Patents

Literature

138results about How to "Avoid inadequate mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

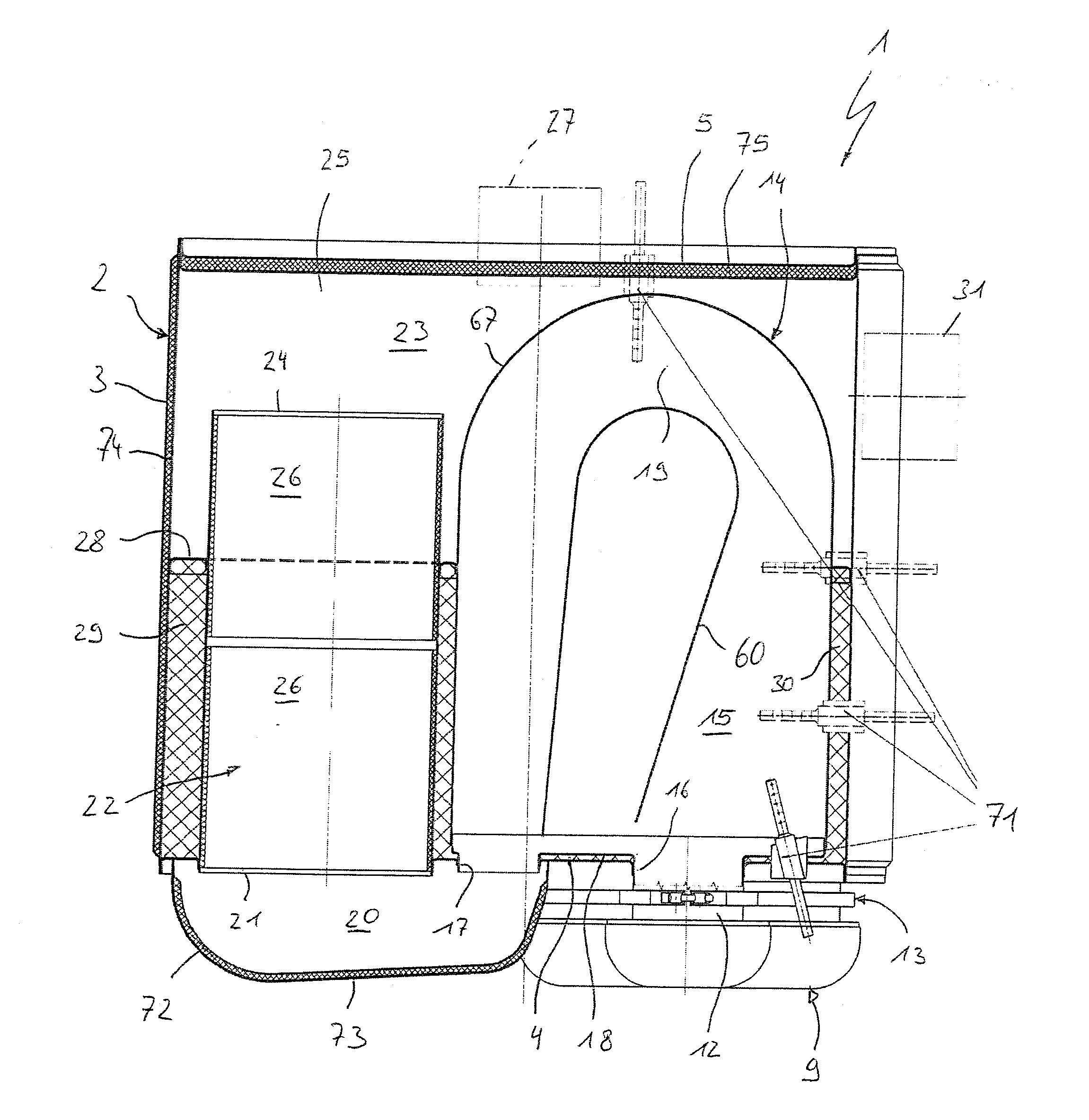

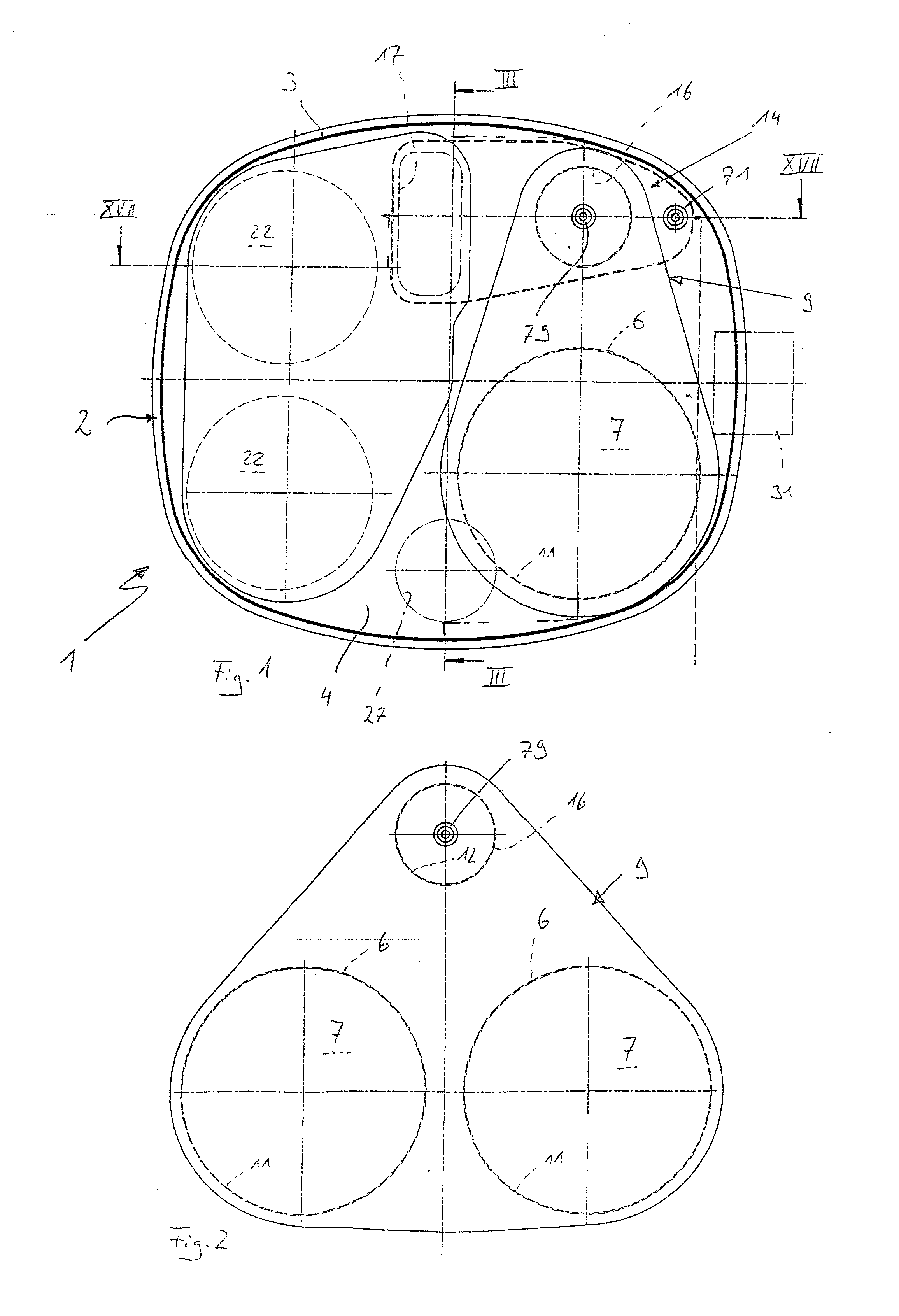

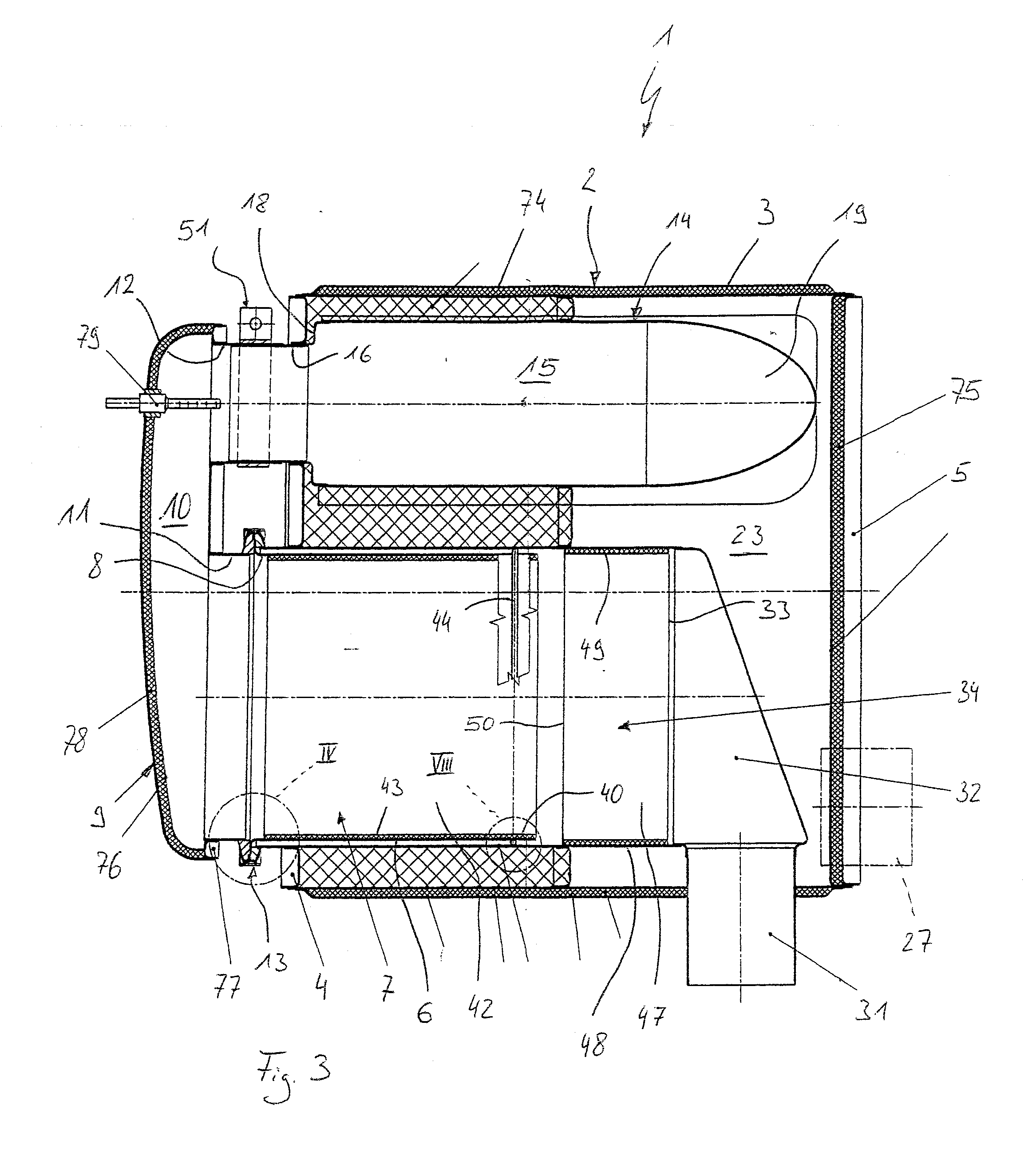

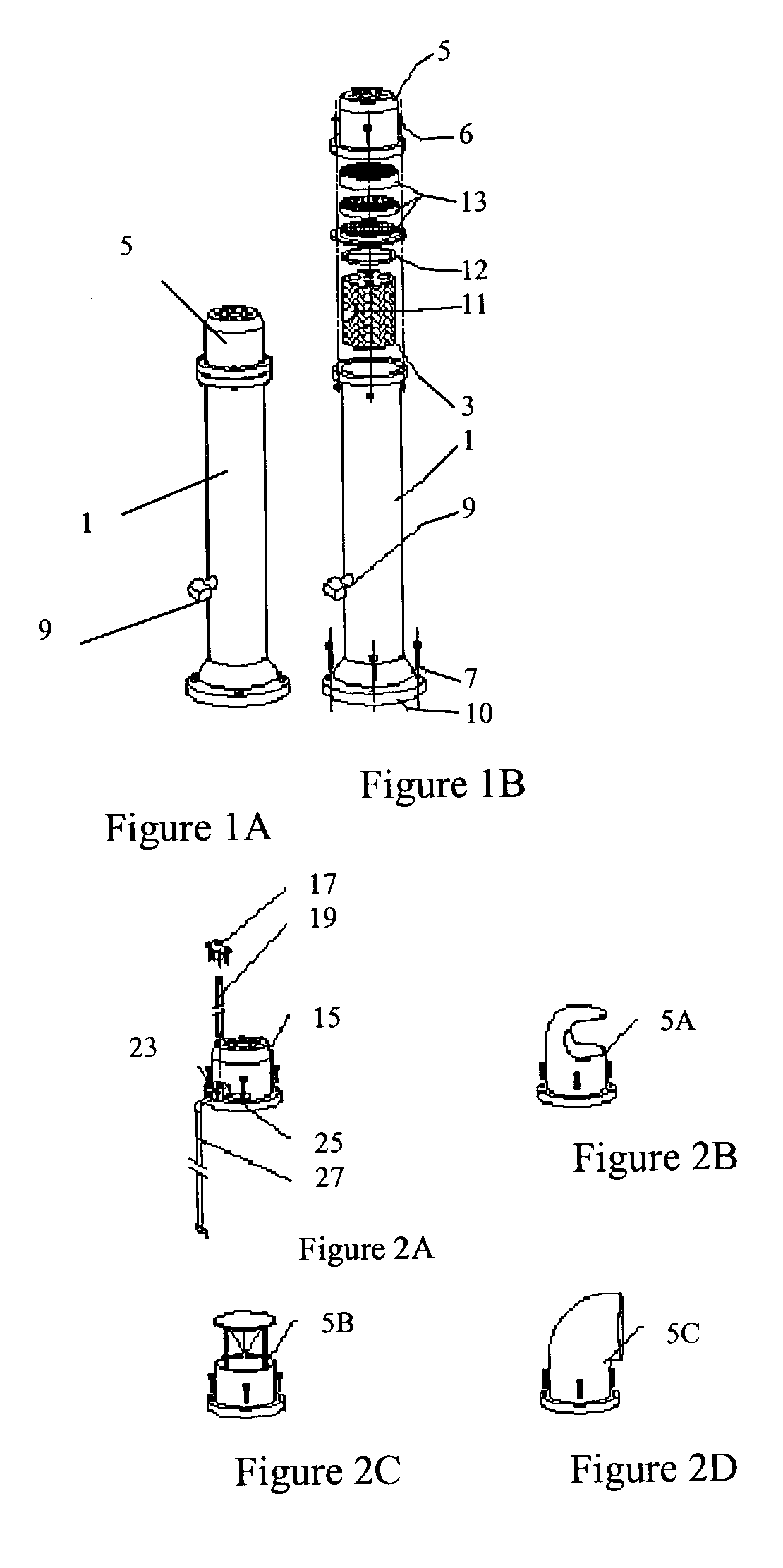

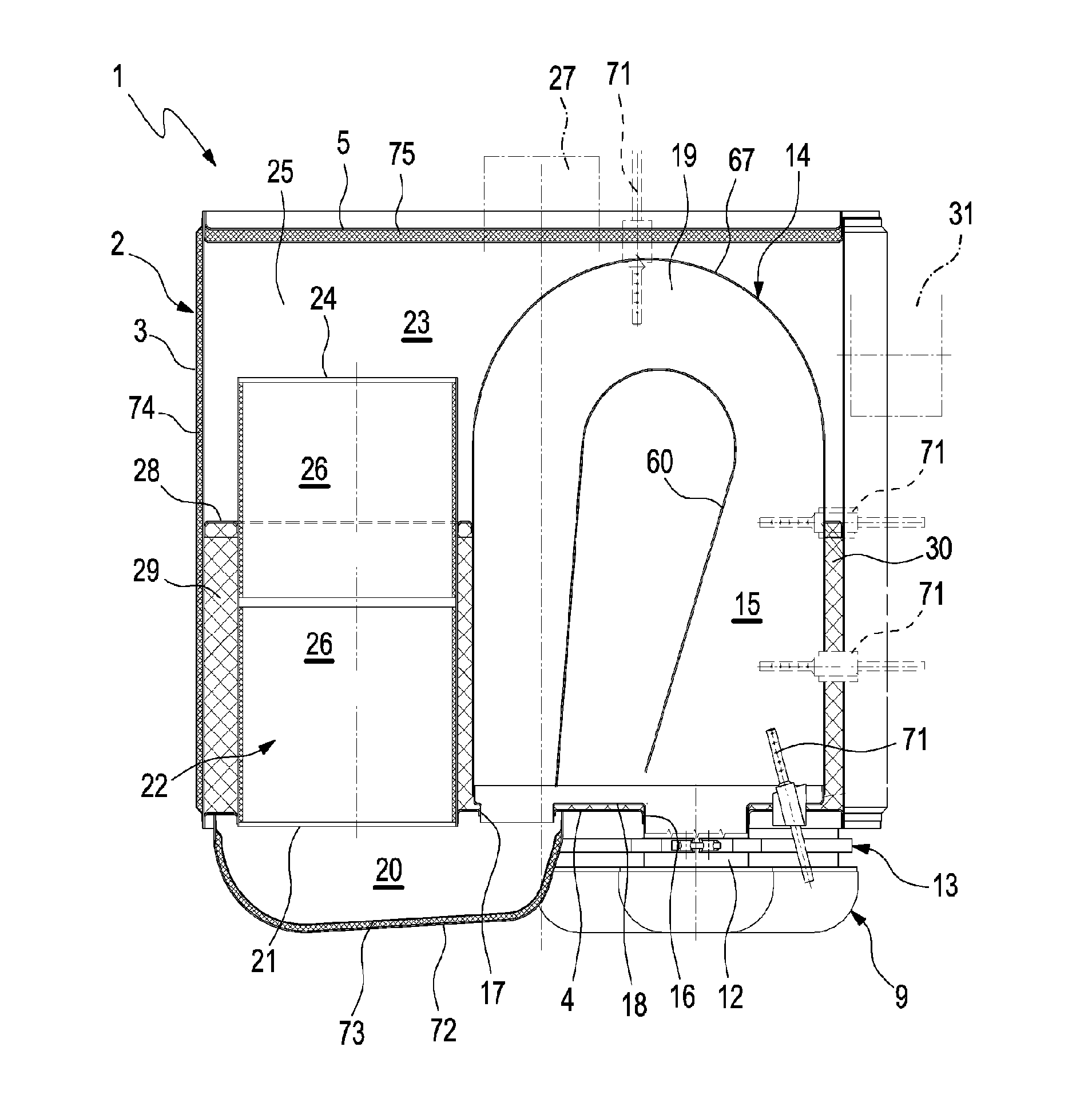

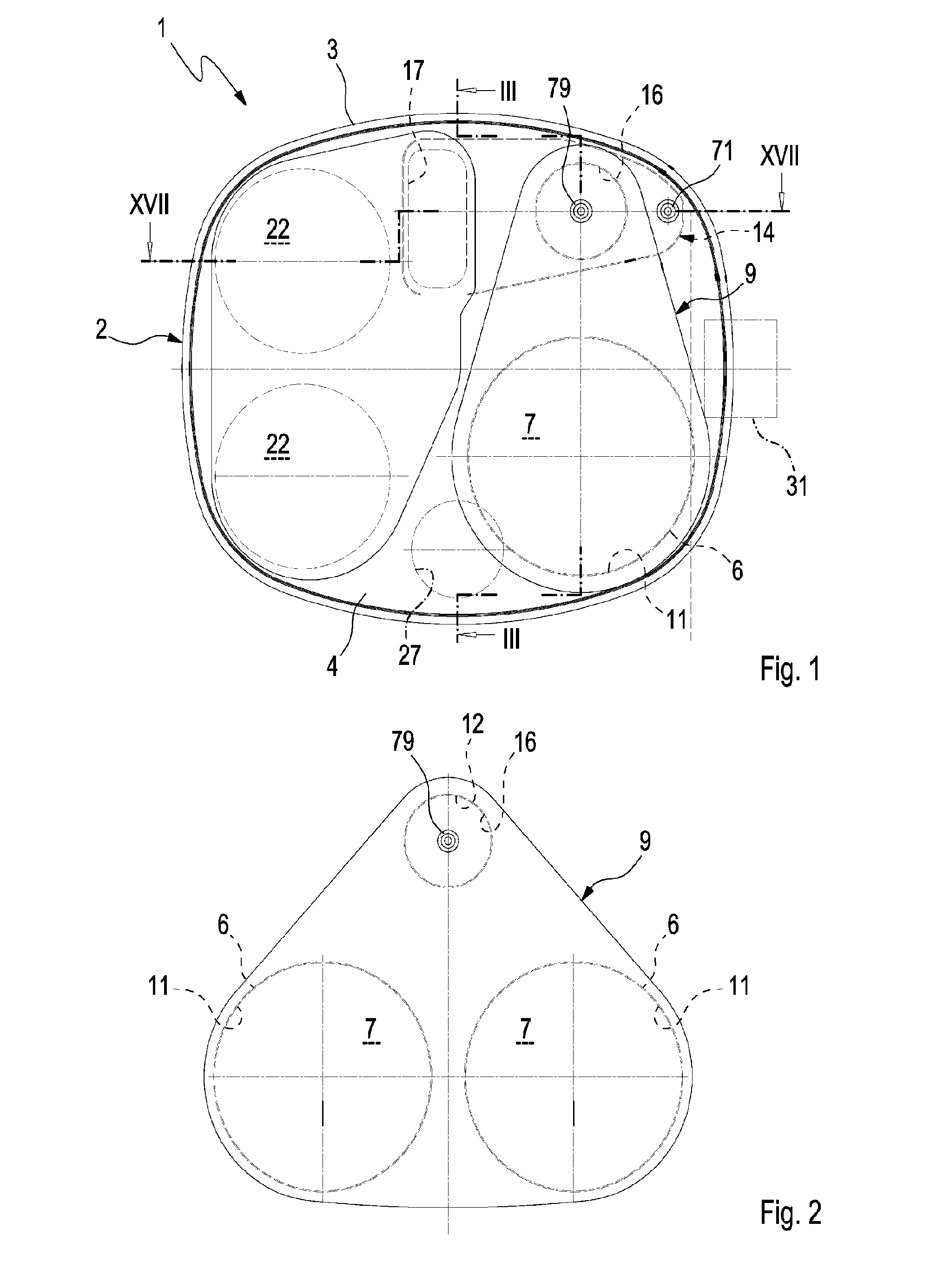

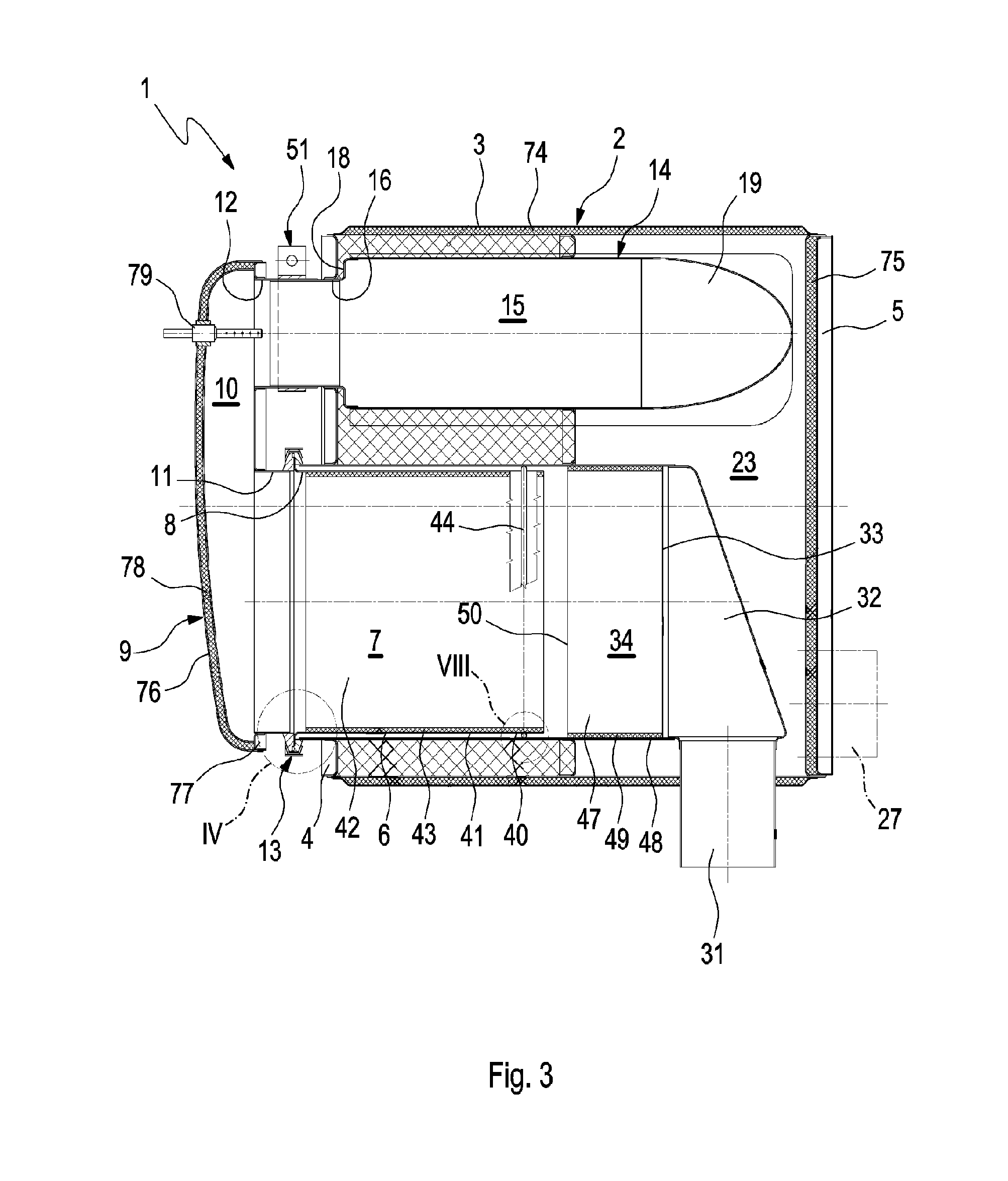

Exhaust gas-treating device

ActiveUS20100242451A1Improve homogenizationSpeed up evaporationInternal combustion piston enginesSilencing apparatusInterior spaceExhaust fumes

An exhaust gas-treating device (1) for an exhaust system of an internal combustion engine, especially of a motor vehicle, is provided with a housing (2), which has a jacket (3) extending circumferentially on the side and at least one bottom (4). The homogenization of the exhaust gas flow is improved with a mixing housing (14), which is arranged in the interior space (23) of the housing (2) and which has a mixing chamber (15). An inlet (16) of the mixing housing passes through the bottom (4) and communicates with the mixing chamber (15). An outlet (17) of the mixing housing passes through the bottom (4) and communicates with the mixing chamber (15).

Owner:VOLVO LASTVAGNAR AB +1

System and method for suppressing fires

InactiveUS7028782B2Minimal “ down time ”Save a lot of costFire rescueBoring toolsProduct gasNitrogen gas

A method and apparatus for suppressing a fire utilizing non-azide solid gas propellant generation to produce and transport a suitable gas for suppressing a fire in a normally occupied area. The nitrogen gas produced by the solid propellant gas generation is optionally treated to remove undesirable elements such as water and / or carbon dioxide from the product gas prior to the delivery of the product gas to the protected hazard area.

Owner:N2 GLOBAL SIA

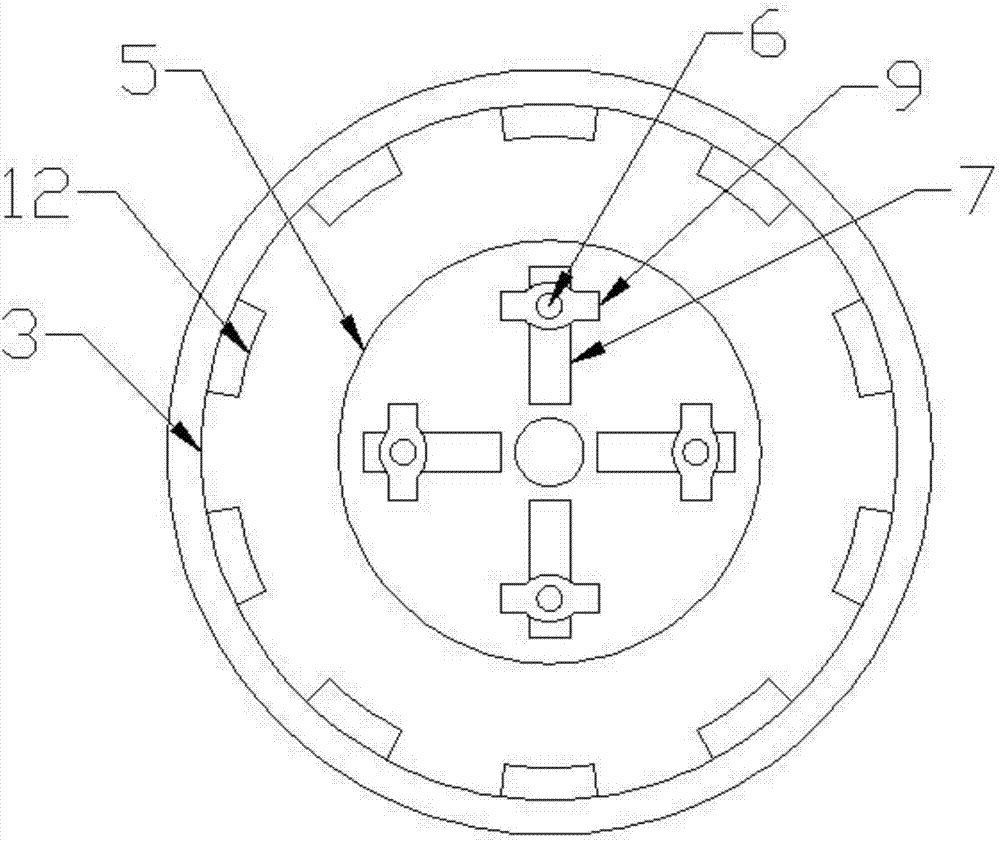

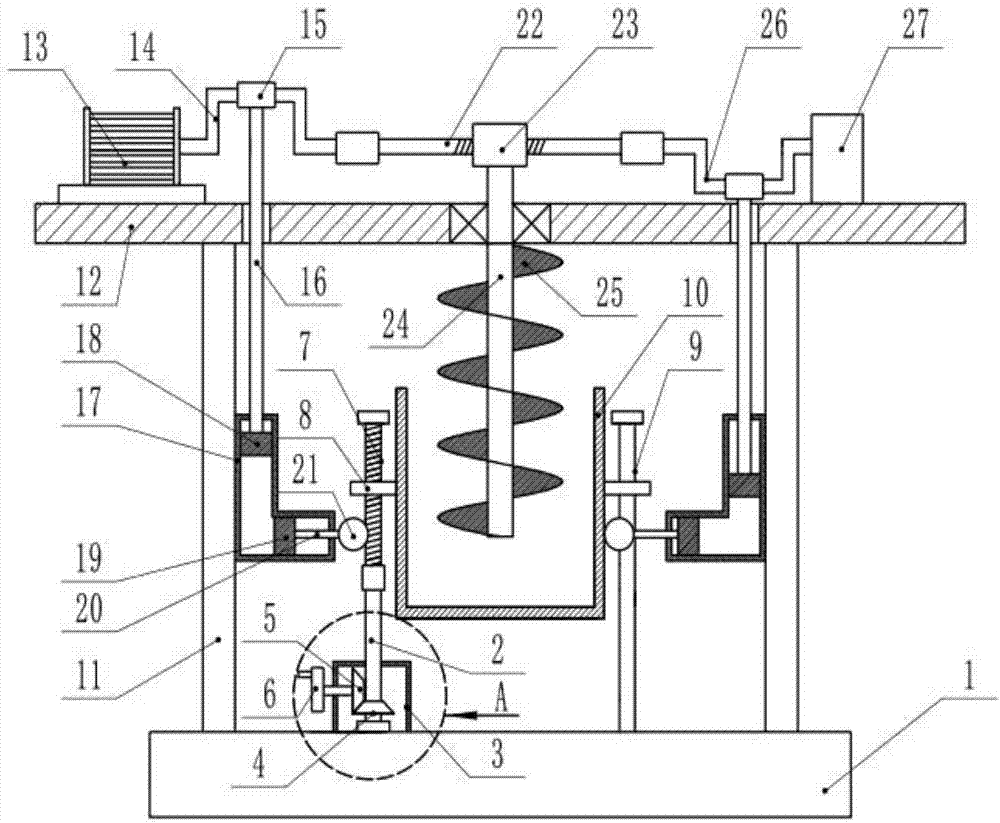

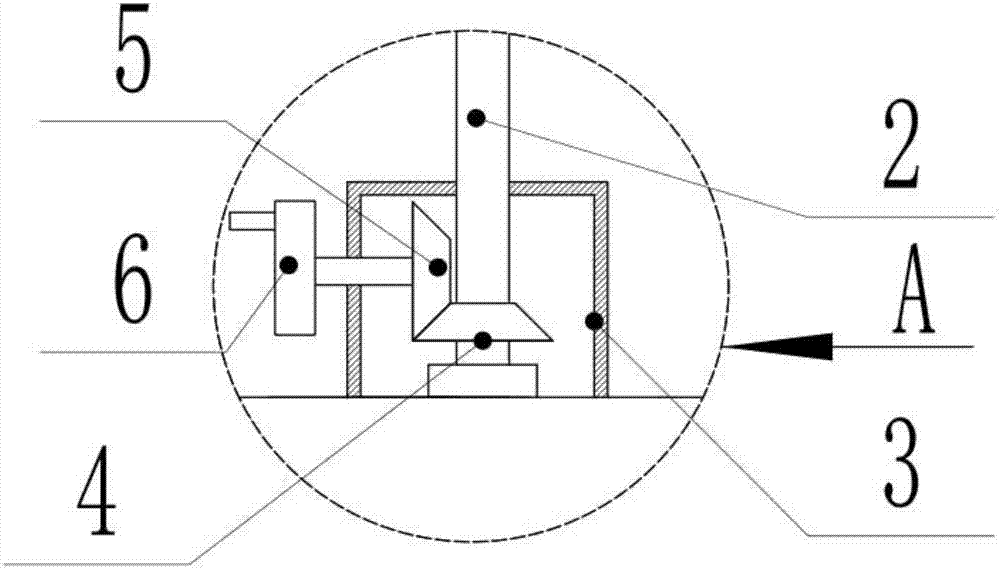

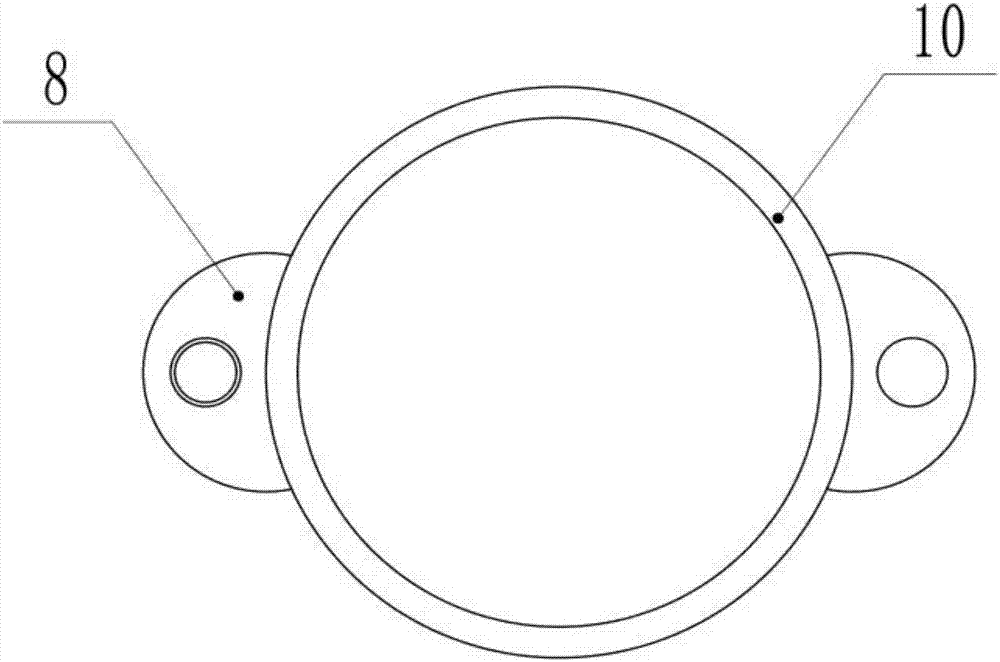

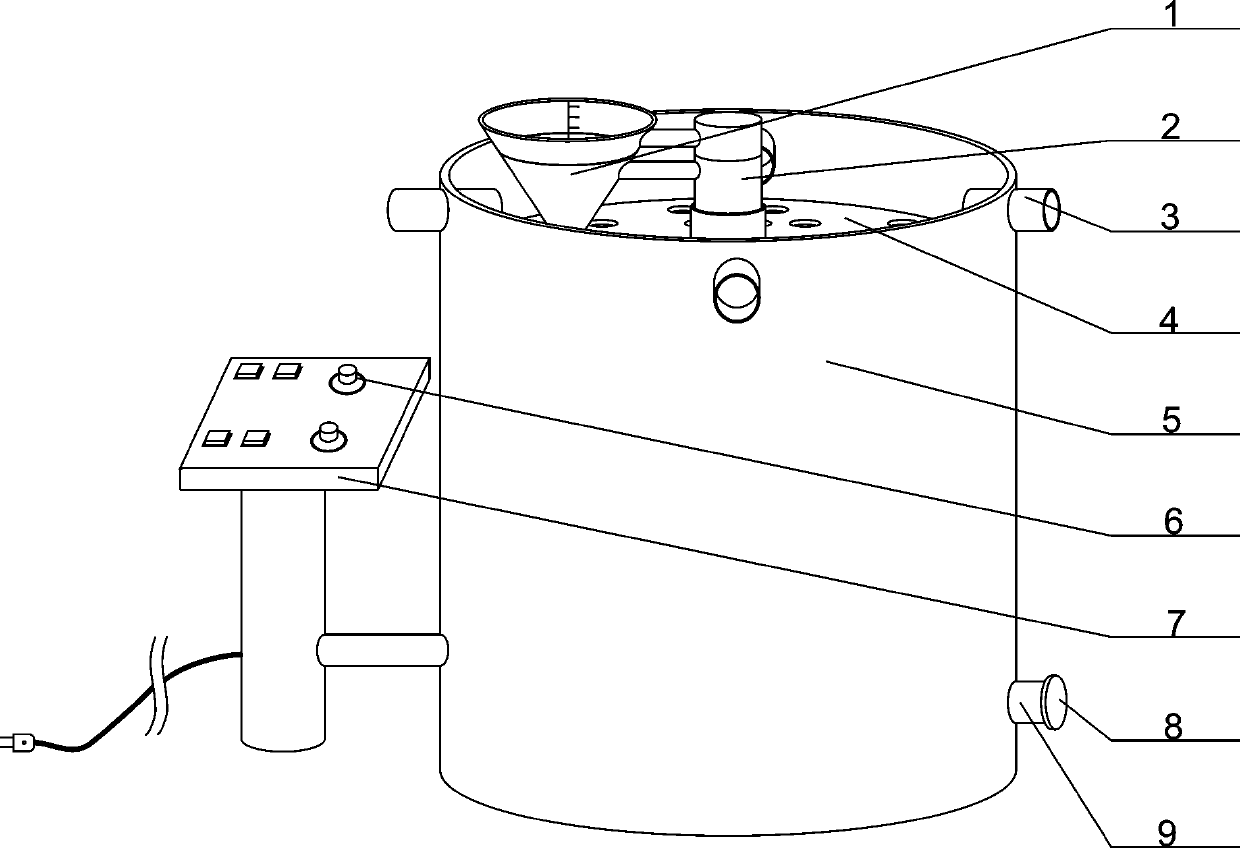

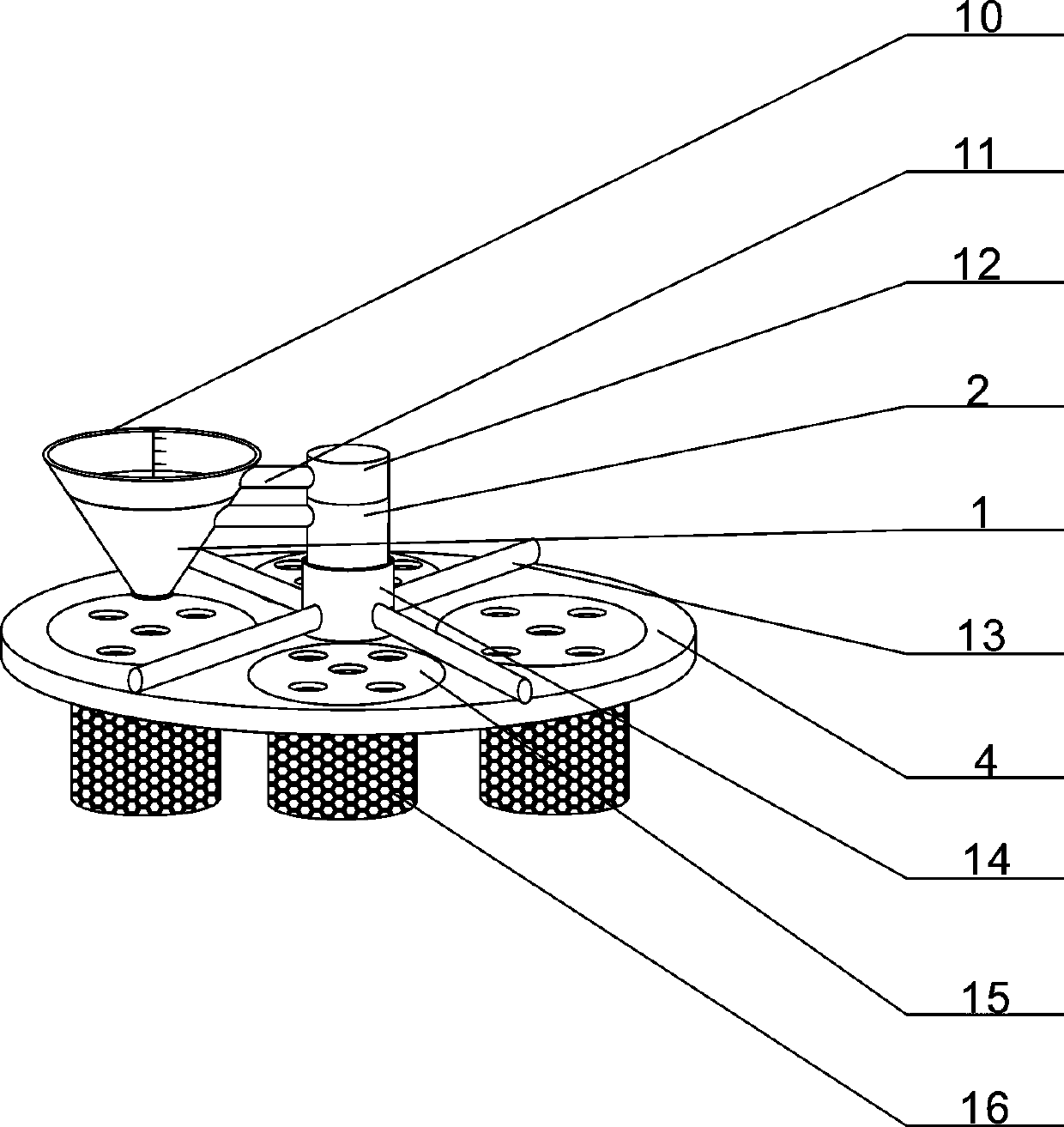

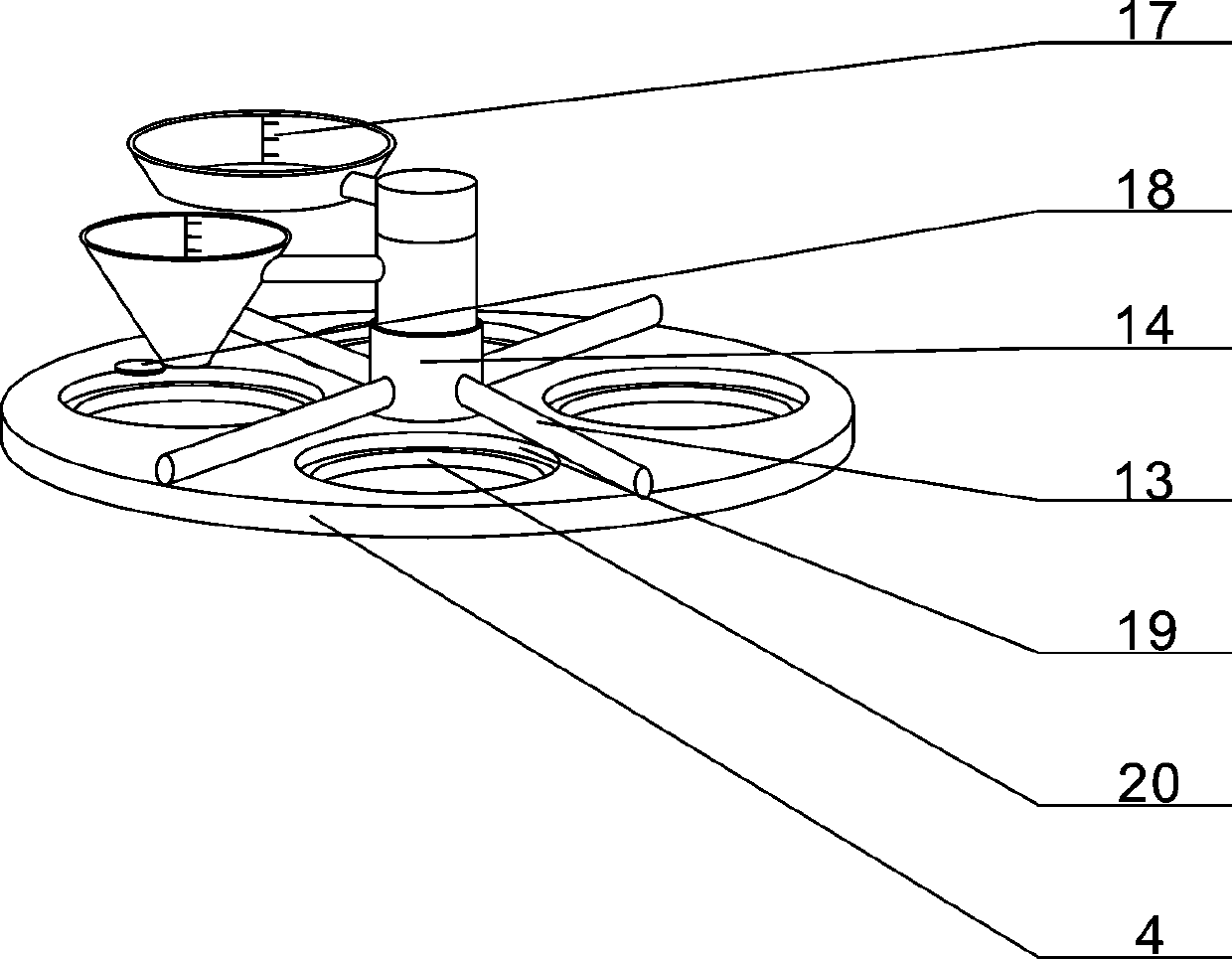

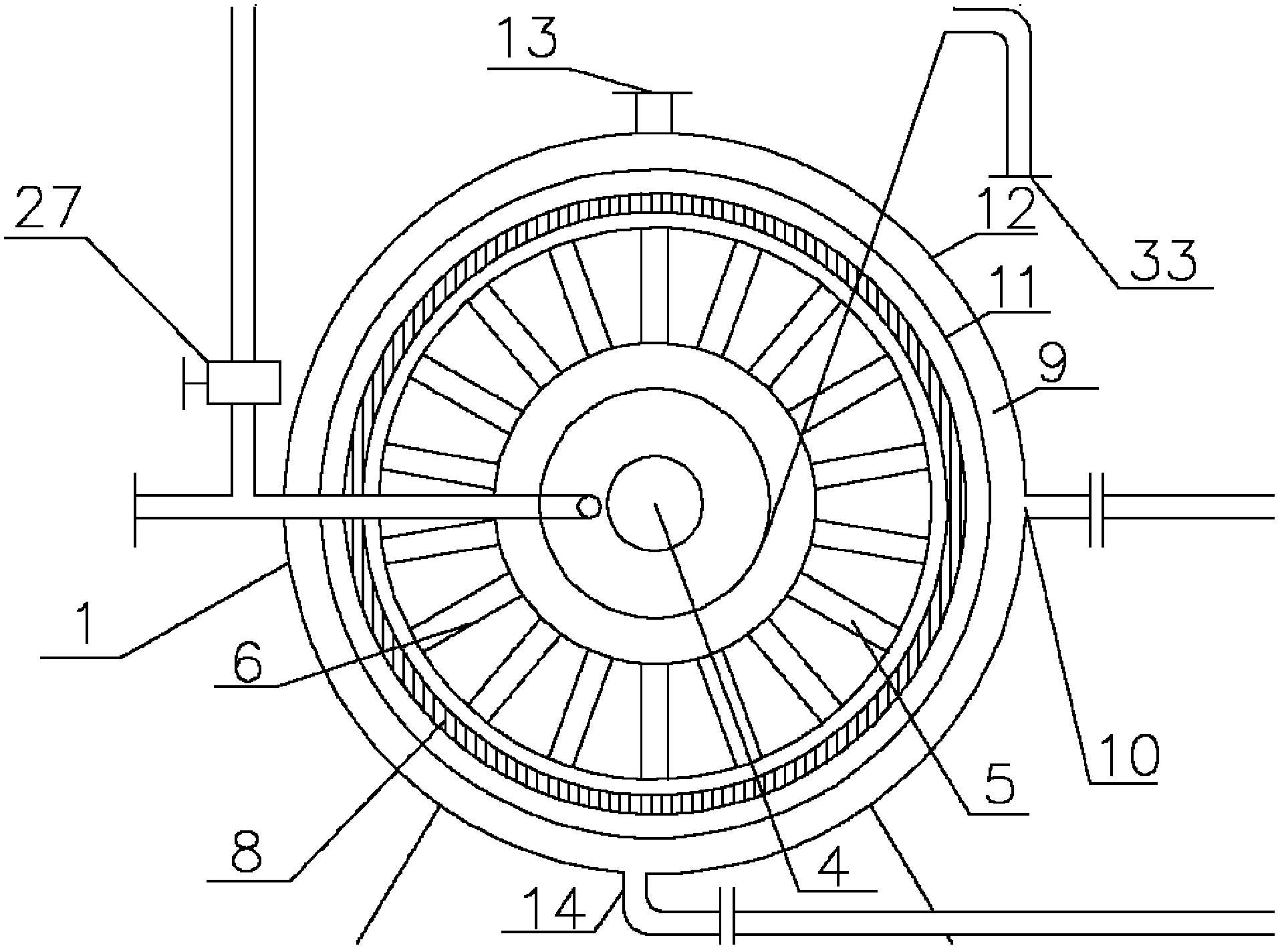

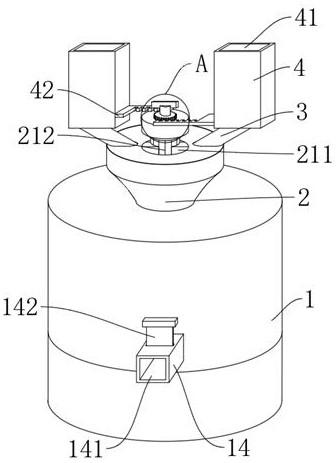

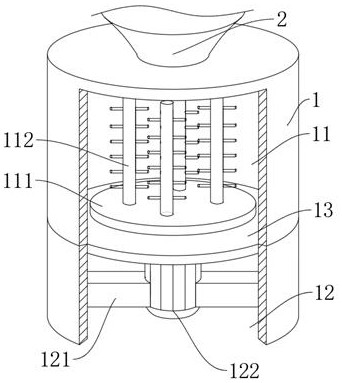

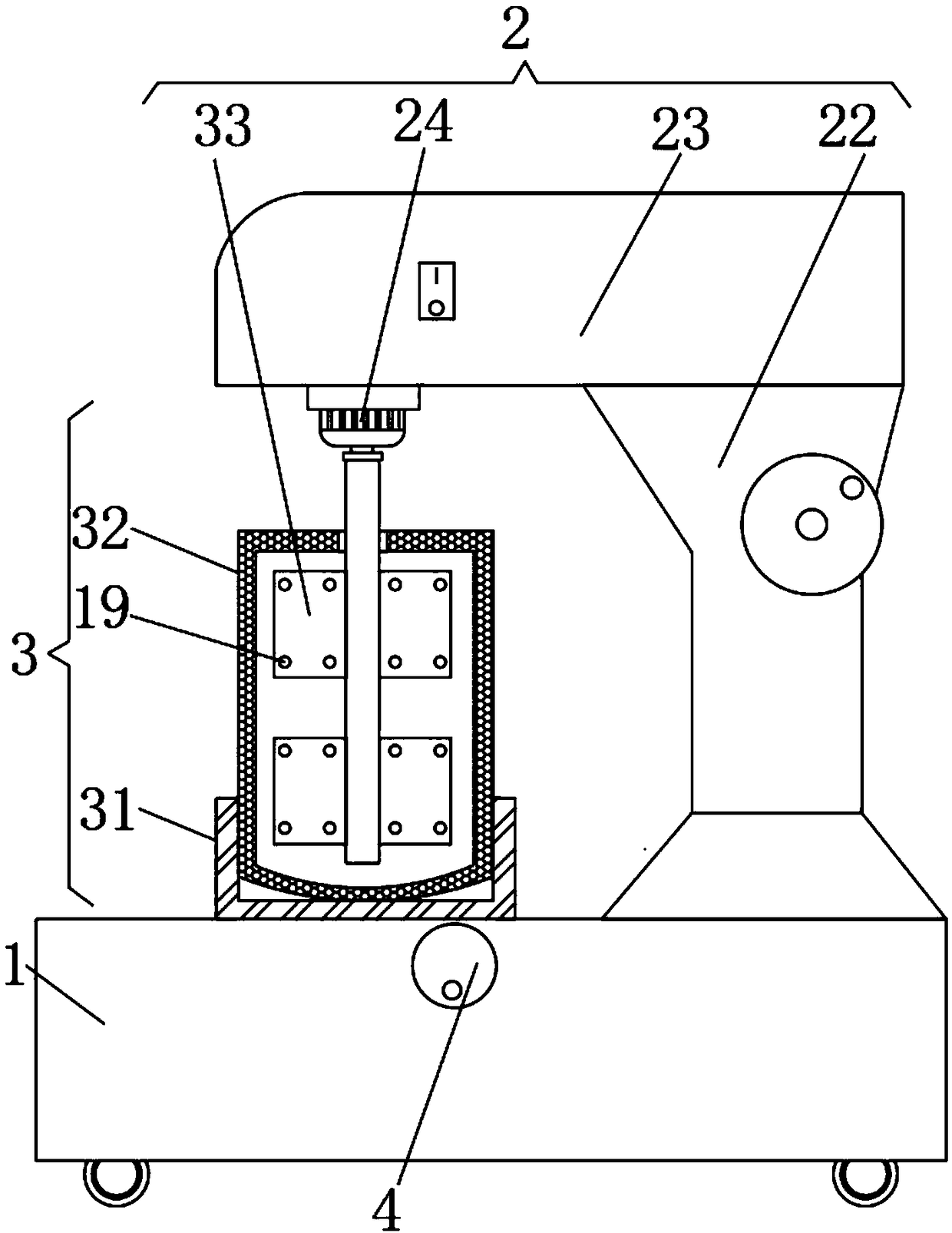

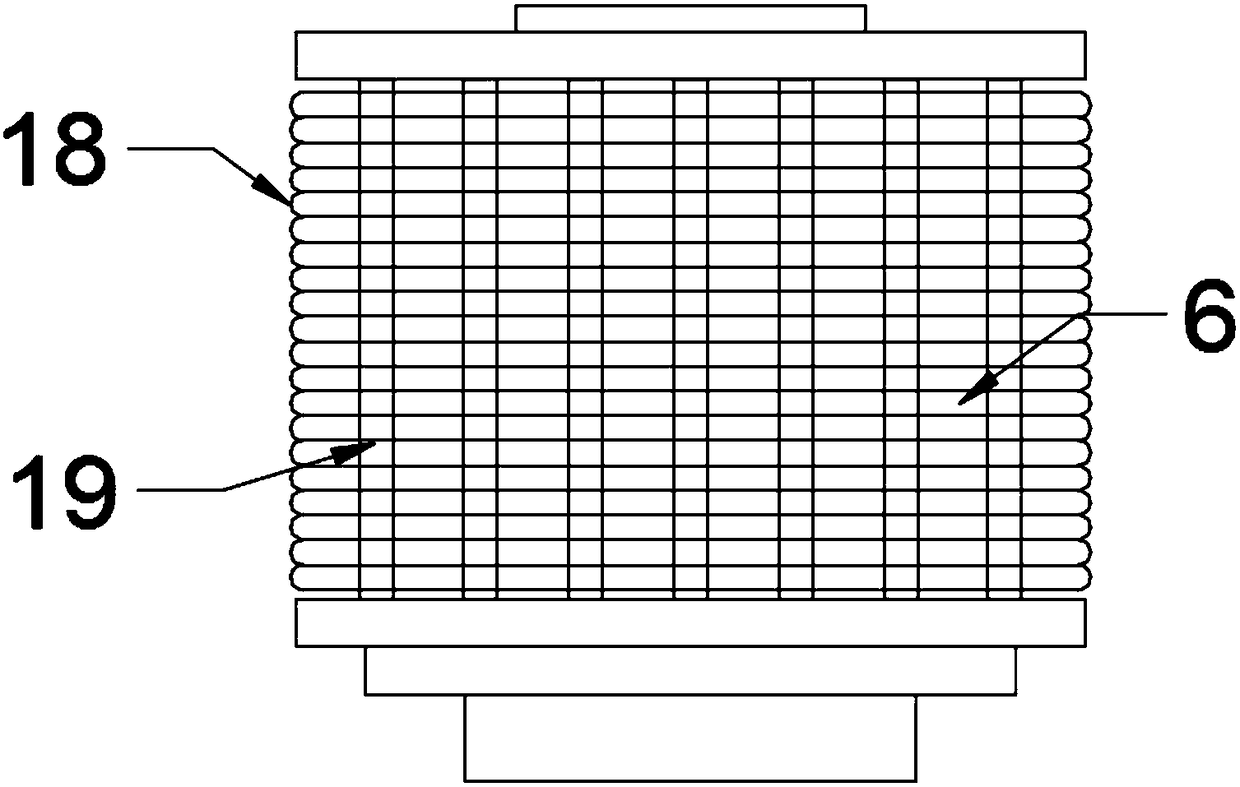

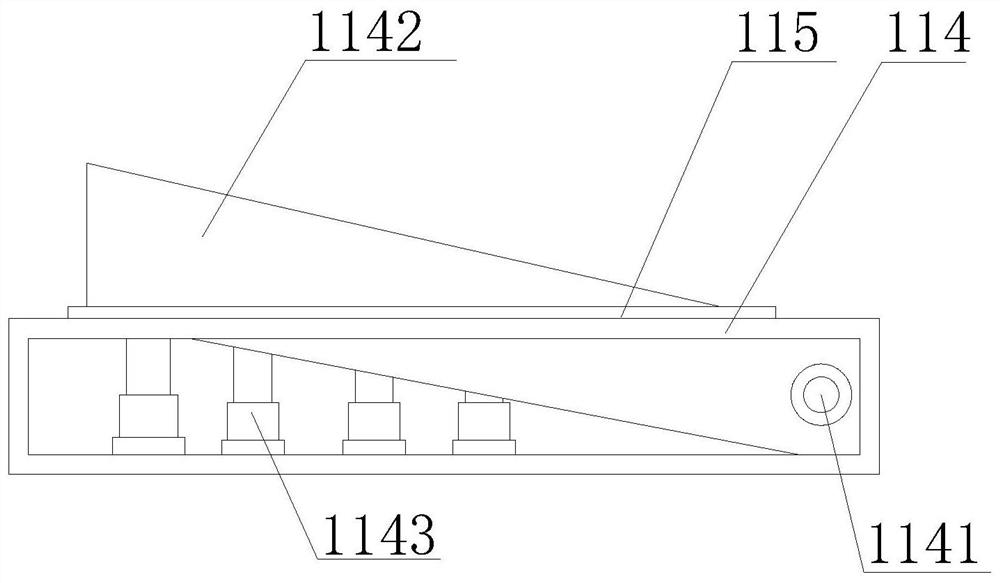

Mixer provided with screening device and used for producing ceramics

InactiveCN104923103AAvoid Insufficient MixingQuality assuranceSievingRotary stirring mixersEngineeringMixing effect

The invention discloses a mixer provided with a screening device and used for producing ceramics. The mixer comprises a mixer body, a circulation material conveying pump and a screening cavity, wherein an oblique discharging pipe is connected to the left end of the upper side of the mixer body, the screening cavity is connected to the top end of the discharging pipe, a feeding funnel is disposed on the upper side of the screening cavity, a screen mesh is obliquely disposed on the middle section inside the screening cavity, and springs are disposed at the left and right ends of the lower side of the screen mesh. The mixer has the advantages that the mixer is small in work noise, two spiral blades rotating reversely are used to mix materials, good mixing effect and high efficiency are achieved, the materials are heated and dried during mixing, the dried materials can be mixed conveniently, mixing effect and work efficiency are increased, the materials at the bottom of the mixer can be pumped into the top in a circulation manner for mixing, insufficient mixing caused by the fact that the materials at the bottom cannot be stirred, and the materials are screened before mixing to guaranteed finished product quality.

Owner:顾马飞

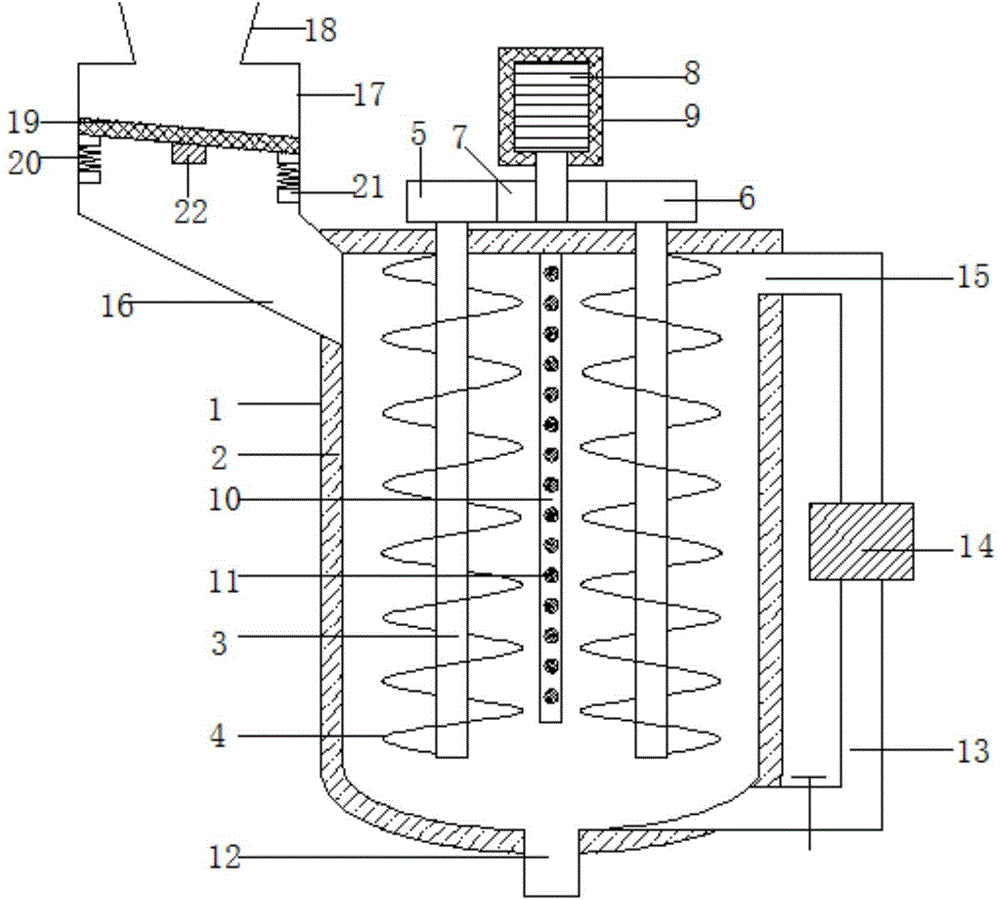

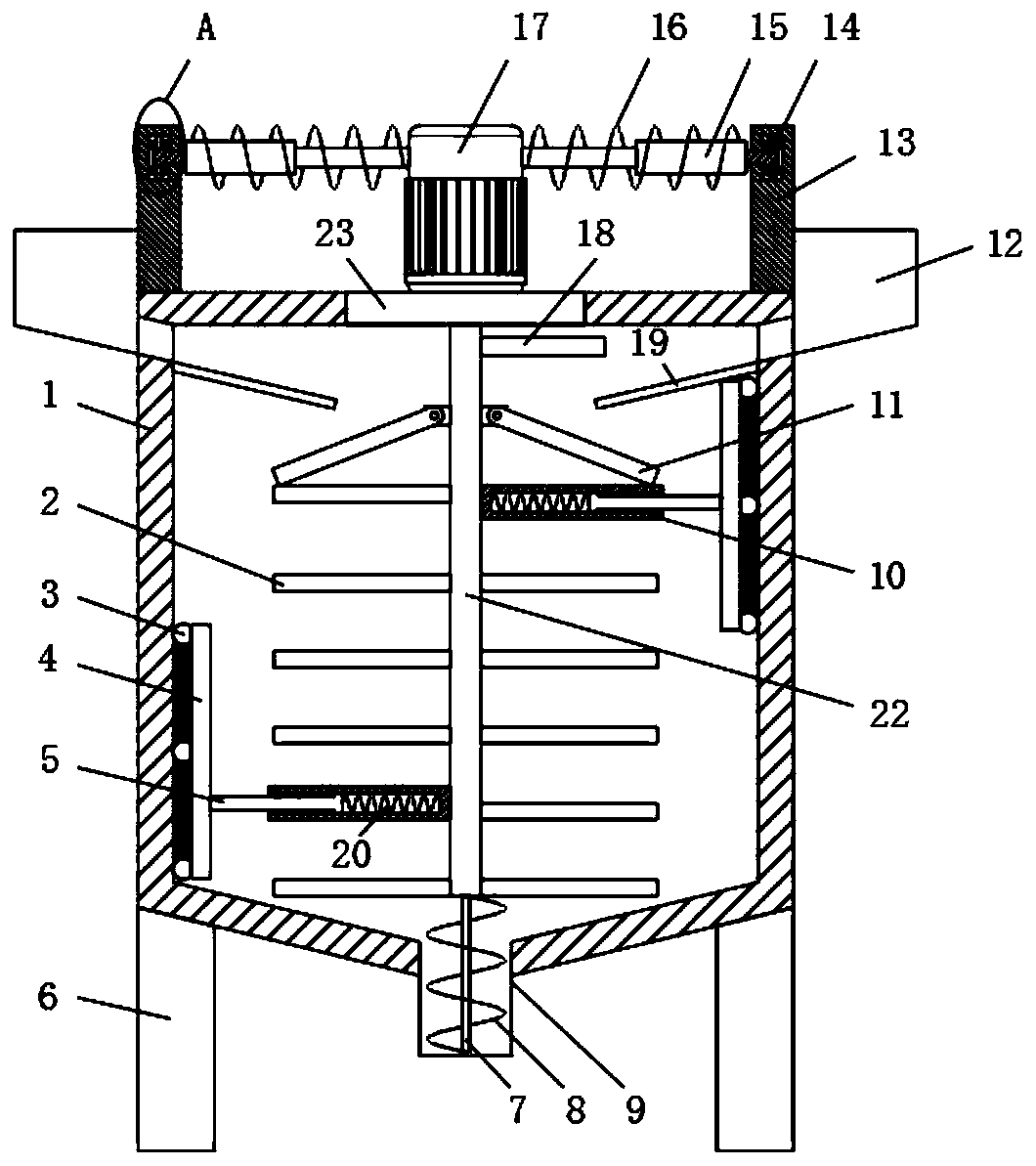

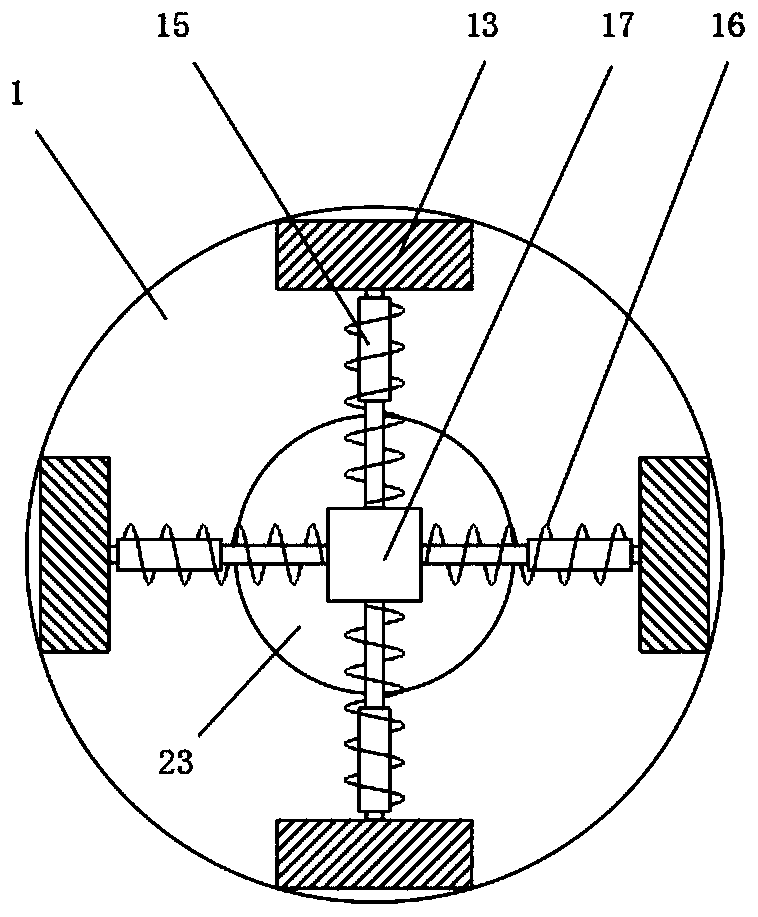

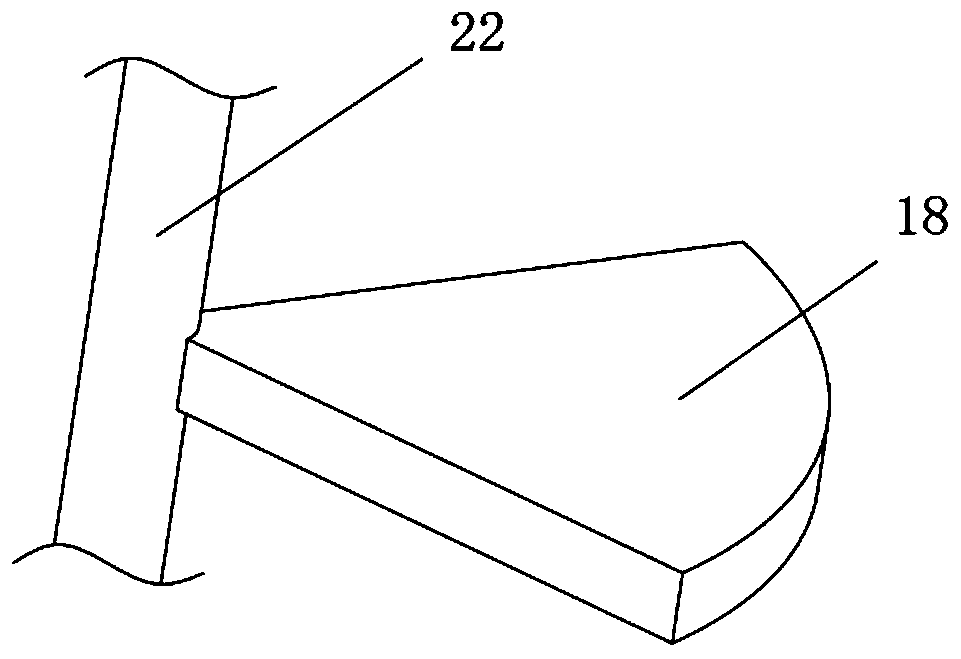

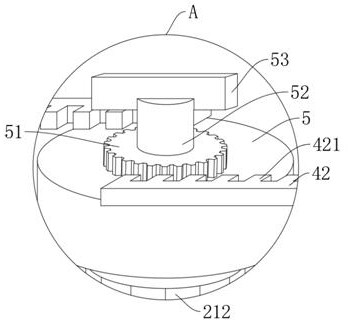

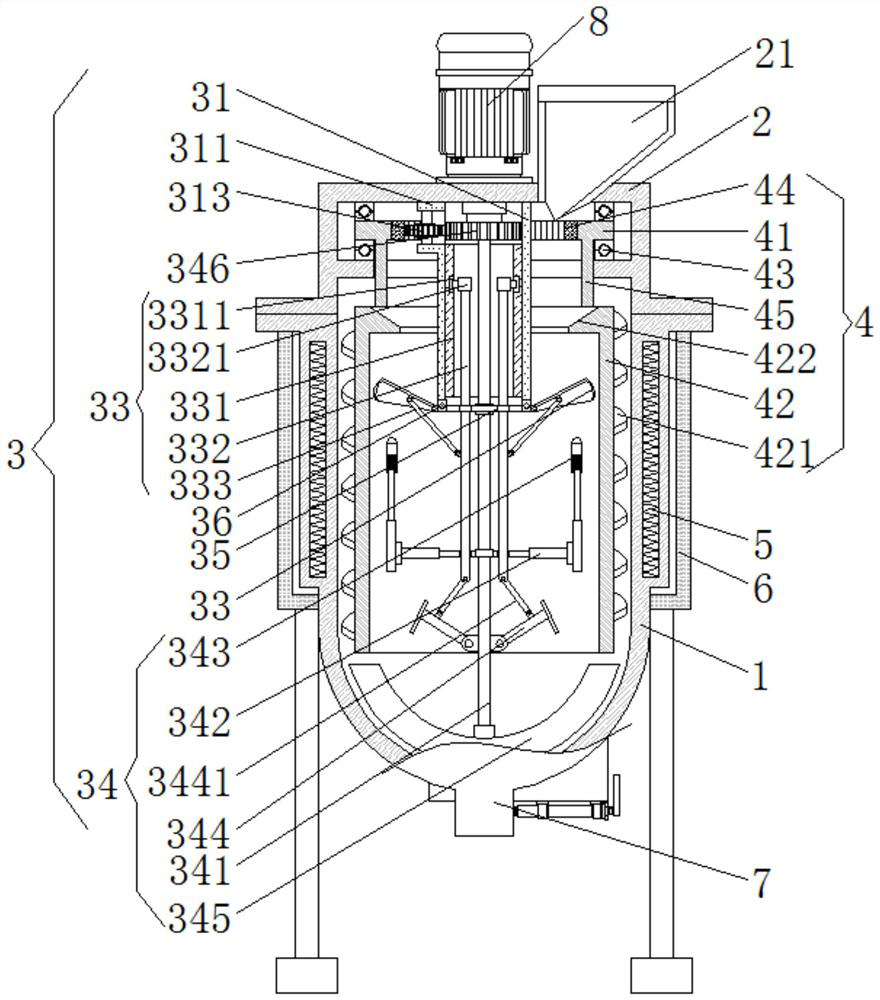

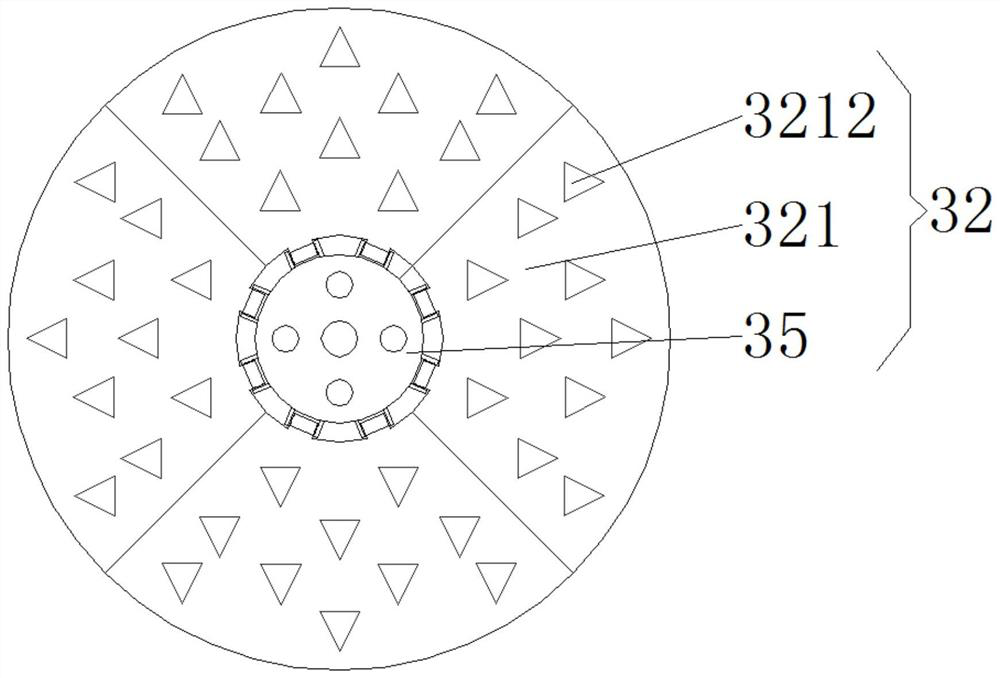

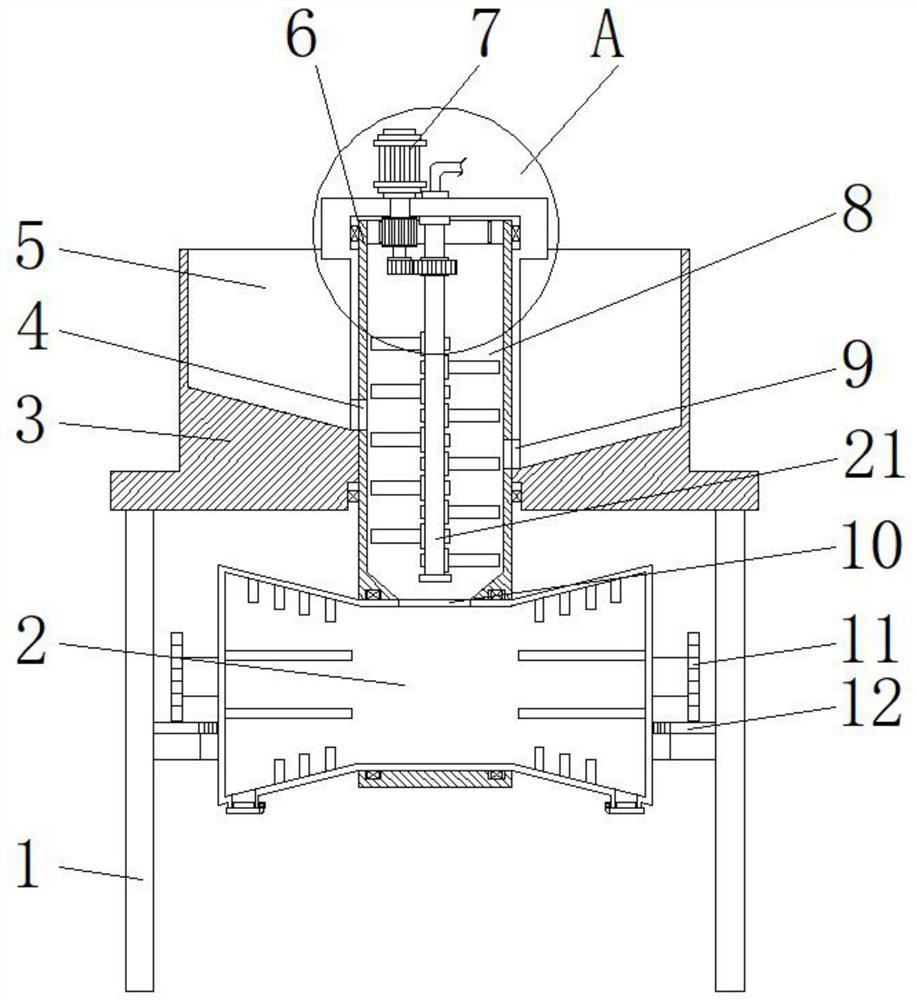

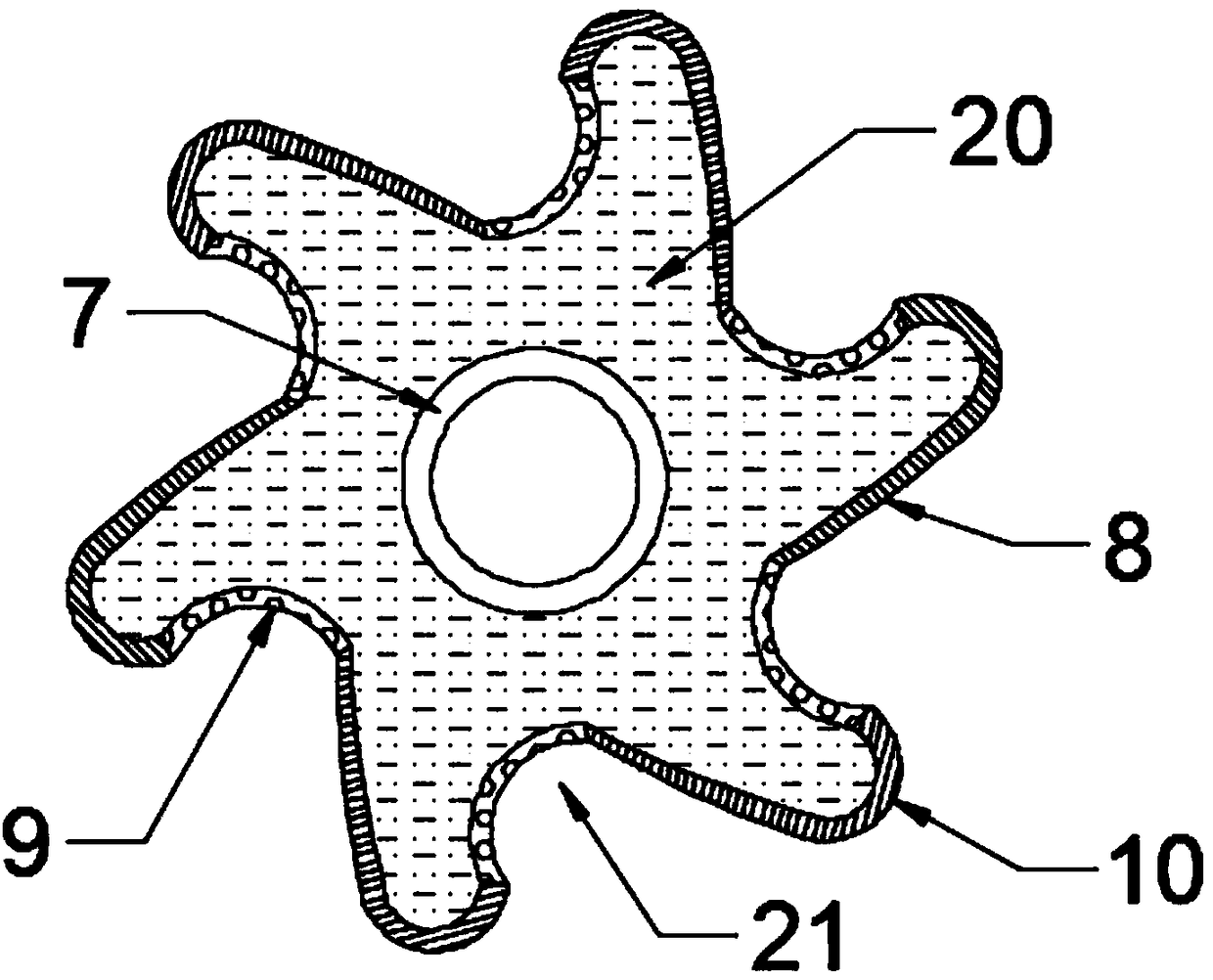

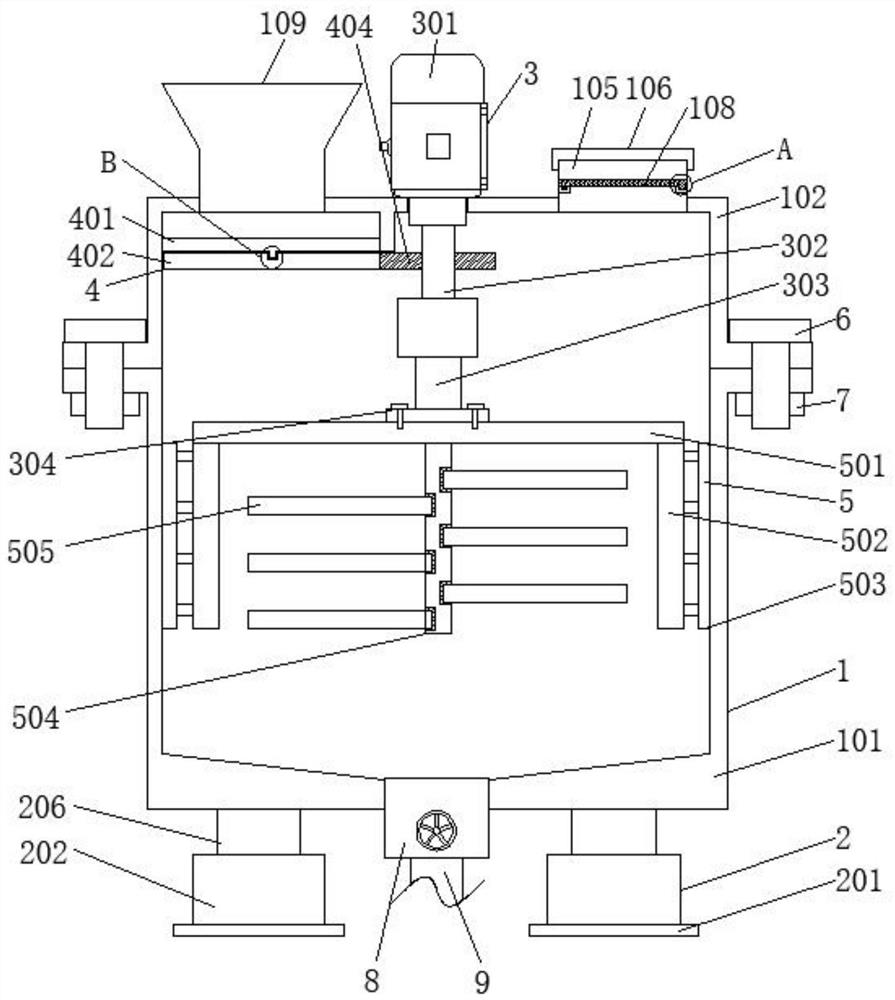

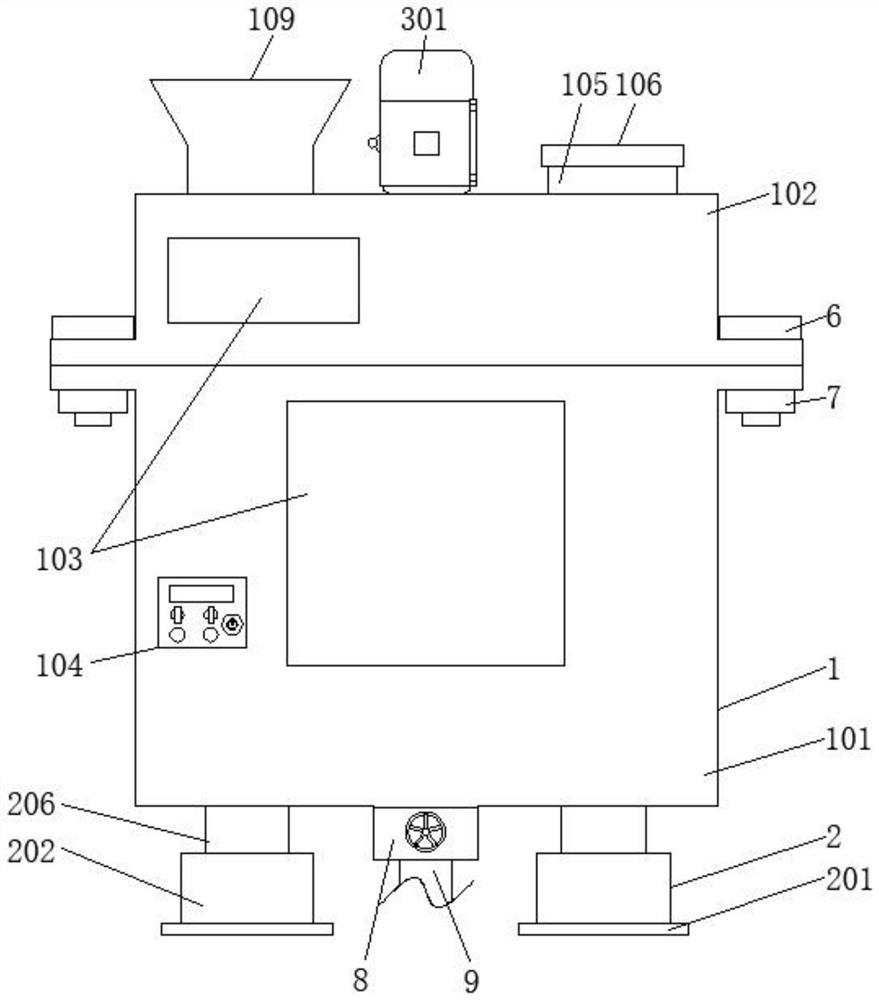

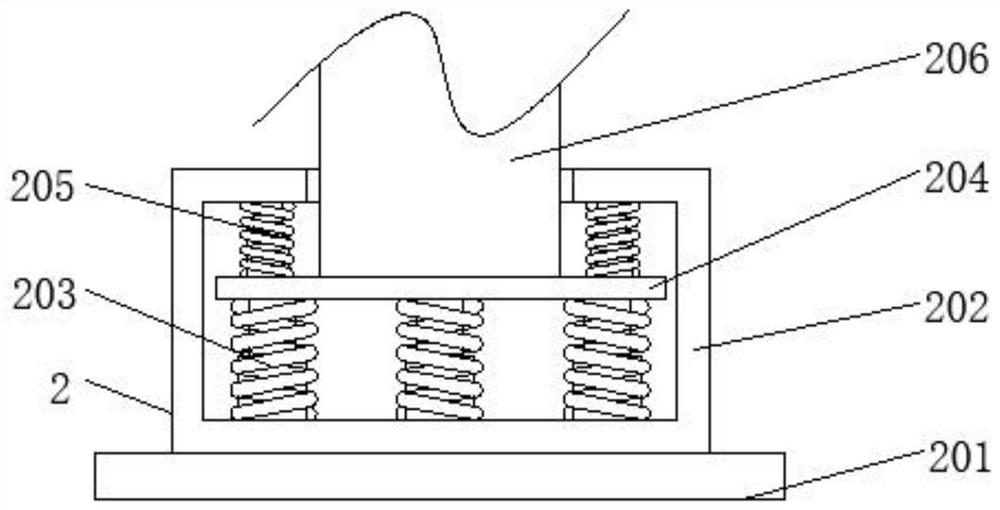

Chemically horizontal vibration reaction kettle

InactiveCN106975433AImprove the mixing effectIncrease stirring radiusShaking/oscillating/vibrating mixersTransportation and packagingCircular discPush pull

The invention discloses a chemically horizontal vibration reaction kettle, which comprises a kettle body, a stirring motor and stirring blades; a plurality of horizontal springs are fixedly arranged on the right side wall of an inner cylinder, and a horizontal push-pull rod is fixedly welded on the left side of the inner cylinder; a driving device consists of a driving motor, a turnplate, a first rotating shaft, a connecting rod and a second rotating shaft; the lower end of an output shaft of the stirring motor is fixedly connected with a vertical stirring shaft, a horizontal disc is fixedly arranged on the upper end and the lower end of the stirring shaft respectively, a vertical slippage rod is inserted into a slippage hole, and a plurality of stirring blades are fixedly arranged on the slippage rod. According to the invention, the arranged slippage rod is far away from the stirring shaft after suffering from centrifugal force, so that the stirring radius can be extended; when the rotating speed of the motor is changed, the centrifugal force suffered by the slippage rod is changed, the distance between the rotating shaft and the slippage rod is also changed, and therefore, the stirring radius is changed in real time, and the mixing effect of materials can be effectively improved.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

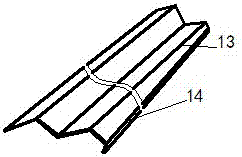

Exhaust gas-treating device

ActiveUS8596044B2Improve homogenizationSpeed up evaporationInternal combustion piston enginesSilencing apparatusInterior spaceExhaust fumes

An exhaust gas-treating device (1) for an exhaust system of an internal combustion engine, especially of a motor vehicle, is provided with a housing (2), which has a jacket (3) extending circumferentially on the side and at least one bottom (4). The homogenization of the exhaust gas flow is improved with a mixing housing (14), which is arranged in the interior space (23) of the housing (2) and which has a mixing chamber (15). An inlet (16) of the mixing housing passes through the bottom (4) and communicates with the mixing chamber (15). An outlet (17) of the mixing housing passes through the bottom (4) and communicates with the mixing chamber (15).

Owner:VOLVO LASTVAGNAR AB +1

Concrete mixing device capable of preventing adhesion of inner wall of stirring barrel

InactiveCN107351249AAvoid stickingAct as a vibrationCement mixing apparatusArchitectural engineeringDrive motor

The invention discloses a concrete mixing device capable of preventing the inner wall of a mixing tank from sticking, comprising a machine table, a screw rod, a guide slide bar, a mixing tank, a driving motor, a beating device, a worm, a worm wheel, a stirring shaft and a stirring blade. The upper end of the rotating shaft is connected with a screw rod through a coupling, and a guide slide bar is fixedly installed on the machine table. This device can use the hitting ball to hit the outer wall of the mixing tank to play a vibration effect and prevent the concrete from breaking out during the mixing process. Adhesion to the inner wall; at the same time, set the crankshaft A and crankshaft B in the opposite state, so as to achieve the intermittent impact on the left and right sides of the mixing tank, so that the vibration effect is the best; you can also use the threaded fit between the screw rod and the mounting ear to pass through the guide slider The position-limiting and guiding effect makes the mixing barrel move up and down, so that the stirring range of the stirring blade on the stirring shaft is increased, and the phenomenon of insufficient stirring at the bottom of the mixing barrel is avoided.

Owner:陈婷

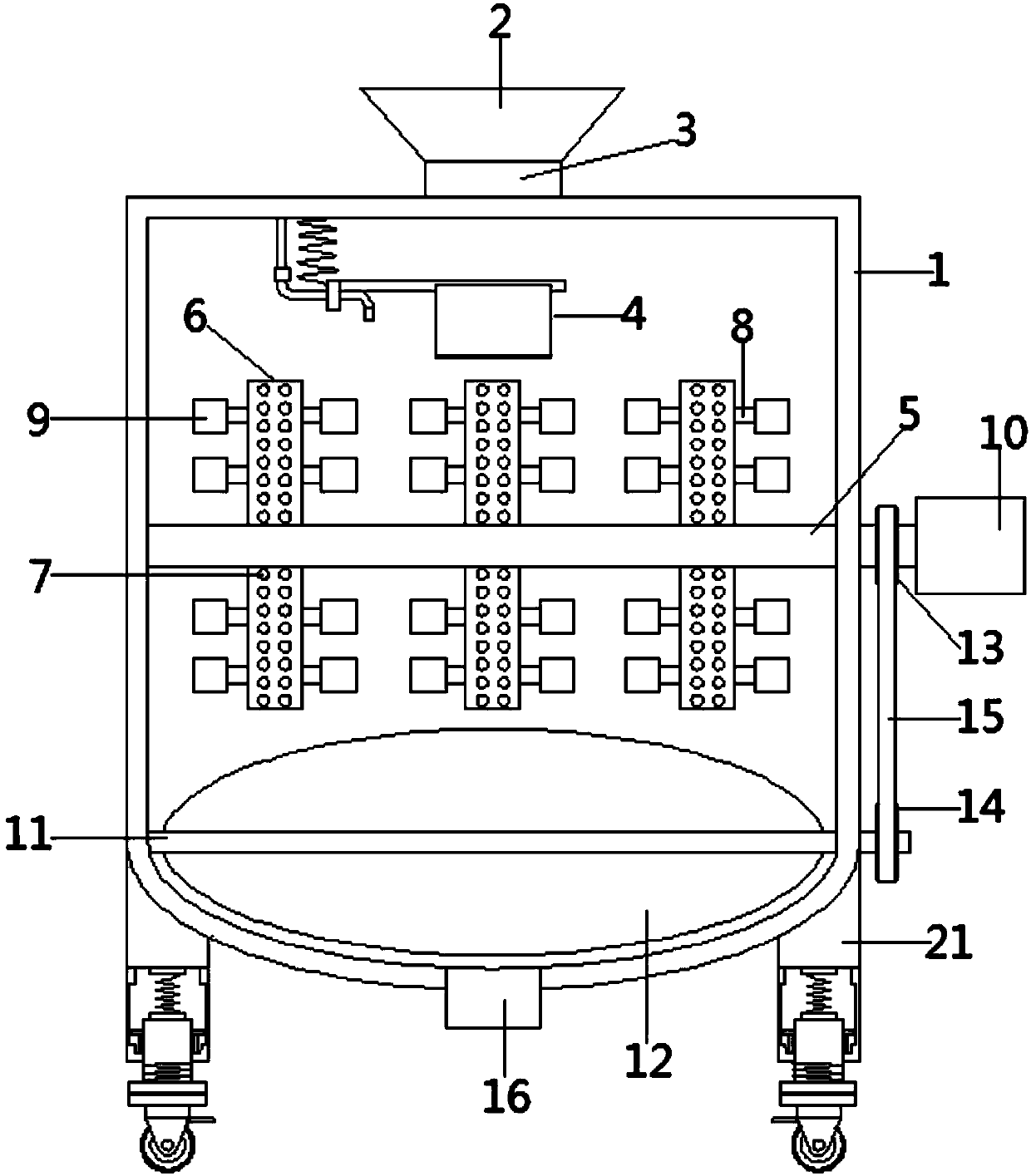

Stirring and mixing device for chemical fertilizer production

InactiveCN107583548AGood mixing effectImprove efficiencyShaking/oscillating/vibrating mixersMixer accessoriesFertilizerSieve

The invention discloses a stirring and mixing device for chemical fertilizer production. The device comprises a machine body, wherein a feeding hopper is arranged in the middle of the upper side of the machine body, the bottom end of the feeding hopper is connected with a feeding port in the upper side of the machine body through a vibrating sieve, a fertilizer additive scattering device is arranged on the upper side in the machine body and comprises a fixed pipe, an elastic pipe, a nozzle, an elastomer and a swing mechanism, and one end of the fixed pipe is connected with the elastic pipe. The stirring and mixing device for chemical fertilizer production can sufficiently stir and mix fertilizer and a fertilizer additive, and the fertilizer mixing efficiency is effectively improved; a stirring mechanism and a turning mechanism are used for stirring and mixing the fertilizer, sufficient and uniform mixing is guaranteed, the stirring mechanism and the turning mechanism are driven by onemotor, and accordingly, energy consumption is effectively reduced. Besides, the stirring and mixing device can be conveniently moved and fixed, effective damping can be realized, and the work stability of the device is improved.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

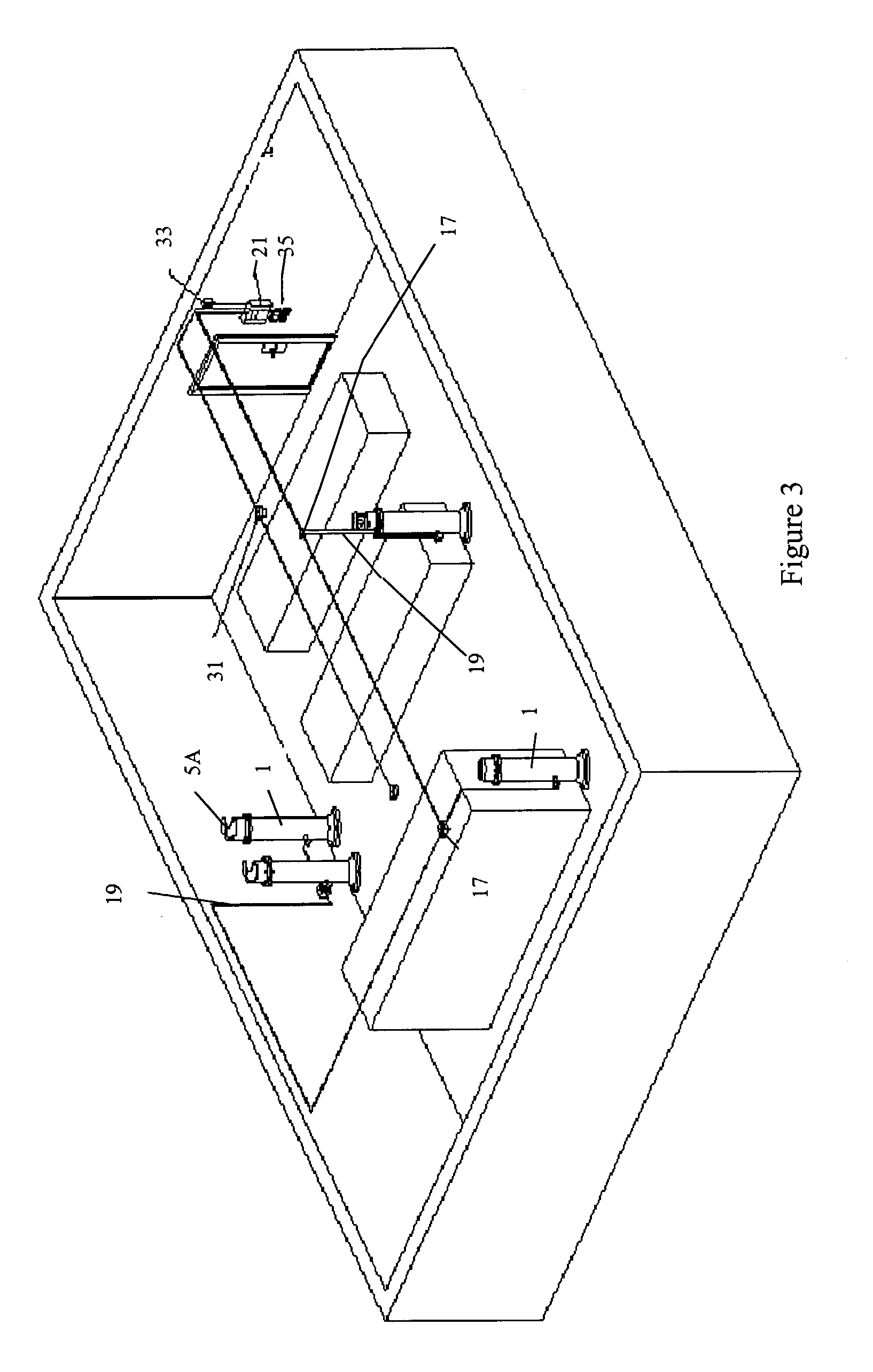

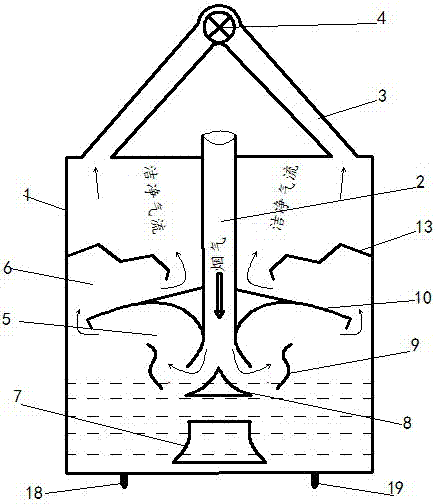

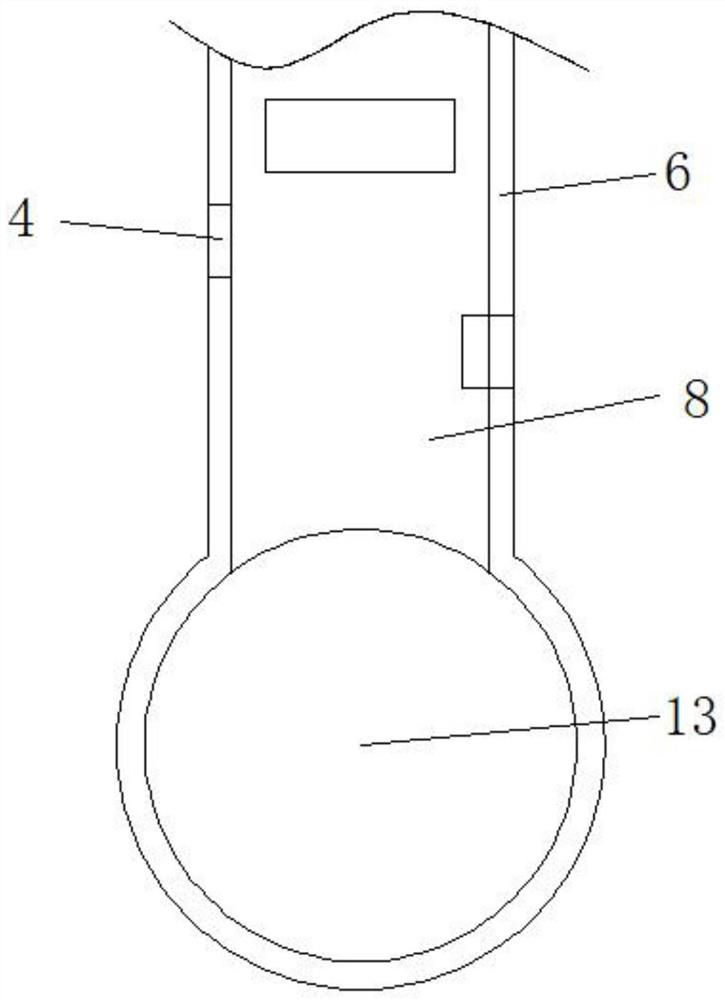

Gas-liquid entrainment mixing apparatus and method

ActiveCN107081044AAvoid inadequate mixingWell mixedGas treatmentUsing liquid separation agentFluid phaseEngineering

The invention relates to a gas-liquid entrainment mixing apparatus and method. The invention relates to an apparatus and a method for physically mixing smoke and purified liquid, which solves the problems in a gas-liquid contact way that the airflow impacts the liquid surface that the gas and liquid are insufficiently mixed due to the intermittent and paroxysmal stimulation of the purified liquid trapping body. When the airflow impacts the liquid surface, the stability of the liquid surface of the purified liquid is adjusted by virtue of a liquid phase flow stabilizing apparatus and a two-phase flow guide apparatus, the high-frequency stimulation of the purified liquid trapping body is adjusted by virtue of the gaseous distributing and pressurizing apparatus and the two-phase flow guide apparatus, a gas-liquid mixing space is controlled by virtue of an entrainment cavity and the two-phase flow guide apparatus, the gas-liquid entrainment and mixing effect is improved, finally the gas and liquid in a purification cavity can be sufficiently mixed, harmful components in the harmful gas can contact with the purified liquid sufficiently, the leakage probability of the harmful components can be reduced, and the purification efficiency can be improved.

Owner:天津矿嘉科技有限公司

Angular flow distribution bottom head

ActiveUS20050255009A1Well mixedSimple methodOrganic chemistryOrganic compound preparationFluidized bedEngineering

An improved angled annular deflector for angular flow distribution in a fluidized bed polymerization reactor The angled annular deflector has an outer surface with a conical shape and an inner cavity along a central axis, said cavity open at both ends. The angled annular deflector being adapted to associate with a cone-shaped bottom portion of a fluidized bed polymerization reactor vessel and when in said association the outer surface of said angled annular deflector is at an angle to be substantially parallel to an inner wall of the cone-shaped bottom portion. This combination leads to increased optimization of fluid flow.

Owner:UNIVATION TECH LLC

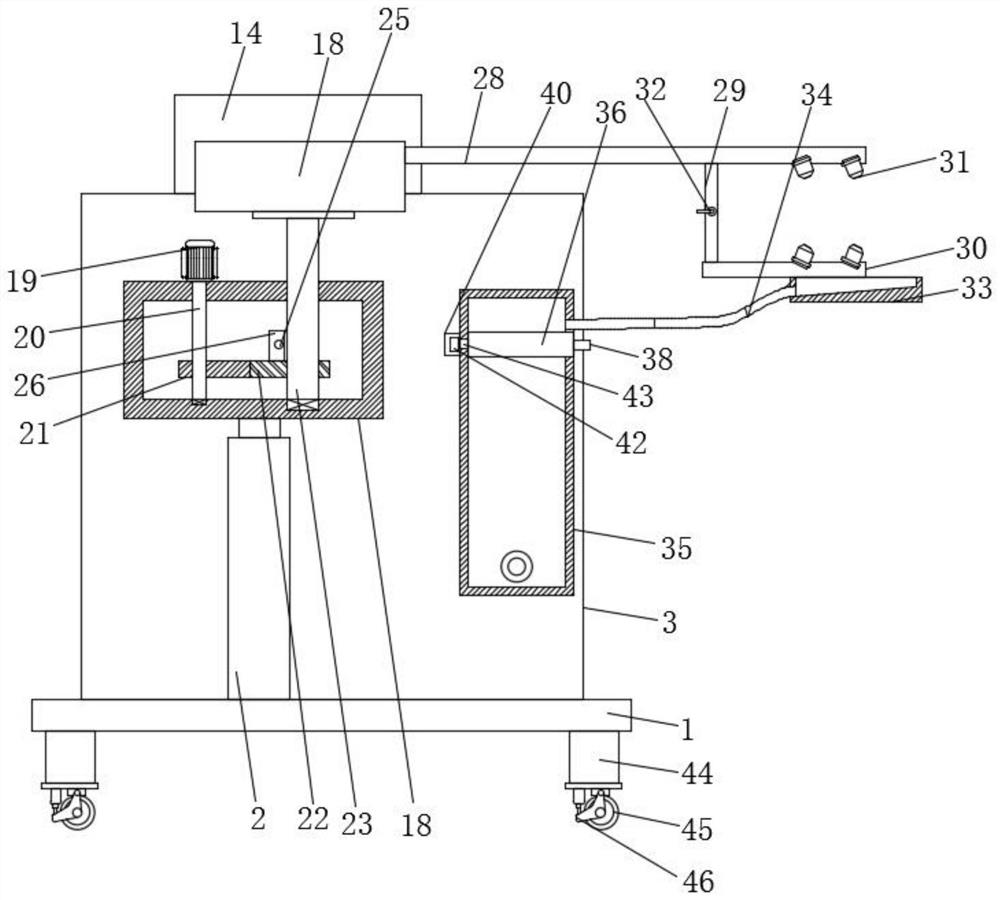

Efficient stirring device for organic compound biofertilizer and use method

PendingCN107684855AAvoid stickingDissolve fastRotary stirring mixersTransportation and packagingAgricultural engineeringOrganic compound

The invention discloses an efficient stirring device for an organic compound biofertilizer and a use method and relates to a stirring device. A rotating motor (34) is arranged in the middle of a bottom plate (35); a rotating rod (26) is arranged at the upper end of the rotating motor; a plurality of vertical plates (32) are arranged on the upper surface of the bottom plate at the bottom of the rotating rod (26); uprights (33) matched with a bucket body (5) are arranged at the upper parts of the outer ends of the vertical plates; a plurality of side rods (30) are sequentially arranged on the inner side faces of the uprights; and motors (29) are arranged at the front ends of the side rods (30) on the inner side faces of the uprights (33). The device can achieve quick and convenient fertilizer stirring for people, greatly improves stirring efficiency of the fertilizer, allows the fertilizer to be stirred more sufficiently and completely, avoids an non-ideal crop fertilization effect caused by nonuniform stirring of the fertilizer and provides powerful guarantee for healthy growth of crops.

Owner:武兴友

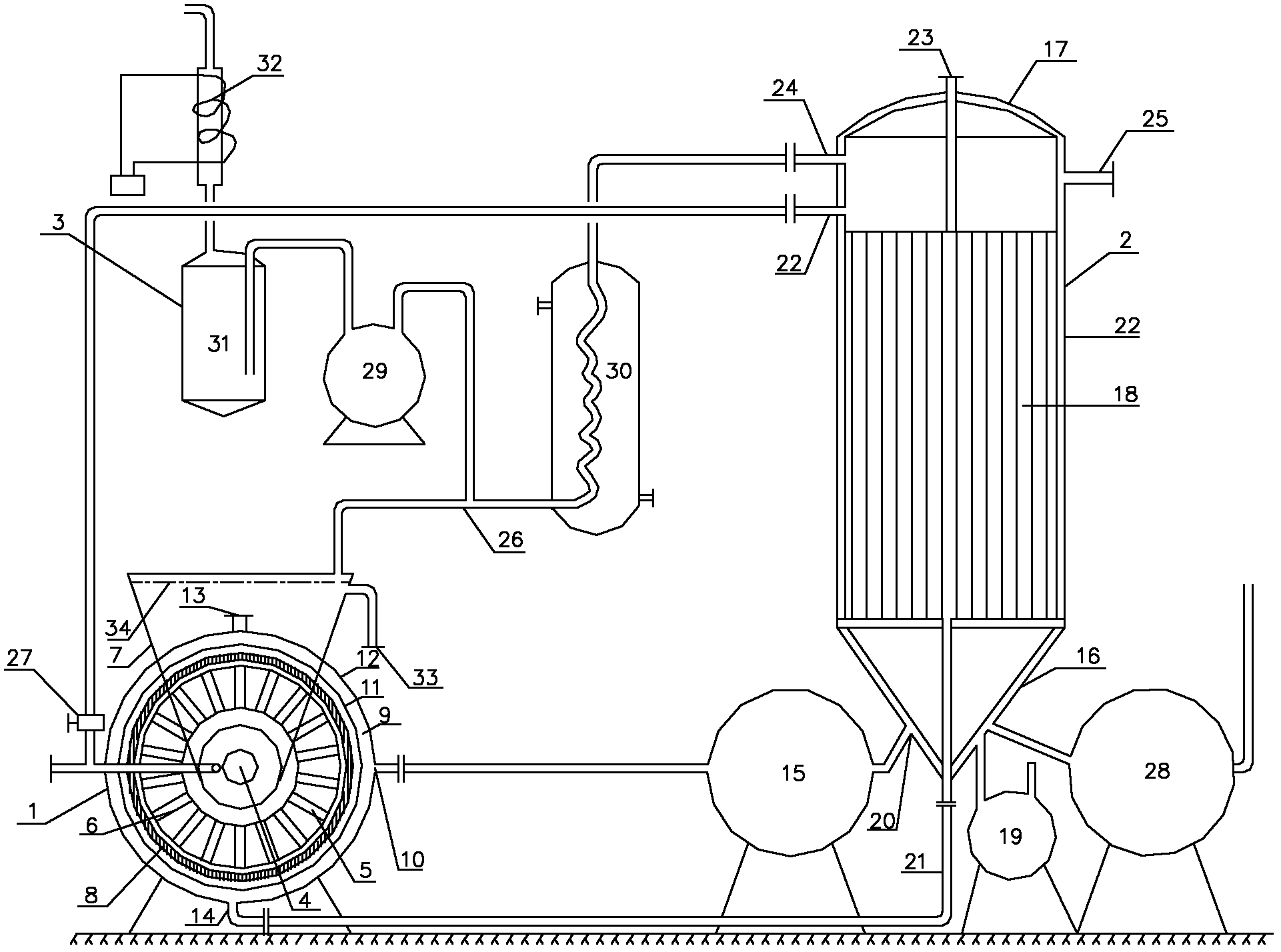

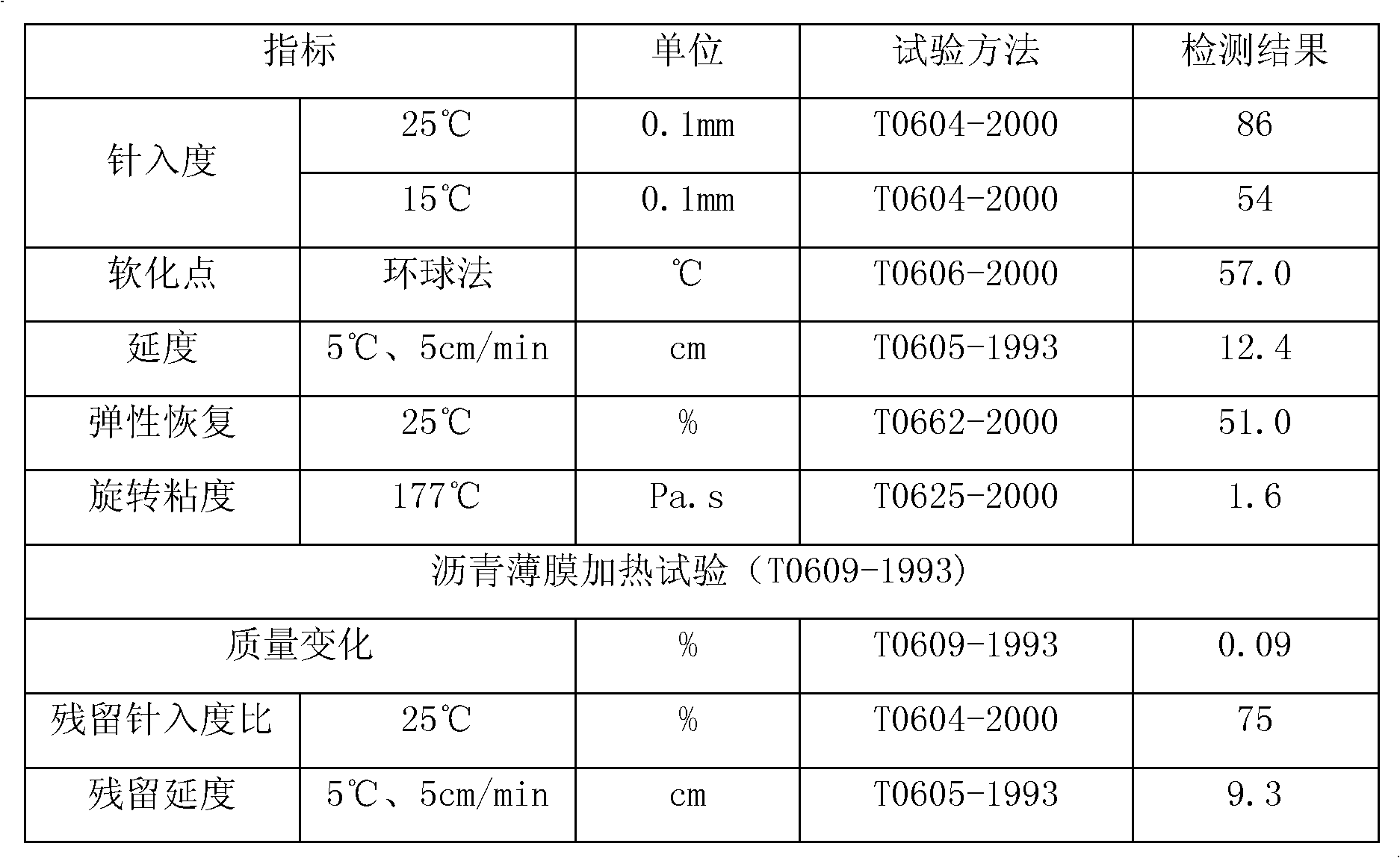

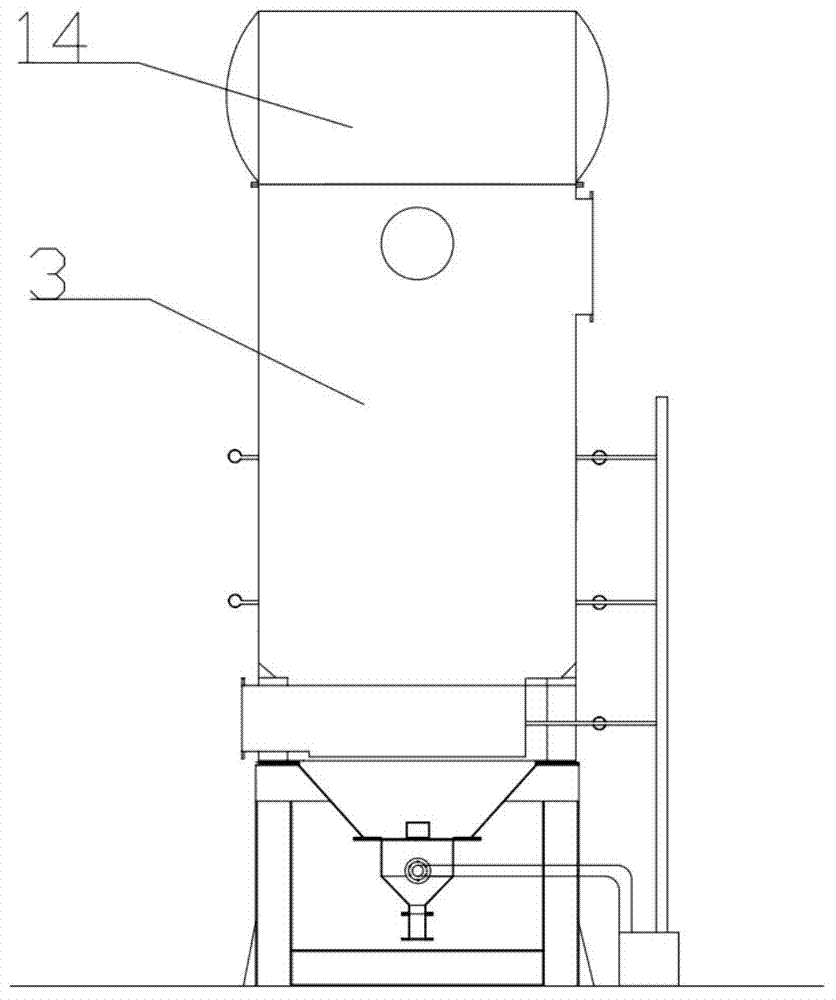

Device for producing modified asphalt and method for producing modified asphalt by using device

InactiveCN102444074AWell mixedViolent reactionRoads maintainenceBuilding insulationsShell and tube heat exchangerEngineering

The invention discloses a device and a synthetic method for producing modified asphalt. The device comprises a mixing device provided with a raw material inlet, wherein the mixing device is communicated with a heat insulation tower; the heat insulation tower is provided with a mixture inlet and a discharge hole, the mixture inlet is formed on the lower part of the heat insulation tower, and the discharge hole is formed on the upper part of the heat insulation tower; and matrix asphalt and modifier are fully mixed and delivered to the heat insulation tower for synthesizing, fluid flows through gaps of shell and tube heat exchangers from bottom to top to exchange heat in a large area, and the mixture follows rise of the fluid level and relative motion of the shell and tube heat exchangers, so that the flowability of the mixture is ensured, and the mixture is heated more uniformly and fully.

Owner:剑阁正能科技有限公司

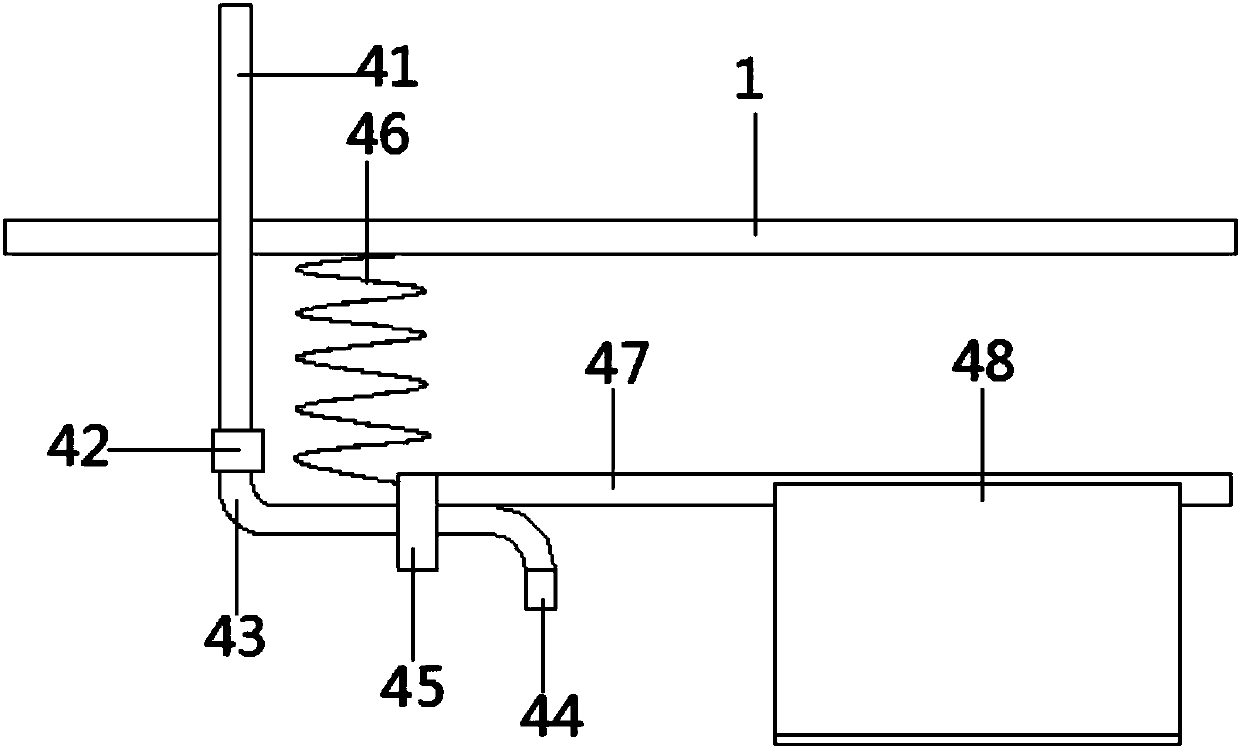

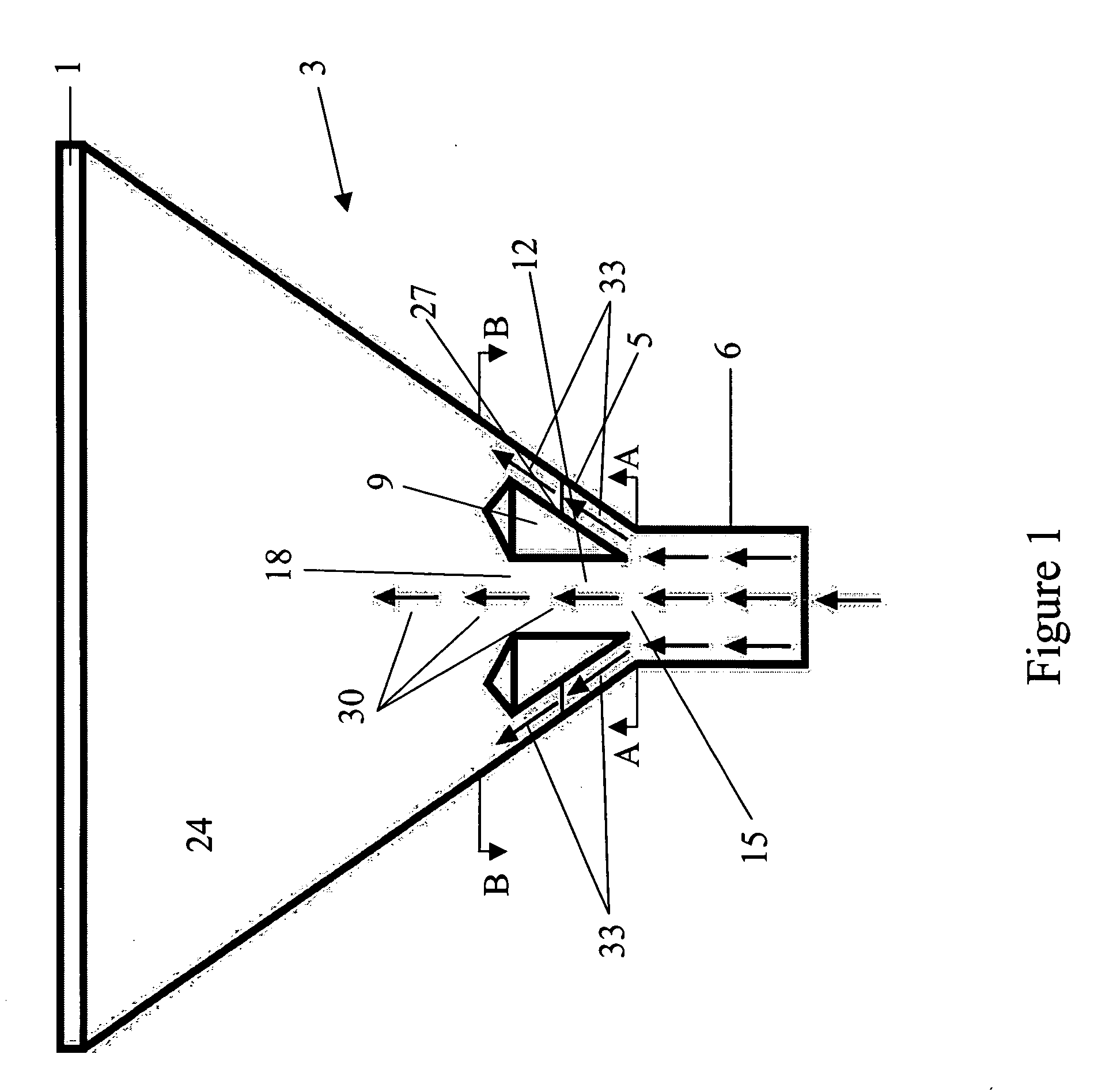

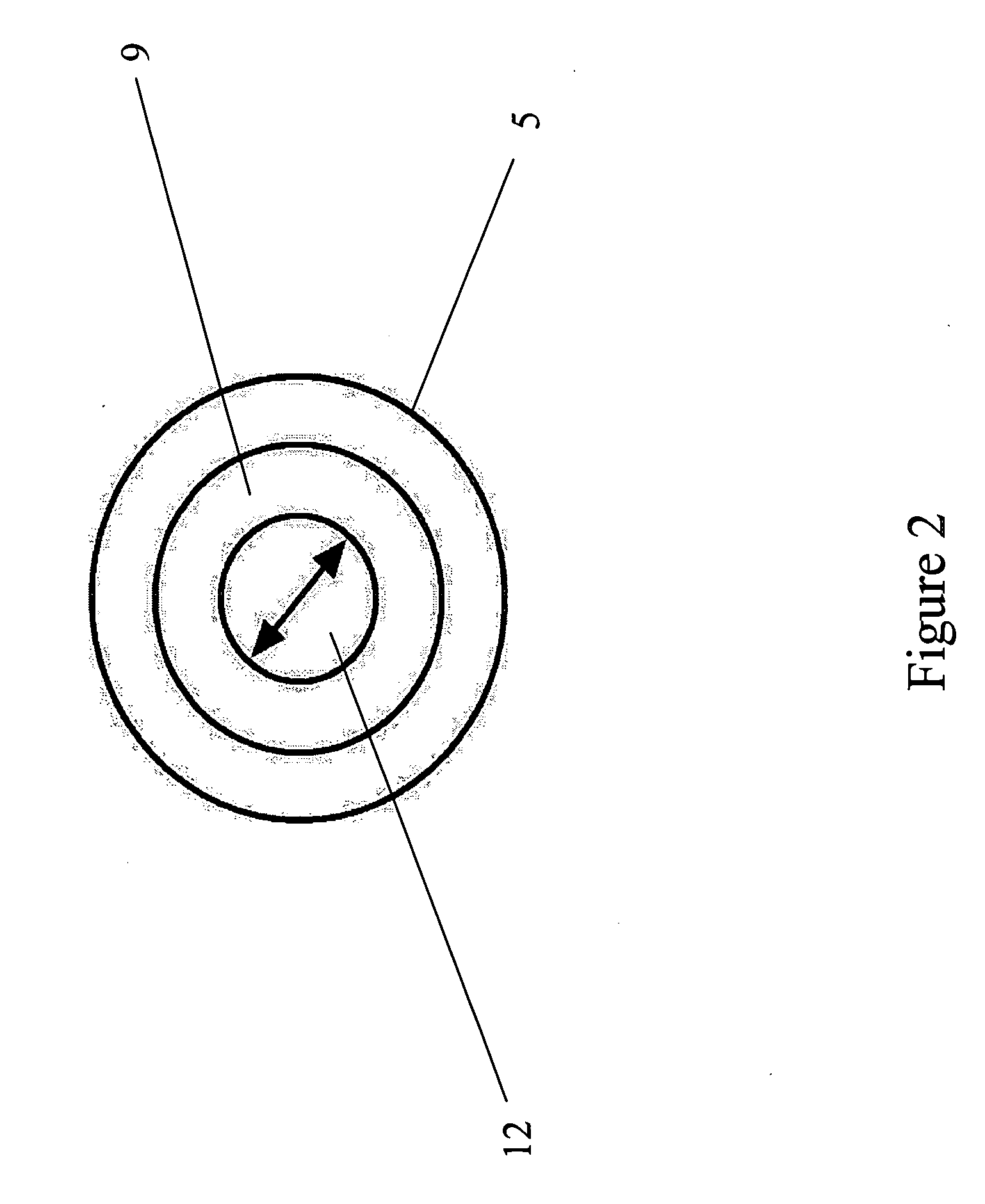

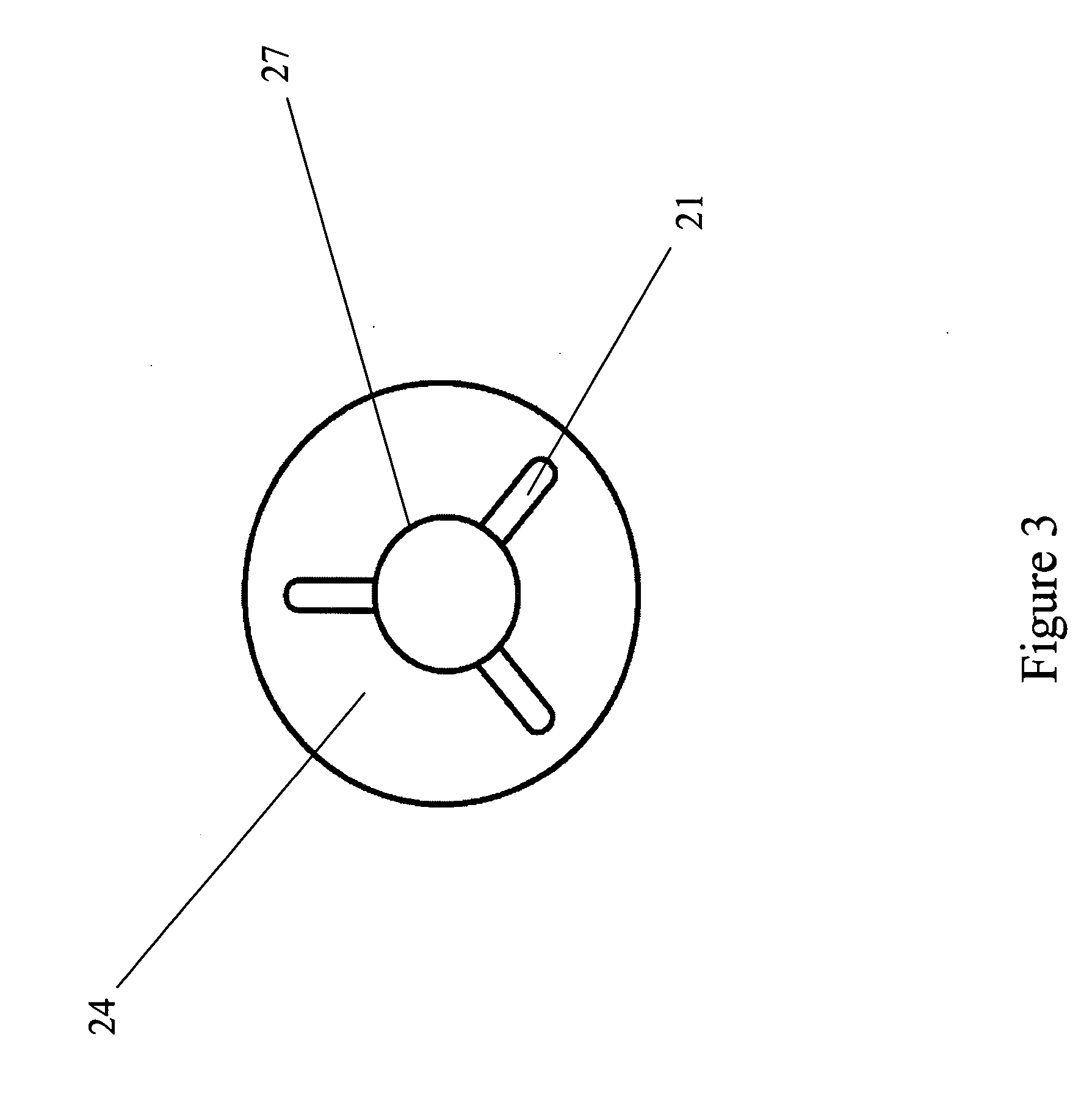

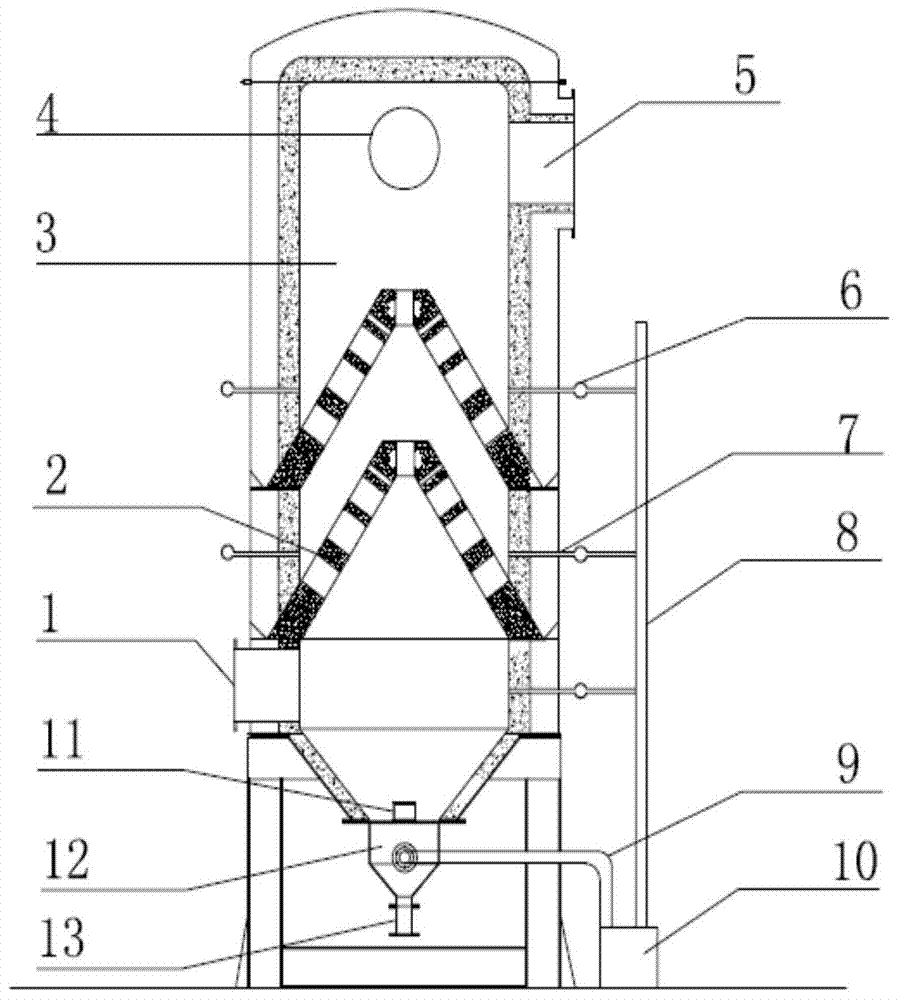

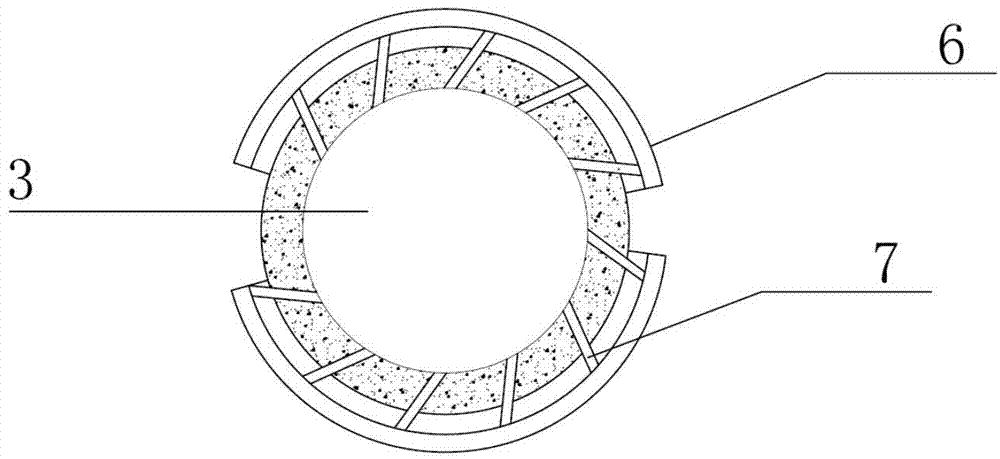

Regenerative combustion device applicable to stable combustion of compounded tangent-flow and direct-flow gas with low calorific value

InactiveCN103868055AAchieve efficient and stable combustionIncreased fluid mixingNon-combustible gases/liquids supplyProcess engineeringHeat supply

The invention relates to the clean utilization field of gas and relates to a device applicable to combustion of gas with the low calorific value. The device comprises a combustion tower (3), a gas inlet (1), a smoke outlet (5), a primary air pipe (9) which is communicated with an air chamber (12), an ignition hole (11), a secondary air pipe (8) and a combustion stabilizing cone (2), wherein the secondary air pipe (8) is connected with a plurality of branch gas pipes (7) through multistage of annular distributors (6); the branch gas pipes (7) are tangentially communicated with the inside of the combustion tower (3); the combustion stabilizing cone (2) is cone-shaped or frustum-shaped and arranged above the gas inlet (1) in the combustion tower (3); a plurality of channels are evenly formed in the wall surface of the combustion stabilizing cone. The device is capable of reducing heat needed by igniting the gas with the low calorific value in a hierarchical air supply manner, increasing the ignition heat supply through a multi-channel regenerative combustion stabilizing cone, facilitating the mixing of the compounded tangent-flow and direct-flow gas and the air in a manner of compounding tangent flows and direct flows, so that the efficient and stable combustion of the gas with the low calorific value is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

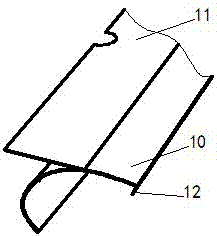

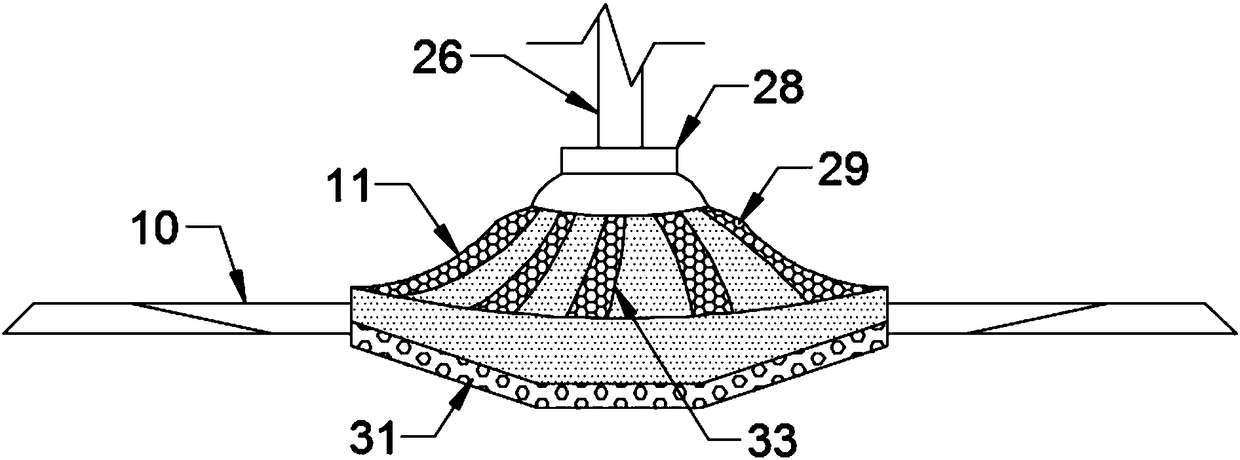

Pesticide spraying device for corn disease and pest control

ActiveCN114097753AEasy dischargeAvoid inadequate mixingSpraying apparatusInsect catchers and killersAgricultural scienceSprayer

The invention relates to the technical field of corn disease and pest control, and discloses a pesticide spraying device for corn disease and pest control. A first fixing block extrudes a reset spring and slides on the surface of a limiting strip, so that the problems that manual pesticide spraying operation is mostly carried out by workers, the labor intensity is high, the spraying efficiency is low, meanwhile, the corn plants cannot be uniformly sprayed, and the labor intensity is high are solved. Therefore, many plants cannot obtain reasonable pesticide spraying, and normal growth of the corn plants is influenced; the front face and the back face of a corn leaf are sprayed with pesticide at the same time through the double-face pesticide spraying device, the problems that an existing electric sprayer cannot conduct pesticide spraying on the front face and the back face of the leaf at the same time, consequently, the working efficiency is reduced, and during independent use, a switch valve is used for blocking conveying of pesticide liquid in a short pipe, and independent pesticide spraying can be conducted are avoided.

Owner:唐山市食品药品综合检验检测中心

Feed stirring device for poultry breeding

InactiveCN111036127AStir wellAvoid inadequate mixingShaking/oscillating/vibrating mixersFeeding-stuffAnimal scienceElectric machinery

Owner:郭娟

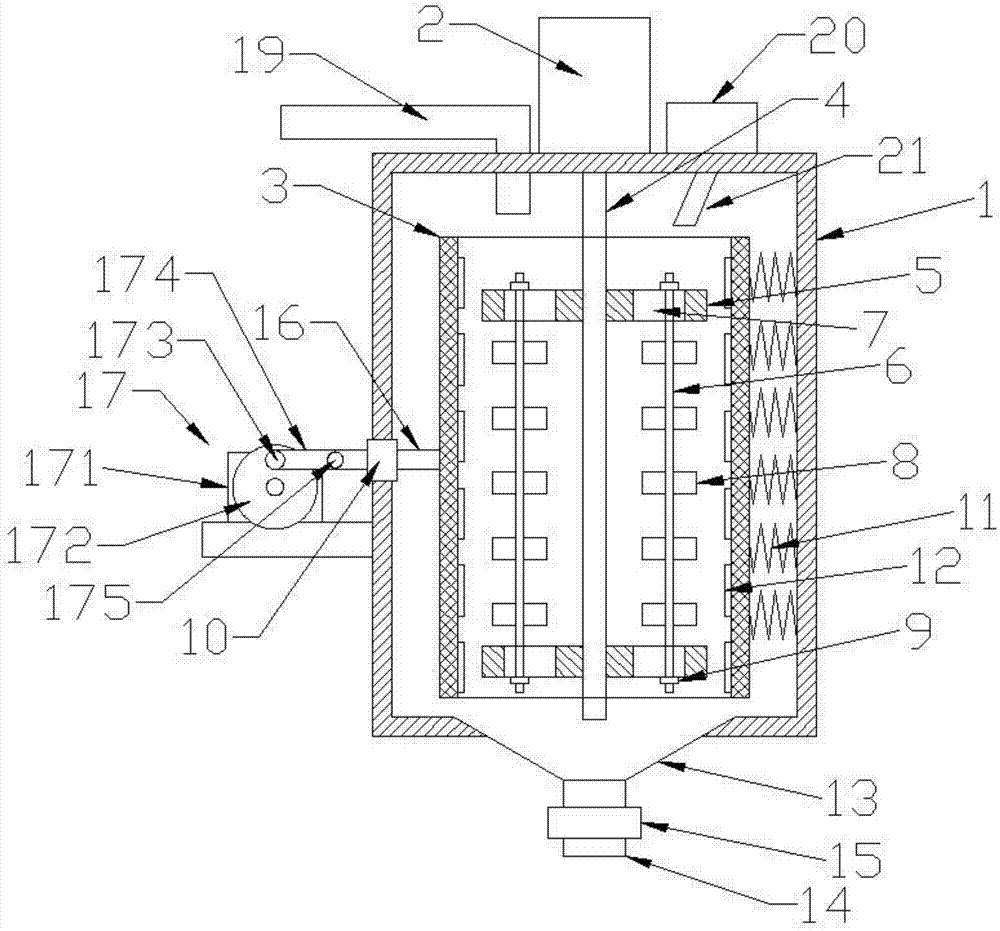

Batching device for fertilizer production

InactiveCN111744420AWell mixedAvoid Inadequate MixingTransportation and packagingMixer accessoriesElectric machineAgricultural engineering

The invention discloses a batching device for fertilizer production. The batching device comprises a shell; a stirring groove and an empty groove are formed in the shell; a partition plate is fixedlyarranged between the stirring groove and the empty groove; symmetrical first connecting blocks are fixedly arranged on the side wall of the empty groove; a first motor is fixedly arranged between thetwo first connecting blocks; a pin shaft is fixedly arranged at the top end of the first motor; the top end of the pin shaft penetrates through the partition plate and is fixedly connected with a rotating disc; a plurality of stirring rods distributed in an annular array are fixedly arranged on the top surface of the rotating disc; a top part and mutually symmetrical connecting pipes are embeddedin the middle of the top surface of the shell; the two connecting pipes are symmetrical with each other relative to the top part; a discharging channel is formed in each connecting pipe; and batchingbarrels are fixedly connected to the top ends of the connecting pipes. According to the batching device of the invention, the pin shaft is fixedly arranged at the top end of the first motor, the top end of the pin shaft penetrates through the partition plate and is fixedly connected with the rotating disc; and the plurality of stirring rods distributed in an annular array mode are fixedly arrangedon the top surface of the rotating disc, so that the device can mix ingredients more sufficiently.

Owner:安徽天河生物科技有限公司

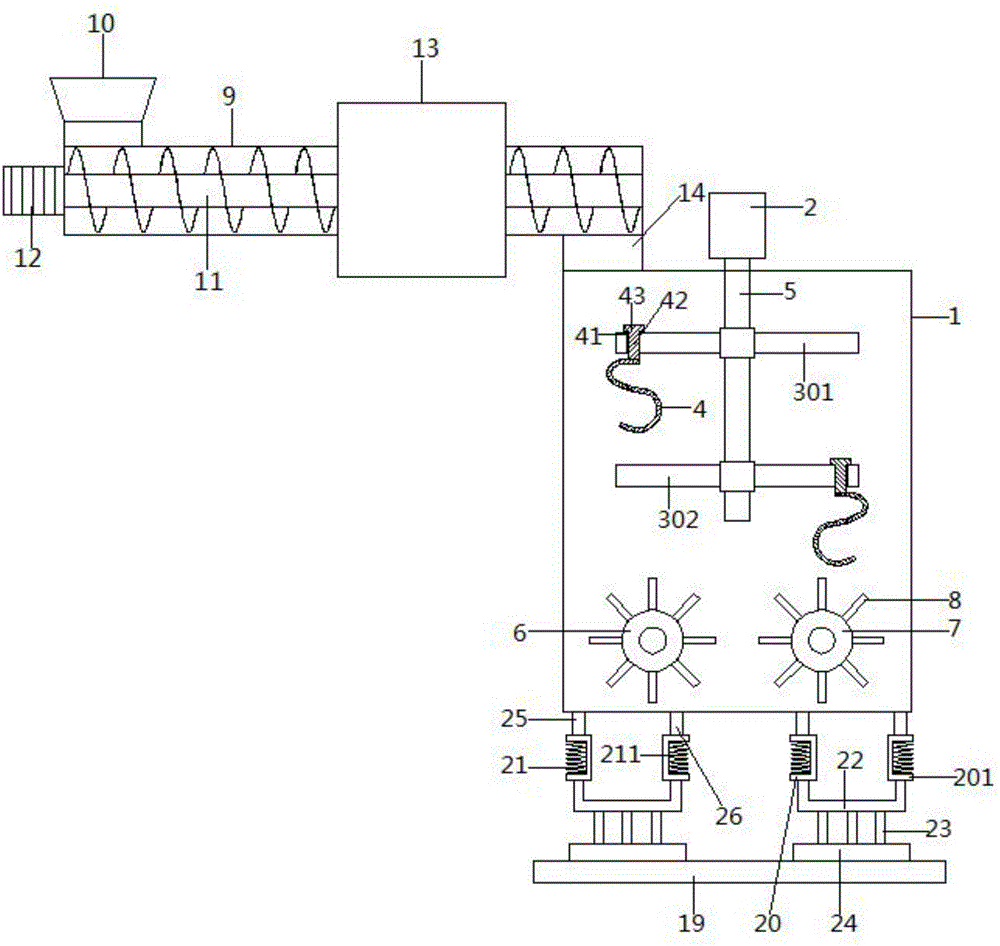

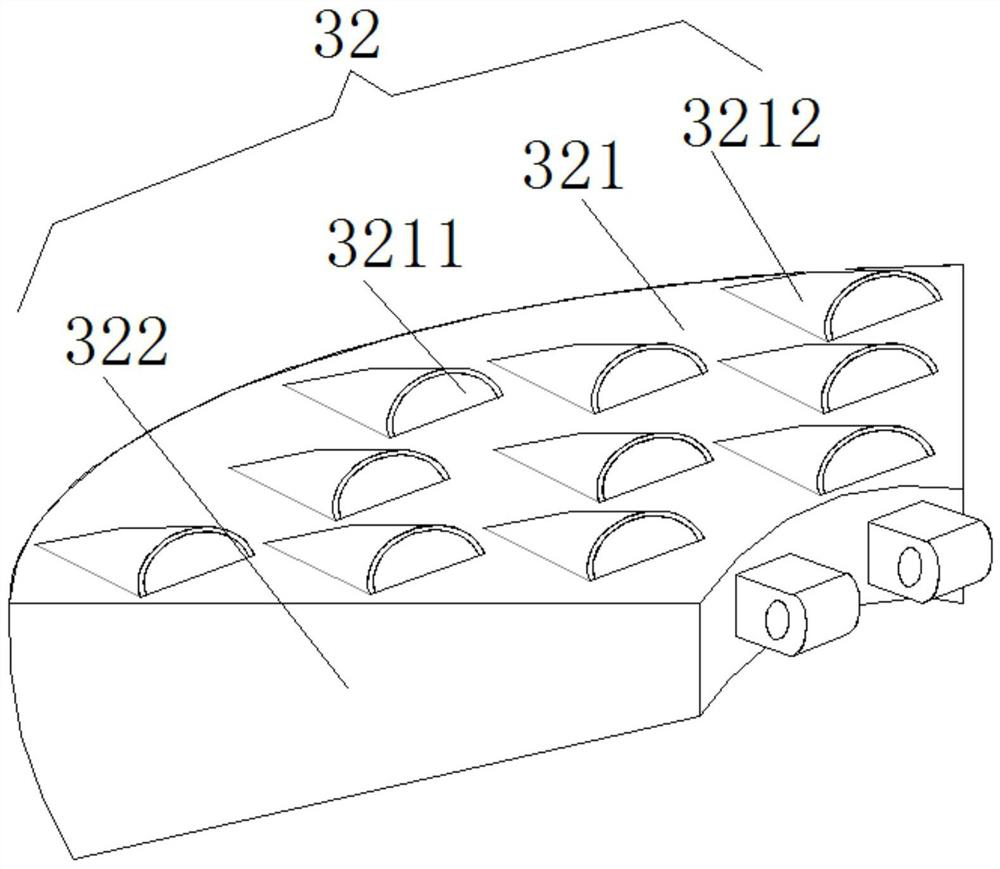

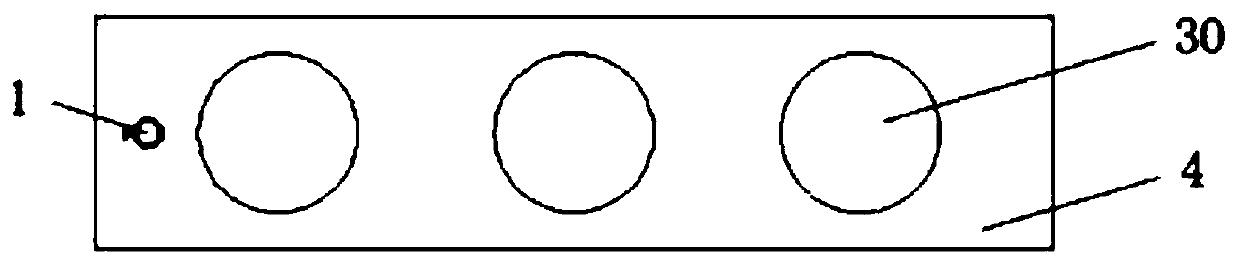

Mixing device with damping bracket for plastic production

InactiveCN106626136AReduce workloadExtended service lifeNon-rotating vibration suppressionGrain treatmentsEngineeringMechanical engineering

The invention discloses a mixing device with a damping bracket for plastic production. The mixing device comprises a body, wherein a feeding cylinder is arranged on the upper side of the body; a feeding mechanism is arranged in the feeding cylinder and comprises a feeding screw and a screw blade arranged on the outer wall of the feeding screw; and a pre-crushing mechanism is arranged on a right section of the feeding cylinder and comprises four semispherical grooves symmetrically formed in the outer wall of the feeding cylinder, rolling cutting rotary shafts arranged at the centers of the semispherical grooves and rolling cutting blades arranged on the outer walls of the rolling cutting rotary shafts. The mixing device with a damping bracket for plastic production disclosed by the invention can realize automatic feeding; in the feeding process, the raw materials are pre-crushed, the crushing effect is good while the efficiency is high, and the stirring effect is good while the efficiency is high; the materials at the bottom in the body can be stirred and mixed, and the working efficiency of the mixer is improved; and the additional damping bracket can realize effective damping and shock prevention, and the service life of the mixer is prolonged.

Owner:ZHENGZHOU HAOEN ELECTRONICS INFORMATION TECH CO LTD

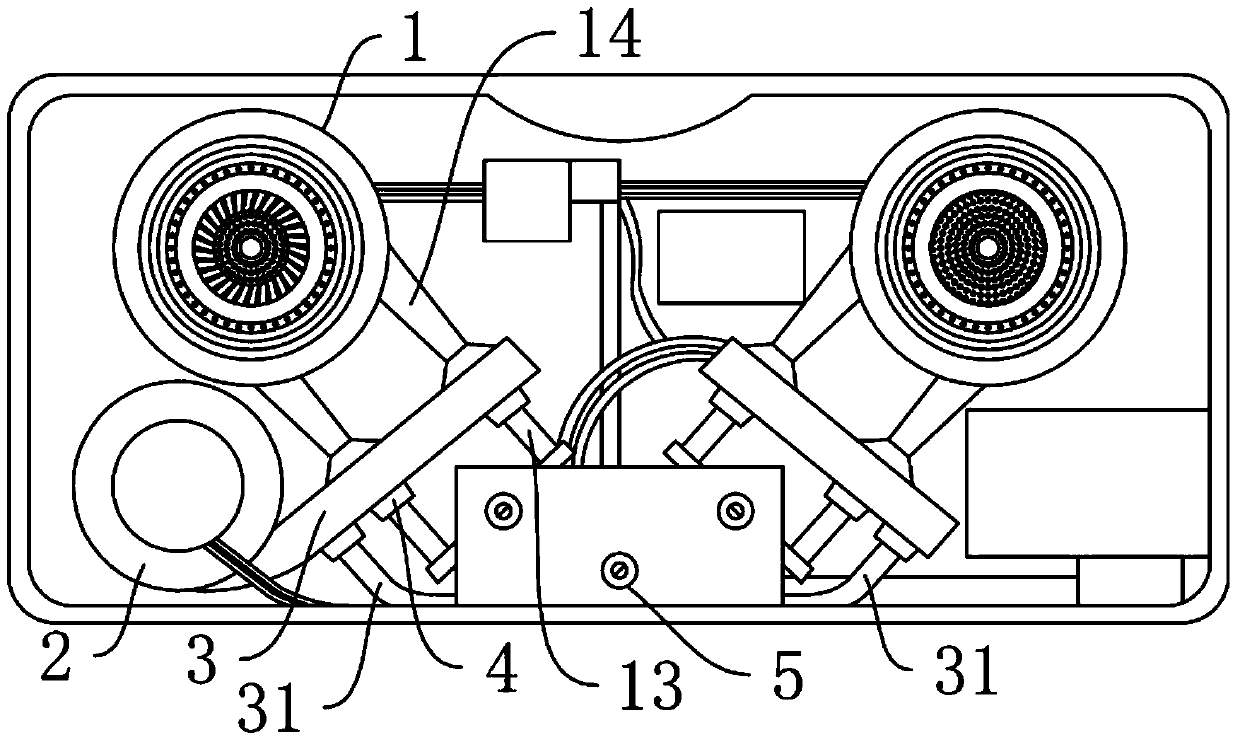

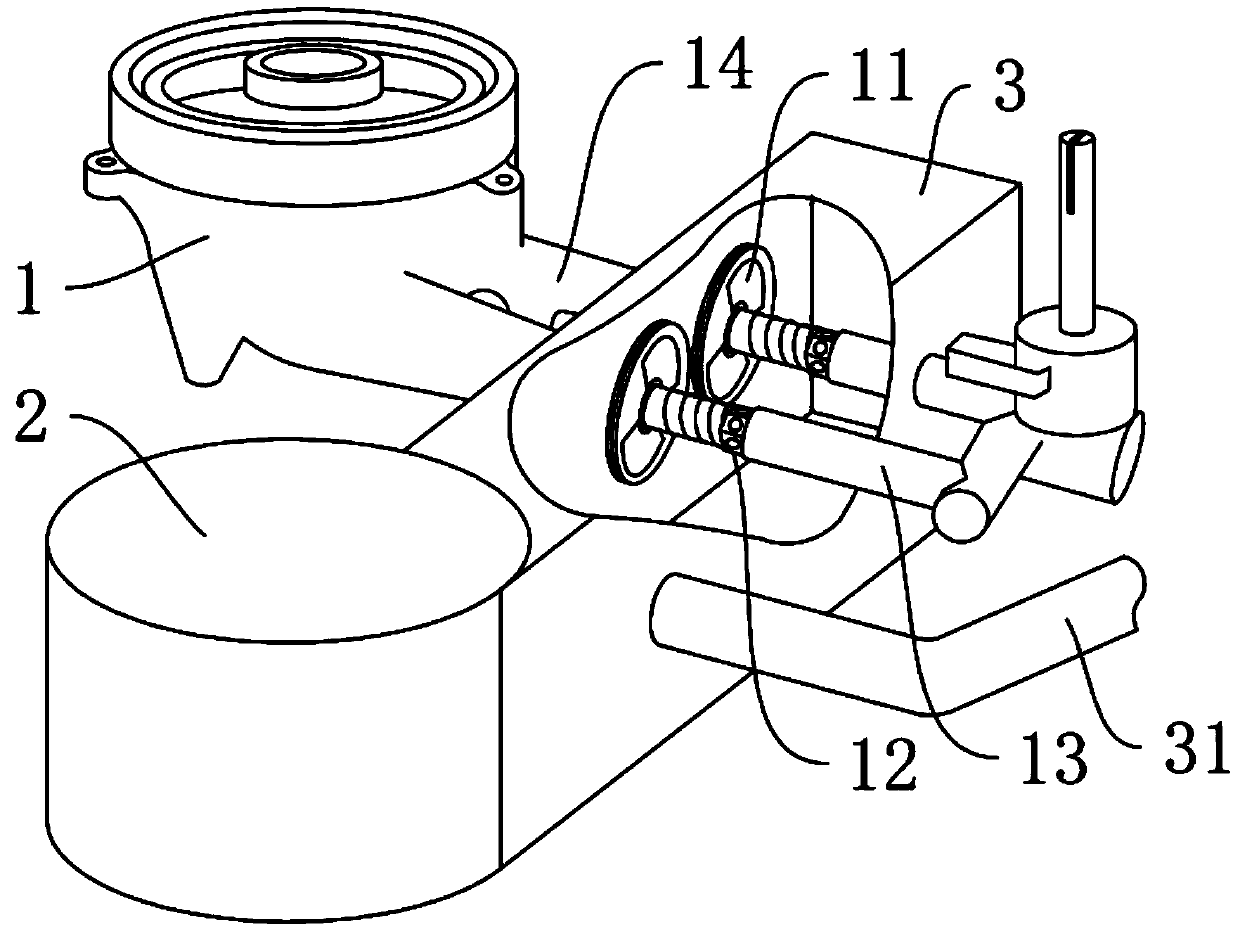

Gas stove with turbo-charging pre-mixer

InactiveCN103759304AAvoid inadequate mixingResolve Insufficient CombustionDomestic stoves or rangesGaseous fuel burnerTurbochargerProcess engineering

The invention discloses a gas stove with a turbo-charging pre-mixer. The gas stove comprises a burner and a turbocharger and is characterized by further comprising a pre-mixing cavity which is communicated with an air outlet of the turbocharger, and the pre-mixing cavity is also communicated with an air inlet and a valve nozzle of the burner.

Owner:许文广

Graphene raw material processing technology

InactiveCN113797831AShorten mixing timeImprove mixing effect and stirring efficiencyGrapheneMixer accessoriesMachining processManufacturing engineering

The invention discloses a graphene raw material processing technology, and mixing equipment comprises a tank body and a tank cover arranged on the upper portion of the tank body, wherein the right side of the upper portion of the tank cover communicates with a feeding hopper. The invention relates to the technical field of graphene processing. According to the graphene raw material processing technology, a transmission main shaft drives a rotating disc to rotate, a first limiting hole in the rotating disc pushes a transmission rod to rotate, the transmission rod slides in an annular curve rail groove through a transmission sliding block, and the transmission rod rotates and moves up and down; and in the up-down moving process of the transmission rod, a first connecting rod pushes a material separating plate to swing up and down, and raw materials enter the tank body through the material leaking holes, so the graphene raw materials are uniformly and slowly fed; therefore, the stirring time is shortened, the mixing effect and the stirring efficiency are improved, the progress of a project is not influenced, the effect that the materials are easily and fully stirred is achieved, and the problem that materials are not fully stirred easily due to the fact that most stirring machines are simple in structure is solved.

Owner:于润发

High-sealing color matching device for artistic designing

InactiveCN109849582AReasonable structureQuality improvementMixer accessoriesOther artistic work equipmentsTraffic volumeEngineering

The invention discloses a high-sealing color matching device for artistic designing. The high-sealing color matching device for artistic designing comprises a shell, an equipment cavity, a matching cavity and a heating cavity. One side of the shell is provided with a control panel, and the control panel is internally provided with a single-chip microcomputer. The top end of the shell is provided with a heating cavity. The equipment cavity is formed in the middle position of the shell. The bottom end of the shell is provided with a control cavity, and the control cavity is internally provided with the matching cavity. One side of the heating cavity is connected with a water inlet, the two sides in the heating cavity are both provided with heating blocks. The two sides of the bottom end in the heating cavity are both provided with temperature sensors. The high-sealing color matching device is provided with a flow control valve, the flow control valve can control flow of each pigment, pigment information is input to the single-chip microcomputer, the single-chip microcomputer sends processed data to the flow control valve, the flow control valve precisely controls the flow of the pigments, and therefore the quality of the pigments is improved, and demands of users are met.

Owner:郭俊宁

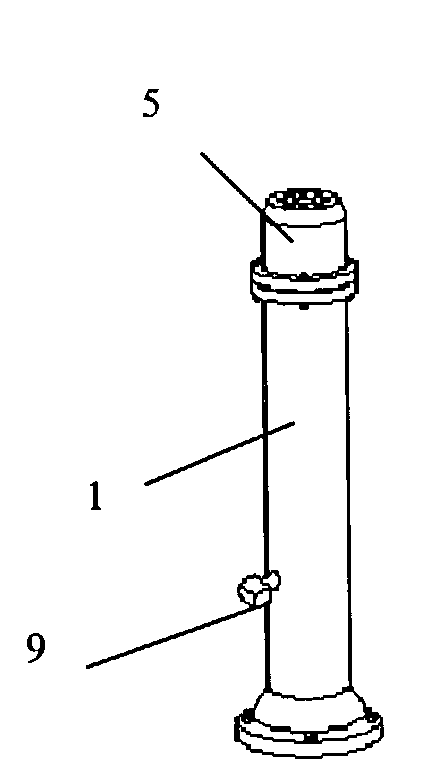

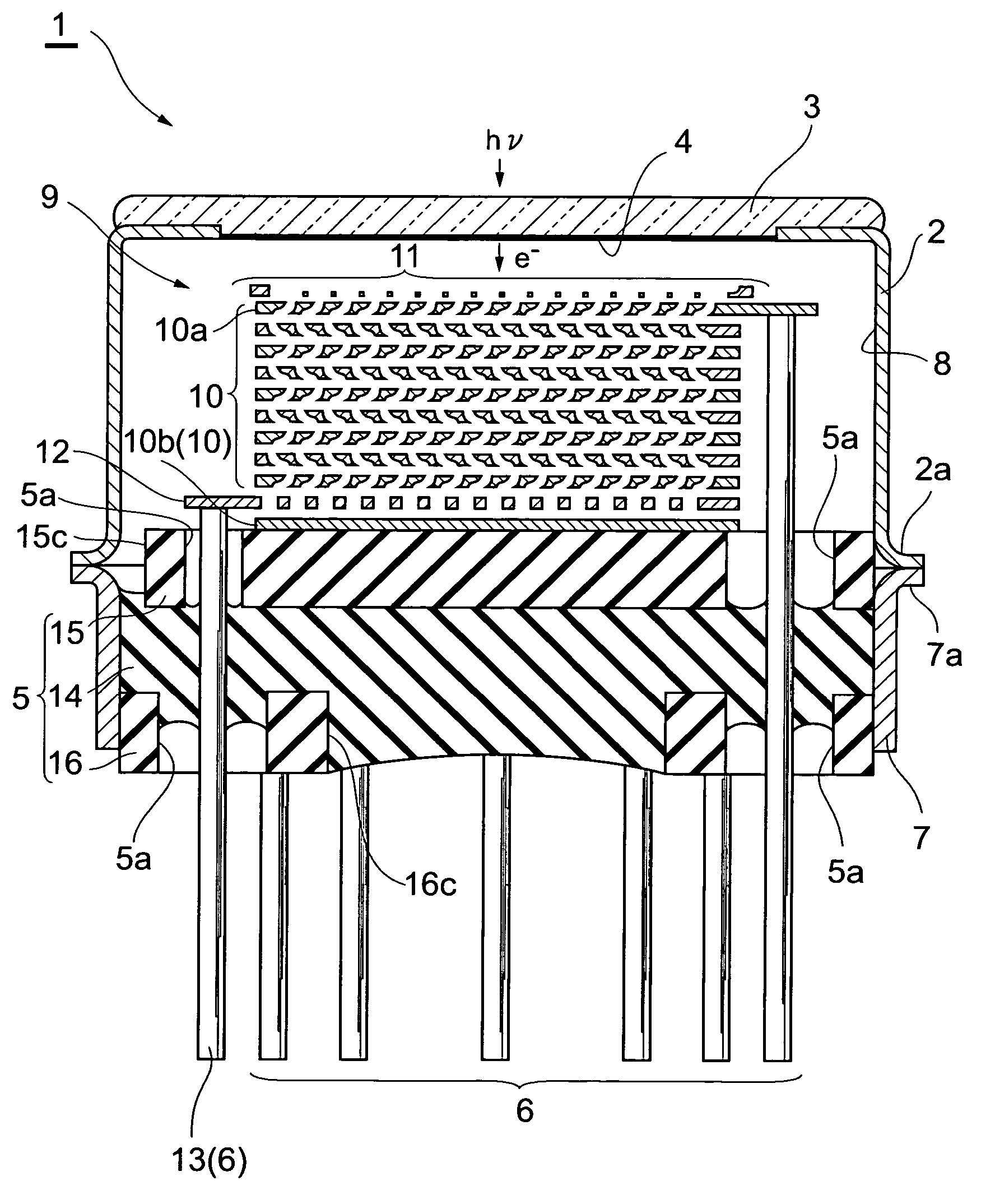

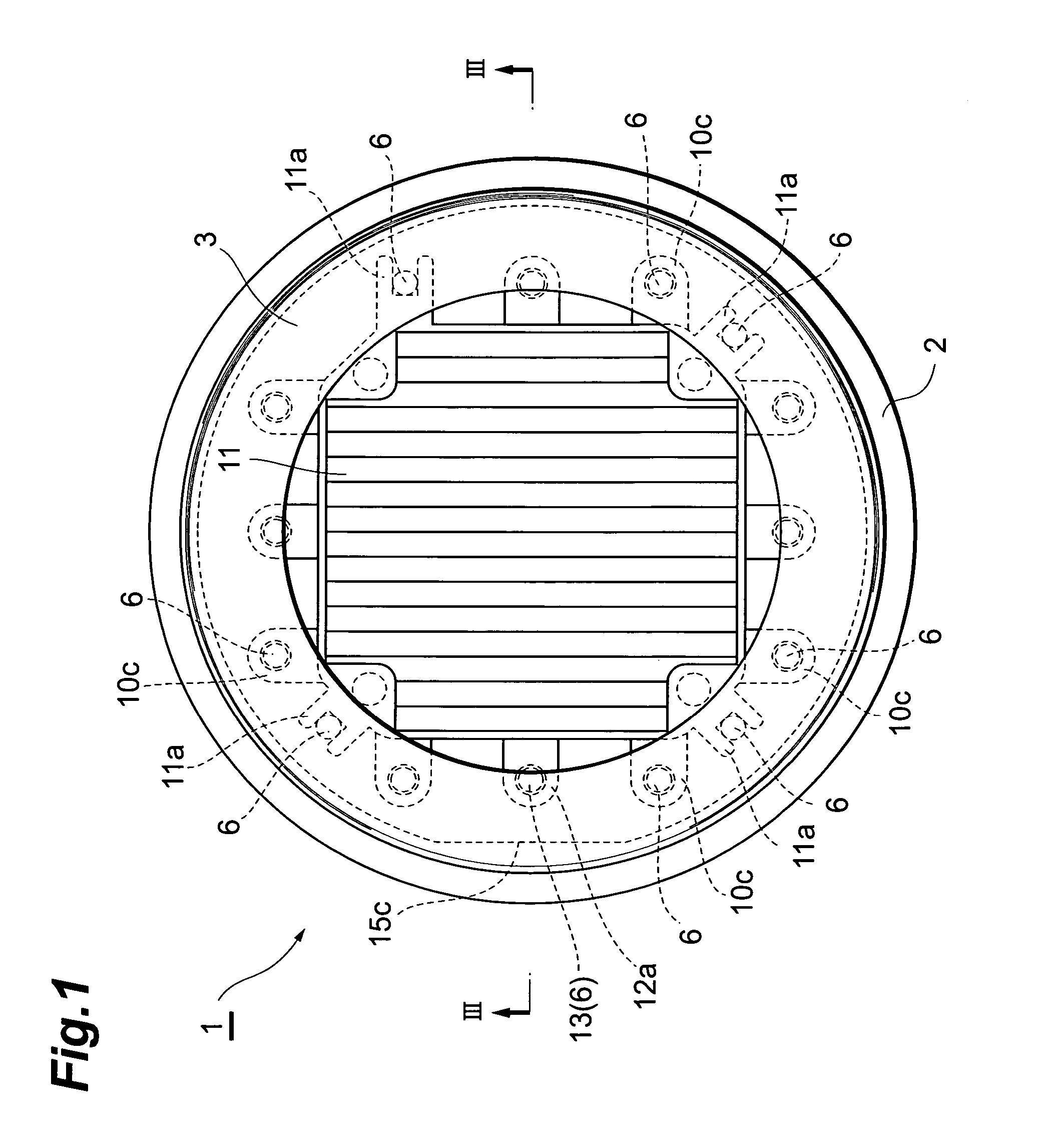

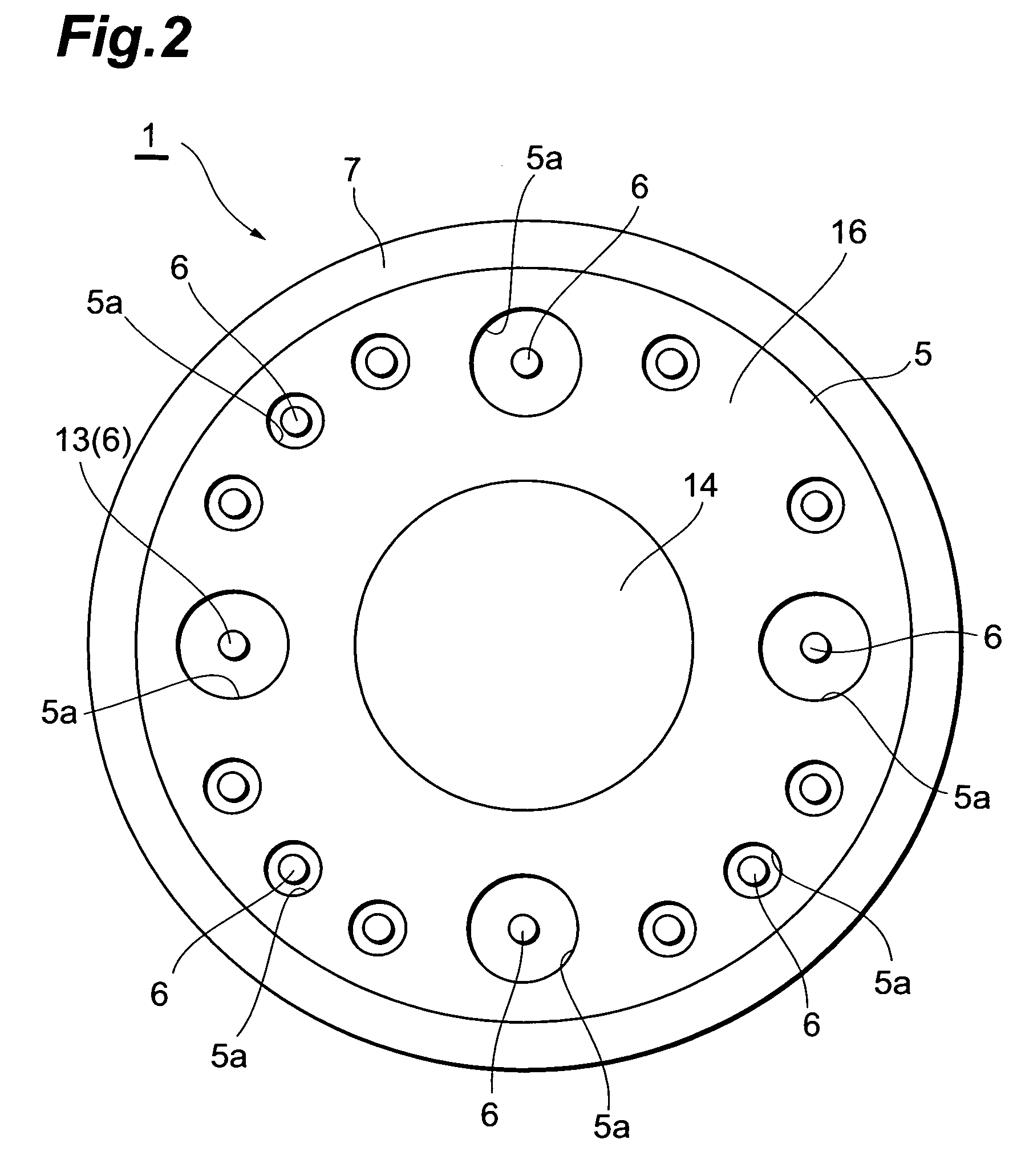

Photomultiplier and radiation detector

ActiveUS7189956B2Precise positioningInhibit overall enlargementMultiplier circuit arrangementsMaterial analysis by optical meansHigh densityPhotomultiplier

In a photomultiplier, a ring-like side tube is not interposed between a side tube and a stem in the radial direction, and the side tube is joined to the ring-like side tube in a state of being directly capped onto a portion of the stem that protrudes out from an open end face at the upper side of the ring-like side tube. The enlargement of the photomultiplier in the radial direction due to overlapping of the side tube and the ring-like side tube can thereby be restricted and a high density, a high degree of integration, etc., can be realized in mounting the photomultiplier.

Owner:HAMAMATSU PHOTONICS KK

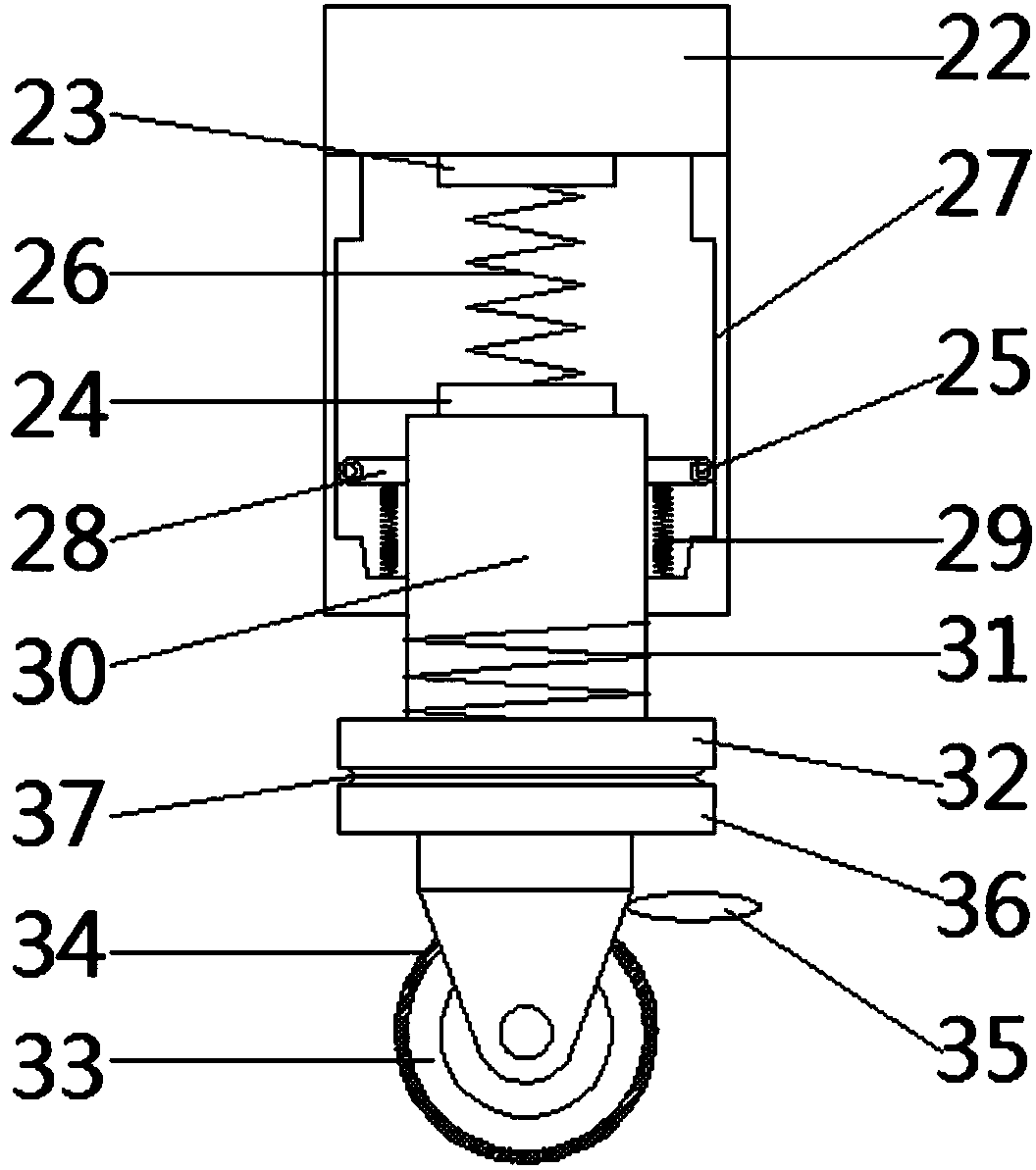

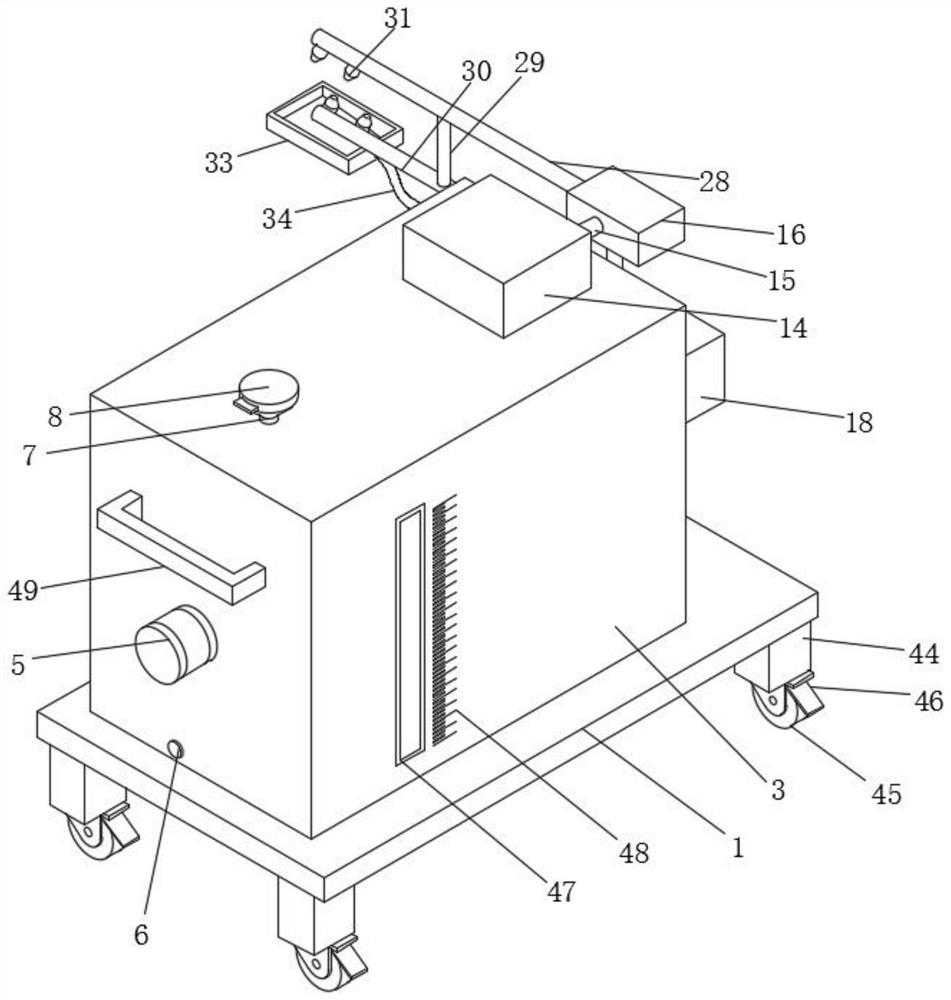

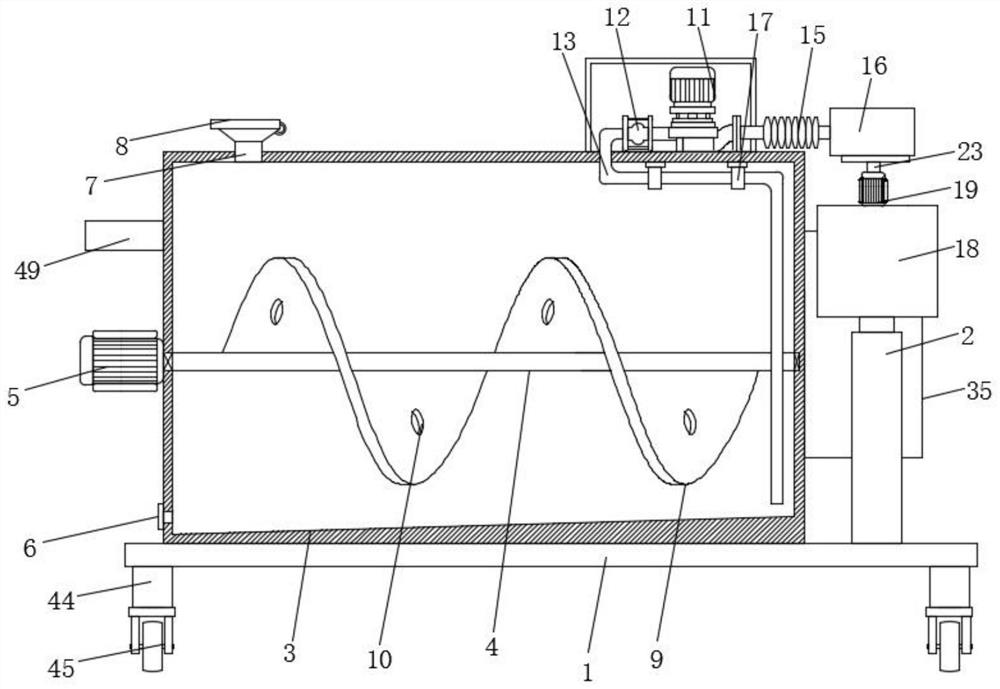

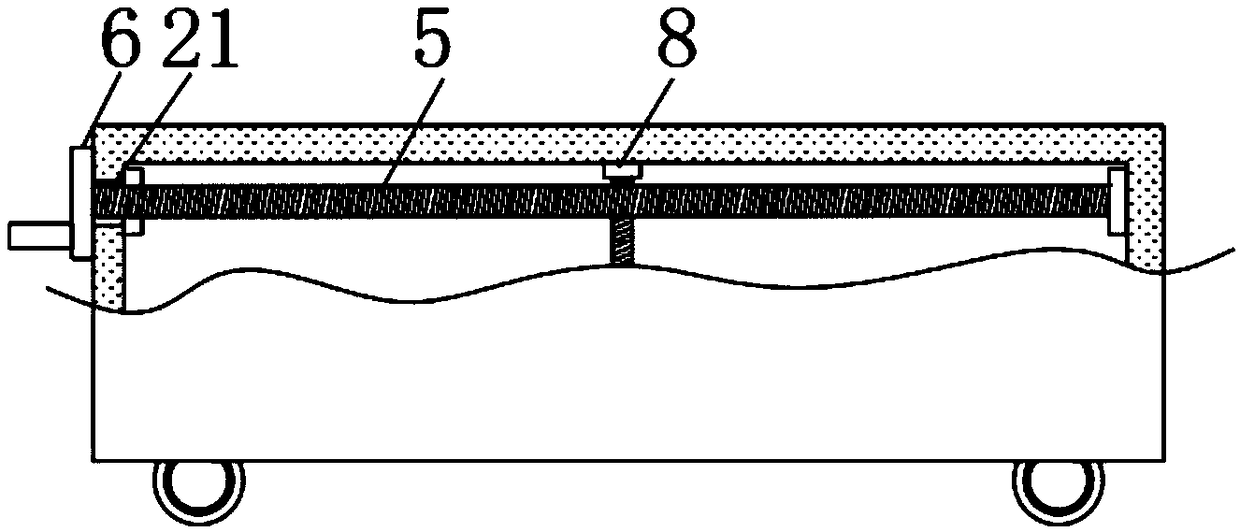

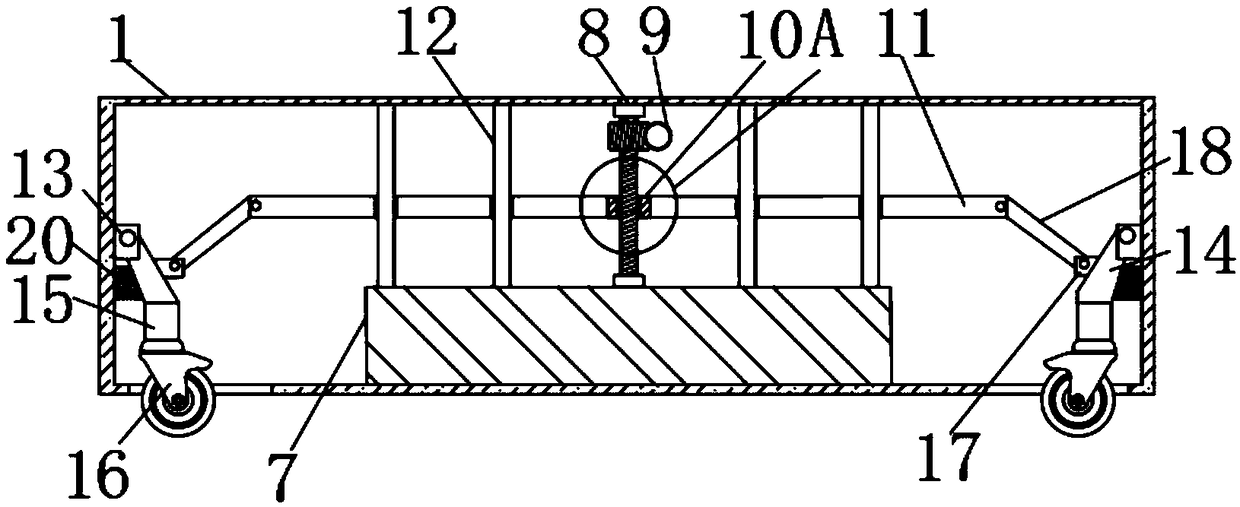

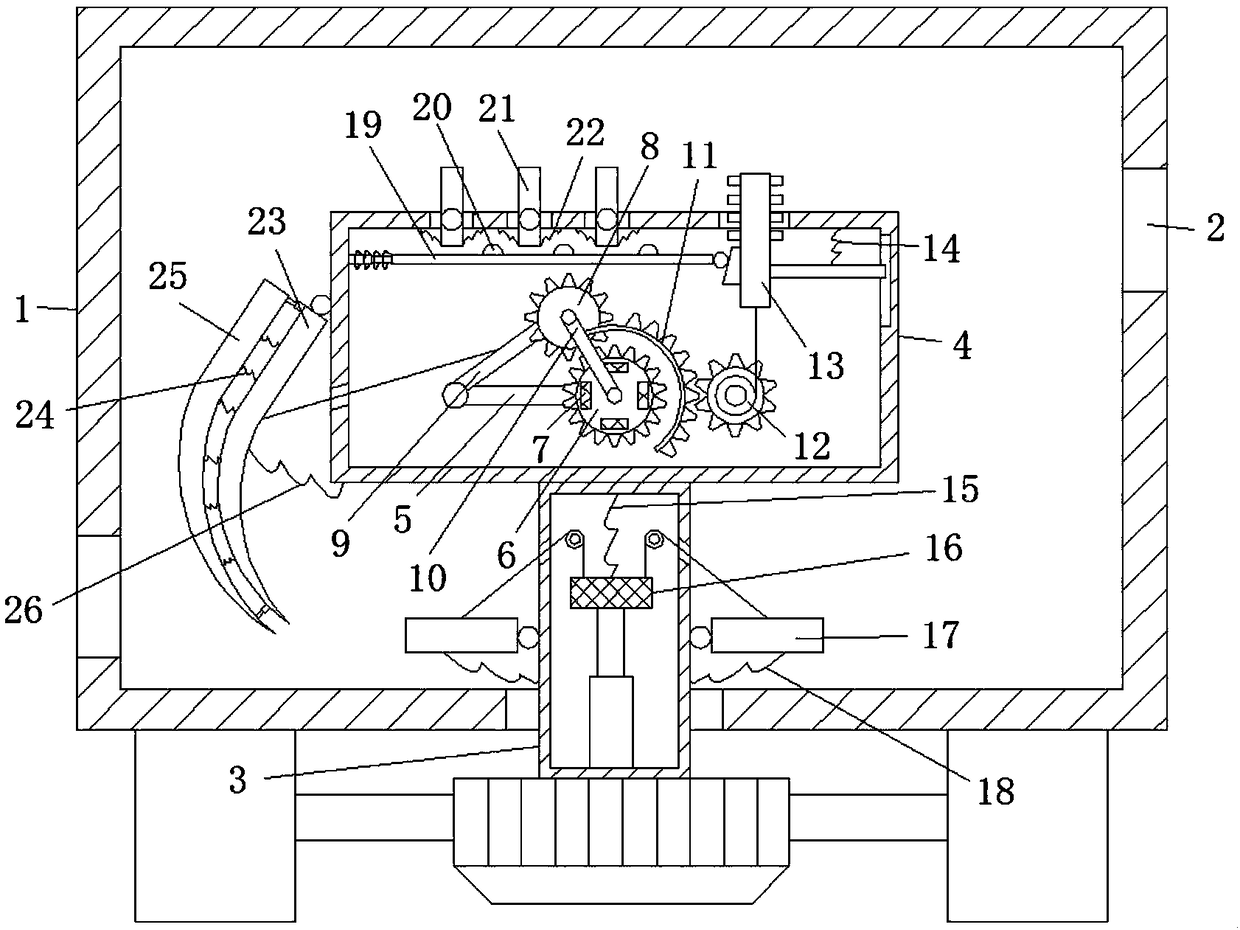

Raw material stirring device for roasted food production

ActiveCN108835144ASolve the problem of being too heavy and inconvenient to moveEasy to moveMixing/kneading structural elementsCastorsEngineeringFood item

The invention discloses a raw material stirring device for roasted food production. The raw material stirring device for roasted food production comprises a bottom box. The top of the bottom box is fixedly connected to a stirring device, the left side of the top of the bottom box is fixedly connected to a material storage mechanism, a rotary disc is arranged on the front face of the bottom box, the top of the inner cavity of the bottom box is movably connected to a worm through a bearing, and the front end of the worm penetrates the bottom box and is fixedly connected to a rotary wheel. By thecoordinated use of the bottom box, the stirring device, the material storage mechanism, the rotary disc, the worm, the rotary wheel, a supporting block, a threaded column, a worm wheel, a threaded sleeve, a positioning plate, a slide column, a first fixed block, a first transmission plate, an H-shaped bracket, universal wheels, a second fixed block and a second transmission plate, the problem that an existing stirrer which is too heavy is inconvenient to move is solved. According to the raw material stirring device for roasted food production, the portable stirrer has the advantage of being convenient to move, the labor force of a user is reduced, the moving time of the user is shortened, and the practicality of the portable stirrer is improved.

Owner:肇庆市端州大酒店饮食服务有限公司

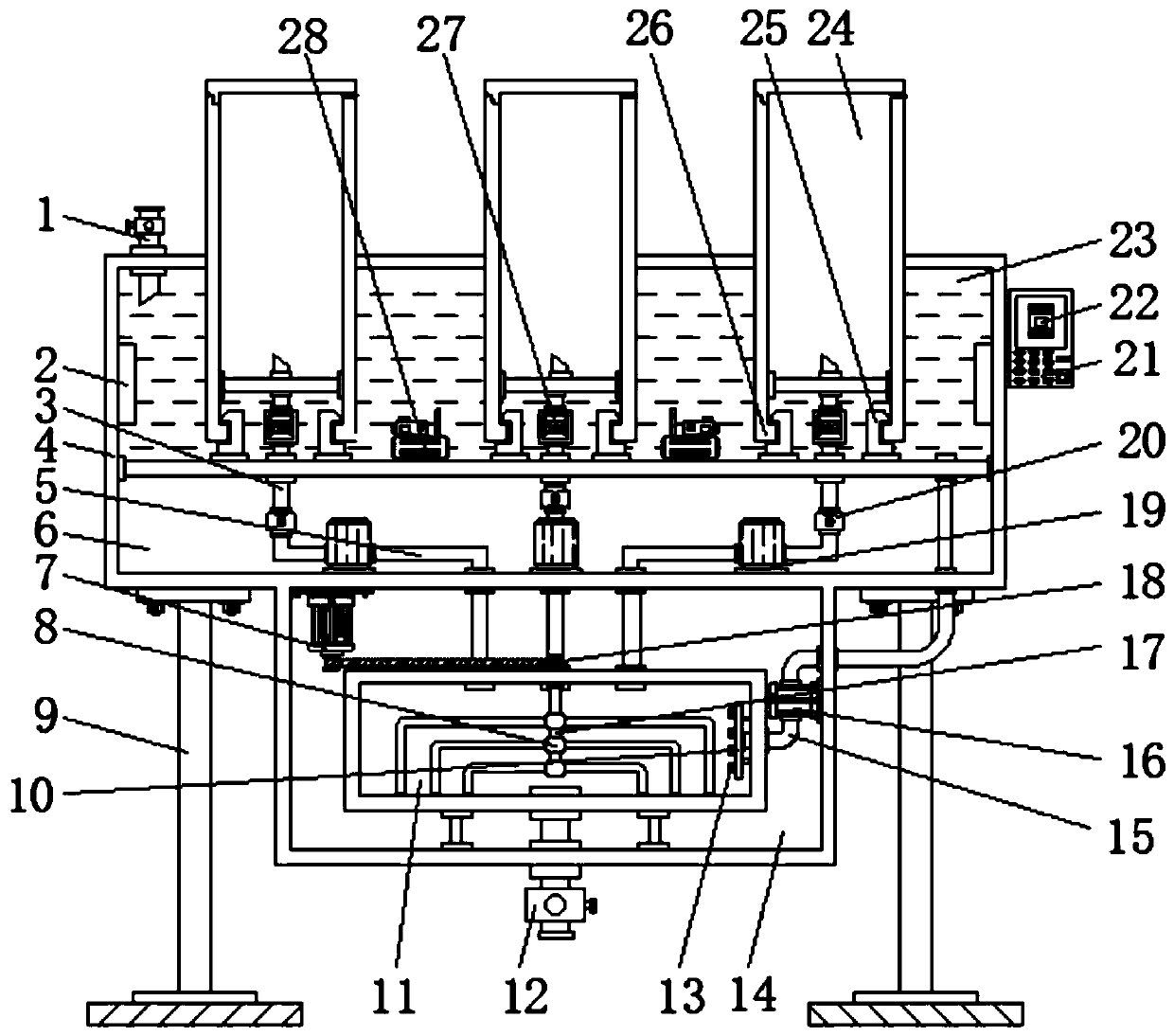

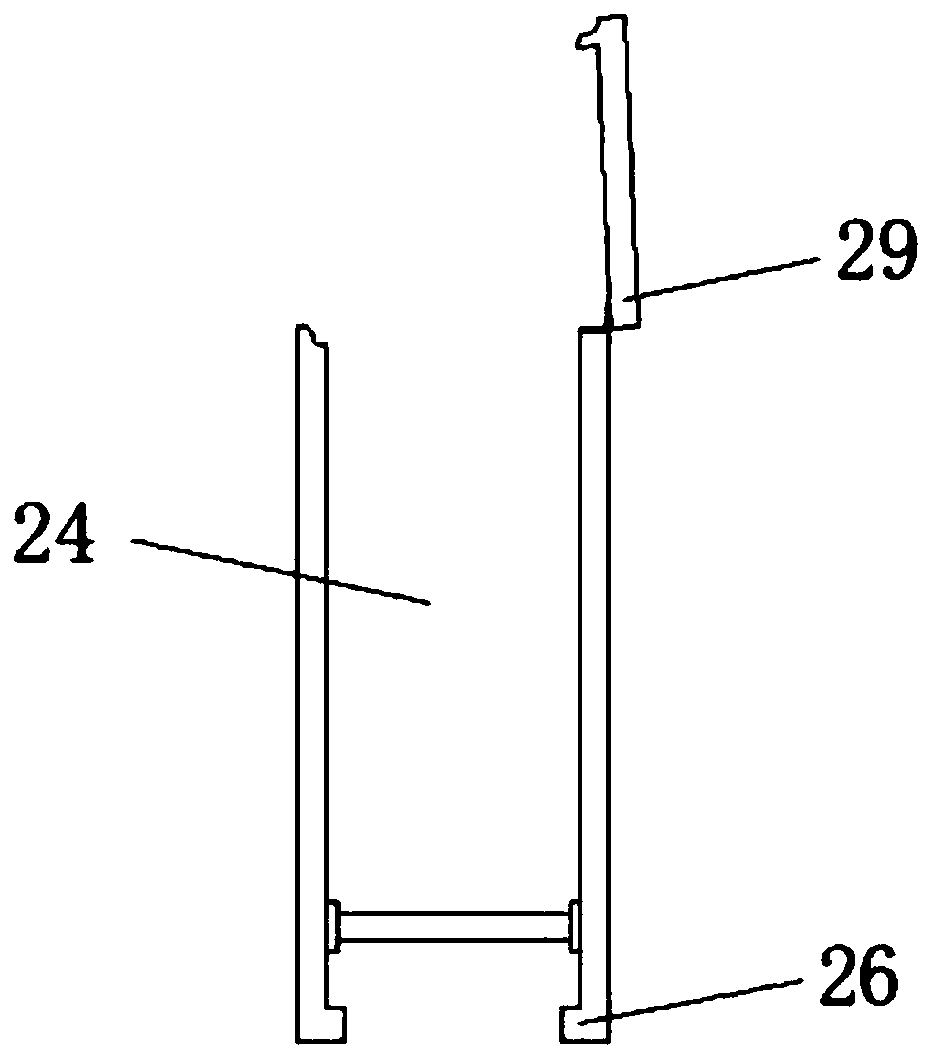

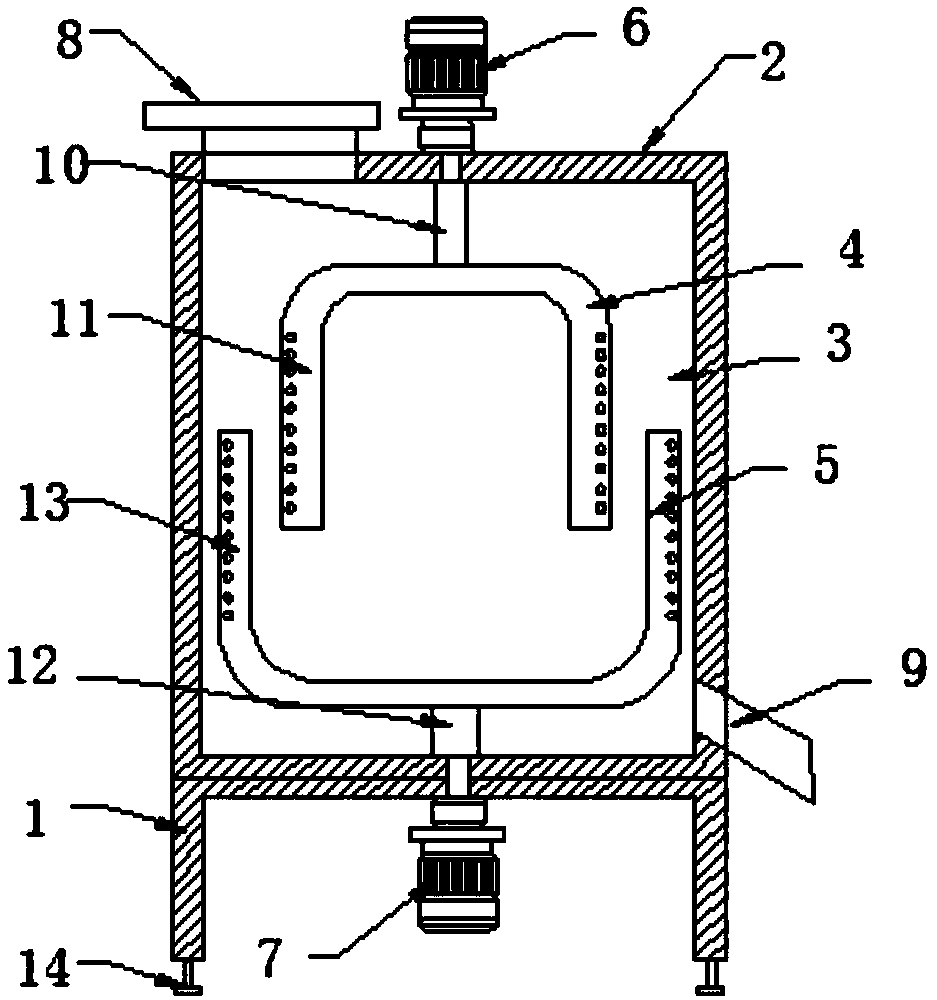

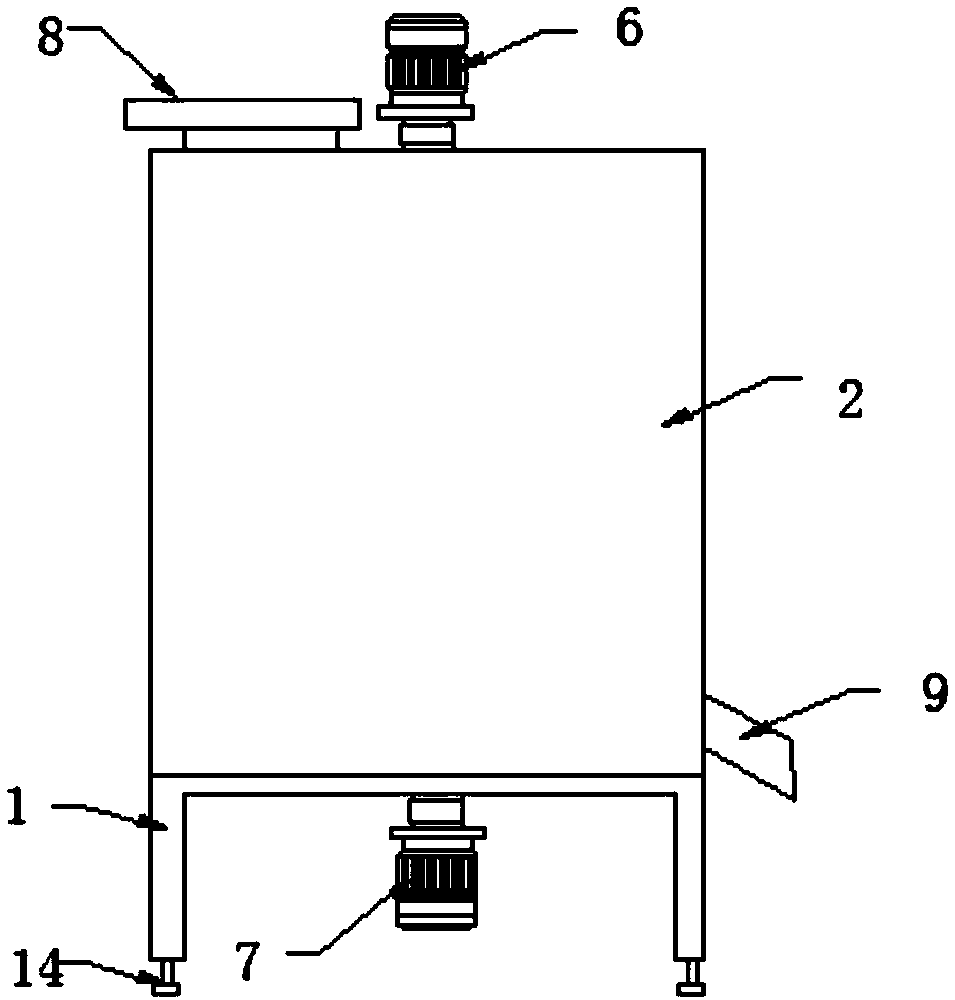

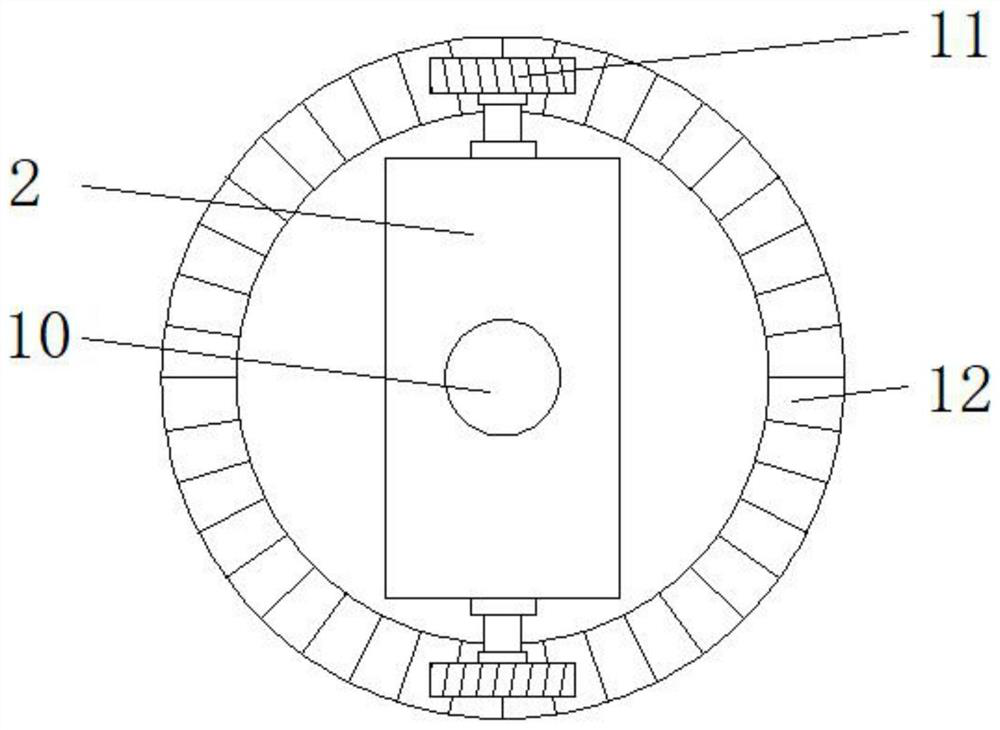

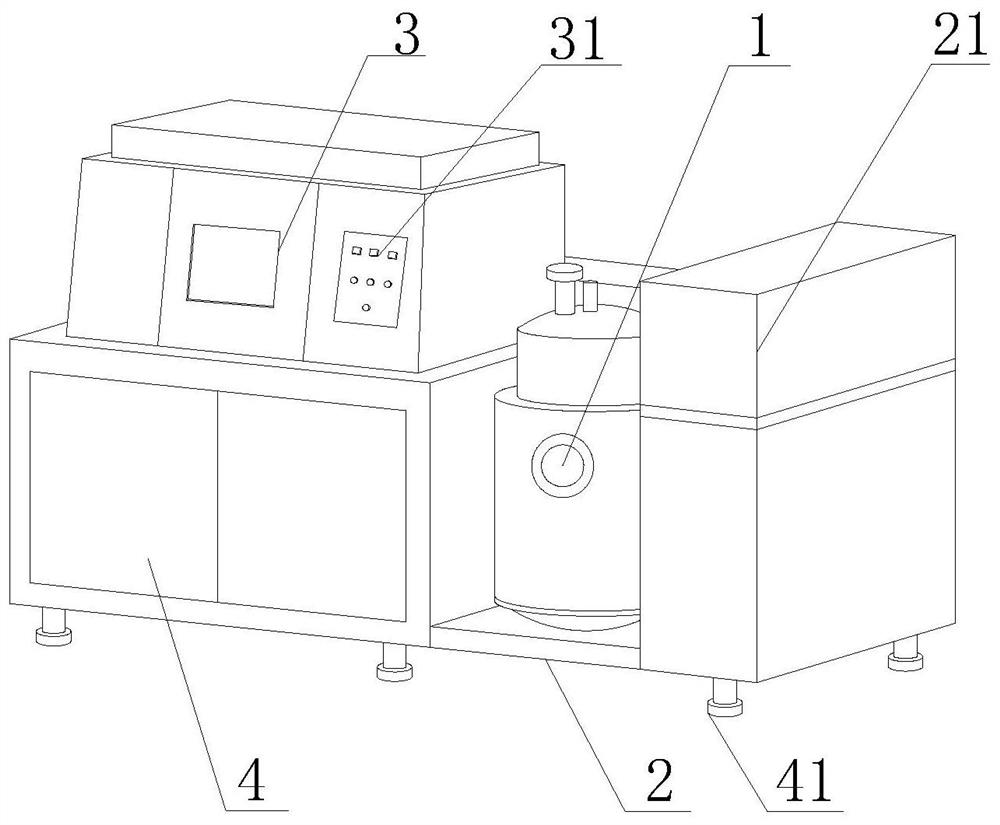

Biomass fertilizer mixing apparatus

PendingCN107715747AAvoid insufficient mixingMix thoroughlyTransportation and packagingRotary stirring mixersFertilizerBiomass

The invention relates to a biomass fertilizer mixing apparatus, which is used for stirring and mixing biomass fertilizer. The biomass fertilizer mixing apparatus comprises a base and a mixing box, wherein the mixing box is arranged on the top of the base, a mixing cavity is formed inside the mixing box, an upper stirring paddle and a lower stirring paddle are arranged in the mixing cavity, the upper stirring paddle and the lower stirring paddle are respectively arranged on the top and the bottom in the mixing cavity, the upper stirring paddle is disposed on the inner side of the stirring paddle, and the top and the bottom of the outer side of the mixing box are respectively provided with a first driving motor and a second driving motor corresponding to the upper stirring paddle and the lower stirring paddle. By adopting the nesting structural design of the two stirring paddles, and designing opposite rotation directions of the upper stirring paddle and the lower stirring paddle, the phenomenon that multiple raw materials are insufficiently mixed due to material vortex of the raw materials in the mixing cavity can be effectively avoided, the biomass fertilizer is enabled to be sufficiently and uniformly stirred, and furthermore the mixing efficiency of the biomass fertilizer can be greatly increased.

Owner:巴东隆生生物科技有限公司

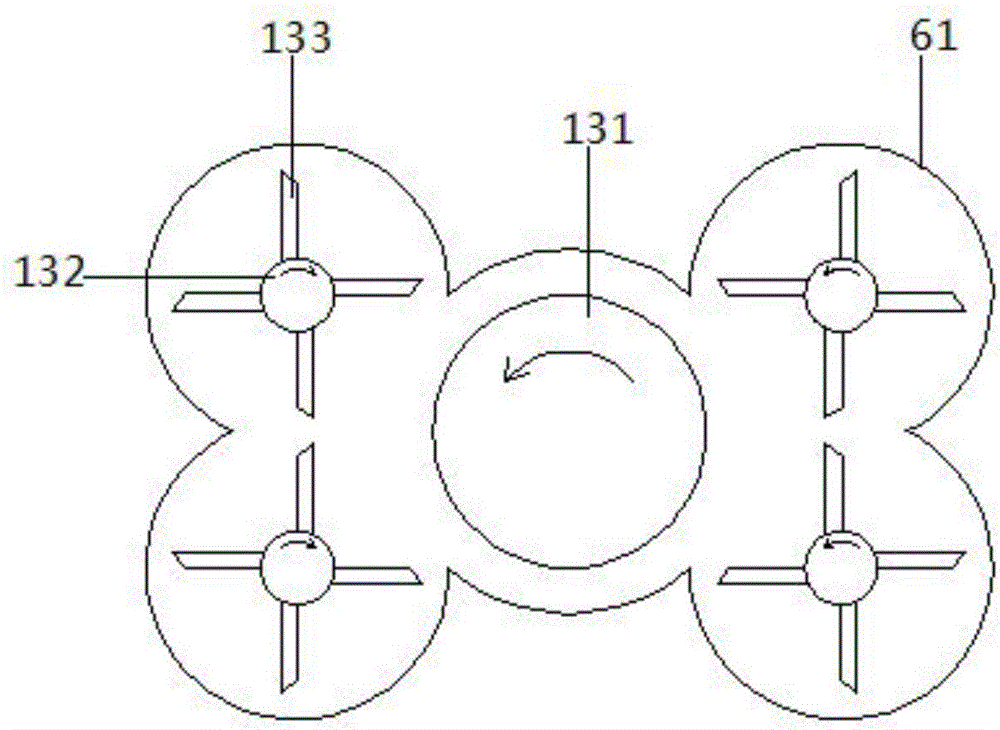

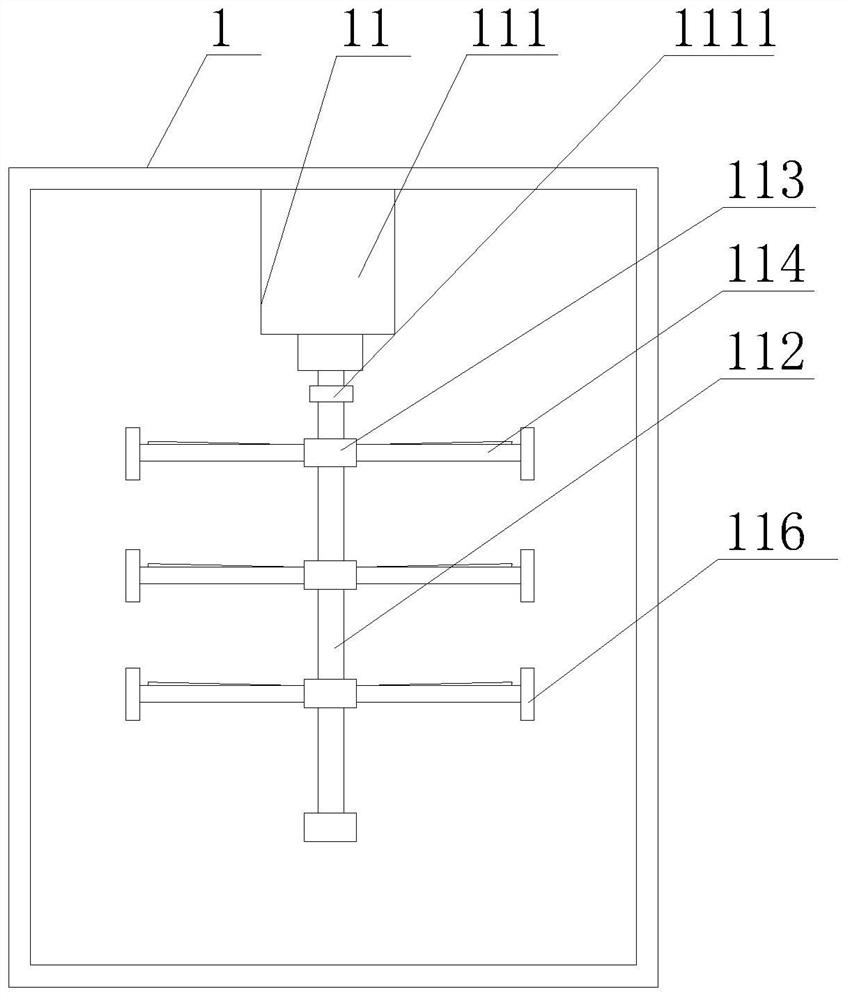

Efficient mixing device for civil engineering

ActiveCN112045861AImprove uniformityEasy to useMixing operation control apparatusIngredients proportioning apparatusGear wheelStructural engineering

The invention discloses an efficient mixing device for civil engineering, and belongs to the technical field of concrete mixing. The efficient mixing device comprises mixing cylinders, a fixed seat and a connecting cylinder, a second connecting cavity is vertically formed in the center of the fixed seat, and three storage cavities are formed in the positions, inside the fixed seat, of the outer side of the second connecting cavity at equal intervals with the second connecting cavity as the circle center; connecting cylinders are mounted at the upper end and the lower end of the interior of thesecond connecting cavity through bearings, a guiding cavity is formed in the middle of the connecting cylinder, a driving gear meshed with a second annular gear is arranged in the second annular gear, and a stirring rod is vertically mounted in the middle of the top of the second connecting cavity through a bearing; and a first connecting cavity is transversely formed in the bottom of the connecting cylinder, and the mixing cylinders are transversely mounted on the inner side walls of the two ends of the first connecting cavity through bearings correspondingly. The efficient mixing device conveniently conducts proportioning according to the proportion of concrete components, and is high mixing efficiency and good in mixing uniformity.

Owner:泉州台商投资区飞翔机械设计服务中心

Liquid double-mixing liquid-mixing device for chemical production

ActiveCN108211965ASolving Difficult to MixAvoid inadequate mixingTransportation and packagingMixer accessoriesEngineeringDistributor

The invention discloses a liquid double-mixing liquid-mixing device for chemical production, wherein the device comprises a primary flow mixing cover, a rotating flow mixer, a diversion pipe, a rotating liquid distributor and a liquid mixing tank body. The interior of the top end of the liquid mixing tank body is welded with the primary flow mixing cover; a primary liquid mixing cavity is surrounded by the primary flow mixing cover and the top of the liquid mixing tank body; the rotating flow mixer is arranged in the primary liquid mixing cavity; the upper end of the rotating flow mixer is connected with a rotating shaft; the top end of the rotating shaft is connected with a motor; the top end of the liquid mixing tank body is connected with a first liquid pipe and a second liquid pipe; the bottom end of the rotating flow mixer is connected with the diversion pipe; the diversion pipe is provided with the rotating liquid distributor. The rotating flow mixer, the diversion pipe and the rotating liquid distributor are driven to rotate by the rotating shaft to primarily mix a liquid in the primary flow mixing cover, the liquid flows into a liquid homogenizing cavity and then flows intoa secondary liquid mixing cavity through liquid distribution holes, and then the liquid is mixed again under rotation of the rotating liquid distributor; the problems of difficult mixing, insufficient mixing and low mixing efficiency of chemical liquids are effectively solved, the mixing effect is good and the efficiency is fast.

Owner:莱州耀胜自动化设备有限公司

Vacuum emulsification device for cosmetic production

PendingCN113713686AExtended service lifeIncrease widthRotary stirring mixersMixer accessoriesElectric machineProcess engineering

The invention discloses a vacuum emulsification device for cosmetic production, and relates to the technical field of cosmetic preparation, the vacuum emulsification device comprises a vacuum emulsification device main body, a placement rack, a console and a base, the bottom of the vacuum emulsification device main body is fixedly provided with the placement rack, and one side of the placement rack is fixedly provided with a storage box. A power motor and a center shaft are matched to drive stirring blades to rotate, so that the stirring blades stir raw materials in the vacuum emulsification device main body to achieve the stirring and mixing effect, and then the telescopic movement of telescopic columns is utilized to enable the multiple telescopic columns to stretch out and draw back in sequence to drive the stirring blocks to move. Then the stirring blocks move on rotating blocks, so that the function of increasing the width of the stirring blade is achieved, the problems that the processing raw materials in the vacuum emulsification device are more, the device is non-uniform in stirring, and the processed raw materials are not fully mixed are solved, the stirring force of the device is favorably increased, and the device is enabled to uniformly stir the raw materials.

Owner:雷凡

Concrete mixer

InactiveCN108340496ASimple structureAvoid inadequate mixingCement mixing apparatusEngineeringMechanical engineering

The invention discloses a concrete mixer. The concrete mixer comprises a mixing tank. A feeding inlet is formed in the upper end of the side wall of the mixing tank. The concrete mixer is simple in structure, by additionally arranging a combined structure of mixing blades, a mashing rod and a swing plate, the mixing blades are driven by a first motor to rotate for mixing, a first gear is driven bya second motor to rotate and engaged with a second gear, thus, a first connecting rod and a second connecting rod swing back and forth, the second connecting rod drives an arc-shaped rack to move back and forth, and the arc-shaped rack is engaged with a third gear, so that the third gear drives a wire spool to rotate forwards and backwards, under the action of a first digging rope and a first spring, the mashing rod circularly moves up and down for scattering and mixing materials, while the mashing rod moves up and down, a movable rod horizontally moves back and forth, a protrusion block pushes the swing plate intermittently, under the action of a forth spring, the swing plate swings back and forth to stir raw materials, and the mixing efficiency is improved.

Owner:周玉良

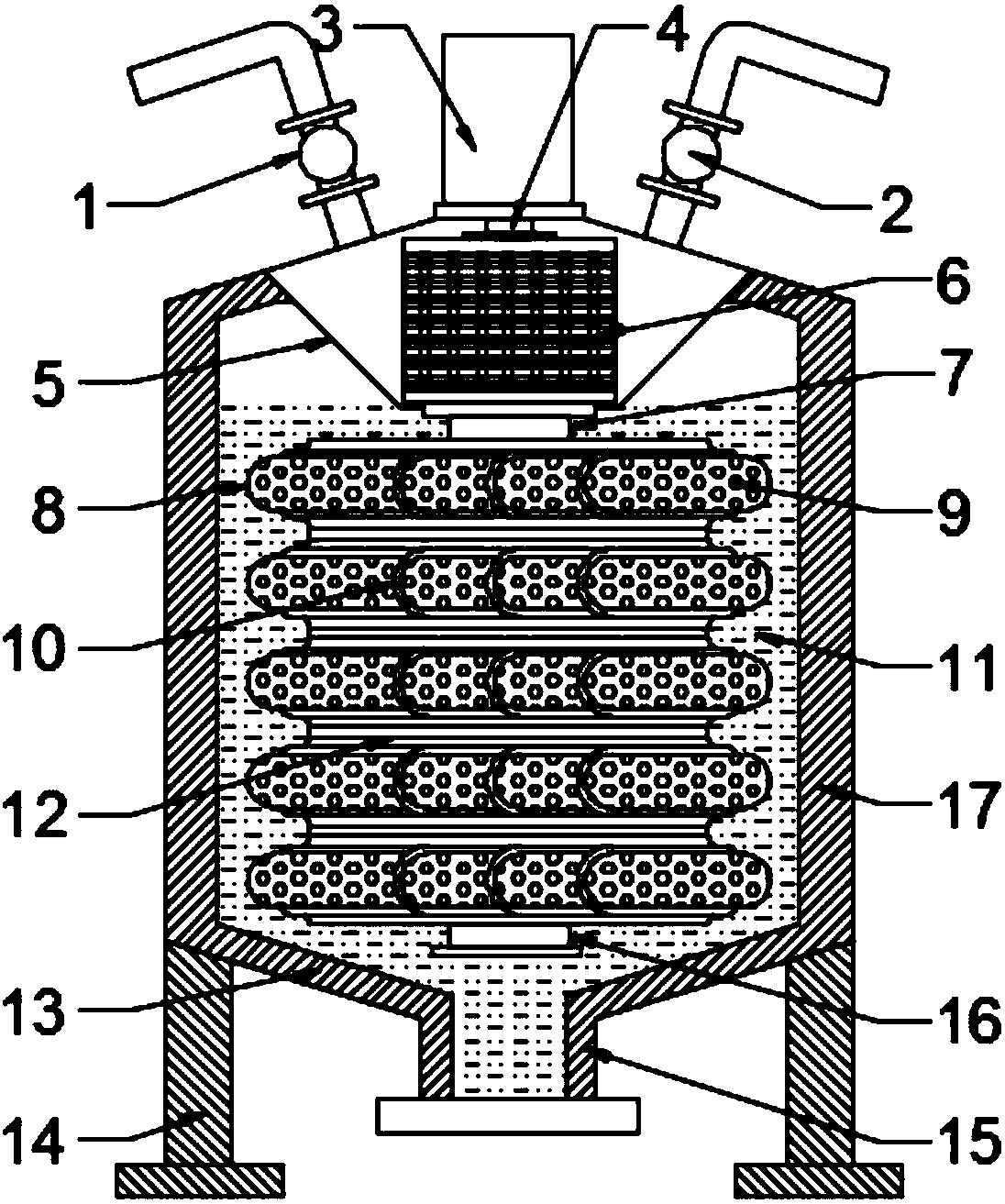

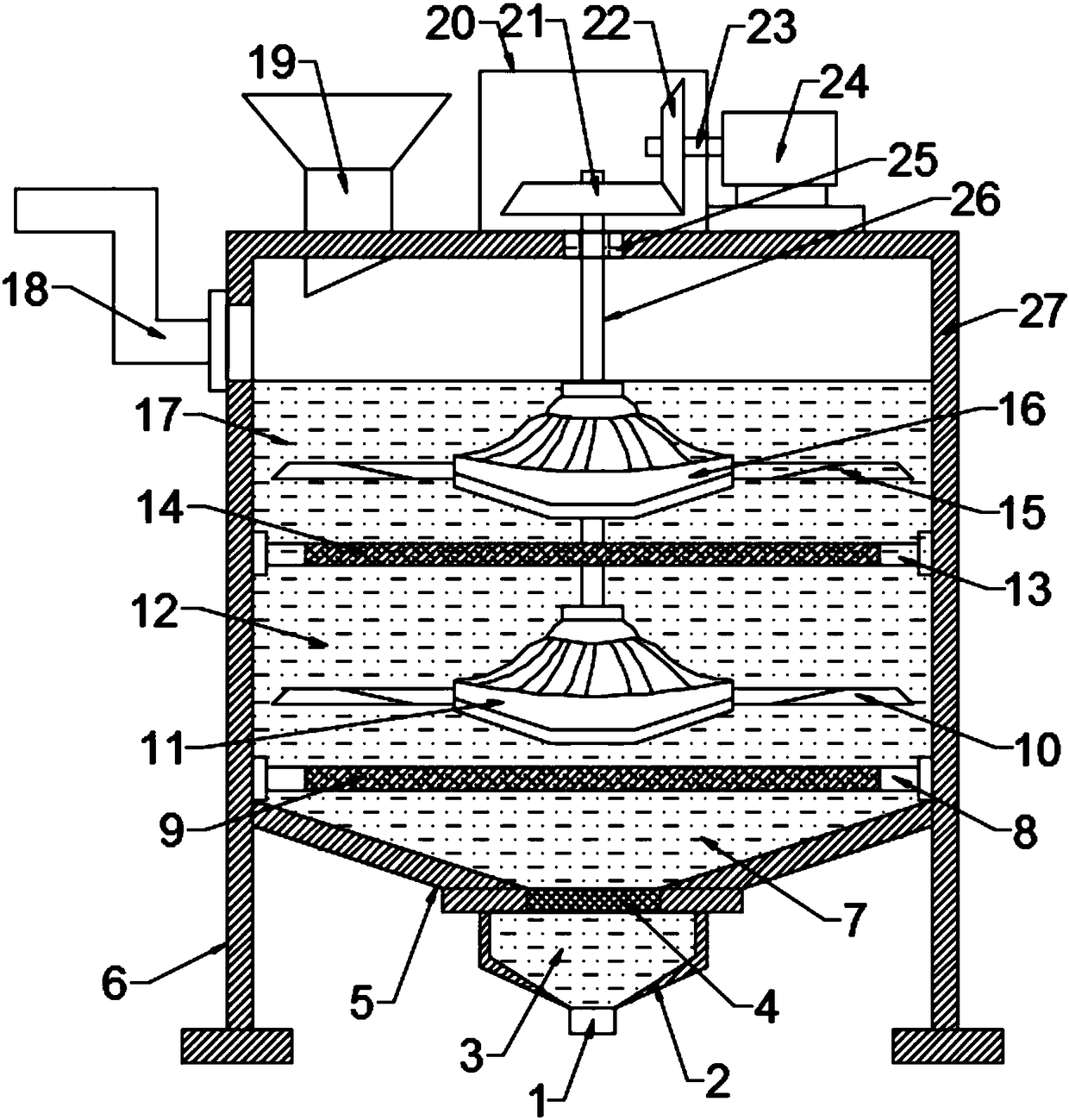

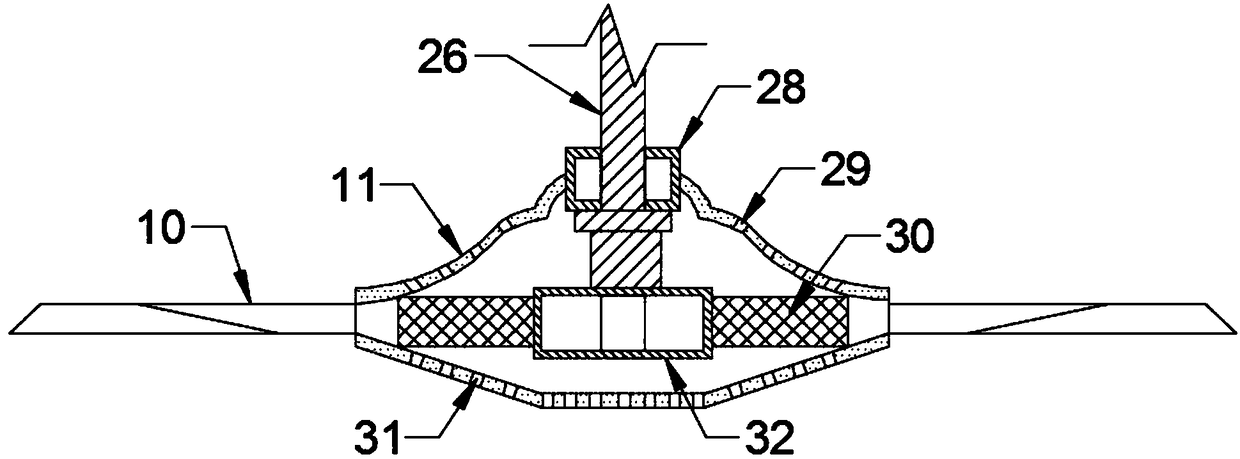

Rotary turbulent-flow fertilizer continuous liquid mixing device for water conservancy irrigation

InactiveCN108211907AIncrease dissolution rateImprove solubilityRotary stirring mixersTransportation and packagingFiltrationEngineering

The invention discloses a rotary turbulent-flow fertilizer continuous liquid mixing device for water conservancy irrigation. The device comprises a liquid outlet hopper, a liquid filter screen, a liquid collection hopper, a second hydrocyclone, a first hydrocyclone, a motor, a rotation shaft and a feed liquid mixing tank body, wherein the bottom end of the feed liquid mixing tank body is fixed ona bracket; the liquid collection hopper is welded at the bottom of the feed liquid mixing tank body; a first screen frame and a second screen frame are fixed in the feed liquid mixing tank body; the first screen frame is arranged above the second screen frame; a first screen is mounted in the first screen frame; a second screen is mounted in the second screen frame; fertilizer is dissolved and mixed through double stirring of the first hydrocyclone and the second hydrocyclone; under the filtration and friction in the first hydrocyclone and the second hydrocyclone, the up-down turbulent flow movement, formed by the cooperation between the fertilizer dissolution and the rotation of an external swirl vane, promotes further dissolution; thus, the fertilization dissolution is accelerated, and sufficient dissolution is improved; the problems of slow fertilizing mixing, insufficient mixing and direct discharge of fertilizer particles that are not completely dissolved are effectively solved.

Owner:浦江县宏创科技开发有限公司

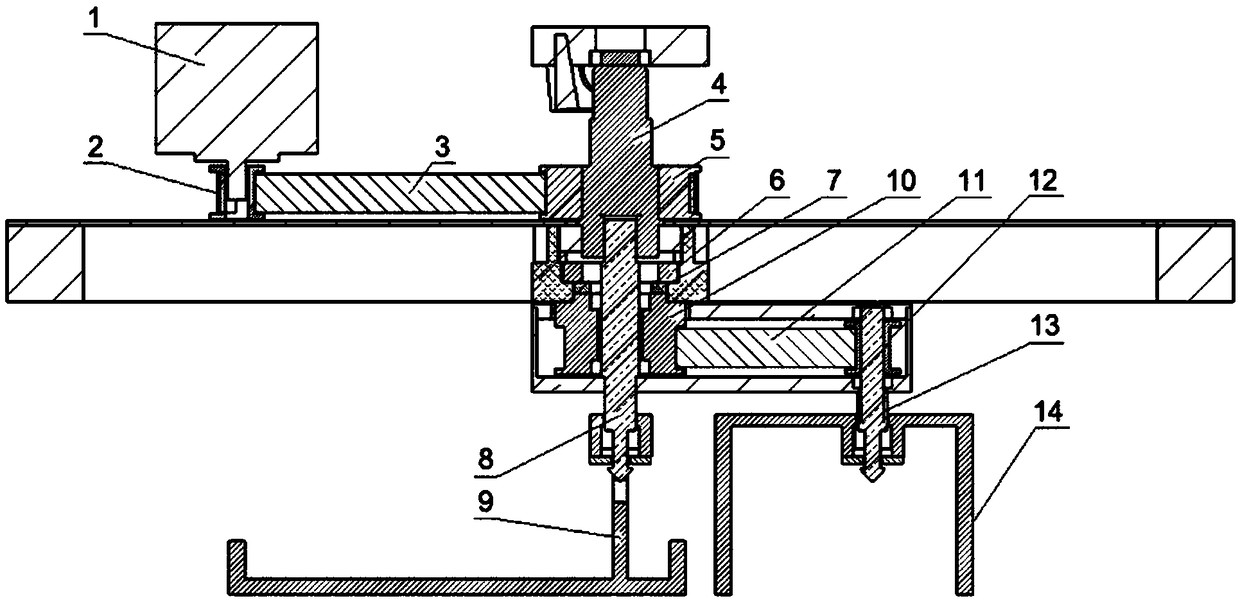

Stirring device of intelligent food processor

The invention belongs to the field of cooking automation and particularly relates to a material stirring device of an intelligent food processor. A stirring motor is started; a synchronous belt wheelof the stirring motor drives a synchronous belt of the stirring motor to be connected with a stirring middle shaft synchronous belt wheel on a stirring connection middle shaft, the stirring connectionmiddle shaft is connected with a stirring middle shaft through a stirring middle shaft adsorption magnet and stirring middle shaft adsorption iron, and the stirring middle shaft is connected with a large stirring claw; the stirring middle shaft rotates to drive a large synchronous belt wheel of a stirring speed reducer to rotate, and a synchronous belt of the stirring speed reducer drives a smallsynchronous belt wheel of the stirring speed reducer to rotate; the small synchronous belt wheel of the stirring speed reducer drives a small stirring claw transmission shaft, the small stirring clawtransmission shaft is connected with a small stirring claw to rotate, and the transmission ratio is different, so that the rotating speed of the large stirring claw is different from that of the small stirring claw. According to the device, the problem that food materials of an existing intelligent food processor are insufficient in stirring is well solved.

Owner:BEIJING GUTING TECH CO LTD

Electrode slurry preparation equipment for lithium battery processing

InactiveCN112371026AAvoid inadequate mixingEasy to prevent cloggingShaking/oscillating/vibrating mixersTransportation and packagingHydraulic cylinderElectric discharge

The invention discloses electrode slurry preparation equipment for lithium battery processing, which comprises a supporting mechanism and an adjusting mechanism, wherein damping mechanisms are symmetrically arranged at the bottom of the supporting mechanism, a second preparation box is arranged above a first preparation box, an electric discharging valve is arranged at the bottom of the first preparation box, a water inlet and a feeding port are formed in the top of the second preparation box, a top cover is in threaded connection with the top of the water inlet, the adjusting mechanism comprises a motor, a rotating rod, a hydraulic cylinder and a transverse plate, and the output end of the motor is connected with the rotating rod. The electrode slurry preparation equipment for lithium battery processing is provided with the motor, the motor can drive a second feeding plate to rotate through a rotating rod and a gear, and when a feeding hole in the second feeding plate coincides with afeeding hole in a first feeding plate, raw materials in a feeding port fall into the first preparation box, so that insufficient mixing of the electrode slurry caused by non-uniform feeding can be avoided to a certain extent.

Owner:江苏超聚新能源科技有限公司

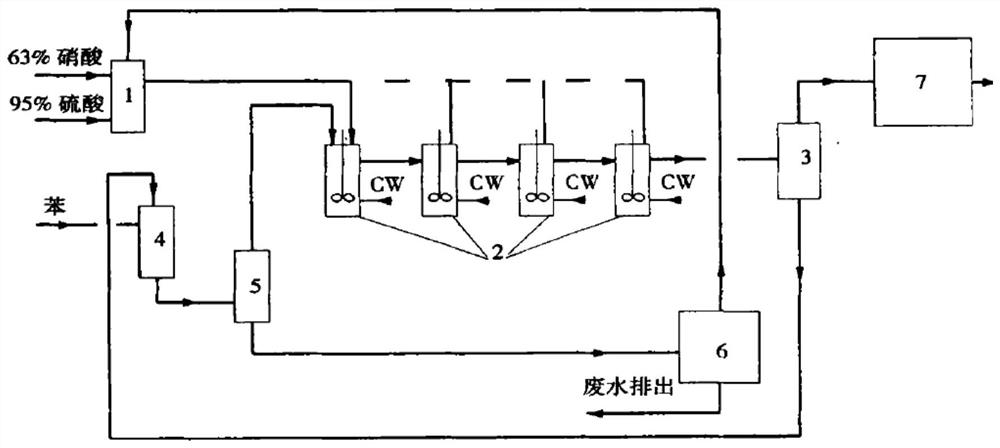

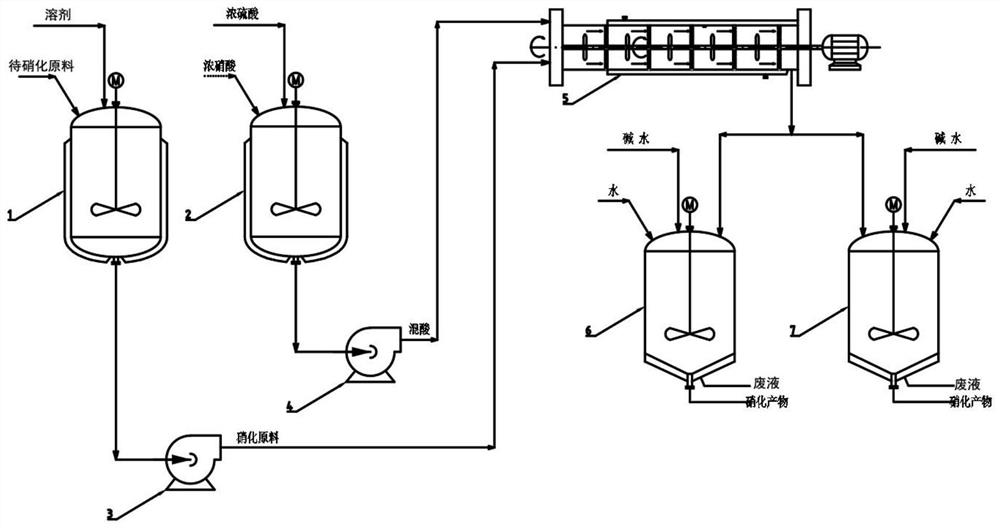

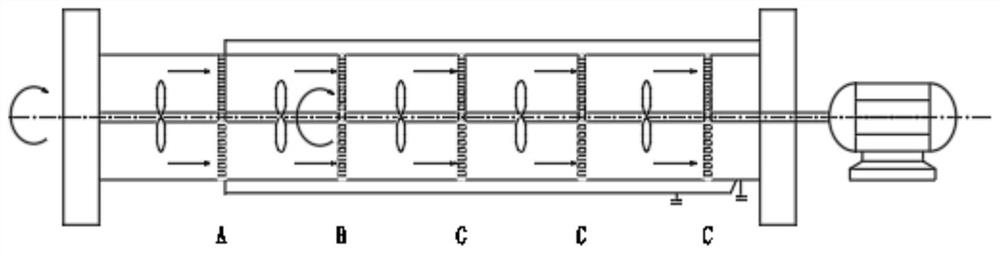

Continuous nitration reaction device and method for benzene ring nitration

ActiveCN113694858AReduce catalysisStrong heat releaseChemical/physical/physico-chemical stationary reactorsFeed devicesBenzeneNitration

The invention discloses a continuous nitration reaction device and method for benzene ring nitration. The device comprises a nitration raw material tank, a mixed acid preparation tank, a nitration feeding pump, a mixed acid feeding pump, a continuous nitration reactor and two coarse nitrate product separation tanks. With the continuous nitration reaction device and method for benzene of the invention adopted, the continuous nitration production is realized. The operation flexibility of the device is high, stable operation can be realized in a wider yield range, the production efficiency is high, the product quality is good, few byproducts are produced, the energy consumption and the raw material consumption are low, and the production process is safe and reliable.

Owner:唐山金坤化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com