Cathode material and preparation method, and plasma torch cathode and preparation method

A plasma torch and cathode material technology, applied in the direction of plasma, electrical components, etc., can solve the problems of short cathode life and restrict the application of plasma torch, so as to improve the cathode life, reduce local excessive ablation, and stabilize the plasma arc Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

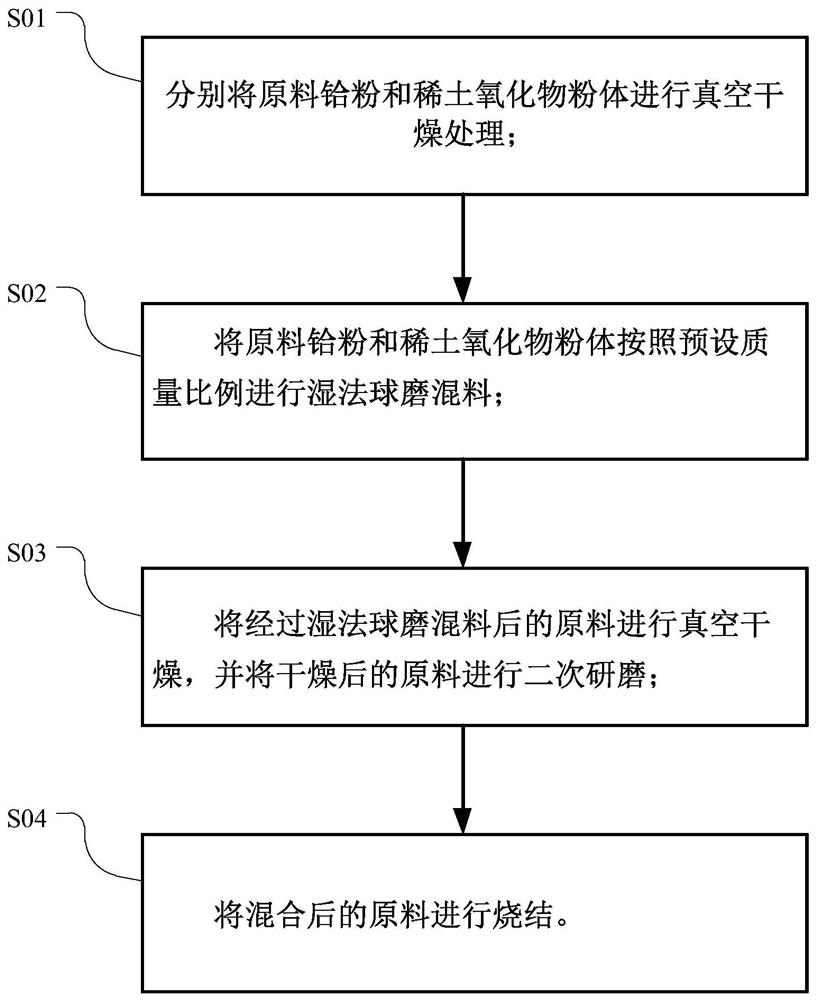

[0045] The present invention provides a method for preparing a cathode material, which includes steps S01)-S04).

[0046] S01), respectively carrying out vacuum drying treatment to the raw hafnium powder and the rare earth oxide powder;

[0047] In this step, the raw hafnium powder and the rare earth oxide powder are firstly pretreated. Hafnium powder with preset purity and particle size, and rare earth oxide powder with preset purity are respectively placed in a vacuum drying oven for drying treatment. Rare earth oxide powders include La 2 O 3 , Y 2 O 3 , Ce 2 O 3 at least one of the three.

[0048] Wherein, the drying temperature of the hafnium powder is 70°C-120°C, and the drying time is 2-4 hours; the drying temperature of the rare earth oxide powder is 45°C-80°C, and the drying time is 1-4 hours.

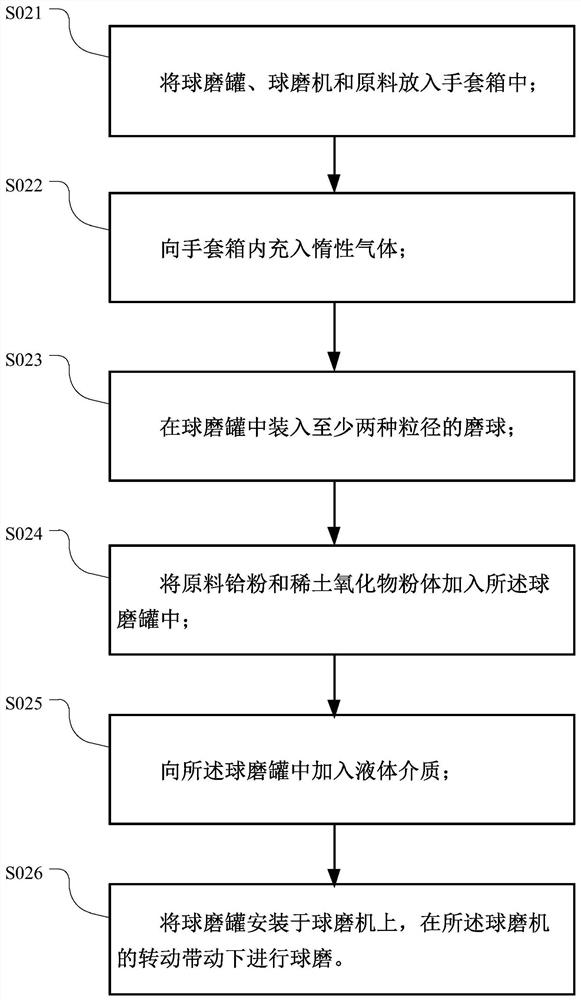

[0049] S02), the raw material hafnium powder and the rare earth oxide powder are mixed according to the preset mass ratio by wet ball milling;

[0050]In this step, it...

Embodiment 1

[0088] The method for preparing the cathode material in this embodiment includes steps S01)-S04).

[0089] In this embodiment, a total of five groups are divided into five groups to carry out control experiments on the preparation method of cathode materials. As shown in Table 1 below, the mass ratio of raw material hafnium powder and rare earth oxide powder in each group is different, that is, the control group and the experimental group 1. The mass ratios of the experimental group 2, the experimental group 4, and the experimental group 5 were respectively weighed; and the composition of the rare earth oxide powder in each group was different. In order to ensure the credibility of the comparison results, except that the composition of the above-mentioned preparation raw materials and rare earth oxides are different in each group, the preparation process and conditions in each group are guaranteed to be the same. The above five groups of preparation experiments are described i...

Embodiment 2

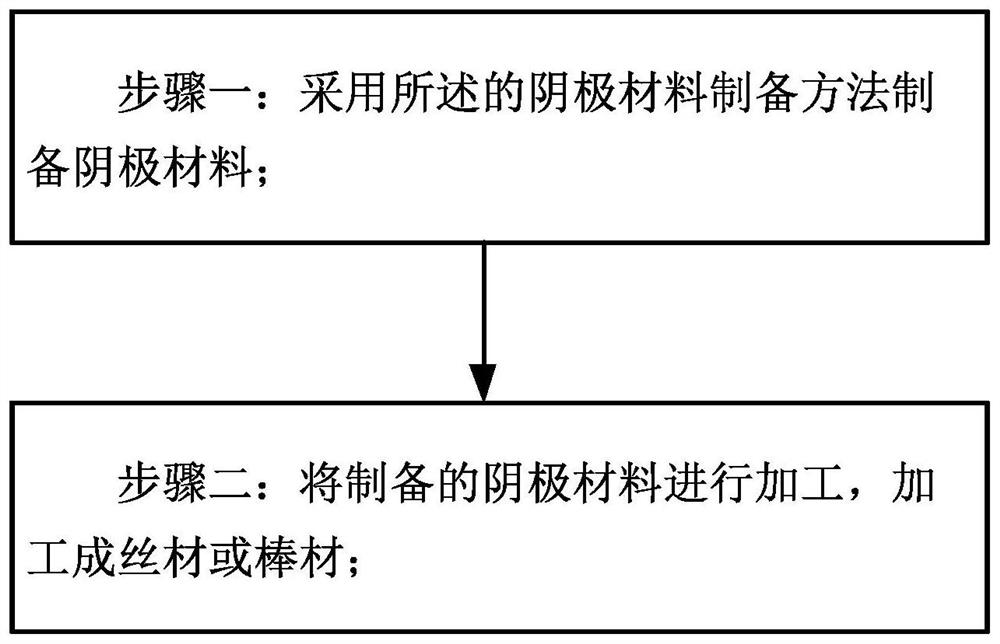

[0160] This embodiment corresponds to the design of Embodiment 2 of the cathode material preparation method, and the preparation method of the plasma torch cathode includes the following steps 1 to 2.

[0161] Step 1: using the cathode material preparation method to prepare the cathode material;

[0162] In this step, the cathode material is prepared by the preparation method in Example 2 of the above cathode material preparation method.

[0163] Step 2: Processing the prepared cathode material into wires and rods;

[0164] In this step, the bulk cathode material obtained by sintering is cut and processed into wires or rods required by the cathode head for use in subsequent steps.

[0165] Step 3: Connect the wire or rod to the base to form the plasma torch cathode.

[0166] In this step, the wire or rod prepared in step 2 is connected to a conductive base, such as a copper base, through inlaying or welding to make a plasma torch cathode that can be used directly.

[0167] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com