Patents

Literature

71results about How to "Protection loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

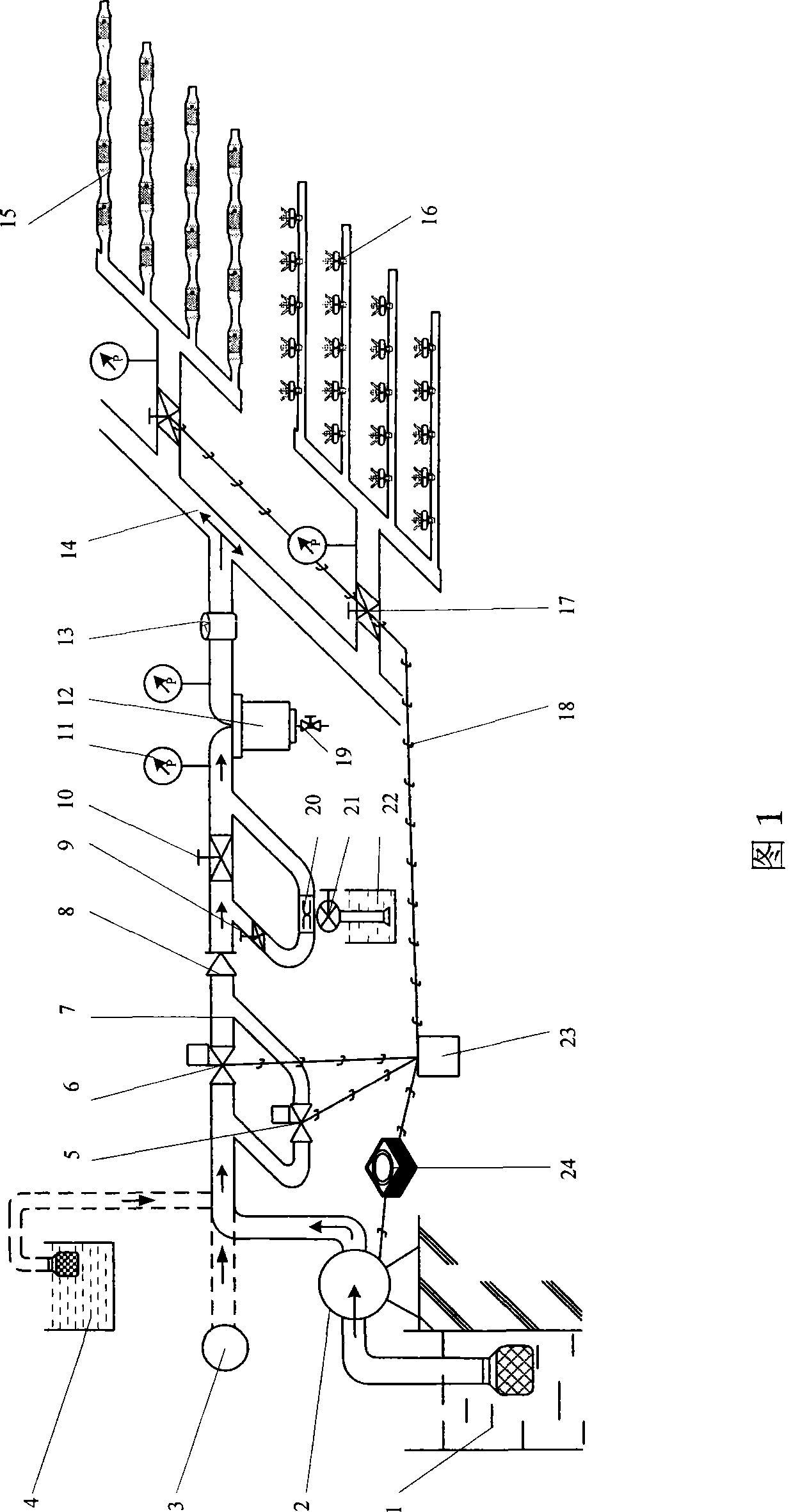

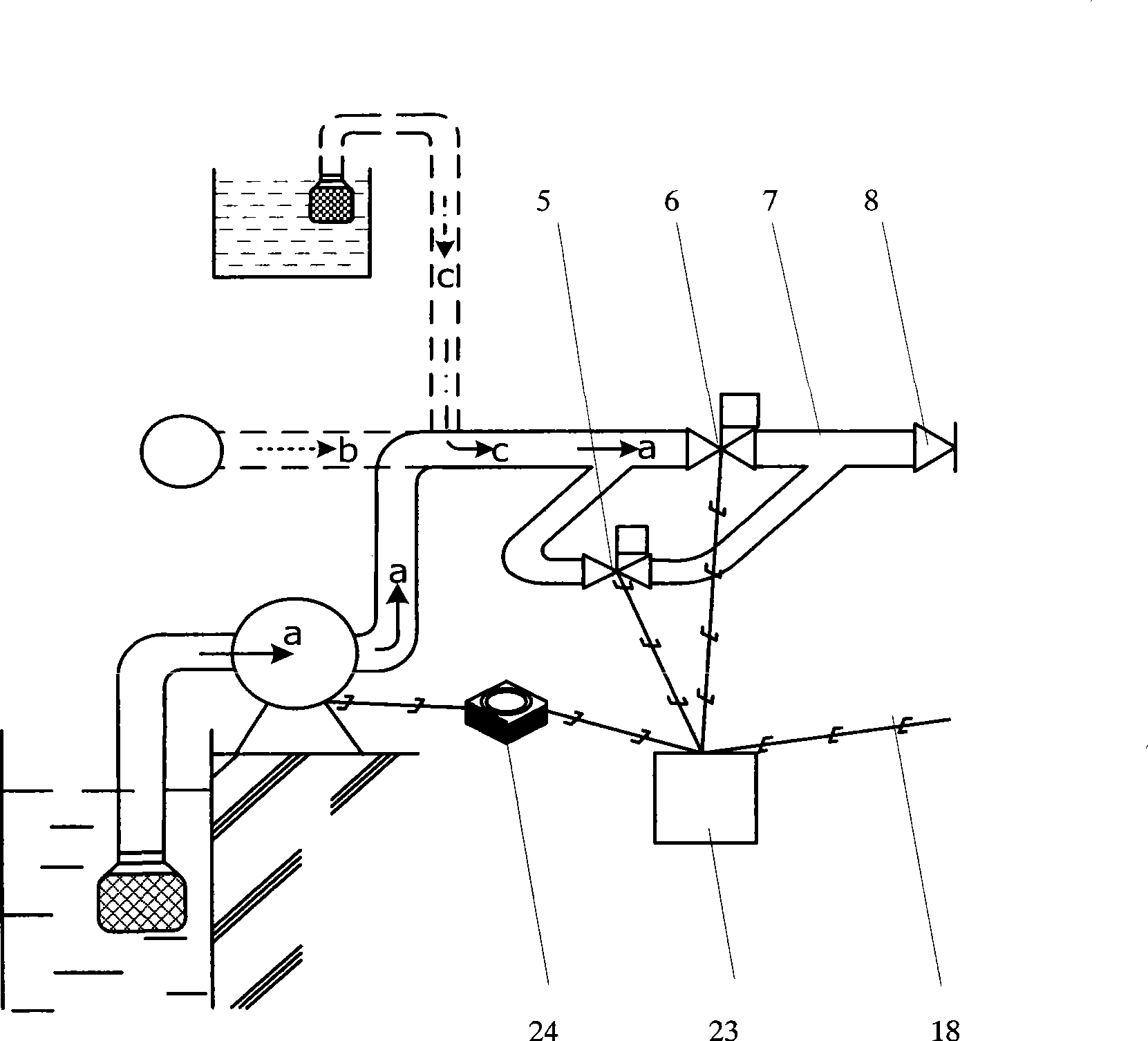

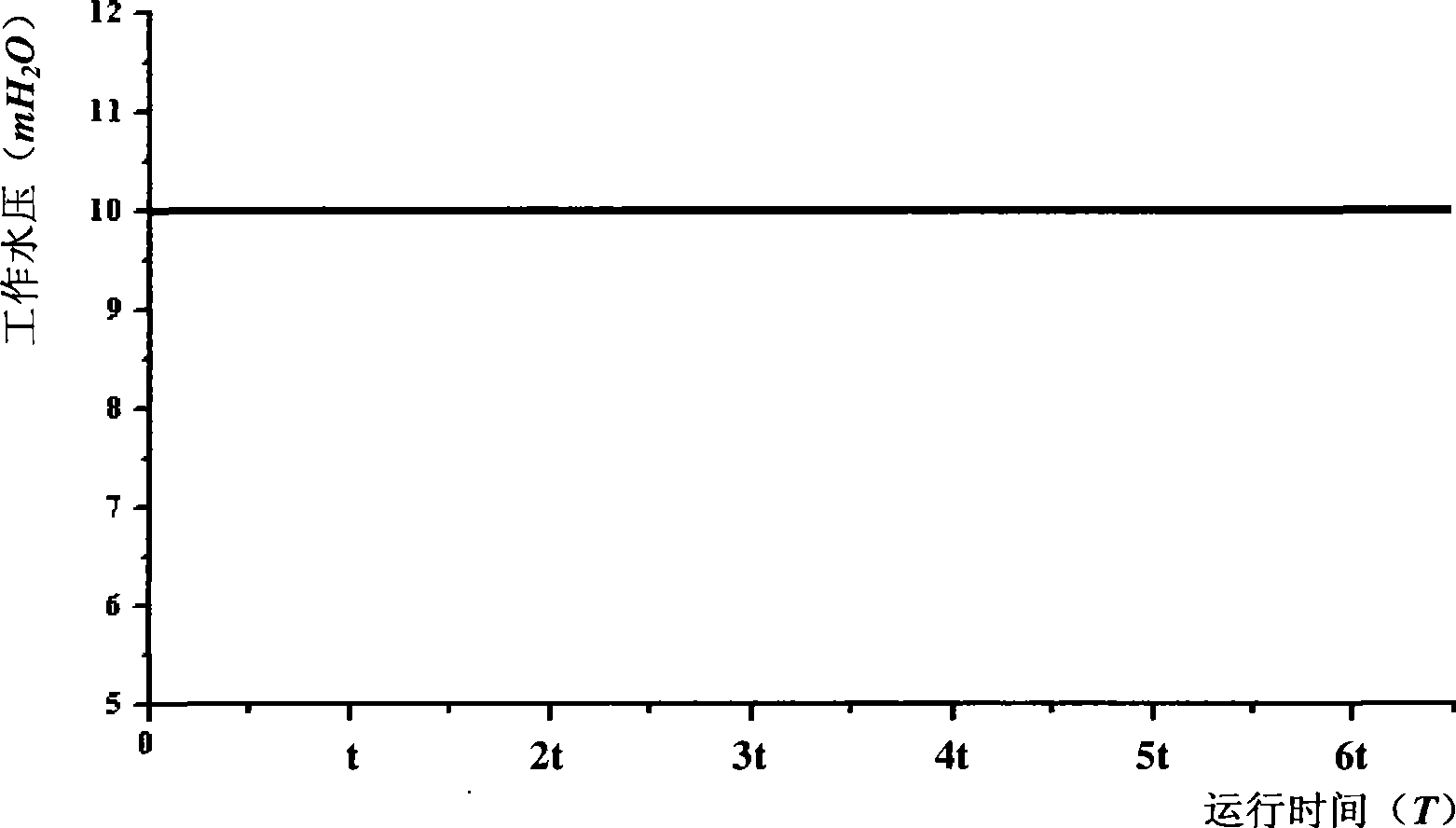

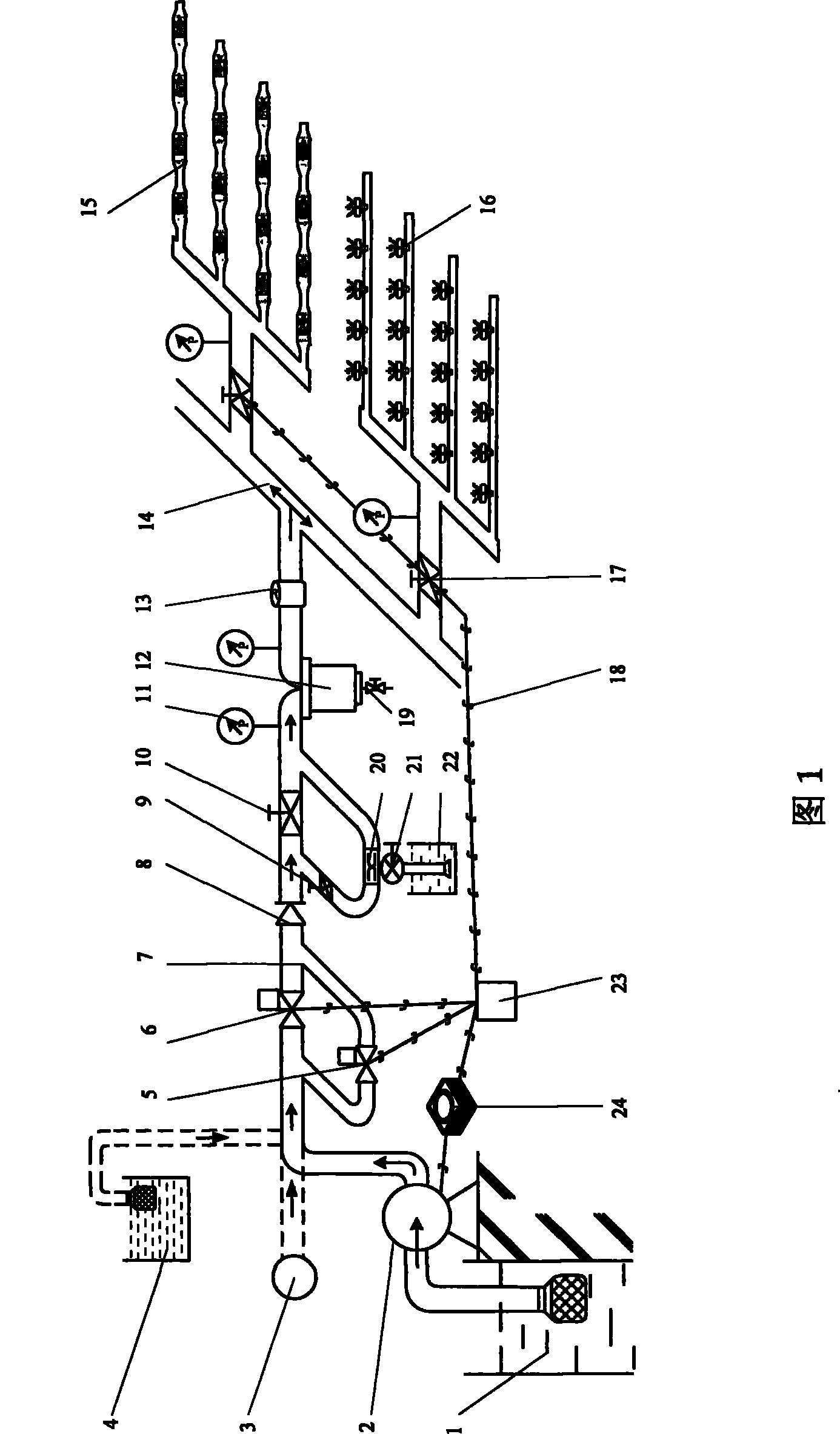

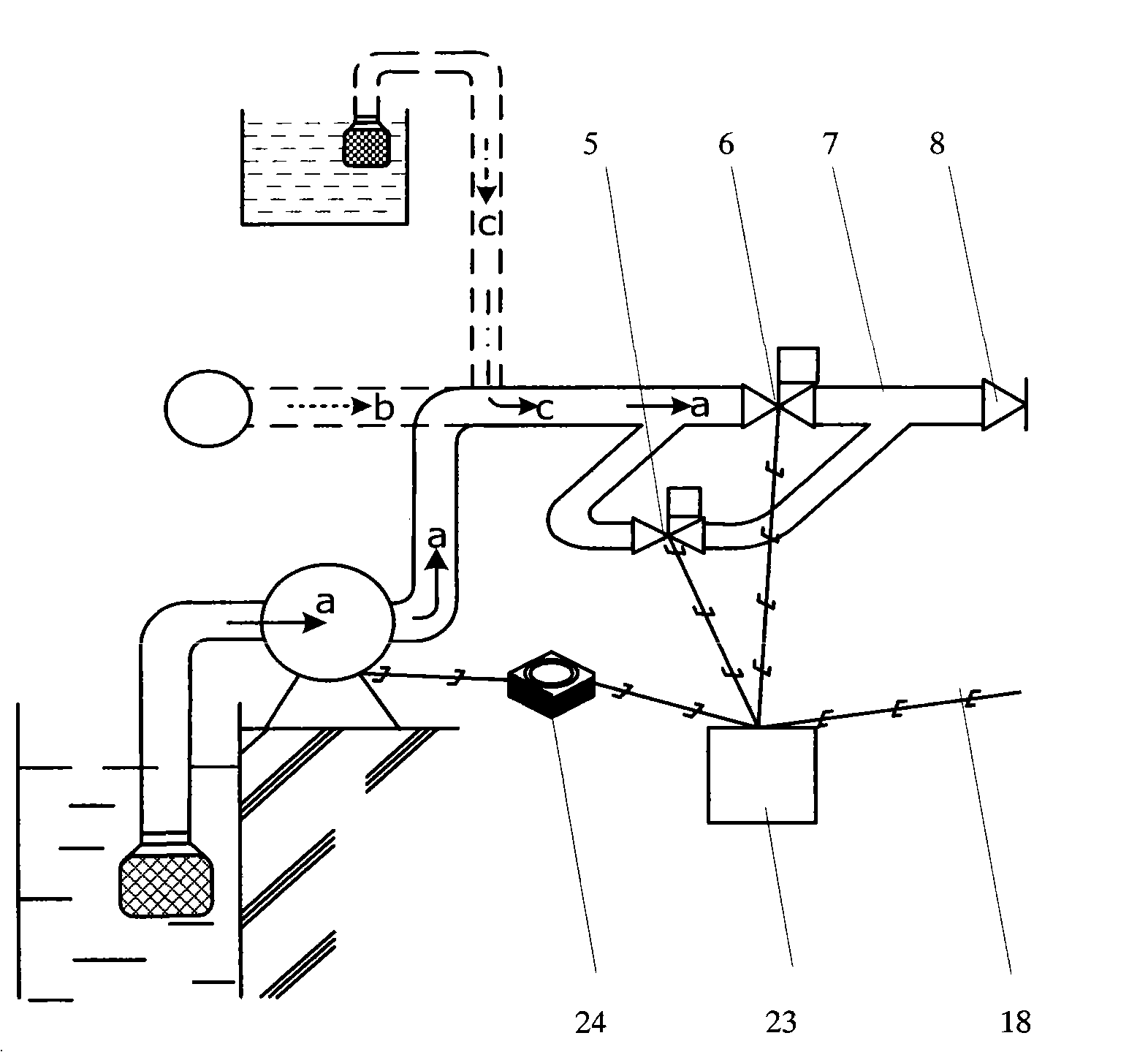

Dynamic water-pressure drip-irrigation system

ActiveCN101449654AAvoid cloggingLow running costClimate change adaptationWatering devicesSolenoid valveWater source

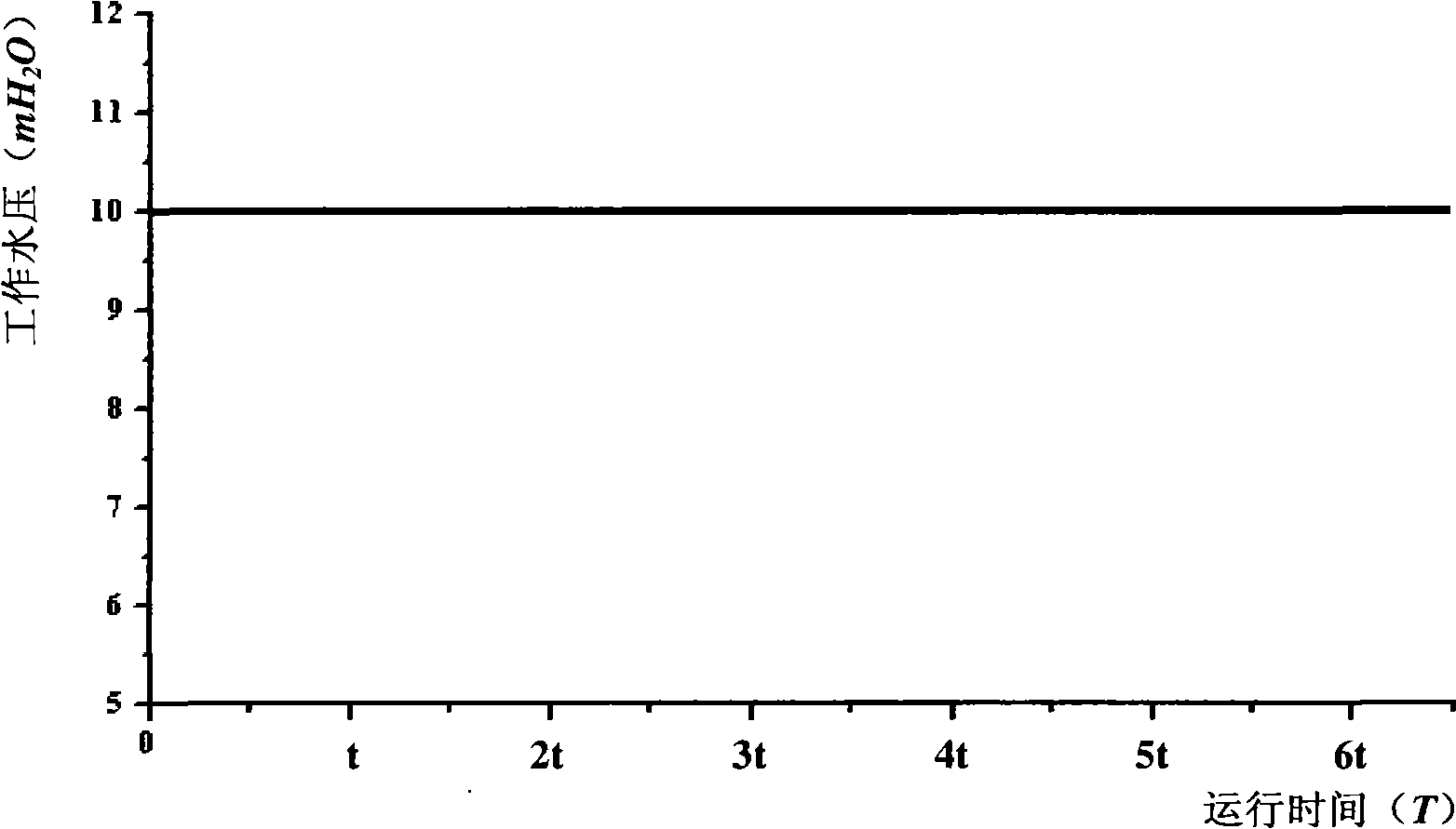

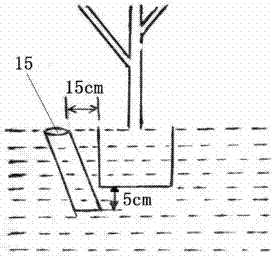

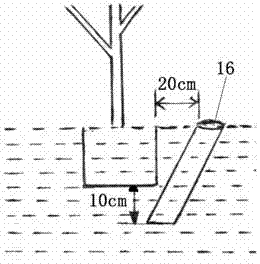

The invention discloses a dynamic hydraulic pressure drip irrigation system, characterized in that, an inlet of a water pump is connected with a caml water source through a pipe, a pressure water source and a reservoir enter a trunk after being connected with an outlet of the water pump; a switch solenoid valve, a check valve, an irrigation main switch and a main filter are arranged in turn on the trunk, a solenoid valve is connected in parallel with the switch solenoid valve through a branch pipe, a fertilization switch and a fertilizer placer are connected with the irrigation main switch in parallel through the branch pipe, a fertilizer controlling valve and a fertilizer pot are connected in turn under the fertilizer placer; a pressure gauge, main filter, a filter flushing valve and a water gauge are arranged on the trunk; a douche is arranged on bottoms of different branches of the branch pipe; each valve is connected with a controller through control lines, a frequency converter is connected between the water pump and the controller. The system causes operation water pressure to change antomatically and dynamically, keeps a larger working water pressure, meanwhile, reduces practical working pressure of the drip irrigation system, also reduces operation cost of the micro irrigation system.

Owner:HUAZHONG UNIV OF SCI & TECH

Chinese medicine residue humic acid organic/inorganic biological compound fertilizer and production method thereof

ActiveCN104447033ALimit churnImprove fertilityExcrement fertilisersFertilizer mixturesBULK ACTIVE INGREDIENTNutrient

The invention provides a Chinese medicine residue humic acid organic / inorganic biological compound fertilizer which comprises the following active ingredients: Chinese medicine residues, humic acid, chicken manure and biological bacteria. According to the compound fertilizer disclosed by the invention, the hardened soil can be effectively improved, the raising soil fertility is improved, the content of organic matters is improved, the soil permeability is improved, the water and fertilizer retention capacity of the soil is improved, available active nutrients of the crops are converted, the activities of pathogenic bacteria are resisted by using special actions and effects of the traditional Chinese medicines, the antibacterial property of the crops is improved, the use amount of pesticides is reduced, and the food safety risk is reduced.

Owner:重庆丰疆中医农业科技开发有限公司

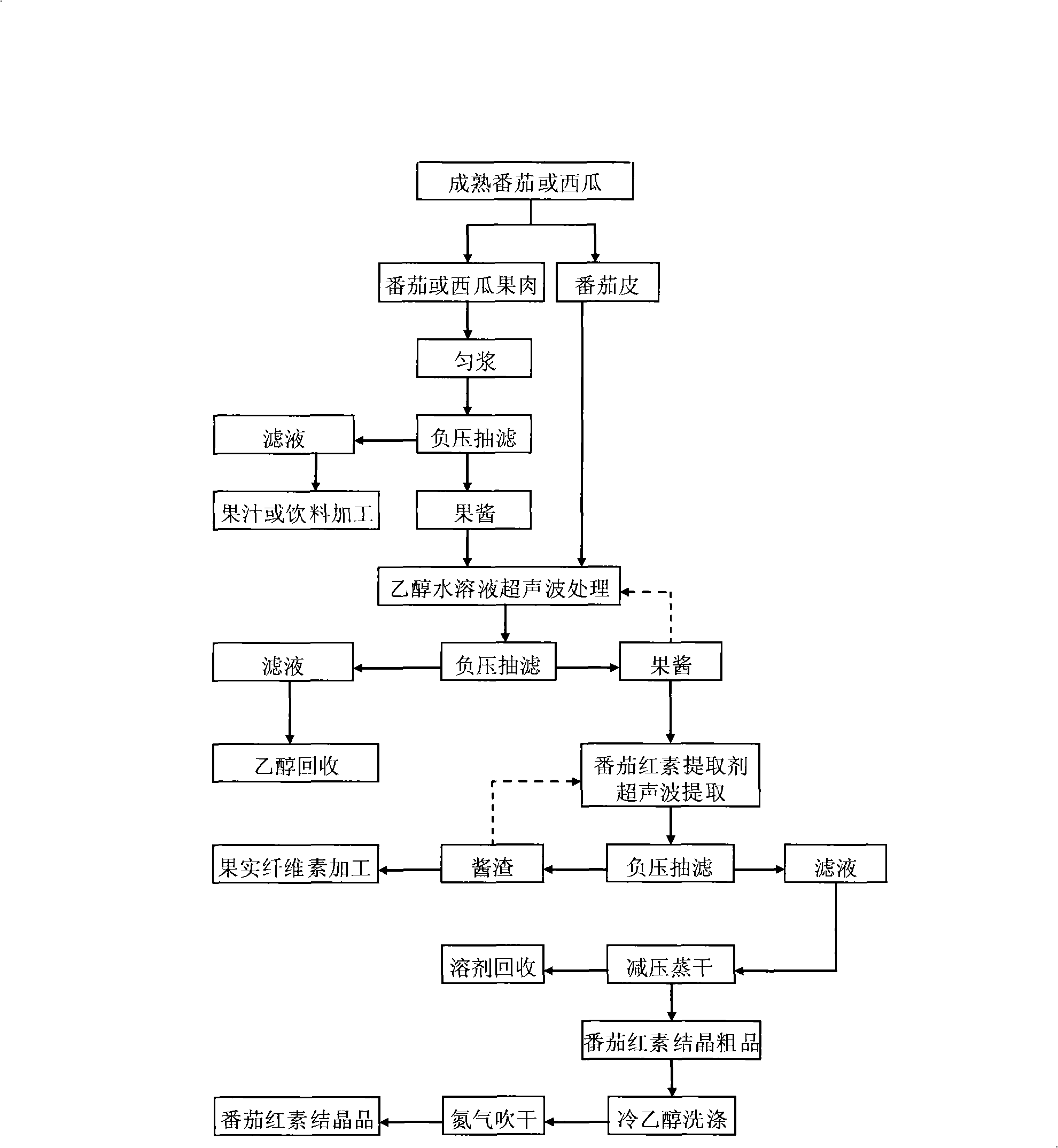

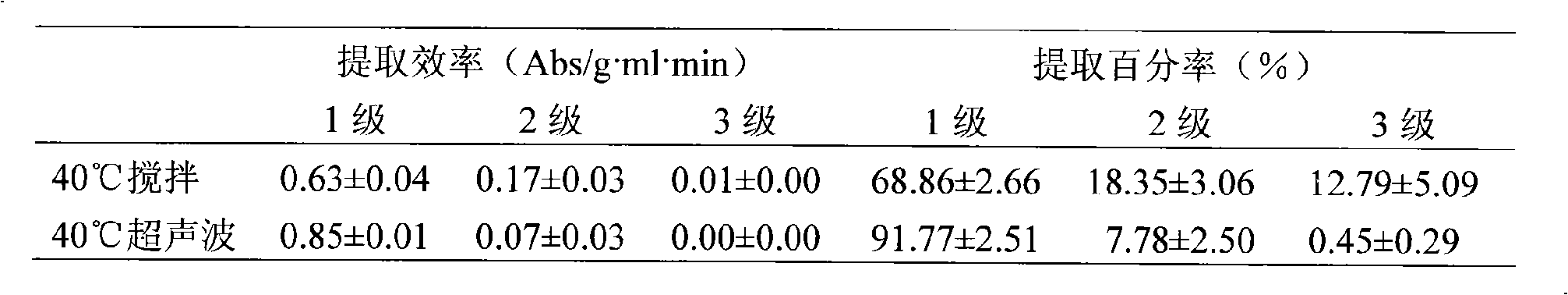

Method for preparing and abstracting lycopene

InactiveCN101289364AHigh speedHigh extraction rateHydrocarbon purification/separationHydrocarbonsLycopeneFood engineering

The invention discloses an extraction preparation method of lycopene, belonging to the technical field of food engineering. The method uses tomatoes or watermelon flesh as raw materials and adopts the technology of ultrasonic and extraction bags, which comprises the following steps: (1) the treatment of the raw materials and beating; (2) the separation of solid puree and liquid puree of fruit puree; (3) the ethanol water treatment of jam;(4) the extraction of the lycopene extractant of the jam and (5) the preparation of crystallization products of the lycopene. The extraction time of the invention is reduced to 10 to 60min from the10 to 20h of conventional time, and moreover the purity content of products is obviously improved from 10 to 20 percent in general to 70 to 80 percent. Therefore, the extraction preparation method is characterized by being efficient and fast, being convenient to be operated, low cost, high content of lycopene in the products, etc and is suitable for the promotion and the application in the industrialized and large scale production enterprises of natural lycopene with high purity.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Special strawberry composite biological fertilizer as well as preparation method and application thereof

InactiveCN107827627AReduce pollutionReduce cost inputCalcareous fertilisersBio-organic fraction processingAureobasidium sp.Nutrients substances

The invention relates to a special strawberry composite biological fertilizer as well as a preparation method and application thereof. The special strawberry composite biological fertilizer comprisesthe following components: EDTA-Ca (Ethylene Diamine Tetraacetic Acid), magnesium sulfate heptahydrate, EDTA-Mg, heptahydrate, EDTA-Zn, manganese sulfate monohydrate, EDTA-Mn, boric acid, EDTA-Fe, EDTA-Cu, soybean molasses, polyglutamic acid fermentation broth, chitosan oligosaccharide, algin, compound amino acid, humic acid, bacillus thuringiensis fermentation broth, bacillus megatherium fermentation broth, bacillus mucilaginosus fermentation broth and streptomyces jingyangensis fermentation broth. Through bacterium activation, seed liquid preparation, fermentation culture and compounding, thecomposite biological fertilizer is prepared, the composite biological fertilizer is applied to strawberry planting, and a diluted composite biological fertilizer liquid is sprayed at different growthstages of strawberry respectively. Due to synergetic effects of substances such as inorganic salts, organic matters and microorganisms, long lasting nutrient substances are provided to strawberry crops, absorption of nutrients in soil by plants is promoted, the fertilizer amount is reduced, and the chemical fertilizer cost is reduced.

Owner:天津北洋百川生物技术有限公司

Control method of dynamic water-pressure drip-irrigation system

ActiveCN101449654BAvoid cloggingLow running costLiquid fertiliser distributionClimate change adaptationWater sourceSolenoid valve

Owner:HUAZHONG UNIV OF SCI & TECH

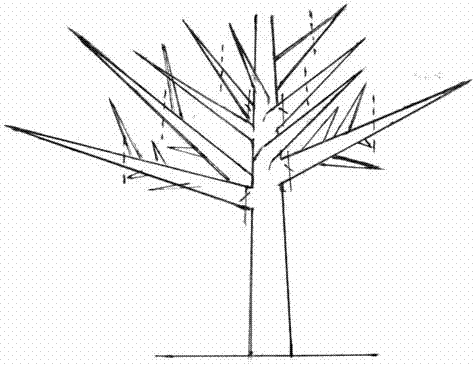

Cultivation method for promoting santalum album to grow into useful timber early and high yield

ActiveCN103798010AChange the way of lifeIncrease material densityForestryHorticultureNitrate nitrogenFarmyard manure

The invention discloses a cultivation method for promoting santalum album to grow into useful timber early and high yield. The cultivation method comprises the steps as follows: A, selecting healthy santalum album seedlings propagated by seeds of healthy and mature seed trees and cultivated with parasitism of kuhnia rosmarnifolia vent; B, selecting an area where bananas can be planted as a planting area; C, loosening soil and digging holes in the selected area according to the pH of land; D, applying mixed farmyard manure in dug pits to serve as a base fertilizer; E, planting the healthy santalum album seedlings in the dug pits; F, appropriately watering dilute manure water or a nitrate nitrogen compound fertilizer dilute solution with the concentration of about 1:300 after planting for 15-20 days; and the like. According to the cultivation method, existing seedling cultivation is inherited as the basis, according to the nature of the survival of the santalum album, artificial and natural conditions are fully used and combined, the planting method of guide, control and gradual removal of parasitism is further adopted, and the survival mode that the santalum album depends on parasitism is changed thoroughly, so that the santalum album grows into the useful timber early and is high in density; and the operation is simple and convenient, and the method can be promoted for large-scale industrialization.

Owner:SHENZHEN LYUSHENGYUAN GARDEN GREENING

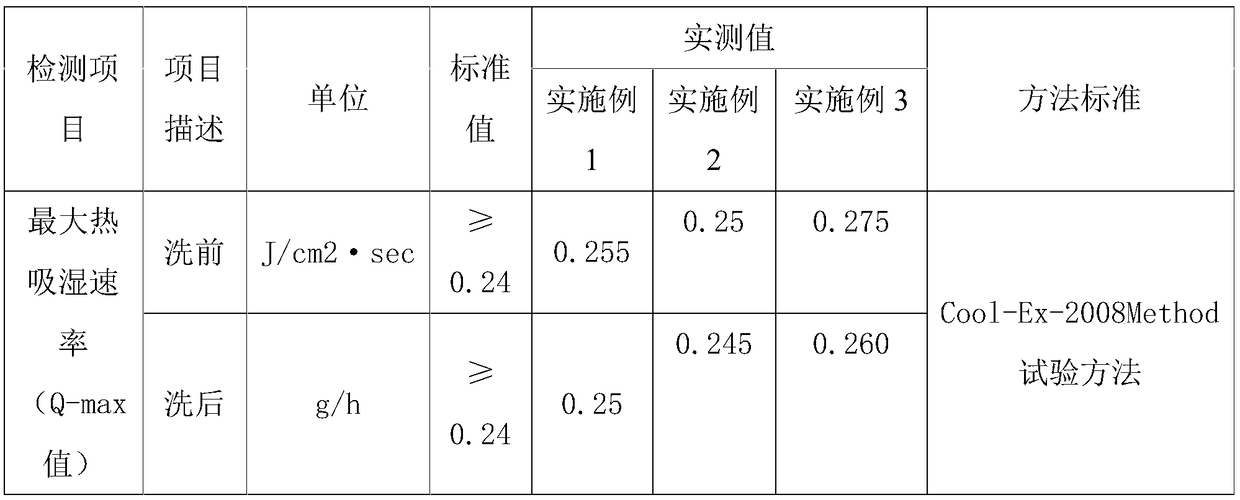

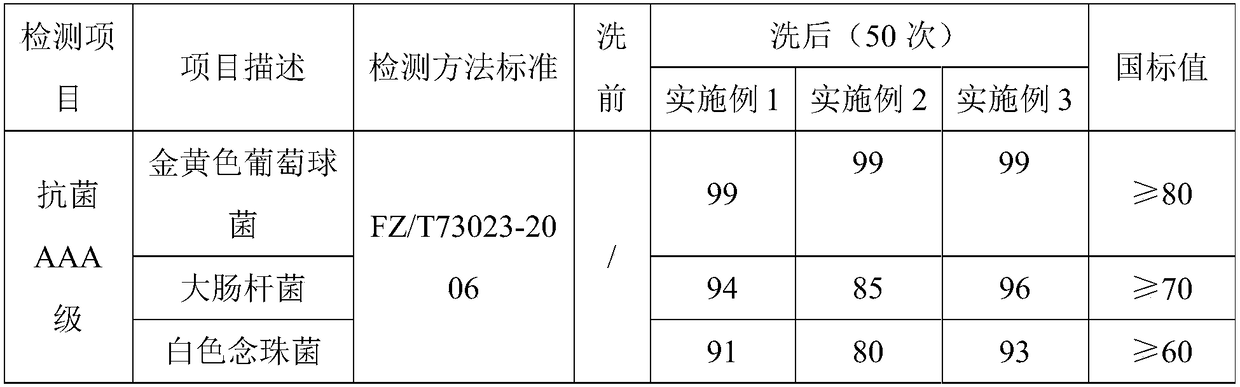

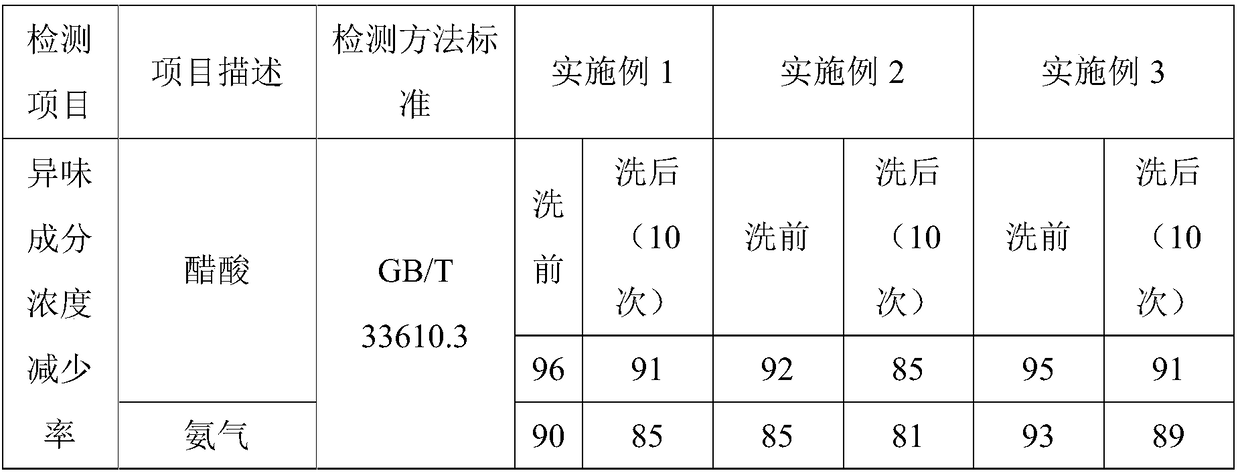

Herba menthae extract microcapsule, acrylic fiber, fabric and related preparation methods

InactiveCN108301060AImprove antibacterial functionProtection lossConjugated synthetic polymer artificial filamentsMicroballoon preparationEmulsionColloid

The invention discloses a herba menthae extract microcapsule, acrylic fiber, fabric and related preparation methods. A microcapsule emulsion serving as a raw material of the herba menthae extract microcapsule is prepared from 1-10wt% of concentrated herba menthae extract, 2-5wt% of hydrophilic colloid, 5-7wt% of modified starch and 0.2-0.6wt% of an emulsifying agent. The herba menthae extract microcapsule disclosed by the invention is stable in structure; the wall of the microcapsule can prevent loss of herba menthae extract in a spinning process; the microcapsule in the fiber releases the effective components of the herba menthae extract by virtue of friction so as to achieve lasting antibacterial and cooling functions; and because the concentration of herba menthae in the herba menthae extract microcapsule is high, when the herba menthae extract microcapsule is added to the acrylic fiber, the addition amount of the herba menthae extract microcapsule can be reduced, thereby lowering the spinning difficulty.

Owner:XIAMEN ANTA SPORTS GOODS CO LTD

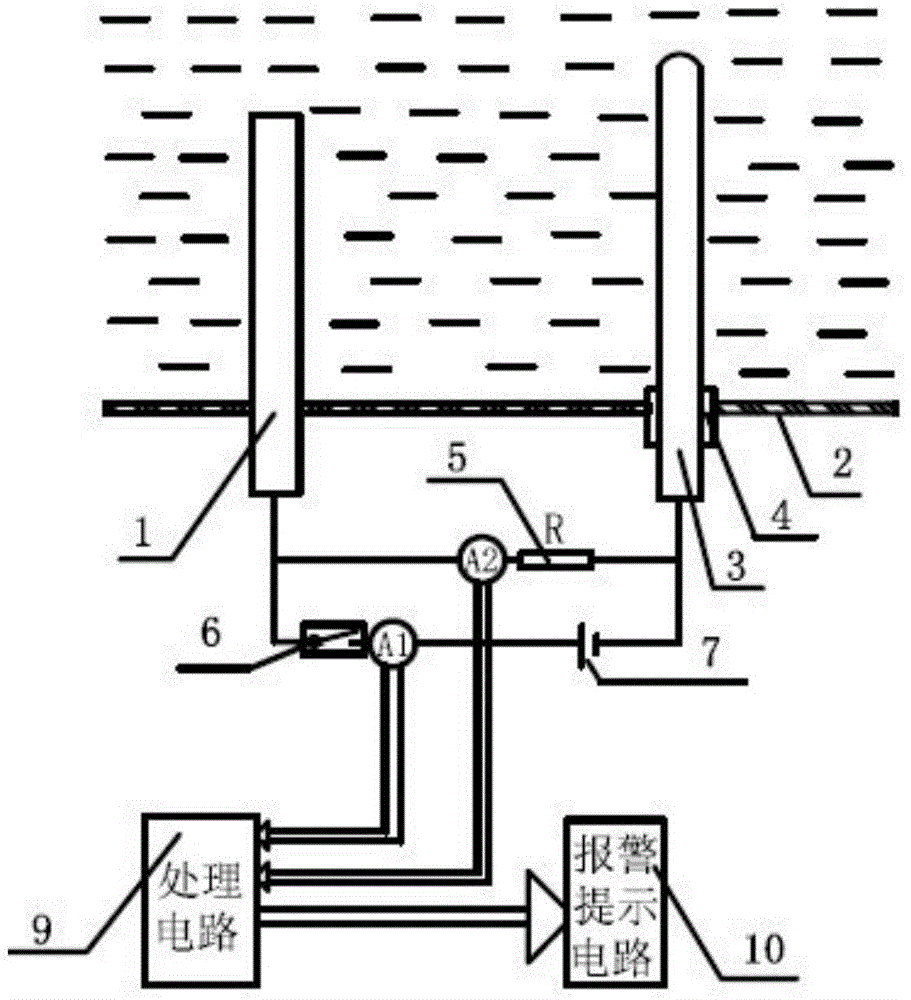

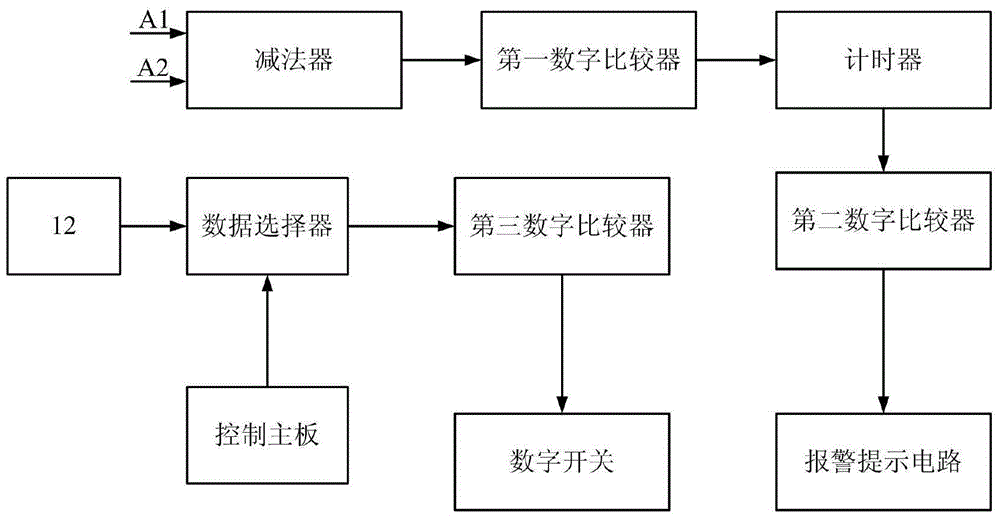

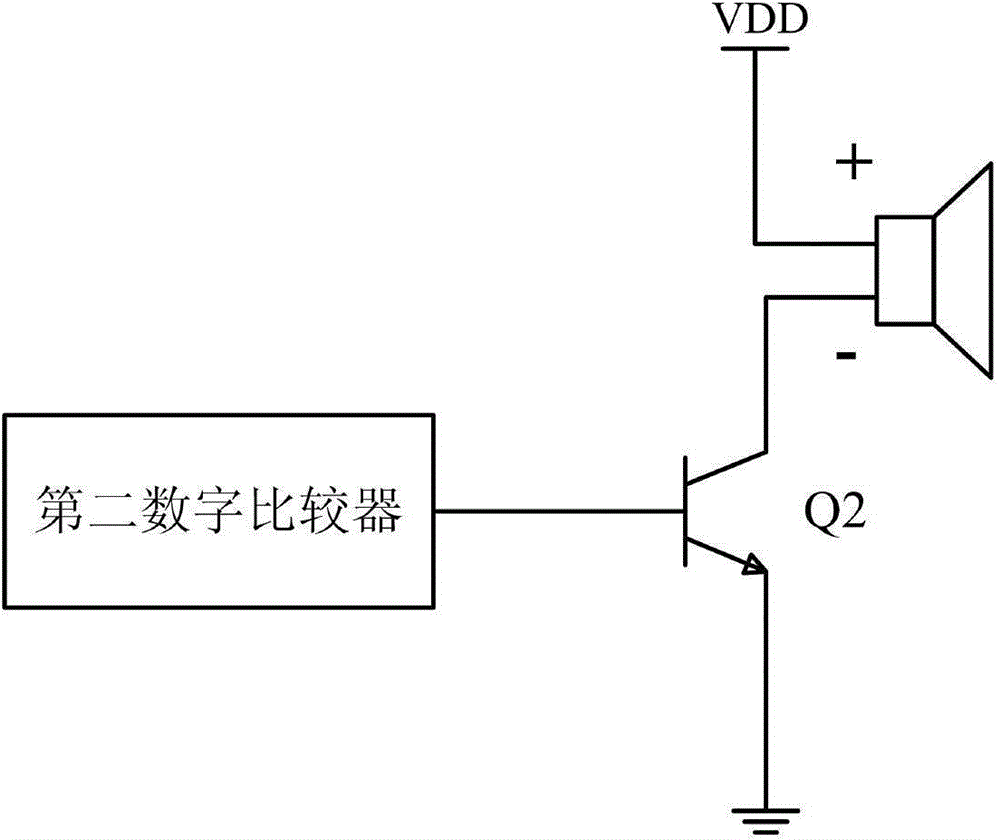

Water heater having anode bar loss detection prompting function and control method thereof

Provided are a water heater having an anode bar loss detection prompting function and a control method thereof. The water heater comprises an inner container arranged inside a housing, an anode bar, an electric heating tube and a control mainboard responsible for water heater control, wherein the anode bar and the electric heating tube are installed inside the inner container. The water heater further comprises a current detection circuit, wherein the current detection circuit is connected with an alarm prompting circuit and is installed outside the inner container. The control method of the water heater comprises the steps of 1S starting the control mainboard of the water heater, supplying water and electricity for the water heater and starting a water heater heating circuit, 2S detecting the loss situation of the anode bar, and 3S enabling the water heater heating circuit and the current detection circuit to be automatically powered off when the temperature of the water heater is up to predetermined temperature. The water heater can automatically detect protective current according to the actual using environments of different uses and self factors and judge the loss situation of the anode bar, and it is ensured that the anode bar conducts comprehensive protection on the electric heater and the inner container.

Owner:山东新基德电器有限公司

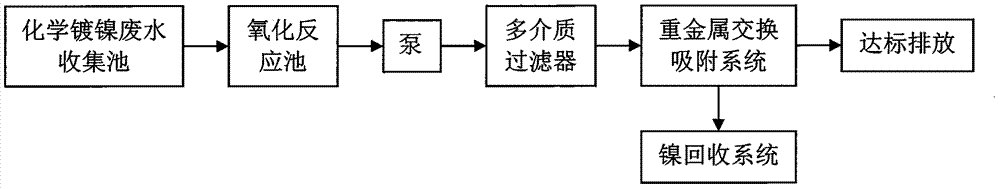

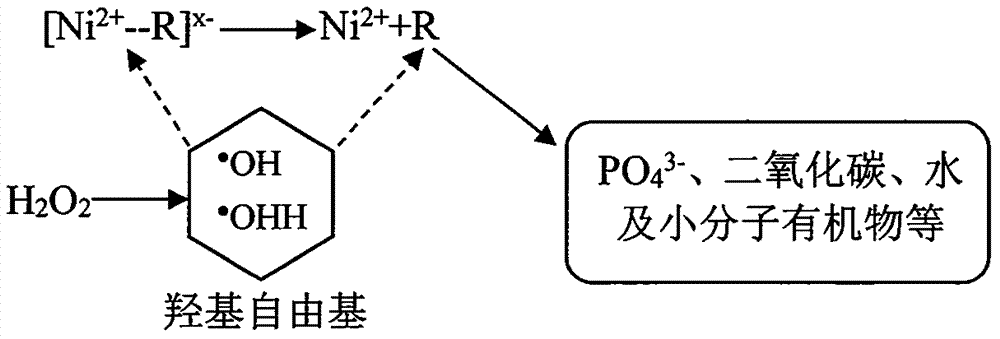

Method for treating electroless nickel-plating wastewater through combination of hydrogen-peroxide oxidation and ion exchange adsorption

InactiveCN107188326AProtection lossGood effectWater contaminantsWater/sewage treatment by ion-exchangeFiberElectroless nickel

The invention provides a method for treating electroless nickel-plating wastewater through the combination of hydrogen-peroxide oxidation and ion exchange adsorption in order to solve the problem that nickel ions are difficult to stably and standardly discharge in the existing electroless nickel-plating wastewater treatment. The method includes the following steps that 1, the hydrogen-peroxide oxidation method is used for decomposing a complex compound, wherein sulfuric acid or sodium hydroxide is poured in electroless nickel-plating wastewater firstly, the pH value is adjusted to 2.0-3.0, a proper amount of hydrogen peroxide is poured to decompose a complexing agent in the wastewater and nickel ions are thus separated from the complexing agent to be in an ionic state; 2, the ion exchange adsorption method is used for treating nickel ions, wherein after being subjected to oxidation and complex compound decomposing, the electroless nickel-plating wastewater passes through a multi-medium filter, impurities in the wastewater are removed, after impurity removal, the wastewater enters a heavy metal exchange adsorption system for exchange adsorption, the nickel ions in the wastewater are removed, effluent can reach discharge standards, exchange adsorption is conducted on the nickel ions on ion exchange fibers, and then eluting, precipitation and thermal decomposition are conducted for recycling. According to the method, it can be effectively ensured that the nickel ions subjected to electroless nickel-plating wastewater treatment are stable and reach the 'emission standard of pollutants for electroplating' (GB21900-2008), at the same time, nickel in wastewater is recycled, the process is simple, operation and management are convenient, and no secondary pollution is caused.

Owner:SHENZHEN QIANHAI ZHONGSHENG ENVIRONMENTAL PROTECTION TECH

Catalyst for converting benzyl alcohol to benzaldehyde, and preparation method thereof

ActiveCN110124717AResolve size inconsistenciesSuitable reducibilityOrganic compound preparationCatalyst activation/preparationN dimethylformamideBenzaldehyde

The invention discloses a catalyst for converting benzyl alcohol into benzaldehyde, and preparation method thereof. The catalyst is composed of gamma-Fe2O3 derived from an amino functionalized metal-organic framework material NH2-MIL-101(Fe), N-doped porous carbon and noble metal Au nanoparticles, wherein a weight ratio of the gamma-Fe2O3 to the porous carbon is 2-5, and the noble metal Au accounts for 0.5-5% of the weight of the catalyst. The preparation method comprises the following steps: adding iron trichloride and 2-aminoterephthalic acid to N,N-dimethylformamide, dropwise adding a HAuCl4 solution to the above obtained mixed solution, heating and stirring the obtained solution, crystallizing the solution, and washing and drying obtained crystals to obtain Au@NH2-MIL-101(Fe); and carrying out high temperature treatment on the obtained solid in an inert atmosphere to obtain the finished catalyst. The catalyst has the advantages of high activity, high selectivity and high stability,can be easily and quickly recovered and reused under the action of an external magnetic field, and can be reused.

Owner:ZHEJIANG NORMAL UNIVERSITY

Lightweight graphite resistance reduction module and preparation method thereof

PendingCN108155489AImprove conductivityStrong moisture absorption and moisturizing abilityLine/current collector detailsConnection contact member materialGlass fiberGraphite

The invention discloses a lightweight graphite resistance reduction module and a preparation method thereof. The lightweight graphite resistance reduction module is prepared form expanded graphite, glass fiber mesh cloth, graphite resistance reduction cloth and graphite woven belt material. The lightweight graphite resistance reduction module can be made into a block shape, a plate shape or a cylindrical shape and is high in plasticity and structural strength. The preparation method includes the processes of laying, fixing, pressing, coating and re-pressing. The lightweight graphite resistancereduction module has the advantages of being small in density, light in weight, high in strength, good in water absorption, excellent in electrical conductivity and the like.

Owner:XIXIAXIAN JINFANGYUAN SEALING MATERIAL

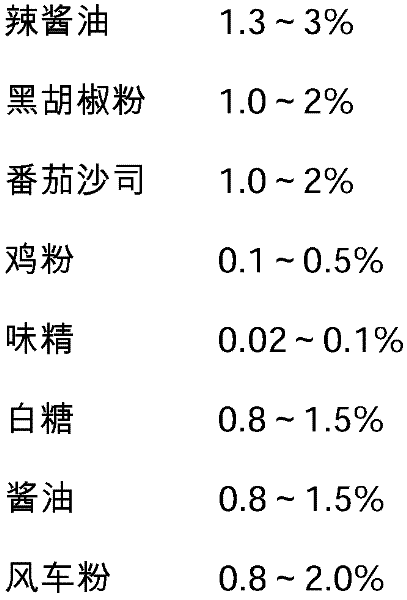

Method for making beef

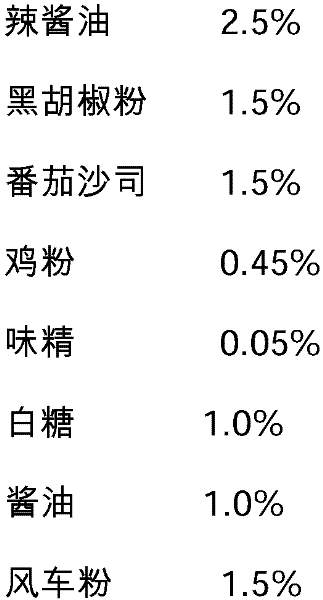

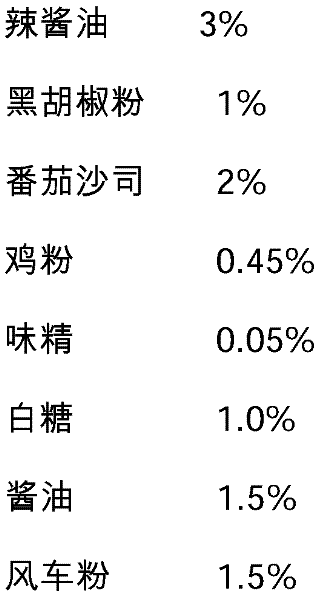

The invention provides a method for making beef. The method comprises the following steps of: selecting beef, removing tendons and cleaning; cutting the beef into a plurality of beef pieces, wherein each beef piece is about 50 grams; salting the beef pieces in soy sauce blended with clean water for 30 to 45 minutes; starching the salted beef pieces, and shaping for 10 minutes at the temperature of between 2 DEG C below zero and 5 DEG C below zero; frying the shaped beef pieces in oil of 150 DEG C for one minute; putting beef accessories into the beef pieces, and stirring; putting the stirred beef pieces into a pot, and cooking for 20 seconds at the temperature of between 100 and 120 DEG C; and fishing out of the pot, and filling. The beef accessories comprise the following components in percentage by weight: 88 to 92 percent of beef, 1.3 to 3 percent of chili sauce, 1.0 to 2 percent of black pepper powder, 1.0 to 2 percent of tomato sauce, 0.1 to 0.5 percent of chicken powder, 0.02 to 0.1 percent of monosodium glutamate, 0.8 to 1.5 percent of white sugar, 0.8 to 1.5 percent of soy sauce, and 0.8 to 2.0 percent of corn starch.

Owner:宝武集团上海宝山宾馆有限公司

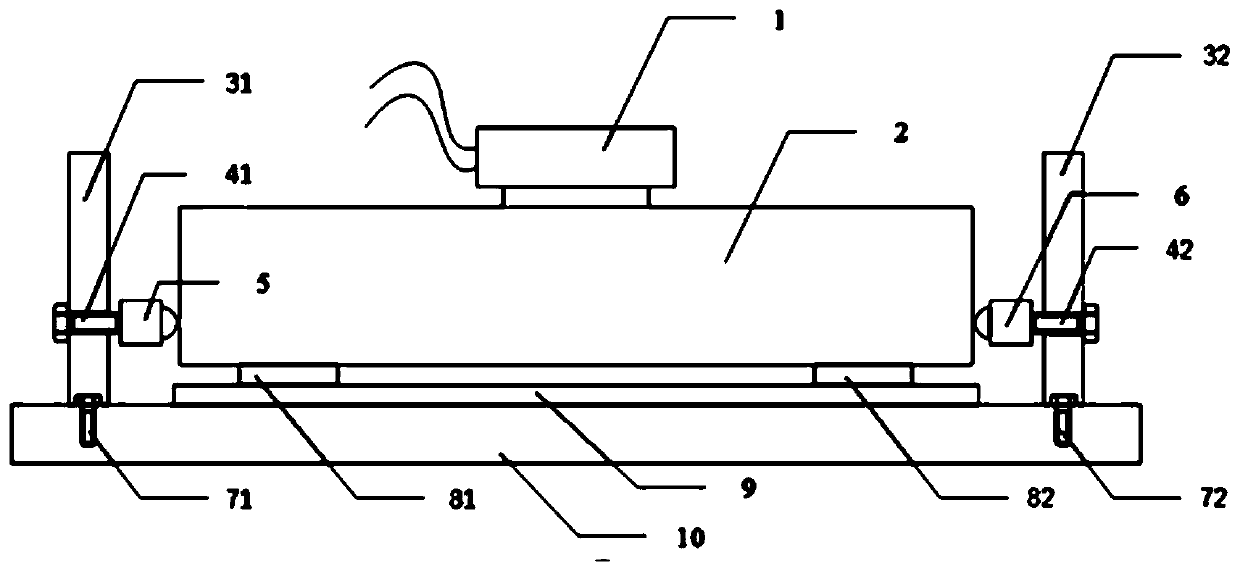

Linear motor thrust measuring device and measuring method

InactiveCN111044196AProtection lossGuaranteed detection accuracyApparatus for force/torque/work measurementDynamo-electric machine testingElectric machineClassical mechanics

The invention provides a linear motor thrust measuring device and a linear motor thrust measuring method. The linear motor thrust measuring device comprises a linear motor and a test platform, whereinthe linear motor comprises a stator and a rotor, and the rotor is fixed on a first sliding block and can linearly move on a first rail relative to the stator along with the first sliding block; a second rail is arranged on the test platform, and the stator is fixed on the second sliding block and can slide along the second rail along with the second sliding sheet; baffles are fixedly arranged atthe two ends of the stator respectively, force sensors are arranged between the baffles and the stator end, the stator is clamped between the two force sensors, the two force sensors are used for detecting counter-acting forces, and therefore electromagnetic thrust of the linear motor is obtained. The linear motor thrust measuring device is simple in structure, the force sensors are static in themeasuring process, extra drag chain wire arrangement is not needed, the loss of the force sensors is small, and the measuring device can be used for measuring the electromagnetic thrust of a no-load linear motor and can further be used for measuring the electromagnetic thrust when a rotor is loaded with a load.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Crab meal fish meat gluten and preparation method thereof

The invention discloses crab meal fish meat gluten, which comprises the following ingredients by weight: 490 to 510 grams of black carp meat, 25 to 35 grams of flour, 25 to 35 grams of glutinous rice flour, 50 to 70 grams of potato starch, 45 to 55 grams of baking powder, 8 to 12 grams of refined salt, 40 to 60 grams of egg white, 490 to 510 grams of edible refined oil, 480 to 520 grams of water and 40 to 60 grams of crab meal. The invention also discloses a method for preparing the crab meal fish meat gluten. The method comprises the following steps of: 1) selecting fresh and alive black carps, washing and picking meat from fish bones; 2) putting the black carp meat into a mincing machine, running for 3 to 5 minutes, and mincing to obtain minced fish; 3) mincing the minced fish, soaking in clear water, mixing and stirring the glutinous rice flour, the potato starch, the bulking powder, the refined salt and the crab meal to form stuffings, and whipping the egg white and the refined oil; 4) mixing and stirring the ingredients in the step 3) for 30 minutes; and 5) frying gluten balls and fishing the gluten balls out.

Owner:宝武集团上海宝山宾馆有限公司

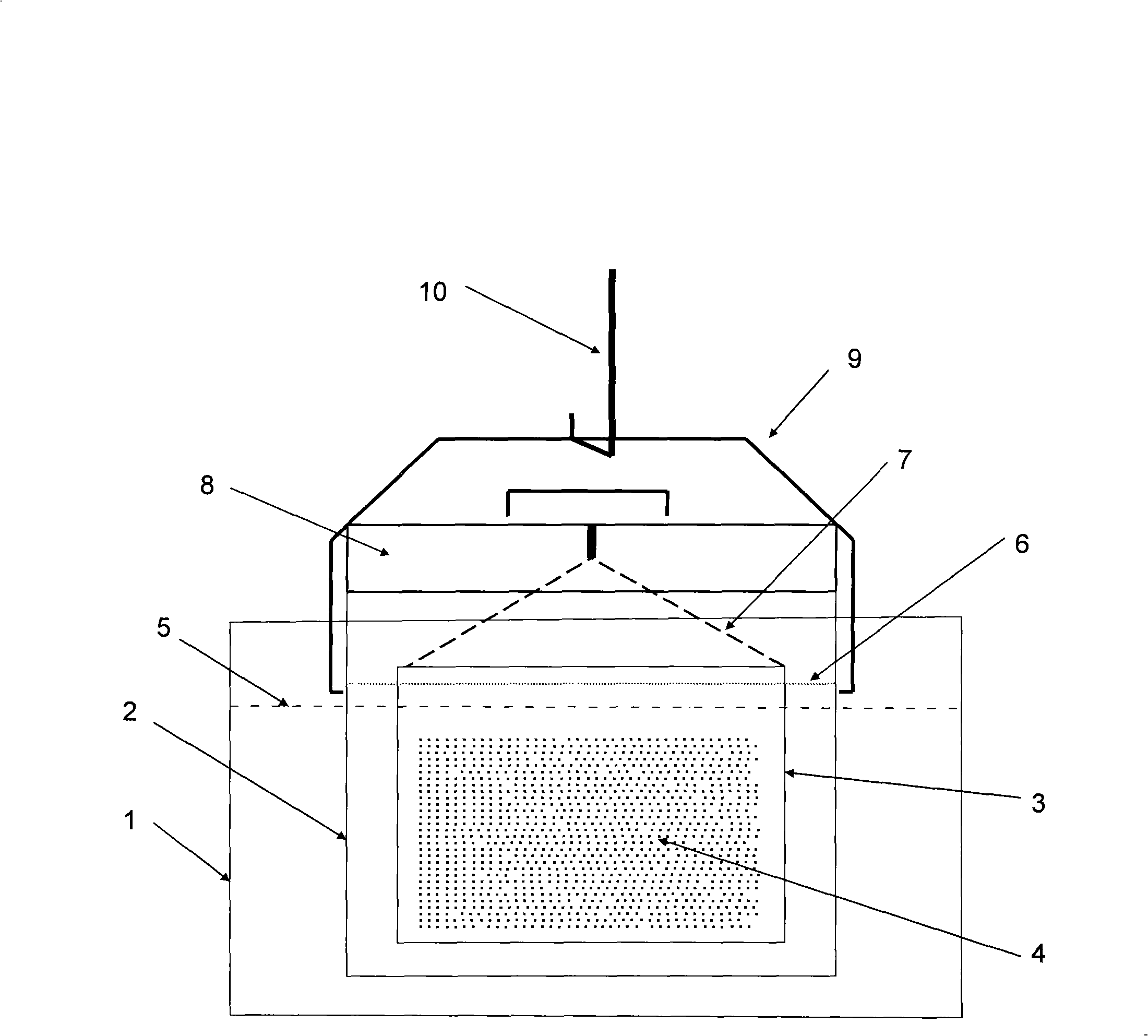

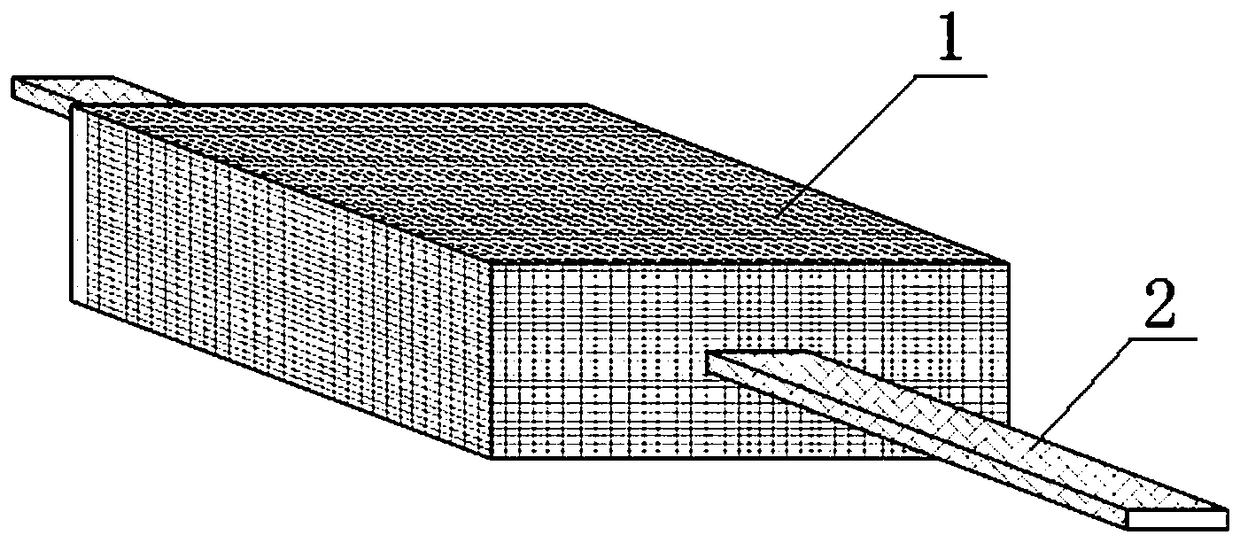

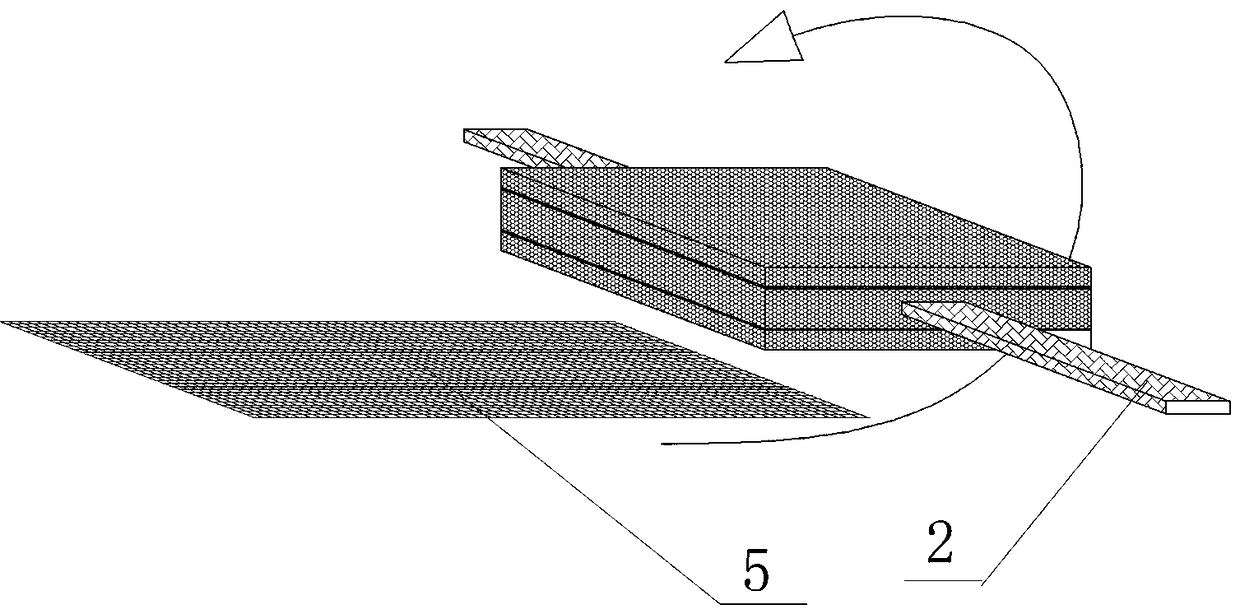

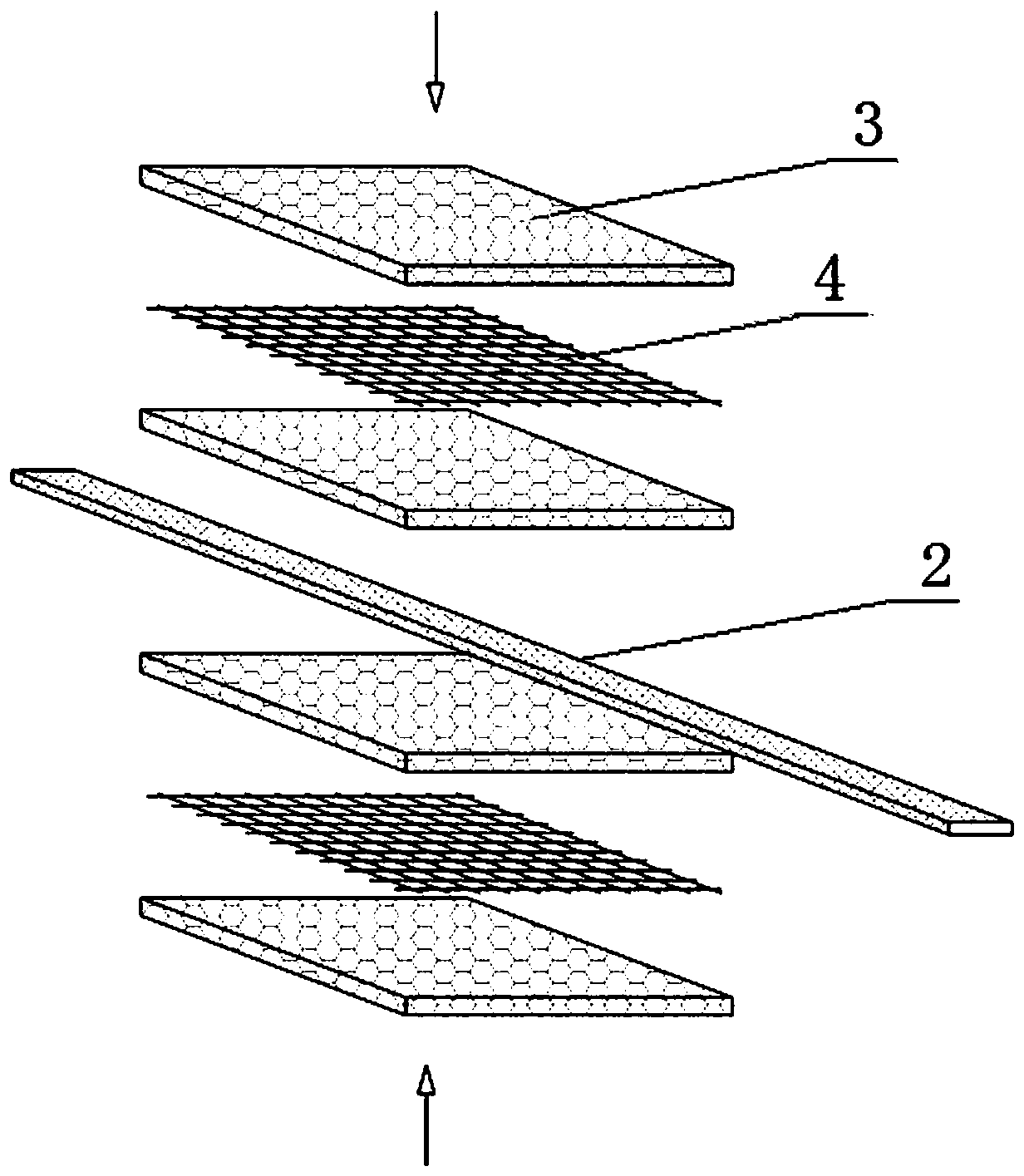

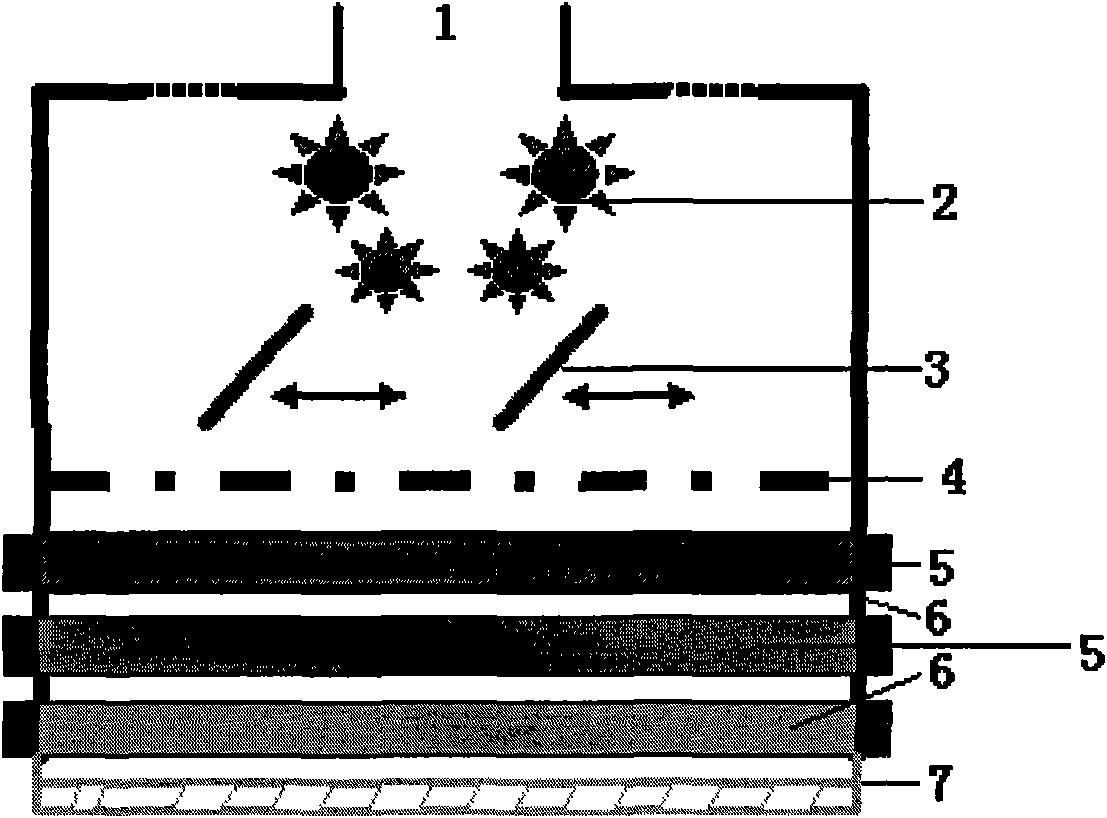

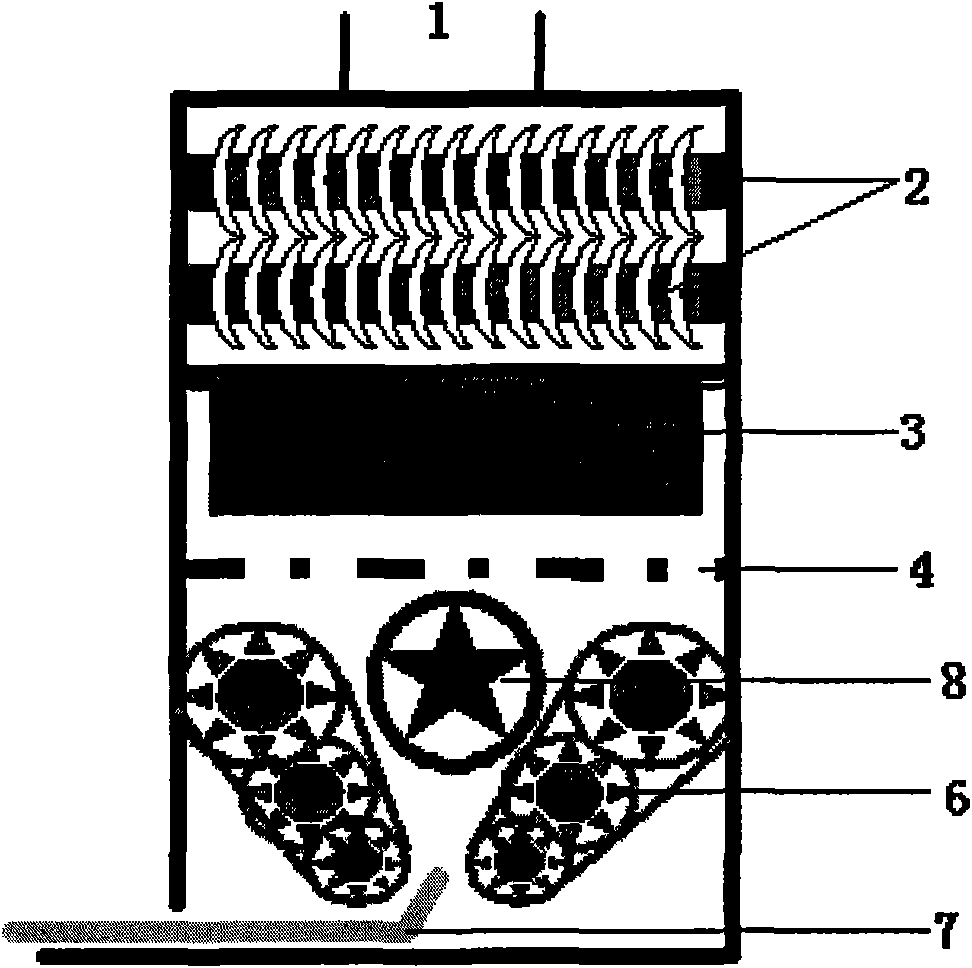

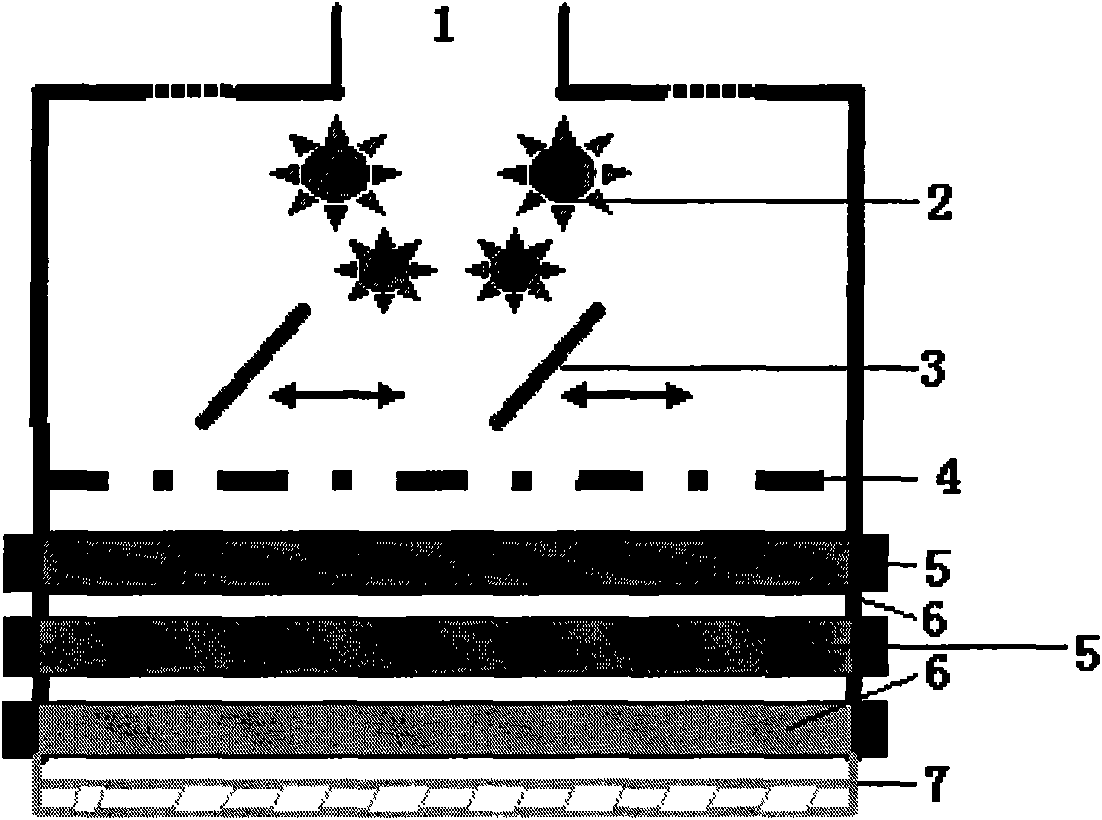

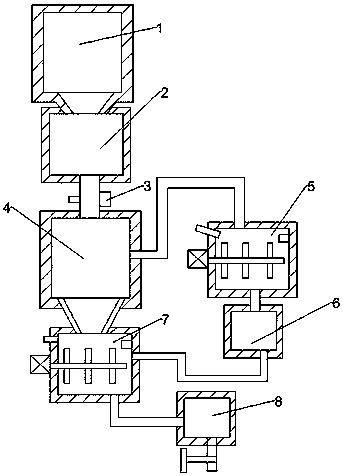

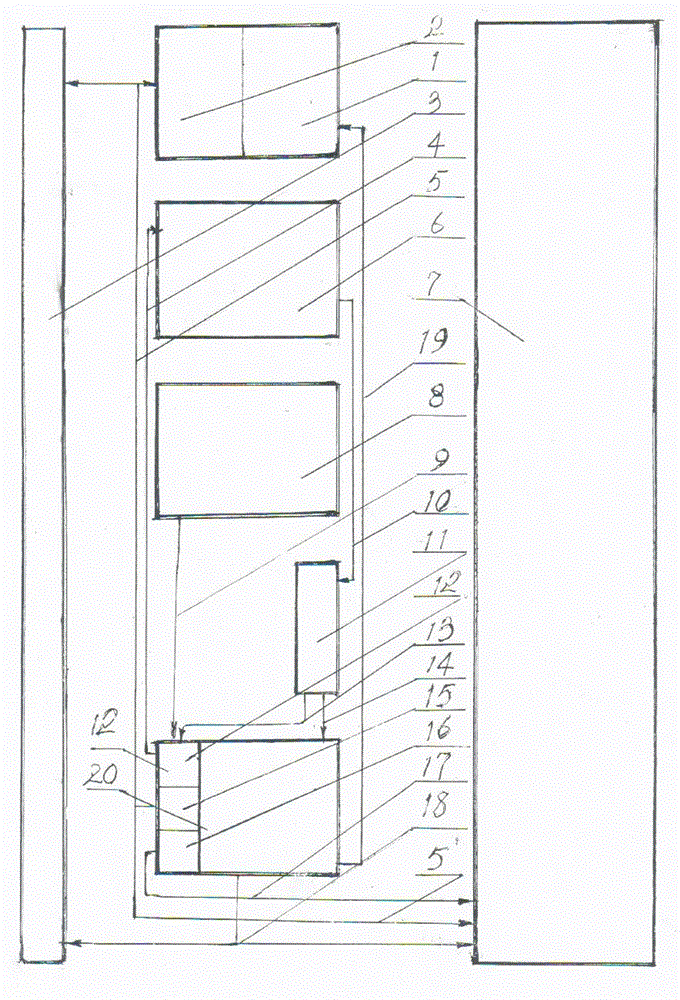

Equipment for producing soil-free grass

ActiveCN102334441ASimple structureEasy to industrializeAgriculture gas emission reductionCultivating equipmentsEngineeringFiber

The invention relates to equipment for producing soil-free grass. The equipment comprises a crushing machine, a pressing machine and a weaving machine, wherein cutting tools of the crushing machine are fixed on a box body longitudinally through a middle axle; swing type material distributors are fixed on the box body longitudinally; four front and rear corners of a vibration grid are fixed on thebox body; transmission devices are arranged on left and right sides of the box body, are connected with pressing shafts, and control 6 pressing shafts which are relatively stressed; and a regulating valve is also arranged among the pressing shafts. The invention has the advantages that: the equipment has a simple structure and is easy to industrialize; and the raw fiber crushing efficiency of theequipment is extremely high, and the production and processing of the soil-free grass are facilitated.

Owner:上海园林绿化建设有限公司

Grounding resistance reduction agent and method for lowering corrosion on grounding body due to grounding resistance reduction agent

ActiveCN104218334AImprove corrosionImprove the environmentConnection contact member materialActivated carbonEnvironmental resistance

The invention relates to the technology of grounding for lightening, in particular to a grounding resistance reduction agent and a method for lowering corrosion on a grounding body due to the grounding resistance reduction agent. The method includes preparation of a long-acting anticorrosive agent, preparation of the grounding resistance reduction agent and mixing of the long-acting anticorrosive agent in the grounding resistance reduction agent. The preparation of the long-acting anticorrosive agent includes the steps: firstly, selecting, by weight, 20-30 parts of ammonium carbonate, 50-60 parts of powdered activated carbon and 50-60 parts of bentonite not less than 400 meshes; secondly, feeding the ammonium carbonate, the powdered activated carbon and the bentonite in the proportion into a mixer for blending and mixing, adsorbing the ammonium carbonate with the powdered activated carbon and coating the ammonium carbonate with the bentonite to obtain the long-acting anticorrosive agent. The long-acting anticorrosive agent has two major features of alkalescence and slow release and can keep long-acting anticorrosive effect, thereby being initiative. The grounding resistance reduction agent is remarkable in resistance reduction effect, environment friendly, convenient to use and low in cost.

Owner:东莞市华炜雷电防护设备有限公司 +1

Long-acting compound fertilizer and preparation process thereof

InactiveCN109988036APromote growthImprove disease resistanceSuperphosphatesMagnesium fertilisersAmmonium sulfateChemistry

The invention provides a long-acting compound fertilizer and a preparation process thereof. The fertilizer is composed of the following chemical fertilizer raw materials: 8% of fulvic acid, 0.7% of magnesium sulfate, 0.7% of ferrous sulfate, 1.2% of zinc sulfate, 1.5% of ammonium sulfate, 0.5% of manganese sulfate, 0.5% of ammonium molybdate, 1.5% of borax, 5% of calcium superphosphate, 20% of polypeptide urea and 20% of potassium sulfate. The invention has the advantages that the fertilizer has the effects of adjusting the too high or too low pH value of soil, resisting salts and alkalis, improving hardened soil, promoting crop growth, improving crop disease resistance, resisting lodging, resisting continuous cropping, resisting plant diseases and insect pests, resisting freezing damage,protecting soil moisture loss, enhancing drought resistance, improving crop yield, improving quality of crops, vegetables and melons and fruits, improving original quality and original flavor of vegetables and melons and fruits, and leading to a long preservation period.

Owner:青岛华夏沃土生物科技有限公司

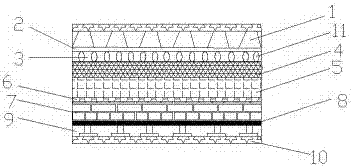

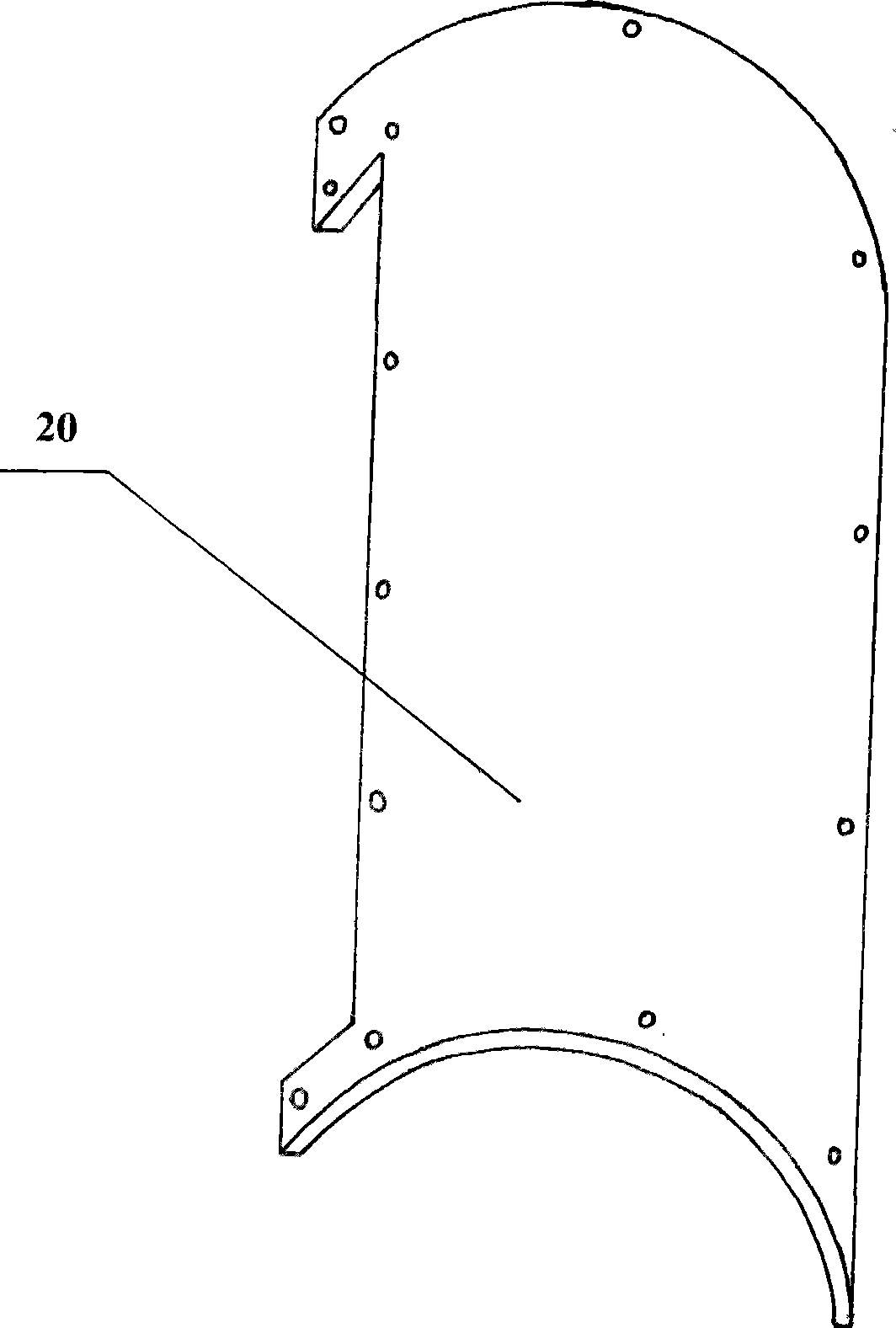

Temporary dwelling roof structure

InactiveCN107152128AWaterproofAvoid crackingBuild-up roofsRoof drainageInsulation layerThermal insulation

The invention discloses a temporary dwelling roof structure which comprises a protective layer, wherein a vapor-proof layer is arranged on the bottom surface of the protective layer; a waterproof layer is arranged on the bottom surface of the vapor-proof layer; a thermal insulation layer is arranged on the bottom surface of the waterproof layer; a heat preservation layer is arranged on the bottom surface of the thermal insulation layer; a shock absorption layer is arranged on the bottom surface of the heat preservation layer; a sound insulation layer is arranged on the bottom surface of the shock absorption layer; a fireproof layer is arranged on the bottom surface of the sound insulation layer; a structural layer is arranged on the bottom surface of the fireproof layer; profiled steel sheets are arranged on the surfaces of the structural layer and the protective layer. The temporary dwelling roof structure disclosed by the invention has the beneficial effects that the strength and firmness of the roof are improved, the heat resistance of the roof is improved, the influence of the roof on external environmental change is reduced, and the condition that the roof is cracked is avoided. Meanwhile, the temporary dwelling roof structure has the waterproof, sound-insulated and shock-absorbing effects, the practicality of the roof is greatly improved, and the service life of the roof is prolonged.

Owner:上海闵轩钢结构工程有限公司

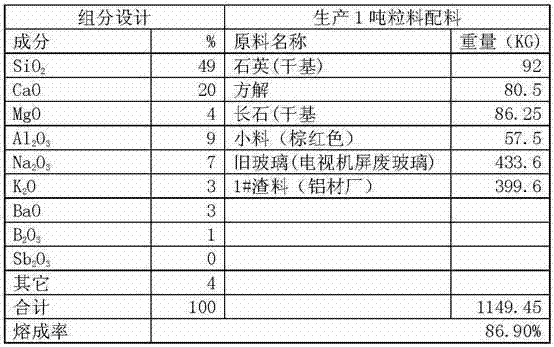

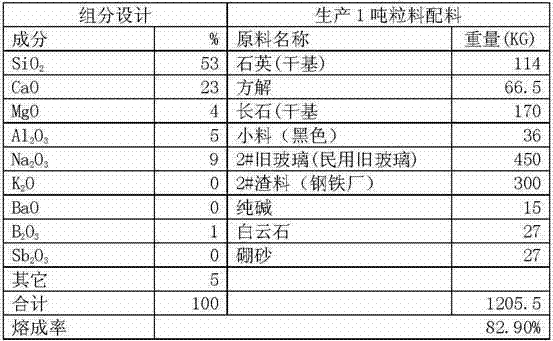

Method for producing stone-simulative microlite from slag and waste glass

The invention discloses a method for producing stone-simulative microlite from slag and waste glass. The method comprises the following steps of 1, crushing slag and waste glass into particles of less than 2 meshes, 2, carrying out primary full pre-mixing on each 100-1000t of the particles, 3, carrying out sampling and carrying out complete chemical analysis, 4, designing a formula and a composition list according to components, 5, carrying out weighing and mixing, 6, melting the mixture to obtain a glass liquid, 7, preparing glass blocks, 8, carrying out air cooling or water cooling to obtain glass blocks with crack patterns (or directly preparing a glass water-quenched material), 9, transferring the glass blocks into a shelf board mold, 10, crystallization, 11, preparing a raw plate blank, 12, carrying out polishing, 13, carrying out trimming, 14 carrying out packaging and 15 conveying the product out of the factory. The method changes slag and waste glass into valuables. The stone-simulative microlite does not produce radiation, is environmentally friendly, has various patterns, can replace stones, reduces stone exploitation, prevents water and soil loss, utilizes the slag and waste glass having wide sources and can replace a plurality of chemical raw materials. The slag used by the method has complex composition and contains various non-ferrous metals. The method reduces a production cost and can prepare colorful stone-simulative microlite.

Owner:冯翠兰

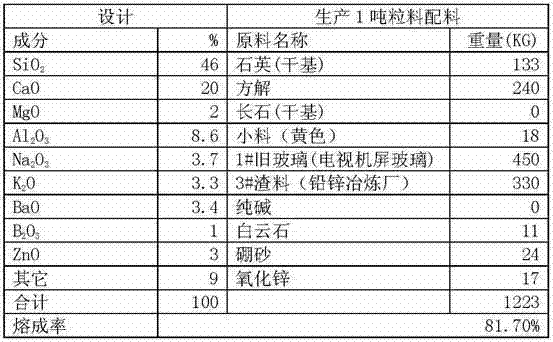

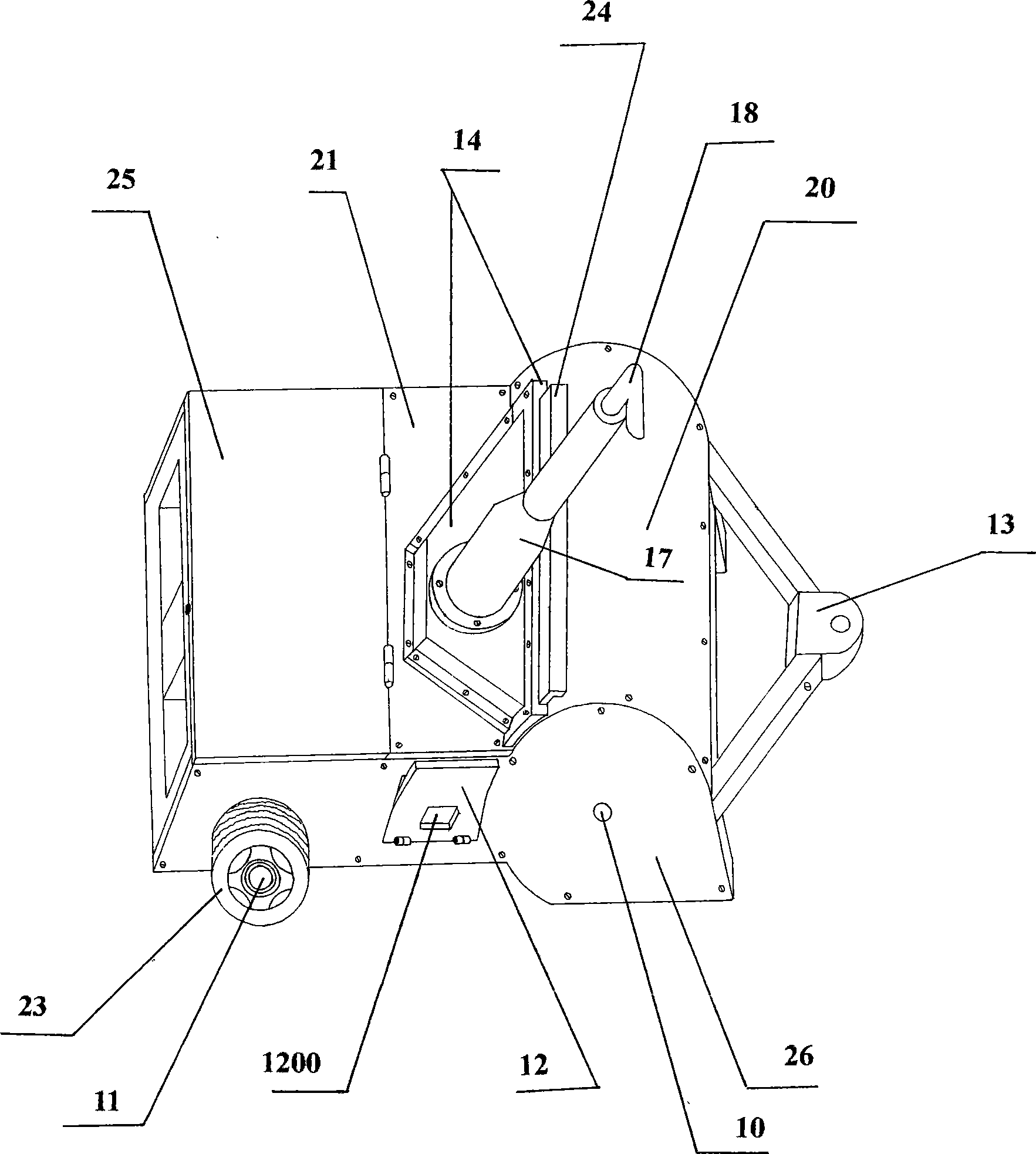

General-purpose machine for recycling, returning and binding stalks

InactiveCN101473734AEasy to loseProtection lossCrop conditionersMowersGeneral purposePulp and paper industry

The invention discloses a universal machine for recovering, returning and bundling straw, comprising a walking frame body, an extrusion body, a suction fan, an automatic cutting machine, an electric motor, a reducer, a power generation diesel engine, row knives, cutting knives, a forward shaft, a backshaft, a splint, a traction block, a shell, chain wheels, chains, a base, a discharge cylinder, ashield, a upper shell, a foreplate, an extrusion awl, walking wheels, a baffle plate, a cover and side plates, wherein the walking frame body is provided with space for arranging the extrusion body, the suction fan, the automatic cutting machine, the electric motor, the reducer and the power generation diesel engine; recovering the straw is favourable for the deep processing of raw materials in cultivation, plant and other industries; returning the straw to the field is favourable for the fertilizer production of soil; bundling is suitable for the unique national power generation after the straw is extruded into charcoal to be used as fuel for power generation; and raw materials for other operations of deep processing are easy to preserve, thereby making a certain contribution to the national energy conservation.

Owner:金聪 +1

Peanut oil extracting technology

InactiveCN108085128AGuaranteed tasteGuaranteed colorFatty-oils/fats refiningFatty-oils/fats productionWarm waterImpurity

The invention discloses a peanut oil extracting technology. The peanut oil extracting technology comprises the following steps: step one, material selection: selecting fresh and full peanut kernels, removing impurities and dust, and under the conditions that the temperature is 8 to 12 DEG C and the humidity is 18 to 22 percent, putting the peanut kernels for 3 to 5 hours or more for standby use; step two, soaking and drying: soaking the standby peanut kernels in the step one in warm water of which the temperature is 30 to 40 DEG C, sending the soaked peanut kernels into a drying baker for drying at the temperature of 35 to 45 DEG C for 45 to 55 minutes, taking out the peanut kernels, rapidly cooling by using a draught fan, and then removing red skin on the outer layers of the peanut kernels. According to the peanut oil extracting technology disclosed by the invention, extracted peanut oil is high in purity and oil yield; in addition, the temperature is well controlled during an extracting process, the quality, the color and the taste of peanut oil are increased, and higher use value and good application prospect are obtained.

Owner:东莞市史雷帝三维数控科技有限公司

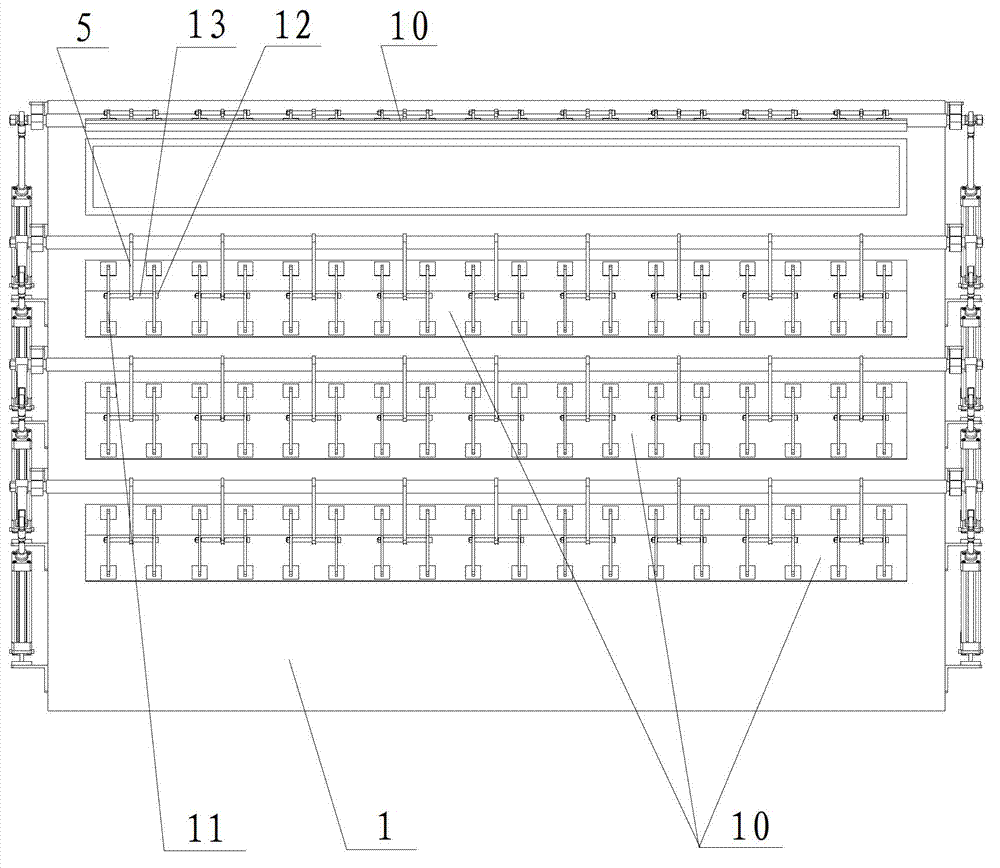

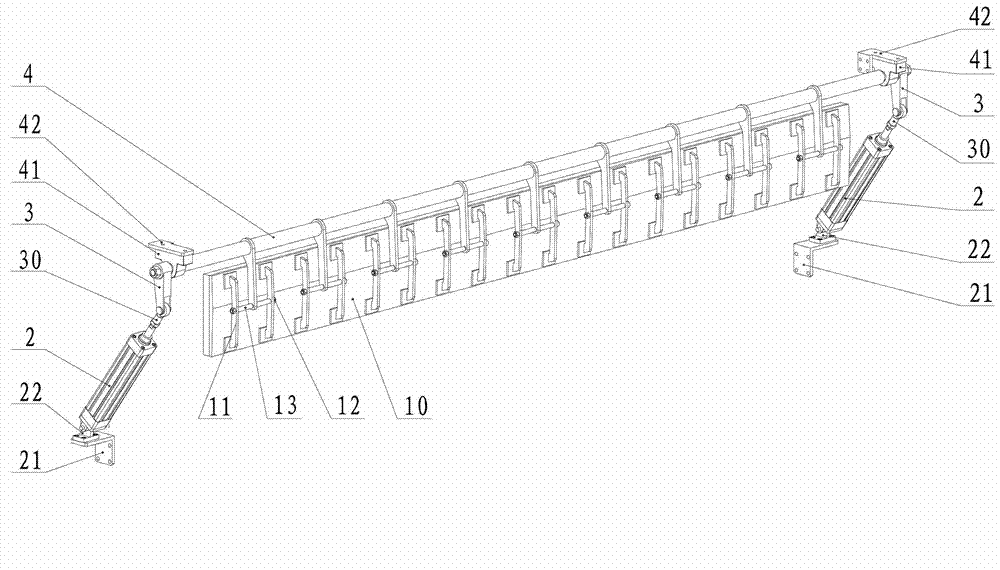

Control mechanism for opening and closing heating furnace door

The invention discloses a control mechanism for opening and closing a heating furnace door. The control mechanism is characterized in that the frontage of a heating furnace is provided with multiple furnace doors which are arranged vertically, wherein each furnace door is respectively connected with a control mechanism; each control mechanism comprises a pair of air cylinders, a pair of air cylinder rotating arms, a furnace door rotating arm and multiple furnace door supporting arms, wherein the pair of air cylinders are arranged on the two side faces of the heating furnace through air cylinder installation bases; one ends of the pair of air cylinder rotating arms are respectively connected with ends of piston rods of the pair of air cylinders through a knuckle bearing one to one; two ends of the furnace door rotating arm are respectively fixedly connected with the other ends of the air cylinder rotating arms one to one and are respectively rotatablely connected to the two side faces of the heating furnace through a bearing base, and so that the furnace door rotating arm is positioned in front of and above each furnace door; and one ends of the multiple furnace door supporting arms are uniformly fixed on the furnace door rotating arm, and the other ends of the multiple furnace door supporting arms are flexibly connected with the external surfaces of the furnace doors.

Owner:SHANGHAI FANUC ROBOTICS

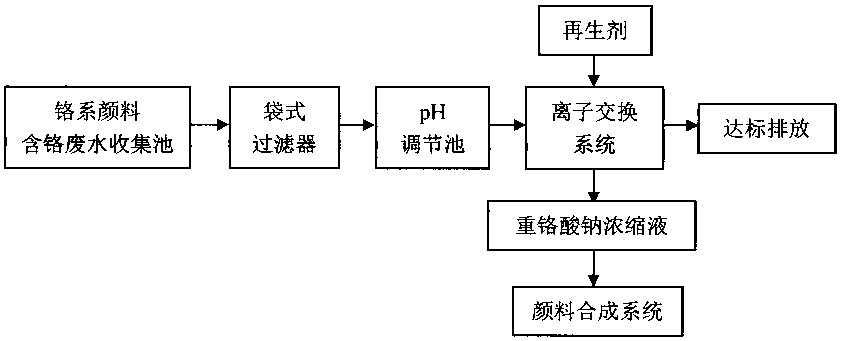

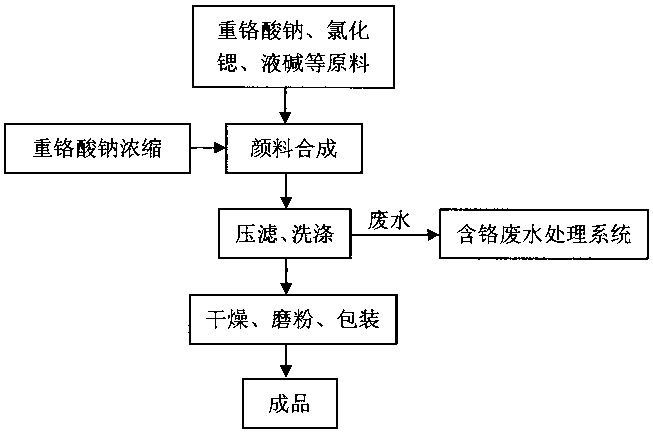

Novel method for treating chrome-containing wastewater and recycling chrome of chrome pigments

InactiveCN105130064AReduce processing costsProtection lossPaint waste treatmentWater contaminantsHigh concentrationFiber

The invention relates to a novel method for treating chrome-containing wastewater and recycling chrome of chrome pigments. The novel method comprises two parts, namely treating the chrome-containing wastewater and recycling the chrome of the chrome pigments. The treatment to the chrome-containing wastewater of the chrome pigments refers to carrying out pressure filtration on the chrome pigments, carrying out physical impurity removal on the chrome-containing wastewater generated in a washing process, adjusting a pH value and then carrying out exchange adsorption in an ion exchange system to ensure that effluent reaches the emission standards of China; after adsorption saturation by ion exchange resin and fiber, a regenerant is used for carrying out regeneration and transformation to obtain a high-concentration sodium dichromate concentrated solution. The recycling of the chrome refers to taking the sodium dichromate concentrated solution as a raw material for pigment production, and adding the solution to a pigment synthesis system to prepare pigment; the prepared pigment is subjected to pressure filtering, washed, dried, ground and packaged to obtain the finished product. According to the method disclosed by the invention, chrome in the wastewater can be resourcefully recycled while ensuring that hexavalent chrome in the chrome-containing wastewater in the chrome pigments is discharged after reaching the standards; the novel method is can either be big or small in scale, simple in process route, low in energy consumption, high in recovery rate of chrome and free of secondary pollution and has favorable economic benefit and social benefit.

Owner:SHENZHEN QIANHAI ZHONGSHENG ENVIRONMENTAL PROTECTION TECH

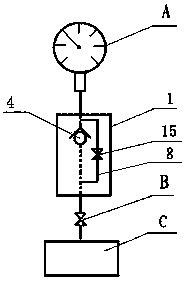

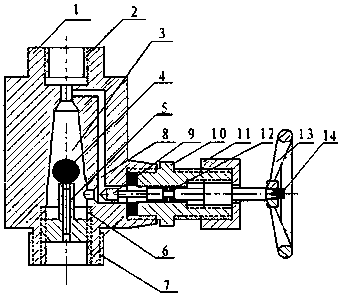

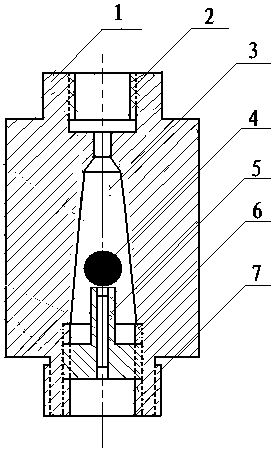

Explosion-proof and leak-proof speed breaker for pressure gauges

InactiveCN109115397AProtection lossPlay the role of one-way closingFluid pressure measurementEngineeringPressure switch

The invention relates to an explosion-proof and leak-proof speed breaker for pressure gauges, comprising a speed breaker body. The speed breaker body includes an outlet end suitable for being connected with a pressure gauge, an inlet end suitable for being connected with a pressure switch, a conical hollow pipe located in the cavity of the speed breaker and vertically communicated with the inlet end and the outlet end, and a bypass pipe of which the water inlet is communicated with the water inlet of the conical hollow pipe and the water outlet is communicated with the water outlet of the conical hollow pipe, wherein the conical hollow pipe is configured with a flow regulating screw and a one-way valve core in turn in the direction from the large-diameter water inlet to the small-diameterwater outlet, the flow regulating screw is fixedly connected with the inner wall of the inlet end, the one-way valve core is suitable for moving along the axis to the water outlet in the conical hollow pipe, and a pressure regulating valve assembly is arranged at the water inlet of the bypass pipe.

Owner:淮安市冰青建设工程管理有限公司

Shredded hot pepper Nang and preparation method thereof

PendingCN110810815AProtects against loss of nutrientsProtect the loss of capsanthinFood scienceHorticultureNutritional composition

The invention relates to the technical field of Nang making, and in particular to shredded hot pepper Nang and a preparation method thereof. The shredded hot pepper Nang is prepared by the following steps: mixing flour, eggs, table salt, sugar, rapeseed oil and fermentation powder, then adding water, performing uniform stirring, and kneading the mixture into a dough; after the dough is fermented,kneading the fermented dough into strips, cutting the strips into blocks, and rolling the blocks to be flat; spreading shredded hot pepper sauce special for making Nang onto the rolled doughs, wrapping the shredded hot pepper sauce, and performing rolling to obtain Nang blanks, wherein the upper half part of each Nang blank is provided with vent holes; and baking the Nang blanks to obtain the shredded hot pepper Nang. According to the invention, original nutrient components and capsorubin are greatly protected from being lost by combination of shredded hot pepper special for cold-stirred Nangpreparation and the Nang blanks, and meanwhile, the obtained shredded hot pepper Nang is fragrant and delicious, has full sauce flavor and slightly hot taste, and is suitable for being eaten by peopleof all ages. The preparation method is simple and convenient, types of Nang products are enriched, and applications of hot pepper sauce are broadened.

Owner:新疆西尔丹食品有限公司

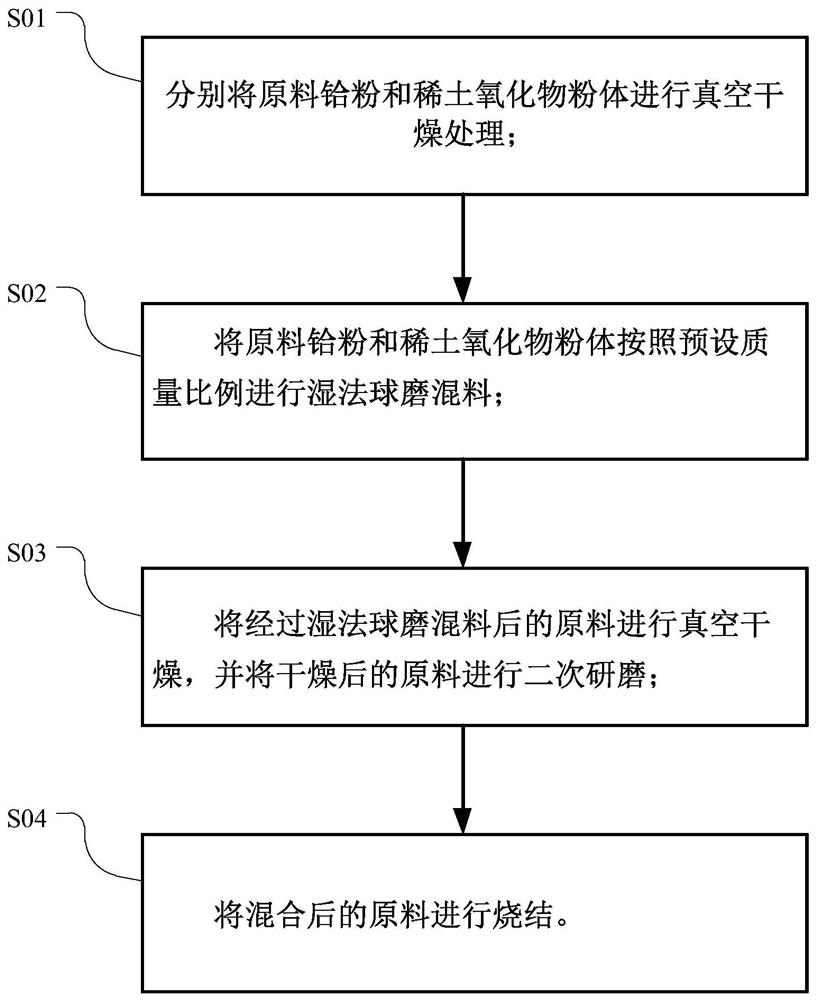

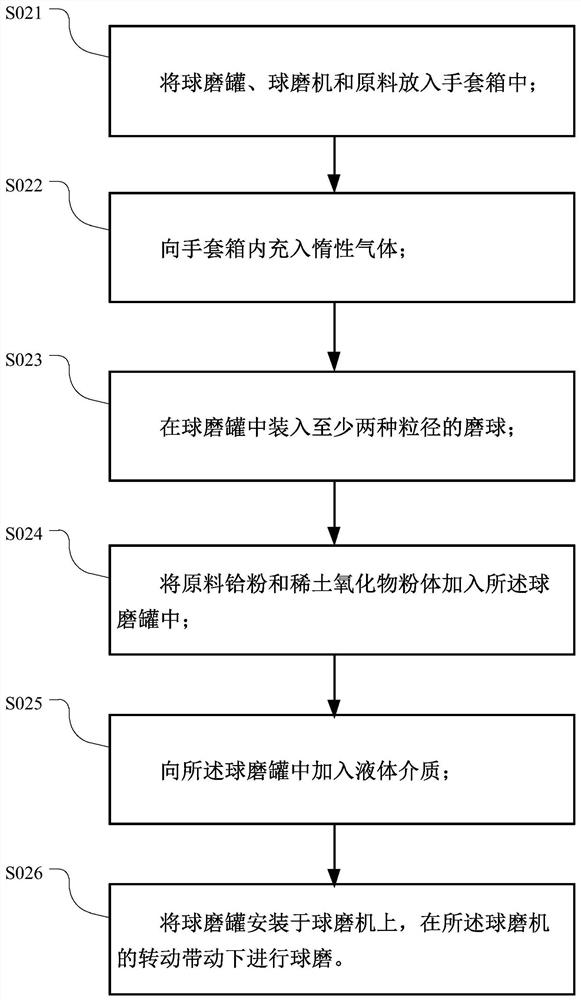

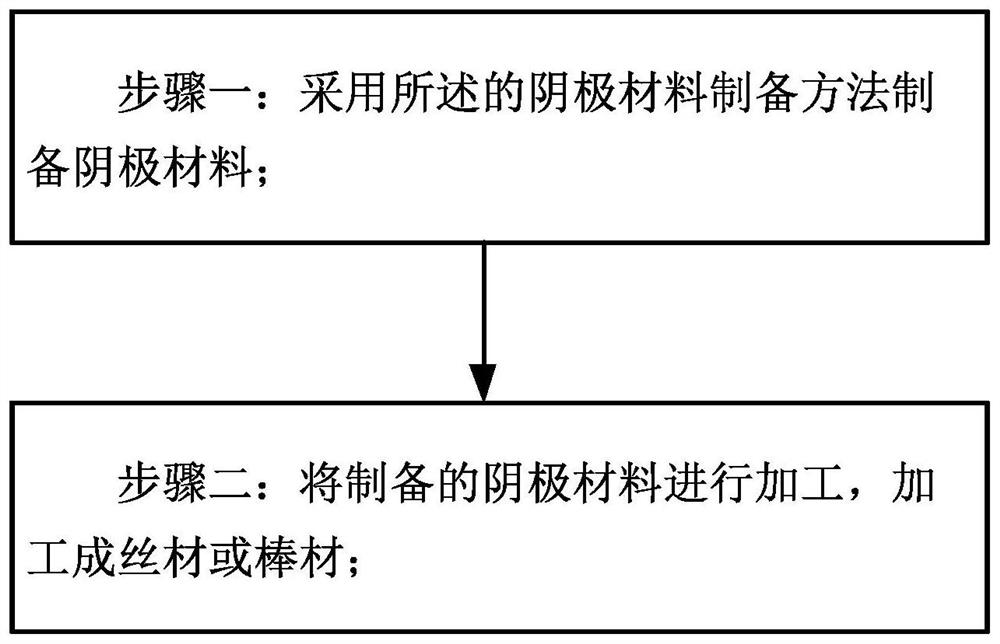

Cathode material and preparation method, and plasma torch cathode and preparation method

InactiveCN112481538AReduce the temperatureStable plasma arcPlasma techniqueWork functionOxide composite

The invention relates to a cathode material which comprises raw materials of hafnium and rare earth oxide. The mass of the rare earth oxide is smaller than 35% of the total mass of the raw materials of hafnium and rare earth oxide. The cathode material is a rare earth oxide composite hafnium cathode and can be used for manufacturing cathodes of electronic components, such as cathodes of plasma torches and cathodes of magnetrons. Because the electron work function of the rare earth oxide is low, when the rare earth oxide is uniformly distributed in the hafnium matrix material, atoms in the rareearth oxide diffuse and migrate to the surface of the cathode material in the operation process of the plasma torch cathode made of the cathode material, so that electrons are easier to emit. And meanwhile, under the dual action of an electric field and heat, the effect of stabilizing the plasma arc is achieved, local over-fast ablation of the cathode material is reduced, and the service life ofthe cathode is prolonged. The invention further discloses a cathode material preparation method, a plasma torch cathode and a preparation method.

Owner:ENN SCI & TECH DEV

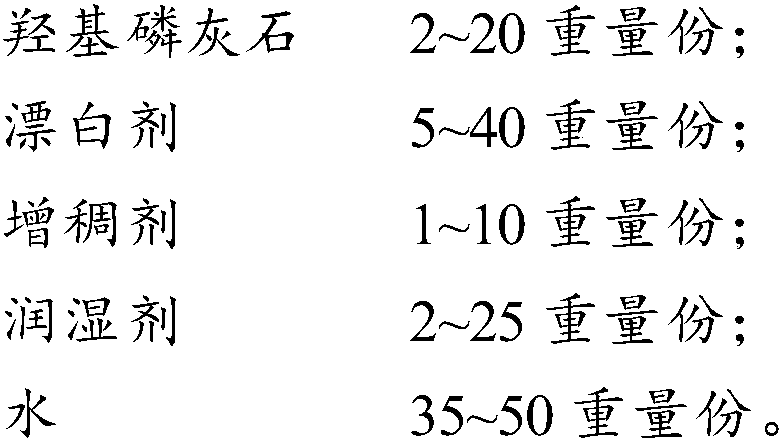

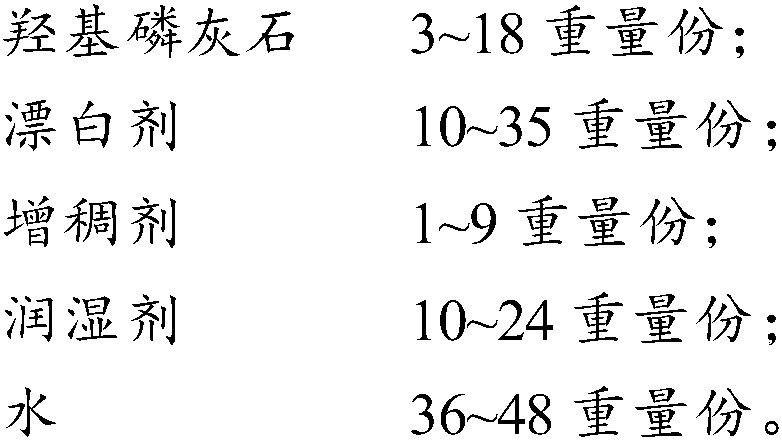

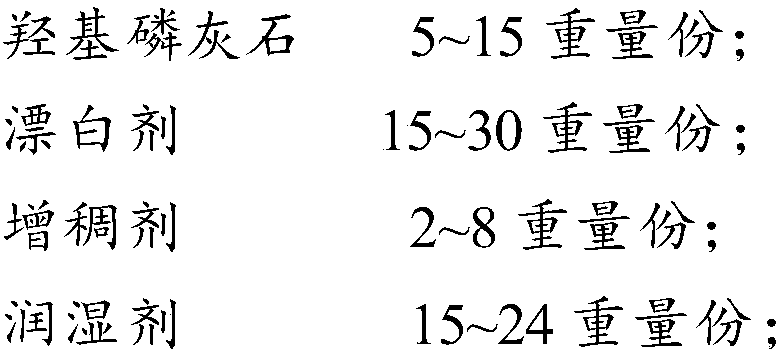

Tooth cold-light whitening composition and application thereof

ActiveCN108451793APrevent mineralizationGood whitening effectCosmetic preparationsToilet preparationsDentistrySpecific mass

The invention provides a tooth cold-light whitening composition. The tooth cold-light whitening composition is prepared from 2-20 parts by weight of hydroxyapatite, 5-40 parts by weight of a whitener,1-10 parts by weight of a thickening agent, 2-25 parts by weight of a wetting agent and 35-50 parts by weight of water. According to the tooth cold-light whitening composition, through the combined action of the whitener, the hydroxyapatite, the thickening agent, the wetting agent and the like with a specific mass ratio, when the composition is used for tooth cold-light whitening, the whitening effect is good, meanwhile, tooth mineralization can be prevented, and tooth sclerotin loss can be prevented.

Owner:吉林省登泰克牙科材料有限公司

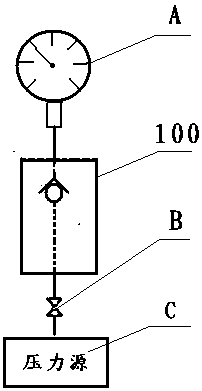

Explosion-proof and leak-proof protector for pressure gauges

InactiveCN109115398ASimple structureProtection lossFluid pressure measurementEngineeringPressure difference

The invention belongs to the technical field of protective devices for explosion-proof and leak-proof automatic closure of pressure gauges, and specifically relates to an explosion-proof and leak-proof protector for pressure gauges. The protector comprises a protector body, a conical hollow pipe and a one-way valve core. The conical hollow pipe is arranged in the protector body, and the one-way valve core is arranged in the conical hollow pipe. The one-way valve core contacts the exit conical surface of the conical hollow pipe under the action of pressure difference. The explosion-proof and leak-proof protector for pressure gauges of the invention has a simple structure, and implements automatic closure based on pressure difference and the principle of flow control. The loss of water, gas,oil and other liquid and gases after damage and failure of pressure gauges can be protected, and economic losses and safety accidents can be prevented.

Owner:淮安市冰青建设工程管理有限公司

Ecological restoration and environmental protection self-drainage system

ActiveCN103782855BProtection lossMitigate heat island effectWater/sewage treatment by irradiationClimate change adaptationEnvironmental resource managementWater source

The invention relates to an ecological-reduction environment-friendly water recovery system and belongs to fields of energy saving technique and equipment, efficient energy-saving products, energy-saving service industry, advanced environmental protection technique and equipment, environment-friendly products and environment-friendly service, solving problems about water source supply, river pollution, earth surface ecological pollution and also solving the major issue in water and soil conservation. With the ecological-reduction environment-friendly water recovery system, heat island effect due to artificial Karst landform generated during urbanization is relieved effectively, loss of water sources is prevented effectively, pollution control is enabled to be accurate and creative to pollution sources to bring macroscopic positive energy, and thus research on management strategy for controlling loss of water sources, urban waterlogging, dried-up farmland, drought, environmental degradation of inland rivers and earth surface of our country is provided.

Owner:余美平

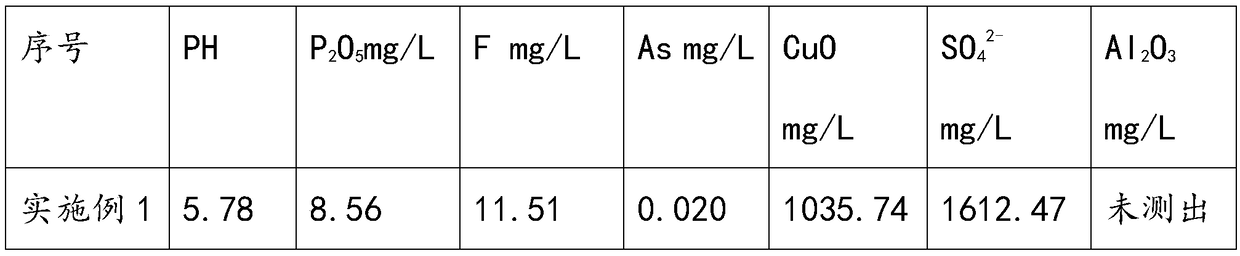

Ecological stony desertification restoring matrix with ardealite being raw material and preparation method and application of ecological stony desertification restoring matrix

InactiveCN108934914AAchieving mass recyclingGood for repairing propertiesCalcareous fertilisersBioloigcal waste fertilisersVegetationEcological environment

The invention discloses an ecological stony desertification restoring matrix with ardealite being a raw material. The ecological stony desertification restoring matrix is composed of, by weight, 80-90parts of ardealite, 5-15 parts of red mud, 10-30 parts of mud, 8-20 parts of starch, 1.5-4.5 parts of artemisia apiacea and 5-35 parts of swelling agent; a preparation method includes the following steps that 1, the ardealite, red mud, the artemiasiaapiacea and LuShan mountain barberry roots are taken, smashed and sieved for usage; 2, the prepared raw materials for usage are mixed and stirred with other raw materials, then, the mixture is dried until the water content is smaller than or equal to 15%, and after the treatment, the ecological stony desertification restoring matrix with ardealitebeing the raw material is obtained. The ardealite, the red mud and other waste residues in industrial product are sufficiently utilized and transformed into the matrix material capable of being usedfor planting and growing of vegetation, and the matrix is beneficial to the ecological environment.

Owner:贵州贵和隆科技研发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com