Device for producing modified asphalt and method for producing modified asphalt by using device

A technology of modified asphalt and mixing device, which is used in roads, building components, road repair and other directions, can solve the problems of difficult mixing, small heat exchange area, and agglomeration of modifiers, and achieves avoiding reverse flow of liquid and safety. The effect of good performance and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

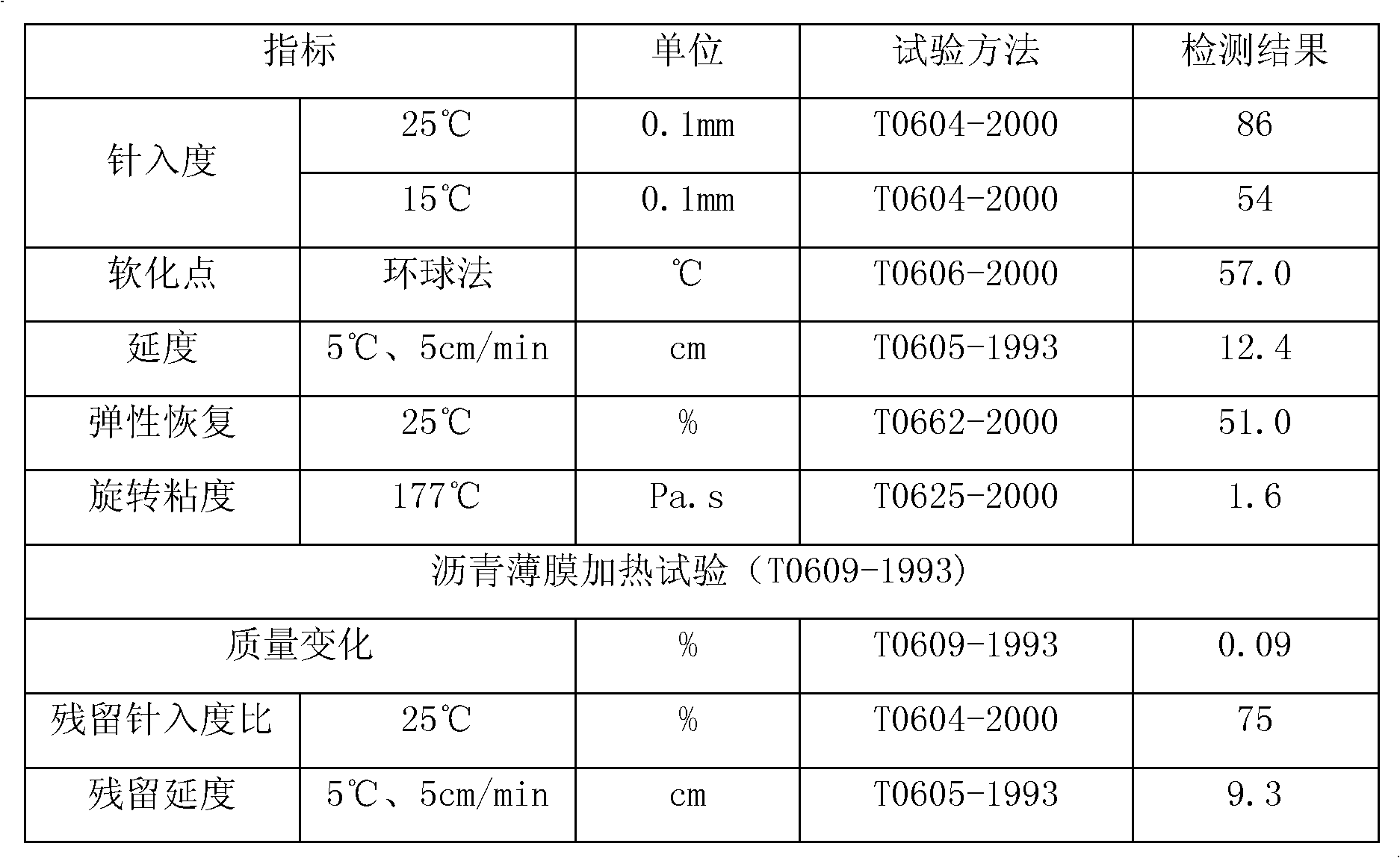

Embodiment 1

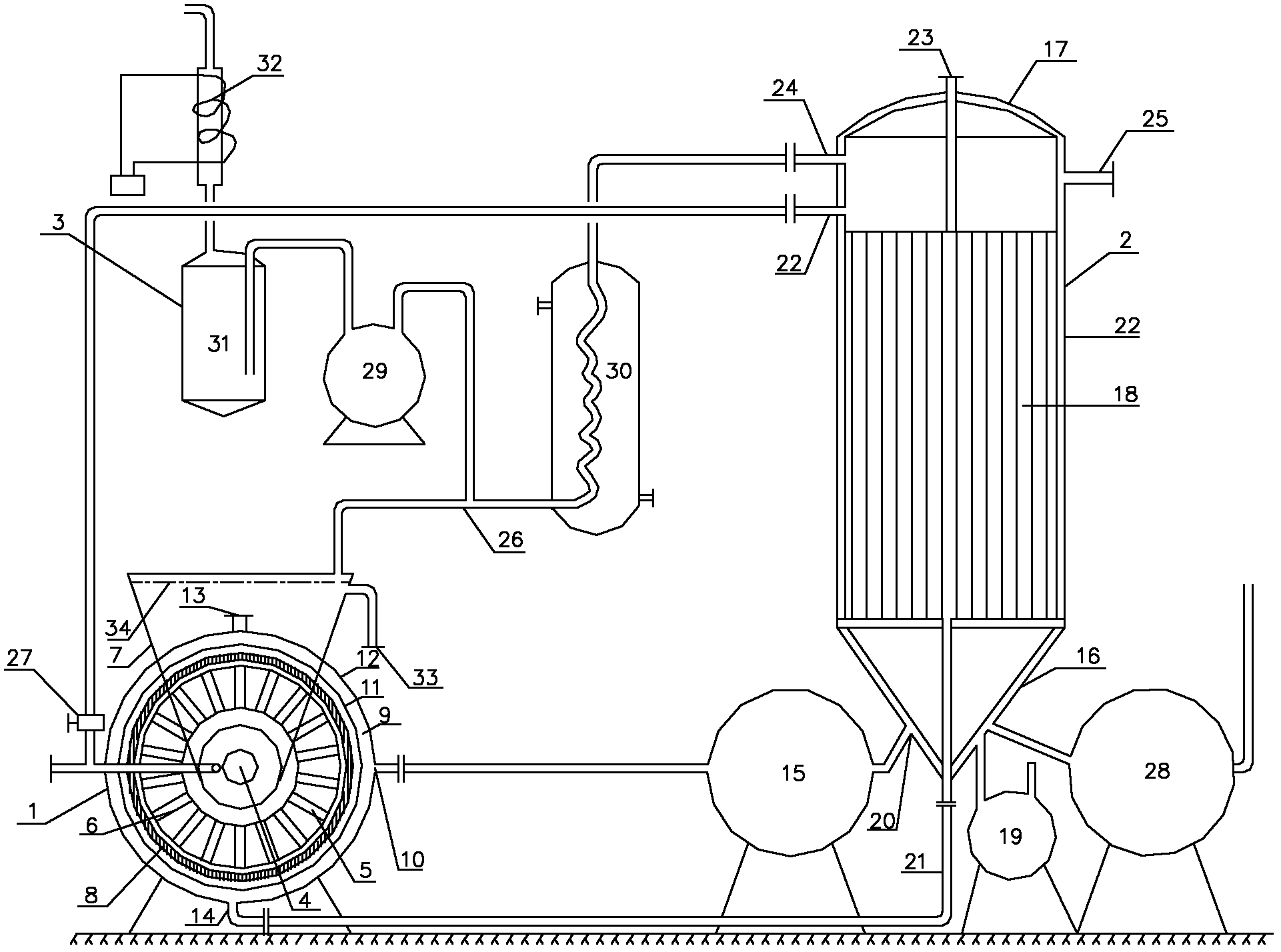

[0074] The device for producing modified asphalt that the present embodiment enumerates comprises the mixing device that is provided with raw material inlet, and mixing device comprises mixing pump, and this mixing device communicates with insulation tower 2, is provided with between mixing device and insulation tower 2 Asphalt pump 15, insulation tower 2 is provided with mixture inlet 20 and discharge port 25, wherein mixture inlet 20 is arranged at the bottom of insulation tower 2, and discharge outlet 25 is arranged at the top of insulation tower 2, and insulation tower 2 is located in mixing A shell-and-tube reactor 18 is arranged in the area between the material inlet 20 and the material outlet 25, wherein the shell-and-tube reactor 18 is a shell-and-tube heat exchanger.

[0075] The method for producing modified asphalt using the device of this embodiment to produce modified asphalt may further comprise the steps:

[0076] (1), the base asphalt and the modifier are enter...

Embodiment 2

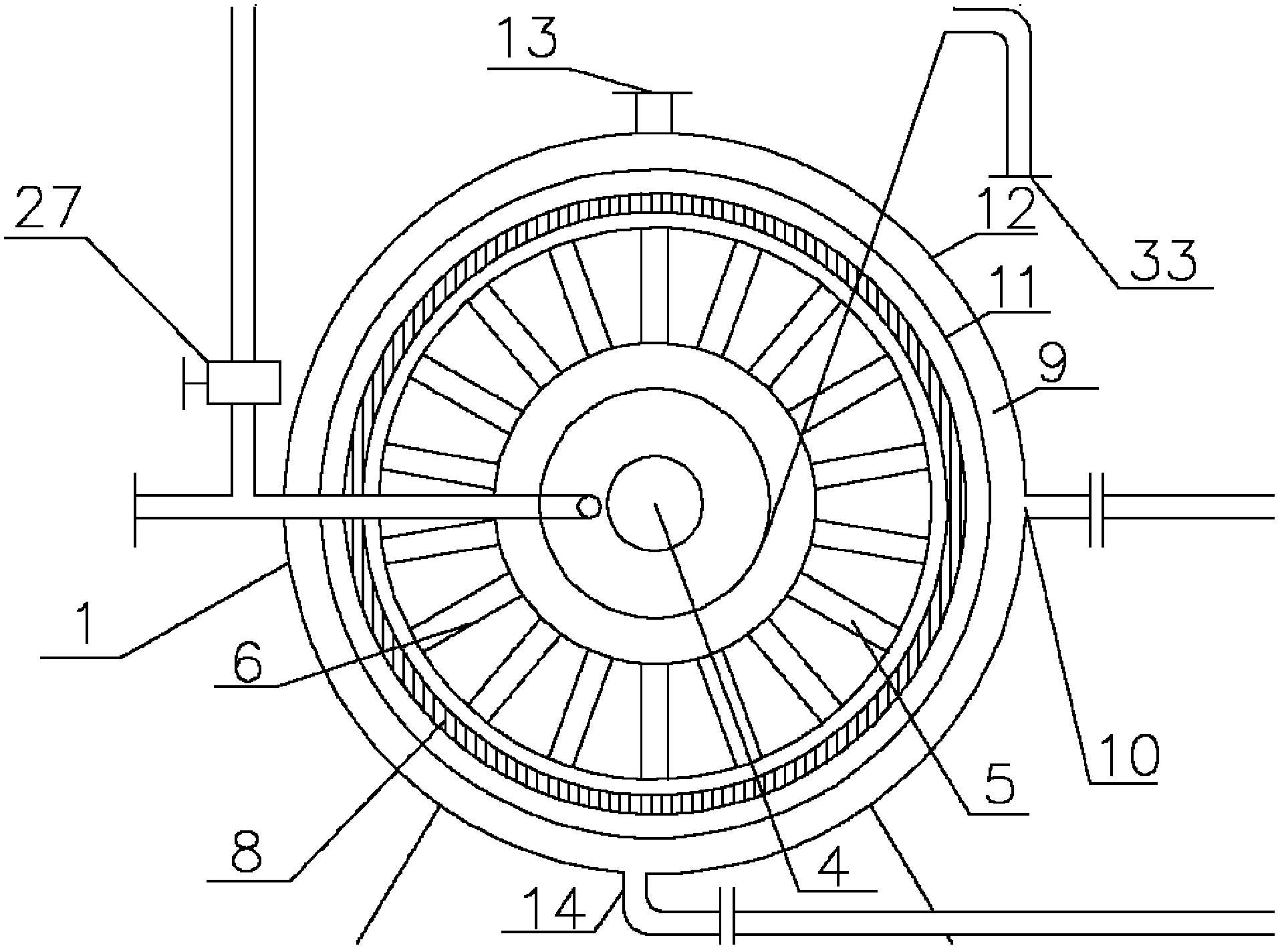

[0080]The device for producing modified asphalt in this embodiment includes a mixing device provided with a raw material inlet. The mixing device includes a mixing pump 1 with a moving coil 6 on the rotating shaft. The rotating shaft of the mixing pump 1 passes through a coupling 5 and a motor 4. The rotating head is connected to realize the rotation, and the moving coil 6 realizes coaxial rotation by means of a key connection with the rotating shaft of the mixing pump 1. The radially outer side of the moving coil 6 is provided with a fixed ring 8. When the rotating shaft of the mixing pump 1 rotates, The fixed coil 8 does not rotate with it, and realizes relative rotation with the coaxially rotating moving coil 6. The fixed coil 8 covers the moving coil 6. The moving coil 6 is an impeller. There is a gap between the moving coil 6 and the fixed coil 8. , the size of the gap is 5mm, the raw material inlet is connected to the inside of the fixed ring 8, after the asphalt and modi...

Embodiment 3

[0087] The device for producing modified asphalt in this embodiment includes a mixing device provided with a raw material inlet, the mixing device communicates with the insulation tower 2, an asphalt pump 15 is arranged between the mixing device and the insulation tower 2, and the mixture is mixed by the asphalt pump 15. The mixed material in the device is pressurized and input into the heat preservation tower 2. The heat preservation tower 2 includes a double-layer vacuum shell and an upper head 17 and a lower head 16 respectively connected to the upper and lower ends of the double-layer vacuum shell. A mixture inlet 20 and a discharge port 25 are provided, the mixture inlet 20 is arranged on the lower head 16 of the heat preservation tower 2, the discharge port 25 is arranged on the upper head 17 of the heat preservation tower 2, and the inside of the lower head 16 The chamber is in the shape of a cone with a large top and a small bottom, and a tube-and-tube reactor 18 is arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com