Ecological stony desertification restoring matrix with ardealite being raw material and preparation method and application of ecological stony desertification restoring matrix

The technology of phosphogypsum and ecological stone is applied in the field of ecological rocky desertification restoration matrix and its preparation, which can solve the problems of insufficient adhesion of common matrix and ineffective consumption of phosphogypsum, and achieve the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

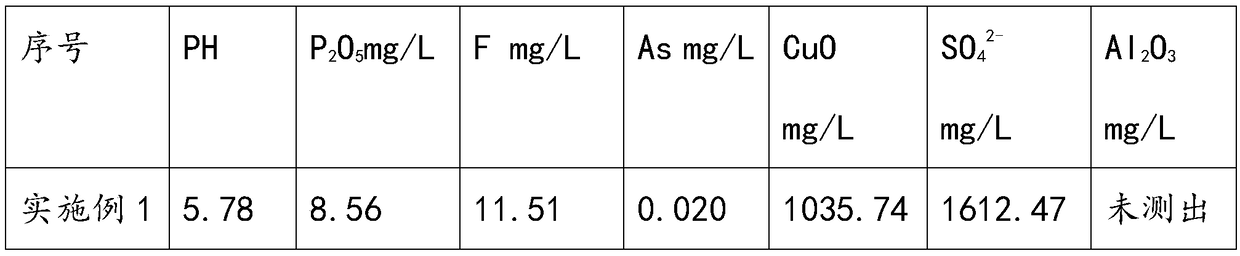

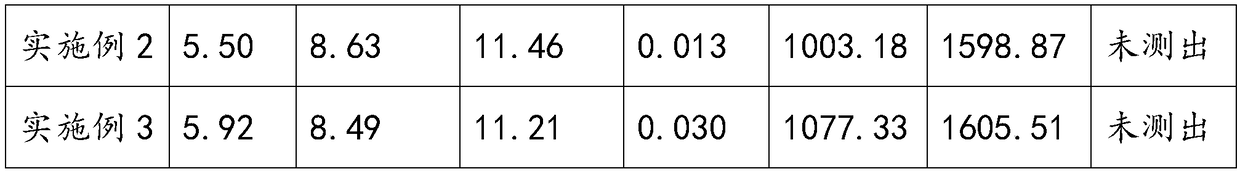

Embodiment 1

[0027] Embodiment 1: the preparation and application of the ecological rocky desertification restoration matrix taking phosphogypsum as raw material in the present invention:

[0028] Raw material ratio: 80kg of phosphogypsum, 5kg of red mud, 10kg of mud, 10kg of starch, 2kg of cellulose, 1.5kg of Artemisia annua, 1.5kg of thorn lotus, 3kg of oily dryness and 5kg of leavening agent, the leavening agent in this example For fungal spores;

[0029] Preparation:

[0030] (1) Get phosphogypsum and pulverize through a 90-mesh sieve, mud pulverize through an 80-mesh sieve, annua annua pulverize through an 80-mesh sieve, and prickly lotus pulverize through an 85-mesh sieve for subsequent use;

[0031] (2) Dry the standby raw material prepared in step (1) with red mud, starch, cellulose, oil dryness and swelling agent after mixing and stirring, so that the total water content is 8%, that is, phosphogypsum is used as raw material ecological rocky desertification restoration matrix.

...

Embodiment 2

[0037] Embodiment 2: the preparation and application of the ecological rocky desertification restoration matrix using phosphogypsum as raw material in the present invention:

[0038] Raw material ratio: 90kg of phosphogypsum, 15kg of red mud, 30kg of mud, 20kg of starch, 5kg of cellulose, 4kg of Artemisia annua, 3kg of thorny lotus, 6kg of oil and 30kg of leavening agent. The leavening agent in this example is bacteria spore;

[0039] Preparation:

[0040] (1) Get phosphogypsum and pulverize through 80 mesh sieves, mud pulverize through 95 mesh sieves, Artemisia annua pulverize through 85 mesh sieves and C. chinensis pulverize through 90 mesh sieves and set aside;

[0041] (2) Dry the standby raw material prepared in step (1) with red mud, starch, cellulose, oil dryness and swelling agent after mixing and stirring, so that the total water content is 8%, that is, phosphogypsum is used as raw material ecological rocky desertification restoration matrix.

[0042] Applied means...

Embodiment 3

[0047] Embodiment 3: the preparation and application of the ecological rocky desertification restoration matrix using phosphogypsum as raw material in the present invention:

[0048] Raw material ratio: 85kg of phosphogypsum, 10kg of red mud, 20kg of mud, 16kg of starch, 5kg of cellulose, 3.5kg of Artemisia annua, 2kg of thorny lotus, 4.5kg of oil dryness and 20kg of leavening agent, the leavening agent in this example For fungal spores;

[0049] Preparation:

[0050] (3) Get phosphogypsum and pulverize through a 90-mesh sieve, pulverize mud through a 90-mesh sieve, pulverize Artemisia annua and cross an 80-mesh sieve, and pulverize a thorny lotus through an 85-mesh sieve for subsequent use;

[0051] (4) Mix and stir the spare raw materials prepared in step (1) with red mud, starch, cellulose, oil dryness and expansion agent, and then dry them so that the total water content is 12%, that is, phosphogypsum is used as raw material ecological rocky desertification restoration m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com