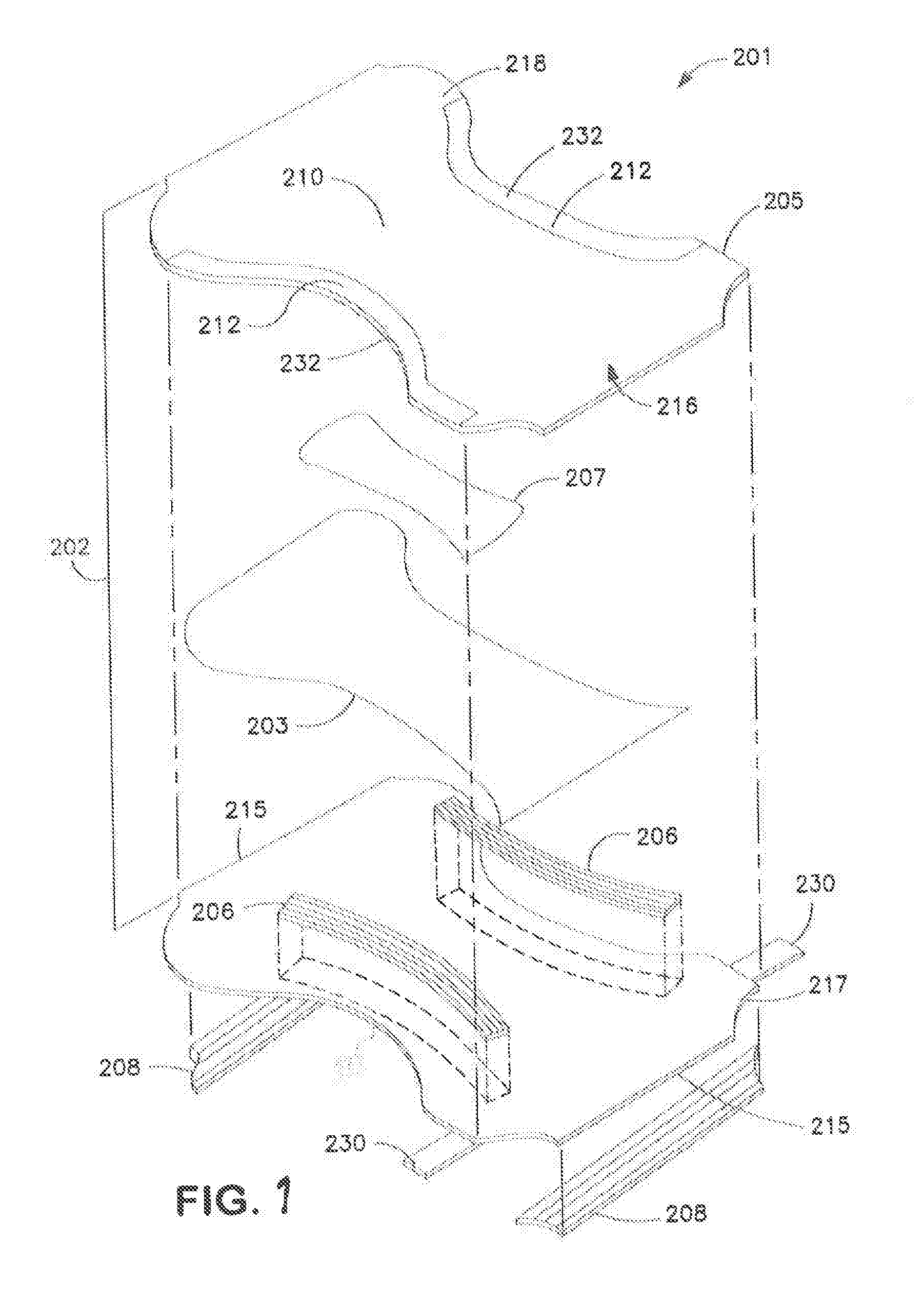

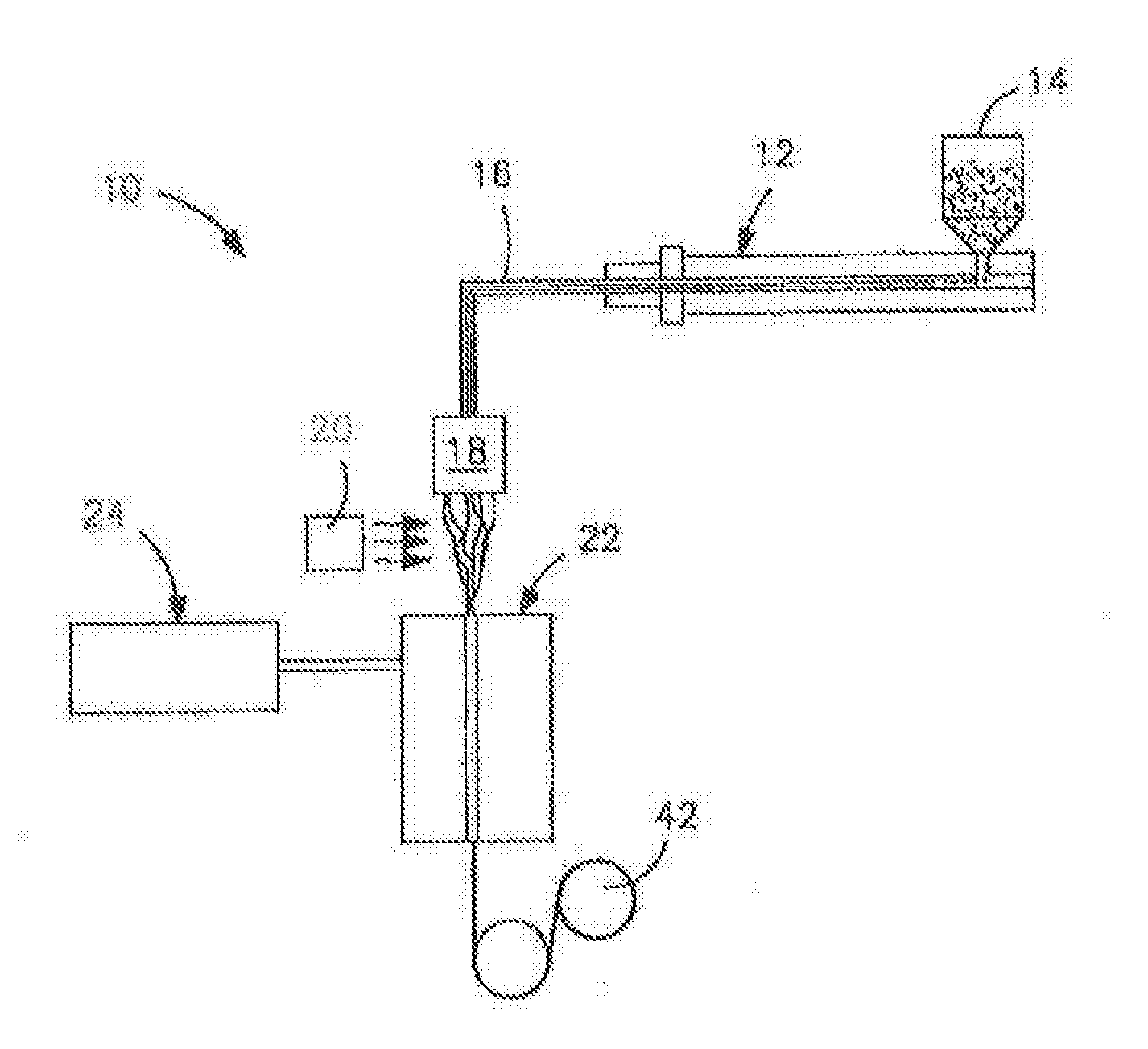

Heating apparatus and process for drawing polyolefin fibers

ActiveUS7370395B2Lower capital expenditureLower expensesDrying gas arrangementsDrying machines with progressive movementsFiberPolyolefin

Owner:HONEYWELL INT INC

Adhesive alpha-olefin inter-polymers

InactiveUS20020007033A1Minimize adverse interactionHigh activityWax adhesivesPolymer scienceUnsaturated hydrocarbon

The invention relates to novel adhesive alpha-olefin inter-polymers which are largely amorphous and have a Theological behavior that makes them suitable for adhesive use, both without and with minimzed amounts of tackifying resins. Specifically, the invention poly-alpha olefin inter-polymer may be composed of A) from 60 to 94 % of units derived from one alpha mono-olefin having from 3 to 6 carbon atoms and B) from 6 to 40 mol % of units derived from one or more other mono-olefins having from 4 to 10 carbon atoms and at least one carbon atom more than A); and C) optionally from 0 to 10 mol % of units derived from another copolymerizable unsaturated hydrocarbon, different from A) and B); the diad distribution of component A in the polymer as determined by 13C NMR as described herein showing a ratio of experimentally determined diad distribution over the calculated Bernoullian diad distribution of less than 1.07; and the storage modulus G' of said polymer, determined upon cooling as described herein, intersecting a value of 3.105 Pa at a temperature of less than 85 ° C. The invention also describes polymerization processes suitable for the manufacture of these adhesive alpha-olefin inter-polymers.

Owner:EXXONMOBIL CHEM PAT INC

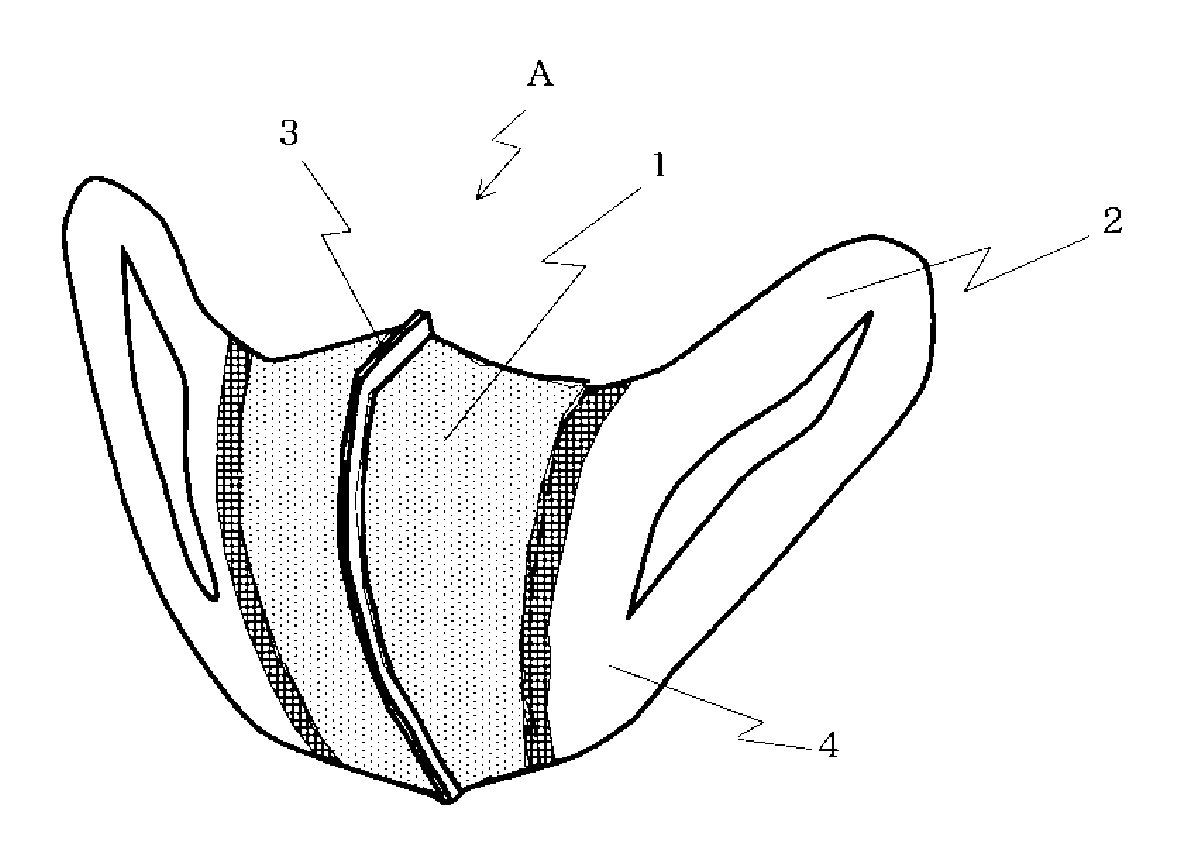

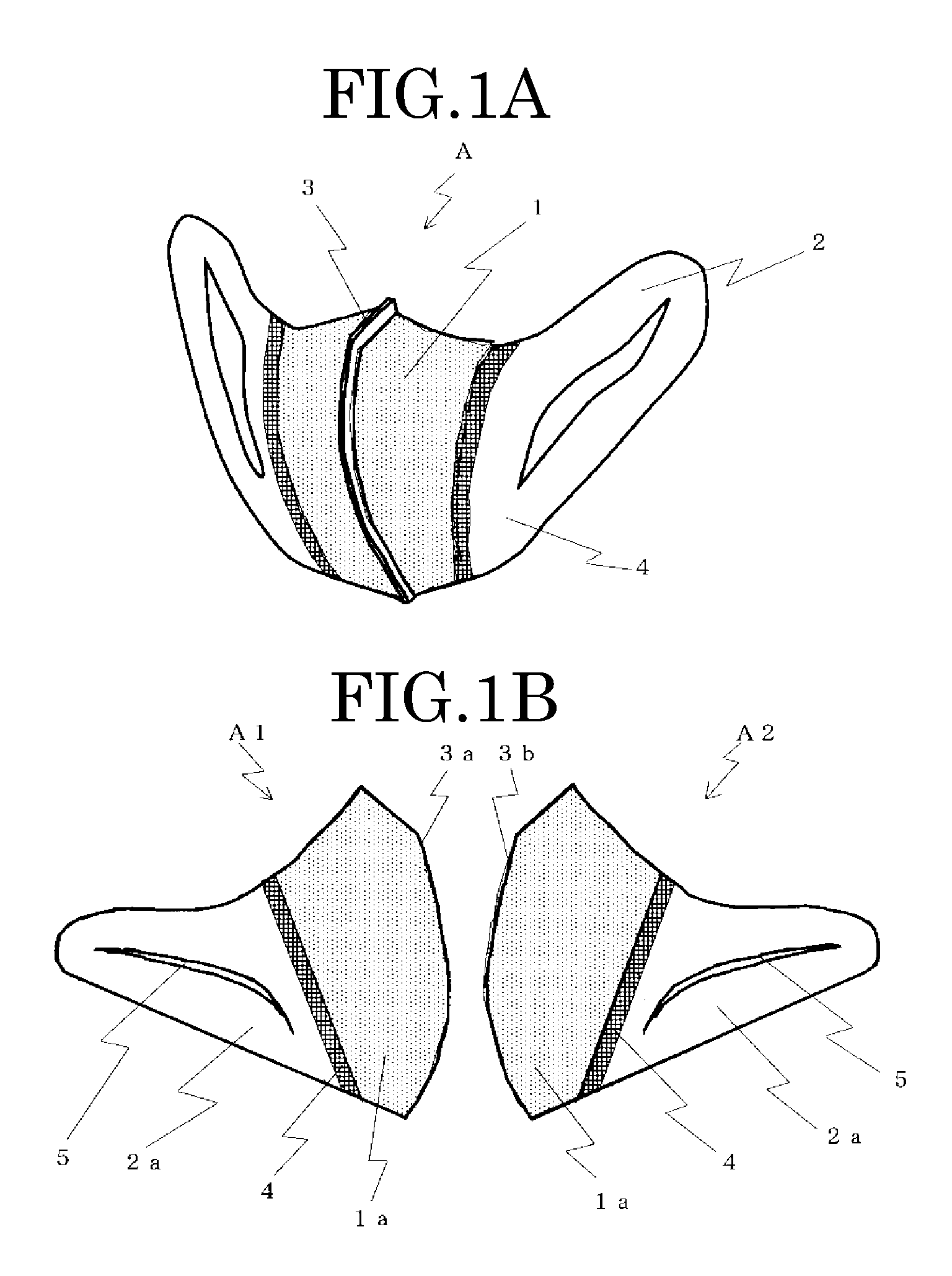

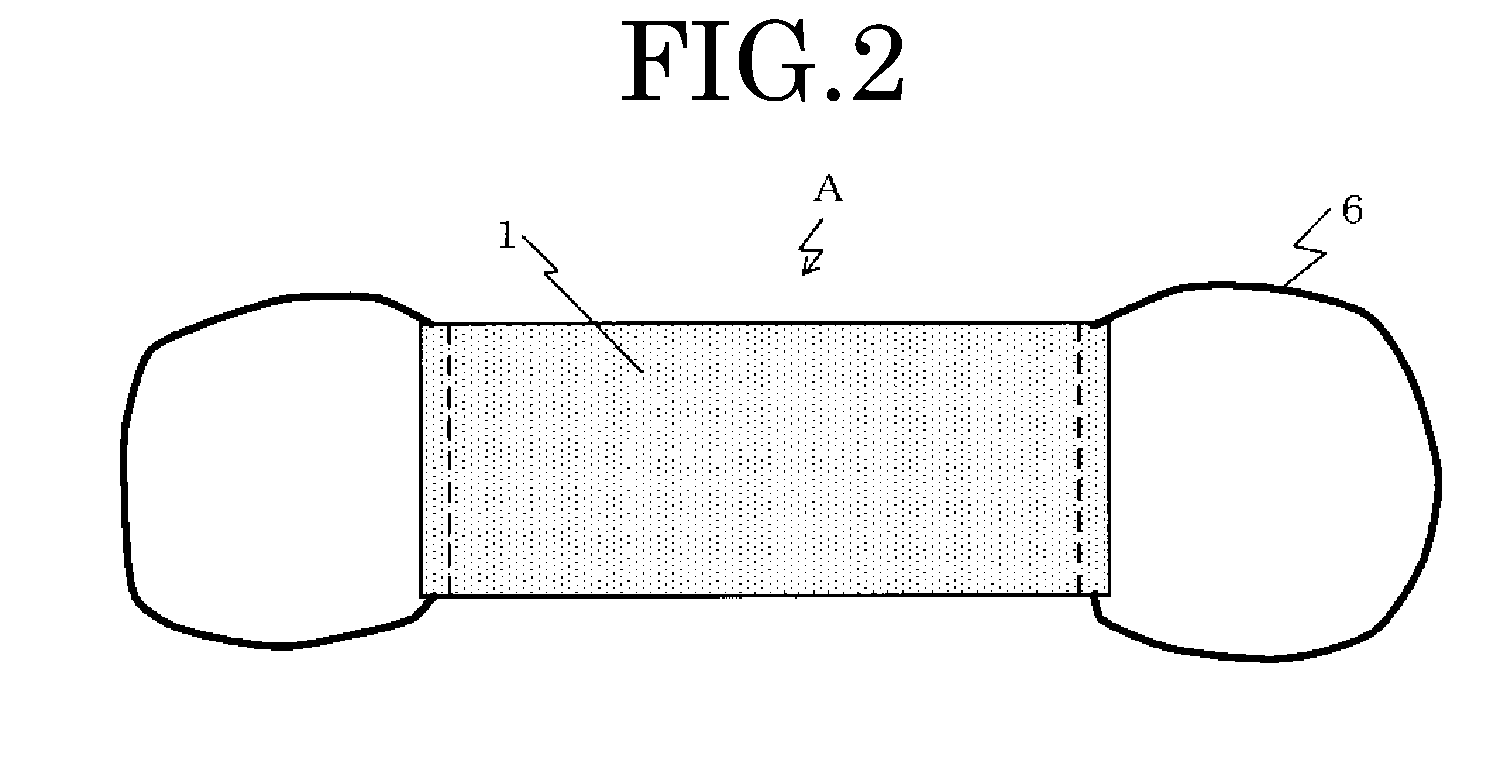

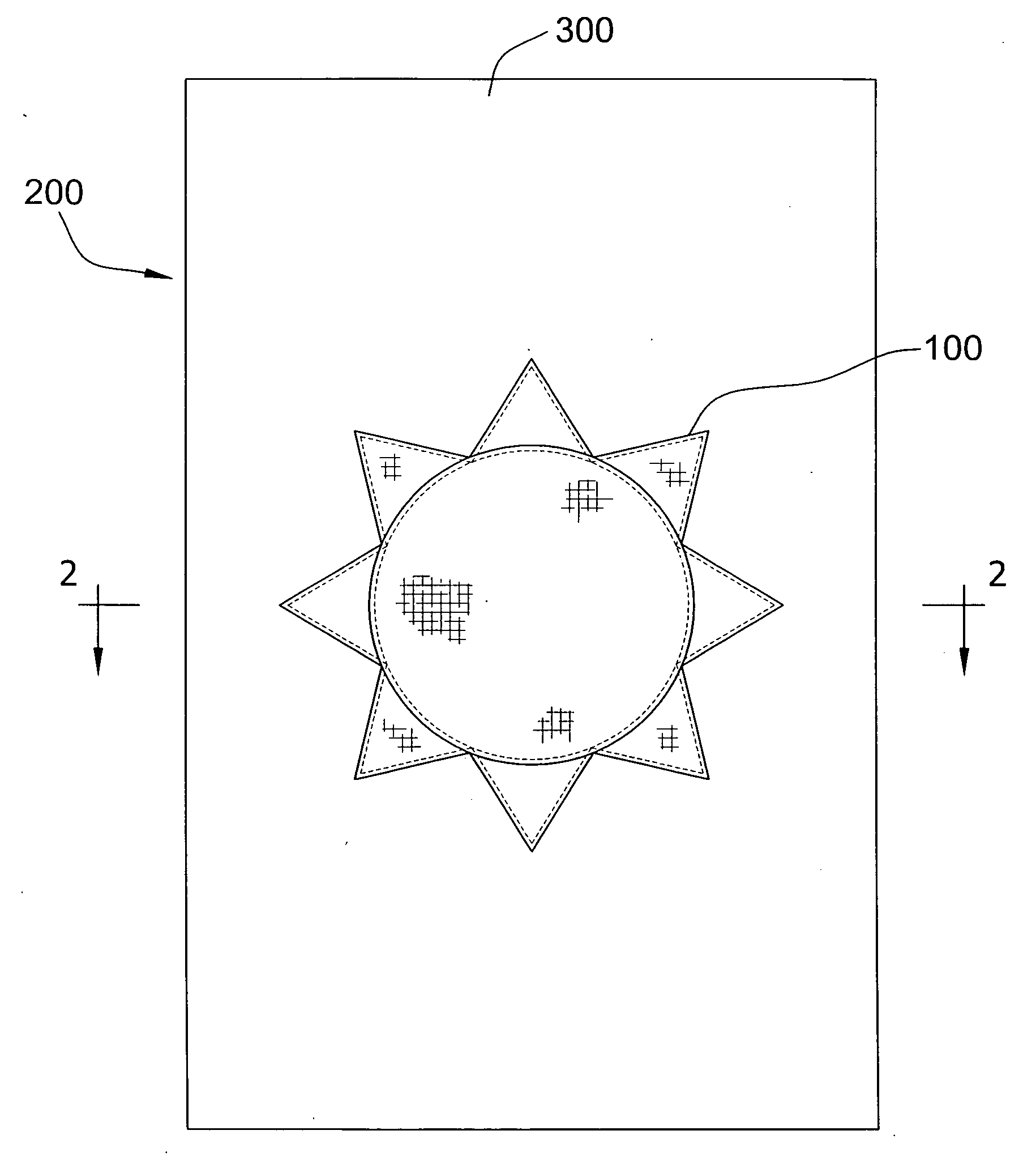

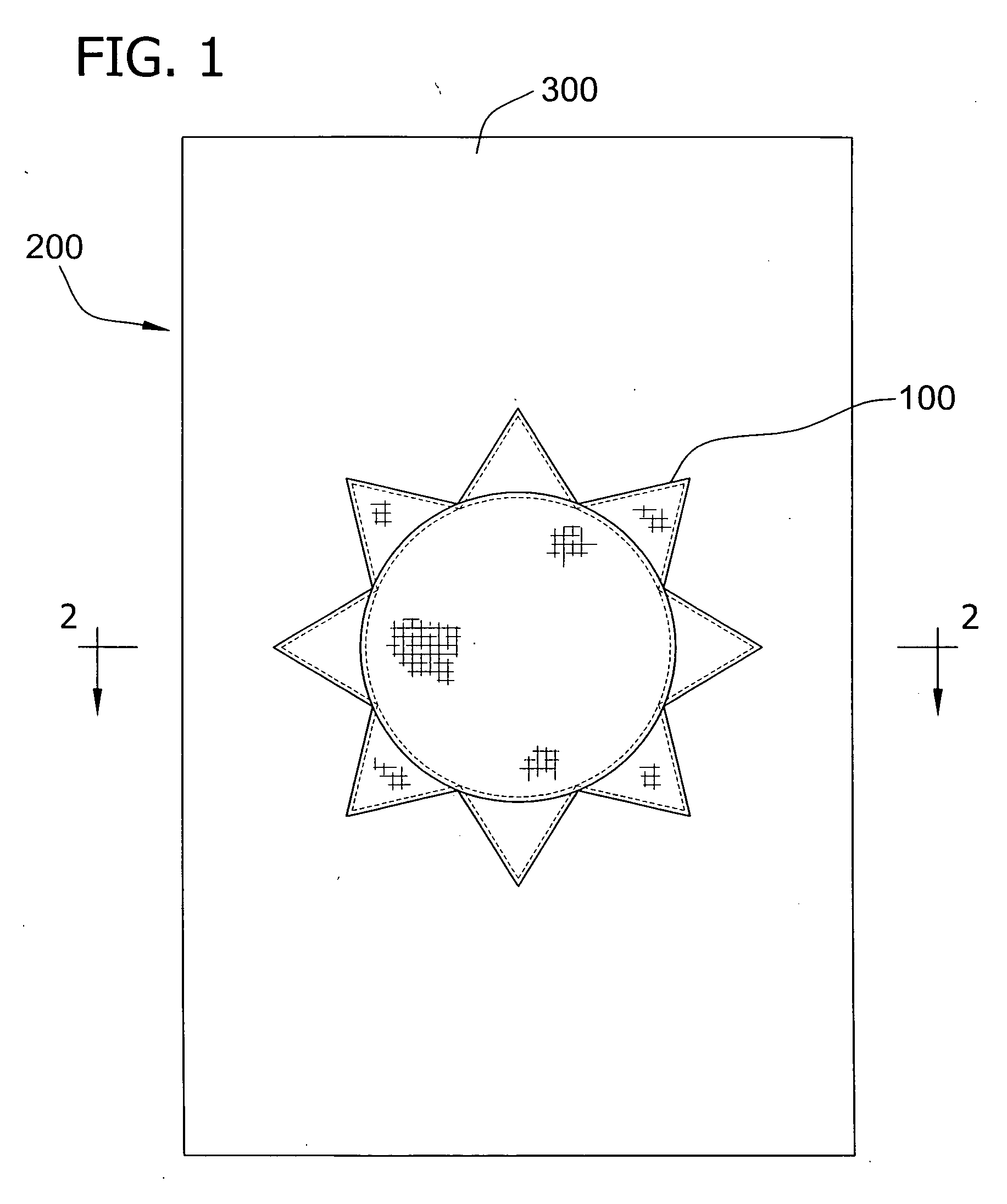

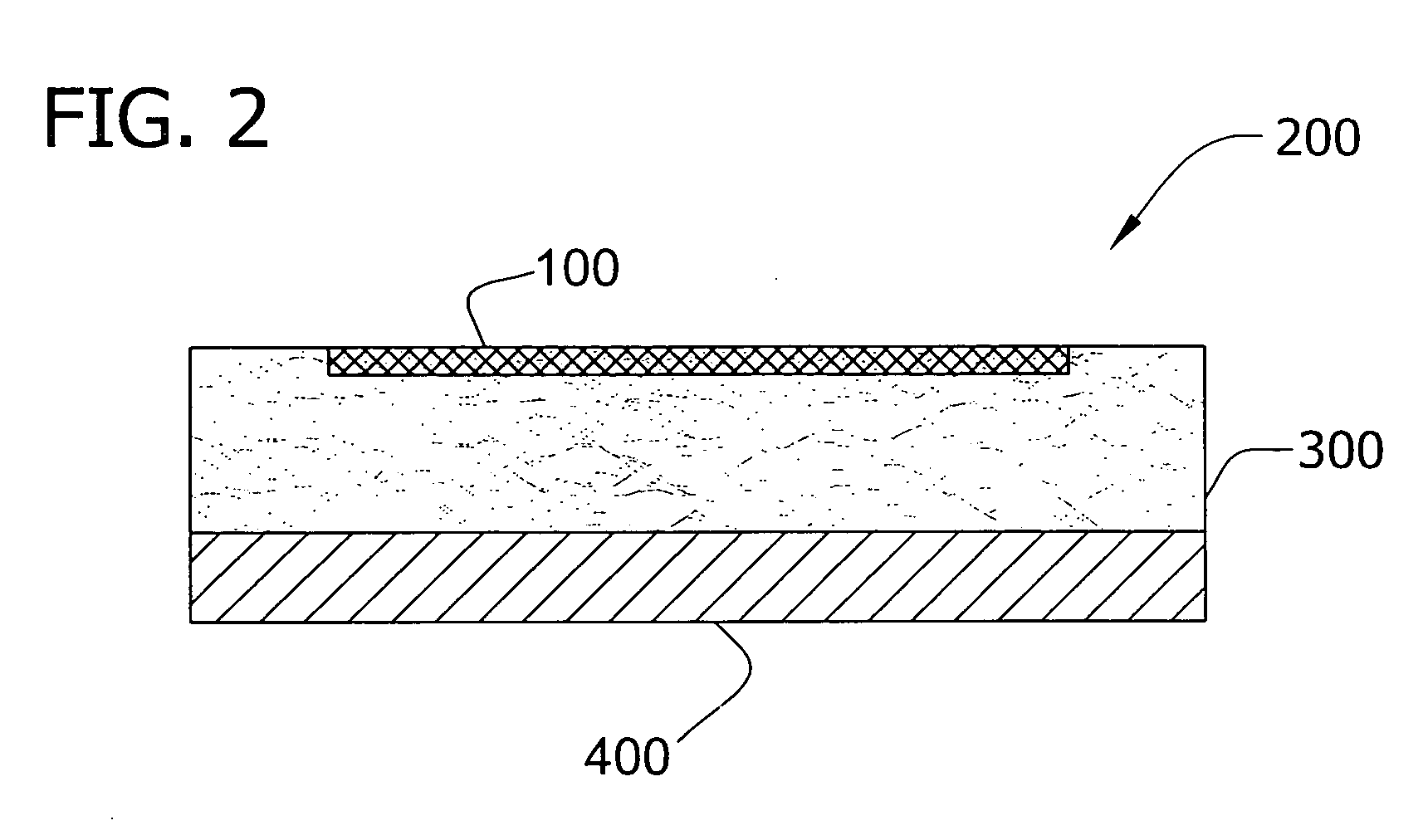

Mask filter and mask produced using the same

InactiveUS20100307503A1Improve antibacterial propertiesEfficient activationBreathing filtersProtective equipmentPolymer sciencePolyolefin

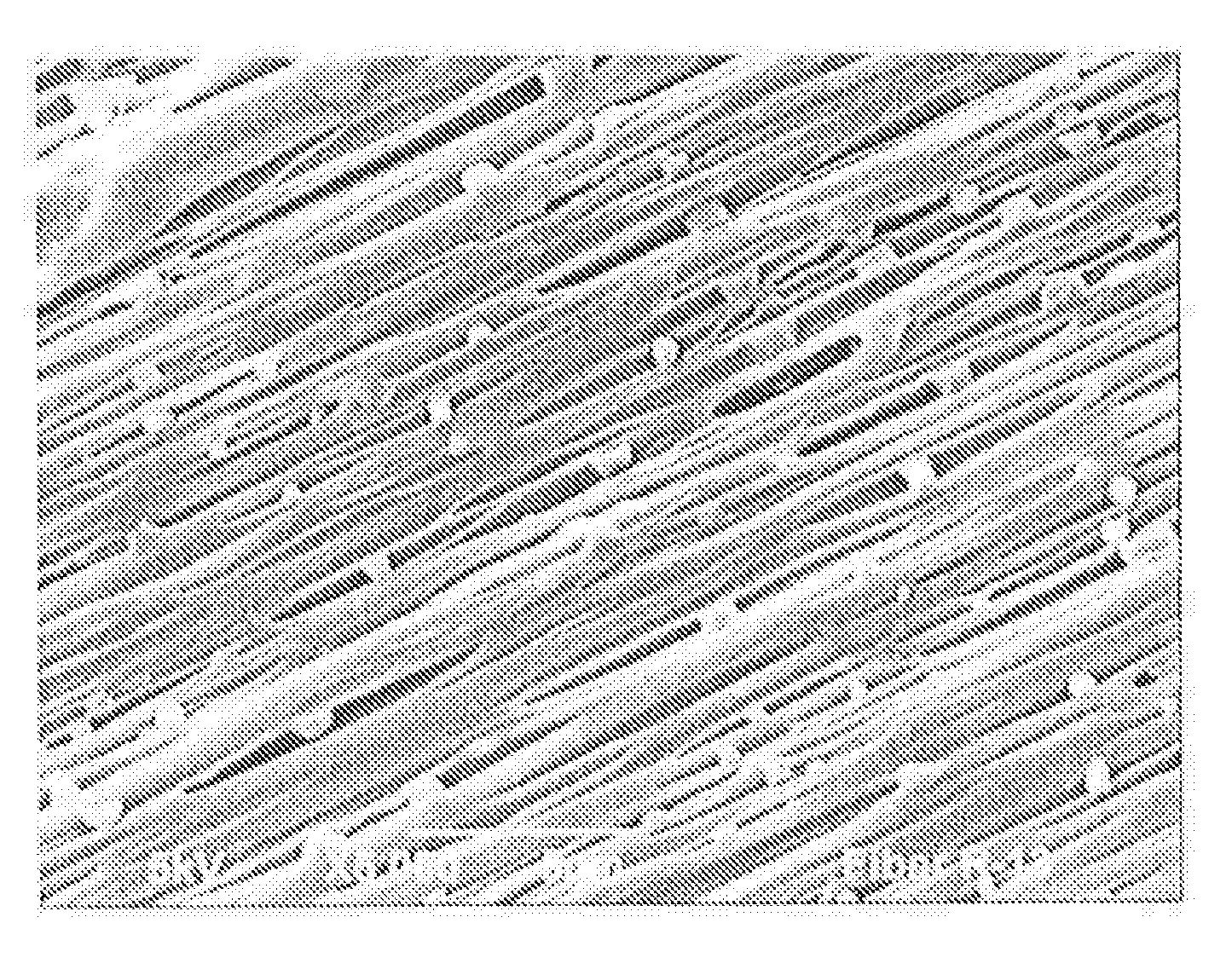

The present invention provides a mask filter exhibiting a high antimicrobial / antiviral activity, a high dust filtration ability, a high ventilation characteristic, a high failure-strength and a high workability into a mask and the mask produced using such mask filter. An antimicrobial polyolefin fiber sheet is provided wherein the polyolefin fiber sheet has one or more spots in which 1 / 100 or more by volume of individual inorganic antimicrobial agent particles are exposed on surfaces of polyolefin fibers per fiber sheet area of 1.0×10−2 mm2 or has one or more spots in which the inorganic antimicrobial agent particles are exposed on the surfaces of polyolefin fibers each occupying an area of 0.01 μm2 or larger per fiber sheet area of 1.0×10−2 mm2. Such polyolefin fiber sheet is arranged as the core layer and this core layer is sandwiched between upper and lower layers of dry nonwoven fabric to form the mask filter in the form of a laminated sheet. Such mask filter is used to form the mask.

Owner:UNI CHARM CORP

High performance ballistic composites having improved flexibility and method of making the same

ActiveUS20080064280A1Increase flexibilityComfortable to wearArmourSynthetic resin layered productsFiberPolyolefin

A composite material which has excellent ballistic performance and has improved flexibility. Surprisingly, it has been found that a combination of poly(alpha-olefin) fiber and matrix resin provides these desirable product features. The resin matrix is a block copolymer of a conjugated diene and a vinyl aromatic monomer, preferably a styrene-isoprene-styrene block copolymer, that is applied as an aqueous composition. The fiber has a tenacity of at least about 35 g / d and a tensile modulus of at least about 1200 g / d. The composite has a total density equal to or less than about 100 g / m2 and a stiffness of less than about 2.5 pounds (1.14 kg) for a two layer structure of the composite, and a total areal density equal to or less than about 190 g / m2 and a stiffness of less than about 3.0 pounds (1.36 kg) for a four layer structure of the composite. The Peel Strength for a two layer structure of less than about 1.0 pounds (0.45 kg) for a two layer structure of the composite, and less than about 0.7 pounds (0.32 kg) for a four layer structure of the composite. The process of this invention permits fabrication of these desirable products in a cost-effective manner. Body armor made from the composite has improved flexibility and excellent ballistic characteristics.

Owner:HONEYWELL INT INC

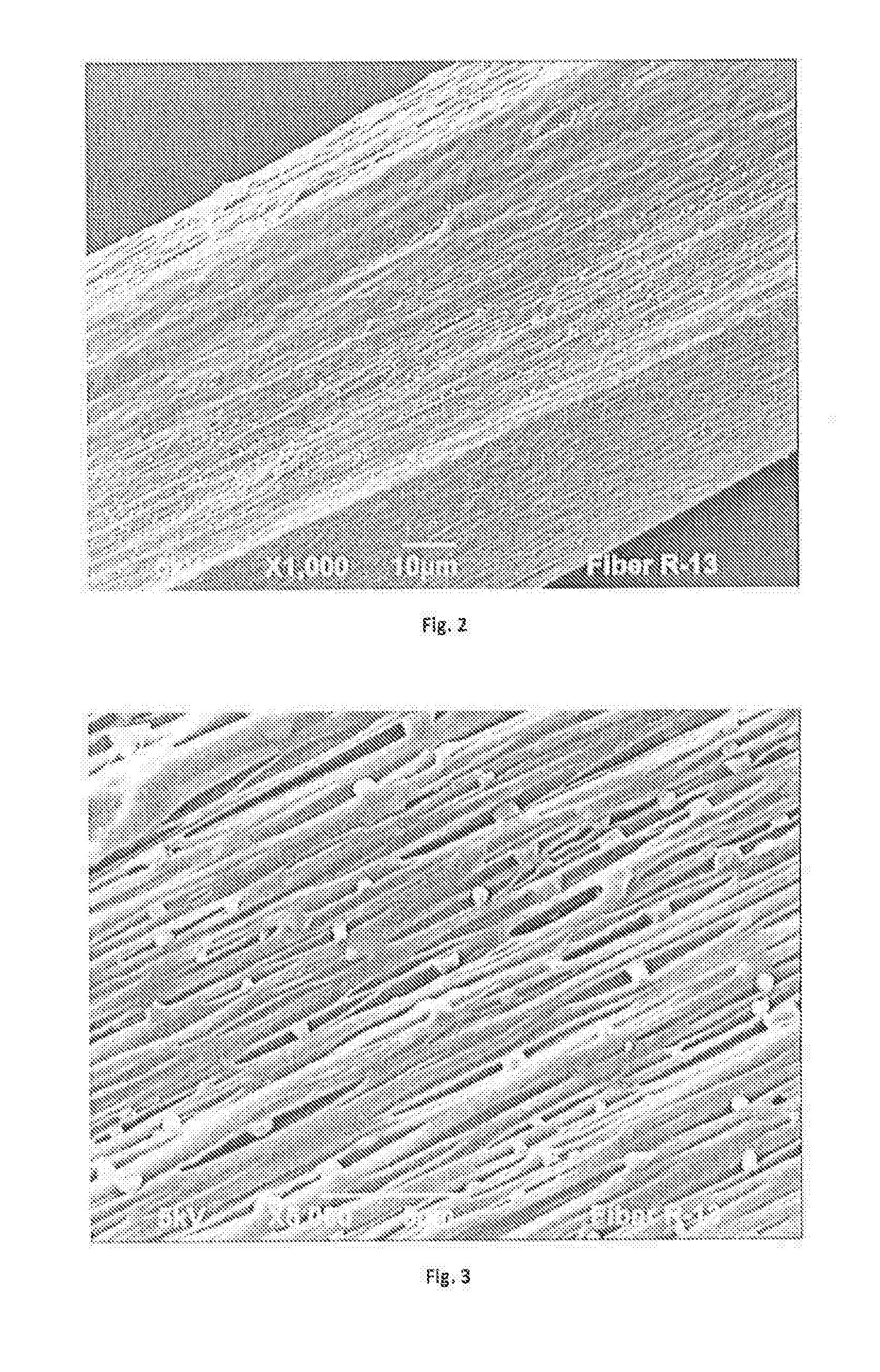

Absorbent Article Containing a Nonwoven Web Formed from a Porous Polyolefin Fibers

An absorbent article containing a nonwoven web that includes a plurality of polyolefin fibers is provided. The polyolefin fibers are formed by a thermoplastic composition containing a continuous phase that includes a polyolefin matrix polymer and nanoinclusion additive is provided. The nanoinclusion additive is dispersed within the continuous phase as discrete nano-scale phase domains. When drawn, the nano-scale phase domains are able to interact with the matrix in a unique manner to create a network of nanopores.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Helmets for protection against rifle bullets

ActiveUS20100275337A1Increase resistancePrevent penetrationPersonal protection gearAdhesivesPolyolefinResin matrix

A helmet shell is formed having an outer section of fibrous layers, a middle section of fibrous layers and an inner section of fibrous layers. The outer section layers contain high tenacity abrasive fibers in a resin matrix. The middle section layers contain high strength polyolefin fibers and are in the form of woven or knitted fabrics with a resin matrix. The inner section layers contain high strength polyolefin fibers and are in the form of non-woven fabrics with a resin matrix. The helmet is lightweight and resists penetration of rifle bullets.

Owner:HONEYWELL INT INC

Process for making a non-woven substrate with vibrant graphic thereon

ActiveUS20060092431A1Digitally marking record carriersSynthetic resin layered productsPolyolefinEngineering

A non-woven substrate having a vibrant graphic applied thereto is made by feeding to a printing apparatus a non-woven substrate having a fibrous non-woven web formed at least in part of polyolefin fibers. An ink composition having a viscosity in the range of about 28 seconds to about 35 seconds as determined using a Zahn #2 cup and including at least one solvent having an evaporation rate relative to n-butyl acetate of less than 0.8 is supplied to the printing apparatus. The printing apparatus is operated to apply the ink composition to the fibrous non-woven web while the fibrous non-woven web is in a generally dry condition to form a graphic thereon having a thickness of less than or equal to about 5 microns. The ink composition is then allowed to dry on the fibrous non-woven web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Manufacturing method for polyolefin fiber for adsorbing organic liquid

InactiveCN102383215ALarge adsorption capacityImprove mechanical propertiesOther chemical processesMelt spinning methodsPolyolefinPolymer science

The invention discloses a manufacturing method for a polyolefin fiber for adsorbing an organic liquid, which comprises the following steps: 1) adding 500-2000ml polymeric monomers, initiating agents accounting for 0.5-0.8% of the total mass of the polymeric monomers, 1500-6000ml deionized water and dispersing agents accounting for 0.5-1% of the total mass of the deionized water into a polymeric kettle, fully stirring till forming a homogeneous phase solution, and then introducing nitrogen, heating up to 80-85 DEG C and reacting for 2-5 hours, and then heating up to 90-95 DEG C and continuing reacting for 1-2 hours, thereby obtaining a reaction product; washing, drying and crushing the reaction product, thereby obtaining a white powdered copolymer; 2) drying the obtained copolymer, mixing the copolymer with polyolefin granular materials according to the mass fraction of (10-50):(90-50), and then extruding from a double-screw machine and pelletizing, wherein the polyolefin granular materials are fibrous polypropylene or polyethylene granular materials with a spinning temperature of 140-250 DEG C; and 3) melting and spinning the granular materials by using the double-screw machine, thereby obtaining the polyolefin fiber.

Owner:TIANJIN POLYTECHNIC UNIV +1

Lubricant composition for internal combustion engine

InactiveUS8637438B2Improve low temperature fluidityImprove Oxidation StabilityHydrocarbon distillationHydrocarbon purification/separationOligomerCombustion

Owner:IDEMITSU KOSAN CO LTD

Lofted lightly needlepunched flame-retardant nonwovens

The present invention concerns a flame retardant (FR) lofted lightly needlepunch nonwoven fabric useful in household goods and particularly for mattresses. The nonwoven fabric comprises at least one of FR rayon fiber, FR acrylic fiber, FR melamine fiber, FR polyester fiber, FR polyolefin fiber, or FR resin coated fiber and nonbonding, nonFR synthetic and / or natural fiber mechanically bound together by a needlepunch process. The present invention also contemplates a mattress constructed from the FR lofted lightly needlepunch nonwoven fabric comprising FR rayon fiber, FR acrylic fiber, FR melamine fiber, FR polyester fiber, FR polyolefin fiber, or FR resin coated fiber. The mattress from this construction passes the California Test Bulletin 603 stringent conditions for mattresses used in residential places. Preferably the nonwoven fabric has a batt weight of at least 2.25 oz. / sq.yd. and preferably between 2.25 oz. / sq.yd. and 20 oz. / sq.yd.

Owner:SYLVAN CHEM CO

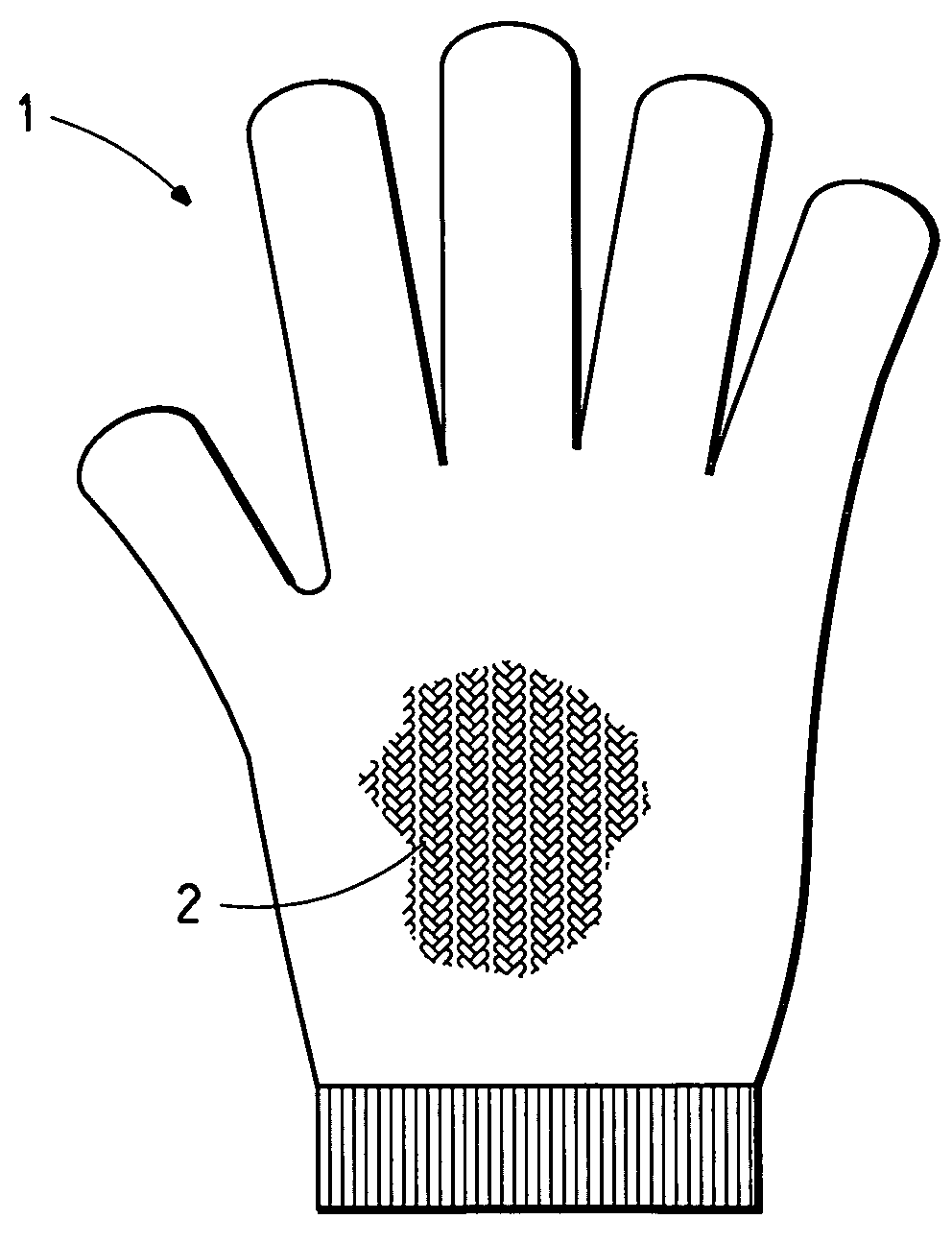

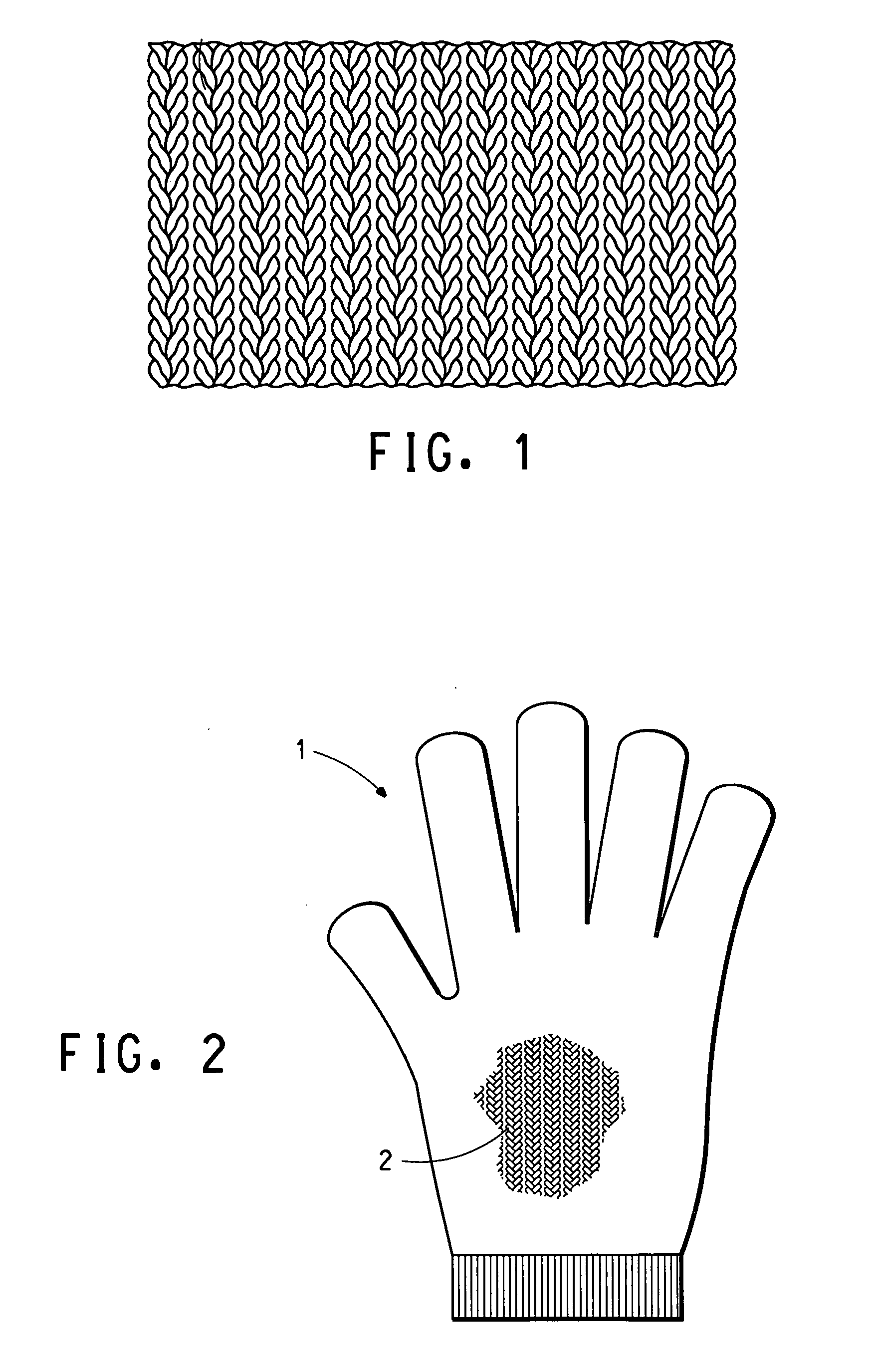

Stain masking cut resistant gloves and processes for making same

ActiveUS20080083047A1Reduce resistanceIncrease flexibilityProtective fabricsGlovesChemistryPolyolefin

This invention also relates to stain-masking cut resistant gloves and methods for making the same, the gloves comprising at least one aramid fiber and at least one lubricating fiber selected from the group consisting of aliphatic polyamide fiber, polyolefin fiber, polyethylene fiber, acrylic fiber, and mixtures thereof; wherein up to and including 15 parts by weight of the total amount of fibers in the glove are provided with a dye or pigment such that they have a color different from the remaining fibers; the dye or pigment selected such that the colored fibers have a measured “L” value that is lower than the measured “L” value for the remaining fibers.

Owner:DUPONT SAFETY & CONSTR INC

Helmets for protection against rifle bullets

ActiveUS8853105B2Increase resistancePrevent penetrationPersonal protection gearAdhesivesFiberPolyolefin

A helmet shell is formed having an outer section of fibrous layers, a middle section of fibrous layers and an inner section of fibrous layers. The outer section layers contain high tenacity abrasive fibers in a resin matrix. The middle section layers contain high strength polyolefin fibers and are in the form of woven or knitted fabrics with a resin matrix. The inner section layers contain high strength polyolefin fibers and are in the form of non-woven fabrics with a resin matrix. The helmet is lightweight and resists penetration of rifle bullets.

Owner:HONEYWELL INT INC

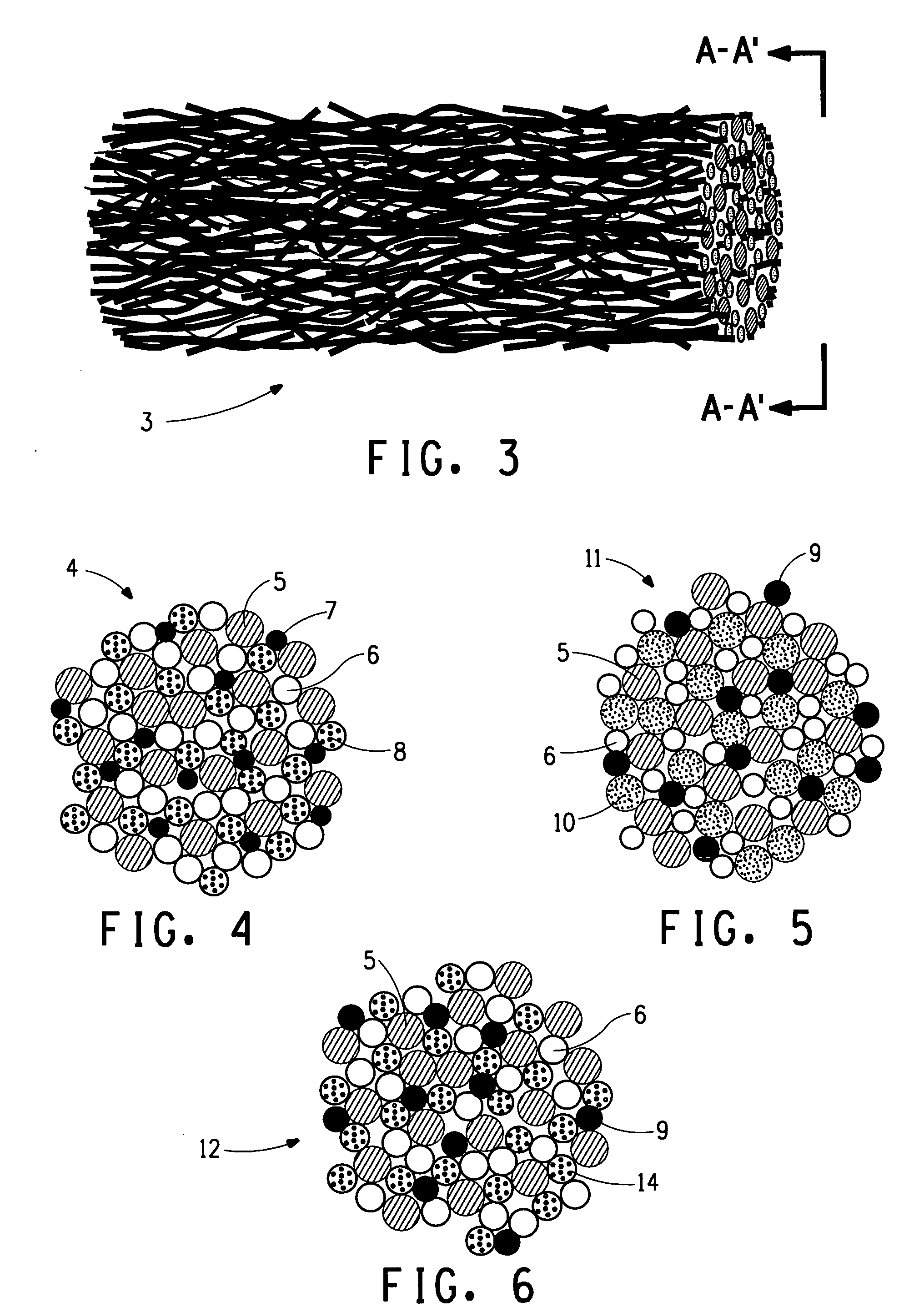

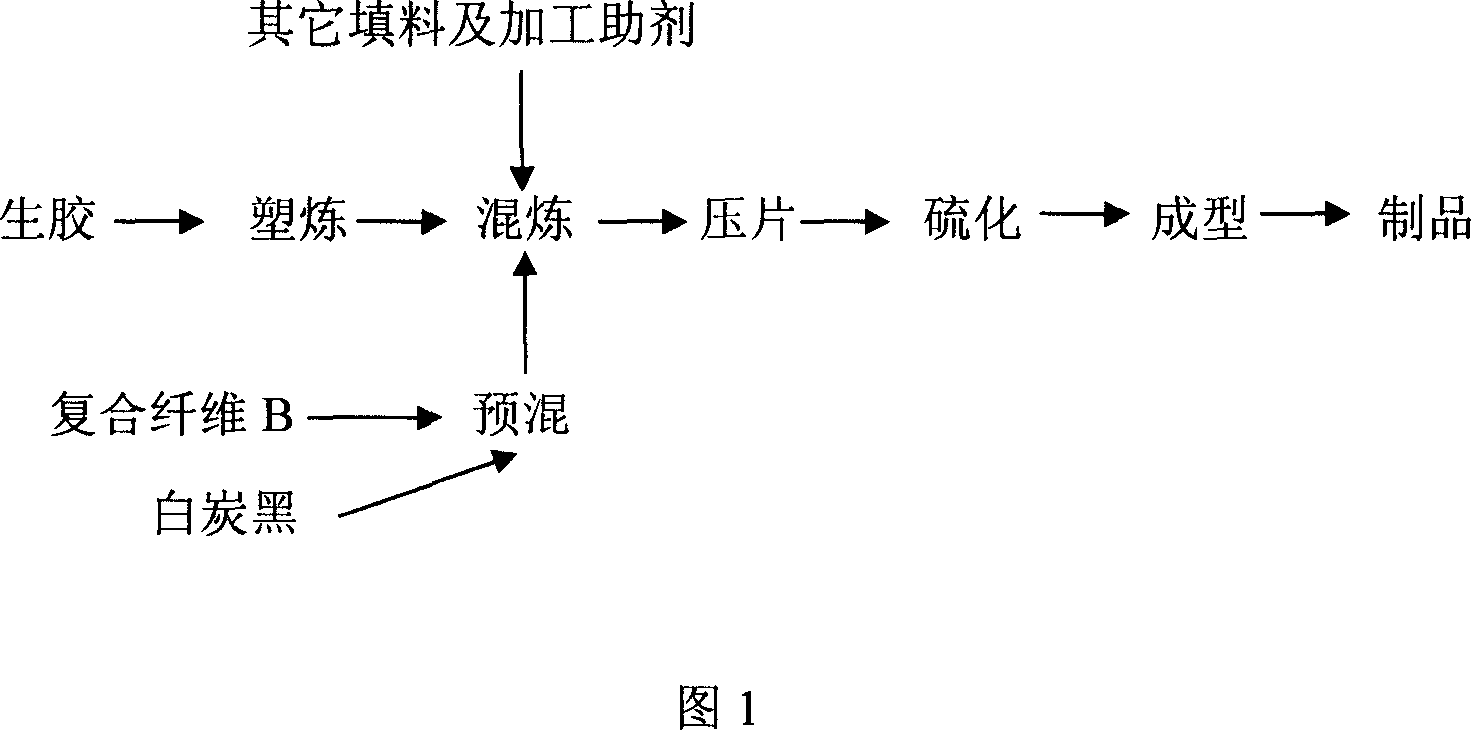

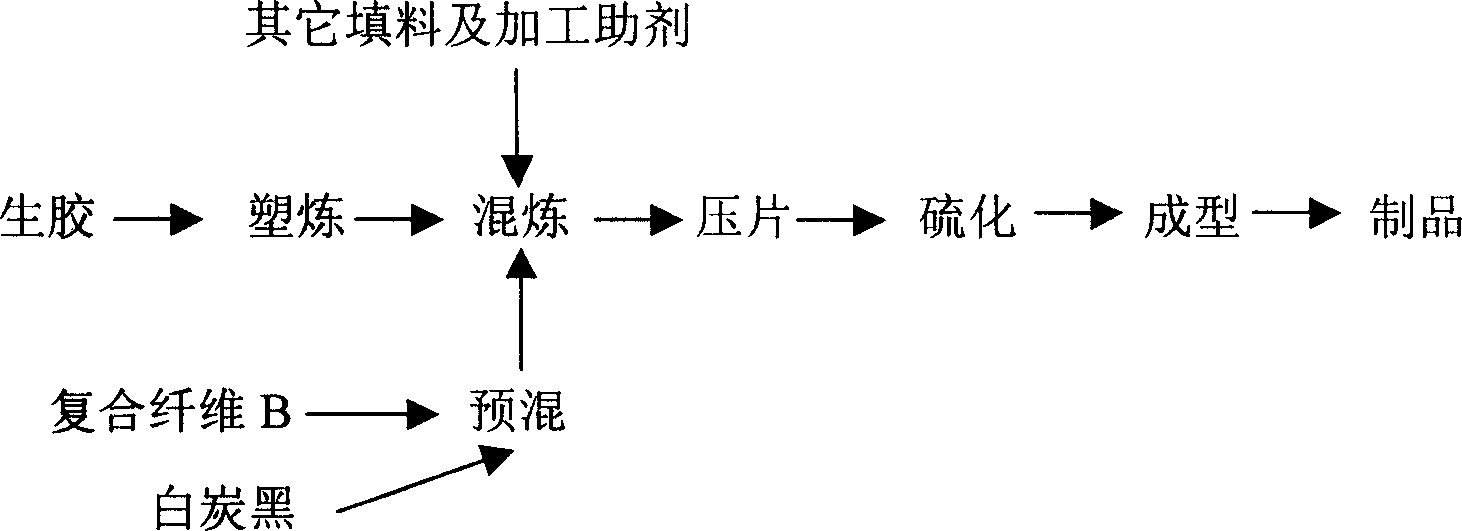

Composite fibre for substituting asbestos

The present invention discloses a composite fiber which can replace asbestos. It includes enhanced short fiber and adjuvant producing pulp fiber, among the both, the pulp fiber covers the face of short fiber uniformly. Said enhanced short fiber contains at least one of the following fibers: polyacrylonitrile fiber, polyvinyl alcohol fibers, aromatic amide fiber, polyamide fiber, polyolefin fiber, glass fiber and so on; said pulp fiber contains at least one of the following pulps: polyacrylonitrile pulp, aromatic amide pulp, polyester pulp, cellulose pulp and so on. The composite fiber can replace asbestos in composite materials of friction materials, sealing materials, cement concrete products and so on, the enhanced short fiber provides base mechanical strength, the adjuvant producing pulp fiber catches fine particles and inhibits components leaking, the adjuvant producing pulp fiber covers the face of short fiber and avoids the short fiber entanglement each other in the materials mixing process and the phenomenon of fiber balling up, the fiber has excellent integrated performance.

Owner:SHANGHAI LABON TECHNICAL FIBER CO LTD

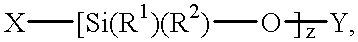

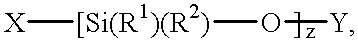

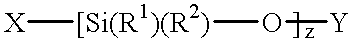

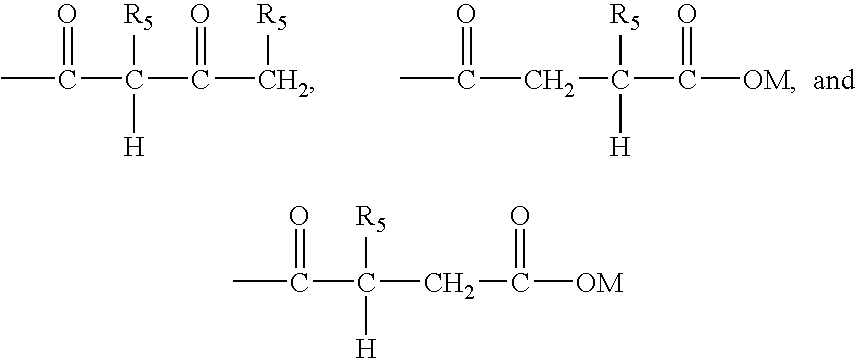

Internally lubricated fiber, cardable hydrophobic staple fibers therefrom, and methods of making and using the same

InactiveUS6177191B1Less migrationImprove thermal stabilitySynthetic resin layered productsFilament/thread formingFiberAryl

Hydrophobic polyolefin fibers are provided with an internal hydrophobic polysiloxane of the formulain which X, Y, R1, and R2, which may be the same or different, or substituted or unsubstituted independently of each other, are aliphatic groups having not more than about sixteen carbon atoms, R1 and R2 also being selected from among aryl groups, and z being a positive number sufficiently high that the polysiloxane is hydrophobic (z is generally a least 10). The invention also provides a novel polymer melt for spinning these hydrophobic fibers. The fibers can be cut into staple lengths and carded and bonded to form hydrophobic woven and nonwoven products suitable for use in hygiene devices such as diapers. Such devices are improved by these fibers, which, as spun, present a greater hydrophobicity than melt-spun polyolefin fibers lacking the internal siloxane lubricant, the improved hydrophobicity is evidenced by an advancing contact angle for the as-spun fibers of at least about 95°.

Owner:FIBERVISIONS LP

Composite membrane for secondary nickel-zinc cell and preparation method of composite membrane

ActiveCN105098128ASimplify the assembly processGuaranteed smoothCell seperators/membranes/diaphragms/spacersNickel accumulatorsPolyolefinNonwoven fabric

The invention belongs to a composite membrane for a secondary nickel-zinc cell. The composite membrane is in a two-layer composite structure; one layer is a polypropylene microporous membrane; the other layer is nonwoven fabric containing an ultrafine polyolefin fiber; the surface density of the composite membrane is 38g / m<2> to 80g / m<2>; and the thickness is 0.1-0.2mm. According to the composite membrane for the secondary nickel-zinc cell, the battery assembly process becomes simple and feasible; malposition and creases between two layers are avoided; base cloth of the membrane does not easily generate the crease in the radiation grafting process; keeping of the smooth membrane is facilitated; internal surface carboxyl and external surface carboxyl of the composite membrane and (or) sulfonyle hydrophilic functional groups are provided by radiation grafting of acrylic acid and (or) sodium p-styrenesulfonate; and the composite membrane has permanent hydrophilicity.

Owner:HENAN KEGAO RADIATION CHEM TECH

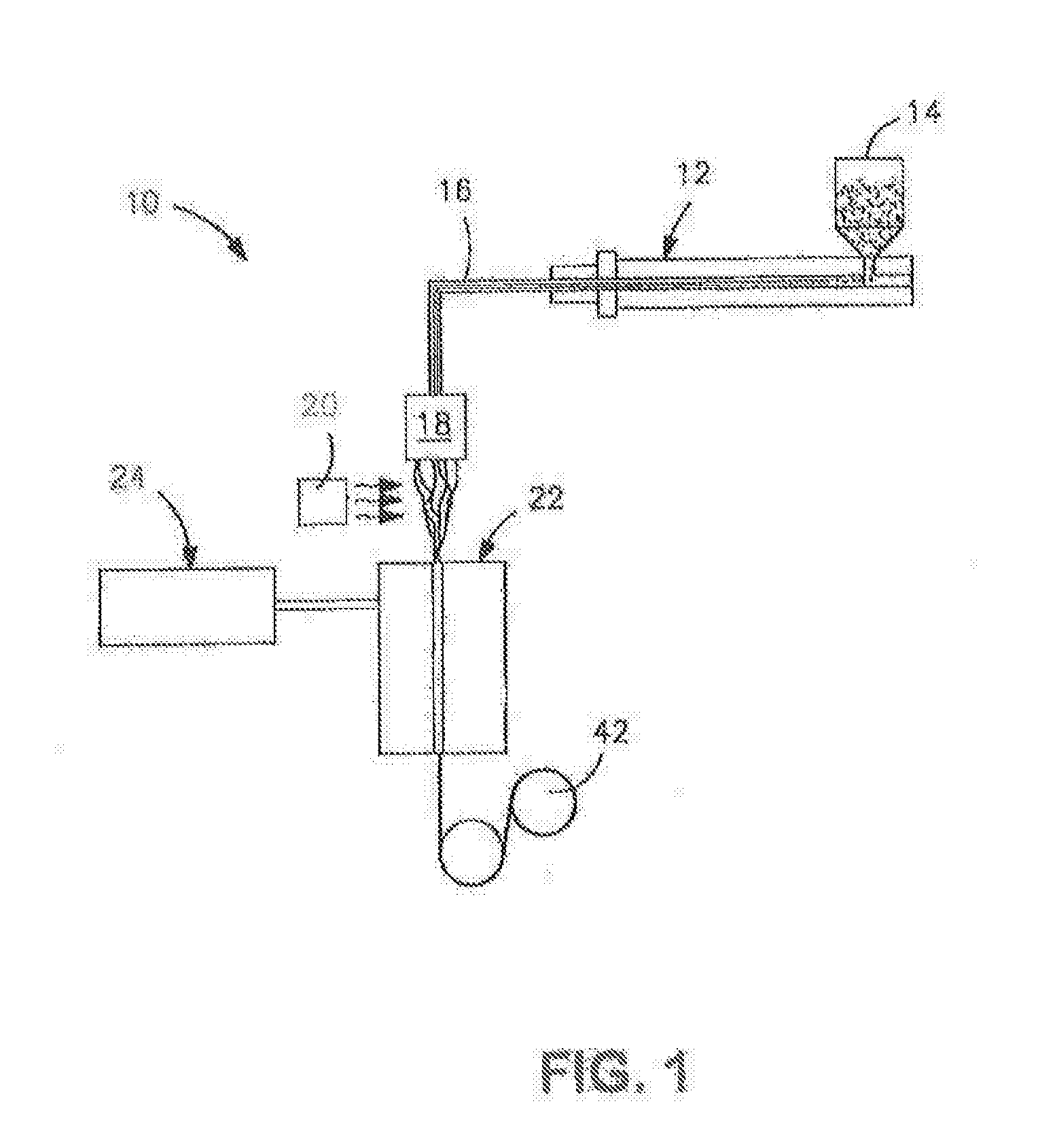

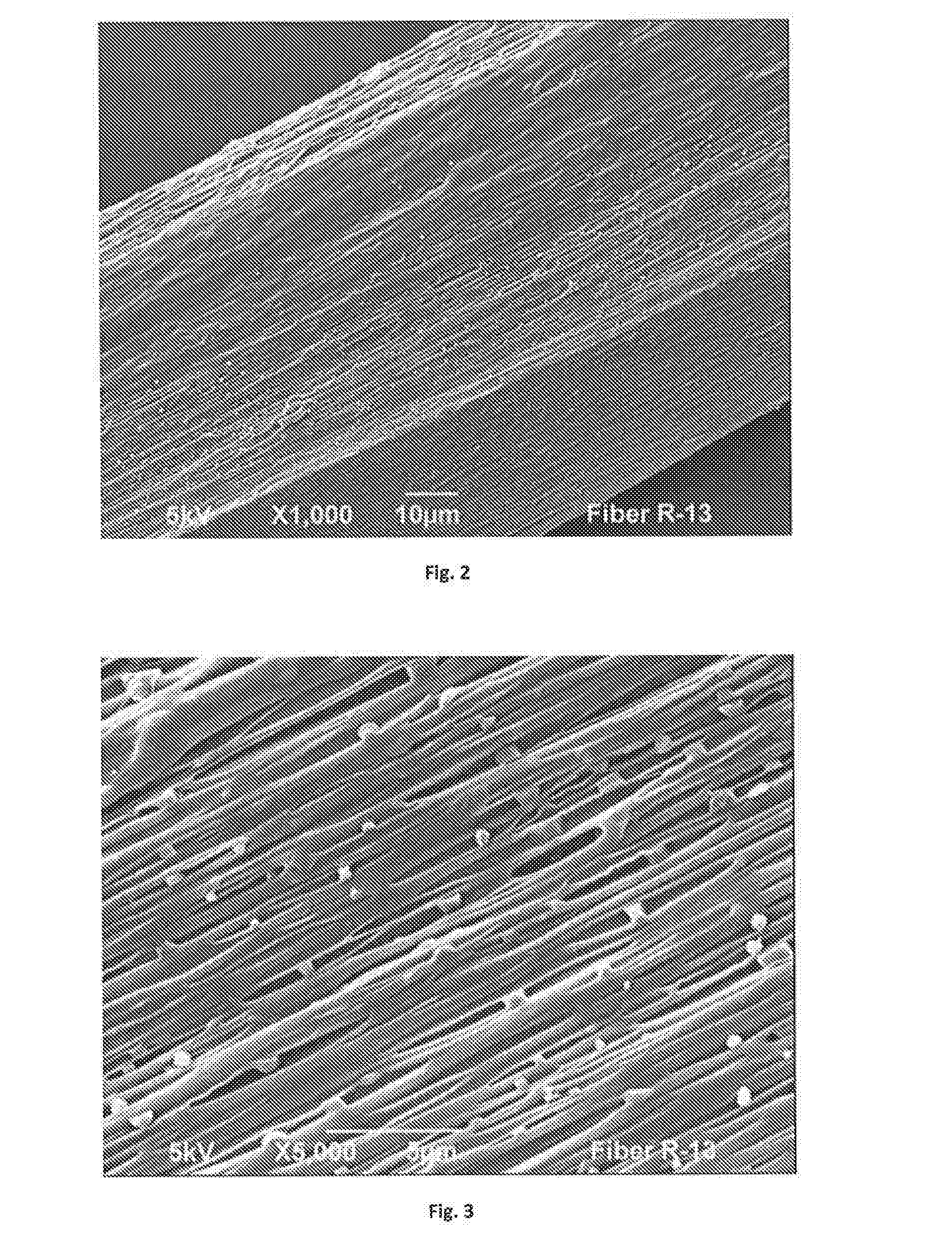

Porous Polyolefin Fibers

A polyolefin fiber that is formed by a thermoplastic composition containing a continuous phase that includes a polyolefin matrix polymer and nanoinclusion additive is provided. The nanoinclusion additive is dispersed within the continuous phase as discrete nano-scale phase domains. When drawn, the nano-scale phase domains are able to interact with the matrix in a unique manner to create a network of nanopores.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Composite membrane used for secondary alkaline zinc-manganese dioxide battery, and preparation method therefor

ActiveCN105098127AGood chemical stabilityGood resistance to zinc oxide dendritesCell component detailsManganeseUltra fine

A composite membrane used for a secondary alkaline zinc-manganese dioxide battery, and a preparation method therefor are disclosed, belonging to the technical fields of battery membranes. The composite membrane is in a dual-layer composite structure comprising polypropylene microporous membrane and wet process nonwoven fabrics containing ultra-fine polyolefine fibers and vinylon fibers; and the composite membrane is 0.08-0.12 mm in thickness. The composite membrane has the following aspects of performances: (1) the composite membrane is good in zinc oxide dendritic crystal resistance due to the existence of the microporous membrane; (2) the composite membrane can be processed into membrane pipes easily through an automatic winding machine; (3) the composite membrane is radiation grafted with crylic acid and / or sodium styrene sulfonate to endow the inner and outer surfaces with carboxyl and / or sulfonic acid group hydrophilic functional group, so that the composite membrane has permanent hydrophilicity; and (4) the composite membrane is quite high in chemical stability.

Owner:HENAN KEGAO RADIATION CHEM TECH

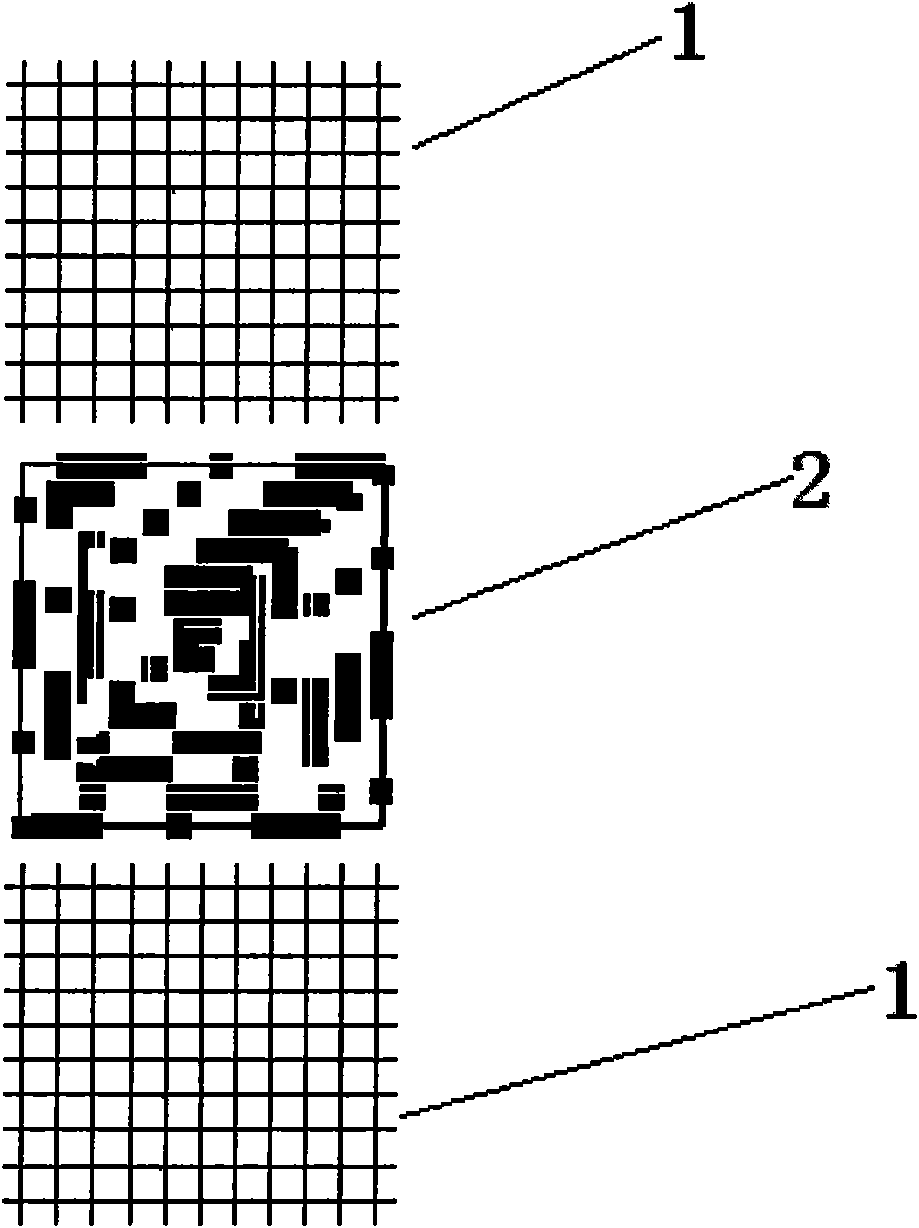

Soilless sod, its preparation method and application

ActiveCN102334399ANo lossSimple structureSynthetic resin layered productsAgriculture gas emission reductionSeederPolyolefin

The invention relates to a soilless sod and its preparation method and an application thereof. The soilless sod is prepared by the recombination of polyolefin fibrous reticulums and mixed fiber cloth, wherein the mixed fiber cloth is positioned between two layers of polyolefin fibrous reticulums. The mixed fiber cloth is made from raw materials of bamboo fiber, crop straw, coir fiber and nylon wire. Plant seeds are uniformly distributed on the mixed fiber cloth by the use of a seeder so as to form the mixed fiber cloth containing plant seeds. The preparation method provided by the invention comprises the following steps of: respectively compacting the polyolefin fibrous reticulum and the mixed fiber cloth through a briquetting machine, placing the compacted mixed fiber cloth between the two layers of polyolefin fibrous reticulums, braiding them together by the use of a braiding machine to form net cloth, and compacting by the briquetting machine to obtain the soilless sod. The invention has the following advantages: the polyolefin fibrous reticulum has strong permeability, corrosion resistance and strong tension; the raw material straw source is abundant; waste is changed into values; production processing is simple; cost is low; construction is fast; the soilless sod is widely applied with no environmental pollution, has an obvious effect of protecting water and soil and is easily popularized.

Owner:上海园林绿化建设有限公司

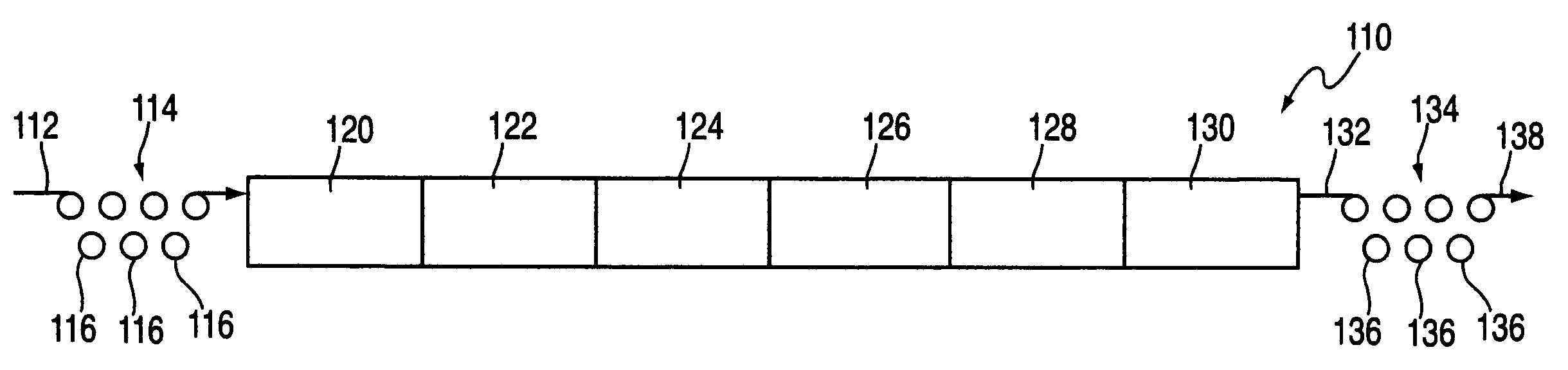

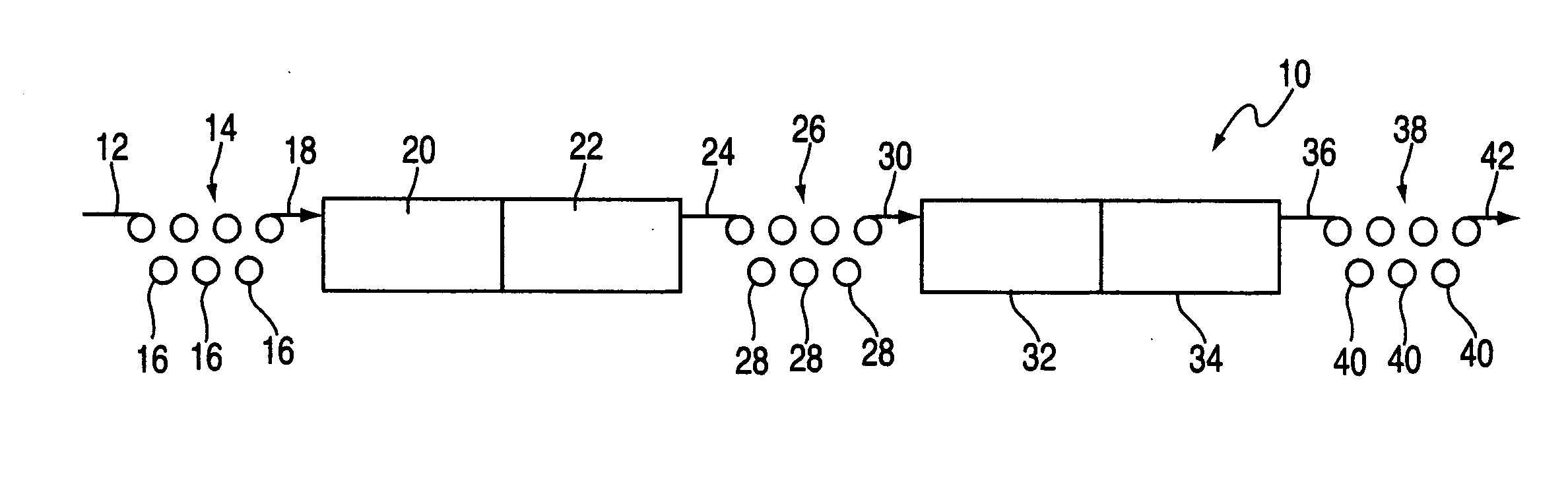

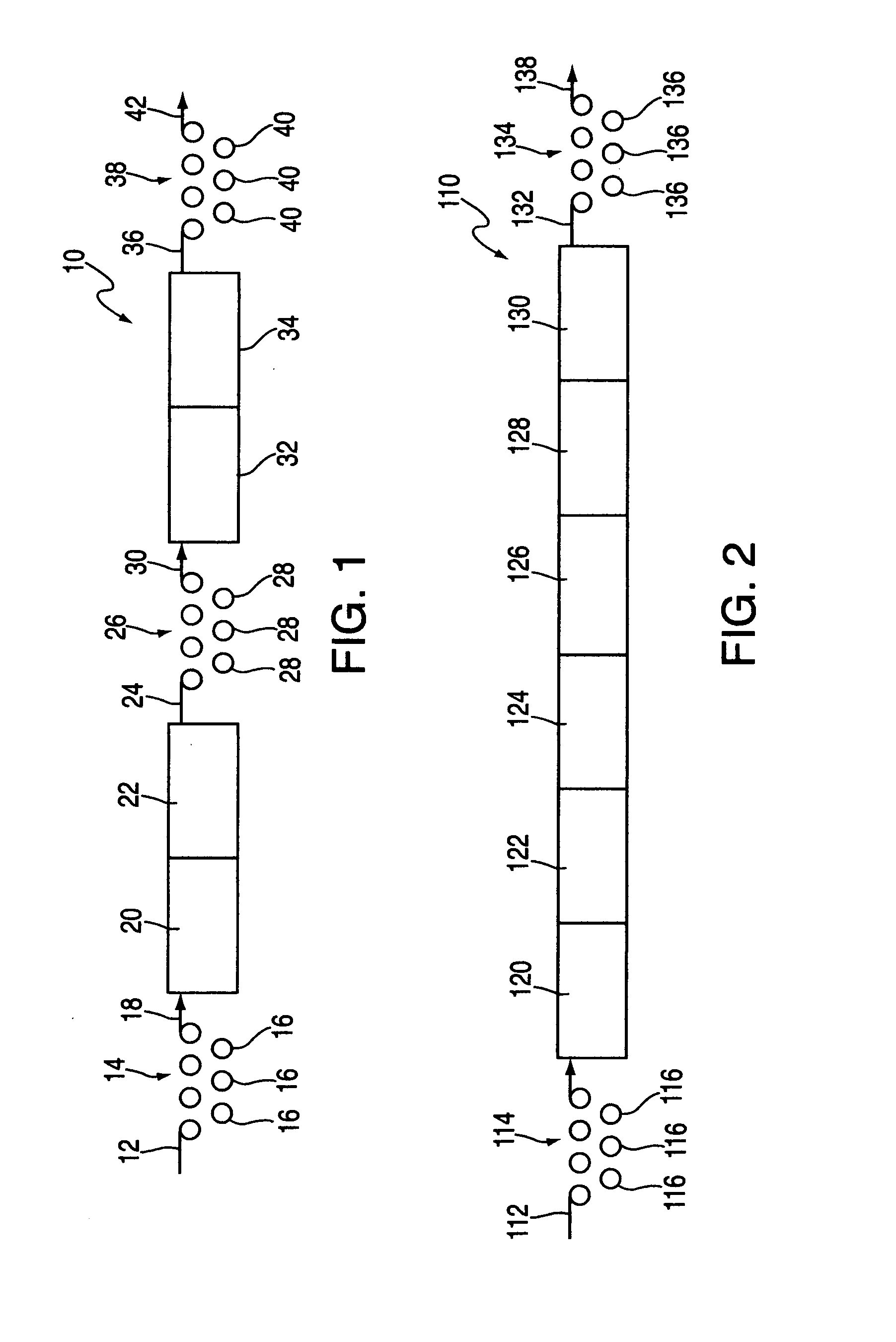

Heating apparatus and process for drawing polyolefin fibers

ActiveUS20070137064A1Lower capital expenditureImprove throughputDrying gas arrangementsDrying machines with progressive movementsFiberPolyolefin

A heating apparatus and process useful for drawing ultrahigh molecular weight polyolefin fibers, such as polyethylene fibers. The heating apparatus includes a first set of rolls and a plurality of aligned ovens. The apparatus includes a second set of rolls at the exit of the ovens which rolls are adapted to provide the desired drawing of the polyolefin fibers. The apparatus and process provide a single draw step in a heated environment, with the use of preferably four or six horizontal ovens.

Owner:HONEYWELL INT INC

Polyolefin fiber

InactiveUS20110173874A1Homogeneous structureSmall widthSynthetic resin layered productsFilament/thread formingFiberPolyolefin

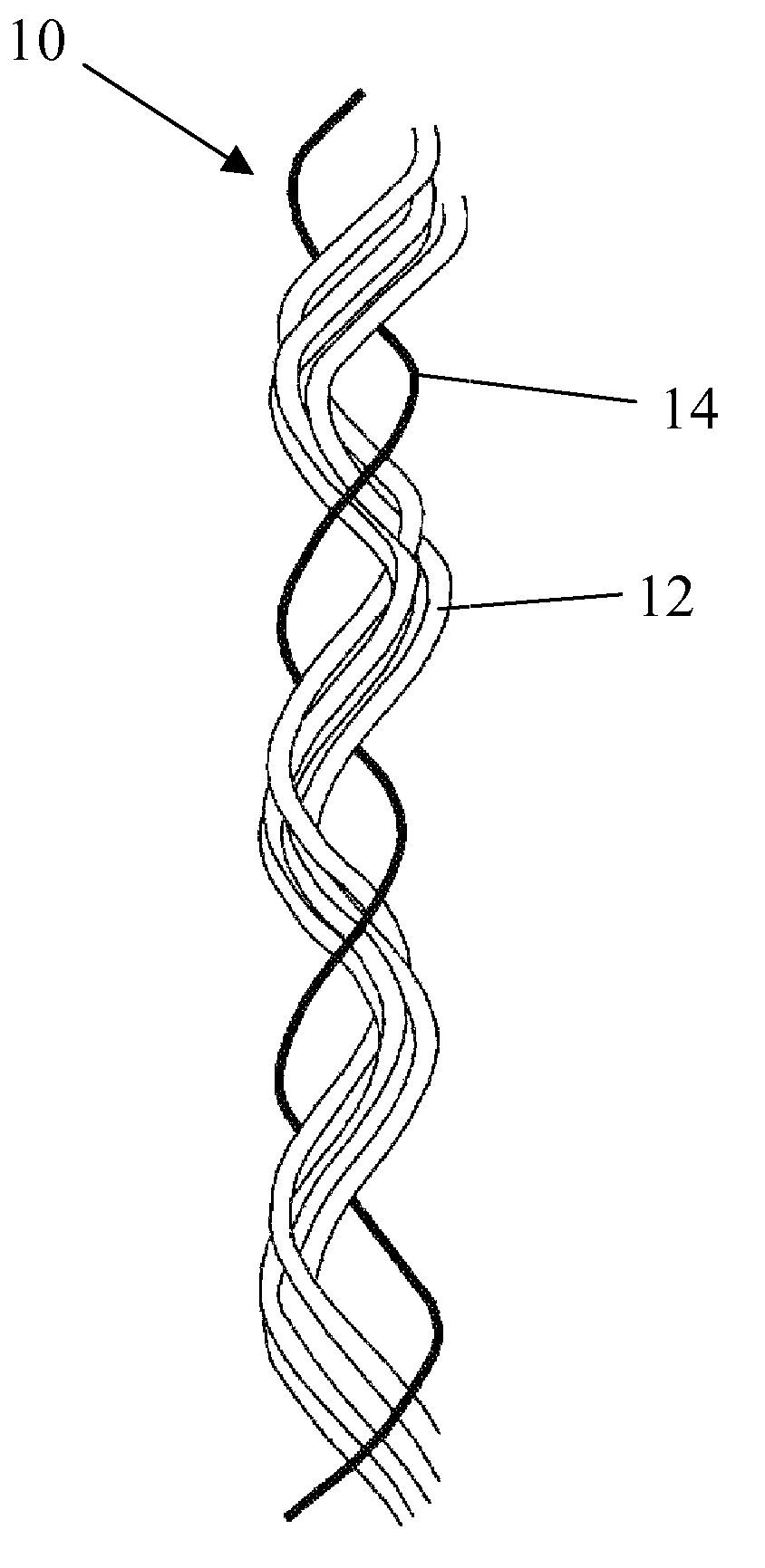

The invention relates to a process for making a polyolefin fiber. The process comprises the steps of providing at least one polyolefin tape; twisting or folding the at least one polyolefin tape longitudinally to obtain a precursor fiber and exposing the precursor fiber under tension to a temperature within the melting point range of the polyolefin for a time sufficient to at least partly two or more parts of the precursor fiber. The invention also relates to the fiber obtainable thereby.

Owner:DSM IP ASSETS BV

Lubricant composition for internal combustion engine

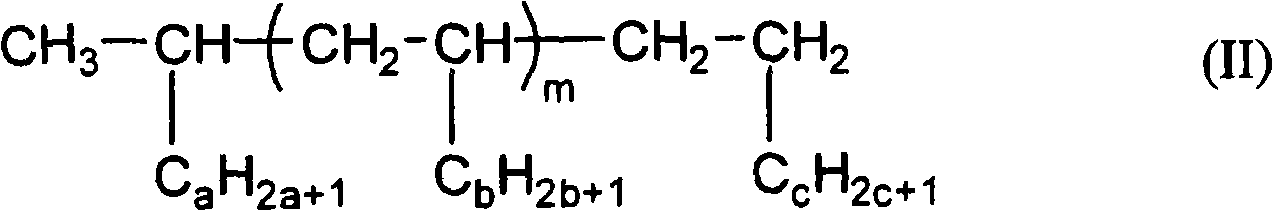

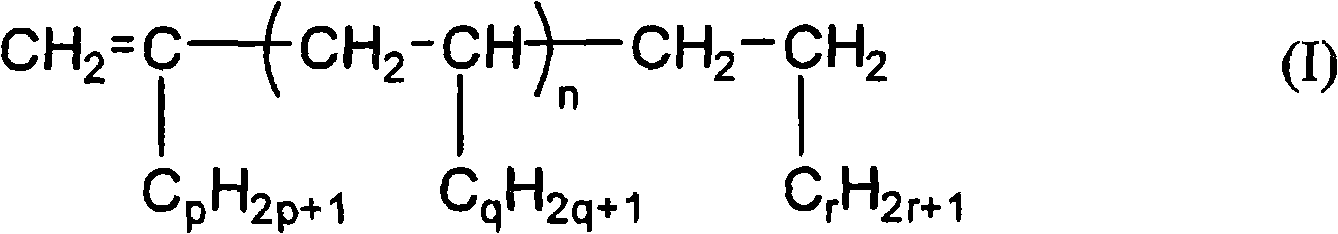

InactiveCN101310002AGood fluidity at low temperatureImprove oxidation stabilityBase-materialsOligomerCombustion

Disclosed is a lubricant composition for internal combustion engines which comprises a base oil containing at least one substance selected from an a-olefin oligomer having 16-40 carbon atoms which is obtained by oligomerizing an a-olefin having 2-20 carbon atoms by using a metallocene catalyst, a hydrogenated product of such an a-olefin oligomer, an a-olefin oligomer having 16-40 carbon atoms which is derived from an a-olefin dimer obtained by using a metallocene catalyst, a hydrogenated product of such an a-olefin oligomer and the like. This lubricant composition for internal combustion engines is excellent in low-temperature fluidity, while having low evaporativity and good oxidation stability.

Owner:IDEMITSU KOSAN CO LTD

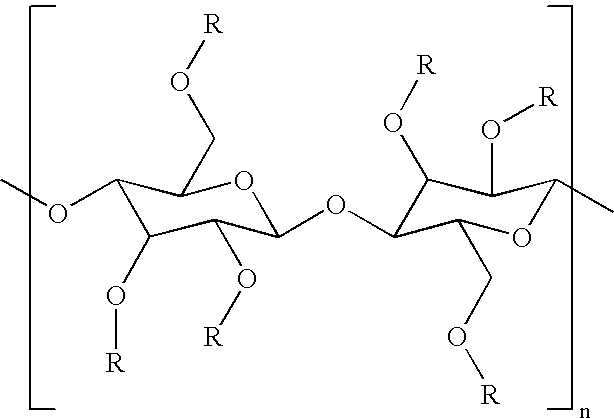

Textile benefit compositions

The present invention relates to textile benefit compositions comprising a cellulosic based polymer component; a material selected from the group consisting of a dispersible polyolefin, a chlorine inhibitor, a dye fixative and mixtures thereof; a cross-linking agent; a carrier and an optional wetting agent or, alternatively, a chlorine inhibitor; a material selected from the group consisting of a dispersible polyolefin, a cellulosic based polymer component, a dye fixative and mixtures thereof; a cross-linking agent; a carrier and an optional wetting agent. The present invention also relates to processes for making and using the aforementioned compositions and textiles treated with such compositions.

Owner:THE PROCTER & GAMBLE COMPANY

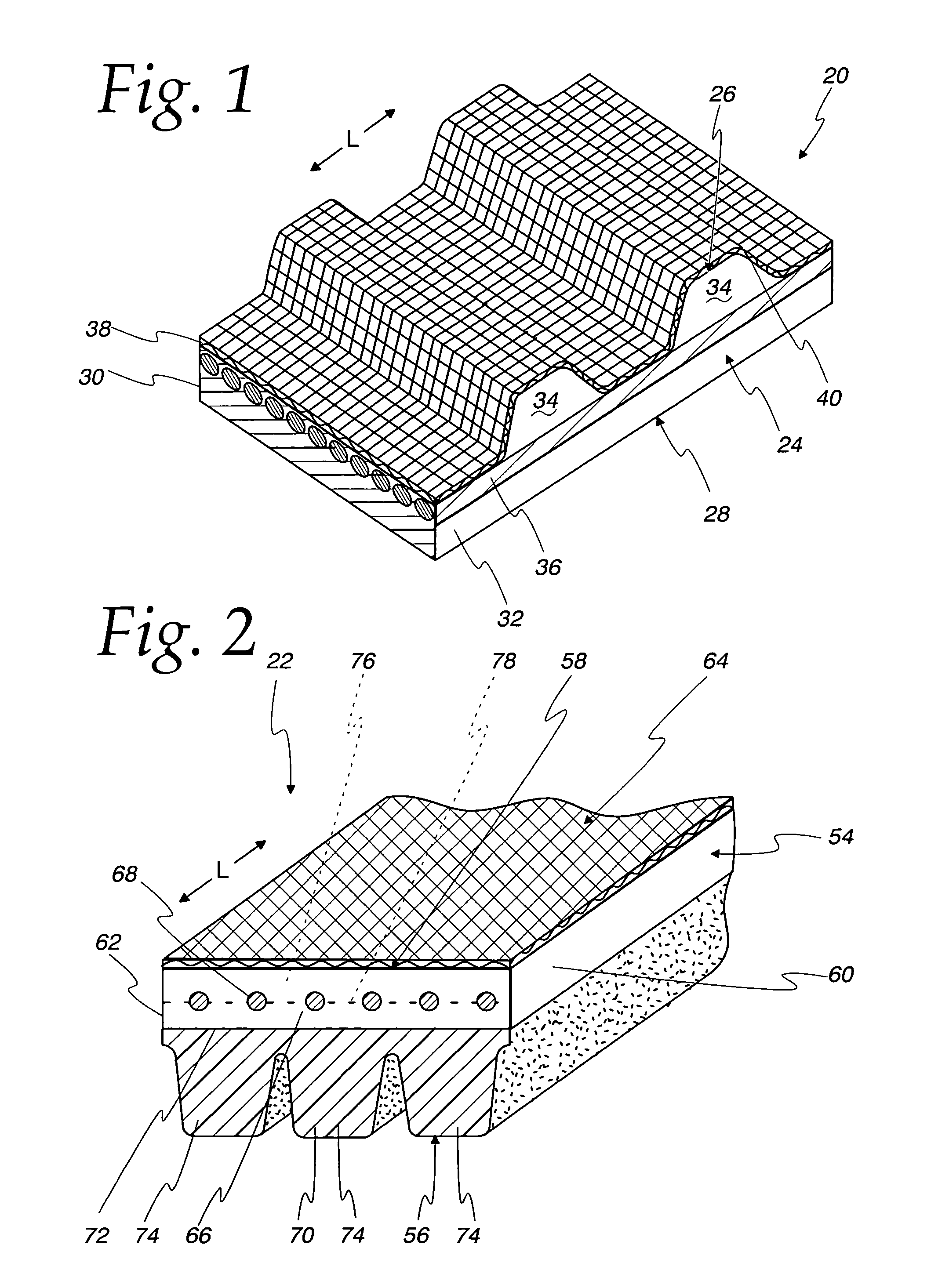

Power transmission belt

A power transmission belt having a body with a length, an inside, an outside, and laterally spaced side surfaces. The body has a first rubber composition that includes an organic peroxide used as a cross-linking agent and N,N′-m-phenylenedimaleimide and / or quinone dioxime in an amount of 0.5 to 13 parts by weight per 100 parts by weight of rubber components. The rubber components include (a) ethylene-vinyl ester copolymer and / or an ethylene-α,β-unsaturated carboxylate copolymer, and (b) an ethylene α-olefin rubber in a ratio of from 5:95 to 100:0 by weight.

Owner:MITSUBOSHI BELTING LTD

Adhesive alpha-olefin inter-polymers

The invention relates to novel adhesive alpha-olefin inter-polymers which are largely amorphous and have a rheological behavior that makes them suitable for adhesive use, both without and with minimzed amounts of tackifying resins. Specifically, the invention poly-alpha olefin inter-polymer may be composed of A) from 60 to 94% of units derived from one alpha mono-olefin having from 3 to 6 carbon atoms and B) from 6 to 40 mol % of units derived from one or more other mono-olefins having from 4 to 10 carbon atoms and at least one carbon atom more than A); and C) optionally from 0 to 10 mol % of units derived from another copolymerizable unsaturated hydrocarbon, different from A) and B); the diad distribution of component A in the polymer as determined by 13C NMR as described herein showing a ratio of experimentally determined diad distribution over the calculated Bernoullian diad distribution of less than 1.07; and the storage modulus G′ of said polymer, determined upon cooling as described herein, intersecting a value of 3.105 Pa at a temperature of less than 85° C. The invention also describes polymerization processes suitable for the manufacture of these adhesive alpha-olefin inter-polymers.

Owner:EXXONMOBIL CHEM PAT INC

Polypropylene resin compositions

The present invention provides a polypropylene resin composition prepared by mixing a polypropylene master batch, a high crystalline polypropylene, an ethylene-styrene copolymer rubber, an ethylene-α-olefin rubber and an inorganic filler. The polypropylene resin produced has reduced swirl marks, superior melting tension, fluidity, foaming magnitude, impact resistance, and cooling rate, and is useful for construction of vehicle interior parts.

Owner:HYUNDAI MOTOR CO LTD +1

Yarns spun from olefin and cotton fibers and products made therefrom

A textile yarn consisting of a blend lightweight olefin fibers that has a specific gravity of 0.91 to 1.0 blended with cotton fibers that have a specific gravity of more that 1.0 made using commercially available cotton spinning systems, and the textile articles manufactured using said yarn. This invention takes advantage of the fact that during the spinning process, centrifugal force slings most of the heavier cotton fiber to the outside while the lighter weight olefin remains mostly in the core of the yarn thus formed. The system is especially useful when using cotton open end or air jet spinning systems. Novel fabrics can be made from the new yarns.

Owner:NEGOLA EDWARD J

Cardable hydrophobic polyolefin fibres comprising cationic spin finishes

InactiveCN1077182CEvenly distributedReduce hydrophobicitySynthetic fibresWoven fabricsPolyolefinPolymer science

A method for producing cardable, hydrophobic polyolefin-based staple fibres by applying to spun filaments a first spin finish comprising at least one cationic antistatic agent, in particular a quaternary ammonium salt, stretching the filaments, applying to the stretched filaments a second spin finish in the form of a dispersion comprising at least one hydrophobic lubricant selected from a fatty acid amide condensation product and a hydrocarbon wax, the second spin finish optionally further comprising a polydiorganosiloxane in an amount of up to 15 % by weight, and crimping, drying and cutting the filaments to obtain staple fibres; as well as texturized, cardable, polyolefin-based staple fibres prepared by the method and hydrophobic nonwoven materials produced from such fibres. The fibres are able to be carded at extremely high speeds and are particularly suitable for use in the preparation of thermally bonded hydrophobic nonwoven fabrics in which a dry, water-repellant surface which can function as a liquid barrier is desired, e.g. for disposable diapers, feminine hygienic products and medical products.

Owner:FIBERVISIONS VARDE

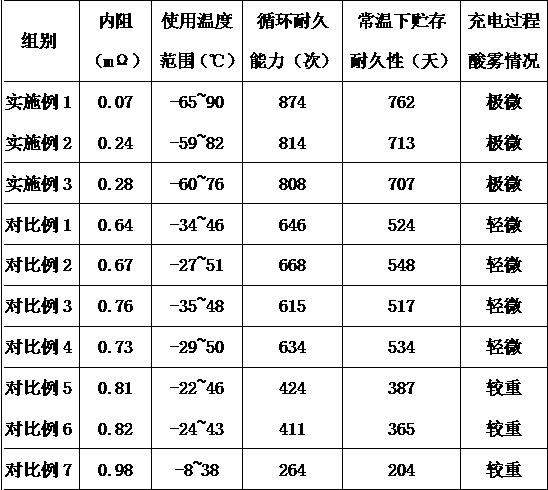

Super-energy olefin polymer lead storage battery unformed plate lead paste

ActiveCN109904448AIncrease specific energyImprove acceleration performanceLead-acid accumulatorsCell electrodesFiberCarbon fibers

The invention relates to the technical field of lead storage batteries, in particular to super-energy olefin polymer lead storage battery unformed plate lead paste. The super-energy olefin polymer lead storage battery unformed plate lead paste contains positive plate lead paste and negative plate lead paste; the positive plate lead paste contains lead powder, red lead, tetrabasic lead sulfate, bismuth trioxide, stannous sulfate, a polytetrafluoroethylene emulsion, carbon fibers, graphite olefin fibers, potassium sulfate, a graphene solution, ultrapure water and sulfuric acid; and the negativeplate lead paste contains lead powder, ultrafine barium sulfate, sodium sulfate, sodium lignosulphonate, humic acid, aquadag, a graphene solution, acetylene black, conductive carbon black N220, graphite olefin fibers, carbon fibers, ultrapure water and sulfuric acid. A lead storage battery made from the battery positive and negative plate lead paste prepared through the method is extremely small in internal resistance and wide in temperature adaptive range, produces tiny acid mist in the charging process, is extremely small in self-discharge, can be used under an extra large current, is strongin circulation durability and belongs to novel environment-friendly energy-saving batteries.

Owner:汉和新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com