Manufacturing method of zirconium oxide porcelain piece used for all-ceramic false tooth

A production method and technology of zirconia, applied in dentures and other directions, can solve problems such as poor internal density uniformity, and achieve the effects of high finished product density, high mechanical strength, and high material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

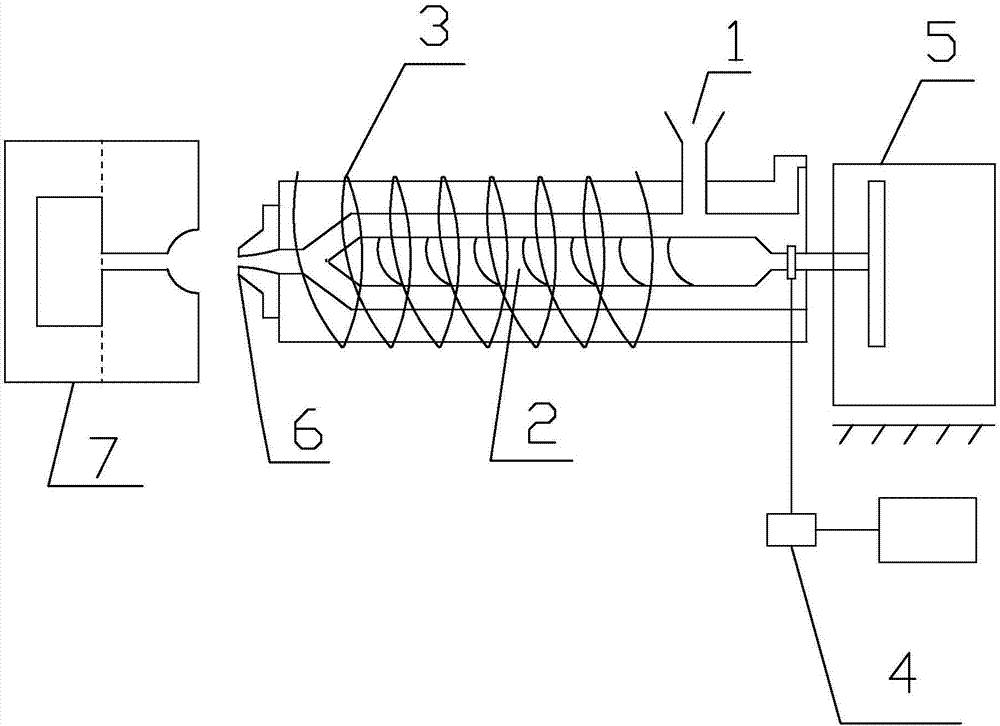

[0017] A method for making zirconia porcelain blocks for all-ceramic dentures according to the present invention comprises the following steps: firstly use zirconium-porcelain mixture as a raw material, and adopt an injection molding process to prepare zirconia porcelain block blanks for all-ceramic dentures, and then prepare all-ceramic dentures The blanks of zirconia ceramic blocks are sequentially passed through the wax discharge process, low-temperature pre-sintering process, mechanical processing process, and screen printing process, and finally inspected and packaged to form a finished product.

[0018] In this embodiment, the injection molding process is carried out using an injection molding machine, including injecting the zirconium-ceramic mixture into the mold cavity under high temperature and high pressure for molding, wherein the high temperature is 180°C ± 30°C, and the high pressure is 70Mpa ± 25Mpa .

[0019] combine figure 1 As shown, the specific process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com