Peanut oil extracting technology

A peanut oil and process technology, applied in the directions of producing fat, fat oil/fat production, fat oil/fat refining, etc., can solve the problems that it is difficult to meet the requirements of peanut oil processing technology, affect the quality of peanut oil, and the purity of peanut oil is not high, so as to improve the quality of peanut oil. Effects of peanut utilization, loss of protective nutrients, and improved oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

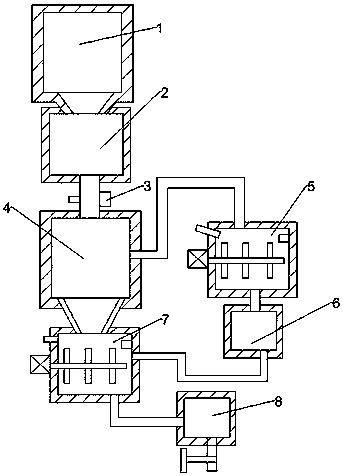

[0029] see figure 1 , the peanut oil refining device of the present invention, the peanut oil passes through the soaking equipment 1, then through the drying equipment 2, and then cools rapidly with the blower fan 3, removes the red coat of the outer layer of peanuts, squeezes for the first time through the press 4, and is sent to the second Stir in a mixer 5, and then send it to a supercritical extractor 6. The peanut residue is squeezed for a second time in a press 4, and then the second mixer 7 is used to control the temperature to remove ethanol, and finally dried in a vacuum dryer 8 to obtain refined After canola oil.

[0030] A kind of peanut oil refining process of the present embodiment comprises the following steps:

[0031] Step 1, material selection: select fresh, full-grained peanuts, remove impurities and dust, and place the peanuts at a temperature of 10°C and a humidity of 20% for more than 4 hours for later use;

[0032] Step 2, soaking and drying: Put the sp...

Embodiment 2

[0043] A kind of peanut oil refining process of the present embodiment comprises the following steps:

[0044] Step 1, material selection: select fresh, full-grained peanuts, remove impurities and dust, and place the peanuts at a temperature of 10°C and a humidity of 20% for more than 4 hours for later use;

[0045] Step 2, soaking and drying: Put the spare peanuts in step 1 into warm water at a temperature of 35°C for 1.5 hours, then send the soaked peanuts to a drying box for drying at a temperature of 40°C for 50 minutes, take them out , use a fan to cool quickly, and then remove the red coat of the outer layer of peanuts;

[0046] Step 3, squeezing: Send the peanuts with the outer red coat removed to the squeezer for the first squeeze, squeeze for 50 minutes, send the squeezed mixture into the mixer for stirring, stir for 50 minutes, and the stirring speed is 55r / min, Add an organic solvent to it, continue to stir for 45 minutes, then send it to a supercritical extractor ...

Embodiment 3

[0056] A kind of peanut oil refining process of the present embodiment comprises the following steps:

[0057] Step 1, material selection: select fresh, full-grained peanuts, remove impurities and dust, and place the peanuts at a temperature of 10°C and a humidity of 20% for more than 4 hours for later use;

[0058] Step 2, soaking and drying: Put the spare peanuts in step 1 into warm water at a temperature of 35°C for 1.5 hours, then send the soaked peanuts to a drying box for drying at a temperature of 40°C for 50 minutes, take them out , use a fan to cool quickly, and then remove the red coat of the outer layer of peanuts;

[0059] Step 3, squeezing: Send the peanuts with the outer red coat removed to the squeezer for the first squeeze, squeeze for 50 minutes, send the squeezed mixture into the mixer for stirring, stir for 50 minutes, and the stirring speed is 55r / min, Add an organic solvent to it, continue to stir for 45 minutes, then send it to a supercritical extractor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com