Soilless sod, its preparation method and application

A technology of soilless grass and mixed fiber, which is applied in the direction of seed treatment, botanical equipment and methods, applications, etc., can solve the problems of not achieving the effect of soilless cultivation, achieve protection of water and soil erosion, fast construction, and improve soil structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Raw materials

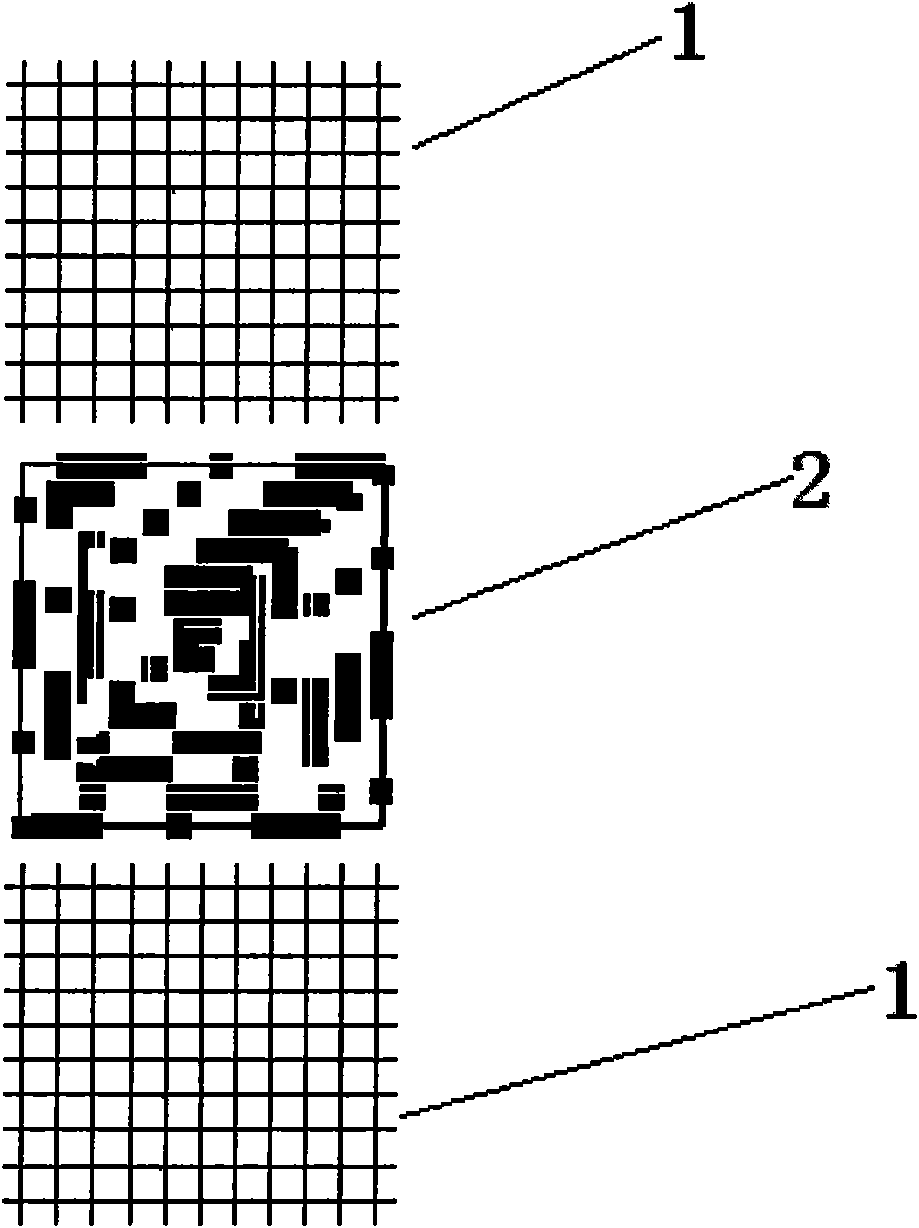

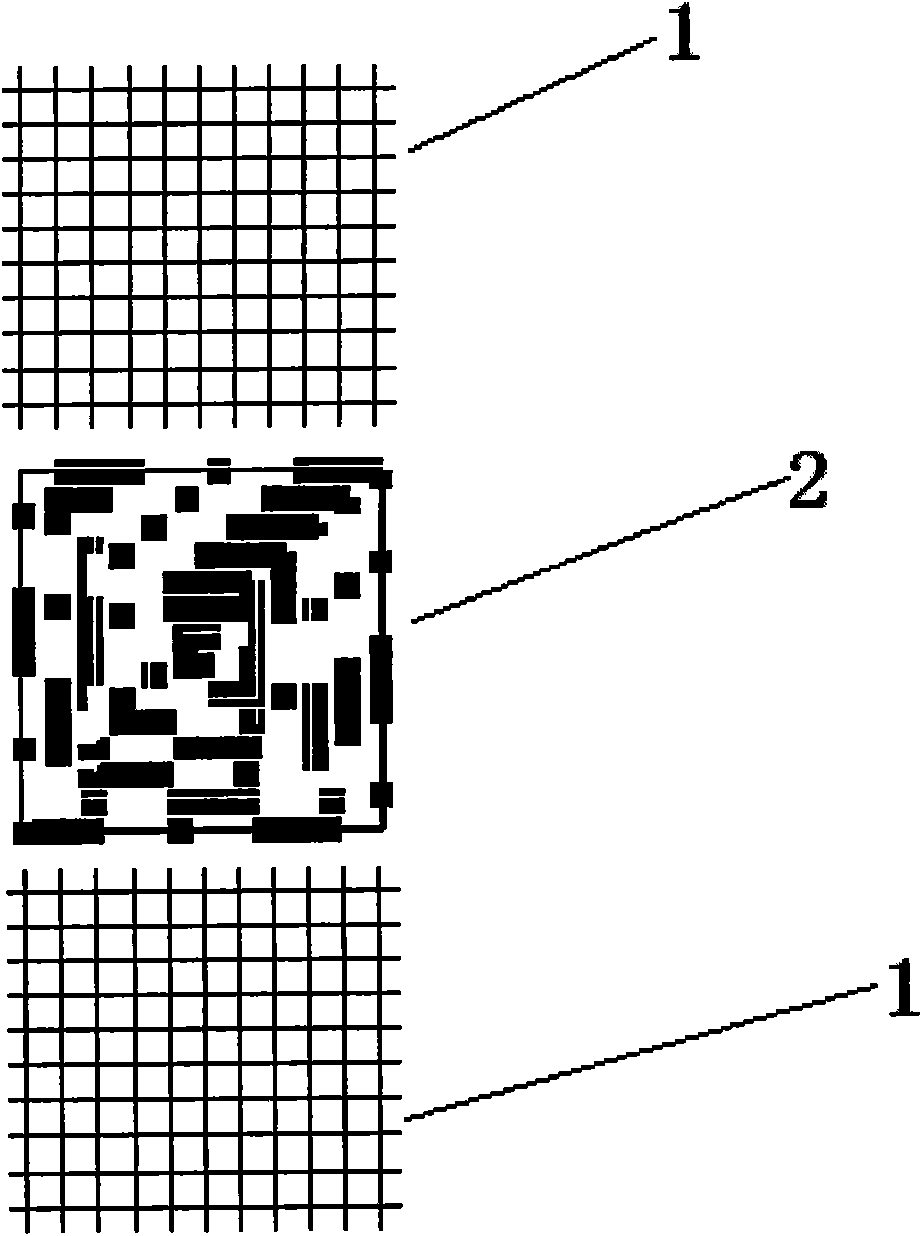

[0035] A kind of soilless grass, composed of polyolefin fiber net 1 and mixed fiber cloth 2, wherein the mixed fiber cloth is located between two layers of polyolefin fiber net, please refer to the attached figure 1 .

[0036] The raw material of the polyolefin fiber web is polyolefin fiber;

[0037] The area of the gap of the polyolefin fiber web is 2cm 2 ;

[0038] The mixed fiber cloth is evenly distributed with plant seeds by a planter to form a mixed fiber cloth containing plant seeds;

[0039] The raw materials of the mixed fiber cloth are bamboo fiber, crop stalks, coconut shell fiber and nylon silk; wherein, the mass percentage of raw materials in the mixed fiber cloth is:

[0040] Bamboo Fiber 5%

[0041] Coir 5%

[0042] Nylon 3%

[0044] The crop straw is wheat straw;

[0045] 2. Preparation method

[0046] A kind of preparation method of soilless grass, its concrete steps are:

[0047] (1) heat-melt and...

Embodiment 2

[0051] 1. Raw materials

[0052] A kind of soilless grass, composed of polyolefin fiber net 1 and mixed fiber cloth 2, wherein the mixed fiber cloth is located between two layers of polyolefin fiber net, please refer to the attached figure 1 .

[0053] The raw material of the polyolefin fiber web is polyolefin fiber;

[0054] The area of the gap of the polyolefin fiber web is 4cm 2

[0055] The mixed fiber cloth is evenly distributed with plant seeds by a planter to form a mixed fiber cloth containing plant seeds;

[0056] The raw materials of the mixed fiber cloth are bamboo fiber, crop stalks, coconut shell fiber and nylon silk; wherein, the mass percentage of raw materials in the mixed fiber cloth is:

[0057] Bamboo Fiber 10%

[0058] Coir 10%,

[0059] Nylon 4%

[0060] Crop straw 76%

[0061] The crop stalks are rice stalks and corn stalks;

[0062] 2. Preparation method

[0063] A kind of preparation method of soilless grass, its concrete steps are:

[0064] ...

Embodiment 3

[0068] 1. Raw materials

[0069] A kind of soilless grass, composed of polyolefin fiber net 1 and mixed fiber cloth 2, wherein the mixed fiber cloth is located between two layers of polyolefin fiber net, please refer to the attached figure 1 .

[0070] The raw material of the polyolefin fiber web is polyolefin fiber;

[0071] The area of the gap of the polyolefin fiber web is 6cm 2 ;

[0072] The mixed fiber cloth is evenly distributed with plant seeds by a planter to form a mixed fiber cloth containing plant seeds;

[0073] The raw materials of the mixed fiber cloth are bamboo fiber, crop stalks, coconut shell fiber and nylon silk; wherein, the mass percentage of raw materials in the mixed fiber cloth is:

[0074] Bamboo Fiber 15%

[0075] Coir 15%,

[0076] Nylon 5%

[0077] Crop straw 65%

[0078] The crop stalks are a mixture of corn stalks and leguminous plant stalks;

[0079] 2. Preparation method

[0080] A kind of preparation method of soilless grass, its c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com