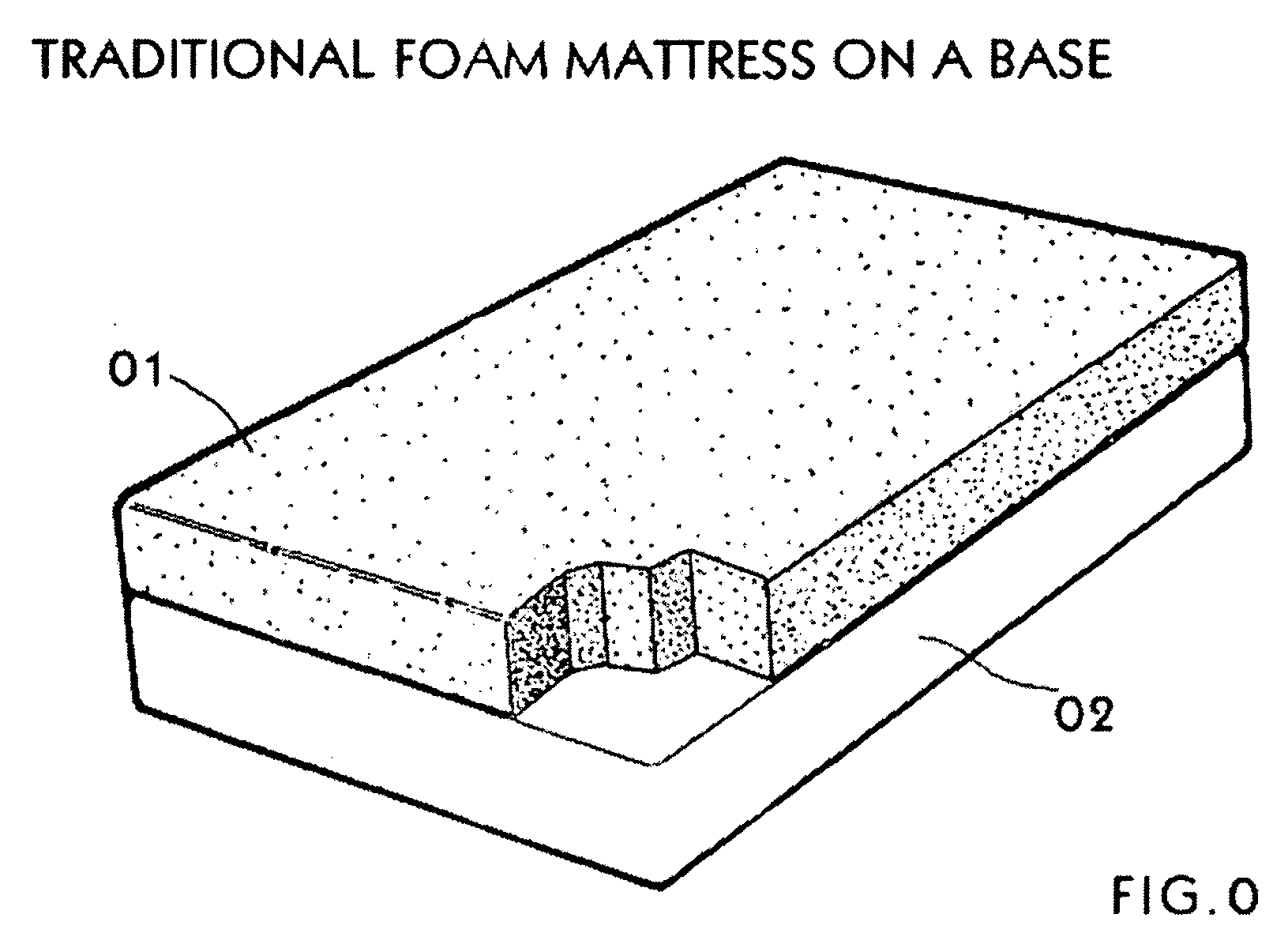

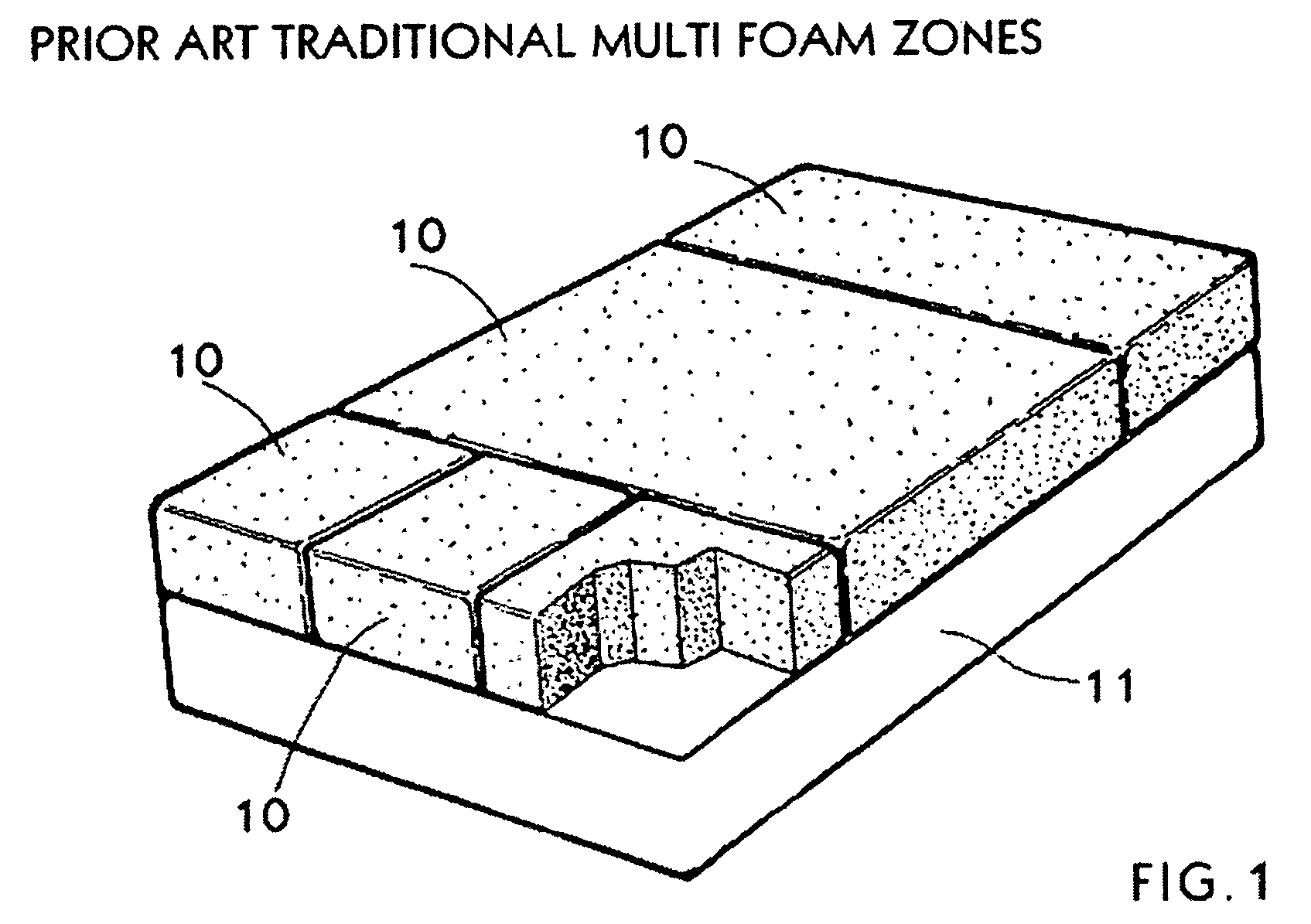

[0020] The present invention teaches how to control and modulate the principal characteristics of open-

cell flexible

polyurethane foam in a specific integration with airtight covers and pressure valves for the use in any form of comfort support device, for instance, mattresses. The principal characteristics pertain to industry standards of subjective tactile softness in the sense of espousing body contours so as to optimally distribute pressure points of a person reclining on a planar surface, and of bodyweight-carrying support firmness. They are controlled and modulated in a way to not only greatly enhance comfort, but particularly to offer an infinite choice of easily adjustable levels of comfort, defined as a balance between softness and firmness. This is done at lower comparable cost and weight compared to

high density foam varieties such as visco-elastic foam, and in combination with known, traditional techniques, it enhances versatility, allowing for a great number of variations in the choice and

adaptation of materials to go together with self-inflating, modulable foam into comfort level adjustable support devices.

[0021] The invention teaches how the Indentation Force Deflection (IFD) and density properties of a certain quality range of flexible open-cell polyurethane foam are modulated by removing some of the air from within the foam cells and altering the

cellular density of the foam core. Since

high density, more expensive foams, such as visco-elastic foams, are very desirable as to comfort, the principal teaching of the invention is how to modulate comparatively less expensive, lower density foam to exhibit the feel-characteristics of

high density foam, and also attain support and

comfort levels of a higher density, more expensive foam, without locking the user into a single, fixed comfort level.

[0022] IFD and density modulation are achieved by altering open-cell, flexible polyurethane foam or material of similar characteristics within a fixed framework of controllable valves and airtight bladders. This art teaches that the material is fashioned in a particular form and that it is of a

molecular composition as to permit the extraction of air in the alveolate structure in a uniform manner throughout, thus increasing

material density equally uniformly. A further

specialty of the material is that, by virtue of its structure, particular manufacturing and finishing processes, it affords in its low IFD number modulated state a commensurably higher support stability, heretofore only associated with foam or similar material of a very much higher density and greatly higher price. Finally, it is much lighter in weight than the latter and can also be reduced in size and volume for easy transport and storage.

[0023] The application of the principles of this teaching extends to a great number of possible combinations of foam only and foam plus traditional support devices used in the architecture of, for example, mattresses, that users may adjust to their personal preference. But in all its combinations, the

pivotal point of the invention is that specifically fashioned types of foam will soften when air is extracted from their

cell structure. Compared to its original firmness, which is indicated by the manufacturer's IFD number, its resilience will decrease to about half of its original value. The density on the other hand increases considerably to about double its original value, creating the much needed body support a mattress should have. Density of foam is its weight per

cubic foot, hence the heavier a

cubic foot of foam weighs, the higher will be its density rating.

[0024] The present invention teaches that removing air from a foam core uniformly reduces the volume of the core, hence increases its density without adding weight to the overall mattress, which would be undesirable for the user. One of the disadvantages of high density foams, such as visco-elastic foam, is that they are very heavy and difficult to fashion in the form of a mattress. In this invention the single foam core mattress as well as its combination with other

bedding materials are much lighter of weight but yet exhibit the same comfort and support characteristics as, for instance, a visco-elastic mattress. It has the additional

advantage of being adjustable. Removing air from visco-elastic foam or similar materials in the same manner is not possible, because their cellular structure is very tight and would solidify almost immediately (densification).

[0028] The chamber's vacuum in this example is controlled by valves which operate under spring pressure. When air is evacuated from a self-inflating foam core within a hermetically sealed cover, the foam material's cellular elasticity exerts pressure to expand to its original form by drawing air back into its open cells, developing a measurable

suction force. The more air is removed from the foam cells, the higher the foam core's re-inflation force. Springs in the valve assemblies connected to the partially emptied chamber oppose the re-inflation force reciprocally. Hence a balance between the opposing forces can be established, depending on the

spring force and the

suction force. Tests conducted in a laboratory environment show that CS can be prevented in a totally deflated foam core if the re-inflating force is slightly greater than the closing force of the valve spring. In this manner, air is drawn back into the mattress at a very

slow rate, and stops entering the mattress when the re-inflation force of the foam equals the compression force of the spring in the valve. A fixed spring-force setting, allowing foam to re-inflate to a specific degree greatly reduces the occurrence of CS and preserves the deflated product from malfunctioning when allowed to re-inflate after

extended storage periods. The principle of residual air retention to off-set CS has been validated in laboratory experiments for polyurethane foam used in a wide variety of mattress architectures, be it by itself or in a combination with other arrangements. To balance the closing force of the valve spring within the valve

assembly against the re-inflating force of the various foams, a great number of specific compression values are being used to adapt to foams having different IFD and density ratings.

Login to View More

Login to View More  Login to View More

Login to View More