Linear motor thrust measuring device and measuring method

A technology of linear motors and measuring devices, applied in measuring devices, motor generator testing, force/torque/power measuring instruments, etc., can solve the problems of easy fatigue, reduce service life, increase costs, etc., and achieve simple structure of measuring devices, The effect of maintaining detection accuracy and protecting loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

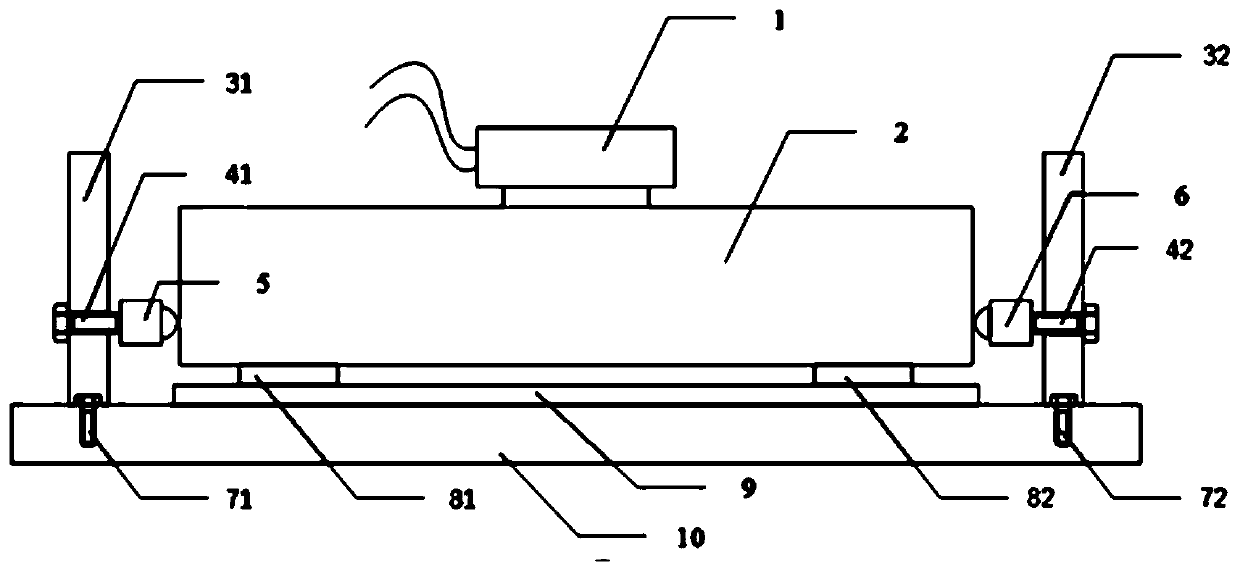

[0039] Such as figure 1 As shown, the linear motor thrust measurement device includes a test platform 10 , a linear motor, a first baffle 31 , a second baffle 32 , a first force sensor 5 , and a second force sensor 6 .

[0040] The linear motor includes a mover 1, a stator 2, a first slider (not shown in the figure) and a first track (not shown in the figure), the mover 1 is fixed on the first slider, and can follow the first slider It moves linearly relative to the stator 2 on the first track.

[0041] The second track 9 is fixed on the test platform 10 . The stator 2 is fixed on the second slider, such as figure 1 As shown, the second sliding piece in this embodiment is composed of the second sliding piece A81 and the second sliding piece B82, and the stator can slide along the second track 9 along with the second sliding piece.

[0042] Along the direction of the second track, the left end of the stator 2 is marked as the stator A end, and the right end is marked as the ...

Embodiment 2

[0052] In this embodiment, the linear motor thrust measuring device is completely the same as that in Embodiment 1.

[0053] In this embodiment, the method of measuring the electromagnetic thrust of the linear motor by using the above-mentioned measuring device is basically the same as that of the embodiment, the difference is that in step (2), the linear motor is energized, the mover has a load, and moves under the action of the electromagnetic thrust. The stator carries the load and moves linearly relative to the stator along the first track.

Embodiment 3

[0055] In this embodiment, the linear motor thrust measuring device is basically the same as that in Embodiment 1. The difference is that the other end of the first force sensor is connected to the end of the stator A through a first rigid connection, and the other end of the second force sensor is connected to the end of the stator B through a second rigid connection.

[0056] The method of measuring the electromagnetic thrust of the linear motor by using the above-mentioned measuring device is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com