Cable outer coating molding device and molding method

A molding device and cable technology, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve the problems of low material utilization rate, poor coating quality, and complex molding process of the outer coating, so as to improve the molding quality , flexibility and strength improvement, and the effect of improving the quality of the cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to understand the present invention more clearly, the following will further describe the present invention in detail with reference to the accompanying drawings and specific embodiments.

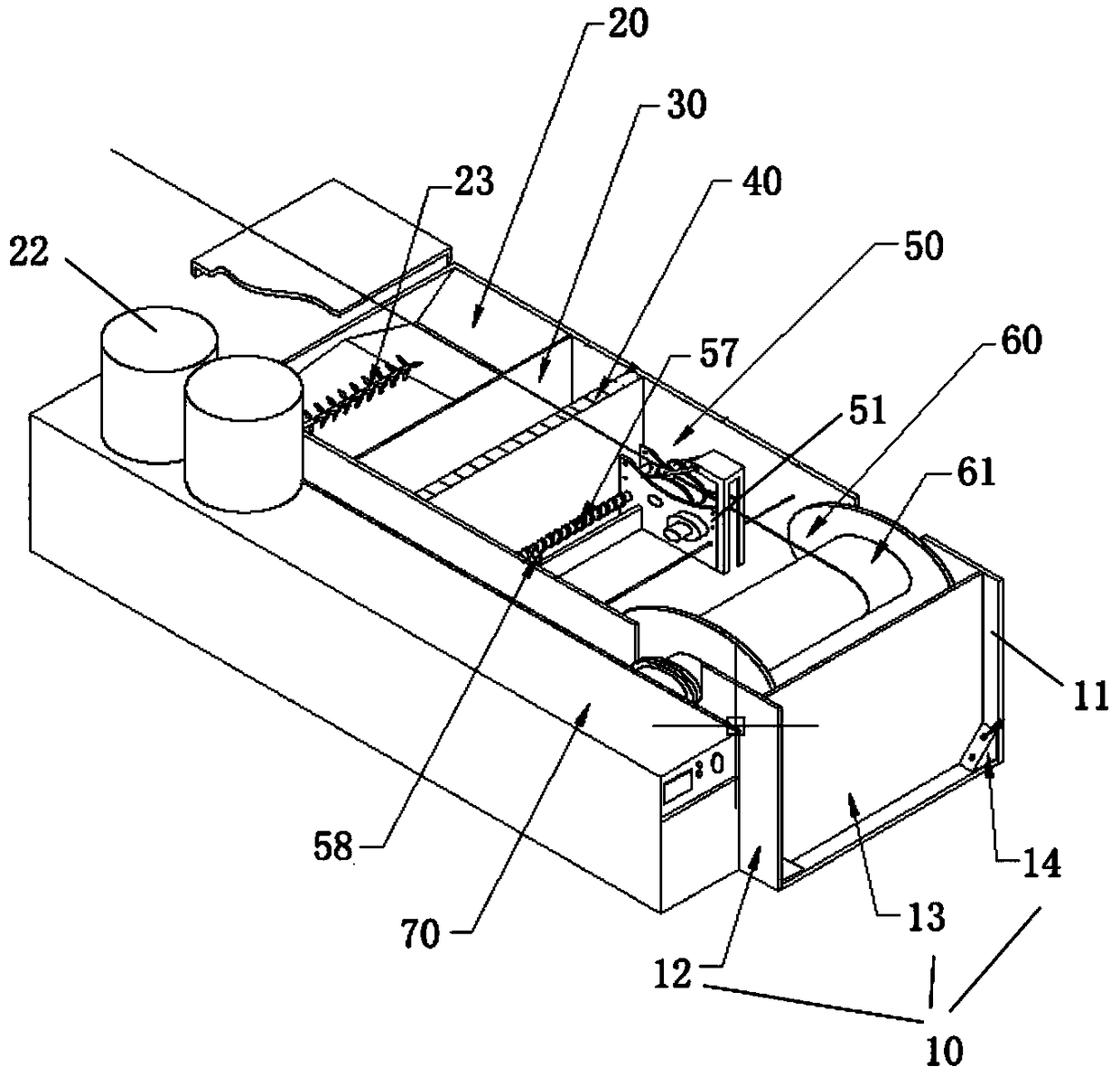

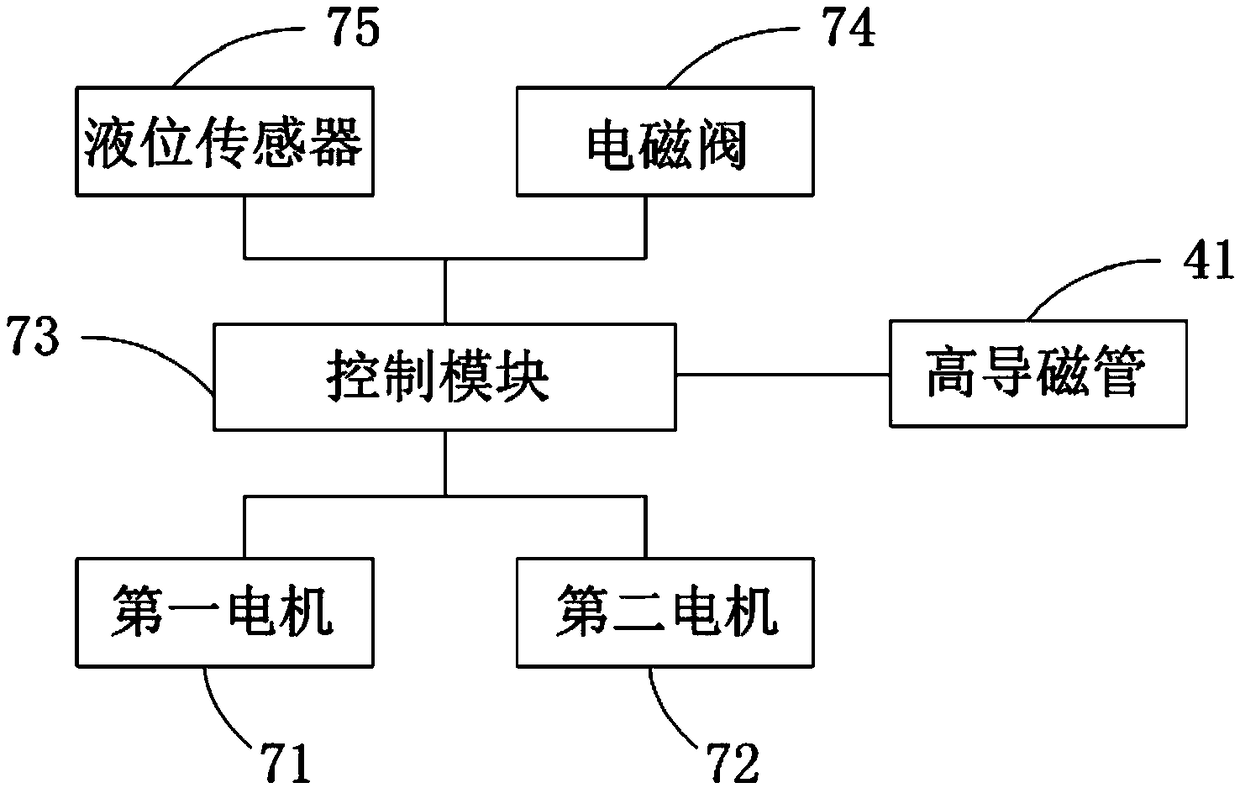

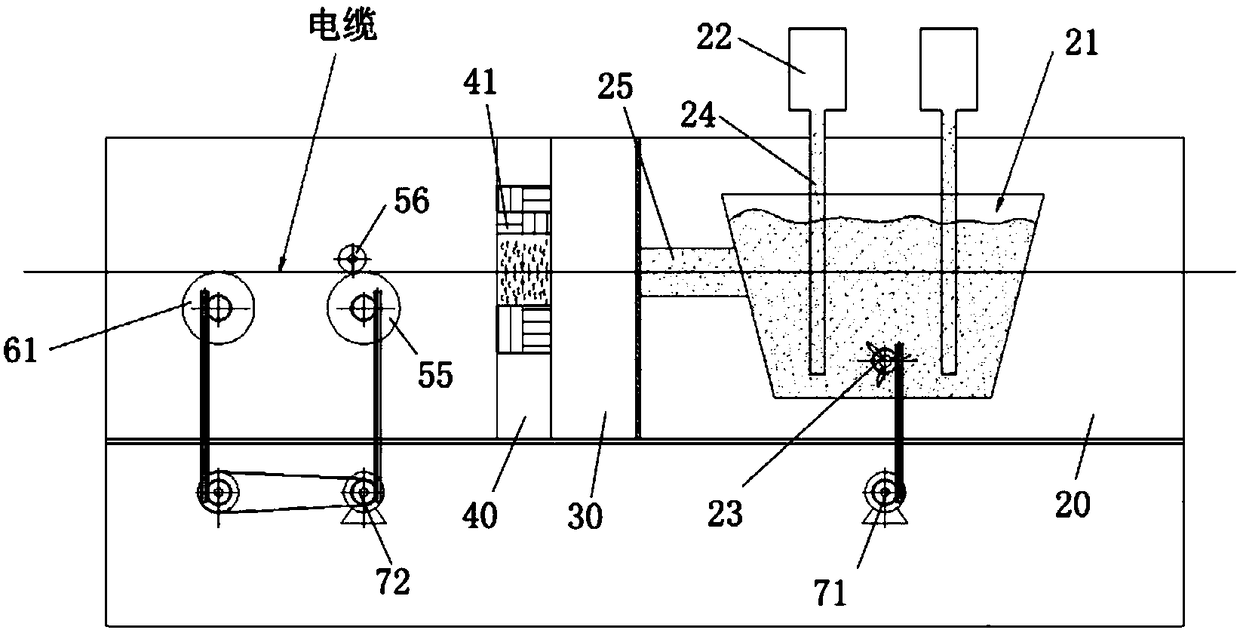

[0039] In order to solve the problems that the existing cable outer coating molding process is complicated, the material utilization rate is low, and the uniformity and smoothness of the material coated on the cable outer cover are difficult to guarantee, the present invention provides a cable outer coating forming device The core idea of the forming method is that the forming device includes a soaking bin, a natural curing bin, a heating bin, a guide wheel shaping bin, and an outlet bin which are sequentially arranged along the cable conveying direction, so that the outer coating of the cable can be removed from the raw material The integrated automatic forming of mixed dipping, self-heating curing, heating semi-qualitative, guide wheel shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com