Equipment for producing soil-free grass

A technology for production equipment and soilless grass, which is applied in the direction of soilless cultivation, botany equipment and methods, and seed treatment methods, etc., can solve problems such as reports of no soilless grass production equipment, and achieve protection of soil erosion and improvement of soil The structure, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A specific embodiment of a soilless grass production equipment of the present invention is provided below.

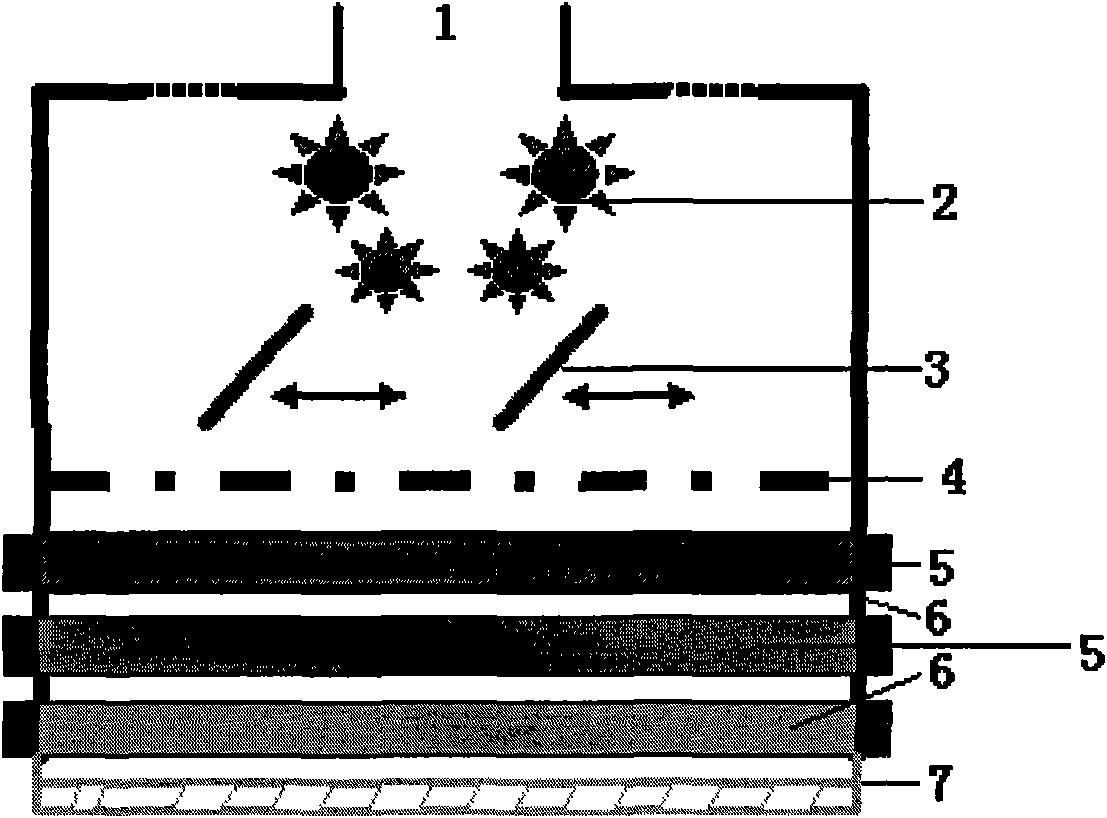

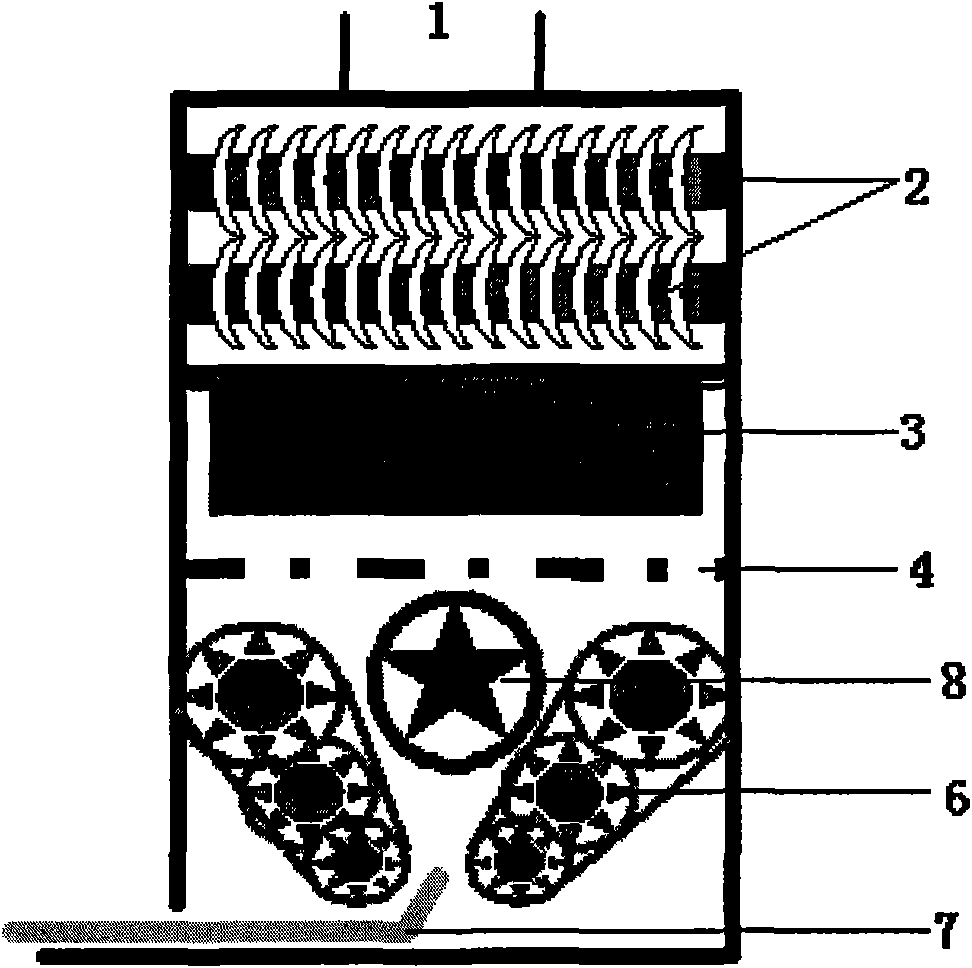

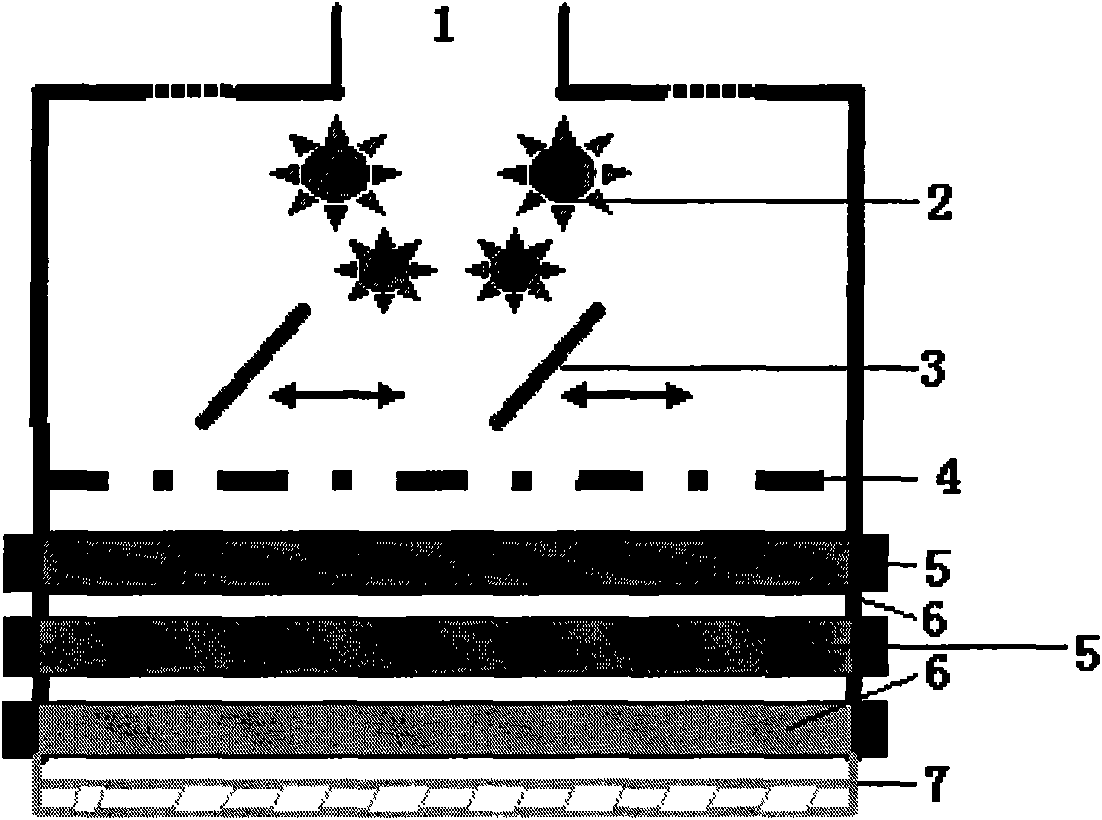

[0029] Please see attached figure 1 and 2 , a kind of production equipment without soil and grass, comprising a pulverizer, a pressing machine and a weaving machine, characterized in that, in the pulverizer, the cutting tool 2 is fixed on the box body through the central axis, and the swing type distributor 3 is fixed on the front and back Fixed on the box body, the front and rear four corners of the vibrating grid 4 are fixed on the box body, the transmission device 5 is arranged on the left and right sides of the box body, and connected with the pressing shaft 6, the transmission device controls the 6 relatively stressed pressing shafts, and when pressing There is also a regulating valve 8 between the shafts; these parts are powered by a motor, wherein the raw material enters from the feed port 1, and after being crushed, it is discharged from the discharge po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com