Patents

Literature

90results about How to "Increase material density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

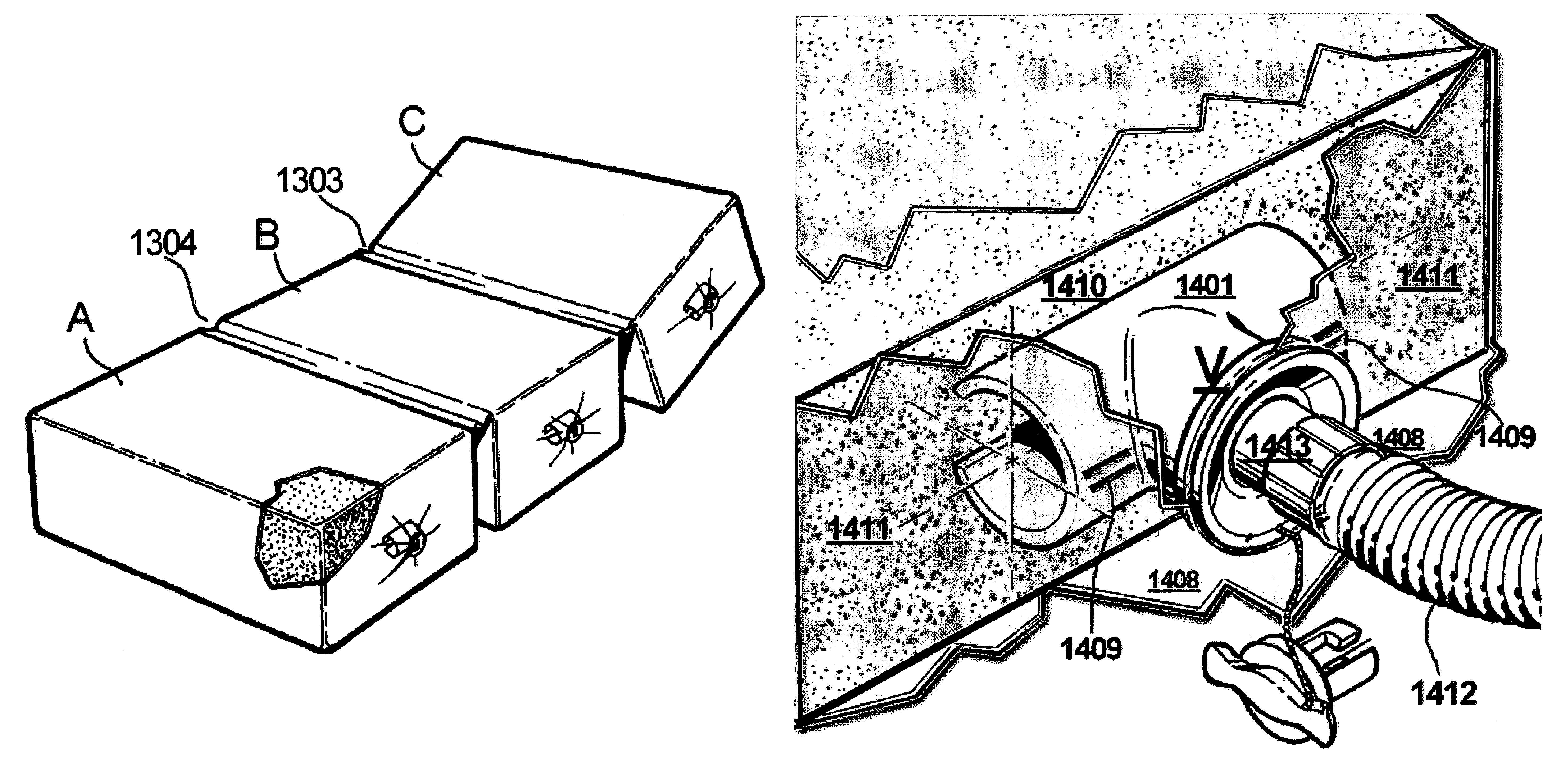

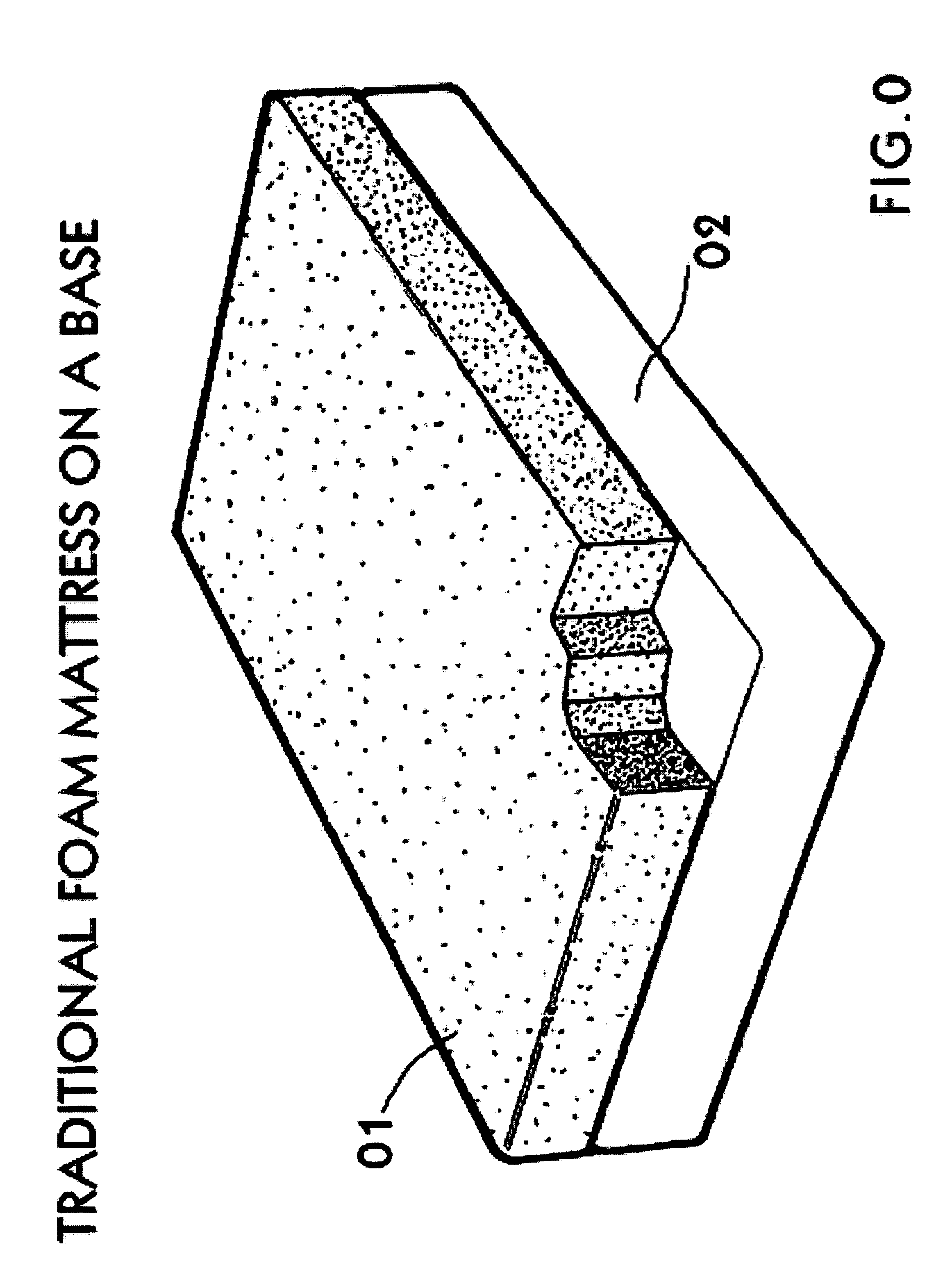

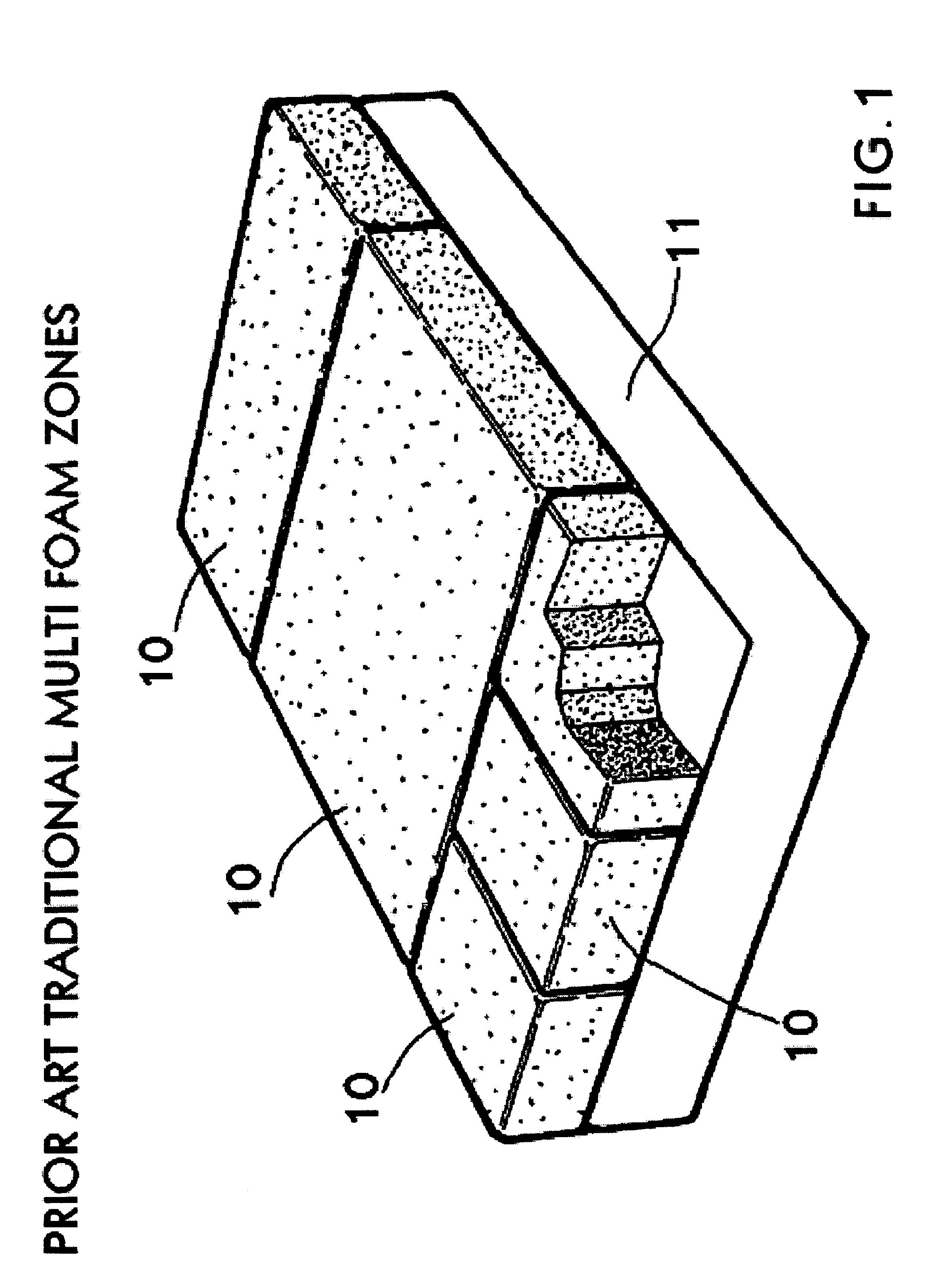

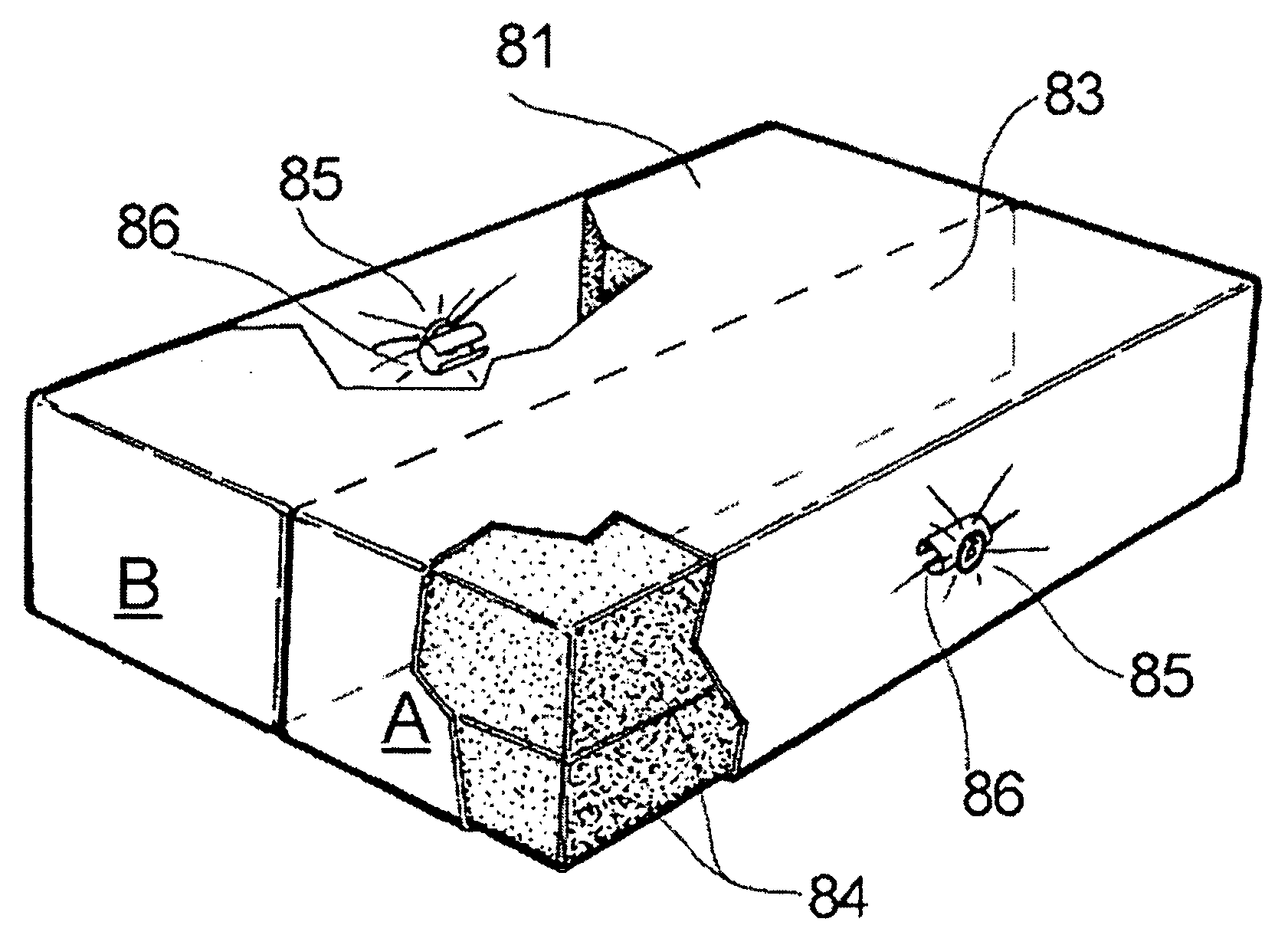

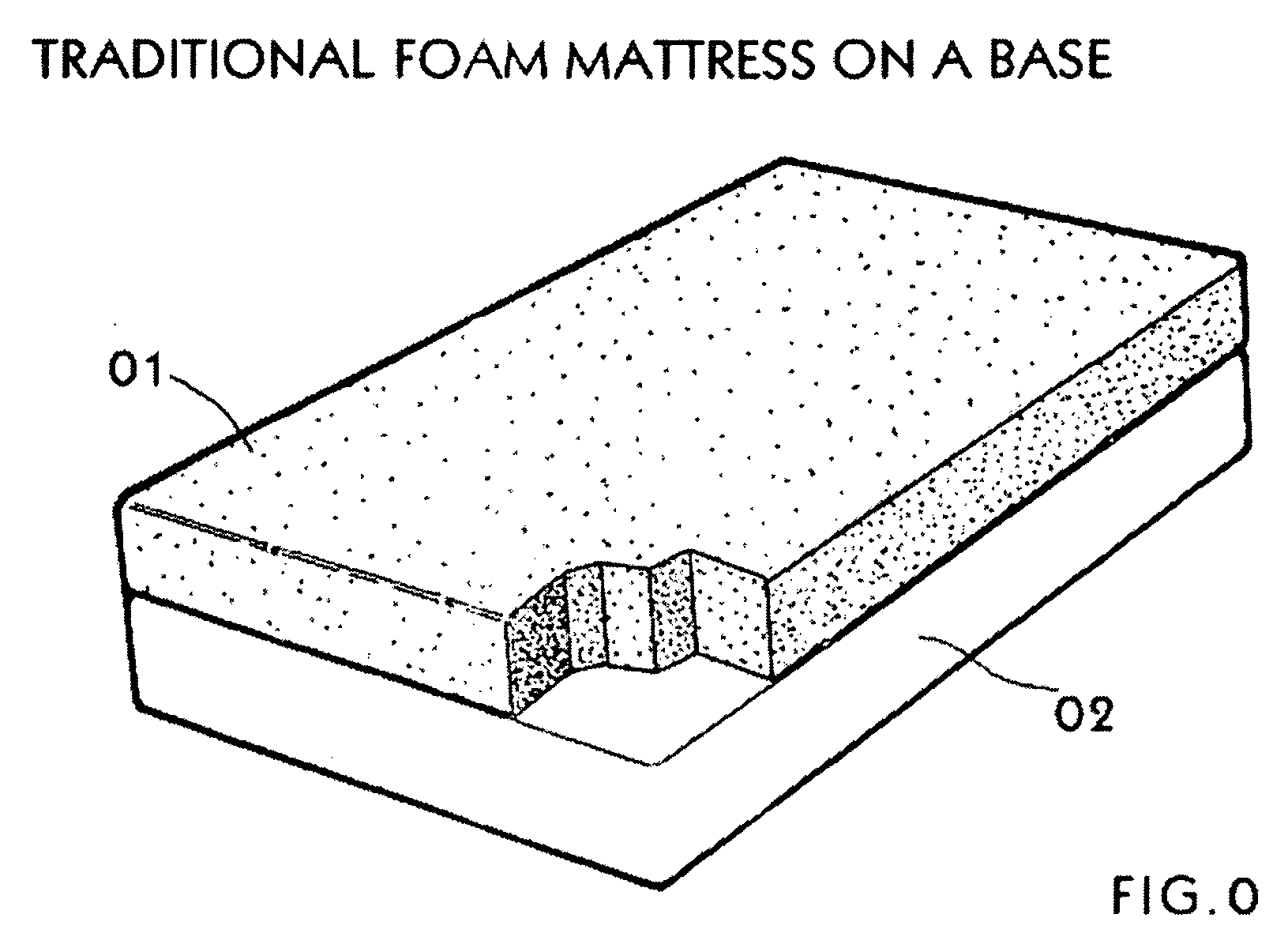

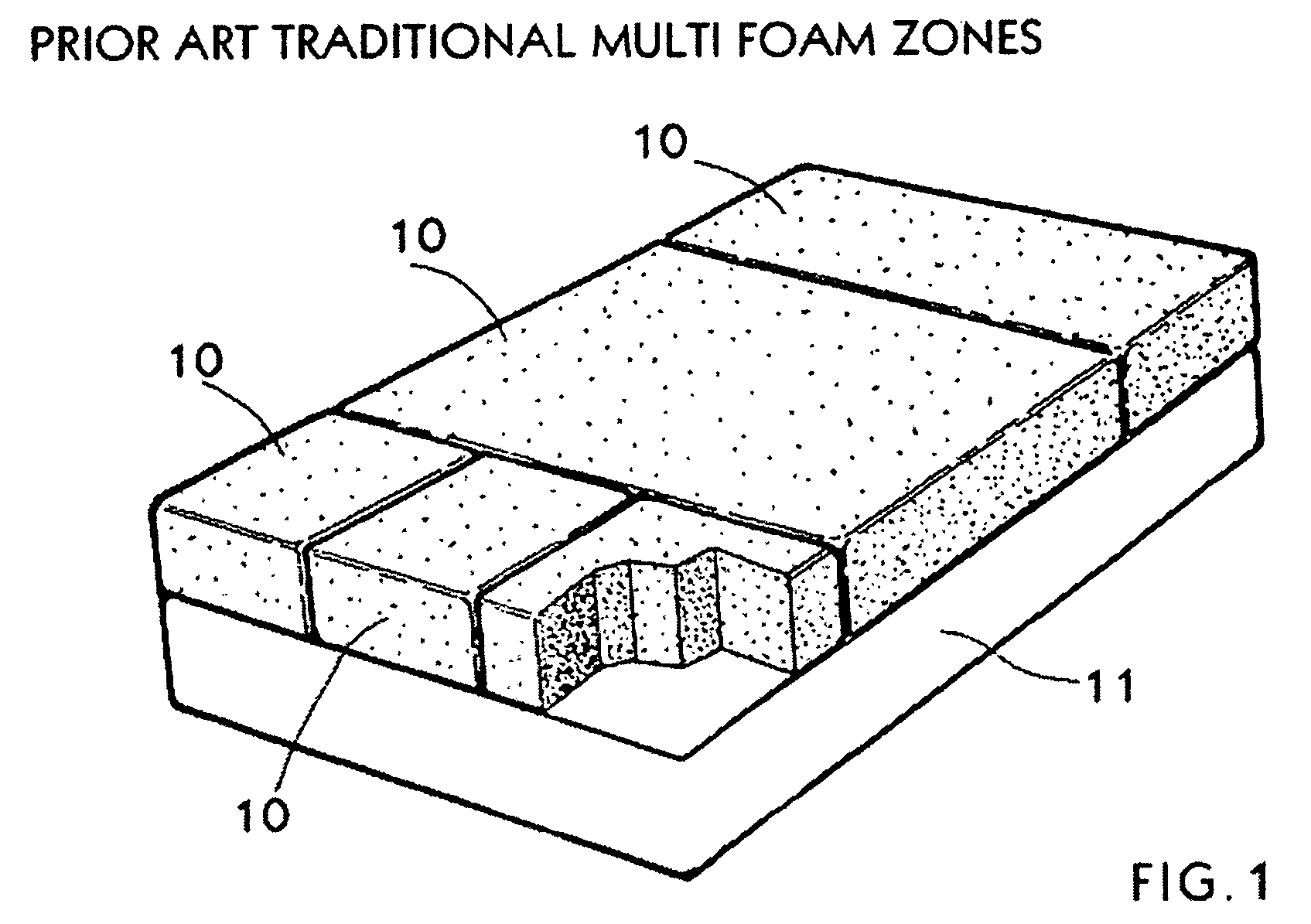

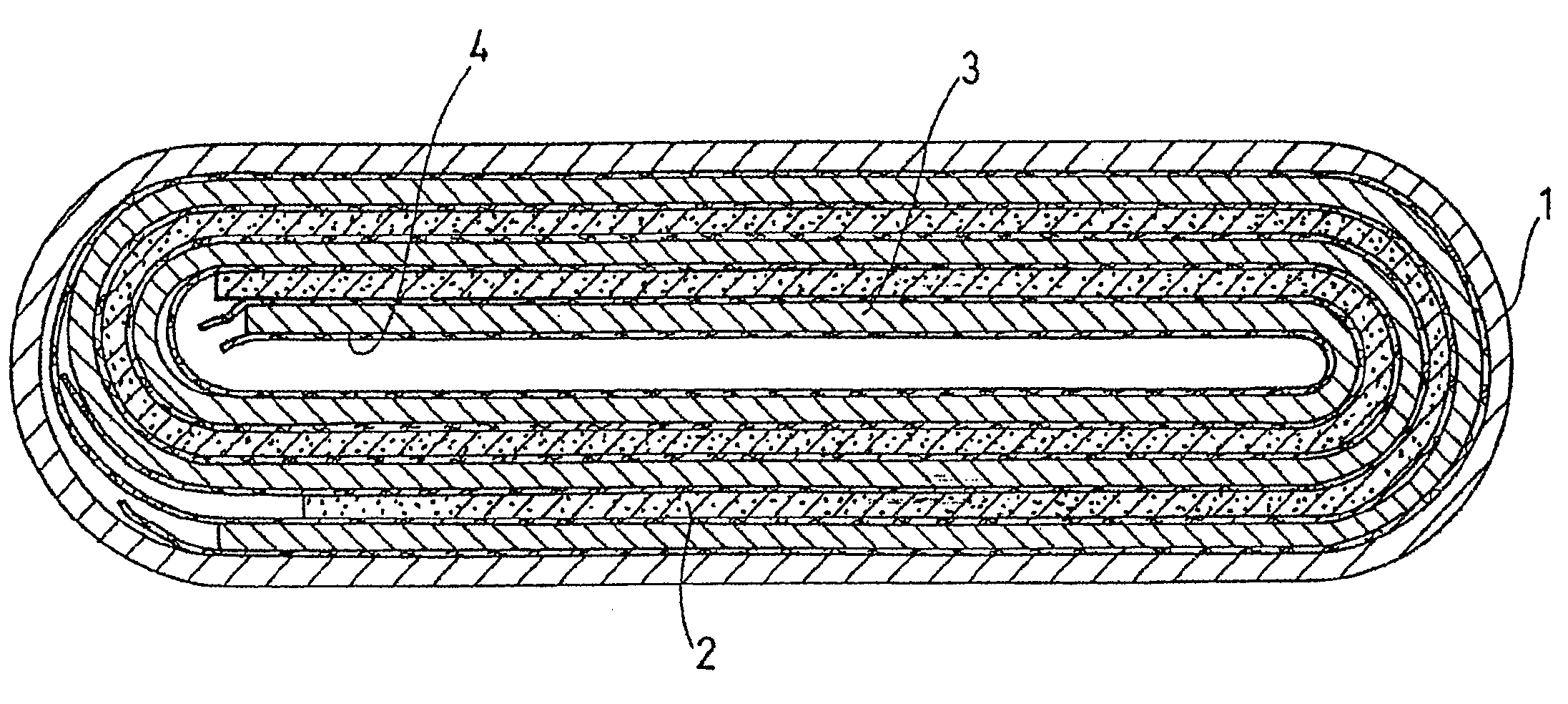

Adjustable foam mattress

InactiveUS6922863B2Improve comfortLower comparable costStuffed mattressesSpring mattressesAir volumeCoil spring

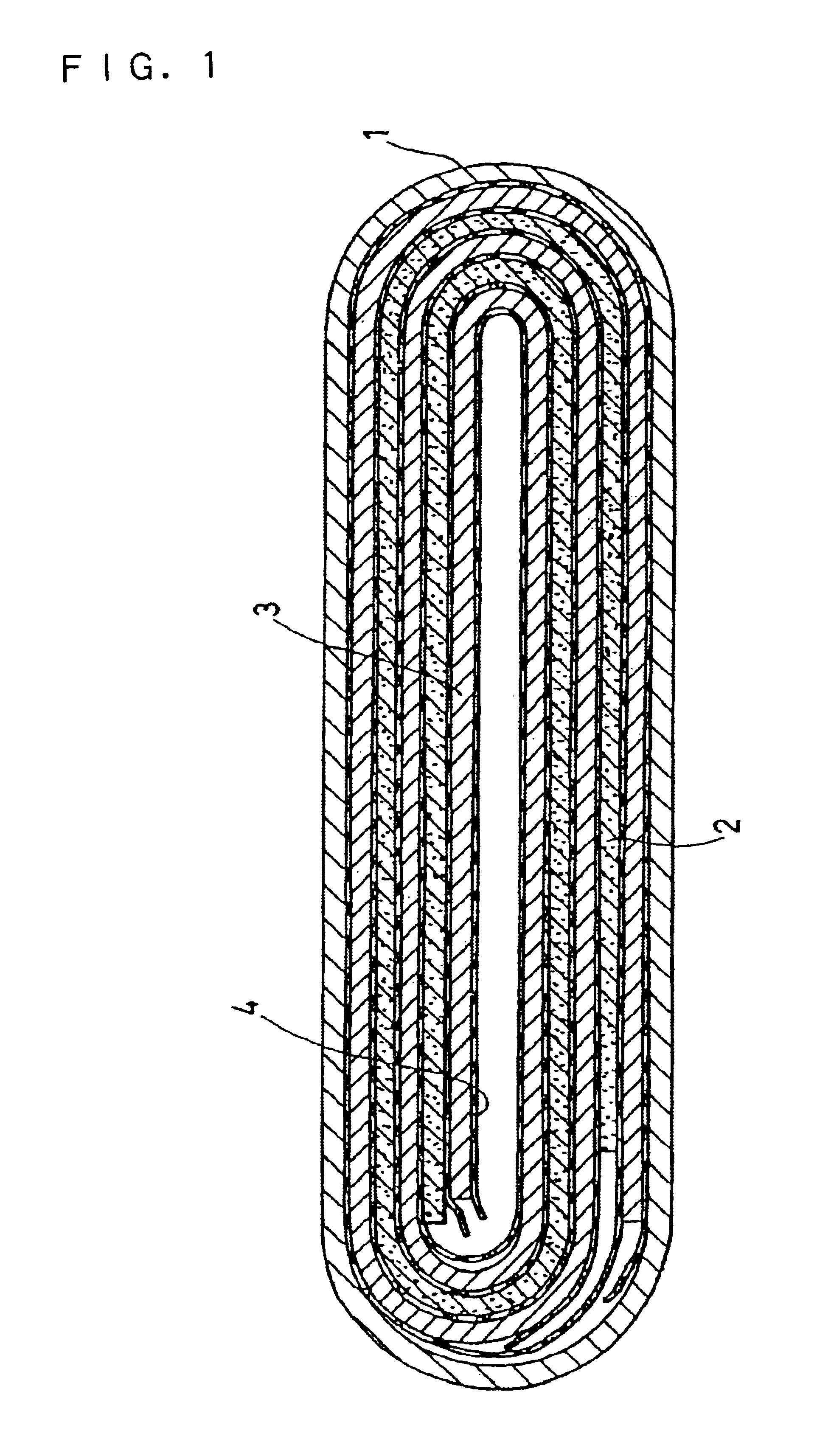

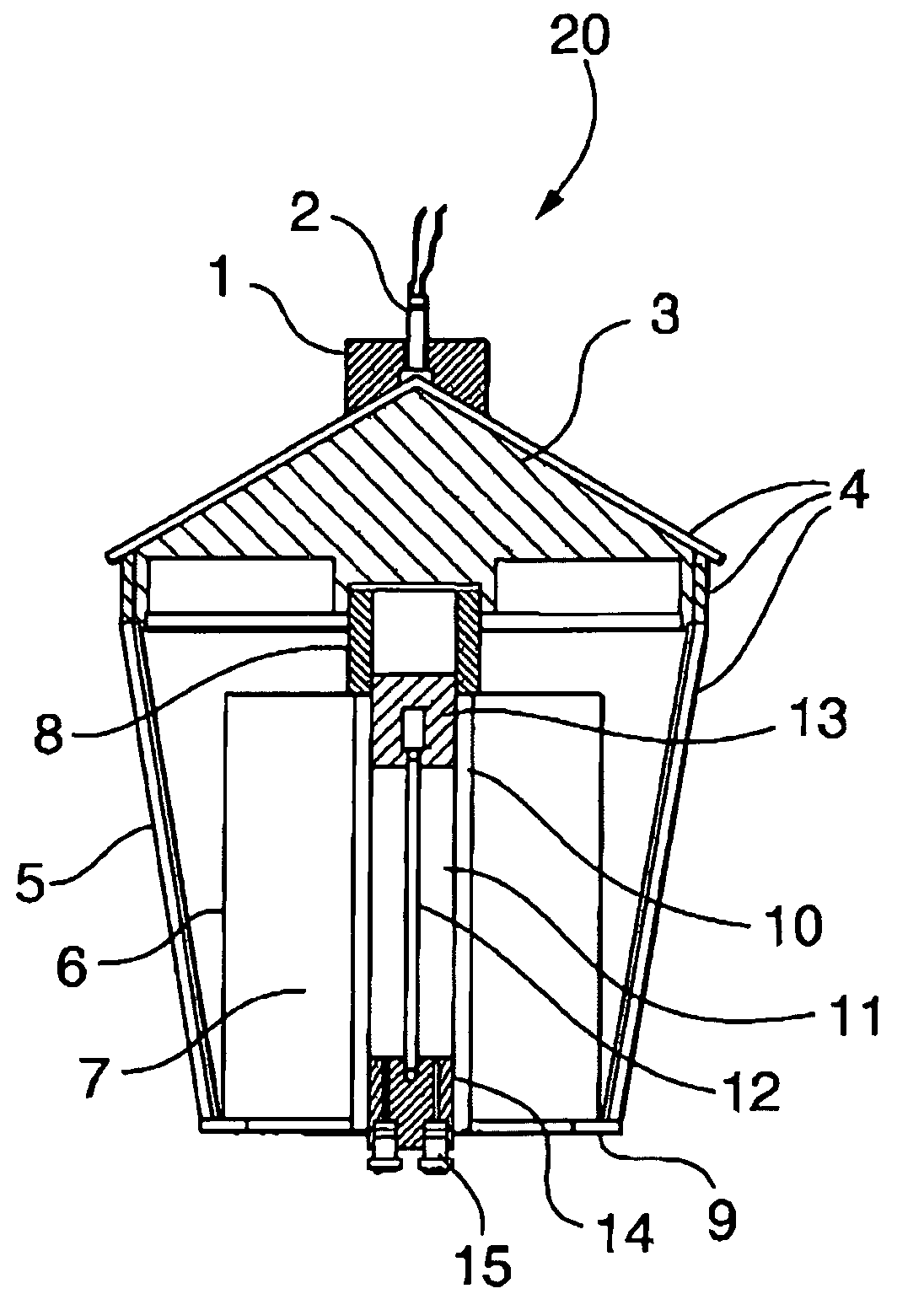

The invention modulates the air volume in foam cores of cushioning support devices and any other support apparatus using foam or similar materials. The foam core can be incrementally modulated to realize an infinite number of comfort levels as to softness and support firmness. The core consists of self-inflating open-cell flexible polyurethane foam and is completely sealed within an enclosure fitted over it, with one or more valves installed in the side walls which communicate with the outside air. Through the valves air is selectively withdrawn from the foam core, allowing the foam's density to increase. The invention uses relatively inexpensive foam, but through air volume modulation achieves a tactile feel of supreme softness for the user, without giving up the necessary firmness to support the body, as happens with very soft foam (bottoming-out or hammock-effect). When air is extracted from a self-inflating foam core, the surface of the core will soften uniformly while maintaining its support firmness. Contrary to this, when pressure is exerted on, for example, traditional coil spring core mattresses, their surface will harden. Integral part of the invention is a device using balanced springs in valve assemblies to avoid compression set, an irreversibly solid state of totally air-depleted foam.

Owner:GIORI GUALTIERO G +1

Adjustable foam mattress

InactiveUS20060075569A1Improve comfortLower comparable costStuffed mattressesSpring mattressesAir volumeEngineering

The invention modulates the air volume in foam cores of cushioning support devices and any other support apparatus using foam or similar materials. The foam core can be incrementally modulated to realize an infinite number of comfort levels as to softness and support firmness. The core consists of self-inflating open-cell flexible polyurethane foam and is completely sealed within an enclosure fitted over it, with one or more valves installed in the side walls which communicate with the outside air. Through the valves air is selectively withdrawn from the foam core, allowing the foam's density to increase. The invention uses relatively inexpensive foam, but through air volume modulation achieves a tactile feel of supreme softness for the user, without giving up the necessary firmness to support the body, as happens with very soft foam (bottoming-out or hammock-effect). When air is extracted from a self-inflating foam core, the surface of the core will soften uniformly while maintaining its support firmness. Contrary to this, when pressure is exerted on, for example, traditional coil spring core mattresses, their surface will harden. Integral part of the invention is a device using balanced springs in valve assemblies to avoid compression set, an irreversibly solid state of totally air-depleted foam.

Owner:GIORI GINO +1

Slurry for lithium ion secondary battery positive electrodes

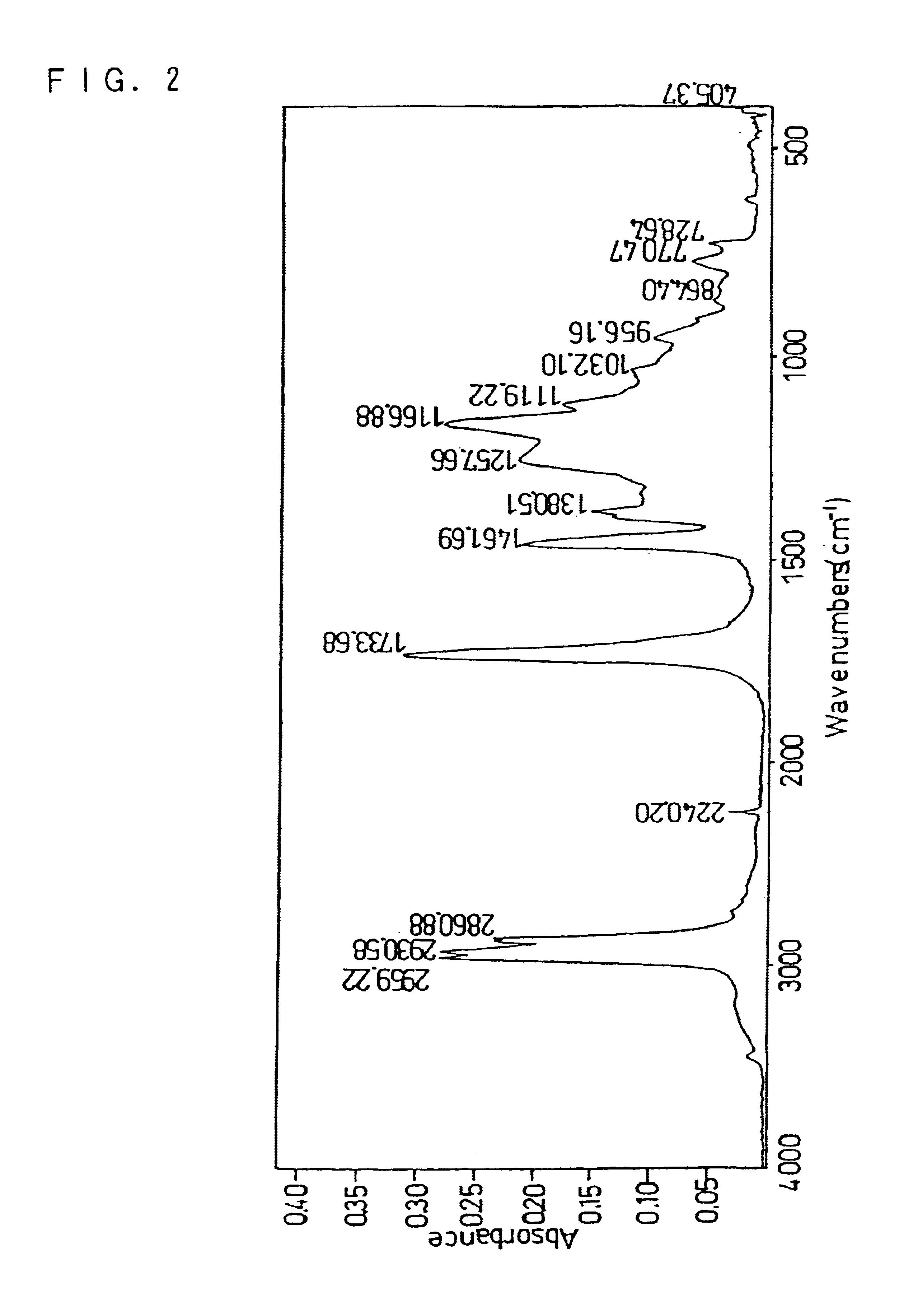

ActiveUS20150357648A1High target accuracyHigh positive electrode active material densityNon-metal conductorsConductive materialLithiumOrganic solvent

To provide a slurry for positive electrodes having excellent weight accuracy at the time of application, which enables the production of a lithium ion secondary battery that has high capacity and excellent cycle characteristics at high potentials, said lithium ion secondary battery being flexible and free from the occurrence of cracks in an active material layer when bent.[Solution] A slurry for lithium ion secondary battery positive electrodes according to the present invention contains a positive electrode active material, a binder, a conductive material and an organic solvent. The binder contains a nitrile group-containing acrylic polymer and a fluorine-containing polymer; and the viscosity ratio ((viscosity at a shear rate of 2 sec−1) / (viscosity at a shear rate of 20 sec−1)) of this slurry as measured by a coaxial double cylinder viscometer is 1.0-2.5.

Owner:ZEON CORP

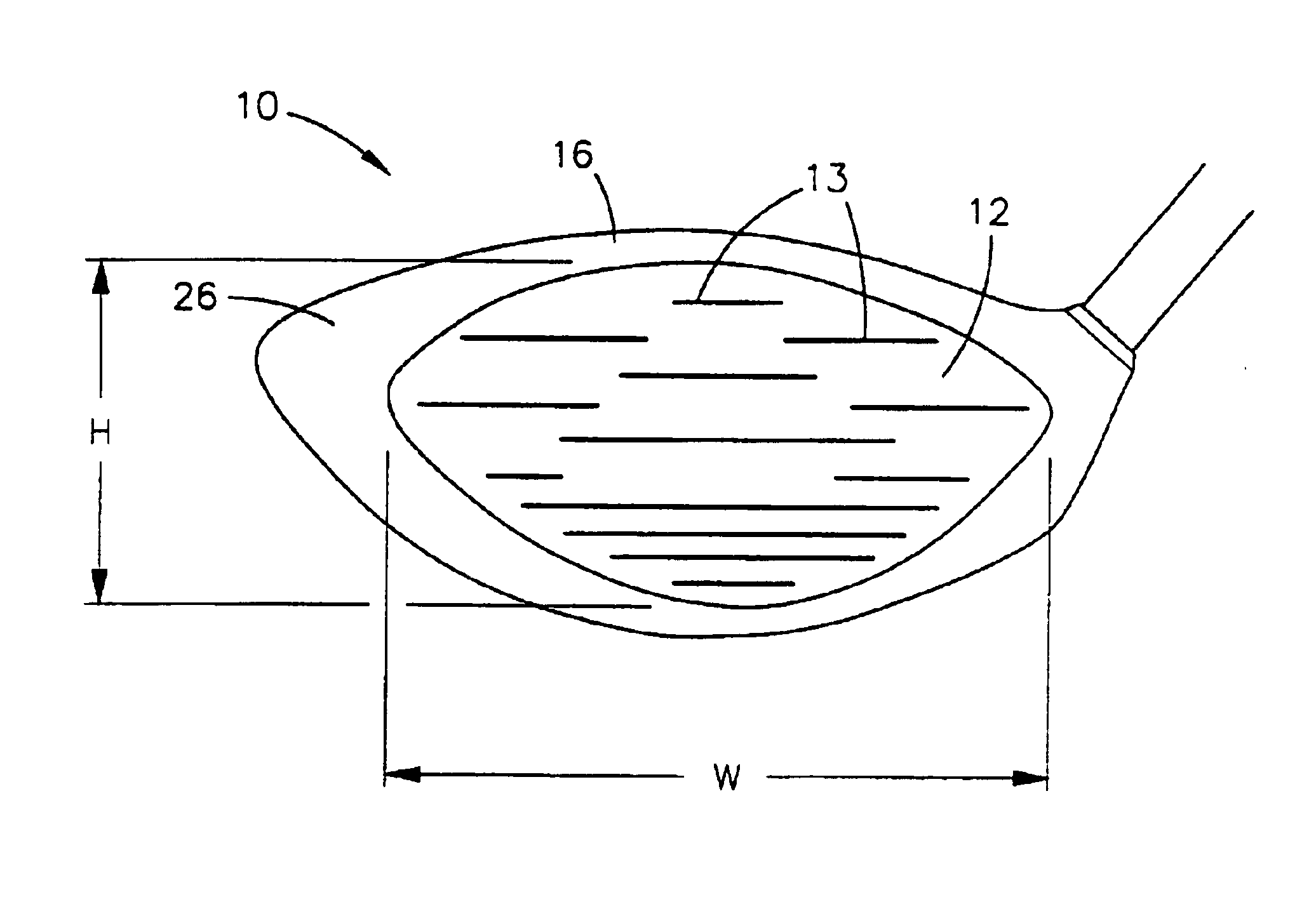

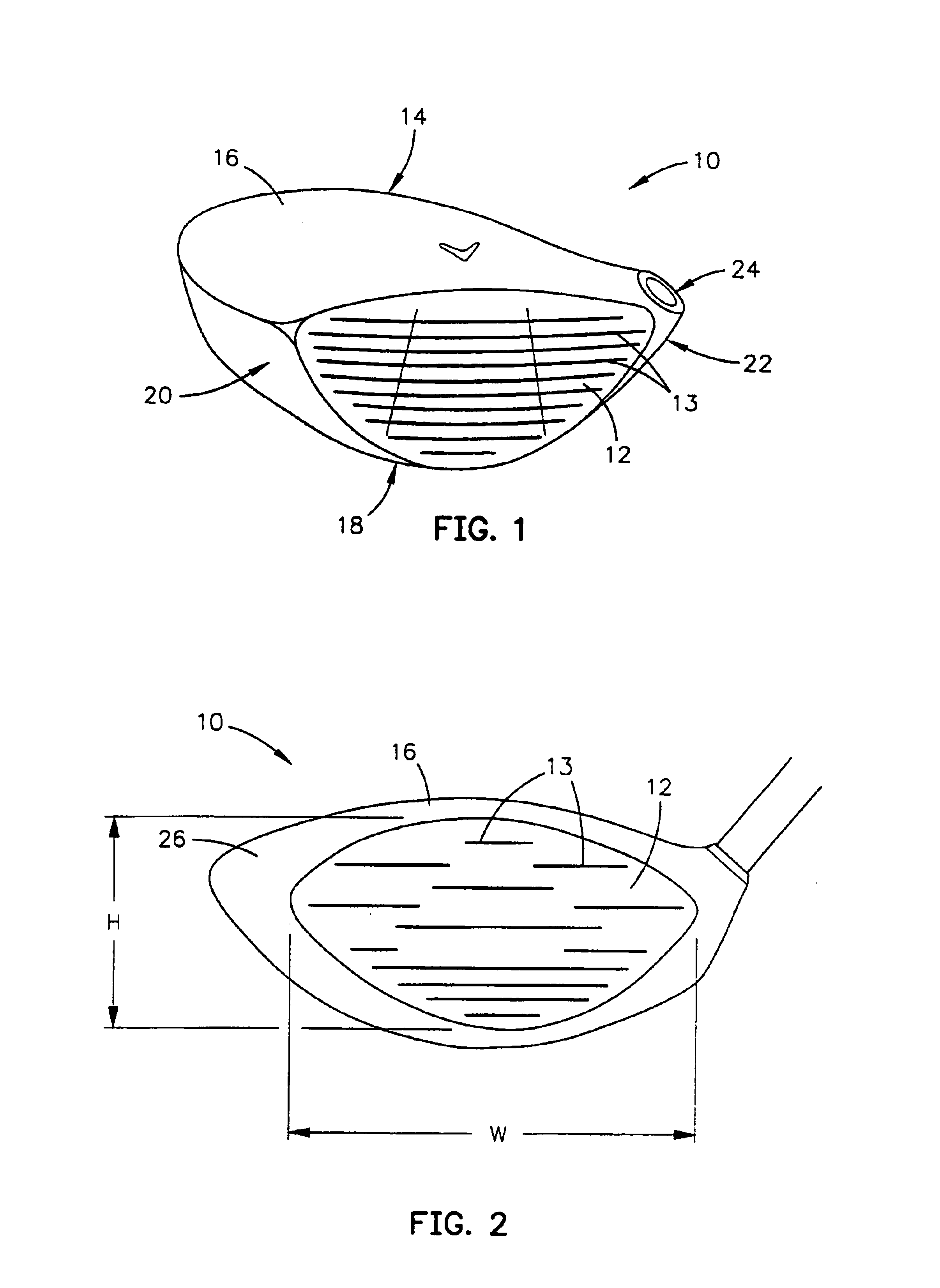

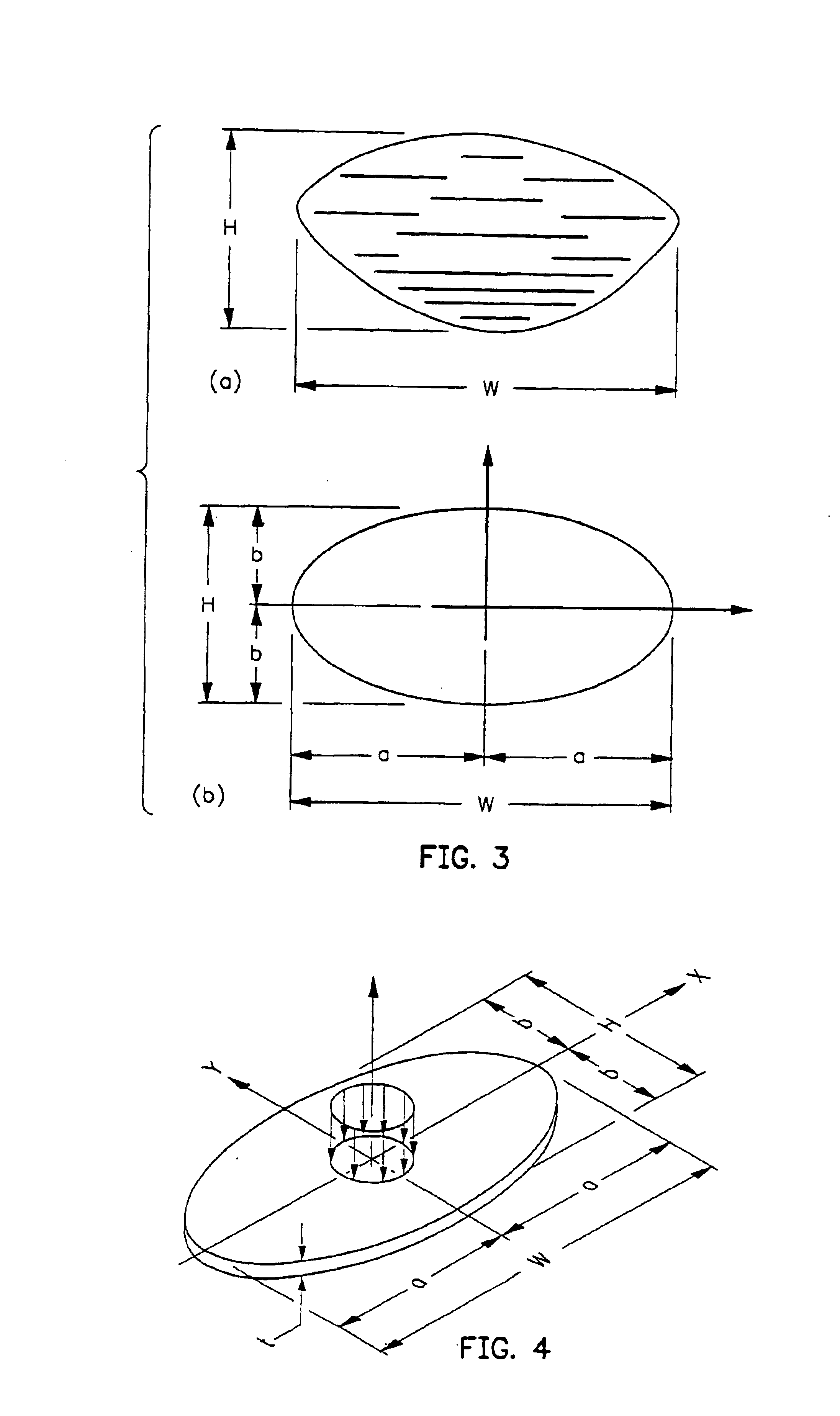

Golf club head having a striking face with improved impact efficiency

InactiveUS6949032B2Improve energy efficiencyReduced magnitudeGolf clubsRacket sportsStrain rateEnergy loss

A compliant golf club head permits a more efficient impact between a golf ball and the golf club head. Material and geometry constraints of a striking plate of the golf club head can reduce energy losses caused by large strain and strain rate values of the golf ball, these constraints on the striking plate yield a measure of the impact efficiency of the golf club head. Designating a required natural frequency range of the striking plate provides improved impact efficiency between the golf ball the golf club head.

Owner:CALLAWAY GOLF CO

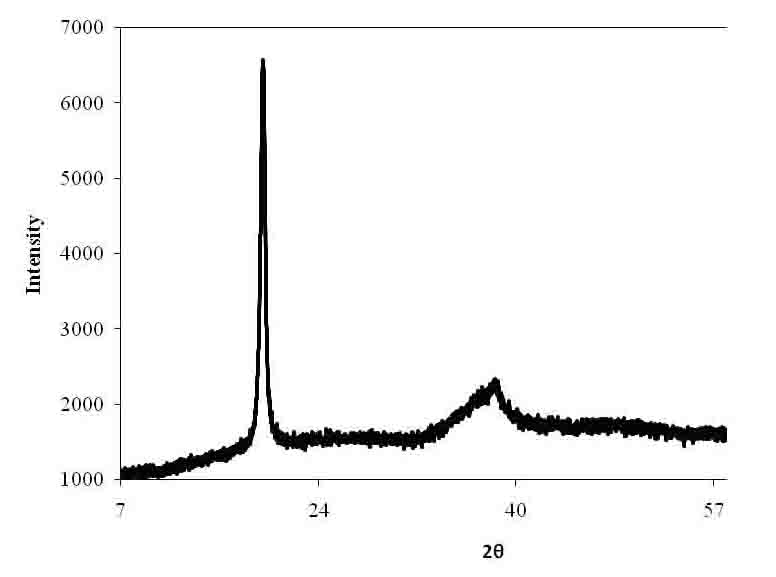

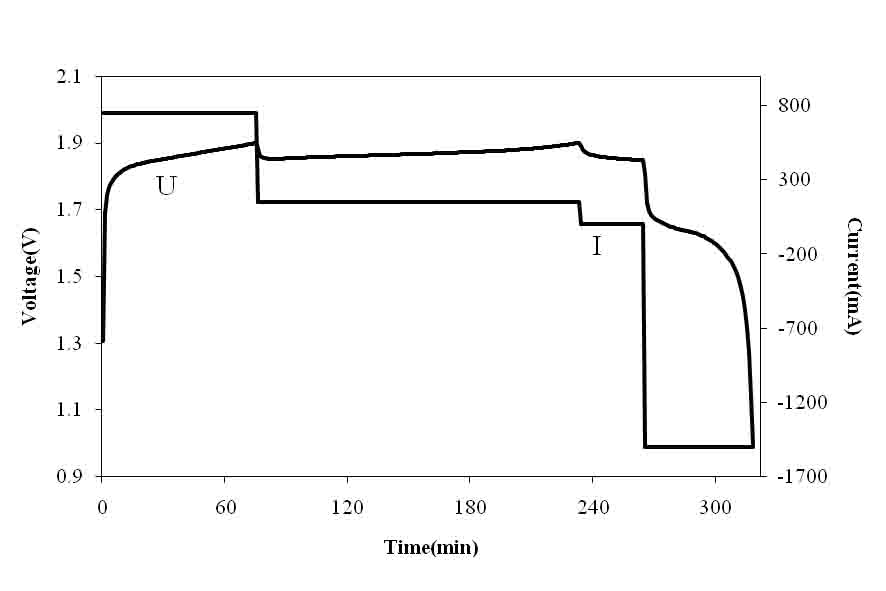

Nickel-zinc secondary battery and preparation method thereof

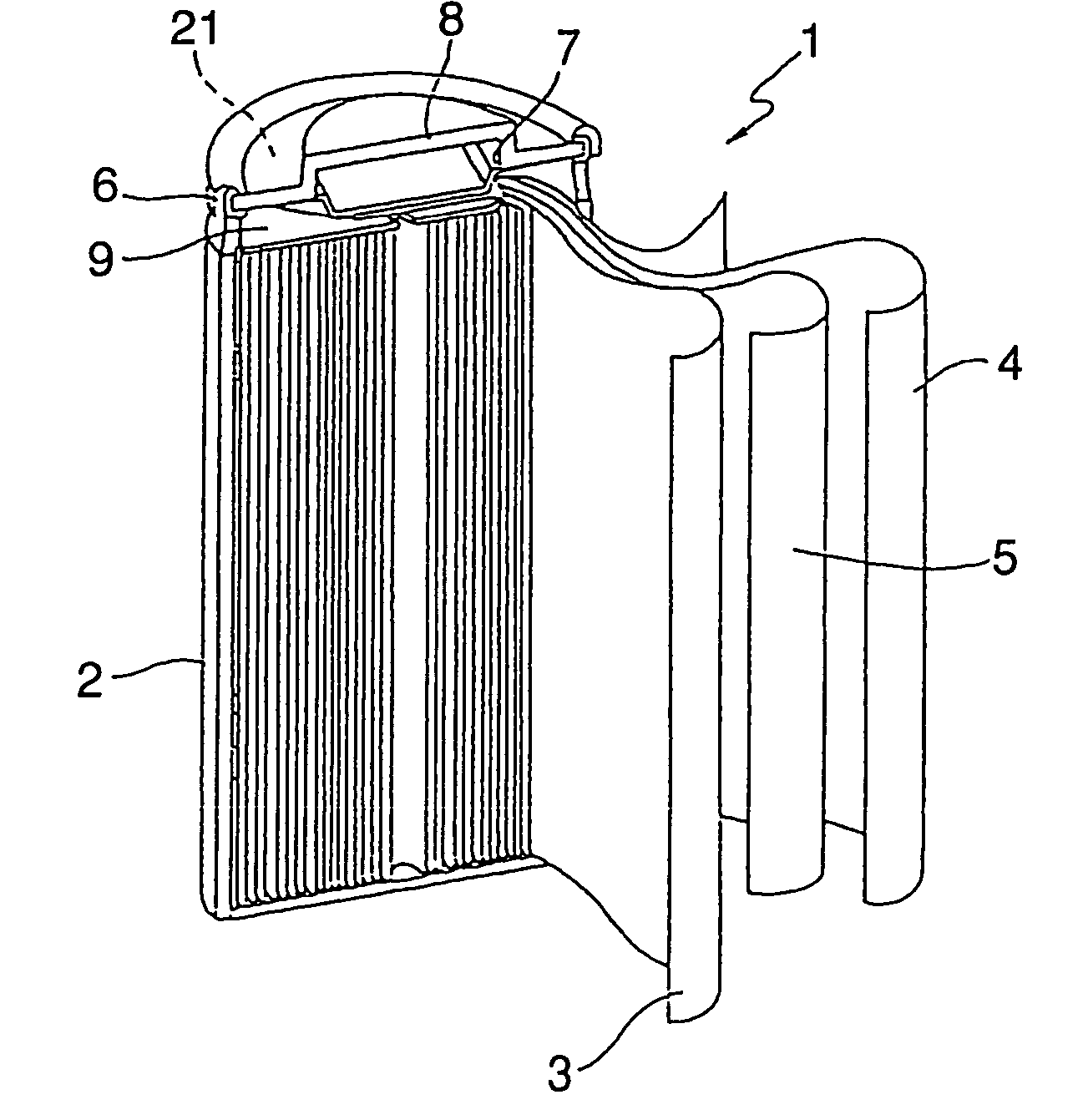

ActiveCN102024994AHigh discharge platformImprove performanceFinal product manufactureElectrode carriers/collectorsElectrolytic agentBattery cell

The invention relates to a nickel-zinc secondary battery and a preparation method thereof. The technical scheme is that: the preparation method comprises the following steps of: mixing 85 to 99 weight percent of anode active substance, 0.5 to 10 weight percent of anode additive and 0.5 to 5 weight percent of anode bonding agent uniformly; adding water into the mixture to prepare paste; coating the paste on an anode conductive matrix; drying, performing roll forming and slicing to obtain an anode plate; mixing 75 to 99 weight percent of cathode active substance, 0.5 to 20 weight percent of cathode additive and 0.5 to 5 weight percent of cathode bonding agent uniformly; adding water into the mixture to prepare paste; coating the paste on a cathode conductive matrix; drying, performing roll forming and slicing to obtain a cathode plate; separating the anode plate from the cathode plate by using diaphragm paper; winding the separated anode plate and cathode plate to be a cylindrical shape; sleeving the cylindrical object into a battery case; injecting electrolyte, wherein the anode plate is connected with an anode cap by a lug and the cathode plate contacts with the battery case; and sealing the battery to form the nickel-zinc secondary battery. The nickel-zinc secondary battery prepared by the method has a long cycle life, a high discharging platform and high specific energy.

Owner:LIAONING JIUYI ENERGY TECH

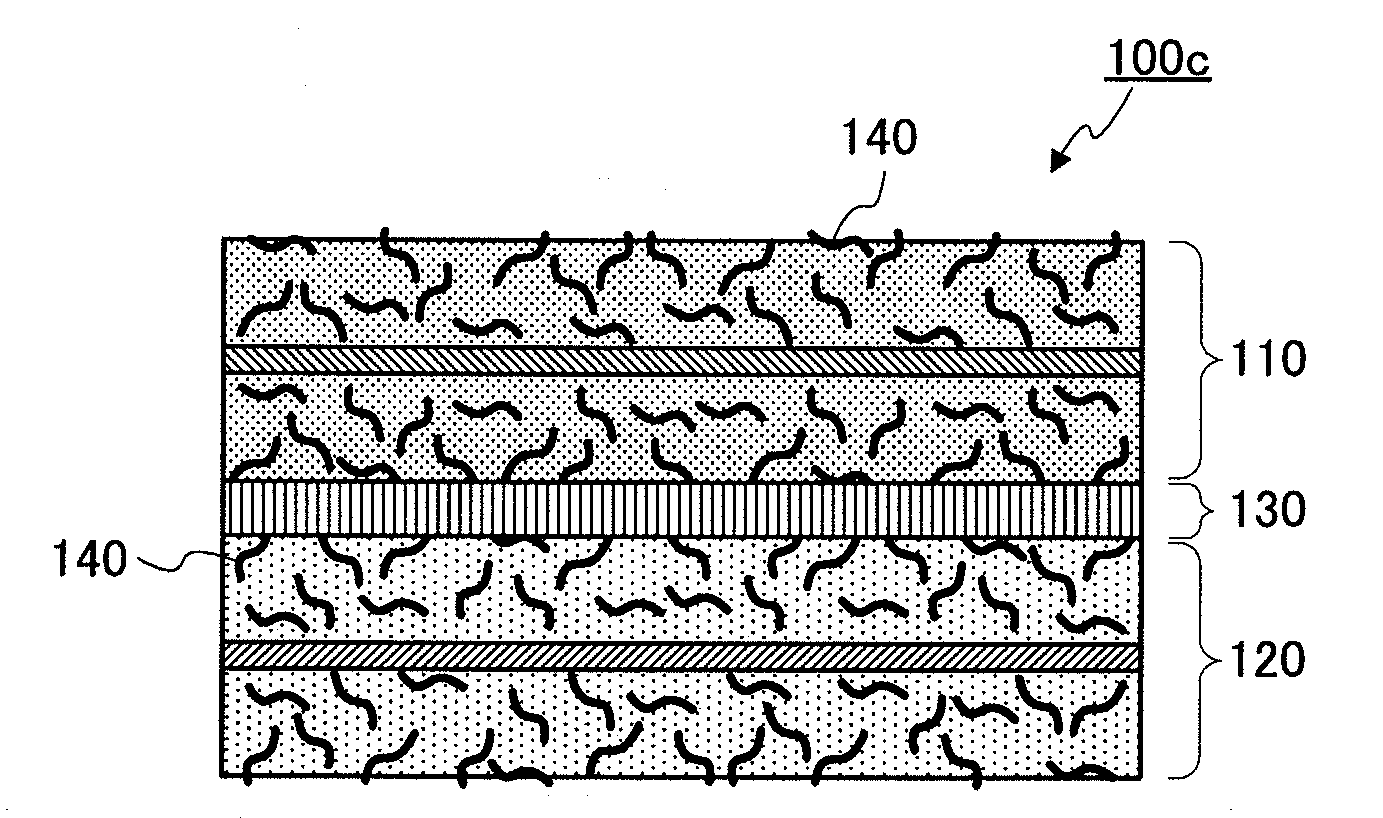

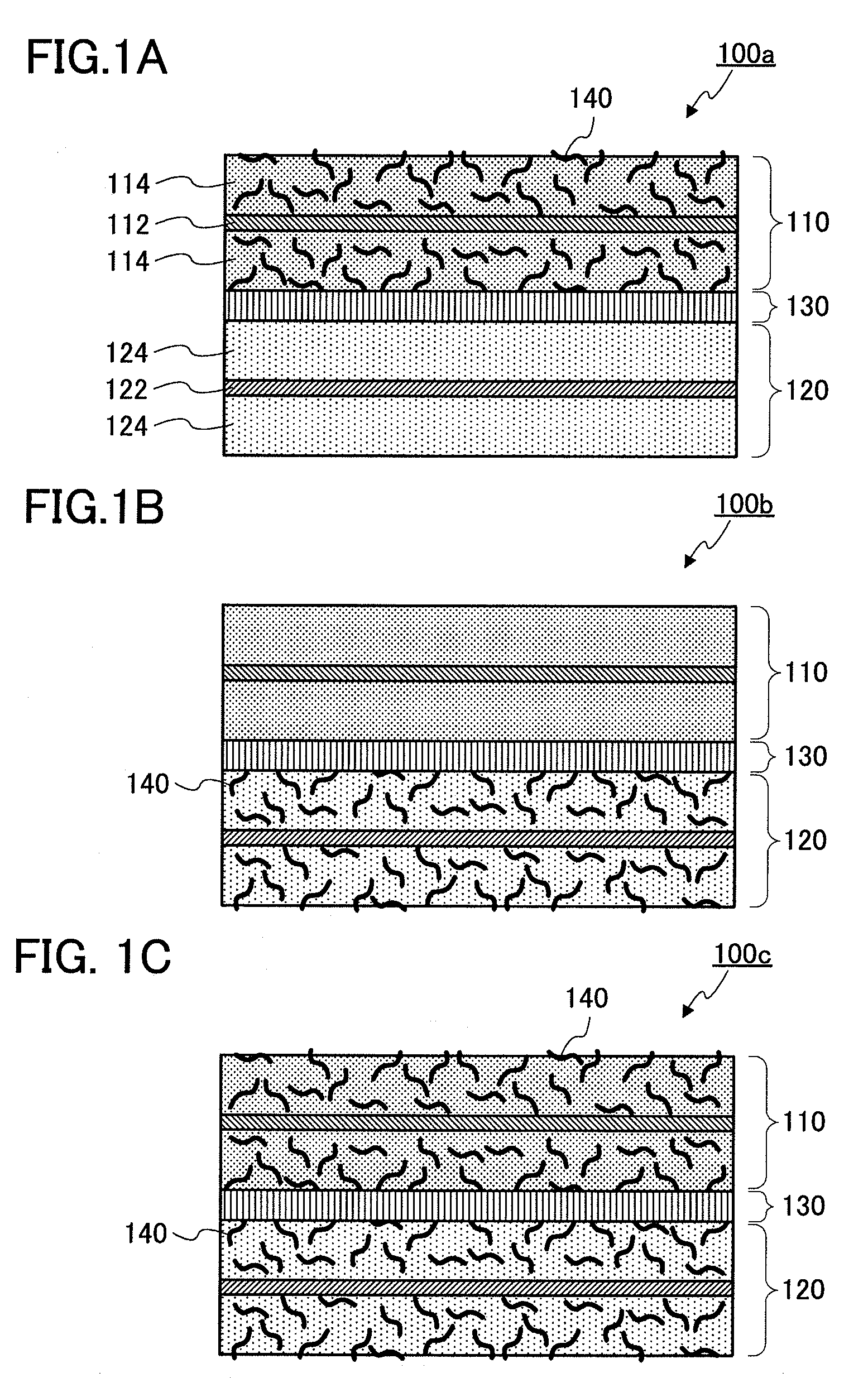

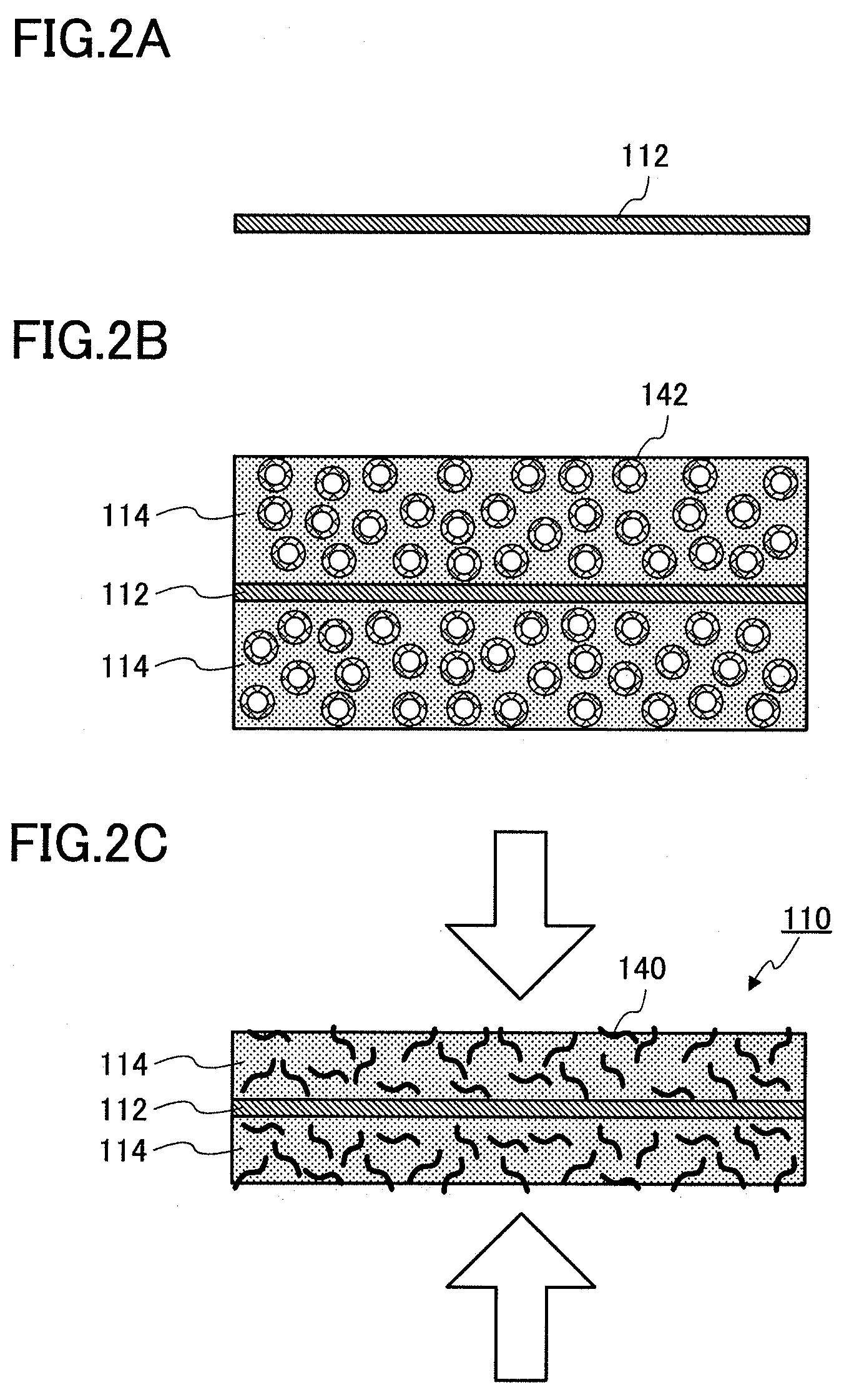

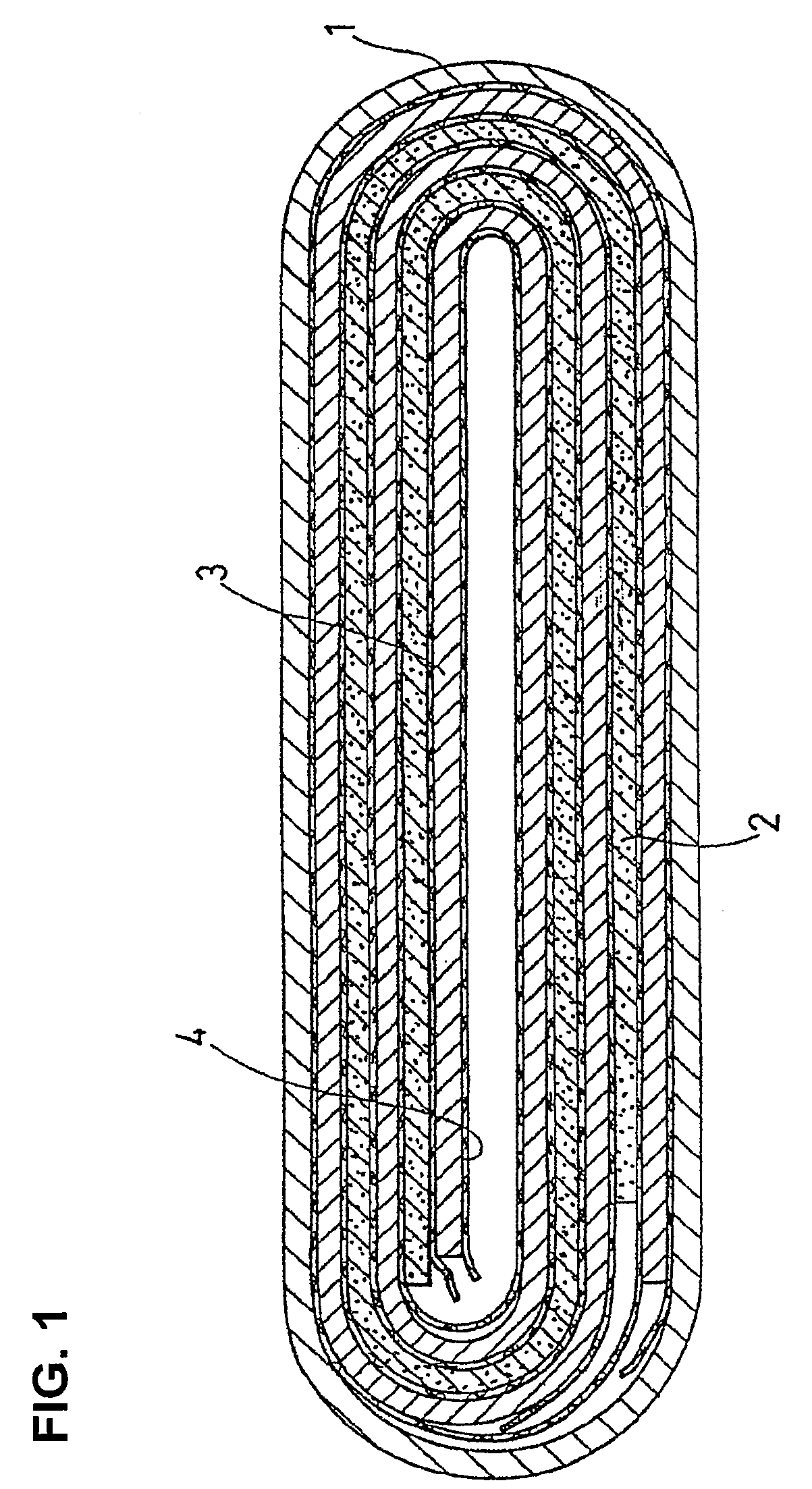

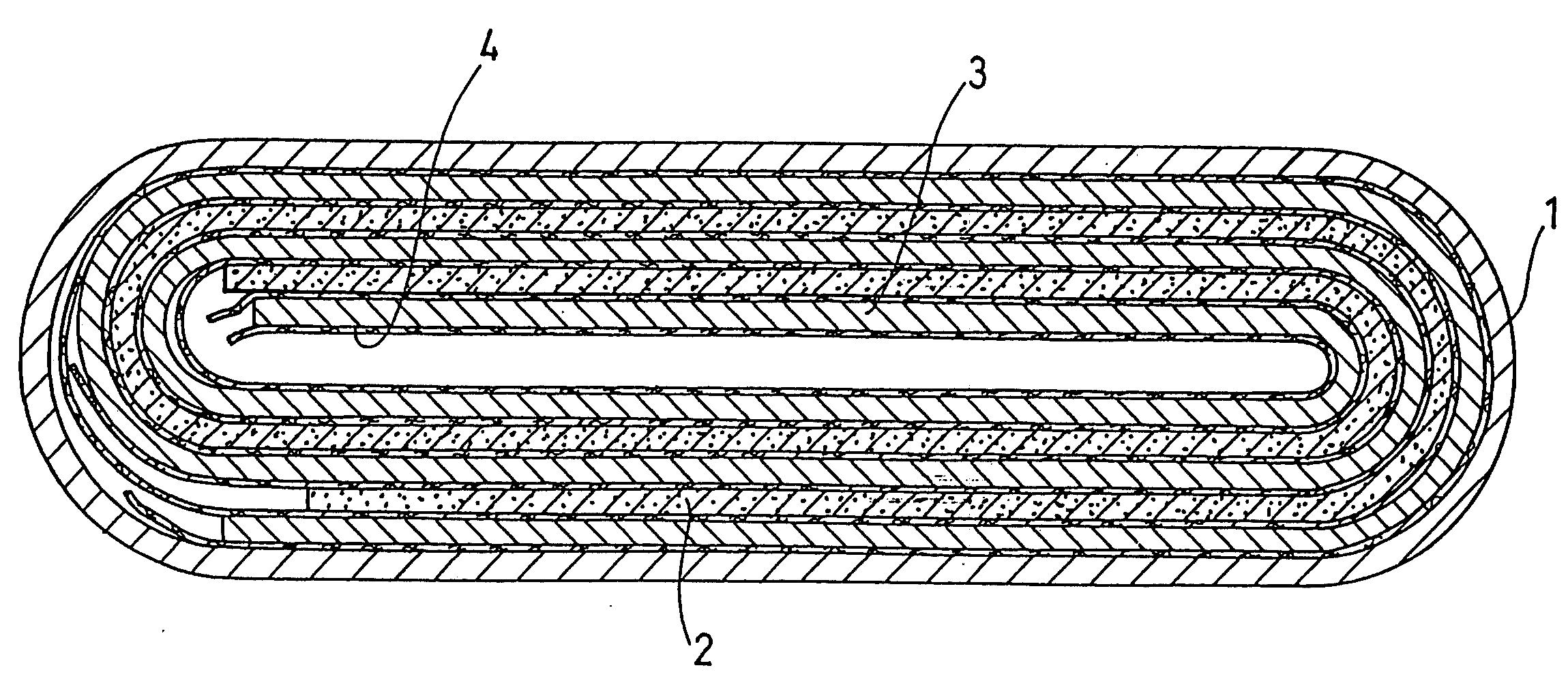

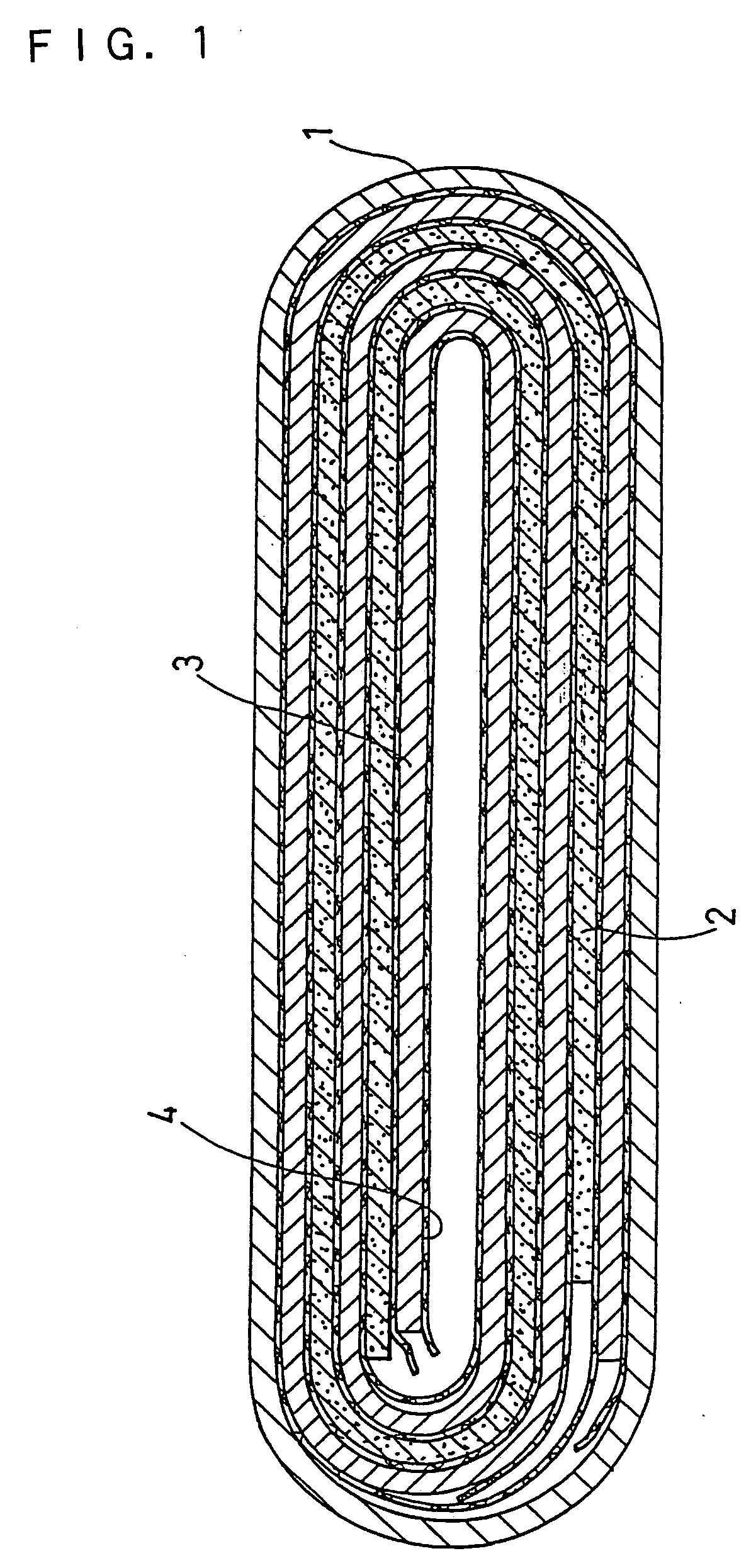

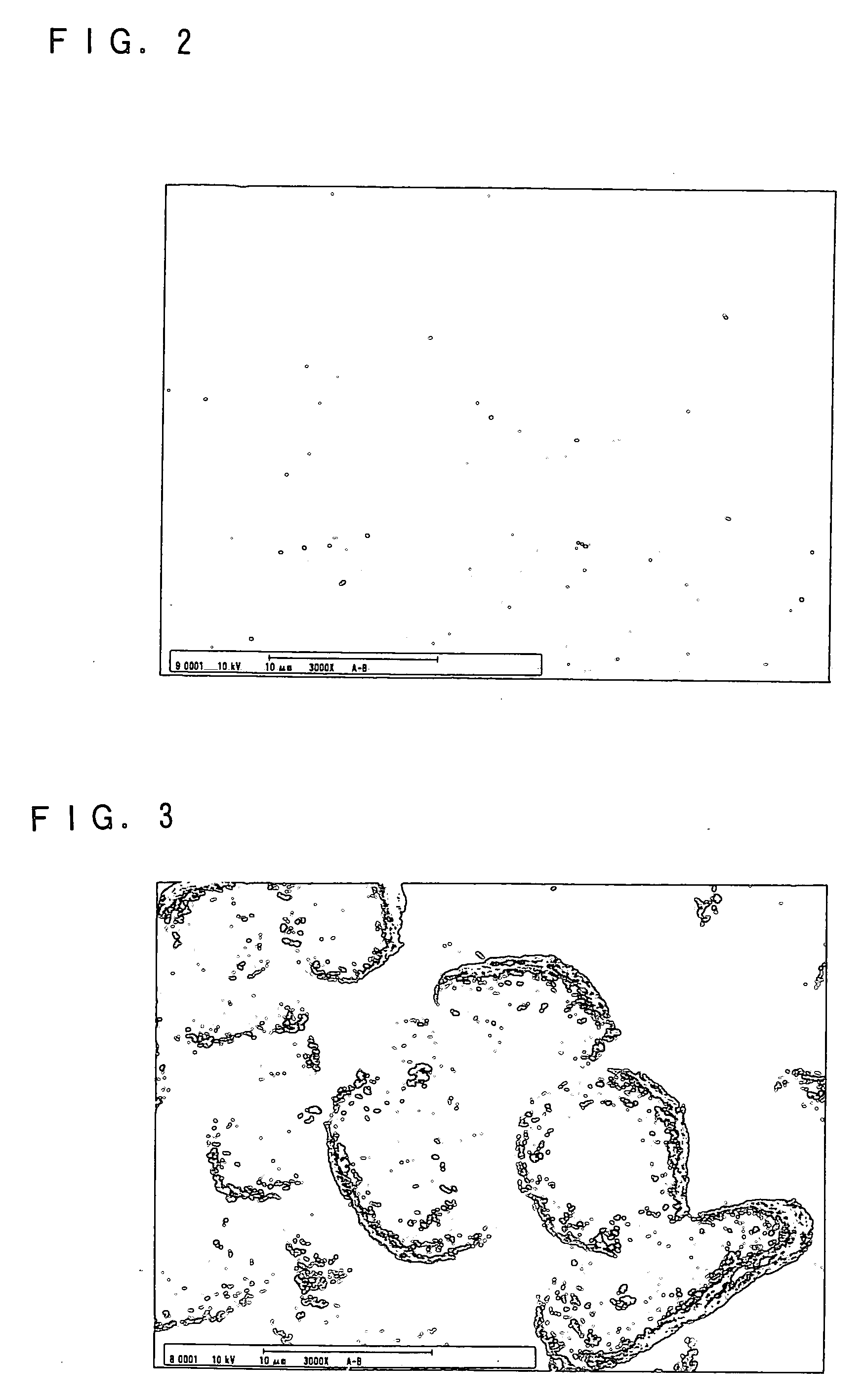

Rechargeable lithium ion battery and method for producing the same

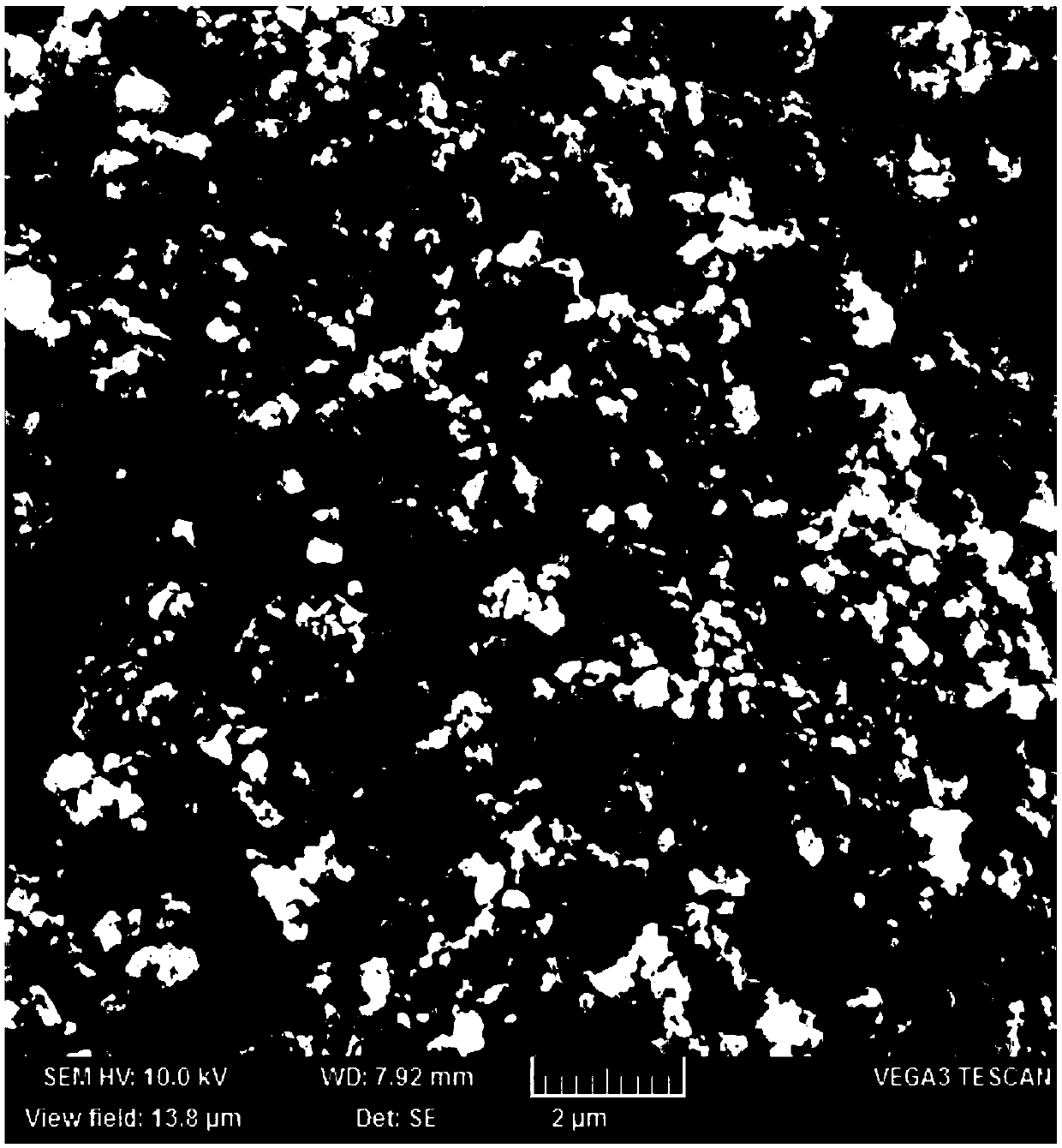

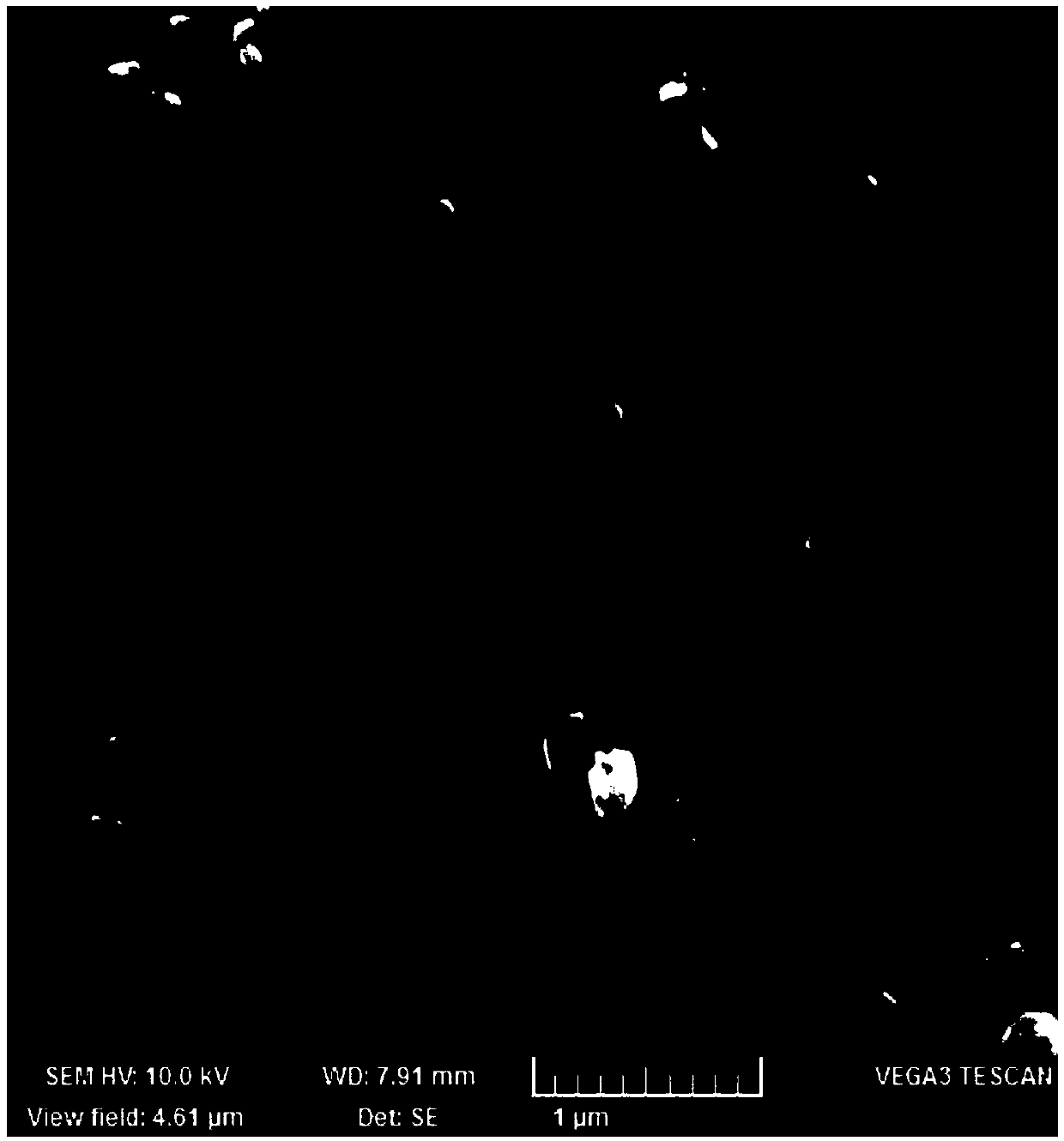

ActiveUS20080292965A1Increase material densityIncrease capacityElectrode rolling/calenderingFinal product manufactureLithium-ion batteryMaterial density

The present invention relates to a rechargeable lithium ion battery having an electrode plate with a high active material density and high electrolyte permeability. Upon producing the rechargeable lithium ion battery, hollow resin particles that can be collapsed by rolling are incorporated in a positive electrode mixture layer or a negative electrode mixture layer before the electrode mixture layer is rolled. The hollow resin particles are collapsed in the course of rolling the positive electrode mixture layer or the negative electrode mixture layer, so that the active material density can be easily increased. Further, the collapsed resin particles form unevenness on the surface of the electrode plate and also form open pores in the electrode plate, so that electrolyte permeability can be enhanced. As a result, the discharge capacity and rate characteristics of rechargeable lithium ion batteries can be increased.

Owner:PANASONIC CORP

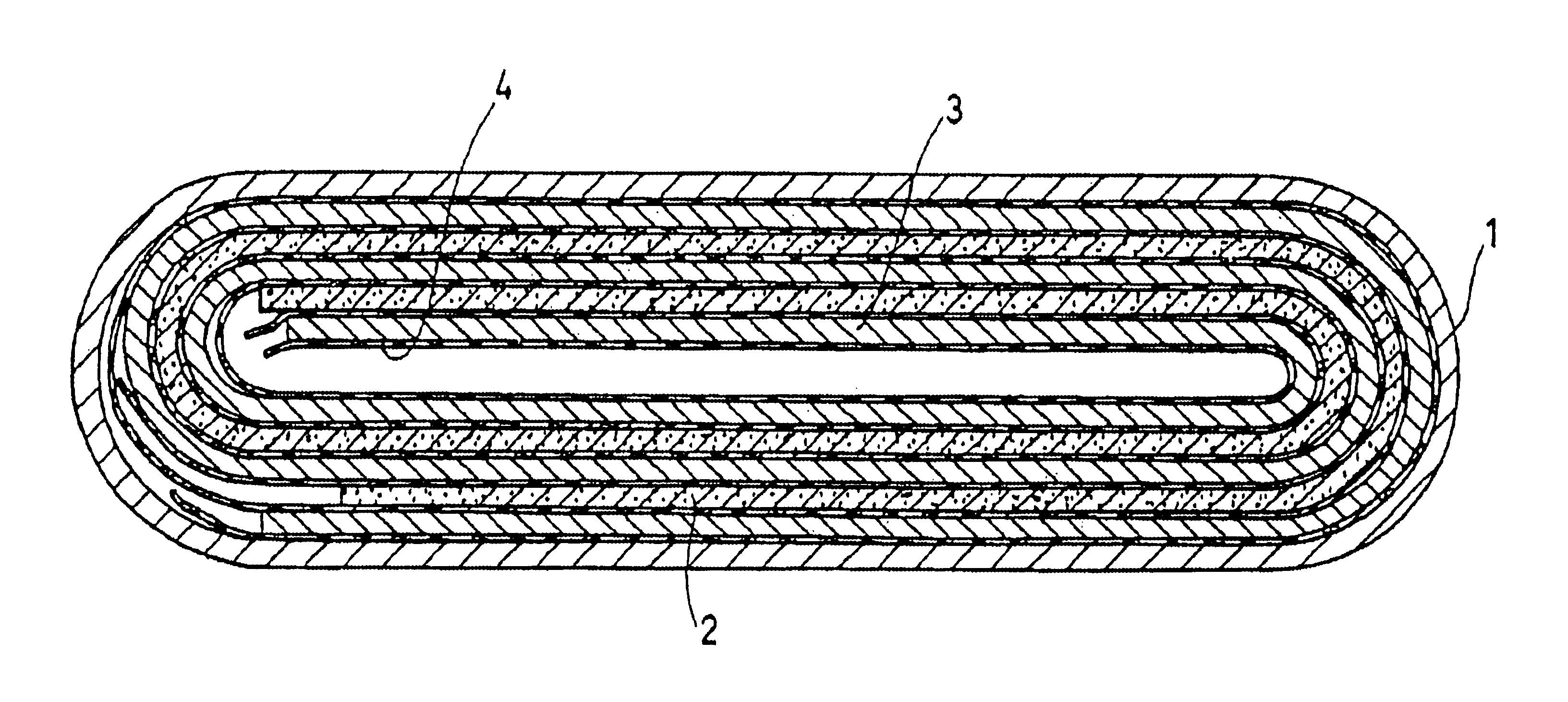

Non-aqueous electrolyte secondary battery and positive electrode for the same

InactiveUS6869724B2Long lifeHigh energy densityFinal product manufactureActive material electrodesHigh energyEnergy density

A non-aqueous electrolyte secondary battery comprises: a positive electrode sheet comprising a positive electrode mixture containing a lithium-containing transition metal oxide as an active material and a particulate binder; a negative electrode sheet comprising a negative electrode mixture containing a carbon material; a separator interposed between the positive electrode sheet and the negative electrode sheet; and a non-aqueous electrolyte containing a lithium salt, wherein the positive electrode sheet and the negative electrode sheet are wound with the separator interposed therebetween to form an electrode assembly, and the positive electrode mixture has an active material density of 3.0 to 4.0 g / ml. The battery has a long life, high energy density and high output.

Owner:GK BRIDGE 1

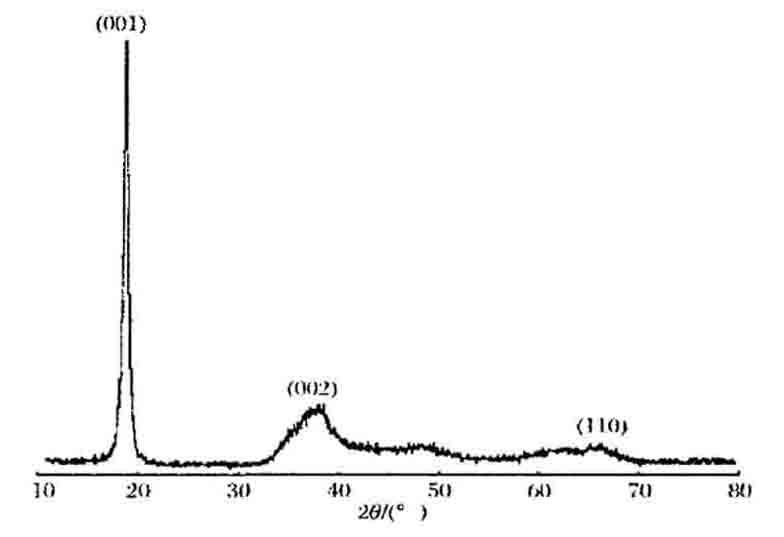

Nickel electrode material,and production method therefor, and nickel electrode and alkaline battery

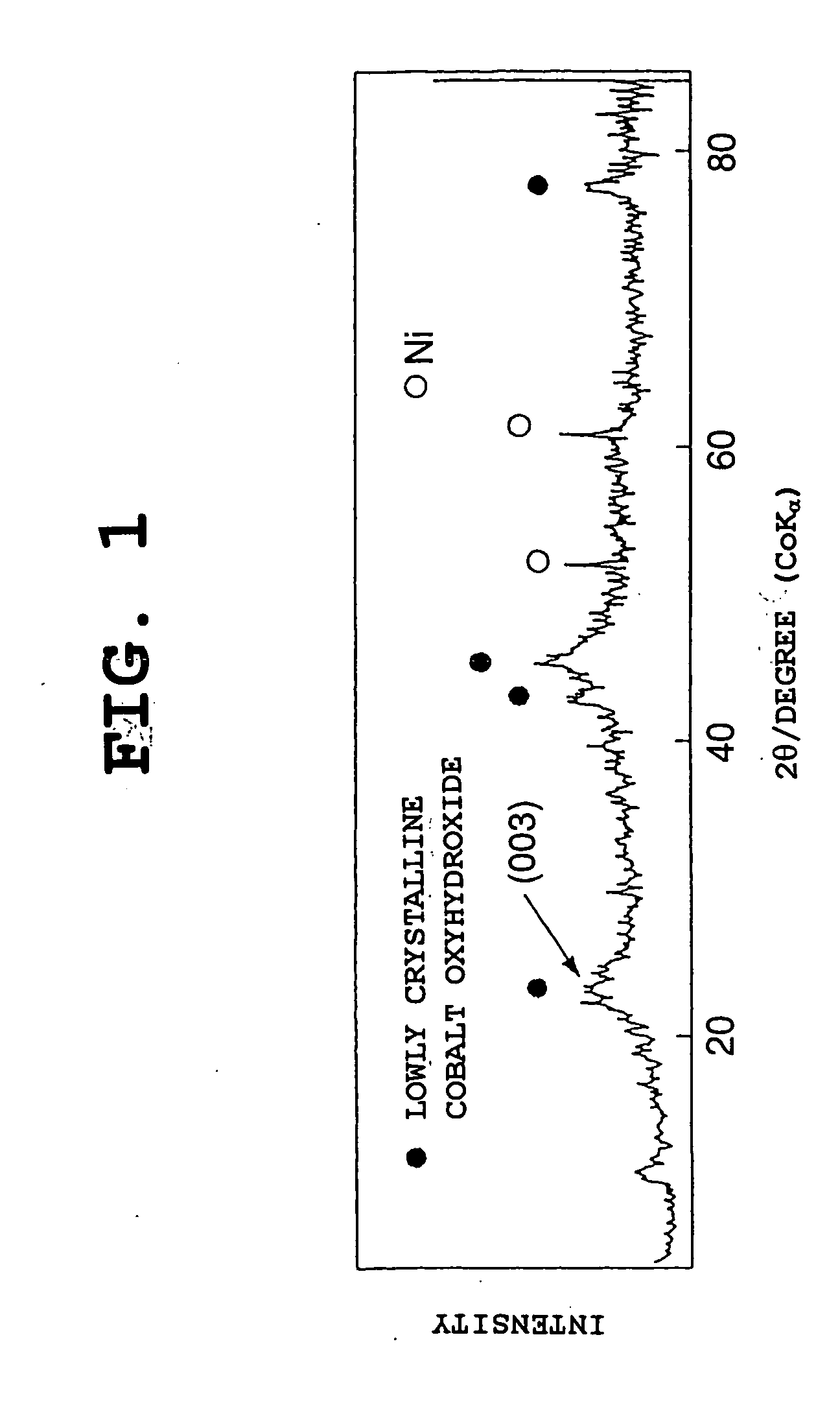

ActiveUS20040241545A1Improved cycle life characteristicsHigh degreeElectrochemical processing of electrodesLayered productsInternal pressureNickel oxide hydroxide

Subjects for the invention are to provide a nickel electrode material having a satisfactory tap density and capable of attaining a sufficient reduction in discharge reserve and a process for producing the nickel electrode material, and to provide a nickel electrode and an alkaline storage battery having a high capacity and excellent internal-pressure characteristics. For accomplishing the subjects, the invention provides a nickel electrode material for use in a nickel electrode, wherein the positive-electrode material constituting the electrode material comprises: positive active material particles which comprise as the main component either a nickel hydroxide or a solid solution in a nickel hydroxide of one or more other elements and in which part of the nickel hydroxide has been oxidized; and a coating layer formed on the surface of the positive active material particles and comprising as the main component a high-order cobalt compound in which the cobalt has an oxidation number larger than 2, the average oxidation number of the nickel in the positive active material particles and the cobalt in the coating layer being from 2.04 to 2.40, and the positive-electrode material having a tap density of 2.0 g / cm<3 >or higher. The invention further provides a process for producing the electrode material, a nickel electrode employing the electrode material, and an alkaline storage battery having the nickel electrode.

Owner:GS YUASA INT LTD

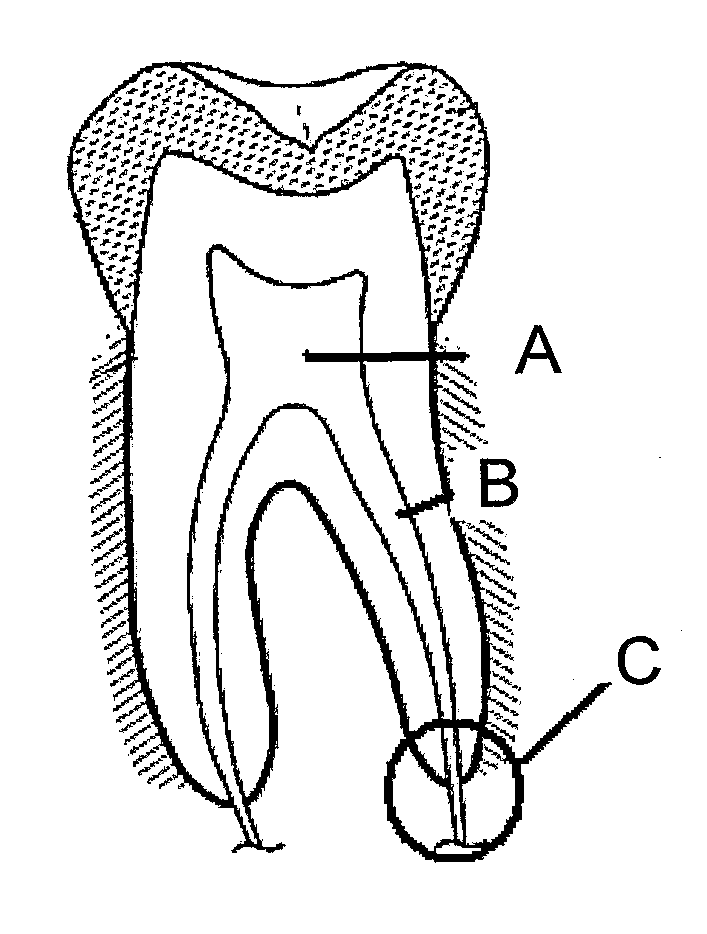

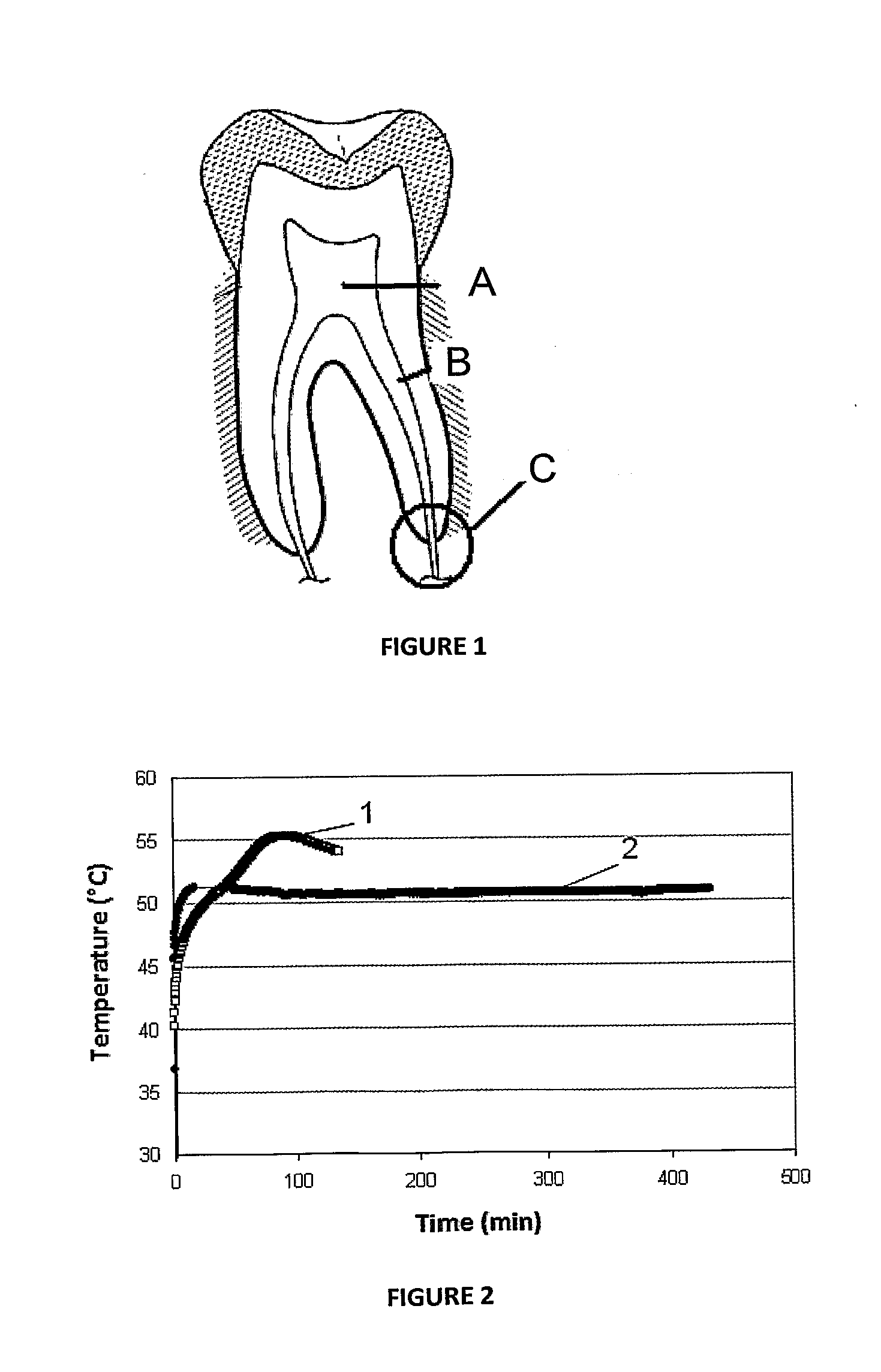

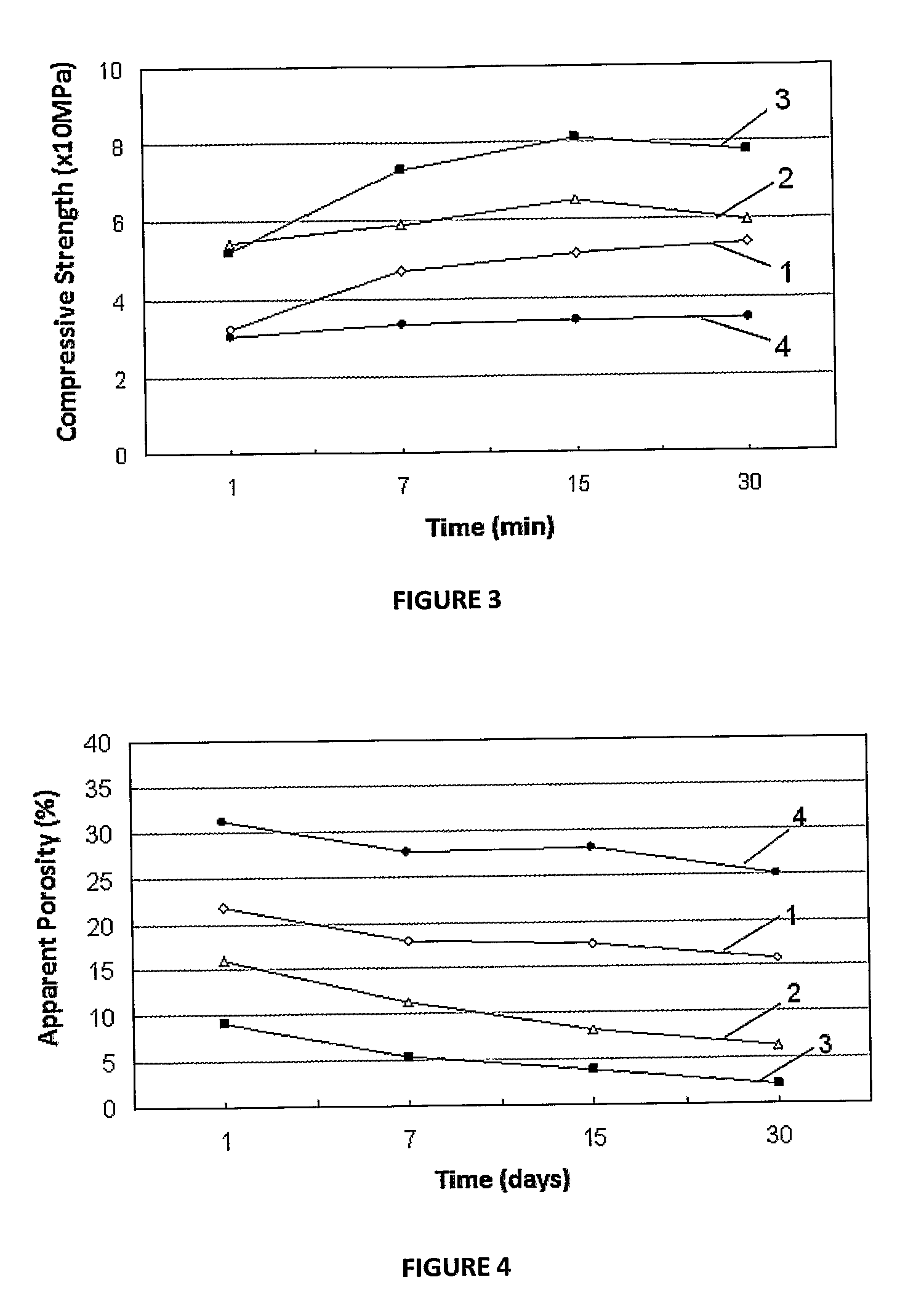

Aluminous cement-based composition for application in endodontics and cementitious product obtained thereof

InactiveUS20110281241A1Improve rheologyImprove workabilityCosmetic preparationsImpression capsRadiopaque agentPlasticizer

The present invention provides a composition based on calcium aluminate cement (CAC) for application in endodontics, comprising: (a) a cement—Al2O3 (>68.5 wt %), CaO (<31 wt %), SiO2 (0.3-0.8 wt %), MgO (0.4-0.5 wt %), and Fe2O3 (<0.3 wt %); (b) additives: dispersant at a content of 0.4 to 0.8% by weight of the cement, a plasticizer at a content of 2.0 to 4.0% by weight of the cement, and a radiopaque agent at a content of 20 to 35% by weight of the cement; and (c) water, wherein water / cement ratio lies in the range of 0.19-0.24 in the presence of additives. Cementitious product obtained thereof, after setting time, is also disclosed and characterized by enhanced properties when compared to the most used commercial repair cement, MTA.

Owner:UNIVE FEDERAL DE SAO CARLOS

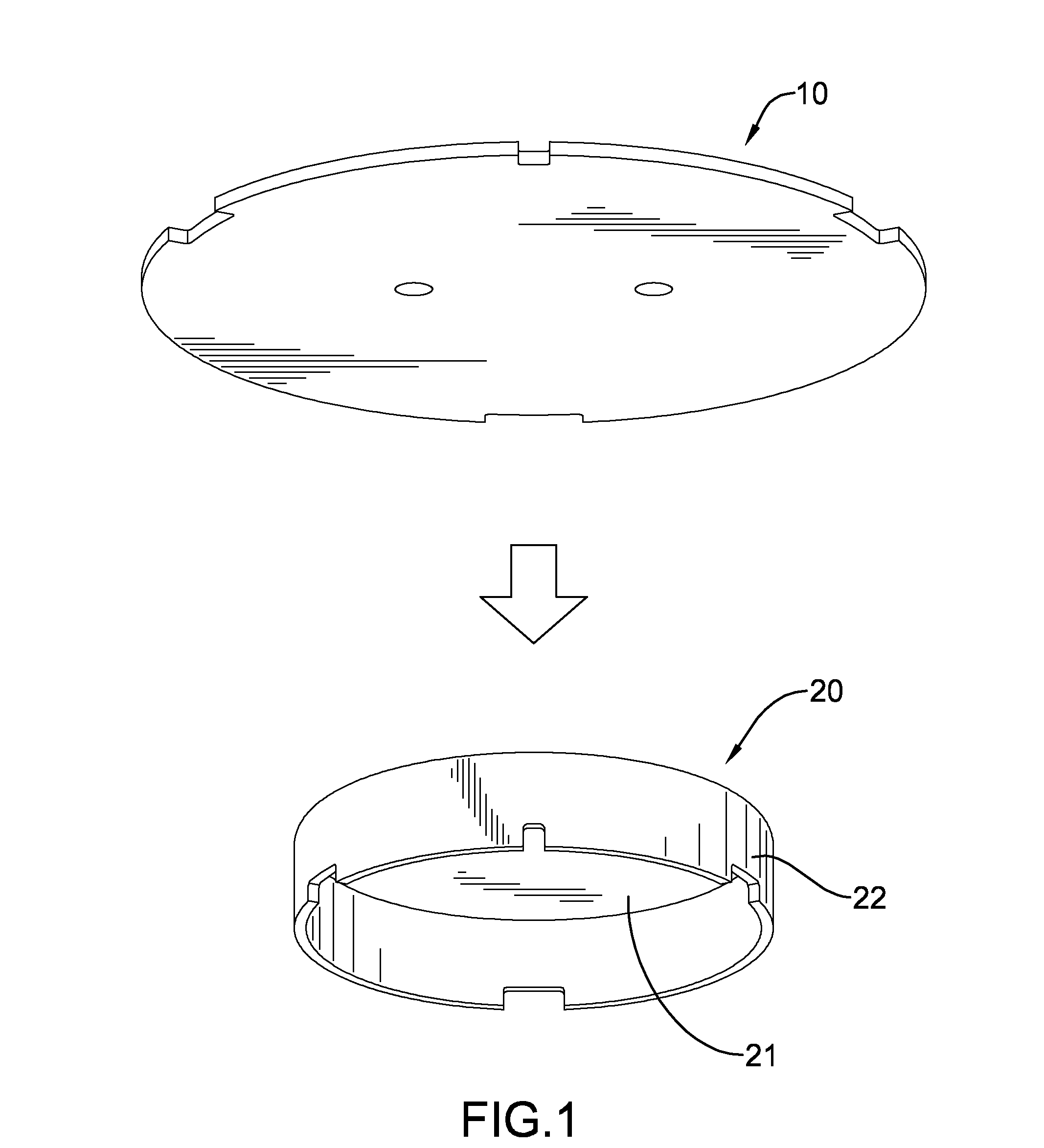

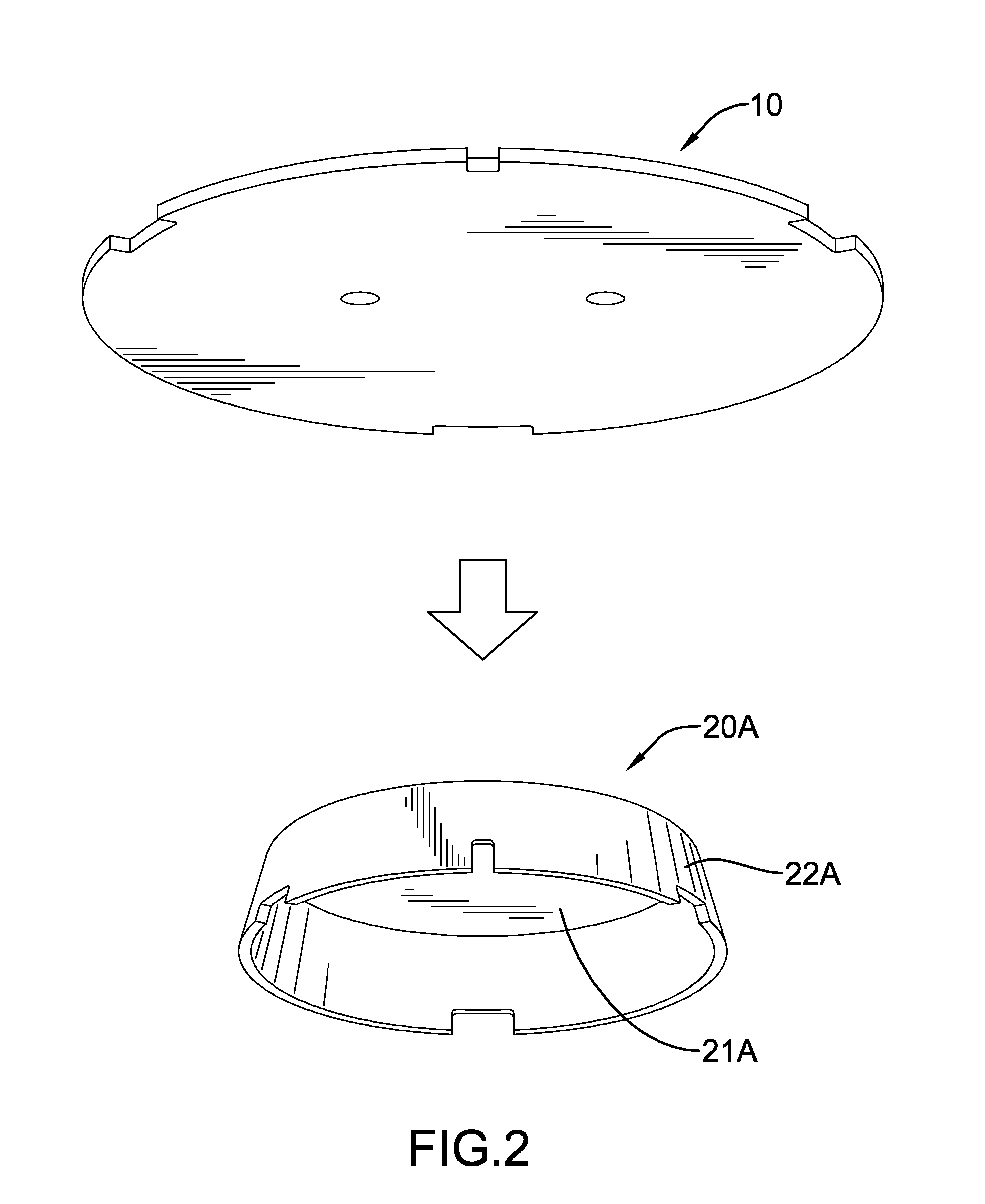

Reusable crucibles and method of manufacturing them

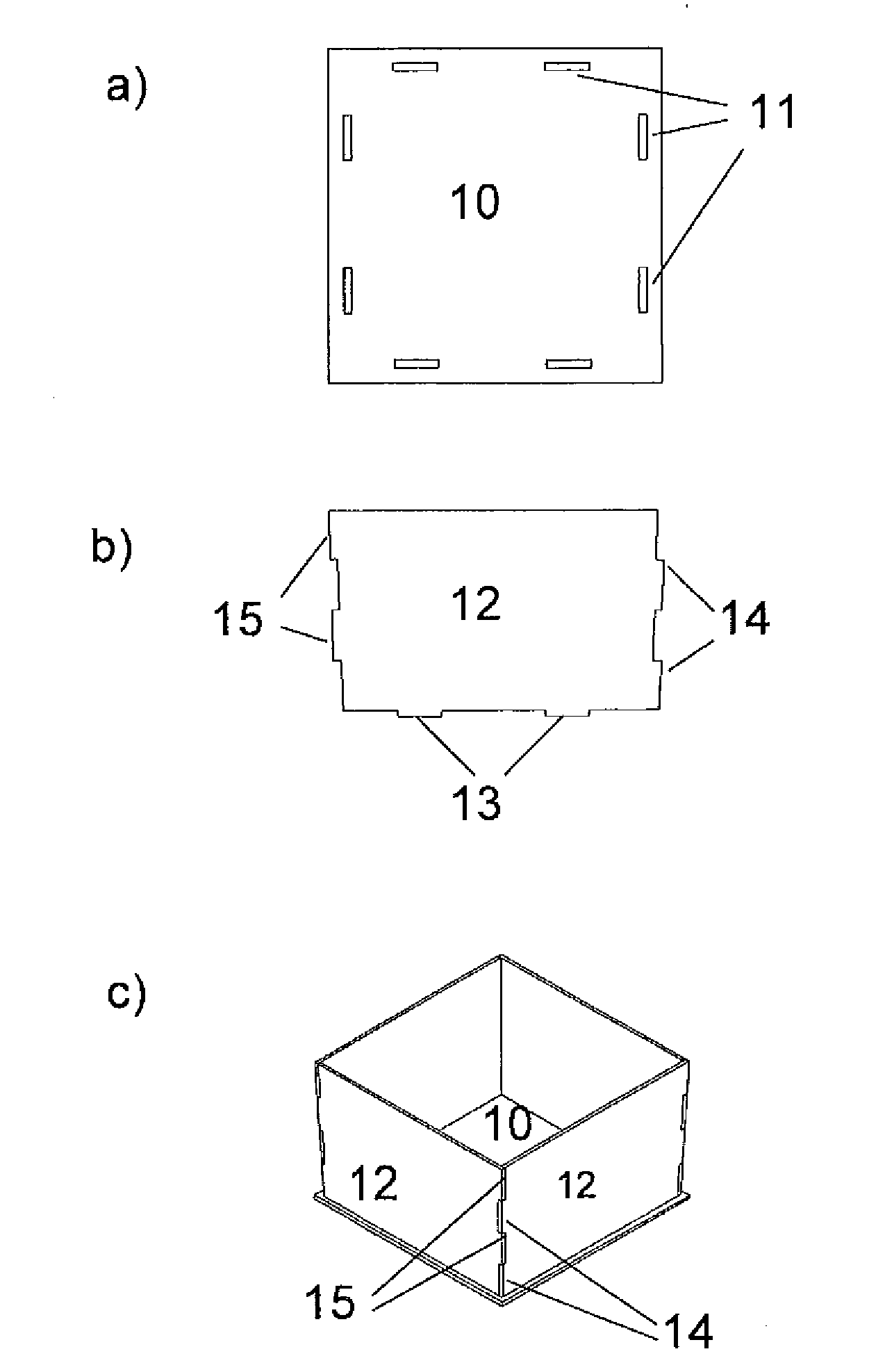

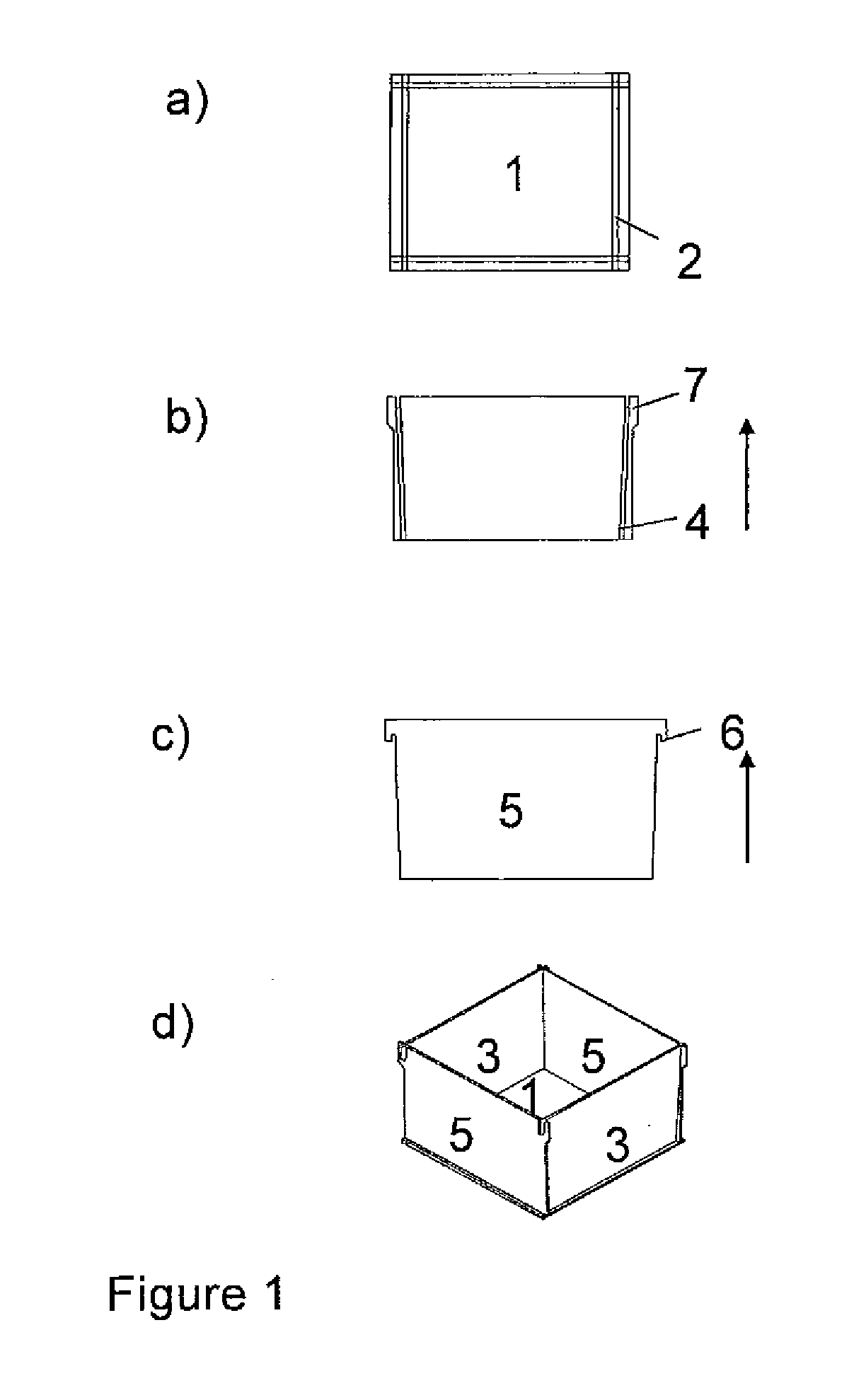

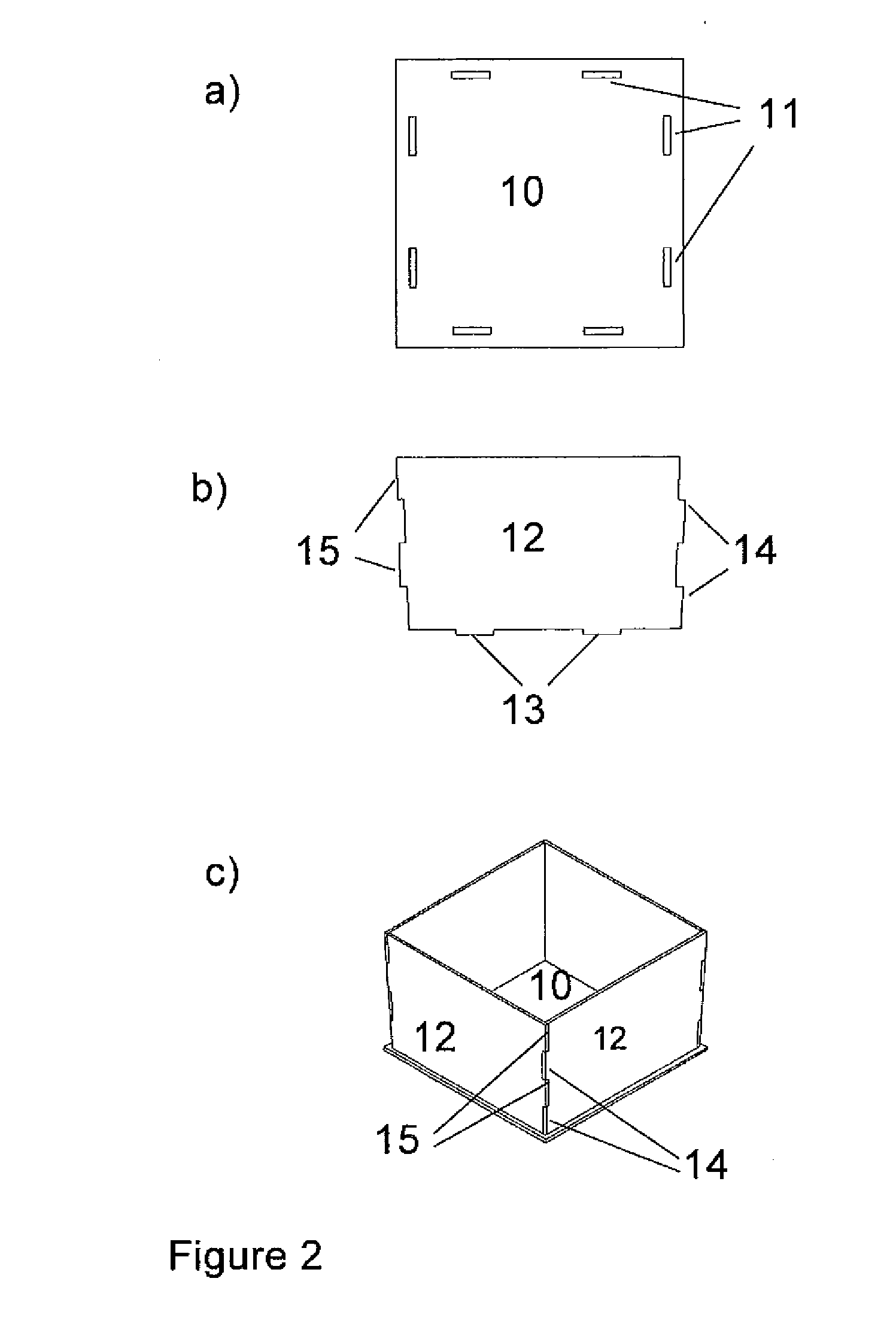

InactiveUS20090249999A1Reduce releaseLow failure rateNitrogen compoundsFinal product manufactureSquare cross sectionCrucible

This invention relates to reusable crucibles for production of ingots of semiconductor grade silicon made of nitride bonded silicon nitride (NBSN). The crucibles may be made by mixing silicon nitride powder with silicon powder, forming a green body of the crucible, and then heating the green body in an atmosphere containing nitrogen such that the silicon powder is nitrided forming the NBSN-crucible. Alternatively the crucibles may assembled by plate elements of NBSN-material that are to be the bottom and walls of a square cross-section crucible, and optionally sealing the joints by applying a paste comprising silicon powder and optionally silicon nitride particles, followed by a second heat treatment in a nitrogen atmosphere.

Owner:REC SCANWAFER

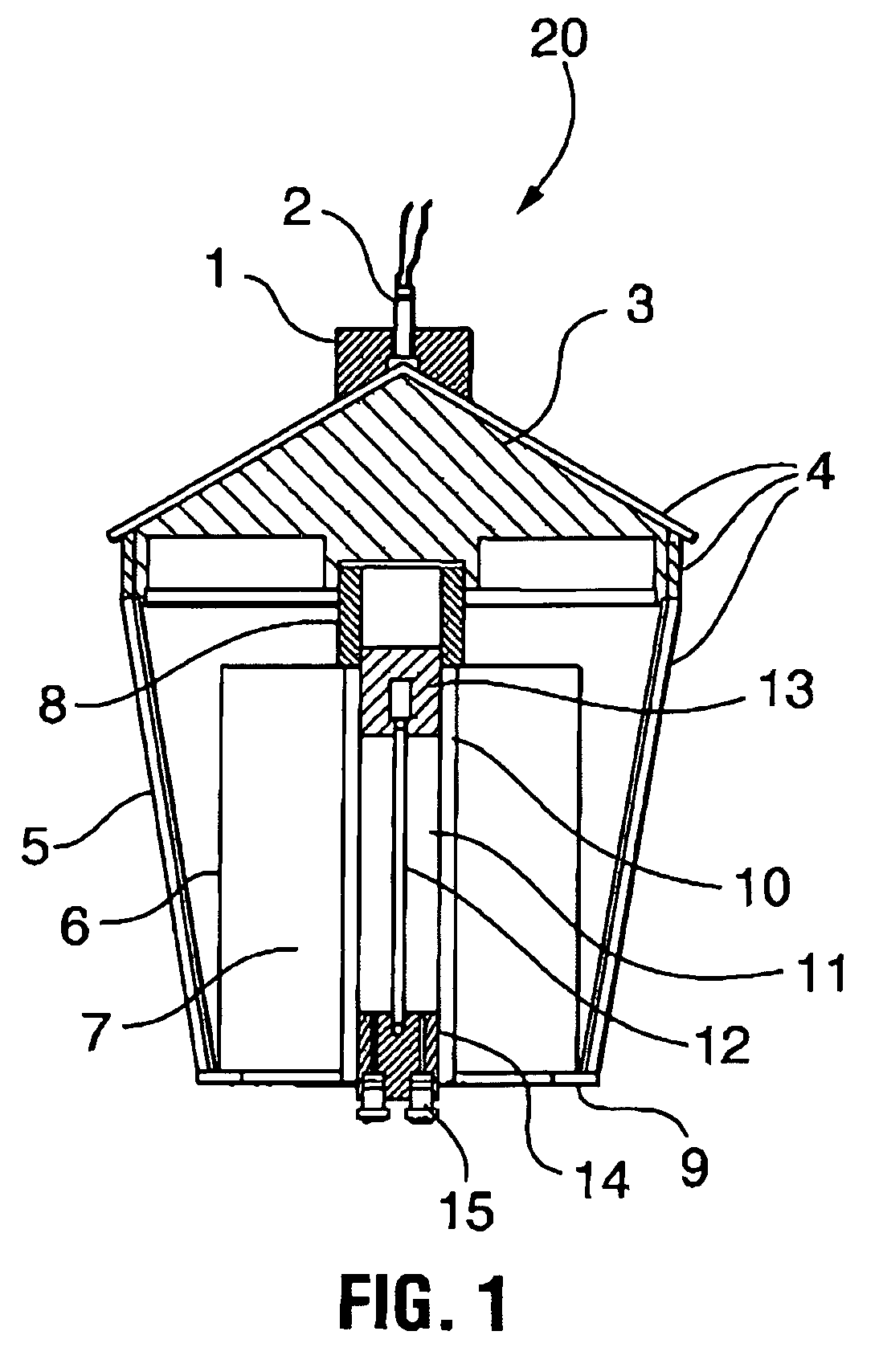

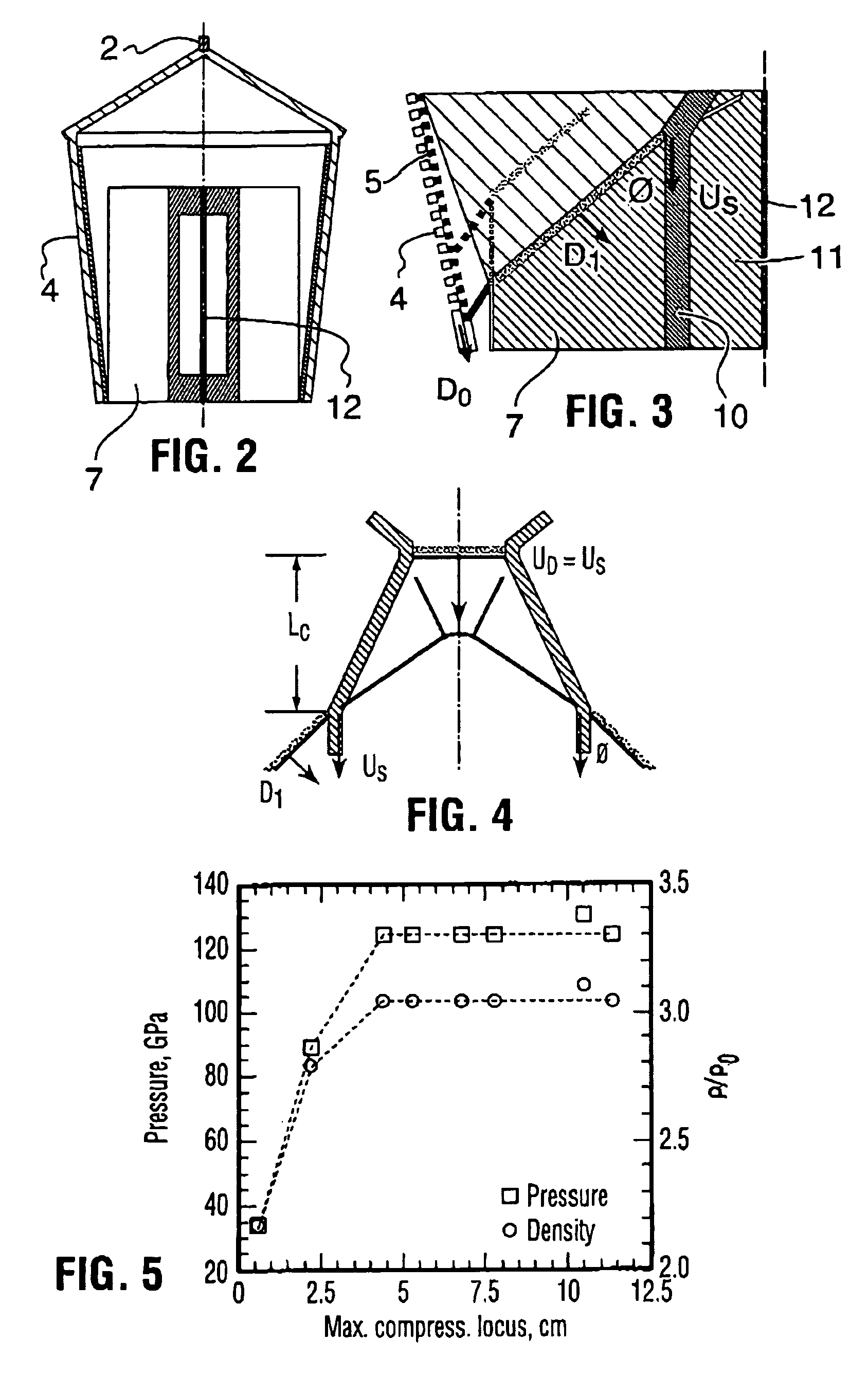

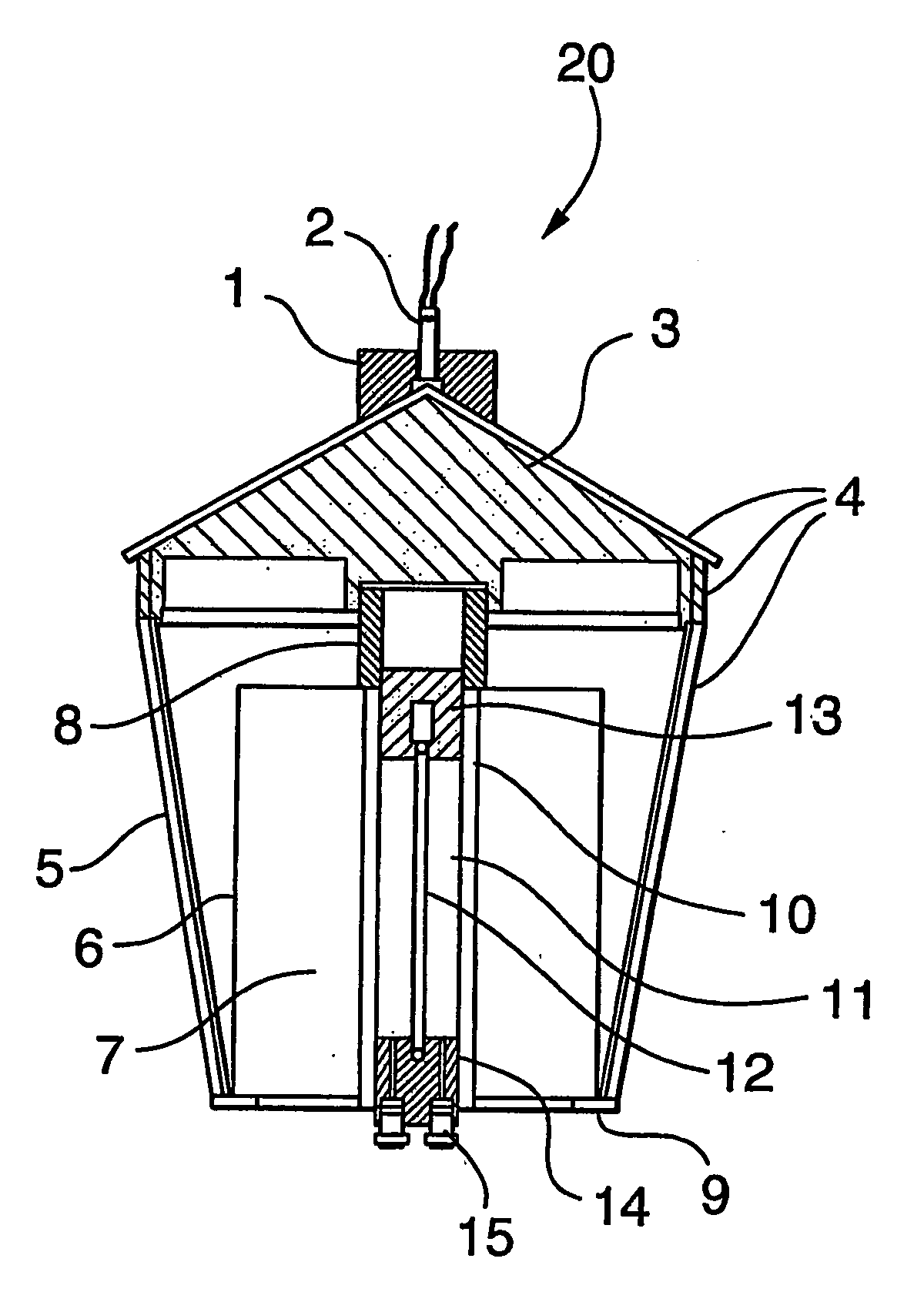

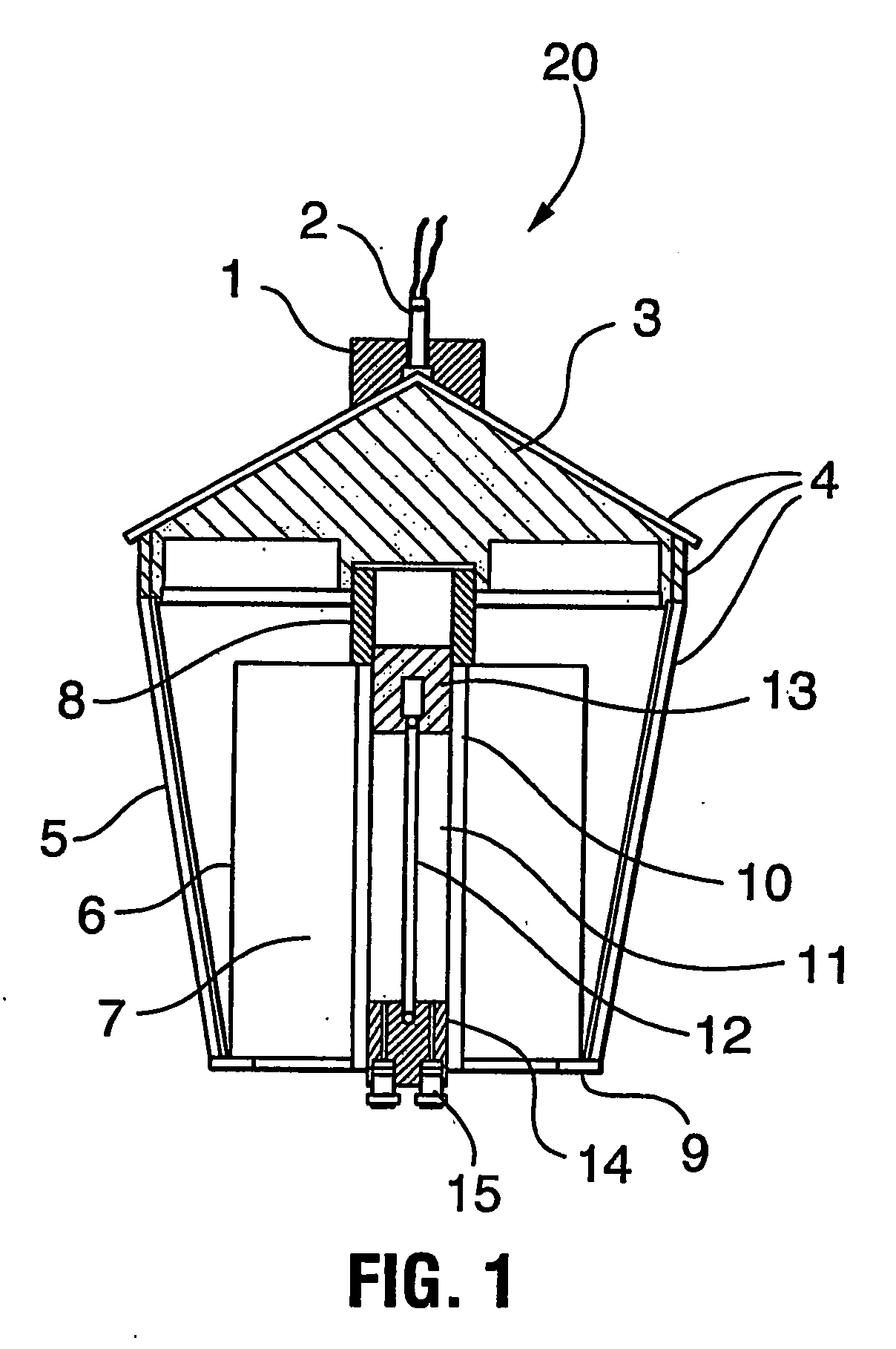

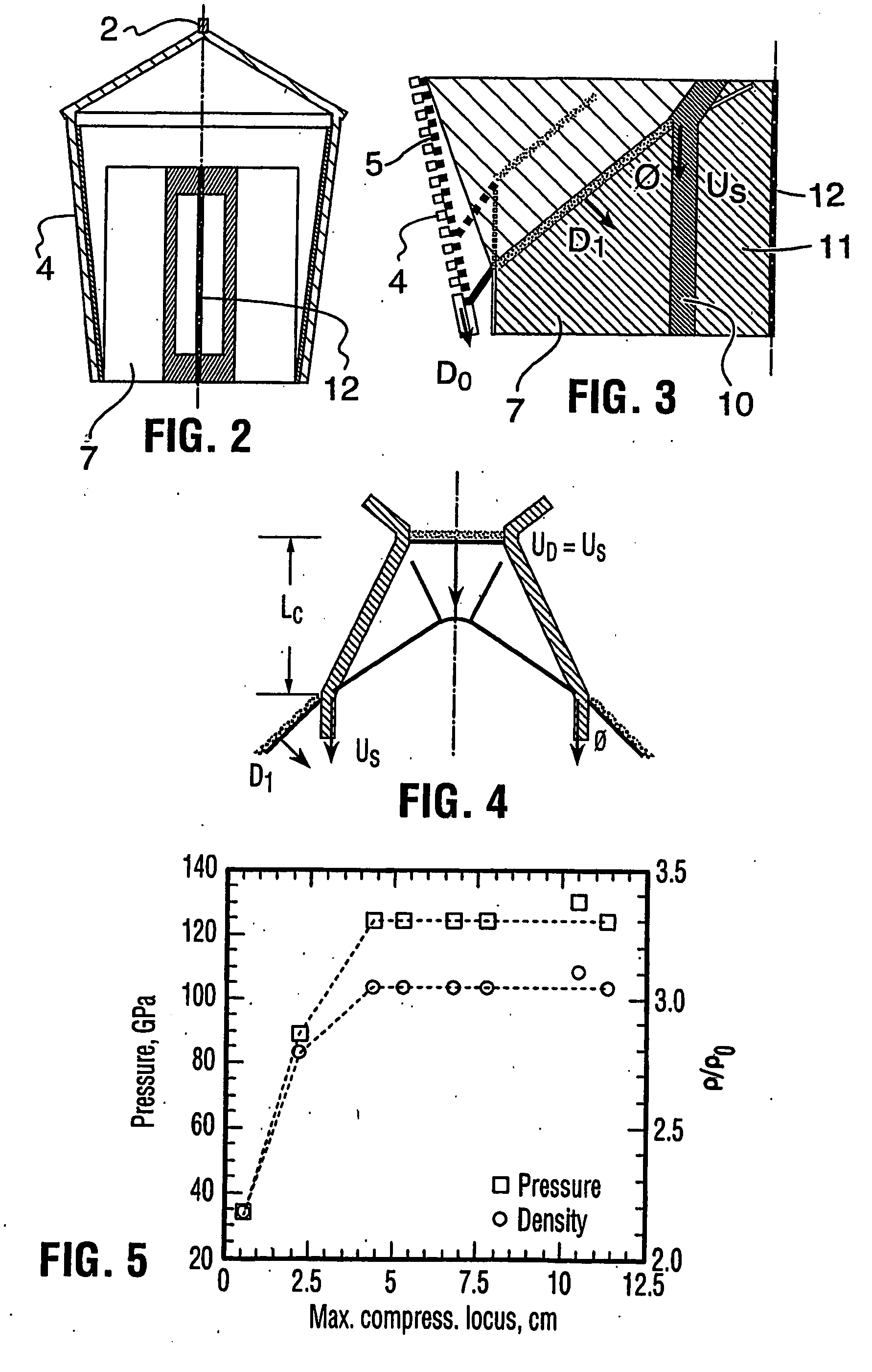

Super compressed detonation method and device to effect such detonation

ActiveUS7513198B2Improve propertiesHigh energyExplosive chargesAmmunition projectilesShock waveDelayed time

A method and apparatus are provided for detonation of a super-compressed insensitive energetic material by cylindrical implosion followed by an axial detonation to a detonation velocity several times that of TNT and a detonation pressure in excess of ten times that of TNT. The device provides a conical metal flyer shell within which is disposed a cylindrical anvil surrounded by explosive. The anvil retains an insensitive energetic material to be compressed and detonated. A first detonation of explosive by impact of the flyer shell generates a reverberating oblique shock wave system for sample compression. Axial detonation of the compressed sample through any length of a sample is achieved following the principal of matching the axial velocity and compression time of the oblique shock wave system to the detonation velocity and induction delay time of the compressed sample. The method and apparatus are also applicable to enhancing the effect of anti-armour and anti-hard-target munitions. The apparatus is also applicable to inert sample compression to the megabar range without using the axial detonation.

Owner:HER MAJESTY THE QUEEN AS REPRESENTED BY THE MINIST OF NAT DEFENCE OF HER MAJESTYS CANADIAN GOVERNMENT

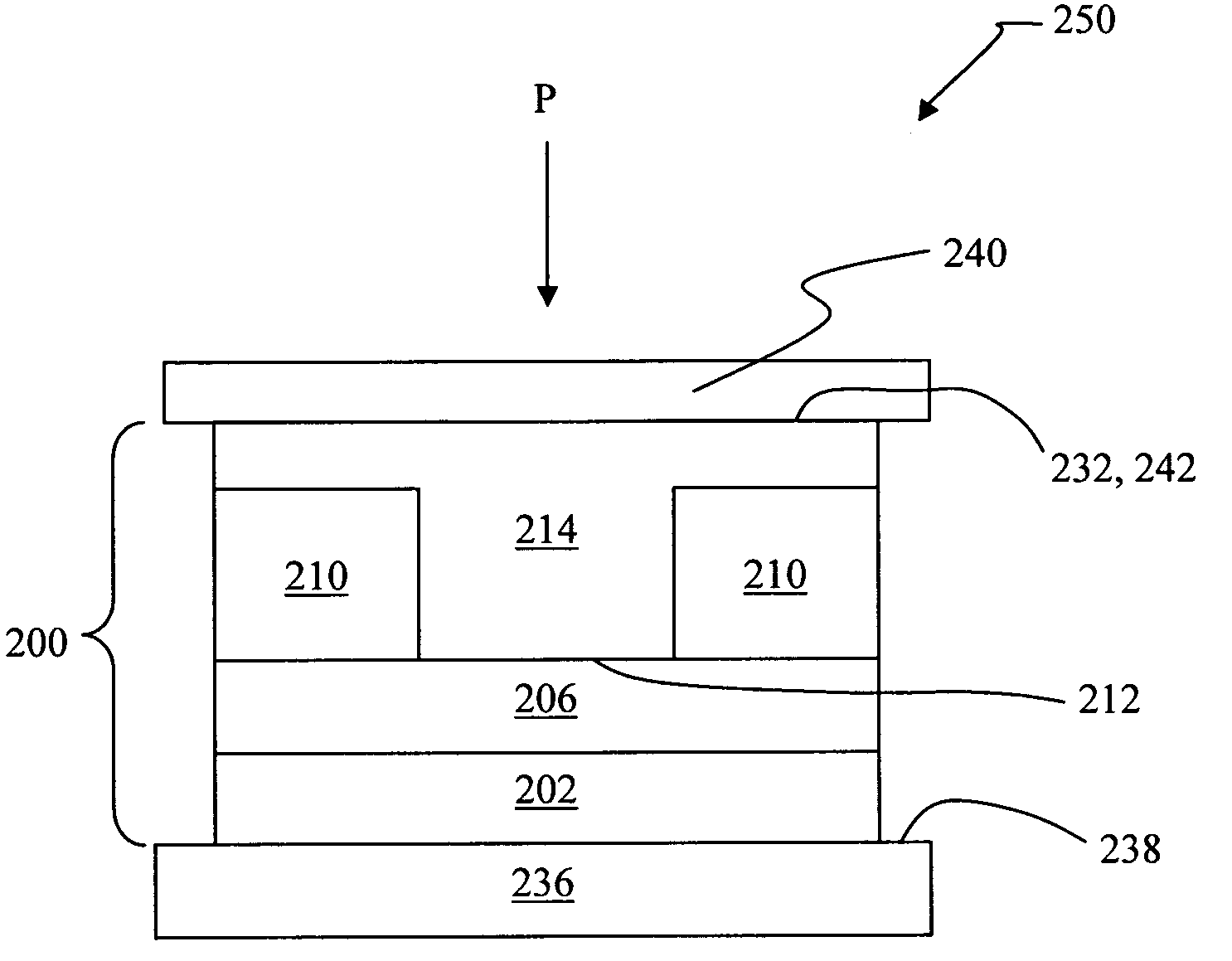

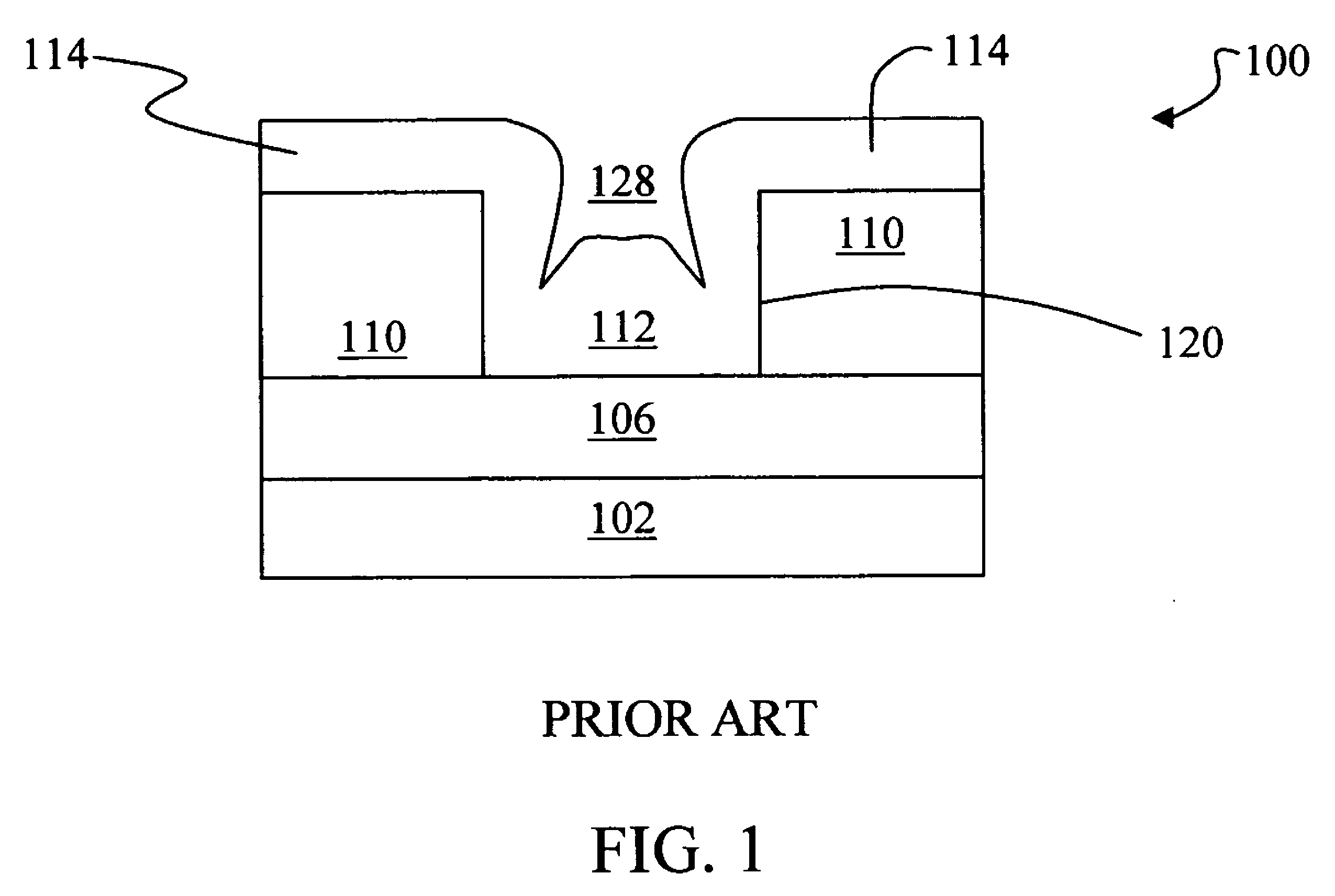

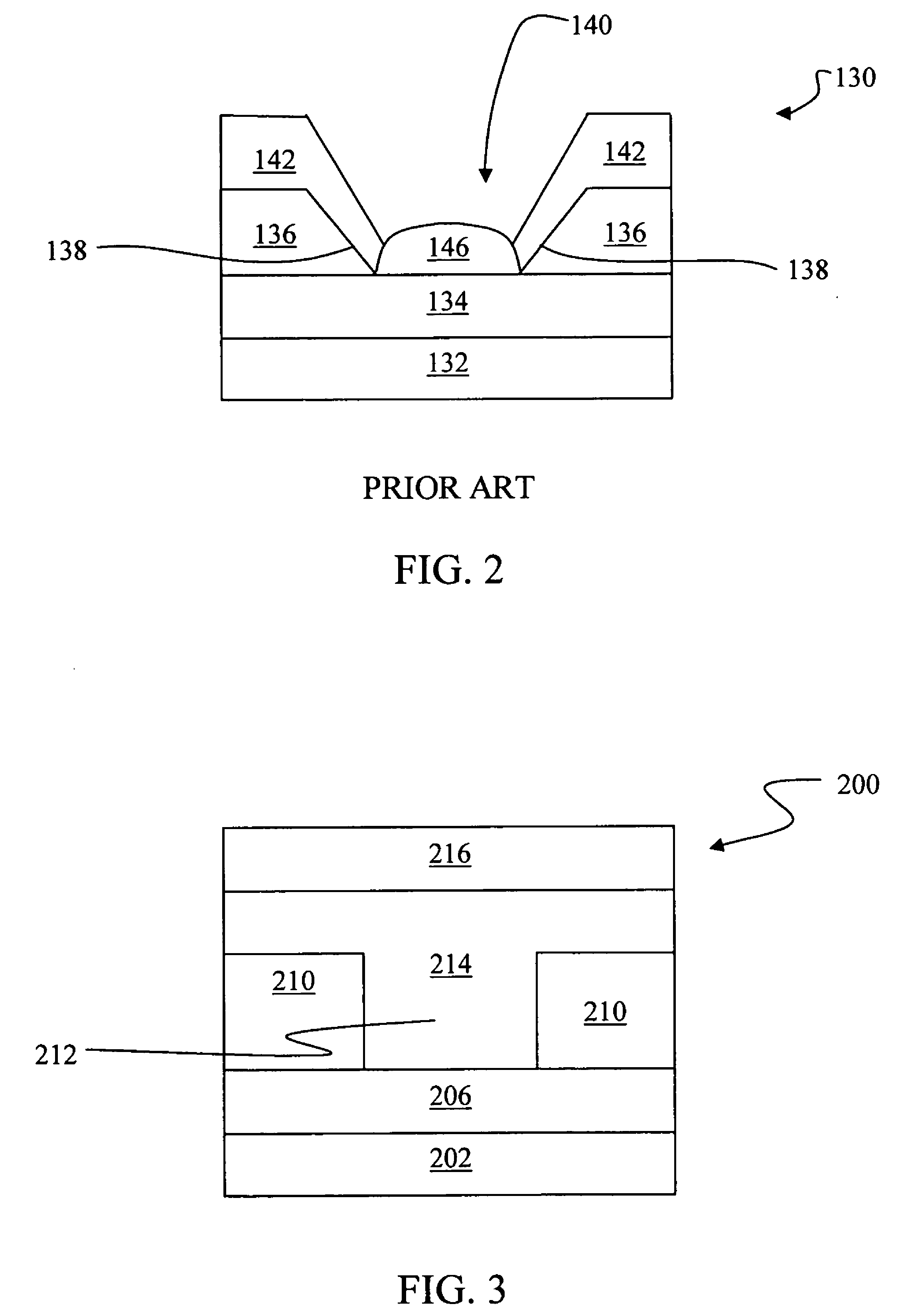

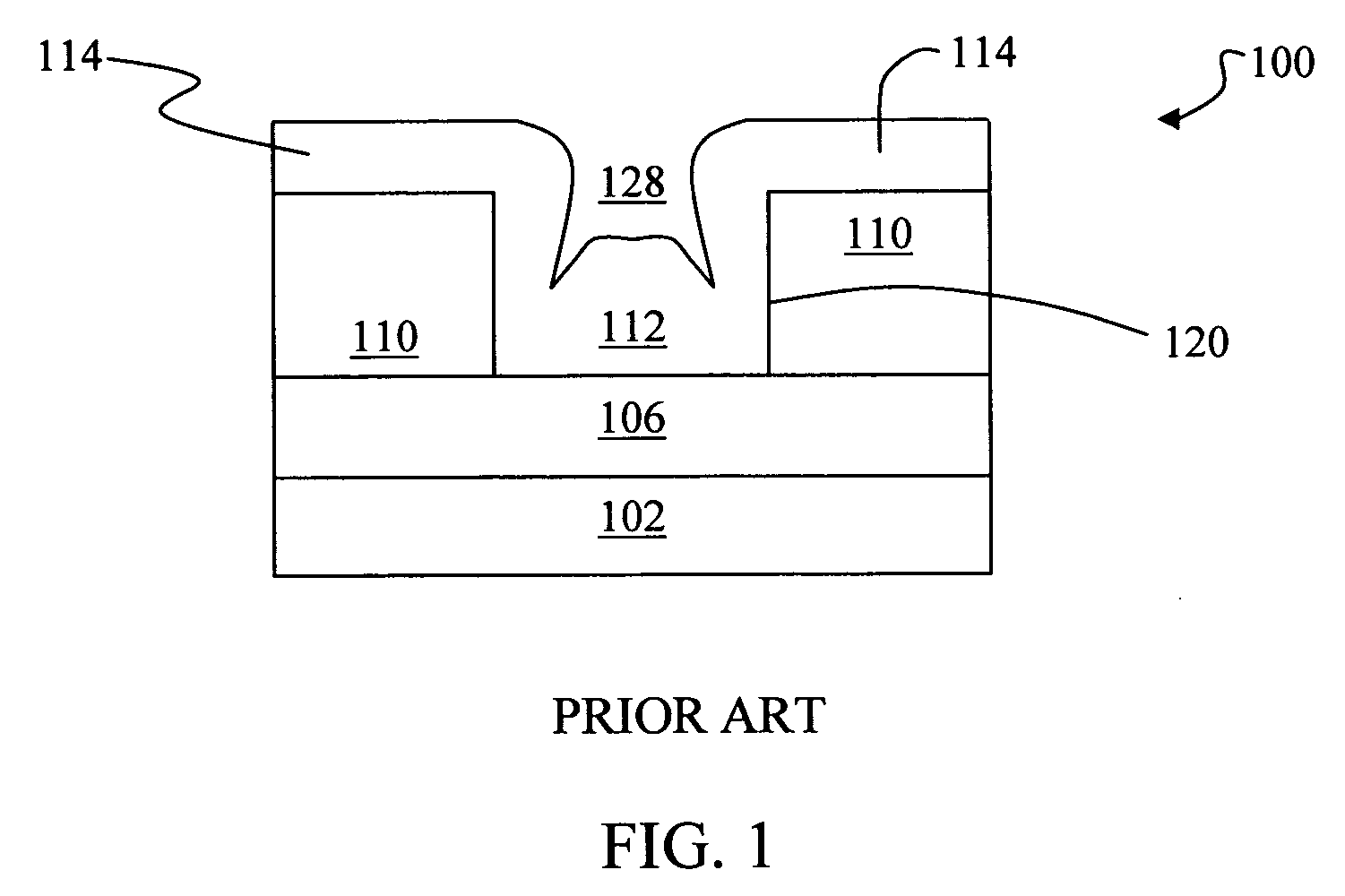

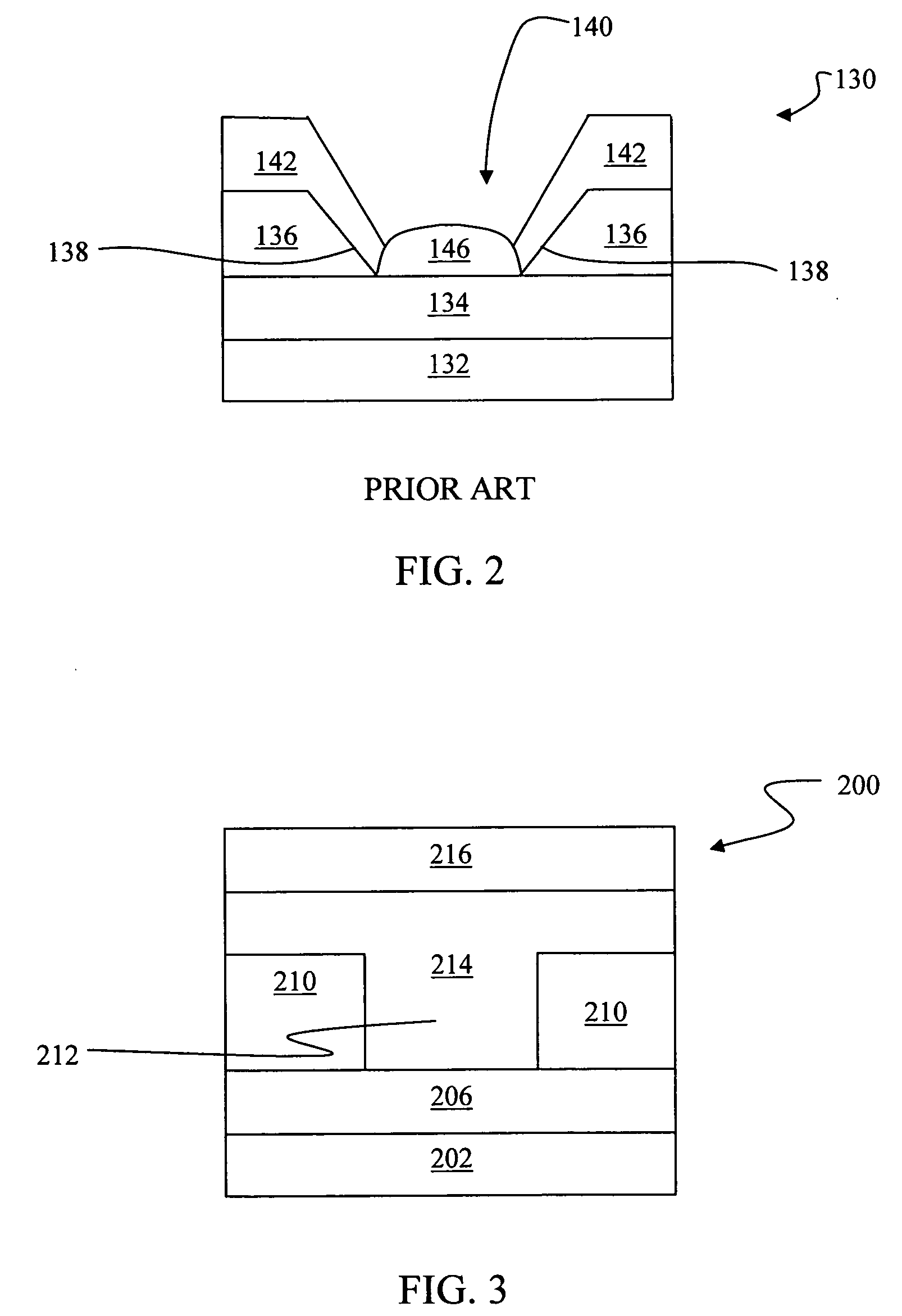

Temperature and pressure control methods to fill features with programmable resistance and switching devices

ActiveUS7994034B2Improve surface mobilityReduce thickness variationSemiconductor/solid-state device manufacturingEngineeringPhase-change material

A programmable resistance, chalcogenide, switching or phase-change material device includes a substrate with a plurality of stacked layers including a conducting bottom electrode layer, an insulative layer having an opening formed therein, an active material layer deposited over both the insulative layer, within the opening, and over selected portions of the bottom electrode, and a top electrode layer deposited over the active material layer. The device uses temperature and pressure control methods to increase surface mobility in an active material layer, thus providing complete coverage or fill of the openings in the insulative layer, selected exposed portions of the bottom electrode layer, and the insulative layer.

Owner:OVONYX MEMORY TECH LLC

High-rate high-safety long-life lithium iron phosphate battery and preparation method thereof

ActiveCN109687013AHigh magnificationRaise the ratioFinal product manufactureElectrode carriers/collectorsHigh rateCeramic coating

The invention discloses a high-rate high-safety long-life lithium iron phosphate battery and a preparation method thereof, and relates to the field of lithium batteries. Anode slurry of the battery uses lithium iron phosphate, conductive carbon black, carbon nanotube, polyvinylidene fluoride and N-methylpyrrolidone; an anode current collector adopts a carbon coated aluminum foil; cathode slurry uses artificial graphite composite material, conductive carbon black, thickener CMC and binder SBR; a cathode current collector uses a microporous copper foil; an electrolyte adopts a lithium hexafluorophosphate organic solvent electrolyte with the liquid injection amount of 6.0-6.2 g; a diaphragm adopts a ceramic coating diaphragm. The lithium iron phosphate battery has the advantages of high rateperformance, high use safety and long service life.

Owner:江西省汇亿新能源有限公司

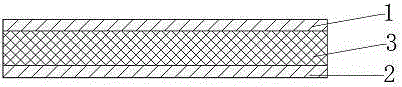

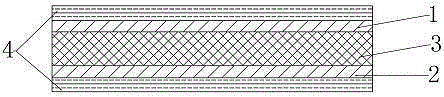

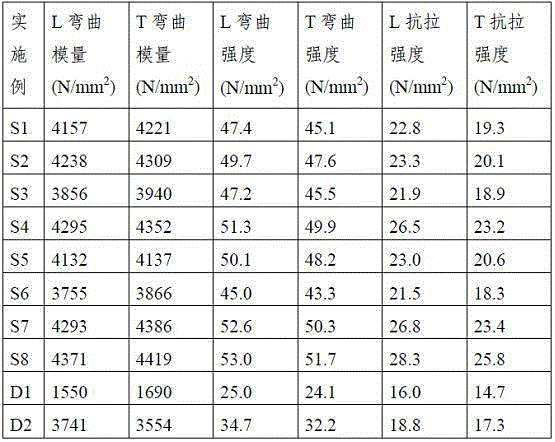

Natural fiber/polymer fibrous layer laminated automobile chair-back sheet material and production method

InactiveCN105235300AImprove breathabilityEffective bondingSynthetic resin layered productsLaminationWood fibrePalm fiber

A disclosed natural fiber / polymer fibrous layer laminated automobile chair-back sheet material comprises an integrated sheet material formed through lamination and combination of a first surface layer, a core layer and a second surface layer, the first surface layer and the second surface layer are non-woven fabrics, the core layer is a mixed fiber plate, the mixed fiber plate is prepared by compacting natural fiber and needle felt employing polymer fiber as the main composition, and the natural fiber is at least one selected from fibrilia, bamboo fiber, palm fiber and wood fiber. The invention also discloses a production method for the natural fiber / polymer fibrous layer laminated automobile chair-back sheet material. The automobile chair-back sheet material possesses the characteristics of being light in weight, small in density, excellent in breathability, and excellent in strength and toughness. By employing twice baking compaction and cold-press shaping processing in the production process, the sheet material density is improved.

Owner:JIANGYIN YANLI AUTOMOBILE DECORATIVE PARTS

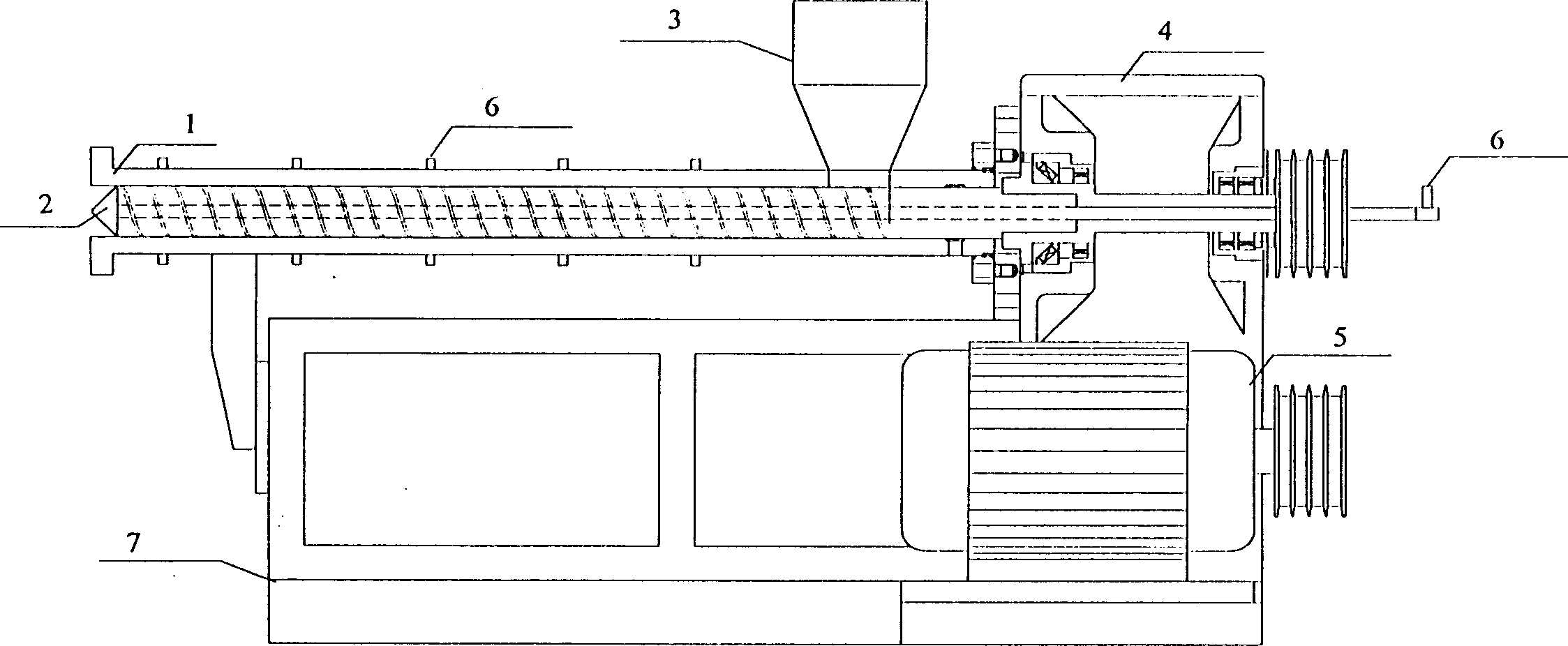

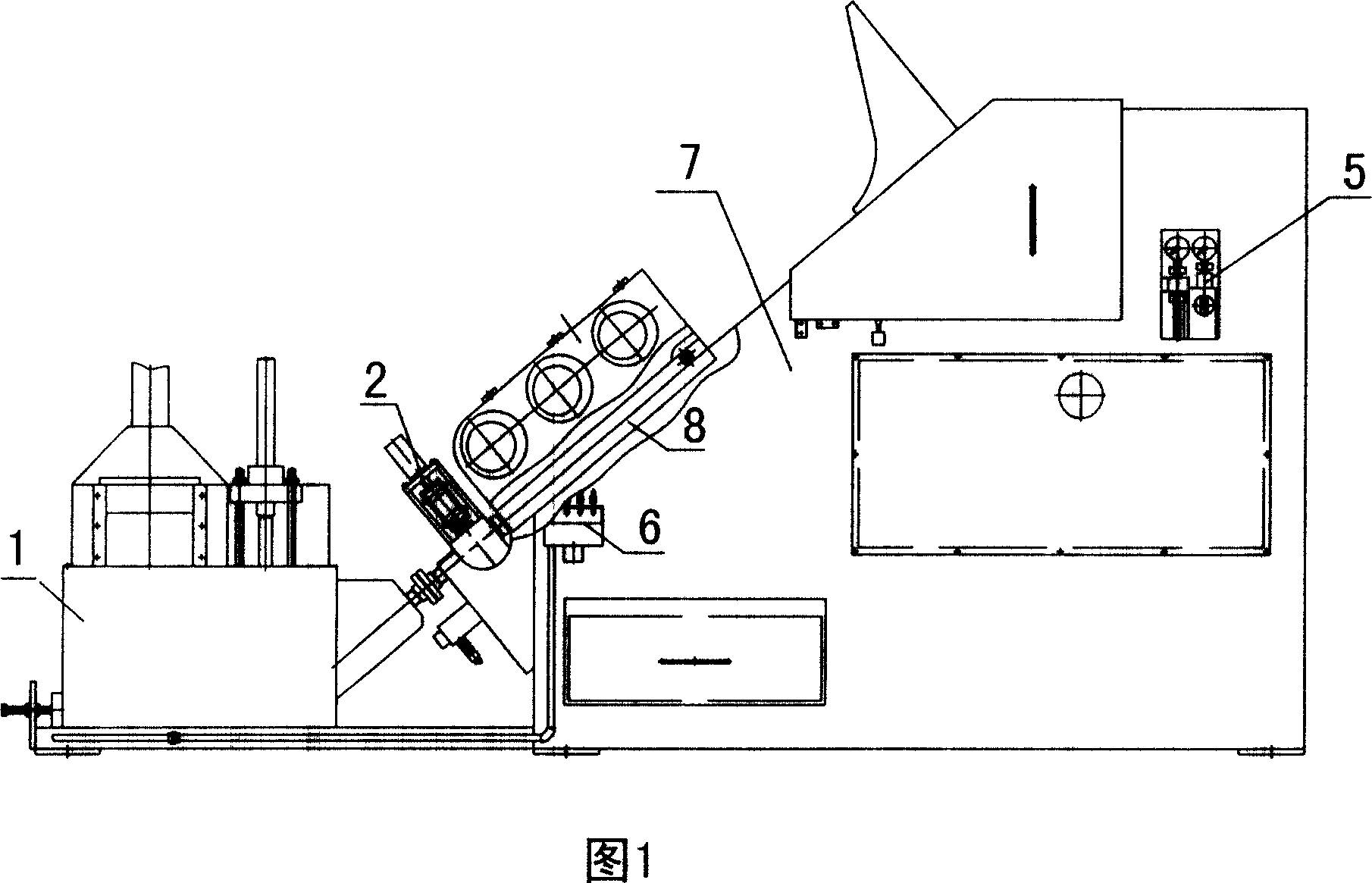

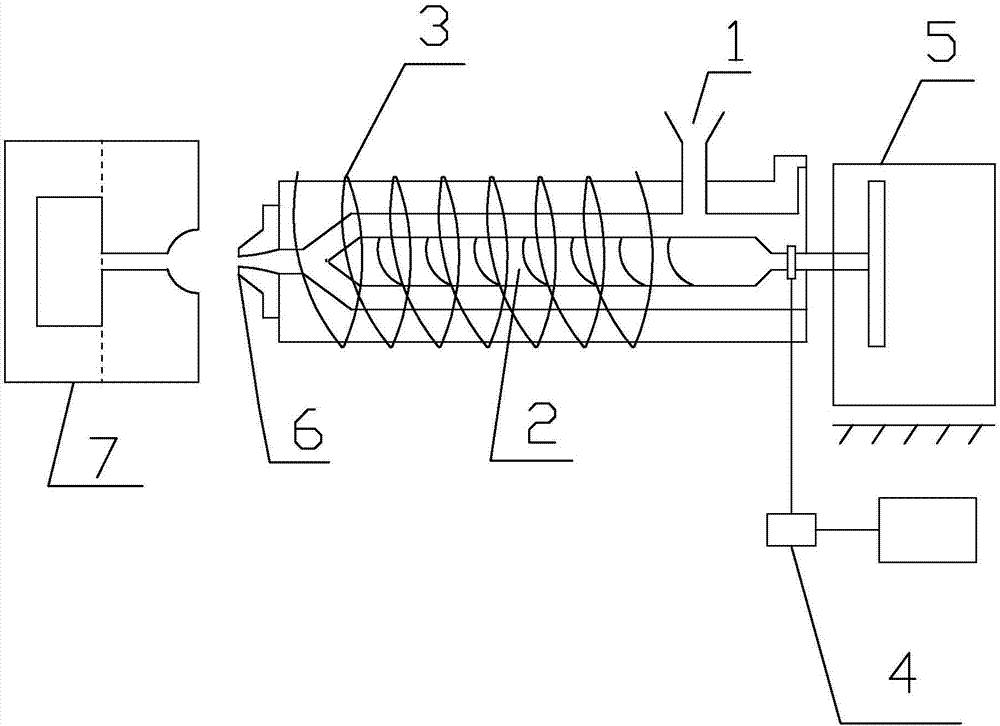

Super high-pressure single screw extruder

The invention relates to a hyper-pressure single-worm extrusion machine, comprising: a machine barrel, a screw bolt, a charging hopper, a driver, a motor, a cooling device, and an engine base. The invention is characterized in that: the cooling device is arranged on the machine barrel and the screw bolt; the geometric compression ratio of screw bolt is designed as high as 10-120; and the rotational speed of screw bolt is 30-1500 r / min. The invention has following advantages that: the cooling devices are arranged on the machine barrel and the screw bolt to eliminate the temperature over normal ones caused by the high-speed friction between chemical material and the machine barrel and screw bolt; the compression ratio of screw bolt is designed as high as 10-120 (according to the property of chemical material) to form a hyper-pressure solid transfer piston formed by extruded chemical material between the machine barrel and screw bolt; then the chemical material and the screw bolt, the chemical material and the machine barrel, the chemical material and the chemical material has friction in the hyper-pressure condition to generate heat, with which the chemical material can be melt and molded in short time, to be incised and mixed smelt; according to the friction temperature, the rotational speed of screw bolt is set at 30-1500 r / min, for controlling the amount of feeding material, the cooled amount and the friction temperature in stable balance condition.

Owner:包赟元

Non-aqueous electrolyte secondary battery and production method thereof

InactiveUS20080311471A1Increase capacityHigh characteristicNon-aqueous electrolyte accumulatorsFinal product manufactureMetalMaterials science

A method for producing a non-aqueous electrolyte secondary battery comprising the steps of: (i) mixing a positive electrode active material, a first binder A and a dispersion medium to prepare a paste A, the active material comprising a lithium-containing transition metal oxide; (ii) mixing a conductive agent, a second binder B and a dispersion medium to prepare a paste B, the conductive agent comprising carbon black; (iii) mixing the paste A and the paste B to prepare a positive electrode material paste C; (iv) applying the positive electrode material paste C onto a positive electrode core member and rolling and drying the resultant member to prepare a positive electrode; and (v) fabricating a battery using the positive electrode, a negative electrode and a non-aqueous electrolyte, wherein contact angle θA between the non-aqueous electrolyte and the binder A and contact angle θB between the non-aqueous electrolyte and the binder B satisfy the formula (1): θB−θA≧15°.

Owner:PANASONIC CORP

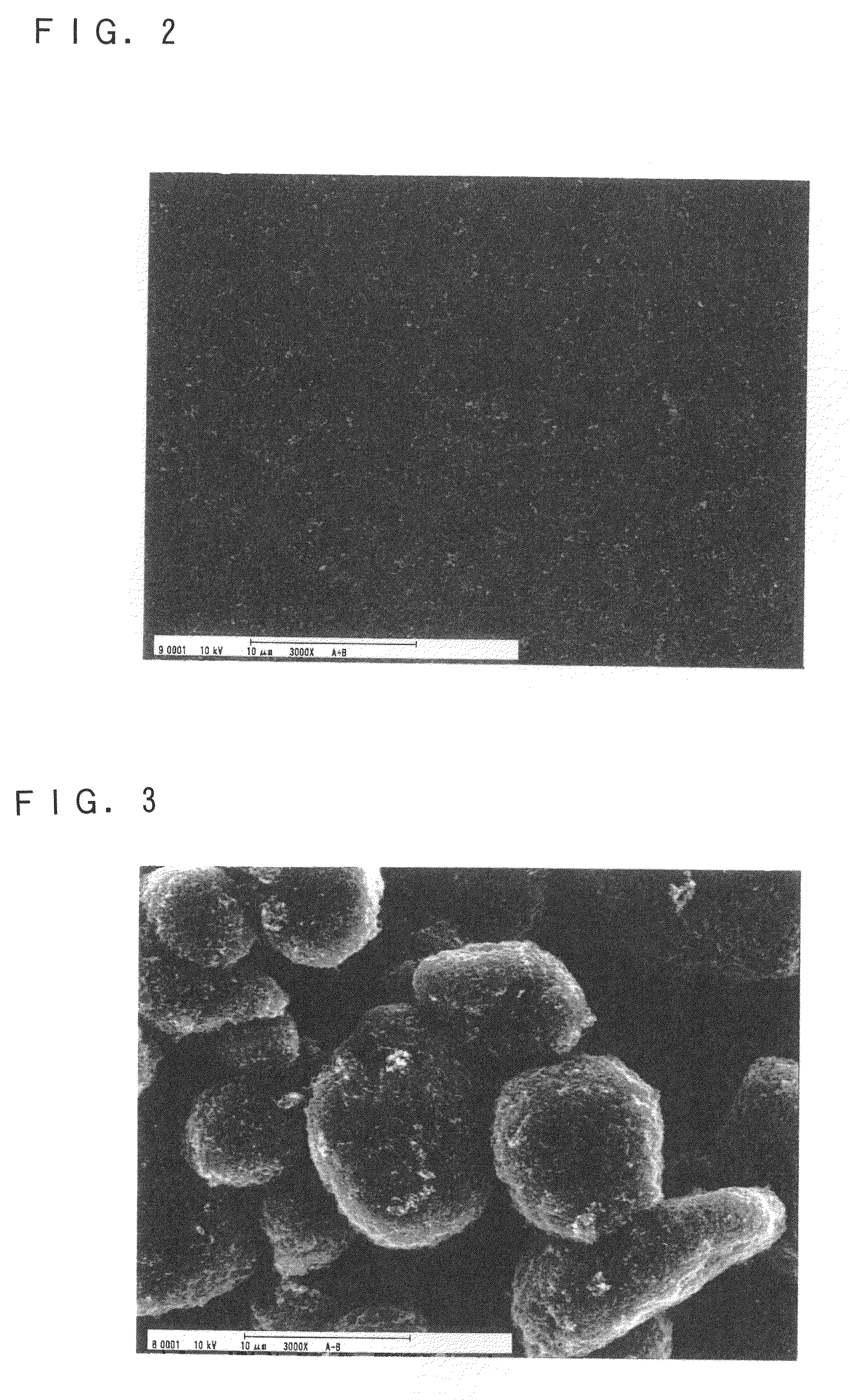

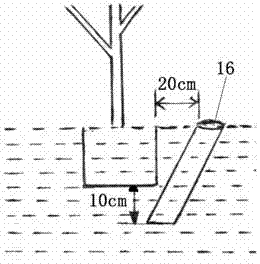

Cultivation method for promoting santalum album to grow into useful timber early and high yield

ActiveCN103798010AChange the way of lifeIncrease material densityForestryHorticultureNitrate nitrogenFarmyard manure

The invention discloses a cultivation method for promoting santalum album to grow into useful timber early and high yield. The cultivation method comprises the steps as follows: A, selecting healthy santalum album seedlings propagated by seeds of healthy and mature seed trees and cultivated with parasitism of kuhnia rosmarnifolia vent; B, selecting an area where bananas can be planted as a planting area; C, loosening soil and digging holes in the selected area according to the pH of land; D, applying mixed farmyard manure in dug pits to serve as a base fertilizer; E, planting the healthy santalum album seedlings in the dug pits; F, appropriately watering dilute manure water or a nitrate nitrogen compound fertilizer dilute solution with the concentration of about 1:300 after planting for 15-20 days; and the like. According to the cultivation method, existing seedling cultivation is inherited as the basis, according to the nature of the survival of the santalum album, artificial and natural conditions are fully used and combined, the planting method of guide, control and gradual removal of parasitism is further adopted, and the survival mode that the santalum album depends on parasitism is changed thoroughly, so that the santalum album grows into the useful timber early and is high in density; and the operation is simple and convenient, and the method can be promoted for large-scale industrialization.

Owner:SHENZHEN LYUSHENGYUAN GARDEN GREENING

Method for bleaching fibrous materials

InactiveUS20060130984A1Cost-effectiveReduce material densityPulp bleachingPulping with inorganic basesFiberBleach

The invention relates to a method for bleaching fibrous materials, in particular lignin-containing materials for producing paper consisting in adding at least a first additive and at least one type of bleaching liquid to a fibrous solution which contains at list one bleaching agent. After mixing said bleaching solution with the fibrous suspension and at the end of determined bleaching time, the bleaching process is ended by adding at least a second additive. Said invention is characterised in that the pH of the fibrous suspension is obtained by adding lime.

Owner:LHOIST NORTH AMERICA INC

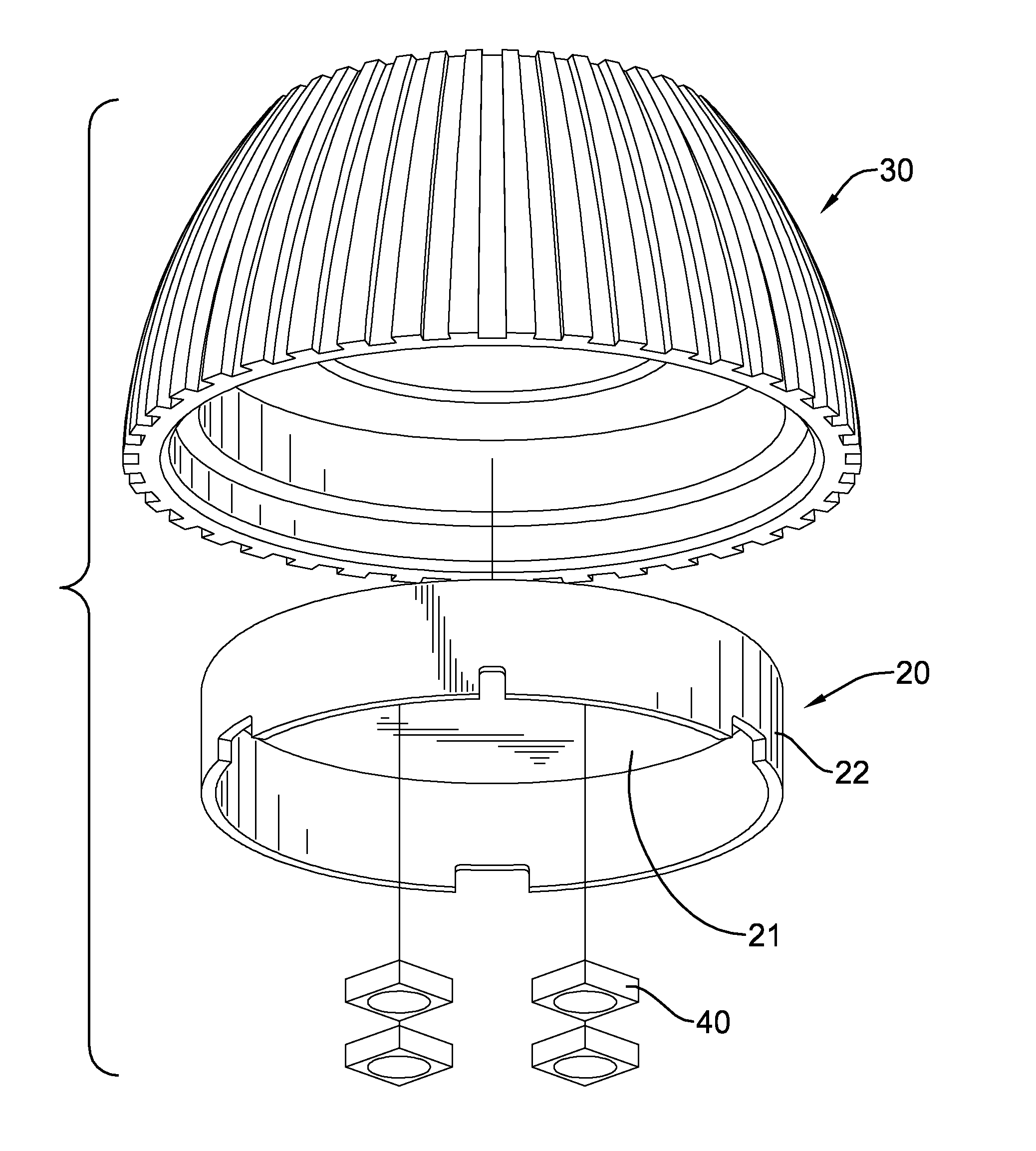

Manufacturing method of a heat conductive device for a light-emitting diode

InactiveUS20120311849A1Improve thermal efficiencyFast heat conductionPoint-like light sourceWave amplification devicesHeat conductingEngineering

A manufacturing method of heat conductive device for an LED has steps of forming a heat sink and an engagement recess in the heat sink by cold forge, punching a heat-conducting disc to form an LED carrier having a mounting portion and a heat-conducting wall formed around the mounting portion, soldering multiple LEDs on the LED carrier, and heating the heat sink to thermally expand the heat sink and assembling the LED carrier and the heat sink so that the heat-conducting wall is assembled with the engagement recess and further chilling the heat sink to thermally retract and tightly hold the LED carrier. The manufacturing method increases contact area and reduces air gaps between the LED carrier and the heat sink to effectively enhance the heat-conducting efficiency of the LED carrier so that the LEDs are operated at a suitable operating temperature to secure a prolonged life duration.

Owner:PAN JIT INT

Composition Based on Phosphatic Raw Materials and Process for the Preparation Thereof

InactiveUS20100269735A1Increase material densityReduced pore volumeInorganic phosphateMaterials science

Owner:TECH TRADE

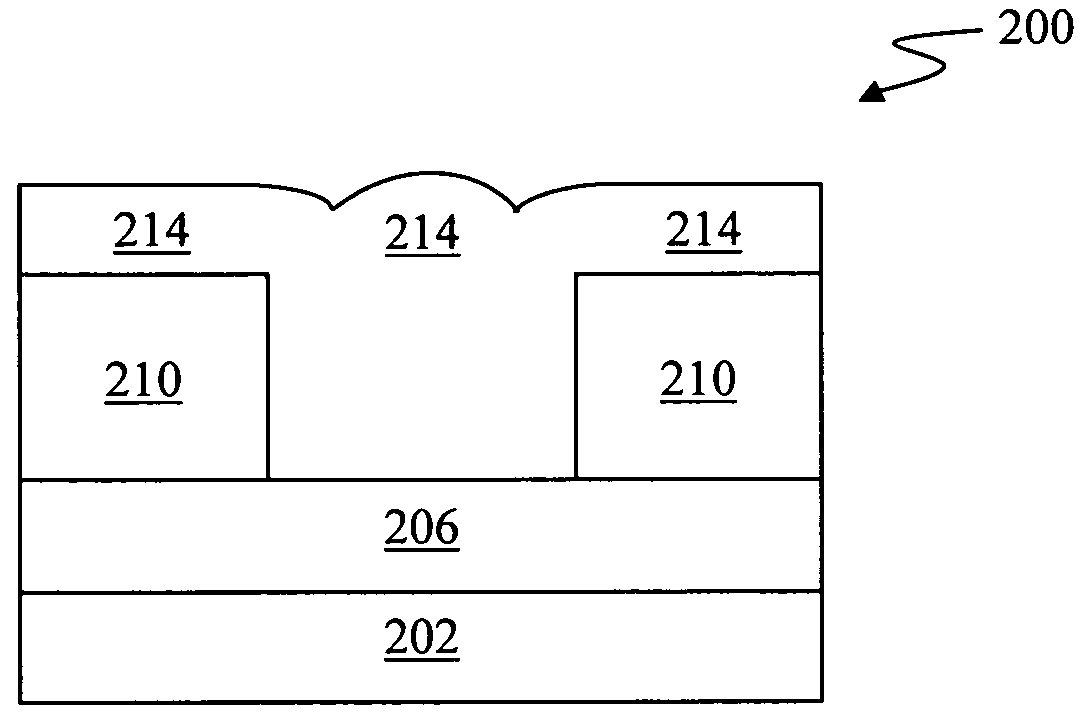

Temperature and pressure control methods to fill features with programmable resistance and switching devices

ActiveUS20090227092A1Improve surface mobilityReduce thickness variationSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesEngineeringPhase-change material

A programmable resistance, chalcogenide, switching or phase-change material device includes a substrate with a plurality of stacked layers including a conducting bottom electrode layer, an insulative layer having an opening formed therein, an active material layer deposited over both the insulative layer, within the opening, and over selected portions of the bottom electrode, and a top electrode layer deposited over the active material layer. The device uses temperature and pressure control methods to increase surface mobility in an active material layer, thus providing complete coverage or fill of the openings in the insulative layer, selected exposed portions of the bottom electrode layer, and the insulative layer.

Owner:OVONYX MEMORY TECH LLC

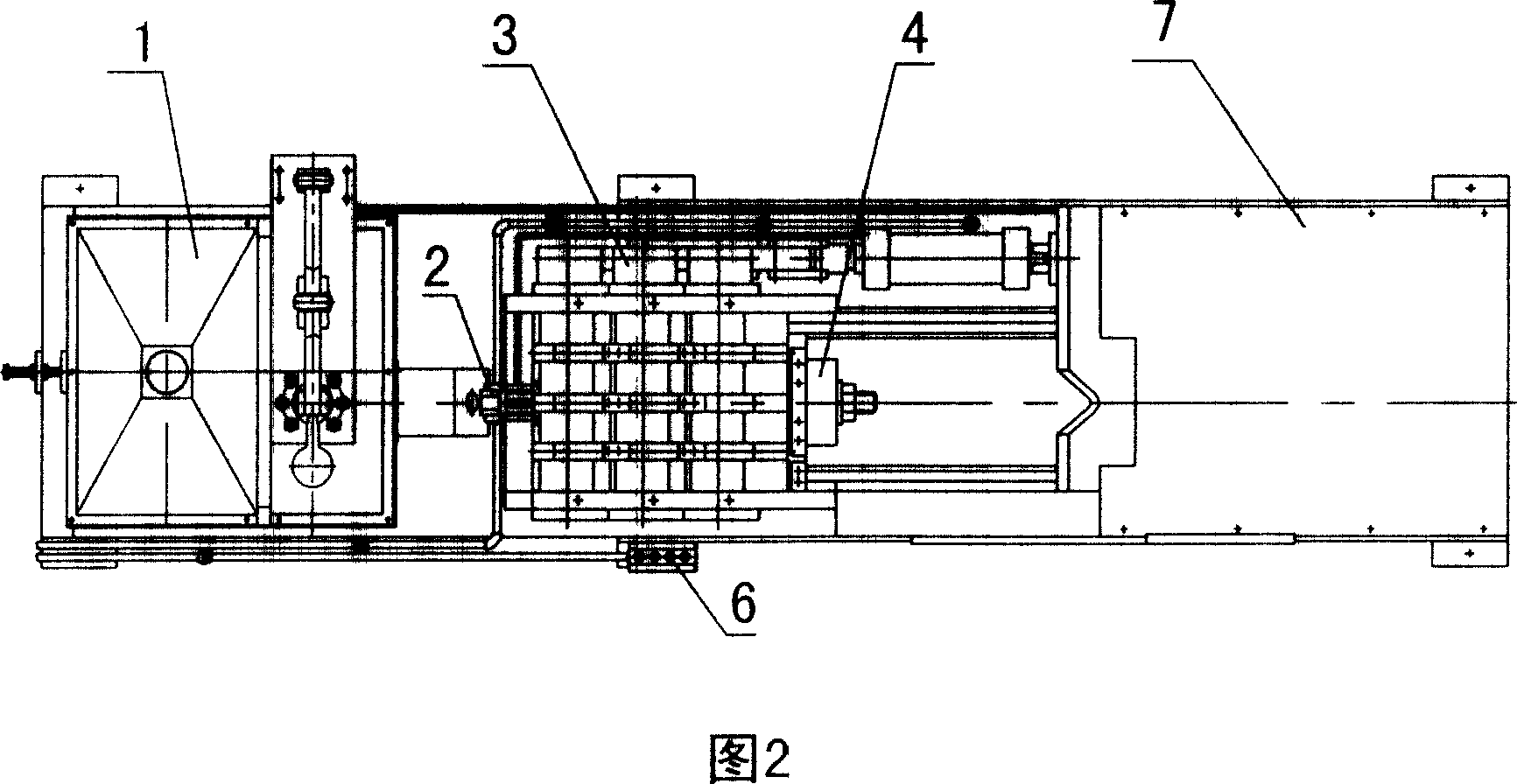

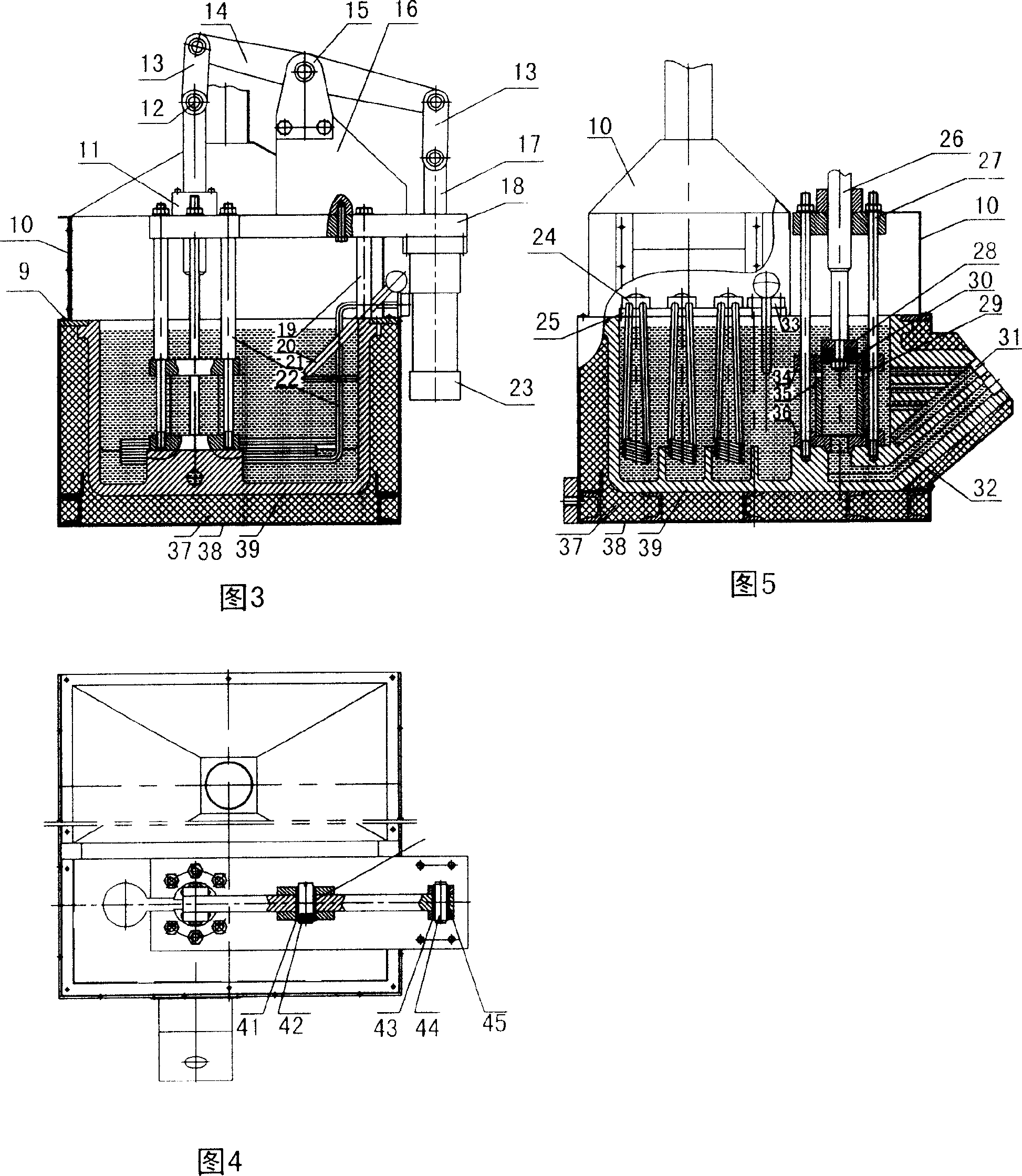

Automatic die casting machine for producing grid of accumulator

An automatic pressure caster for casting the grid plate of electric accumulator is composed of a lead smelting pot, a nozzle unit, an eccentric clamping unit with mould locking cylinder, a mould moving unit with mould moving cylinder, hydraulic system, water cooling system, machine body and mould set.

Owner:ZIBO TORCH ENERGY +1

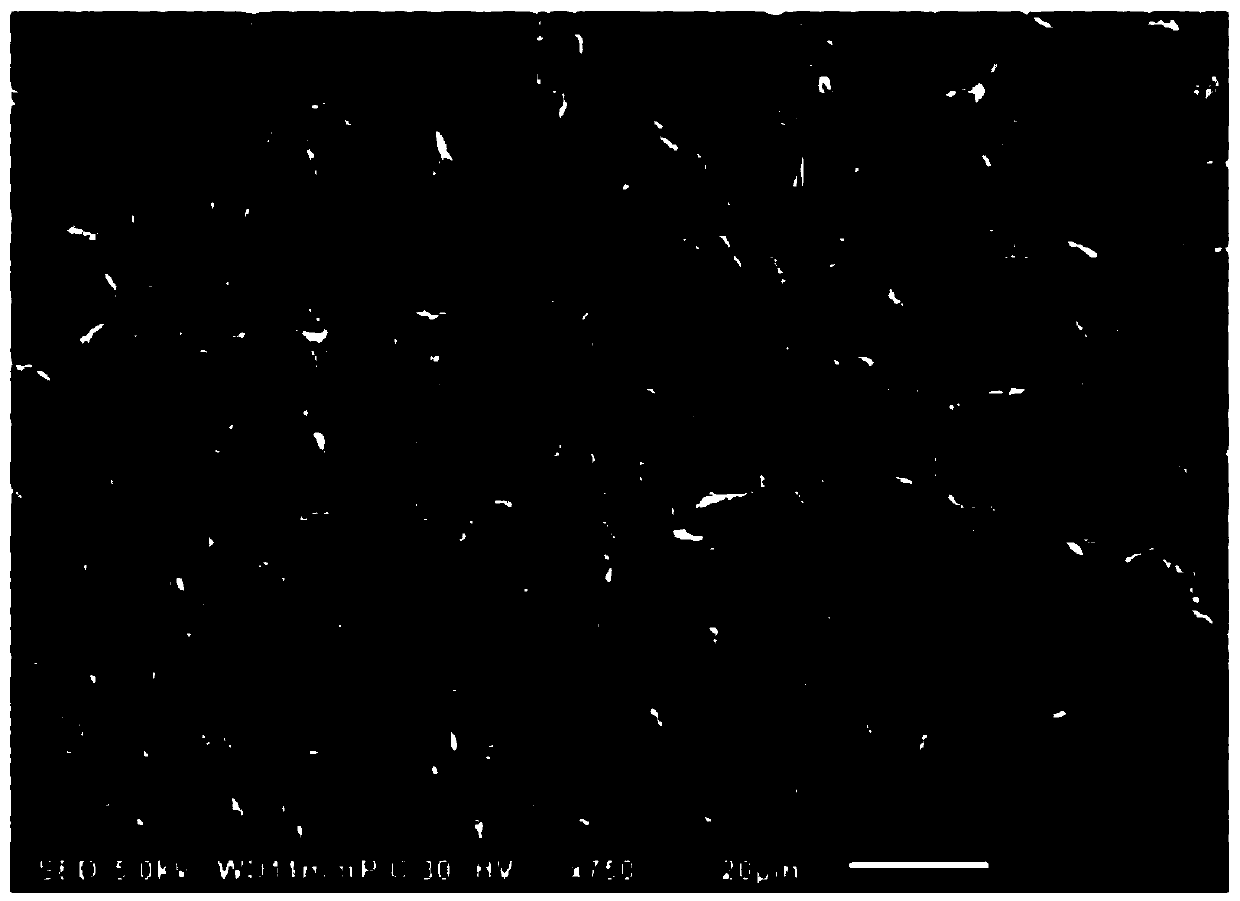

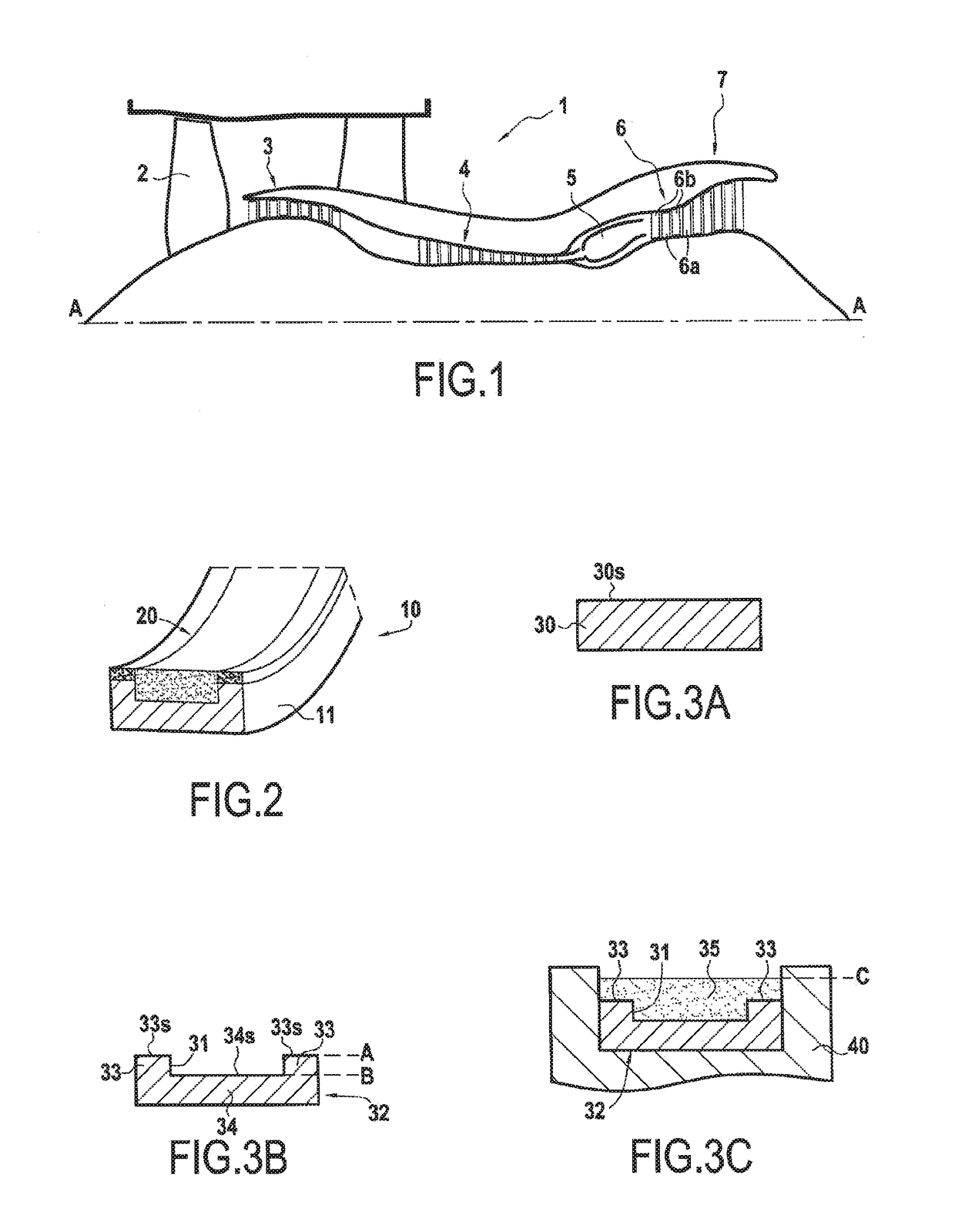

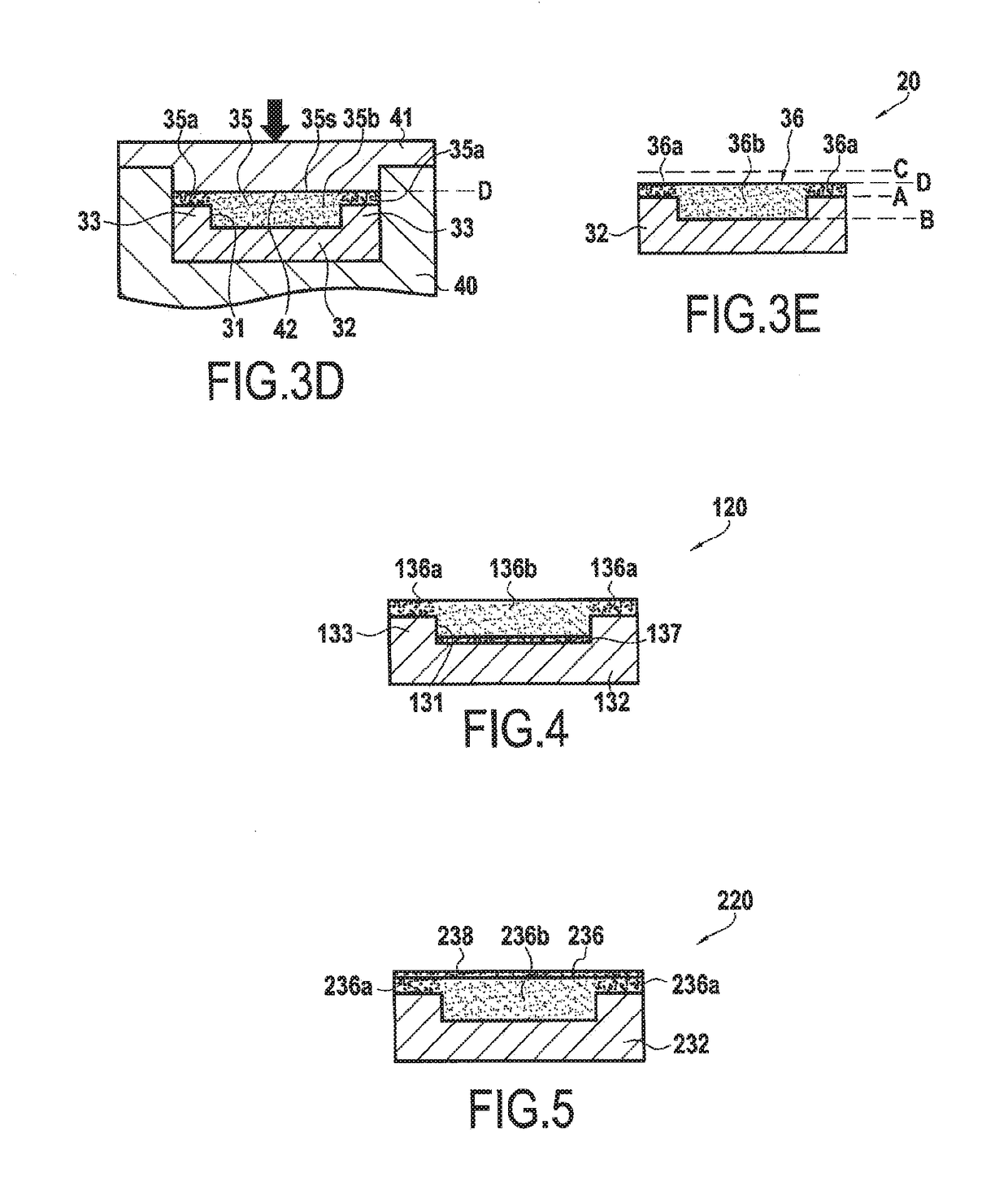

Abradable coating having variable densities

ActiveUS20180361480A1Easily abradableIncrease material densityPump componentsEfficient propulsion technologiesBearing surfaceVariable density

A method of fabricating an abradable coating of varying density, and such an abradable coating of varying density. According to the invention, the method comprises the following steps: providing a substrate (32) having a first portion with its surface situated at a first level (A), and a second portion with its surface situated at a second level (B) different from the first level; depositing a precursor material on the first and second portions of the substrate (32); compressing the precursor material between the substrate and a bearing surface; and sintering the precursor material as compressed in this way in order to obtain an abradable coating (36) having a first portion (36a) on the first portion of the substrate, and possessing a first density, and a second portion (36b) on the second portion of the substrate, and possessing a second density distinct from the first.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A +2

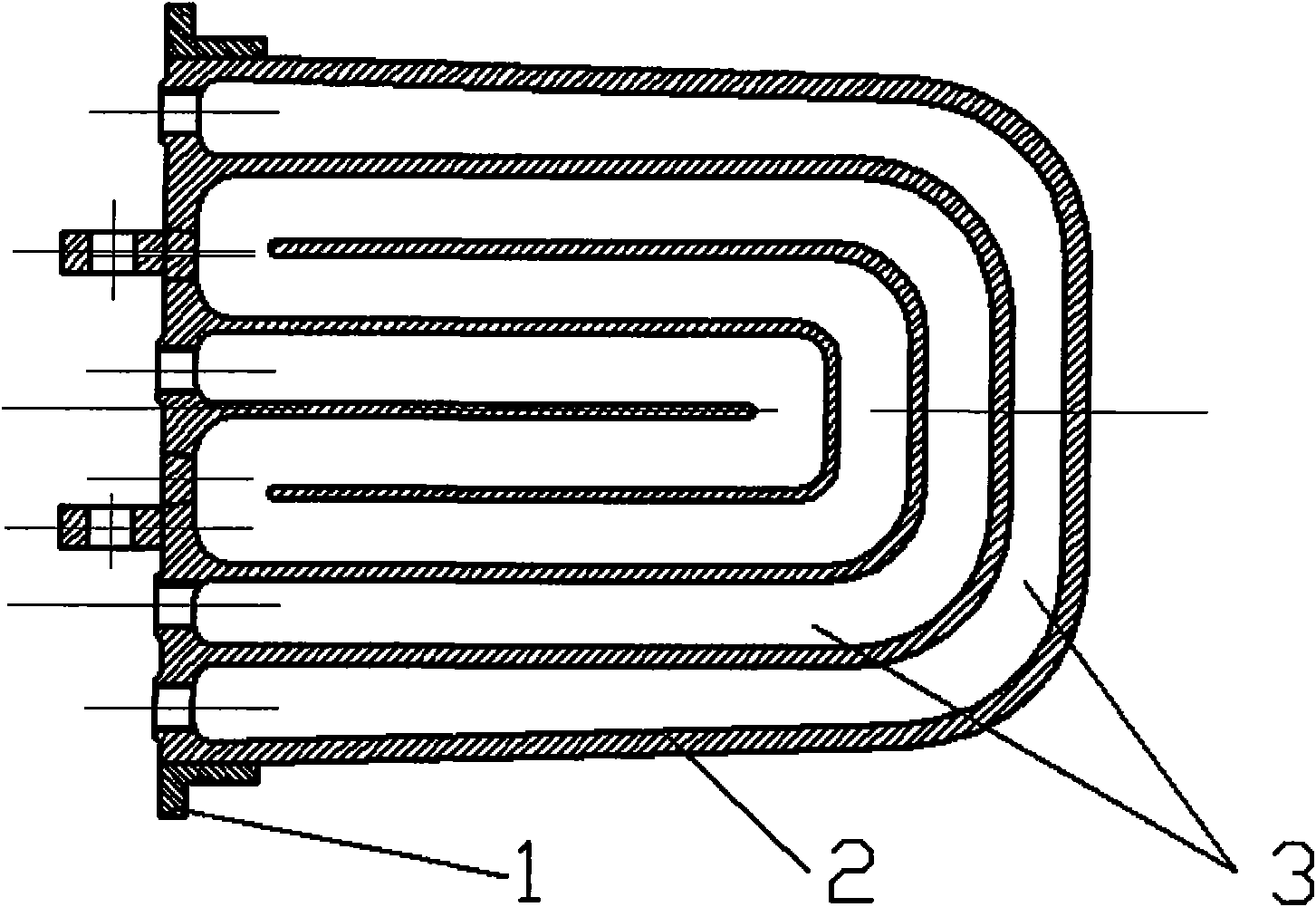

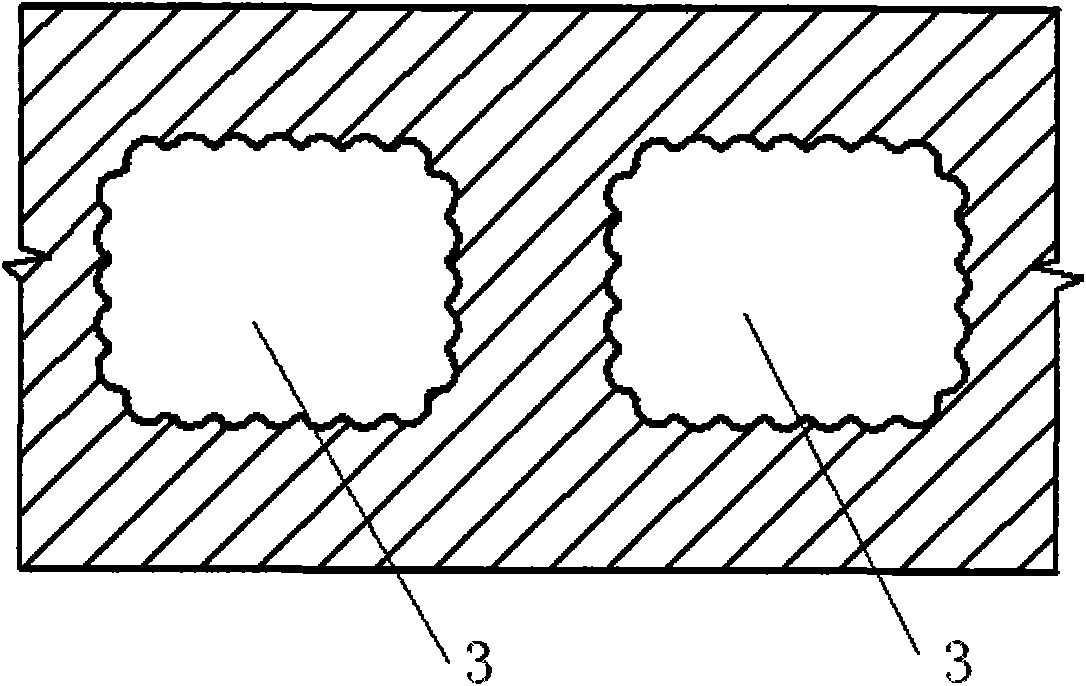

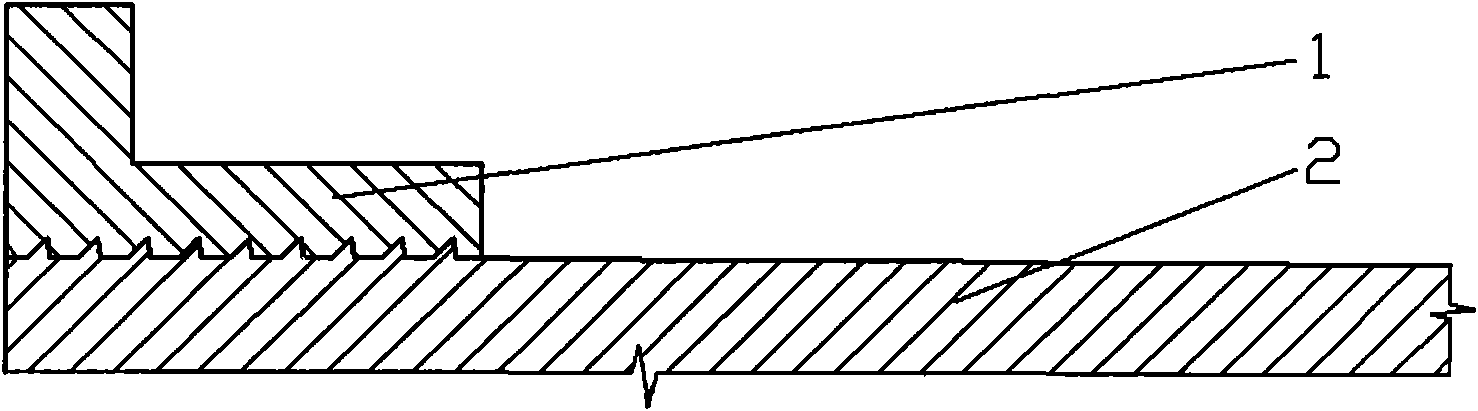

Copper cooling plate and manufacturing process thereof

InactiveCN101570801AIncrease cooling areaIncrease material densityCooling devicesCurve shapeSteel belt

The invention relates to a copper cooling plate and a manufacturing process thereof. The outer edge of the cross section of an inner cavity water way has a curved shape or a plum blossom petal shape, and a steel belt or a steel ring contact surface for mounting the copper cooling plate has a tooth shape. The process comprises the following steps: using a spraying gun to evenly spray a graphite paint on the die cavity inner surface or a die core surface of a die, fixing the steel ring or the steel belt prefabricated with the tooth shape on the inner surface in the die, and preheating the die, the die core and the steel belt or the steel ring until the temperature is between 150 and 400 DEG C; pouring molten copper into the die; closing and pressurizing the die and keeping the pressure with a specific pressure of between 50 and 300 MPa; opening the die to take out the coagulated and formed copper cooling plate; and drawing out steel wire inner cores one by one from the coagulated and formed copper cooling plate, and performing mechanical processing to remove the excess part of the appearance of the copper cooling plate. The copper cooling plate is manufactured by adopting a liquid forging process method, thus the material density, the heat conductivity factor, the appearance precision and the mechanical property are greatly improved, and simultaneously, the characteristic of integral molding is kept.

Owner:XI AN JIAOTONG UNIV

Thermoplastic Cellulosic Fiber Granules Useful as Infill Materials for Artificial Turf

ActiveUS20180179711A1Improve performanceIncrease elasticityGround pavingsThin material handlingInfillFilling materials

An artificial turf system has polymeric turf fibers resembling grass, and infill particles interspersed among said turf fibers. At least some of the infill comprises synthetic composite particles containing a thermoplastic polymer and cellulosic fibers, in which thermoplastic polymer is a matrix that binds together the other components of each synthetic particle into a composite particle.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

Non-aqueous electrolyte secondary battery and production method thereof

InactiveUS20050198815A1Increase capacityHigh characteristicElectrode manufacturing processesNon-aqueous electrolyte accumulatorsDispersed mediaMaterials science

A method for producing a non-aqueous electrolyte secondary battery comprising the steps of: (i) mixing a positive electrode active material, a first binder A and a dispersion medium to prepare a paste A, the active material comprising a lithium-containing transition metal oxide; (ii) mixing a conductive agent, a second binder B and a dispersion medium to prepare a paste B, the conductive agent comprising carbon black; (iii) mixing the paste A and the paste B to prepare a positive electrode material paste C; (iv) applying the positive electrode material paste C onto a positive electrode core member and rolling and drying the resultant member to prepare a positive electrode; and (v) fabricating a battery using the positive electrode, a negative electrode and a non-aqueous electrolyte, wherein contact angle θA between the non-aqueous electrolyte and the binder A and contact angle θB between the non-aqueous electrolyte and the binder B satisfy the formula (1): θB−θA≧15°.

Owner:PANASONIC CORP

Method for integrally forging combined bow-shaped rake

The invention relates to a method for producing a rake head as a gardening tool, in particular to a method for integrally forging a combined bow-shaped rake which is made of 65Mn steel. The method comprises the steps of: sending a rake head steel blank into a heating furnace for heating to above 1000 DEG C, integrally punching and forming rake teeth by using a punching device, and reserving bow-shaped handle stocks at two sides of the rake teeth; secondarily sending into the heating furnace for heating to above 900 DEG C, and forging the bow-shaped handle stocks; thirdly heating to above 1000 DEG C by using a high-frequency heating device, and roll-forging and drawing the bow-shaped handle stocks until the length of the bow-shaped handle stocks reaches the length of half of a bow-shaped handle at most by using a roll-forging device; fourthly heating to above 900 DEG C, synthesizing the bow-shaped handle stocks at two sides of the rake teeth by using a bending machine, then welding, reinforcing and forming the bow-shaped handle; fifthly heating to above 900 DEG C, forming radian of the rake teeth by using the punching device; and cleaning the surface of a rake body, baking finish and spraying. The bow-shaped rake produced by adopting the method has more excellent property, flexibility, elasticity, tensile strength and the like, and can not have phenomena such as deformation, breaking and the like during the use.

Owner:TANGSHAN SHUSHI HARDWARE TOOLS MFR

Super compressed detonation method and device to effect such detonation

InactiveUS20090255432A1Improve propertiesHigh energyExplosive chargesAmmunition projectilesShock waveDelayed time

A method and apparatus are provided for detonation of a super-compressed insensitive energetic material by cylindrical implosion followed by an axial detonation to a detonation velocity several times that of TNT and a detonation pressure in excess of ten times that of TNT. The device provides a conical metal flyer shell within which is disposed a cylindrical anvil surrounded by explosive. The anvil retains an insensitive energetic material to be compressed and detonated. A first detonation of explosive by impact of the flyer shell generates a reverberating oblique shock wave system for sample compression. Axial detonation of the compressed sample through any length of a sample is achieved following the principal of matching the axial velocity and compression time of the oblique shock wave system to the detonation velocity and induction delay time of the compressed sample. The method and apparatus are also applicable to enhancing the effect of anti-armour and anti-hard-target munitions. The apparatus is also applicable to inert sample compression to the megabar range without using the axial detonation.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA

Manufacturing method of zirconium oxide porcelain piece used for all-ceramic false tooth

InactiveCN107162588AGood material uniformityHigh densityArtificial teethClinical therapyMaterials science

The invention discloses a manufacturing method of a zirconium oxide porcelain piece used for an all-ceramic false tooth and belongs to the field of all-ceramic false tooth materials used for lost teeth repair. The manufacturing method includes the following steps: 1) with a zirconium porcelain mixture material as a raw material, performing injection molding to obtain a green body of the zirconium oxide porcelain piece for all-ceramic false teeth; 2) performing dewaxing treatment, low-temperature pre-sintering, mechanical processing and silk-screen printing to the green body; and 3) inspecting and packaging the final product. The zirconium oxide porcelain piece used for all-ceramic false teeth has high internal homogeneity, high density and high breaking strength. An all-ceramic false tooth inner crown produced from the zirconium oxide porcelain piece has high mechanical strength and high density. The zirconium oxide porcelain piece used for the all-ceramic false teeth is designed through CAD / CAM and is processed to manufacture an all-ceramic false tooth inner crown green body which is then sintered, so as to reach strength and appearance effects required in clinical therapy.

Owner:SHAOXING HUAJING SCI TECH

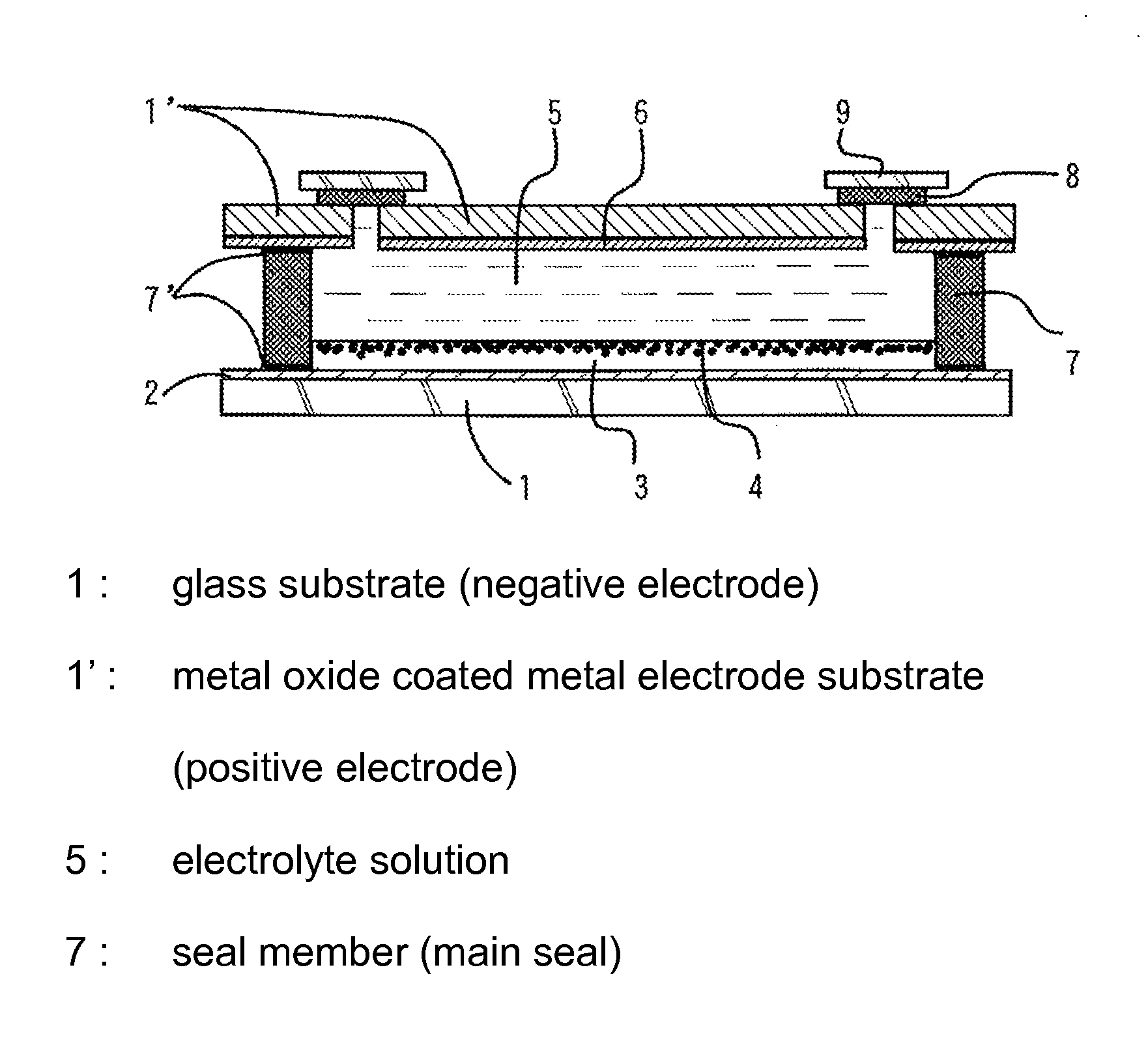

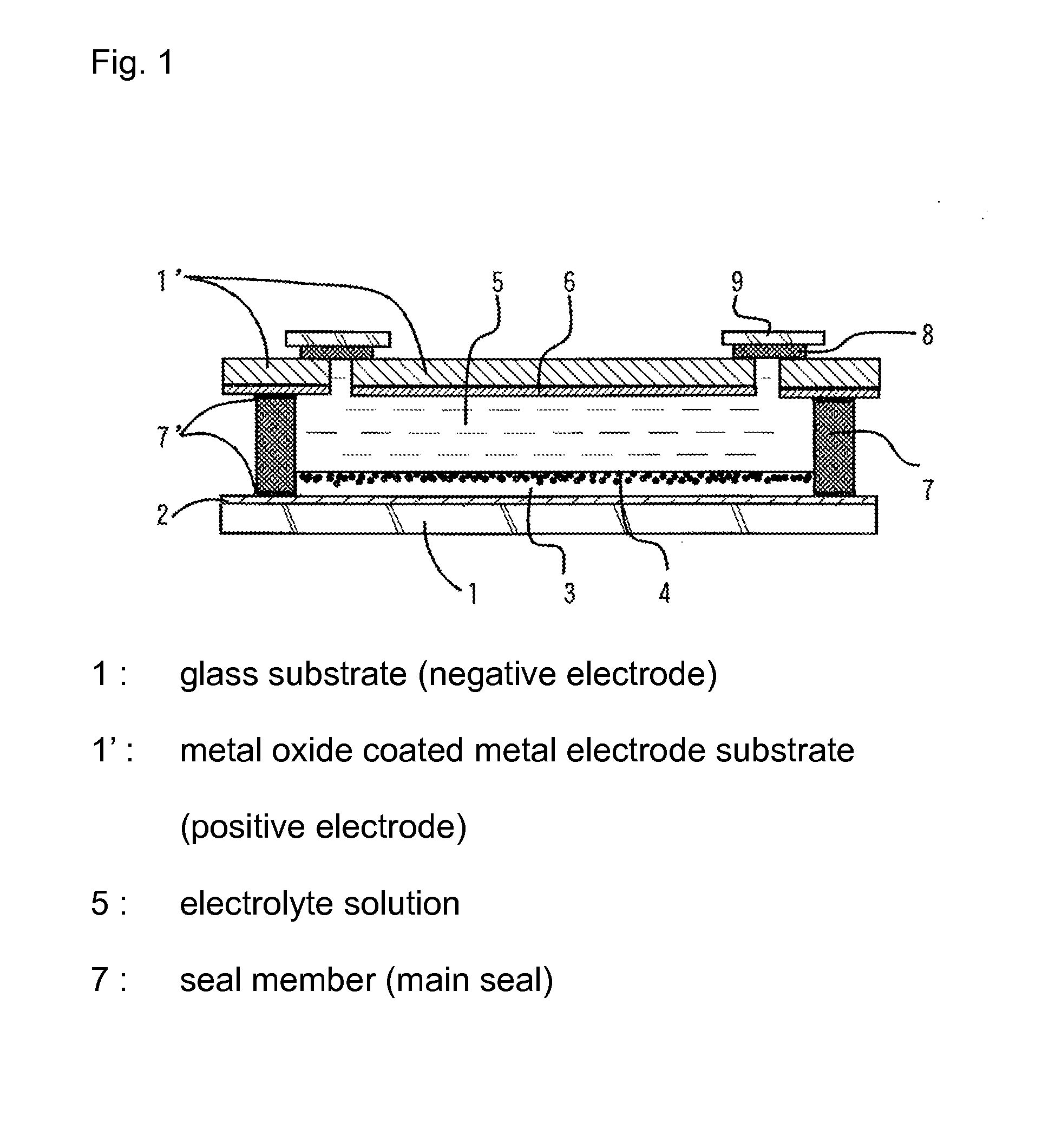

Dye-sensitized solar cell

InactiveUS20120017979A1Light weightEasy to convertLight-sensitive devicesSolid-state devicesElastomerEngineering

A dye-sensitized solar cell is provided, which includes a seal member that is free from swelling and degradation during prolonged sealing use and highly excellent in sealability. The dye-sensitized solar cell includes: a pair of electrode substrates spaced a predetermined distance from each other with their electrically conductive electrode surfaces facing inward; a seal member disposed along peripheries of inner surfaces of the electrode substrates to seal a space between the electrode substrates; and an electrolyte solution filled in the sealed space. The seal member is composed of a material cured by photopolymerizing the following photopolymerizable composition (A), and the electrode substrates each have a portion coated with a (meth)acryloxyalkylsilane silane coupling agent in contact with the seal member. The photopolymerizable composition (A) contains a hydrogenated elastomer derivative having at least one (meth)acryloyl group at at least one of its opposite molecular terminals.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com